Patents

Literature

51results about How to "Avoid overfeeding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

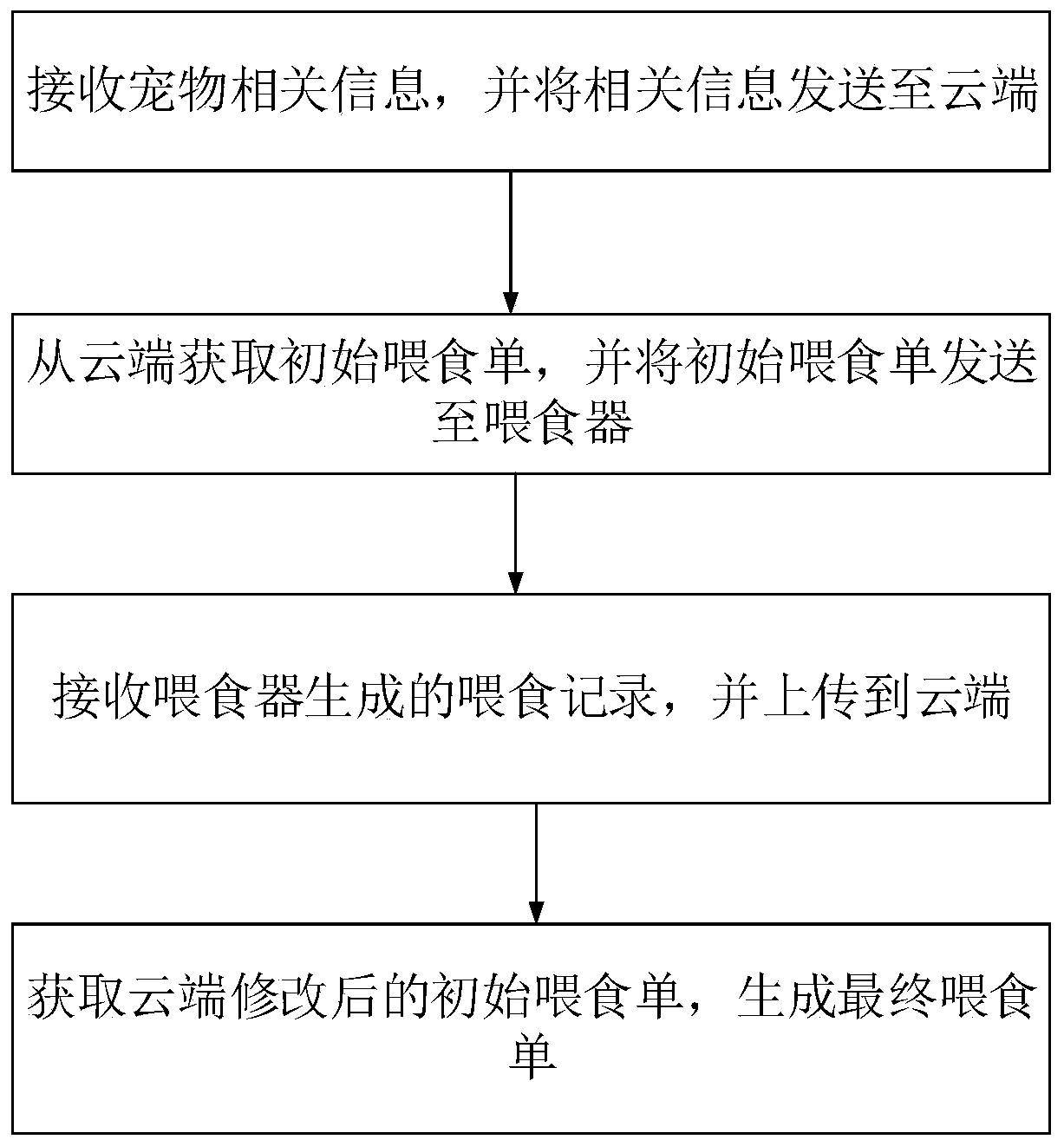

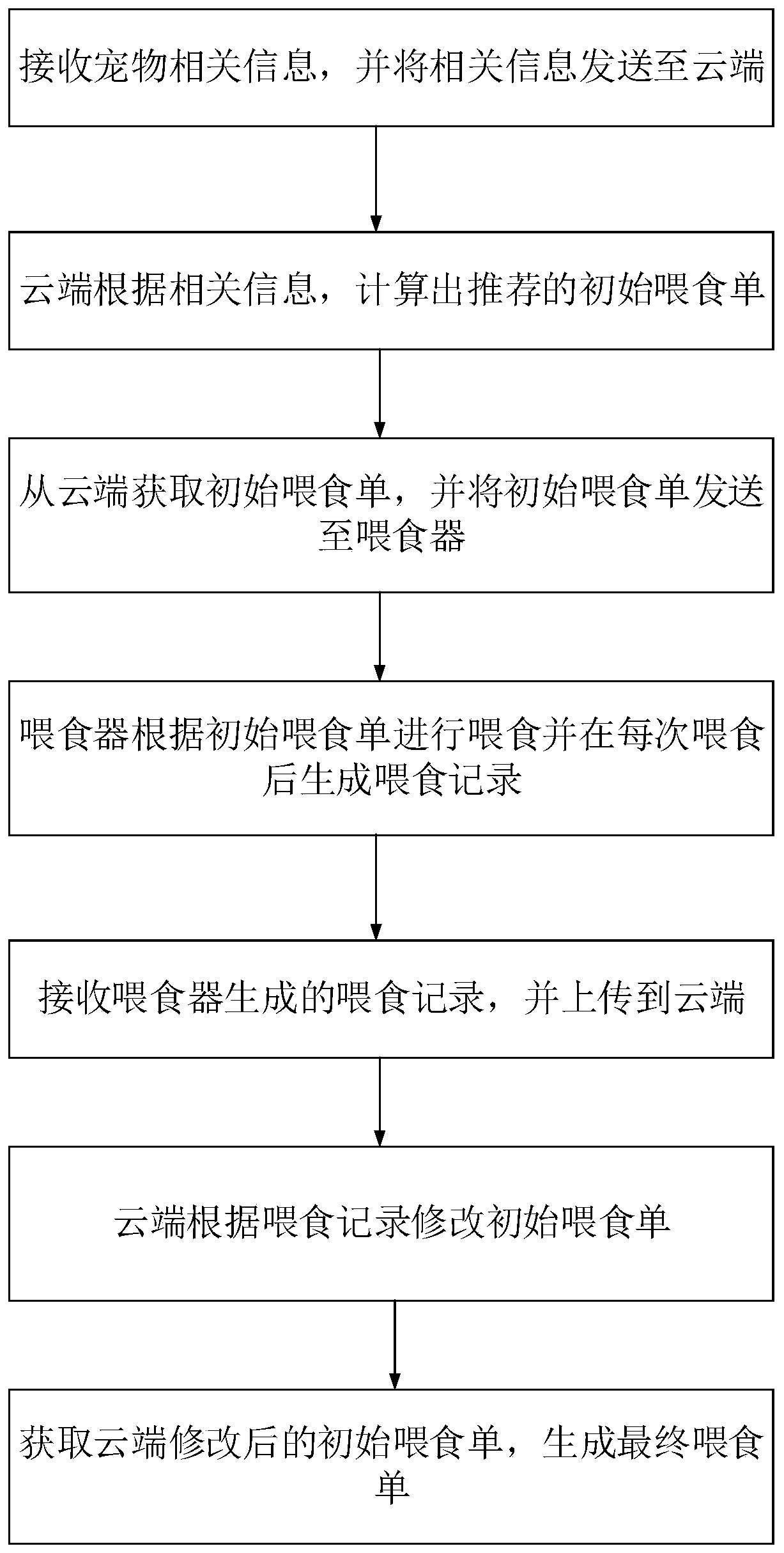

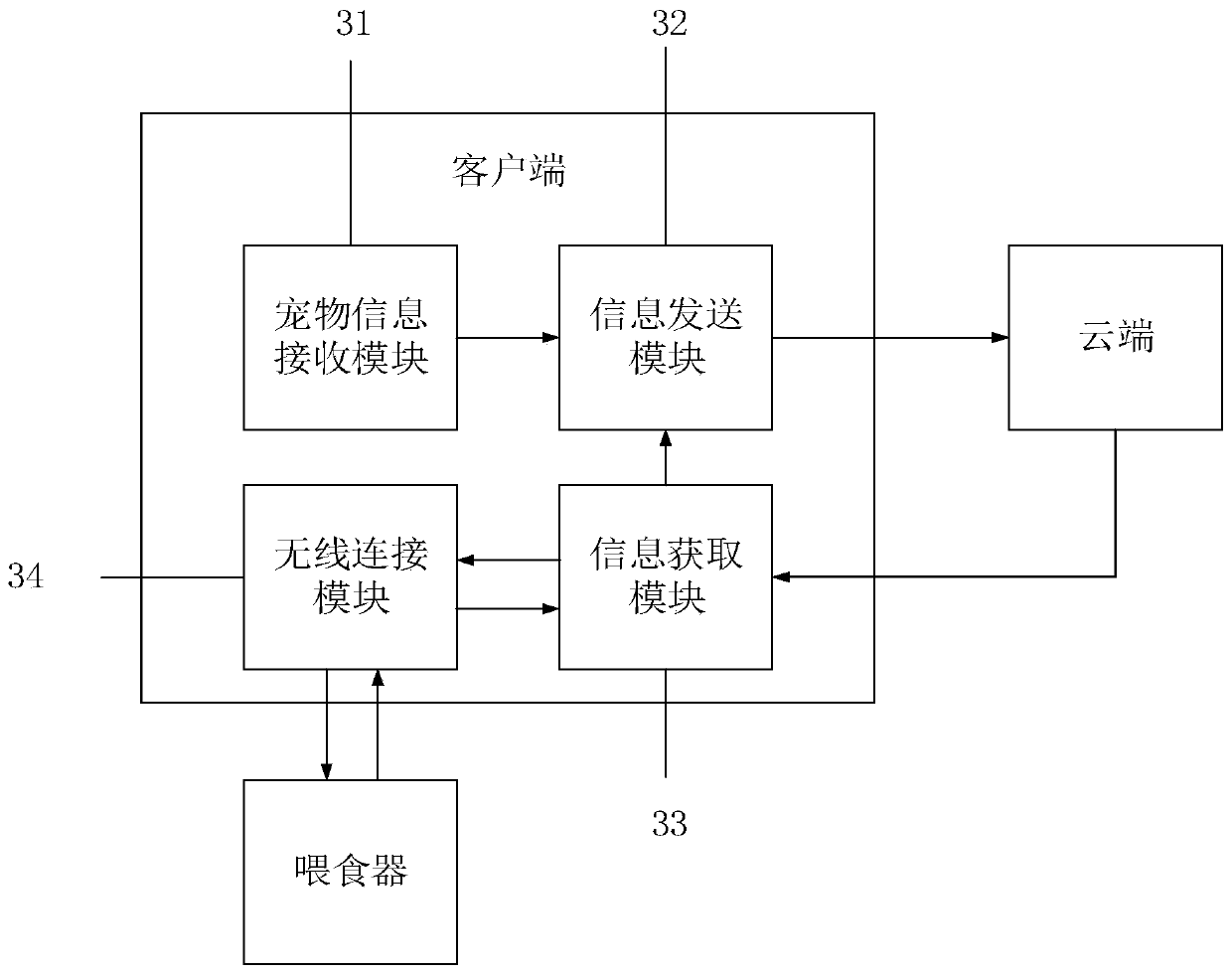

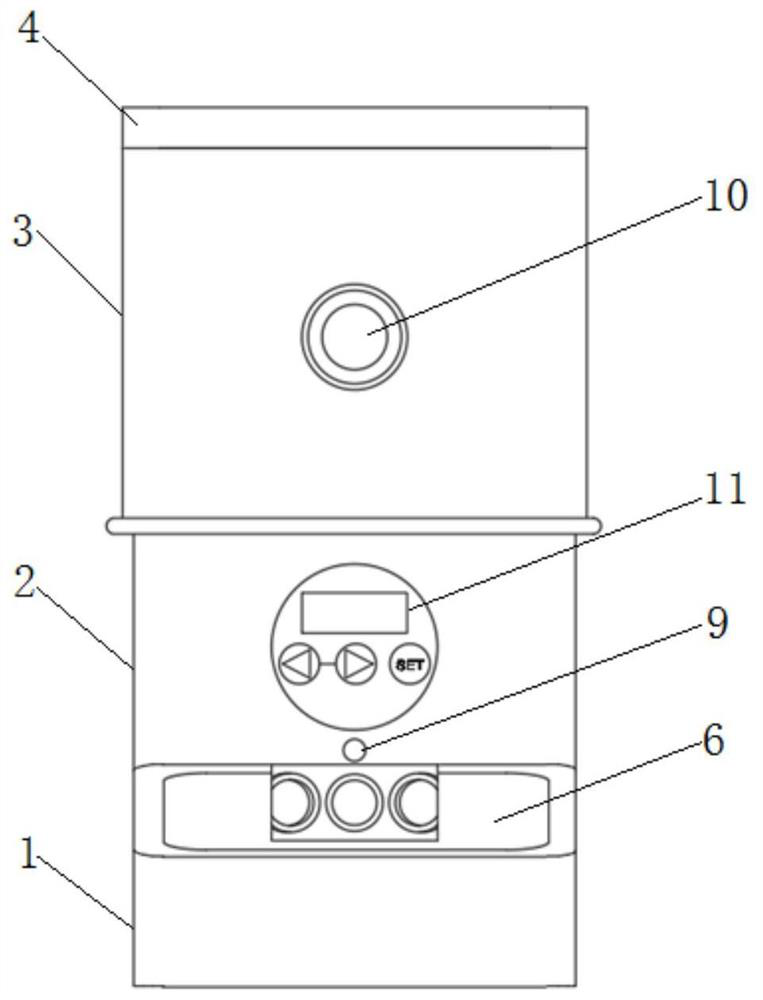

Client, feeder and generation method of pet feeding list

InactiveCN110122352AEasy to feedReasonable feedingTransmission systemsAnimal feeding devicesAgricultural scienceCompanion animal

The invention discloses a client, a feeder and a generation method of a pet feeding list. An initial feeding list is obtained by calculation according to related information of a pet and is sent to the feeder, and therefore, the feeder feeds the pet conveniently; feeding records are generated after feeding by the feeder, the initial feeding list is modified according to the feeding records, and afinal feeding list is generated. The initial feeding list is modified according to the feeding records, so that the condition of too much or too little feeding for the pet is avoided, the pet is fed more reasonably, and the pet is promoted to grow healthily.

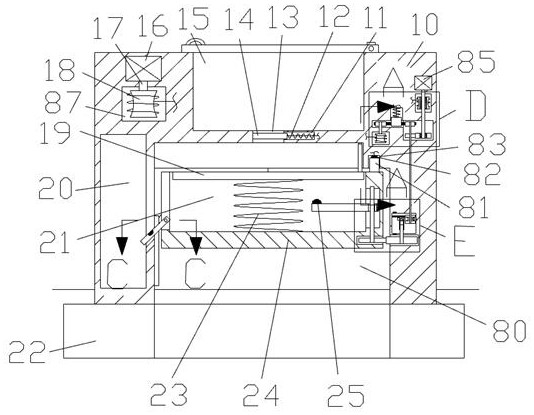

Self-control fish feed feeding device capable of reducing pollution for reservoir

InactiveCN111616092APrevent eutrophicationAvoid precipitationClimate change adaptationPisciculture and aquariaEutrophicationFishery

The invention discloses a self-control fish feed feeding device capable of reducing pollution for a reservoir. The device comprises a main body box, wherein a lifting cavity with a downward opening isformed in the main body box; an annular floating block positioned on the outer side of the lifting cavity is fixedly connected to the lower end face of the main body box; a waste through cavity is communicated with the left side of the lifting cavity; a waste cavity is communicated with the left side of the waste through cavity; and a feeding box which can be slidably and cooperatively connectedwith the lifting cavity is arranged in the lifting cavity. Through the design of the liftable feeding box, the feeding box is positioned on the upper side of the water surface during non-feeding time,the situation is avoided that feed is soaked in water for a long time and accordingly water eutrophication is caused, and meanwhile the situation can also be avoided that feed precipitation is causedby direct feeding; and after feeding is completed each time, waste is scraped off through a scraping plate, whether or not the waste is left is judged through a contact sensor, accordingly the heightof an abutting plate is adjusted, the feeding amount of the next time is adjusted, the feeding amount is adjusted in real time, and the situation is avoided that the feeding amount is too large or too small due to fish flow.

