Patents

Literature

33results about How to "Control feeding amount" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

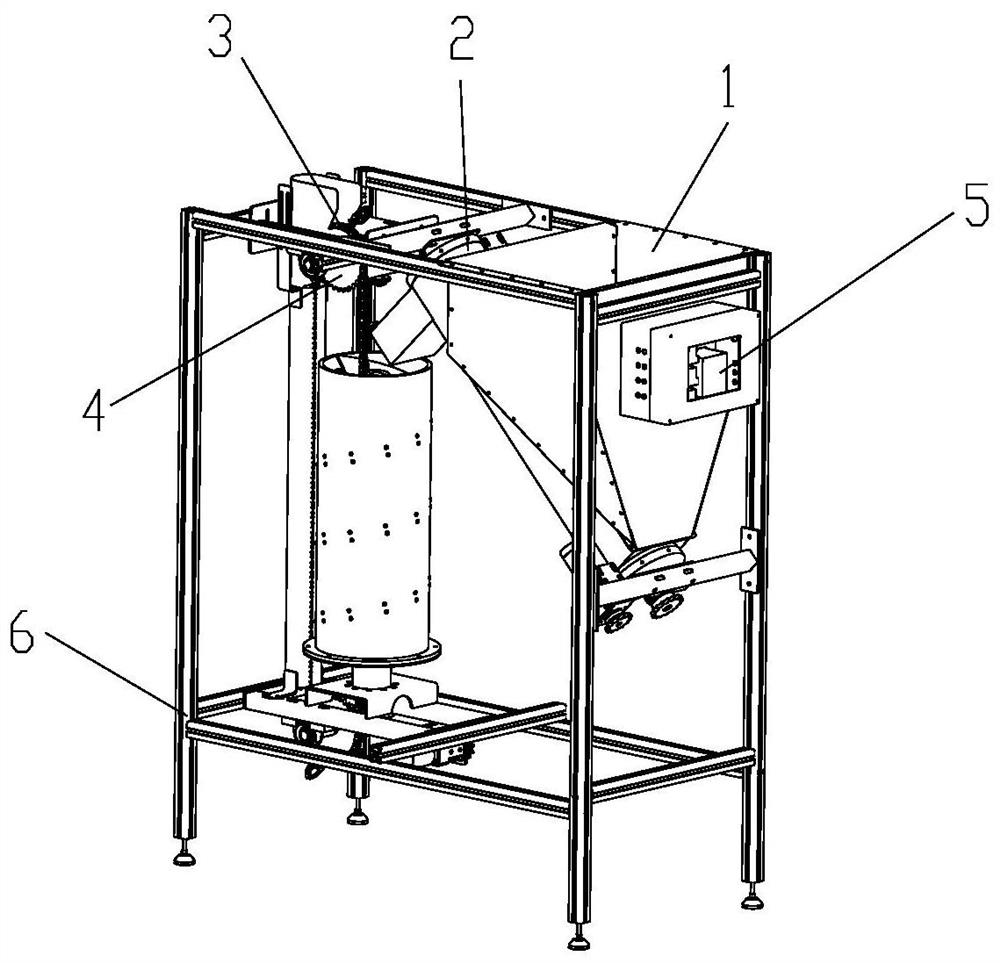

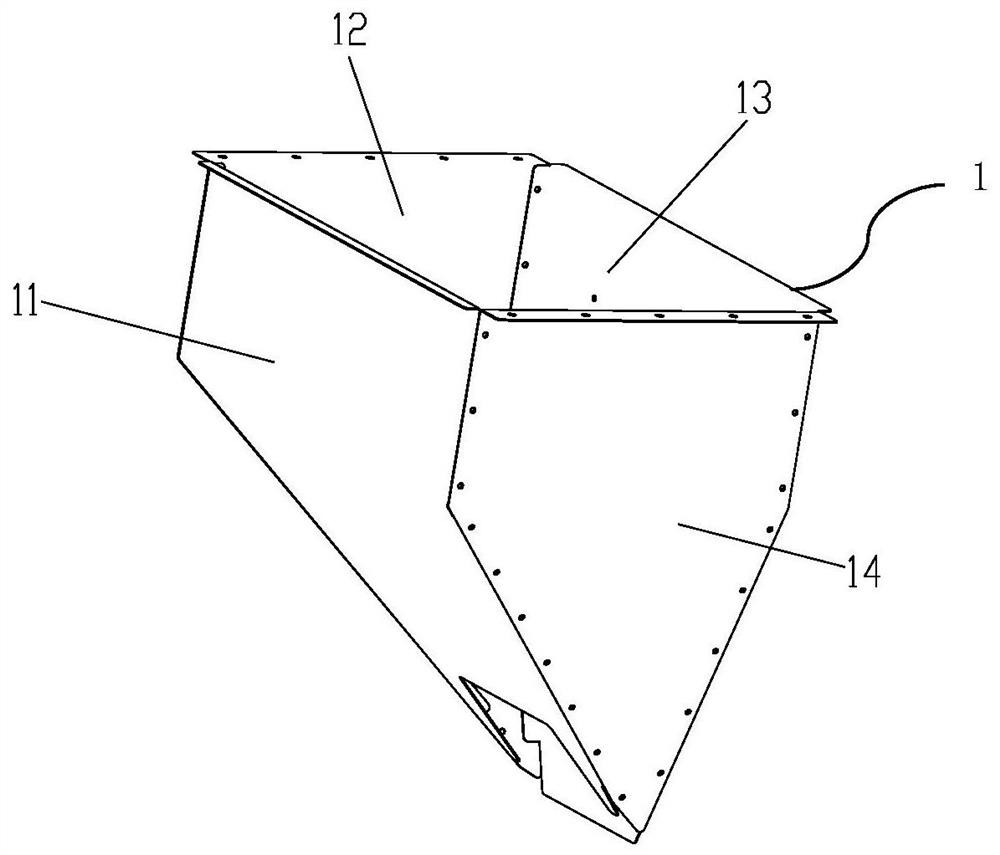

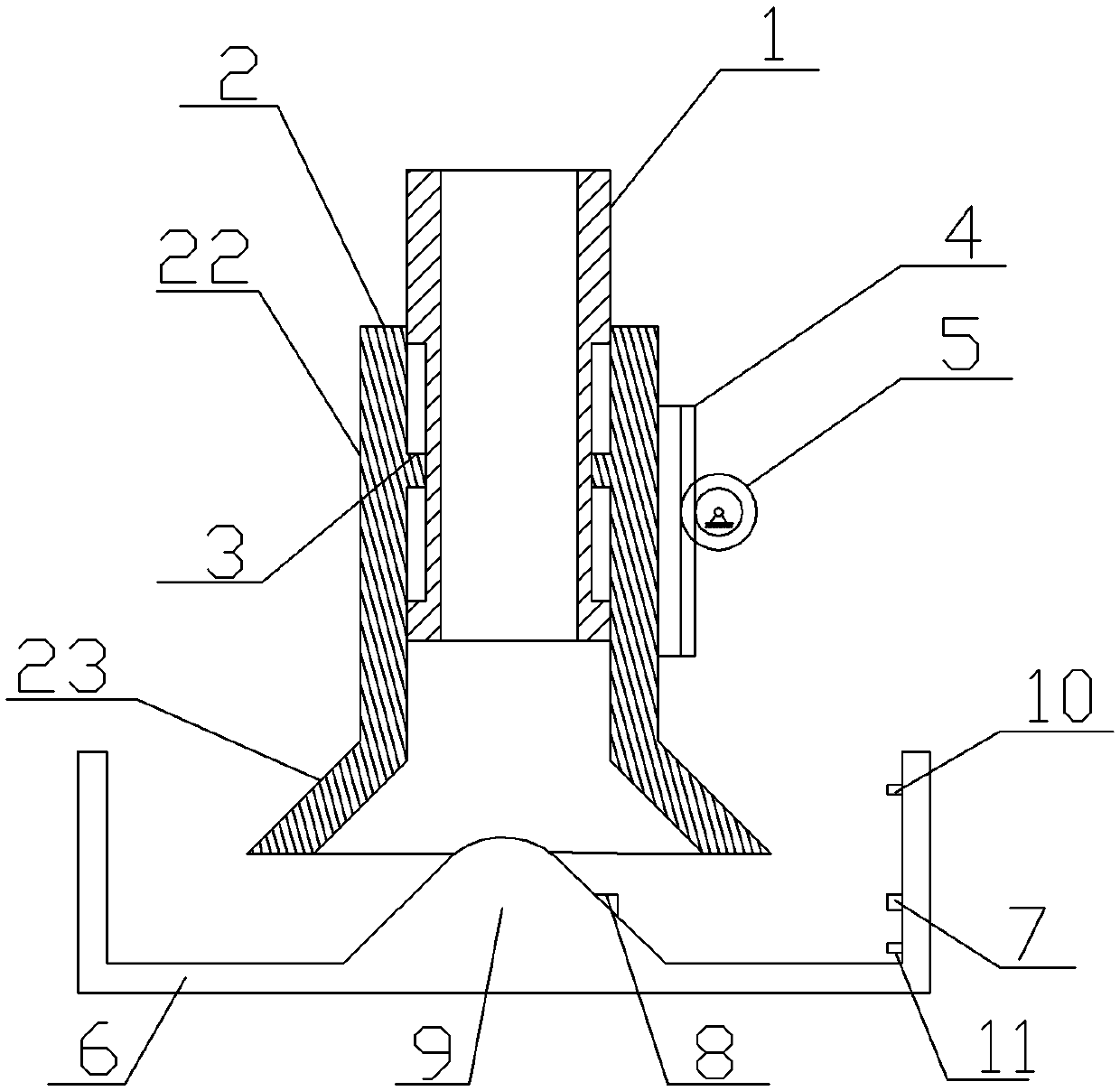

Spray feeder for granulated feed

InactiveCN105613339ARealize automatic feedingControl feeding amountPisciculture and aquariaAvicultureEngineering

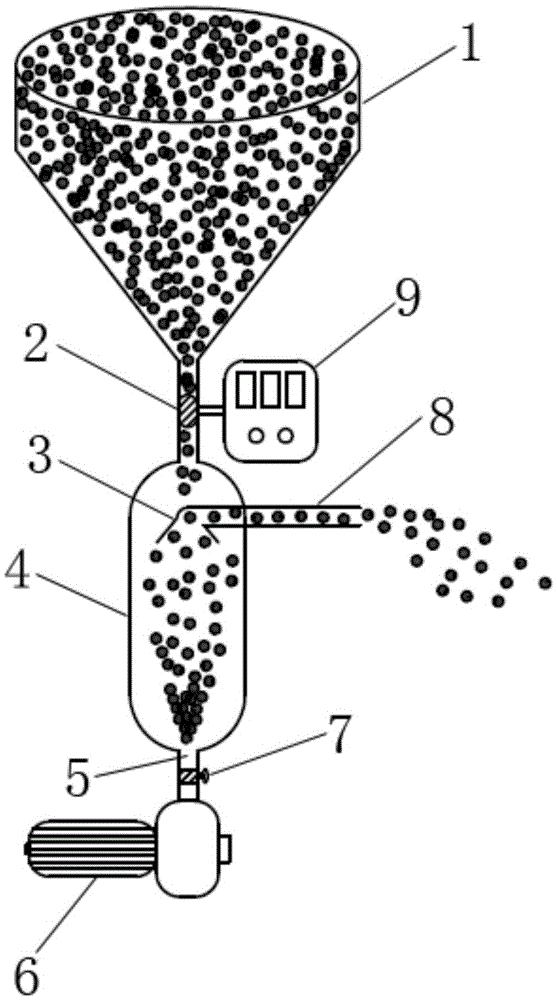

The invention relates to a spray feeder for granulated feed. The spray feeder comprises a granulated feed feeding hopper, a dispersing tank, a collecting hopper, a discharging pipe and an air source device, wherein the granulated feed feeding hopper and the collecting hopper are of conical structures, and the lower end of the feeding hopper is communicated with the upper end of the dispersing tank. A discharging valve is arranged between the feeding hopper and the dispersing tank and is subjected to on-off control by a connected controller, an air inlet in the lower end of the dispersing tank is communicated with the air source device, an air flow regulating valve is arranged between the air inlet and the air source device, the upper end of the collecting hopper is communicated with the discharging pipe, the open lower end of the collecting hopper is arranged right above the air inlet correspondingly, and the discharging pipe penetrates out of the dispersing tank. The spray feeder for the granulated feed has the advantages that automatic spray feeding of the granulated feed is achieved, so that physical labor is reduced, feed feeding quantity, feeding time and spray feeding areas are controlled accurately, and granulated feed waste is avoided.

Owner:INST OF OCEANOLOGY & MARINE FISHERIES JIANGSU

Production device of fiber color points and spinning method of color point yarns

The invention provides a production device of fiber color points and a spinning method of color point yarns, and improves the common cotton spinning machinery, i.e. adding a cotton feeding system on various carding machines, simultaneously being dispensed with a cotton stripping device, installing a stripping and conveying device, configuring all the technological parameters (e.g. transmission rate, cutting die, doffer space and the like) of the carding machines, and being reformed into a device capable of producing various fiber color points. The spinning method utilizes the production device, selects the kind and the dosage of an adhesive suitable for the fiber to produce color points with different size specifications, different tightness and extensive color change according to different fiber types during the production process of the color points.

