Patents

Literature

93results about How to "Resolve wrinkles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

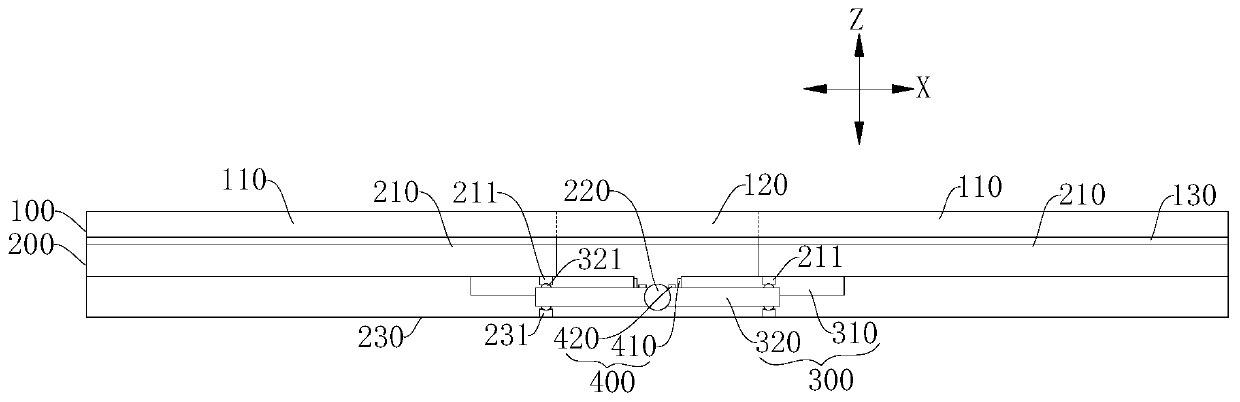

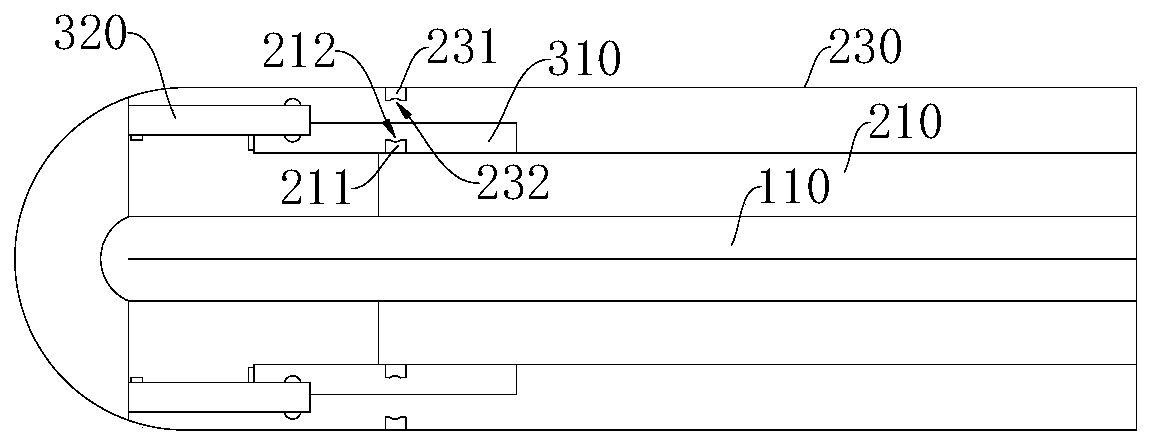

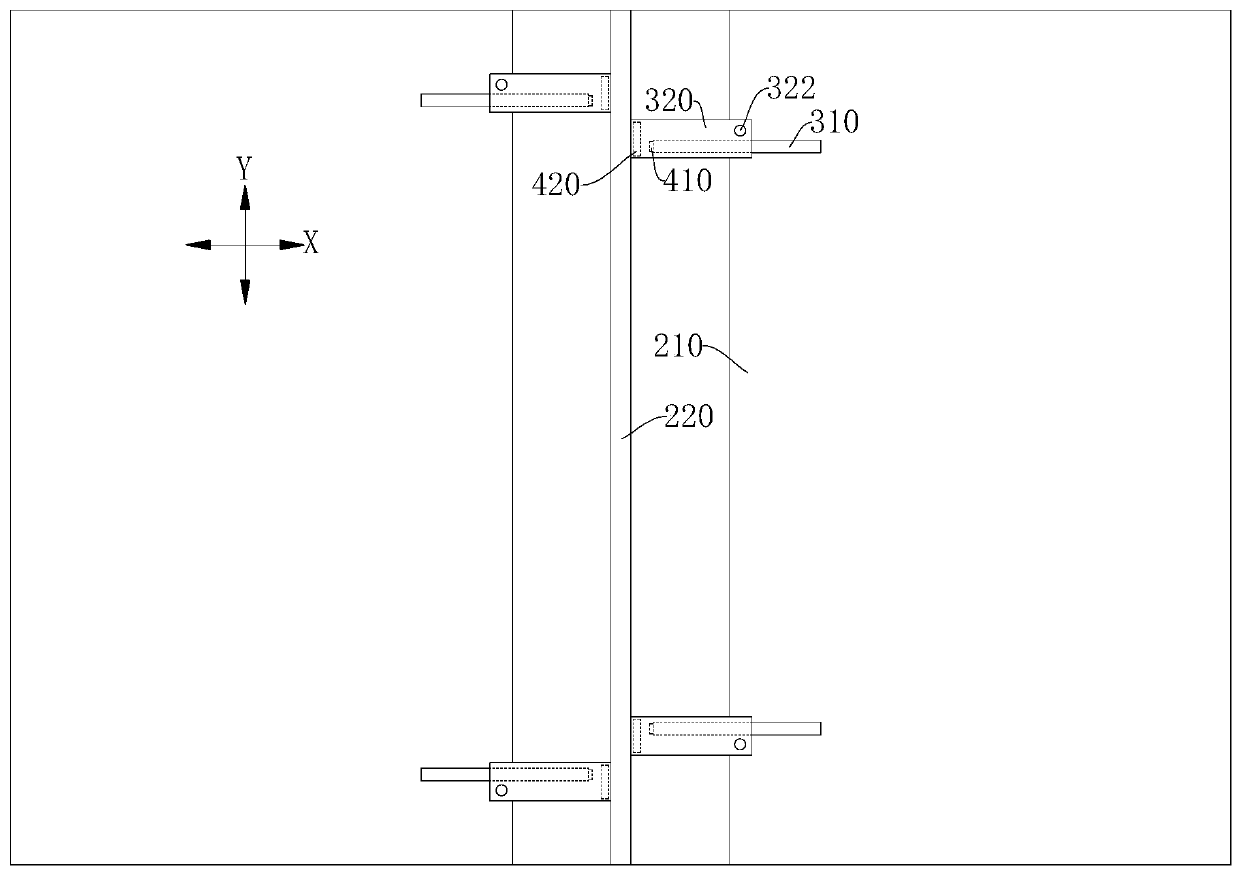

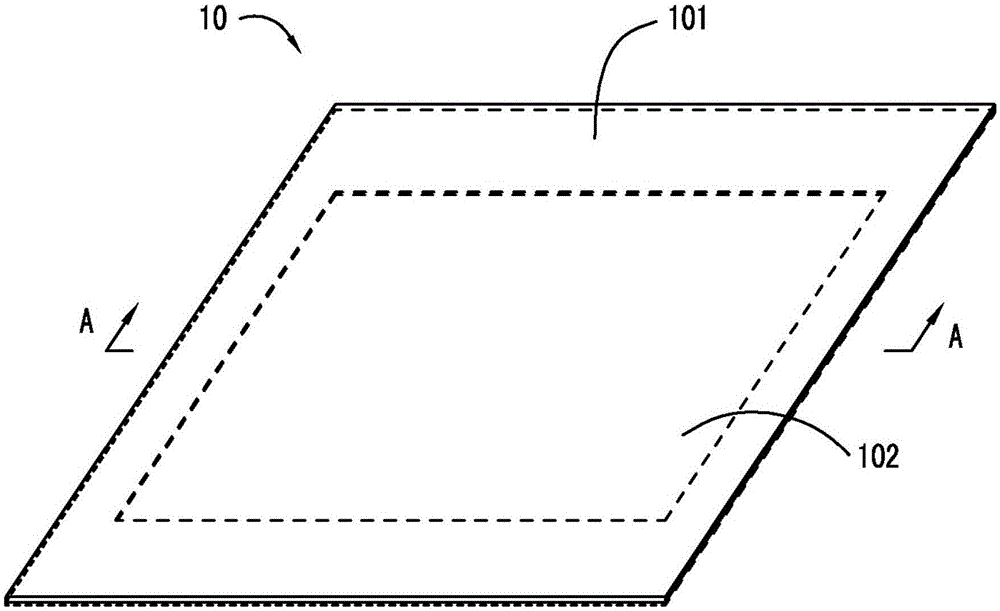

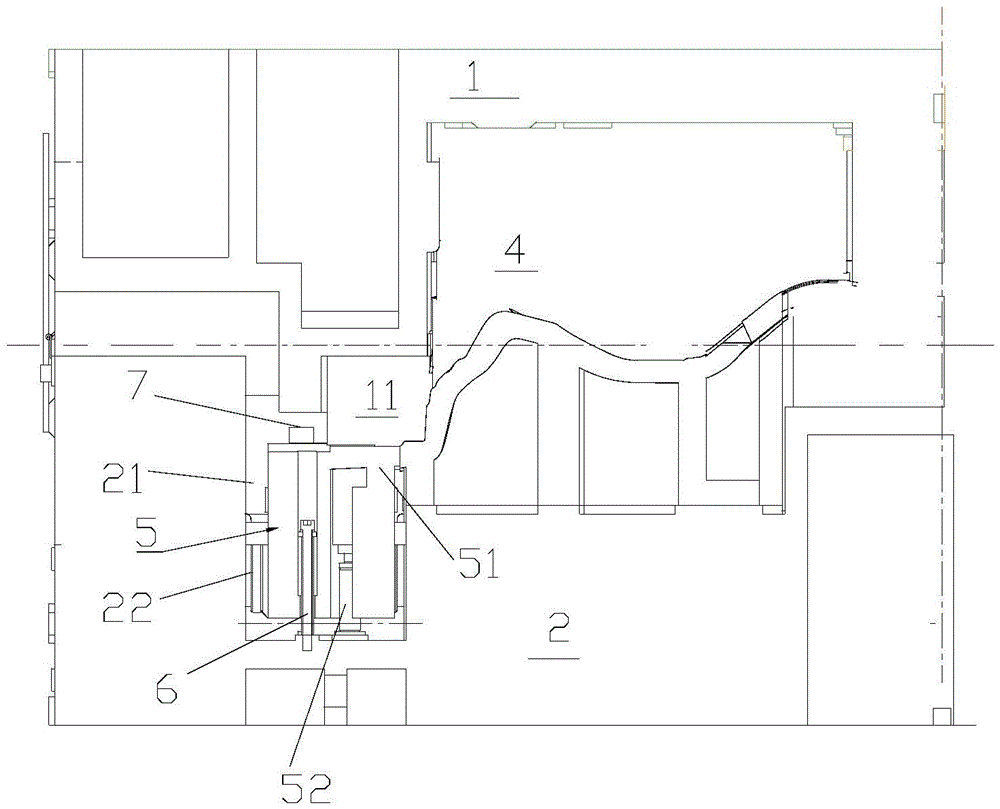

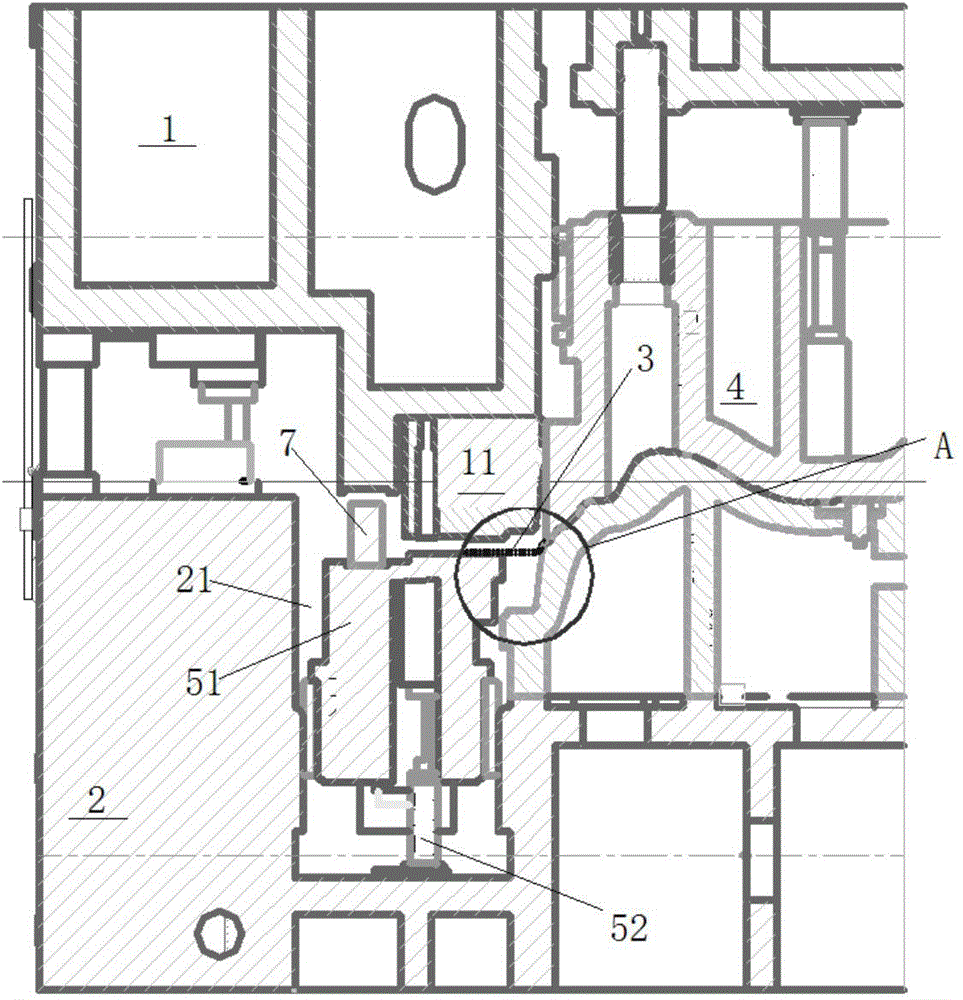

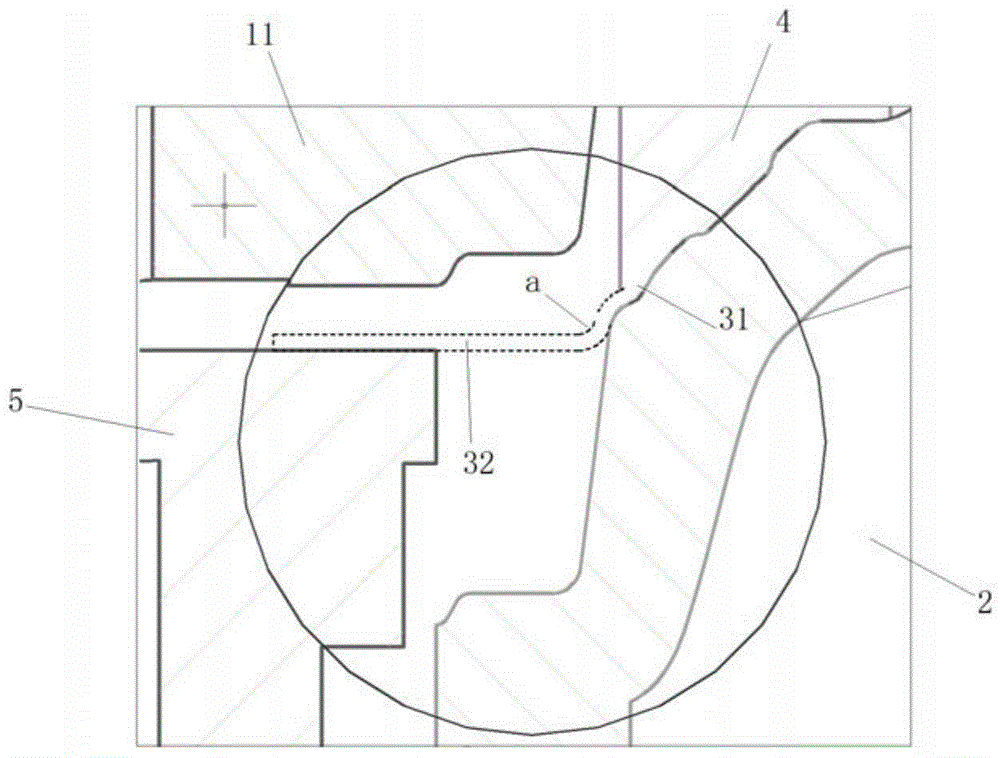

Display device and mobile terminal

ActiveCN111343310AService life effectExtended service lifeDetails for portable computersTelephone set constructionsDisplay deviceStructural engineering

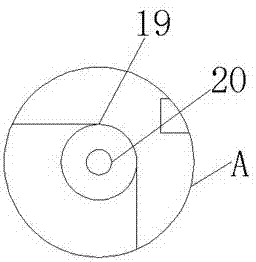

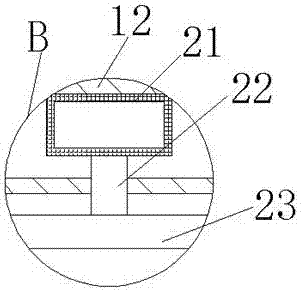

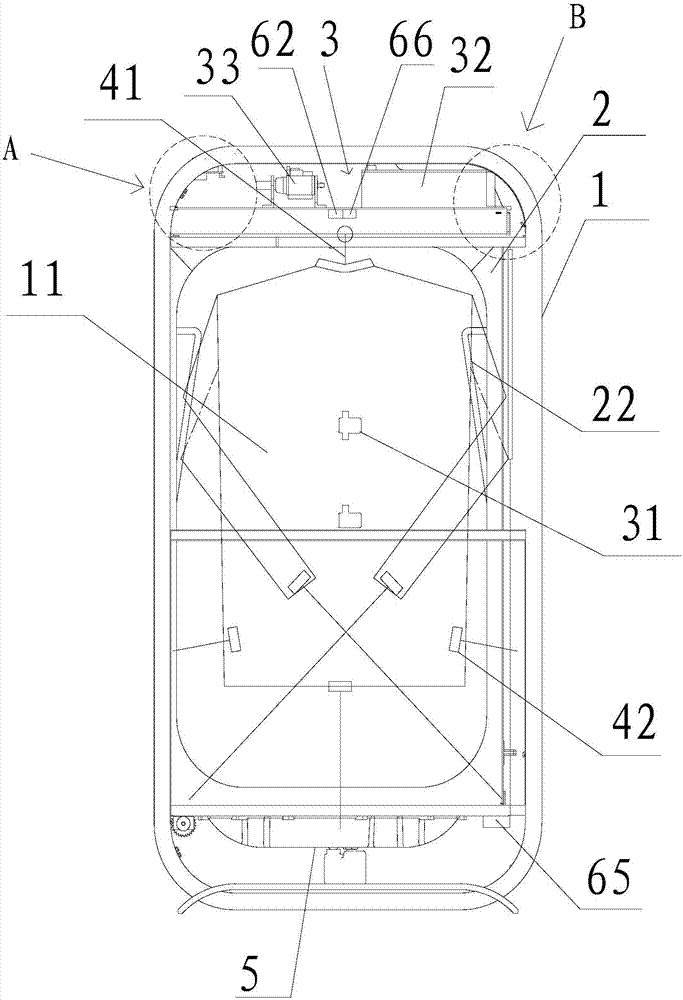

The embodiment of the invention provides a display device and a mobile terminal, and the display device comprises: a flexible display panel which comprises fixing parts and a bendable part located between two adjacent fixing parts; a supporting assembly which comprises two supporting parts, wherein the two supporting parts are arranged on the surfaces of the two fixing parts correspondingly so asto support the flexible display panel; a rotating shaft, wherein the rotating shaft is positioned between the two supporting parts and is arranged corresponding to the bending part; a sliding assembly, wherein the sliding assembly comprises a first sliding piece and a second sliding piece which are slidably connected in the direction perpendicular to the rotating shaft, the first sliding piece isconnected to the supporting part, and the second sliding piece is rotatably connected to the rotating shaft; a driving assembly, wherein the driving assembly comprises a first magnetic part and a second magnetic part, and magnetic force between the first magnetic part and the second magnetic part provides driving force for the first sliding part to move away from the rotating shaft. The display device provided by the embodiment of the invention can solve the problem that in the prior art, a folded product has wrinkles in a flattened state.