Owner:福州市长乐区拓密斯电子科技有限公司

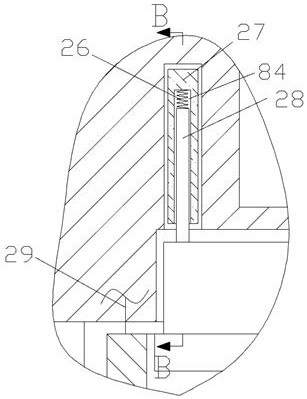

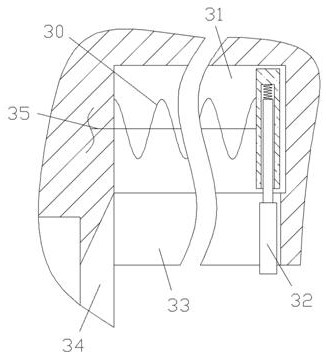

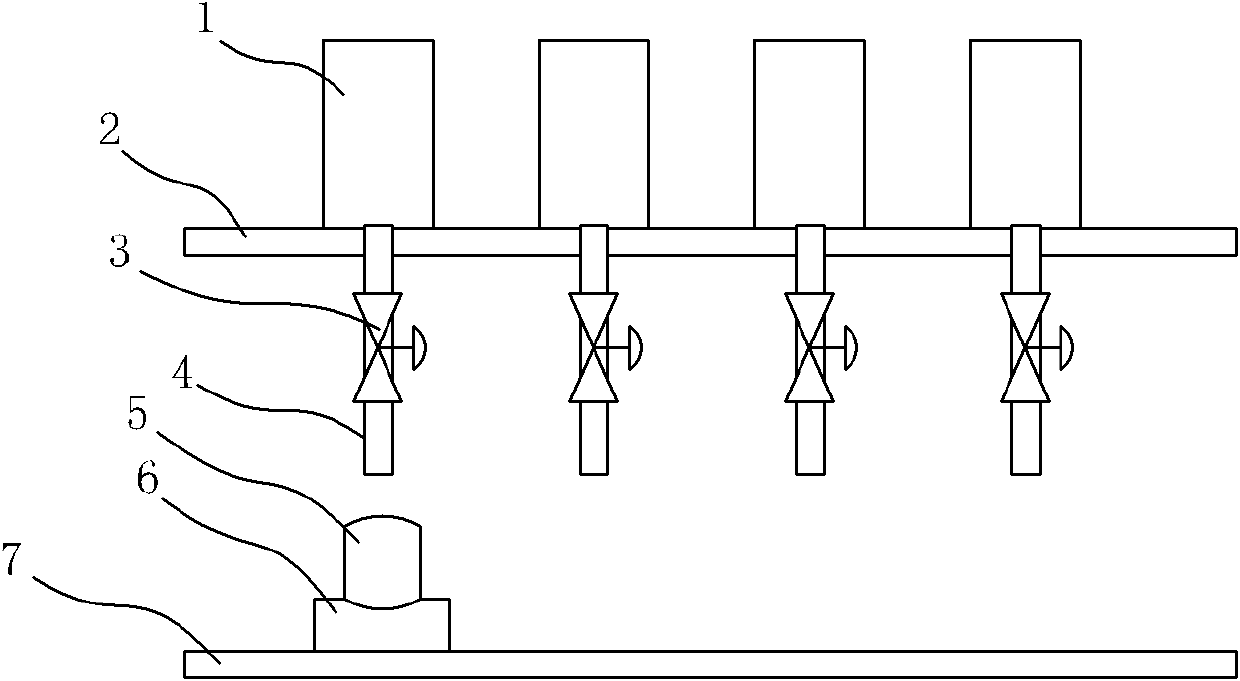

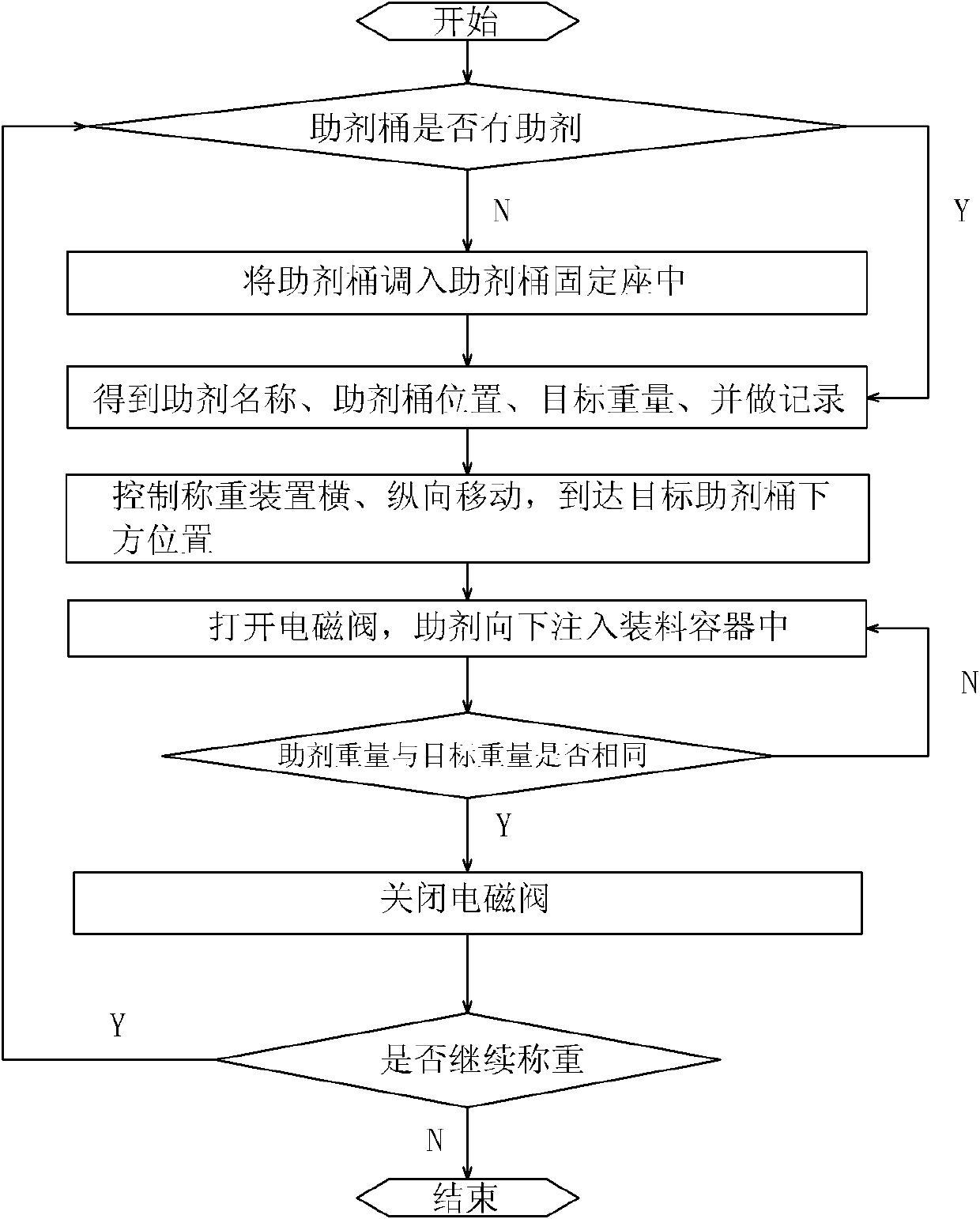

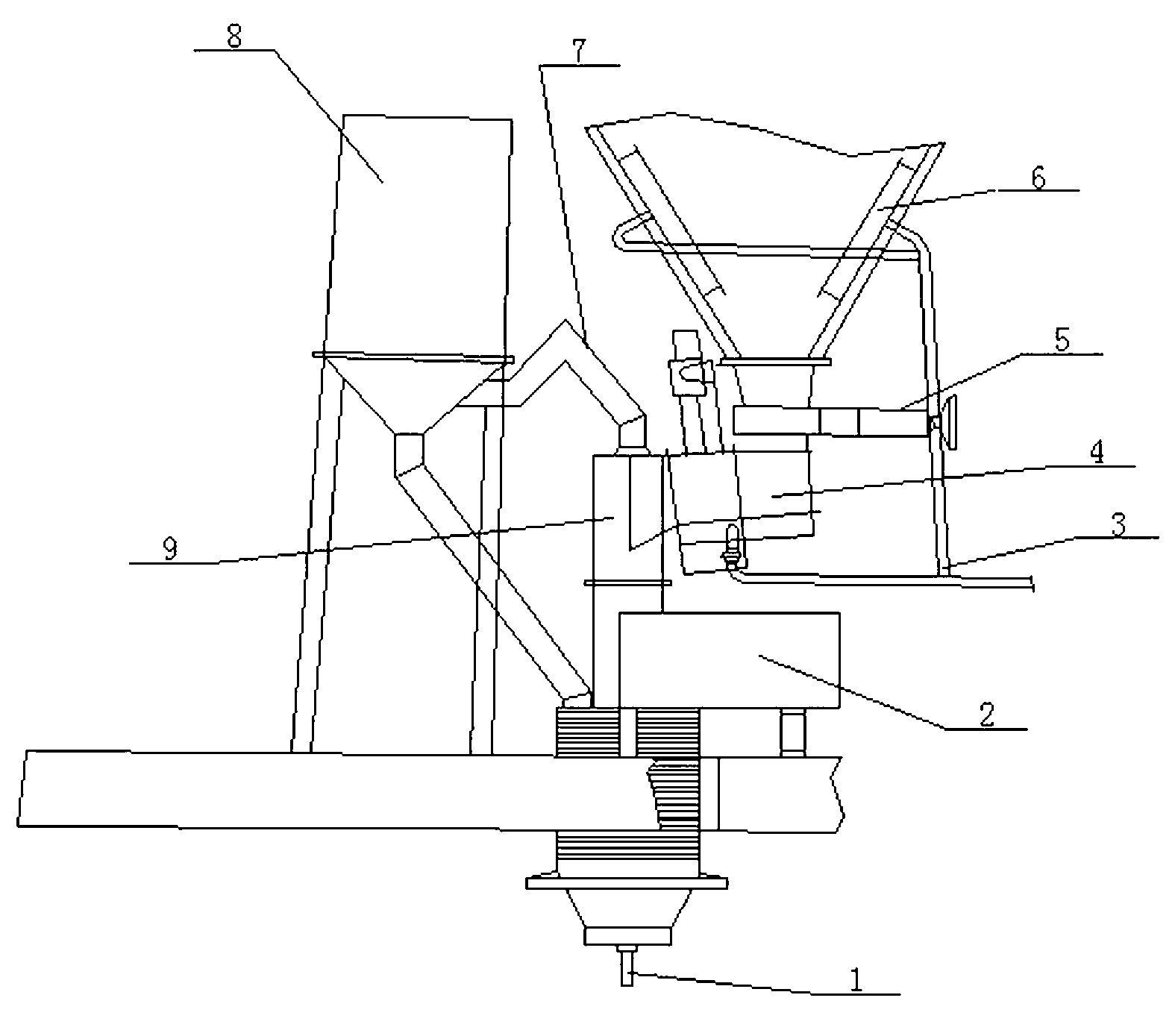

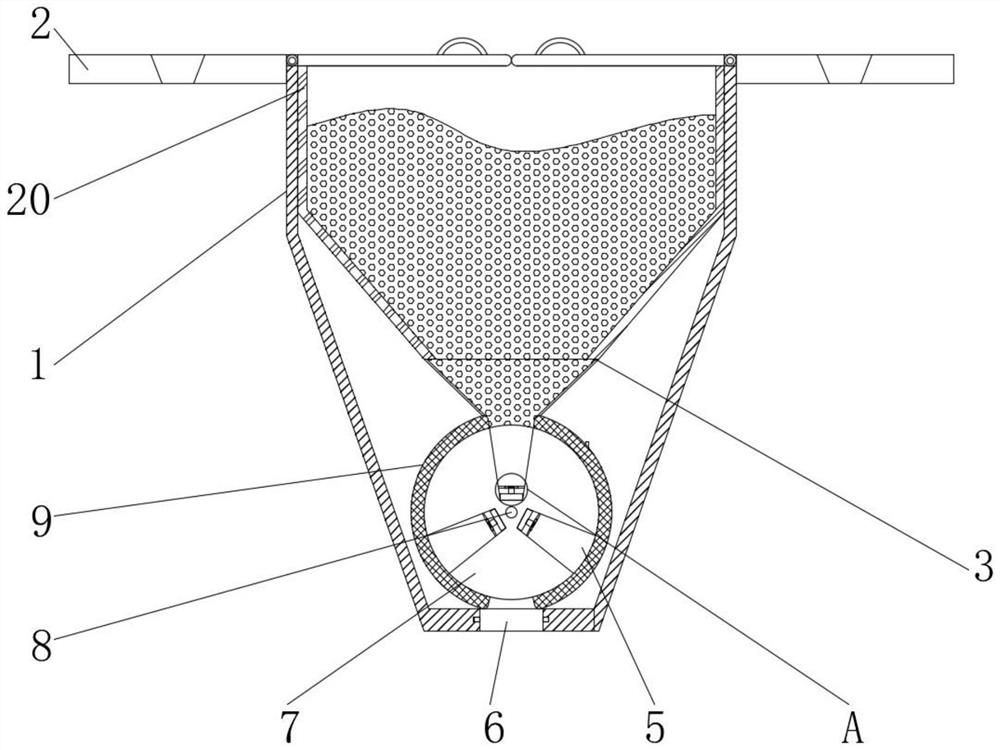

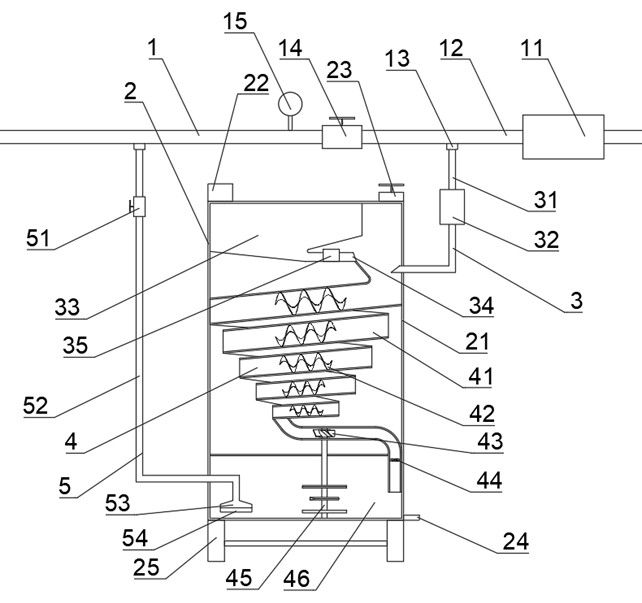

Automatic auxiliary feeding system

ActiveCN102560935AImprove extraction accuracyReduce openingTextile treatment machine partsMechanical engineeringElectromagnetic valve

An automatic auxiliary feeding system comprises a plurality of auxiliary buckets, a weighing device, a driving device and a control main unit. The auxiliary buckets are used for storing various auxiliaries and are supported at high positions through supports, and each auxiliary bucket is provided with a discharge pipe communicated with the inside of the auxiliary bucket and electromagnetic valves used for controlling on and off of the discharge pipes. The weighing device is provided with an auxiliary container. The driving device is used for driving the weighing device to move below the auxiliary buckets. When the weighing device is arranged below one of the auxiliary buckets, corresponding auxiliaries can be injected into the auxiliary container through the discharge pipes of the auxiliary buckets. The control main unit is respectively connected with the electromagnetic valves, the weighing device and the driving device. The automatic auxiliary feeding system is capable of feeding the various auxiliaries automatically and accurately and has the advantages of simple structure, low cost, convenience in operation and the like.

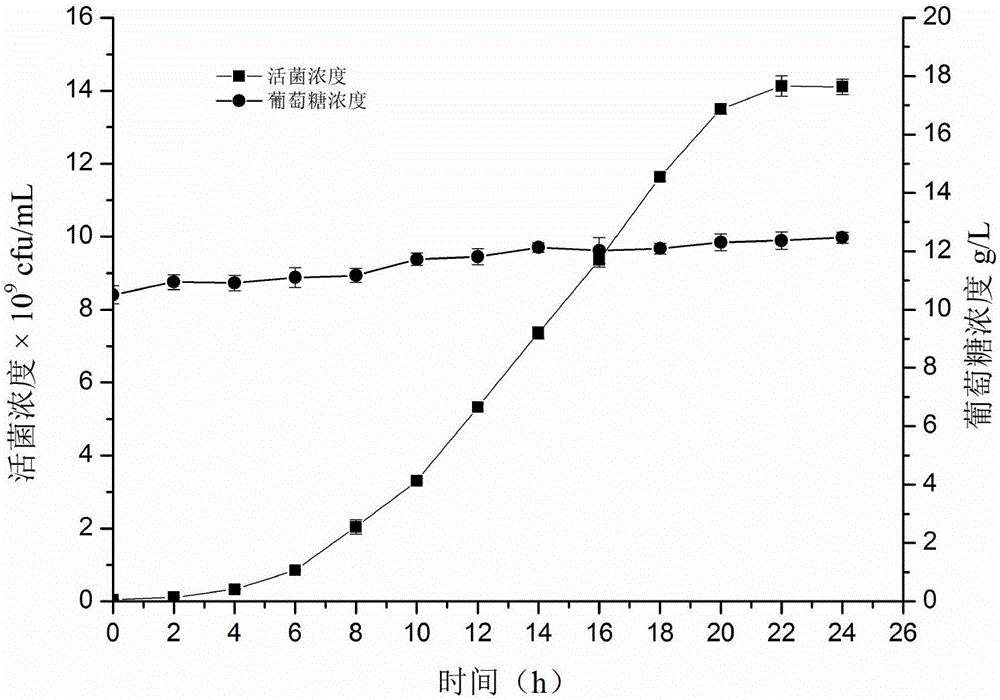

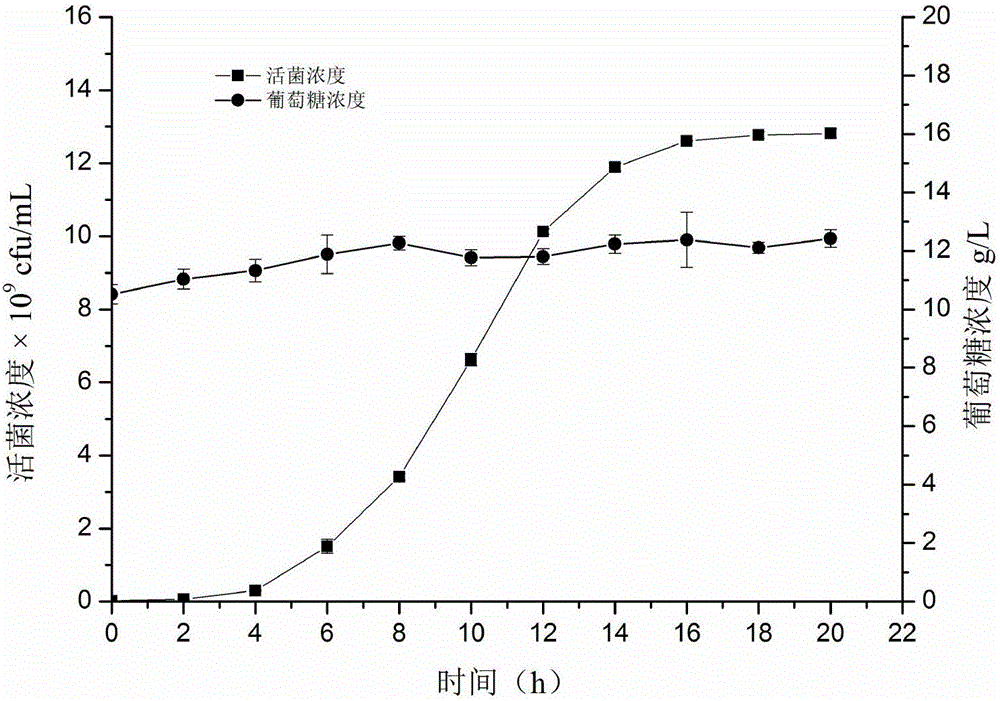

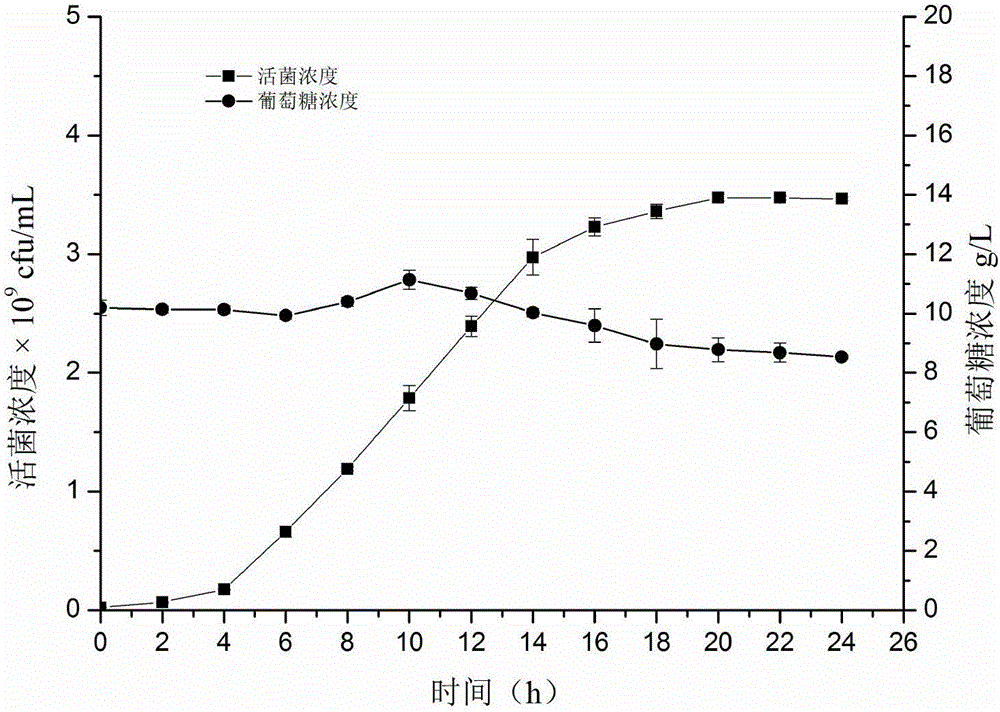

Automatic feedback supplementing method for high-density culture of lactic acid bacteria

ActiveCN105886439ADe-inhibitionGuaranteed stabilityBacteriaMicroorganism based processesLactobacillus rhamnosusSubstrate concentration

The invention discloses an automatic feedback supplementing method for high-density culture of lactic acid bacteria, and belongs to the field of microbial fermentation engineering. According to the automatic feedback supplementing method disclosed by the invention, in the culturing process of the lactic acid bacteria, alkali liquor is automatically added according to a pH value so as to keep a neutral environment of a culture system; a supplementing pump is associated with an alkali supplementing pump, so that a supplementing culture medium and the alkali liquor are automatically added into the culture system according to a certain ratio, thereby ensuring stability of concentration of a substrate in the culture system. According to the automatic feedback supplementing method disclosed by the invention, not only is the requirement of bacteria for the substrate ensured, but also the substrate is automatically added according to consumption of the bacteria without exceeding the standard. The method disclosed by the invention is applicable to all homofermentative lactobacillus fermentium, such as lactobacillus casei, lactobacillus plantarum, lactobacillus rhamnosus, lactobacillus acidophilus, lactobacillus helveticus, lactobacillus bulgaricus and the like, and all bifidobacterium, such as bifidobacterium bifidum, bifidobacterium adolescentis, bifidobacterium animalis, bifidobacterium longum, bifidobacterium breve and the like.