Owner:广东广纺检测技术股份有限公司

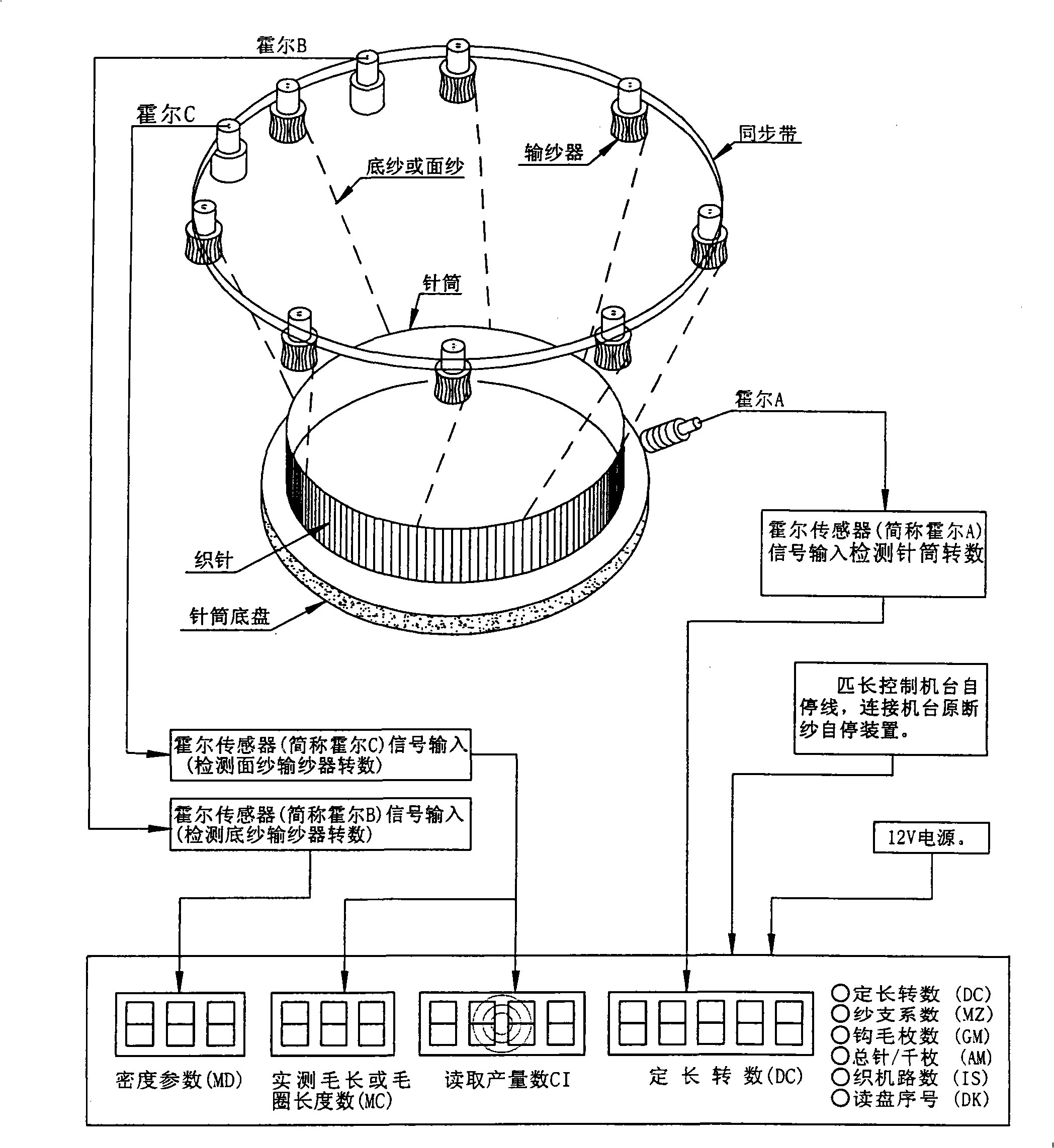

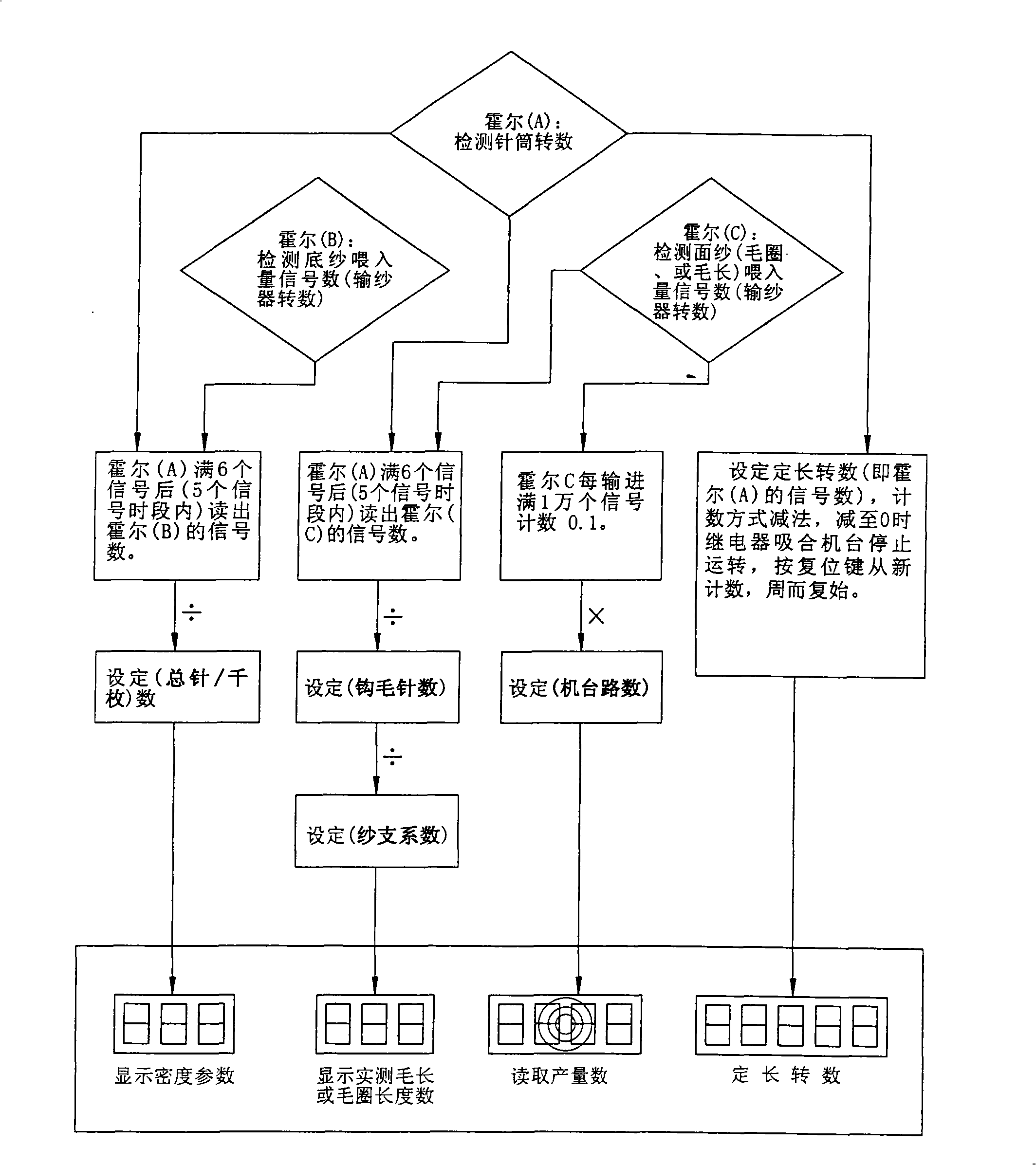

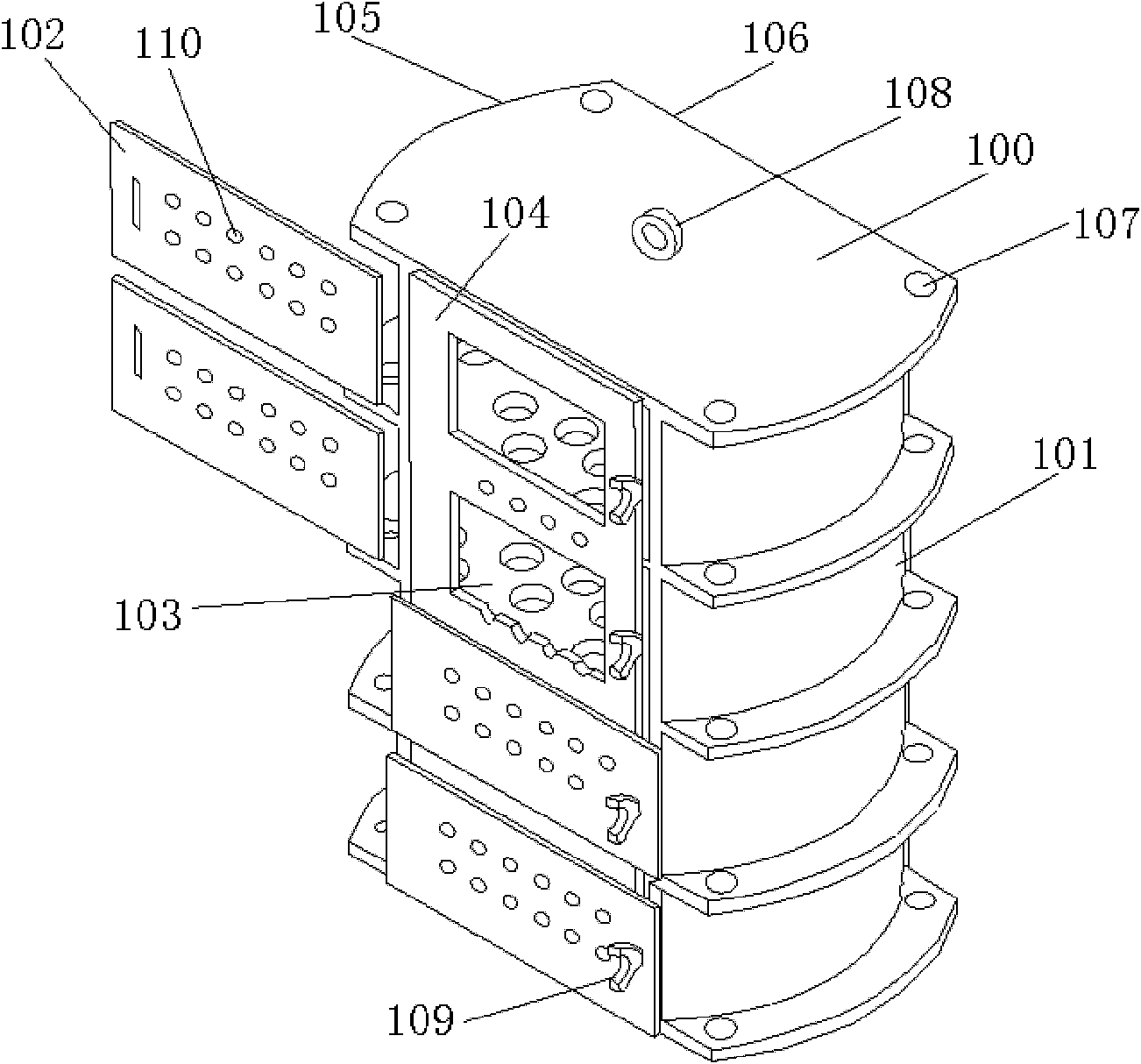

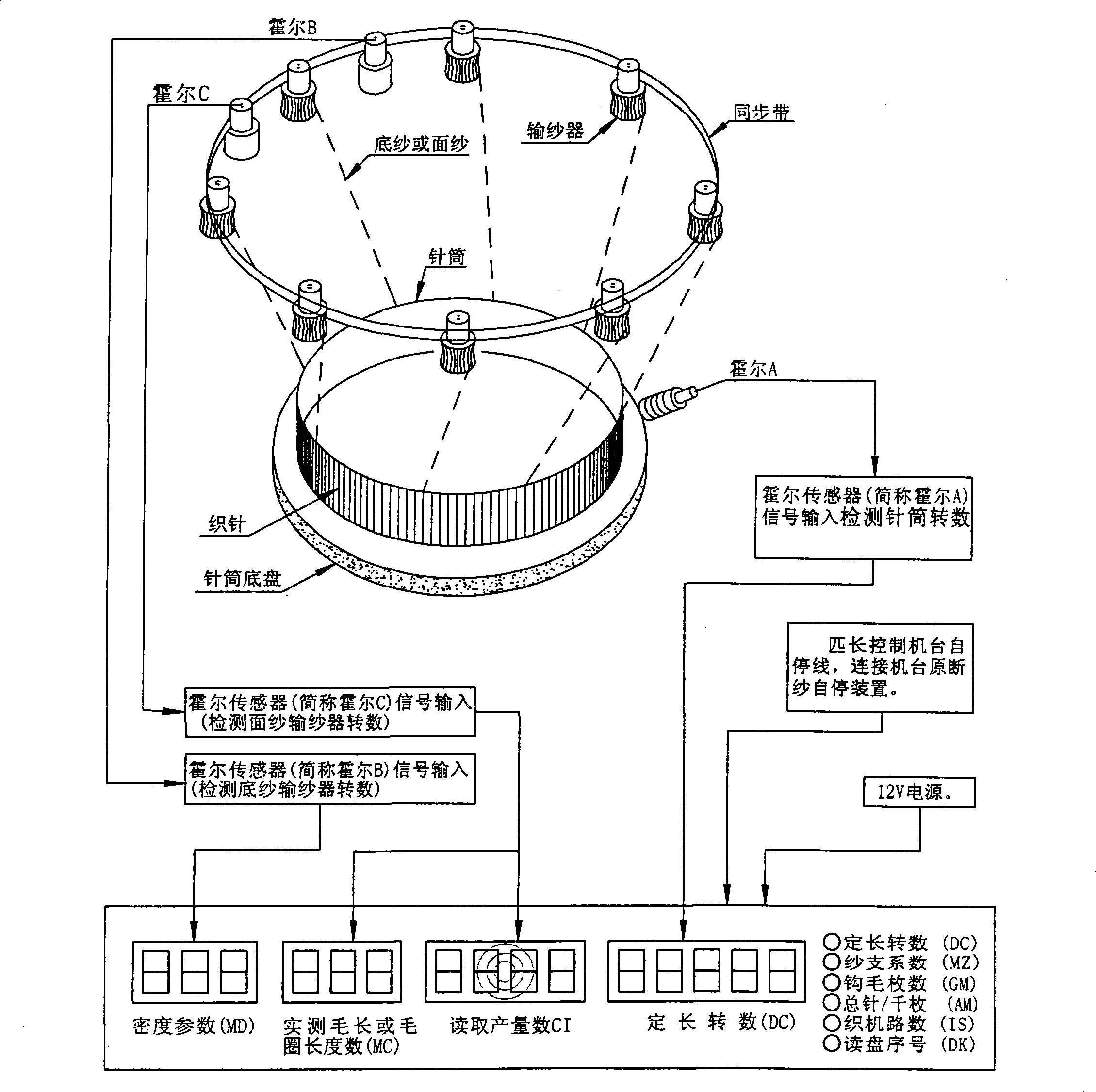

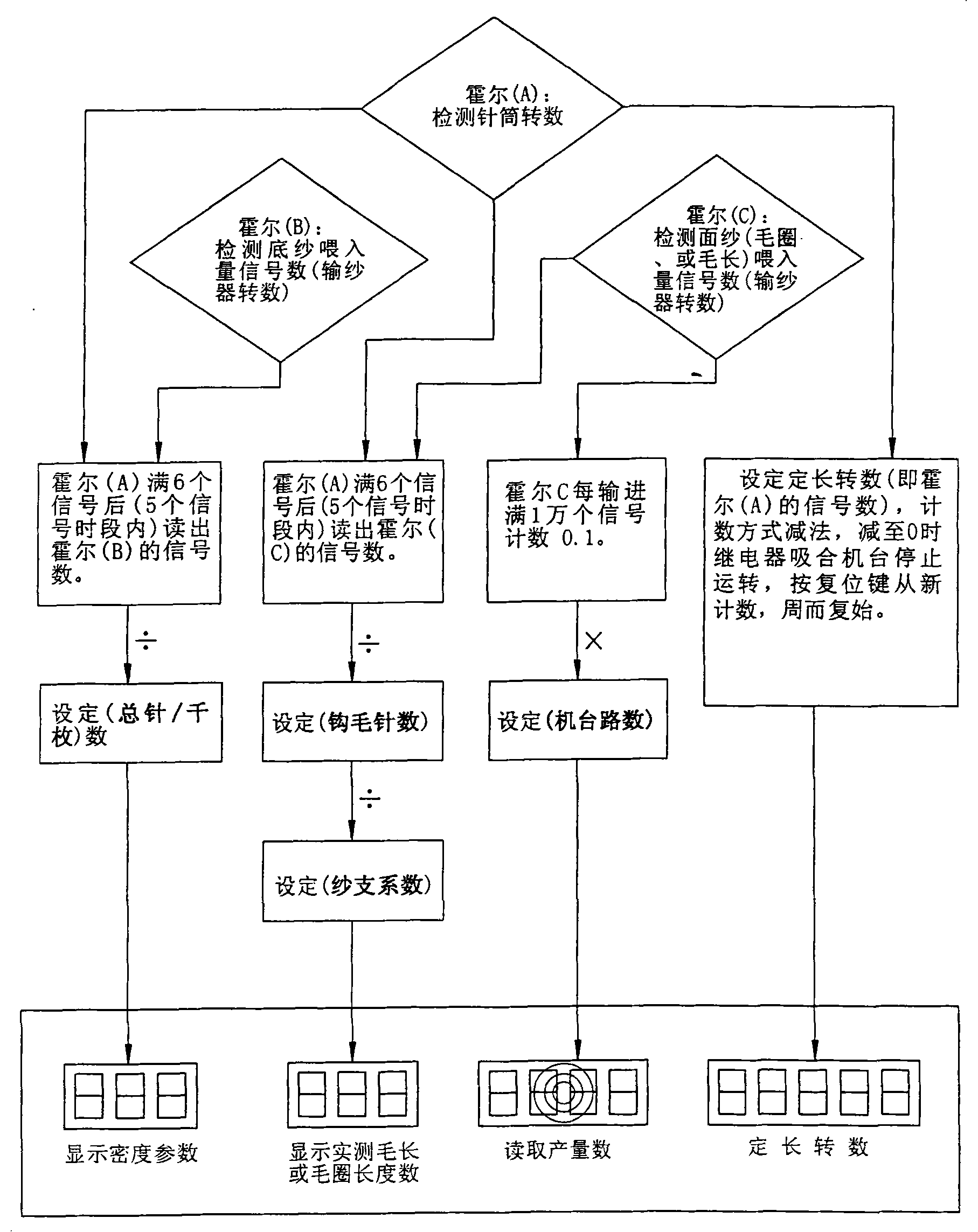

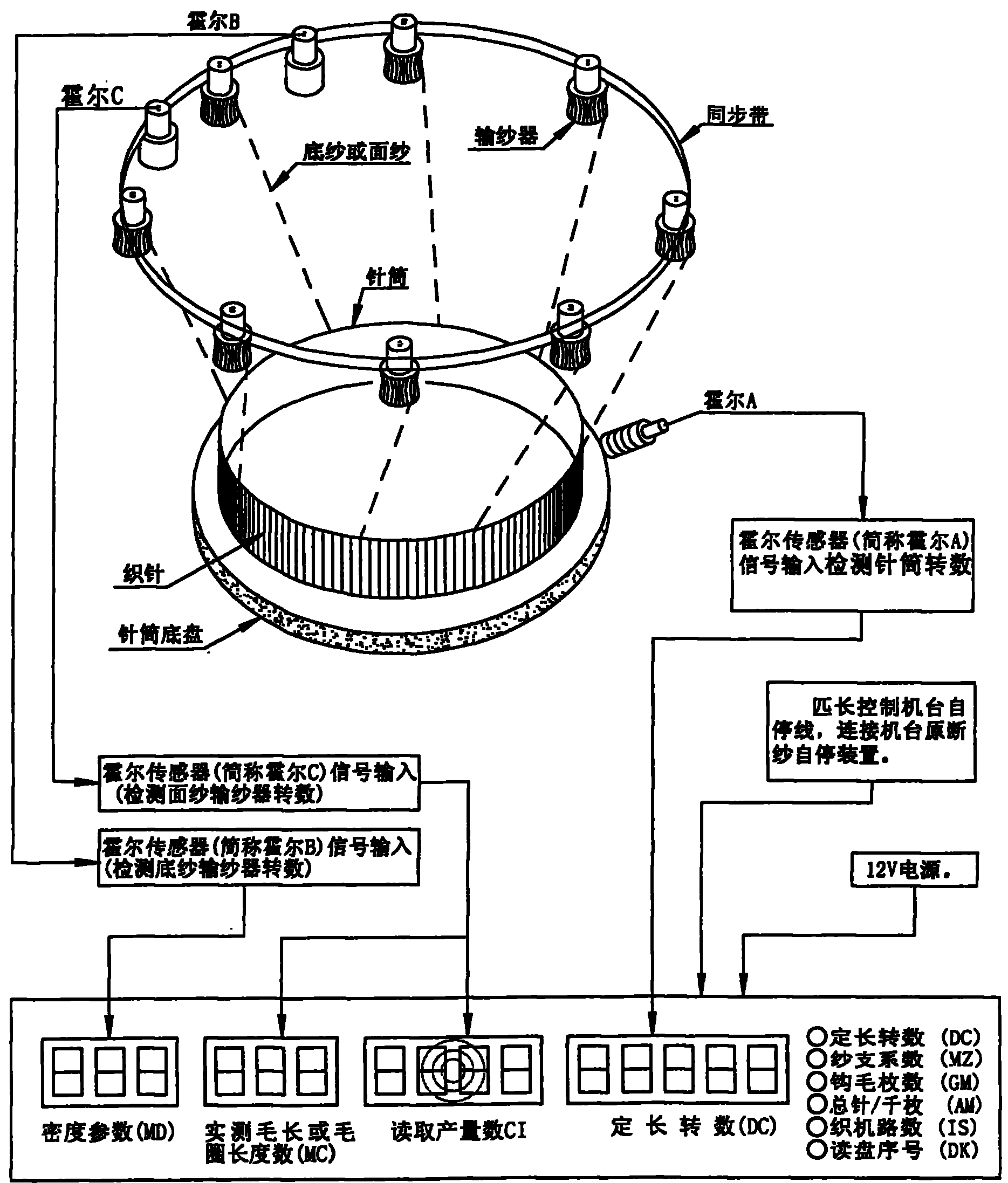

Parameter detecting device and method for textile weaving process

InactiveCN101270544AImprove efficiencyImprove accuracyInspecting textilesKnittingYarnComputer module

A parameter detecting device in the weaving process of a fabric and a detecting method thereof relate to the technical field of detecting. The invention aims at solving the technical problem of improving the product quality during the weaving process of the fabric; the parameter detecting device includes a needle cylinder revolution detecting sensor, a bottom yarn detecting sensor, a surface yarn detecting sensor, a display screen and a microprocessor connecting the display screen; wherein, the microprocessor includes a density parameter module, a hair length or hair ring length amount module, an output amount module and a fixed-length rotating amount module; the density parameter module is respectively connected with the needle cylinder revolution detecting sensor and the bottom yarn detecting sensor; the hair length or hair ring length amount module is respectively connected with the needle cylinder revolution detecting sensor and the surface yarn detecting sensor; the parameter detecting method includes the parameter detecting methods of the density parameter detecting, the hair length or hair ring length amount detecting, the output amount detecting and the fixed-length rotating amount detecting. The invention is characterized by being capable of improving the efficiency, the accuracy, the product quality and realizing the automatization of output counting.

Owner:上海好力纺织机电设备有限公司

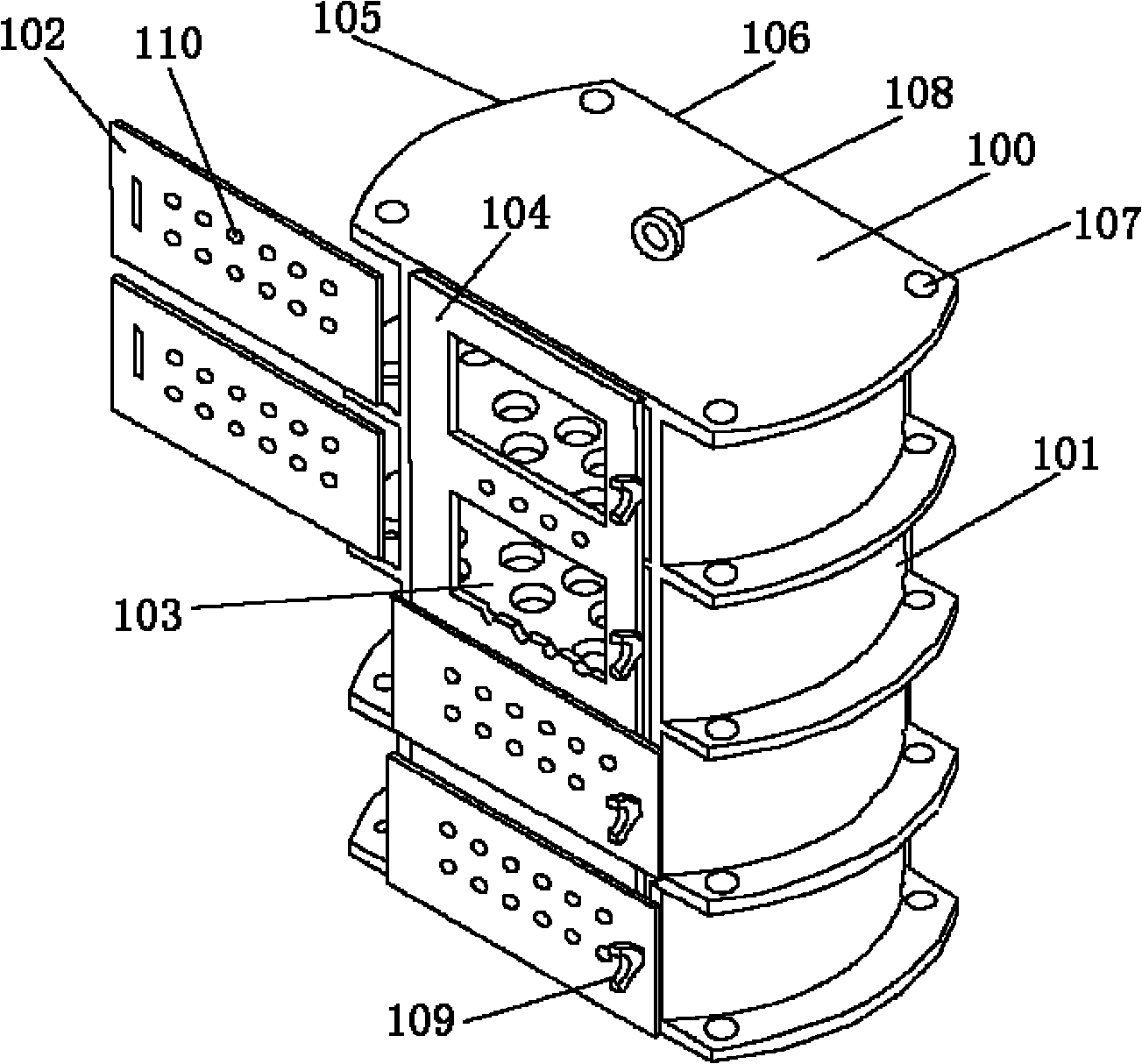

Layered cage rearing device and using method thereof

InactiveCN102106283AImprove survival rateImprove yield per muClimate change adaptationPisciculture and aquariaHigh densityVolumetric Mass Density

The invention relates to a layered cage rearing device and a using method thereof. The cage rearing device comprises at least one cage body, wherein the cages are overlaid to form a group; a movable feeding door is arranged on the lateral side of the cage body; round holes are formed on the cage separator and coaming of the cage body; the cage body is formed by two pairs of symmetric arc edges and straight edges; a plurality of through holes are formed symmetrically on the outer rims of the arc edges; and a lantern ring is arranged in the center of the top of the cage body. By using the device and the method, the raising density is increased to 4,000 to 12,000 crabs per Mu from hundreds of crabs per Mu, 6 to 20 crabs can be reared in every square meter (on square meters, the raising density includes soil pond raising, and also can be used as calculation bases for indoor high-density raising), so that mutual killing among crabs is completely avoided, and the survival rate of the crabs is improved.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI +1

