Patents

Literature

61results about How to "Improve intrinsic performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

External preparation for skin containing a phosphorlated saccharide

ActiveCN101282708AAvoid formingGood moisturizing effectCosmetic preparationsHair cosmeticsIron saltsMagnesium salt

Disclosed is a pharmaceutical preparation for external application to the skin, which comprises a phosphorylated sugar. The phosphorylated sugar may be an inorganic salt of a phosphorylated sugar. The phosphorylated sugar may be in the form of a calcium salt, a magnesium salt, a potassium salt, a zinc salt, an iron salt or a sodium salt. Also disclosed is a pharmaceutical preparation for externalapplication to the skin, which comprises a phosphorylated sugar and a second component. The second component is selected from the group consisting of a moisturizing component, a skin-whitening agent,an UV-absorber, an anti-inflammatory agent, a cell-activating agent and an anti-oxidant. The moisturizing agent may be ascorbic acid or an ascorbic acid derivative.

Owner:EZAKI GLICO CO LTD

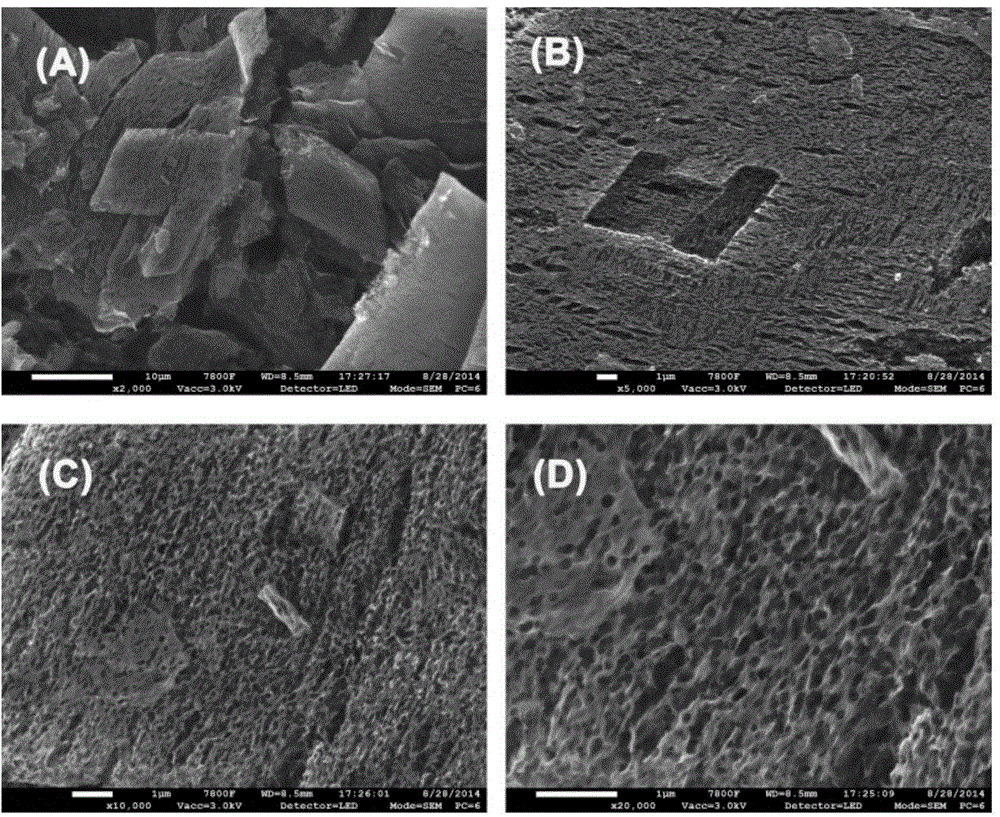

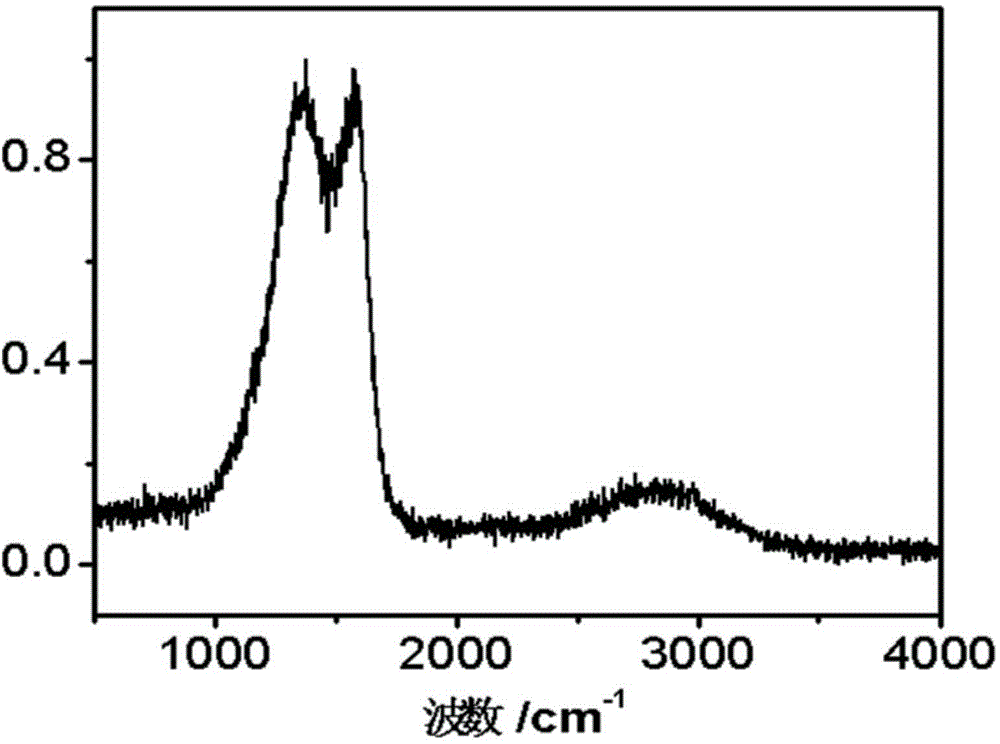

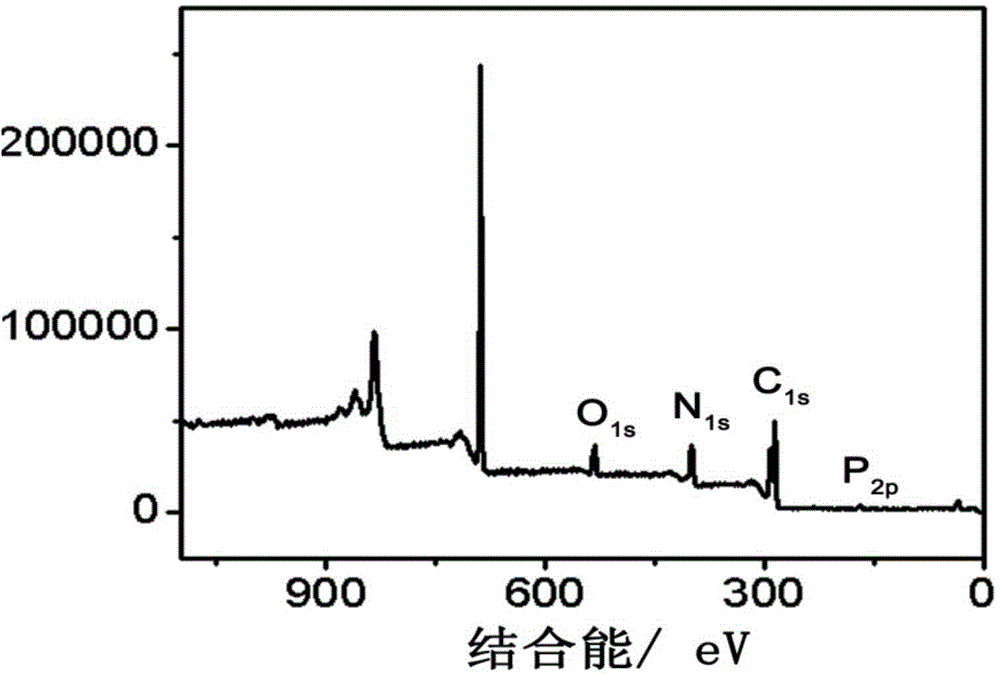

Porous carbon material and preparation and application thereof

ActiveCN105692580AImprove intrinsic performanceStable structureCarbon preparation/purificationPorous carbonIn situ polymerization

The invention relates to porous carbon and its preparation method. Specifically, the carbon material has a prismatic block shape from macroscopic view, and the size of a single block body is 5-20 m (side length of the prism). The single-block material has a hierarchical porous structure, including macropores of 50-300 nm, a mesoporous structure of 2-10 nm and micropores of less than 2 nm. The macropore structure is composed of three-dimensional graphene wall, and the mesopores and the micropores are composed of holes in the graphene wall. Nitrogen and phosphor are doped in crystal lattice of the carbon material, wherein doping concentration of nitrogen is 0.5-15.5%, and doping concentration of phosphor is 0.5-8.5%. The material is formed by in situ polymerization of a soft template and metal under catalytic dual effects. The material has potential application value in fields of catalysis, energy storage, adsorption and the like.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