Owner:JIANGNAN UNIV

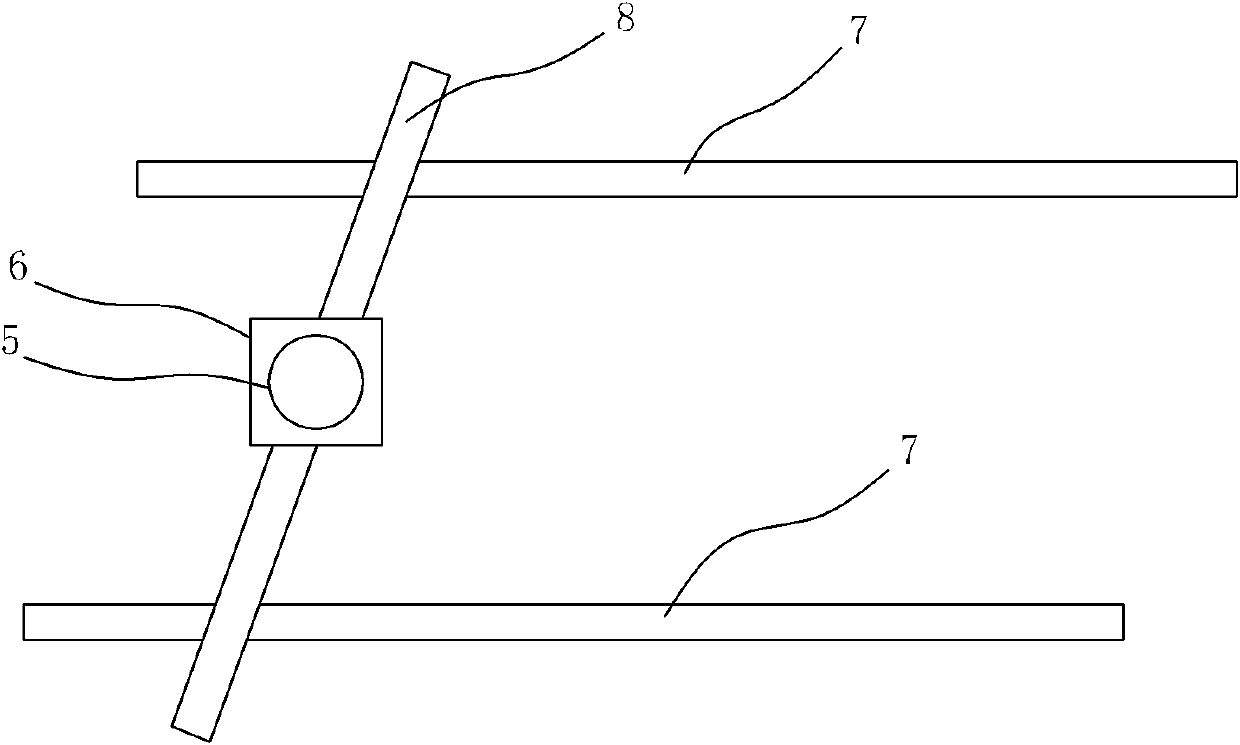

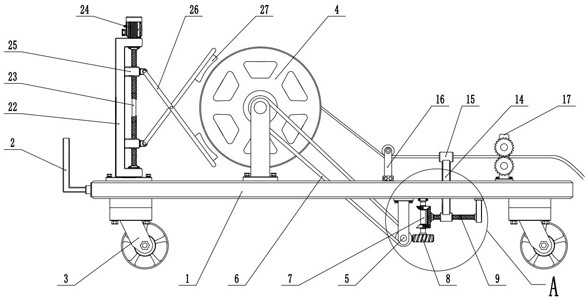

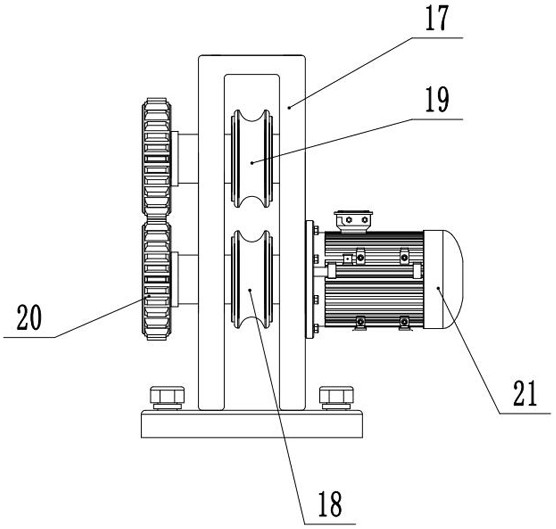

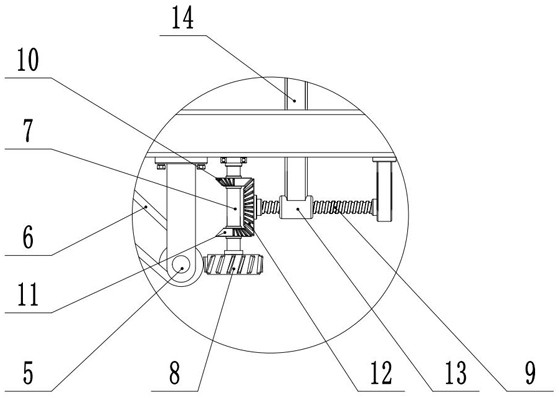

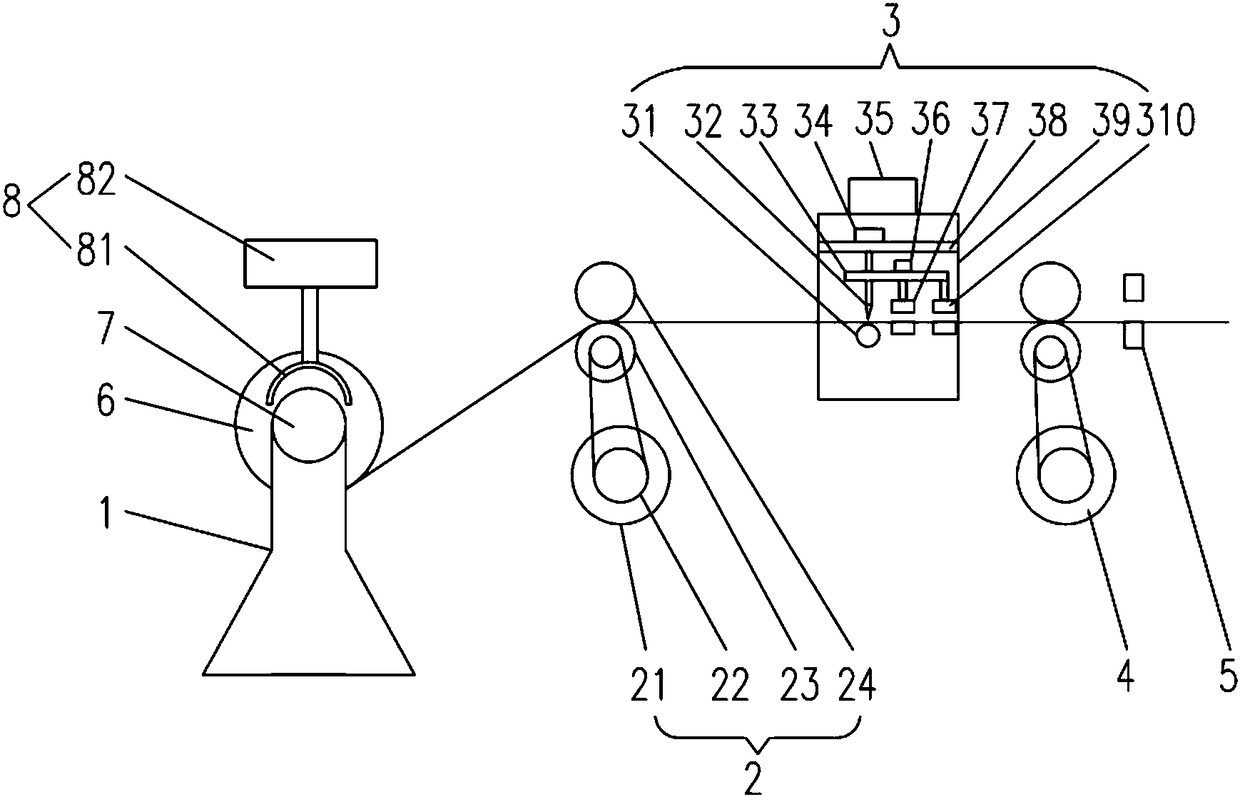

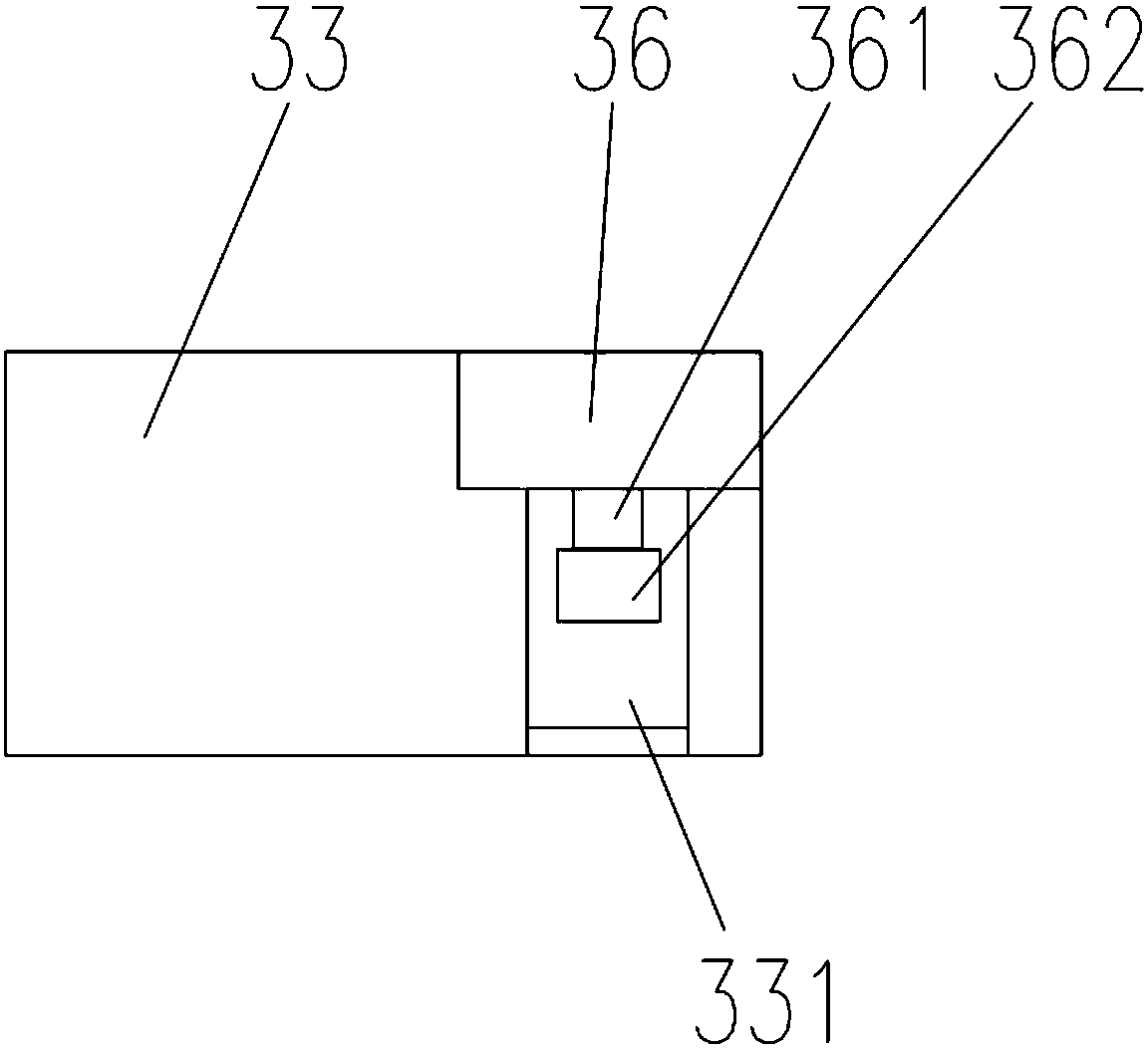

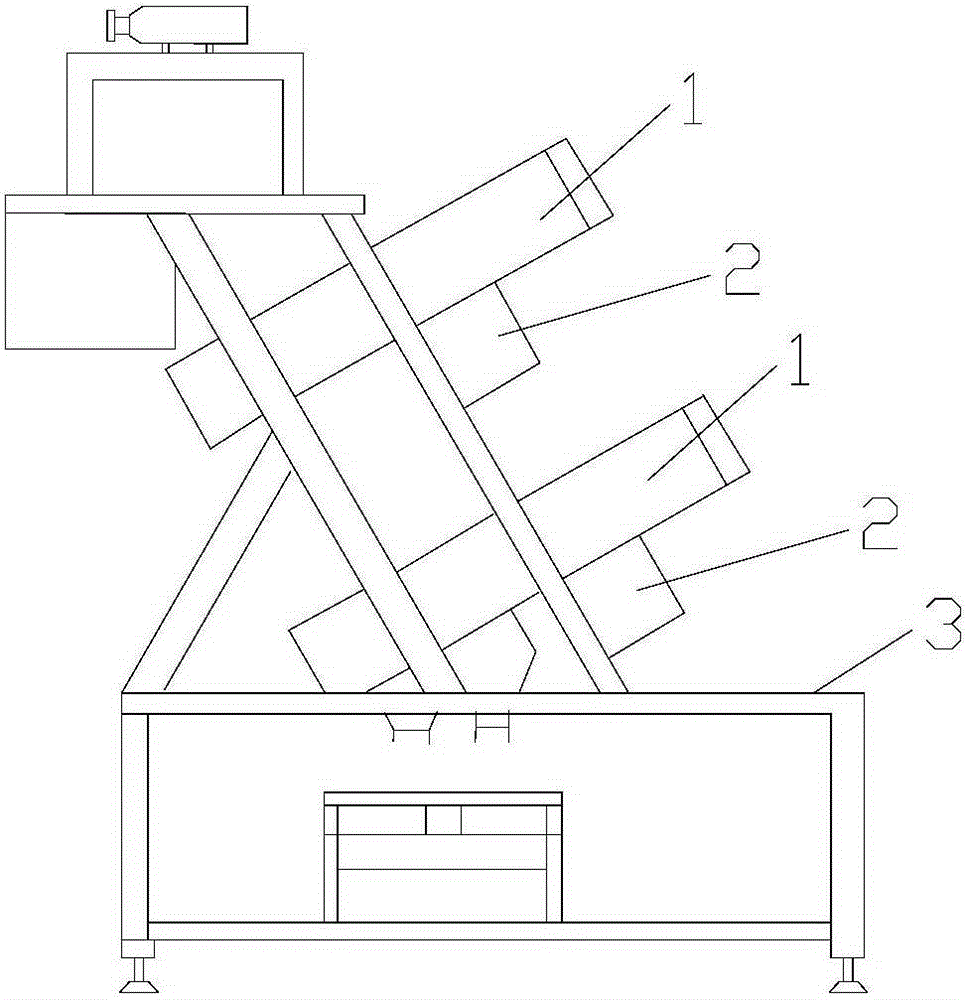

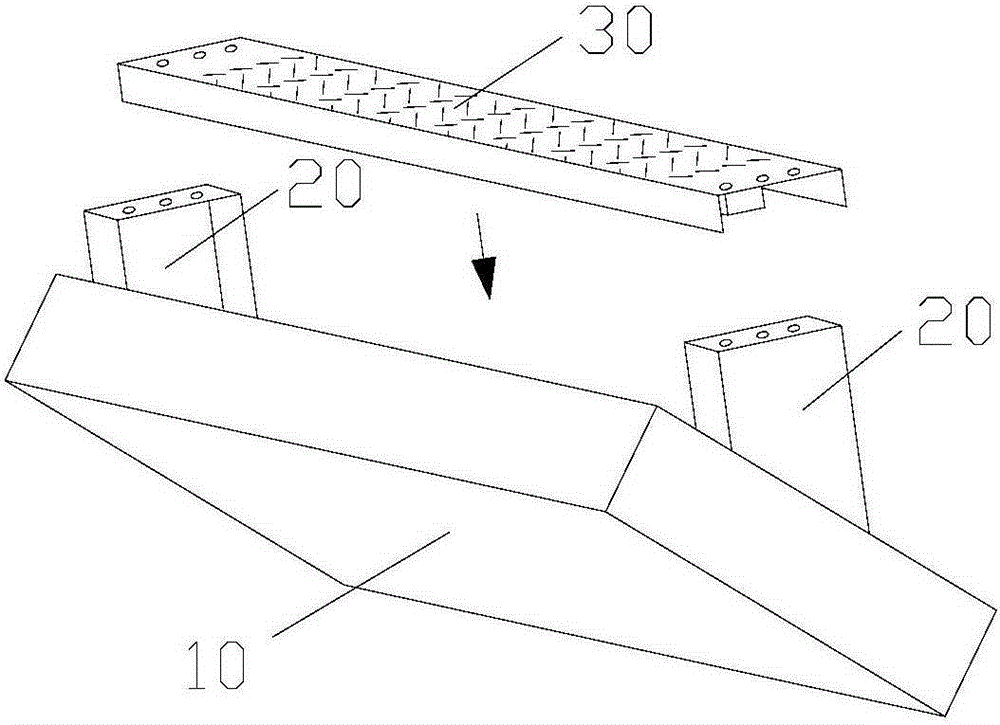

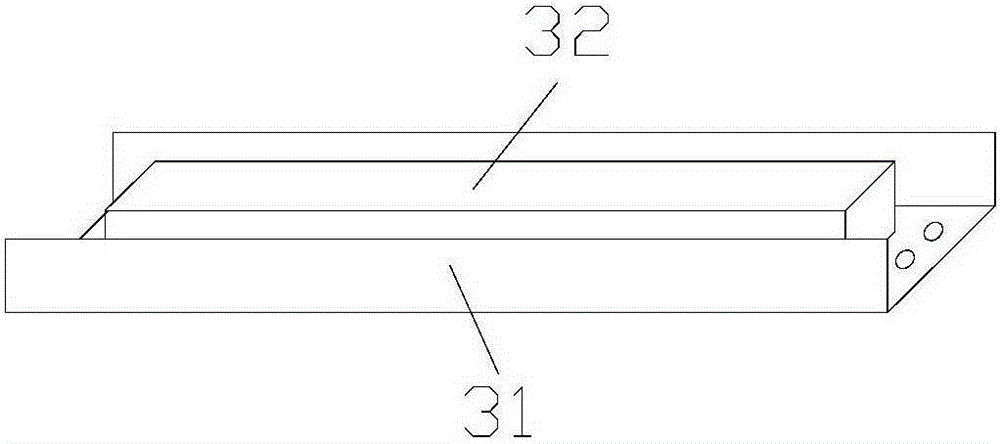

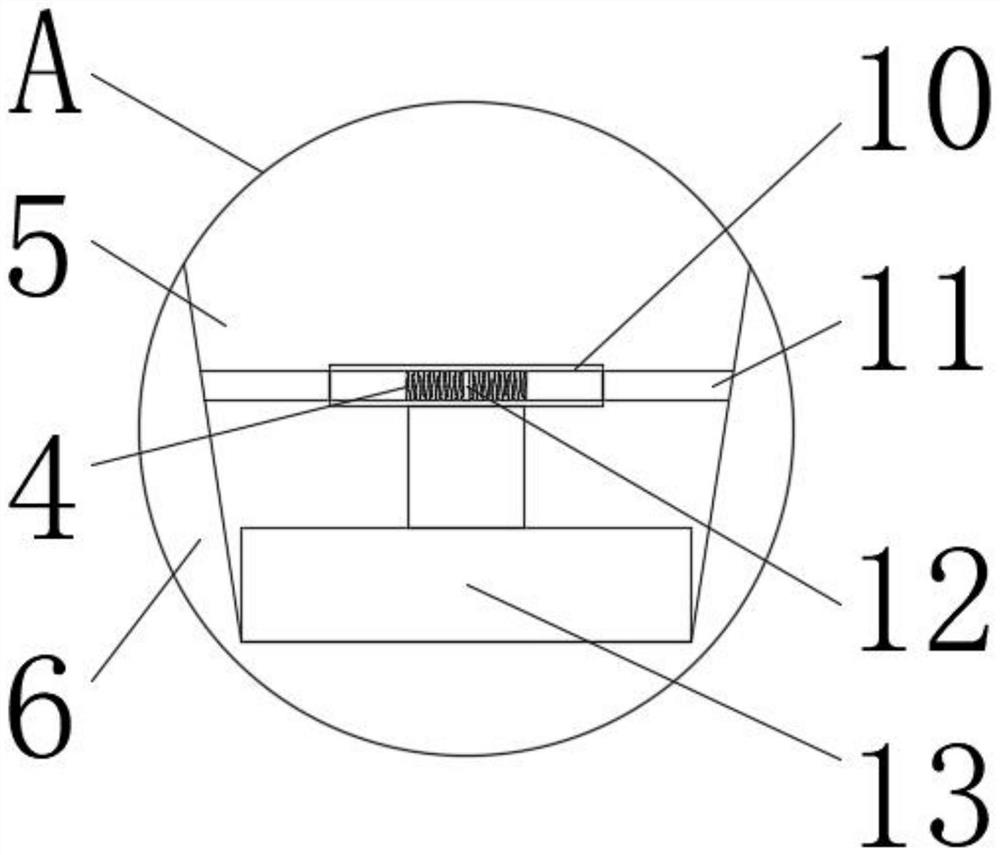

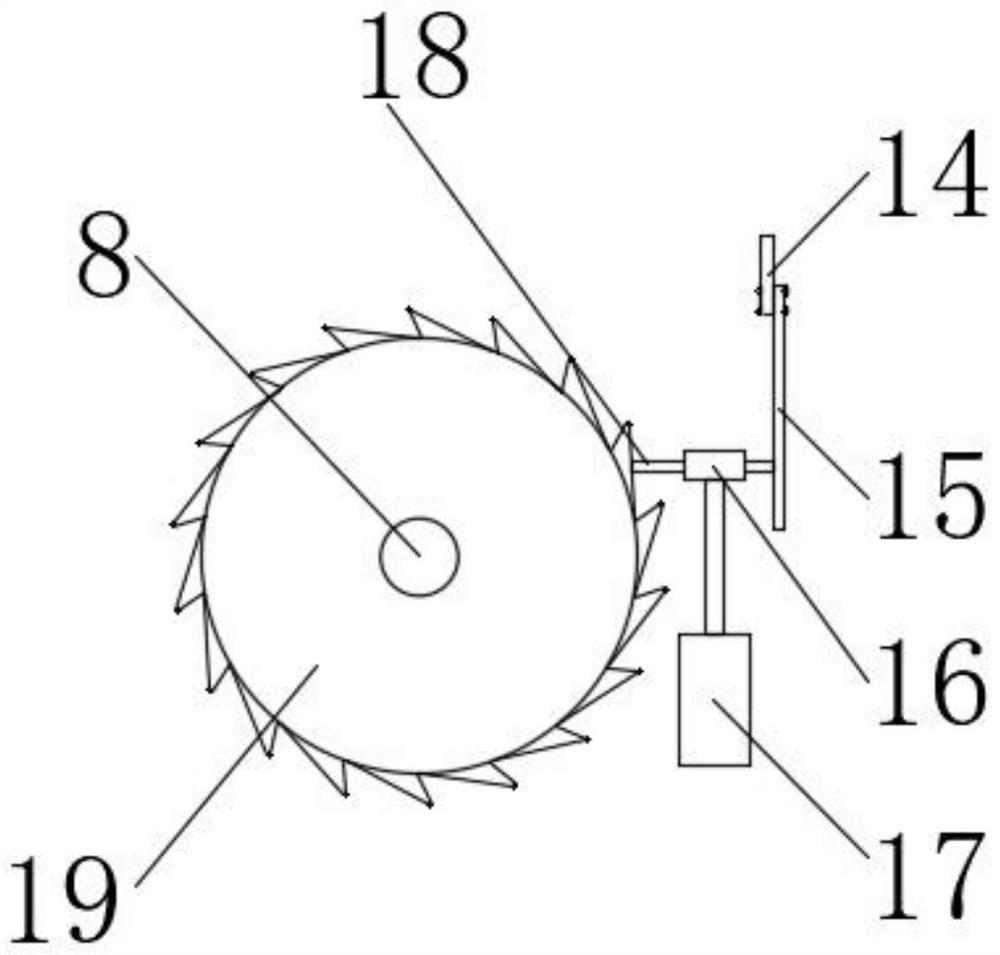

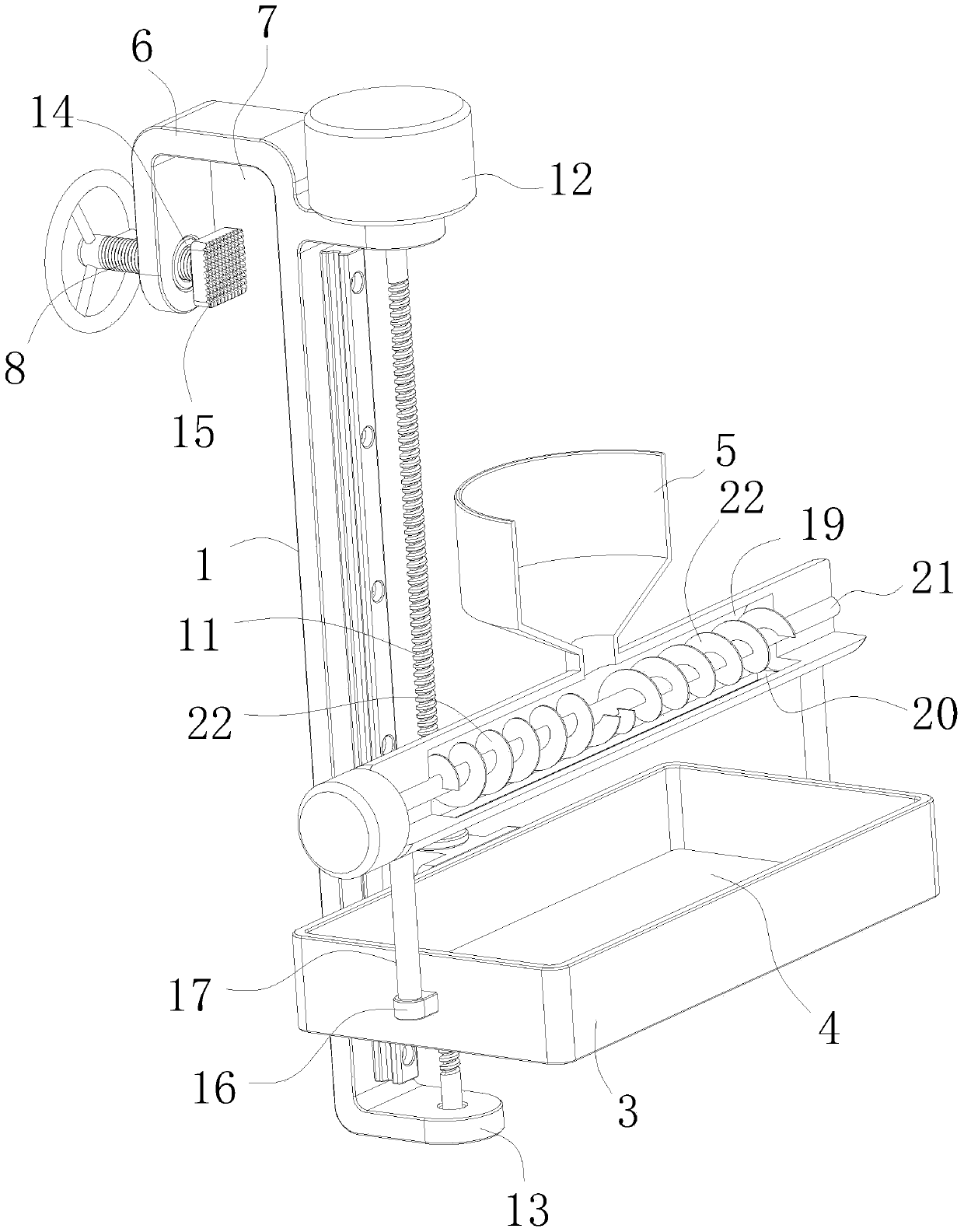

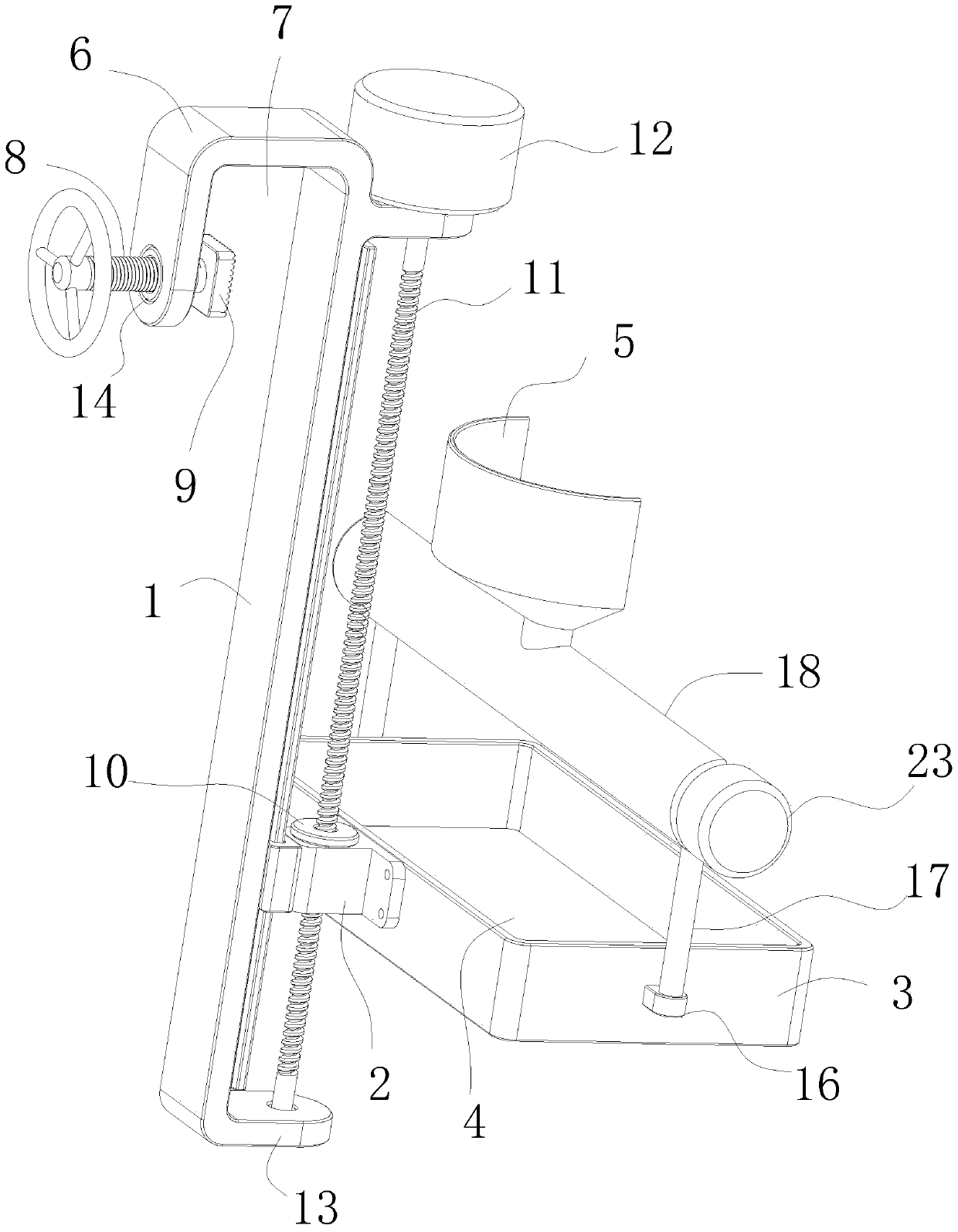

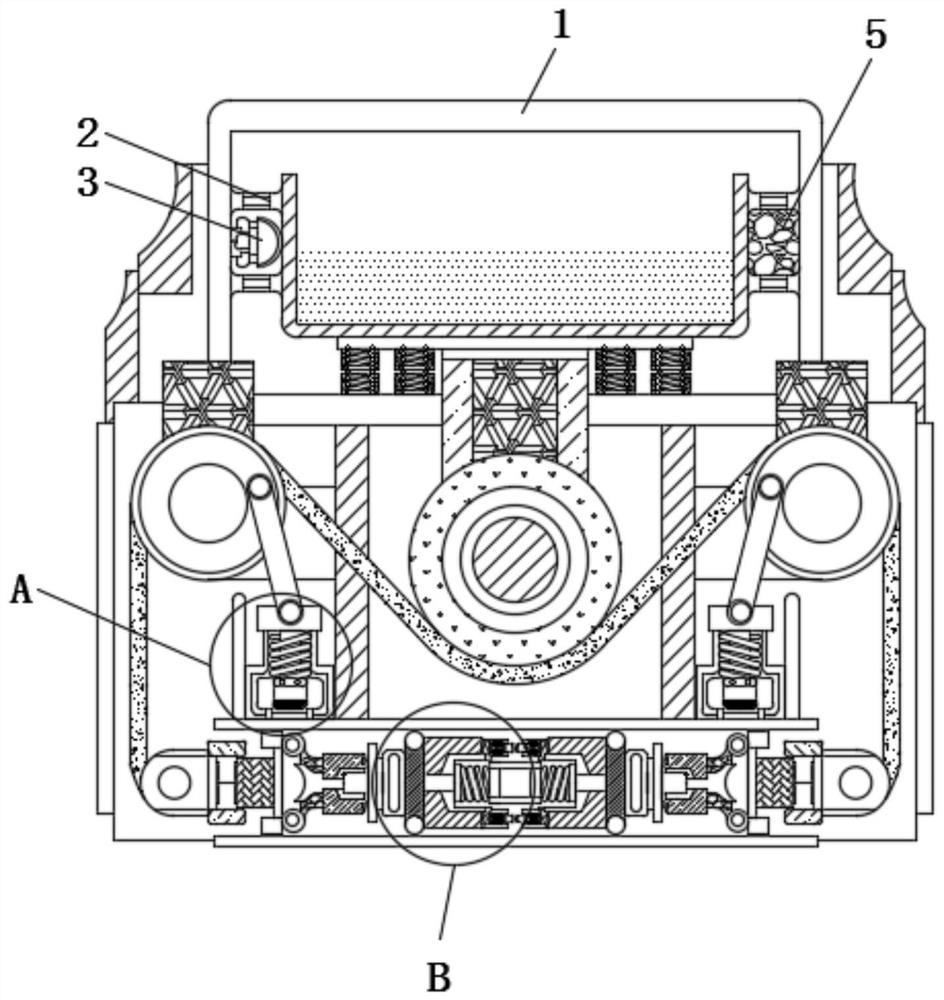

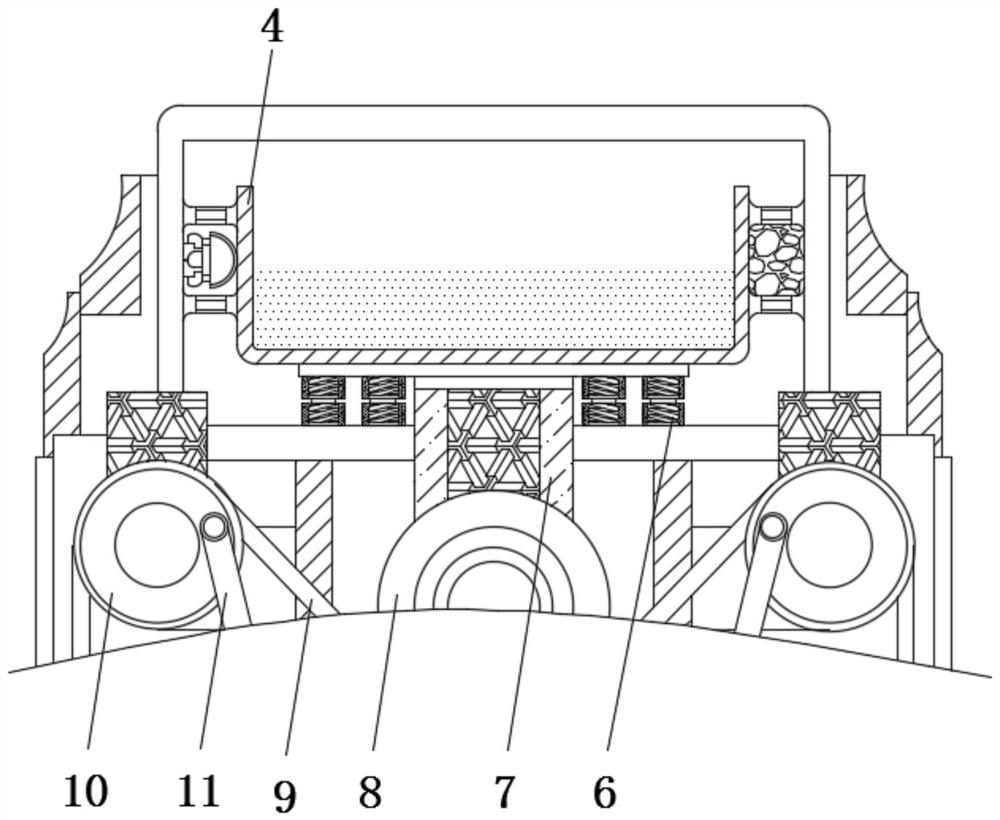

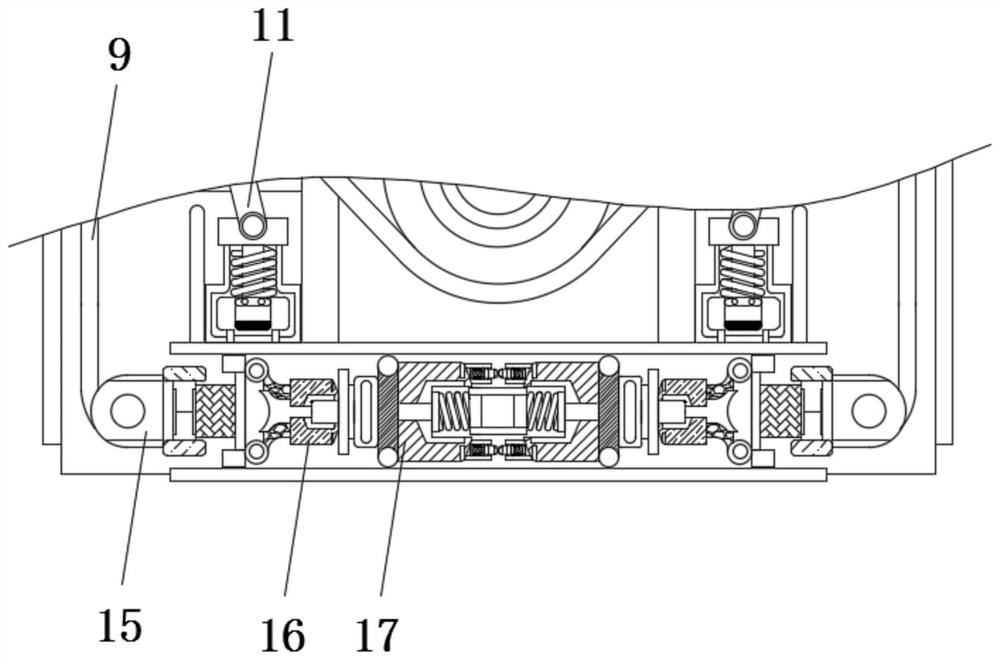

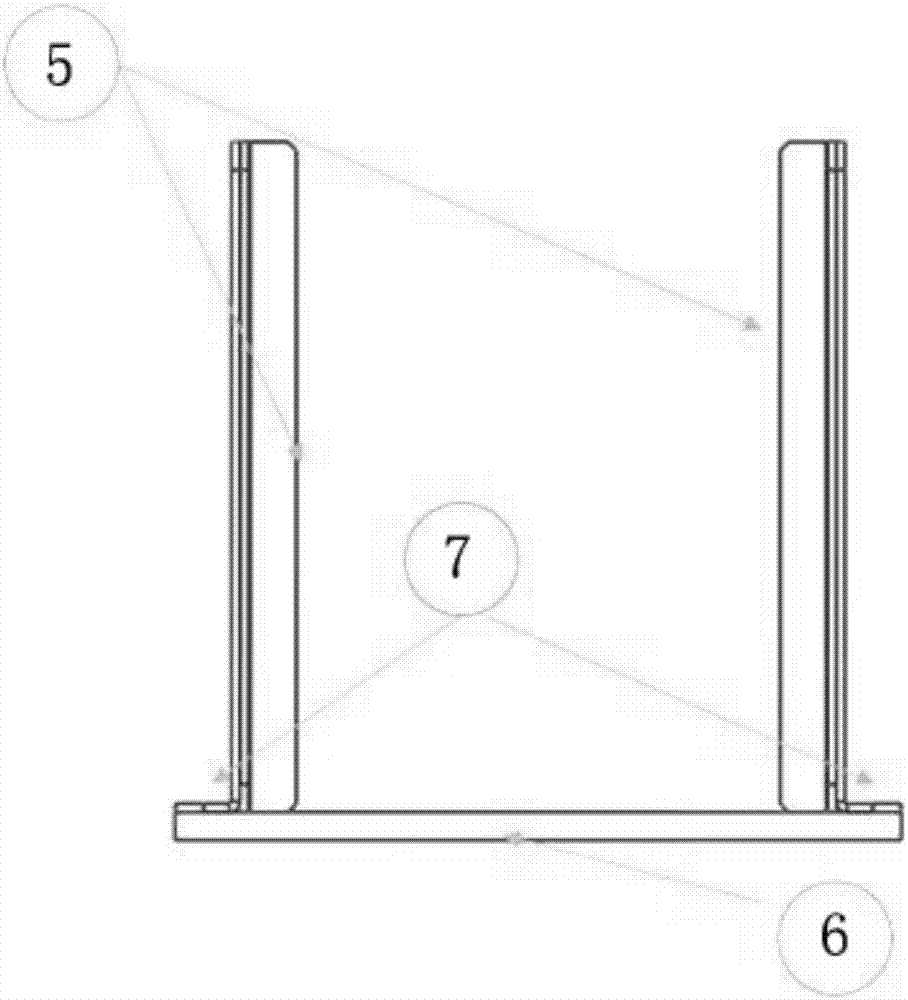

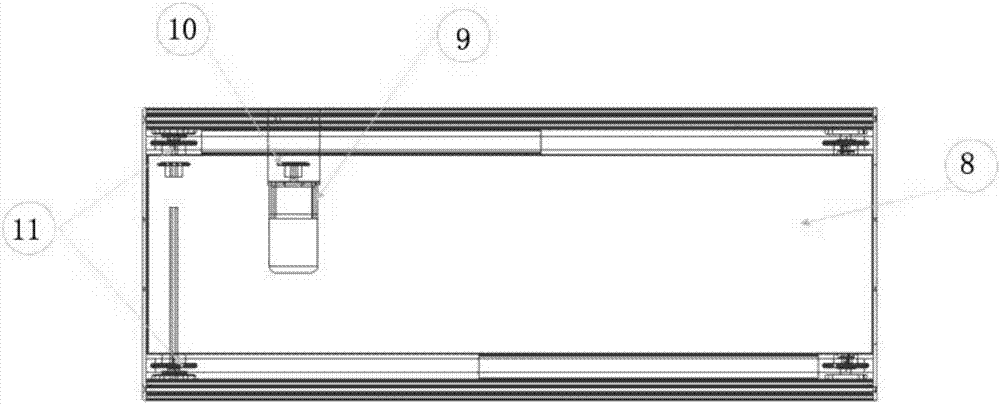

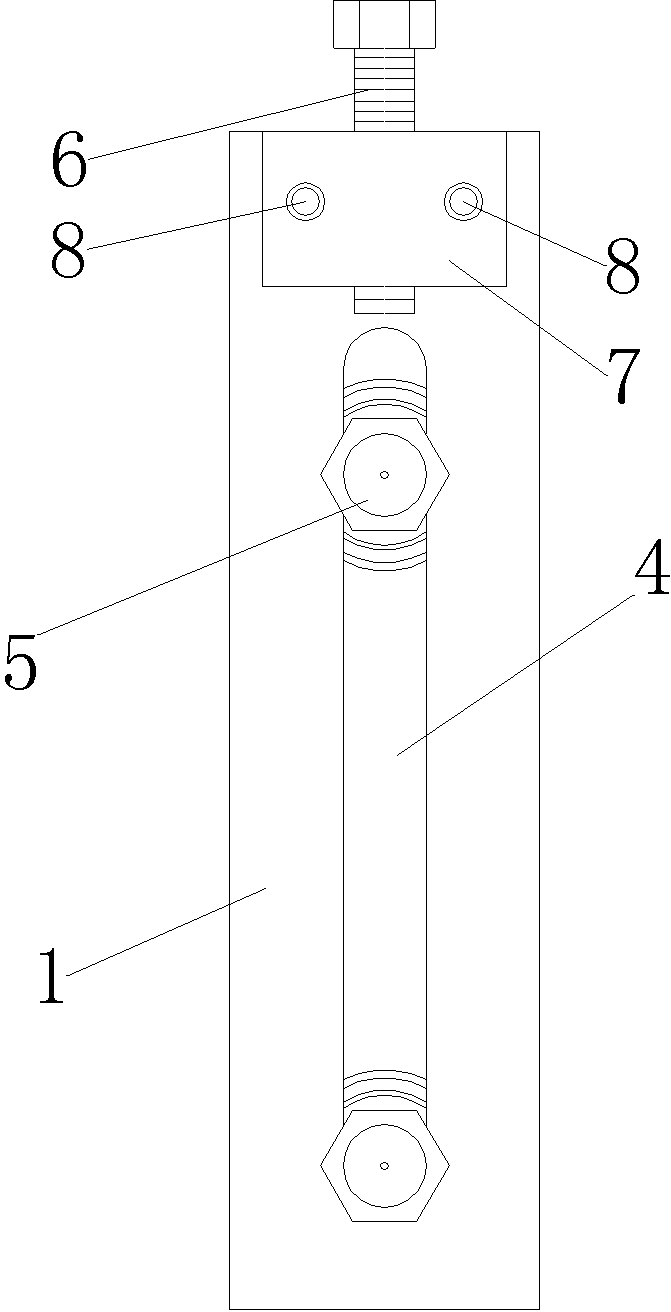

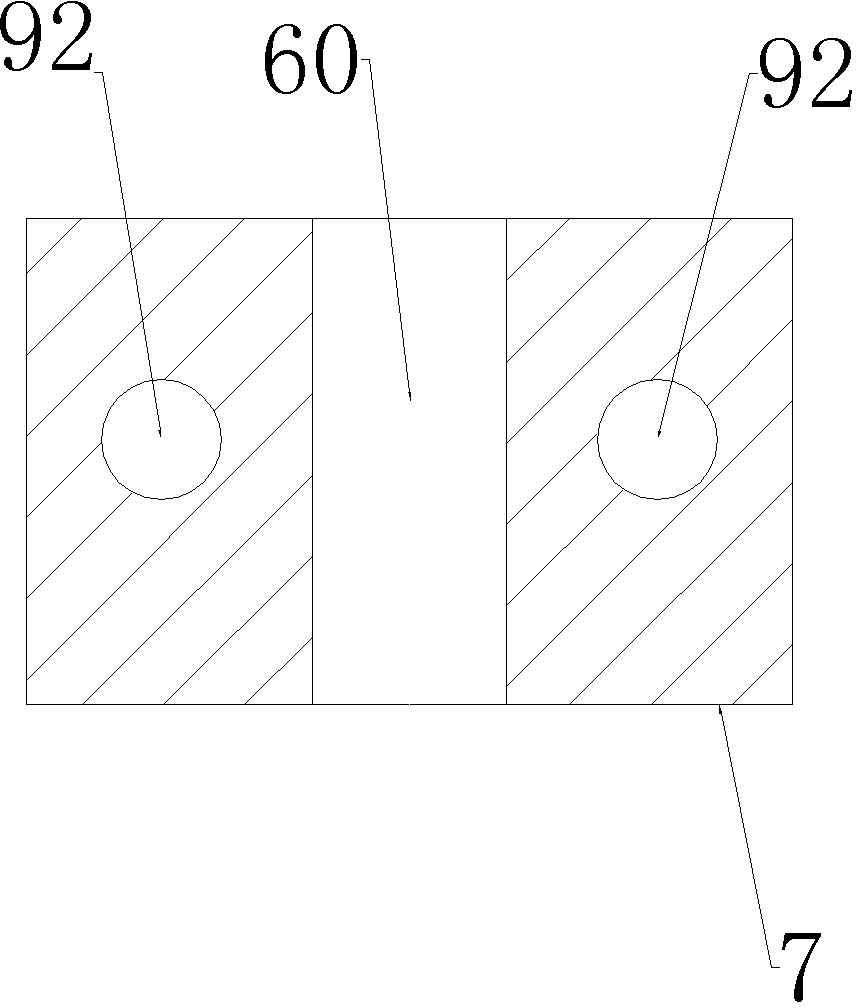

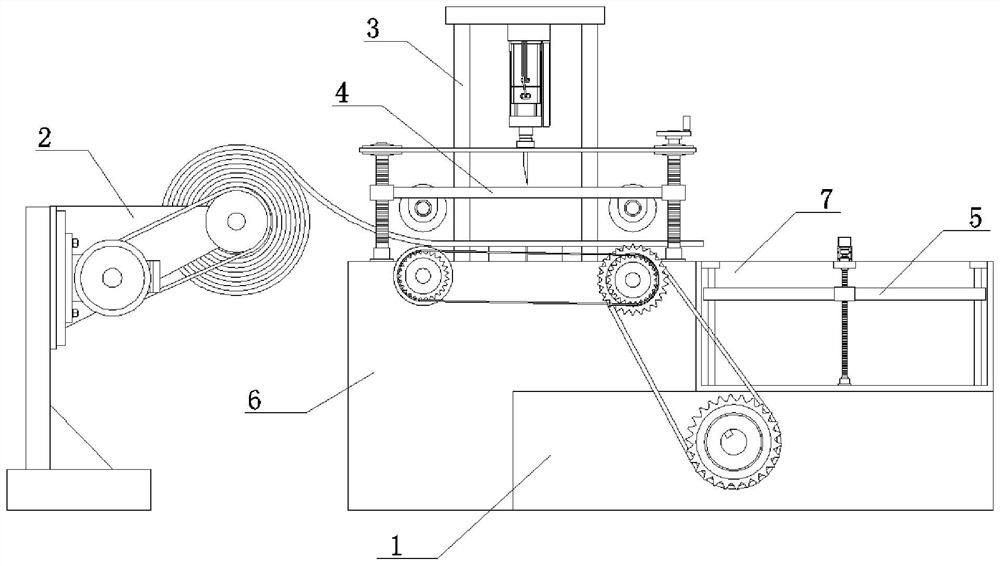

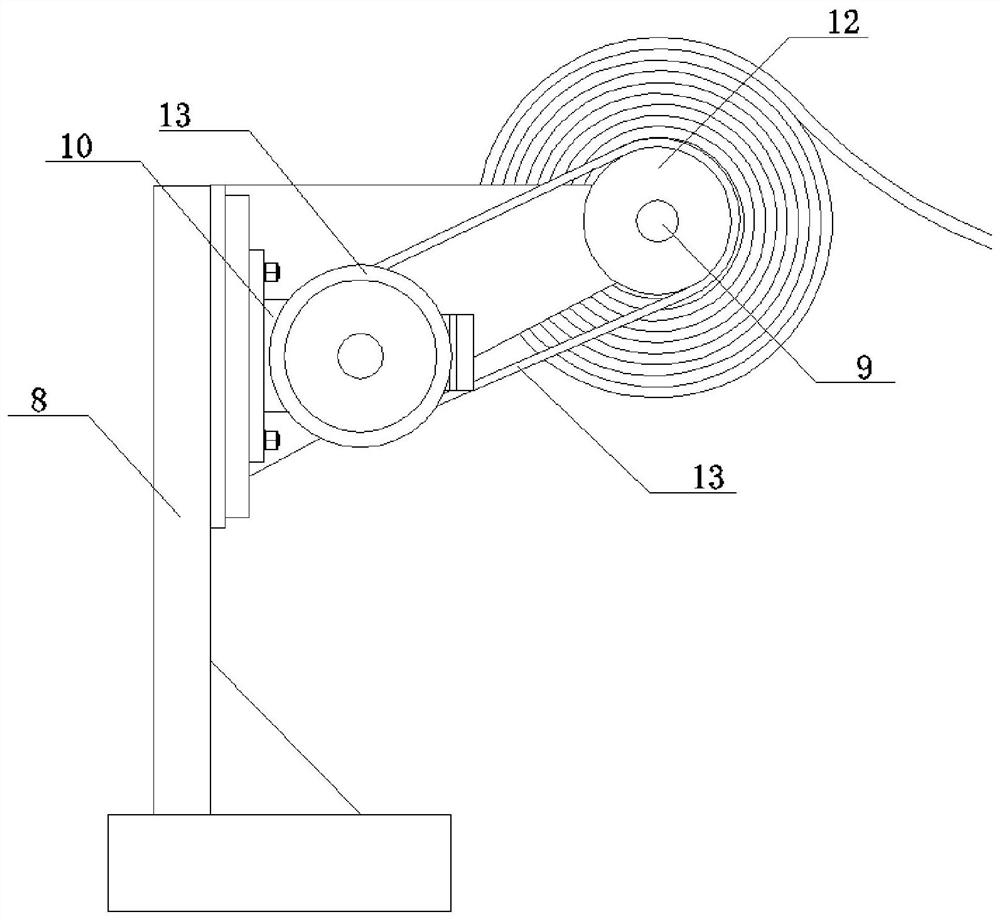

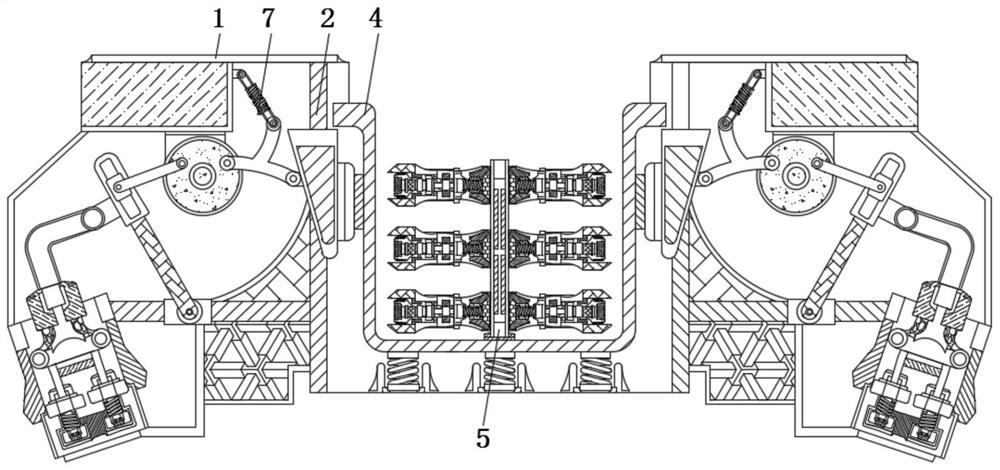

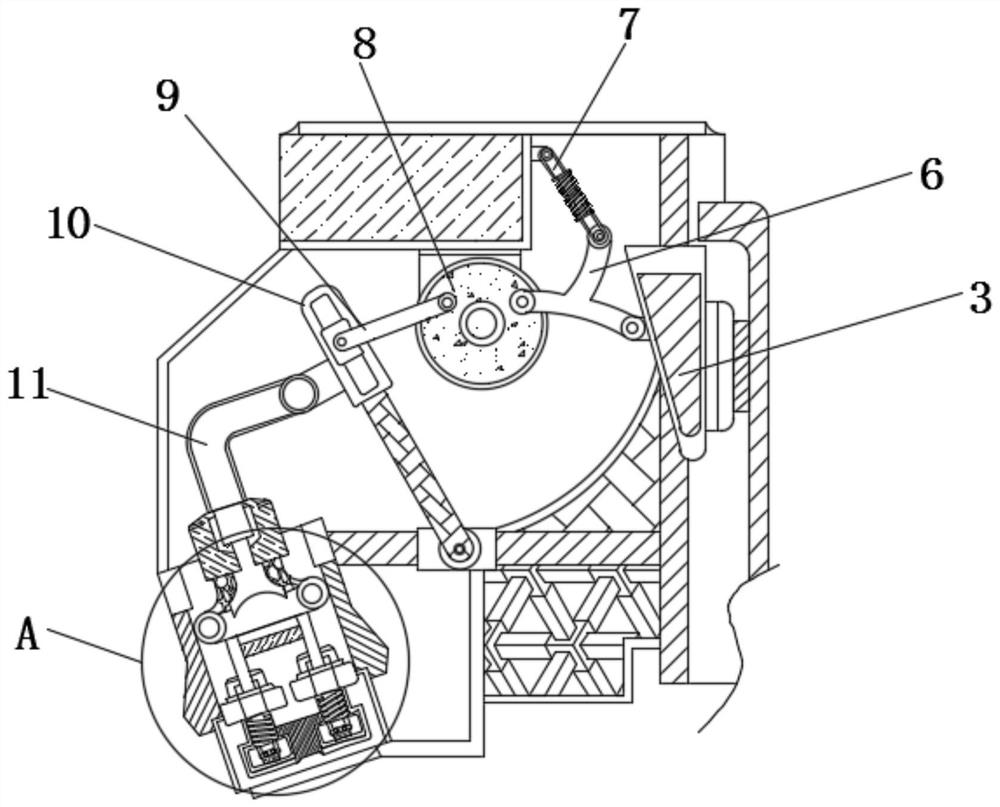

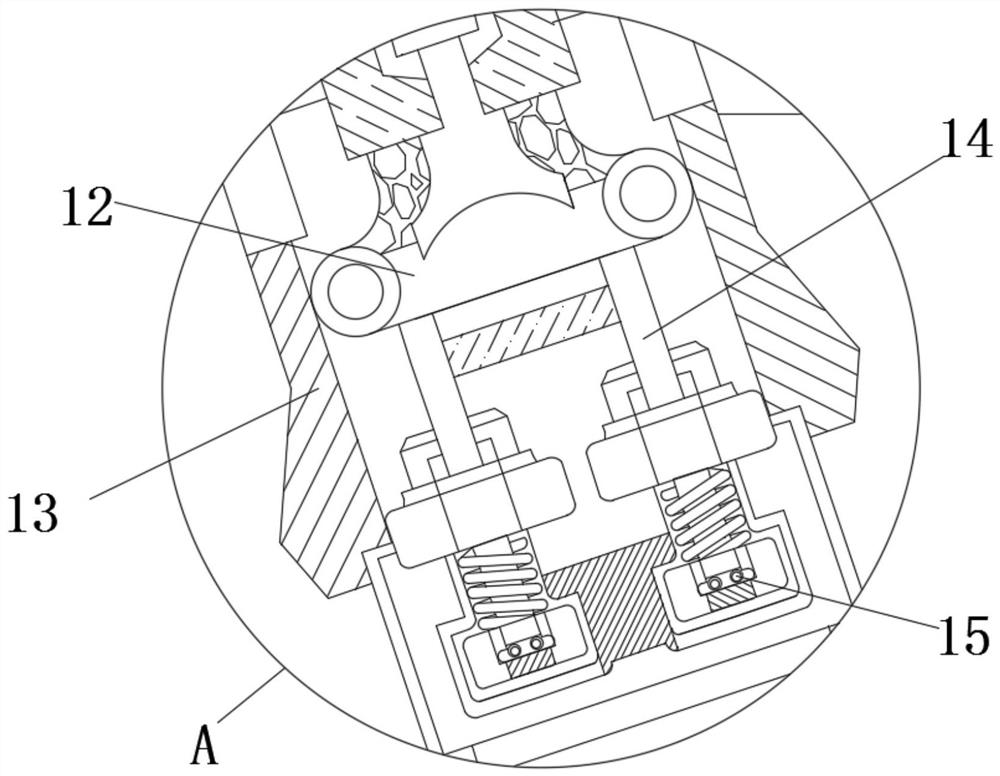

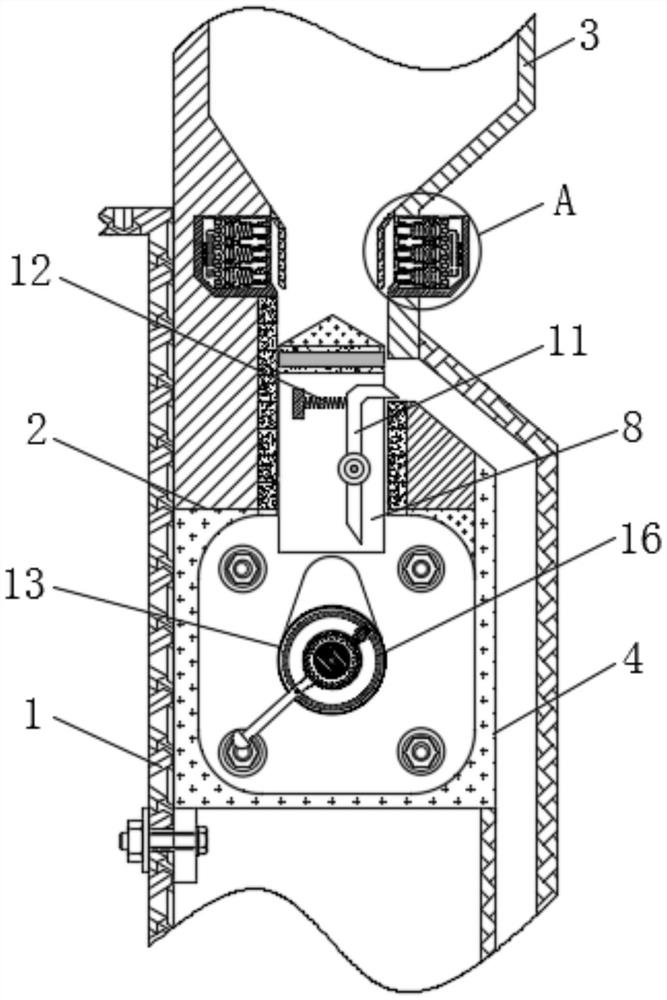

Wire feeding assembly and discharging device for electric power wire laying

PendingCN112660912AAvoid overfeedingReduce laborFilament handlingCleaning using toolsStructural engineeringMechanical engineering

The invention discloses a wire feeding assembly and a discharging device for electric power wire laying. The wire feeding assembly comprises a rack, a wire reel, a power mechanism, a transmission mechanism and a cleaning mechanism. The wire reel is rotatably mounted on the rack, and a wire is wound on the wire reel; the power mechanism is installed on the rack and used for pulling the wire wound on the wire reel to carry out wire feeding operation; the transmission mechanism is mounted at the bottom of the rack, and the transmission mechanism is connected with the wire reel; the cleaning mechanism is installed on the rack, the wire penetrates through the cleaning mechanism, the cleaning mechanism is connected with