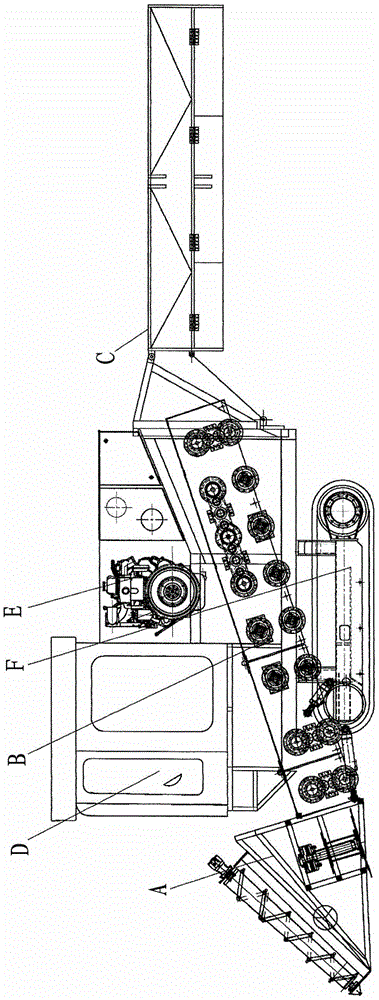

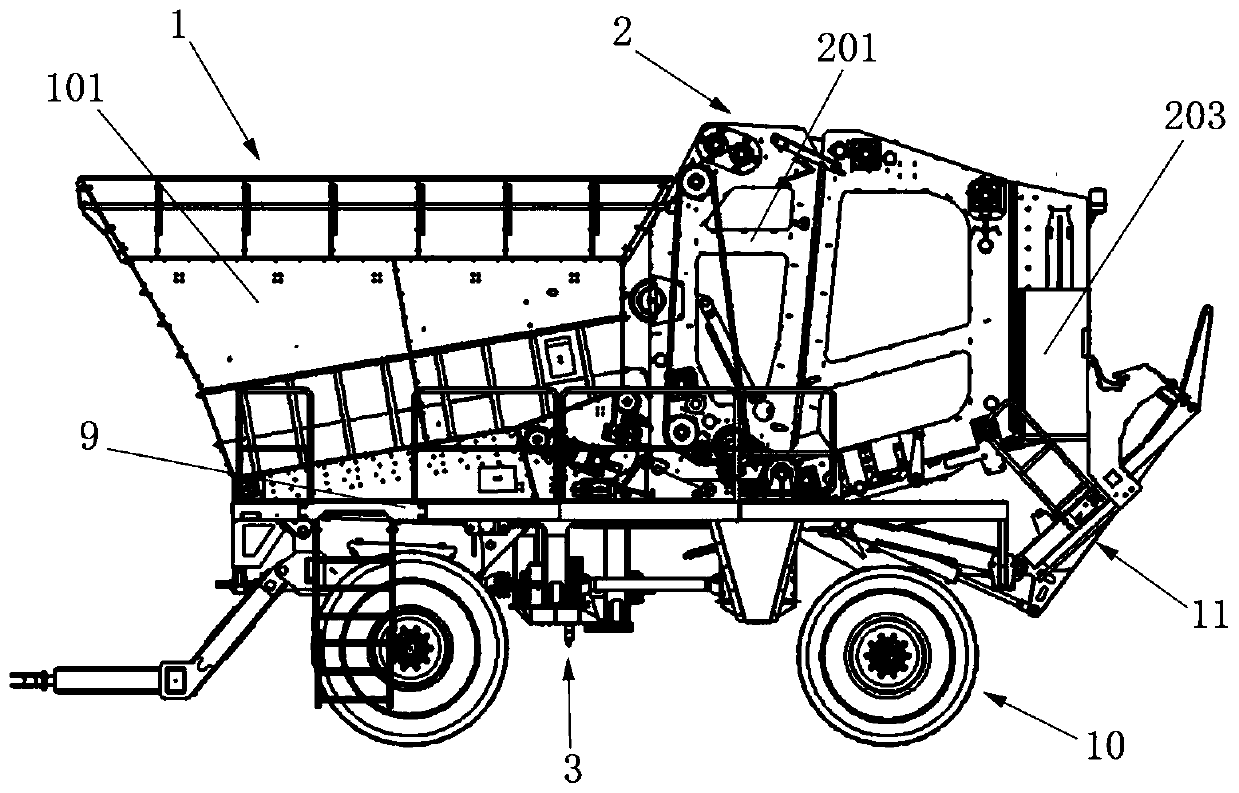

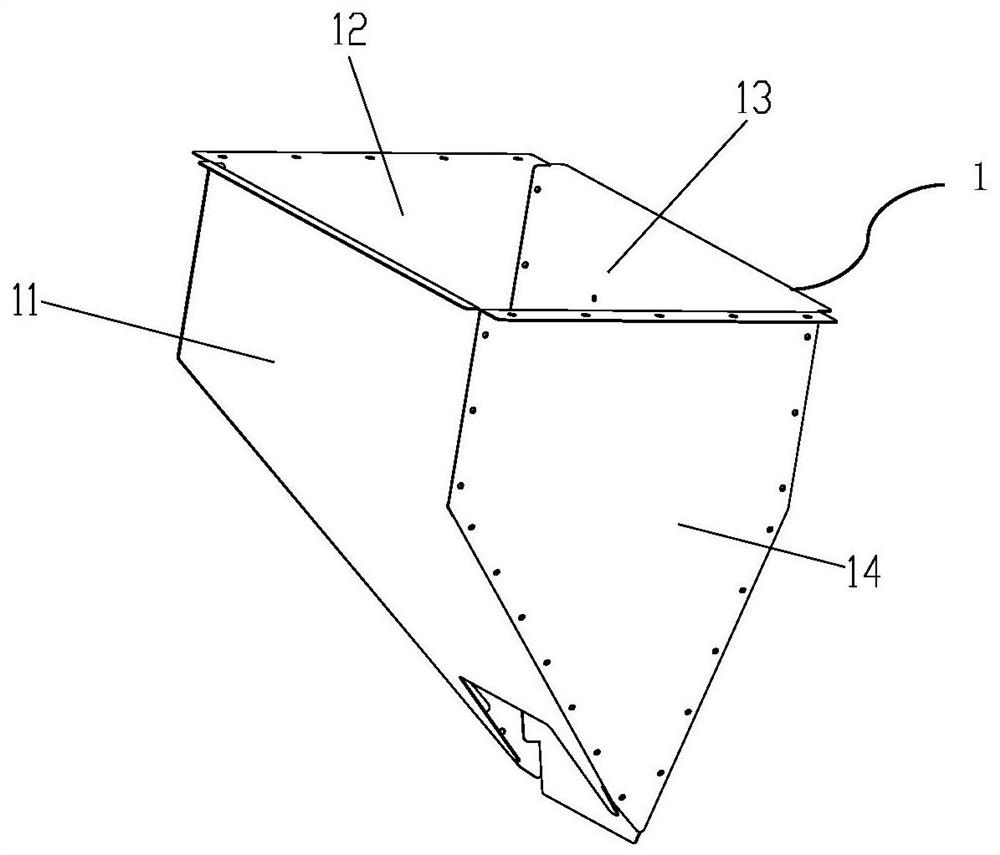

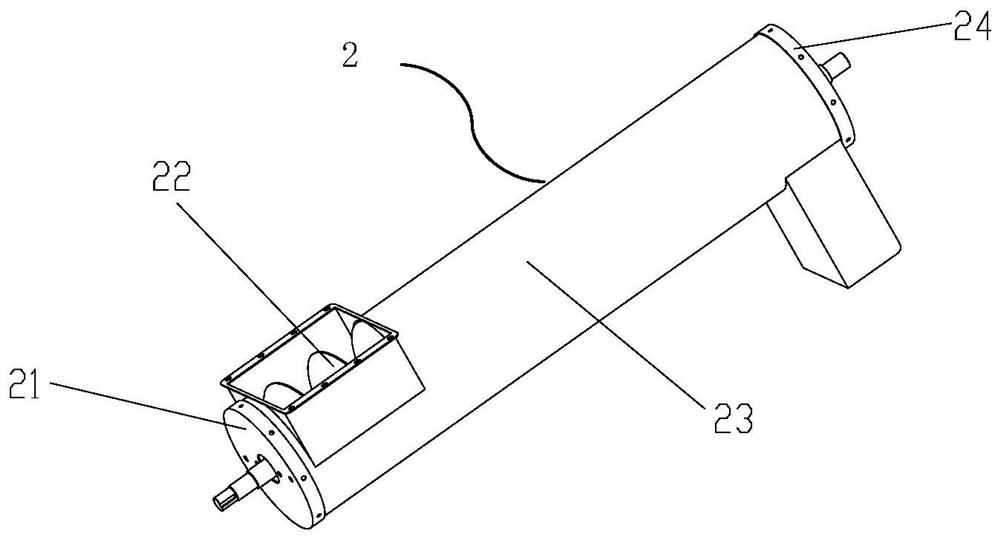

Novel cane harvester

The invention discloses a novel cane harvester. A traveling mechanism is arranged under the chassis, a feeding and conveying mechanism is aslant arranged on the chassis, a discharge hopper is gradually inclined upwards from inside to outside, the top portions of the left and right sides of the inner side end of the discharge hopper are respectively fastened with the rear side of the feeding and conveying mechanism, the waist portion of each of the left and right sides of the inner side end of the discharge hopper is supported by an angle adjusting cylinder which can adjust the inclination angle of the discharge hopper, a header is arranged at the front end of the feeding and conveying mechanism for cutting off cane stems and feeding into a conveying channel, the cane stems are peeled in the conveying channel, the cane stems are finally conveyed into the discharge hopper for performing windrowing, bundling and docking processes, a hydraulic system is arranged above the feeding and conveying mechanism, and a covering part assembly is also arranged above the feeding and conveying mechanism. The novel cane harvest has the characteristics of being compact in structure, flexible to operate, reliable in work, light and durable, low in cost and high in work efficiency.

Owner:泉州市劲力工程机械有限公司

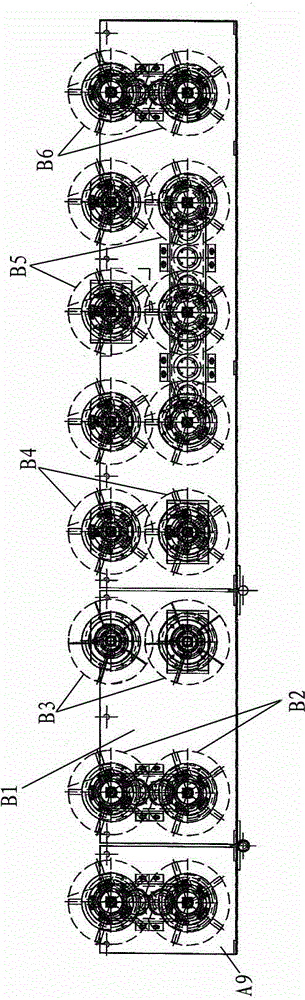

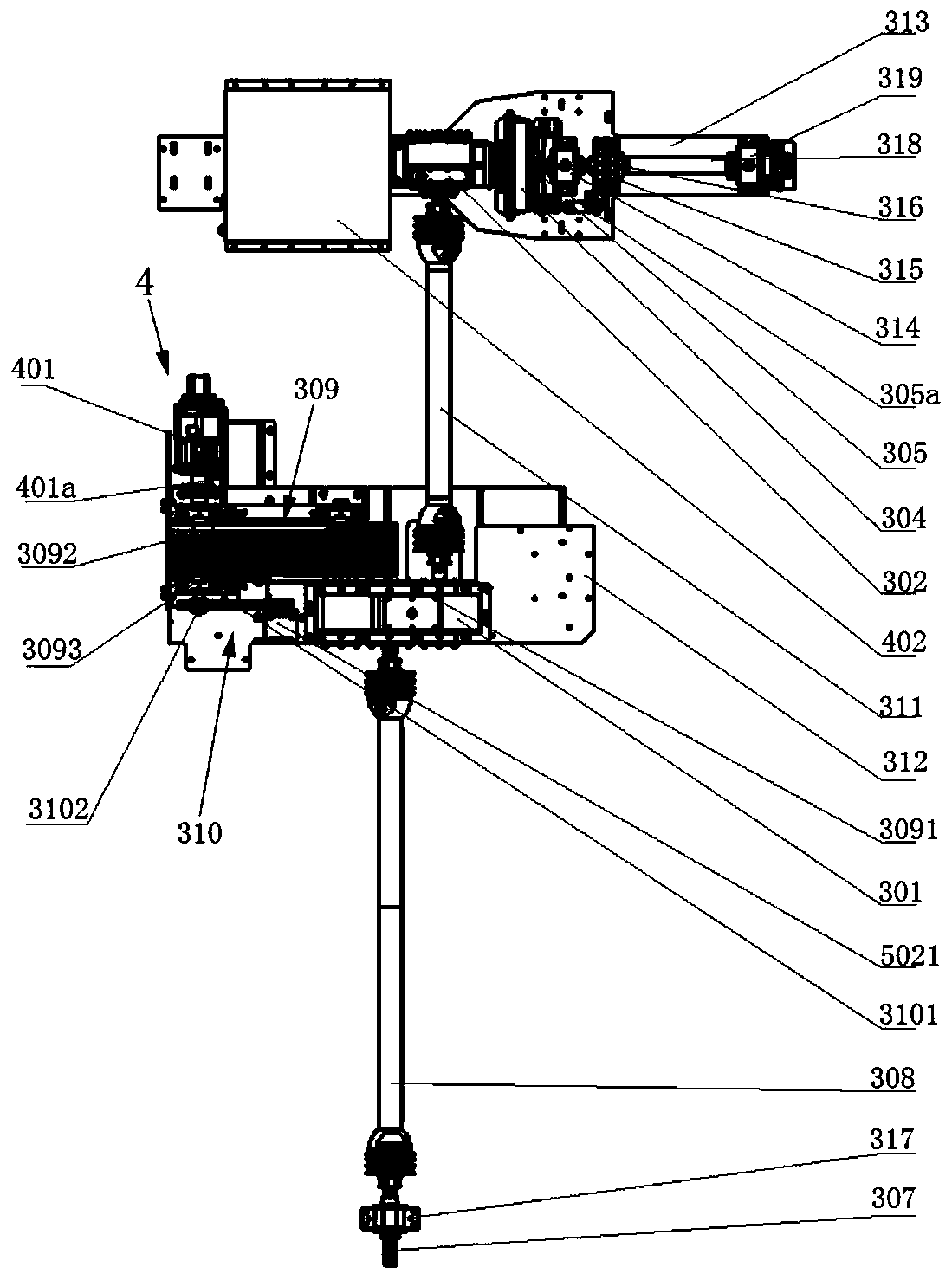

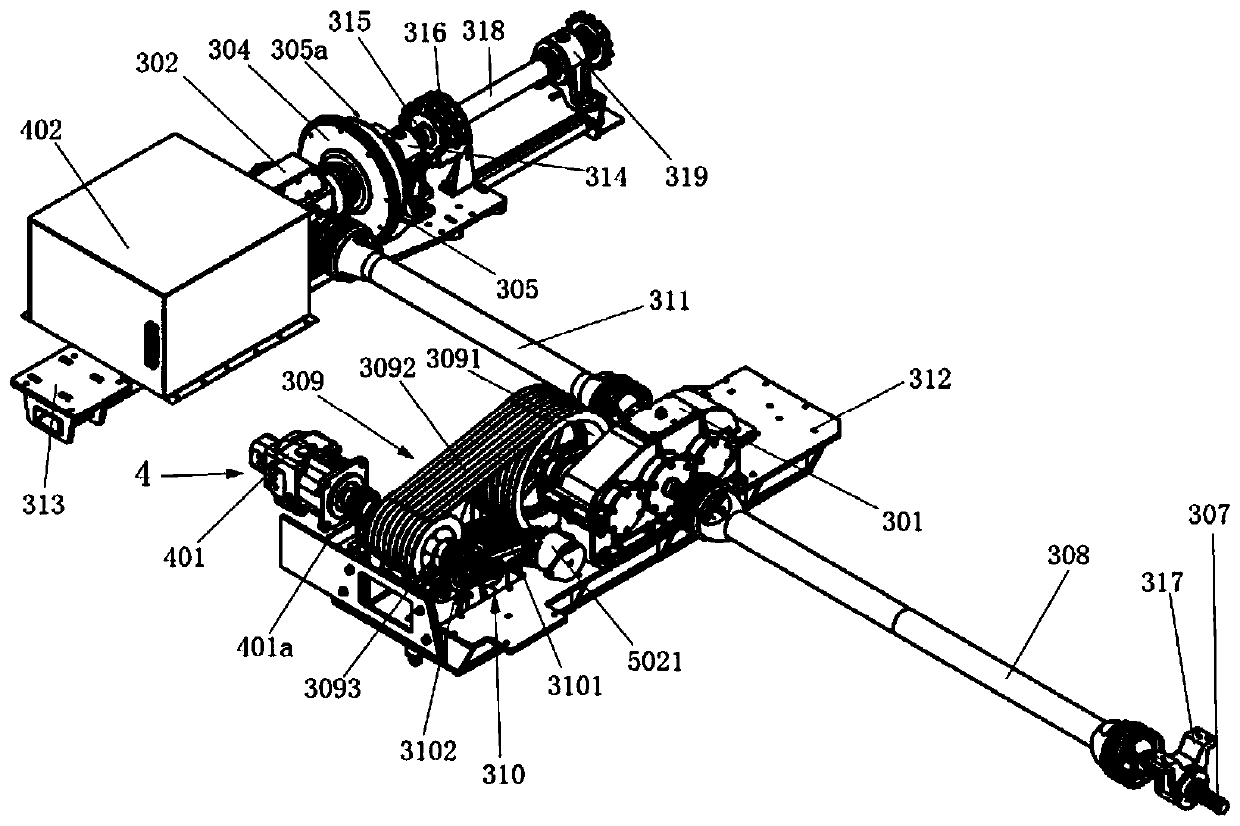

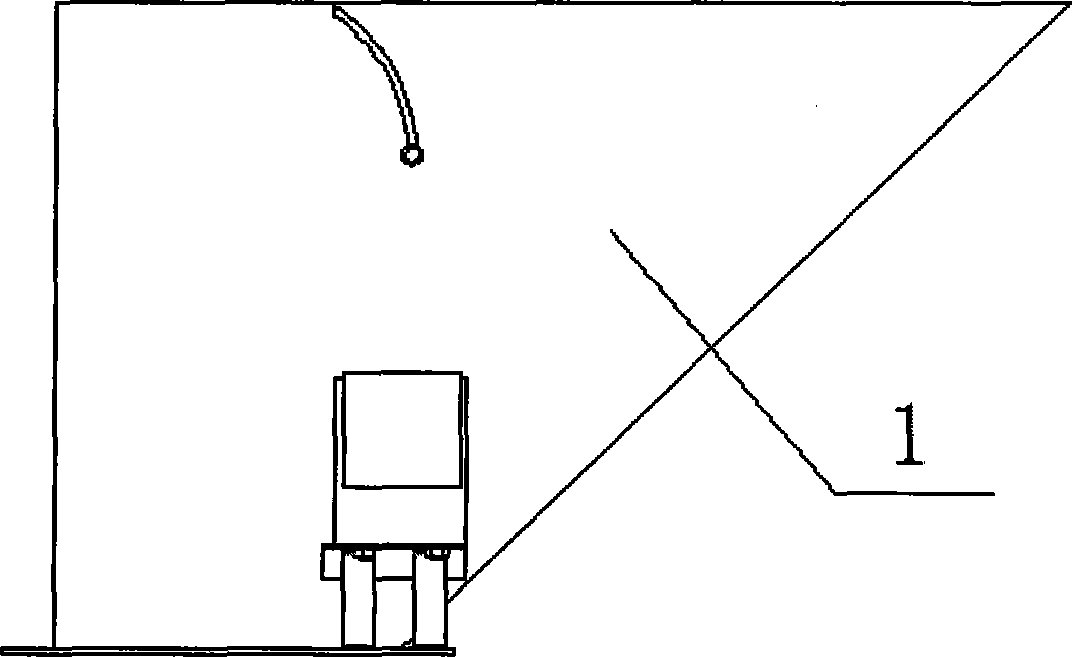

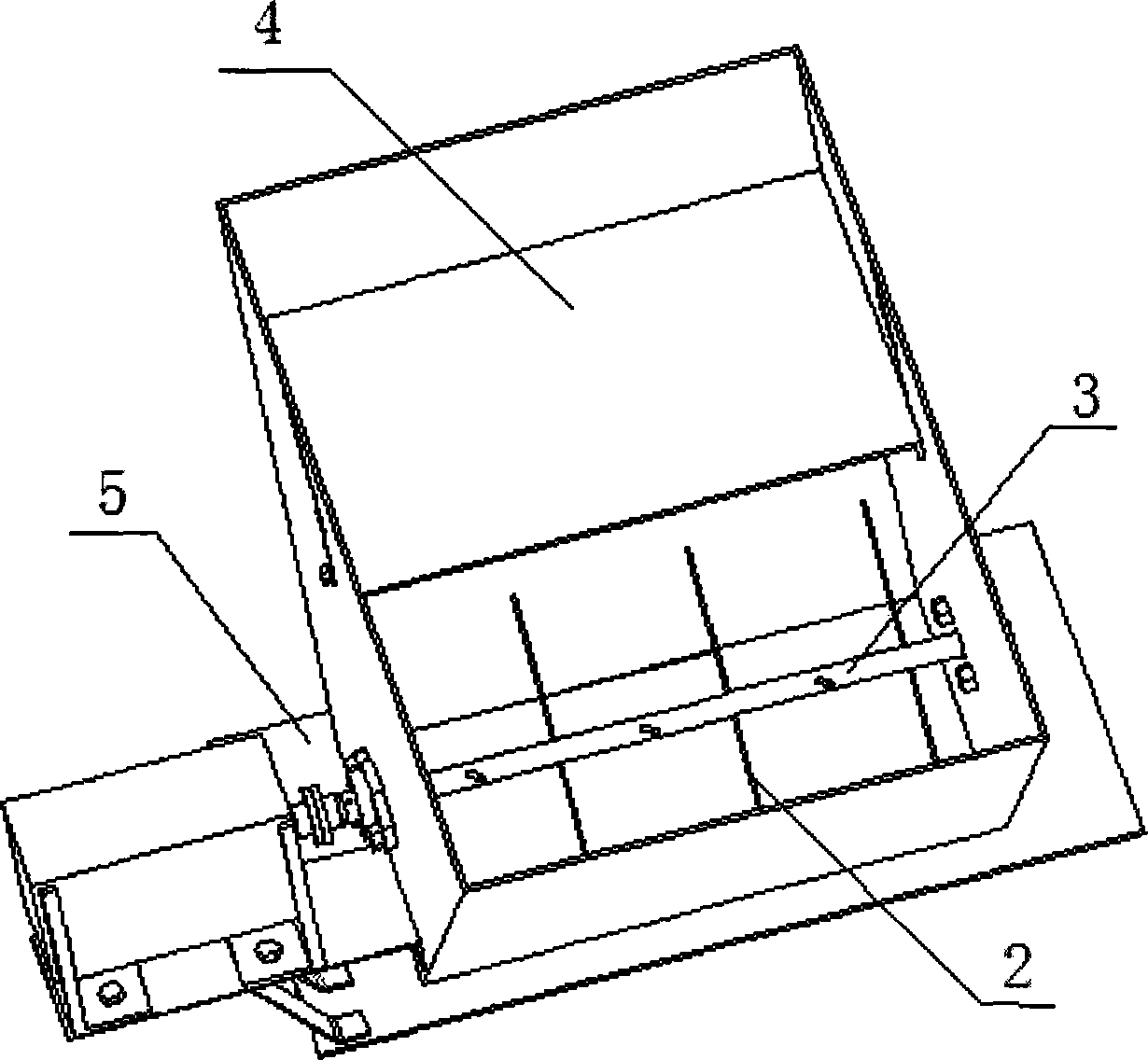

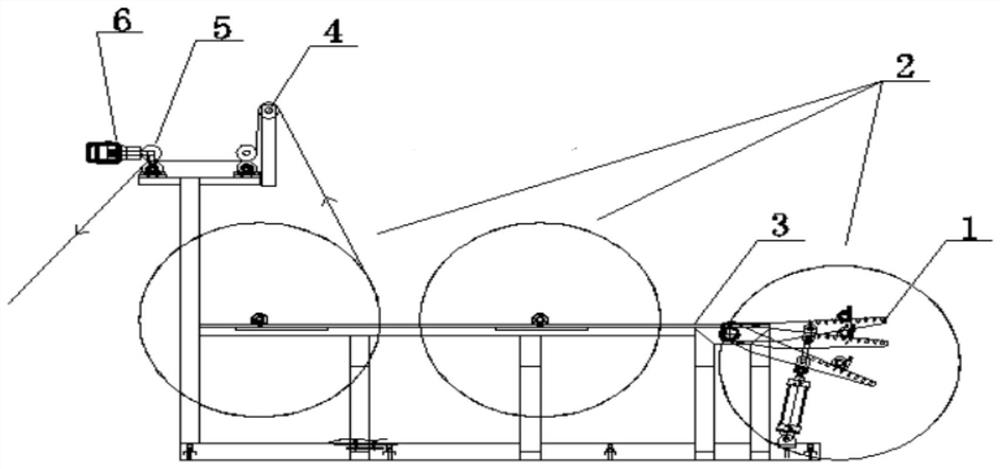

Traction-type intelligent cotton press

PendingCN110884711ATimely processingImprove comfortBinding material applicationPackaging automatic controlControl setProcess engineering

The invention relates to a traction-type intelligent cotton press. The cotton press comprises a cotton collecting mechanism (1), a forming mechanism (2), a power input device (3), a hydraulic controldevice (4), a main control device (5) and a detection unit, wherein the cotton collecting mechanism (1) is used for receiving cotton, extruding cotton into pieces and outputting the pieces; the forming mechanism (2) is used for receiving the cotton pieces output by the cotton collecting mechanism (1) and packaging the cotton pieces into cotton bales; the power input device (3) is used for receiving power transmitted into the traction type intelligent cotton press and distributing the power to drive the cotton collecting mechanism (1) and the forming mechanism (2) to operate; the hydraulic control device (4) is used for controlling operation of the cotton collecting mechanism (1) and the forming mechanism (2); the main control device (5) is used for controlling the hydraulic control device(4); and the detection unit is used for collecting sizes of the cotton bales in the forming mechanism (2) and collecting pressure applied to the cotton bales. By using the traction-type intelligent cotton press, the cotton bales with the same size and compactness can be manufactured, baling and film wrapping are automatically controlled, meanwhile, an impurity rate is reduced so that a blowing process link does not need to be added in later cotton processing, and production cost is reduced.

