Patents

Literature

167results about How to "Stable unwinding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

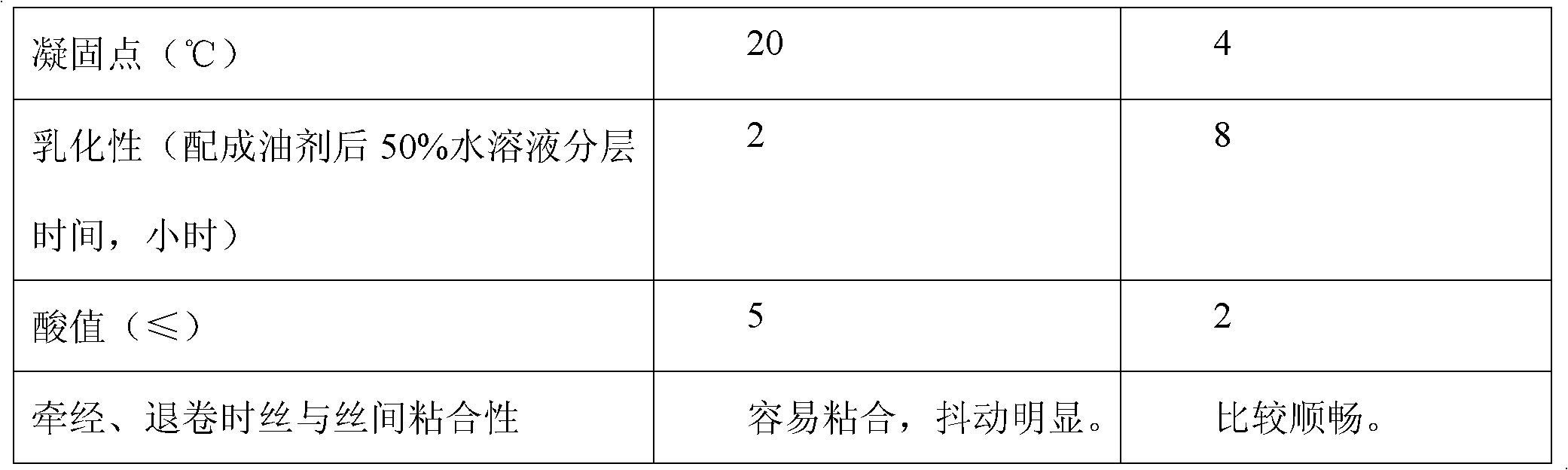

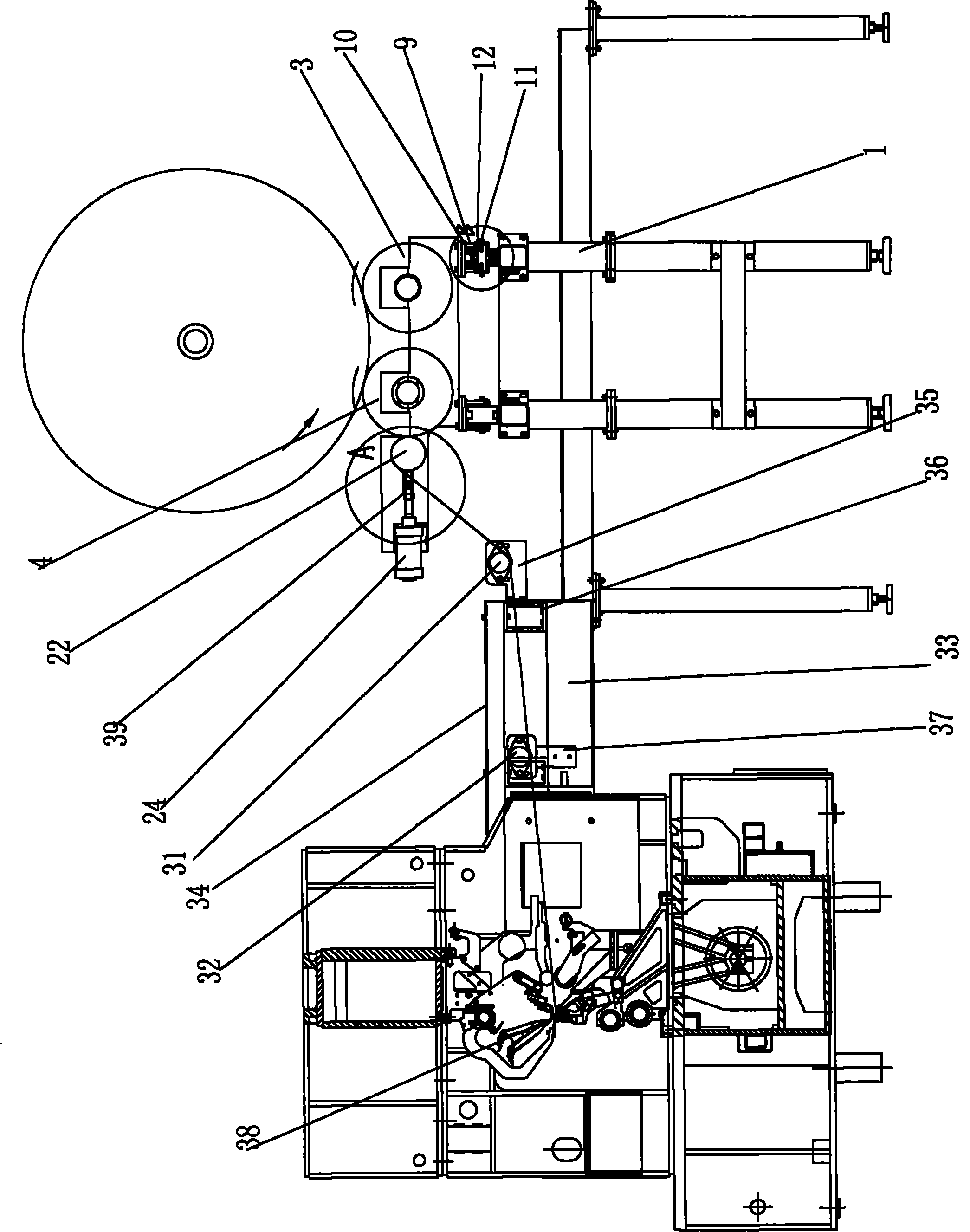

Reeling machine

ActiveCN104009249ATension balanceStable tensionPrimary cell manufactureAssembling battery machinesControl engineeringMachine

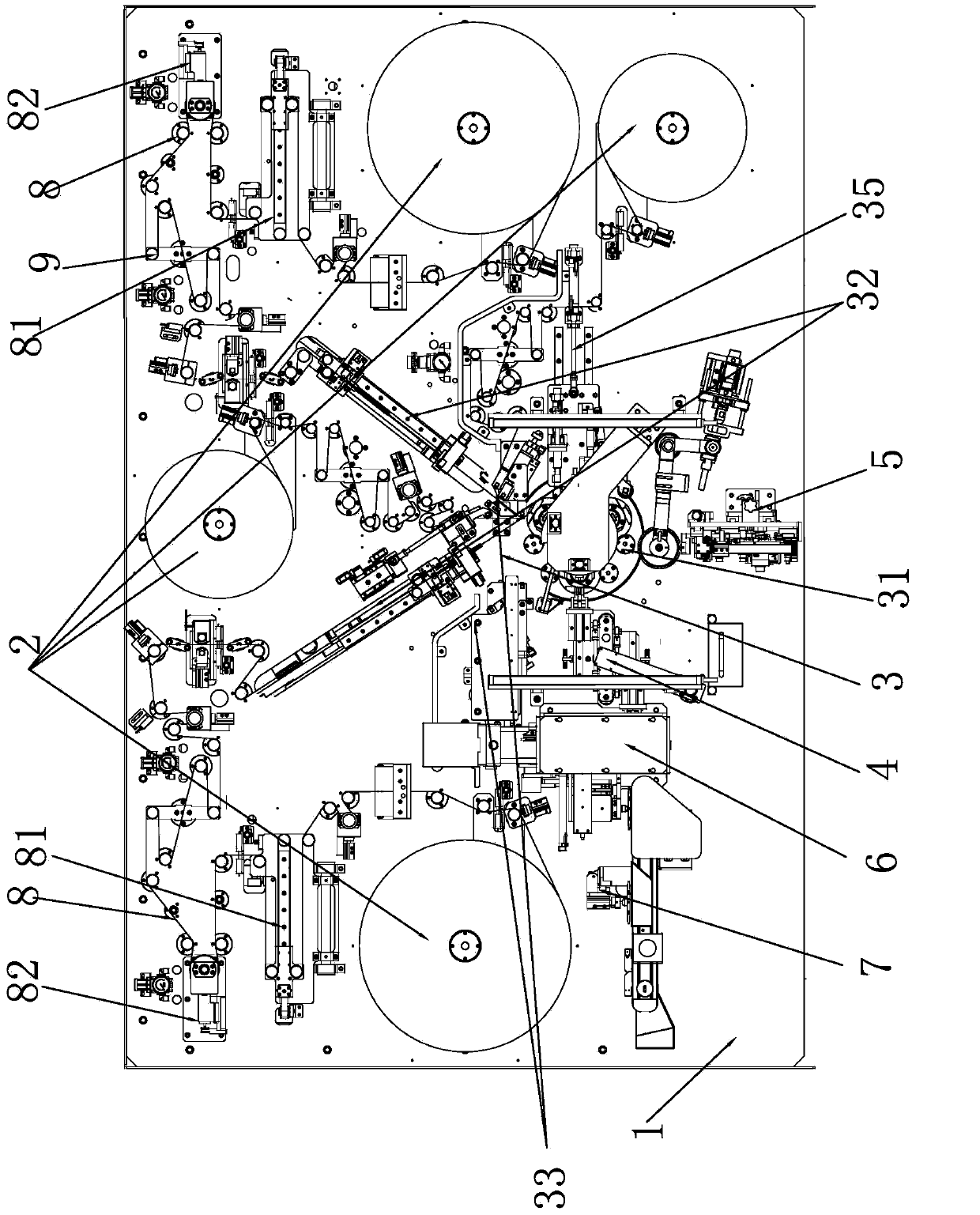

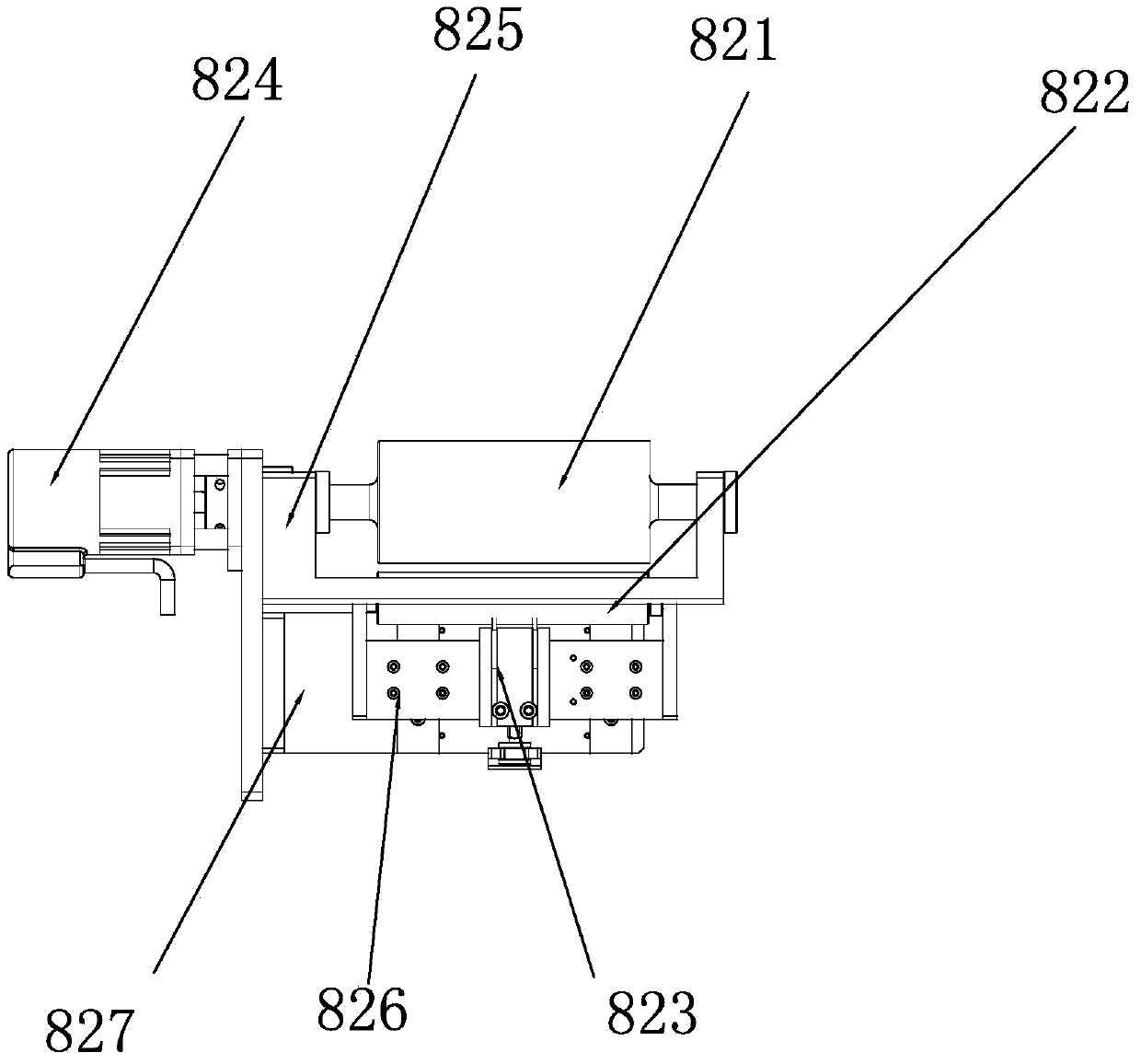

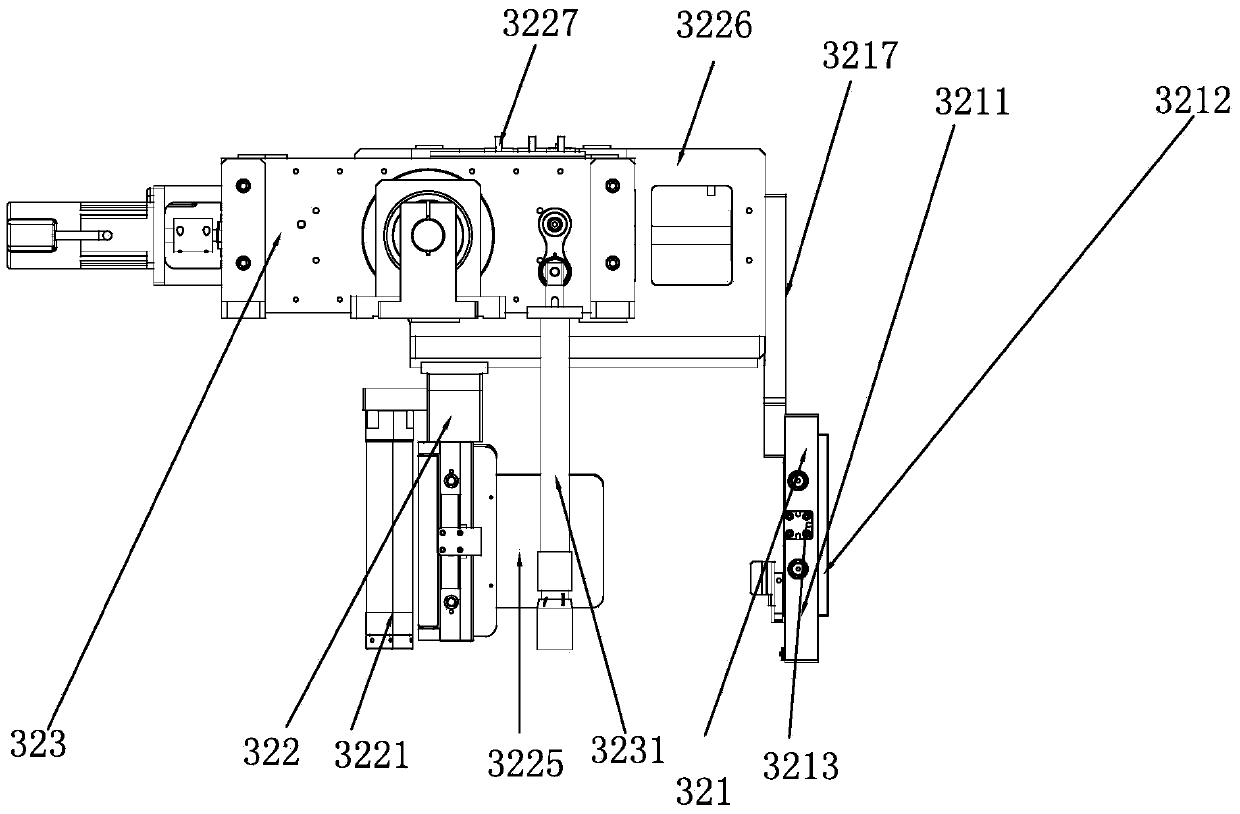

The invention discloses a reeling machine which comprises a rack assembly, an unreeling mechanism, a reeling mechanism, a feeding mechanism, a rubberizing device and a tension control mechanism, wherein the tension control mechanism comprises a pole piece deviation correcting device and a driving device which are arranged between the unreeling mechanism and the reeling mechanism; a reeling needle of the reeling mechanism performs a cam motion; the driving device is used for driving a pole piece to be synchronous with the traction of the reeling needle performing the cam motion to the pole piece and simultaneously preventing the unreeling of the pole piece and an deviation correcting operation from influencing the tension of the pole piece. According to the reeling machine, the stable tension control is effectively realized.

