Lead guider

A lead guide and guide hole technology, applied in the direction of the use of reel/photosensitive drum arrangement, electrical components, etc., can solve the problems of messy power lines and data lines, wrinkled printing paper, unusable and other problems, and achieve shortening The effect of printing time, practical function and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

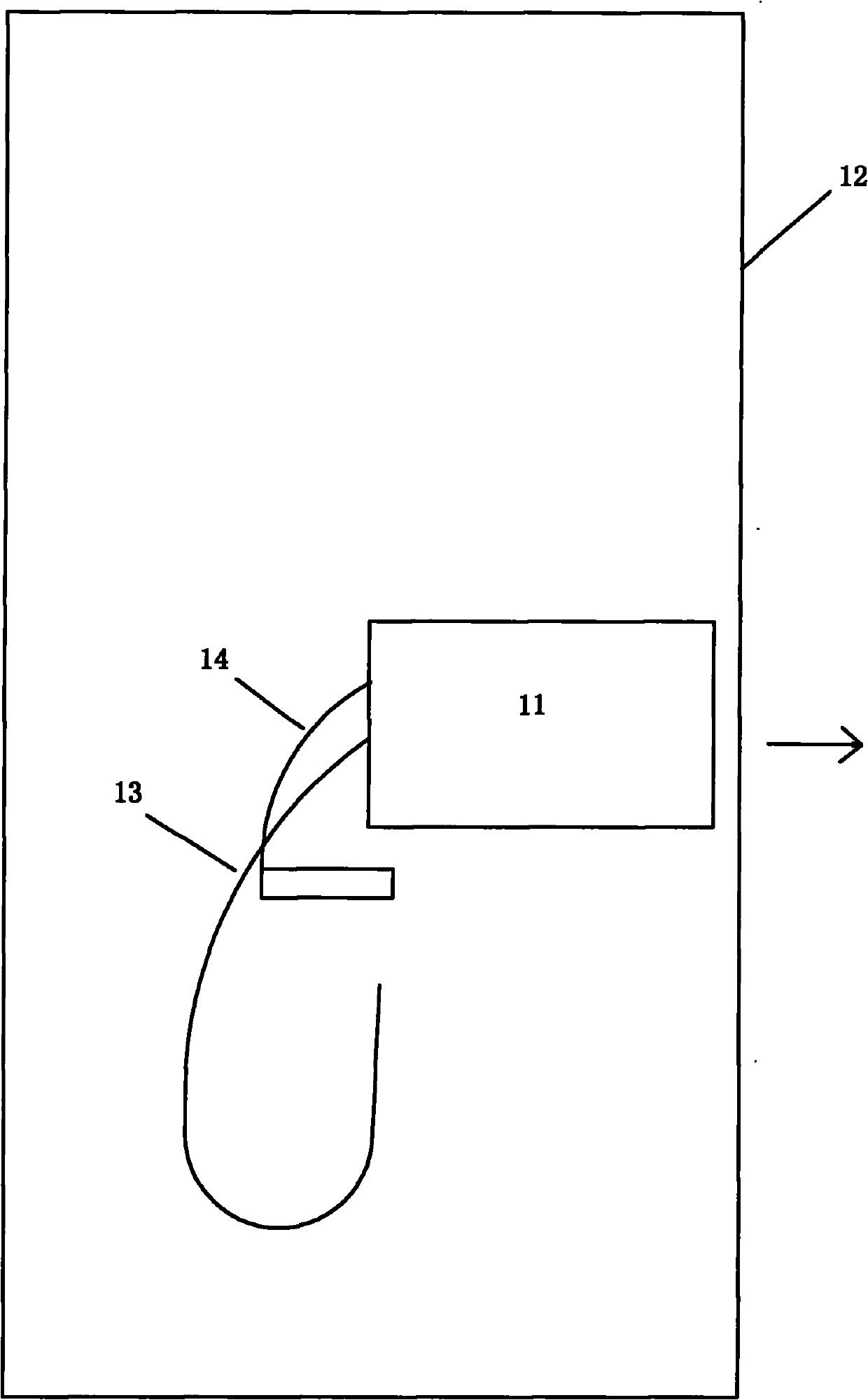

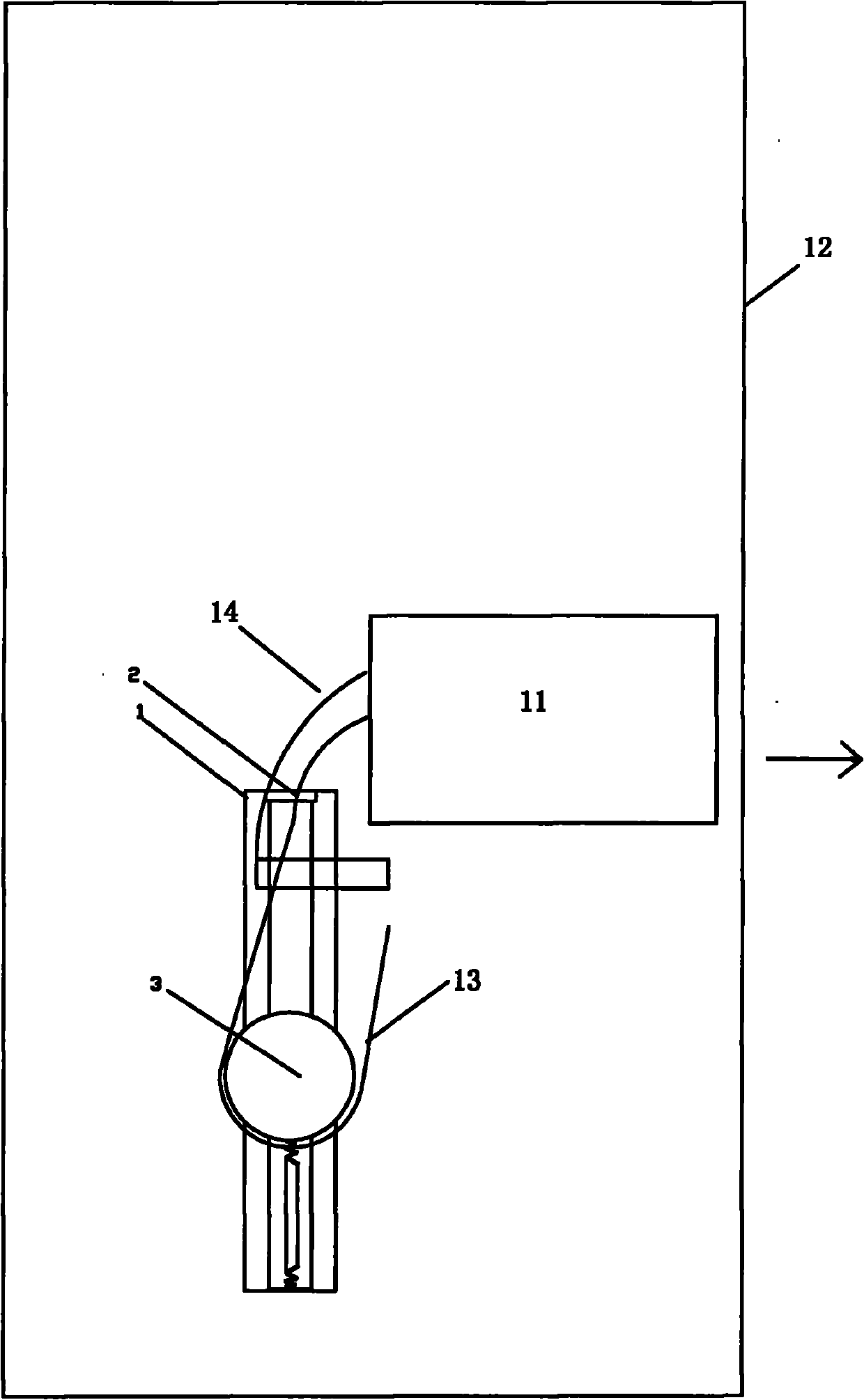

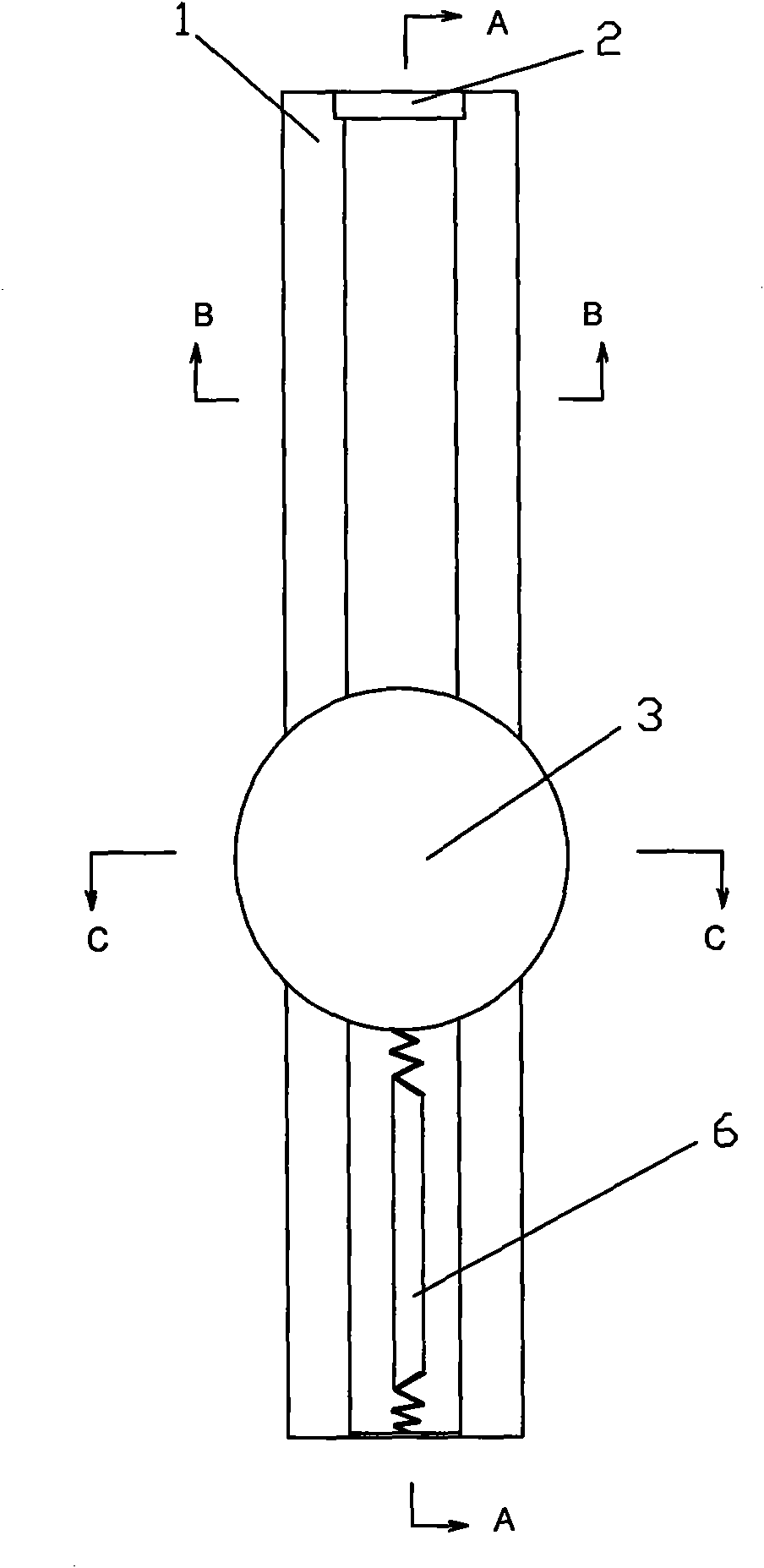

[0013] Example: such as Figure 2-6 As shown, the lead wire guide is arranged at the rear and lower part of the substation protection screen 12 and the printer 11, and includes a vertically arranged "C"-shaped slot 1. The upper end of the "C"-shaped slot 1 is provided with a guide hole 2, and the "C"-shaped slot 1 The inner card is provided with a slider 5, a tension spring 6 is provided between the slider 5 and the lower end of the "C"-shaped groove 1, and a rotating shaft 4 is fixed on the slider 5 corresponding to the opening position of the "C"-shaped groove 1, The rotating shaft 4 is provided with a pulley 3 that can rotate on a vertical plane, and the power line / data line 13 is set around the pulley 3 and passed through the guide hole 2 . The inner end of the rotating shaft 4 is screwed and fixed to the slide block 5, and the outer end of the rotating shaft 4 is provided with a circular stop cap whose diameter is larger than that of the rotating shaft.

[0014] The guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com