Owner:KUNSHAN NEW FLAT PANEL DISPLAY TECH CENT +1

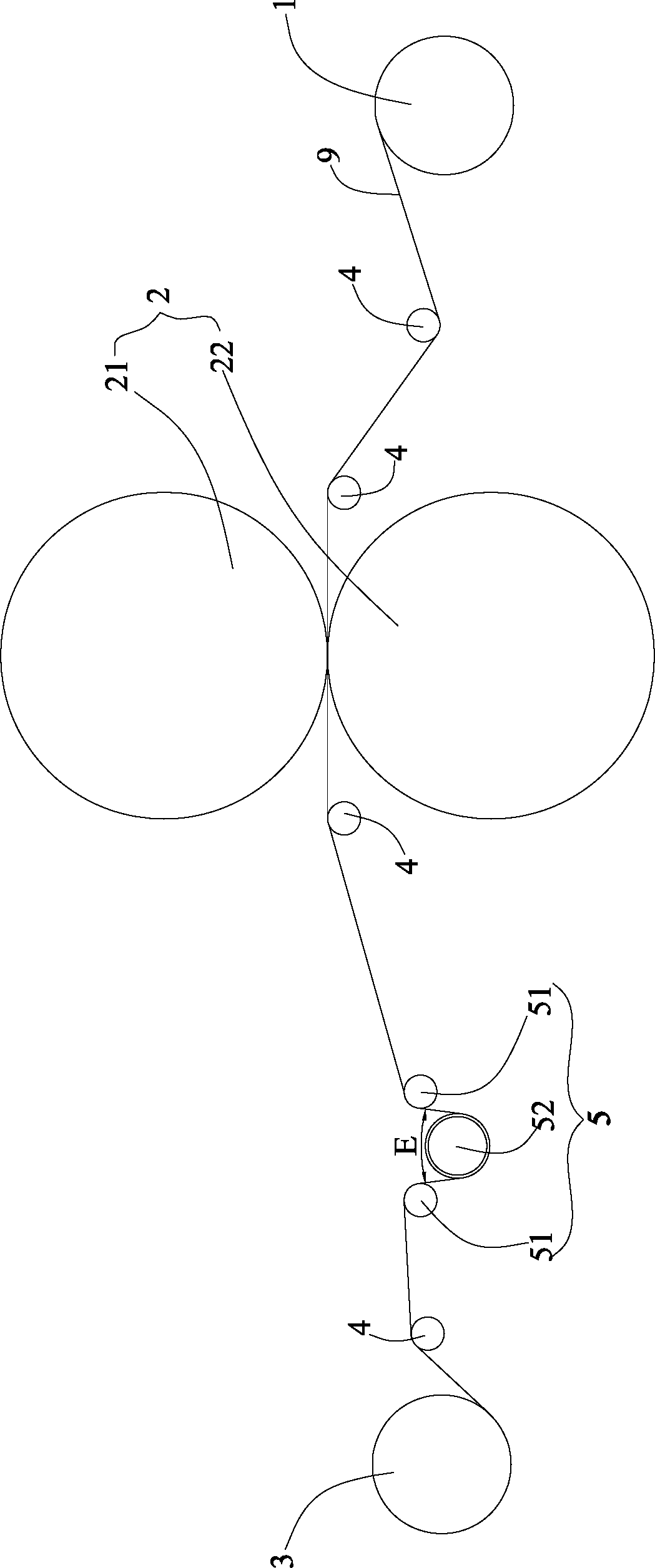

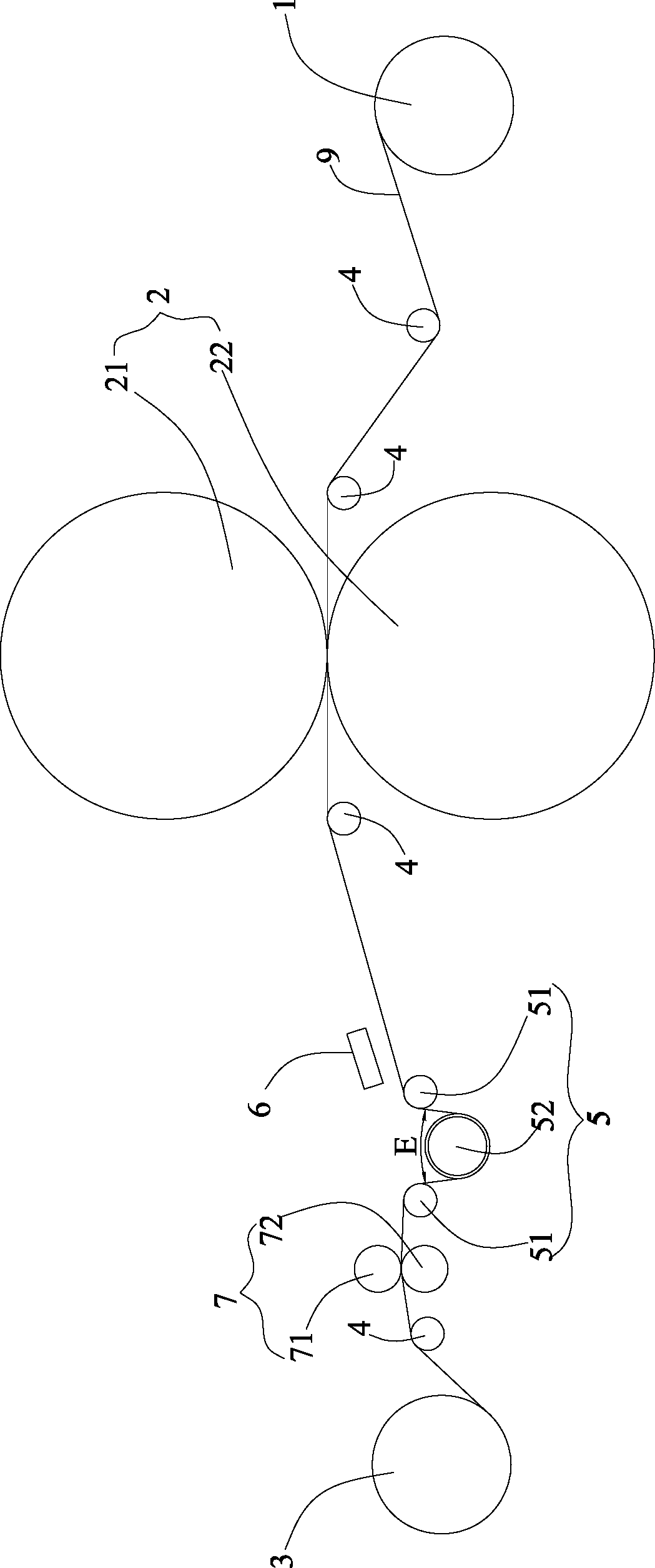

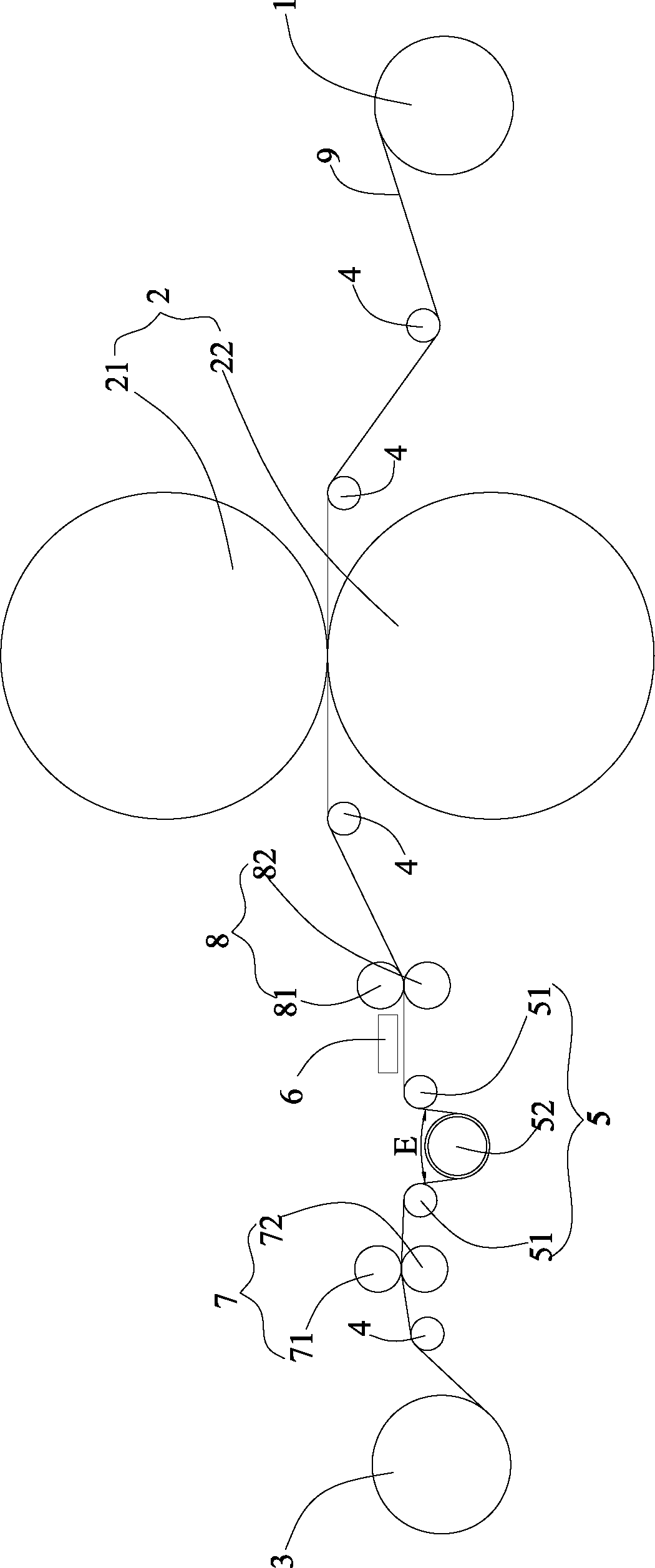

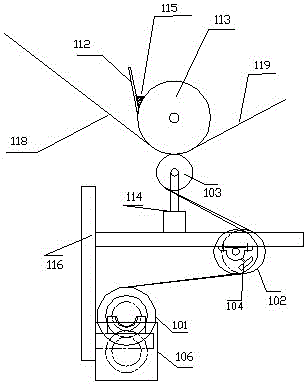

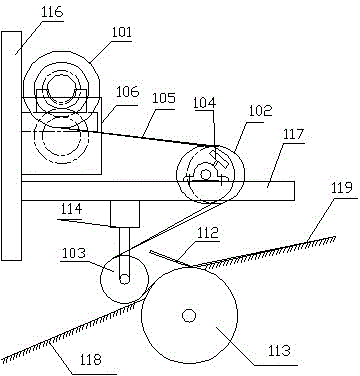

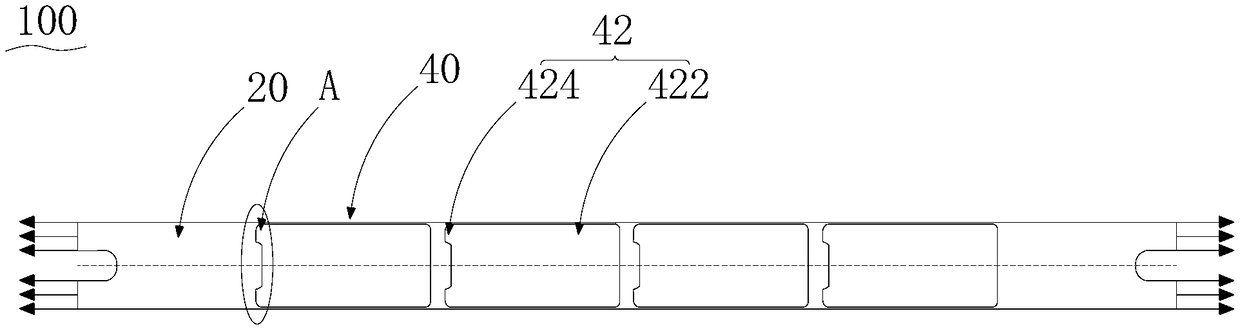

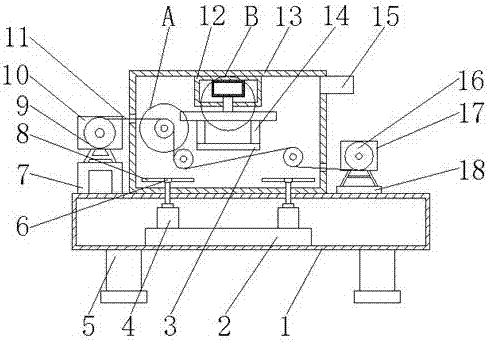

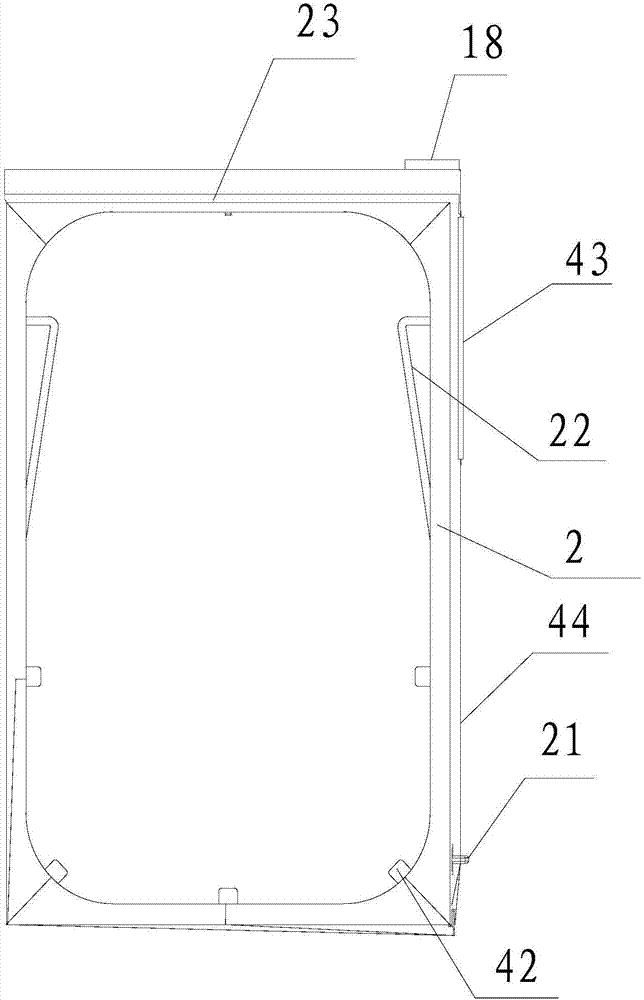

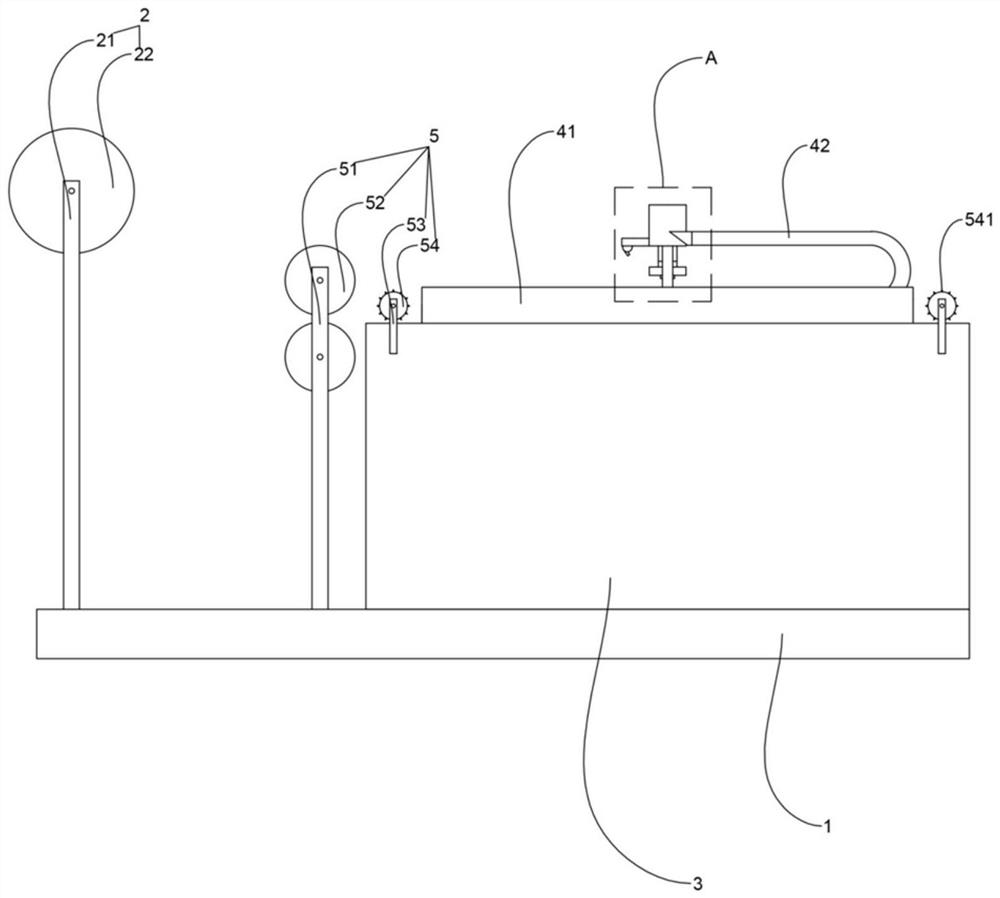

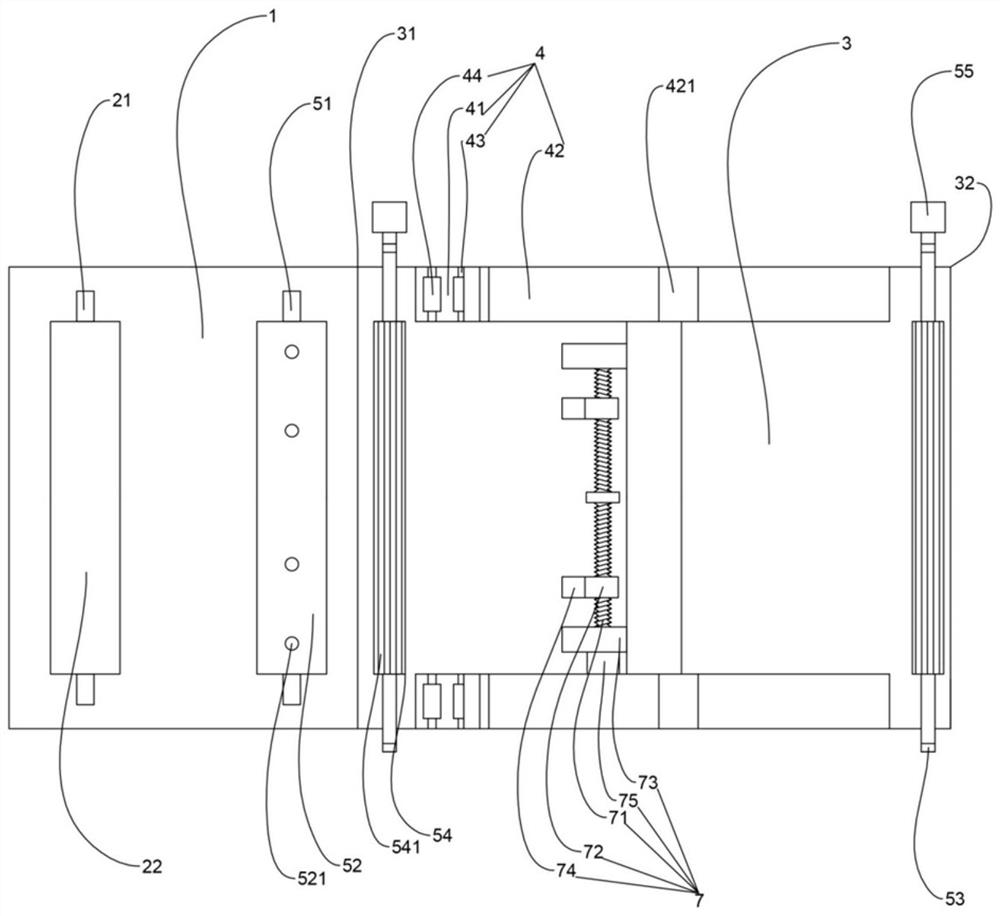

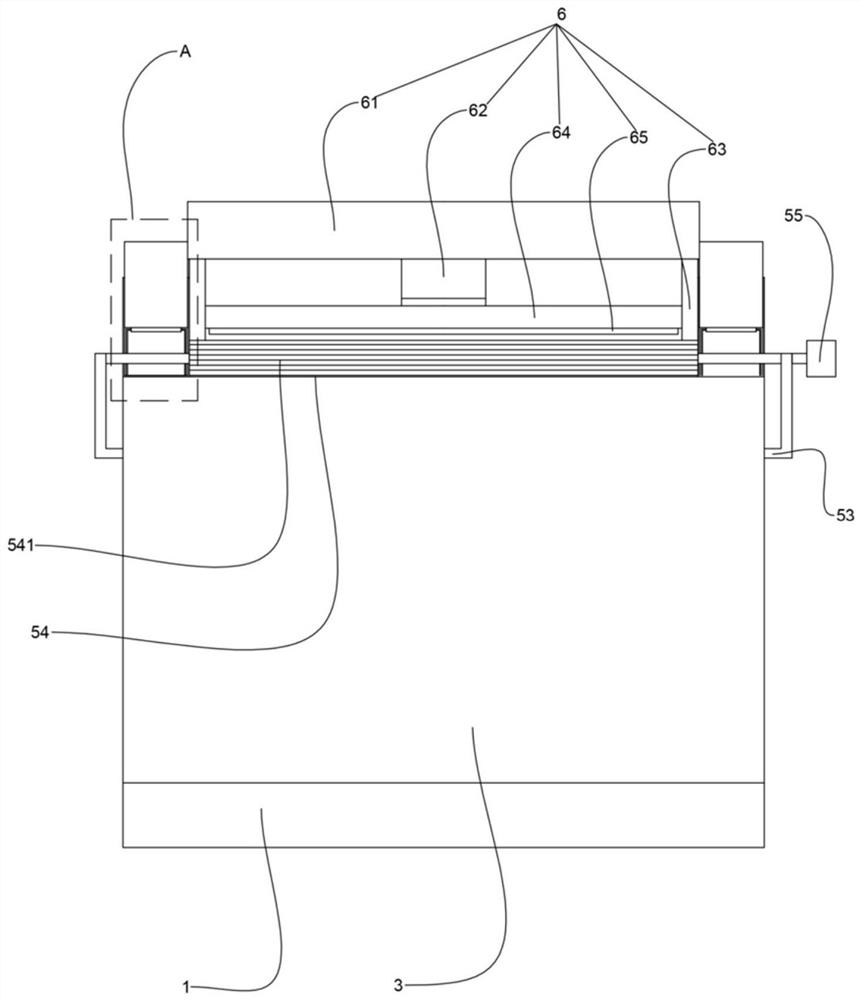

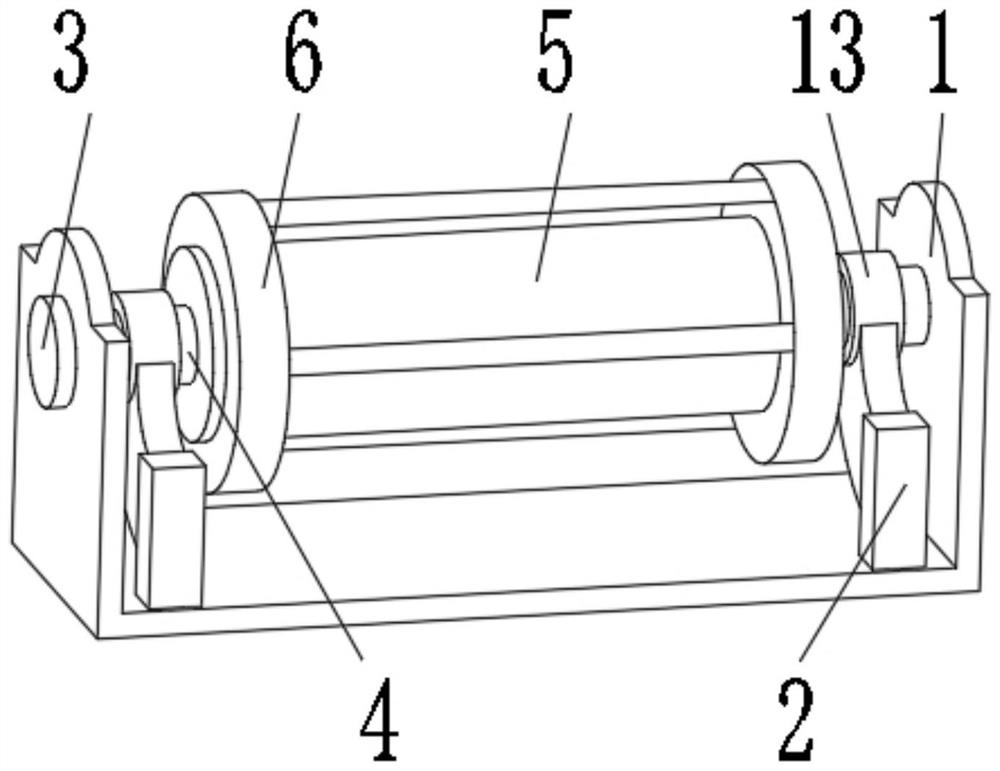

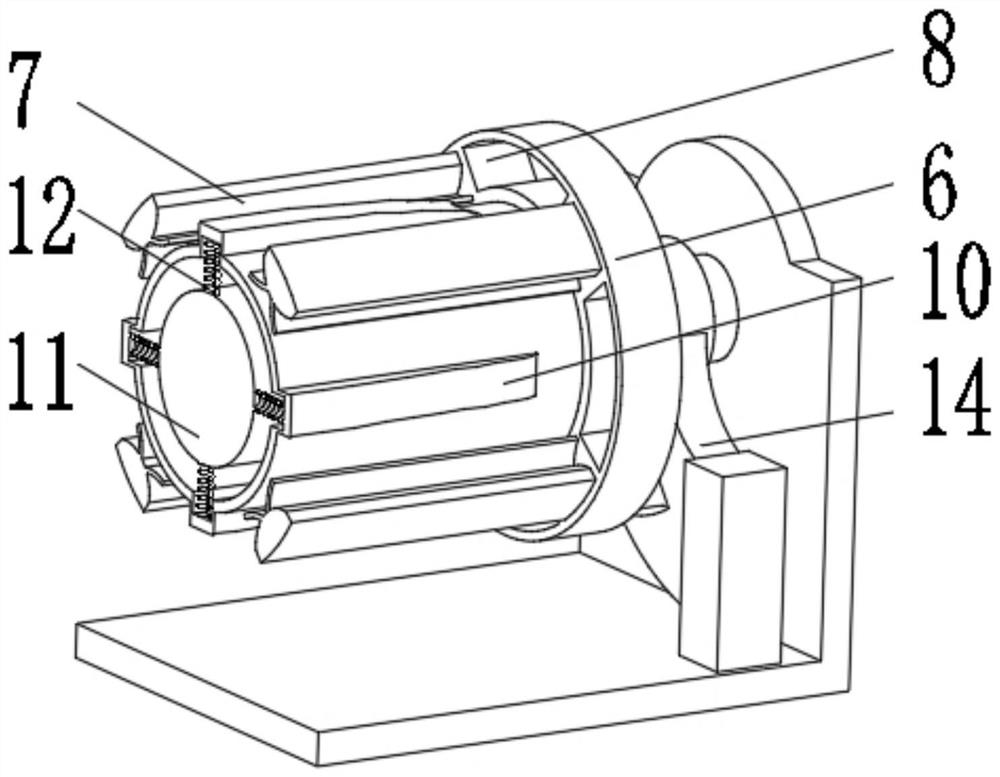

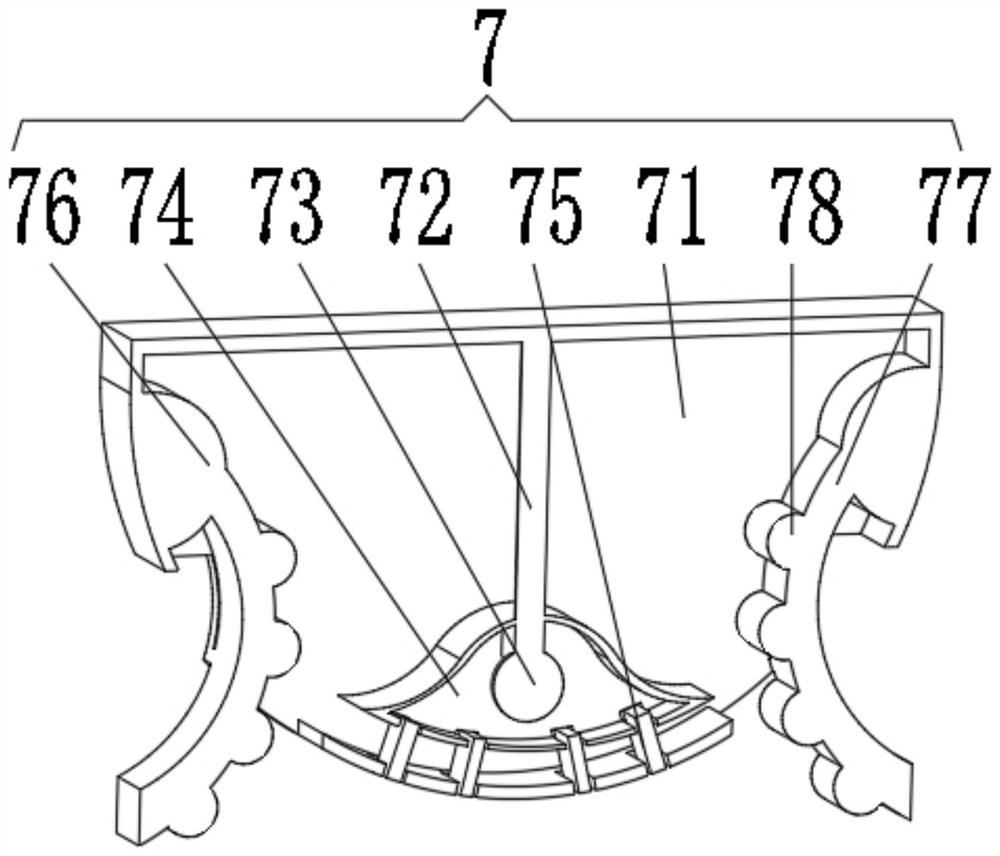

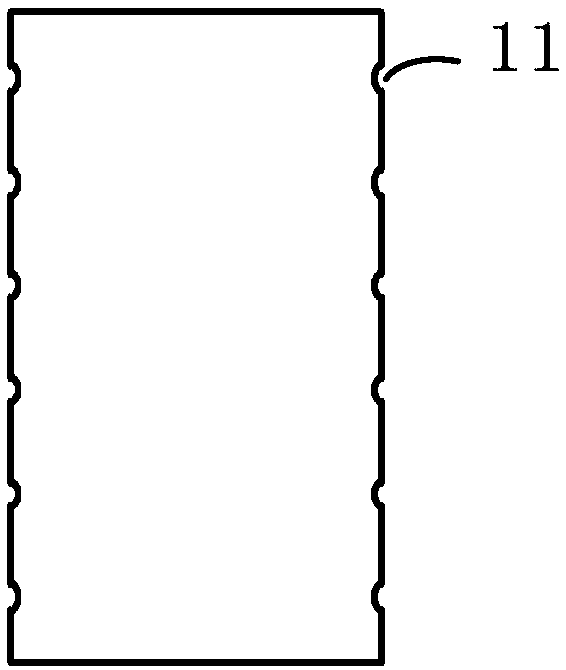

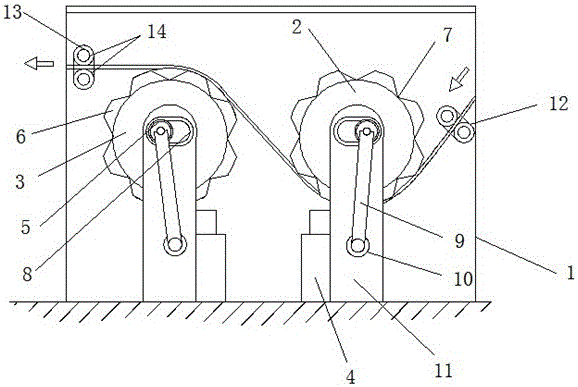

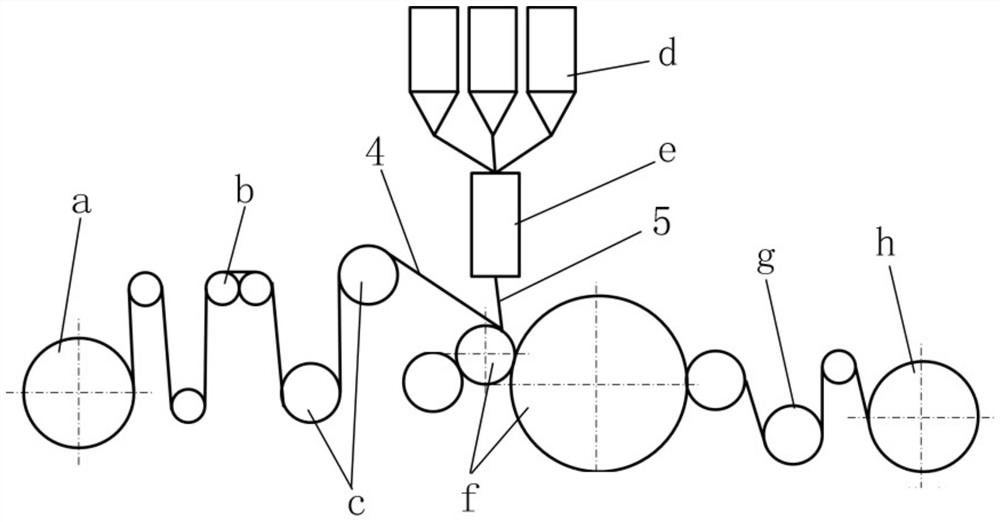

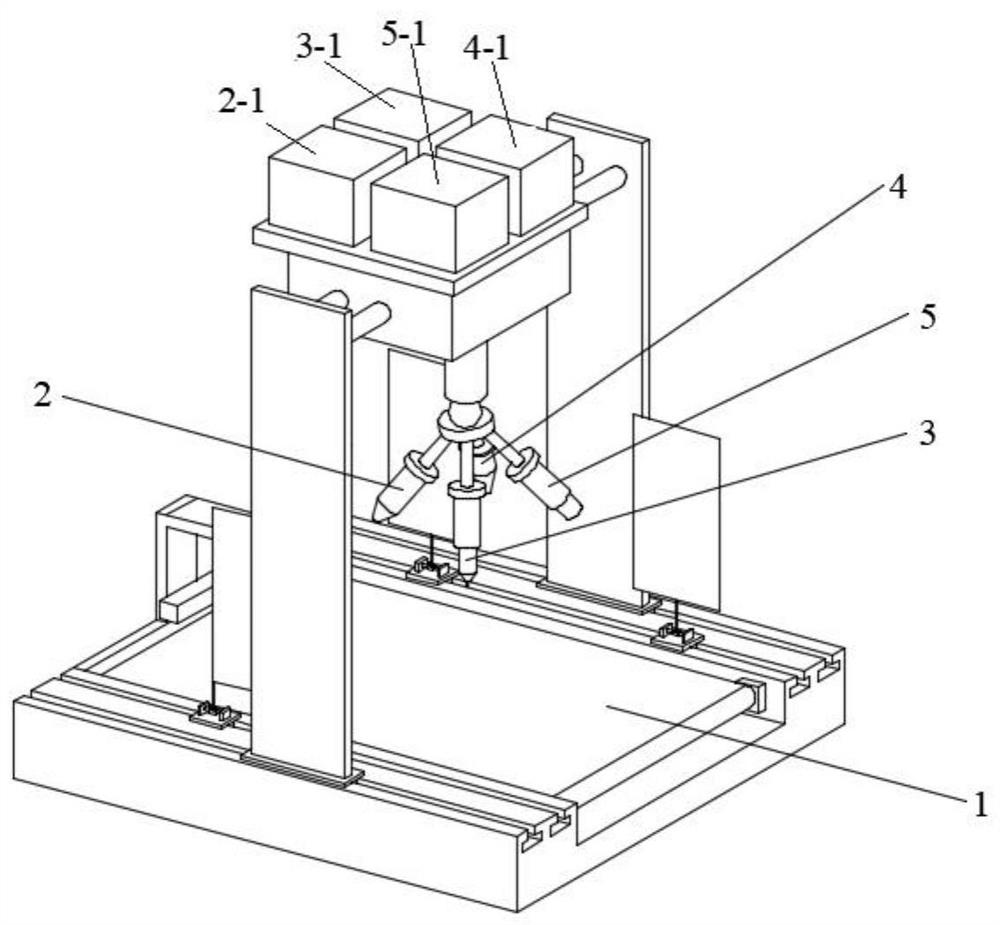

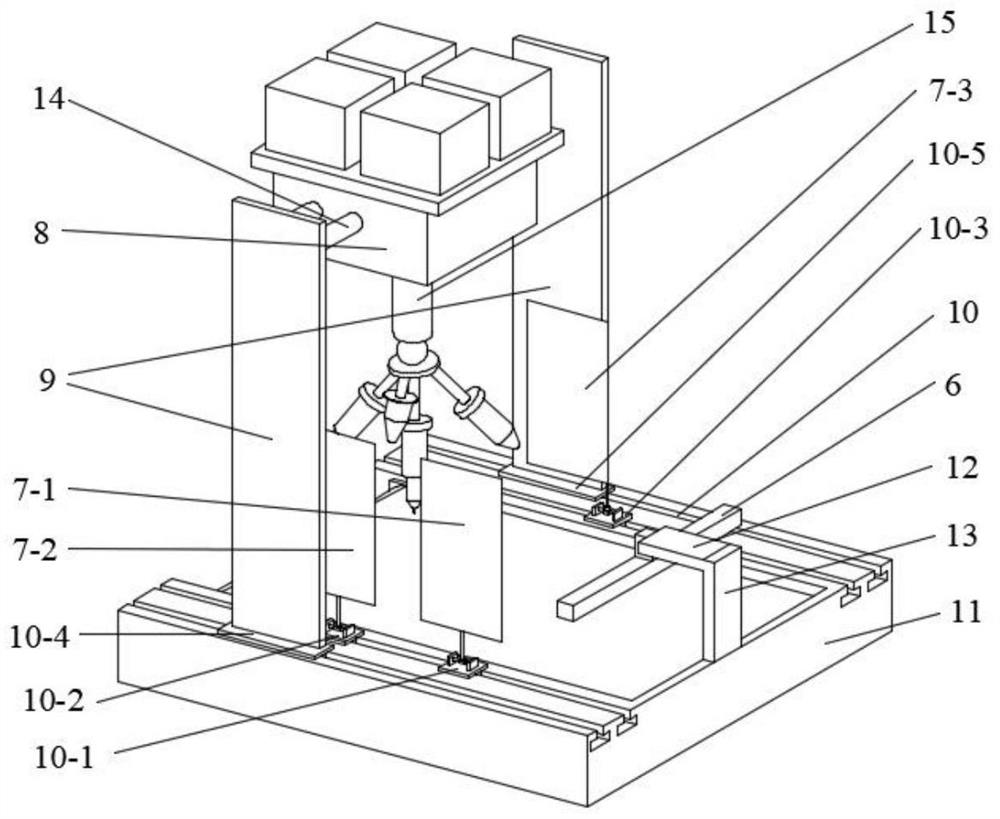

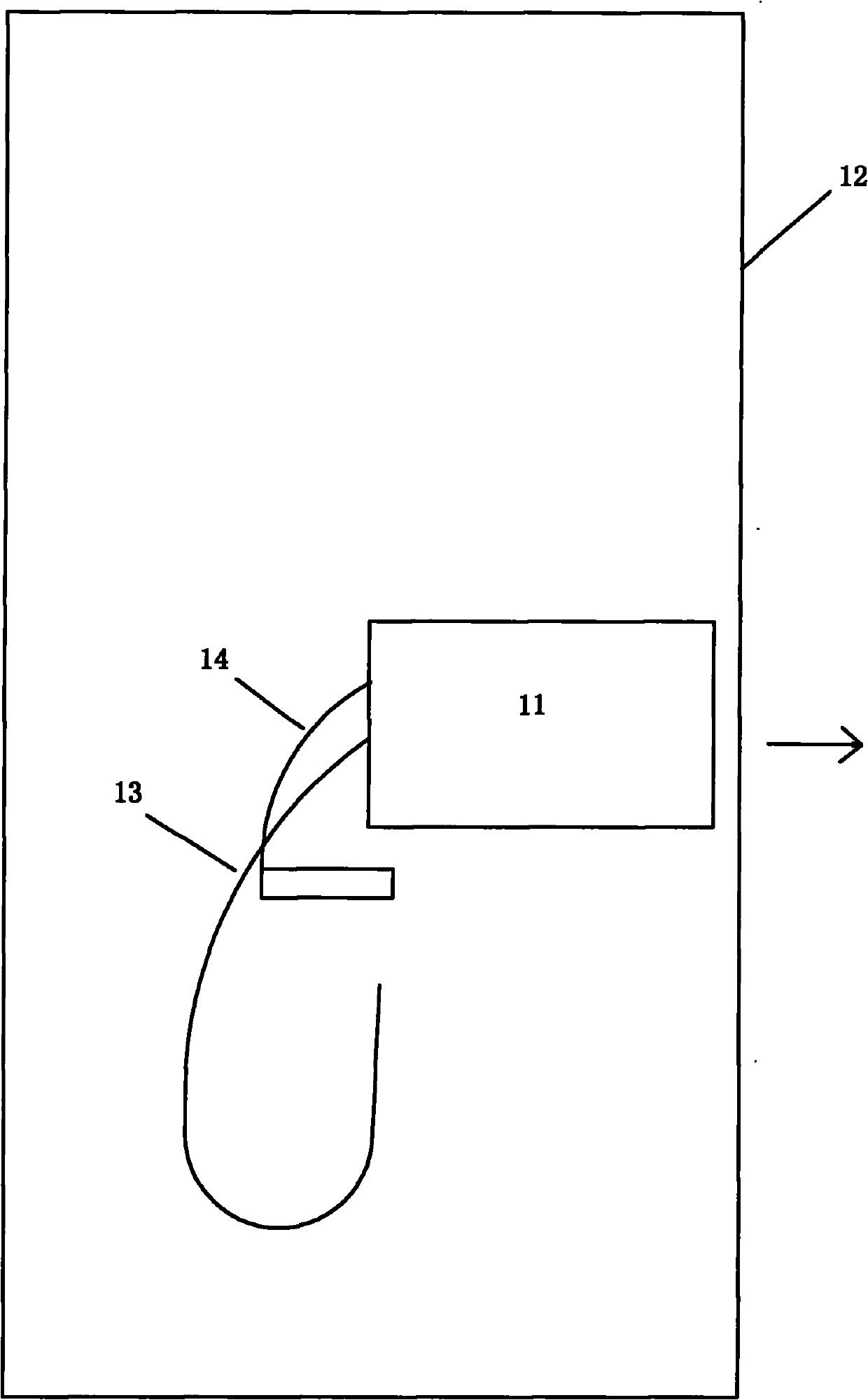

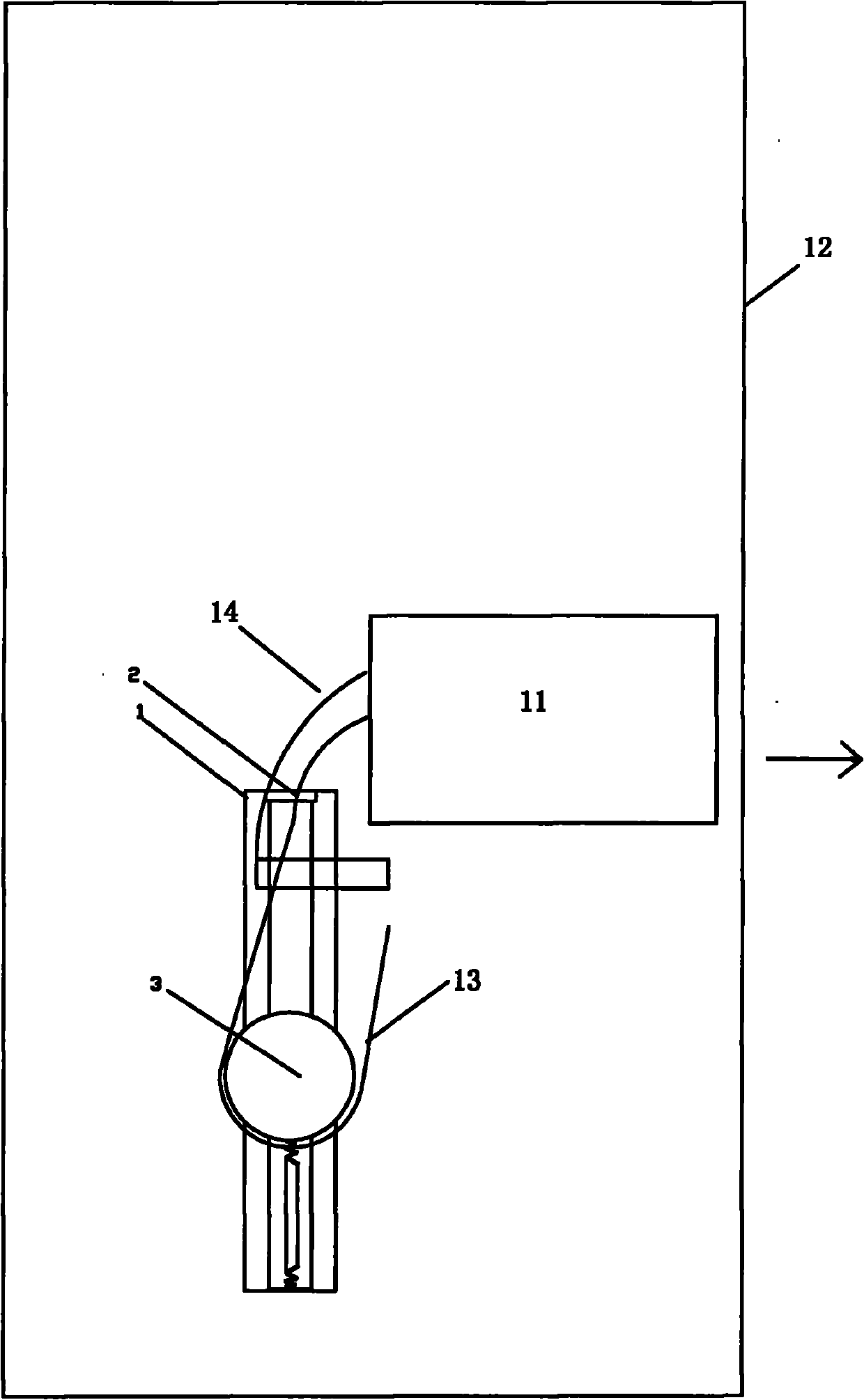

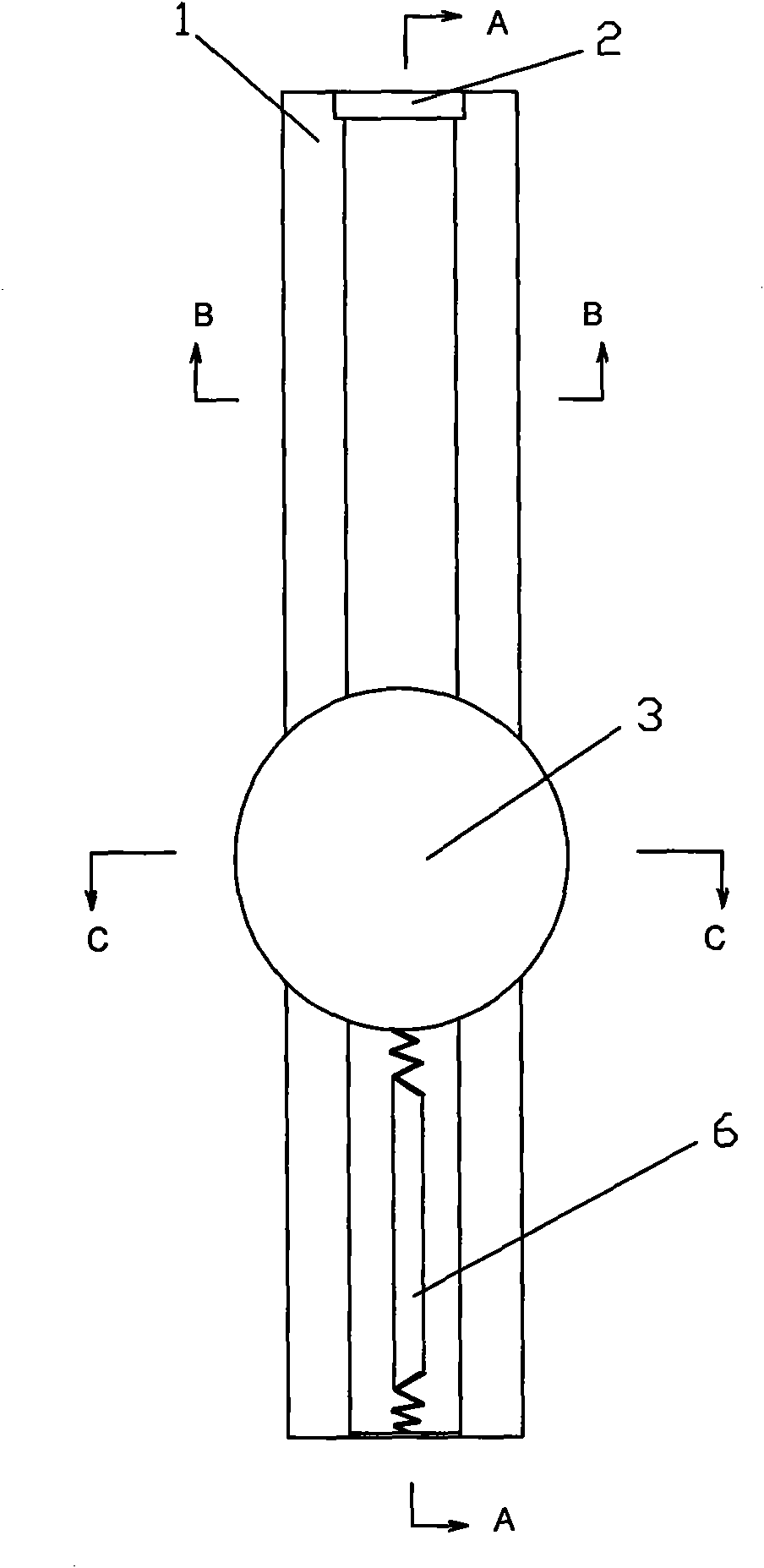

Roll-in device

InactiveCN104001720AResolve wrinklesElectrode rolling/calenderingFinal product manufactureEngineeringMechanical engineering

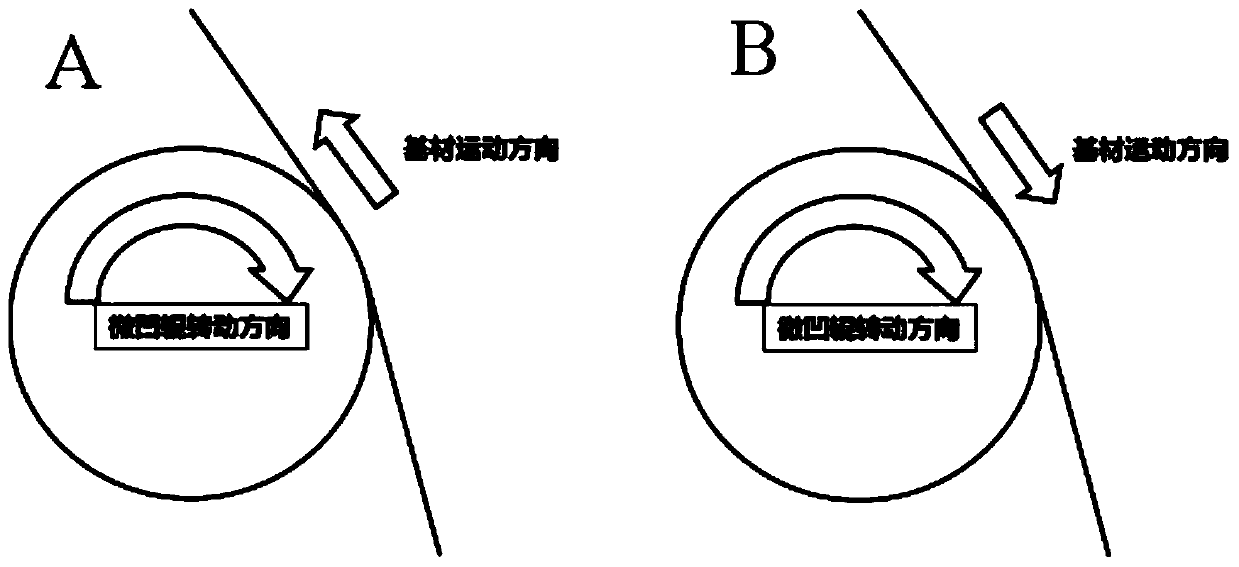

The invention provides a roll-in device. The roll-in device comprises an unwinding mechanism, a roll-in mechanism, a winding mechanism and a stretching mechanism, wherein the unwinding mechanism is wound by a pole piece to be rolled, the pole piece to be rolled is output, the pole piece to be rolled is provided with a foil piece and a film layer arranged on at least one face of the foil piece, the corresponding face, provided with the film layer, of the foil piece is provided with at least one film coating zone and a foil-exposed zone, the film coating zone extends in the longitudinal direction of the foil piece, the foil-exposed zone is located in the lateral direction of the film coating zone, the film layer is arranged on the film coating zone of the foil piece, and no film layer is arranged on the foil-exposed zone of the foil piece. The roll-in mechanism comprises a compression roller and a back roller, wherein the compression roller and the back roller are oppositely arranged and used for rolling the pole piece. The winding mechanism is used for winding the rolled pole piece. The stretching mechanism is arranged between the roll-in mechanism and the winding mechanism. The stretching mechanism comprises two guide rollers and a concave-convex roller located between the two guide rollers. A wrap angle is formed by the concave-convex roller and the two guide rollers. The concave-convex roller is matched with the pole piece in size, so that the convex portion of the concave-convex roller acts on the portion, with the foil-exposed zone, of the foil piece and plastic deformation of the portion, on the foil-exposed zone, of the foil piece is achieved.