Owner:SHENZHEN YINGHE TECH

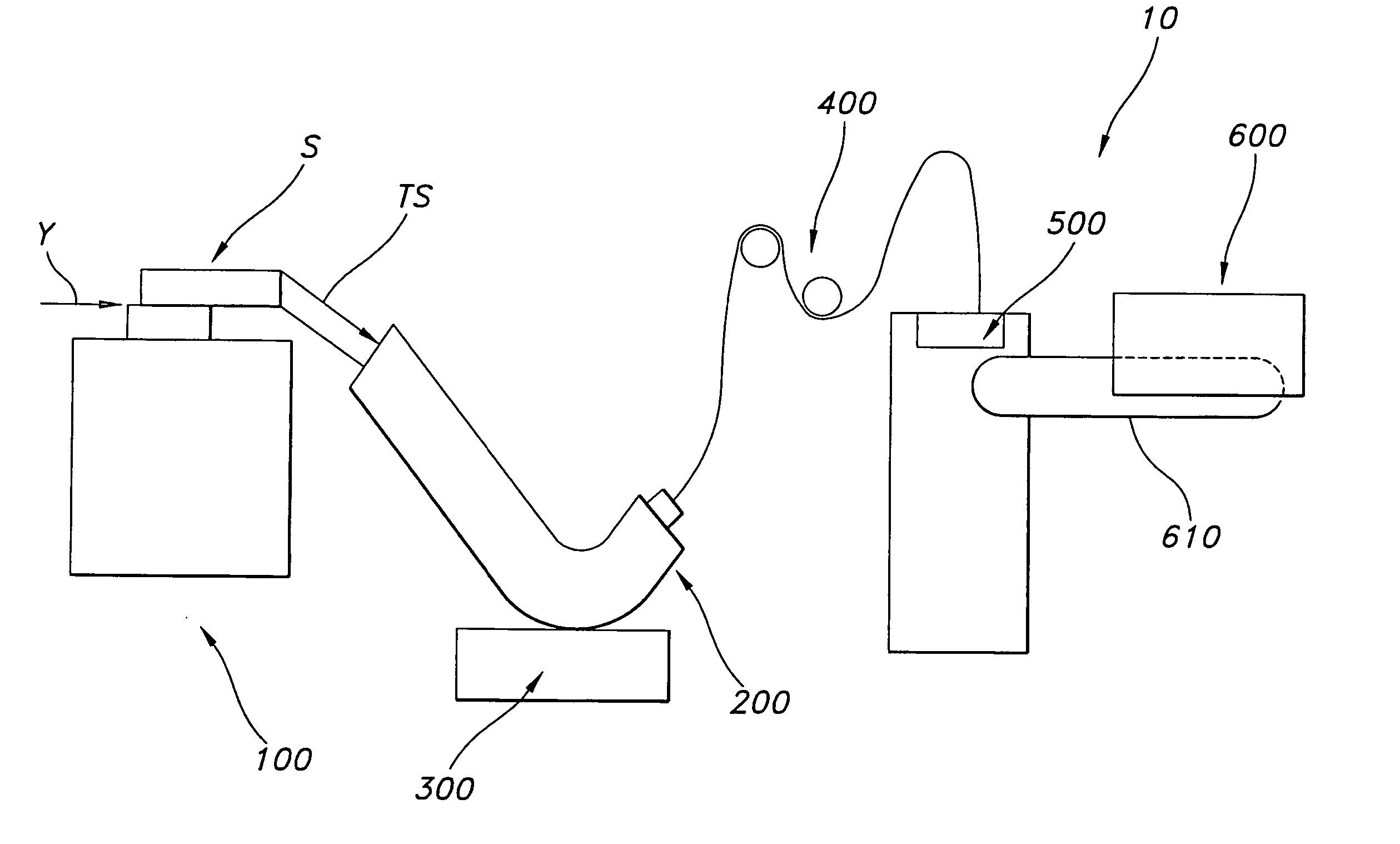

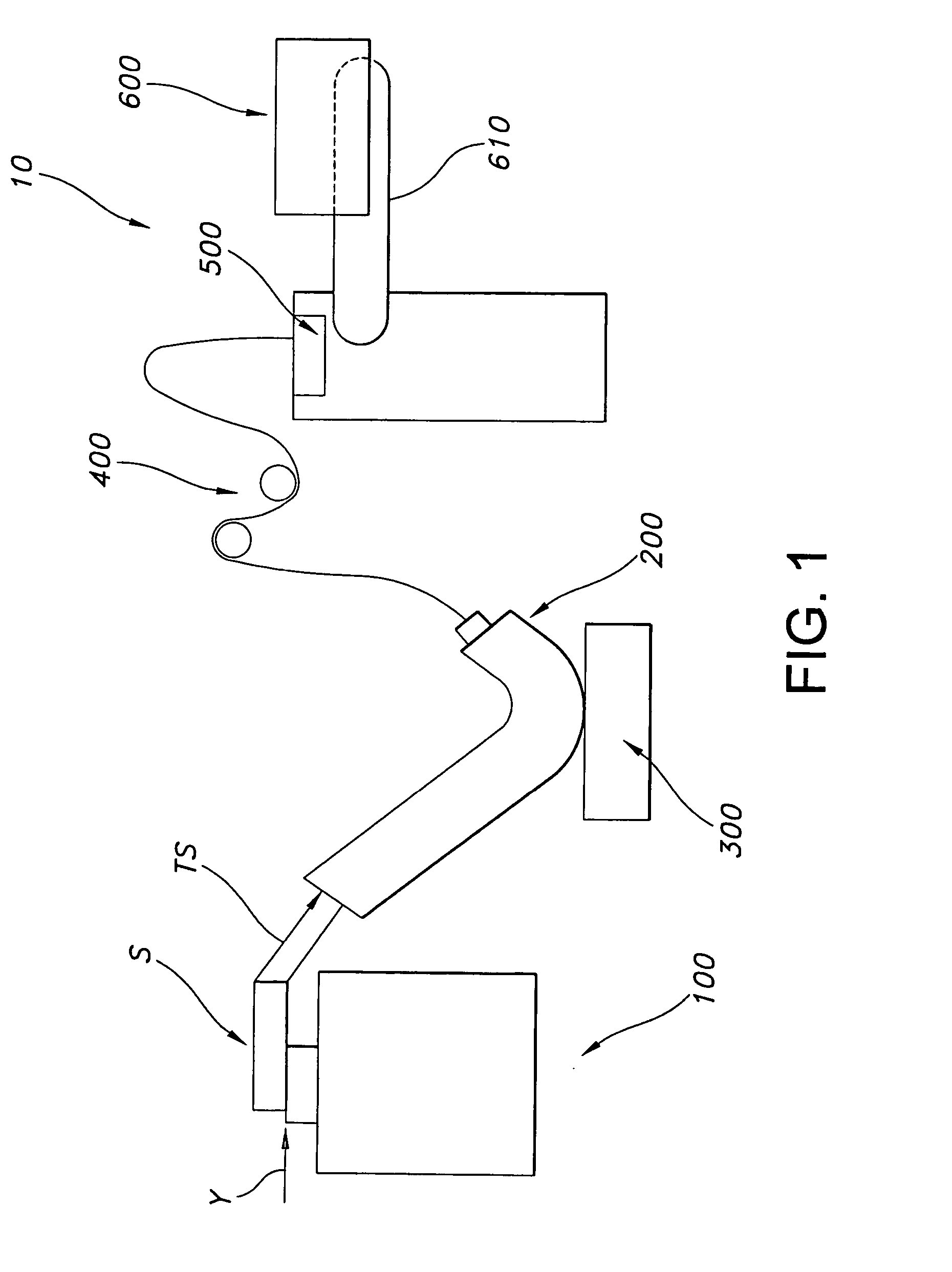

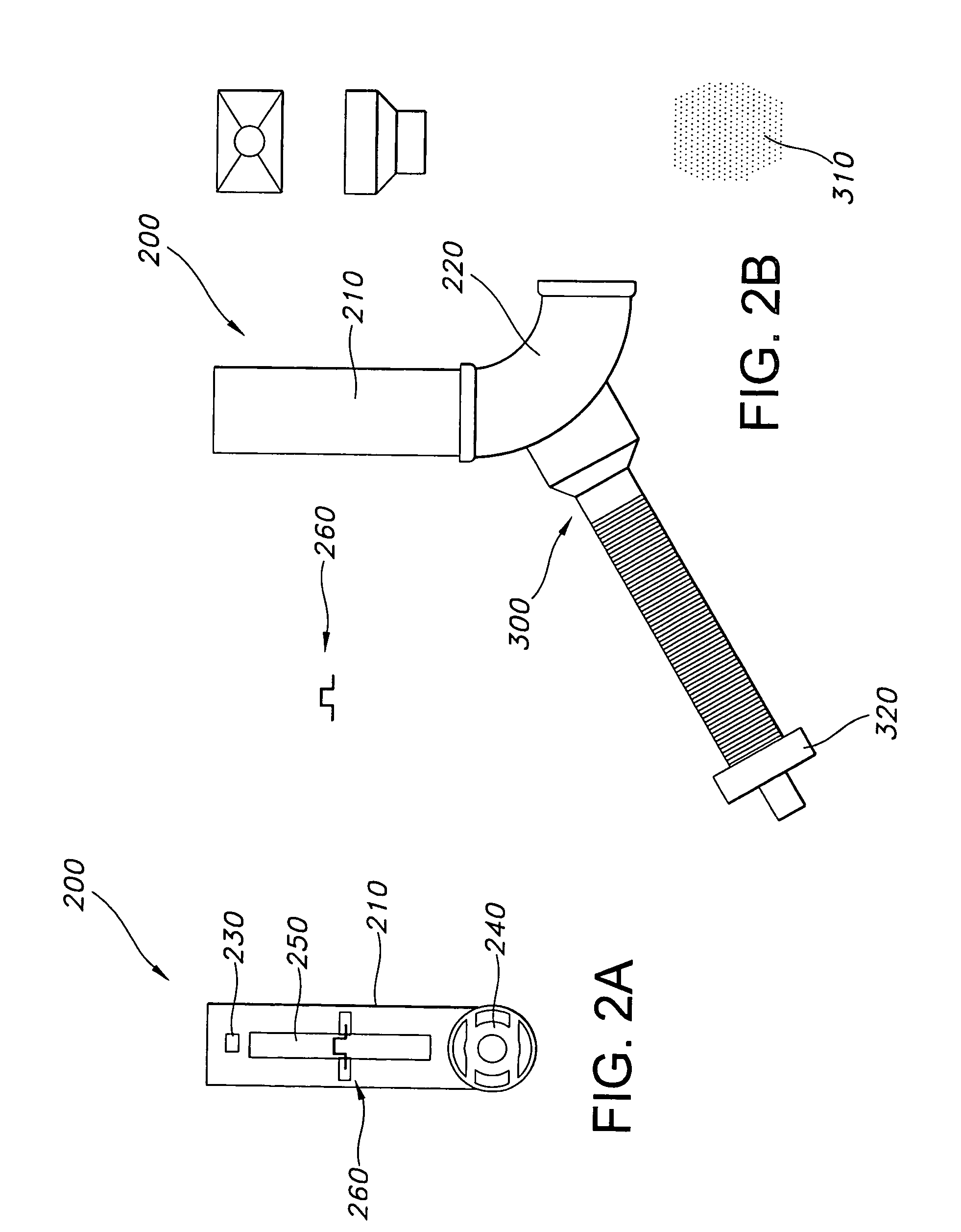

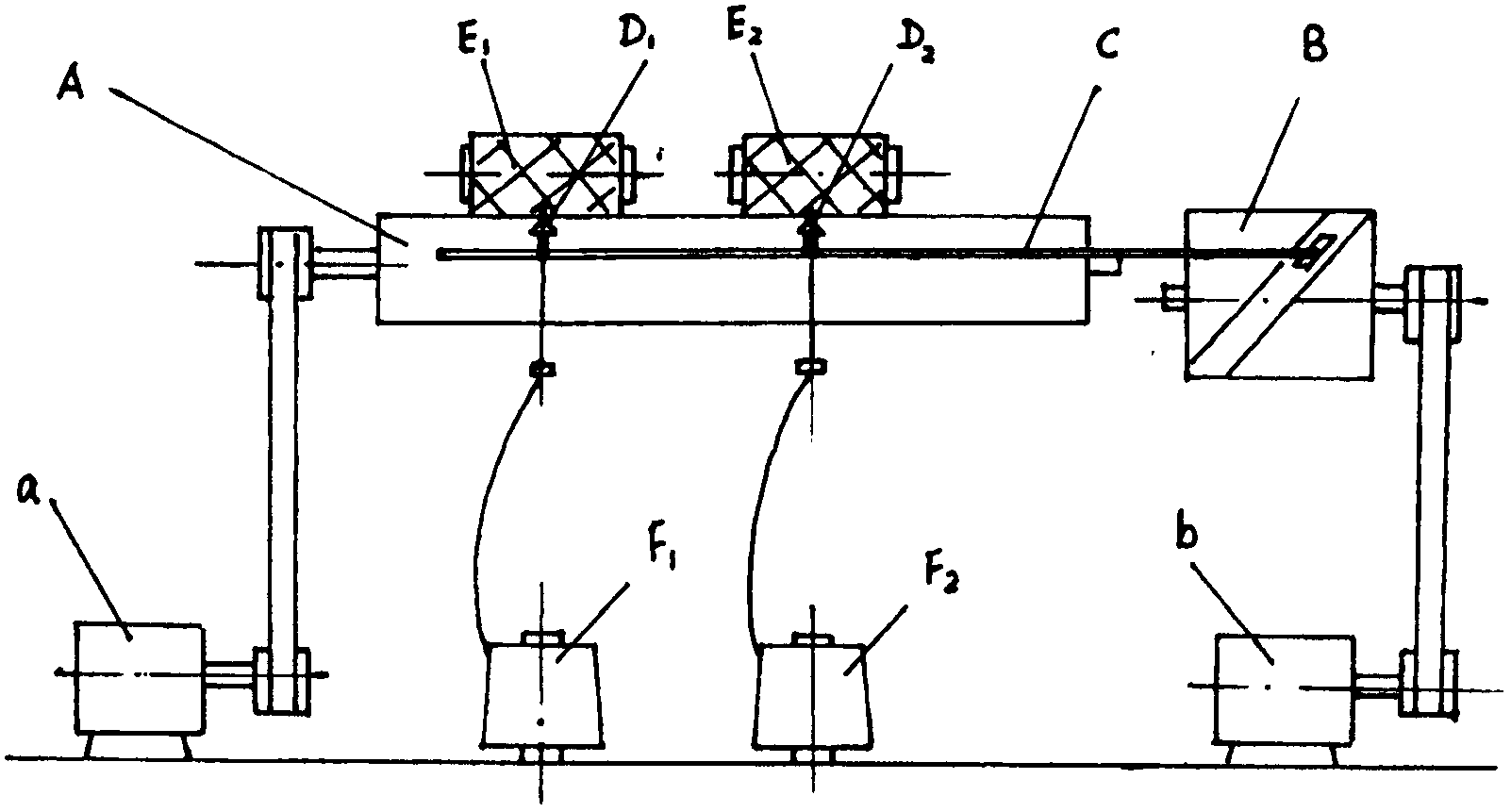

Devices and methods for heat-setting yarns

This invention is directed to flow management improvement to the known yarn texturing process, and is directed to devices and methods to accumulate one or more yarns between texturing device(s) and coiling device(s) prior to treatment in a heat-setting chamber. The devices and methods of the present invention may further provide for the removal of texturizing media from yarn prior to setting. The present invention allows for the deposition of yarn or yarns onto conveyor for a setting treatment to set an applied form to impart desirable properties to the yarn. The present invention may include any natural or synthetically produced yarn. The devices and methods of the invention may be used to improve the production capability of said heat setting and texturing equipment.

