Biaxial stretching polypropylene 9 mu m ultra thin type compound film and method of preparing the same

A biaxially stretched, polypropylene technology, applied in the field of packaging materials, can solve the problems of reducing the elastic modulus, stiffness, and product performance of the composite film that cannot meet the requirements for use, affecting the anti-blocking and anti-static effects of the film, and saving Effect of processing material, high elastic modulus, high gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

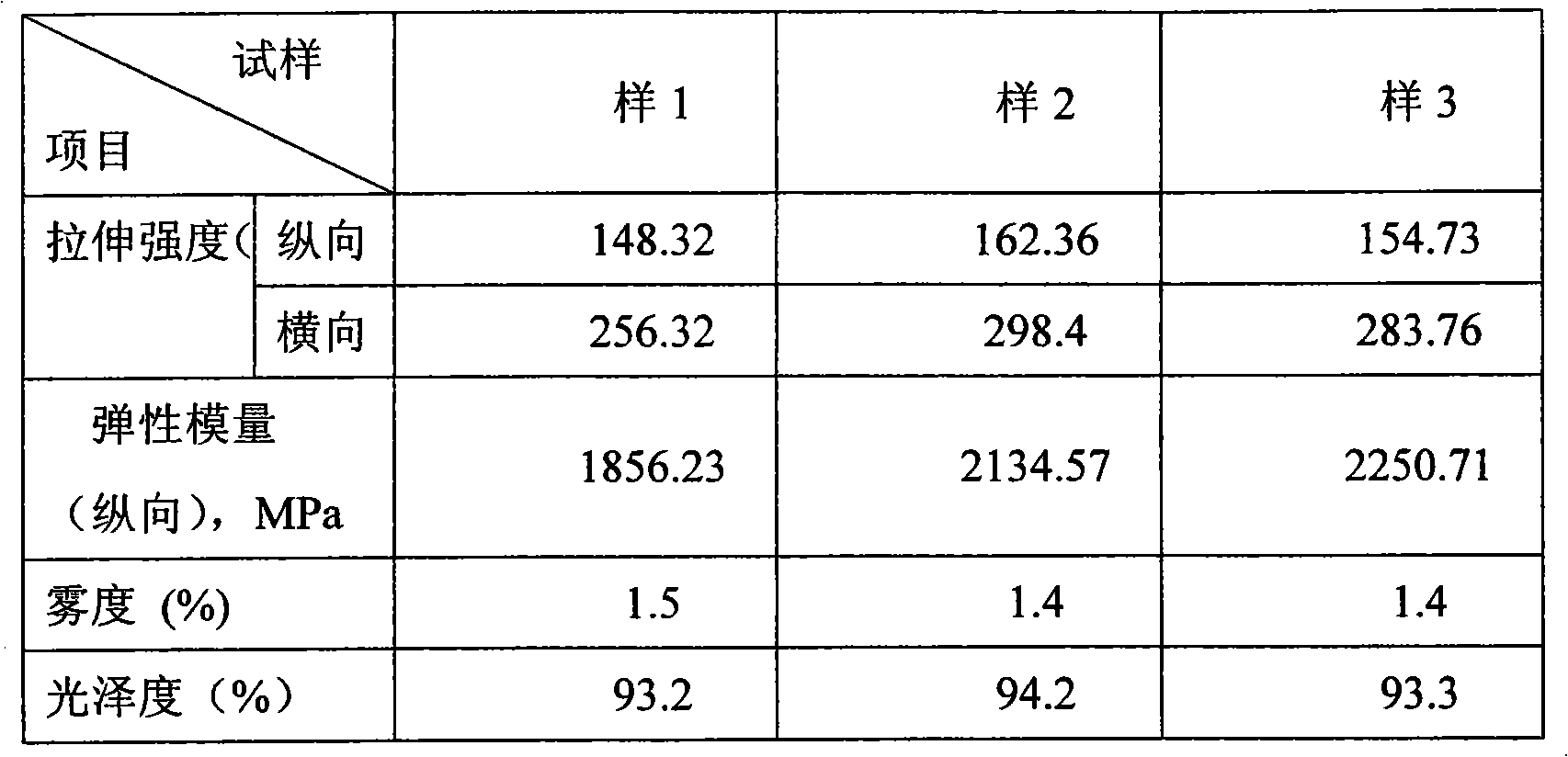

Examples

Embodiment 1

[0017] 1) Ingredients

[0018] Upper surface layer and lower surface layer: weigh 96.5kg of homopolypropylene and 3.5kg of cross-linked methyl acrylate.

[0019] Middle layer: take 91.6kg of homopolypropylene, 8.0kg of C9 hydrogenated petroleum resin, 0.2kg of alkyl (C14-18) bis(2-hydroxyethyl)amine and 0.2kg of oleic acid amide 0.1-0.3%.

[0020] 2) Extrude thick slices

[0021] 3) cast piece

[0022] 4) Longitudinal stretching

[0023] The longitudinal stretching is 4.50 times, during the longitudinal stretching process, the preheating temperature is 130-140°C, and the stretching temperature is 120-130°C.

[0024] 5) Horizontal stretch

[0025] The transverse stretching is 7.80 times. During the transverse stretching process, the preheating temperature is 160-170°C, and the stretching temperature is 150-160°C.

[0026] 6) Rewinding.

Embodiment 2

[0028] 1) Ingredients

[0029] Upper surface layer: weigh 96.0kg of homopolypropylene and 4.0kg of cross-linked methyl acrylate.

[0030] Lower surface layer: weigh 97.0kg of homopolypropylene and 3.0kg of cross-linked methyl acrylate.

[0031] Middle layer: Weigh 92.6kg of homopolypropylene, 7.0kg of C9 hydrogenated petroleum resin, 0.1kg of oleic acid amide and 0.3kg of alkyl (C14-18) bis(2-hydroxyethyl)amine.

[0032] 2) Extrude thick slices

[0033] 3) cast piece

[0034] 4) Longitudinal stretching

[0035] The longitudinal stretching ratio is 4.80, during the longitudinal stretching process, the preheating temperature is 130-140°C, and the stretching temperature is 120-130°C.

[0036] 5) Horizontal stretch

[0037] The transverse stretching ratio is 7.50. During the transverse stretching process, the preheating temperature is 160-170°C, and the stretching temperature is 150-160°C.

[0038] 6) Rewinding.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com