Owner:NINGDE AMPEREX TECH

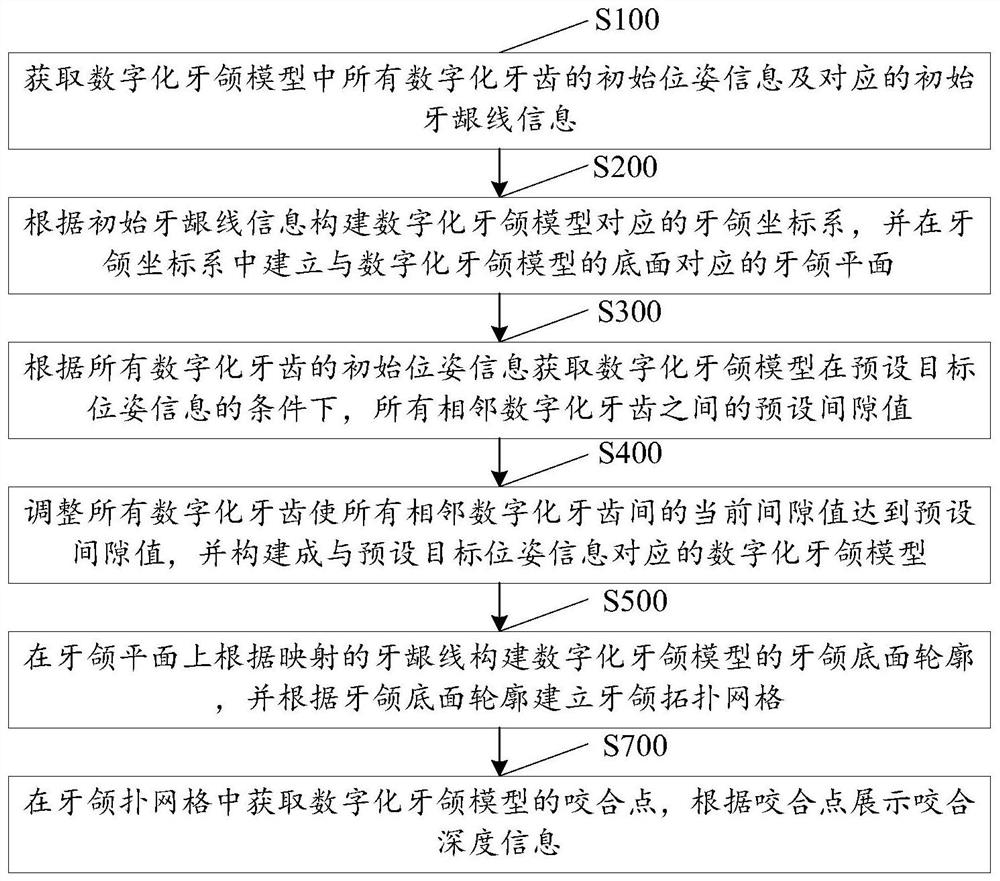

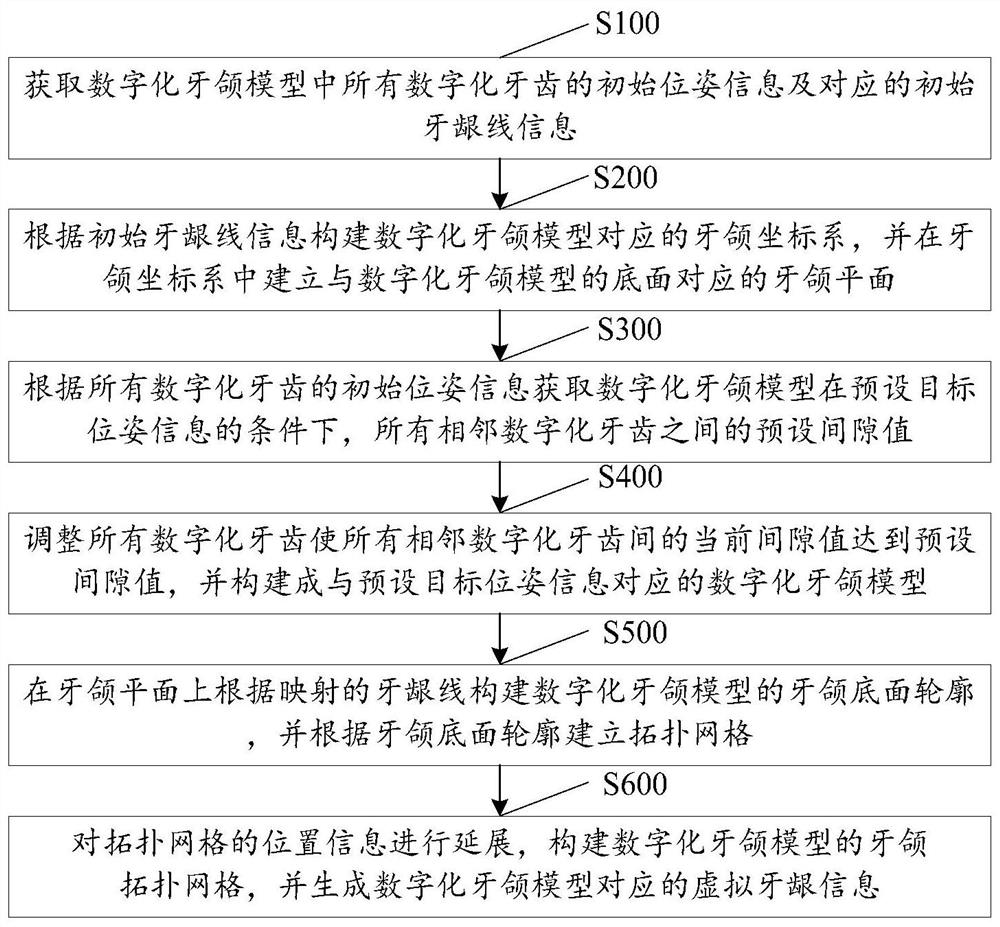

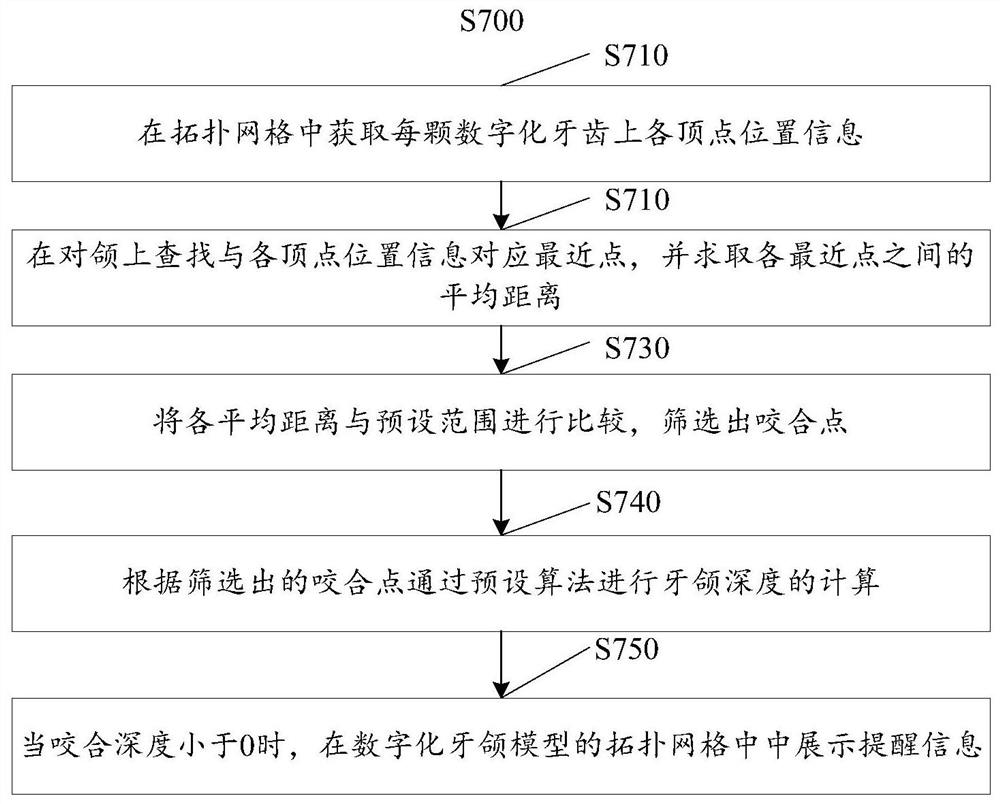

Method and system for acquiring tooth correction information

ActiveCN112006791AFacilitate communicationReduce communication barriersOthrodonticsEngineeringBiomedical engineering

The invention discloses a method and a system for acquiring tooth correction information. The method comprises the following steps: acquiring initial pose information of all digital teeth in a digitaldental model and initial gingival line information corresponding to the initial pose information; constructing a dental coordinate system corresponding to the digital dental model according to the initial gingival line information, and establishing a dental plane corresponding to the bottom surface of the digital dental model in the dental coordinate system; adjusting all digitalized teeth in thedental coordinate system to enable current gap values between all of adjacent digitalized teeth to reach preset gap values; constructing a digital dental model corresponding to the preset target poseinformation, mapping a gingival line of the updated digital dental model to a dental plane, constructing a dental bottom surface contour of the digital dental model on the dental plane, and establishing a planar topological grid on the dental bottom surface contour; and further constructing a tooth jaw topological grid of the digital tooth jaw model, and displaying occlusion depth information inthe tooth jaw topological grid according to obtained occlusion points.

Owner:SHANGHAI SMARTEE DENTI TECH CO LTD

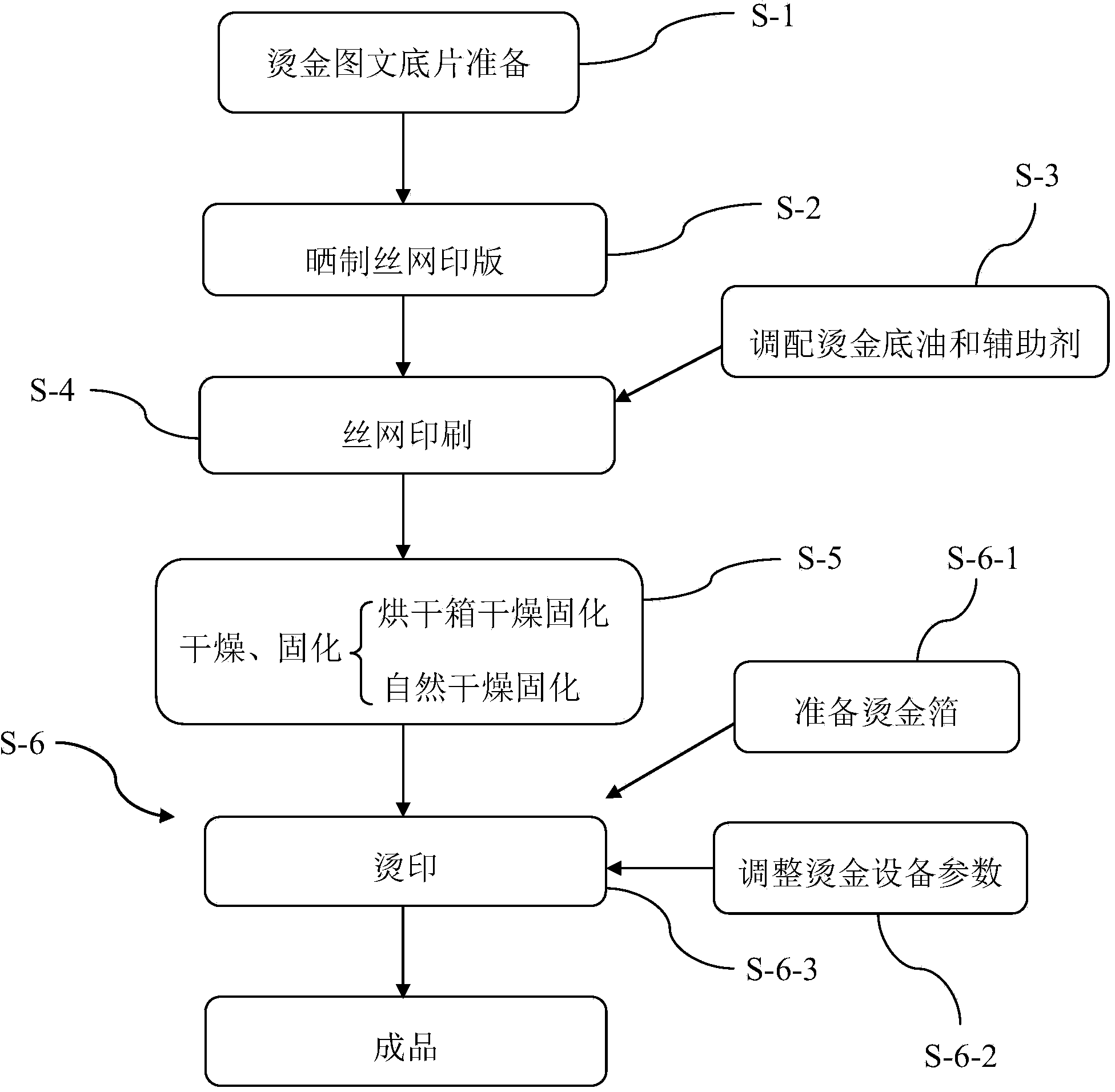

Silk-screen printing based plate-free hot-stamping process

InactiveCN104309347ASolve crackingResolve wrinklesOther printing apparatusScreen printingHot stamping

The invention provides a silk-screen printing based plate-free hot-stamping process. The plate-free hot-stamping process is characterized by including: for preparation of hot stamping image-text films, selecting the positive image-text films as the image films; for drying of silk-screen printing plates, manufacturing the plate in sensitization by adopting a direct method; for blending of hot-stamping bottom oil and additives, respectively blending the hot-stamping bottom oil, curing agent and diluent in the mass ratio of 10: (1.5-2.5): (1.0-1.5); for silk-screening printing plate, printing mixture obtained from blending of the hot-stamping bottom oil and the additives on the silk-screen printing plate to obtain a hot-stamping image-text bottom layer; for drying and curing, placing the hot-stamping image-text bottom layer under indoor temperature for 30mins prior to sending the same to a drying box for drying at the temperature ranging from 60DEG C to 70DEG C for 8-13mins, and naturally cooling the hot-stamping image-text bottom layer under the indoor temperature for 1 hour after drying. The surface temperature of a hot-stamping drum is heated to 90-110DEG C, pressure of a stamping machine is regulated to the largest, and stamping speed is regulated to be slow.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

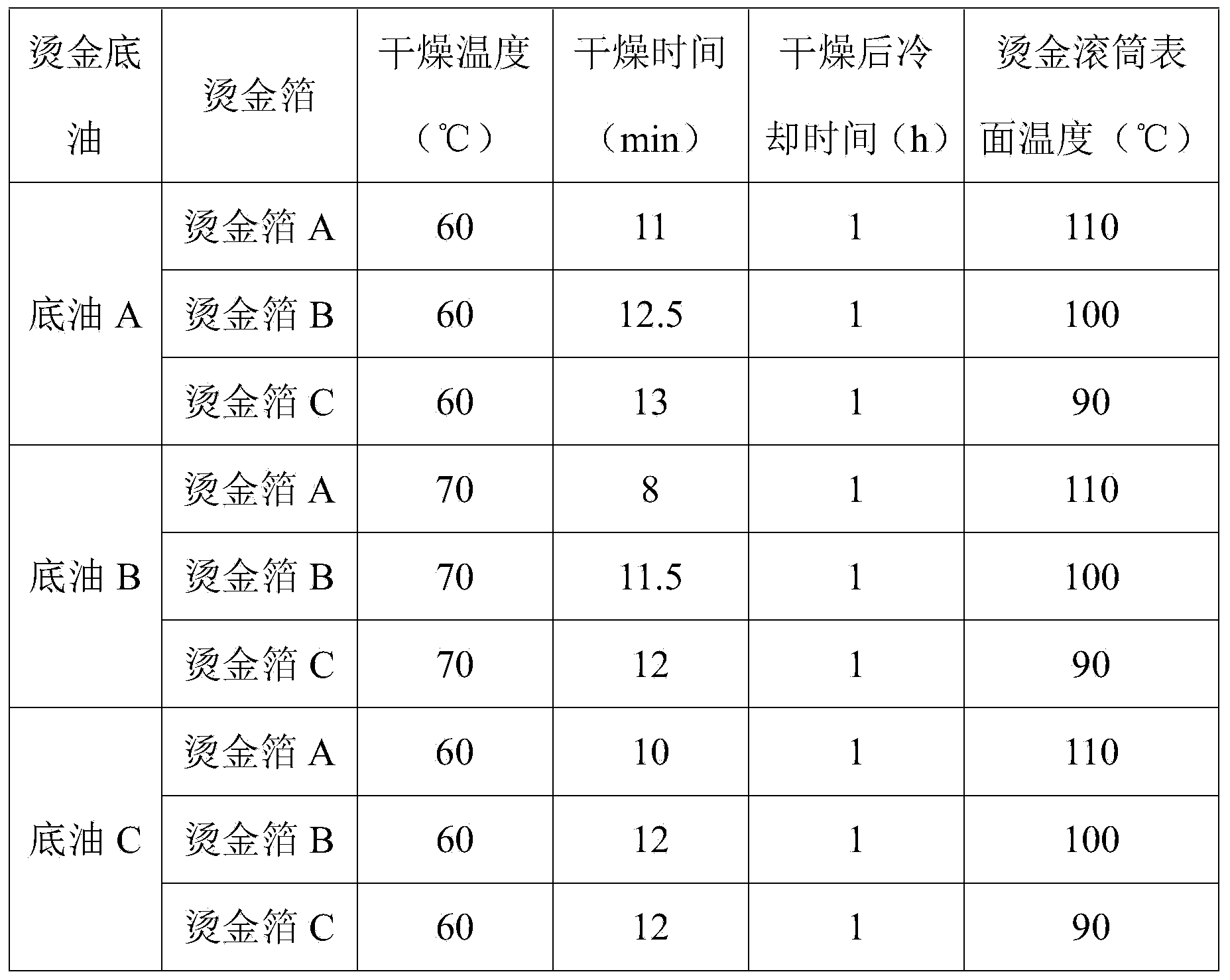

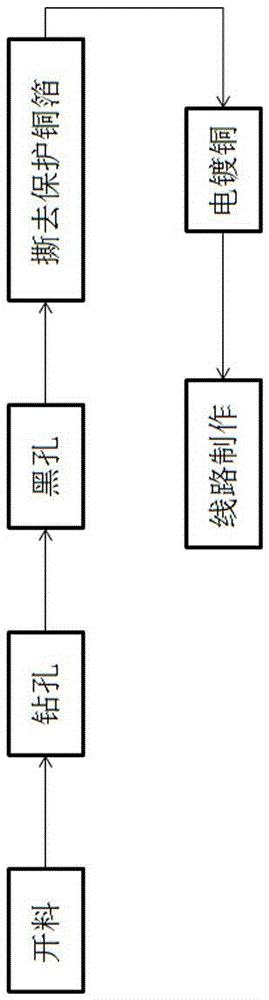

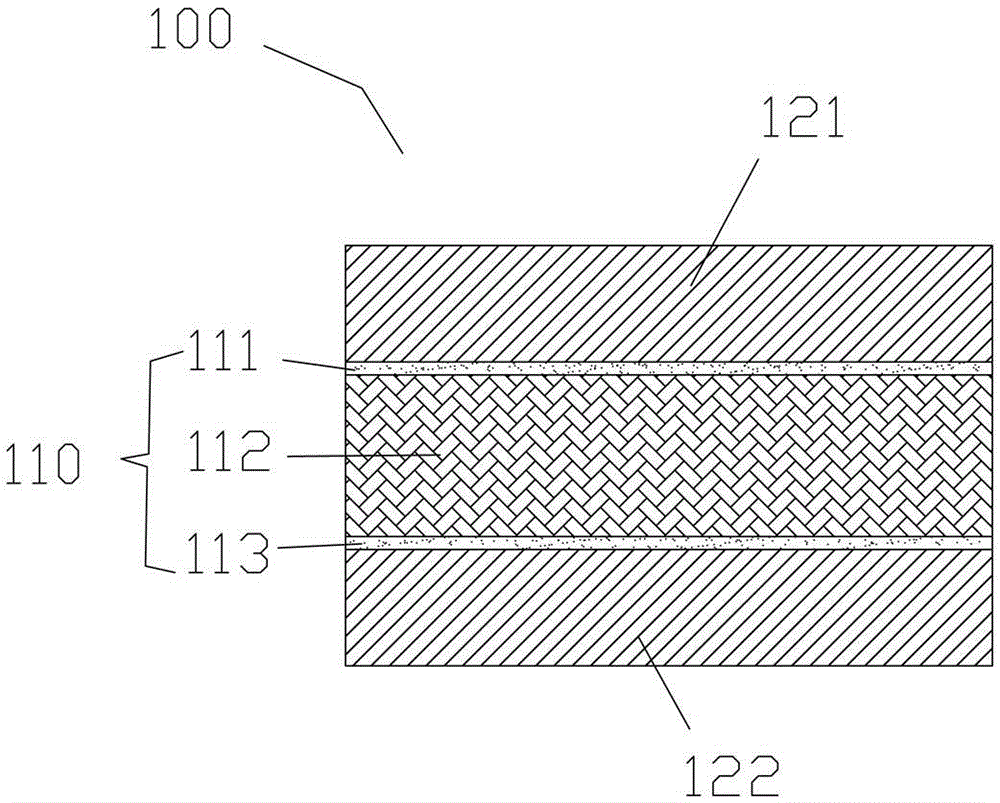

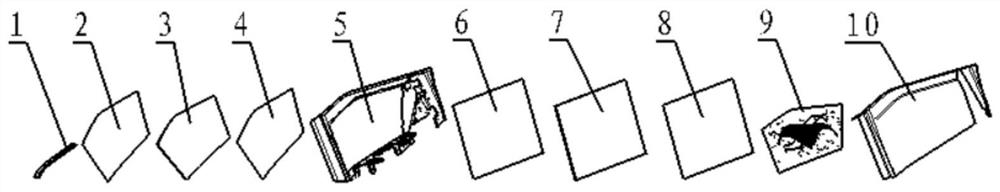

Processing technology optimization method of ultrathin flexible plate

InactiveCN105263263ASimple processing technologyDoes not break tensionPrinted circuit manufactureCopper platingCopper foil

The invention belongs to the technical field of processing of an ultrathin flexible plate, in particular relates to a processing technology optimization method of the ultrathin flexible plate. The invention discloses the processing technology optimization method of the ultrathin flexible plate, and a processing technology of the ultrathin flexible plate comprises the following steps of: A, cutting; B, laser drilling; C, hole blacking; D, a protective copper foil tearing; E, copper plating; and F, circuit fabricating. By the processing technology optimization method, the processing technology of the ultrathin flexible is optimized; by optimizing the processing technology, the problem of product folding and deformation is solved, the yield of circuit fabrication is greatly improved, and finally, the quality and the yield of the product are enhanced.