Owner:MOHAWK CARPET

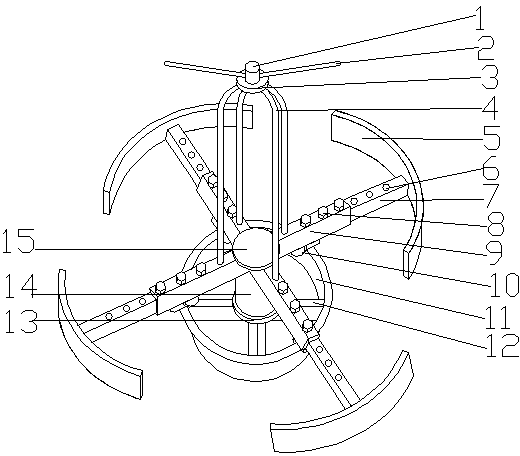

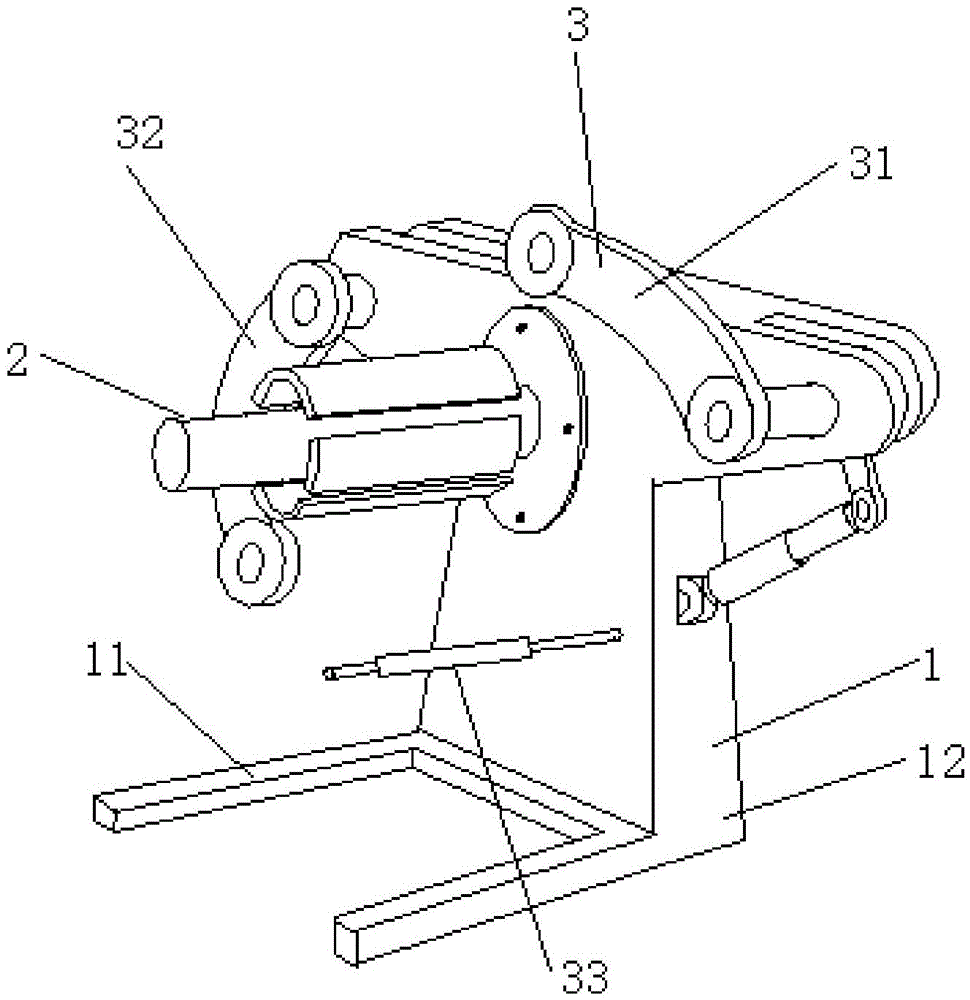

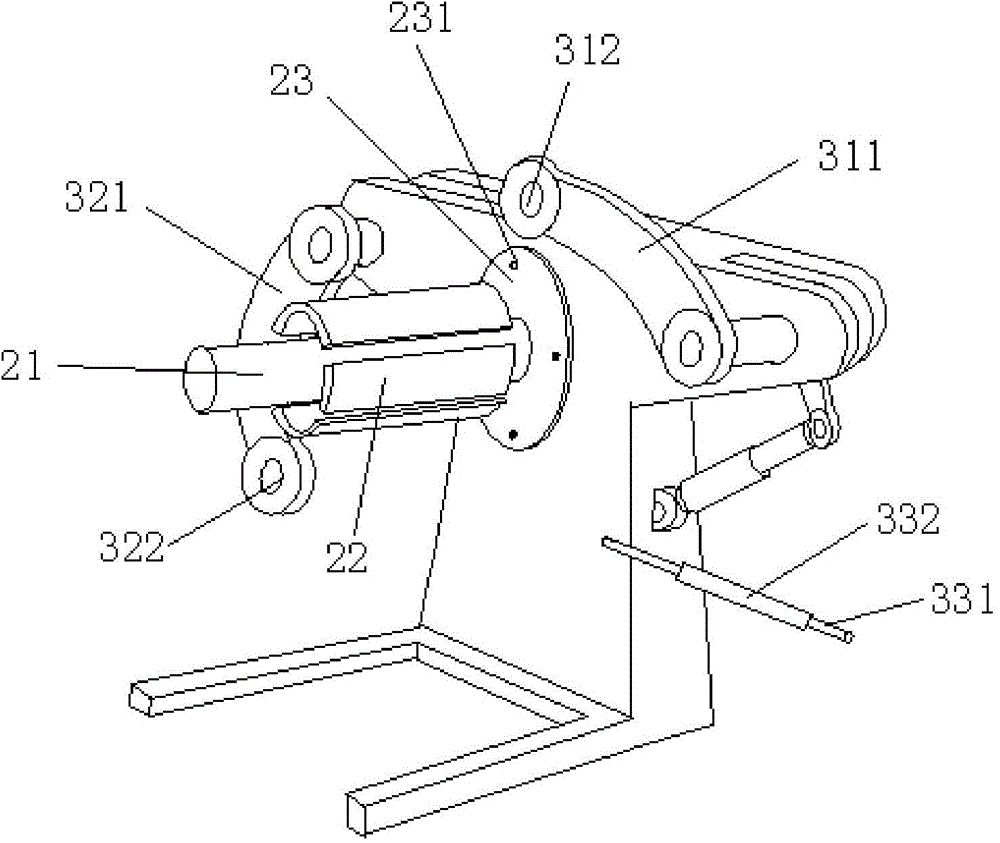

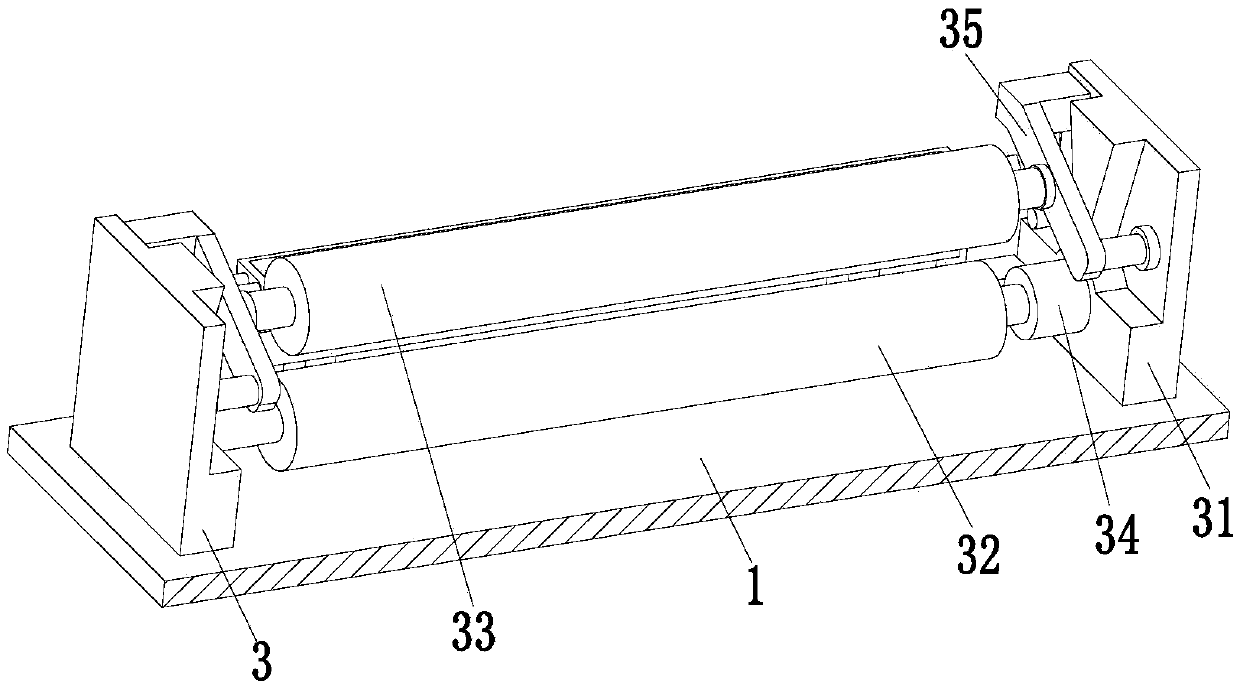

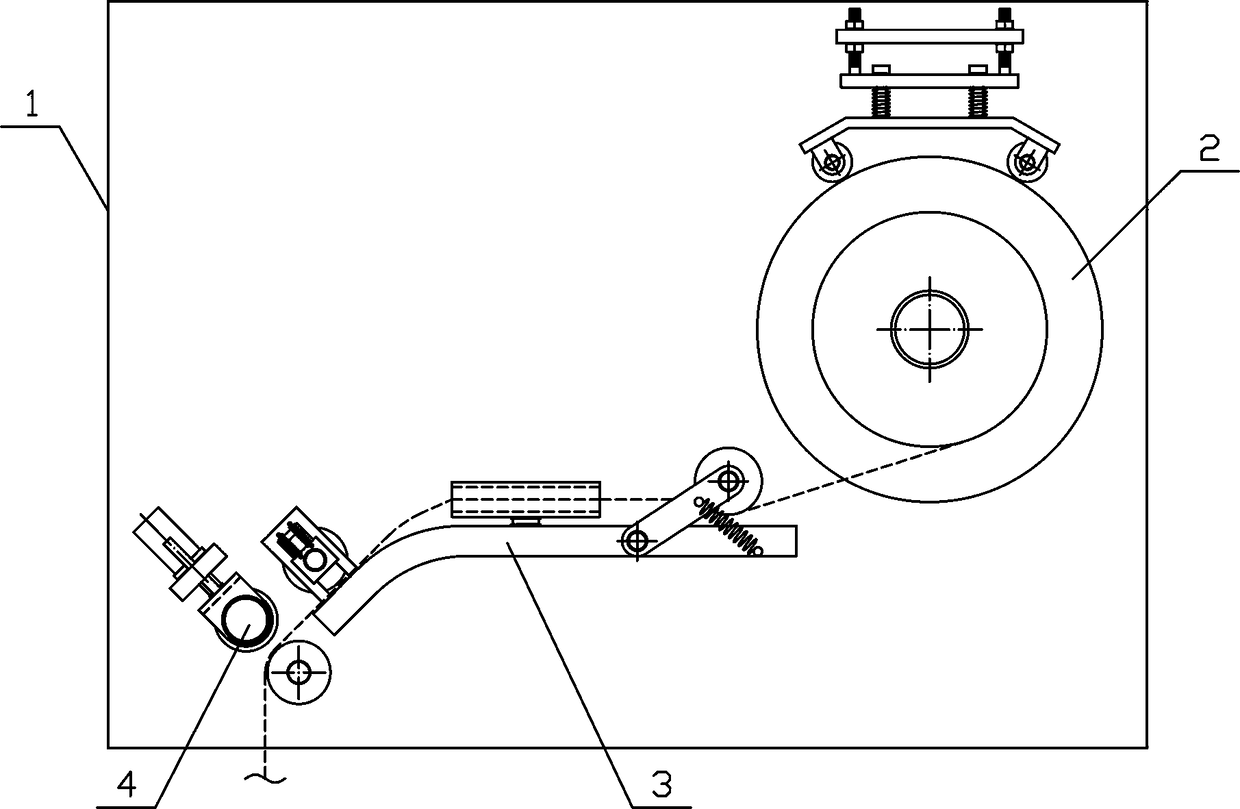

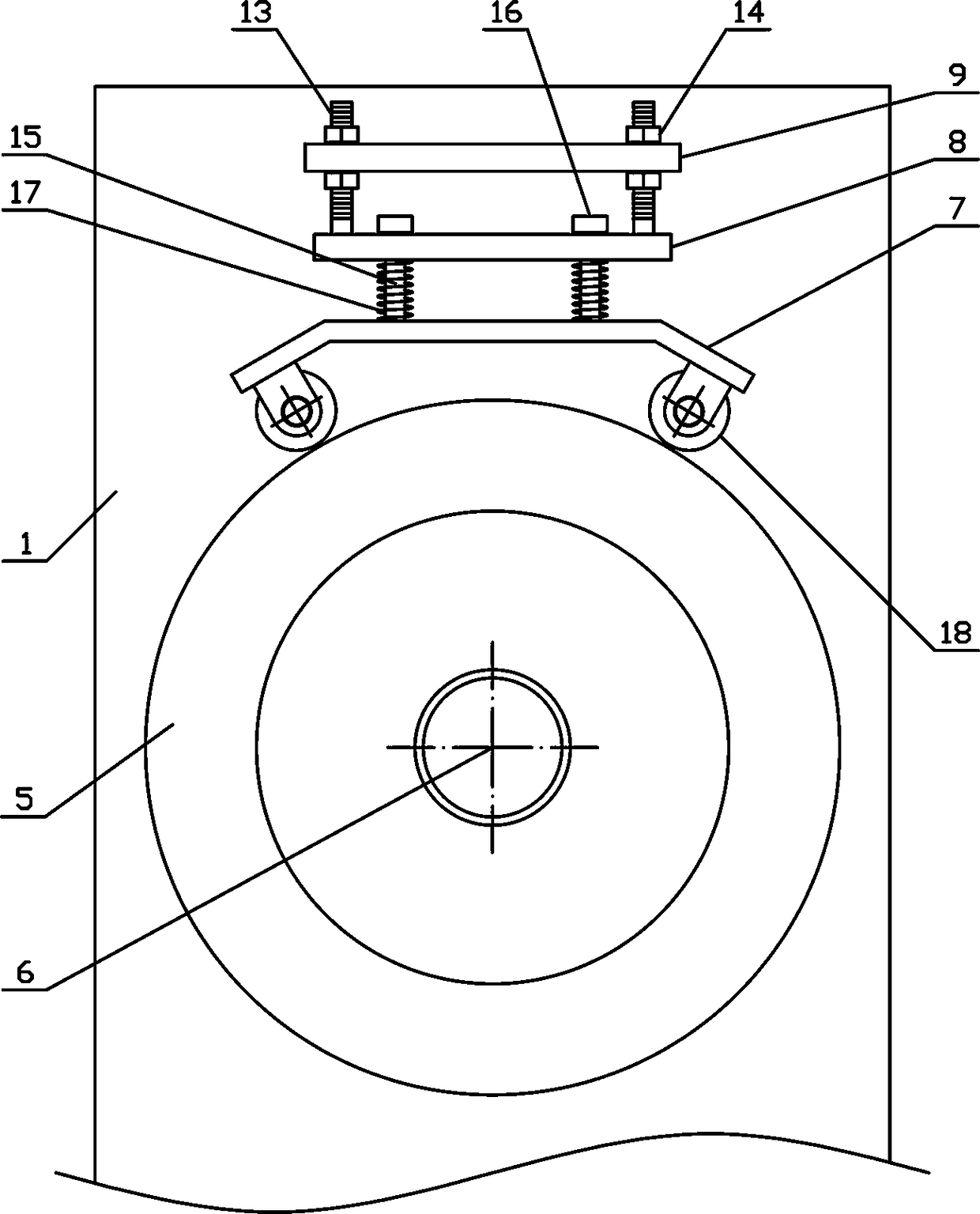

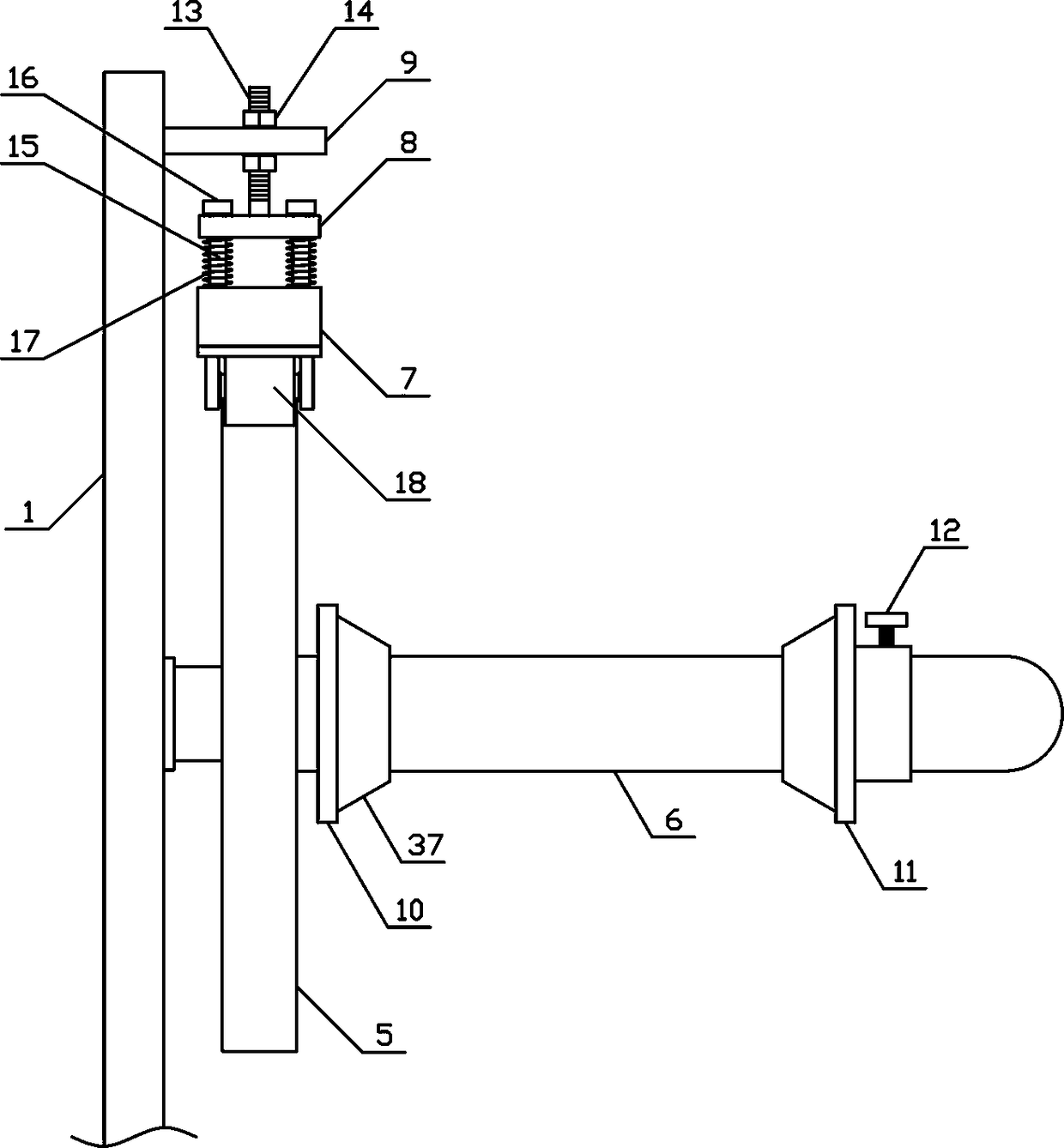

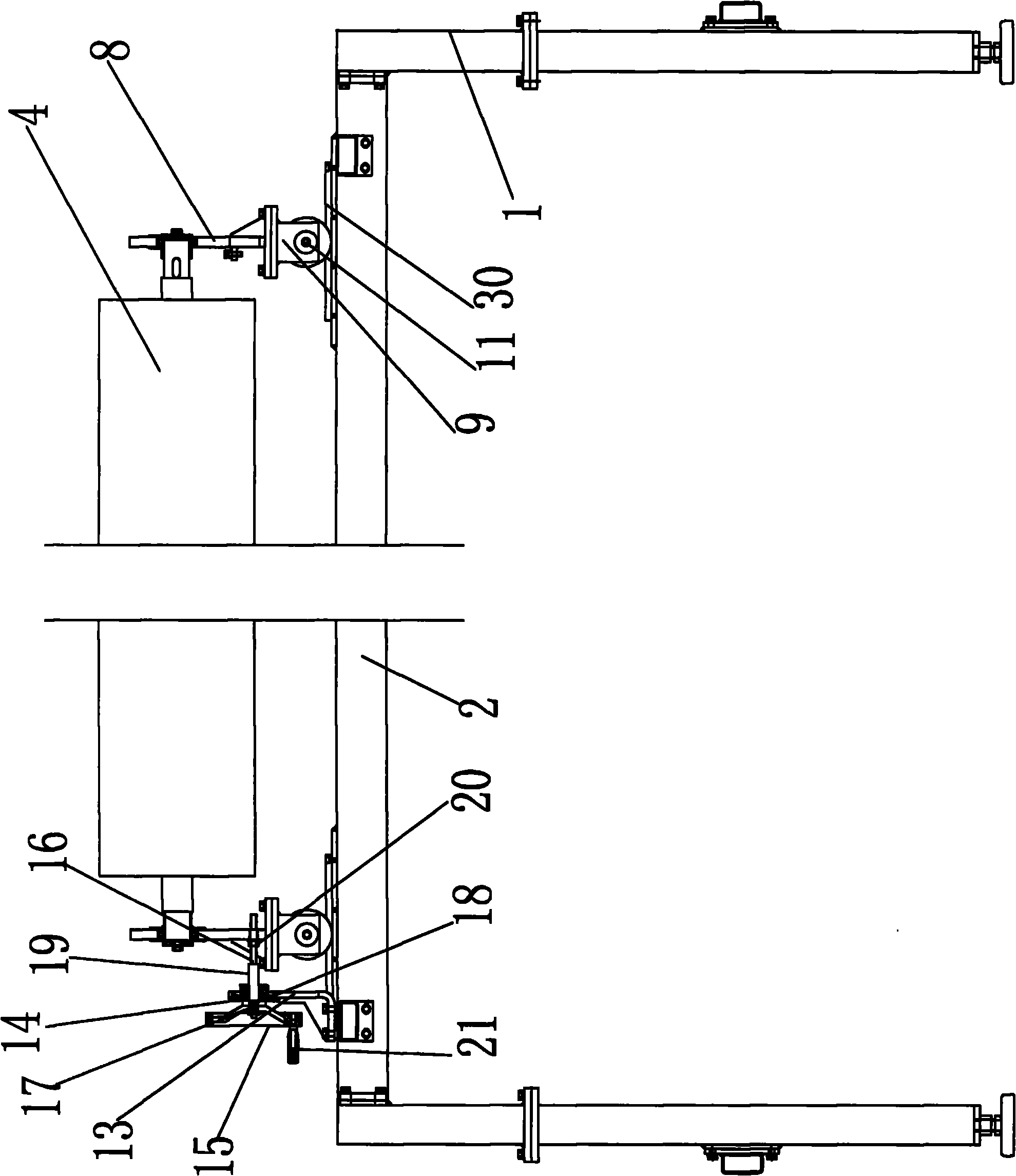

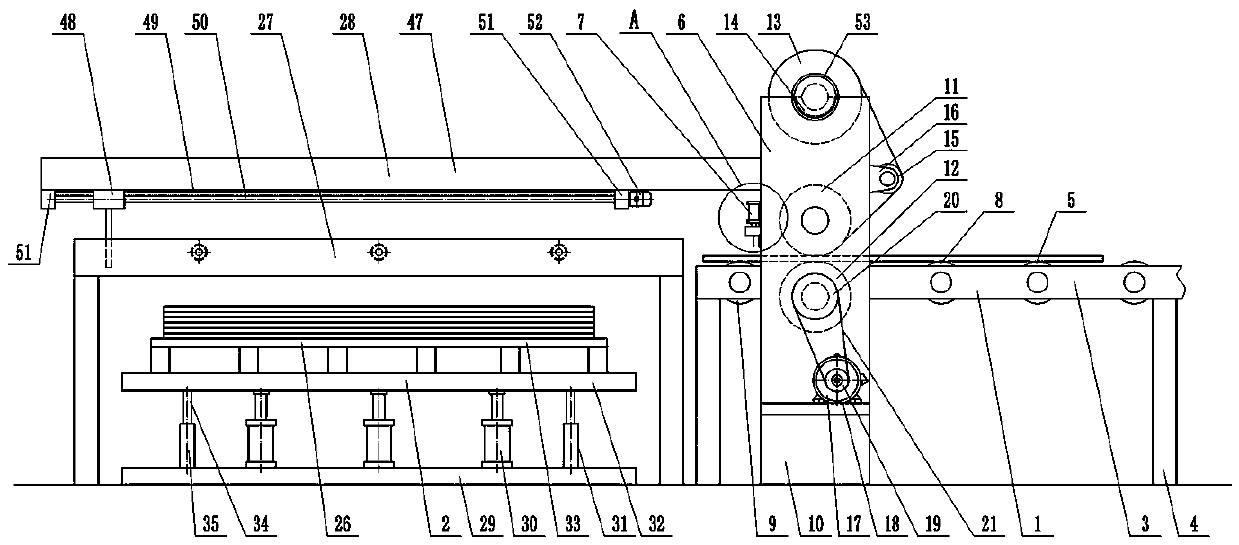

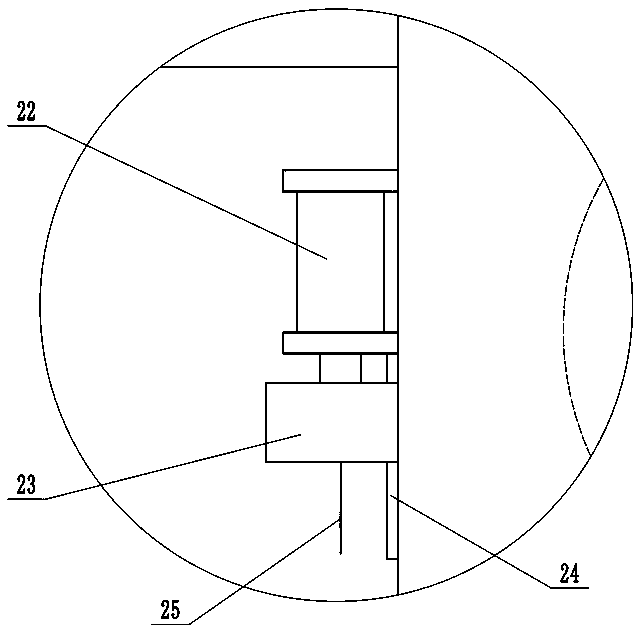

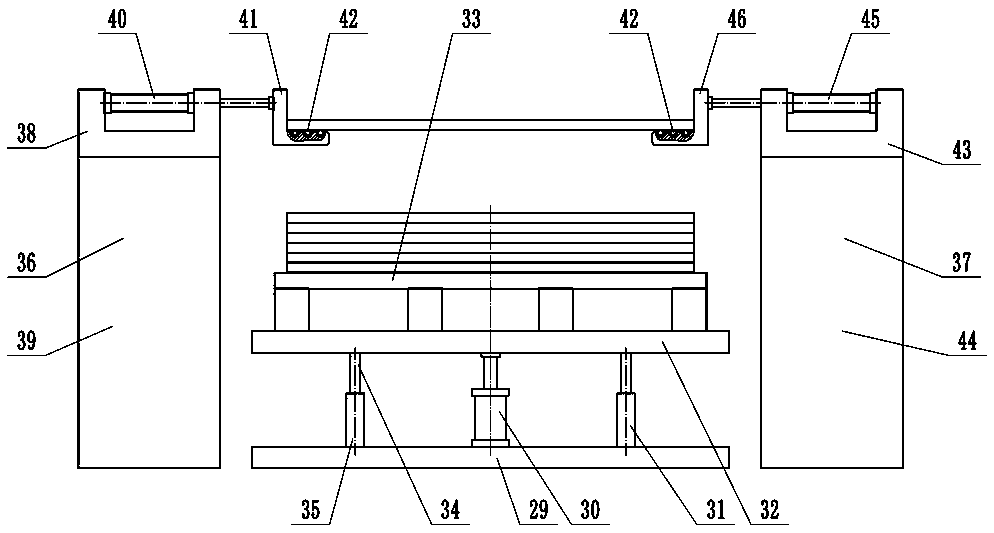

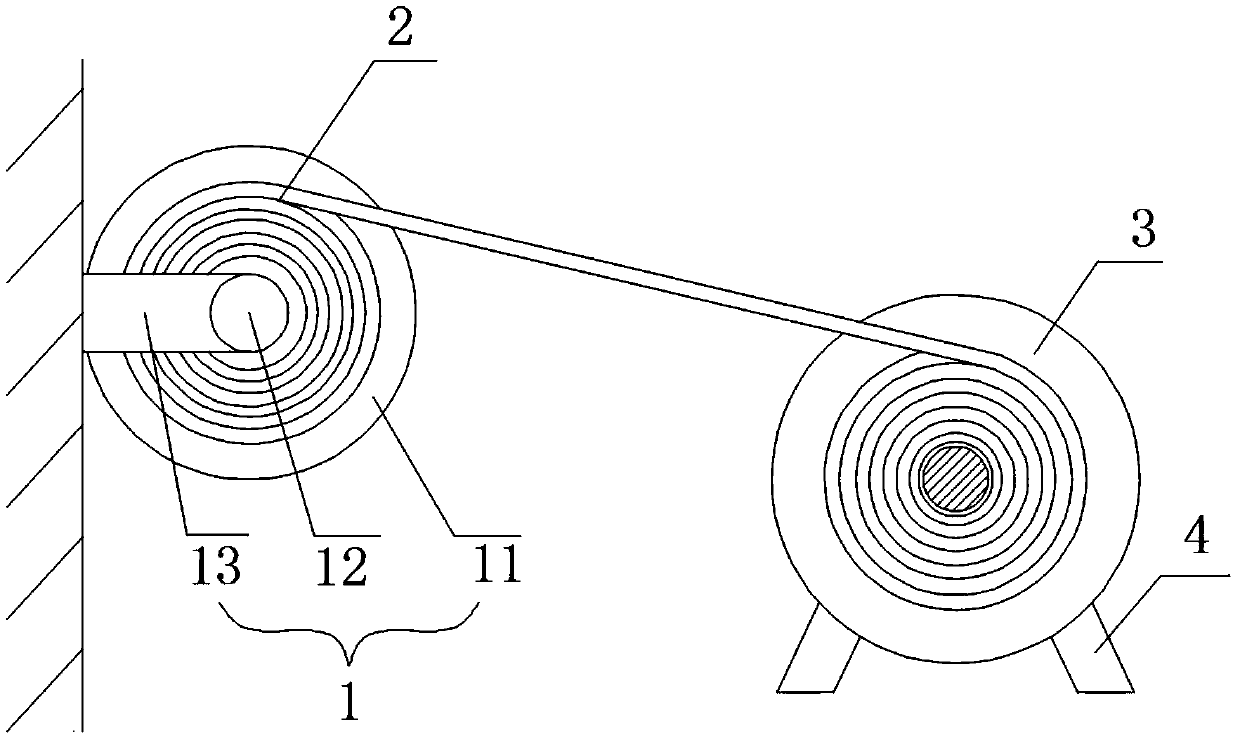

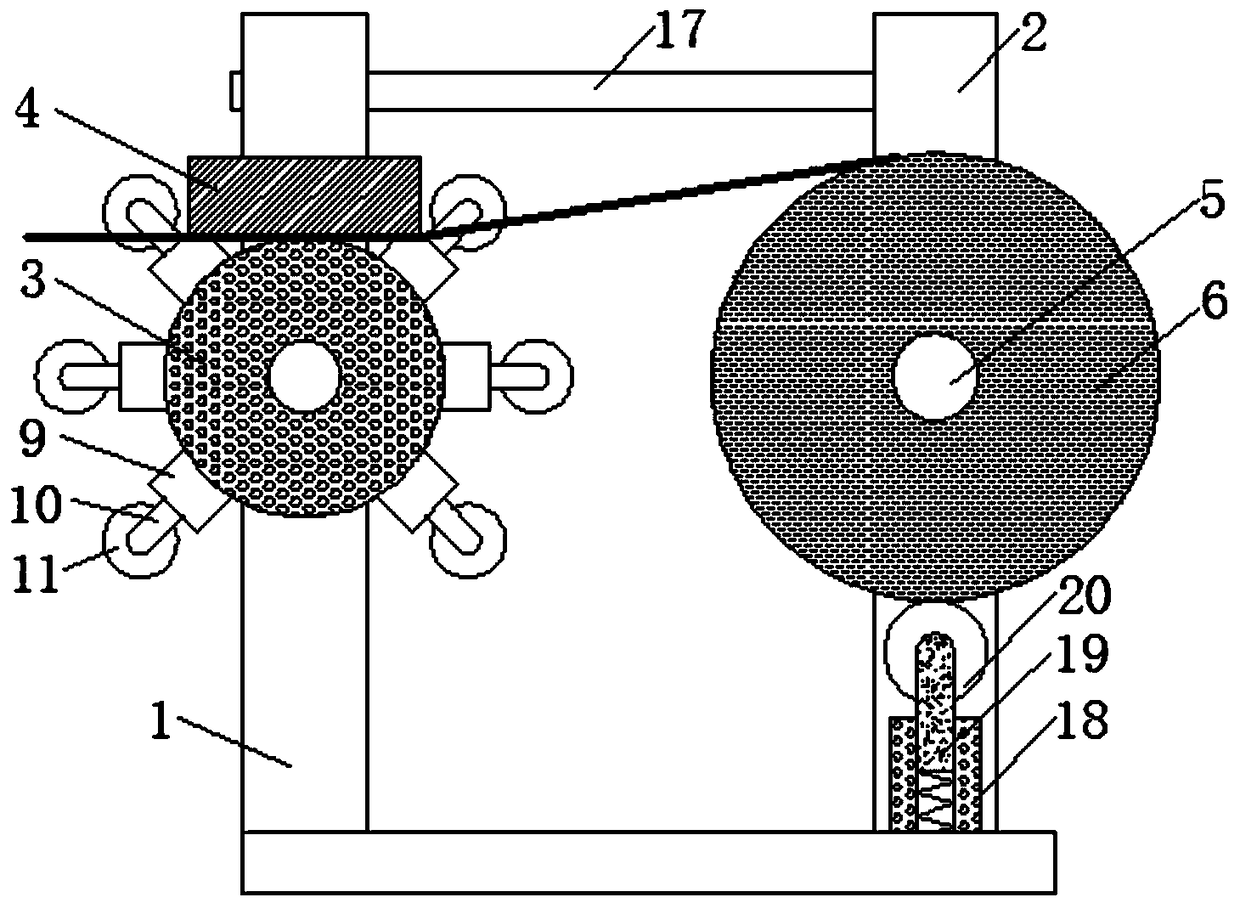

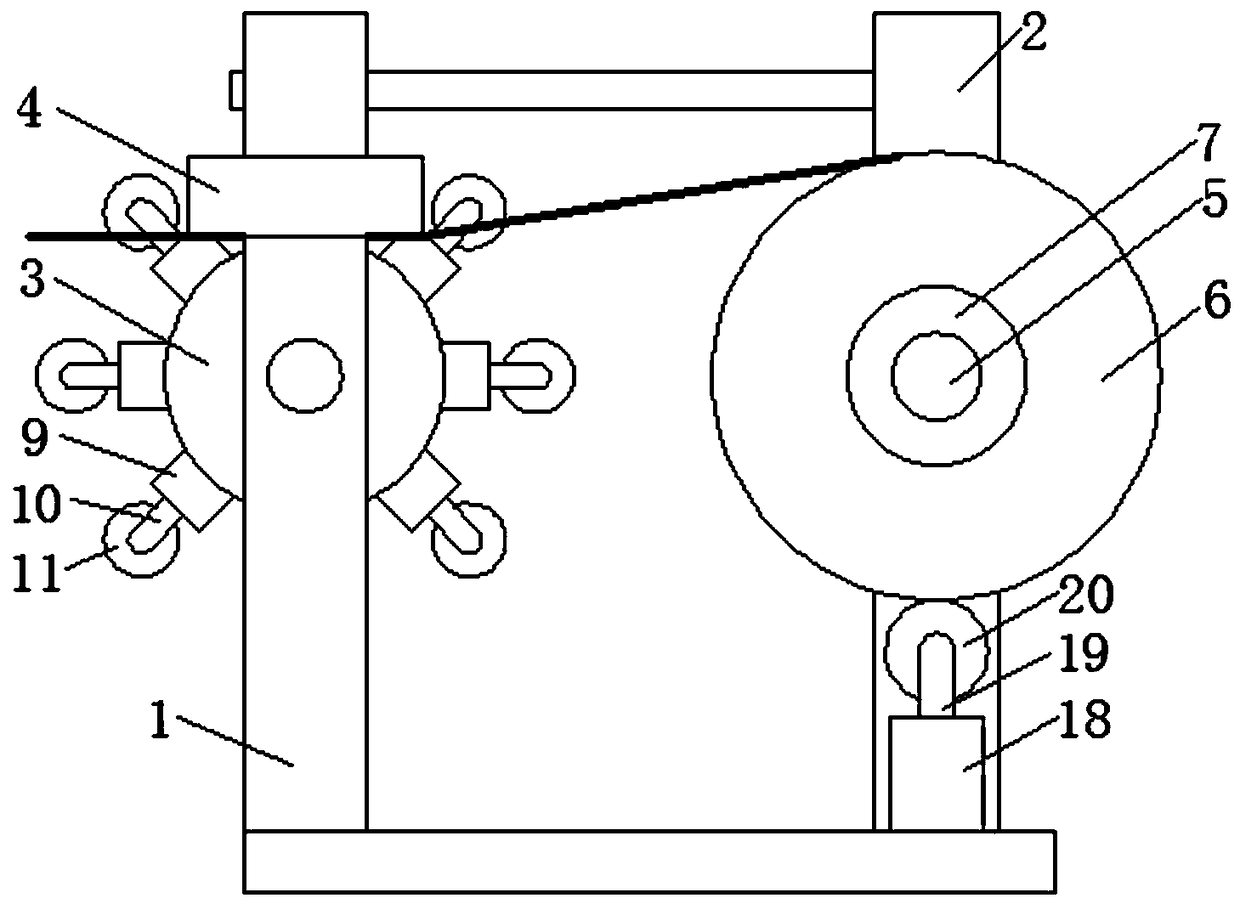

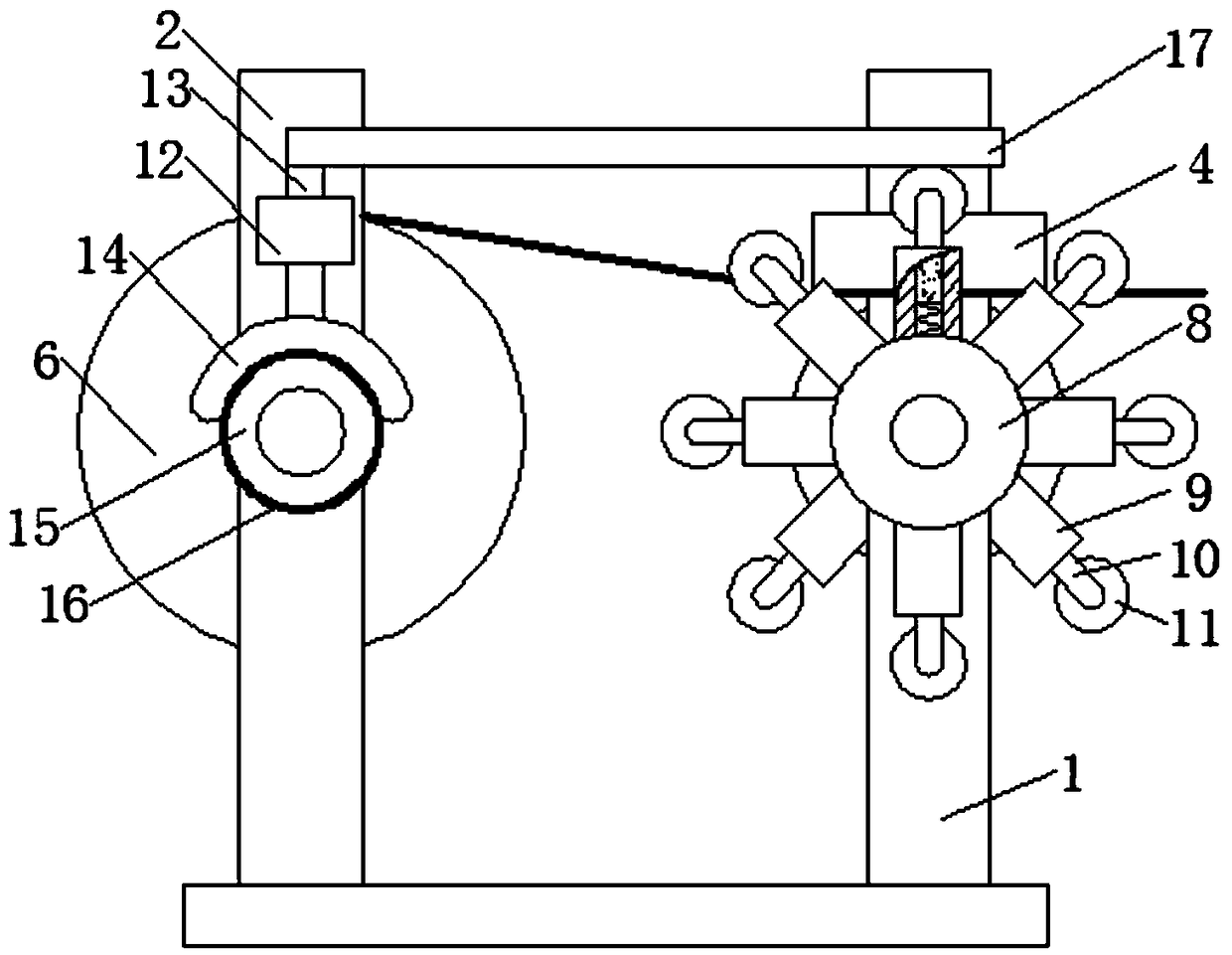

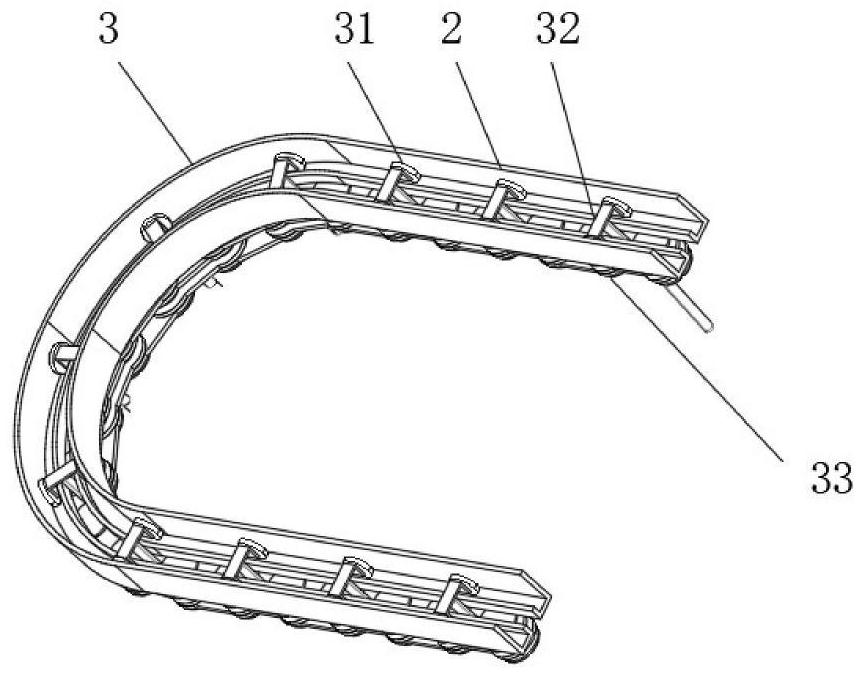

Adjustable take-up and pay-off stand

ActiveCN104310115AAvoid offline situationsStable unwindingFilament handlingElectric machineryStructural engineering

The invention discloses an adjustable take-up and pay-off stand, and belongs to the field of mechanical equipment. The adjustable take-up and pay-off stand comprises a fixed part and a rotating part, wherein the fixed part comprises a first pedestal, a fixed ring and a first connecting rod; the rotating part comprises a second pedestal, a motor, a second connecting rod, a protective ring, a rotating frame, a fixed seat, a guide seat and two to four guide rods; the motor is arranged at the upper end of the first pedestal and is fixedly connected with the second pedestal, and the lower end face of the second connecting rod is provided with a roller; the roller comprises a positioning wheel, a cylindrical wheel and an wheel axle; one end of the second connecting rod is fixedly connected with the second pedestal, and a loop bar is arranged on the other end of the second connecting rod in a sleeving manner; a protective ring circular arc block is fixedly arranged at the other end of the loop bar; the guide rods are equally spaced from one another on the guide seat, are in threaded connection with the guide seat and all form an included angle of 10-30 degrees with the horizontal line. Loosening and winding during pay-off can be avoided, active pay-off is realized, the bearing capacity of one-time pay-off can be adjusted, the bearing capacity is improved by arranging the roller, and the stand adapts to spools of different sizes and materials.

Owner:浙江亿正电工科技有限公司

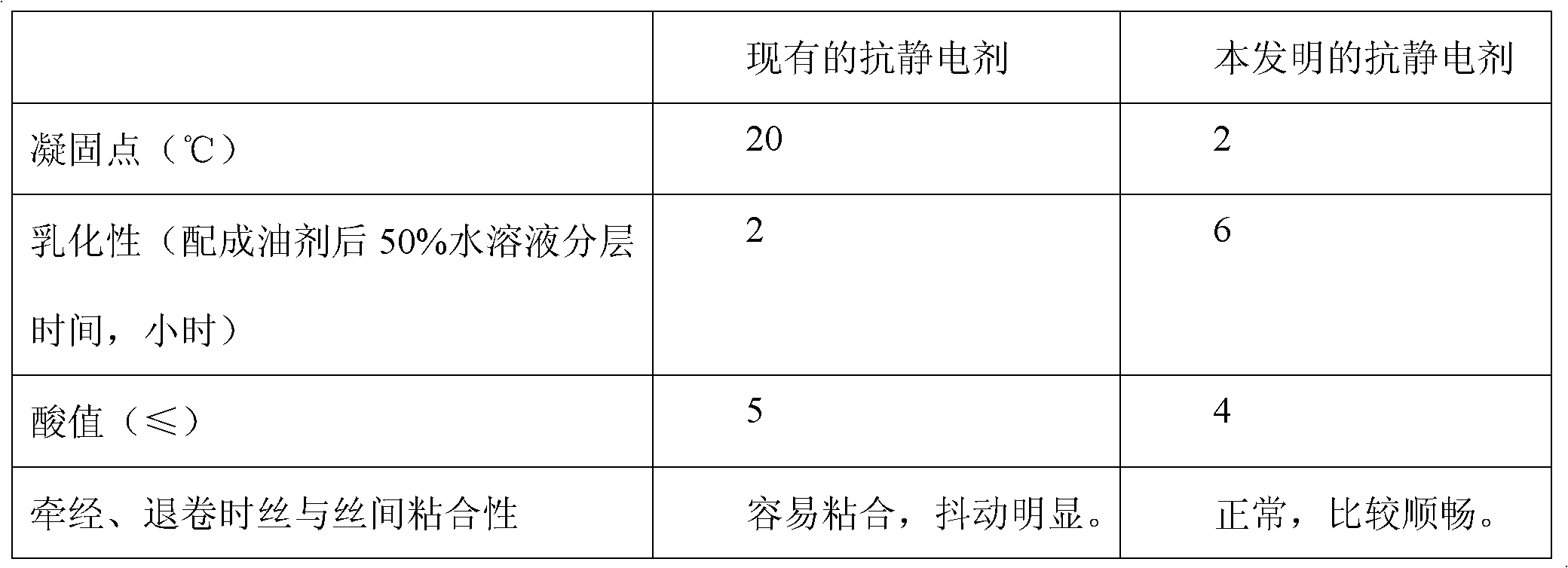

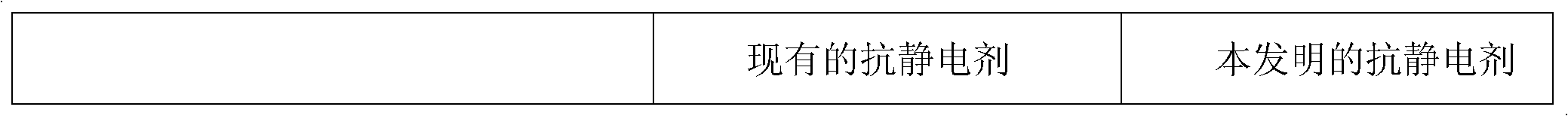

Antistatic agent for polyester elasticizing oiling agent and manufacturing method thereof

InactiveCN102182059ALow costImprove conductivityFibre typesPhosphorus organic compoundsPolyesterAlcohol

The invention discloses an antistatic agent for a polyester elasticizing oiling agent. The antistatic agent comprises the following components in part by weight: 30 to 40 parts of fatty alcohol, 10 to 12 parts of ethylene oxide, 40 to 50 parts of phosphorus pentoxide, 1 to 3 parts of potassium hydroxide and 2 to 5 parts of deionized water. The manufacturing method comprises the follow steps of: firstly, synthesizing the fatty alcohol and the ethylene oxide to obtain fatty alcohol-polyoxyethylene ether; secondly, synthesizing the fatty alcohol-polyoxyethylene ether and the phosphorus pentoxide to obtain fatty alcohol-polyoxyethylene ether organic phosphate; thirdly, synthesizing the fatty alcohol-polyoxyethylene ether organic phosphate and the ethylene oxide to obtain fatty alcohol-polyoxyethylene ether organic phosphate alcohol-polyoxyethylene ester; and fourthly; and fourthly, synthesizing the fatty alcohol-polyoxyethylene ether organic phosphate alcohol-polyoxyethylene ester and the potassium hydroxide to obtain fatty alcohol-polyoxyethylene ether organic phosphate alcohol-polyoxyethylene ester sylvite. The antistatic agent produced by the method has the advantages of high efficiency, low cost, strong frost resistance, easiness in emulsification and capability of meeting series of requirements of post-processing such as elasticizing.

