Roll-in device

A roll pressing and convex roll technology, applied in the field of lithium-ion battery production equipment, can solve problems such as foil wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

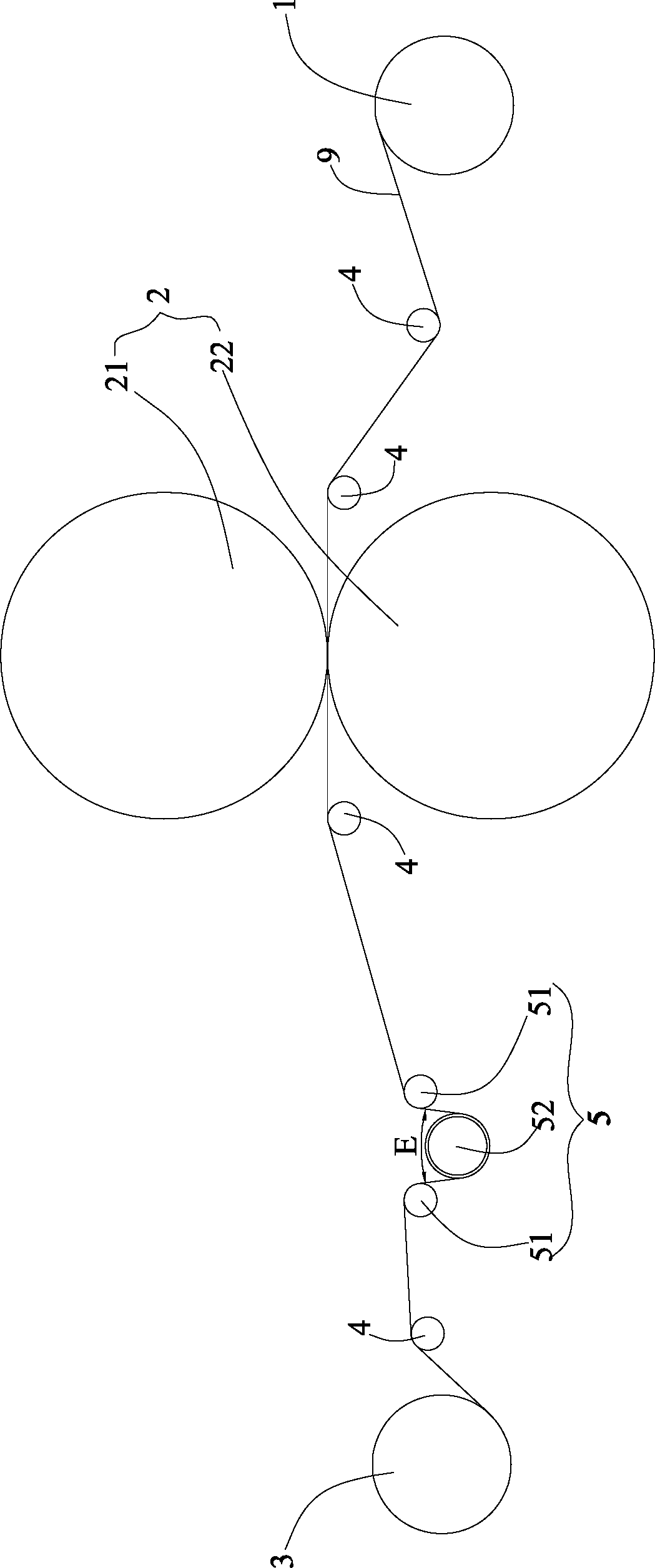

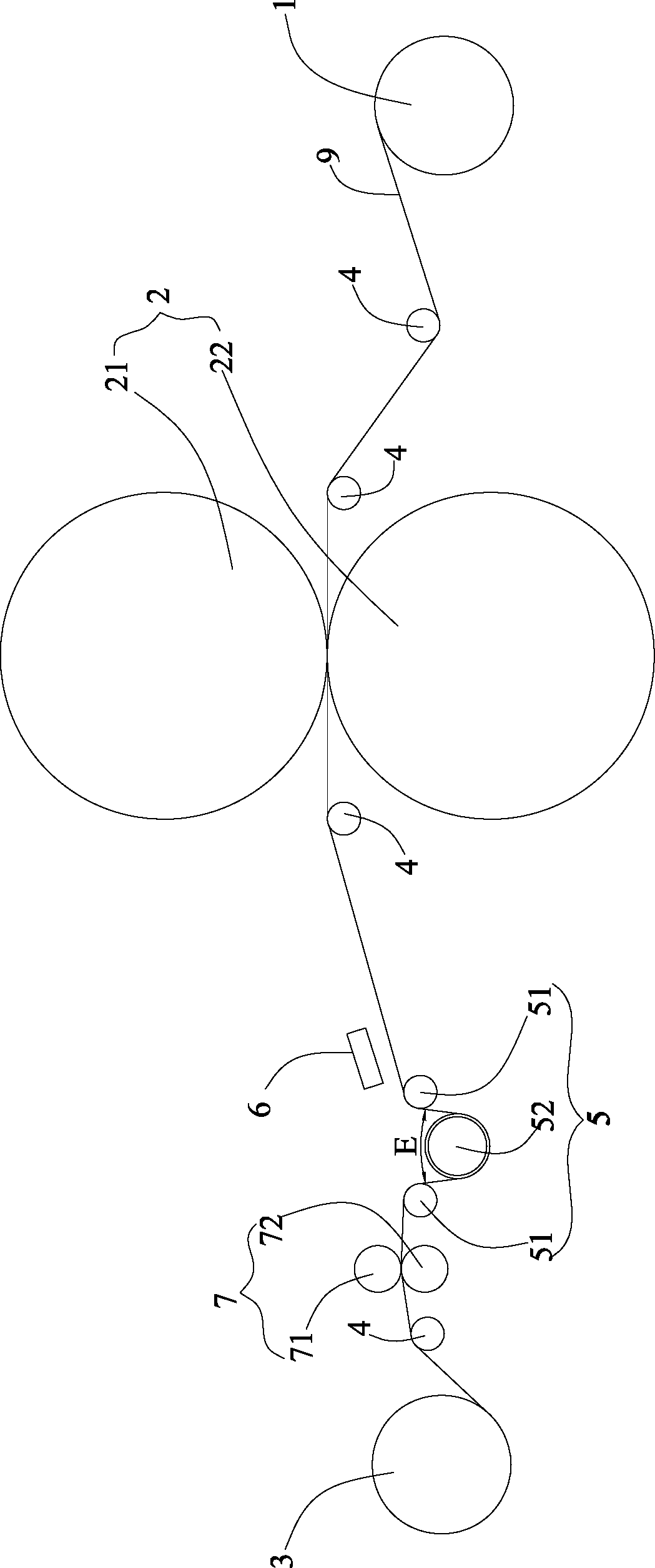

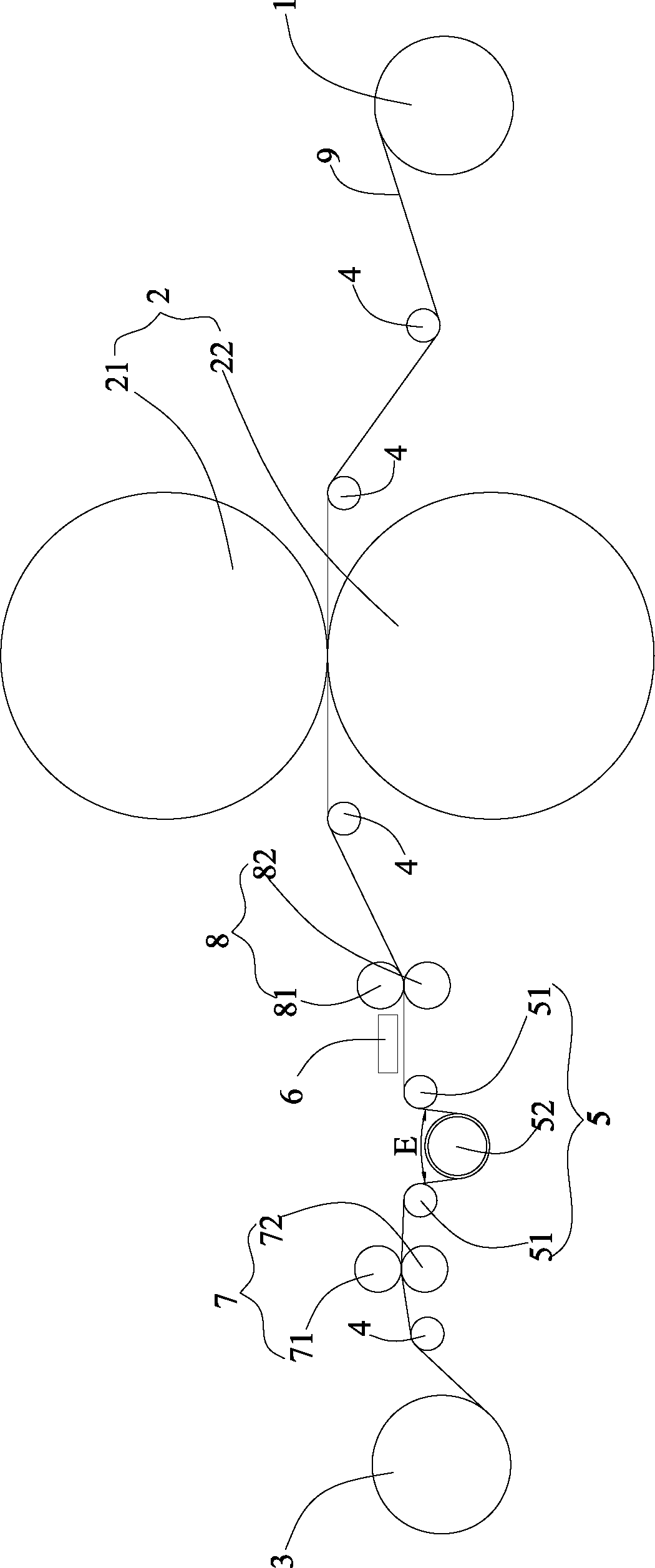

[0028] The rolling device according to the present invention will be described in detail below with reference to the accompanying drawings.

[0029] refer to Figure 1 to Figure 7 , the rolling device according to the present invention includes: an unwinding mechanism 1, on which the pole piece 9 to be rolled is wound, and the pole piece 9 to be rolled is output, and the pole piece 9 to be rolled has a foil 91 and a set The film layer 92 on at least one face of the foil 91, the foil 91 has at least one film coating region 911 extending longitudinally along the foil 91 on the corresponding face provided with the film layer 91 and is positioned at the film coating region 911 side To the empty foil area, the foil 91 is provided with a film layer 92 in the film-coating area 911 and has no film layer 92 in the empty foil area; the rolling mechanism 2 includes an oppositely arranged pressing roller 21 and a back roller 22, which are used for opposing poles. The sheet 9 is rolled; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com