Extrusion compounding equipment and process for battery packaging aluminum-plastic composite film

An aluminum-plastic composite film and extrusion compounding technology, which is applied to battery pack parts, circuits, electrical components, etc., can solve the problems of large elongation and wrinkles of materials, improve peel strength, compensate for slack, and reduce coating The effect of length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

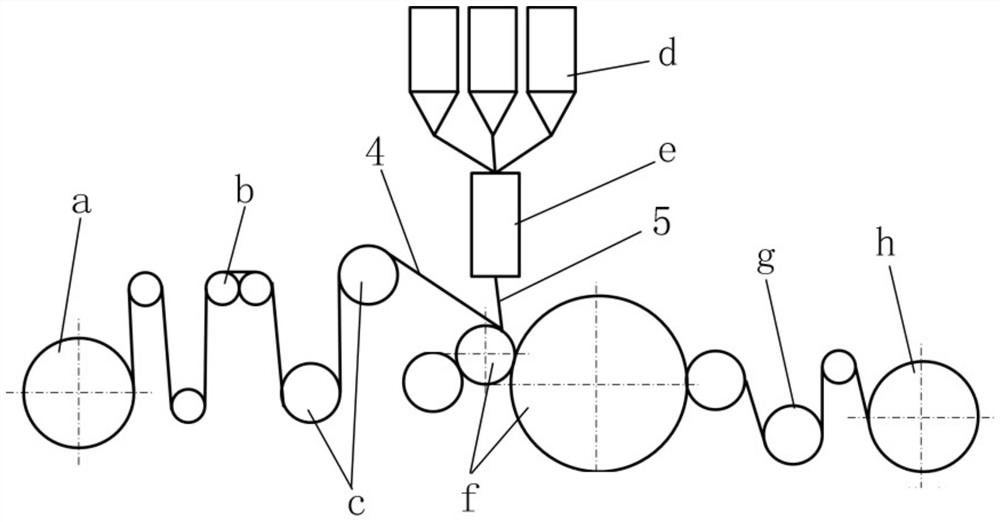

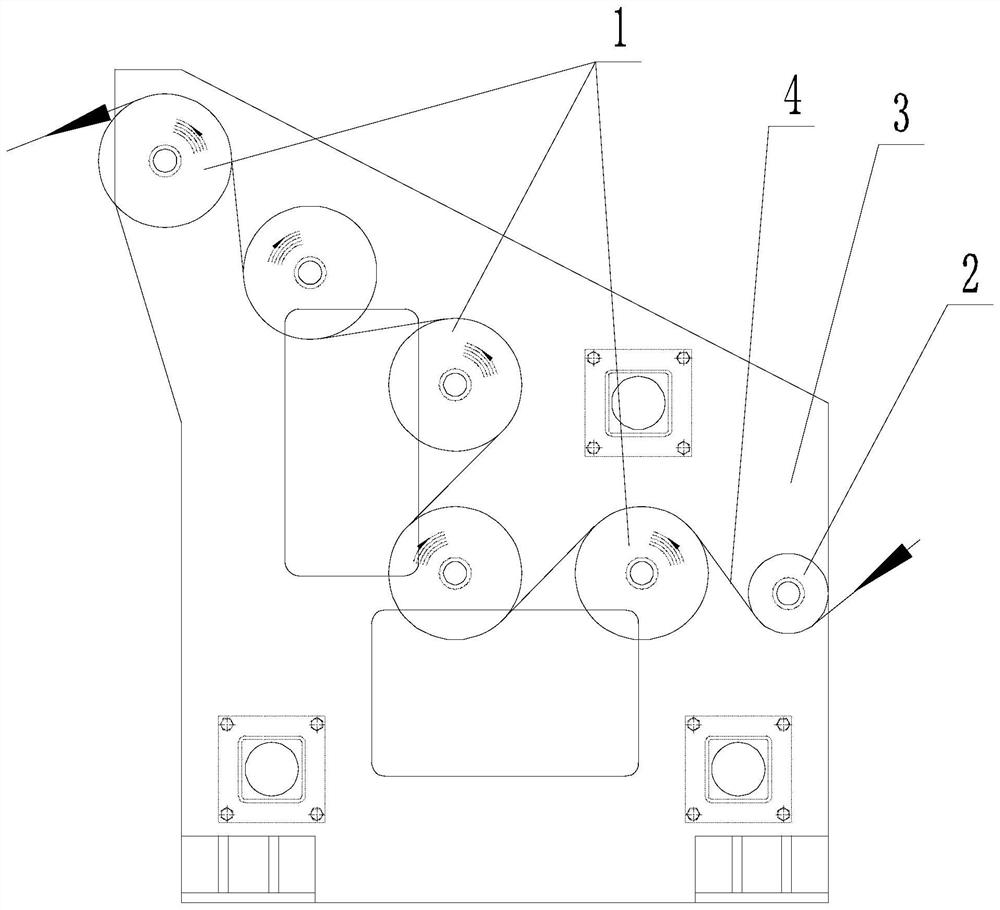

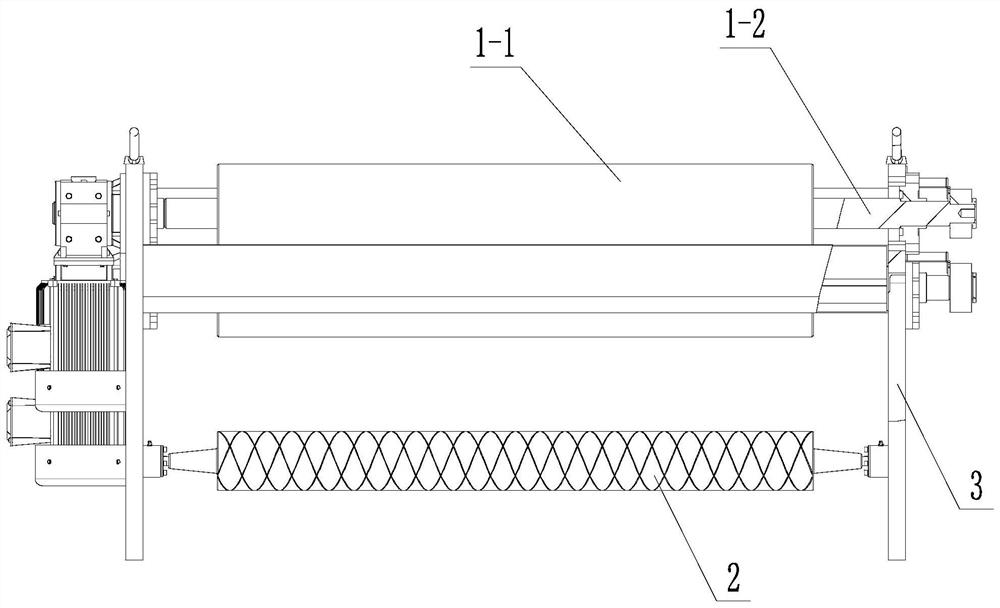

[0031] In this embodiment, a kind of extrusion composite equipment for battery packaging aluminum-plastic composite film, such as figure 1 As shown, it includes an unwinding mechanism a, a corona device b, a preheating device c, a composite device f, a cooling device g, and a winding mechanism h connected in sequence along the conveying direction of the aluminum foil layer. The composite device is also provided with at least one extruder Extruder d (in this embodiment, three extruders are used, and the three extruders are jointly connected to a co-extrusion die head e, and the output end of the co-extrusion die head is located above the composite part of the compound device). That is to say, when a single extruder is used to extrude a polymer material film layer, the main component of the polymer material film layer is a single material or a mixture of multiple materials, forming a single-layer material layer after molding; When two extruders jointly extrude the polymer materi...

Embodiment 2

[0042] Compared with Example 1, this embodiment is an extrusion compounding process of aluminum-plastic composite film for battery packaging. Add the second unwinding mechanism to release the second polymer material film layer, and the aluminum foil, the polymer material film layer extruded in step (2) and the second polymer material film layer are compounded by the composite roller to form an AL / extrusion high-score The three-layer composite film of film / second polymer film is cooled and rolled.

[0043] In addition, in step (1), before the corona treatment is performed on the surface of the aluminum foil layer, after the aluminum foil layer is released by the unwinding mechanism, deviation correction treatment and electrostatic dust collection treatment are also performed in sequence.

[0044] After the aluminum-plastic composite film is formed and cooled, the thickness of the aluminum-plastic composite film can be detected online by using a thickness gauge, and the surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com