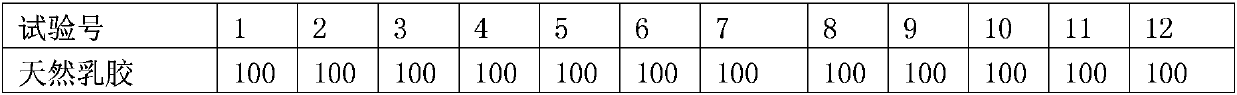

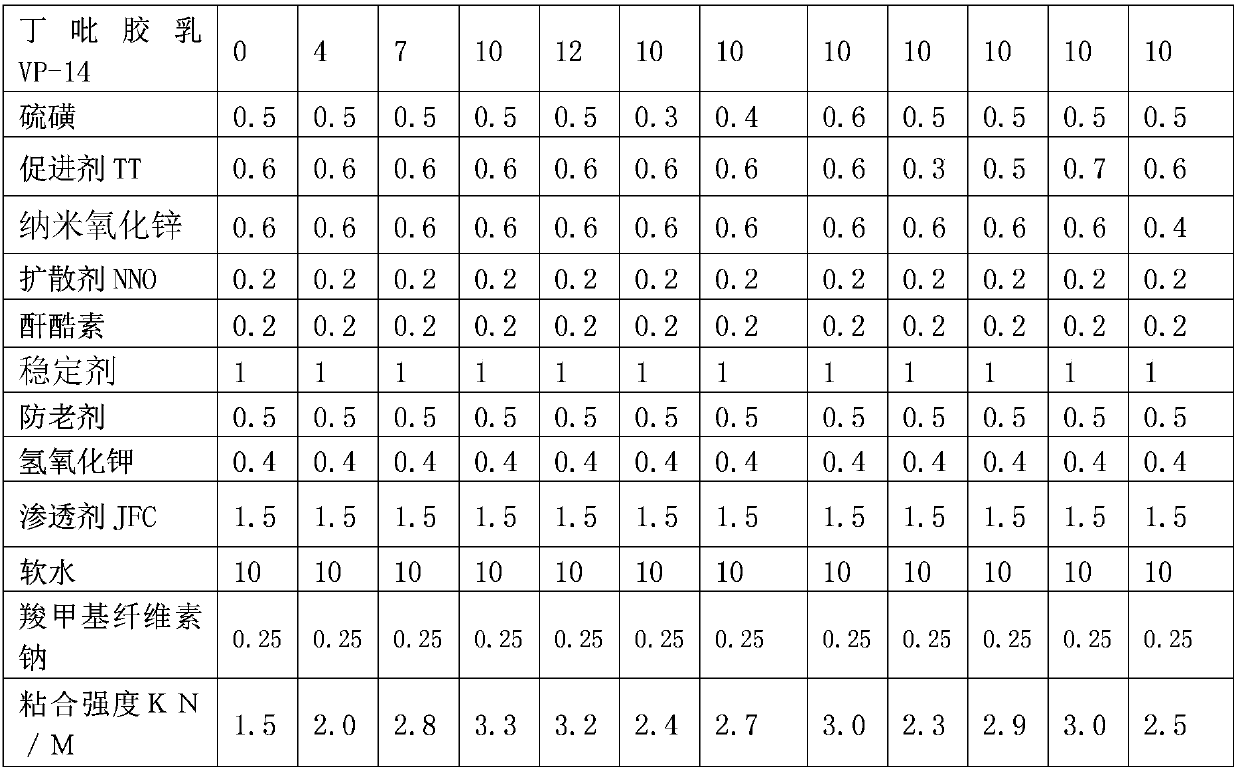

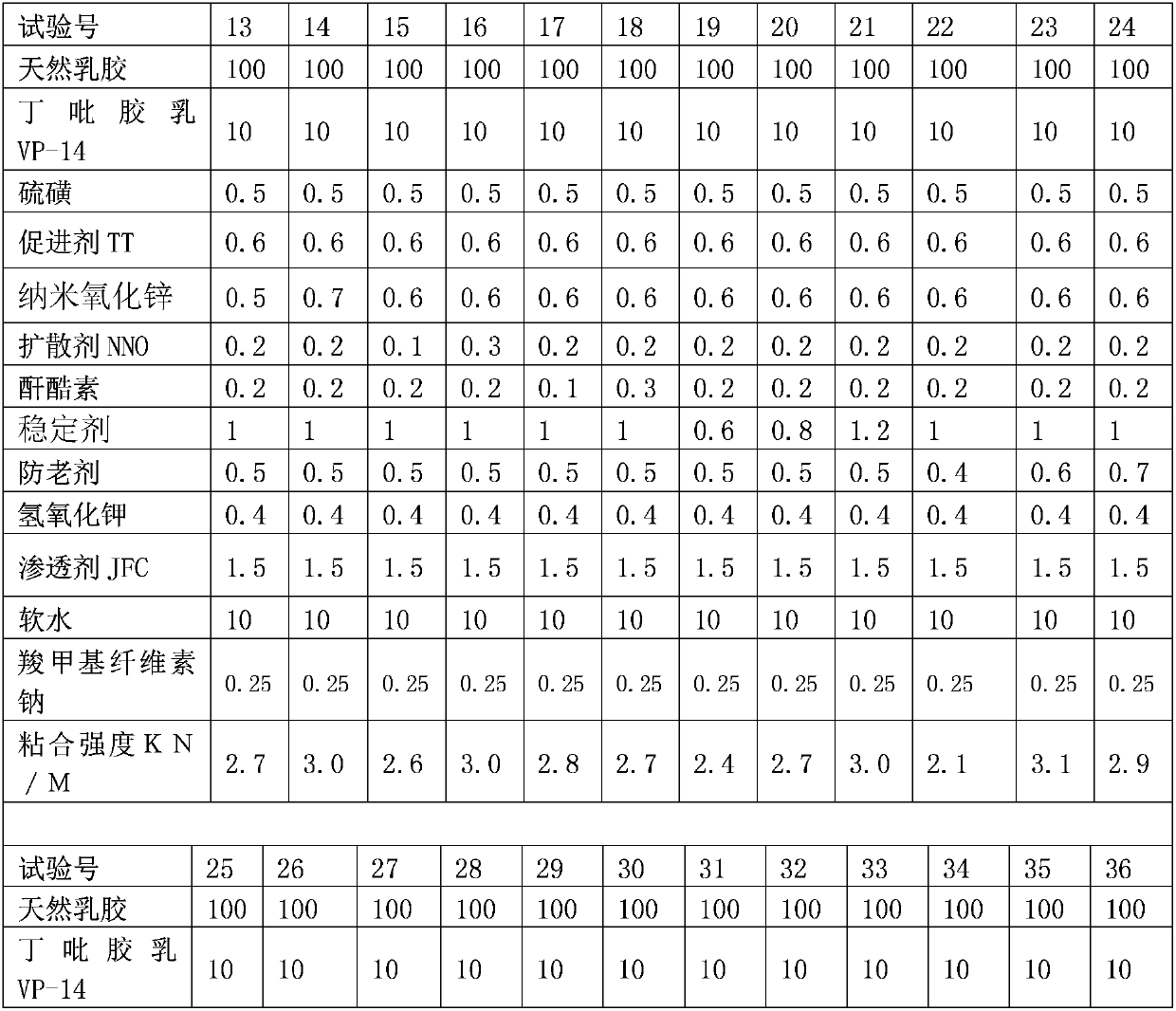

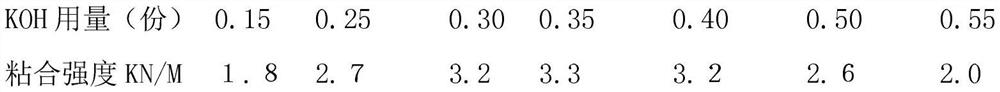

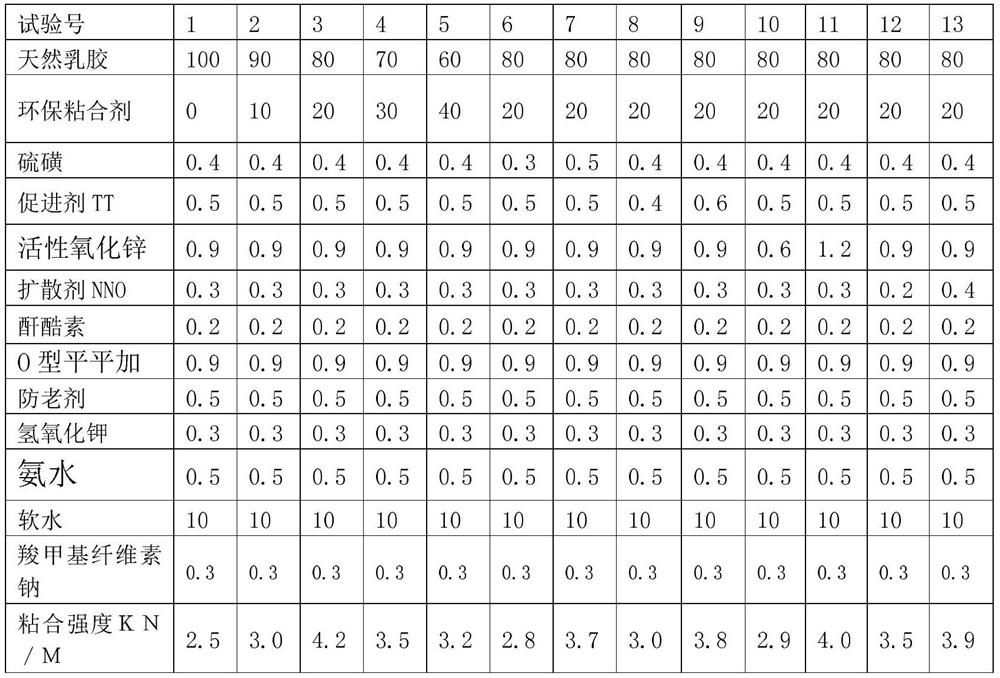

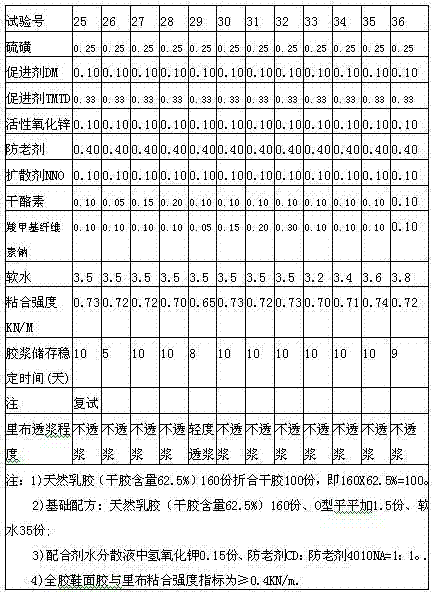

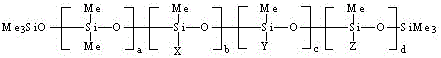

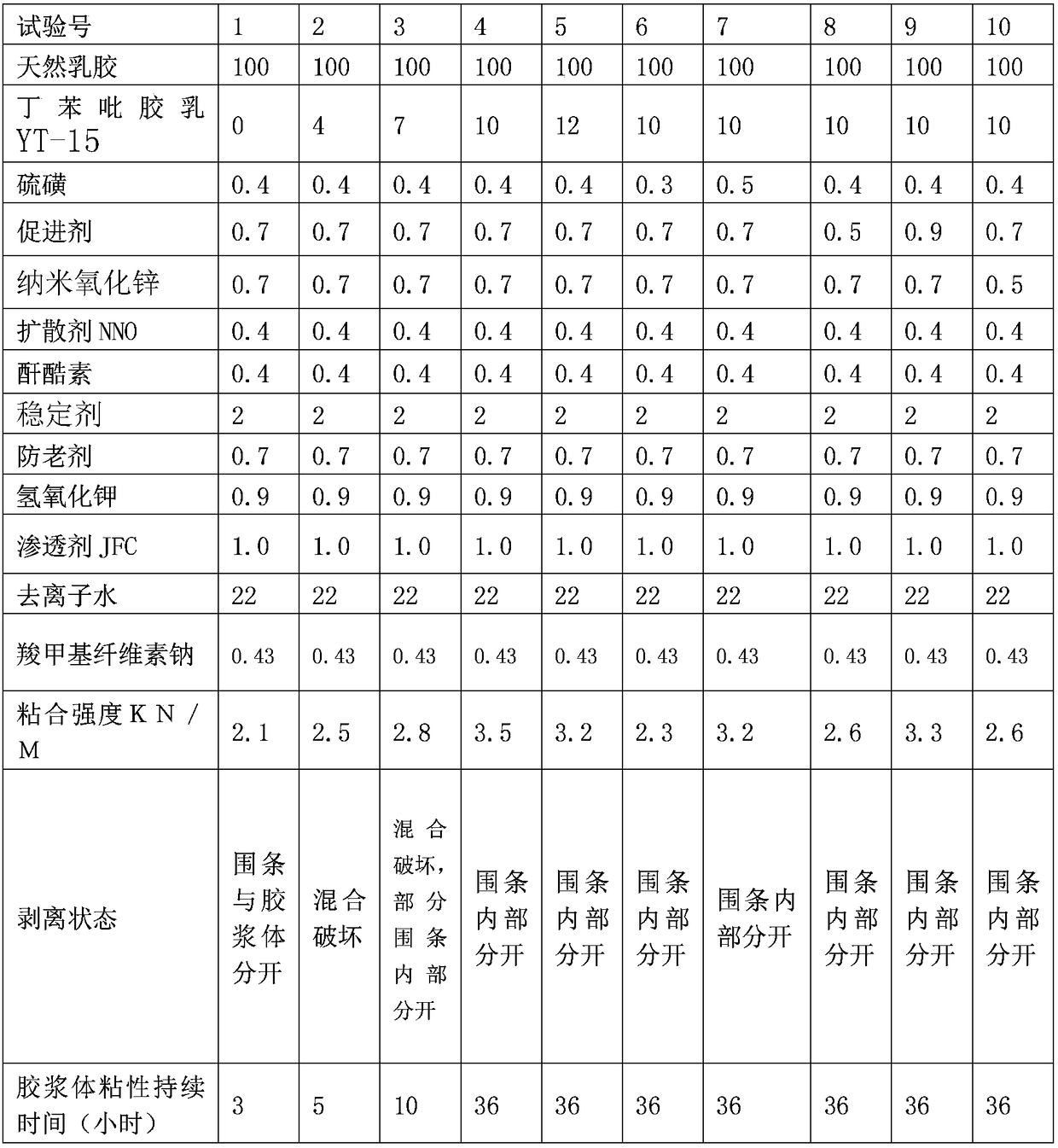

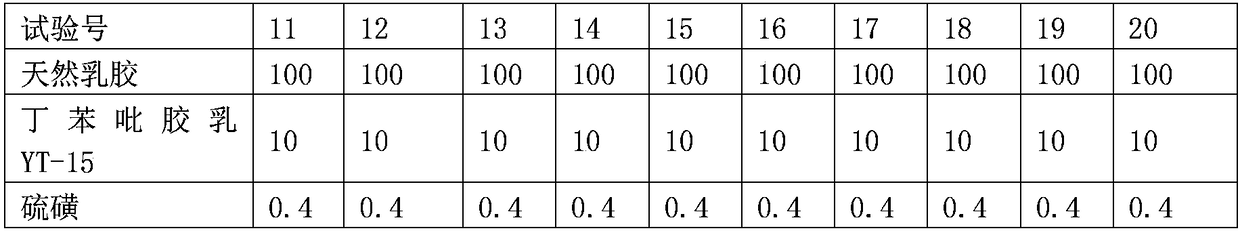

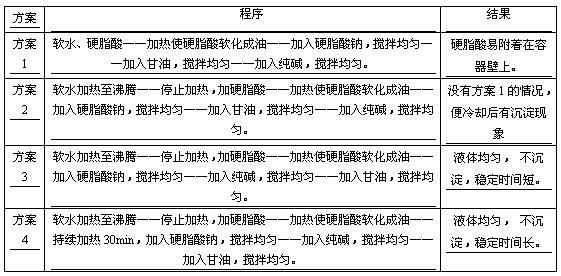

Water soluble adhesive and preparation method thereof

ActiveCN101486882APrevent agingMaintain performanceNatural rubber adhesivesFootwearNon toxicityPolymer science

The invention provides a water-soluble adhesive and a preparation method thereof. The water-soluble adhesive is prepared mainly by natural latex, soft water, a vulcanizing agent, a vulcanization accelerator, a vulcanizing activator, a dispersant, anhydride casein, borax, a stabilizer, a wetting agent, ammonia and potassium hydroxide. In order to improve the performance of the water-soluble adhesive, carboxymethyl cellulose sodium, the wetting agent, an age inhibitor, an antifoaming agent and a mildew inhibitor also can be added; the obtained water-soluble adhesive is an environment-friendly material which is used for shoes, has the processing advantages of low energy consumption, non-toxicity, good processing property, simple operation and the like in the preparation process, strengthens self deterioration resistance, greatly prolongs the storage stabilization period of slurry, improves the intrinsic performance of the adhesive, and fundamentally realizes the demand of high adhesive strength on rubber shoes.