Owner:TONGXIANG HENGLONG CHEM CO LTD

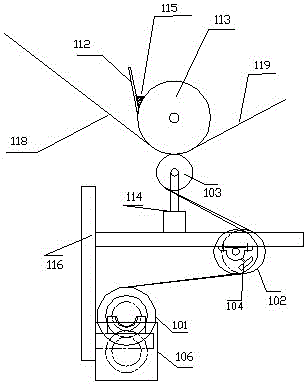

Simple parallel spreading and laminating device and technology for wide ultrathin membrane

The invention discloses a simple parallel spreading and laminating device for a wide ultrathin membrane. The simple parallel spreading and laminating device comprises a membrane unreeling roller, a magnetic powder damper, a bent roller, a gluing roller, a flat roller and a rack. A technology comprises the steps that the wrapping angle of the bent roller and the wrapping angle of the flat roller are adjusted by setting proper unreeling tension; the relative position relation of the unreeling roller, the bent roller and the flat roller is adjusted; the protruding direction of the bent roller is adjusted; and the membrane passes through the unreeling roller, the bent roller and the flat roller and then is combined with pre-soaked cloth to complete the laminating procedure. According to the simple parallel spreading and laminating device and technology for the wide ultrathin membrane, non-uniform elastic deformation is generated in the middle area and the edge areas of the membrane through the axial stroke linear change of the bent roller and the elasticity of the membrane, the spread membrane is fixed in the weft direction through the flat roller so that the ultrathin membrane can be spread, and the problems that the ultrathin membrane has wrinkles and is unevenly spread in the unreeling process can be effectively solved; unreeling is stable, the spreading parallelism of the ultrathin membrane is good, the breadth is stable, bonding to glued fibers is good, the phenomenon that bubbles are brought due to wrinkles of the membrane is thoroughly eliminated, and the finished product rate of the pre-soaked cloth is increased.

Owner:JIANGSU SHENTAI SCI & TECH DEV +1

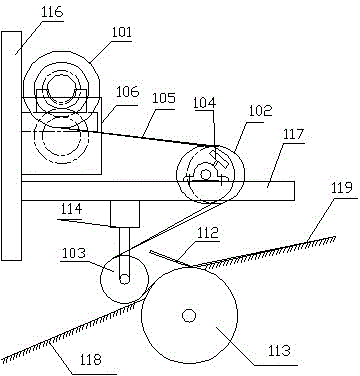

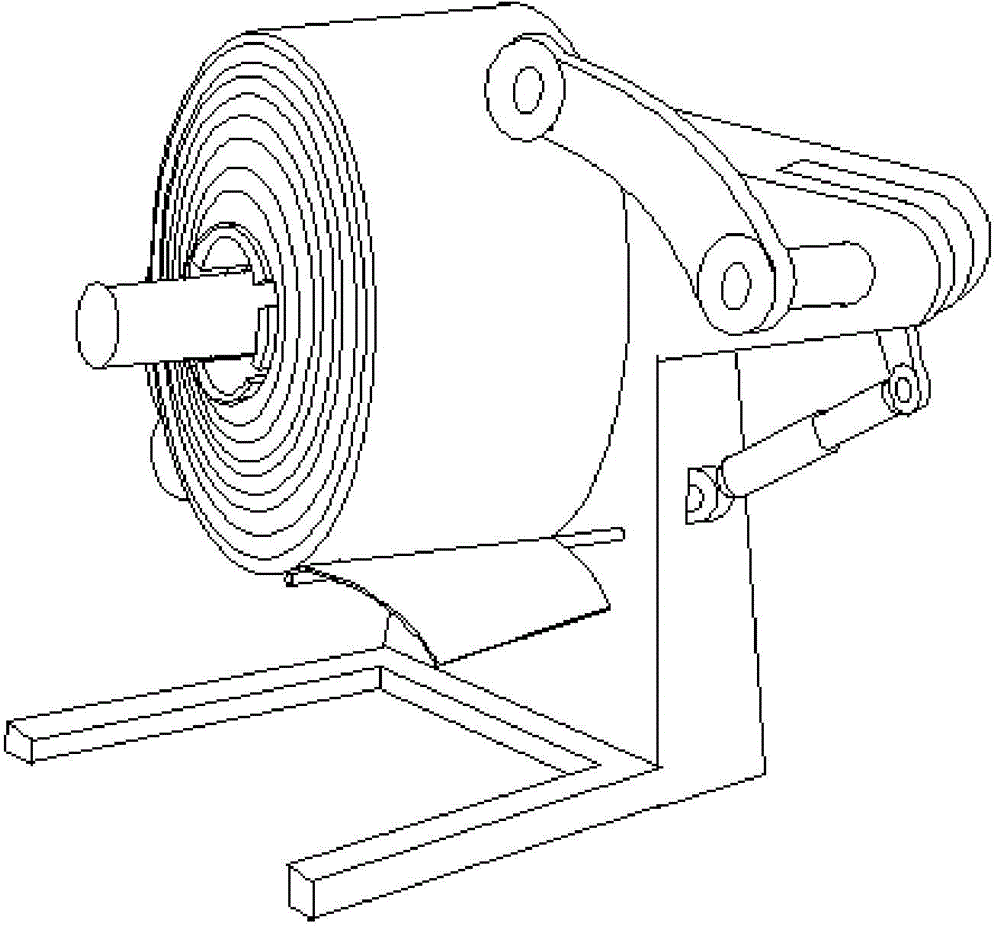

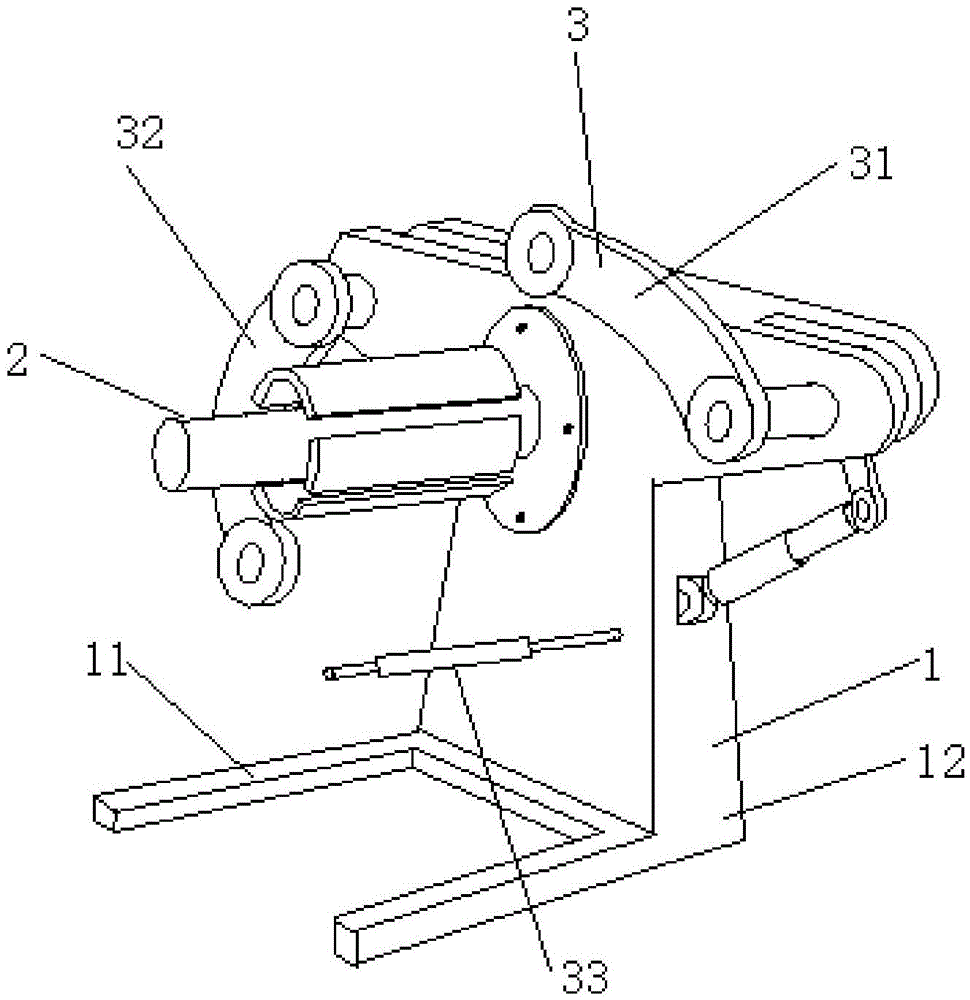

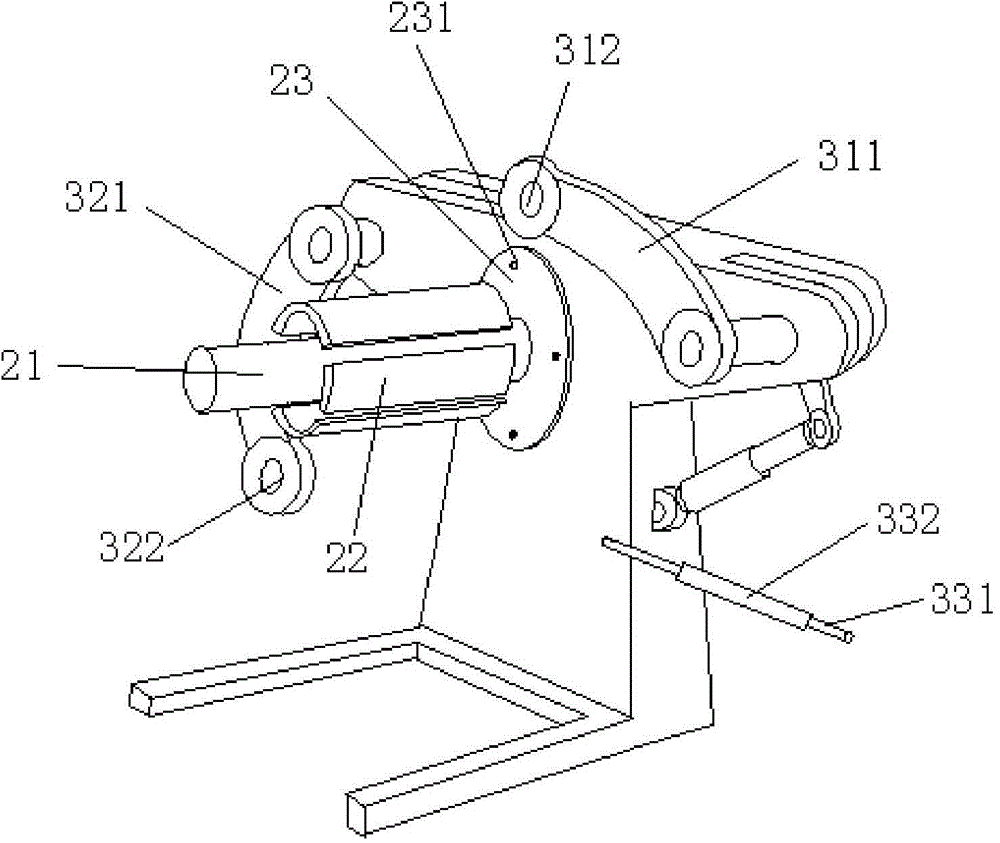

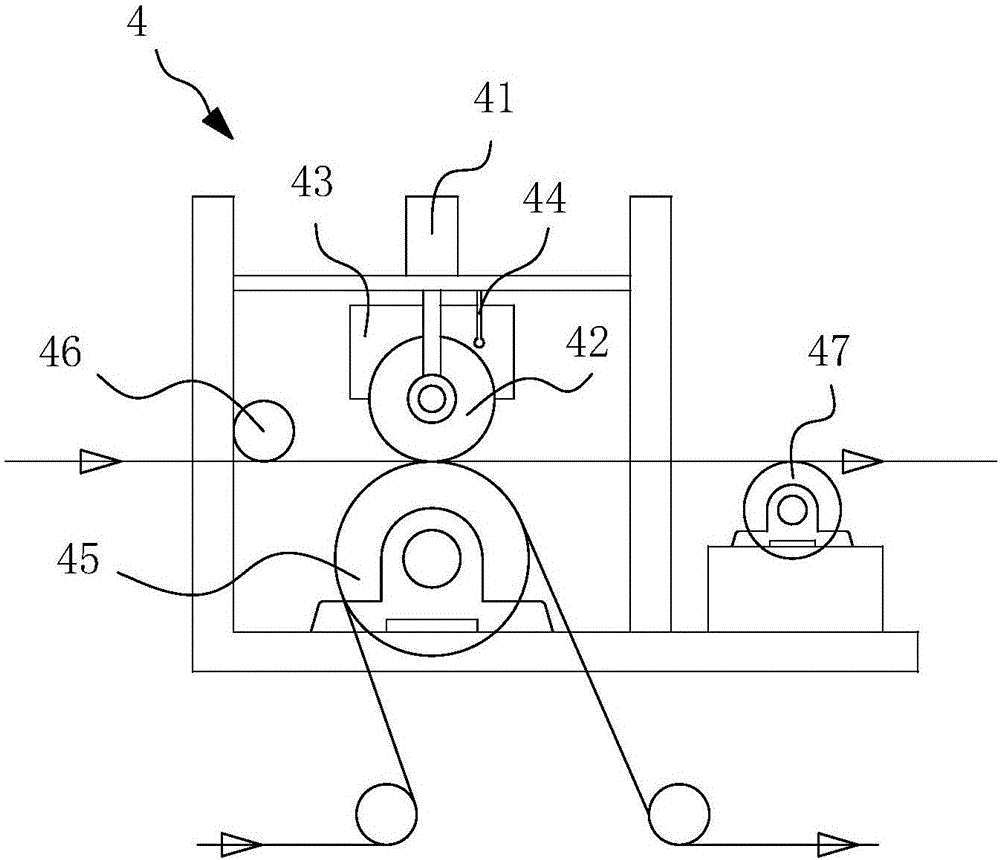

Uncoiler

The invention provides an uncoiler. The uncoiler comprises a frame body, an uncoiling device and a material feeding device. The frame body comprises an under frame and a vertical frame. The vertical frame is arranged on the under frame. The vertical frame and the under frame are arranged in a vertical mode. The material feeding device comprises a material pressing mechanism, a first material feeding mechanism and a second material feeding mechanism. The material pressing mechanism and the first material feeding mechanism are arranged on the two sides of the uncoiling device respectively. The second material feeding mechanism is arranged below the material pressing mechanism. The uncoiler has the advantages and the positive effects that due to the structure, the material feeding of the uncoiler is stable, and the drooping problem during the sheet material feeding procedure is solved.