Owner:呼伦贝尔市蒙拓农机科技股份有限公司

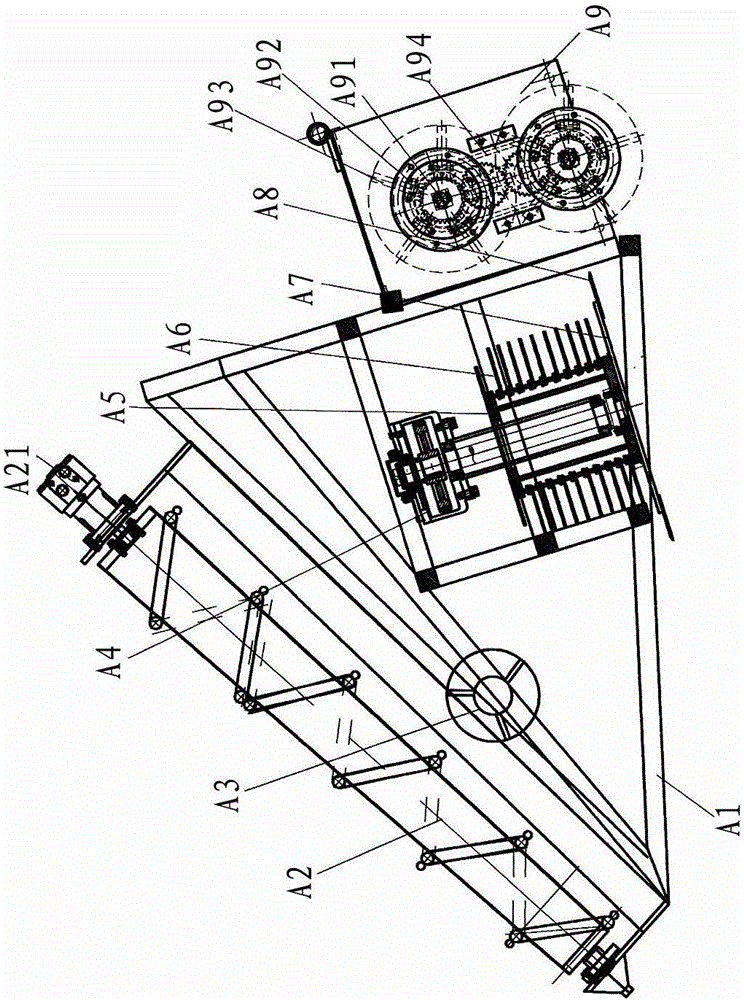

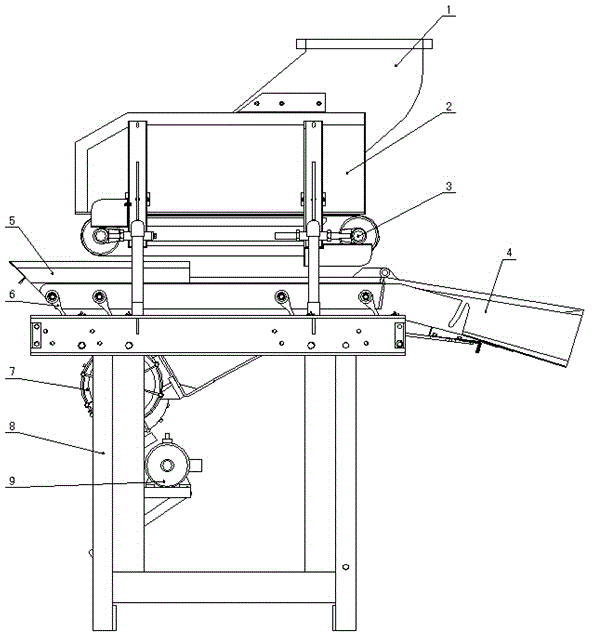

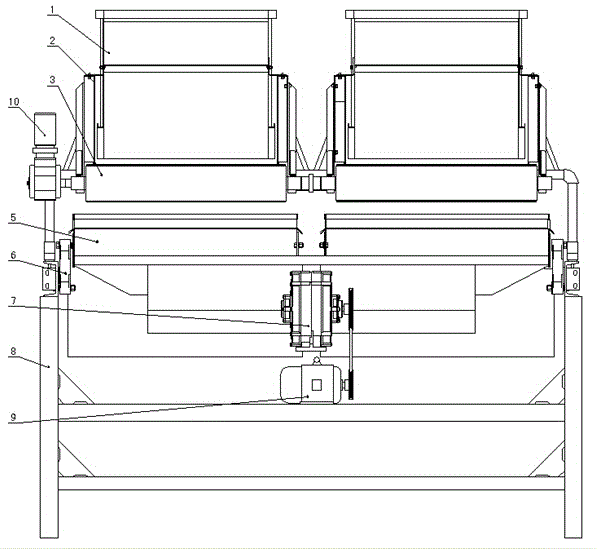

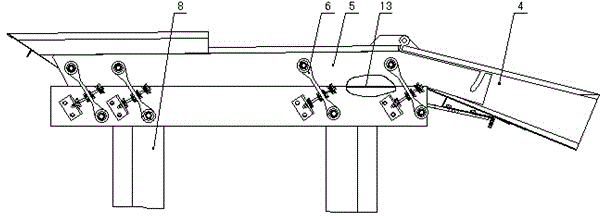

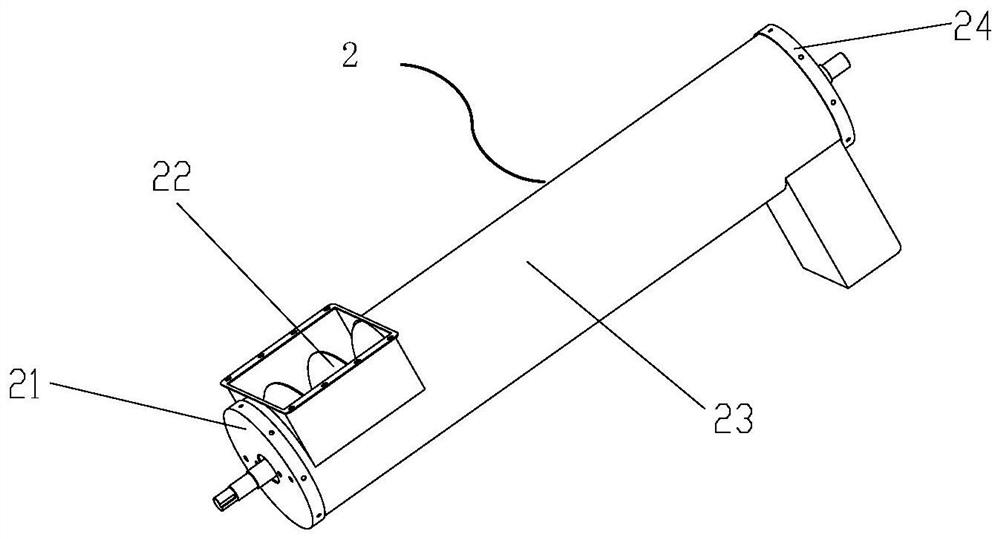

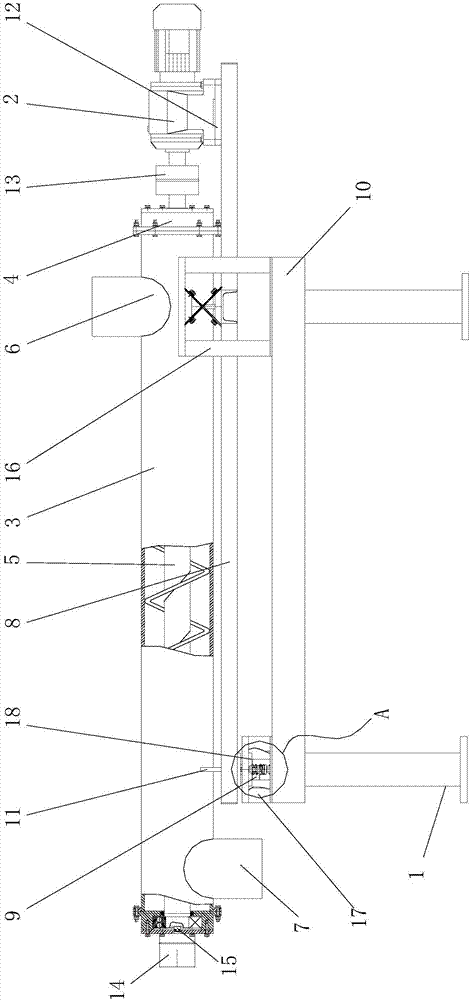

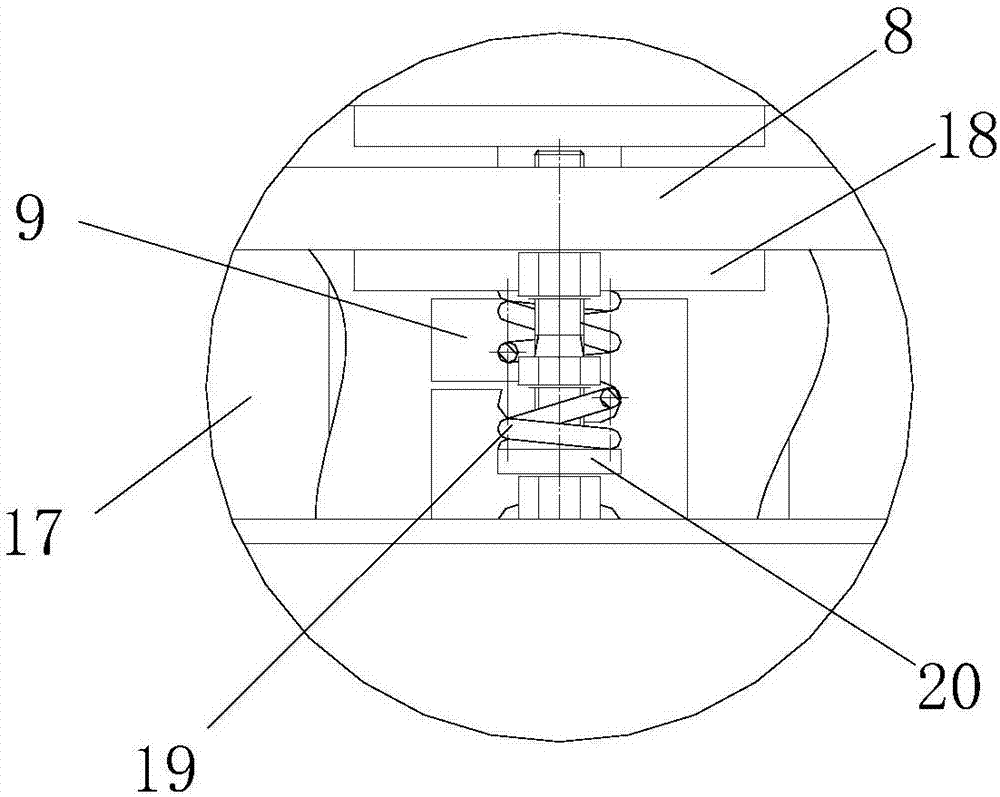

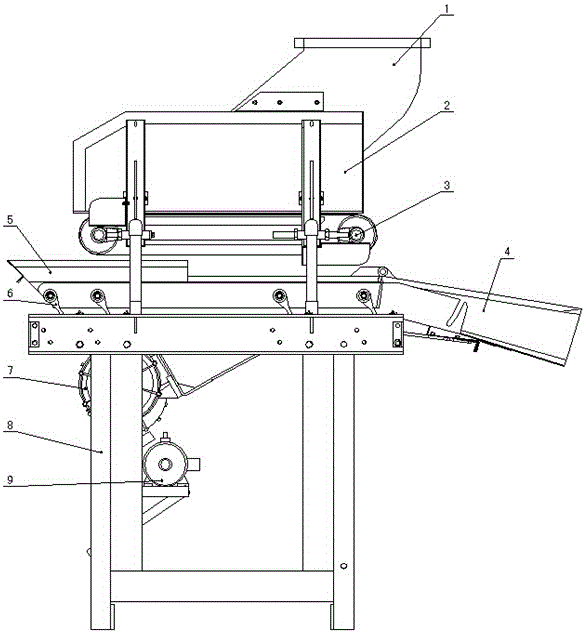

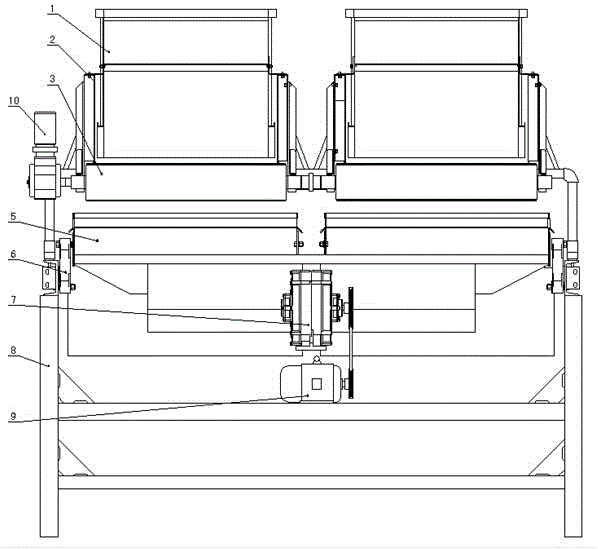

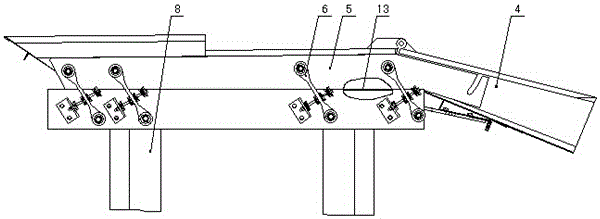

Feeding unit for corn huskers

The invention relates to the technical field of corn husking equipment and discloses a feeding unit for corn huskers. The feeding unit comprises a feed bucket, a belt conveying mechanism, a frame and a reducer. A conveying trough is provided below the belt conveying mechanism and connected with a frame through a plurality of support arms. A joint of each support arm and the frame is provided with a pressure spring. The conveying trough is connected with a rocking vibrator mounted on the frame; the discharge end of the conveying trough is connected with the feed end of a chute. A small guide plate and a large guide plate both in pyramid shapes are disposed at intervals within the chute. The discharge end of the chute is connected with a main unit of the corn husker. The feeding unit has the advantages that harvested corn ears disorderly entering the feed bucket are neatly arranged with ends facing forward and enter the main unit of the corn husker one by one, the corn ears are avoided blocking an entry of the main unit, the corn ears can be completely husked in the corn husker, operating efficiency of the corn husker is improved, fewer scattered kernels are damaged, and optimal husking is achieved.

Owner:JIUQUAN OK SEED MACHINERY

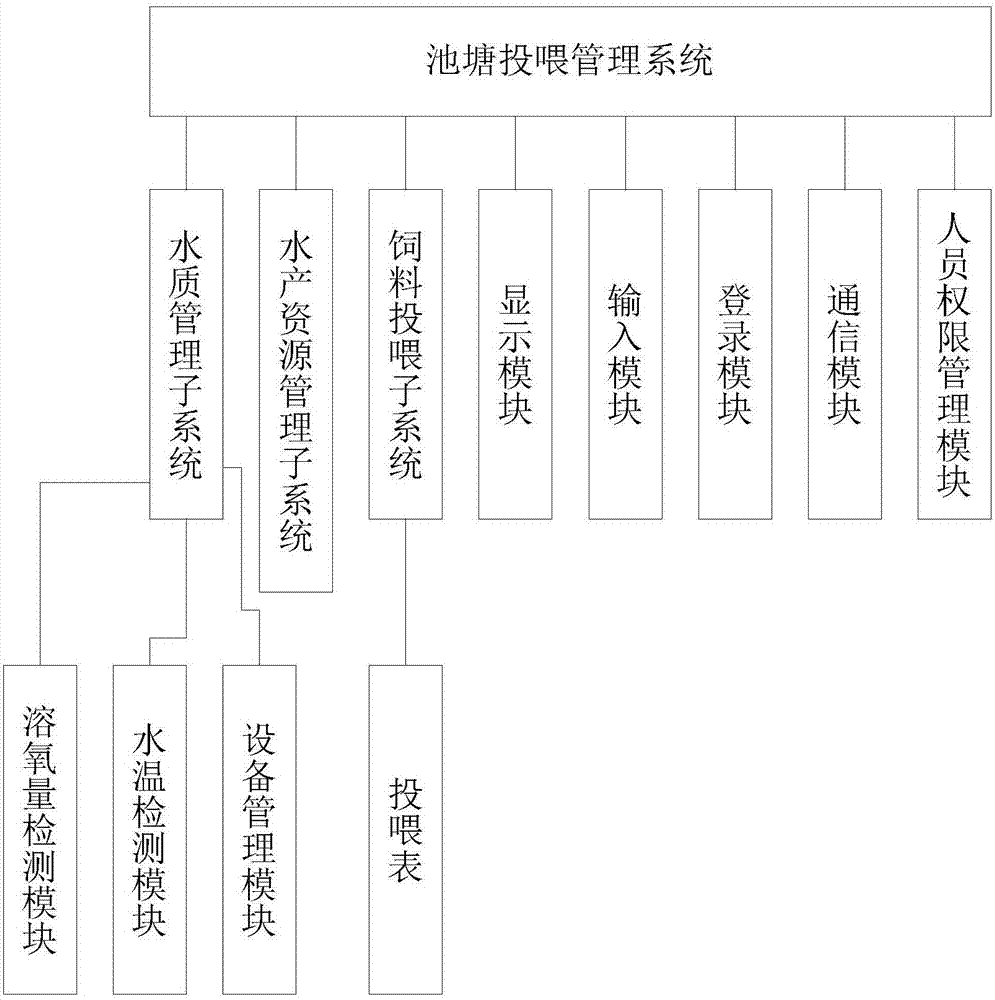

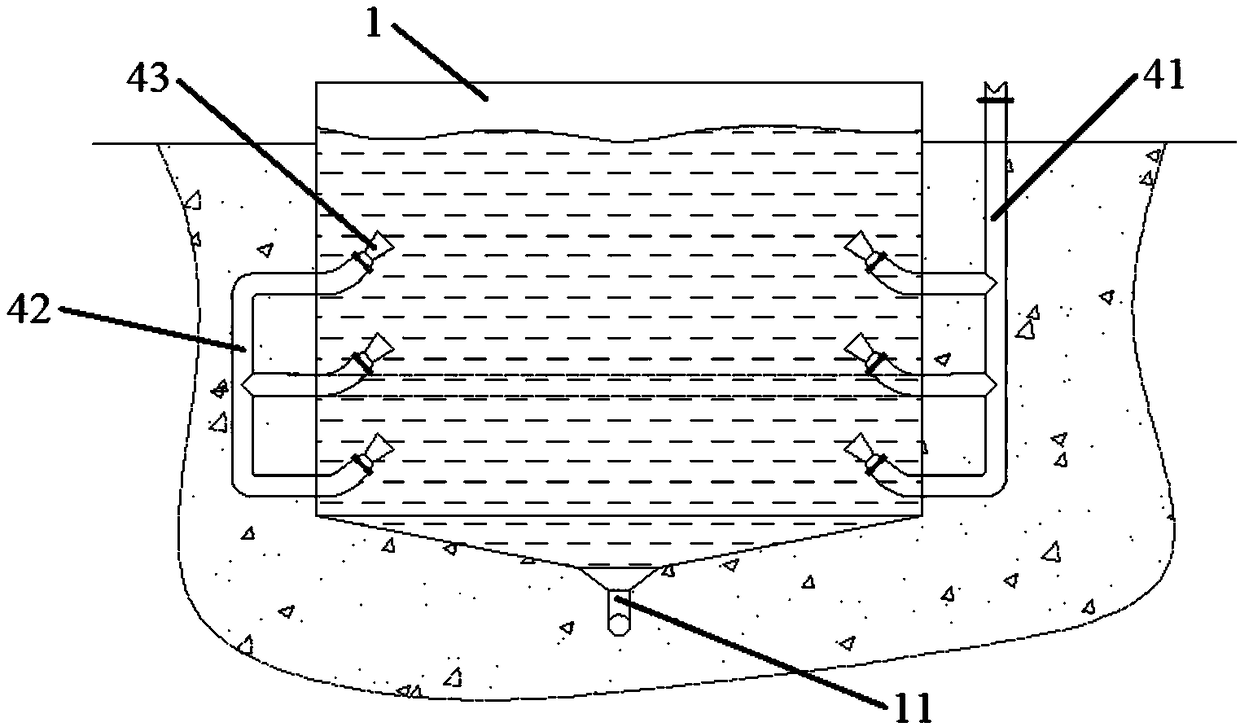

Pond feeding management system

InactiveCN107491022AReal-time detection and recording of feedingReal-time detection and recording of growthProgramme controlComputer controlFisheryAquatic product

The invention discloses a pond feeding management system which comprises the components of a water quality management subsystem that detects and records dissolved oxygen amount and water temperature of a fish trough; an aquatic product resource management subsystem which records kinds, numbers and average single weight of the fishes in the fish trough; and a forage feeding subsystem which searches and / or calculates the inputting amount of the forage in the fish trough according to the related parameters of the water quality management subsystem and the aquatic product resource management subsystem, wherein the related parameters comprise the dissolved oxygen amount, the water temperature, the kinds, the number and the average single weight of the fishes. The pond feeding management system can effectively control the feeding amount of the forage according to the aquatic product resource and the pond environment.

Owner:CHENGDU TONGWEI AUTOMATION EQUIP

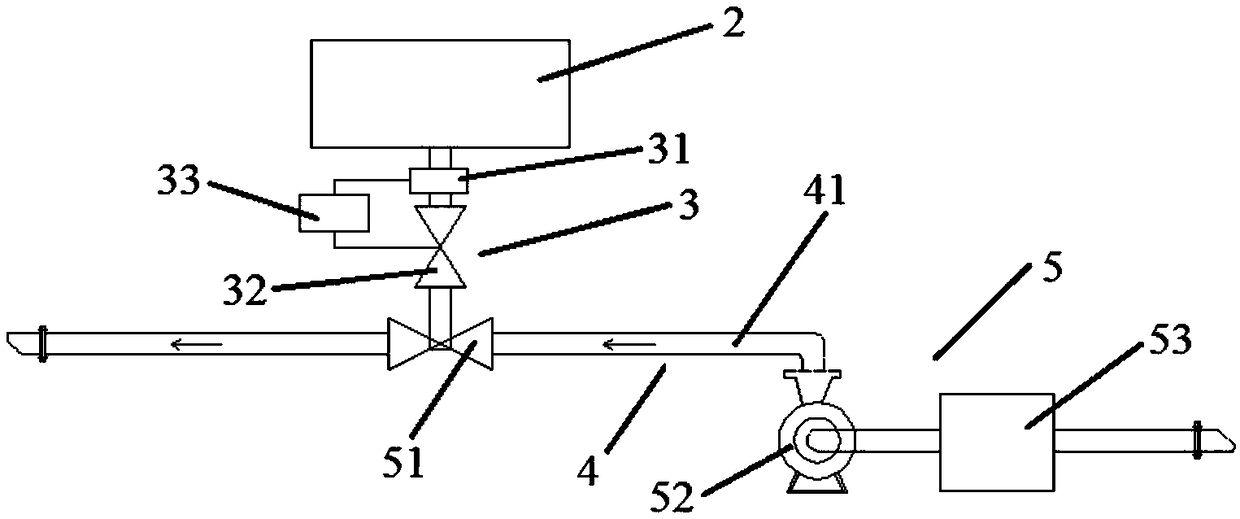

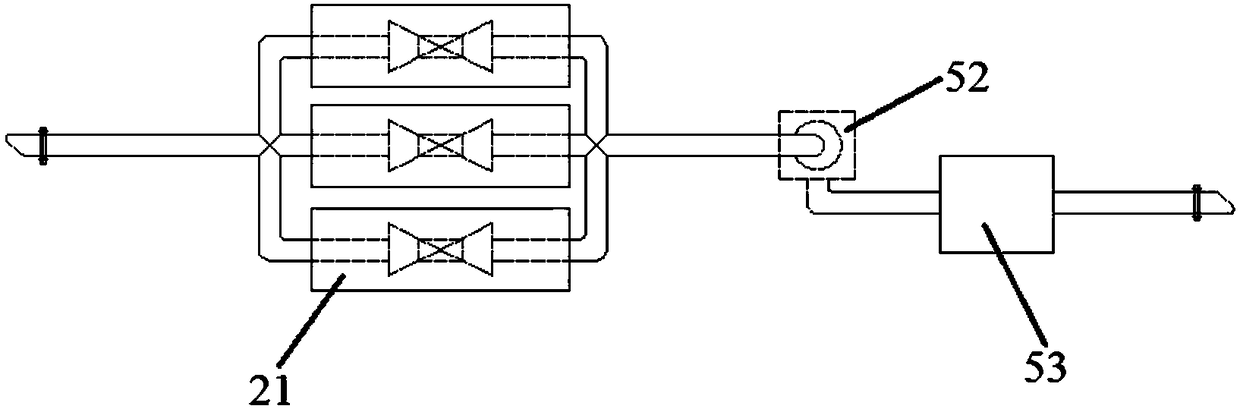

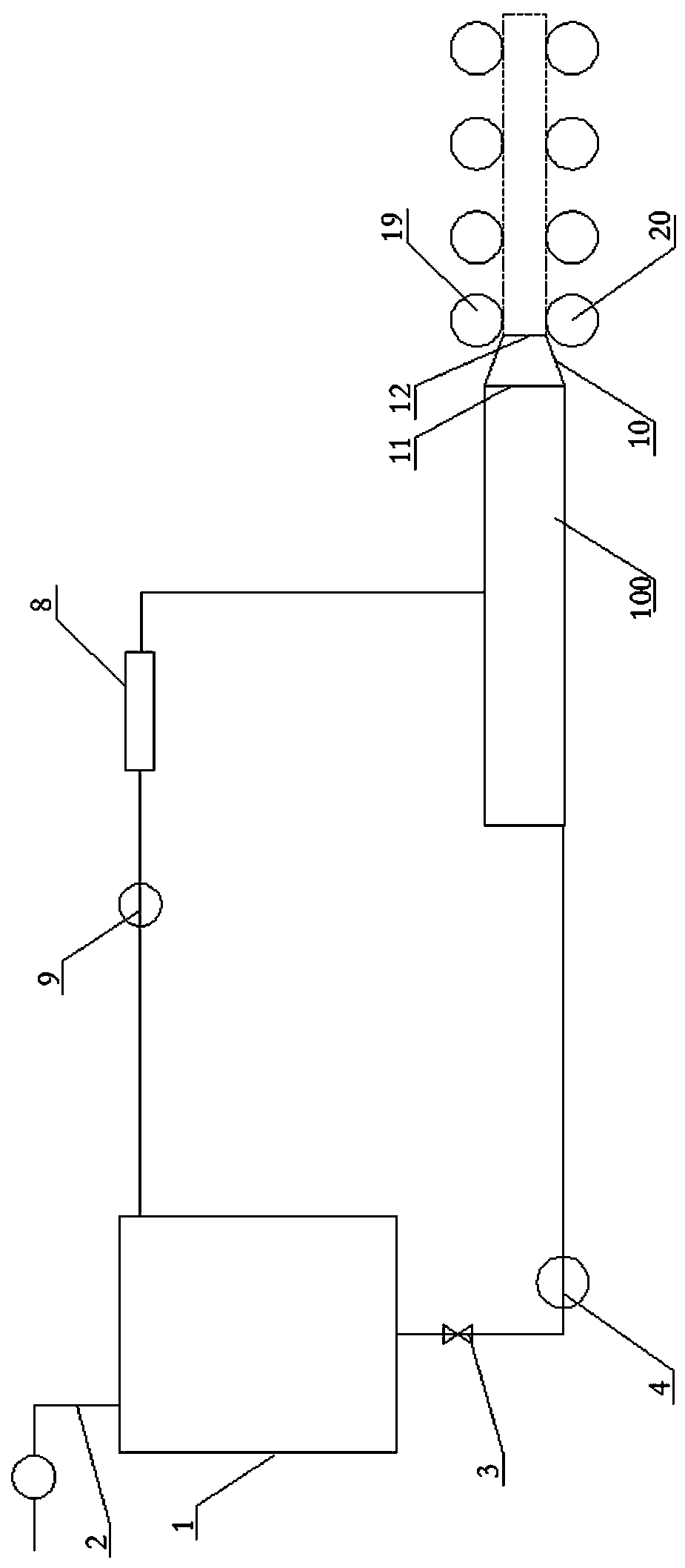

Feeding system for aquaculture

PendingCN108464269ASmooth entryImprove diffusivityClimate change adaptationPisciculture and aquariaDispersityEutrophication