Owner:SUIWA HIGH TECH ELECTRONICS INDS XIAMEN

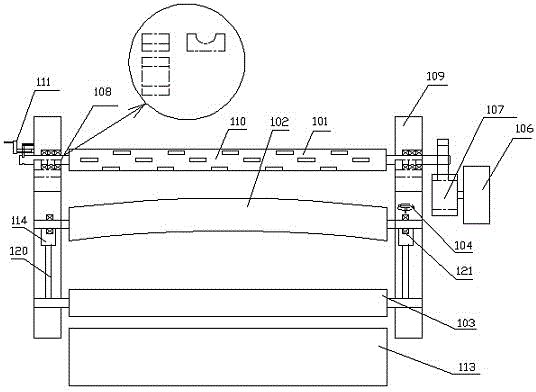

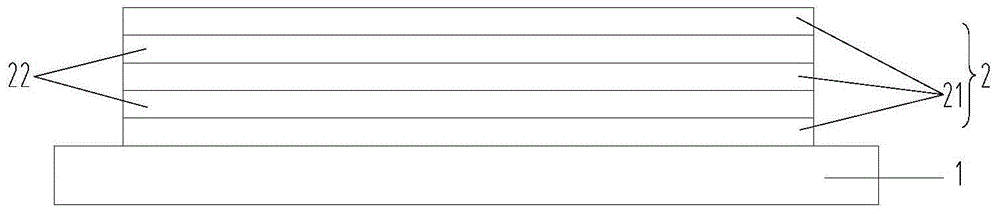

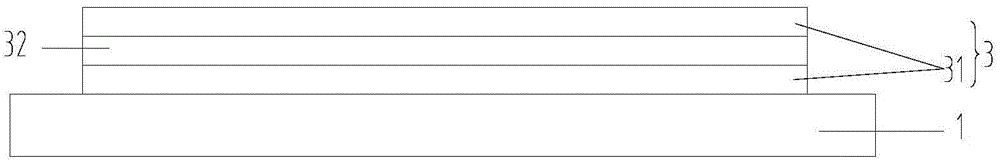

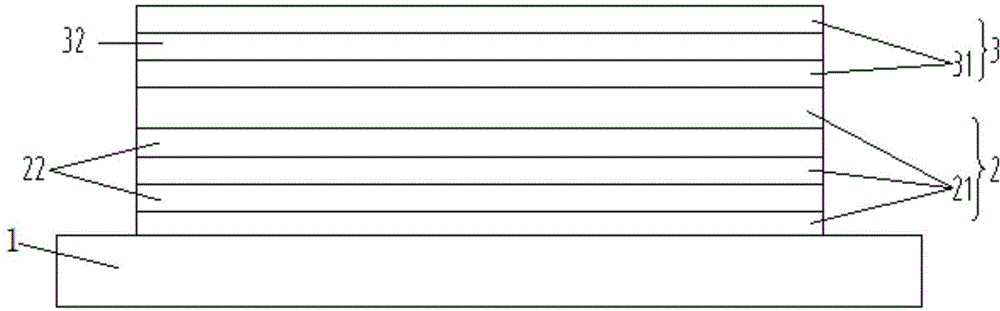

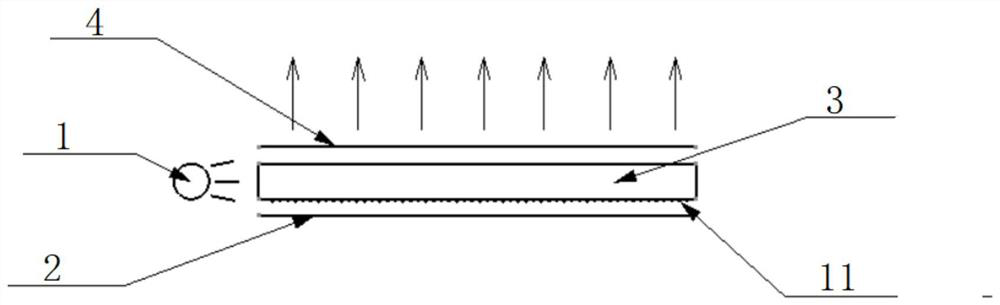

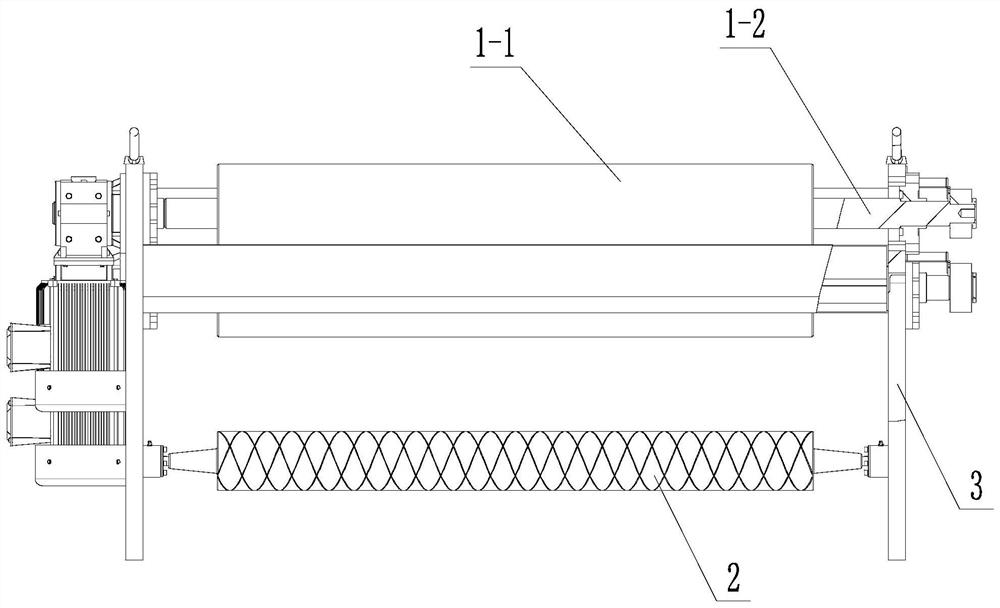

Simple parallel spreading and laminating device and technology for wide ultrathin membrane

The invention discloses a simple parallel spreading and laminating device for a wide ultrathin membrane. The simple parallel spreading and laminating device comprises a membrane unreeling roller, a magnetic powder damper, a bent roller, a gluing roller, a flat roller and a rack. A technology comprises the steps that the wrapping angle of the bent roller and the wrapping angle of the flat roller are adjusted by setting proper unreeling tension; the relative position relation of the unreeling roller, the bent roller and the flat roller is adjusted; the protruding direction of the bent roller is adjusted; and the membrane passes through the unreeling roller, the bent roller and the flat roller and then is combined with pre-soaked cloth to complete the laminating procedure. According to the simple parallel spreading and laminating device and technology for the wide ultrathin membrane, non-uniform elastic deformation is generated in the middle area and the edge areas of the membrane through the axial stroke linear change of the bent roller and the elasticity of the membrane, the spread membrane is fixed in the weft direction through the flat roller so that the ultrathin membrane can be spread, and the problems that the ultrathin membrane has wrinkles and is unevenly spread in the unreeling process can be effectively solved; unreeling is stable, the spreading parallelism of the ultrathin membrane is good, the breadth is stable, bonding to glued fibers is good, the phenomenon that bubbles are brought due to wrinkles of the membrane is thoroughly eliminated, and the finished product rate of the pre-soaked cloth is increased.

Owner:JIANGSU SHENTAI SCI & TECH DEV +1

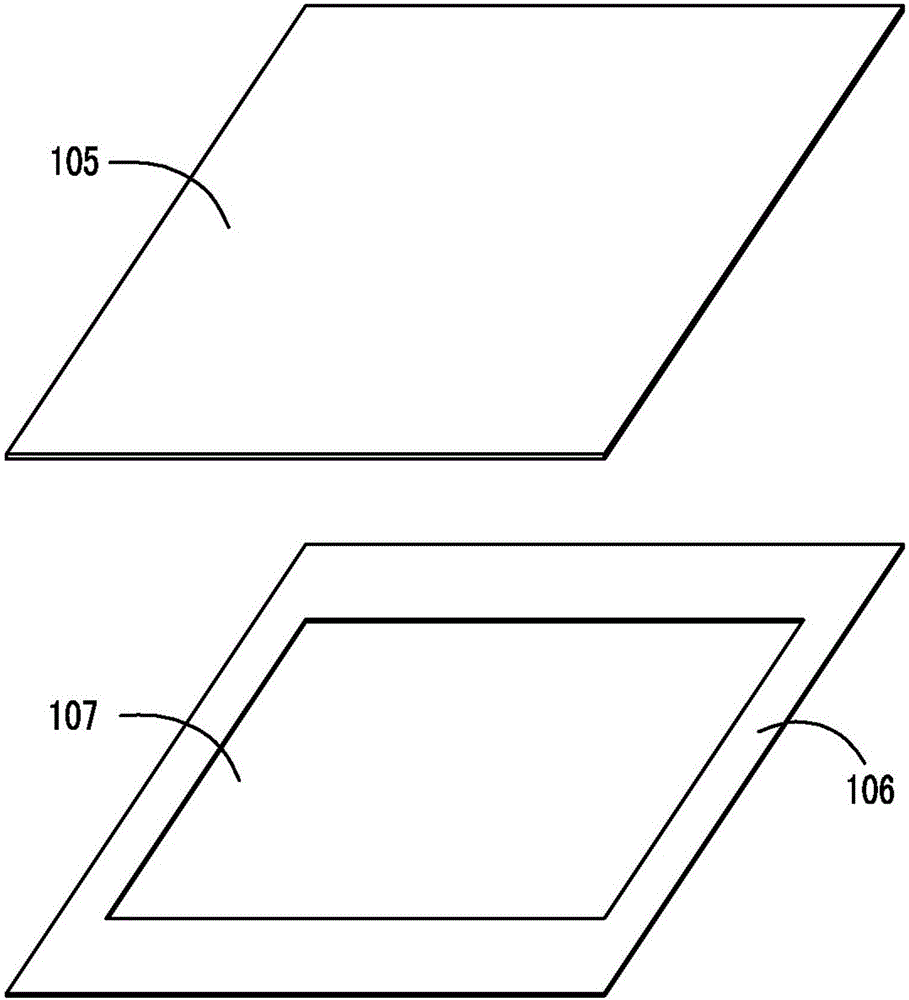

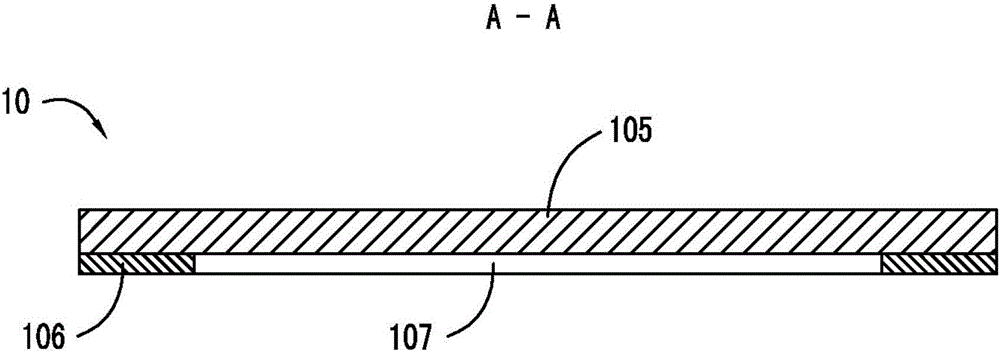

Functional membrane, mobile terminal, hot pressing molding method of functional membrane and tool for hot pressing molding

InactiveCN106738804AImprove bonding yield and finished product qualityReduce processDigital data processing detailsTelephone set constructionsHot pressingCivil engineering

The invention relates to a functional membrane, a mobile terminal, a hot pressing molding method of the functional membrane and a tool for hot pressing molding. The functional membrane is applied to a curved surface cover plate and is provided with a shading region and a light transmitting region, one surface of the cover plate back to a user is the back surface of the cover plate, when the functional membrane is attached to the back surface of the cover plate, the region, corresponding to the shading region, on the cover plate forms a non-display region, the region, corresponding to the light transmitting region, on the cover plate forms a display region, and the shape of the functional membrane is matched with the shape of the back surface of the cover plate. The mobile terminal applies the functional membrane above. The hot pressing molding method of the functional membrane is used to manufacture the functional membrane. The tool for hot pressing molding is used to implement the hot pressing molding method of the functional membrane. The functional membrane is prefabricated into a curved surface model suitable for the curved surface cover plate before attaching, which is favorable for solving the defect problem occurring when a flat functional membrane is attached, such that the attaching yield and finished product quality are improved.

Owner:VIVO MOBILE COMM CO LTD

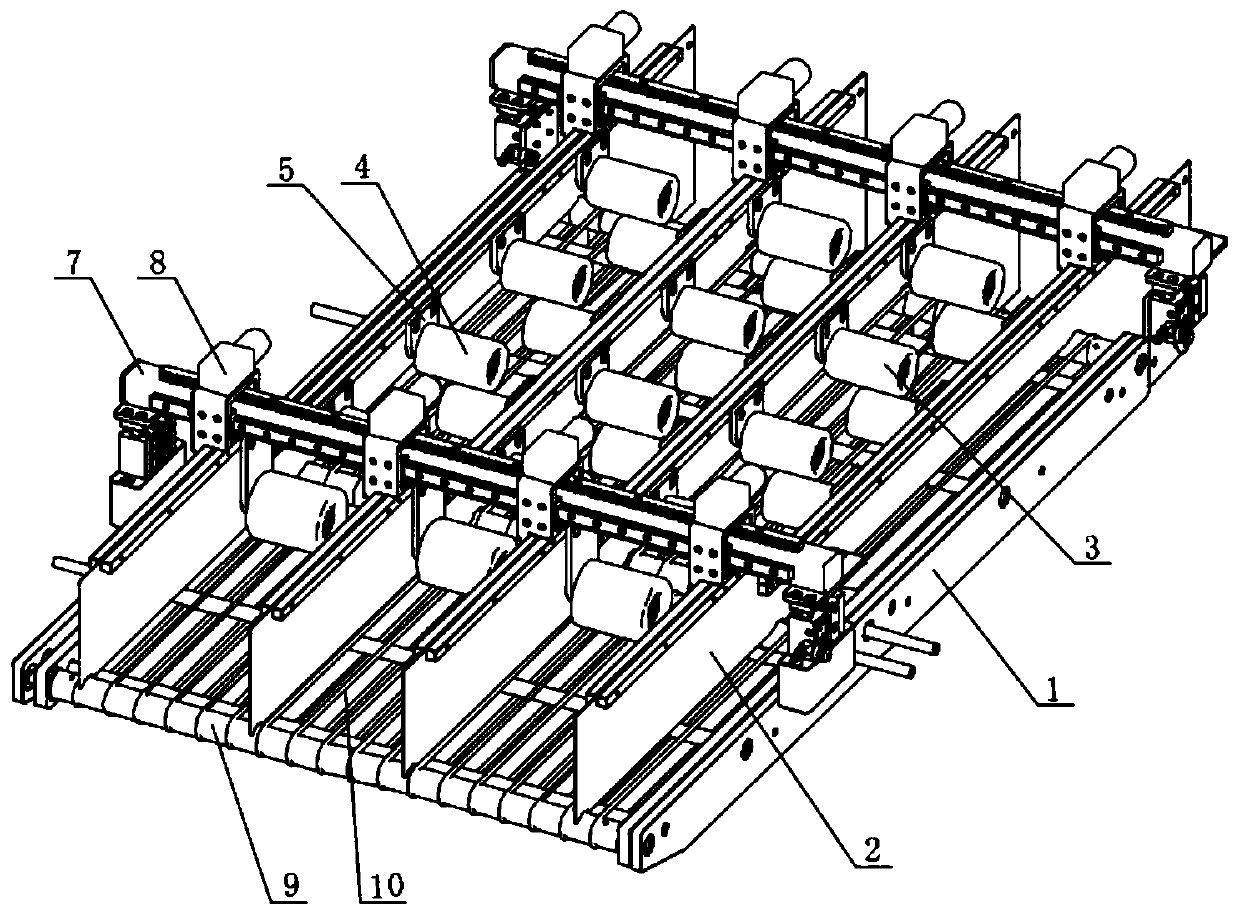

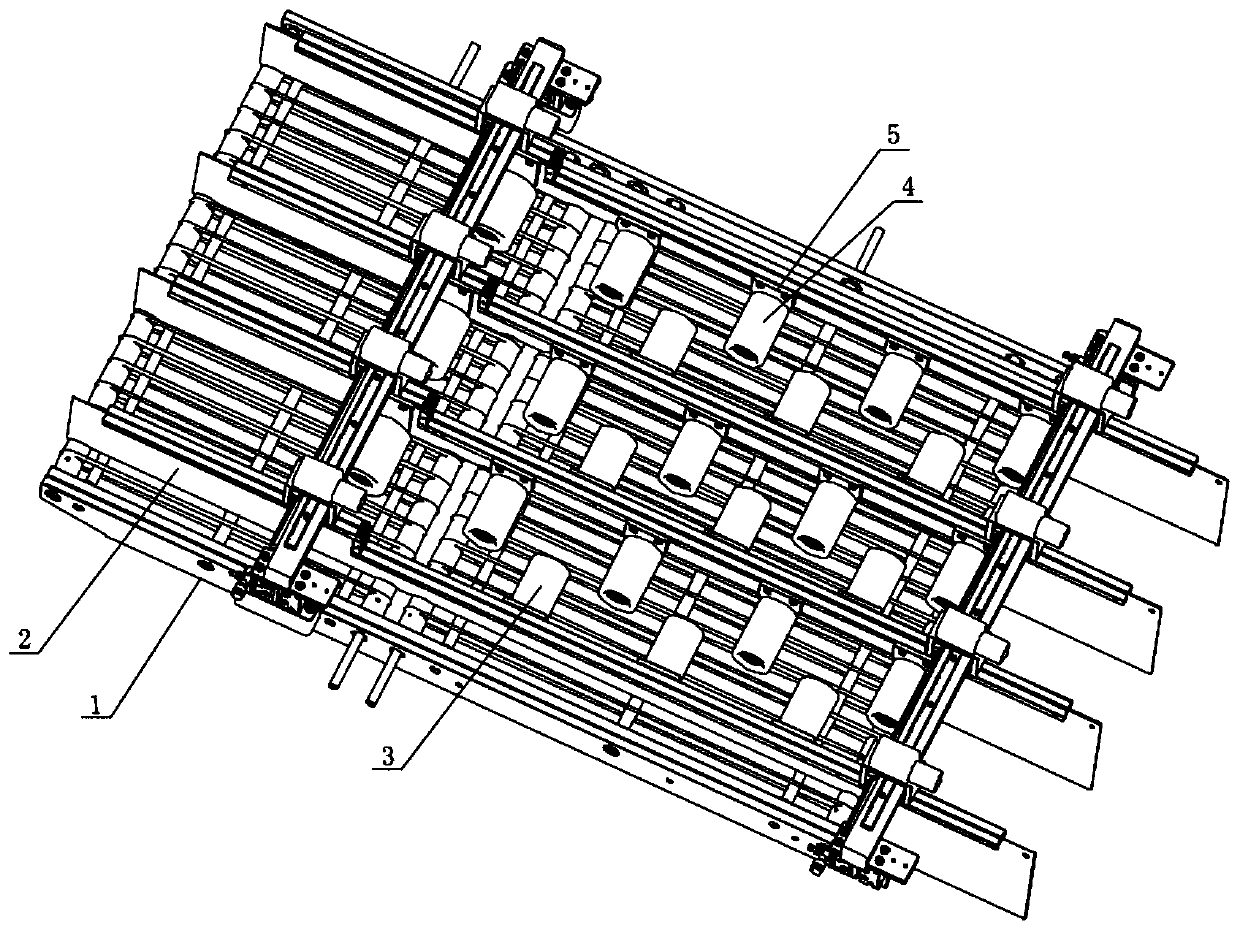

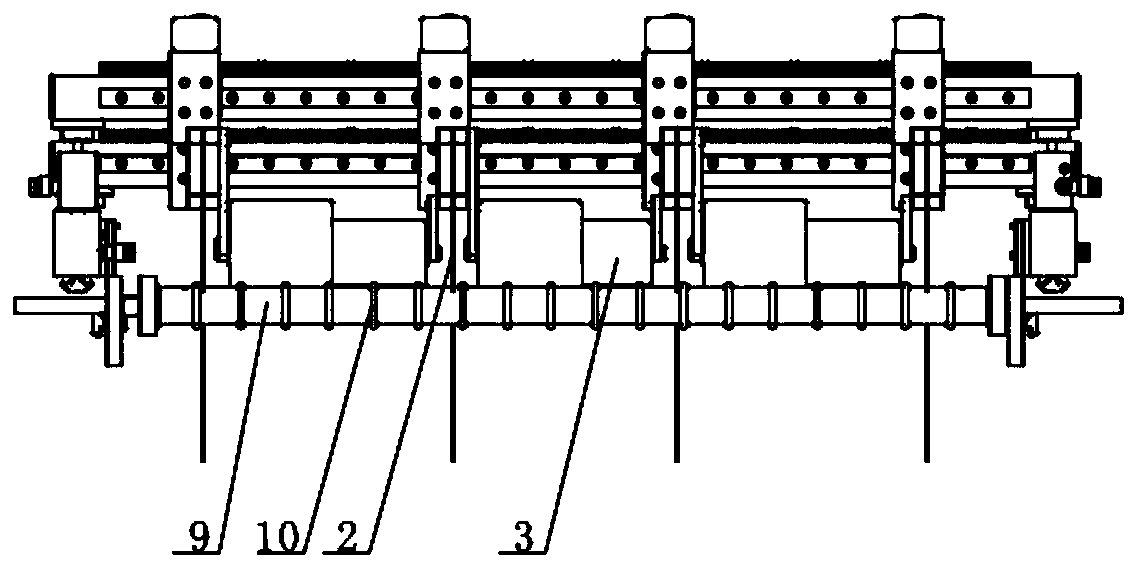

Branching conveying device for sheet-like materials

PendingCN110155768AResolve wrinklesPlay the role of auxiliary transportPackagingArticle feedersEngineeringMechanical engineering

Owner:四川卡库机器人科技有限公司

Non-full-coverage coating diaphragm and preparation method and device thereof

PendingCN109817872AWrinkle freeEvenly distributedCell seperators/membranes/diaphragms/spacersSecondary cellsPole pieceChemistry

The invention discloses a non-full-coverage coating diaphragm as well as a preparation method and a preparation device thereof. The non-full-coverage coating membrane comprises a base membrane and a non-full-coverage coating coated on at least one surface of the base membrane, and the non-full-coverage coating is in uniform point distribution with consistent size and shape. According to the non-full-coverage coating diaphragm disclosed by the invention, the sizes and the shapes of the glue points of the non-full-coverage coating are consistent in height, the glue points are uniformly distributed, and the agglomeration phenomenon is avoided; The non-full-coverage coating diaphragm hardly has the problems of diaphragm denaturation, wrinkling, damage and the like, and the use requirement of thinning the diaphragm can be met. By the adoption of the non-full-coverage coating diaphragm, the interface consistency between the diaphragm and the pole piece can be improved, and then the cycle life of a battery is prolonged.