Owner:TIANJIN SHENYUAN KAILI GRP CO LTD

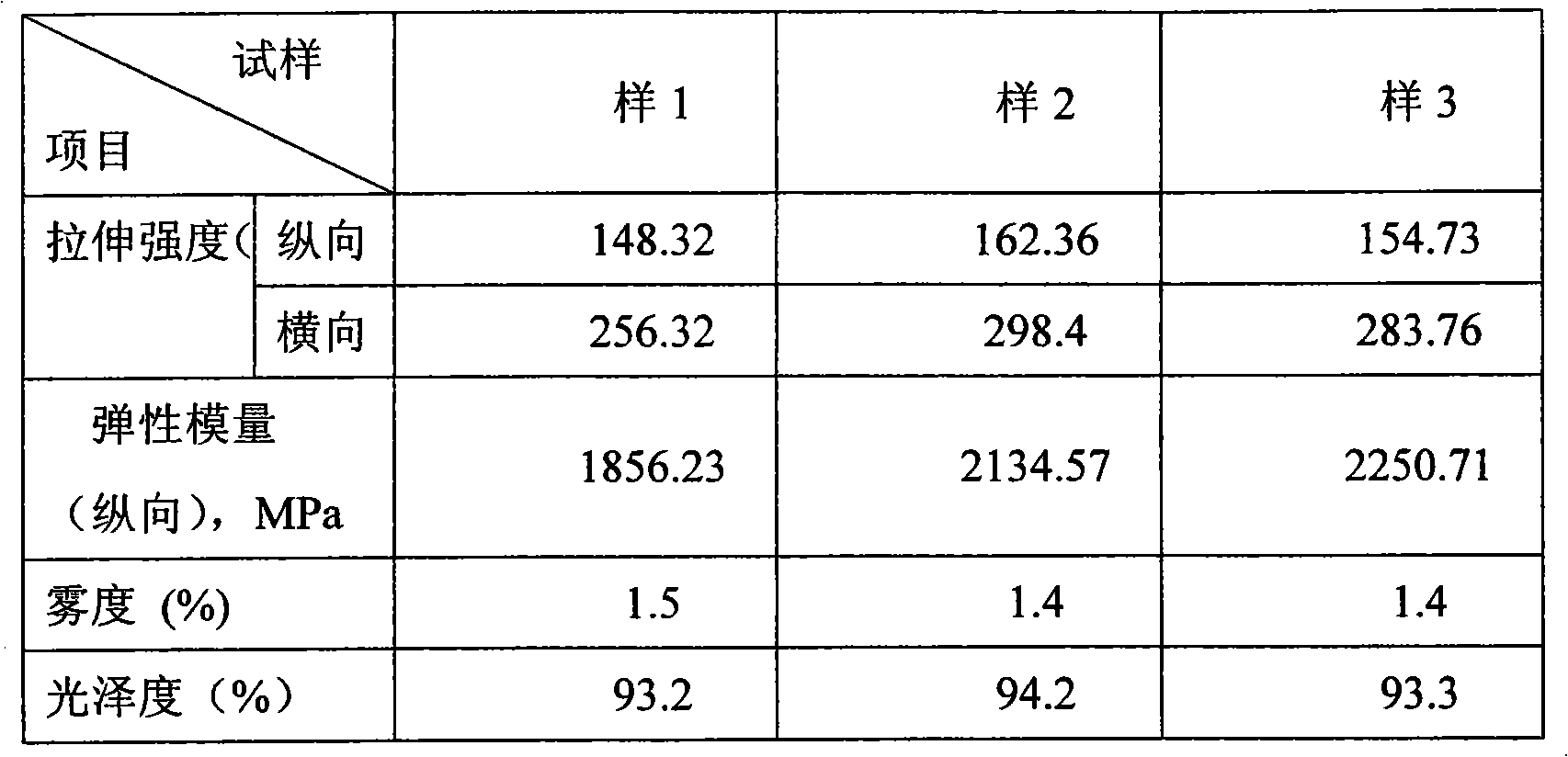

Biaxial stretching polypropylene 9 mu m ultra thin type compound film and method of preparing the same

The invention relates to a biaxial-tensile 9-mum ultra-thin composite polypropylene membrane, which comprises an upper surface layer, a middle layer and a lower surface layer, wherein each layer adopts homo-polypropylene as the base material. The composite membrane is characterized in that cross-linked methyl acrylate with a particle diameter of 2 mum is added into the homo-polypropylene base layer material of the upper and the lower surface layers at a ratio of 3.0 to 5.0% the total weight of the homo-polypropylene base layer material as an anti-adhesion material; and adding C9 hydrogenated petroleum resin into the homo-polypropylene base layer material of the middle layer at a ratio of 5 to 10% the total weight of the homo-polypropylene base layer material as a stiffening agent, adding oleamide with a ratio of 0.1 to 0.3% the total weight of the homo-polypropylene base layer material and adding alkyl(C14 to 18)bis(2-hydrox-yethyl)amine at a ratio of 0.1 to 0.3% the total weight of homo-polypropylene base layer material. The composite membrane has stiffness and no adhesion.

Owner:江苏恒创包装材料有限公司

Method for preparing poly(trimethylene terephthalate) fibre having shape memory characteristic

InactiveCN101200821ANo residual stressStable unwindingMelt spinning methodsMonocomponent polyesters artificial filamentPolymer sciencePolyethylene terephthalate

The invention discloses a preparation method of polytrimethylene terephthalate fiber with shape memory characteristics, including: firstly, selected polyester polymer is provided with at least 0.8dL / g of intrinsic viscosity and contains at least 85mol percent of polytrimethylene terephthalate, wherein, at least 85mol percent of the repeating unit is composed of three-methylene; secondly, the polyester polymer is melted and transported through a screw melting extruder, the melting body is metered through a metering pump and is extruded out through a spinneret, and as-spun fibers are drafted successively through a pair of drafting hot rollers after being cooled through lateral blowing; thirdly, the drafted fibers are introduced into a group of grouping roller stereotype boxes with steam; fourthly, tow is introduced into a winding head to be winded into mold. The fiber made through the invention has the advantages of good packaging appearance forming, good structural stability and soft handle. And with lower modulus, the fiber is still provided with good elasticity and tensile recoverability. The textiles made of the fiber which are produced through the process are provided with good shape memory characteristics.

Owner:方圆化纤有限公司

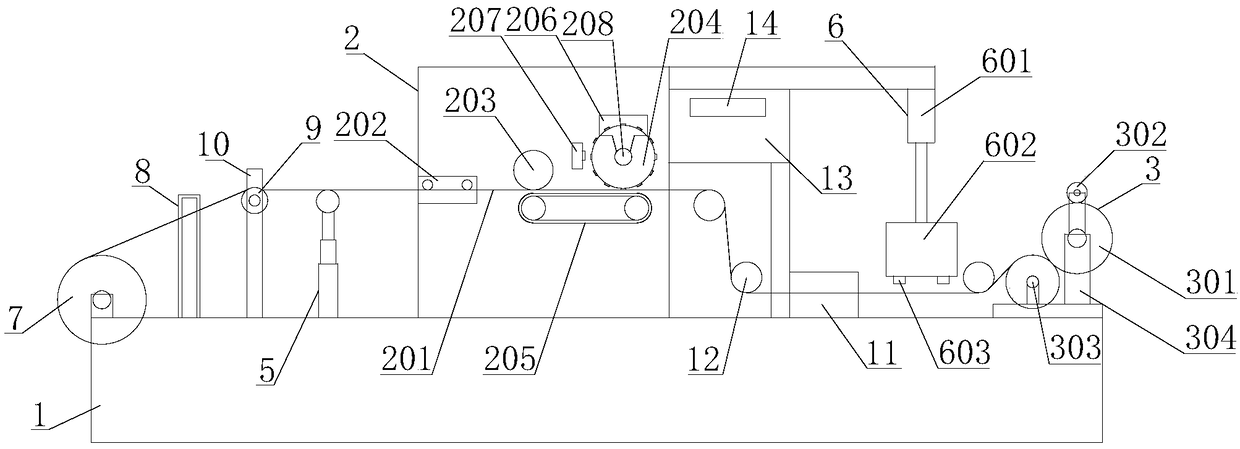

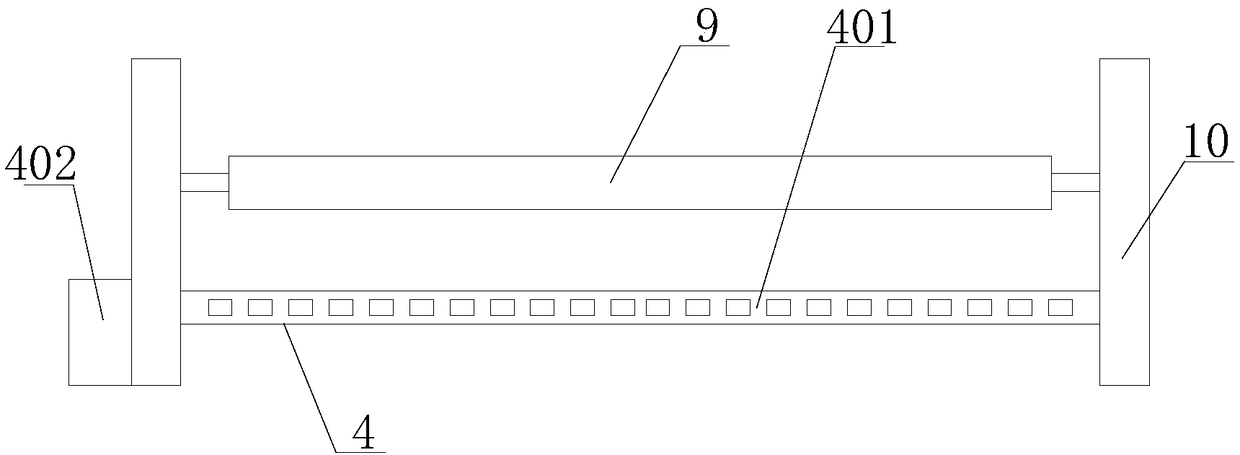

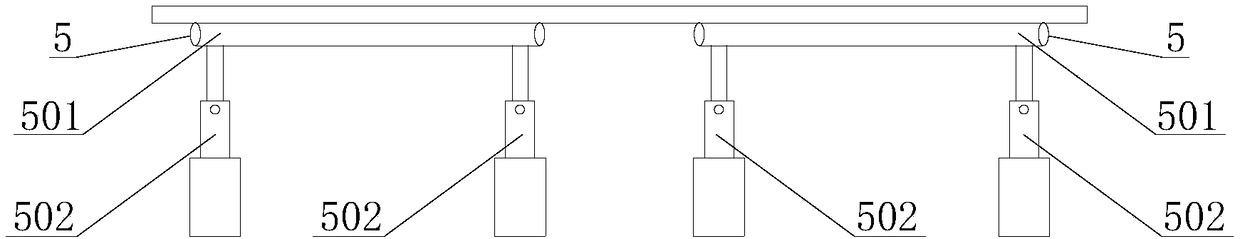

Waterproof aluminum-foil paper production equipment and production method thereof

InactiveCN109591383AFlat sizeUniform sizeMechanical working/deformationCleaning using toolsPaper productionPulp and paper industry

The invention provides waterproof aluminum-foil paper production equipment and a production method thereof. The waterproof aluminum-foil paper production equipment comprises a bottom plate, a windingdevice, an embossing device and a slitting device. The waterproof aluminum-foil paper production equipment and the production method thereof provided by the invention can solve the problems that a, during the volumed aluminum-foil paper embossing anti-fake production process, solid particles exist on the surface of volumed aluminum-foil paper, the aluminum-foil paper is easy to crush so as to be damaged due to direct embossing, and embossing equipment in the general market cannot adjust the appropriate pressure aiming at different aluminum-foil paper thicknesses, so that the application rangeis low; b, the volumed aluminum-foil paper is instable when being unwinded and is easy to shake, so that the production efficiency and the product quality are influenced; and c, when the aluminum-foilpaper is cut, the tension stressed on the aluminum-foil paper is instable, so that the cutting dimension of the aluminum-foil paper cannot be controlled when the aluminum-foil paper is cut, meanwhile, the cut aluminum-foil paper is easy to wrinkle, the product quality is influenced and the like.

Owner:FUYANG CIGARATE MATERIAL FACTORY

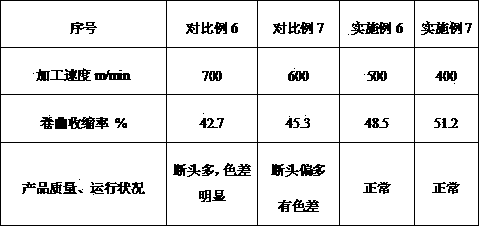

Production method for high-elastic polyester yarn

The invention discloses a production method for high-elastic polyester yarn, wherein polyester POY serves as a raw material. The production method comprises the steps that the polyester POY passes through a raw silk frame, a first roller, a deformation heat box and a cooling plate to achieve false twisting deformation, then passes a second roller, a shaping heat box and a third roller, oil is applied, and the polyester POY winds and is packaged in a classified mode. In the production process, the temperature of the deformation heat box ranges from 210 DEG C to 240 DEG C, and the shaping heat box is closed. By means of the production method for the high-elastic polyester yarn, the crimp shrinking percentage of the polyester yarn can be improved effectively and improved from about 18% in the prior art to about 50%, the yarn is more crimped and fluffy, the elasticity of the yarn is largely improved, the requirements of elastic fabric such as sportswear fabric and elastic jean cloth are met, successful unwinding of the polyester yarn in the later weaving process is ensured, and weaving efficiency is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Non-adhesive biaxially-oriented polypropylene film for hot lamination and preparation method thereof

ActiveCN101633262AWind evenlyStable unwindingSynthetic resin layered productsMasterbatchAntistatic agent

The invention discloses a non-adhesive biaxially-oriented polypropylene film for hot lamination. The film comprises a heat-sensitive function layer, a substrate layer and an anti-sticking layer which are orderly arranged and are formed by co-extrusion lamination, wherein calculated as the weight ratio, the heat-sensitive function layer accounts for 4 to 33 percent of the total weight of the film, and the anti-sticking layer accounts for 4 to 17 percent of the total weight of the film; the substrate layer comprises 85 to 95 percent of polypropylene, 1 to 5 percent of antistatic composite masterbatch, and 4 to 10 percent of hydrogenated petroleum resin composite masterbatch; the antistatic composite masterbatch comprises 10 to 30 percent of antistatic agent and 70 to 90 percent of the polypropylene; the hydrogenated petroleum resin composite masterbatch comprises 40 to 60 percent of hydrogenated petroleum resin and 40 to 60 percent of the polypropylene; and the anti-sticking layer comprises 95 to 99 percent of the polypropylene and / or polyethylene, and 1 to 5 percent of anti-adhesion masterbatch, and the anti-adhesion masterbatch comprises 5 to 15 percent of antiblocking agent. The invention also provides a method for preparing the non-adhesive biaxially-oriented polypropylene film, which comprises the steps of: adding materials of the layers into extruding machines for melting plastification and extrusion respectively; merging for co-extrusion through a T type die head; performing biaxial tension; and performing corona treatment, and winding into the non-adhesive biaxially-oriented polypropylene film for hot lamination.

