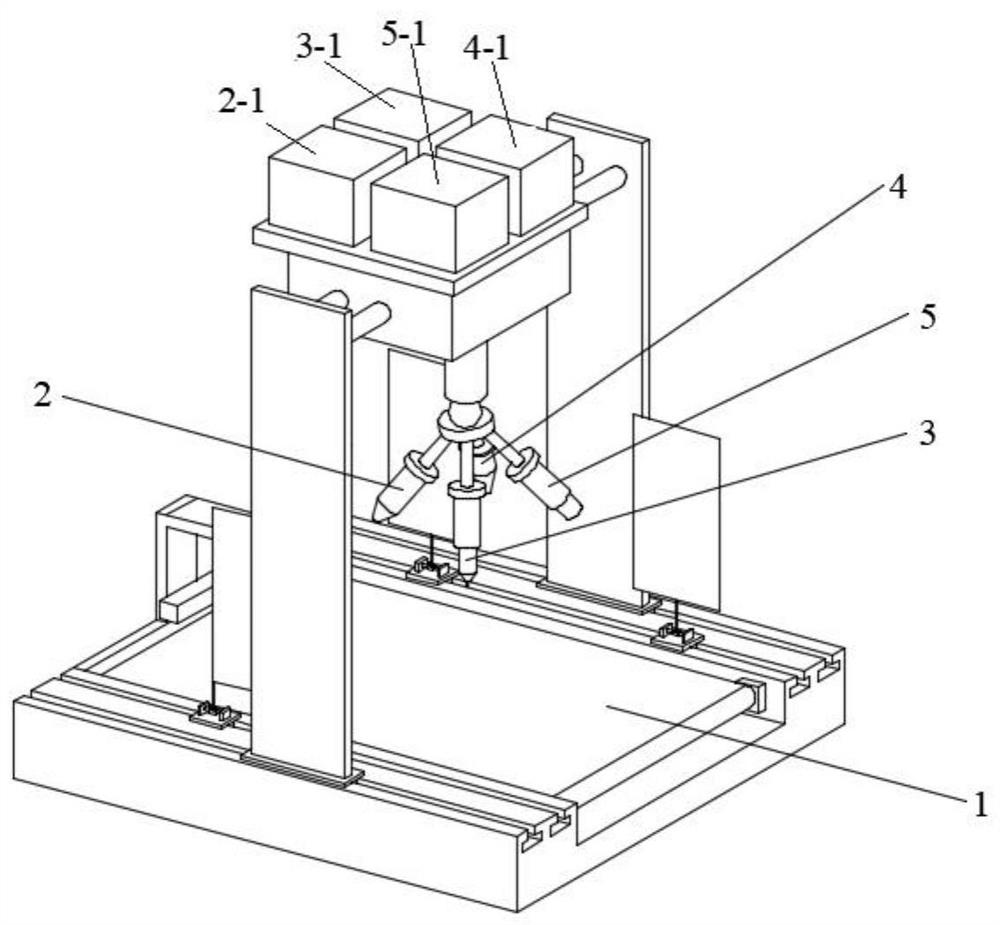

Old book refurbishing device

A refurbisher and old book technology, applied in paper recycling, waste paper post-processing, recycling technology, etc., can solve the problems of heavy book restoration work, lack of perfection, and difficulty in recycling, so as to promote resource conservation and increase resource utilization. The utilization rate and the effect of reducing resource consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