Owner:武汉中兴创新材料技术有限公司

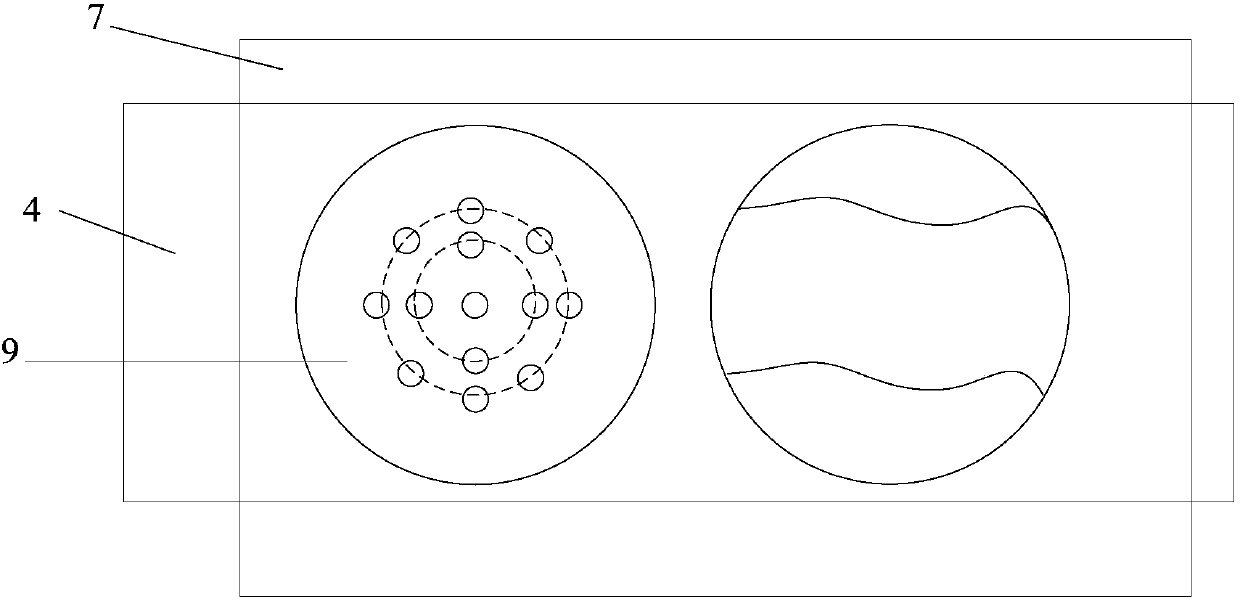

Evaporation device and method

ActiveCN107815649AImprove adsorption strengthEasy switch controlVacuum evaporation coatingSputtering coatingEvaporationEngineering

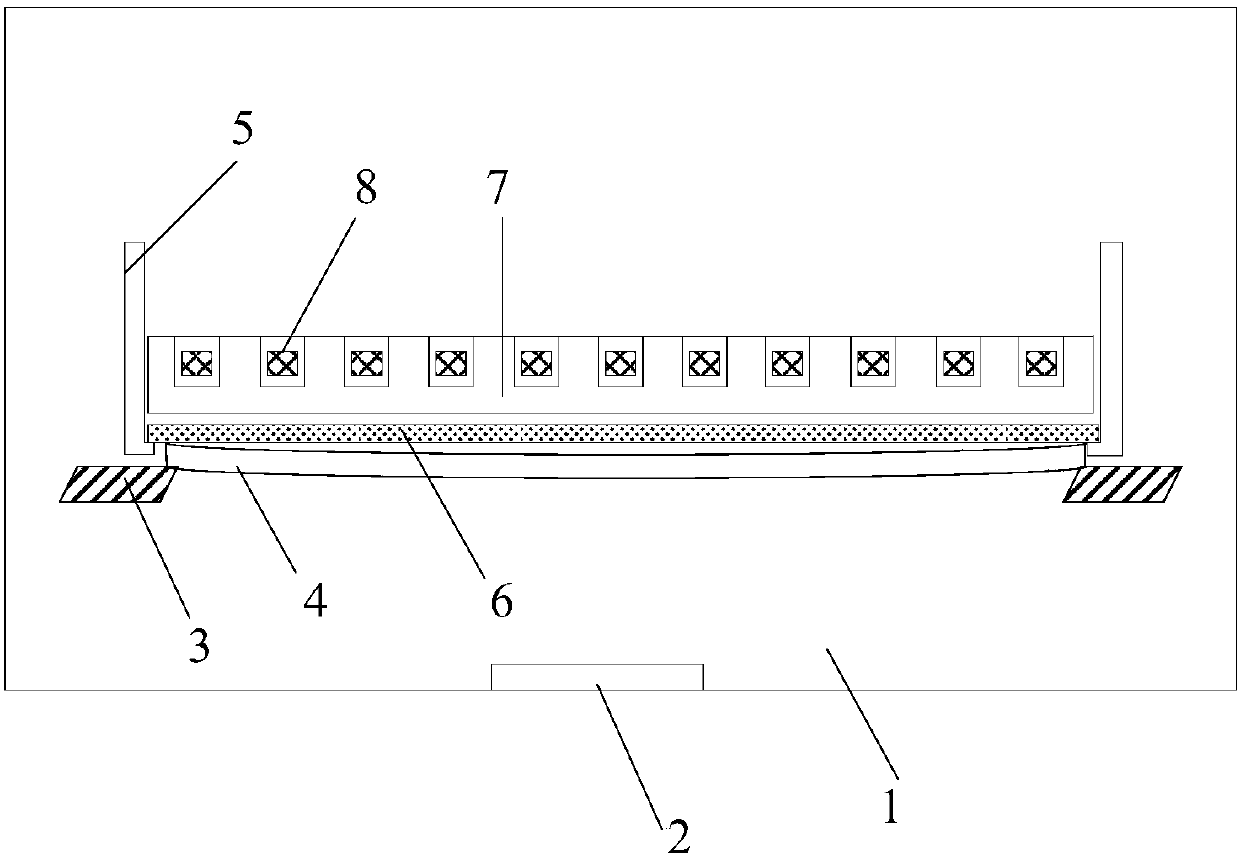

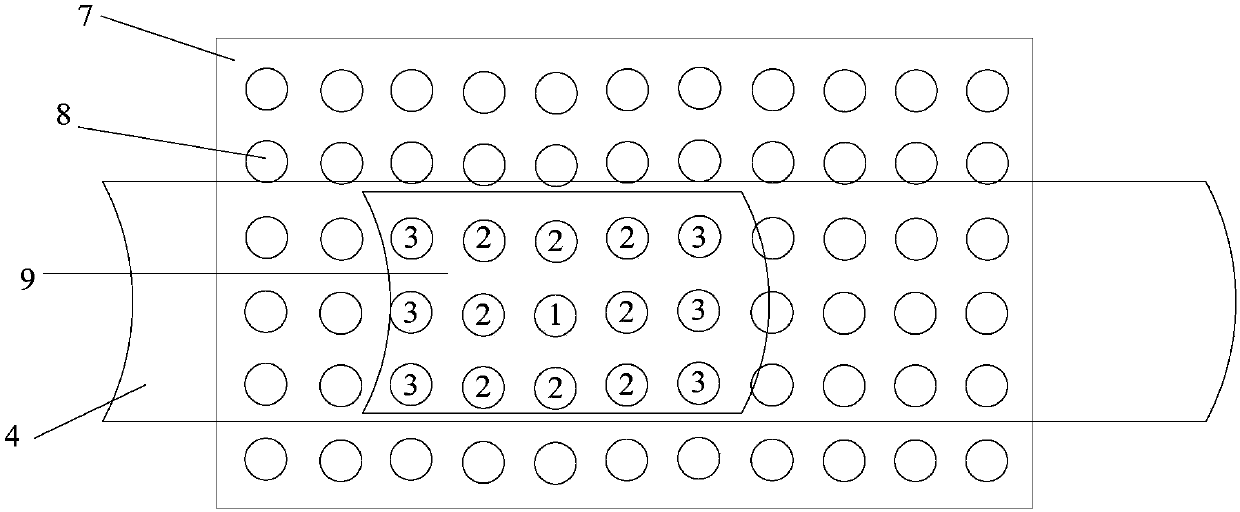

The invention discloses an evaporation device and method. The evaporation device comprises an evaporation base plate carrier. The evaporation base plate carrier is used for carrying an evaporation base plate. An electromagnetic module is arranged in the position, above the zone where the evaporation base plate is located, of the evaporation base plate carrier and comprises a plurality of electromagnetic units. The multiple electromagnetic units are used for energizing according to a preset sequence. According to the technical scheme provided by the invention, by arranging the multiple electromagnetic units for adsorbing metal masks, the problem that the whole metal masks are adsorbed, and consequently the metal masks are winkled or cannot be released due to winkling can be solved, meanwhile, the adsorption strength and switching can be better controlled through the electromagnetic units, and the position precision of patterns on the evaporation base plate can be improved.

Owner:BOE TECH GRP CO LTD +1

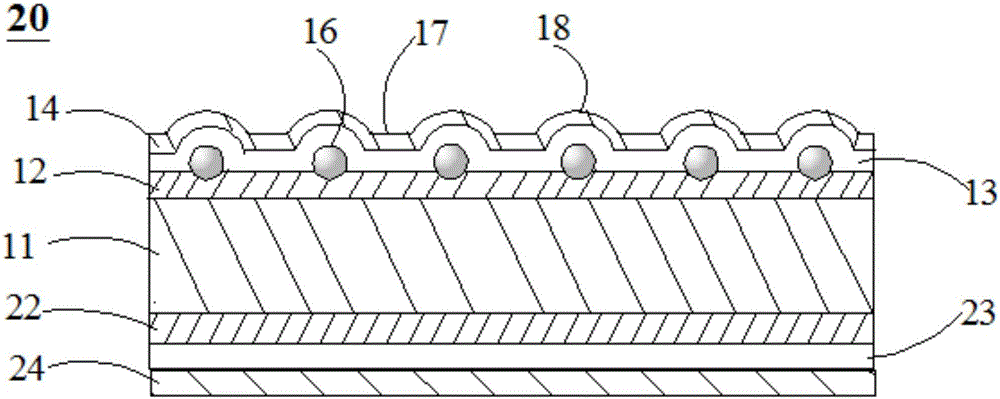

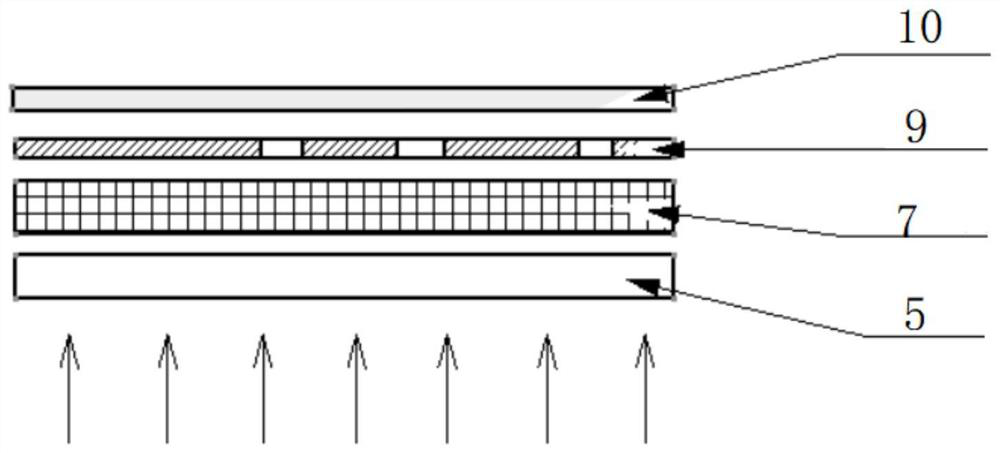

Preparation method of carbon fiber solar panel and carbon fiber solar panel thereof

ActiveCN105810776AAvoid wrinklesResolve wrinklesFinal product manufactureLaminationFiberCarbon fibers

The invention discloses a preparation method of a carbon fiber solar panel and the carbon fiber solar panel thereof. Carbon fiber cloth and a plastic package material layer are stacked on a horizontal carrier for many layers and are pressed to form a horizontal carbon fiber panel. A transparent plastic package material layer, a solar battery piece and a transparent plastic package material layer are sequentially and neatly stacked on another horizontal carrier, and are pressed to form a horizontal pre-pressed solar module. The horizontal carbon fiber panel, a plastic package material layer, the horizontal pre-pressed solar module and a transparent plastic package material layer are neatly stacked and pressed to form the horizontal carbon fiber solar panel. According to the invention, the carbon fiber cloth is heat-pressed and prepared into the horizontal carbon fiber panel; the solar battery piece and the transparent plastic package material layers are pre-pressed; the horizontal carbon fiber panel and the solar module are pressed into a whole body through a lamination machine; and the technical problems of carbon fiber cloth fold, bubble, delamination, shift and the like of the carbon fiber panel in a preparation process are solved.

Owner:紫石能源有限公司

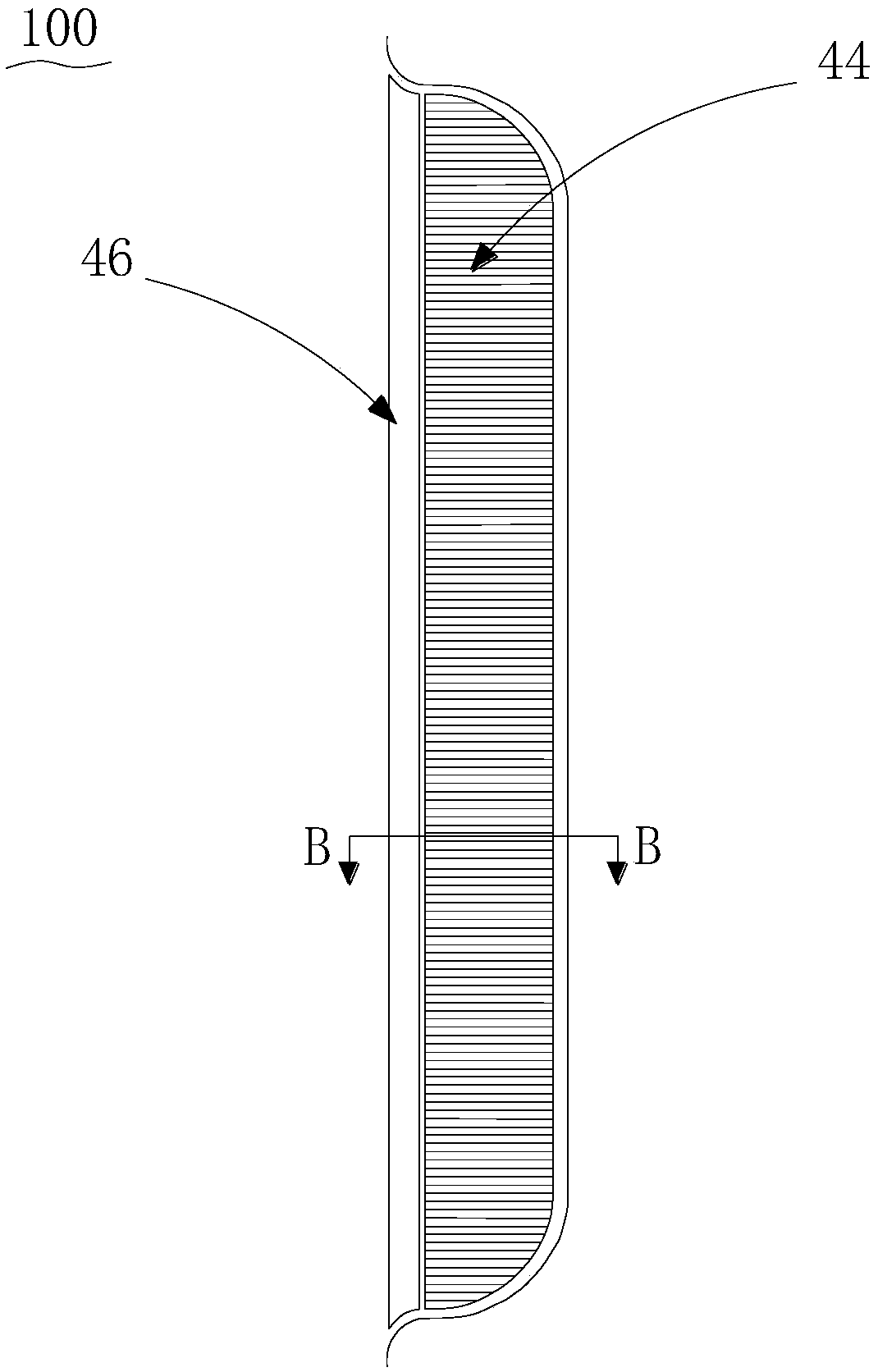

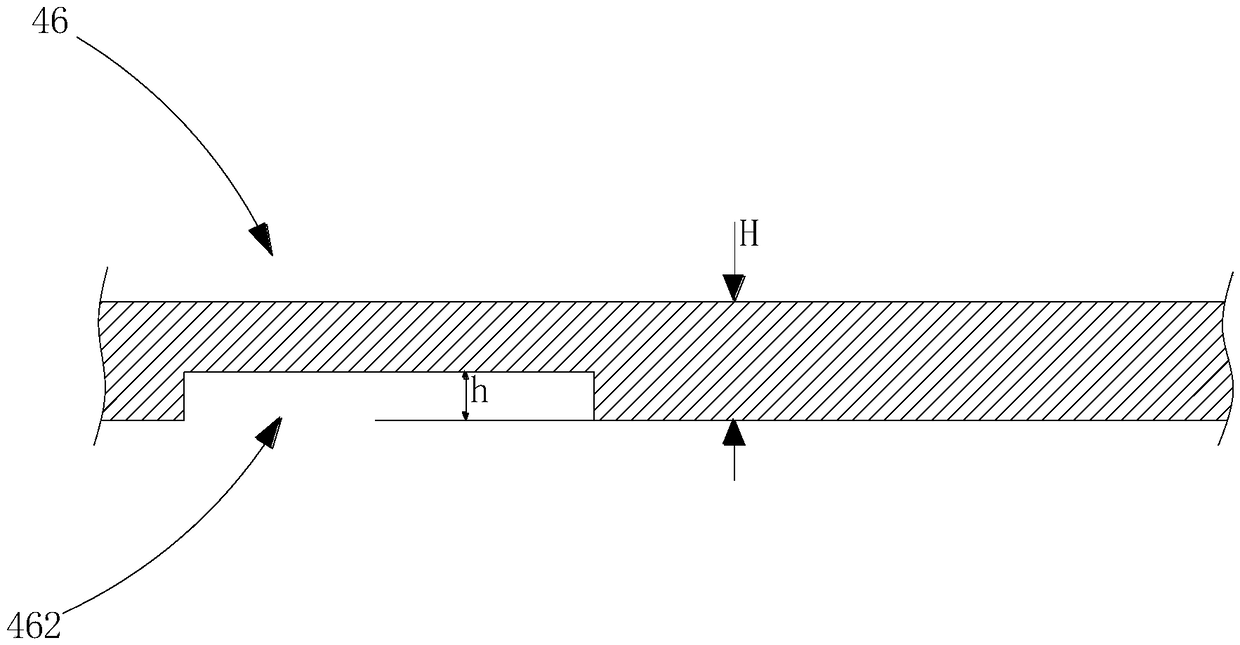

Mask plate

ActiveCN108611596AResolve wrinklesHigh precisionVacuum evaporation coatingSputtering coatingEvaporationEngineering

The invention relates to a mask plate. The mask plate comprises a mask plate body and at least one child mask plate on the mask plate body. Each child mask plate comprises an evaporation area and a first shielding area, wherein a plurality of evaporation holes are formed in the evaporation area in a penetrating mode in the thickness direction of the child mask plate; the depth of the evaporation holes is the same as the thickness of the mask plate body; at least one deformation hole is formed in the first shielding area in a penetrating mode; the depth of the deformation holes is the same as the thickness of the mask plate body; the size of the deformation holes in the net opening direction of the mask plate is larger than that of the evaporation holes in the net opening direction of the mask plate; at least one transition groove is formed in a second shielding area; and the depth of the transition grooves is smaller than the thickness of the mask plate body. According to the mask plate, the tensile strength of the first shielding areas in the net opening direction of the mask plate is smaller than that of the evaporation areas in the net opening direction, and the deformation of the middle areas of the evaporation areas under the tension action is effectively reduced.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

Knitting fabric drying machine

InactiveCN107151880AIncrease productivityImprove practicalityLiquid/gas/vapor removalTextile treatment carriersEngineeringFan blade

The invention discloses a knitting fabric drying machine, which comprises a work table, wherein a fixing rod, a protection box and a fixing plate are sequentially and fixedly connected onto the top of the work table from left side to right side; a support plate is fixedly connected onto the bottom of an inner cavity of the work table; fans are fixedly connected to the two sides of the top of the support plate. Through the arrangement and the matched use of the support plate, a first heat conduction plate, the fan, a support post, a fixing block, the fixing rod, fan blades, a first rolling tube, a first motor, a fabric, a second heat conduction plate, an air outlet, a second rolling tube, a second motor, the fixing plate, a guide wheel, a rotating shaft, a heating machine, a heat transfer rod and a third heat conduction plate, the knitting cleaned fabric is effectively dried; the problem of drapes generated by the fabric in the transportation and storage process when the existing knitting drying machine is used is solved, so that the production efficiency of the knitting fabric is improved; meanwhile, the practical performance of the drying machine is also improved; the knitting fabric drying machine is suitable for being popularized and used.

Owner:SUZHOU COMFORT TEXTILE NEW MATERIALS TECH CO LTD

Multifunctional clothes caring machine

PendingCN107130406AAvoid wrinklesPlay a leveling functionDry-cleaning apparatusIroning apparatusSpray nozzleEngineering

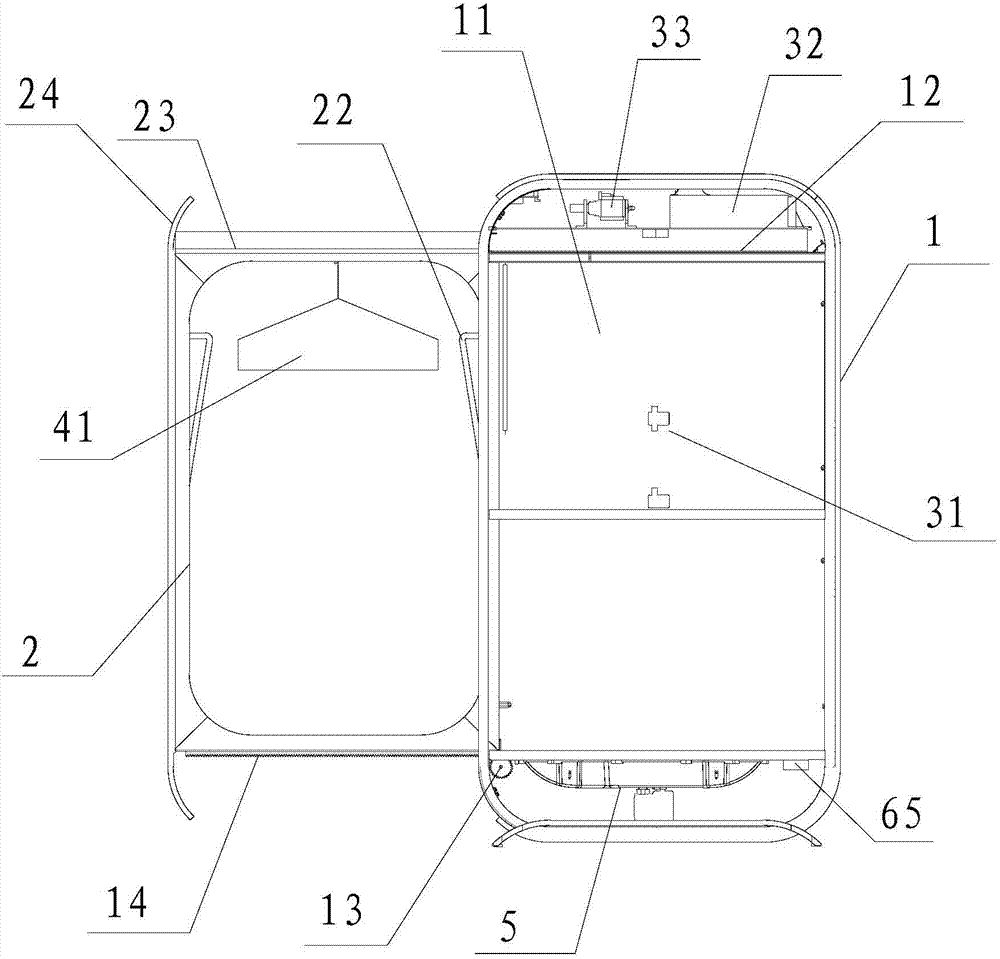

The application discloses a multifunctional clothes caring machine, comprising a shell and an inner frame arranged in the shell, wherein the shell is internally provided with a care solution supply device, a spray nozzle and a heating air supply system; the inner frame is provided with a clothes tensioning device; the shell is internally provided with a working cavity; the spray nozzle is communicated with the care solution supply device; the clothes tensioning device can enable clothes to be in a tensioning state; the heating air supply system is used for providing hot air for drying the clothes. Therefore, the multifunctional clothes caring machine has the functions of micro-dry cleaning, ironing and drying of the clothes, automatic effect identification, and the like, can effectively solve the problems that the clothes have pleats, undesirable odor, humidity and light stains, lightens the labor intensity of consumers and saves the precious time.