Owner:QUANZHOU LICHANG PLASTIC

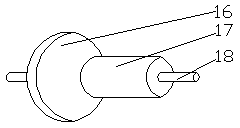

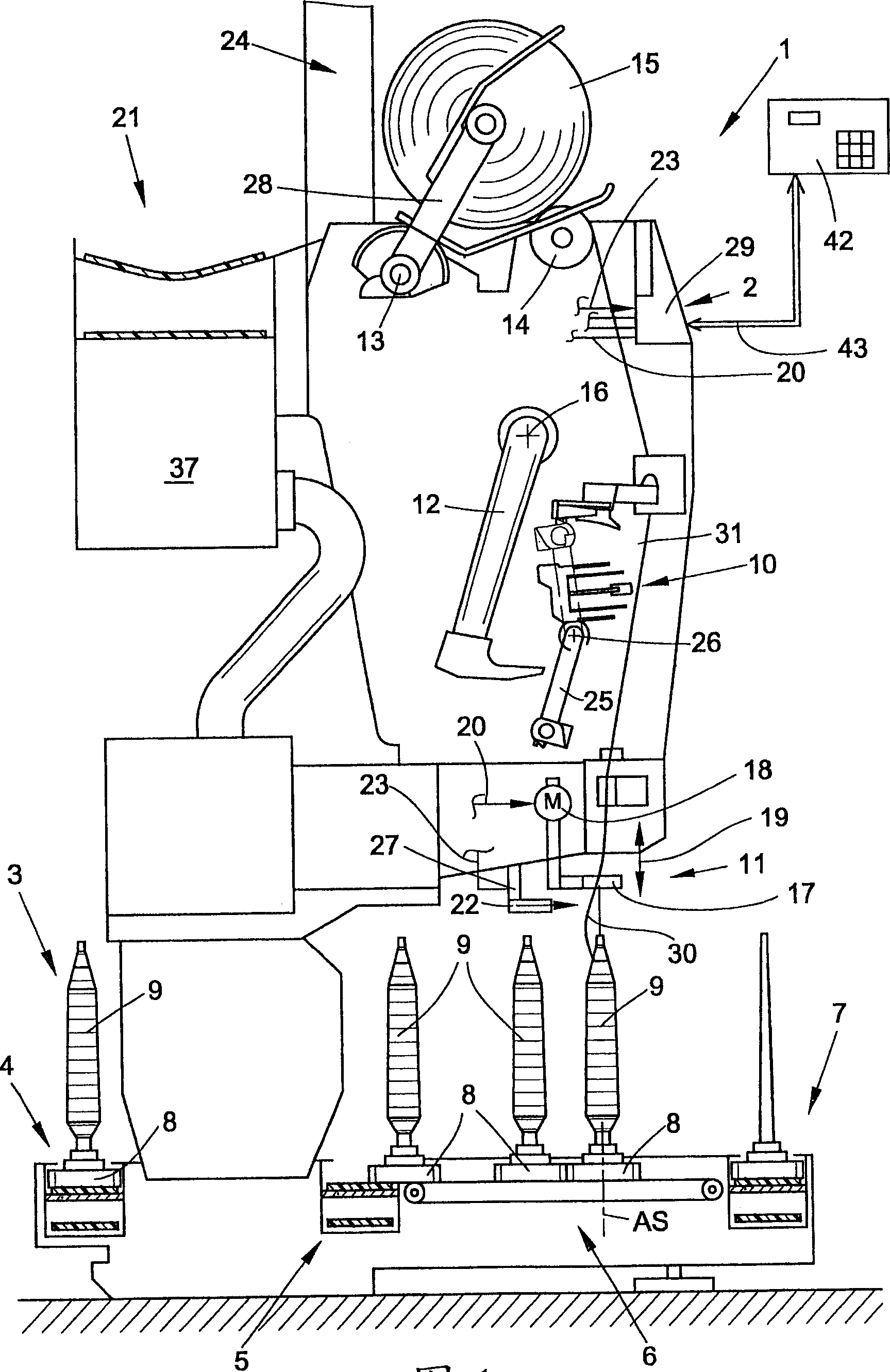

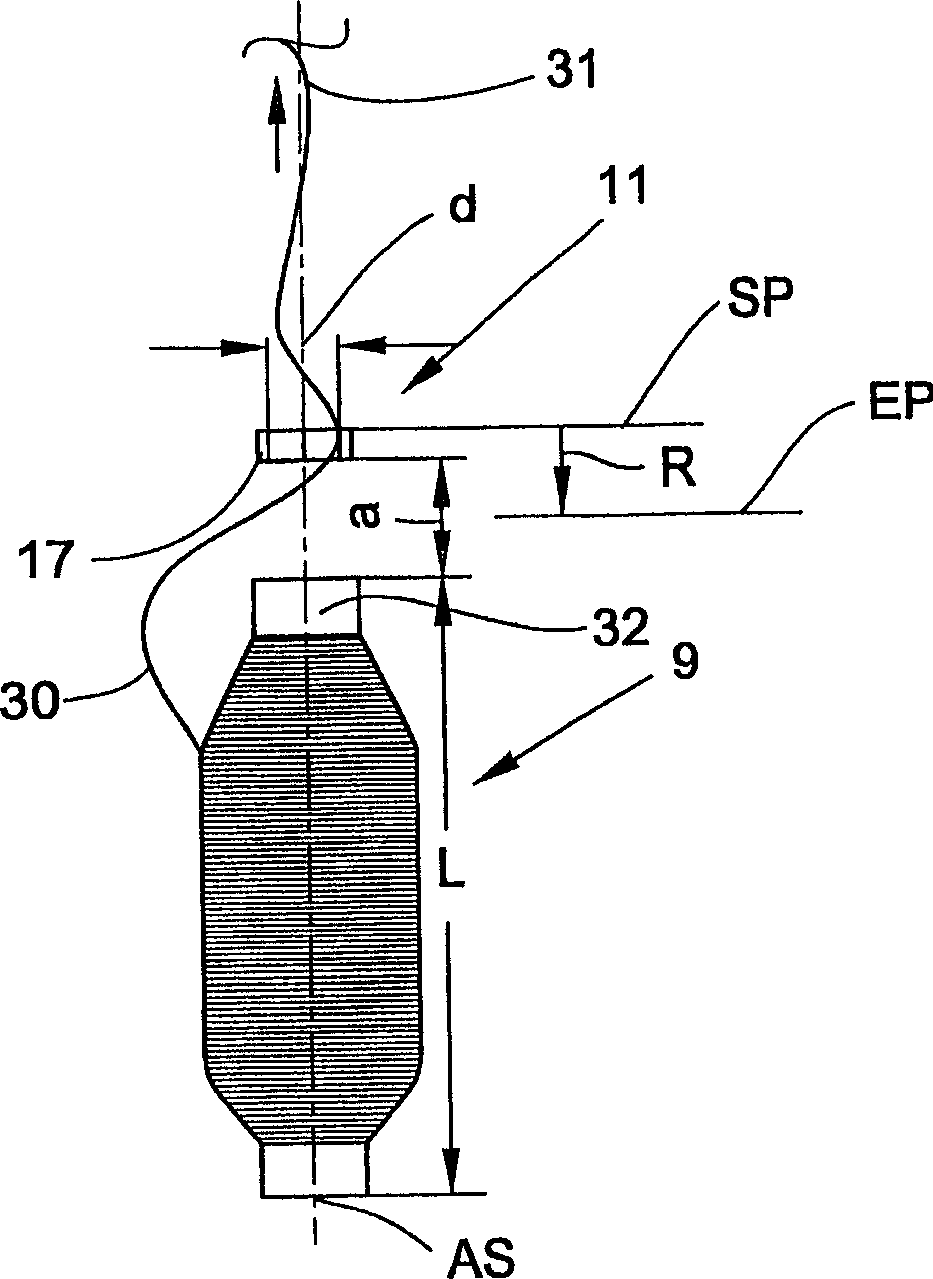

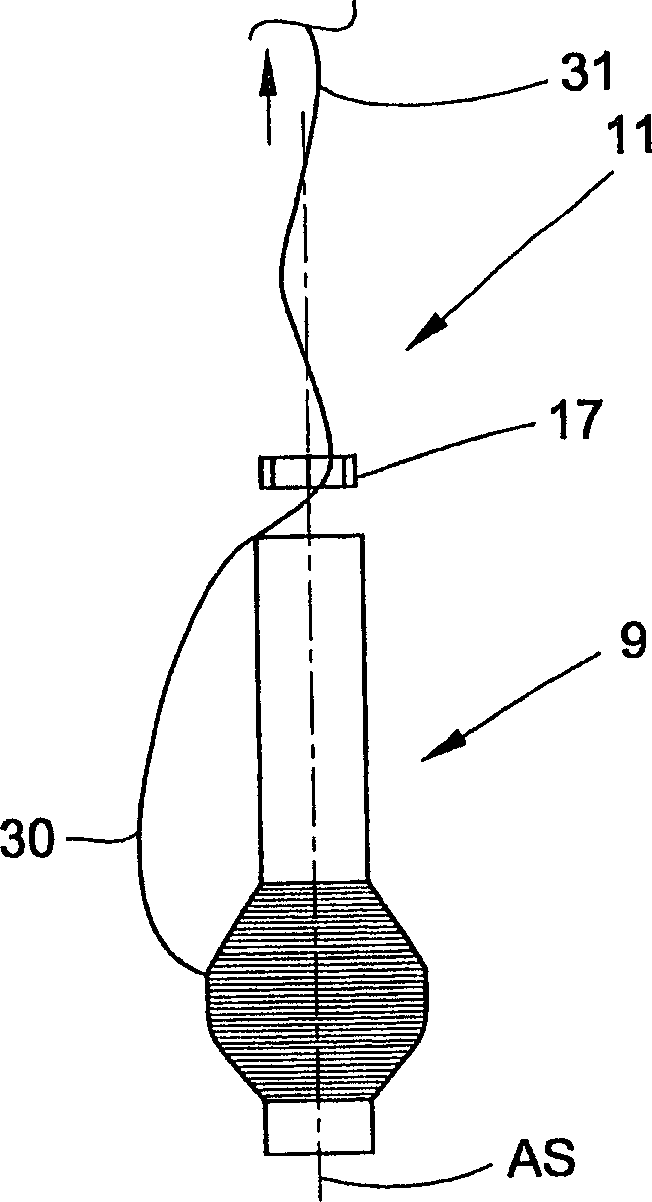

Modified device for withdrawing yarn of automatic cross-winding apparatus

A device for optimizing the yarn unwinding of the winding head of a cross-winding robot, with a vertically moving yarn guide positioned above the unwinding spool, characterized in that a yarn guide (17) is provided The adjusting device (18) of the adjusting device (18) makes the yarn guide (17) which acts as an upper limit on the rotating yarn balloon be positioned vertically in such a way that the formed yarn balloon is a single yarn balloon (30 ), the position of the yarn guide (17) is determined at least according to the winding state of the corresponding unwinding bobbin (9) when the yarn is unwound.

Owner:SAURER GERMANY GMBH & CO KG

Reeling agent for automatic silk reeling production

InactiveCN104480536AIncrease release rateFull penetrationSilk reelingCocamidopropyl betaineBright-white

The invention relates to the technical field of silk production and discloses a reeling agent for automatic silk reeling production. The reeling agent comprises the following raw materials of, by weight, 5 to 10 parts of castor oil polyoxyethylene ether, 6 to 9 parts of lauryl sodium sulfate, 6 to 9 parts of polyoxyethylene lauryl ether, 5 to 10 parts of polyoxyethylene fatty alcohol sodium sulfate, 5 to 8 parts of cocamidopropyl betaine, 10 to 15 parts of hydrogen peroxide, and 10 to 15 parts of sodium silicate. The reeling agent is reasonable in formula, capable of effectively increasing the reelability rate of raw silk, improving product quality, fully permeating cocoon shells, performing uniform reeling, and reducing the influence of cocoon quality differences on silk reeling quality, low in production cost, and small in use amount, silk produced through subsequent processes is bright white and soft and smooth in touch, and the use amount of the reeling agent is easy to control.

Owner:安徽省广德新丰丝绸有限公司

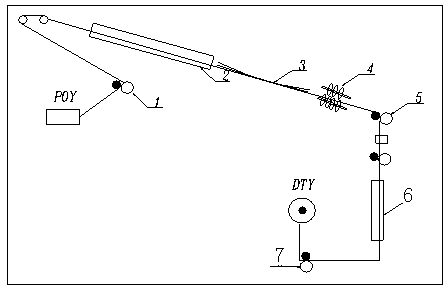

Low boiling water contraction rate polyester fiber drafting textured filament yarn and its producing method and use

ActiveCN1554816ALow boiling water shrinkageAchieve the purpose of the inventionYarnPolymer sciencePolymer chemistry

The present invention relates to drafting deformed dacron filament with low boiling water shrinkage and its production process and application. The POY material filament is processed successively through the first drafting roller, the first heating box, cooling plate, false twisting unit, the second drafting roller, network forming unit, 2bis roller, the second heating box, filament guide unit and filament breaking detector; adding weak network in the resilience increasing process; oiling and winding steps to obtain DTY filament. The present invention has lower deformation temperature, higher settling temperature, short process, reasonable technological control and stable production operation; and the product has boiling water shrinkage not higher than 1.0%, excellent built-in curling elasticity and wrapping. The product may be used in making embroidery string and trademark string.

Owner:SINOPEC OILFIELD SERVICE CORPORATION

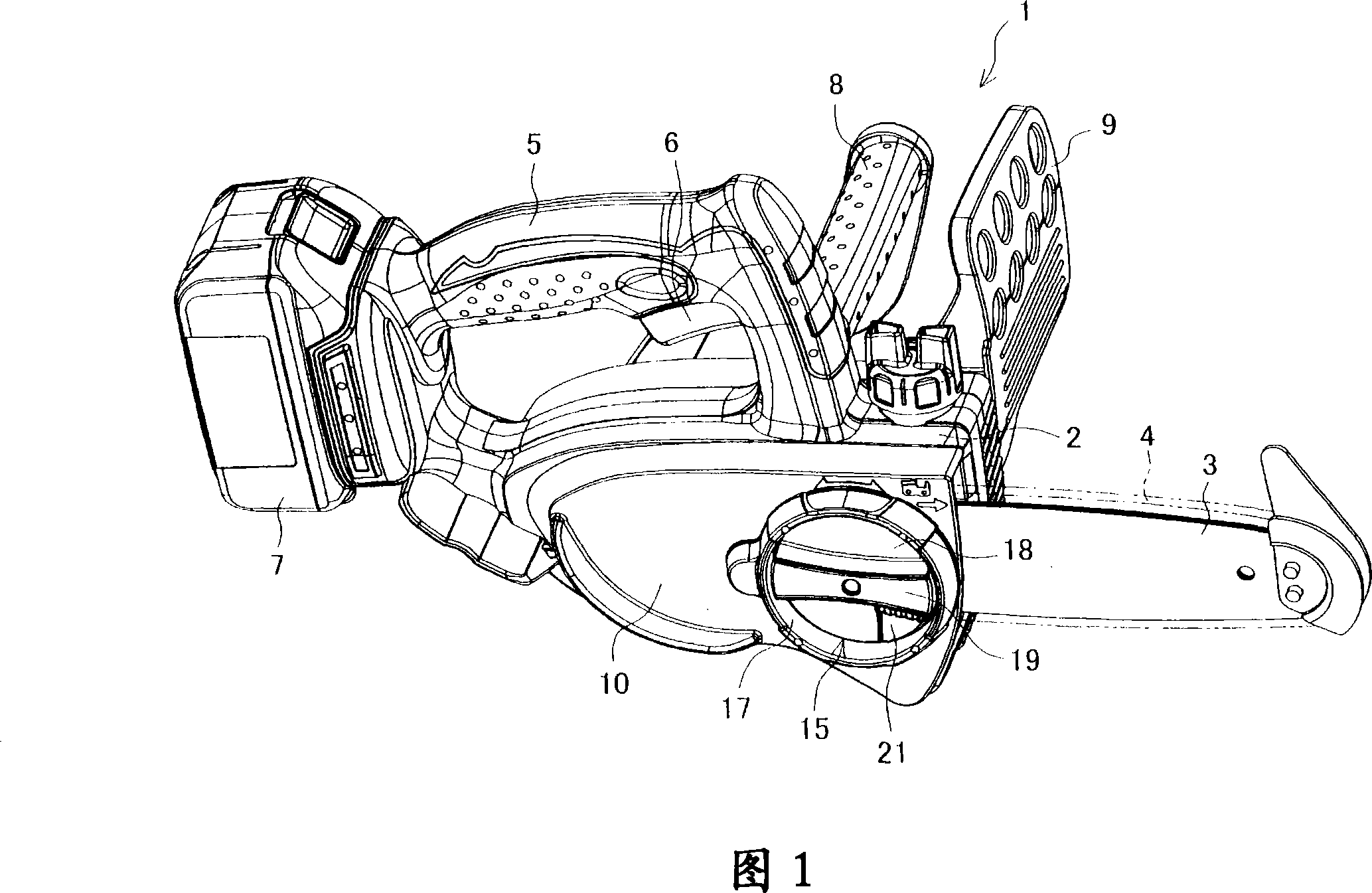

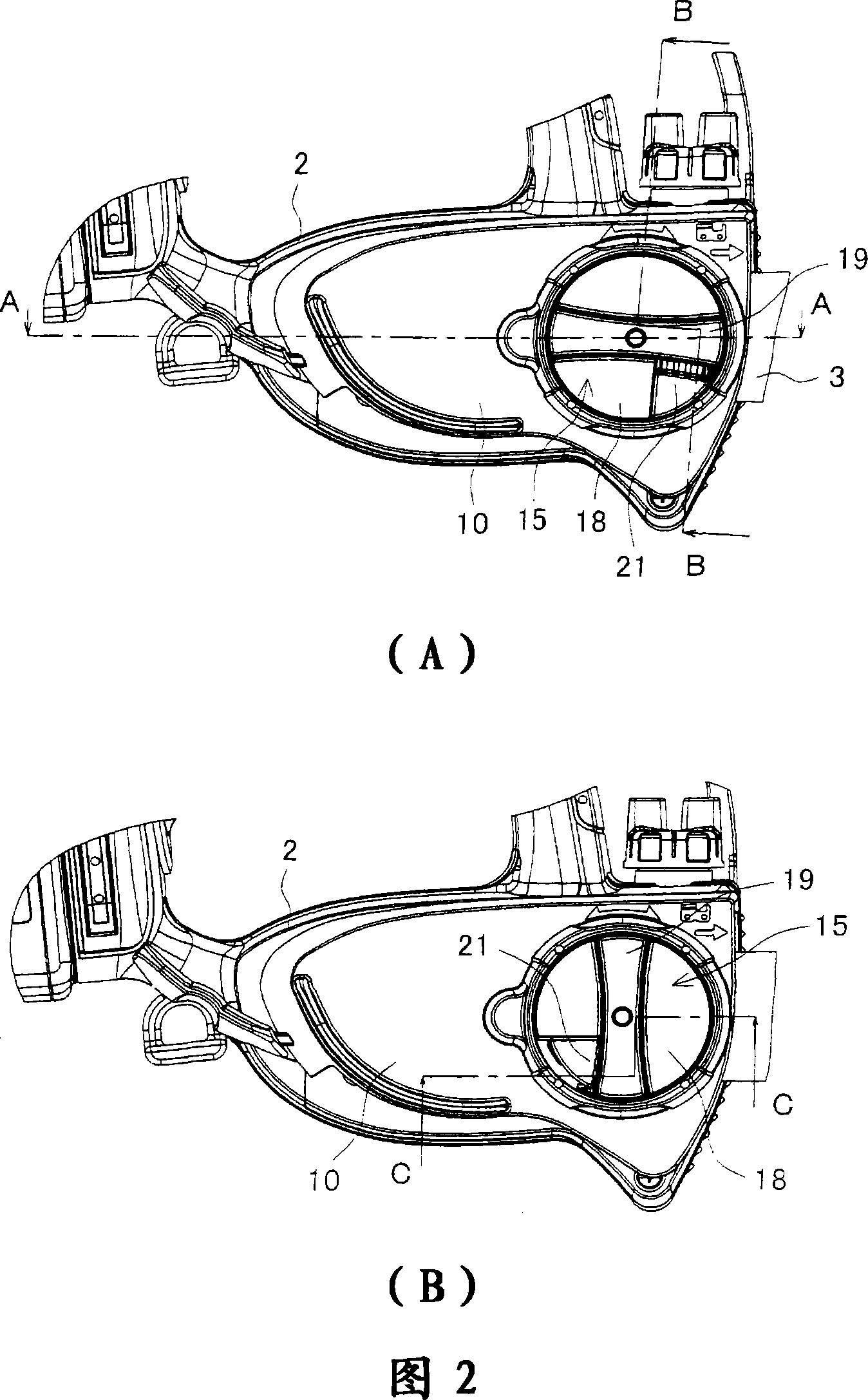

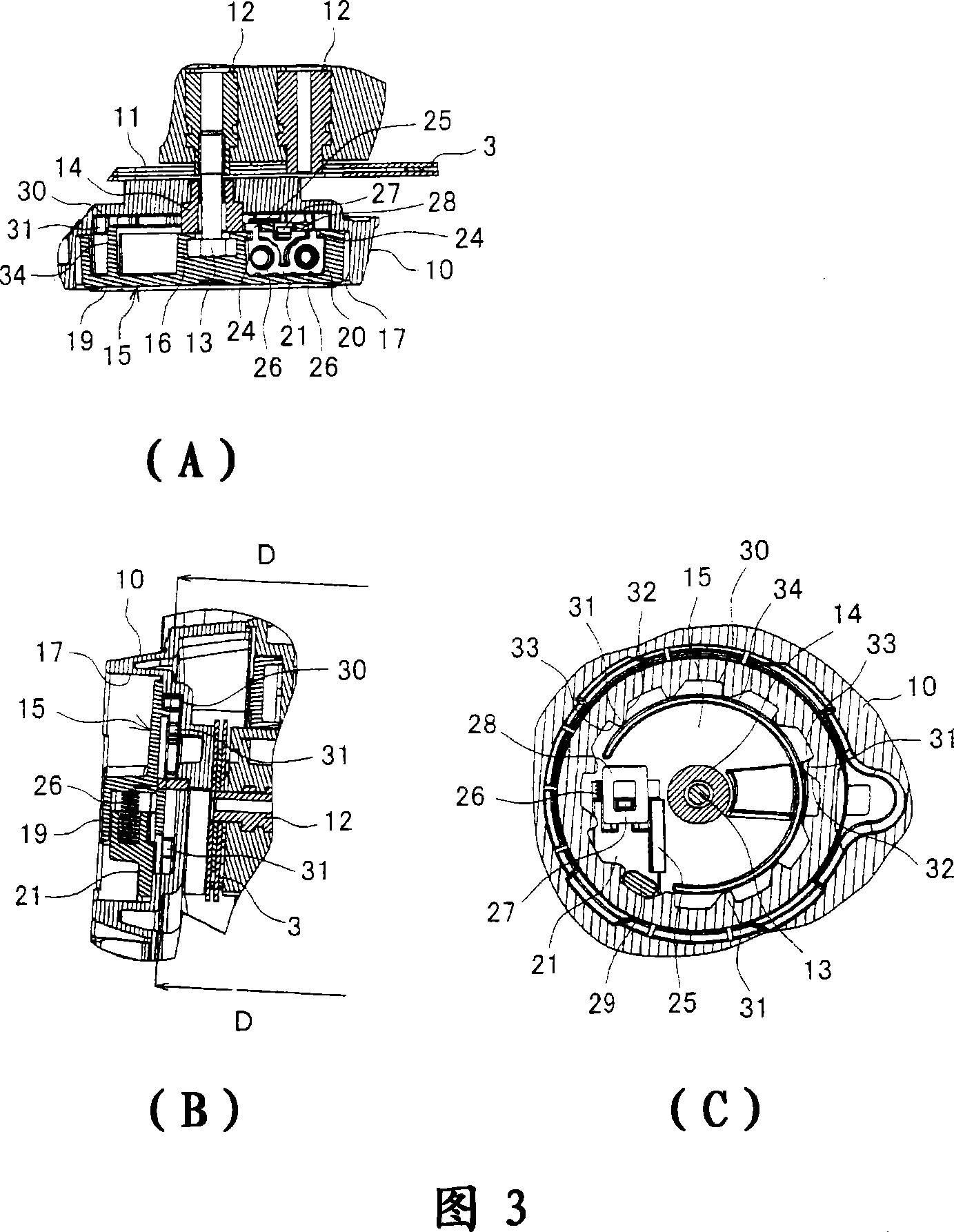

Link tooth saw

ActiveCN101134253ASimple fixed effectsSimple structureMetal sawing devicesChain sawsCoil springEngineering

The invention provides a chain saw for fixing and releasing fixtion of a guide plate through a simple operation. An operation handle (15) of the chain saw is used for fixing and releasing fixtion of a guide plate (3), which is provided with a lock knob (21) being in and out relative to the operation handle, under a normal state, the lock knob is loaded a force by a helical spring (26) in the protrudent direction of the operation handle, which is arranged at following position, at the position, the lock knob is pushed when gripping the operation handle, meanwhile, an accepting part (17) of theoperation handle is provided a plurality of protuberances (31, 31...), the protuberances allow the lock knob to slide when the operation handle is rotated to the fixing side of the guide plate (3), and limit the lock knob to slide when the operation handle is rotated to the fixtion releasing side of the guide plate, need to push the lock knob only when rotating the operation handle while releasing fixtion of the guide plate.