Owner:际华制鞋工业有限公司

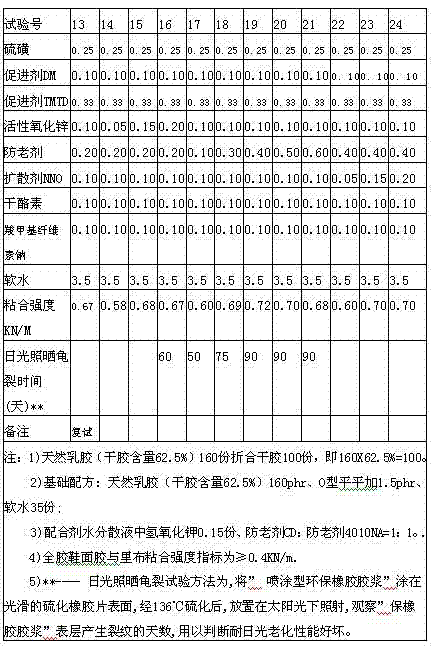

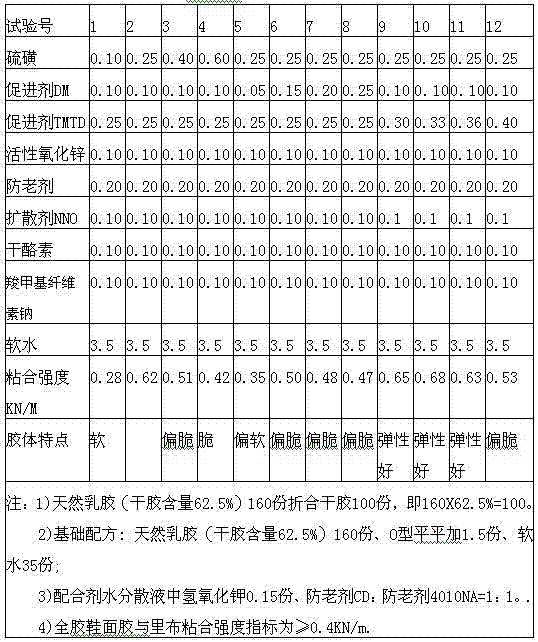

Spraying-type environment-friendly rubber adhesive cement and preparation method thereof

ActiveCN102807830AOvercome the quality problems of degummingPrevent agingNatural rubber adhesivesNon-macromolecular adhesive additivesEmulsionOxide

The invention discloses a spraying-type environment-friendly rubber adhesive cement and a preparation method of the rubber adhesive cement. The spraying-type environment-friendly rubber adhesive cement comprises the following components by weight parts: natural emulsion containing 62.5% of dry glue content, O-type peregal, soft water, and compounding agent aqueous dispersion, wherein the compounding agent aqueous dispersion comprises sulphur, an accelerant DM (2,2'-dibenzothiazoledisulfde), an accelerant TMTD (tetramethyl thiuram disulfide), active zinc oxide, anti-aging agent CD, anti-aging agent 4010NA, mildew preventive BCM, dispersing agent NNO, potassium hydroxide, casein and soft water. By using the natural emulsion as the main material and due to the fact that the original condition of the molecules of the natural emulsion are kept basically, the high initial bonding property of the environment-friendly rubber adhesive cement is ensured; the vulcanized and cross linked adhesive cement and the bonded rubber component form a strong unity, so that the product has a high final bonding property. The manufacturing process disclosed by the invention has the advantages of low energy consumption, no toxic, excellent processing property, simple operation, and the like. In addition, the deterioration resistance of the binder is enhanced, the storage stationary phase of the cement is prolonged greatly, and the internal property of the binder is improved.