Owner:南通欧那电器有限公司

Cloth cutting machine

InactiveCN112160149AResolve wrinklesHigh precisionSevering textilesLiquid/gas/vapor removalElectric machineryEngineering

The invention relates to a cloth cutting machine. The machine comprises a base, a cloth feeding mechanism and a cutting platform are arranged on the base, the cloth feeding mechanism is higher than the cutting platform, the cloth feeding mechanism is used for conveying cloth to the cutting platform, and a cutting mechanism used for cutting the cloth and a sliding mechanism used for changing the position of the cutting mechanism are arranged on the cutting platform. The cutting mechanism is fixed to the sliding mechanism. The cutting machine is characterized by further comprising stretching mechanisms, one end of the cutting platform serves as a feeding end, the other end of the cutting platform serves as a discharging end, and the stretching mechanisms are located at the feeding end and the discharging end respectively and driven by first driving motors; and the rotation direction of the first driving motor located at the feeding end and the rotation direction of the first driving motor located at the discharging end need to be opposite. The cloth cutting machine has the following advantages and effects that cloth can be stretched in the cloth conveying process, wrinkles are reduced, and then the cutting precision is improved.

Owner:嘉善盛立服饰辅料厂(普通合伙)

Winding device for spinning

The invention discloses a winding device for spinning, and relates to the technical field of spinning. The winding device for spinning comprises a device frame, fixing blocks are symmetrically installed at the bottom of the inner side of the device frame, a rotating motor is fixedly connected to one side of the device frame, a rotating rod is rotatably connected to an output shaft of the rotating motor, the end, away from the rotating motor, of the rotating rod penetrates through the device frame, the outer side of the rotating rod is sleeved with a winding frame, the outer side of the rolling frame is rotationally connected with side plates, a flattening device is installed between the side plates, rectangular holes are evenly formed in the sides, close to the flattening device, of the side plates, an extrusion device is installed in the flattening device, wrinkle removing devices are evenly installed on the outer side of the winding frame, a fixing rod is fixedly connected to the interior of the winding frame, and springs are evenly installed on the side, close to the winding frame, of the fixing rod. According to the winding device for spinning, the problem that when cloth is wound, the cloth is prone to wrinkling is solved, and the practicability of the winding device is improved.

Owner:李贵州

Optical glue, method for manufacturing optical glue, and display device

PendingCN109144312AResolve wrinklesAvoid crackingLaser beam welding apparatusInput/output processes for data processingAdhesiveDisplay device

Embodiments of the present invention provide an optical glue, a method for manufacturing the optical glue, and a display device. The surface of the optical glue is provided with a through hole. The optical glue manufacturing method comprises: sandwiching the optical glue between two mask plates, wherein the openings of the two mask plates correspond to each other, and the optical glue is laser-cutthrough the openings of the mask plate in correspondence with the areas on the optical glue to be formed with the through holes; as the through holes are arranged on the optical glue, air bubbles generated in the process of curved touch screen packaging can be discharged, and can also accommodate deformation folds produced when the surfaces are fitted. At the same time, the optical adhesive of the embodiment of the invention has the function of cushioning stress and preventing the generation of cracks. The optical adhesive of the embodiment of the invention can solve the problem that air bubbles are difficult to eliminate and wrinkles exist when the curved surface of the curved touch screen is bonded in the encapsulation process, and can improve the product performance and prolong the service life of the product.

Owner:BOE TECH GRP CO LTD +1

Transparent conductive thin film

PendingCN106782772ANot easy to damageResolve wrinklesConductive layers on insulating-supportsCoated surfaceElectrical conductor

The invention relates to transparent conductive thin film. The transparent conductive thin film comprises a substrate. The substrate comprises a first surface and a second surface. A first hard coating and a first transparent conductor layer are formed on the first surface in sequence. A second hard coating and a second transparent conductor layer are formed on the second surface in sequence. A plurality of particles are embedded on the upper layer of at least one surface of the first hard coating and the second hard coating. The transparent conductor layer and / or the second transparent conductor layer are equipped with a plurality of bulges. The bulges result from the plurality of particles embedded on the surface of the first hard coating and / or the second hard coating. The plurality of particles are embedded on the surfaces of the first hard coating and the second hard coating, so the surface of the substrate is not liable to be damaged, and the problem that press connection and wrinkles occur between two opposite surfaces of the adjacent transparent conductive thin film when the transparent conductive thin film is rolled up to form a cylinder can be solved.

Owner:江西新菲新材料有限公司

Workpiece flange forming method and mould

ActiveCN104826906AReduce residual stressSolving Elasticity ProblemsShaping toolsPlastic propertyFlange

The present invention discloses a workpiece flange forming method and mould. The workpiece flange forming method comprises a material pressing step and a forming step. In the material pressing step, a workpiece is pressed and a to-be-flanged part is exposed; in the forming process, a forming force is applied to one side of the to-be-flanged part and a supporting force which is smaller than the forming force is applied to the other side of the to-be-flanged part, so that the to-be-flanged part is gradually turned and folded towards an edge which is far away from the pressed part. Therefore, different from a manner of overturning the whole part of the to-be-flanged part in the prior art, the flaning process provided by the present invention is used for gradually turning and folding the to-be-flanged part, that is, the whole material of the to-be-flanged part is gradually subjected to once plastic deformation process from the pressed part in the turning and folding process, so that the residual stress to the to-be-flanged part is further eliminated and the to-be-flanged part can be flanged once with high quality; and the problems that a flanged edge is restored, and has folds and turning and folding line traces are solved, and the process is simple and ingenious.

Owner:BEIQI FOTON MOTOR CO LTD

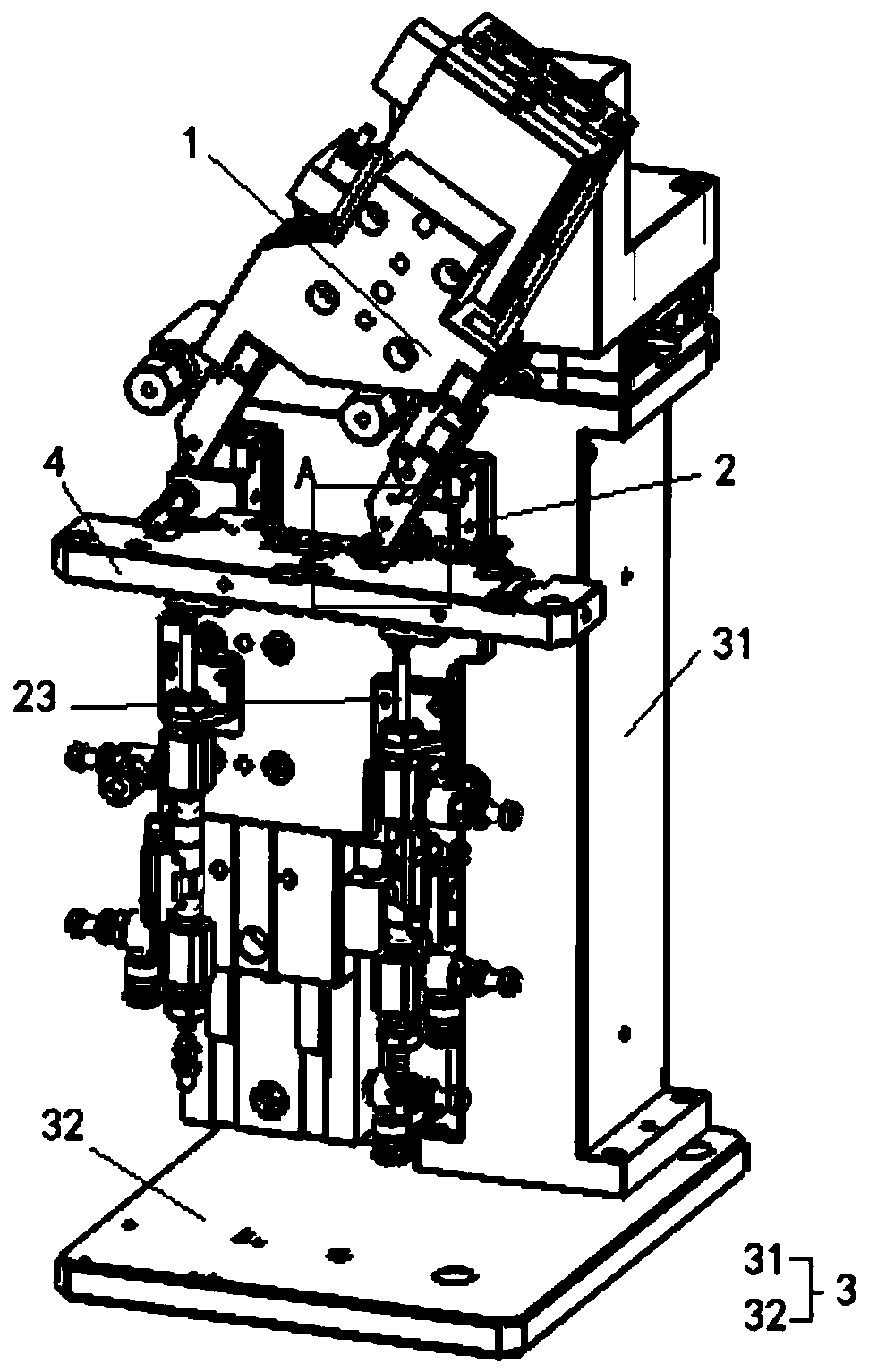

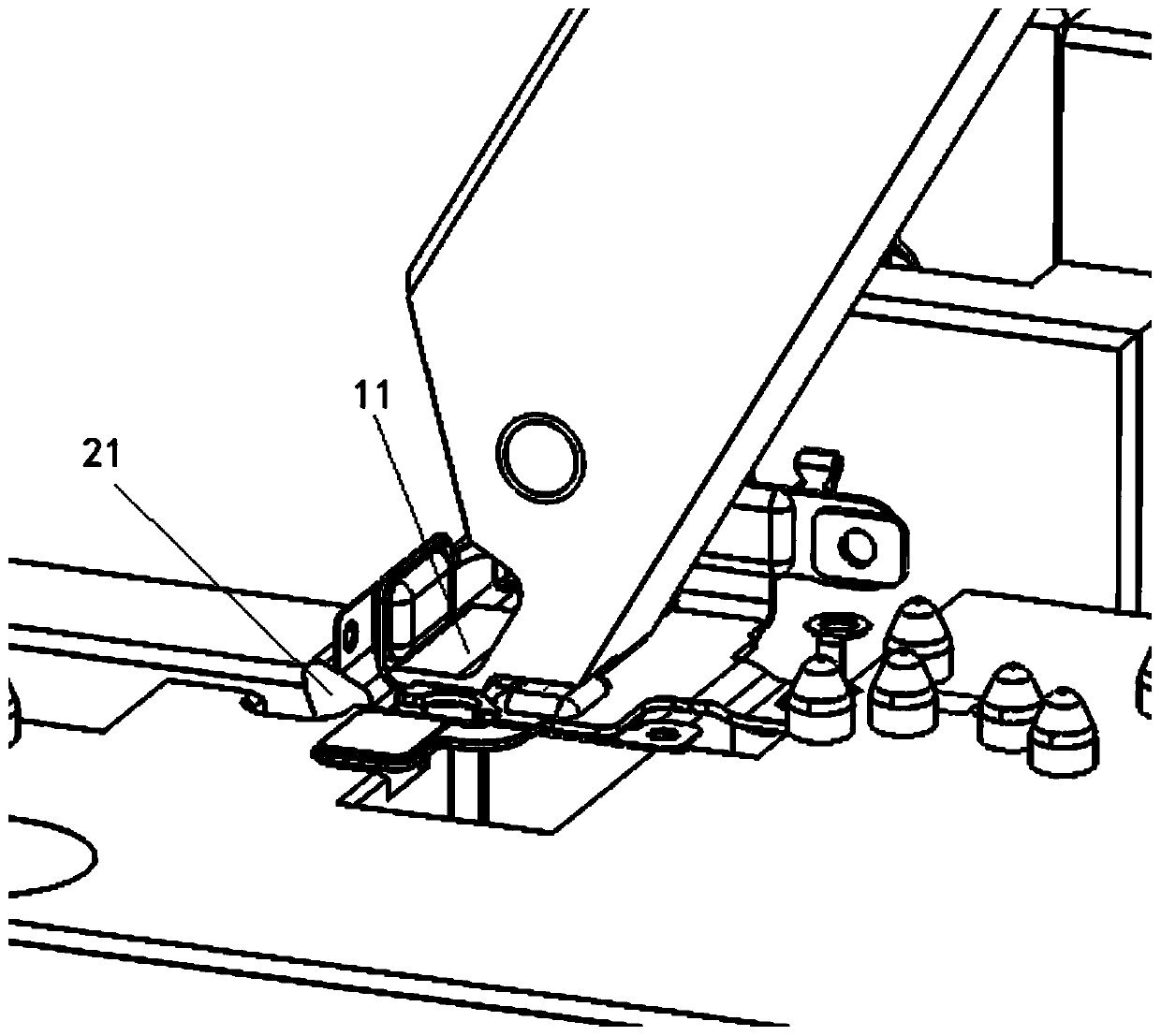

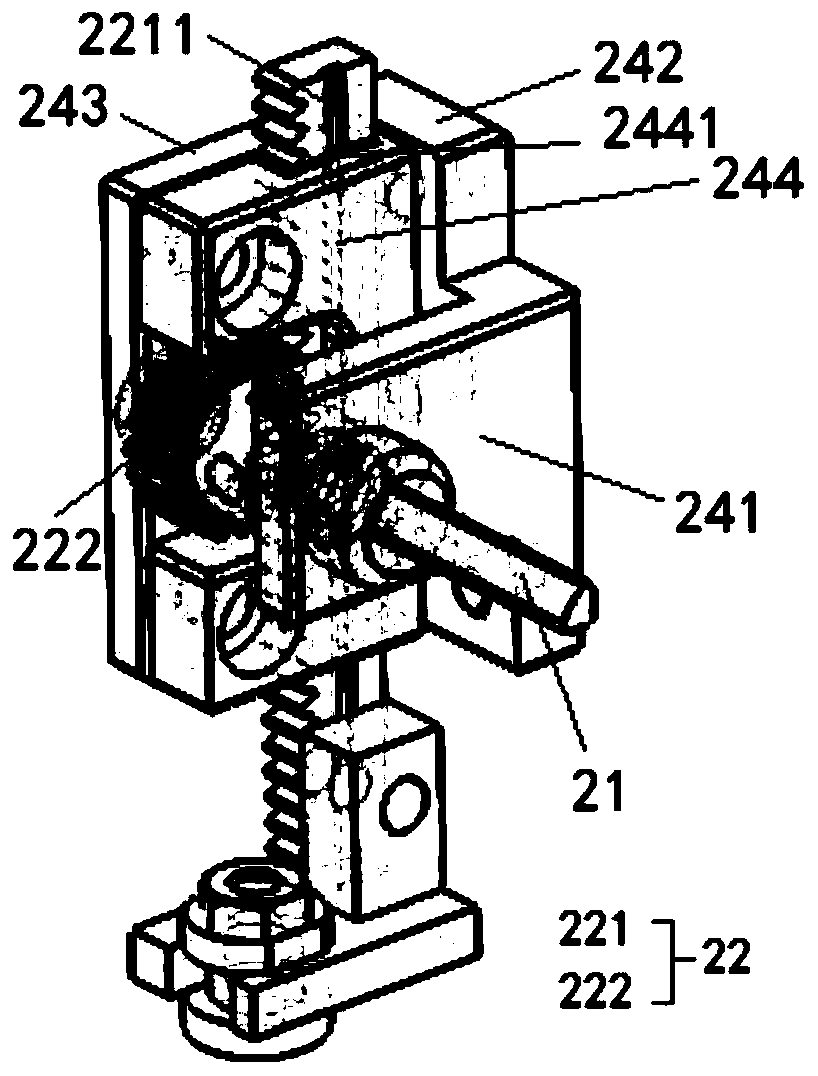

Automatic bending machine for flexible circuit board

PendingCN110757777AResolve wrinklesReduced risk of breakageDomestic articlesFlexible circuitsMechanical engineering

The invention relates to an automatic bending machine for a flexible circuit board. The automatic bending machine comprises a worktable, an upper tool pressing mechanism and a rotating bending mechanism. The upper tool pressing mechanism comprises an upper tool and a first air cylinder, and the upper tool is in drive connection with the first air cylinder. The rotating bending mechanism comprisesa second air cylinder, a transmission assembly and a rotating bending tool. The rotating bending tool is located on the outer side of the worktable. The second air cylinder is in drive connection withthe rotating bending tool through a transmission assembly. During work, the to-be-bent flexible circuit board is placed on the worktable, the first air cylinder drives the upper tool to press downwards and press one part of the to-be-bent flexible circuit board. The rotating bending tool supports the other part, not pressed by the upper tool, of the to-be-bent flexible circuit board. The second air cylinder drives the rotating bending tool to rotate through a transmission assembly so that the to-be-bent flexible circuit board can be pushed to rotate and bend. The flexible circuit board is notextruded in the bending process, the problems that the inner wall of the flexible circuit board is crumpled and the surface is likely to be scratched can be effectively solved, and the risk that an inner core wire of the flexible circuit board is broken is greatly lowered.

Owner:安费诺永亿(海盐)通讯电子有限公司

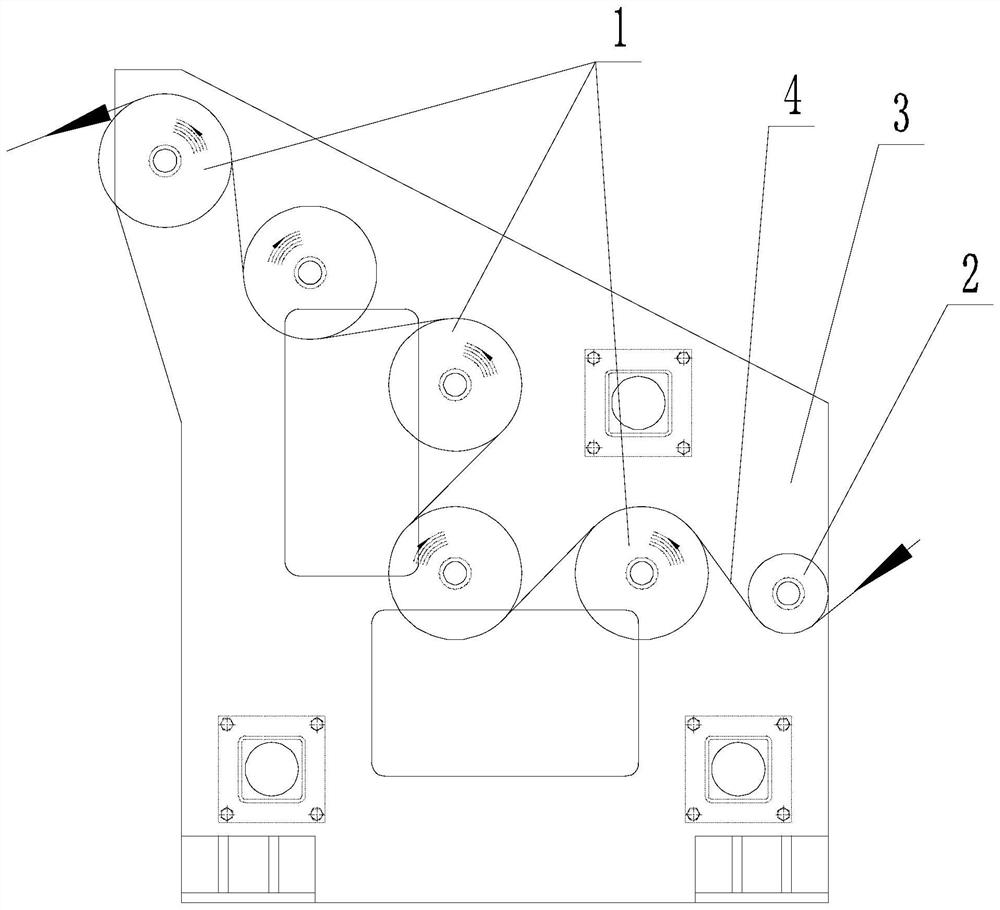

Feeding traction device of multilayer film combining machine

InactiveCN106808787AImprove tensile propertiesResolve wrinklesLamination ancillary operationsLaminationEngineeringMechanical engineering

The invention discloses a feeding traction device of a multi-layer film composite machine, which comprises a fixed bracket, a front traction roller, a rear traction roller and a drive motor, the front traction roller is installed on the side of the rear traction roller, the front traction roller and the rear traction roller The rollers are two identical roller bodies, the middle part of the roller body is provided with a roller shaft, and there are many protruding strip-shaped traction belts evenly distributed on the outer surface of the roller body, and V The upper surface of the traction belt is an arc-shaped upper surface. The roller body is fixed on the ground through the support columns at both ends. The upper part of the support column is provided with a horizontal chute. In the chute; the present invention stretches the raw material film when transporting the raw material film through the special outer surface structure of the roller; through the combination of the front traction roller and the rear traction roller, the raw material film is converted between the two traction rollers , to further improve the stretching effect of the raw material film, solve the problem of wrinkles on the raw material film, and facilitate the uniform distribution of the raw material film.

Owner:JIANGSU YUANHUA LIGHT CHEM EQUIP

Molding method of automotive interior part with multilayered structure

The invention relates to a molding method of an automotive interior part with a multilayered structure. The molding method comprises the following steps: S1, starting a first heating device; heating and softening leather without patterns and then putting the leather into a mold cavity of a concave die; S2, carrying out die assembly; starting vacuum equipment and pressurizing equipment at the same time so that the leather is tightly stuck on the mold cavity surface of the concave die; S3, injecting fused resin; molding the resin and sticking the resin with the leather; meanwhile, copying the patterns of the mold cavity surface of the concave die onto the leather; and S4, carrying out die sinking and taking out the automotive interior part with the multilayered structure. The automotive interior part with the multilayered structure is molded through a one-step method, so that the problems of a low-pressure injection molding method of material leakage, puncturing, folds and non-uniform depths of the surface leather patterns are solved; and the method can avoid disadvantages of a glue covering process that procedures are complicated, toxicity and harms exist and the like.