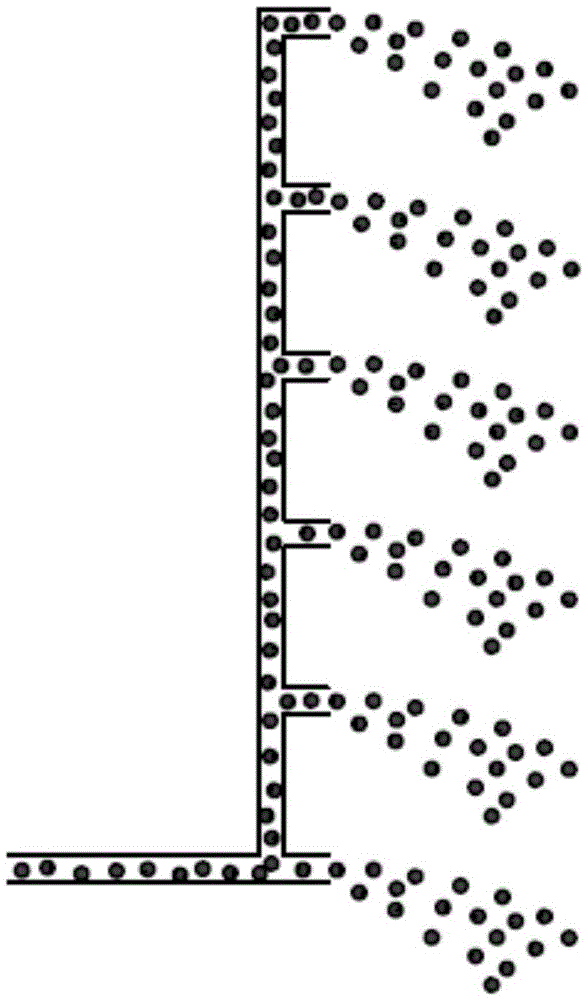

The invention relates to the technical field of aquaculture and discloses a feeding system for aquaculture. The feeding system comprises an aquaculture container and feeding equipment for feeding in the aquaculture container; and the feeding equipment comprises a feed box device, a control device for controlling the automatic feeding of the feed box device, a conveying pipeline and a power device.The control device is arranged to control the feed box device, so that the online dynamic proportioning of nutrients of a feed is realized, the feeding frequency and the feeding amount are controlled, the automation degree is high, the manpower and material resources are saved, and scientific feeding is realized; the power device ensures that the feed successfully enters the aquaculture container, and meanwhile, water entering the aquaculture container is purified, so that an aquaculture environment is kept clean; due to layered multipoint feeding of the conveying pipeline, the dispersity ofthe feed in water is improved, feeding is precise, and the feeding effect is improved; and the uniformity at the early stage of aquaculture of an aquatic product is improved, the utilization and conversion rates of the feed are increased, and the eutrophication degree of an aquaculture water body is reduced.

Owner:CHINA AGRI UNIV

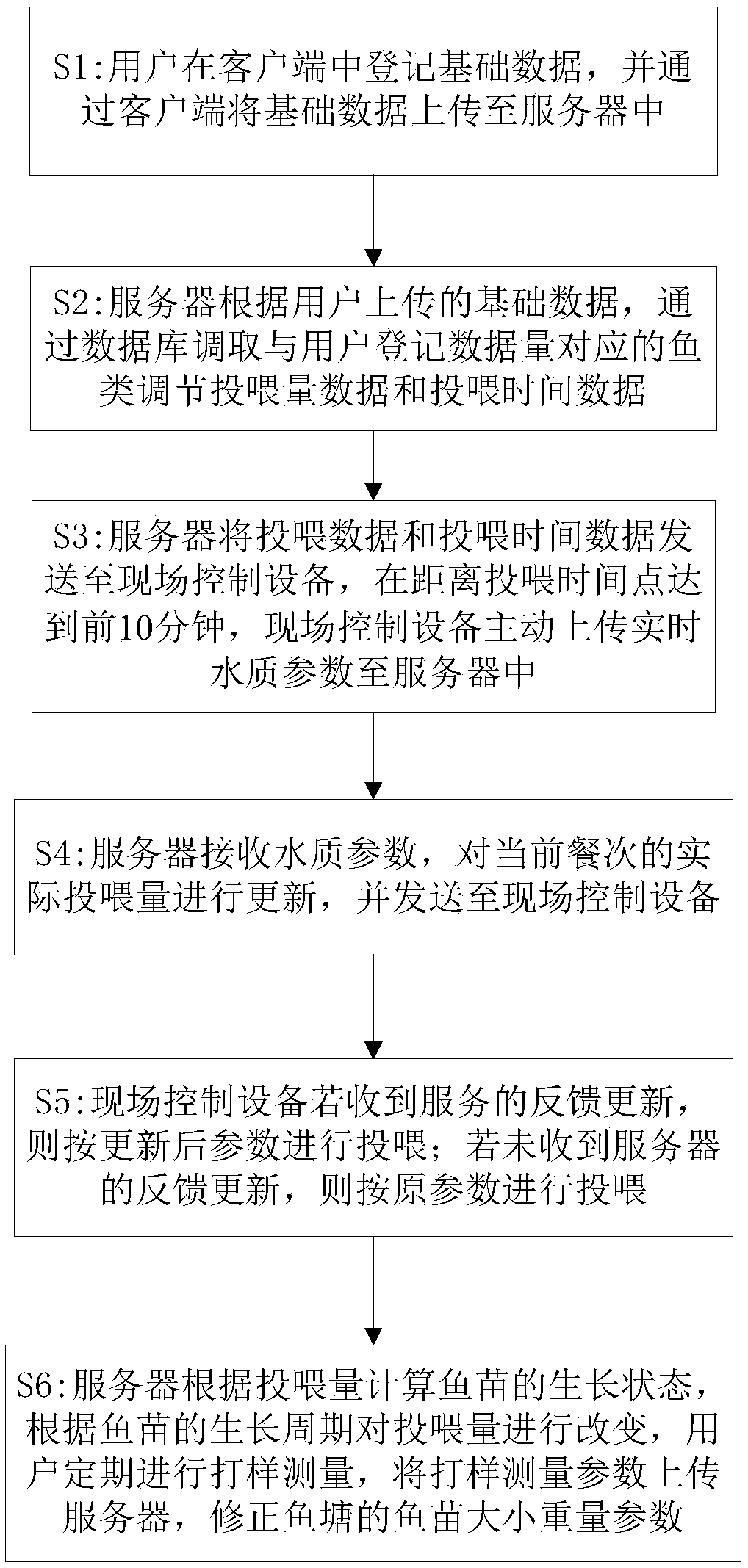

Fixed-time and automatic feeding method for fish pond

InactiveCN109566487ARealize online dynamic ratioRealize scientific feedingClimate change adaptationPisciculture and aquariaWater qualityClient-side

The invention discloses a fixed-time and automatic feeding method for a fish pond. The method is characterized by comprising the following steps that S1, a user registers basic data in a client side,and the basic data is uploaded to a server through the client side; S2, the server calls fish adjustment feeding amount data and feeding time data corresponding to user registration data amount through a database according to the basic data uploaded by the user; S3, the server sends the feeding data and the feeding time data to on-site control equipment, and 10 minutes before a feeding time pointis reached, the on-site control equipment automatically uploads real-time water quality parameters to the server; S4, the server receives the water quality parameters to upload the actual feeding amount of a current meal, and the updated feeding amount is sent to the on-site control equipment; S5, the on-site control equipment conducts feeding according to the updated parameters if the feedback update of a service is received.

Owner:四川渔光物联技术有限公司

Distributed feeding type potato seed metering device

The invention discloses a distributed feeding type potato seed metering device. The device comprises a rack, a test seed box, a lifting conveying auger mechanism, a spoon type seed metering mechanism,a transmission device and a control device. The test seed box is mounted on the rack; the lifting conveying auger mechanism is installed on the rack and located below the test seed box, and an outletof the test seed box is connected with a feeding port of the lifting conveying auger mechanism and used for controlling the feeding amount of seed potatoes; the spoon type seed metering mechanism ismounted on the rack and located behind the lifting conveying auger mechanism, and an outlet of the lifting conveying auger mechanism corresponds to an inlet of the spoon type seed metering mechanism and is used for single-grain separation, seed filling and seed metering of seed potatoes; the transmission device is arranged on the rack and is respectively connected with the lifting conveying augermechanism and the spoon type seed metering mechanism; and the control device is installed on the rack, connected with the transmission device and used for adjusting the working speed of the transmission device in real time. According to the device, the problems of high seed leakage rate, low efficiency and the like of a spoon-type potato seeder are fundamentally solved.

Owner:CHINESE ACAD OF AGRI MECHANIZATION SCI

Indoor domestication method for Japanese eel fries

InactiveCN104381164AAvoid disadvantagesSimple processClimate change adaptationPisciculture and aquariaFresh water organismFresh water

The invention relates to an indoor domestication method for Japanese eel fries. The method comprises the following steps of completely shifting captured glass eels into fresh water for aquaculture by a method of gradually changing fresh water; directly feeding eel fries by taking frozen minced artificial formulated feed as initial feed, and taking an elaborated artificial feeding and management method as assistance; when the glass eels are changed into black fry eels, feeding with powdery artificial formulated feed, matching the weight of the feed and water according to a ratio, controlling the feeding quantity, regularly sucking dirt and changing water each day, and timely feeding individuals in different specifications in different ponds. The method is simple in process and low in cost, effectively overcomes the defect of adopting tubificidae as initial feed, ensures that the survival rate of the eel fries is over 99 percent int the domestication process, and has a good application prospect.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

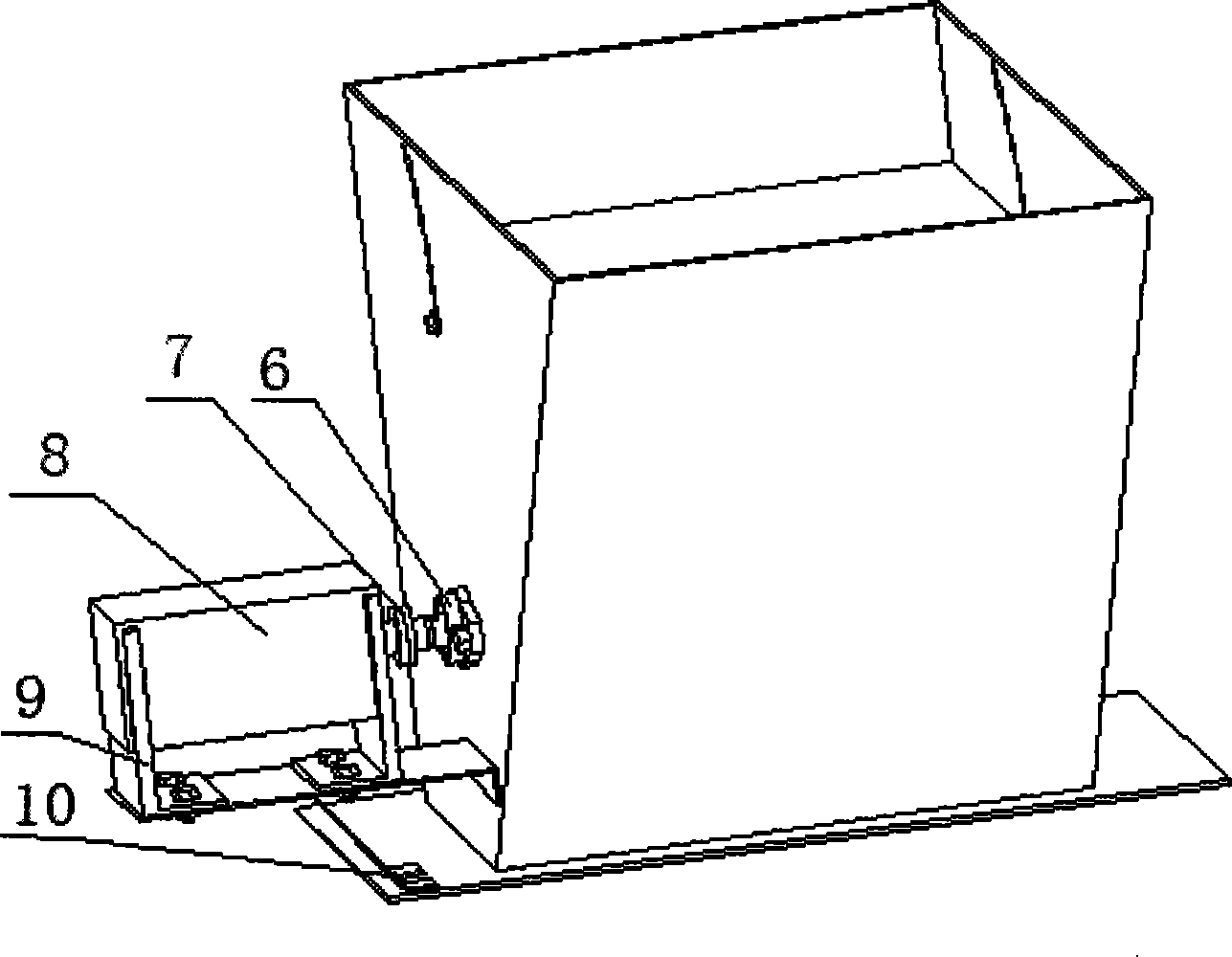

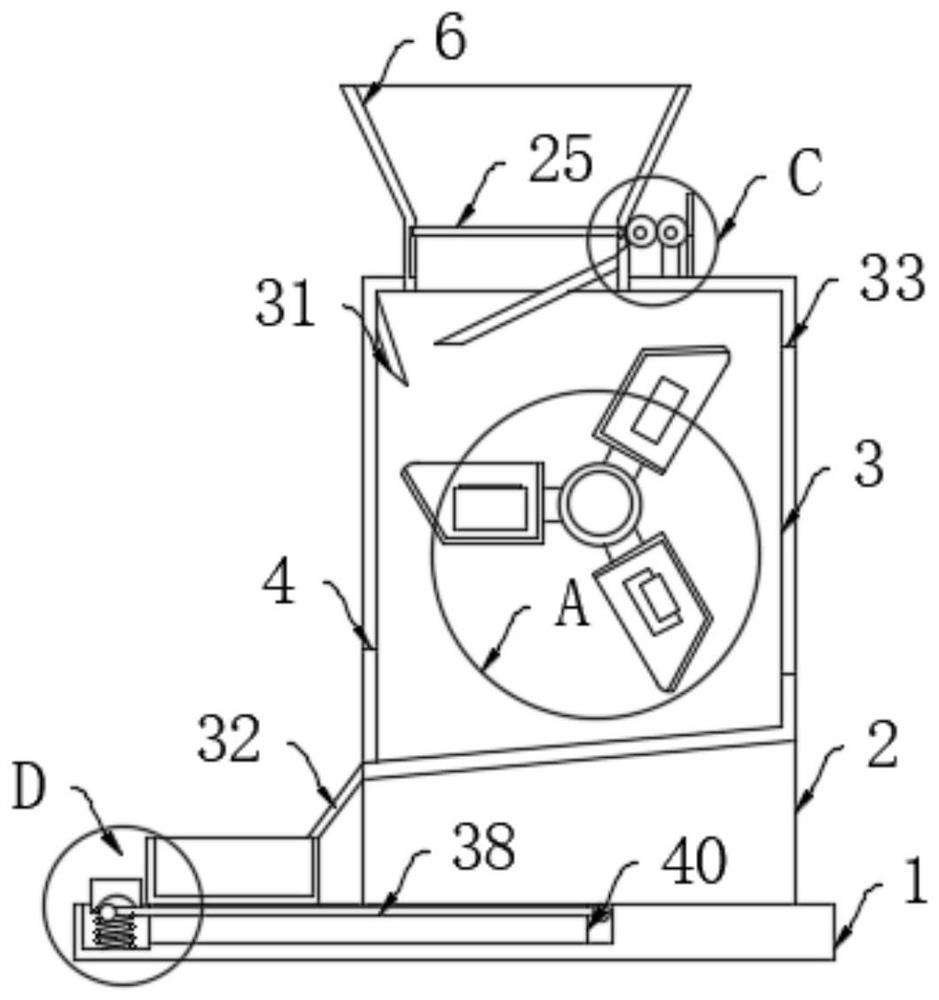

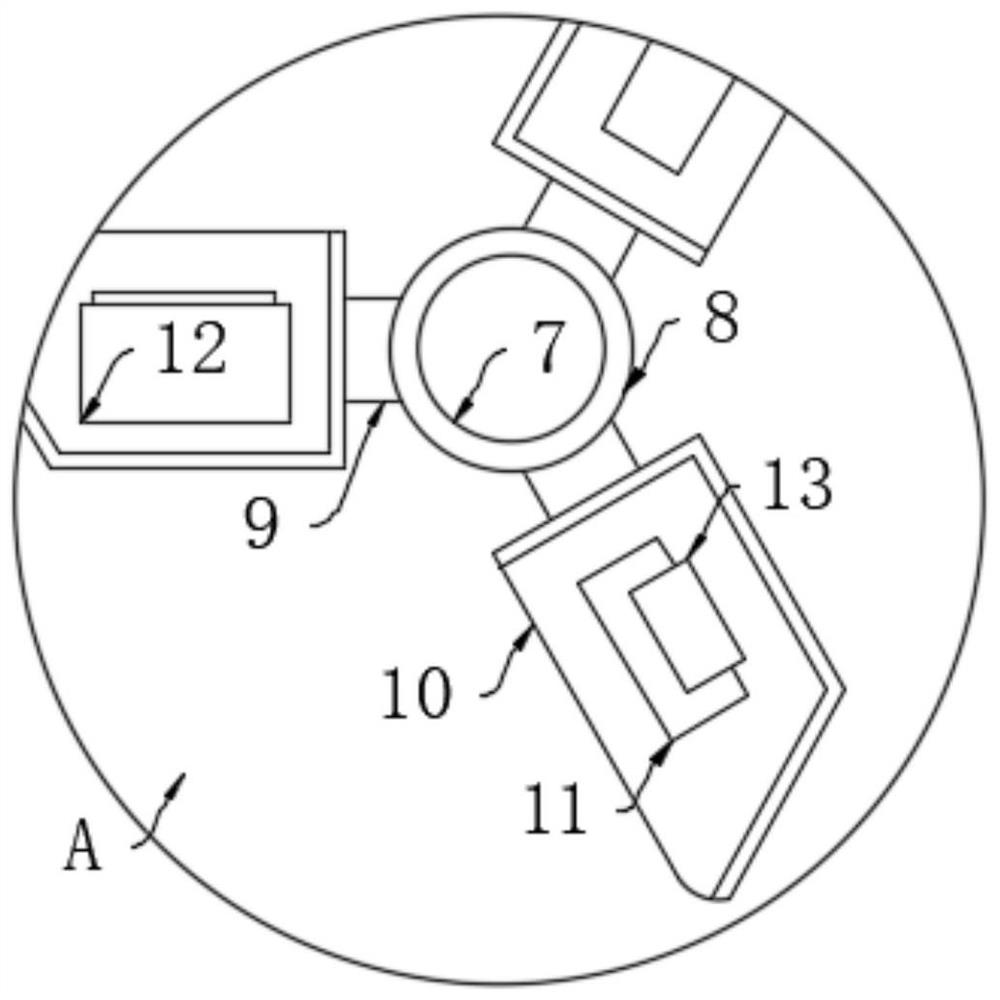

Feeder for crushing of crop straw material

InactiveCN104221899AContinuous and even feedingImprove delivery capacityAnimal feeding devicesCouplingEngineering

The invention discloses a feeder for crushing of crop straw material. The feeder comprises a feeding hopper, wherein the bottom part of the feeding hopper is provided with a rotary shaft, one end of the rotary shaft is fixedly arranged on the outer wall of the feeding hopper by a bearing, the other end of the rotary shaft penetrates through the bearing and is connected with an output shaft of a motor through an elastic coupling, the bottom part of the motor is welded with a motor frame, the bottom part of the motor frame is fixedly arranged on a support plate by a connecting rod, one side of the motor frame is fixedly arranged on the outside surface of the feeding hopper by a connecting rod, the rotary shaft is welded with a plurality of elastic teeth, and a 90-degree staggering structure is formed between the axially arranged elastic teeth. The feeder has the advantages that by controlling the rotation speed of the motor and the lifting angle of a retaining plate, the feeding amount can be controlled, the material is continuously and uniformly fed into a spiral conveying device, and the conveying property of the crop straw in the spiral conveying device is improved; the structure is simple, the installation is convenient, and the operation and use are very rapid.

