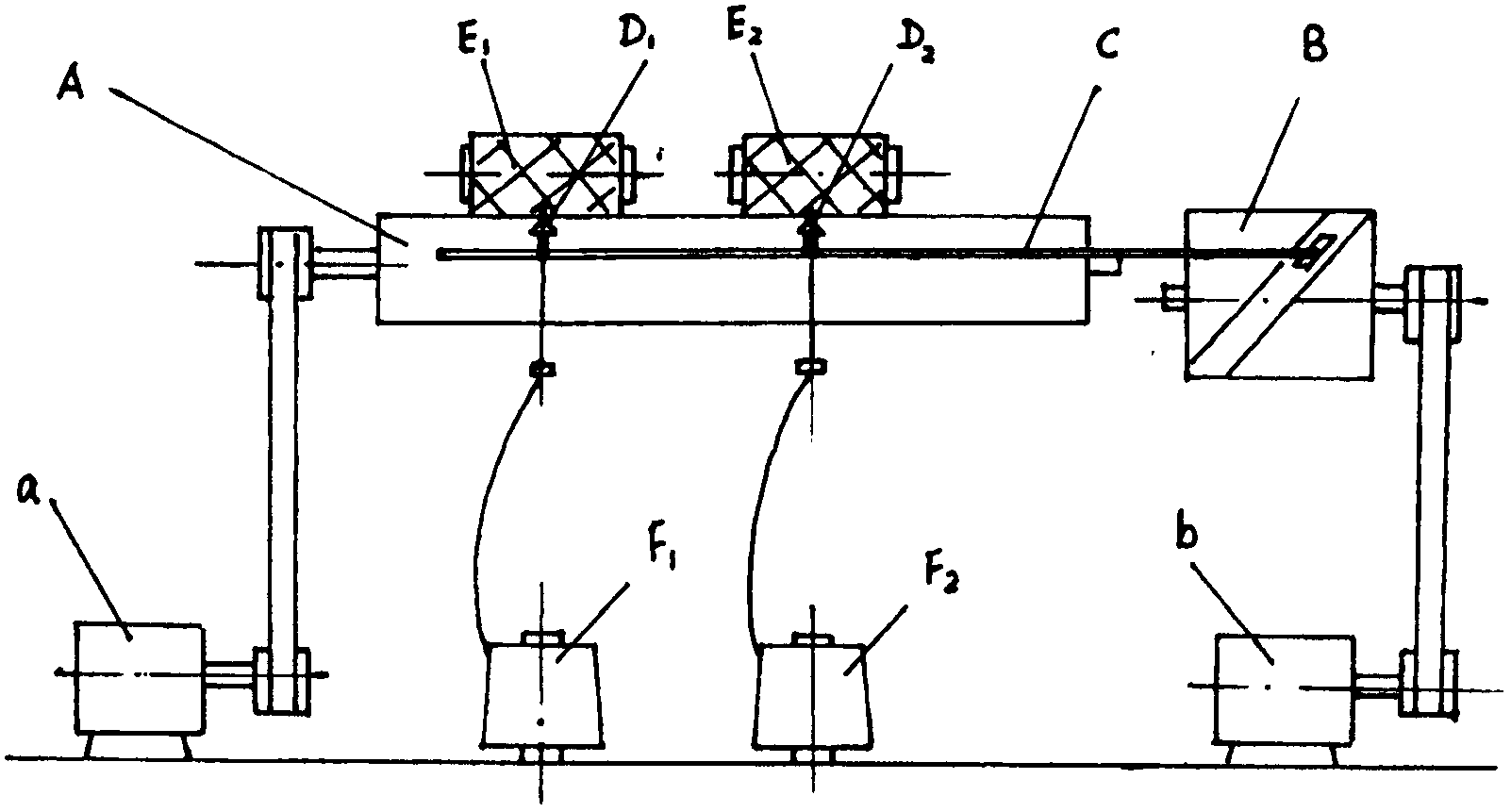

Yarn dyeing package winding device

A yarn dyeing and winding technology, which is applied in the directions of transportation and packaging, delivery of filamentous materials, thin material processing, etc., can solve the problems of high purchase cost and high manufacturing cost of the whole machine, achieve simple structure and reduce the manufacturing cost of the whole machine Cost, good practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0009] Design starting winding angle: 18 degrees

[0010] Coiler bobbin diameter: 64mm; full bobbin diameter: 140mm

[0011] Winding surface line speed of take-up bobbin: 350m / min

[0012] Winding yarn: 120D viscose rayon

[0013] Winding section setting: 4 sections

[0014] Yarn guiding speed of each winding section: 114m / min-100m / min

[0015] The stage time setting of the uniform deceleration of the forming guide wheel in each winding section:

[0016] The first section: 34min; the second section: 41min; the third section: 45min; the fourth section: until the container is full.

Embodiment 2

[0018] Design starting winding angle: 18 degrees

[0019] Coiler bobbin diameter: 64mm; full bobbin diameter: 140mm

[0020] Winding surface line speed of take-up bobbin: 350m / min

[0021] Winding yarn: 68D polyester filament

[0022] Winding section setting: 4 sections

[0023] Yarn guiding speed of each winding section: 114m / min-100m / min

[0024] The stage time setting of the uniform deceleration of the forming guide wheel in each winding section:

[0025] The first section: 50min; the second section: 60min; the third section: 65min; the fourth section: until the container is full.

[0026] The yarn density of the inner and outer layers of the package formed by the above-mentioned embodiment is relatively uniform, and the yarn winding angle is controlled within the range of 16 degrees to 18 degrees. There are no defects such as stains, and it is beneficial to the unwinding process in the back. During the unwinding process, problems such as broken wires and hairs rarely ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com