Owner:SHANGHAIK YANFENG JINQIAO AUTOMOTIVE TRIM SYSTEMS CO LTD

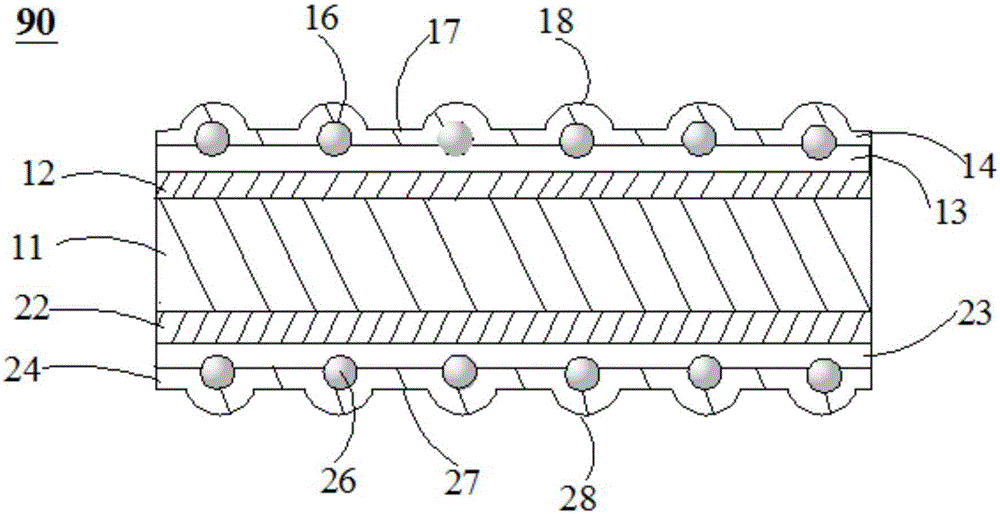

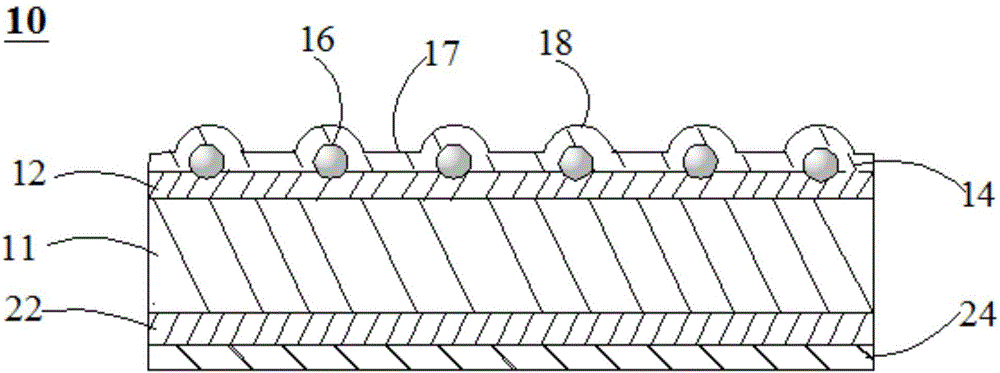

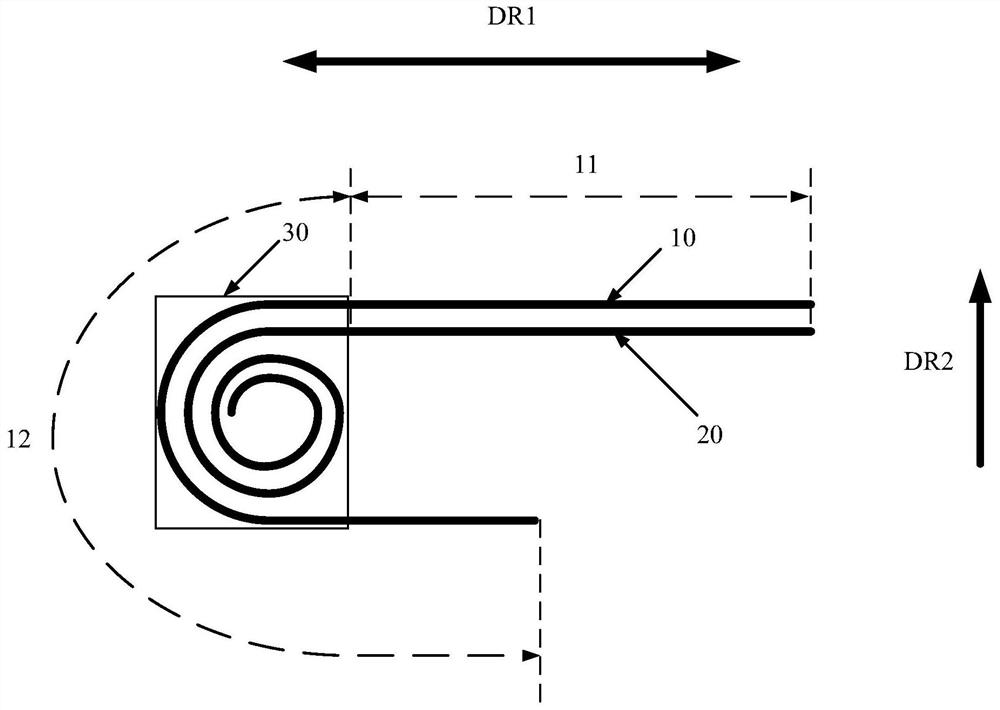

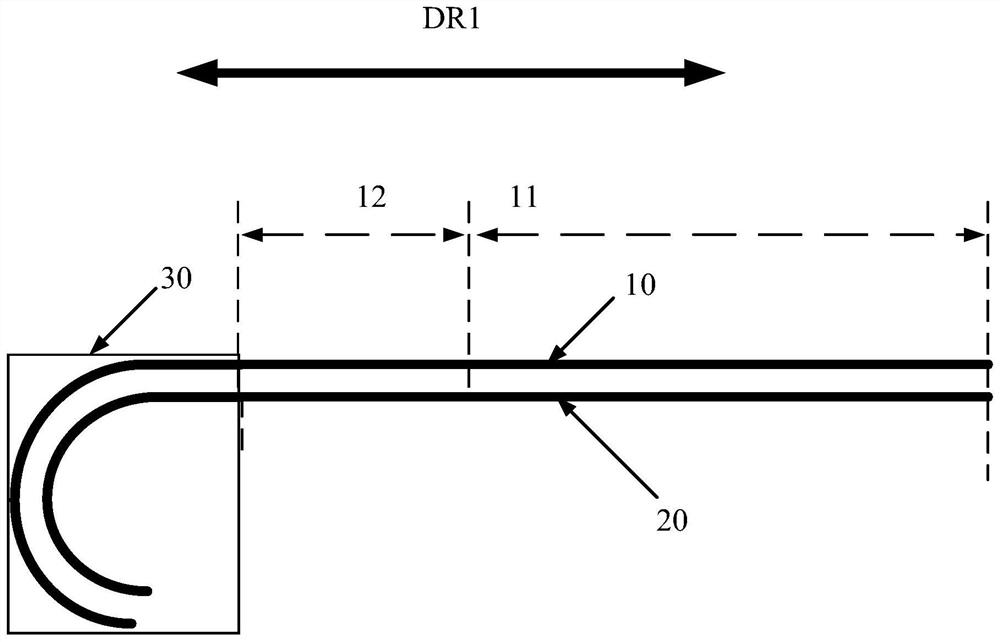

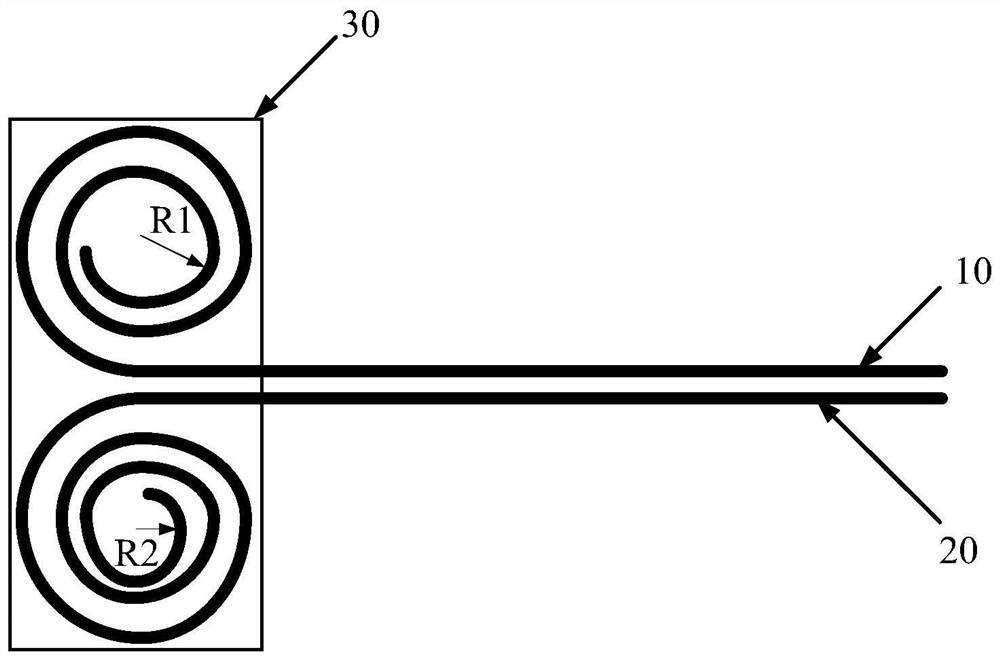

Display device and electronic equipment

InactiveCN111986574AMeet the needs of large-area displayReduce the size of the display areaIdentification meansDisplay deviceEngineering

The invention discloses a display device and electronic equipment. The display device comprises a first functional film layer and a second functional film layer, the display device has a first state and a second state; when the display device is in the second state; the second part of the first functional film layer is at least partially separated from the second part of the second functional filmlayer; at least a part is accommodated in a storage part; the purpose of reducing the display area of the display device is achieved; furthermore, in the storage part, the second part of the first functional film layer has a first storage state; the second part of the second functional film layer has a second storage state; the first storage state is different from the second storage state. The storage demands of the first functional film layer and the second functional film layer which are different in rigidity can be satisfied, the problem that the stress borne by the film layers is too large due to mutual extrusion of the first functional film layer and the second functional film layer is solved, and the problem that when the state of the display device is changed, wrinkles or damage is caused due to the too large stress is solved.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

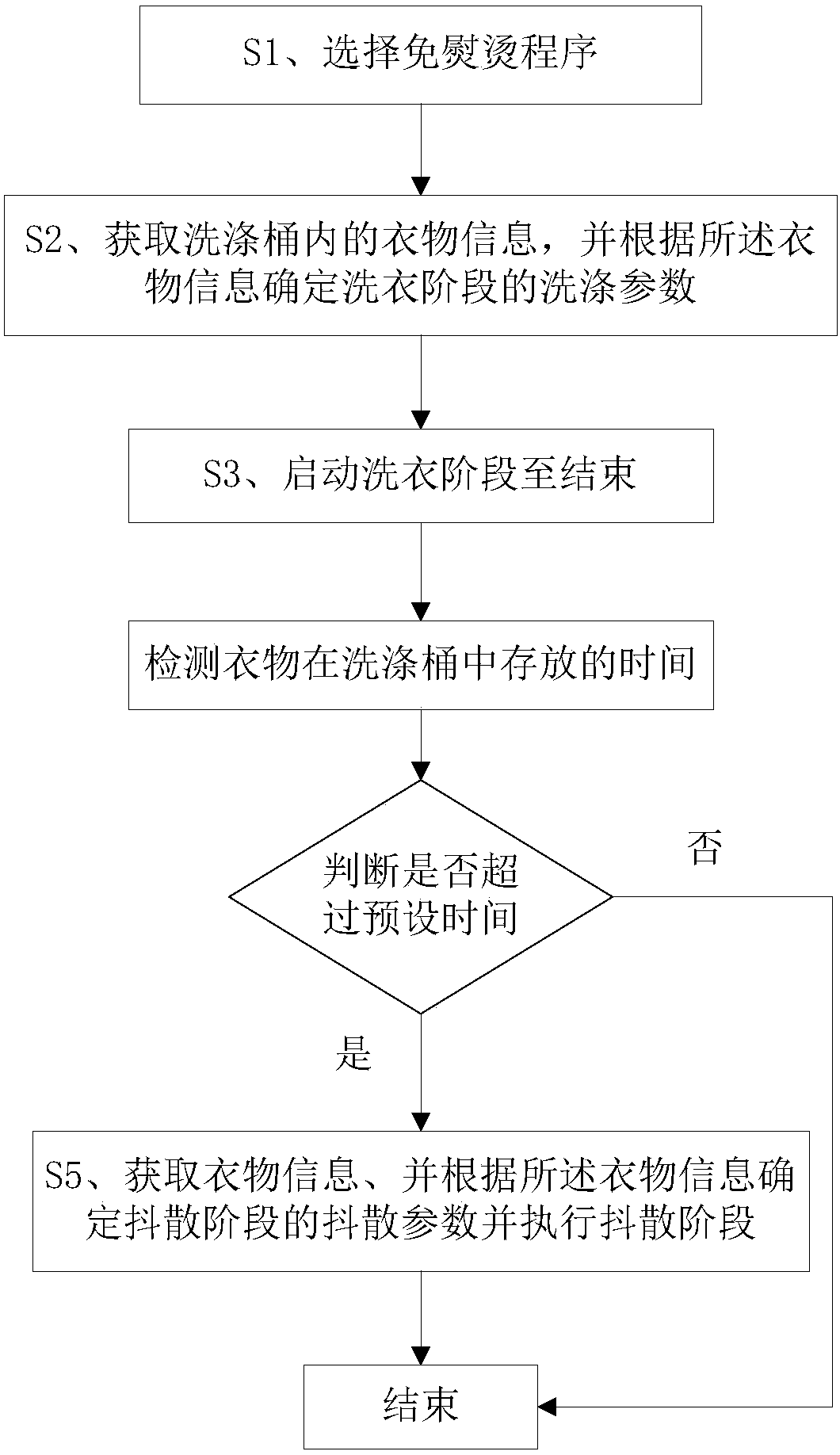

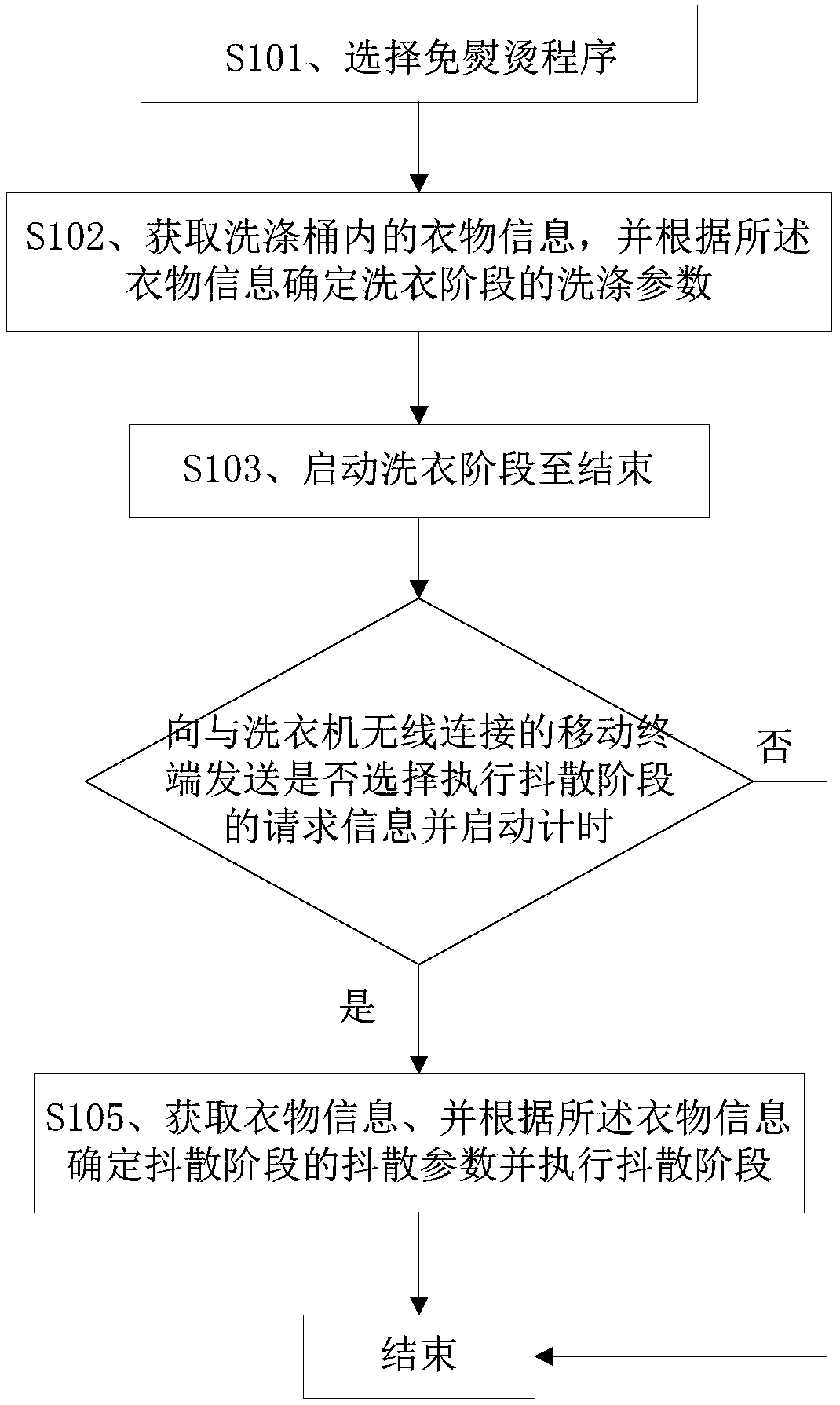

Control method free from ironing and washing

InactiveCN108505282AResolve wrinklesReduce wrinklesControl devices for washing apparatusTextiles and paperUser needsEngineering

The invention discloses a control method free from ironing and washing. The control method is to select a procedure free from ironing, the procedure free from ironing comprises a clothes washing phaseand a shaking looseness phase by intermittently rotating a washtub to make clothes loosen, and the clothes washing phase and the shaking looseness phase are carried out in sequence. The control method free from ironing and washing solves the problem that when a user needs to leave for a long time, the folds of the clothes occur due to the fact that the clothes are accumulated in the washtub for along time, in the procedure free from ironing, the clothes washing phase and the shaking looseness phase are carried out in sequence, the folds of the clothes caused by the long-time accumulation under a humid state are reduced, and then the effect free from ironing of the procedure free from ironing is improved.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

Printing and dyeing technology for chemical fiber woven cloth

InactiveCN109322139AResolve wrinklesQuality improvementHeating/cooling textile fabricsDry-cleaning apparatus for textilesFiberWater baths

The invention discloses a printing and dyeing technology for chemical fiber woven cloth which comprises the following steps: S1, desizing: utilizing a desizing agent and water or steam to finish the desizing step on cloth in an open width desizing machine; S2, drying: performing primary drying operation on the cloth in a drying oven, wherein the dried cloth is in a damp state; S3, pre-shaping: when the cloth is in the damp state, utilizing a shaping machine to perform pre-shaping operation on the cloth; S4, alkali decrement: utilizing water and liquid caustic soda to perform water bath treatment on the cloth; S5, dyeing; S6, dewatering: performing dewatering treatment on moisture of the dyed cloth to make the cloth in the damp state: S7, finished product shaping: performing ironing and shaping operation on the dewatered cloth through the shaping machine. In the printing and dyeing technology for the chemical fiber woven cloth disclosed by the invention, after the cloth is desized and dried, the cloth is in the damp state and has certain plasticity; the cloth is flattened at first, and then the cloth is ironed under high temperature; thus, cloth stress is eliminated, the cloth is ina flat and slack state before the alkali decrement and dyeing, and the dyeing quality is conveniently improved.

Owner:绍兴华南纺织印染有限公司

Soft touch ornament capable of being used for concave surface modeling

PendingCN112895643AReduce refractionReduce scatterSynthetic resin layered productsSuperstructure subunitsEngineeringContact layer

The invention discloses a soft touch ornament capable of being used for concave surface modeling, and relates to the technical field of interior ornaments. The soft touch ornament comprises a light source system, a framework layer, a pattern layer, a soft touch layer and a surface decoration layer, a part of area of the framework layer is made of transparent or semitransparent materials, and the framework layer is located above the light source system; the pattern layer comprises a light-transmitting part and a light-proof part, the pattern layer is located above the framework layer, the soft touch layer is located between the framework layer and the pattern layer and used for providing a soft touch hand feeling, and the soft touch layer is made of a semi-light-transmitting material so that visible light can enter the pattern layer through the soft touch layer; and the front face and the back face of the soft contact layer are both covered with full-transparent or semi-transparent adhesive films, so that the two sides of the soft contact layer are bonded with the framework layer and the pattern layer through adhesive films respectively. By means of the technical scheme, the problems that wrapping bumps, loosening and wrinkles are prone to occurring on a concave surface or a large-area sample piece when an existing soft touch ornament is applied can be effectively solved, and it can be effectively guaranteed that formed patterns are clear and fine.

Owner:CHENGDU AEROSPACE MOLD & PLASTIC CO LTD

Extrusion compounding equipment and process for battery packaging aluminum-plastic composite film

ActiveCN113172978AHigh peel strengthQuality improvementLamination ancillary operationsLaminationElectrical batteryThermal treatment

The invention discloses extrusion compounding equipment and process for a battery packaging aluminum-plastic composite film. The equipment comprises an unwinding mechanism, a corona device, a preheating device, a compounding device, a cooling device and a winding mechanism which are sequentially connected in the conveying direction of an aluminum foil layer, wherein at least one extruder is further arranged at the compounding device, the preheating device comprises a plurality of heating rollers, the temperature of the roller surface of each heating roller is gradually increased in the conveying direction of the aluminum foil layer, and an independent heating temperature area is formed at each heating roller. According to the process, an aluminum foil layer is sequentially subjected to corona treatment and heating treatment while a high polymer material film layer is extruded; and then the heated aluminum foil layer and the extruded high polymer material film layer enter a compounding device together for compounding to form an aluminum-plastic composite film, and the aluminum-plastic composite film is rolled after being cooled. According to the invention, the problem of wrinkles caused by large elongation of the material can be effectively solved, the peel strength of the prepared aluminum-plastic composite film can be effectively improved, and the quality of the aluminum-plastic composite film is improved.

Owner:HUILONG PLASTICS MACHINERY

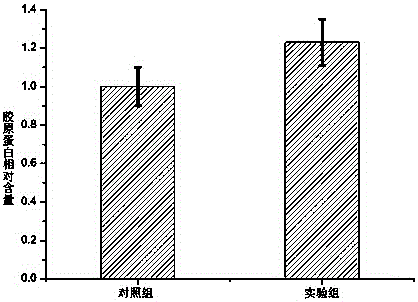

Injection for correcting skin folds and preparation method thereof

The invention relates to an injection (intracutaneous injection) for correcting skin wrinkles and a preparation method thereof. The injection is prepared from the following components by mass: 3-6g / L of high molecular polysaccharide, 50-200mg / L of amino acid, 2-10mg / L of water-soluble vitamin and 2-5g / L of L-carnosine. A sample prepared according to the formula is capable of supplying extracellular matrix to skin and promoting synthesis of spontaneous collagen of skin. The injection has the function of a traditional filling material for supplying lost extracellular matrix, is capable of promoting synthesis of collagen and solving the problem of wrinkled and loose skin caused be senility. Furthermore, compared with a conventional filling material, the injection is lower in viscosity and is more suitable for intracutaneous injection. According to the injection prepared by the method, the problem of sodium hyaluronate and collagen degradation of skin in the aging process can be solved by means of the intracutaneous injection, and an anti-wrinkle and skin-firming effect can be achieved.

Owner:IMEIK TECH DEV CO LTD

Old book refurbishing device

ActiveCN112411255AEfficient repairImprove work efficiencyPaper recyclingOld paper after-treatmentComputer control systemHandwriting

The invention discloses an old book refurbishing device, which comprises a base, a conveying system, a scanning system and a spray head device, and is a multifunctional machine based on a computer control system and capable of being used for processing various old book problems such as paper breakage, wrinkles, handwriting stains, character missing and the like. The working process comprises the steps that after books are conveyed into the machine through the conveying system and pages of a paper supporting plate are turned over, the scanning system analyzes and accurately locates problems existing in paper pages, the work of guniting, humidifying and drying, covering and spraying, typewriting and the like is completed in sequence according to the problem conditions, the operation is repeated till book repairing is completed, and then the books are output. The old book refurbishing machine has great significance in repairing of old books and cyclic utilization of the old books.

Owner:HENAN POLYTECHNIC UNIV

Lead guider

InactiveCN102088174AResolve wrinklesSolve the cracking phenomenonArrangements using take-up reel/drumEngineeringPulley

The invention discloses a lead guider, which is arranged below the back part of a transformer substation protection screen printer. The lead guider comprises a vertically arranged 'C'-shaped groove, wherein a guide hole is formed at the upper end of the 'C'-shaped groove; a slide block is arranged in the 'C'-shaped groove; a tension spring is arranged between the slide block and the lower end of the 'C'-shaped groove; a rotary shaft is fixedly arranged at the position of the slide block, which corresponds to an opening of the 'C'-shaped groove; a pulley capable of rotating on a vertical planeis arranged on the rotary shaft; a power line / a data line winds around the pulley and passes through the guide hole; the internal end of the pulley is screwed and fixed with the slide block; and a circular limit cap the diameter of which is more than the rotary shaft is arranged at the external end of the rotary shaft. The lead guider has a simple structure, practical functions and high reliability, is convenient to mount and use, does not cause a stagnation phenomenon in a using process, effectively overcomes the phenomenon of wrinkled printing paper or broken printing paper caused by unfixed positions of the data line and the power line of a printer, effectively shortens the printing time and improves the working efficiency.

Owner:STATE GRID CORP OF CHINA +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com