Owner:INNER MONGOLIA AGRICULTURAL UNIVERSITY

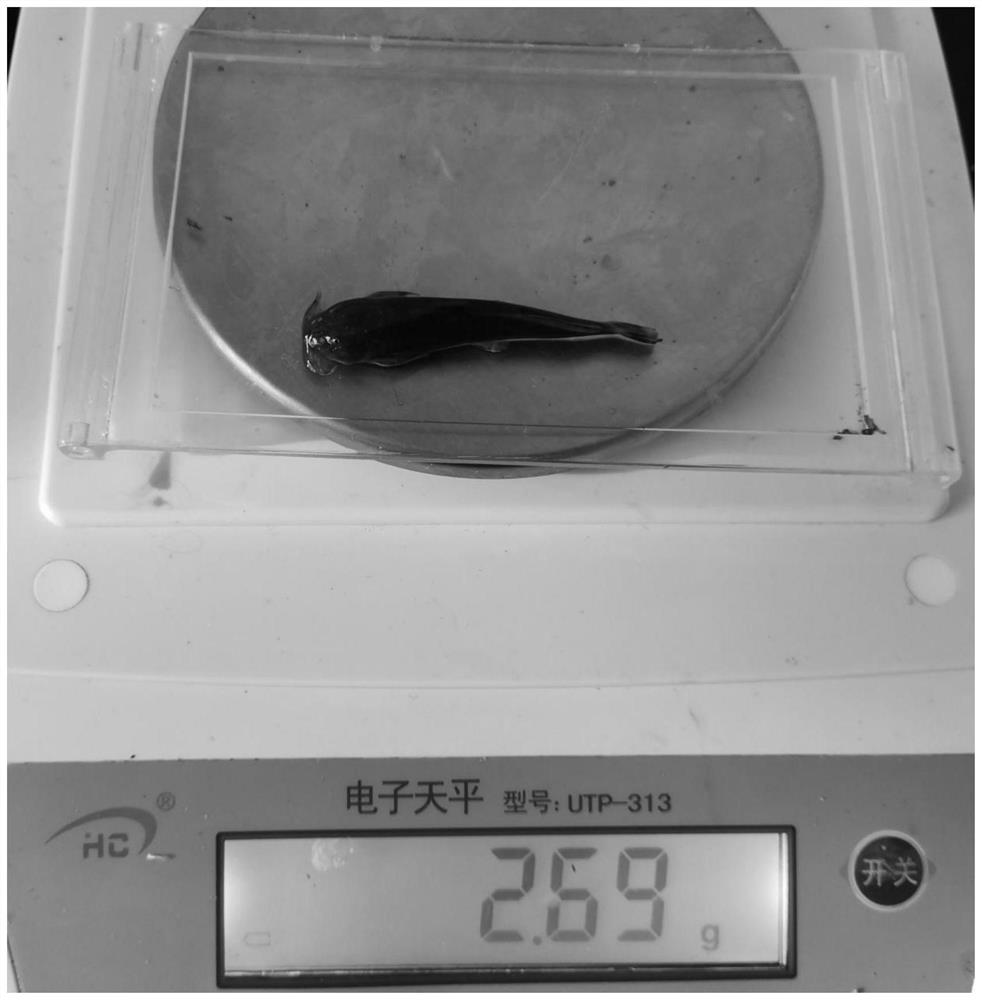

Tachysurus fulvidraco extruded pellet compound feed and production method thereof

InactiveCN108740573AEasy to observe feeding situationKeep abreast of health conditionsFodderClimate change adaptationAnti stressCulture environment

The invention relates to the field of feeds and particularly relates to a tachysurus fulvidraco extruded pellet compound feed and a production method thereof, wherein the tachysurus fulvidraco extruded pellet compound feed comprises an energy feed raw material, a protein feed raw material, a compound premix feed and auxiliary materials. The tachysurus fulvidraco extruded pellet compound feed can float on the water surface, so that the ingestion situation of tachysurus fulvidraco can be conveniently observed, and the feeding amount is controlled, and thus the health situation of tachysurus fulvidraco can be learned in time. By virtue of culturing the tachysurus fulvidraco with the extruded pellet compound feed, the cultured tachysurus fulvidraco is natural in color, uniform in tachysurus fulvidraco body, fresh and tender in flesh, anti-stress, anti-transportation, and low in feed coefficient, so that the tachysurus fulvidraco culturing cost is reduced, labor is reduced, wastes are reduced, the growth speed is increased, tachysurus fulvidraco diseases are reduced, thus the culture benefits are improved, resources are saved, and the culture environment is protected.

Owner:岳阳市新宏饲料有限公司

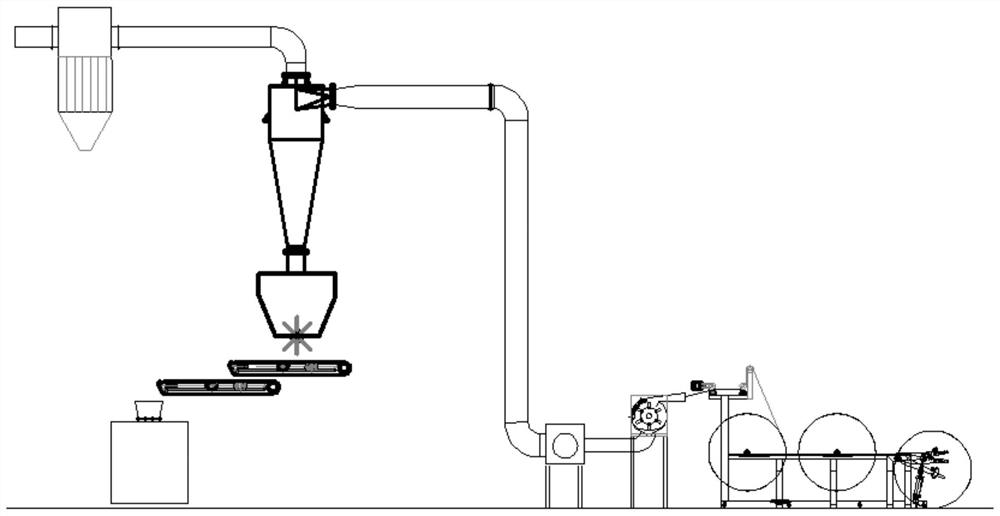

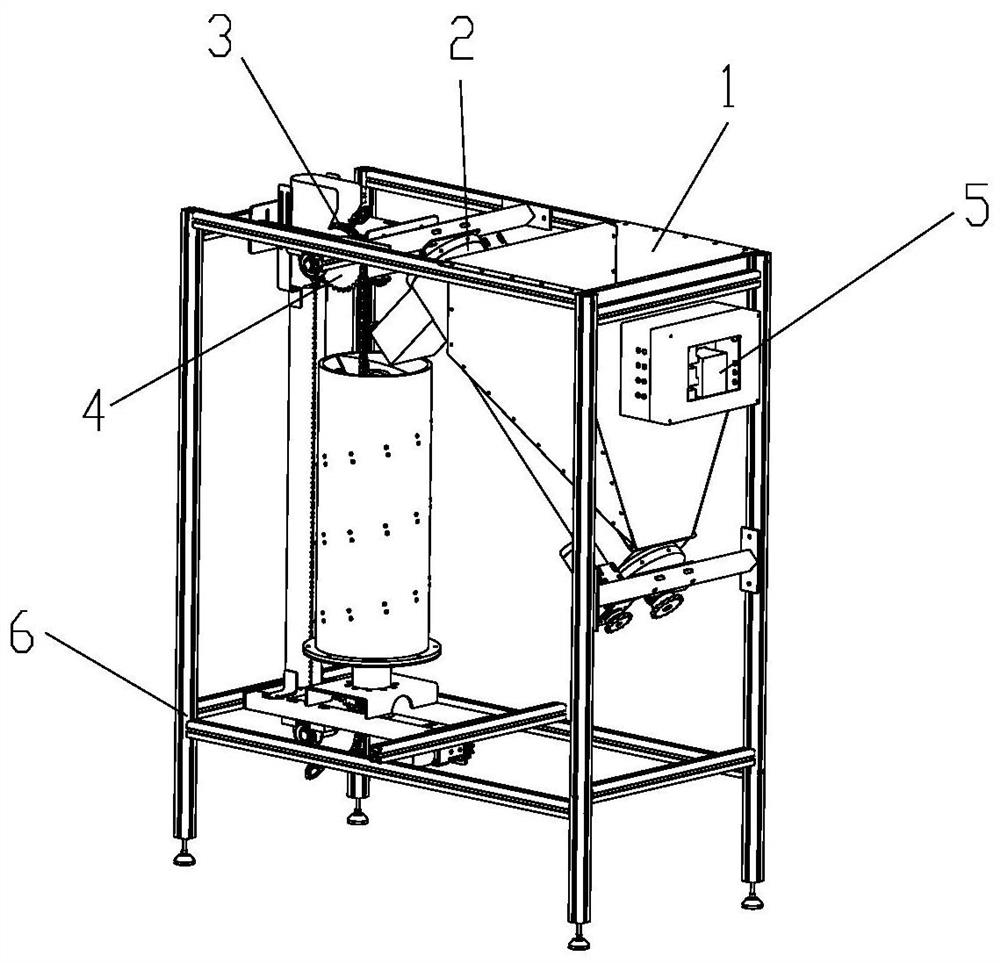

Pulp crushing equipment and method for production of cellulose fiber by solvent method

InactiveCN111841760AGuaranteed crushing effectReduce lossesWeighing apparatus for continuous material flowGrain treatmentsPulp and paper industryCellulose fiber

The invention relates to a pulp crushing equipment and method for cellulose fiber production by a solvent method. The technological process of the pulp crushing method is as follows: pulp is conveyedinto a grinding machine by a feeding system for crushing, and then the crushed pulp is conveyed into a cyclone separator by a conveying fan; and wind and the crushed pulp are separated by the cycloneseparator, the wind is sent into an exhaust channel and treated by a recovery system, and the pulp separated from the wind enters a storage and metering system. The pulp crushing equipment completes the quantitative feeding, crushing, conveying, storage and metering of the pulp through the feeding system, the grinding machine, a conveying system and the storage and metering system. The effect of pulp crushing can be ensured, the degree of pulp crushing after crushing by the grinding machine is 5-200g / L, and all requirements for cellulose fiber production by the solvent method (NMMO) is met. Meanwhile, the recovery system is added, so the loss of pulp powder with low degree of crushing is minimized in the process of conveying and mixing, and the loss is less than 0.01%.

Owner:唐山三友远达纤维有限公司

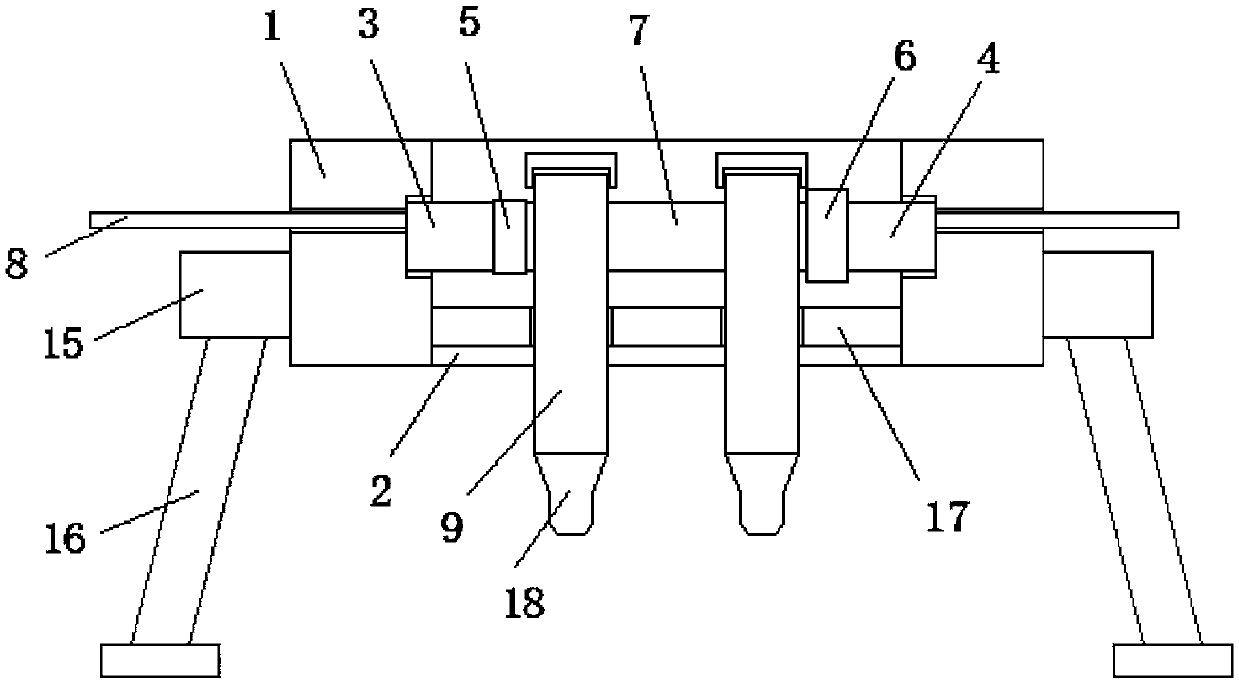

Spiral feeding scale

InactiveCN107131935AUniform feedingHigh measurement accuracyWeighing apparatus for materials with special property/formWeighing apparatus with automatic feed/dischargeImpellerSpiral blade

The invention relates to a screw feeding scale, which is provided with a feeding motor reducer and a screw feeder arranged on a support; the screw feeder includes a silo for storing materials; a skein shaft is coaxially arranged in the silo ; One end of the skein shaft is connected to the rotating shaft of the feeding motor reducer; the impeller or spiral blade is evenly distributed on the circumference of the skein shaft; a weighing mechanism is installed between the screw feeder and the support; the center of the weighing mechanism Corresponding to the setting of the center of gravity of both the feed motor reducer and the screw feeder, the weighing mechanism includes a scale body bracket, a load cell and a scale body support frame arranged in sequence from top to bottom. The invention performs quantitative feeding through the rotation of the twisted wire shaft, so that the material can be fed evenly, which greatly improves the metering accuracy of the material, and can prevent the material from being flushed during the flow. At the same time, adding a weighing mechanism can further improve Control the amount of materials, double guarantee, so that the measurement accuracy is higher.

Owner:蒋丽芳

Method for breeding sepia pharaonis in greenhouse

InactiveCN109526809AReduce cannibalismGrow fastClimate change adaptationPisciculture and aquariaSepia pharaonisGreenhouse

The invention discloses a method for breeding sepia pharaonis in a greenhouse. According to the method, breeding conditions are controlled, breeding management is carried out as follows: water temperature is controlled to be 23-33 DEG C, salinity is controlled to be 24-30, the transparency of pond water is controlled to be 40-60 cm, dissolved oxygen is not lower than 5 mg / L, ammonia nitrogen content is not higher than 0.1 mg / L, meanwhile, by the characteristics that the temperature and humidity of the greenhouse can be regulated, the density of the sepia pharaonis and the size and feeding amount of baits are controlled, mutual killing of the sepia pharaonis in a breeding process is relieved and the like, the sepia pharaonis can grow fast and appear on the markets early, and good advantagesare achieved. Therefore, the method for breeding the sepia pharaonis in the greenhouse is a sepia pharaonis breeding method which is high in rate of survival, high in growing speed and easy to operate, and is stable and high in yield.

Owner:NINGBO UNIV

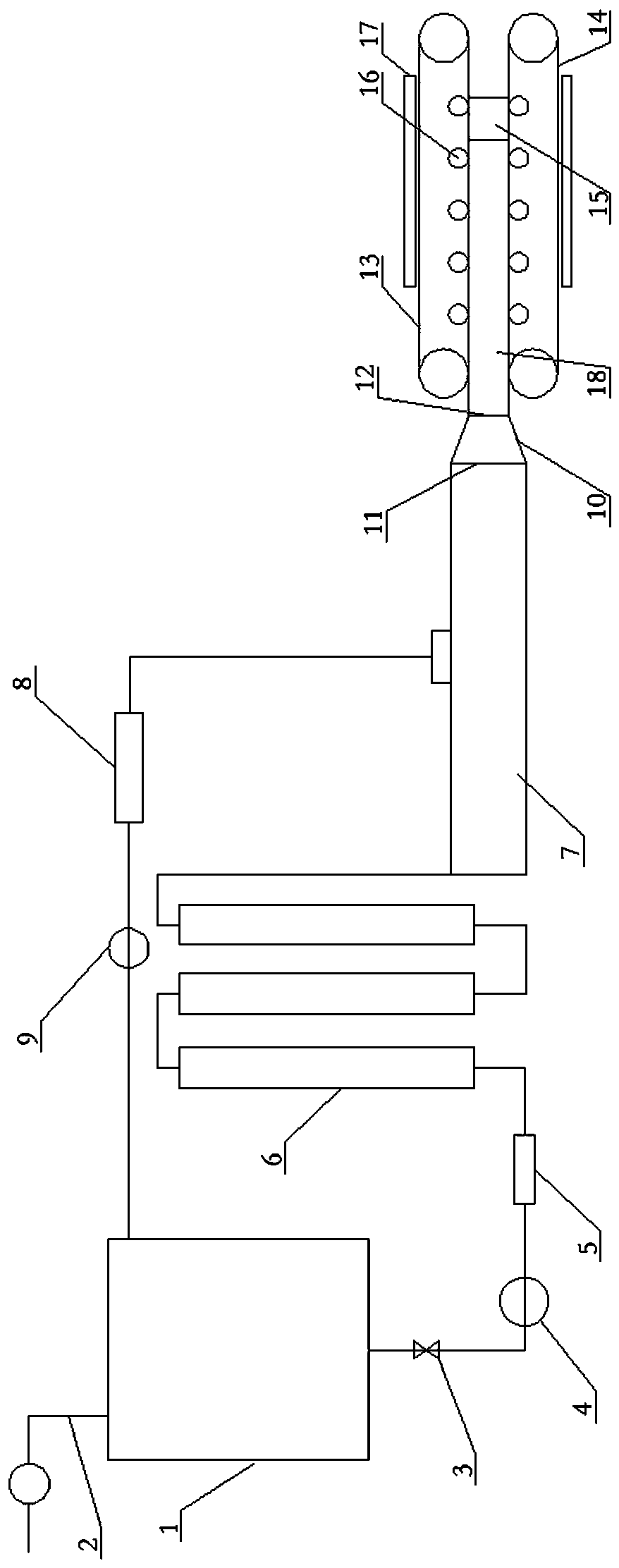

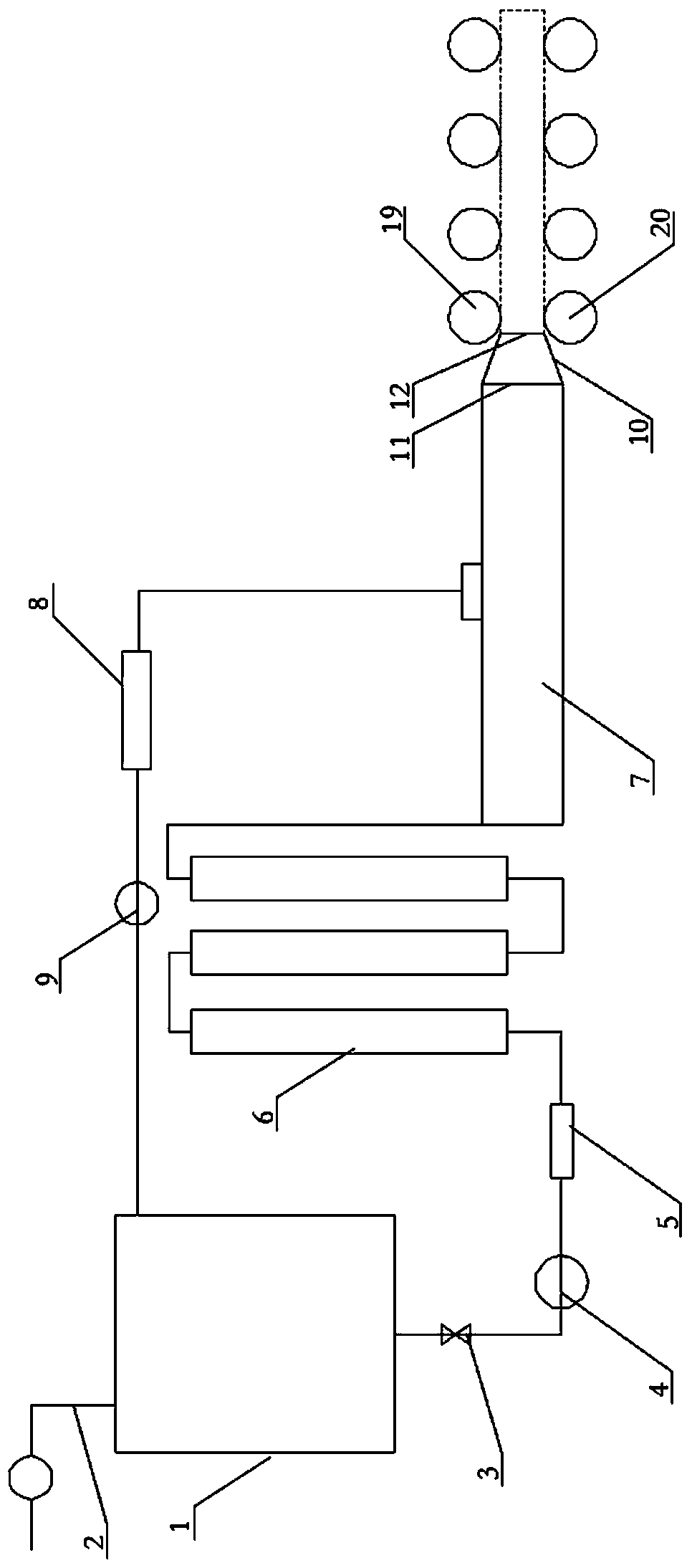

One-time reaction extrusion forming production line for acrylic plates

PendingCN110774554AEnsure molding is free from defectsNo differenceChemical/physical/physico-chemical processesFlat articlesProduction lineReactive extrusion

The invention relates to a one-time reaction extrusion forming production line for acrylic plates. The one-time reaction extrusion forming production line comprises a reaction still with an MMA feed pipe. The lower portion of the reaction still is connected with an initiator adder and multiple tubular reactors in series through a discharge valve and then connected with an inlet of a screw devolatilization device, an exhaust port of the screw devolatilization device is connected to the upper portion of the reaction still through a condenser, an extrusion port of the screw devolatilization device is connected with a cylindrical inlet in one end of a homogenizing and feeding barrel, the middle of the homogenizing and feeding barrel is of a structure stretching from the cylindrical inlet in one end to a horizontal square long-strip-shaped outlet in the other end in a smooth transition manner, and the horizontal square long-strip-shaped outlet in the other end of the homogenizing and feeding barrel is connected with a plate forming device. By means of the production line, the beneficial effects that a raw material one-time full polymerization reaction is achieved, the plates of variouslength specifications are stably produced through extrusion forming, no volatile gas pollution exists, the forming quality is good, the production efficiency is high, and the cost is low are achieved.

