Spiral feeding scale

A screw feeder, material scale technology, applied in special scales, automatic feeding/discharging weighing equipment, weighing equipment with special properties/forms, etc., can solve the interference of powder flow speed, Product quality decline, affecting measurement accuracy, etc., to prevent damage caused by impact, prevent material punching phenomenon, and increase the effect of weighing mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

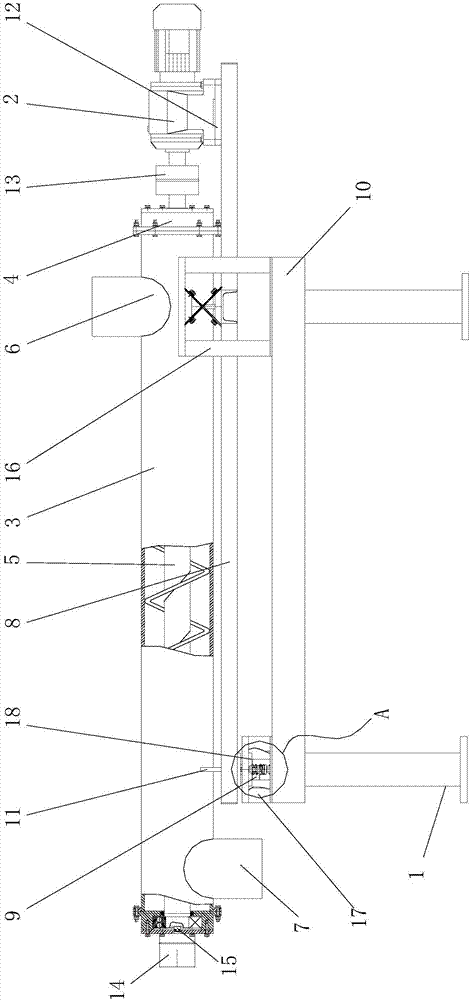

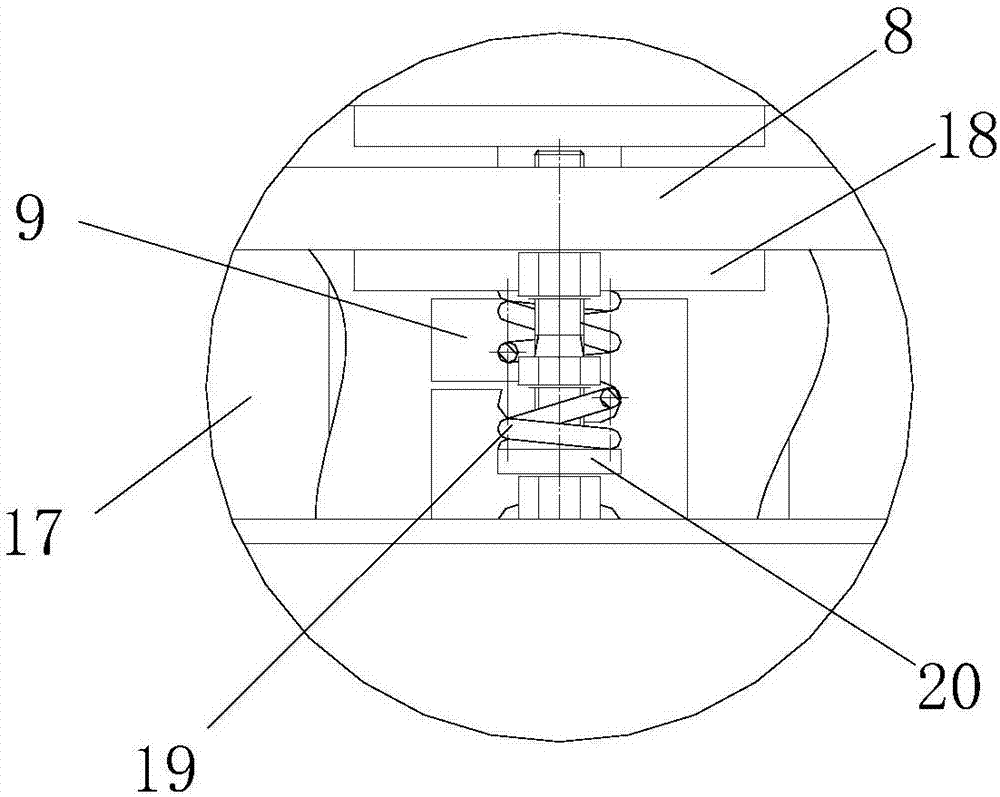

[0021] See figure 1 and figure 2 , the present invention has a feeding motor reducer 2 and a screw feeder arranged on the support 1; the cross section of the support 1 is in an inverted "T" shape; the screw feeder includes a silo 3 for storing materials; the silo 3 The two ends of the bearing housing device 4 connected by the corresponding fastener device, the reeling shaft 5 is coaxially arranged in the silo 3, and the top of the feeding end of the silo 3 is provided with a feed port 6 communicating with the silo 3 , the bottom of the discharge end is provided with a discharge port 7 communicating with the feed bin 3; one end of the twisted wire shaft 5 is connected to the rotating shaft of the feeding motor reducer 2; impellers or spiral blades are evenly distributed on the circumferential surface of the twisted wire shaft 5; A weighing mechanism is installed between the screw feeder and the bracket 1; the center of the weighing mechanism corresponds to the center of gravi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com