the transmission mechanism, during wire feeding operation, the wire sequentially penetrates through the cleaning mechanism and the power mechanism, the power mechanism is used for continuously pulling the wire, and during wire feeding operation, the cleaning mechanism works synchronously; and the cleaning mechanism is used for cleaning the surface of the wire, and when wire feeding operation is finished, an emergency stop mechanism is used for clamping the wire reel, so that the wire reel stops rotating as soon as possible, and excessive discharging of the wire is avoided.

Owner:国网内蒙古东部电力有限公司呼伦贝尔供电公司

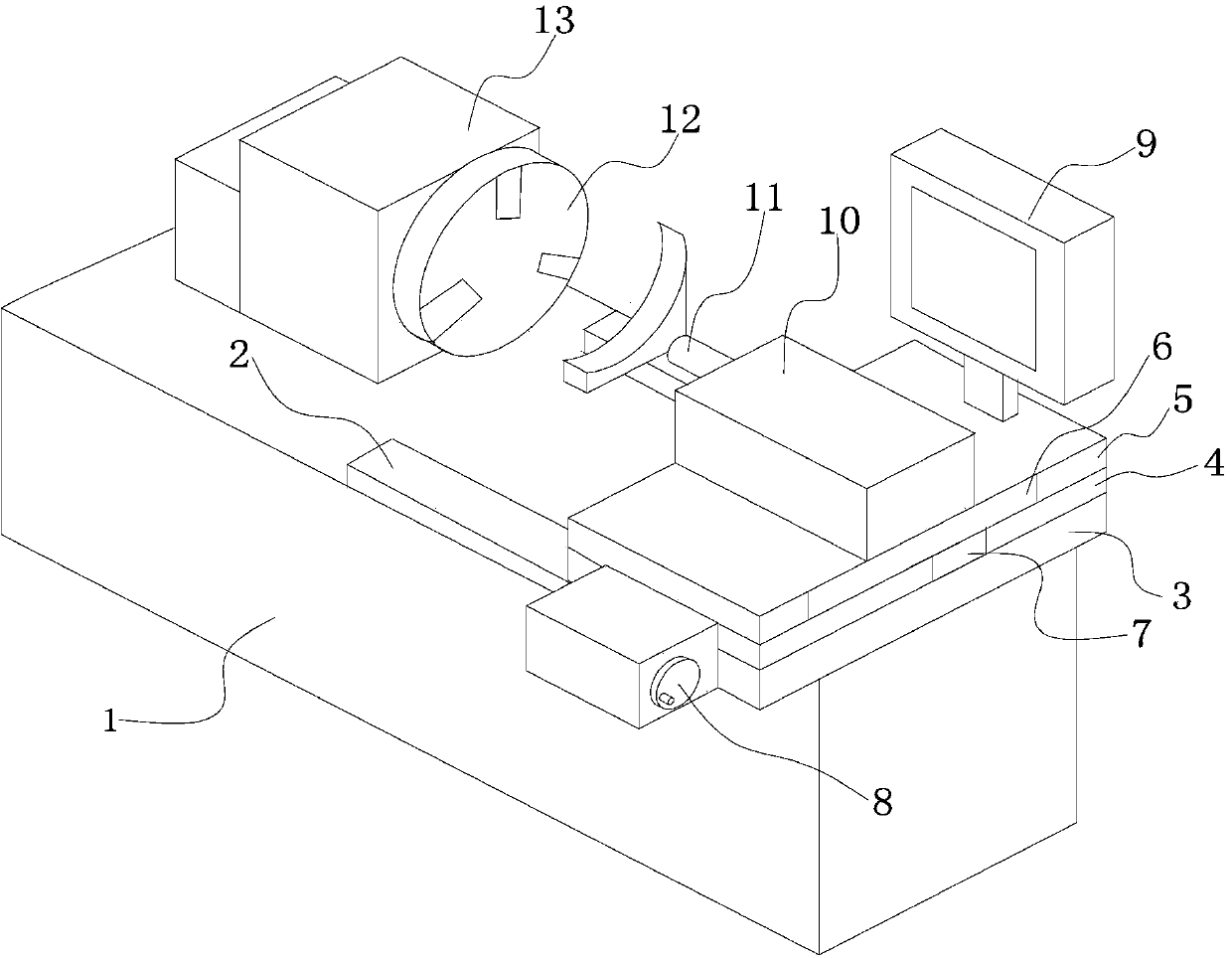

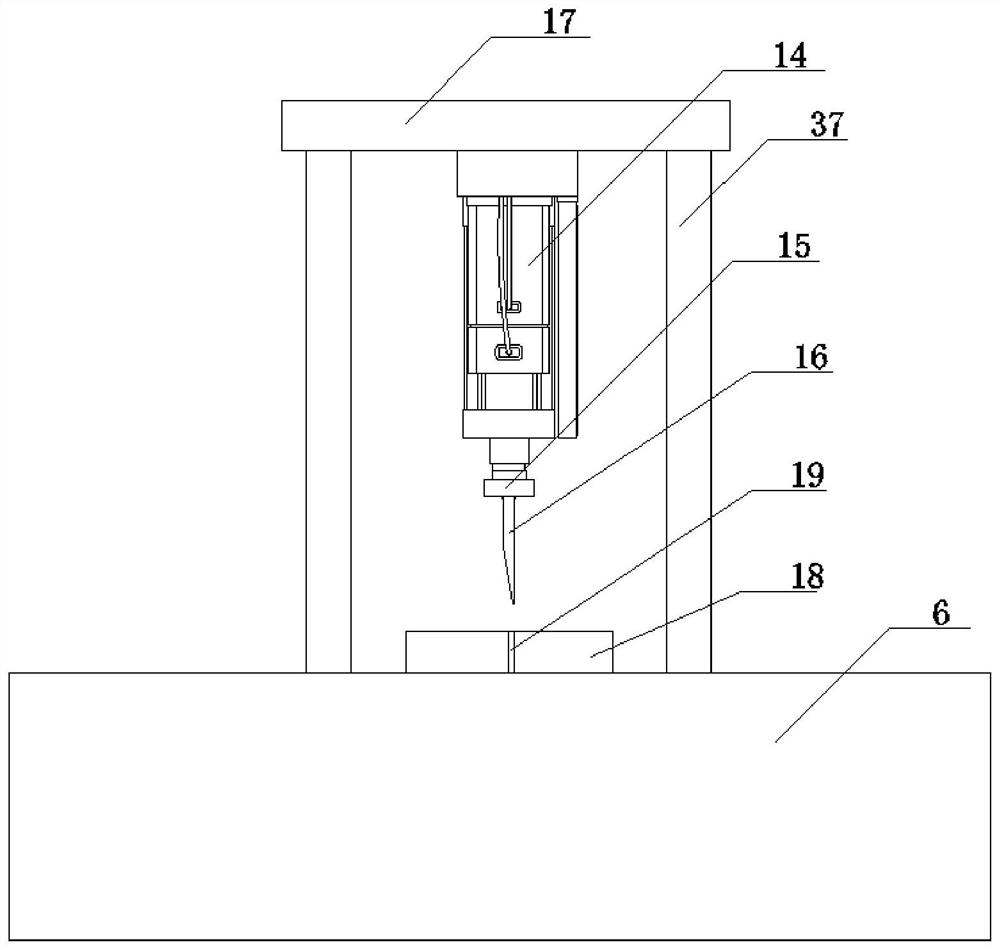

Internal grinding machine

InactiveCN103962902AAvoid overfeedingImprove machining accuracyRevolution surface grinding machinesGrinding drivesData displayGrating

The invention discloses an internal grinding machine. The internal grinding machine comprises a lathe body and a longitudinal workbench which is in sliding connection with the lathe body, wherein a transverse workbench is in sliding connection with the upper part of the longitudinal workbench; a transverse feeding mechanism is arranged on the transverse workbench; the transverse feeding mechanism is connected with a speed reducer; the speed reducer is connected with a feed control mechanism; the internal grinding machine further comprises a grating ruler; the main scale of the grating ruler is arranged on the transverse workbench in the feeding direction of the transverse workbench; a reading head of the grating ruler is arranged below the main scale; the reading head is electrically connected with a data display instrument. The internal grinding machine disclosed by the invention can change the feeding manner and the feed rate measuring manner, improves the stability of the workpiece size and the working accuracy, reduces misoperation frequency of the excessive feed rate, and decreases the rejection rate.

Owner:CHONGQING XINGWANG TOOL MFG

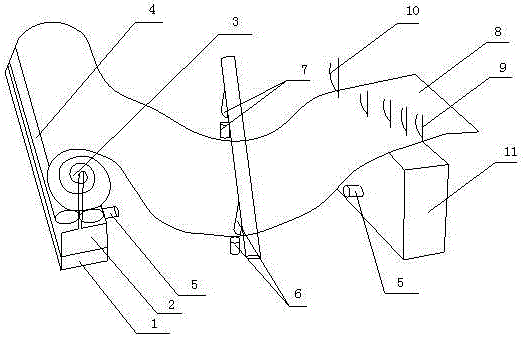

