Automatic feeding and edge-aligning machine for sewing material, method and sewing machine

A technology for automatic material feeding and sewing machines, which is applied to sewing machine components, sewing machine control devices, cloth feeding mechanisms, etc. even material effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

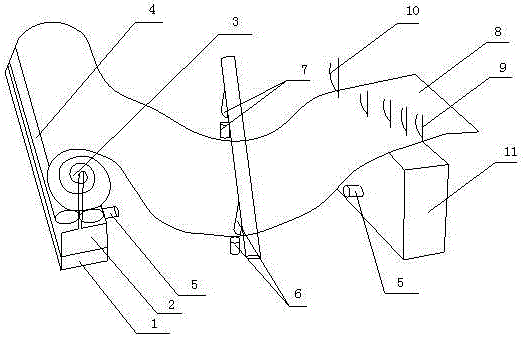

[0023] The present invention includes an automatic feeding and edge-aligning machine for sewing materials, comprising a tubular material 3, a sewing material 8 positioned on the tubular material 3, and a sewing machine base 11, and the tubular material 3 is located on one side of the sewing machine base 11 and is parallel Arrangement, characterized in that it also includes a horizontal chute seat 1, a base 2 and a plurality of push rollers 4 located at the bottom of the cylindrical material 3 and capable of pushing the cylindrical material 3 to move and discharge in the longitudinal direction, and the base 2 is installed on the horizontal chute seat 1 and can slide horizontally, the two ends of the tubular material 3 and a plurality of push rollers 4 are installed on the base 2; on the opposite surfaces of the base 2 and the sewing machine base 11, an infrared through-beam sensor A5 is respectively installed, and two The infrared through-beam sensors A5 are opposite; a pair of ...

Embodiment 2

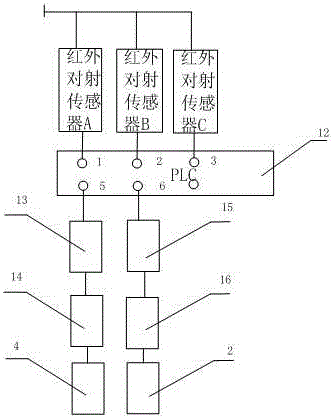

[0027] Such as figure 2 As shown, the present embodiment is preferably as follows on the basis of embodiment 1: the signals of two infrared through-shooting sensors A5 are imported into the sampling input port 1 of PLC programmable logic controller 12, and the signals of a pair of infrared through-shooting sensors B6 are transmitted into the sampling input port 2 of the PLC programmable logic controller 12, the signal of a pair of infrared radiation sensors C7 is introduced into the sampling input port 3 of the PLC programmable logic controller 12, and the output port 5 of the programmable logic controller 12 is connected in turn The solenoid valve 13 , the driving motor A14 and the push roller 4 , and the output port 6 of the programmable logic controller 12 are connected to the relay 15 , the driving motor B16 and the base 2 in sequence. This method is an implementation method. The signals of multiple pairs of infrared cross-radiation sensors are collected by the programmab...

Embodiment 3

[0030] A method for automatically feeding and aligning edges for sewing materials, comprising the steps of:

[0031] a) Use two infrared cross-beam sensors A to conduct cross-fire between the base and the sewing machine base, and detect the length of the tubular material in real time; use a pair of infrared cross-beam sensors B and a pair of infrared cross-beam sensors C respectively Carry out vertical shooting on both sides of the sewing material, and detect in real time whether the sewing material is shifted to the left or right when the roller is put down;

[0032] b) When the infrared pulse beam between the two infrared facing sensors A is blocked, the signal will be transmitted to the sampling input port 1 of the programmable logic controller and trigger the disconnection of the solenoid valve to stop the drive motor A, Avoid pushing the roller to push the tubular material down to the sewing material;

[0033] c) When the infrared pulse beam between a pair of infrared se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com