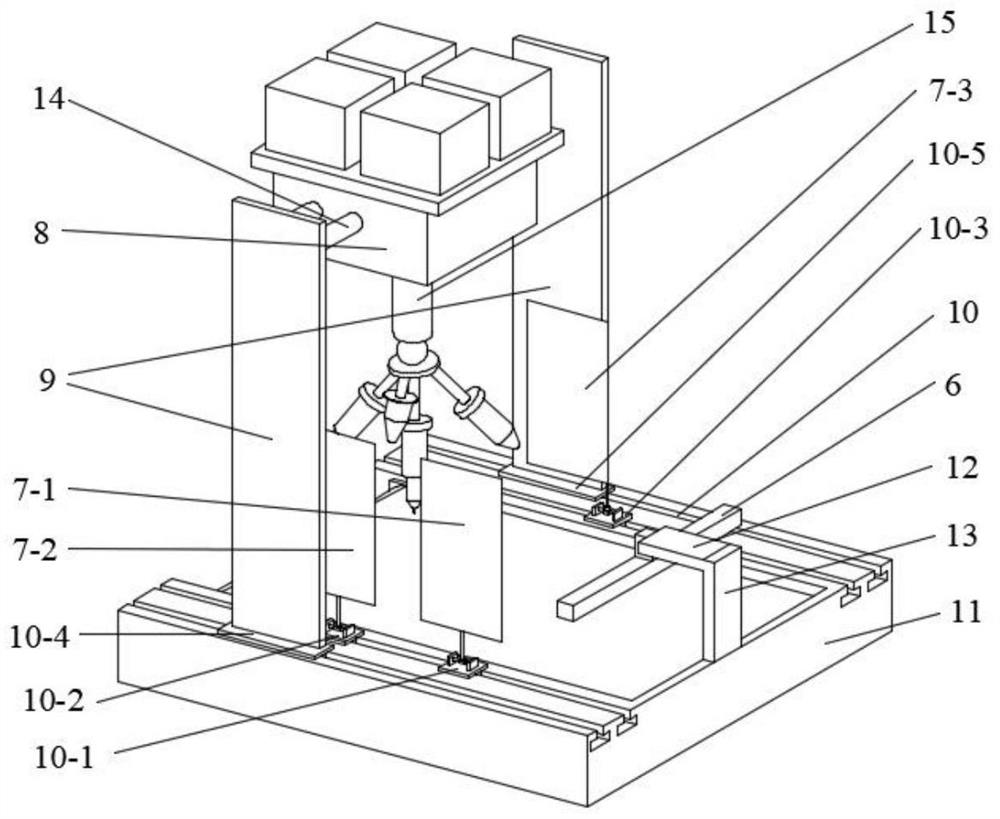

[0071] Implementation Case 1: Damaged paper + wrinkled paper + existing handwriting + missing characters

[0072] After completing the above preparation process, perform the above page turning step 1, and place the page to be checked on the paper tray. Start the camera scanner to check the problems of the paper, and find that the paper is damaged, wrinkled, with handwriting and missing characters, etc. The camera scanner locates, stores, and returns the problem to the original location. Start the nozzle device to make it in the working state, first call the pulp nozzle, the pulp nozzle is vertically downward, spray grout on the gap part under the computer instruction, after the spraying is completed, turn the nozzle device so that the spray nozzle is vertically downward, and the computer instruction Moisturize evenly on the wrinkled part. After the completion, the nozzle device returns to the resting state, the paper support plate 3 7-3 rotates downwards and the paper support...

Embodiment example 2

[0073] Implementation Case 2: Wrinkled Paper + Existing Handwriting + Missing Characters

[0074] After completing the above preparation process, perform the above page turning step 1, and place the page to be checked on the paper tray. Start the camera scanner to check the problems of the paper, and find that the paper has wrinkles, handwriting and missing characters. The camera scanner locates the problem, stores it, and returns it to the original location. Start the nozzle device to make it in the working state, first call the spray nozzle, make the spray nozzle vertically downward, and evenly humidify the wrinkled part under the instruction of the computer. After the completion, the nozzle device returns to the resting state, the paper support plate 7-3 three rotates downwards and the paper support plate 2 7-2 clamps the paper, and slowly dries the paper at 30-45°C and makes it smooth; after completion, The paper support plate 3 7-3 rotates to a standing state, restart th...

Embodiment example 3

[0075] Implementation Case 3: Existence of Handwriting + Missing Characters

[0076] After completing the above preparation process, perform the above page turning step 1, and place the page to be checked on the paper tray. Start the camera scanner to check the problems of the paper, and find that there are handwriting and missing characters on the paper. The camera scanner locates, stores, and returns the problem to the original location. Start the nozzle device to make it in working condition, first use the covering agent nozzle, make the covering agent nozzle vertically downward, and repair the position where the handwriting exists; after repairing, the supporting plate under the paper starts to heat to promote the solidification of the correction fluid; after solidification, Stop heating, rotate the nozzle device to make the print nozzle vertically downward, and repair the missing characters; after the repair is completed, the nozzle device returns to the resting state, tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com