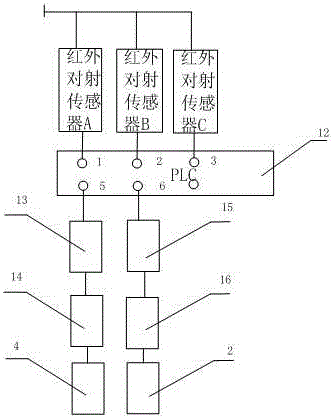

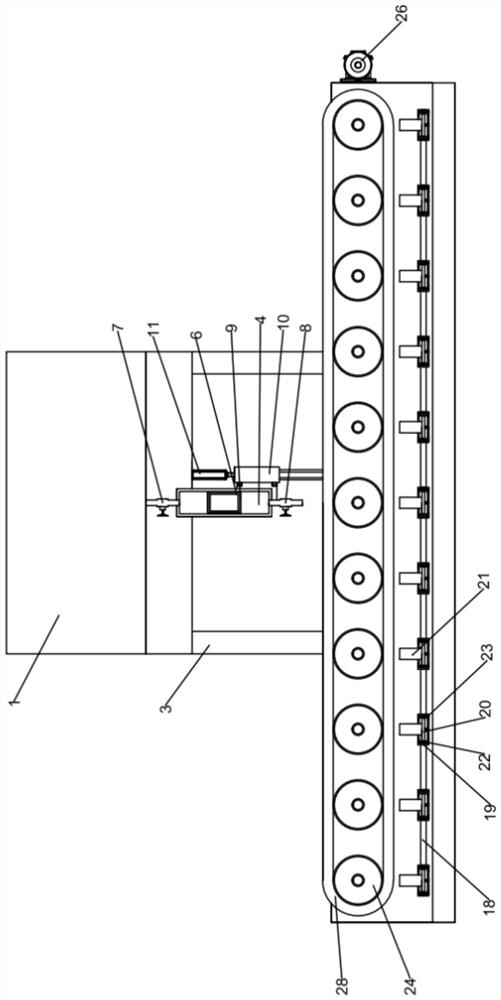

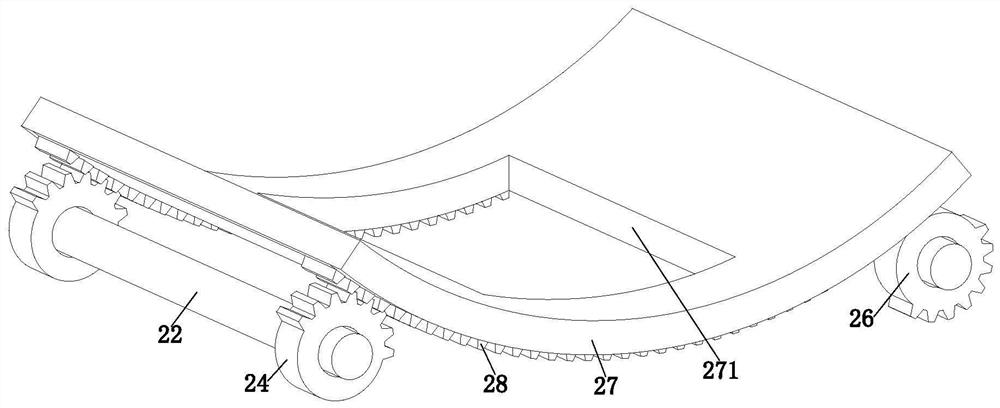

Automatic feeding and edge-aligning machine for sewing material, method and sewing machine

ActiveCN106436053ARealize automatic controlAvoid overfeedingWork-feeding meansSewing-machine control devicesEngineeringSewing machine

The invention discloses an automatic feeding and edge-aligning machine for a sewing material, a method and a sewing machine. The automatic feeding and edge-aligning machine for the sewing material comprises a cylindrical material, the sewing material and a sewing machine base, and also comprises a transverse sliding groove base, a pedestal and a plurality of pushing rollers, wherein the sewing material is positioned on the cylindrical material; the pushing rollers are positioned at the bottom of the cylindrical material and can push the cylindrical material to longitudinally move to be fed; the pedestal is mounted on the transverse sliding groove base and can slide transversely; the two ends of the cylindrical material and the two ends of the pushing rollers are mounted on the pedestal; an infrared opposite-emission sensor is mounted on each of the opposite surfaces of the pedestal and the sewing machine base. A detection method is as follows: the two infrared opposite-emission sensors A perform opposite-emission between the pedestal and the sewing machine base to realize automatic feeding of the sewing material; a pair of infrared opposite-emission sensors B and a pair of infrared opposite-emission sensors C perform opposite-emission in the vertical directions of the two sides of the sewing material correspondingly to realize edge-aligning operation of the sewing material. According to the automatic feeding and edge-aligning machine for the sewing material, the method and the sewing machine, automatic feeding operation of the sewing material and automatic edge-aligning operation of the sewing material are realized, and the labor cost is greatly reduced.

