Parameter detecting device and method for textile weaving process

A technology for parameter testing and textiles, applied in the field of testing, can solve the problems of frequent machine adjustment, judgment errors, inconsistency between proofing and mass production, etc., and achieve the effect of reducing human-technical differences, improving product quality, and facilitating process recording.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings, but the present embodiments are not intended to limit the present invention, and any similar structures and similar changes of the present invention should be included in the protection scope of the present invention.

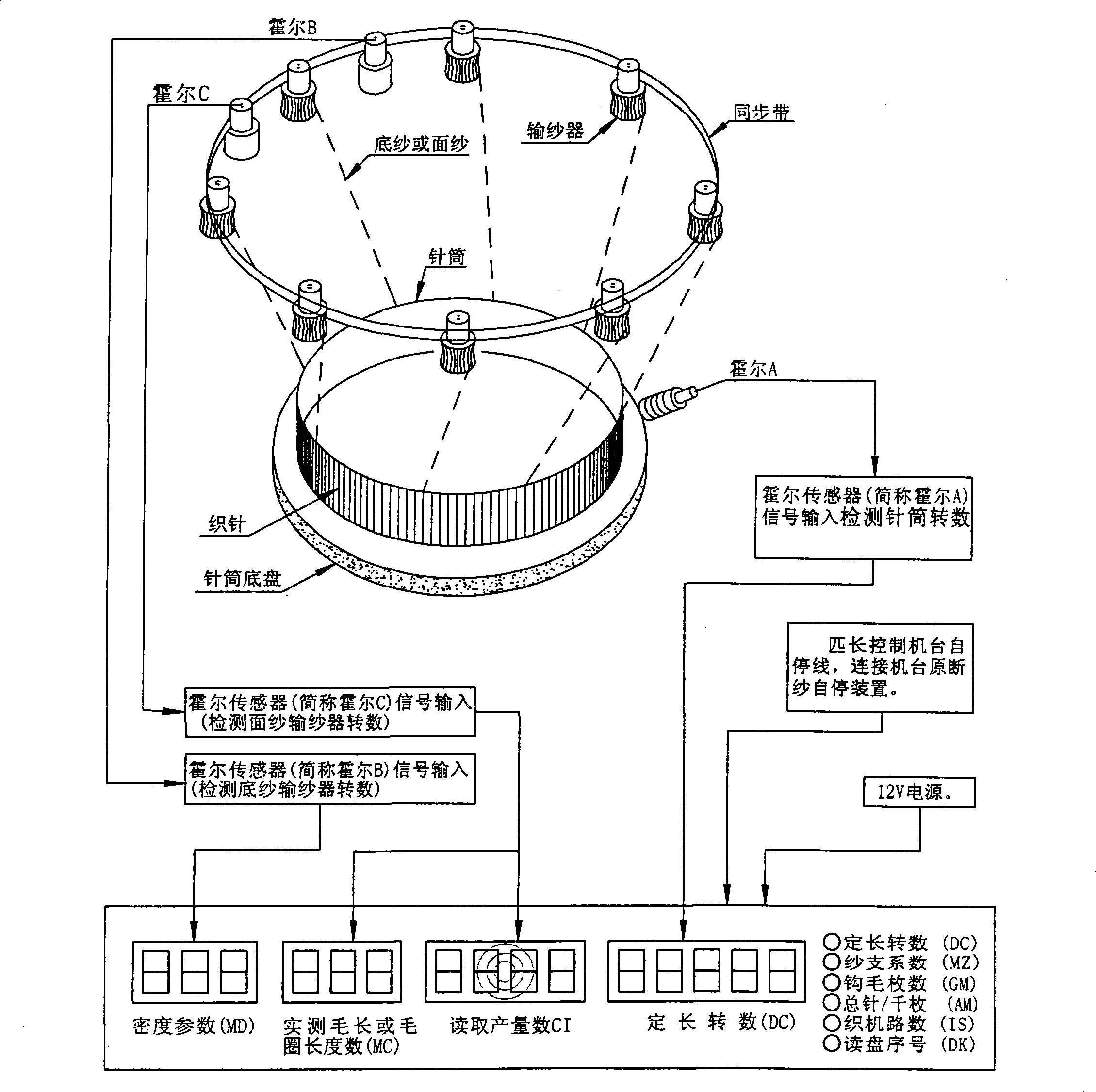

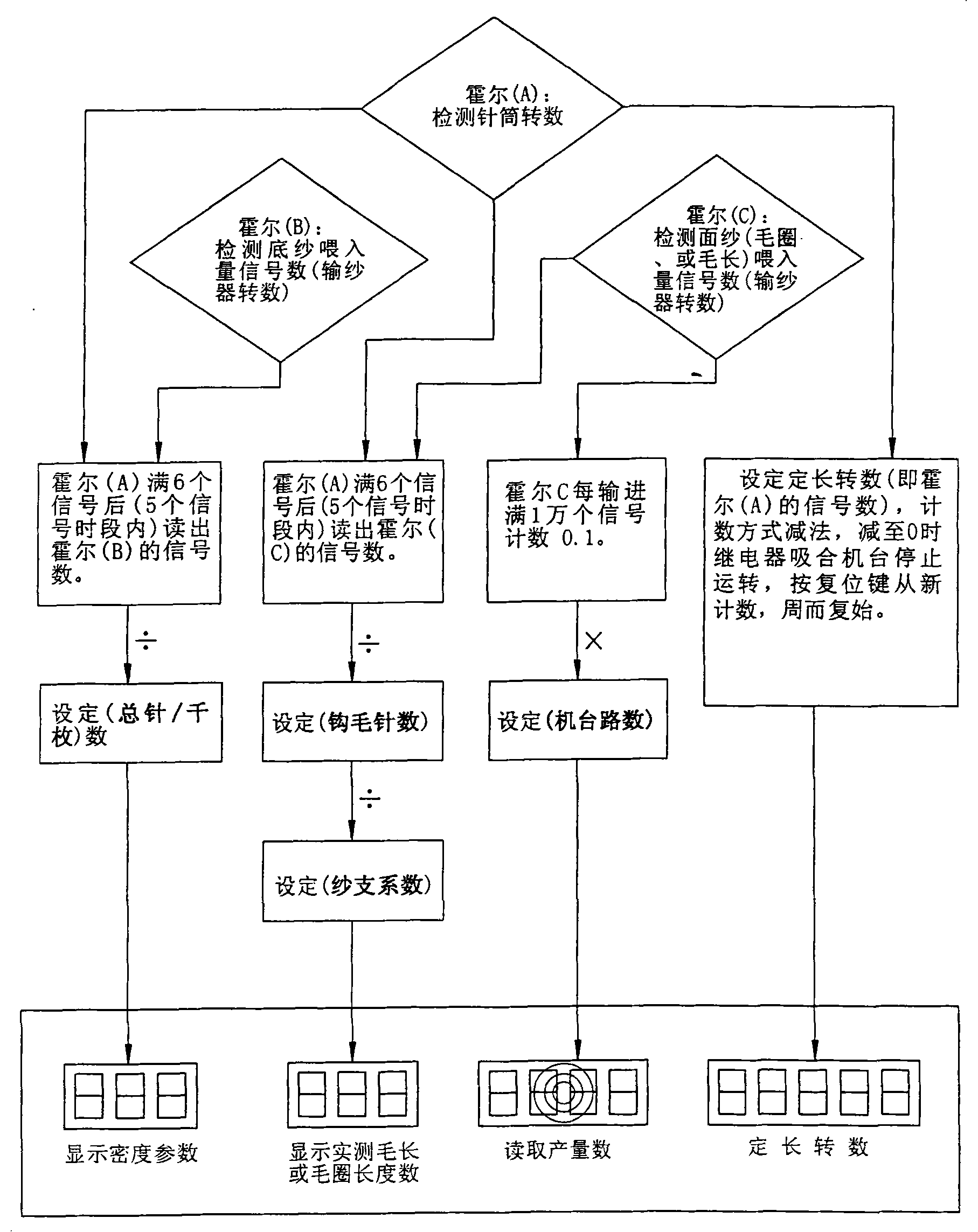

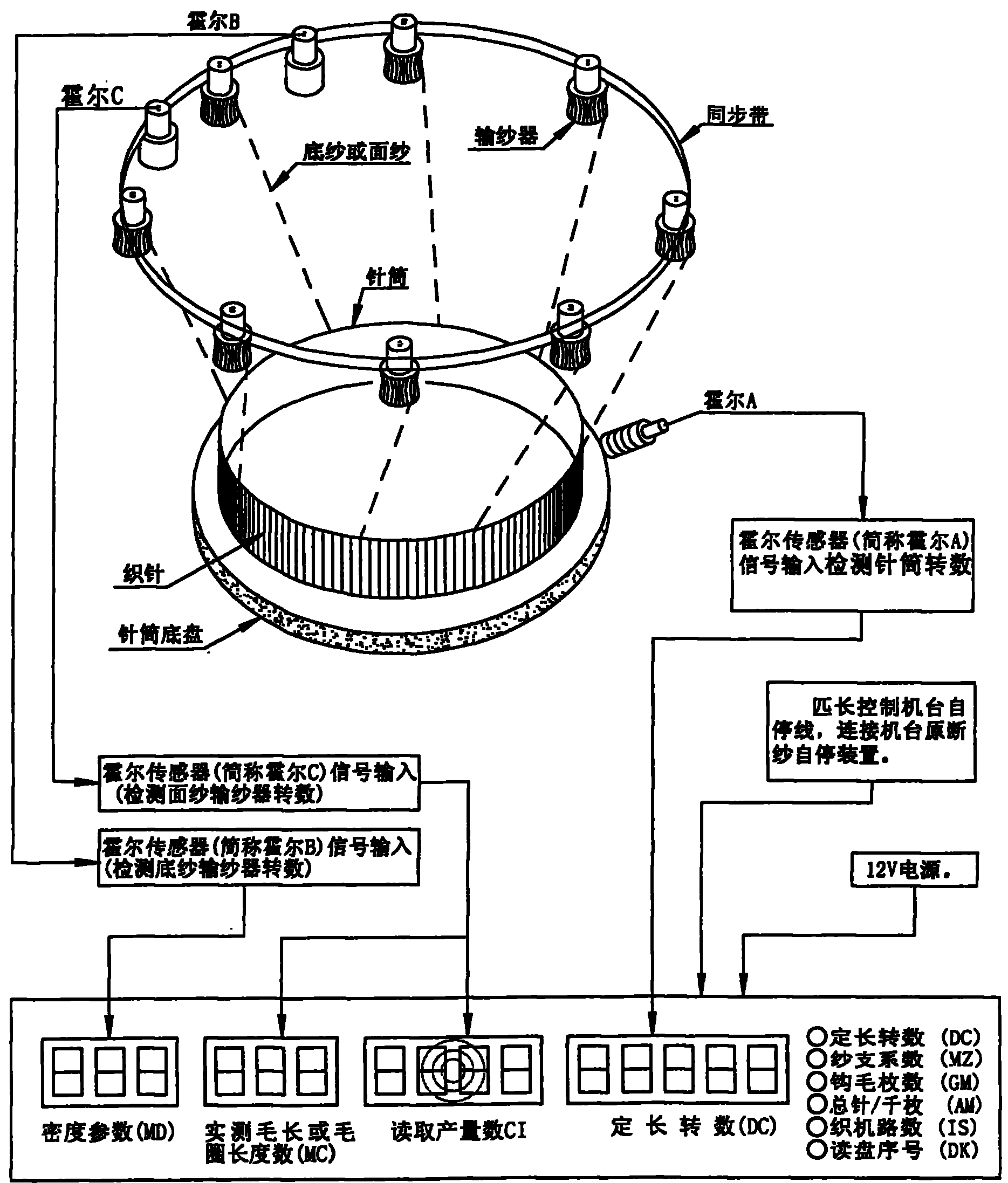

[0029] Depend on figure 1 As shown, the parameter detection device of a textile weaving process provided by the embodiment of the present invention is characterized in that it includes a needle cylinder detection (Hall) sensor A, a bottom yarn detection (Hall) sensor B, a veil detection (Hall ) sensor C, a display screen and a microprocessor connected to the display screen, wherein the needle cylinder detection (Hall) sensor A is arranged on the needle cylinder chassis of the machine for detecting the number of revolutions of the needle cylinder; the bottom yarn detection (Hall ) sensor B is set on the timing belt of the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com