Owner:MAKITA CORP

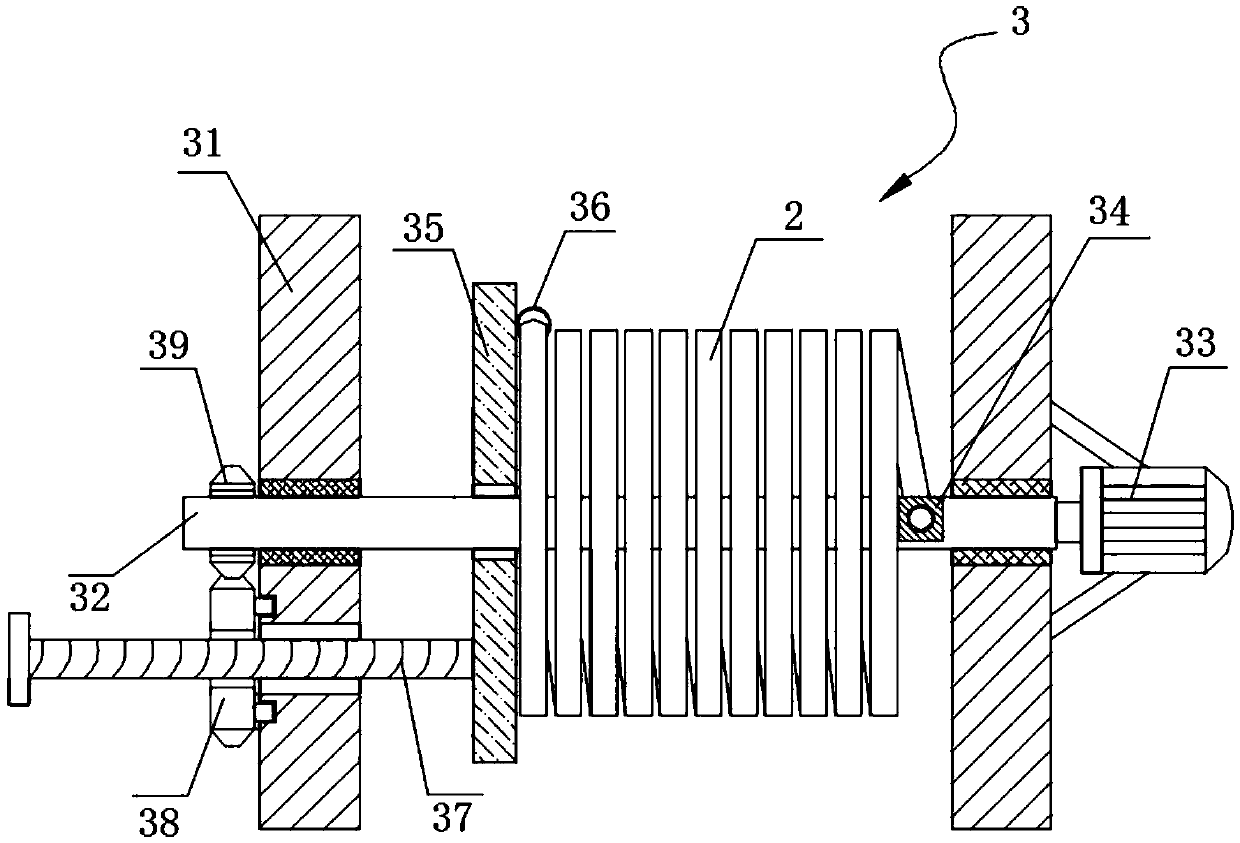

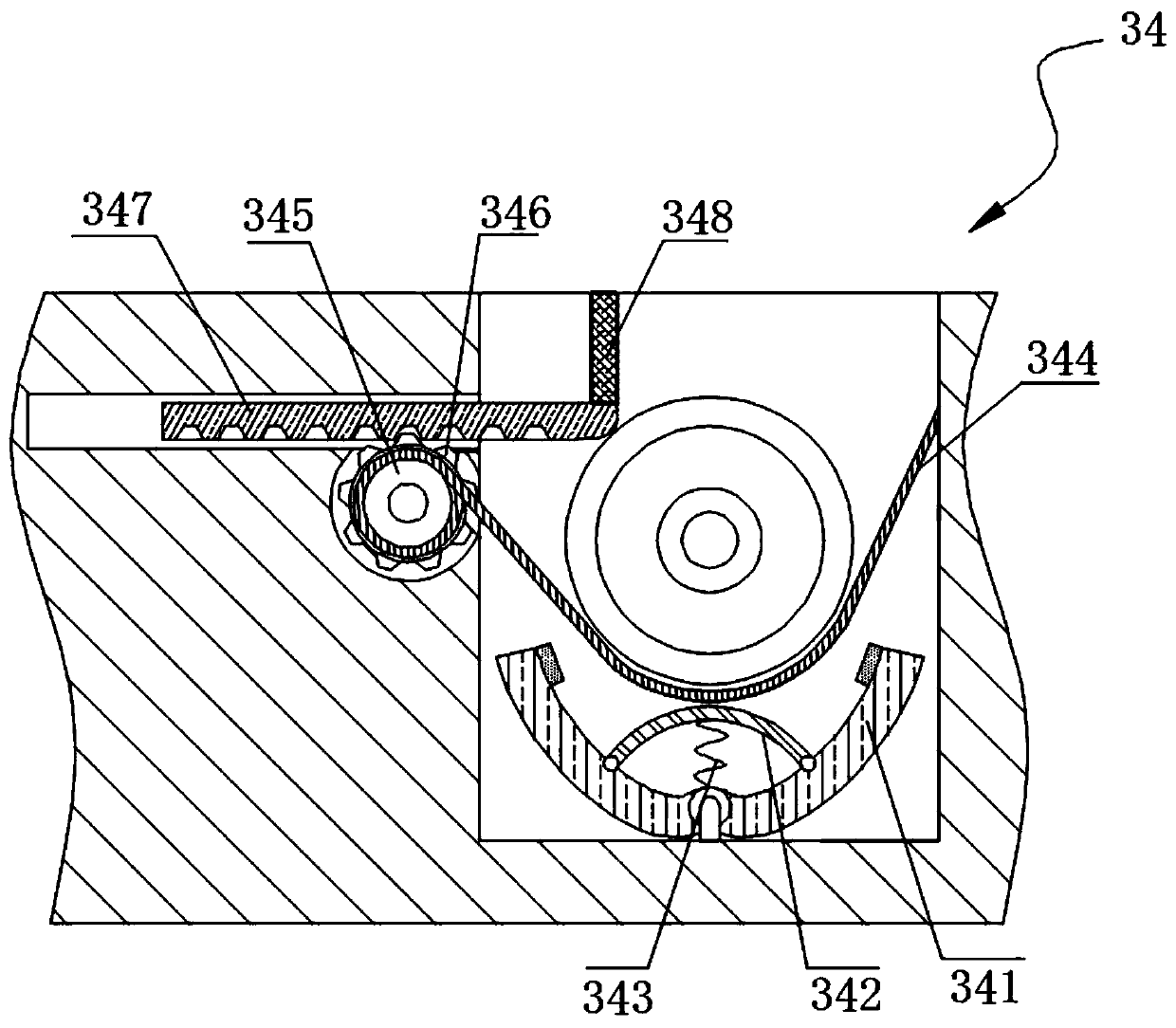

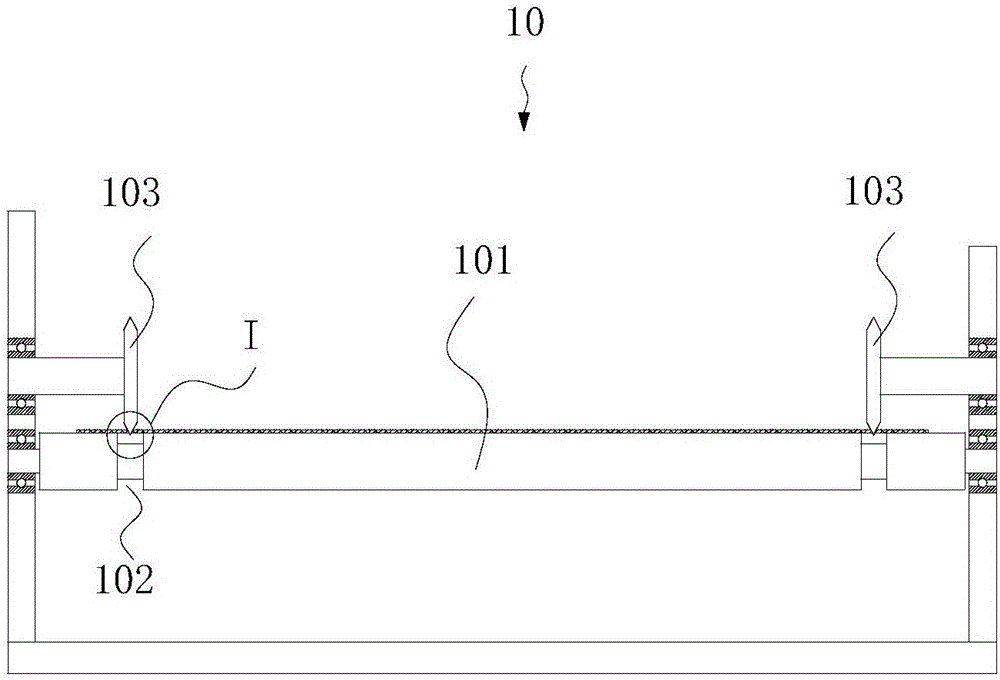

Linen strip damping unwinding mechanism

InactiveCN108861854AStable unwindingSmooth transmissionFilament handlingCircular discMechanical equipment

The invention discloses a linen strip damping unwinding mechanism and belongs to the field of textile processing mechanical equipment. An unwinding mechanism body of the linen strip damping unwindingmechanism is vertically arranged on one side of the upper portion of a fixed bracket. A strip pulling mechanism is arranged on the position, on the lower side of a strip conveying mechanism, of the fixed bracket. A roll-bearing rotary roller is horizontally and fixedly arranged in the middle of one side of a rotating disc. The two sides of the lower portion of a damping bracket are symmetrically and rotationally connected with damping rotary wheels correspondingly. A feeding press roller is horizontally arranged on one side of the upper portion of a strip conveying bracket. A strip guiding channel is horizontally formed in a strip guiding sleeve. The two ends of a strip-guiding press roller are rotationally connected to strip-pressing guiding plates on the two sides of the strip conveyingbracket correspondingly. A material-pulling rotary roller is horizontally and rotationally connected to a lifting bracket. A strip-bearing rotary roller is horizontally and rotationally connected to the position, on the lower side of the material-pulling rotary roller, of the fixed bracket. The linen strip damping unwinding mechanism is reasonable in structural design, linen strips can be stably and accurately unwound and conveyed efficiently, conveniently and rapidly, the unwinding and conveying efficiency and quality of the linen strips are improved, and the needs of production and use are met.

Owner:于星杰

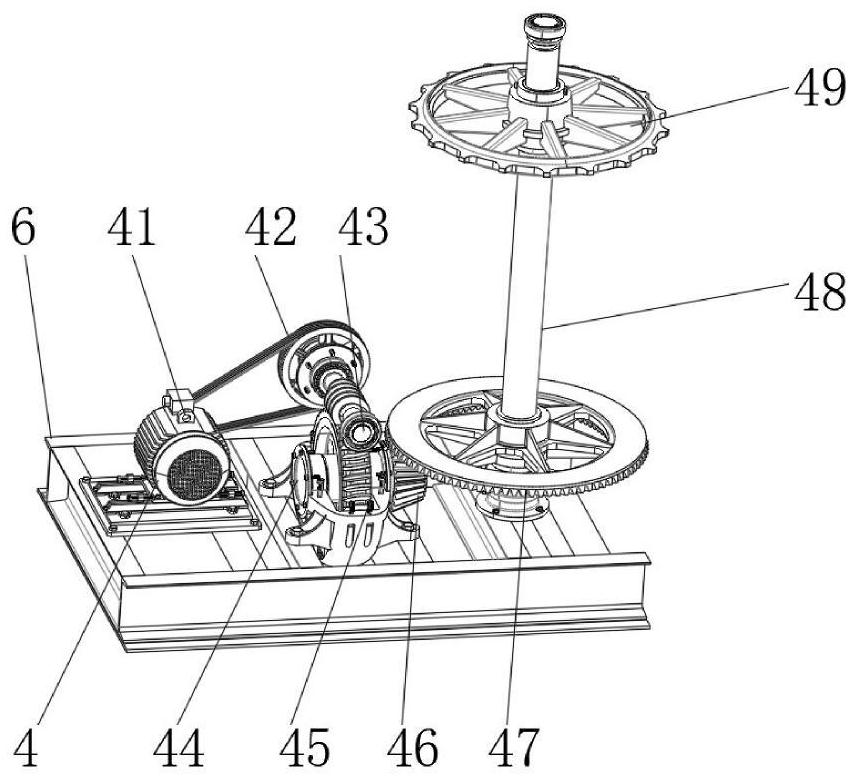

Yarn dyeing package winding device

InactiveCN103482412ASimple structureLow manufacturing costFilament handlingElectric machineryDrive motor

The invention discloses a bobbin package winding device special for use in yarn dyeing, and is suitable for filament yarn package winding for use in dyeing. A special yarn package winding device is designed by improving a progressive precision winding way, so that the special bobbin dyeing requirements of certain special yarns, such as fine denier cellulose filament yarns can be met. The winding device consists of a winding bobbin, an unwinding bobbin, a winding guide roller, a reciprocating shaping rod, yarn guides, a shaping guide roller, two driving motors and a transverse variable-speed shaping rod control system. Transverse speed change of the shaping rod is completed by regularly controlling the rotating speed of the shaping guide roller via a preset program; the control system is simple in structure; a plurality of yarn guides can be arranged on the shaping rod, so that multi-spindle synchronous control of the entire device can be realized by using one shaping guide roller, and the manufacturing cost of the entire device is reduced effectively.

Owner:SUZHOU VOCATIONAL UNIV

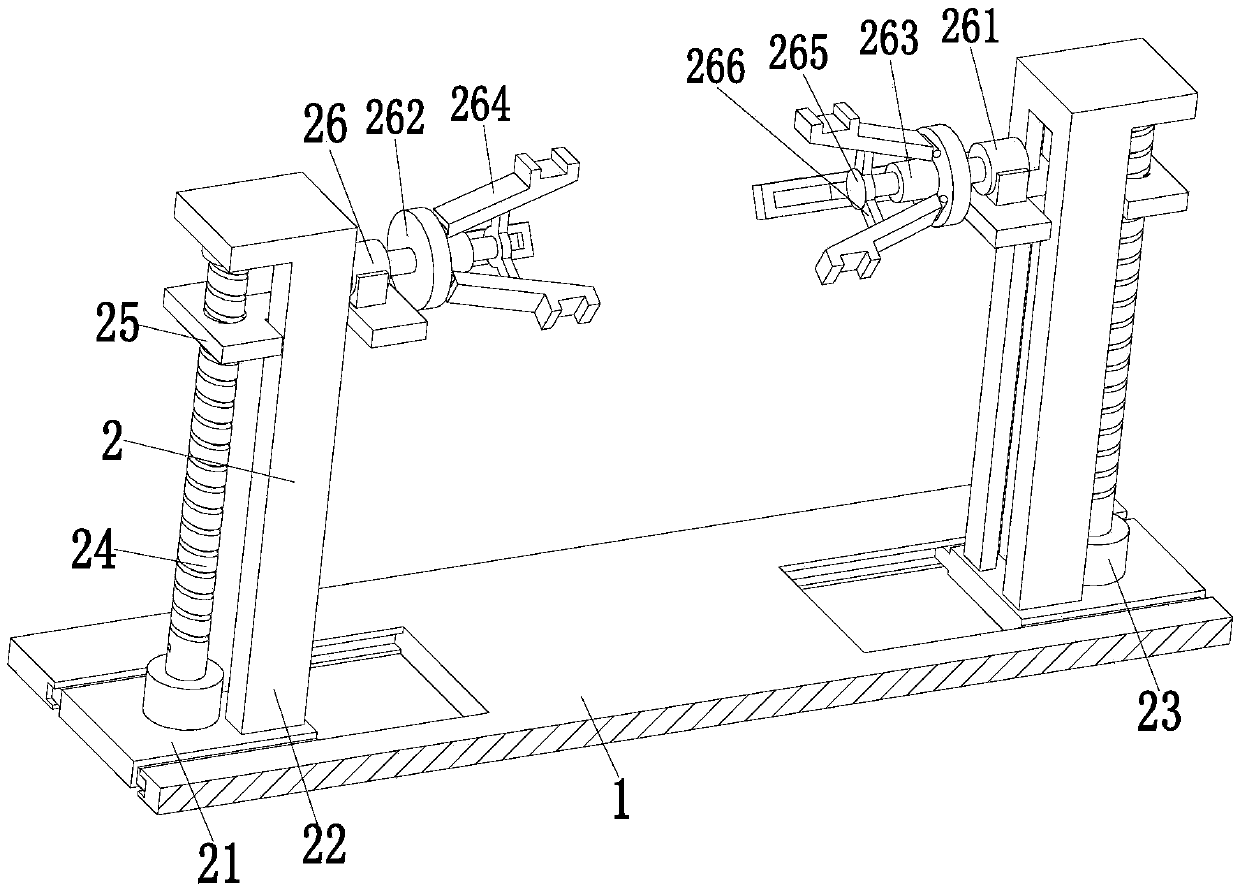

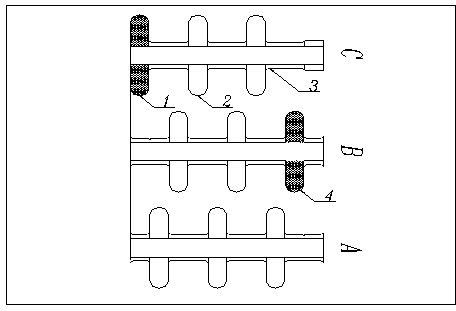

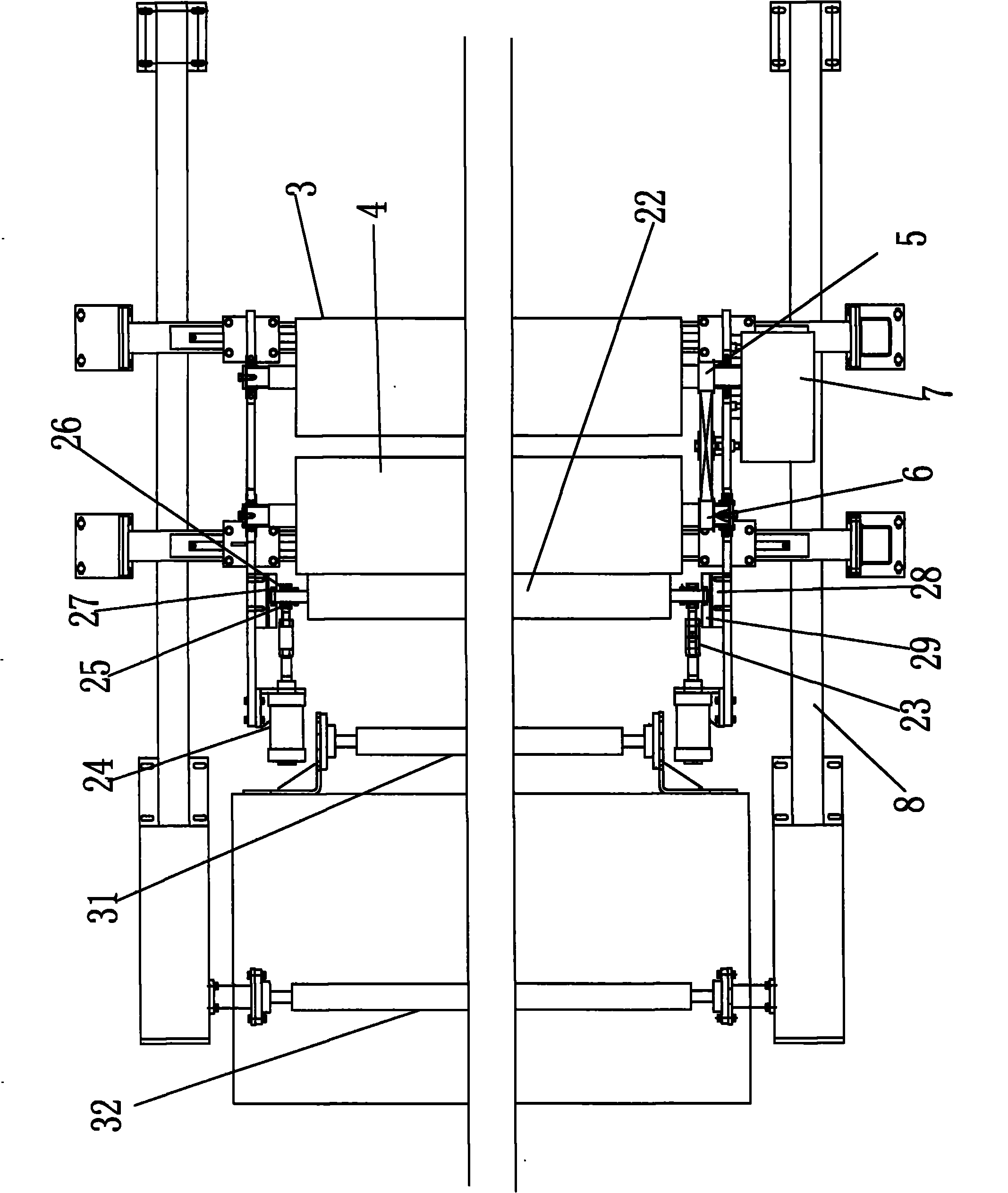

Unwinding device for warp knitting machine

The invention discloses an unwinding device for a warp knitting machine. The unwinding device for the warp knitting machine comprises a fixed frame, a cross beam and an unwinding device, wherein the unwinding device is arranged on the cross beam; the frictionally unwinding device comprises a driving unwinding roll, a driven unwinding roll, a driving synchronous belt wheel and a driven synchronous belt wheel; the driving synchronous belt wheel is used for controlling the rotation of the driving unwinding roll; the driven synchronous belt wheel is used for controlling the rotation of the driven unwinding roll; the driving synchronous belt wheel and the driven synchronous belt wheel are connected with a motor driving device; and the driving unwinding roll and the driven unwinding roll are arranged on an unwinding roll fixing plate. The unwinding device for the warp knitting machine has the advantages of guaranteeing the constant-speed unwinding of a cloth roll during unwinding, adjusting the position of cloth conveniently, pressing the unwound cloth flatly and improving the knitting quality of the warp knitting machine.

Owner:CHANGZHOU DIBA TEXTILE MACHINERY

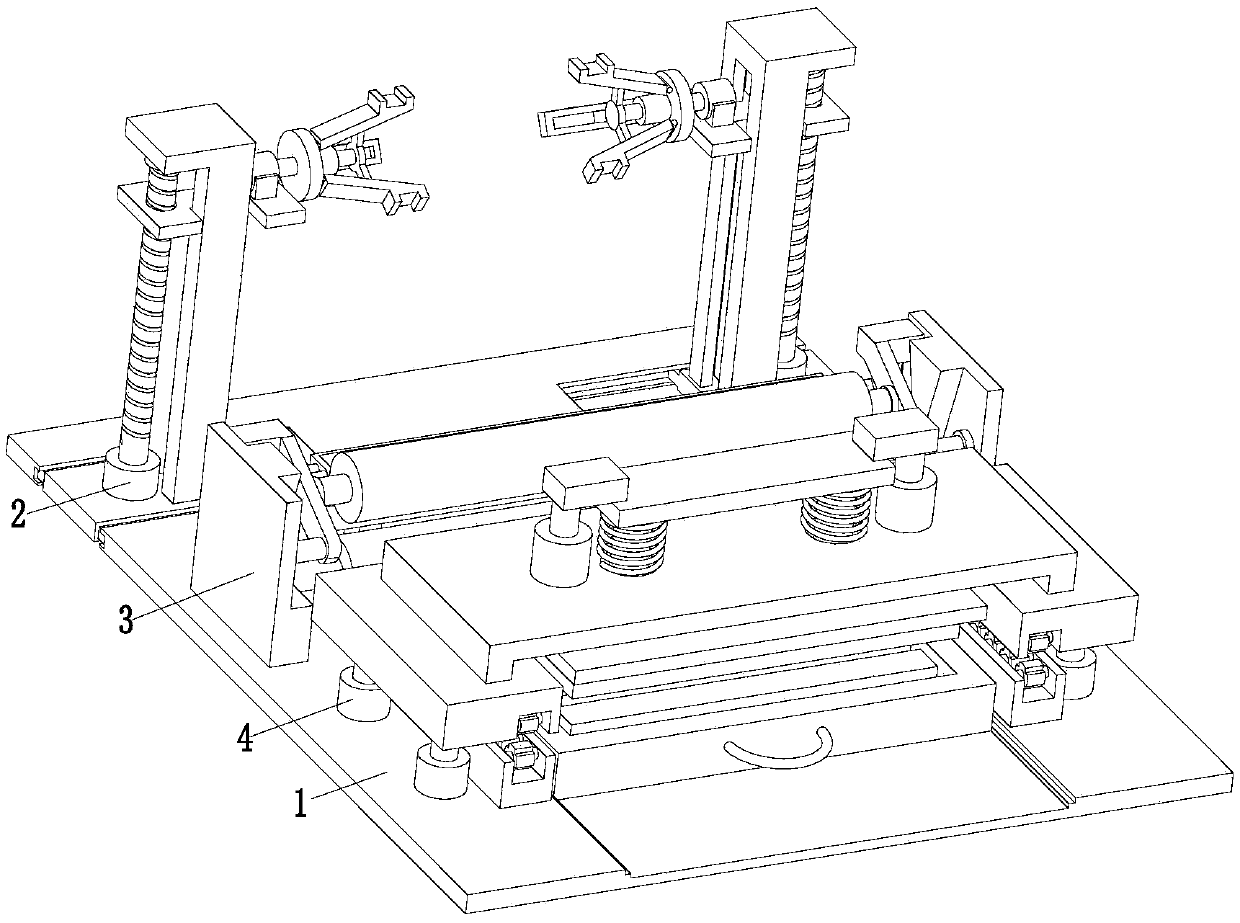

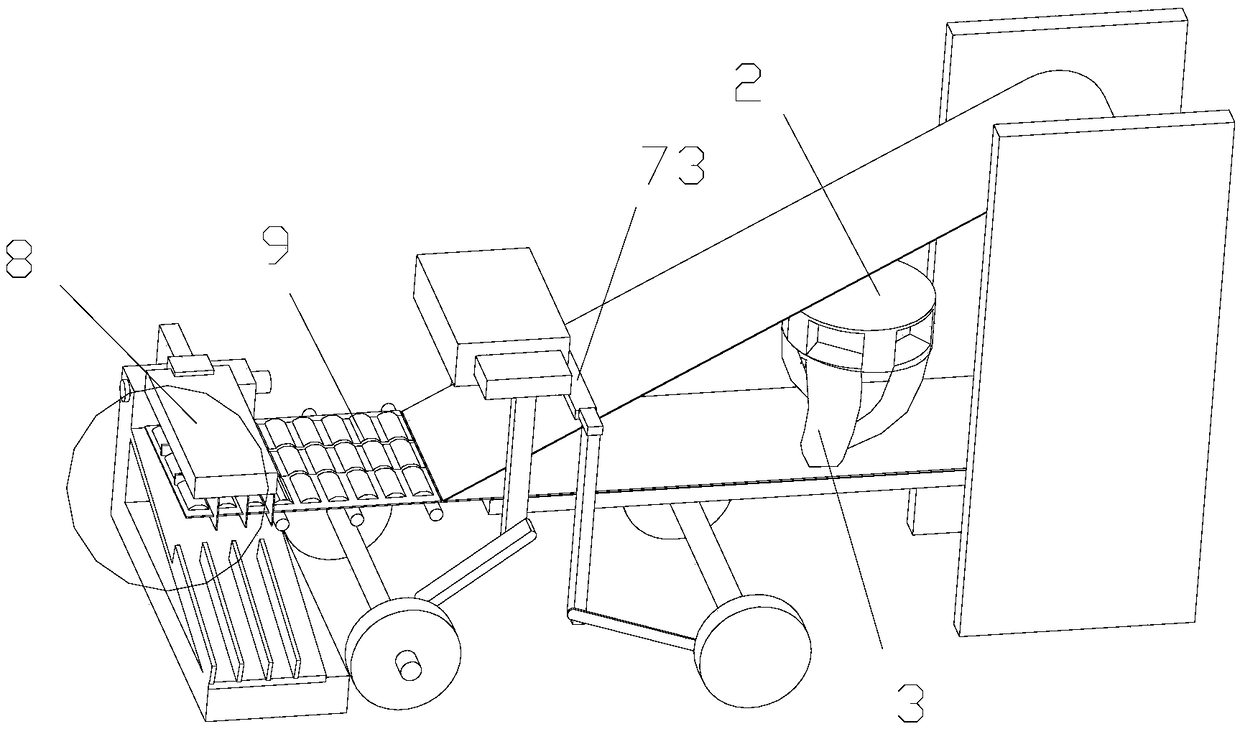

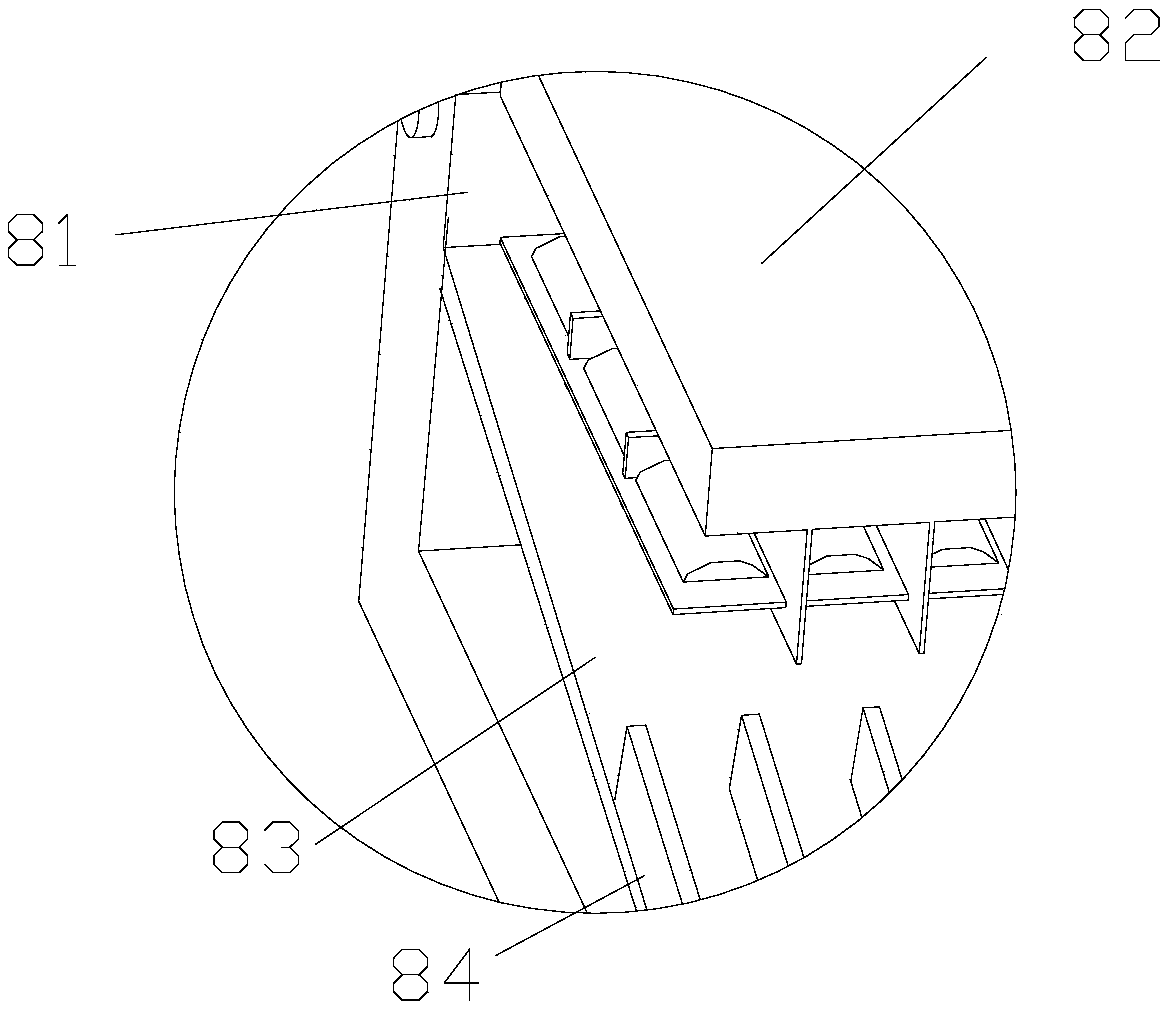

Laminating and stacking equipment for metal plates

ActiveCN111070853AImprove flatnessAvoid damageLamination ancillary operationsLaminationStructural engineeringMechanical engineering