Owner:廖晓阳

Plastic woven bag cutting device

PendingCN108328404APrecise length controlAvoid overfeedingArticle deliveryWebs handlingMechanical engineering

The invention discloses a plastic woven bag cutting device. The plastic woven bag cutting device comprises a discharging rotating shaft used for supporting a woven bag winding ring and a supporting frame used for supporting the discharging rotating shaft, and further comprises a discharging device used for pulling a plastic woven bag to conduct discharging, a cutting structure used for cutting theplastic woven bag, a conveying device used for pulling the cut plastic woven bag, and an infrared sensor which is used for detecting the plastic woven bag and is adjustable in position. The infraredsensor and the cutting structure are arranged on the two sides of the conveying device, and the discharging device, the conveying device, the infrared sensor, a first air cylinder device and a secondair cylinder device are all in signal connection with a controller. The production efficiency and the product quality can be improved effectively through the plastic woven bag cutting device.

Owner:贺州市宜居船木工艺装饰有限公司

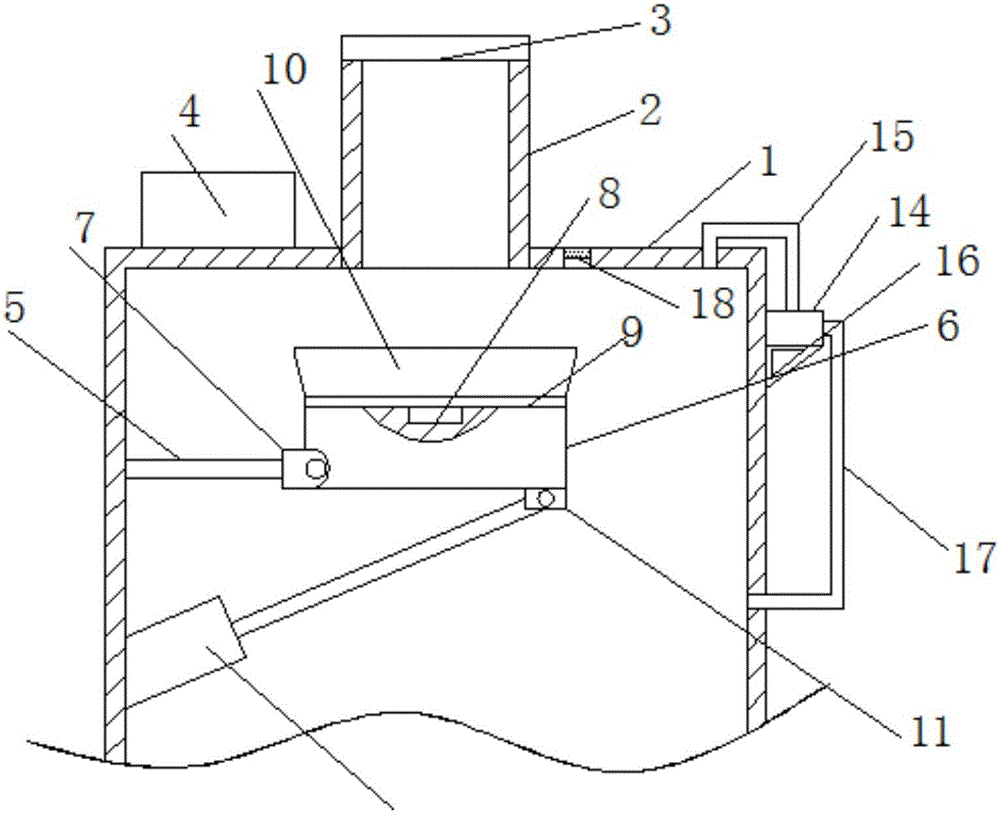

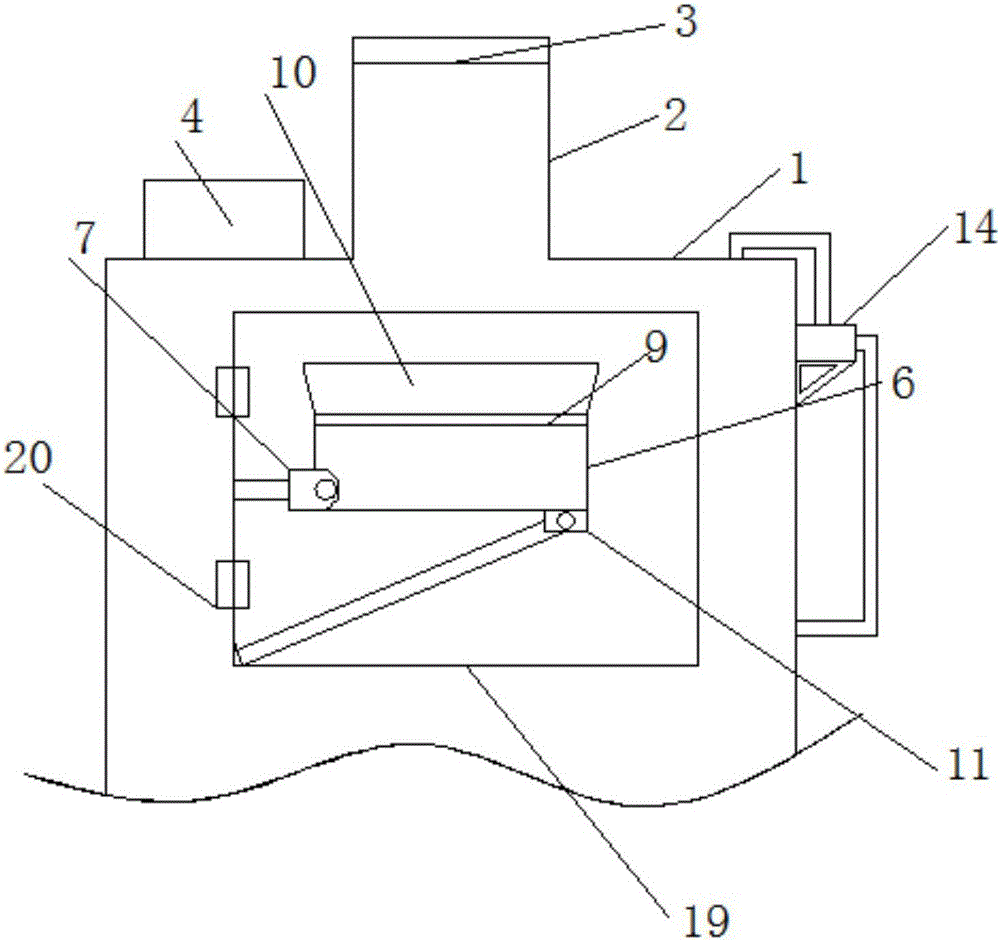

Quantitative weighing and feeding device for biological product auxiliary materials

The invention discloses a device for quantitatively weighing and unloading auxiliary materials of biological products. The left side wall of the material body is provided with a support rod, and the right side of the support rod is movably connected to the electronic scale body, and the inside of the electronic scale body is provided with a heater body, and the top of the heater body is provided with a heat conduction plate. A collection tank is installed on the top of the board, a cylinder body is provided at the bottom of the pole, and the output end of the cylinder body is movably connected to the bottom right side of the electronic scale body, and a temperature control switch is installed on one side of the collection tank. The cylinder body is electrically connected to the temperature control switch. The invention is a quantitative weighing and unloading device for auxiliary materials of biological products. The main body is flipped and unloaded, which has high practicability.

Owner:XIAOGAN YIHONG HOME CREATIVE DESIGN CO LTD

Method for cultivating rotifers

InactiveCN108124796ACultivate stableLow priceClimate change adaptationAnimal feeding stuffAdditive ingredientMonopotassium phosphate

The invention discloses a method for cultivating rotifers. The method disclosed by the invention comprises the steps: arranging a cultivating tank according to the rotifer growing environment; evenlymixing yeast, fish meal, starch, yeast cream, saccharose, magnesium sulfate, monopotassium phosphate and water according to a certain proportion; fermenting about 12h under a certain temperature; after basic bait is fermented, filling a bolting silk mesh bag with the basic bait and hanging in cultivating tank water; adding photosynthetic bacteria into the tank; cultivating for 5 to 8 days from aninoculation day; harvesting when the rotifer density reaches 500 per milliliter or more; in the period, timely adding the bait according to a rotifer breeding speed and a residual bait amount in the mesh bag. The hanging bag cultivation mode avoids the phenomenon that the bait feeding amount is too much or too little; the raw materials are prepared into soft lumps by a method that the yeast and the fish meal are fermented, so that rotifer nutrition enrichment caused by single yeast nutrition is avoided; nutritional ingredients of the basic bait fermented by the yeast can be converted into nutrient substances of micromolecular protein peptide and the like; thus, the basic bait is easy for rotifers to absorb, bait nutrition is comprehensive, a utilization rate is high, and the cultivated rotifers have the advantages of strong physique, high survival rate and stable yield.

Owner:广西海洋研究所有限责任公司

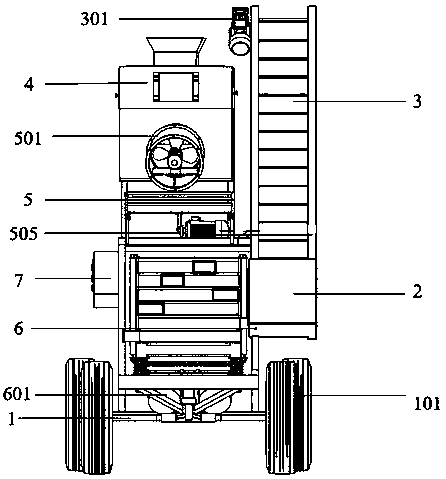

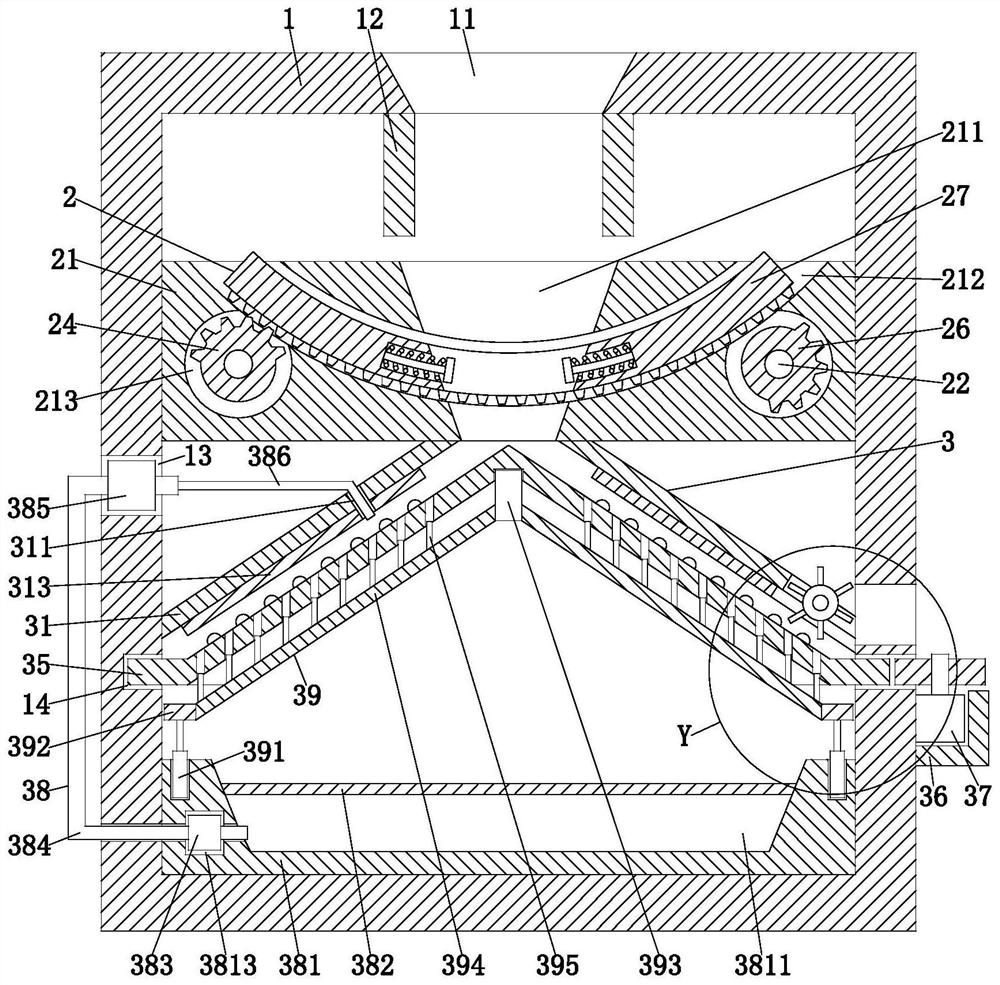

Garlic sectioning and grading mechanized device and control method thereof

PendingCN111545457AReduce speedFeed lessSievingGas current separationStructural engineeringAllium sativum

The invention relates to a garlic sectioning and grading mechanized device and a control method thereof. The garlic sectioning and grading mechanized device comprises a bottom disc, a sectioning device and a grading device, the sectioning device and the grading device are mounted on the bottom disc, the sectioning device comprises an outer box body, two upper rubber rollers rotatably connected into the outer box body and a sectioning driving device for driving the two upper rubber rollers to rotate in the opposite directions, rubber side plates are mounted between side plates of the outer boxbody and the upper rubber rollers, a feeding opening is formed in the top of the outer box body, the feeding opening is fixedly provided with a flow dividing plate extending to the two upper rubber rollers, the grading device comprises a vibration rack connected with the bottom disc through a spring and multiple stages of screen nets mounted on the vibration rack, the discharging ends of the screen nets are provided with collecting pipes, garlic collecting, transporting, sectioning, impurity removing and grading are finished at one time, multiple operation flows are integrated, operation and mobility are high, due to intensification design, the space and the size occupied by the device can be greatly reduced, and the current needs of a peasant can be met.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

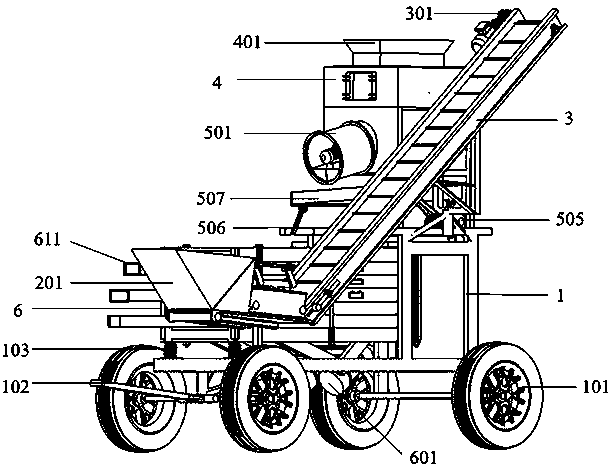

Automatic feeding device based on pet face recognition

PendingCN112167074ALow cost performanceAvoid single phenomenonAnimal watering devicesAnimal feeding devicesAnimal scienceMedicine

The invention discloses an automatic feeding device based on pet face recognition. The automatic feeding device comprises a feeder, a server and a user side, wherein the feeder is provided with a sensor, a camera and a feeding controller; the user side is used for setting a pet face image database and a pet feeding mode; the sensor is used for detecting whether a pet approaches or not, and when the pet approaches, a current face of the pet is shot through the camera and uploaded to the server; and the server identifies a pet face image according to the pet face image database based on an imageidentification algorithm, judges a current pet feeding mode according to an identification result and combined with the pet feeding mode set by a user, and sends a feeding instruction to the feedingcontroller according to a judgment result, and the feeding controller controls the opening and closing states of corresponding valve mechanisms according to the feeding instruction. The automatic feeding device can automatically feed different types and quantities of food to different pets.

Owner:UNIV OF SCI & TECH BEIJING

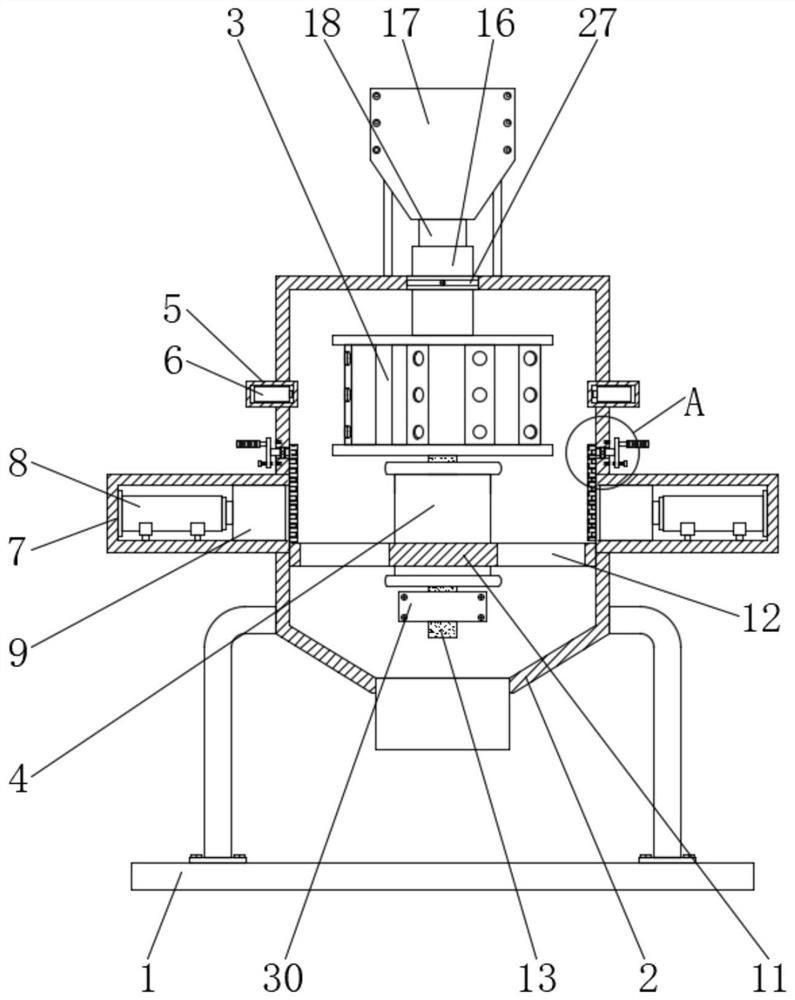

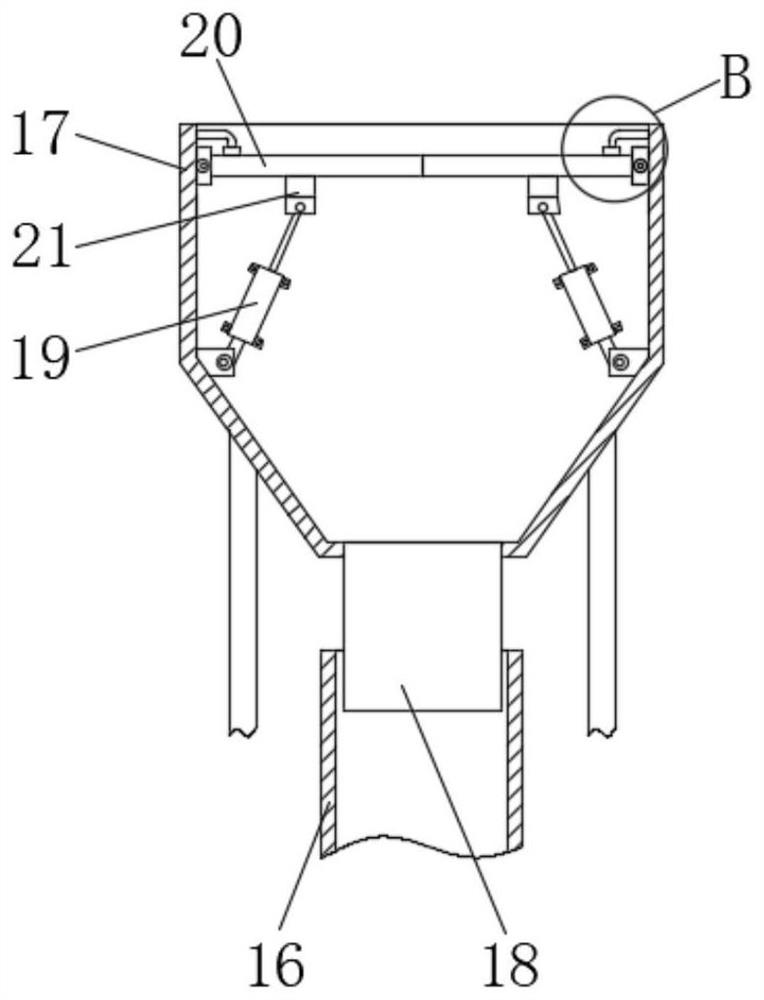

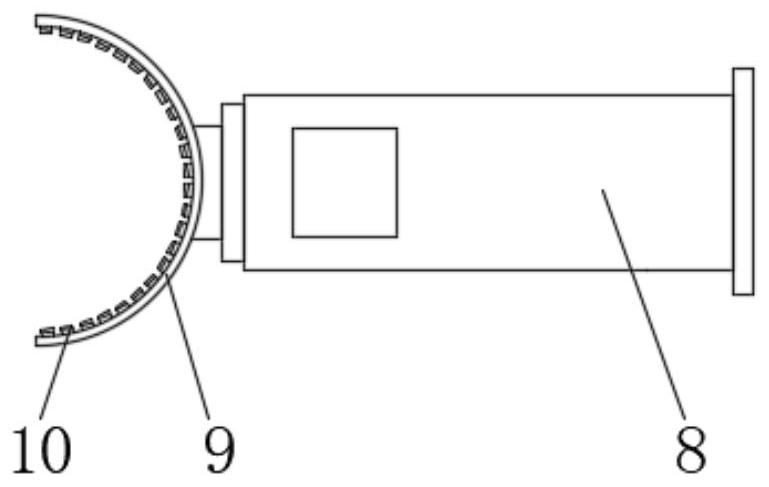

Sand making machine with wear monitoring function and sensor thereof

ActiveCN111701667AReal-time monitoring of operating statusAvoid overfeedingGrain treatmentsImpellerMachine

The invention relates to the technical field of sand making machines, in particular to a sand making machine with a wear monitoring function and a sensor thereof. The sand making machine comprises a base, a shell, an impeller body and a bearing cylinder body, protective shells are embedded above the left and right side surfaces of the shell, cameras are installed in the protective shells, the leftand right sides of the shell communicate with box bodies, and hydraulic rods are mounted in the box bodies. The sand making machine can monitor the operation condition of the impeller in real time, can detect the abrasion degree of the surface of the bearing cylinder, can adjust the feeding amount in unit time, solves the problems that some existing sand making machines lack an internal monitoring function, the abrasion degree of the surface of the bearing cylinder cannot be detected, during detection, shells of the sand making machines need to be disassembled, and much inconvenience is brought to the operation of workers, and meanwhile the situation that the feeding amount is too large in unit time can be avoided.