Owner:际华制鞋工业有限公司

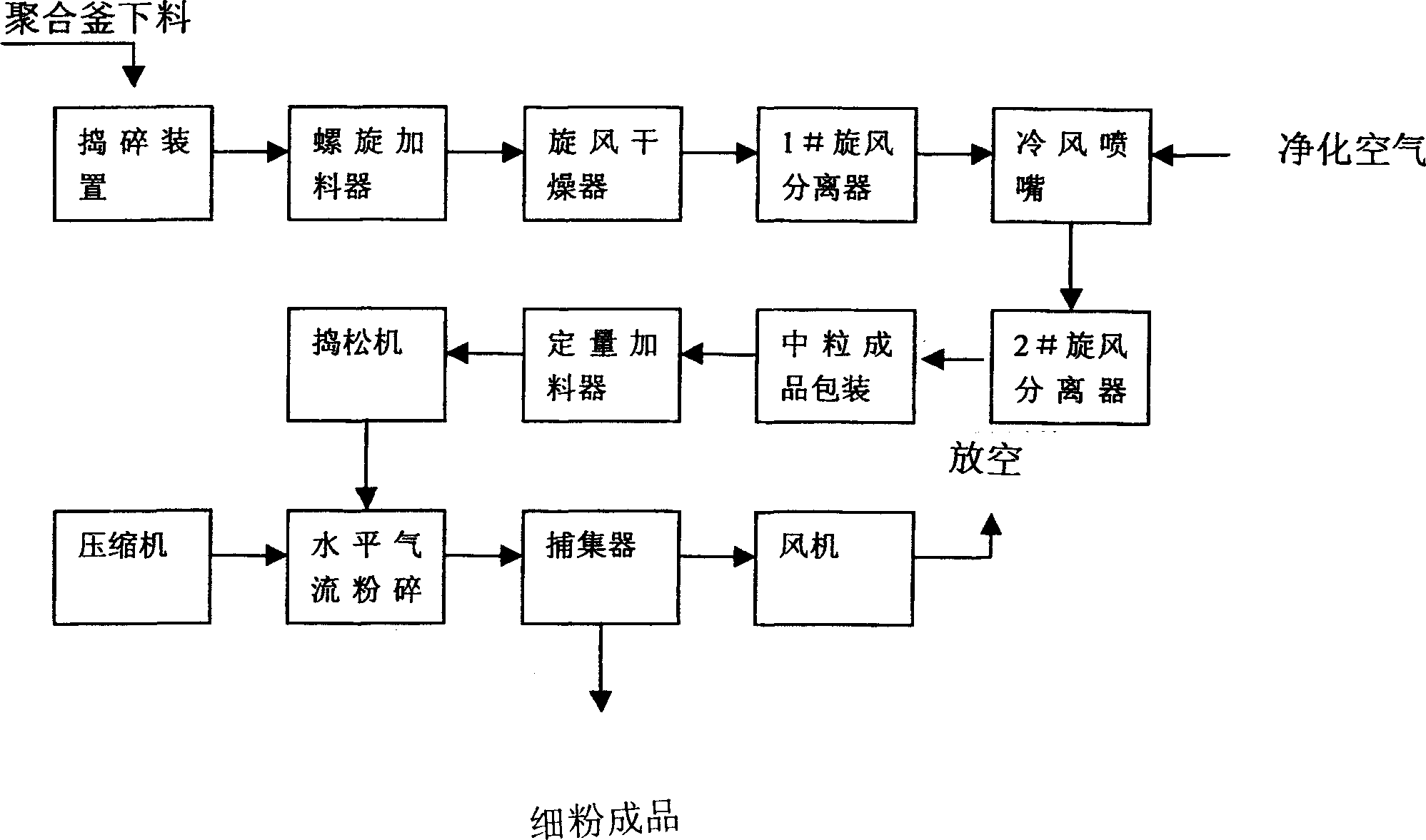

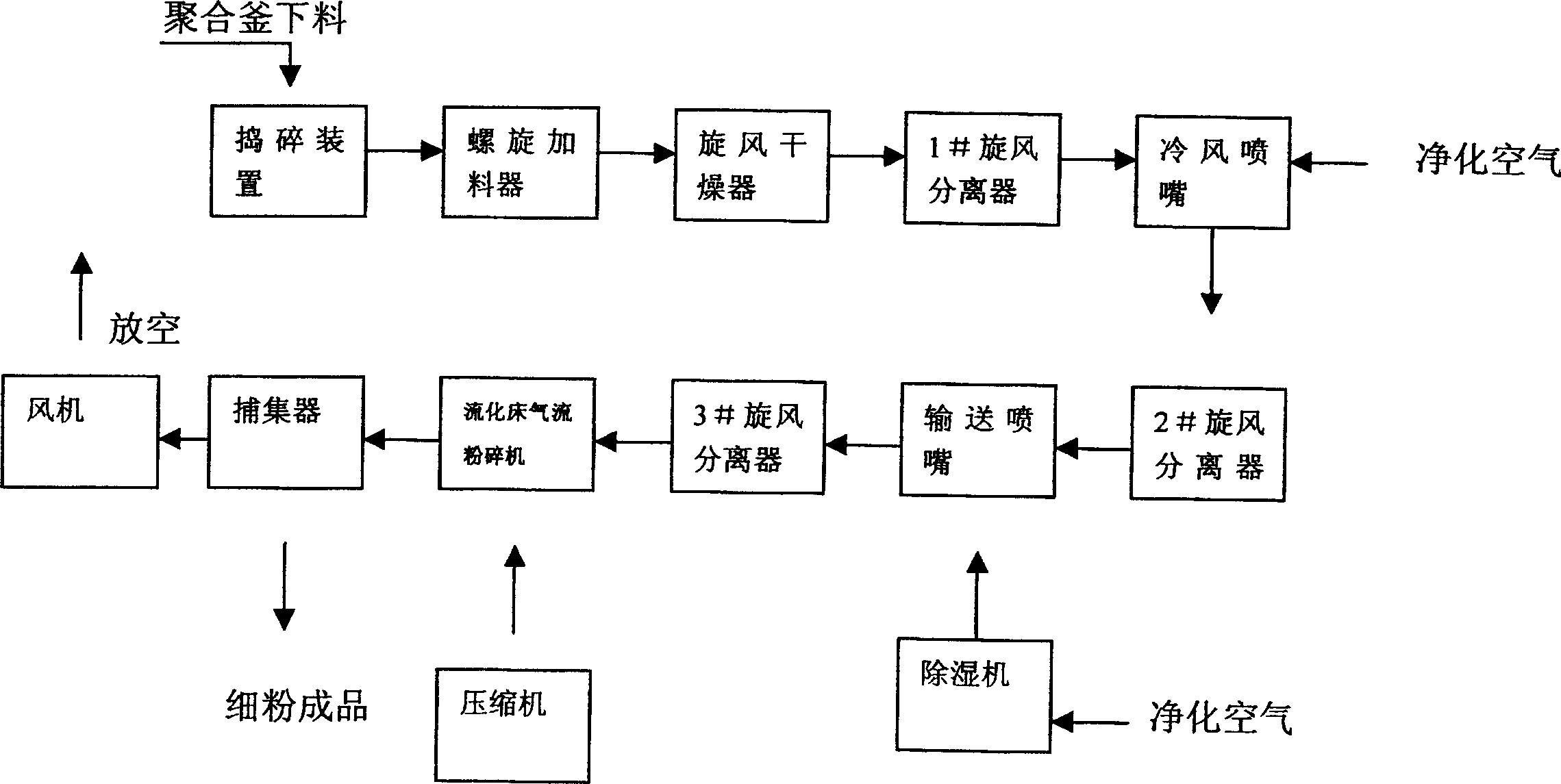

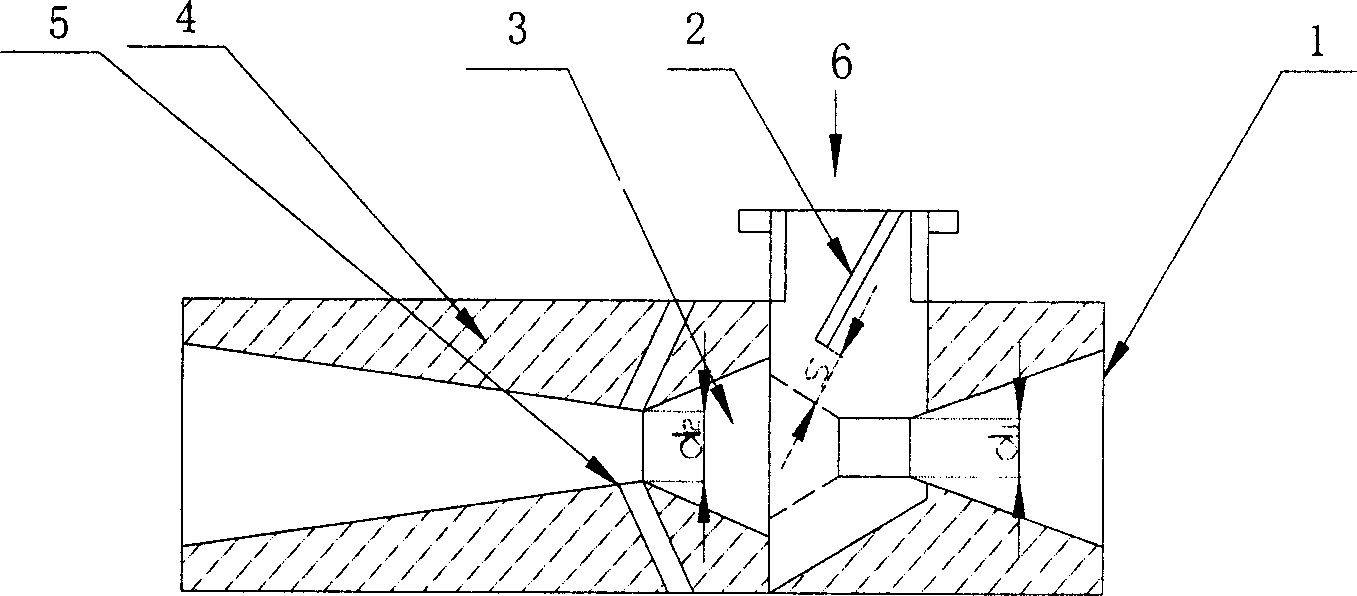

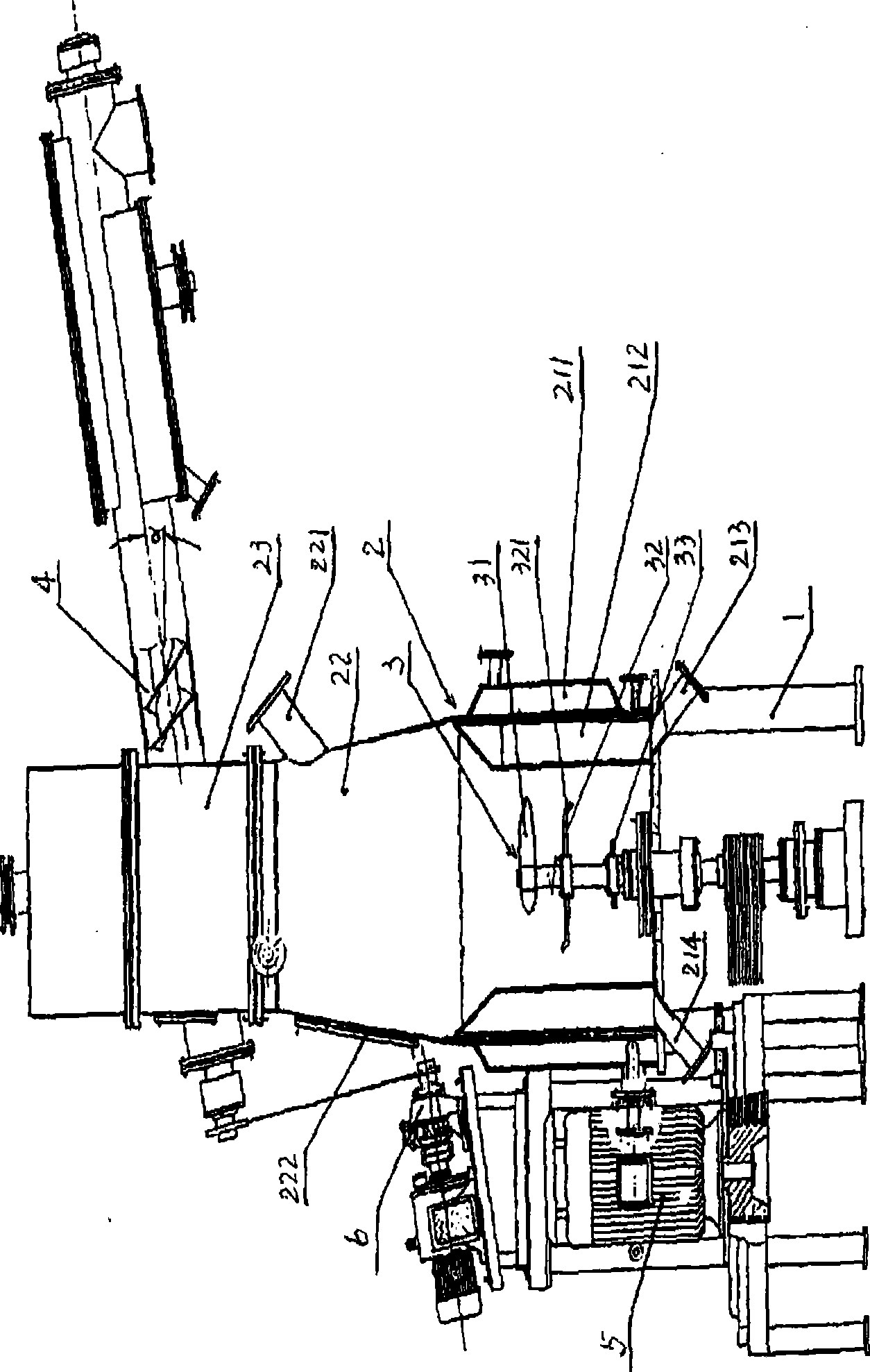

Delivery spray nozzle, polytetrafluoroethylene fine particle processing method and apparatus using the spray nozzle

ActiveCN1876530AReduce lossReduce labor intensityDrying solid materials without heatBulk conveyorsFluidized bedSpray nozzle

The invention relates to a method for continuously preparing politef via suspension method, wherein said method breaks, washes, separates, dries and cools the polymerized politef, to obtain middle particles to be mixed with purified dry air; via cyclone separator, entering into the airflow breaker of fluid bed to be broken and classified; then the fine powder is collected in the collector to generate dry politef powder. The inventnion can continuously and automatically supply politef powder at high quality, in sealed tube.

Owner:SHANGHAI 3F NEW MATERIAL TECH CO LTD

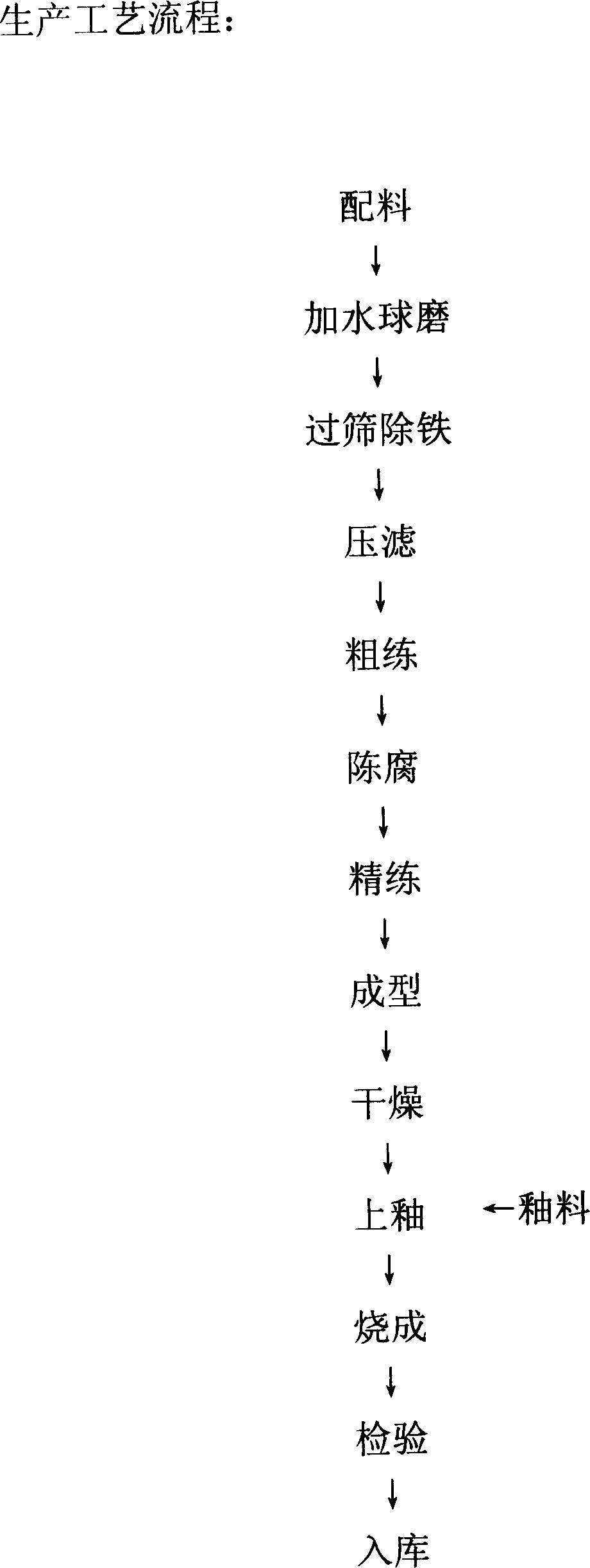

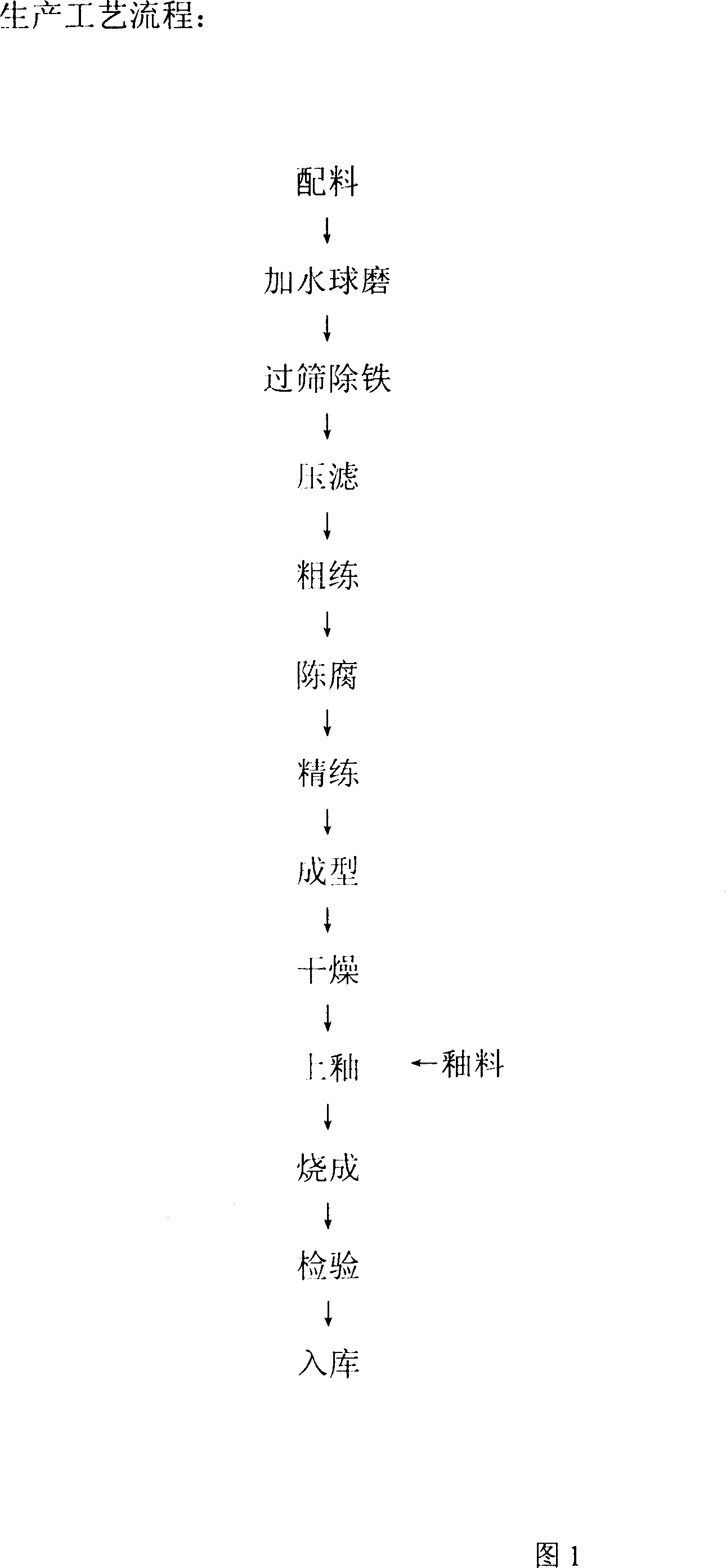

Middle-temperature high-aluminum reinforced porcelain and process for producing same

The invention discloses a middle temperature high-alumina intensification ceramic and manufacturing technique, which comprises the following parts: big-same-sand, wind-transmission potash feldspar, alumina, hunan-wash-mud, Jiangxi lithium chinastone powder, Hunan blach feldspar, calcinations talcum, boundary board soil, and quartz and Guizhou soil. The manufacturing technique comprises the following steps: batching; adding in water and abrading-ball; riddling and deironing; filter-pressing; pugging; ageing scouring; forming; drying; glazing; firing by kiln oven. The veintion has high transverse strength and good heat endurance.