Owner:TAIXING TOMSON ACRYLIC CO LTD

Using method for automatic feed tray

The present invention discloses a using method for an automatic feed tray. The method comprises the following steps: (1) opening a screw feeder, wherein the screw feeder pushes forage to move toward an orifice of an upper end of a feed pipe; (2) discharging the forage from the upper end of the feed pipe, and entering a trough along a channel between a circular cone and a height-limiting cylinder; (3) after the height of a forage layer is lower than that of a laser emitter / a laser receiver, receiving a laser signal by using the laser receiver and transmitting the signal to a central processing unit; (4) after the central processing unit receives the laser signal, driving a drive gear to rotate counterclockwise by using a rotary electric machine, so that the height-limiting cylinder welded to a rack gear moves upward and stops moving until the height-limiting cylinder touches an upstroke switch; and (5) after the height of the forage layer is higher than that of the laser emitter / the laser receiver, controlling the height-limiting cylinder to move downward by using the central processing unit and stops moving until the height-limiting cylinder touches a downstroke switch. According to the using method for the automatic feed tray, forage replenishment quantity is controlled by adjusting channel width.

Owner:重庆市合川区麒麟畜产品有限责任公司

A Distributed Feeding Potato Seed Metering Device

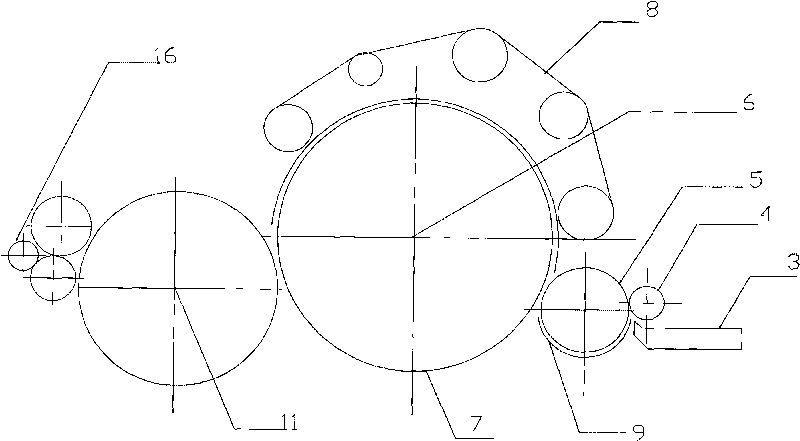

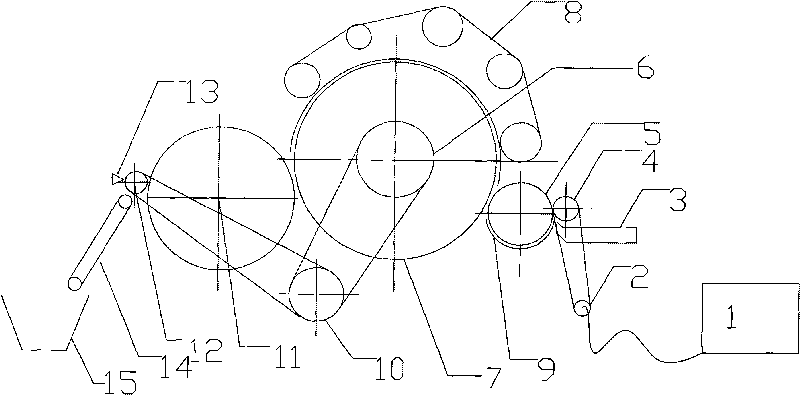

A distributed feeding potato seeding device, comprising: a frame; a test seed box installed on the frame; a lifting auger mechanism installed on the frame and located under the test seed box , the outlet of the test seed box is connected to the feeding port of the lifting auger mechanism for controlling the feeding amount of seed potatoes; the spoon type seeding mechanism is installed on the frame and is located in the lifting Behind the auger mechanism, the outlet of the lifting auger mechanism is set corresponding to the entrance of the scoop-type seed metering mechanism, which is used for single seed separation, filling and seeding of seed potatoes; the transmission device is installed on the on the frame, and respectively connected with the lifting auger mechanism and the scoop type seeding mechanism; and the control device, installed on the frame, the control device is connected with the transmission device, and adjusts the The operating speed of the transmission. The invention fundamentally solves the problems of high seed leakage rate and low efficiency of the spoon-type potato planter.

Owner:CHINESE ACAD OF AGRI MECHANIZATION SCI

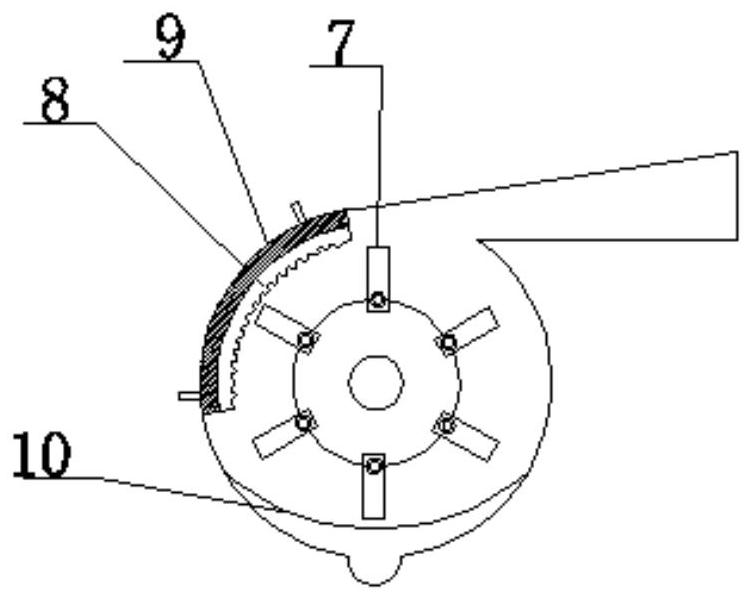

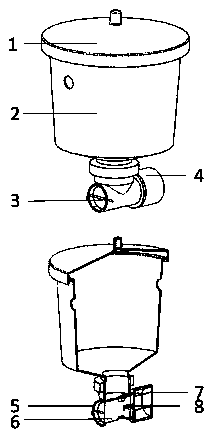

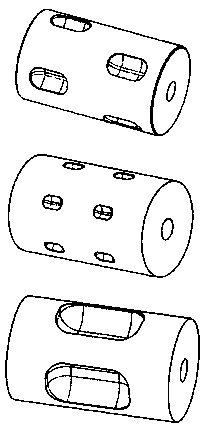

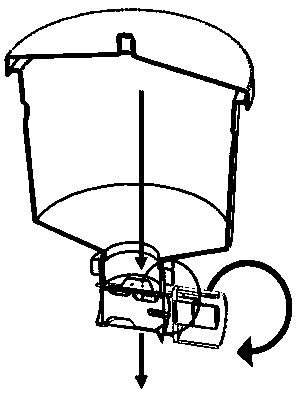

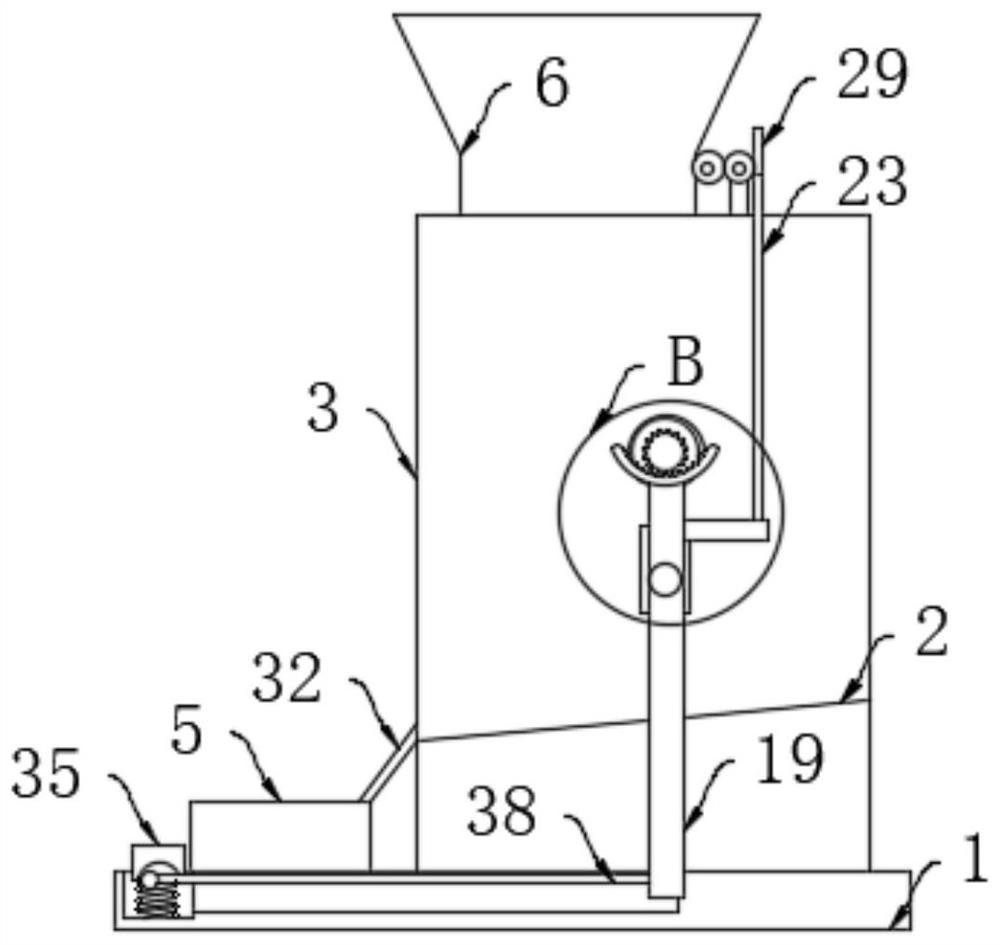

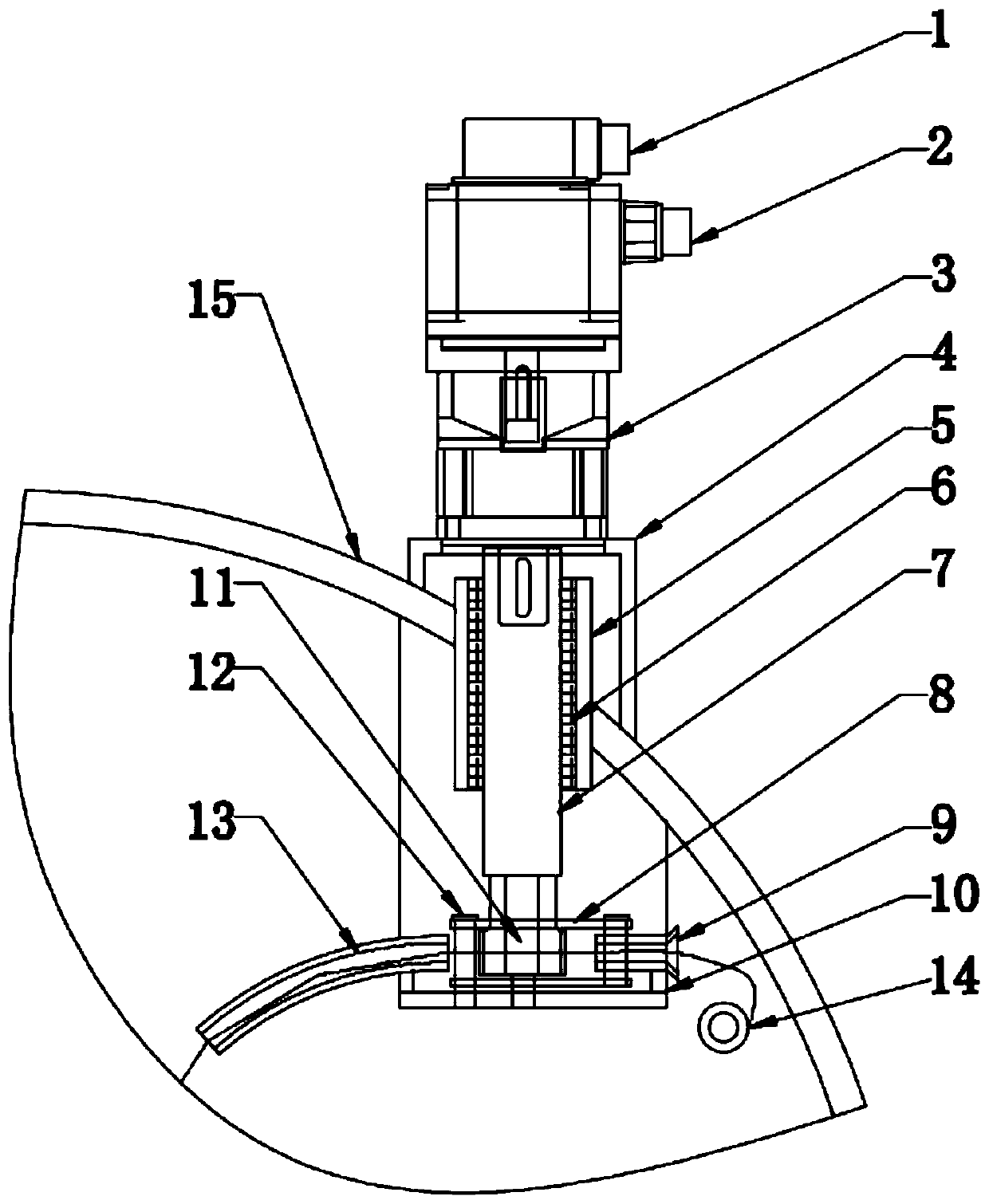

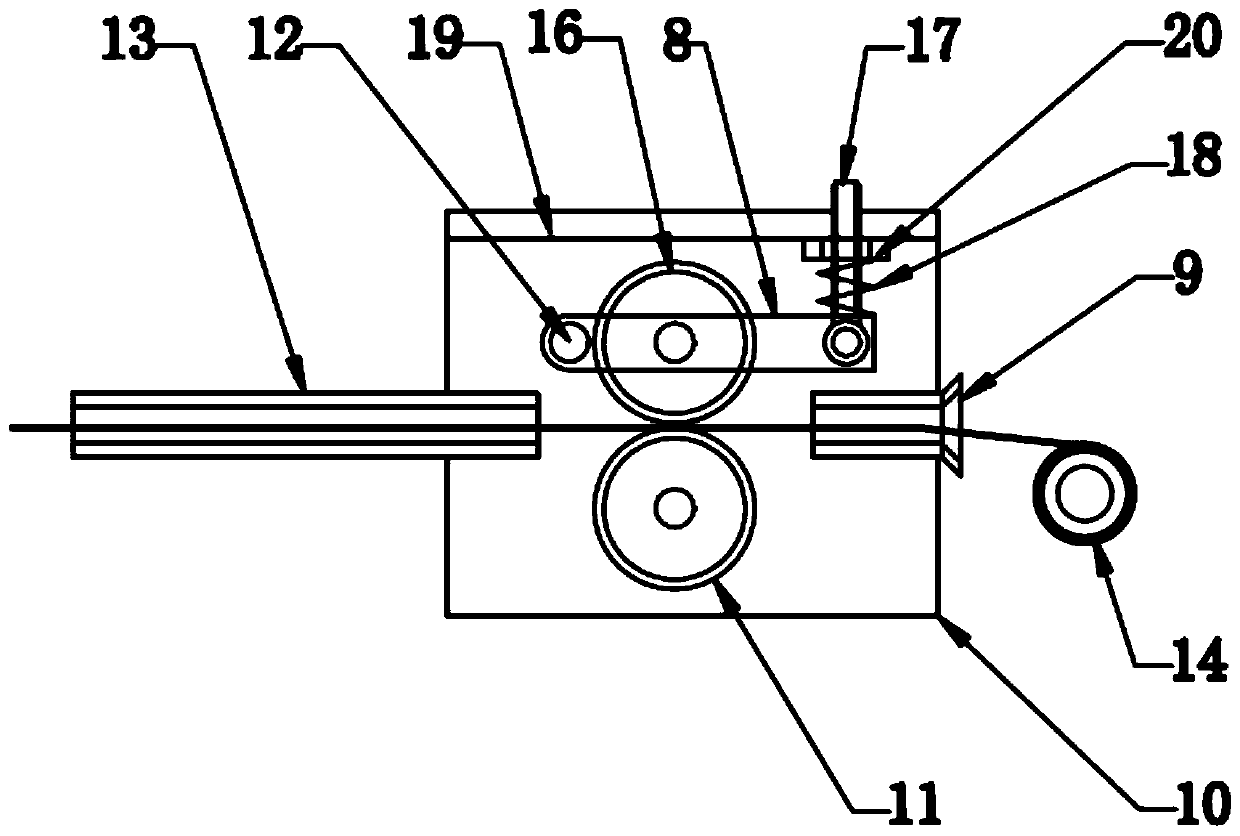

Cave-type accurate automatic bait feeder

PendingCN110074032ASuitable for growthThe feeding effect is suitableClimate change adaptationPisciculture and aquariaMotor driveElectric machinery

The invention discloses a cave-type accurate automatic bait feeder, comprising a storage bin portion and a charging and feeding portion connected to a lower mouth of a storage bin. The storage bin portion is composed of a bait bin and a bait bin cover. The charging and feeding portion is composed of a quantitative discharger, a gear motor, a neck bush, a connecting shaft and a shell. The bait in the bait bin covers on the quantitative discharger which is provided with a cave and the cave are fully filled with the bait; when working, the gear motor drives the quantitative discharger to rotate,when the cave rotates to the opening below the shell, bait in the cave falls automatically, so as to realize feeding. Through customizing the size and number of the cave and setting the rotation speedand working duration of the gear motor, the timed and quantitative feeding of the bait is realized by the structure, the workload of bait feeding is greatly reduced, the waste of the bait is greatlyreduced, and large amount of manpower and material resources are saved.

Owner:苏州益品德环境科技有限公司

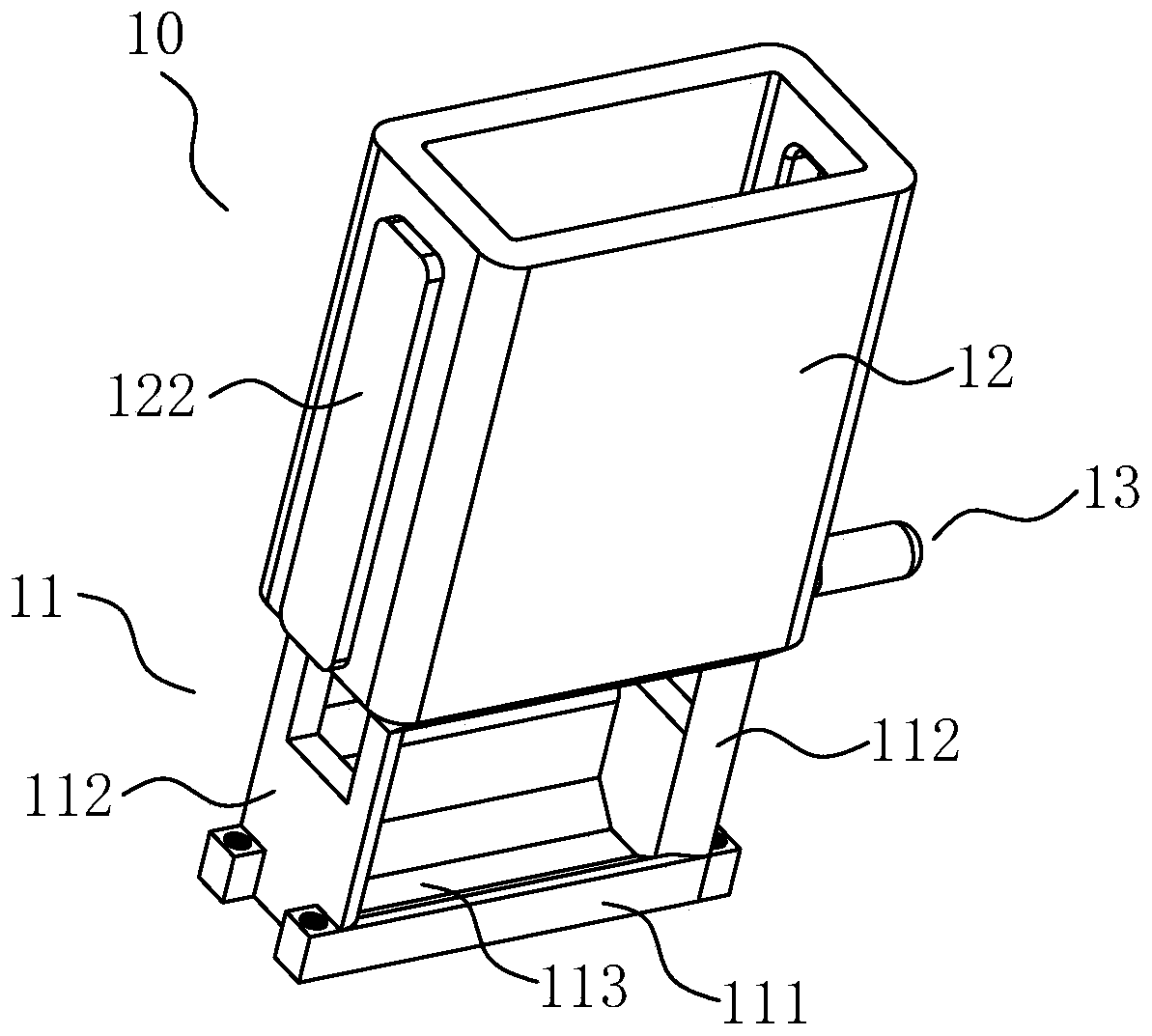

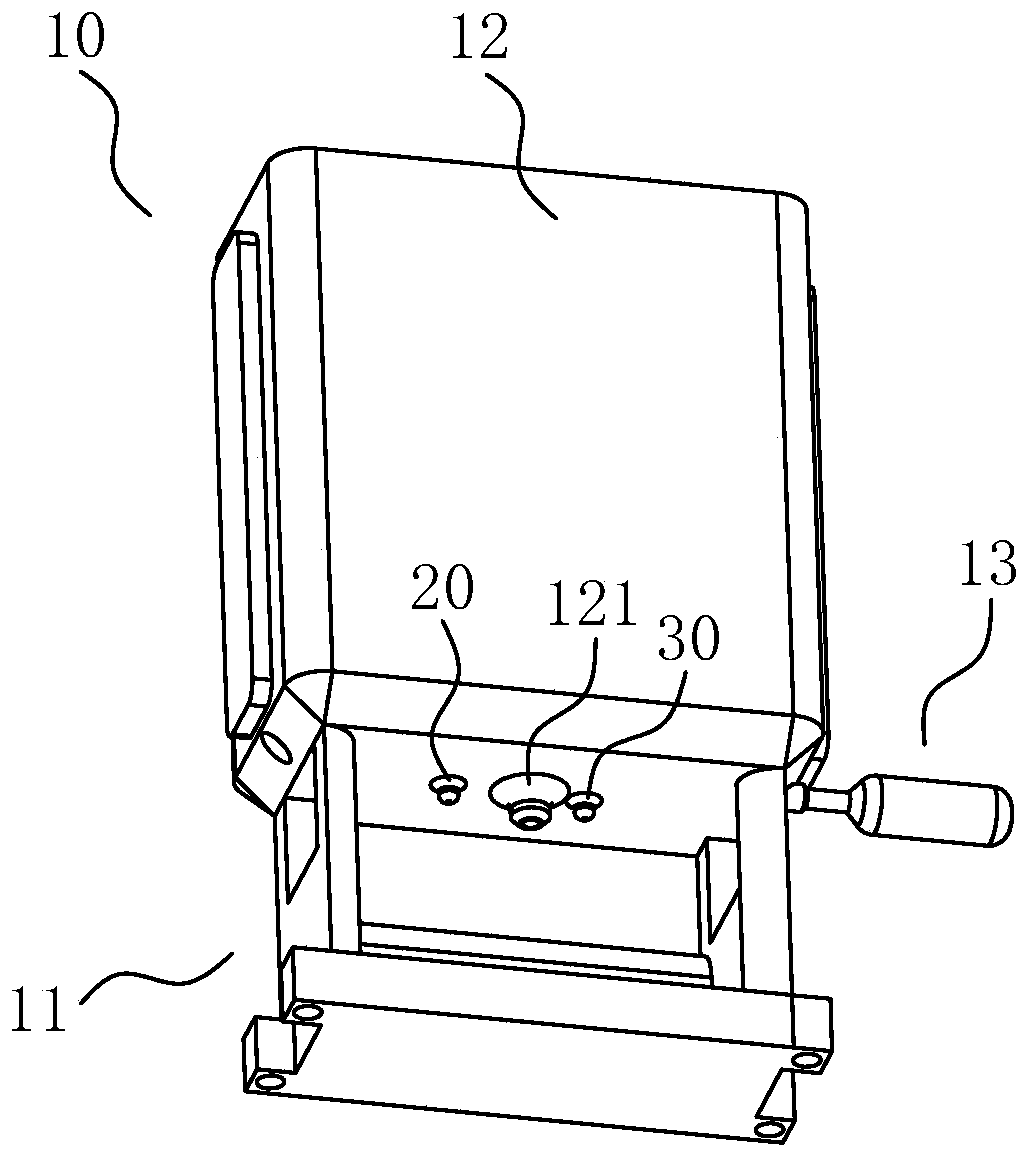

A slow-feeding natural feeding equipment for sheep breeding

ActiveCN112088788BControl feeding amountAvoid wastingAnimal feeding devicesSheep farmingAnimal science

The invention discloses a slow-feeding natural feeding equipment for sheep breeding, which comprises a support platform and a food trough fixedly installed on the base, a feeding frame is fixedly installed on the support platform, and the feeding frame A slide plate is fixedly installed between the feeding trough, a discharge trough matching the slide plate is provided on the feeding frame, a feeding hopper is fixedly installed on the feeding frame, and the feeding frame is rotated by a rotating rod Attached with mounting sleeve. The advantage is that the present invention can automatically control the feeding amount of feed more accurately, avoiding the problem of starvation of sheep caused by feeding less feed, or the problem of waste caused by feeding too much feed, and the feeding time is the same as that of most sheep. Matching habits can avoid the problem of irregular diet of sheep caused by irregular feeding time. In addition, it can also avoid the problem of continuous falling of feed caused by some sheep standing in front of the trough, and avoid the health problems of some sheep caused by overeating .