Owner:上海砼力人工砂装备有限公司

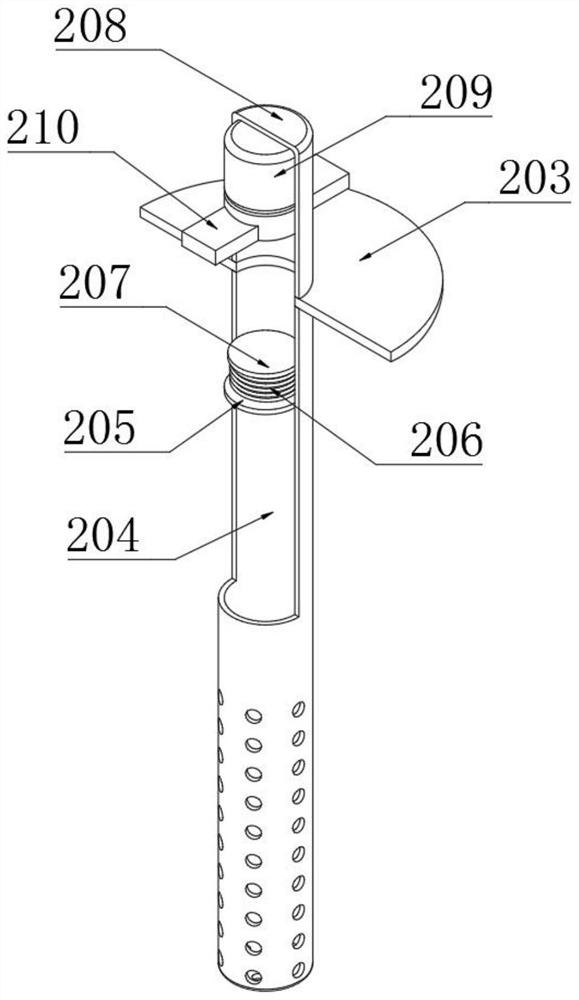

Warehouse bottom bulk loader

A warehouse bottom bulk loader relates to the technical field of machinery, and comprises a material level probe, a hoisting mechanism assembly, a pipeline system, a bent trough, a spiral gate and a fluidized device, wherein the hoisting mechanism assembly is connected with the upper part of the material level probe; the fluidized device is arranged above the hoisting mechanism assembly; the spiral gate is arranged at the bottom of the fluidized device, and is connected with the bent trough; the pipeline system is connected to one side of the fluidized device; the bent trough is connected with a discharging chute; and the discharging chute is connected with a dust collector through a dust collecting pipe. The warehouse bottom bulk loader has the benefits that the dust collector is provided; the design is reasonable; the environment-friendly performance is good; material waste is avoided; the operation is easy; the use is convenient; the automation degree of loading is effectively improved; defects of excess discharging or insufficient discharging can be avoided; and the working performance is stable and reliable.

Owner:JIANGSU HONGMINGDA MACHINERY

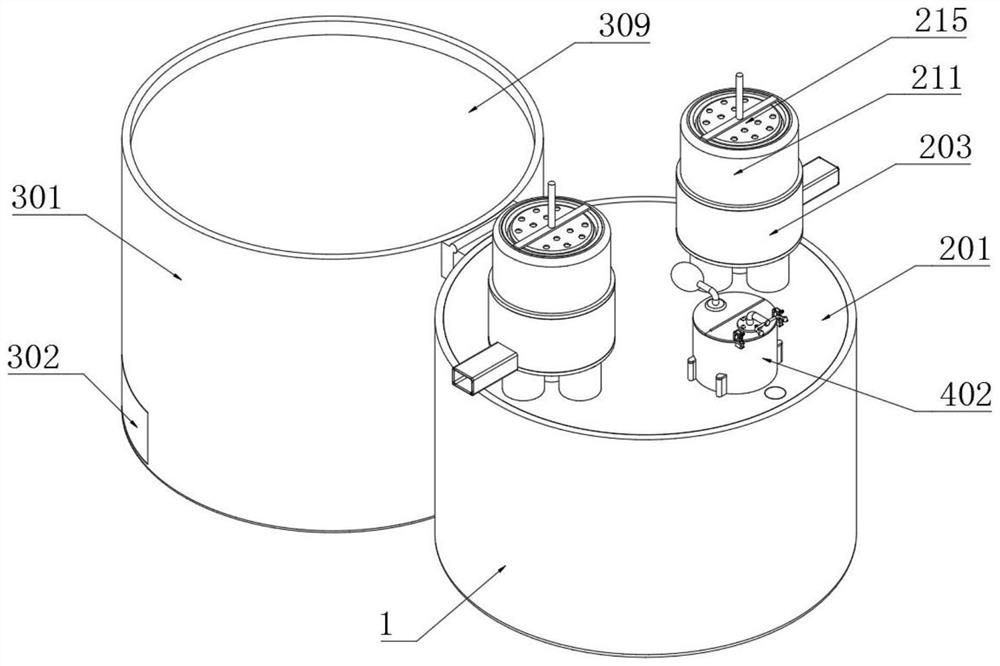

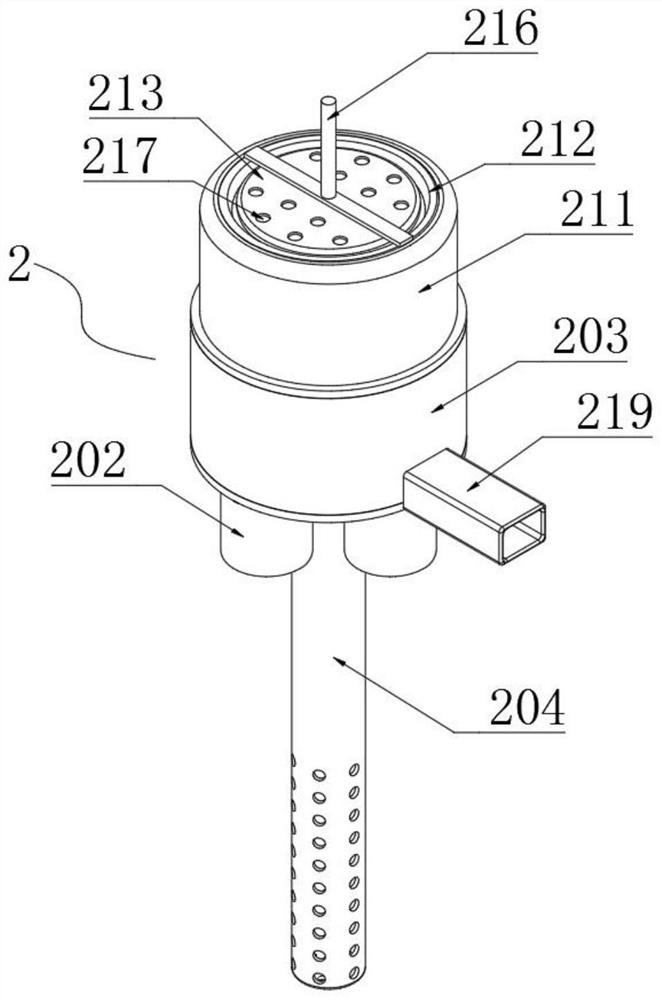

Culture method of river crab megalops larvae

InactiveCN107897069AIncrease productionImprove survival rateClimate change adaptationAccessory food factorsGreenhouseZoology

The invention discloses a culture method of river crab megalops larvae and relates to the technical field of crab breeding. The culture method comprises the following steps: constructing a nursery pond, planting aquatic plants, breeding parent fries outside cages, feeding baits, carrying out water quality management and carrying out greenhouse management. By adopting the method disclosed by the invention, the survival rate of the river crab megalops larvae can be improved; the megalops larvae have the advantages of rapid development, large size, high yield, low sexual precocity rate and easiness for management; and after the megalops larvae are cultured into phase-V juvenile crabs, the phase-V juvenile crabs can be transferred into a juvenile crab culture phase by ponds to be cultured, andthe culture method has very good culture popularization value.

Owner:无为县瑞康特种水产养殖有限公司

Vibration sieve

InactiveCN105149205AImprove work efficiencyAvoid overfeedingSievingScreeningMechanical engineeringSieve

The invention relates to a vibration sieve for material discharging of a color sorter. The vibration sieve comprises a square sieve body provided with a feeding section and a discharging section; striker plates are arranged on four sides of the sieve body; the discharging section at least comprises three discharging openings; uniformly distributed partitions are arranged between every two discharging openings; the discharging side of each discharging opening is arranged in an inclined manner relative to the flow direction of the material, and the inclined angles of the discharging sides of all the discharging openings are the same; a connecting line between each partition and the corresponding discharging side is parallel to the flow direction of the material. As the uniformly distributed partitions are arranged between every two discharging openings, and the inclined angles of the discharging sides of all the discharging openings are the same, the material enters each discharging opening with the same probability, and uniform material discharging is ensured; meanwhile, the connecting line between each partition and the corresponding discharging side is parallel to the flow direction of the material, the phenomenon that the discharged material close to the partitions is excessive, due to the influence of the partitions on the flow direction of the material is avoided, so that the uniformity of the material discharging is further ensured, and the working efficiency of the color sorter is improved.

Owner:ANHUI JIEXUN OPTOELECTRONICS TECH

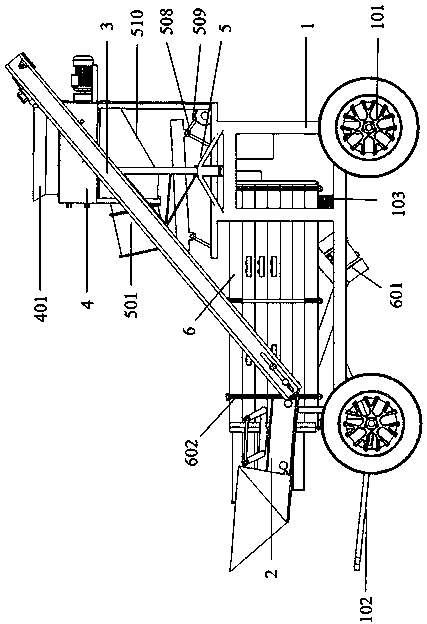

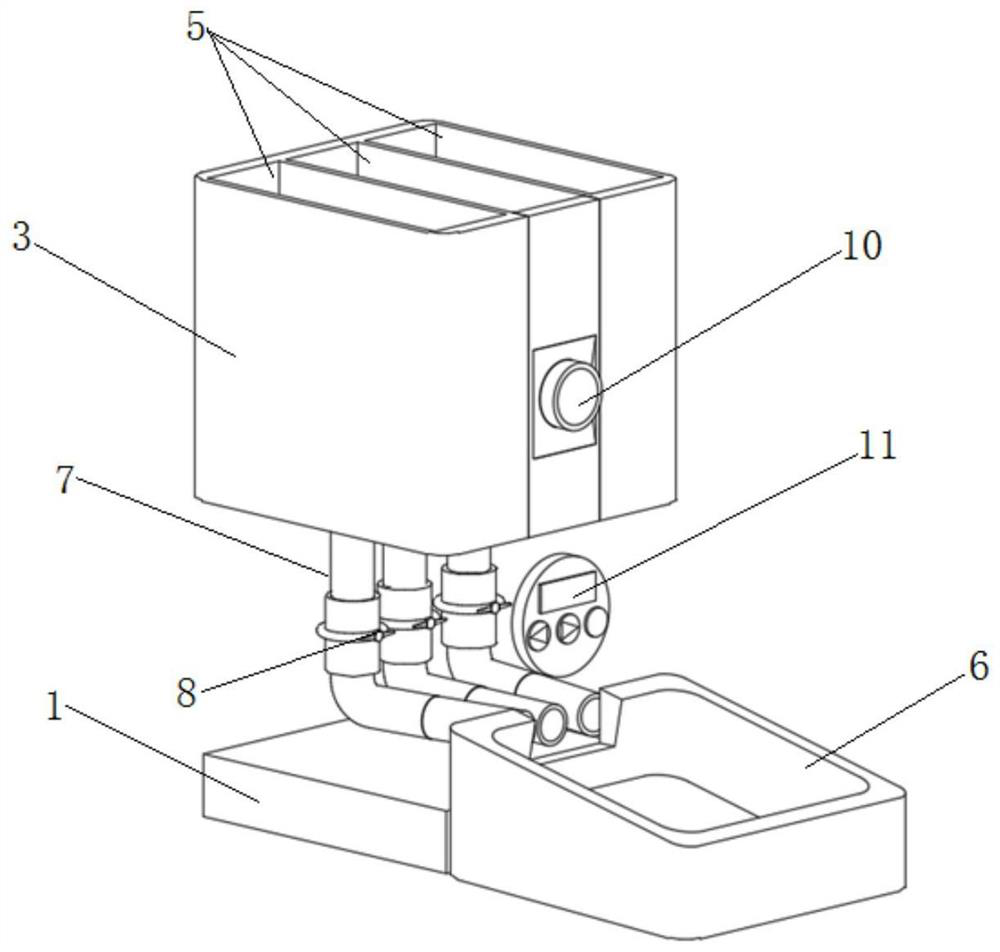

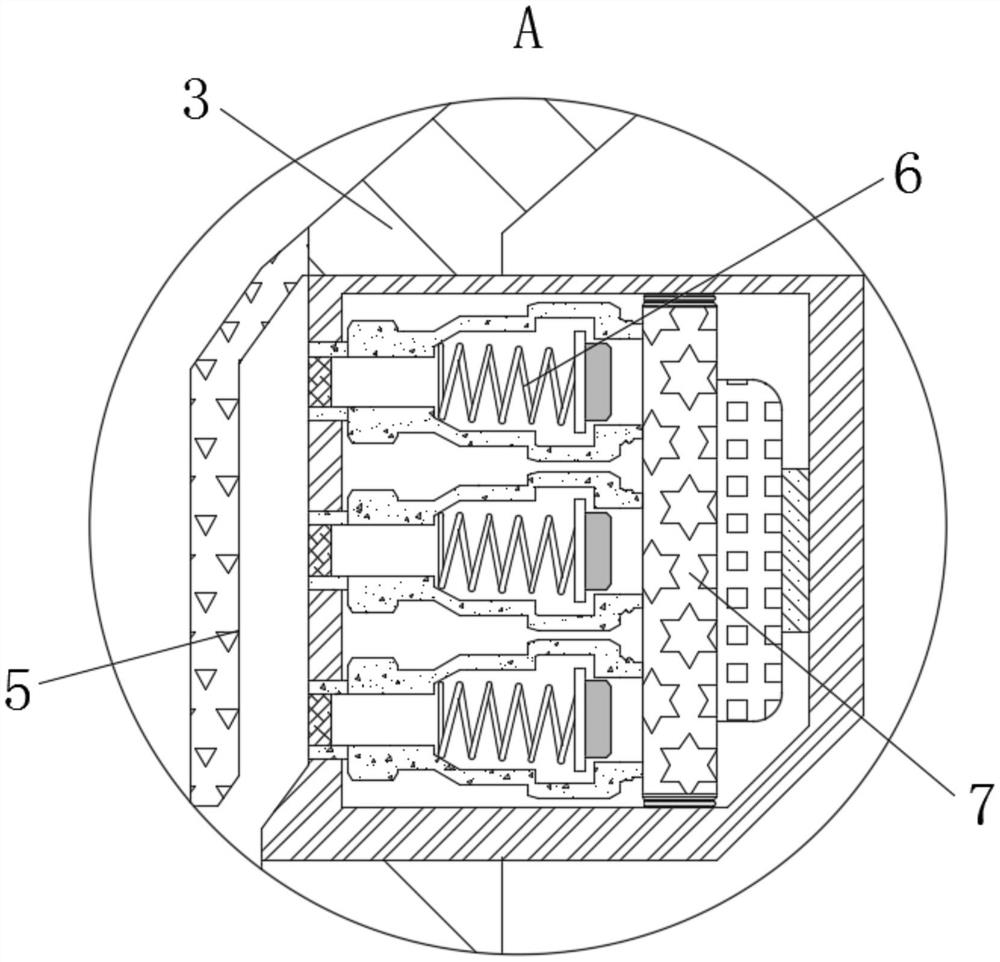

Quantitative fodder feeding device suitable for livestock breeding

InactiveCN112189580AGuaranteed accuracyAvoid overfeedingAnimal feeding devicesAvicultureAnimal scienceCrop livestock

The invention provides a quantitative fodder feeding device suitable for livestock breeding, and belongs to the technical field of animal husbandry fodder feeding equipment. The quantitative fodder feeding device suitable for livestock breeding comprises a mounting box, a mounting frame, a brake air cylinder and a fodder storage box, the bottom of the fodder storage box communicates with a drainage funnel, the drainage funnel is fixedly connected with the inner side wall of the mounting box, and a mounting limiting ring is arranged under the drainage funnel; and the mounting limiting ring is fixedly connected with the inner side wall of the mounting box, and a feeding rotary disc is rotatably connected into the mounting limiting ring. The quantitative fodder feeding device has the beneficial effects that under the transmission effect of a transmission shaft, the feeding rotary disc is made to do the same rotating motion, when a feeding groove is aligned with an opening in the top of the mounting limiting ring, the feeding rotary disc is static, feeding is conducted in the feeding groove, discharging is conducted when the feeding rotary disc rotates and the opening of the feeding groove is aligned with the opening in the bottom of the mounting limiting ring, the accuracy of single-time feeding can be guaranteed, and the phenomenon of excessive or insufficient feeding can be avoided.

Owner:马鞍山市黄池食品(集团)金菜地畜业有限公司

Pig feed putting device

InactiveCN110278880AEvenly dispersedReduce accumulationAnimal feeding devicesAssistive device/technologyBall screw

The invention relates to the technical field of auxiliary equipment for breeding, in particular to a pig feed putting device. The pig feed putting device comprises a mounting frame, a moving base, a feeding disc, a feed storage bin, a lifting unit, a folding plate, a screw rod and an abutting block. The pig feed putting device has the advantages that through the arrangement of the lifting unit, after feeding is finished, the feeding disc is moved upwards, and excessive feeding is avoided; through the arrangement of the folding plate, the screw rod and the abutting block, a clamping space is clamped on a fence of an external pigpen, and thus the mounting frame is fixed; the lifting unit is composed of a ball screw, a screw nut and a servo motor, through the servo motor, the rotating stroke of the feeding disc is precisely controlled through an external controller so that the height of the feeding disc can be precisely adjusted, and thus feeding height demands of different breeding stages can be met.

Owner:镇江乾文农业技术有限公司

Energy-saving and environment-friendly production auxiliary equipment for processing animation colored drawing pigment

InactiveCN112619537APrevent overflowAvoid pollutionTransportation and packagingMixer accessoriesPhotopigmentWorking environment

The invention relates to the technical field of colored drawing pigment processing equipment, particularly to energy-saving and environment-friendly production auxiliary equipment for animation colored drawing pigment processing. The equipment comprises an equipment main body, wherein positioning frames are fixedly connected to the left side and the right side of the inner wall of the equipment main body, a laser lamp is fixedly connected to the interior of the equipment main body, a machining groove is slidably connected to the interior of the right side face of the positioning frame, a photoresistor is fixedly connected to the position, located on the right side of the machining groove, of the interior of the equipment main body, a reset frame is fixedly connected to the lower surface of the machining groove, and feeding in the equipment is stopped, so that excessive feeding can be well avoided, the phenomenon of overflow of the processing groove is avoided, resources can be well saved, the working environment is prevented from being polluted, the working efficiency of the device can be well improved, and the processing efficiency of the device can be well improved by reminding a worker of completing pigment processing so as to avoid unnecessary color errors.