Owner:林伟河

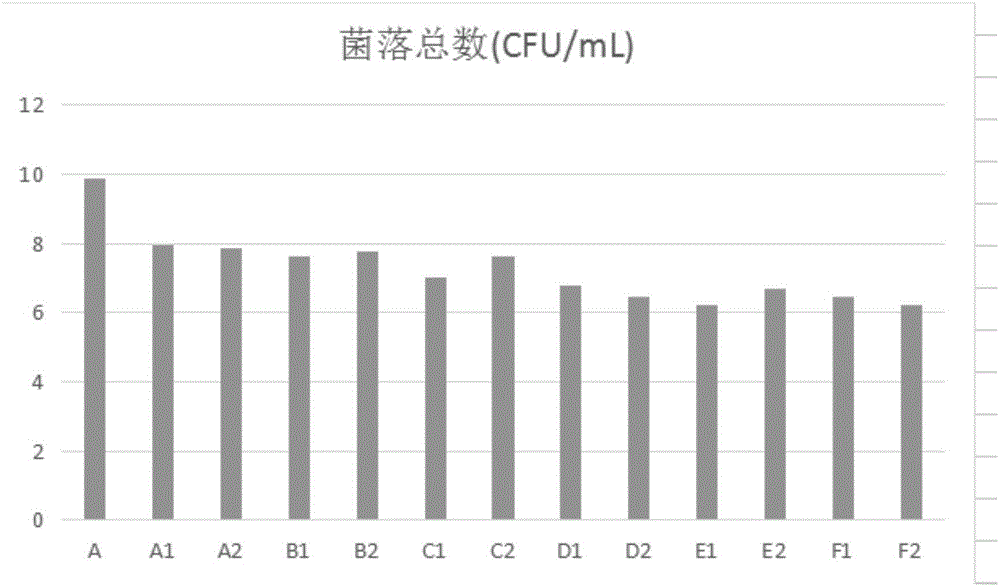

Multifunctional plastic with anti-microbial effect, oxidation resistance and metal-chelating property and preparation method thereof

The invention provides a multifunctional plastic with an anti-microbial effect, an oxidation resistance and a metal-chelating property and a preparation method thereof. The plastic material is mainly prepared from the following raw materials in parts by weight: 6%-10% of active anti-microbial agent, 2%-6% of active antioxidant, 3%-8% of metal-chelating agent and the balance of macromolecule resin base membrane. The modified resin substrate has certain anti-microbial effect, oxidation resistance and metal-chelating property. A novel application material is supplied for the products, such as, electronic cigarette, and the fields, such as, food packaging. The plastic has certain various characteristic functions; on the basis of improvement for the inherent performance of the products, the plastic is endowed with a more practical characteristic; the guarantee period of the products is prolonged and the application thereof is improved, so that the market value is promoted; the original raw material cost is lowered; the market space is expanded and the incoming is increased.

Owner:CHINA TOBACCO GUANGXI IND

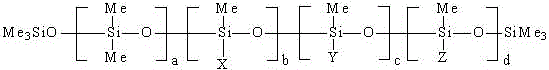

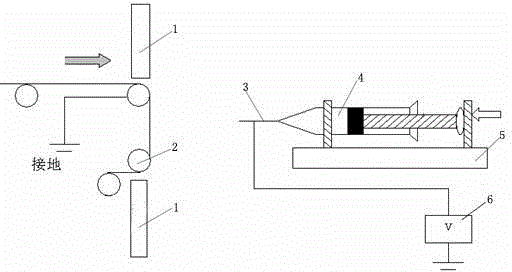

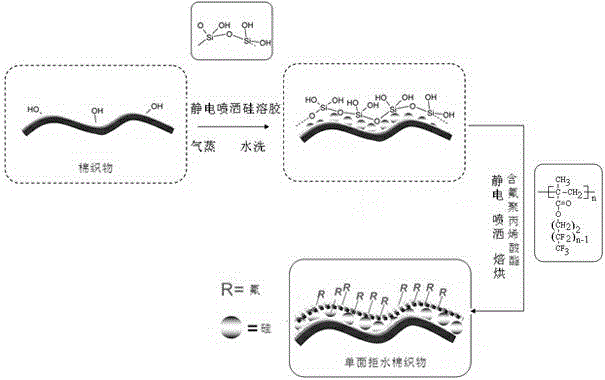

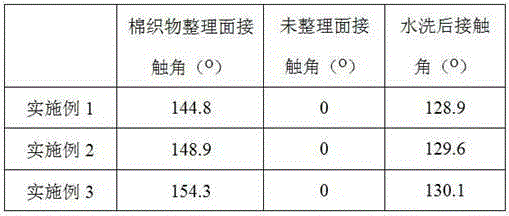

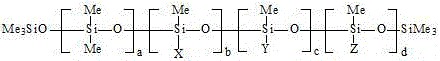

Arranging method of super-hydrophobic and hydrophilic double-faced heterologous cotton fabric

The invention discloses an arranging method of a super-hydrophobic and hydrophilic double-faced heterologous cotton fabric. The method comprises the steps of spraying a silicon dioxide sol finishing agent and a water-based fluorine-containing polyacrylic acid water repellent finishing agent on the surface of the cotton fabric by using a high voltage static field, keeping low amounts of condensing liquids, controlling the finishing agent only on the single face of the cotton fabric without permeation, then steaming, baking and washing, forming a coating on one surface of the cotton fabric to rough on the single face of the fabric, reducing the surface free energy of the cotton fabric and endowing the super-hydrophobicity of single face of the cotton fabric; on the other side, the good inherent hygroscopicity can be kept to obtain the super-hydrophobic and hydrophilic double-faced heterologous cotton fabric; furthermore, the arranging method provided by the invention is convenient to operate, simple in process and good in operability; meanwhile, the amounts of condensing liquids of the cotton fabric are low, therefore the method is applicable to the single water repellent finish of uneven heavy cotton fabrics, and the prepared super-hydrophobic and hydrophilic double-faced heterologous cotton fabric can meet the special requirements on functionality and comfort.

Owner:ZHONGYUAN ENGINEERING COLLEGE

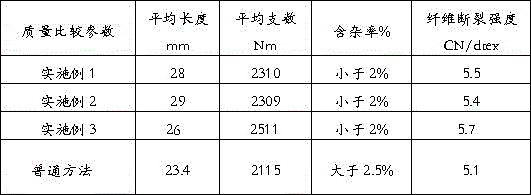

Preparation method of composite yarns

InactiveCN105780234AImprove intrinsic performanceImprove comfortBiochemical treatment with enzymes/microorganismsYarnYarnTextile technology

The invention belongs to the technical field of spinning and particularly relates to a preparation method of composite yarns. Preferably, composite yarns provided by the invention are multi-element functional yarns including bamboo fibers, wool fibers, natural silk yarns and the like, and inner performances of the yarns are improved, so that a finally produced textile has the properties of softness and fineness of cotton, smoothness of hemps, moisture absorption and perspiration, antibacterial properties and sanitation and the like; and the comfort of the textile is increased. After hemp fibers and cotton fibers are subjected to modification treatment by a biological enzyme, the dyeing effect of the yarns can also be improved.

Owner:孙宁

Linen, cotton and tencel blended yarn process

The invention provides a linen, cotton and tencel blended yarn process. The whole process includes: degumming and humidifying linen staples, removing linen knots and overlength fibers, opening picking, carding, drawing and rotor spinning. In linen staple degumming and humidifying: manually opening packed linen fibers, mixing linen-cotton finishing auxiliary with water, well mixing according to the portion of 1:5 of auxiliary to water, spraying the mixture on the linen staples, and piling and covering with a plastic film for at least 24 hours; in opening picking: allowing a plucker beater to descend 2-2.5mm each time, and increasing pipe air feed amount by 15-20%; in rotor spinning: adding 10-15% of polyester fibers or viscose. The products of the process have the advantages that inherent performance of yarn is improved, spinning adaptability of the yarn is increased, environment-friendly materials are used, and product application range is expanded.

Owner:NINGBO SHUANGDUN TEXTILE CANVAS IND

Preparation method of cotton-linen blended yarn containing infrared heating fibers

ActiveCN105926098ASolve the lack of cohesionImprove comfortSolvent-treatmentBiochemical fibre treatmentFiberYarn

The invention discloses a preparation method of cotton-linen blended yarn containing infrared heating fibers. The method comprises the following steps: (1) blending prepared cotton-linen blended functional fibers with the infrared heating fibers in proportion, plying and twisting to obtain cotton-linen blended yarn containing the infrared heating fibers; spinning the obtained yarn into raw thick yarn by mixing and matching, and then scouring and bleaching the thick yarn; (2) carrying out semi-degumming on the thick yarn; (3) treating the obtained thick yarn by using antibacterial liquid; (4) carrying out bio-enzyme pretreatment before dyeing; (5) softening, oiling and drying: softening the cotton-linen blended yarn containing the infrared heating fibers after bio-enzyme pretreatment, oiling and drying to obtain dried cotton-linen blended yarn containing the infrared heating fibers; (6) dyeing; (7) carrying out wet spinning to obtain spun yarn; drying and then carrying out tight tube winding to obtain a finished product. The product prepared by the method has the characteristics of having the functions of health care and physical therapy, and being high in quality, bright and soft, good in neatness, less in impurity content and low in strength loss.

Owner:YIWU MASHANGSHENG KNIT GOODS CO LTD

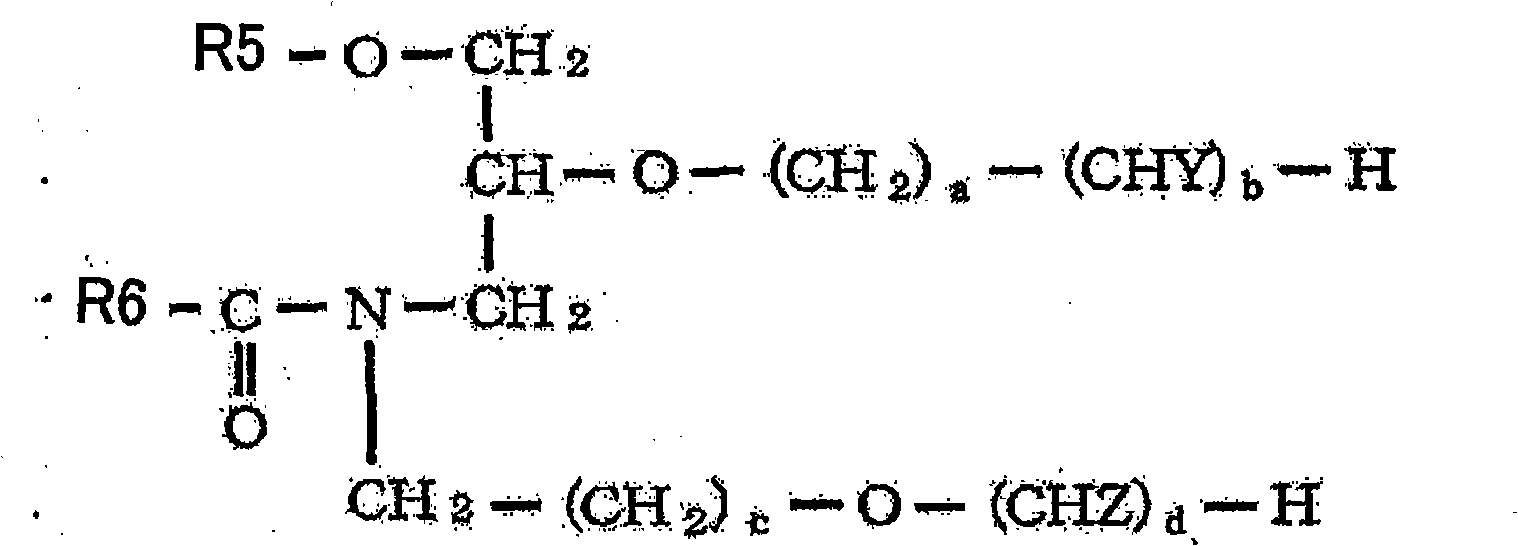

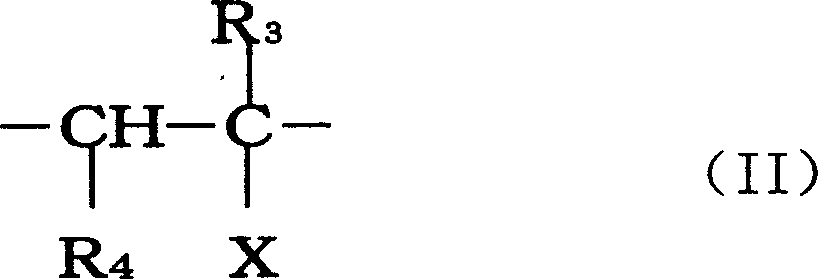

Method for synthetizing anion type and non-ion type dispersoid for water-soluble polymer

InactiveCN1519259AImprove intrinsic performanceTake full advantage of the performanceWater soluble polymersIon

A process for synthesizing the anionic and non-ionic water-soluble high-molecular dispersion system features that under the action of the composite disperser composed of more than one non-ionic high-molecular compound soluble in saline and more than one polyol compound, the water-soluble non-ionic monomer and / or water-soluble anionic monomer take part in polymerizing (or copolymerizing) reaction to obtain said dispersion system.