Owner:SHANDONG VOCATIONAL ANIMAL SCI & VETERINARY COLLEGE

Corn peeling machine feeding device

Owner:JIUQUAN OK SEED MACHINERY

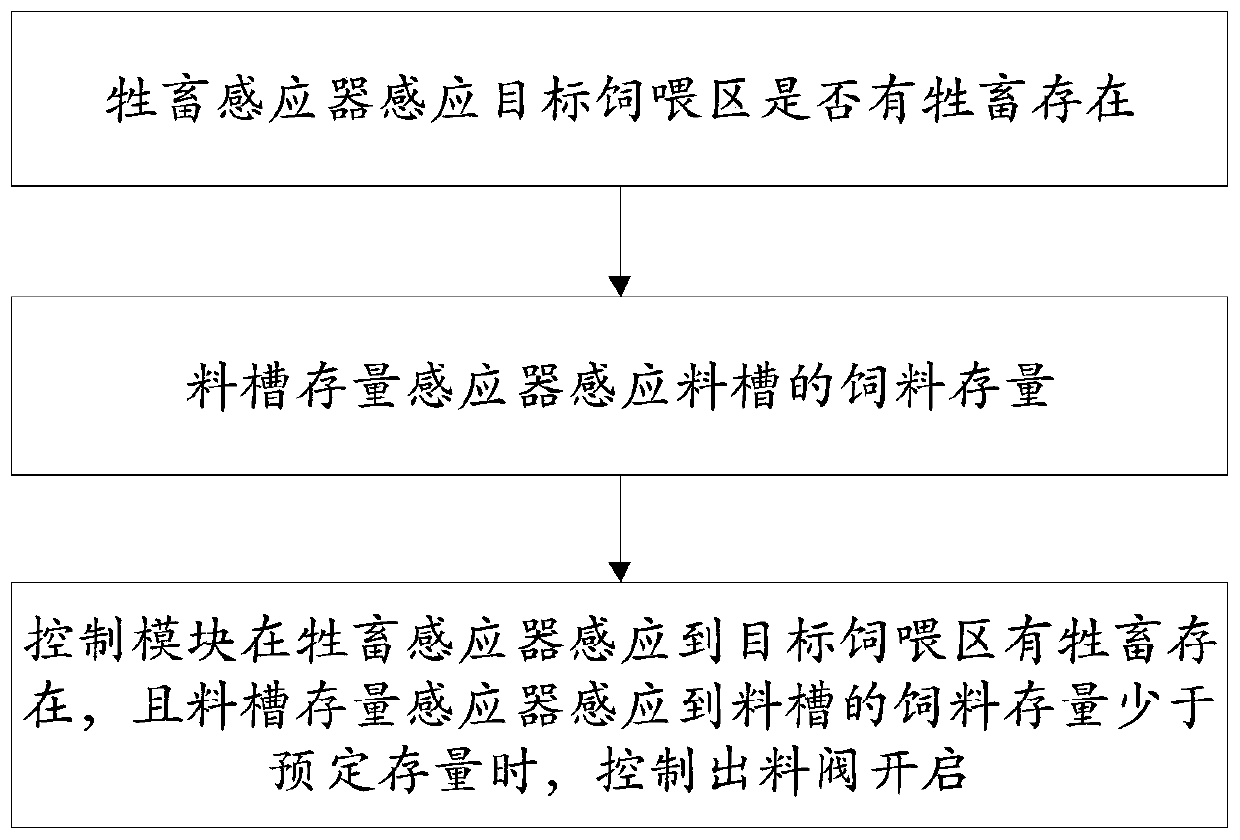

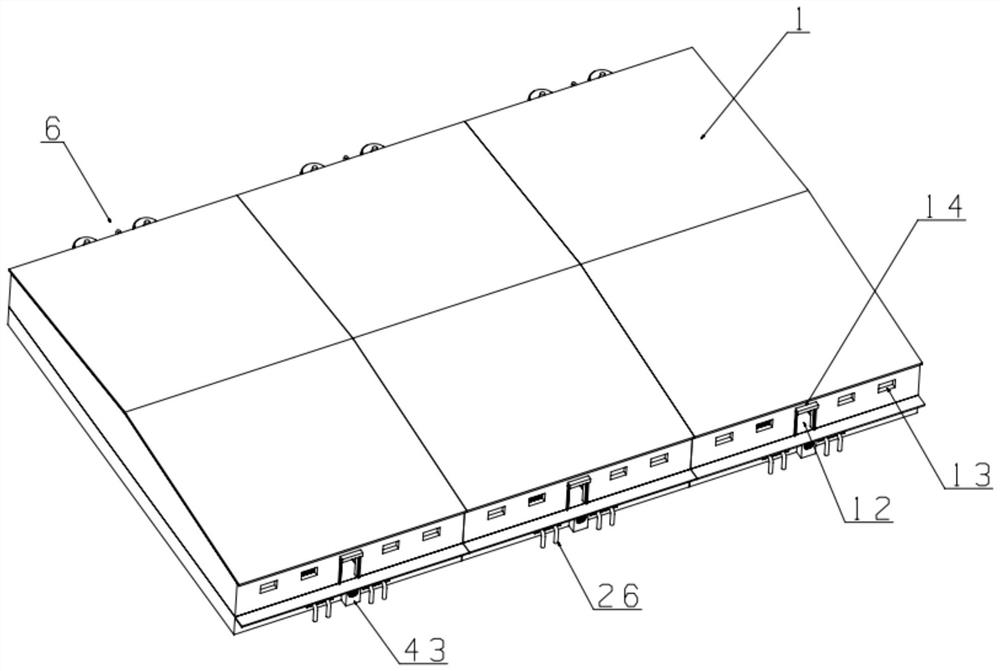

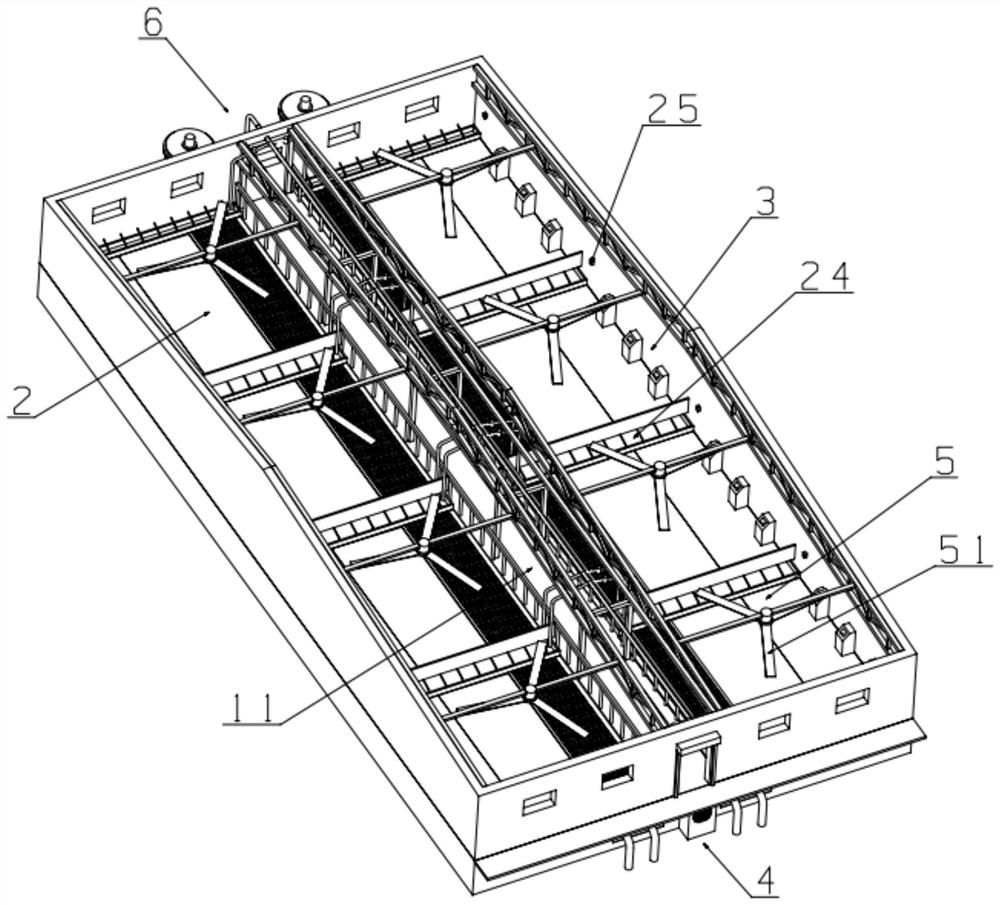

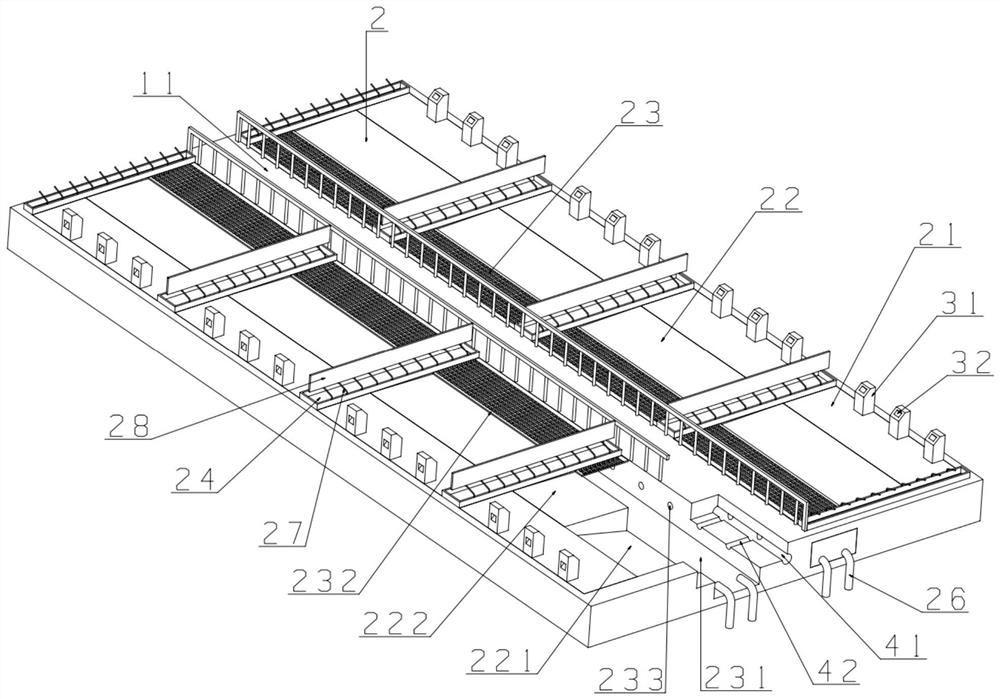

Livestock feed casting device and livestock feed casting method

PendingCN111066669AAvoid overfeedingReduce wasteLevel controlAnimal feeding devicesAgricultural scienceDraft animals

The invention provides a livestock feed casting device and a livestock feed casting method. The livestock feed casting device comprises a livestock feed casting mechanism, a livestock sensor, a feed trough stock sensor and a control module, wherein the livestock feed casting mechanism comprises a feed trough and a discharge hole; a discharge valve is arranged at the discharge hole; the livestock sensor is used for sensing whether livestock exists in a target feeding zone or not; the feed trough stock sensor is used for sensing the feed stock of a feed trough; the control module is used for controlling the discharge valve to be opened when the livestock sensor senses that the livestock exists in the target feeding zone and the feed trough stock sensor senses that the feed stock of the feedtrough is less than a preset stock. By adopting the livestock feed casting device and the livestock feed casting method provided by the invention, the feed stock of the feed trough is sensed by the feed trough stock sensor, and a feed is cast by the livestock feed casting device only when the livestock exists in the target feeding zone and the feed stock of the feed trough is less than the presetstock, so that excessive casting of the feed can be avoided.

Owner:MIAOZHEN INFORMATION TECH CO LTD

Positive pressure ventilation epidemic prevention type intelligent pig raising system and control method

PendingCN114271192AGuaranteed drynessEnsure hygieneAnimal feeding devicesAnimal housingPig breedingEnvironmental engineering

The invention relates to the technical field of live pig breeding, and particularly discloses a positive pressure ventilation epidemic prevention type intelligent pig breeding system which comprises a plurality of independent breeding rooms, a breeding area with a drying area, a grit area and a negative pressure pollution discharge area, a positive pressure system, a negative pressure system, an emergency system, a feed feeding system and a controller. The invention further discloses a positive pressure ventilation epidemic prevention type intelligent pig raising control method. According to the method, the pigs are distributed into the independent closed breeding rooms for breeding, so that the pigs are isolated from one another, and when an epidemic situation occurs in a certain breeding room, the pigs can be rapidly isolated, and the loss is reduced; a drying area, a grit area and a negative pressure pollution discharge area are arranged in the breeding area, dryness and sanitation of the breeding environment can be guaranteed, breeding of bacteria can be prevented, air in the breeding room can circularly flow through a positive pressure system, a negative pressure system and an emergency system, the feeding amount and the feeding temperature of water feed can be controlled through a feed feeding system, and the breeding efficiency is improved. Digestion and absorption are facilitated, and feeding management is facilitated.

Owner:象州县罗秀镇恒信养殖有限公司

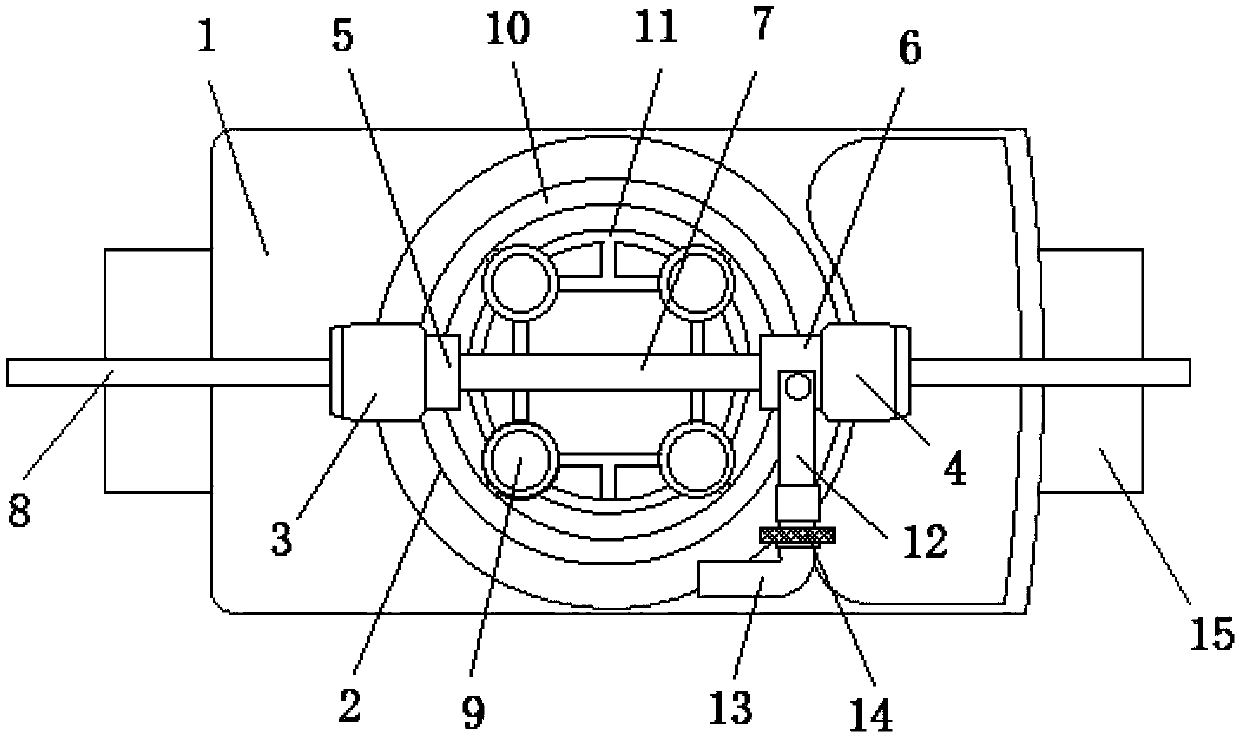

Vacuum furnace wire-feeding device

The invention provides a vacuum furnace wire-feeding device. The vacuum furnace wire-feeding device comprises a drive device and a transmission device, wherein the drive device comprises a counter, amotor and a speed reducer; the transmission device comprises a transmission shaft, a drive wheel and a pressing wheel; the counter is mounted on the motor, and is used for obtaining rotation times ofa rotor of the motor; the rotor is connected to the input shaft of the speed reducer; the output shaft of the speed reducer is connected to one end of the transmission shaft; the drive wheel is connected to the other end of the transmission shaft; the pressing wheel is adjacent to the drive wheel; and a transmission channel is defined between the pressing wheel and the drive wheel. The wire-feeding device provided by the invention can precisely control wire feeding amount, and is simple and convenient in operation.

Owner:LONGNAN LONGYI HEAVY RARE EARTH TECH CO LTD

Automatic feeding device suitable for feeding pet pups

InactiveCN111248094AControl feeding amountControl food intakeAnimal feeding devicesVeterinary instrumentsEngineeringLiquid storage tank

The invention discloses an automatic feeding device suitable for feeding pet pups. The automatic feeding device suitable for feeding the pet pups includes a fixed box; supporting mechanisms are fixedly connected to both sides of the fixed box; the inside of the fixed box is provided with an annular hollow groove with openings at the top and bottom; a first liquid storage tank and a second liquid storage tank are fixedly connected to opposite inner walls of the annular hollow groove separately; liquid inlet pipes are penetrated on both sides of the fixed box; the opposite ends of the two liquidinlet pipes communicate with the side walls of the first liquid storage tank and the second liquid storage tank separately; a first transition pipe and a second transition pipe are fixedly connectedto the opposite side walls of the first liquid storage tank and the second liquid storage tank separately; and the first transition pipe and the second transition pipe are connected by a communicationpipe. The automatic feeding device suitable for feeding pet pups has a compact structure and is convenient and feasible to operate; no manual feeding by manpower is needed; a plurality of pet pups can be fed at the same time; the efficiency is high; and the using effect is good.

Owner:许浪

A kind of indoor domestication method of Japanese eel seed

InactiveCN104381164BControl feeding amountBreeding in separate ponds in timeClimate change adaptationPisciculture and aquariaFresh waterAnguilliformes

The invention relates to an indoor domestication method for Japanese eel fries. The method comprises the following steps of completely shifting captured glass eels into fresh water for aquaculture by a method of gradually changing fresh water; directly feeding eel fries by taking frozen minced artificial formulated feed as initial feed, and taking an elaborated artificial feeding and management method as assistance; when the glass eels are changed into black fry eels, feeding with powdery artificial formulated feed, matching the weight of the feed and water according to a ratio, controlling the feeding quantity, regularly sucking dirt and changing water each day, and timely feeding individuals in different specifications in different ponds. The method is simple in process and low in cost, effectively overcomes the defect of adopting tubificidae as initial feed, ensures that the survival rate of the eel fries is over 99 percent int the domestication process, and has a good application prospect.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Parameter detecting device and method for textile weaving process

InactiveCN101270544BImprove efficiencyImprove accuracyInspecting textilesKnittingYarnComputer module

A parameter detecting device in the weaving process of a fabric and a detecting method thereof relate to the technical field of detecting. The invention aims at solving the technical problem of improving the product quality during the weaving process of the fabric; the parameter detecting device includes a needle cylinder revolution detecting sensor, a bottom yarn detecting sensor, a surface yarndetecting sensor, a display screen and a microprocessor connecting the display screen; wherein, the microprocessor includes a density parameter module, a hair length or hair ring length amount module, an output amount module and a fixed-length rotating amount module; the density parameter module is respectively connected with the needle cylinder revolution detecting sensor and the bottom yarn detecting sensor; the hair length or hair ring length amount module is respectively connected with the needle cylinder revolution detecting sensor and the surface yarn detecting sensor; the parameter detecting method includes the parameter detecting methods of the density parameter detecting, the hair length or hair ring length amount detecting, the output amount detecting and the fixed-length rotating amount detecting. The invention is characterized by being capable of improving the efficiency, the accuracy, the product quality and realizing the automatization of output counting.

Owner:上海好力纺织机电设备有限公司

A kind of artificial breeding method of juveniles

ActiveCN112772470BAvoid disinfectionAvoid changeClimate change adaptationAnimal feeding stuffJuvenile fishPlatypus

The invention provides a method for artificial cultivation of juveniles of P. nigra, including: disinfection of breeding tools and parallel tanks; daily management and cleaning; selection of bait; and feeding methods of chironomid larvae. The method for cultivating the juveniles of the black spotted platypus has the advantages of simple operation, low cost, good quality of domesticated seedlings, etc., breaks through the bottleneck of cultivating the juveniles of the black spotted platypus, and the survival rate of the seedlings cultivated to 19 months of age reaches 80% It can effectively solve the problem of high mortality of larvae caused by the discomfort of bait, feeding method and environment during the domestication and breeding of the fry, and it also provides a reference for the cultivation of fry and seed of other species.

Owner:HEILONGJIANG RIVER FISHERY RES INST CHINESE ACADEMY OF FISHERIES SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com