The invention provides laminating and stacking equipment for metal plates, and belongs to the technical field of metal plate processing. The laminating and stacking equipment comprises a film laminating device and a stacking device, the film laminating device comprises a film laminating guide mechanism, a film laminating mechanism and a film cutting mechanism; the film laminating guide mechanism comprises a laminating feeding guide roller and a laminating discharging guide roller; the laminating mechanism is arranged between the laminating feeding guide roller and the laminating discharging guide roller; the film cutting mechanism is arranged on one side of the film laminating mechanism; the stacking device comprises a stacking supporting mechanism, a stacking carrying mechanism and a stacking limiting alignment mechanism, a tray of the stacking supporting mechanism is placed on the stacking supporting table, the stacking carrying mechanism comprises a left stacking carrying assembly and a right stacking carrying assembly, and the left stacking carrying assembly and the right stacking carrying assembly are symmetrically arranged on the two sides of the stacking supporting mechanism. The metal plates can be automatically stacked after being laminated, metal plates are stacked in order, the labor intensity of workers is greatly reduced, and personal injuries to the workers are effectively avoided.

Owner:ZHEJIANG HUASHUN METAL MATERIAL CO LTD

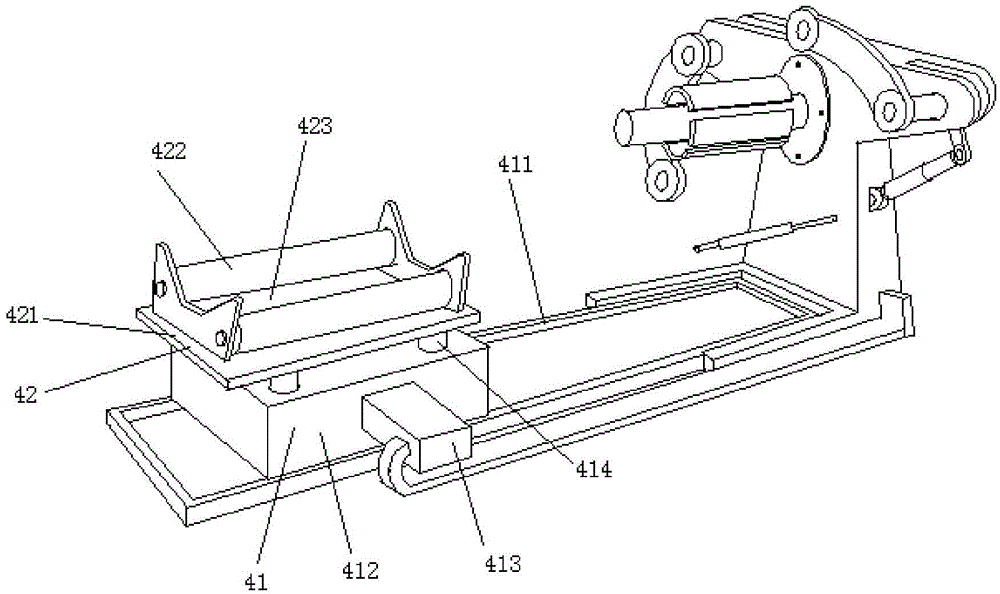

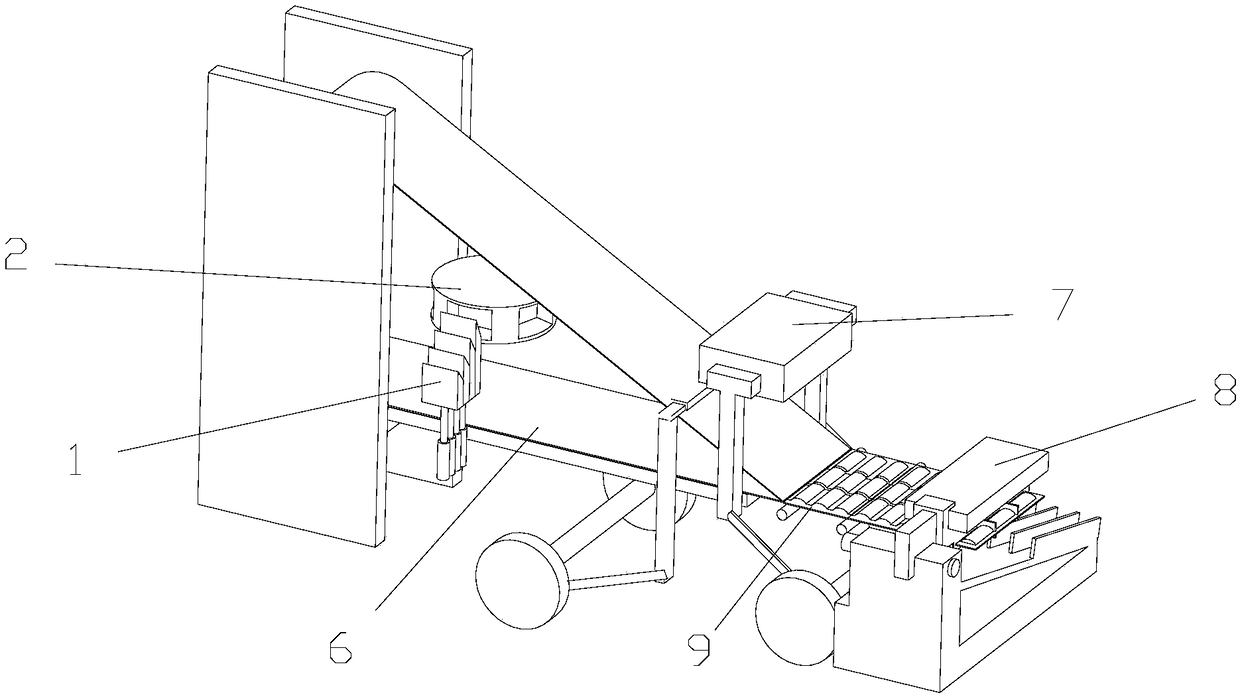

Plate uncoiler and matched equipment

The invention provides a plate uncoiler and matched equipment. The plate uncoiler comprises a frame body, an uncoiling device and a feeding device. The frame body comprises a base frame and a vertical frame, the vertical frame is located on the base frame, and the vertical frame and the base frame are perpendicularly arranged. The feeding device comprises a material pressing mechanism, a first feeding mechanism and a second feeding mechanism. The material pressing mechanism and the first feeding mechanism are located on the two sides of the uncoiling device respectively, and the second feeding mechanism is located below the material pressing mechanism. A coiling device comprises a sliding mechanism and a supporting mechanism, and a motor supplies power to the sliding mechanism. The plate uncoiler and the matched equipment have the advantages that the uncoiler of the structure is stable in feeding, the drooping problem of plates in the feeding process is solved, and the coiling device which is matched with the plate uncoiler for use is high in degree of automation and convenient to use.

Owner:TIANJIN SHENYUAN KAILI GRP CO LTD

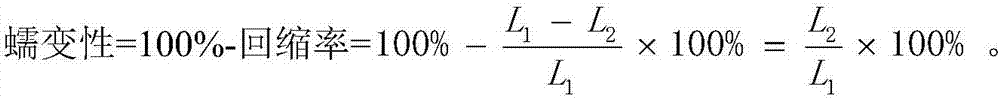

Spandex with improved backing-off property and creep property for paper diaper and production method thereof

ActiveCN107502978AImprove unwindingImprove creepMonocomponent synthetic polymer artificial filamentArtifical filament manufactureUreaMagnesium stearate

The invention discloses a spandex with improved backing-off property and creep property for a paper diaper and a production method thereof. Thermoplastic polyurethane which accounts for 3-35% of the spandex by weight percent and cellulose acetate butyrate or cellulose acetate propionate which accounts for 0.5-2.0% of the spandex by weight percent or a mixture of the two, as well as an internal lubricant and external lubricant composition which accounts for 0.3-5.0% of the spandex by weight percent, are added into a polyurethane-urea stock solution, and drying spinning is performed to prepare a polyurethane elastic fiber, wherein an internal lubricant is one or more of n-butyl stearate, oleamide, ethylene bis stearamide and amino silicon oil; and an external lubricant is one or more of talcum powder, carbon monofluoride and magnesium stearate. The prepared spandex has favorable backing-off property and creep property, can be effectively applied to the field of elastic materials of paper diapers, and meanwhile, is suitable for two modes of rotary backing off and axial backing-off.

Owner:ZHEJIANG HUAFENG SPANDEX

Winding device for 3D printing consumable processing

The invention discloses a winding device for 3D printing consumable processing. A base is included. A mounting box is fixed to one side of the base. A shaking mechanism is arranged in the mounting box. The shaking mechanism is connected with a mounting frame. Sliding blocks are fixed to two sides of a lower end of the mounting frame. A lower side of each sliding block is slidably connected with aguide rail. The guide rail is fixed on the base. A first motor is fixed to a bottom end of an internal portion of the mounting frame through a bolt. A rotating shaft is fixed to an end portion of an output shaft of the first motor through a coupler. The rotating shaft penetrates through a front side of the mounting frame and extends to an outer side. A wire roller sleeves the rotating shaft, a threaded rod is integrally formed at one end, away from the first motor, of the rotating shaft, and a nut is fixedly connected to the threaded rod in a threaded mode so that wire rods are evenly and sequentially wound on the wire roller, the wire rods are prevented from being wound on the wire roller disorderly, smoothness of subsequent wire rod unwinding is guaranteed, and working efficiency is improved.

Owner:安徽三绿科技股份有限公司

Orderly-arranging and in-batch-bagging mechanism and in-batch bagging method after broiled-sliced-eel broiling

ActiveCN109229536AImplement interval feedingImprove work efficiencyWrappingPackaging foodstuffsCircular discEngineering

The invention discloses an orderly-arranging and in-batch-bagging mechanism after broiled-sliced-eel broiling. The orderly-arranging and in-batch-bagging mechanism comprises a rubbing plate assembly,a rotary feeding disc, guiding pipes, an upper thin-film feeding roller, a lower thin-film feeding roller, a working platform, a lifting hot pressing part, a cutting discharging device and a conveyingplatform. The rotary feeding disc comprises a disc body, feeding bins are arranged on the lateral side of the disc body, and discharging openings are formed in the bottoms of the feeding bins respectively and controlled by valves to be opened or closed. The rubbing plate assembly is used for feeding broiled sliced eels into the corresponding bins in batches; the working platform is located belowthe guiding pipes. Projections of discharging openings of the guiding pipes in the vertical direction are arranged into a matrix structure; the lifting hot pressing part is used for hot pressing an upper-layer thin film and a lower-layer thin film into a plurality of bag structures. The cutting discharging device is arranged behind the conveying platform. The invention further discloses an in-batch-bagging method after broiled-sliced-eel broiling. The orderly-arranging and in-batch-bagging mechanism and the in-batch-bagging method have the advantages that multiple groups of the broiled slicedeels can be automatically and orderly arranged and bagged at the same time.

Owner:福建铭发水产开发有限公司

Automatic cable storage reel

Owner:天长市运成电缆辅料有限公司

Centrifugal printing cloth unwinding mechanism

InactiveCN108910588AGuaranteed tensionImprove unwinding qualityWebs handlingMechanical engineeringBrake force

The invention relates to the technical field of printing cloth roll unwinding, in particular to a centrifugal printing cloth unwinding mechanism. A top rod is inserted in a supporting cylinder, the lower end of the top rod is connected with the bottom end of an inner chamber of the supporting cylinder through an abutting spring, the upper end of the top rod is provided with a metering roller, andthe metering roller abuts against a printing cloth roll on the upper side. When stopping is performed, a traction disappears, resistance is provided under the action of a pressing plate, a roller stops, a telescopic rod is taken back under the action of a returning spring, and a top plate moves downwards; under the action of the gravity of the top plate and a brake rod, a friction plate presses abrake wheel to perform braking, so that the rotation of the printing cloth roll caused by inertia is prevented, a tightened state of a printing cloth is ensured, the unwinding quality is improved, sothat the pressing plate provides resistance to ensure unwinding stability; when stopping is performed, the pressing plate performs braking, at the same time a braking force is provided for a right rotating shaft, so that the printing cloth between the roller and the printing cloth roll keeps a tightened state and does not loosen, and an effect is better by the combination of the two.

Owner:太仓市霍普思机械技术有限公司

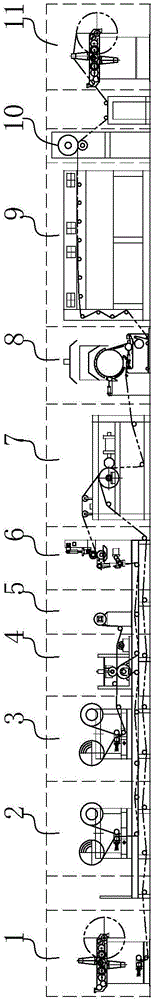

Wall cloth transfer-printing and embossing processing system

ActiveCN106739452AStable winding and unwindingRewinding and unwinding are smoothTransfer printingLamination ancillary operationsProduct patternEngineering

The invention relates to the field of wall cloth production and provides a wall cloth transfer-printing and embossing processing system. The wall cloth transfer-printing and embossing processing system aims at achieving the effects that the automation degree is high, and product quality is good. According to the technical scheme, the wall cloth transfer-printing and embossing processing system comprises a gauze unrolling device, a thin film unrolling device, a transfer-printing film unrolling device, a transfer-printing device, a transfer-printing film withdrawing device, an adhesive application device, an attachment device, a heating and embossing device, a drying device, an edge cutting device and a rolling device, wherein the gauze unrolling device, the thin film unrolling device, the transfer-printing film unrolling device, the transfer-printing device, the transfer-printing film withdrawing device, the adhesive application device, the attachment device, the heating and embossing device, the drying device, the edge cutting device and the rolling device are sequentially arranged in a linear manner. According to the wall cloth transfer-printing and embossing processing system, the transfer-printing film printing technology is adopted; processed wall cloth product patterns are formed integrally; the process is simple; no color difference is generated; and efficiency is high. Compared with the traditional mode that multiple printing machines are adopted for conducting pattern printing, on one hand, equipment cost is lowered, and energy is saved; and on the other hand, the production cycle is shortened, and wall cloth production efficiency is improved.

Owner:ANHUI BAUHINIA WALLPAPER

Novel cloth embossing machine

The invention relates to a novel cloth embossing machine. The machine comprises a rack, and an unwinding roller, a pre-processing device, an embossing box, an after-processing device and a rewinding mechanism are installed on the rack. The novel cloth embossing machine has the advantages that through pre-processing of dust removal, static removal and tension adjustment, heating of an ultrasonic generator and a traction effect of the rewinding mechanism, it is kept that cloth is stably unwound in the embossing process and the texture is clear; a PLC senses a signal of the thickness, detected through a sensor, of cloth on a conveying belt, on the basis of detection data of the PLC, the height of a supporting rail is adjusted through a height adjustment device, and it is guaranteed that the supporting rail can meet the use requirements of cloth different in thickness; the PLC senses the signal of the contact sensor so that an embossing detection block can clearly detect embossing of the cloth in the lifting process of a lifting air cylinder, it is guaranteed that the embossing can be clearly seen on a touch control display screen, and accordingly the high-quality detection effect is achieved.

Owner:广东南豆科技有限公司

Spinning oil for fine-denier melt-spun spandex fiber

The invention discloses spinning oil for a fine-denier melt-spun spandex fiber. The oil comprises the following components by weight percentage: 30-60% of dimethyl silicon oil, 30-50% of modified silicone oil, 0-10% of nonionic surfactant and the balance of other additive, wherein the modified silicone oil is amino modified silicone oil or polyether modified silicone oil; polysiloxane chain segments m and n in the amino modified silicone oil are equal to 30-120; an adduct number b of polyoxyethylene chain segments in the polyether modified silicone oil is equal to 0-10; an adduct number a of polyoxypropylene chain segments is equal to 0-10; the nonionic surfactant is fatty alcohol polyoxyethylene ether, fatty alcohol polypropylene oxide ether or fatty alcohol polyoxyethylene polyoxypropylene ether; and other additive is phosphate potassium salt of alkyl alcohol polyoxyethylene ether.

Owner:TIANJIN POLYTECHNIC UNIV +1

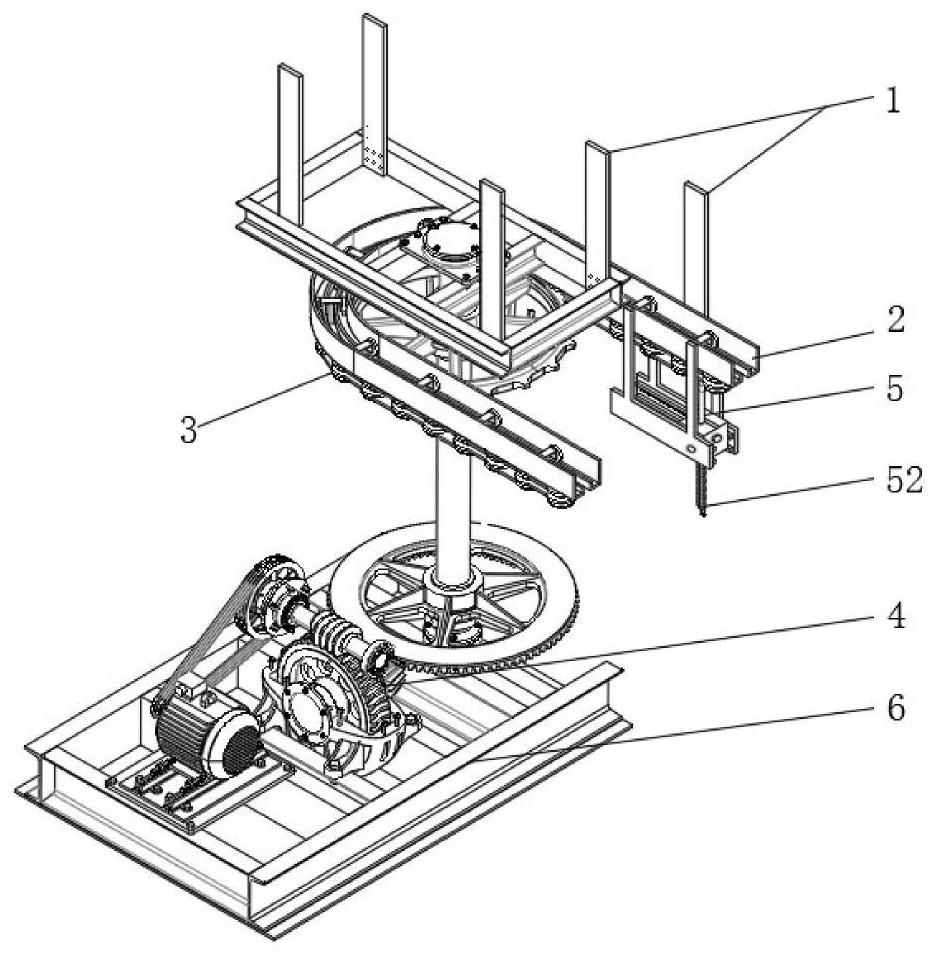

Intelligent suspension conveying system and method based on vision measurement

InactiveCN113173392AFlexible locationIncrease flexibilityMechanical conveyorsEngineeringPower apparatus

The invention relates to an intelligent suspension conveying system and method based on vision measurement, and belongs to the technical field of automatic logistics. The intelligent suspension conveying system comprises a mounting shaft, double rails, a conveying mechanism, a power device and a lifting mechanism, wherein the mounting shaft is used for fixing a suspension conveying device and a power device fixedly mounted on a base; the double rails are fixedly suspended through the mounting shaft; the conveying mechanism is connected to the double rails in a sliding manner; a chain is arranged on the conveying mechanism and is used for connecting the power device and the conveying mechanism; the top end of the power device is fixed through the mounting shaft and is arranged on the base; the lifting mechanism is fixedly mounted on the conveying mechanism; and the lifting mechanism is composed of a reversing mechanism and a winding mechanism, the reversing mechanism is matched with a plurality of sets of reversing rails installed on the double rails, and the winding mechanism is used for winding or unwinding a rope according to the actual working condition. The intelligent suspension conveying system can be installed at the high position of a workshop, the conveying height can be adjusted, curve rail conveying can be achieved, and meanwhile shaking generated when materials are conveyed at the high position is avoided.

Owner:NANJING XUANSHI QIYUAN SOFTWARE TECH CO LTD

Production method of low boiling water contraction rate polyester fiber drafting textured filament yarn

ActiveCN100489168CLow boiling water shrinkageAchieve the purpose of the inventionYarnContraction rateEngineering

The present invention relates to drafting deformed dacron filament with low boiling water shrinkage and its production process and application. The POY material filament is processed successively through the first drafting roller, the first heating box, cooling plate, false twisting unit, the second drafting roller, network forming unit, 2bis roller, the second heating box, filament guide unit and filament breaking detector; adding weak network in the resilience increasing process; oiling and winding steps to obtain DTY filament. The present invention has lower deformation temperature, higher settling temperature, short process, reasonable technological control and stable production operation; and the product has boiling water shrinkage not higher than 1.0%, excellent built-in curling elasticity and wrapping. The product may be used in making embroidery string and trademark string.

Owner:SINOPEC OILFIELD SERVICE CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com