Owner:王丕新

Preparation method of polyimide film

The invention discloses a preparation method of a polyimide film. According to the preparation method, the polyimide film is produced by virtue of a tape-casting method, the adopted device has high precision, the produced polyimide film has the advantages of good uniformity, clean and flat surface, unlimited length and excellent performance and can be continuously produced; and a novel material is added into an original formula so as to protect the film from damage and improve the flatness and intrinsic property of the film. The high-quality polyimide film can be produced by the preparation method which is convenient, fast, safe, efficient and the like.

Owner:六安市杜尔邦绝缘材料有限公司

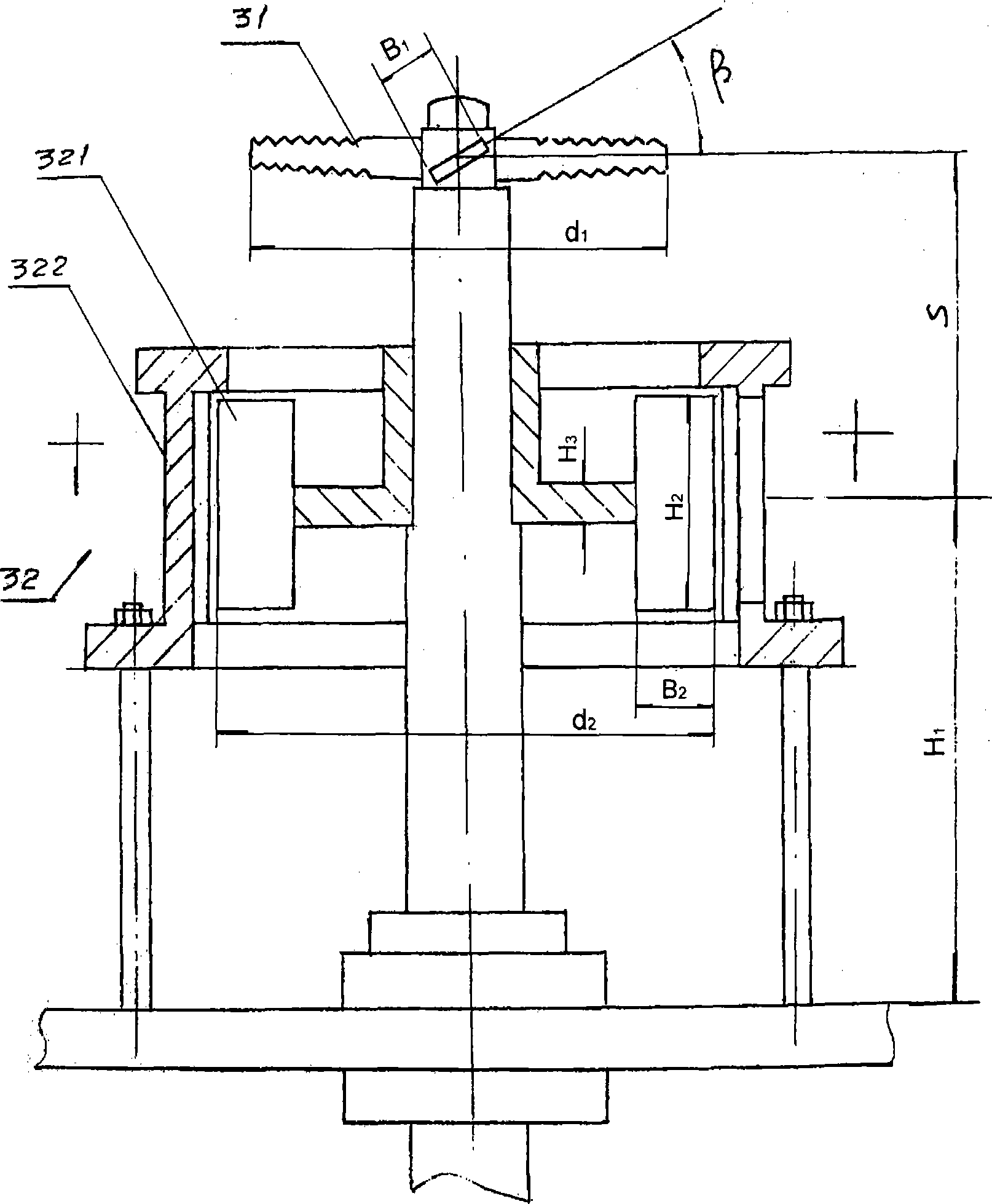

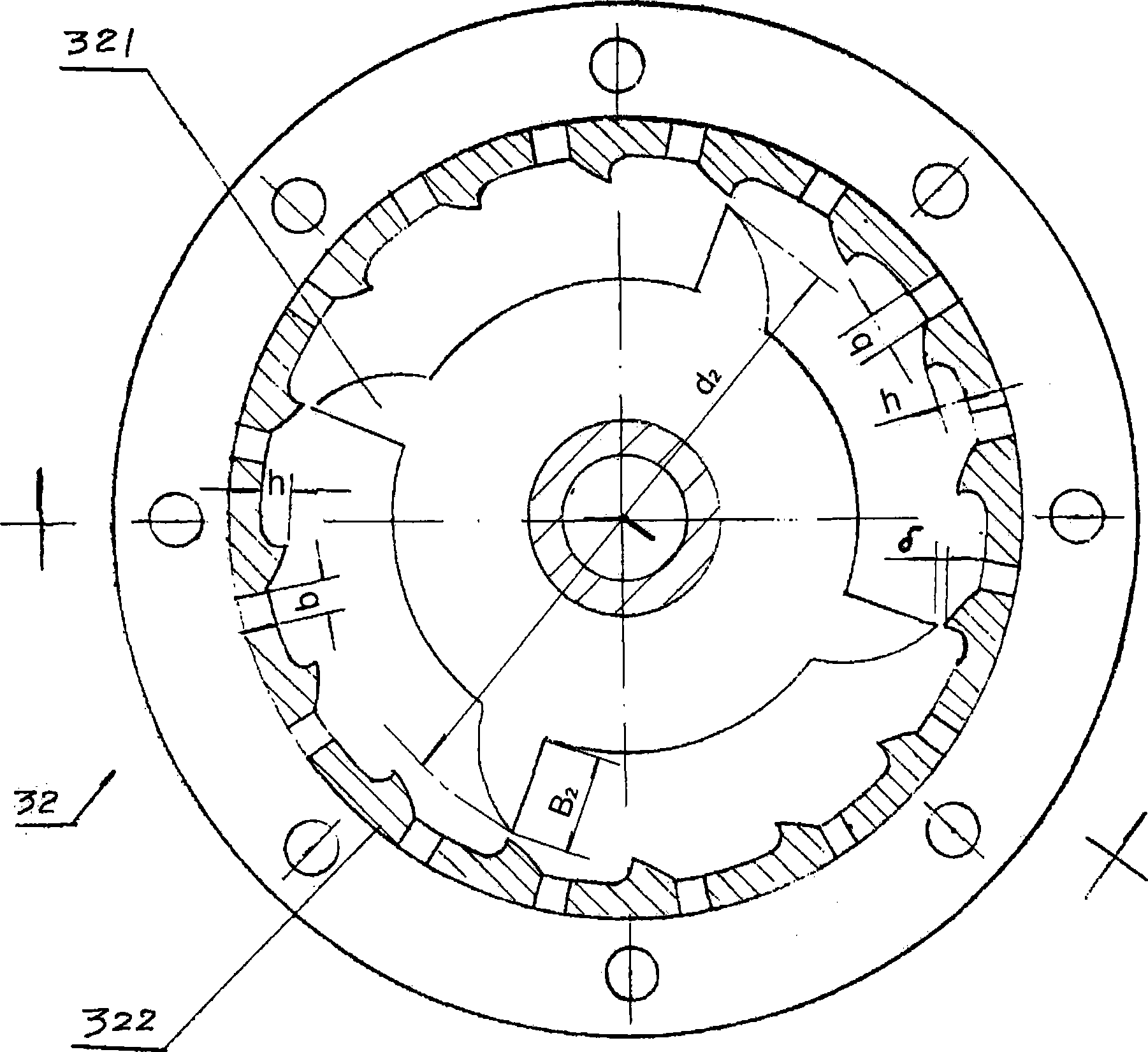

Crushing device and crushing method for preparing suspended polytetrafluoroethylene (PTFE) resin

The invention discloses a crushing device (3) used in PTFE resin prepared through adopting a high-pressure suspension method. The crushing device consists of an upper layer paddle blade (31) and a lower layer paddle blade (32), wherein the upper layer paddle blade (31) is a bias cutting paddle blade and consists of toothed whirling paddles arranged on a rotating shaft; the intersection angle beta between the bias cutting paddle blade (31) and a horizontal plane is between 20 and 70 degrees; the lower layer paddle blade (32) is an impact paddle blade and consists of a rotating blade (321) arranged on the rotating shaft and an arc trough-shaped gear ring (322) fixed with the rotating blade (321) concentrically; the arc trough-shaped gear ring comprises a concentric ring protruding towards the circle center along the inside ring of the gear ring and a protrusion with a recess arranged at one end of the inner ring of the ring near the circle center against the rotating direction of the rotating blade; a straight strip trough is arranged between two arc trough-shaped grooves; and the height h of the concave protrusion is between 3 and 20 mm, while the breadth b of the straight strip trough is between 2 and 20 mm.

Owner:SHANGHAI 3F NEW MATERIAL TECH CO LTD +1

Composite functional fabric with multiple cotton-hemp blends and functional fibers

ActiveCN105839272AImprove intrinsic performanceImprove comfortBiochemical treatment with enzymes/microorganismsWoven fabricsHemp fiberWeft yarn

The invention belongs to the technical field of textiles, and particularly relates to a composite functional fabric with multiple cotton-hemp blends and functional fibers. The fabric is formed by blending hemp fibers, cotton fibers, bamboo fibers and wool fibers; warp yarns of the fabric are formed by blending the hemp fibers, the bamboo fibers and the wool fibers according to the proportion of (1-3):1:1; weft yarns of the fabric is formed by blending the cotton fibers, the bamboo fibers and the wool fibers according to the proportion of (2-6):1:1. According to the fabric provided by the invention, the functional fibers such as the bamboo fibers and the wool fibers are optimized, so that the inner performances of the fabric are improved, the finally produced fabric has the characteristics of softness and smoothness of cottons as well as slipperiness, moisture absorption and sweat releasing, antibacterium and health, and the like of the hemp, and the comfort of the fabric is improved. According to the composite functional fabric with the multiple cotton-hemp blends and the functional fibers provided by the invention, after the hemp fibers and the cotton fibers are modified by biological enzyme, the dyeing effect of the yarns can be also improved.

Owner:YIWU MASHANGSHENG KNIT GOODS CO LTD

Water-borne rubber cement for cotton canvas rubber shoe foxing bonding and preparation method thereof

InactiveCN109294478AUniform vulcanizationConsistent vulcanizationNatural rubber adhesivesNon-macromolecular adhesive additivesFiberRubber material

The invention discloses a water-borne rubber cement for cotton canvas rubber shoe foxing bonding and a preparation method thereof. A combination of natural latex and pyridine-styrene-butadiene rubberlatex is adopted as the host material, a vulcanized and cross-linked adhesive, a bonded part and cotton canvas fiber form a high strength and uniform adherend, and the final bonding strength is high.The rubber cement has long-lasting surface stickiness, has low temperature requirement for the bonded part, and lowers the requirement of the bonded rubber material for thermal insulation performance.The three major quality problems of cotton canvas rubber shoes, i.e. lace delamination, base fabric disengaging and undersole delamination are effectively solved, and the quality defect of glue failure during use of cotton canvas rubber shoes can be thoroughly eliminated.

