Non-full-coverage coating diaphragm and preparation method and device thereof

A non-full coverage and coating technology, which is applied in the direction of electrical components, electrochemical generators, circuits, etc., can solve the problems of disallowed, damaged, and flat diaphragms, and achieve improved interface consistency, improved cycle life, and glue point distribution uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

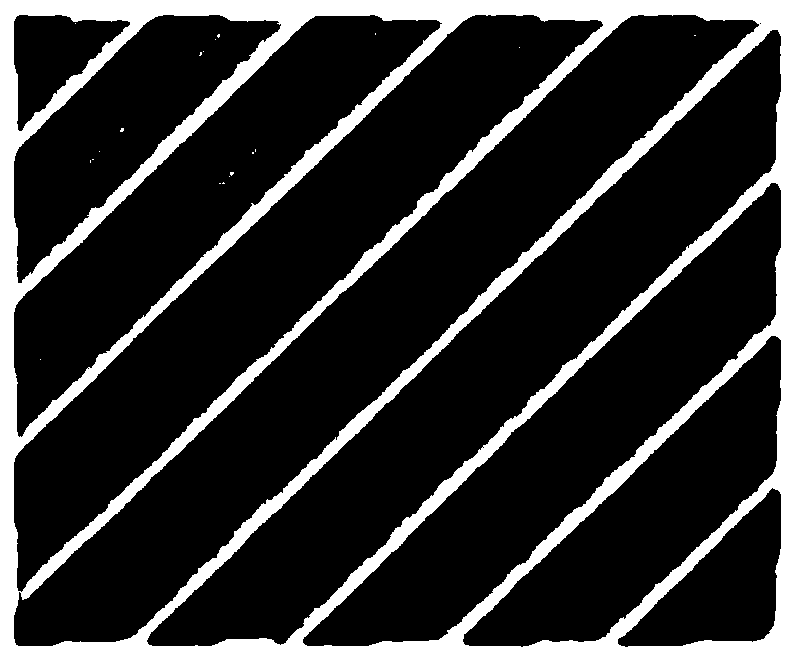

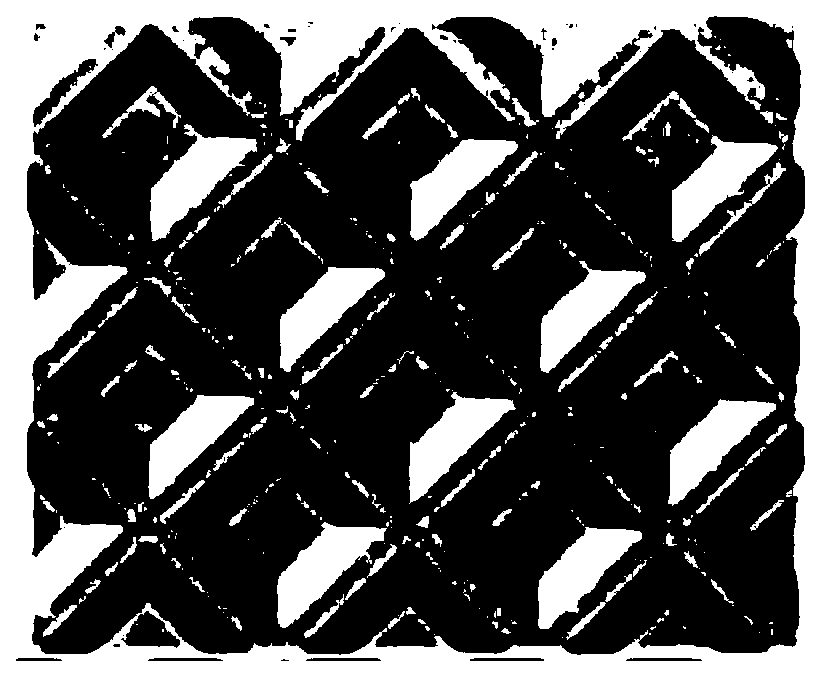

[0047] The device used in this example to prepare a non-full coverage coating membrane includes a micro-grooved roll with improved structure, and the micro-grooved roll adopts a similar figure 2 The discontinuous texture structure shown, the difference is that the mesh of this example is circular; and, in the dimpled roller of this example, the single mesh area of the discontinuous texture structure is 250000μm 2 , the mesh wall width is 70 μm, and the mesh depth is 200 μm. The rest of the device is the same as the existing micro-gravure roller coating device, so it will not be repeated here.

[0048] Based on the preparation device of the non-full coverage coating diaphragm of this example, the preparation method of the non-full coverage coating diaphragm of this example specifically includes the following steps:

[0049] Preparation of coating slurry: Add 40g of polyvinyl alcohol to 200g of deionized water, mix and stir until completely dissolved, then add 100g of vinyli...

Embodiment 2

[0053] In this example, the device and method of the same improved micro-gravure roll as in Example 1 were used to prepare a non-full coverage coating separator. The difference is that the coating slurry formulation in this example is different, and the base film is also different, as follows :

[0054] Coating slurry: Add 40 g of polymethyl methacrylate to 200 g of deionized water, mix and stir until completely dissolved, then add 100 g of alumina powder, and stir at room temperature to make an aqueous slurry.

[0055] Using the same method as in Example 1, the coating slurry is coated on one surface of a 25 μm thick polyethylene terephthalate porous base film to obtain the non-full coverage coating separator of this example, the total coating amount 0.5g / m 2 , the coating thickness is 2.1 μm.

[0056] Among them, the 25 μm thick polyethylene terephthalate porous base film is a self-made base film with a porosity of 65% and a Gurley value of 25s / 100cc.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com