Simple parallel spreading and laminating device and technology for wide ultrathin membrane

A film coating device and ultra-thin film technology, which is applied in the field of film unwinding and unwinding devices, can solve the problems that cannot be driven, cannot be realized, and the friction coefficient between the film and spokes is low, so as to improve the yield, stabilize the width, and expand the parallelism Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

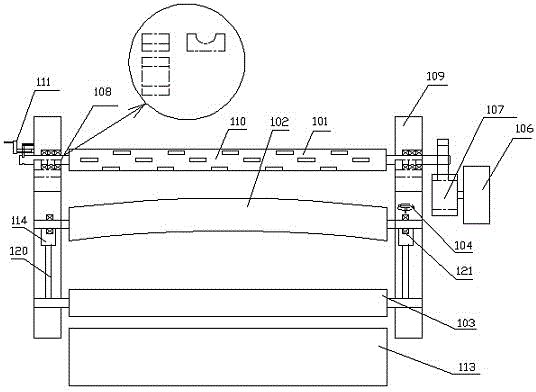

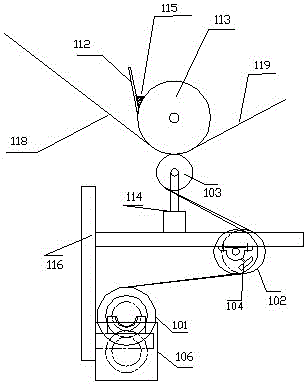

[0039] The polyethylene film 105 has a width of 1700mm and a thickness of 0.006mm. The axial working length of the bending roller 102 and the flat roller 103 is 1900mm. The wrapping angle of the bending roller 102 is 130°-165°, the bending degree of the bending roller 102 is 20mm / m, the distance between the flat roller 103 and the top rubber roller 113 is 50-150mm, and the wrapping angle of the prepreg cloth on the flat roller 103 is 28° , the protruding direction of the bending roll 103 is the direction of the outer extension of the angle bisector of the angle bisector of the triangle formed by the film unwinding, bending roll, and flat roll with the bending roll 102 as the apex, as figure 1As shown, adjust the tension of the magnetic powder damper 106 to make the film rotate on the bending roller 103, the cylinder piston rod is connected to the flat roller 103, and the relative position of the flat roller and the prepreg cloth and the film pressure are controlled by the elong...

Embodiment 2

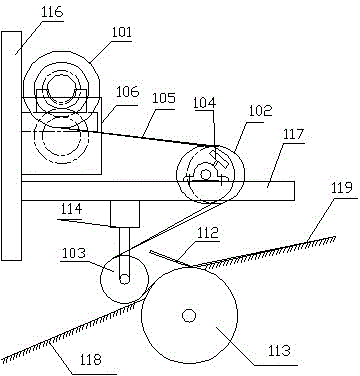

[0042] Using the film coating process below, the film coating device is the same as in Example 1, and the direction is opposite, such as image 3 As shown, glue is applied at the glue roller, and the gap (10 μm) between the scraper 112 and the glue roller 113 is controlled to control the amount of glue to be uniform, and then the ultra-thin film of the prepreg cloth is laminated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com