Owner:杭州蕊宸智能技术有限公司

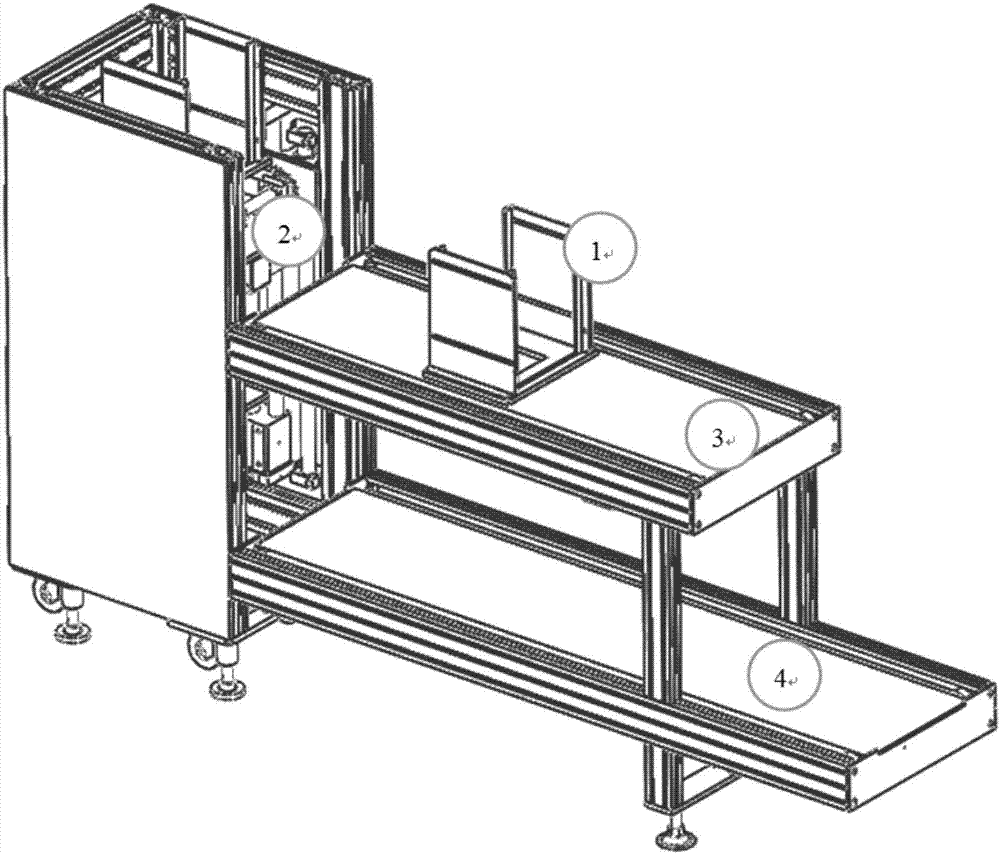

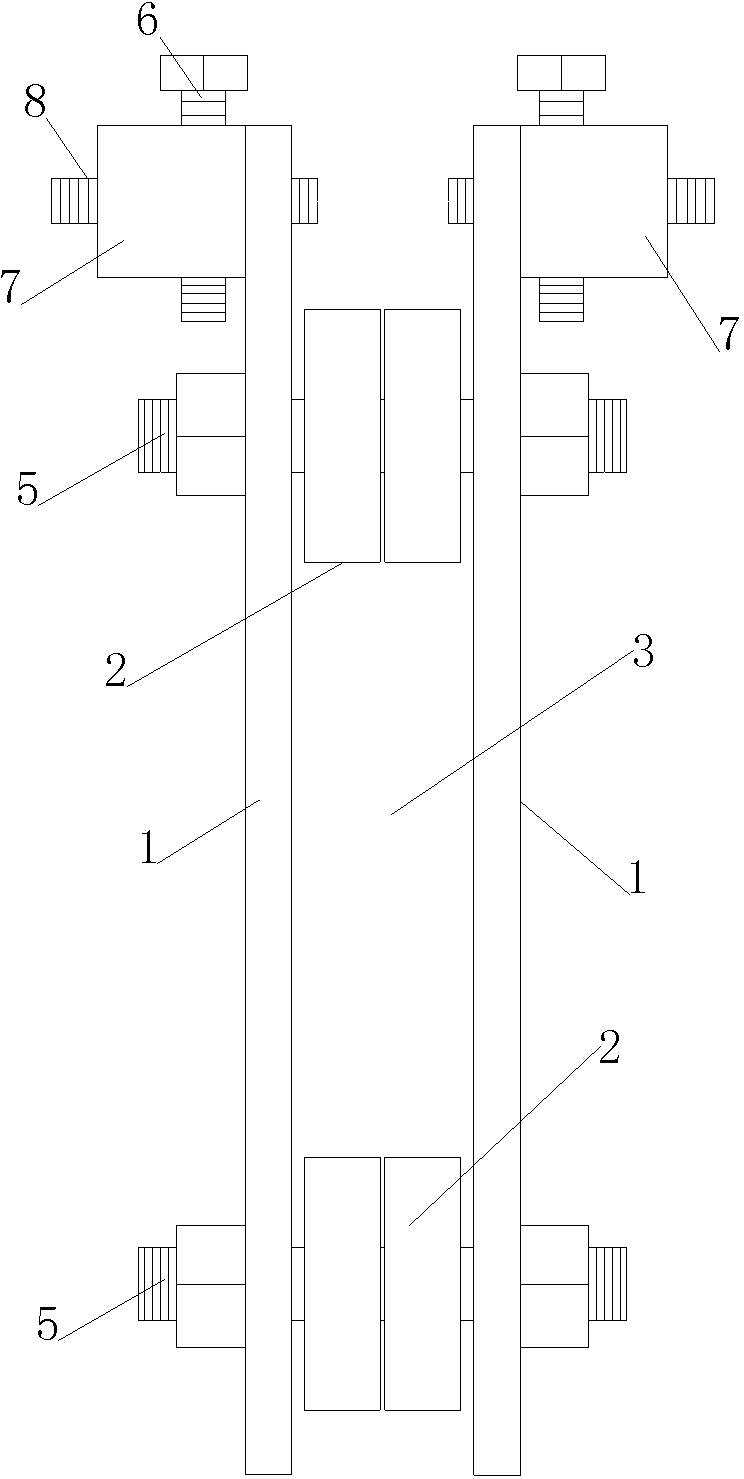

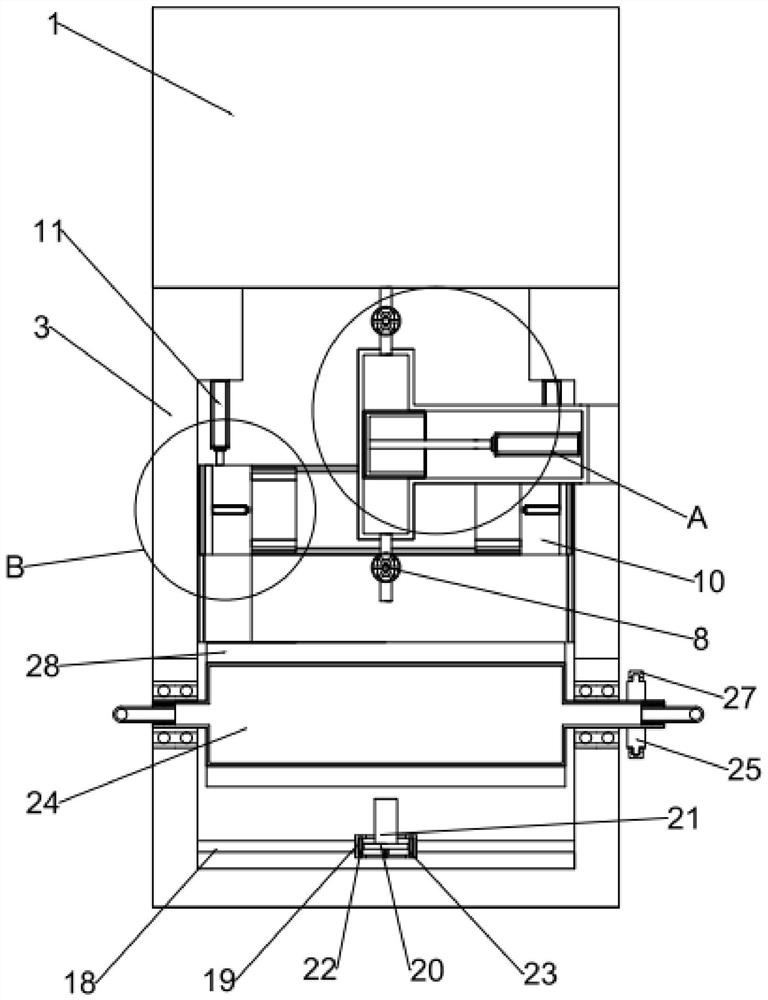

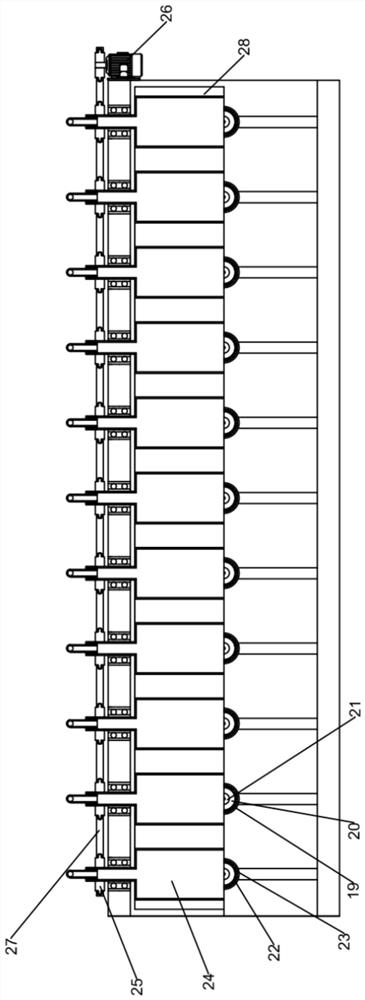

Continuous feeding device for specifications and cards

The invention discloses a continuous feeding device for specifications and cards. The device comprises a universal bin, a bin jack, a full feeding assembly line and an empty bin backflow assembly line. The full feeding assembly line and the empty bin backflow assembly line are horizontally arranged, the full feeding assembly line is located above the empty bin backflow assembly line, one end of the full feeding assembly line and one end of the empty bin backflow assembly line are connected with the bin jack respectively. By means of the continuous feeding device, the problems of excessive feeding, material-free detection, bin jacking and bin backflow are avoided, the stability of feeding can be completely and effectively ensured, quick feeding is achieved, and the labor is saved.

Owner:CHANGZHOU VOCATIONAL INST OF ENG

Fertilizer water device for vegetable cultivation

InactiveCN114391353AAvoid overfeedingAvoid the situationTransportation and packagingLiquid fertiliser regulation systemsAgricultural engineeringWater flow

The invention discloses a water fertilizing device for vegetable cultivation. The water fertilizing device comprises a water supply mechanism, a tank body mechanism, a fertilizer injection mechanism, a mixing mechanism and a fertilizer conveying mechanism. The tank body mechanism is arranged below the water conveying mechanism, the fertilizer injection mechanism is arranged in the tank body mechanism, the fertilizer injection mechanism comprises a water conveying pipe and is connected with the water conveying mechanism through the water conveying pipe, the mixing mechanism is connected below the fertilizer injection mechanism, the fertilizer conveying mechanism is connected below the mixing mechanism, and the fertilizer conveying mechanism comprises a fertilizer conveying pipe and is connected with the water conveying mechanism through the fertilizer conveying pipe; controllability of fertilizer feeding is achieved through a flow control valve A and a flow control valve B in the fertilizer injection mechanism, water and fertilizer are mixed to form fertilizer water through continuous rotation of water flow in a spiral pipeline in the mixing mechanism and stirring of a stirring rod in a mixing cavity, and the fertilizer water enters the water conveying mechanism through a fertilizer conveying pipe and finally flows into the irrigation system. The control of the fertilizing amount and the uniformity of fertilizer and water are realized.

Owner:张文倩

Chain tightener, chain transmission mechanism with same and tobacco cutting device

The invention relates to a chain tightener, a chain transmission mechanism with the chain tightener and a tobacco cutting device. The chain tightener comprises two spaced clamping plates, two tightening wheels used for tightening the two sides of a transmission chain in the thickness direction are arranged between the two clamping plates, and a channel allowing the transmission chain to pass through is defined by the tightening wheels and the clamping plates. When the chain tightener is used, the two tightening wheels can tighten the two sides of the transmission chain in the thickness direction, the problems that a single side is tightened to cause a loose side and a tight side, instant loads borne by the transmission chain are too large, and related equipment is damaged are solved, the two sides of the transmission chain can be tightened through the chain tightener, and the chain tightener cannot be damaged when the transmission chain rotates reversely.

Owner:CHINA TOBACCO HENAN IND

Cut section storage device for tent cloth processing

ActiveCN111908243AAvoid overfeedingEasy to operateSevering textilesPile receiversElectric machineryEngineering

The invention discloses a cut section storage device for tent cloth processing. The cut section storage device comprises a base, a discharge mechanism, a cutting mechanism, a material guide mechanismand a storage mechanism, wherein the base is fixedly connected with a workbench and a storage groove, the cutting mechanism and the material guide mechanism are arranged at the upper end of the workbench, and the storage mechanism is arranged in the storage groove. According to the cut section storage device, the storage groove is formed to store a cloth cutting section; and meanwhile, the storagemechanism is arranged, so that the rotating speed of a storage motor can be adjusted according to the tent cloth cutting speed, a movable bottom plate is matched with the frequency of the cloth cutting section entering the storage groove, and the storage motor drives a second lead screw to rotate; and the second lead screw drives the movable bottom plate to continuously descend according to the feeding of the cloth cutting section, so that the fall of the cloth cutting section entering the storage groove is reduced, and the situations that because the cloth cutting section is curled after entering the storage groove, curled cloth is pressed to generate marks during storage, and the storage space is not sufficiently utilized are avoided.

Owner:安徽北极户外用品有限公司

Filling equipment for adhesive production

PendingCN113697746APrevent flowPrevent fallingFilling device cleaningAdhesive glueComposite material

The invention discloses filling equipment for adhesive production. The equipment has the beneficial effects that a glue bottle is extruded to the position under a transferring and quantitative feeding structure through a lifting and positioning structure, glue is prevented from flowing to the outer side in the feeding process of the transferring and quantitative feeding structure, and meanwhile, the phenomenon of excessive feeding is avoided through the transferring and quantitative feeding structure. After feeding is completed, contraction is conducted firstly, residual glue is absorbed back, the glue is prevented from falling onto conveying equipment, meanwhile, through a cleaning structure and a conveying structure, the glue bottle is cooled, the glue on a conveying belt is cleaned, and the phenomenon that the glue bottle inclines during conveying due to the fact that particles appear on the belt is avoided.

Owner:今强实业瑞昌有限公司

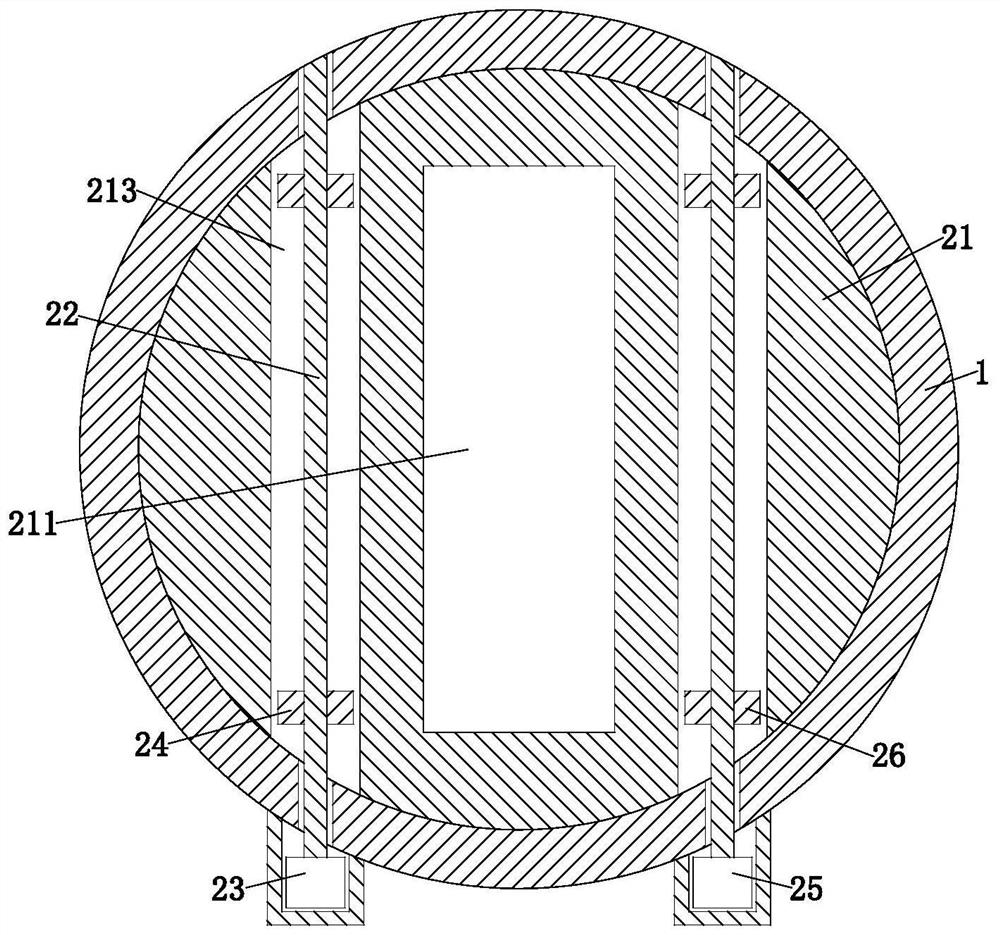

Circular weaving machine

InactiveCN109371537AProtect the life of the whole machineHigh quality factorCircular loomsMotor speedYarn

A circular weaving machine includes a warp feeding system and a cloth coiling system. The warp feeding system includes a warp feeding motor, a warp feeding motor controller, a warp feeding device anda drive system. The warp feeding motor is a permanent magnet brushless direct current motor or a permanent magnet synchronous motor, the warp feeding motor controller is in communication connection with a main motor, the warp feeding device is provided with a warp feeding rod, and the drive system is driven by the warp feeding motor and used for driving the warp feeding device and the warp feedingrod of the circular weaving machine. The warp feeding motor controller makes the speed of warp yarn and the speed of the warp feeding rob synchronized and the speed adjustable in advance through control over the motor speed, and the warp feeding motor controller adopts a timing stop control method. Through the timing stop control method, shutdown of the warp feeding system can be delayed, the phenomenon that excessive warp yarn is fed is effectively avoided, and the problem is effectively solved that an existing warp feeding motor and a main motor shunt down and stop at the same time and thuswarp yarn thus is easily broken. The shut-down time can be controlled and adjusted, and the service life of the whole circular weaving machine is effectively guaranteed.

Owner:黄君华

Cultivation method of pea crab seeds in paddy field

InactiveCN110352886AIncrease oxygen contentImprove cleanlinessWater treatment parameter controlTreatment using aerobic processesLarge eyesWater quality

Disclosed is a cultivation method of pea crab seeds in the paddy field. The cultivation method includes the steps of 1), preparation of a cultivation pond, namely digging an annular trench and a diversion trench, preparing inlet and drainage facilities, performing disinfecting with quicklime, cultivating water quality and planting water peanuts; 2), raising of the pea crab seeds, namely at the beginning of May, raising young crabs with large eyes in the pond at the ratio of 2kg / mu; 3), fodder feeding, namely after 10 days of raising the large-eye larvae in the paddy field, performing fodder feeding at a fixed position and time every day, wherein fodder of the large-eye larvae is mainly based on free feeding of aquatic plants; 4), control of water quality and sediment, namely applying photosynthetic bacteria and nitrifying bacteria to maintain dissolved oxygen content in water and changing water once every 5 days from May to March of the next year; 5), harvest of the pea crabs, namely performing fishing in December of the year and January to March of the following year. In the method that the pea crabs are cultivated under paddy field conditions, the yield of 150g per mu of the peacrabs can be realized, the pea crabs are strong in growth and good in the immunity and adaptability, and the yield of the pea crabs per unit water body can be effectively increased.

Owner:澧县湘琼大闸蟹养殖专业合作社

Blending equipment with reminding function for interior decoration coating processing

InactiveCN112619487AGood blendingIncrease profitRotary stirring mixersTransportation and packagingCrankInterior Furnishings

The invention relates to the technical field of coating blending equipment, in particular to blending equipment with the reminding function for interior decoration coating processing. The blending equipment comprises a device body, a vertical sliding rail is fixedly connected to the top surface of the interior of the device body, and a sliding block is slidably connected to the temporal part of the front surface of the vertical sliding rail; a processing groove is fixedly connected to the right side face of the sliding block, a driving shaft is rotatably connected to the bottom face of the interior of the processing groove, a crank connecting rod is movably connected to the left side face of the sliding block through a shaft, and by increasing the contact area between the whole stirring frame and paint, the paint can be blended more uniformly by the equipment. According to the equipment, the working efficiency of the equipment can be well improved. The utilization rate of the coating can be well increased. Workers are reminded to stop feeding, so that excessive feeding is avoided. The coating splashing during later coating processing is avoided, environmental pollution is avoided, and meanwhile resources can be well saved.

Owner:广州谷地建筑装饰有限公司

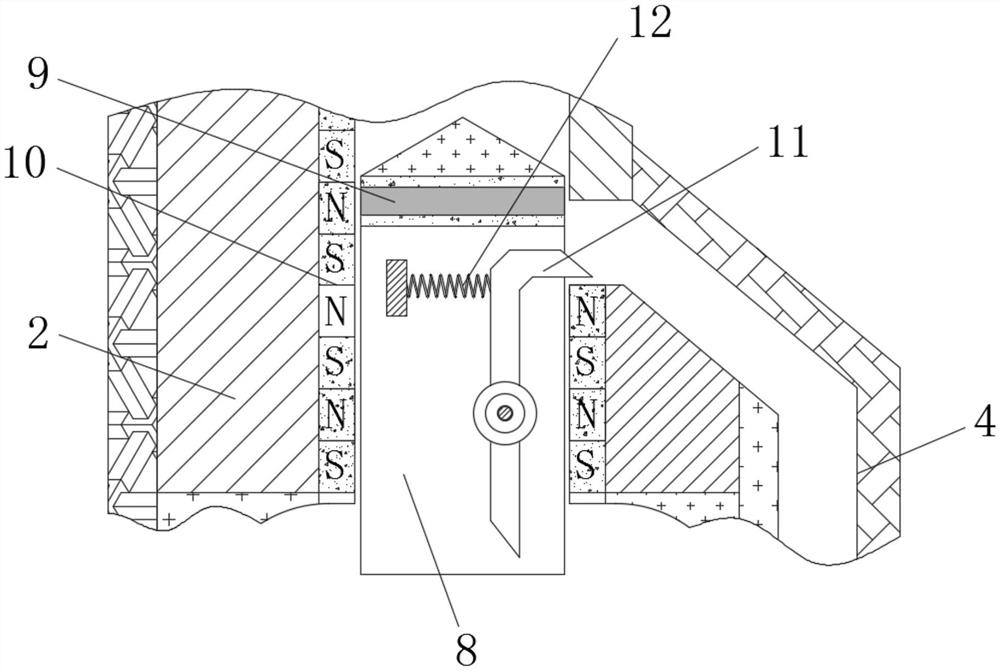

Poultry farm quantitative feeding mechanism utilizing new-generation information technology

InactiveCN112344042AEasy to startAchieve intelligent controlOperating means/releasing devices for valvesSlide valveAnimal scienceAgricultural science

The invention relates to the technical field of feed equipment, and discloses a poultry farm quantitative feeding mechanism utilizing a new-generation information technology. The quantitative feedingmechanism comprises a frame cage, a feeder is fixedly connected to the outer part of the frame cage, a containing hopper is arranged at the top of the feeder, and a discharging channel is arranged atthe bottom of the containing hopper. An air outlet is formed in the discharging channel, an air valve is arranged in the feeder, an air channel is fixedly connected to the outer part of the air valve,an ejector block is slidably connected to the bottom of the containing hopper, and a copper ring is fixedly connected to the outer part of the ejector block. Through cooperative use of the ejector block, the copper ring, a magnetic block, a positioning rod, a positioning spring and a cam, the feeding amount of feed fed to a feed trough each time is fixed, automatic feeding is achieved in a scattered mode, the feeding effect is effectively guaranteed, the feeding uniformity and feeding determinacy are guaranteed, thus the feeding effect is effectively guaranteed, excessive feeding is avoided,the health condition of poultry is effectively guaranteed, and the waste of the feed is effectively reduced.

Owner:黄丽容

Powdery medicine inhalation treatment system for patient

InactiveCN114344640AEfficient dischargeAvoid overfeedingMedical insufflatorsInhalatorsPharmacy medicineInhalation

The invention discloses a powdery medicine inhalation treatment system for patients, which is characterized in that a fixed placement barrel is clamped at the top ends of a plurality of fixed insertion tubes, the air extraction end of an air extraction pump is connected with one end of an extraction placement box, a rubber soft cylinder is adhered to the inner side of an annular threaded sleeve, and a rotating isolation plate is welded to one end of a torsion spring; a fixed placement barrel is clamped to the inner side of a fixed insertion pipe, a porous feeding pipe is embedded into the inner side of a storage sliding barrel, and a sucking pump is used for sucking powder medicament placed on the inner side of the storage sliding barrel through a sucking placement box, so that the medicament can be effectively discharged, and operation can be quickly and effectively carried out when feeding needs to be controlled; and the situation that too much medicine is supplied at a time is avoided, a downward pressing spring and a downward pressing sealing gasket are attached to the top end of a fixed supporting ring, the interior is sealed through a rotating isolation plate and a torsion spring, and therefore the feeding position can be effectively sealed and protected in the using process.

Owner:焦作市第二人民医院

Waste collecting device for operating room nursing

ActiveCN112978302AReduce the risk of viral infectionAvoid overfeedingRefuse cleaningConveyor partsVirus presentOperation room

The invention provides a waste collecting device for operating room nursing, which comprises a machining shell, a discharging unit and a cleaning unit, wherein the discharging unit is installed on the upper side of the inner wall of the machining shell, and the cleaning unit is arranged along the lower side of the discharging unit. The waste collecting device can solve the problems that firstly, after collection of waste for operating room nursing is completed, most of the waste is discharged in a manual feeding mode, and workers cannot control the feeding amount, so that the risk of virus infection exists when too many persons make contact with the waste, and the waste contains a large number of cotton swabs and gauze and is inconvenient to use, and therefore, the machine is easy to damage due to excessive feeding; and secondly, the problems that when existing waste for operating room nursing is cleaned, cleaning liquid is generally used in a disposable mode, so that resource waste is easily caused, the environment is easily polluted, the cleaned waste needs to be salvaged manually, the human body is easily injured, and the work efficiency is influenced are solved.

Owner:青岛市中医医院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com