Owner:JIHUA 3537 SHOE MAKING

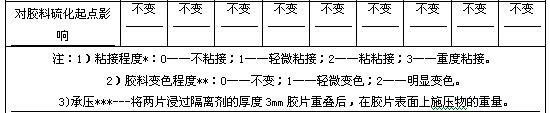

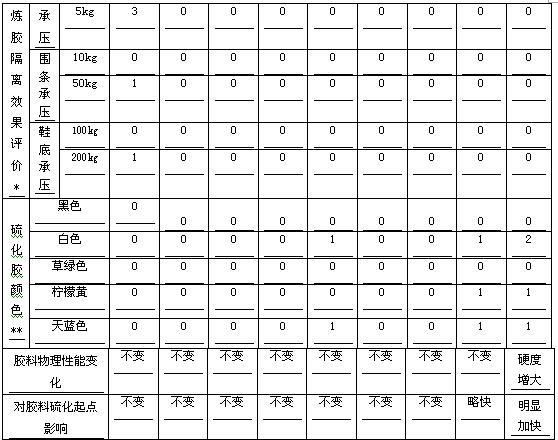

Formula and preparation method of transparent water-based rubber parting agent

The invention discloses a formula and a preparation method of a transparent water-based rubber parting agent. The transparent water-based rubber parting agent comprises 100 parts of water, 0.3-3 parts of fatty acid salt, 1-4 parts of fatty acid and 0.3 to 5 parts of polyol. The parting agent of the invention is an environmentally friendly rubber film parting agent, and has the processing advantages of low energy consumption, no toxicity, excellent process performance, simple operation and the like in the manufacture or use process, thus enhancing the self deterioration resistance of the parting agent, greatly prolonging the storage stable phase of slurry, improving the intrinsic property of the parting agent, being suitable for rubber with various colors, and effectively solving the quality problem that the parting agent can cause color rubber to be vulcanized and decolored. The parting agent influences neither the physical property of rubber nor the processing performance of subsequent processing. Compared with other like products, the parting agent has the advantages of good environmental protection property, no dust flying, and no corrosivity on processing tools such as conveyer belts an the like.

Owner:JIHUA 3537 SHOE MAKING

Middle-temperature high-aluminum reinforced porcelain and process for producing same

The invention discloses a middle temperature high-alumina intensification ceramic and manufacturing technique, which comprises the following parts: big-same-sand, wind-transmission potash feldspar, alumina, hunan-wash-mud, Jiangxi lithium chinastone powder, Hunan blach feldspar, calcinations talcum, boundary board soil, and quartz and Guizhou soil. The manufacturing technique comprises the following steps: batching; adding in water and abrading-ball; riddling and deironing; filter-pressing; pugging; ageing scouring; forming; drying; glazing; firing by kiln oven. The veintion has high transverse strength and good heat endurance.

Owner:林伟河

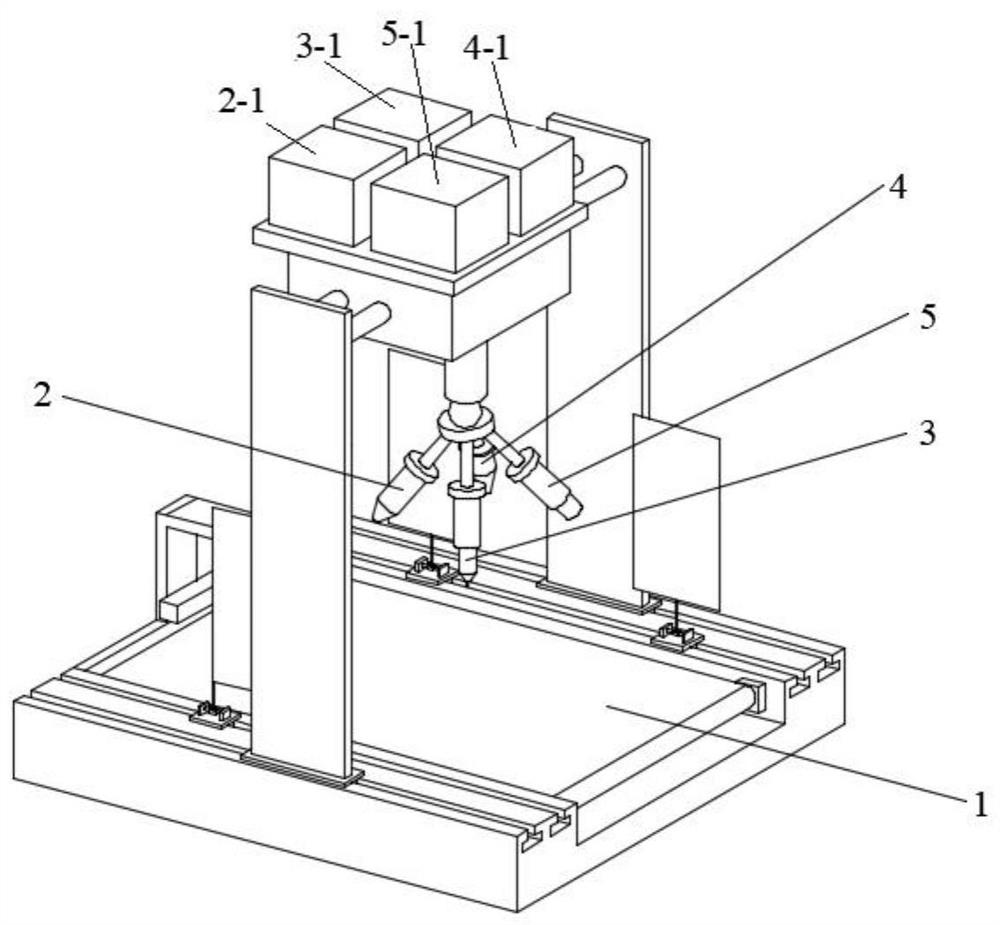

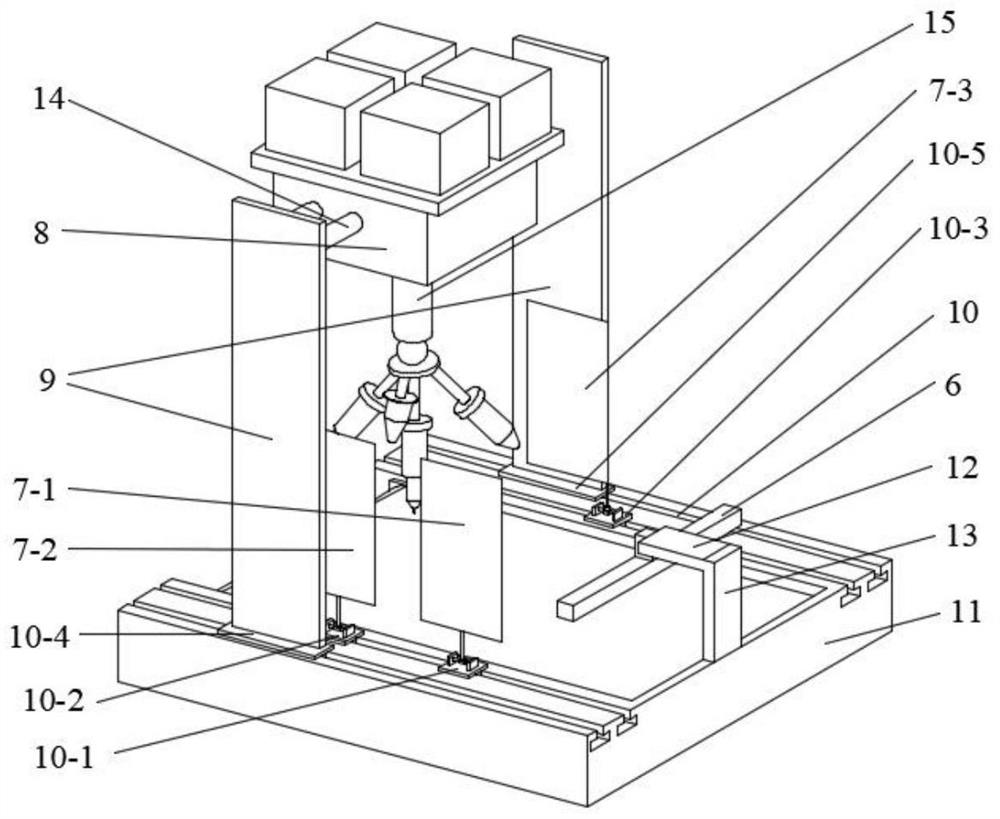

Old book refurbishing device

ActiveCN112411255AEfficient repairImprove work efficiencyPaper recyclingOld paper after-treatmentComputer control systemHandwriting

The invention discloses an old book refurbishing device, which comprises a base, a conveying system, a scanning system and a spray head device, and is a multifunctional machine based on a computer control system and capable of being used for processing various old book problems such as paper breakage, wrinkles, handwriting stains, character missing and the like. The working process comprises the steps that after books are conveyed into the machine through the conveying system and pages of a paper supporting plate are turned over, the scanning system analyzes and accurately locates problems existing in paper pages, the work of guniting, humidifying and drying, covering and spraying, typewriting and the like is completed in sequence according to the problem conditions, the operation is repeated till book repairing is completed, and then the books are output. The old book refurbishing machine has great significance in repairing of old books and cyclic utilization of the old books.

Owner:HENAN POLYTECHNIC UNIV

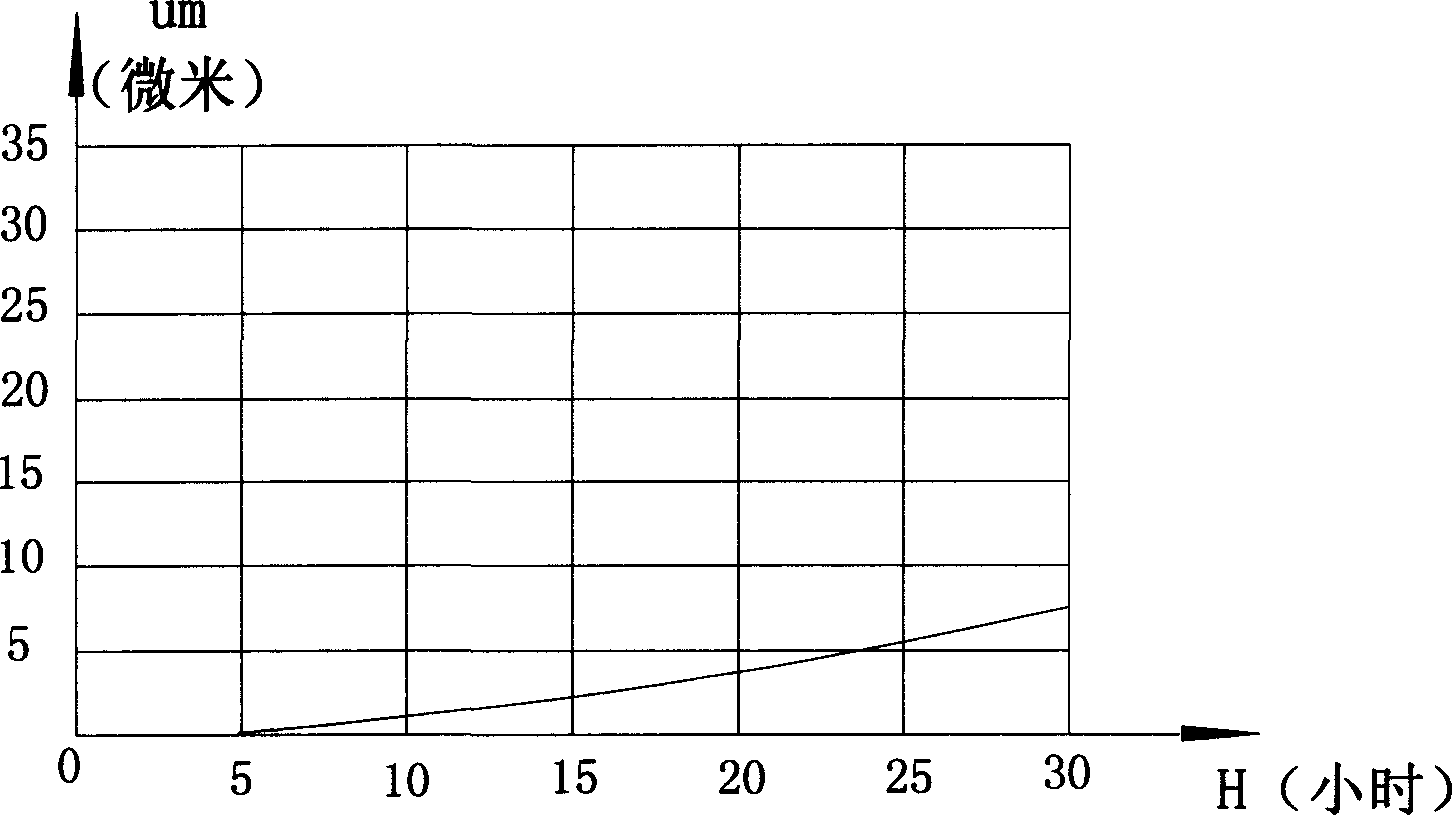

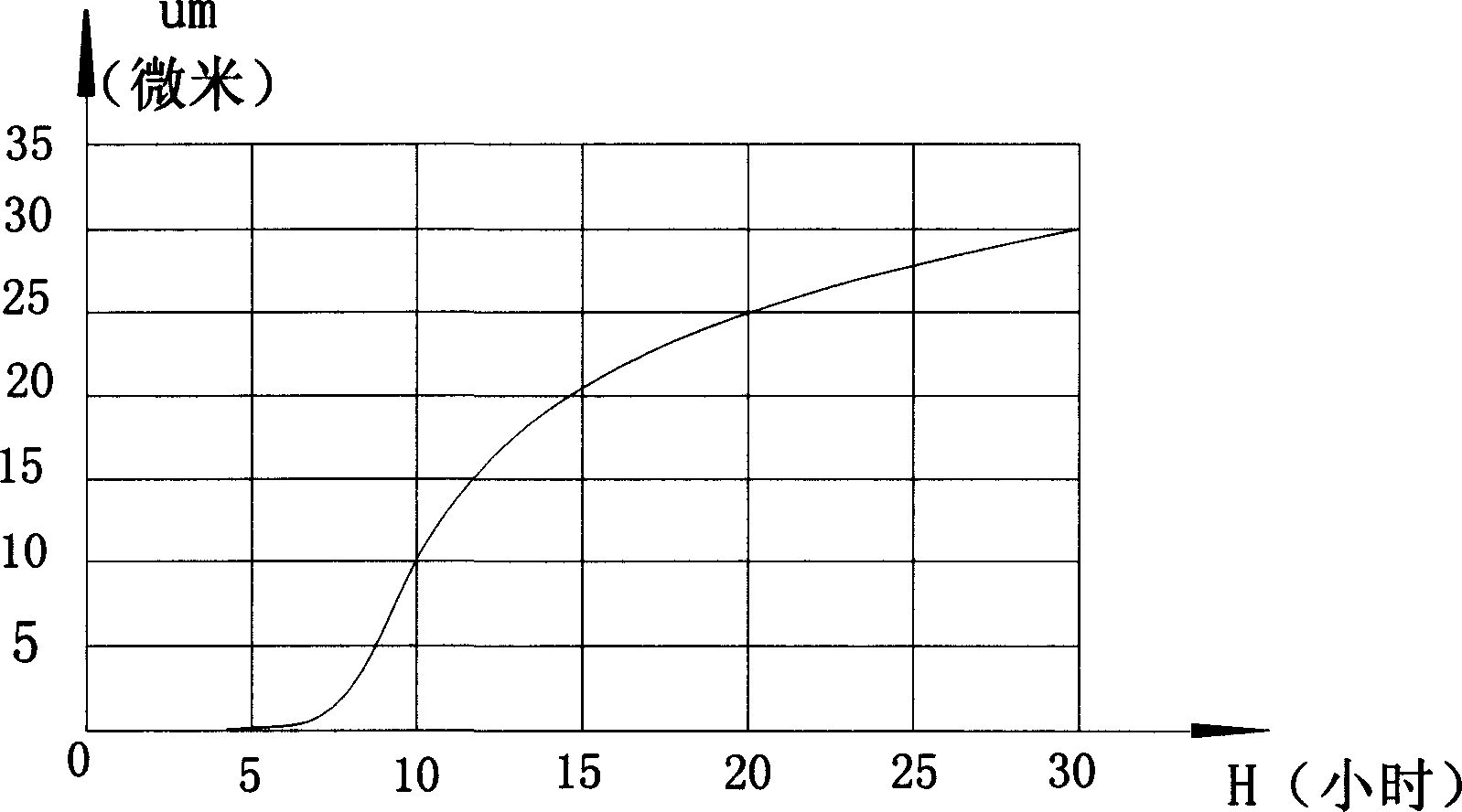

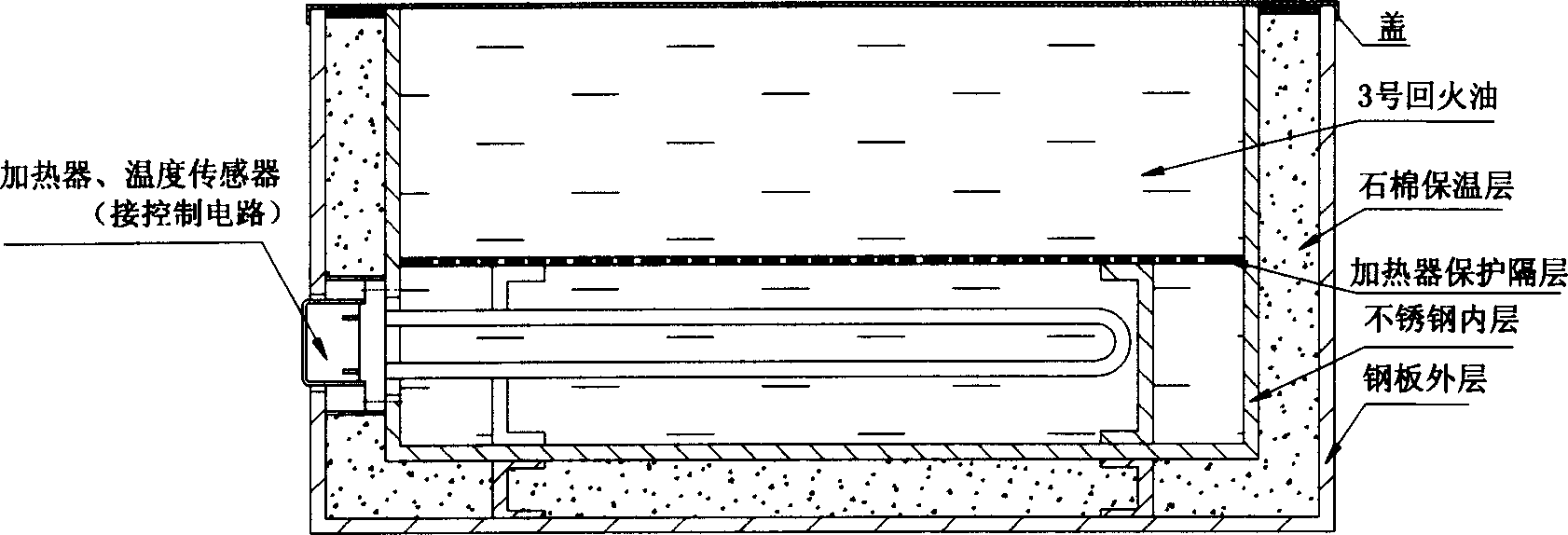

Preparation method and preparation system of 4.5 [mu]m ultrathin copper foil for lithium battery

ActiveCN111850620AImprove intrinsic performanceElectrolysis componentsElectroforming processesElectrolytic agentThiourea

The invention discloses a preparation method and a preparation system of a 4.5 [mu]m ultrathin copper foil for a lithium battery. The preparation method comprises the following steps of preparing an electrolyte; adding additives into the prepared electrolyte, wherein the additives comprise cellulose, polyethylene glycol, thiourea compounds and a leveling agent; and filtering the electrolyte with the additives added, and feeding the electrolyte into an electrolytic cell for electrolytic foil formation, wherein the cellulose comprises a combination of one or more of hydroxyethyl cellulose, hydroxypropyl cellulose and hydroxypropyl methyl cellulose, one or two of sodium 2-mercaptoethane sulfonate and 2-propenyl thiourea are adopted as the thiourea compounds, and one or two of polyethyleneimine and 9-phenylacridine are adopted as the leveling agent. According to the preparation method and the preparation system, the 4.5 [mu]m ultrathin copper foil can be prepared only with a small amount of additives, organic matters in the finished copper foil are reduced, and the internal performance of the copper foil is improved.

Owner:JIANGDONG ELECTRONIC MATERIALS CO LTD

Reviving waste product of bearing with inner and outer bearing ring over size

InactiveCN1821426ASmall geometryLow costFurnace typesHeat treatment process controlMechanical componentsWaste product

During bearing production, waste bearing rings with oversized outer and inner diameter in 2-8 % is produced, and the present invention provides the method of reviving these waste products. It is found that the additional tempering can alter the size of waste bearing rings, and controlling the tempering mode, temperature and time can increase or decrease the size of bearing rings. Controlling the temperature and time of tempering in hot oil can increase the outer diameter of bearing rings in 0.01-0.035 mm, and local HF tempering can decrease the inner diameter of bearing rings in0.005-0.015 mm. The principle of the present invention may be also used for other precise mechanical parts.

Owner:马跃林 +1

Environment-friendly type high-bonding heat-vulcanization rubber overshoes water-emulsion adhesive and preparation method thereof

InactiveCN107674610AEnhance anti-deterioration abilityImprove intrinsic performanceNatural rubber adhesivesNon-macromolecular adhesive additivesPolymer scienceVulcanization

The invention discloses an environment-friendly type high-bonding heat-vulcanization rubber overshoes water-emulsion adhesive and a preparation method thereof. According to the invention, natural latex and styrene-butadiene latex are used as main materials, the latex molecules basically keep an original state, high initial bonding capability of an environment-friendly type high-bonding heat-vulcanization rubber overshoes water-emulsion bonding system can be ensured, rubber polymer is not changed, the vulcanized crosslinked adhesive and a to-be-bound part form a high-tenacity unity, the unity has high final-bonding intensity, the surface viscosity requirement of the to-be-bound part is not high, the temperature requirement of the to-be-bound part is low, and the thermal-insulation performance requirement of the to-be-bound part is reduced. The initial bonding force of the adhesive and the to-be-bound part as well as affinity are increased, plastic flowing of the molecules on a bonding surface of high temperature vulcanized initial rubber part is prevented, and the rubber part and a shoe upper part are firmly bound, so that three quality problems of lace delamination, base fabric disengaging, and large base elastic edge of the rubber overshoes can be effectively solved.

Owner:JIHUA 3537 SHOE MAKING

Method of preparing mixed yarn through blending multi-element cotton and linen materials and adding functional silk

InactiveCN106521738AReduce usageImprove intrinsic performancePhysical treatmentBiochemical treatment with enzymes/microorganismsTextile technologyYarn

The invention belongs to the technical field of textile, and particularly relates to a method of preparing mixed yarn through blending multi-element cotton and linen materials and adding functional silk. The mixed yarn is prepared by blending cotton fiber, linen fiber, bamboo fiber, wool fiber and tencel fiber. Through the cotton-linen blending method, consumption of the linen fiber which is expensive in price can be reduced, so that production benefit is increased; multi-element functional silk like the bamboo fiber, the wool fiber and the tencel fiber are preferentially selected, so that inherent performance of the yarn is improved, fabric products which are finally produced can have the characteristics of softness and smoothness of cotton and smoothness, moisture absorption and sweat release, antimicrobial performance and sanitation of linen, and comfort of users is improved.

Owner:YIWU MASHANGSHENG KNIT GOODS CO LTD

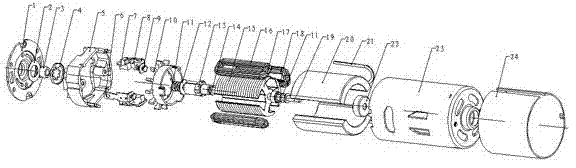

Motor

InactiveCN103095083AReduce volumeReduce weightMagnetic circuit rotating partsDC commutatorElectric machineEngineering

A motor relates to the technical field of electric tools. An iron cover of the motor is positioned on an inner cover. A gasket, a ball bush and a bush cover are sequentially arranged between the iron cover and the inner cover. A terminal and a carbon button are both installed in the inner cover, an elastic arm is positioned on the carbon button, a rivet is positioned on the elastic arm, a fan blade is sleeved on one side of a shaft, an oil changer is positioned on one side of the fan blade, a limit washer and an oil prevention washer are arranged between the fan blade and the oil changer, a fibber washer is arranged on one side of a diverter, a punched piece is arranged on one side of the fibber washer, a patent leather line is positioned on the outer side of the punched piece, insulation powder layers are arranged at two ends of the punched piece, a copper washer is arranged on one side of the punched piece, a magnet is sleeved on the outer side of the punched piece, an elastic bow is positioned on the magnet, a straight bush is positioned in the iron cover, the iron cover is sleeved on the magnet, and a magnet change ring is sleeved on the iron cover. The motor is small in size, light in weight, large in torque, long in service life, high in safety and capable of saving energy and protecting the environment.

Owner:黄正滨

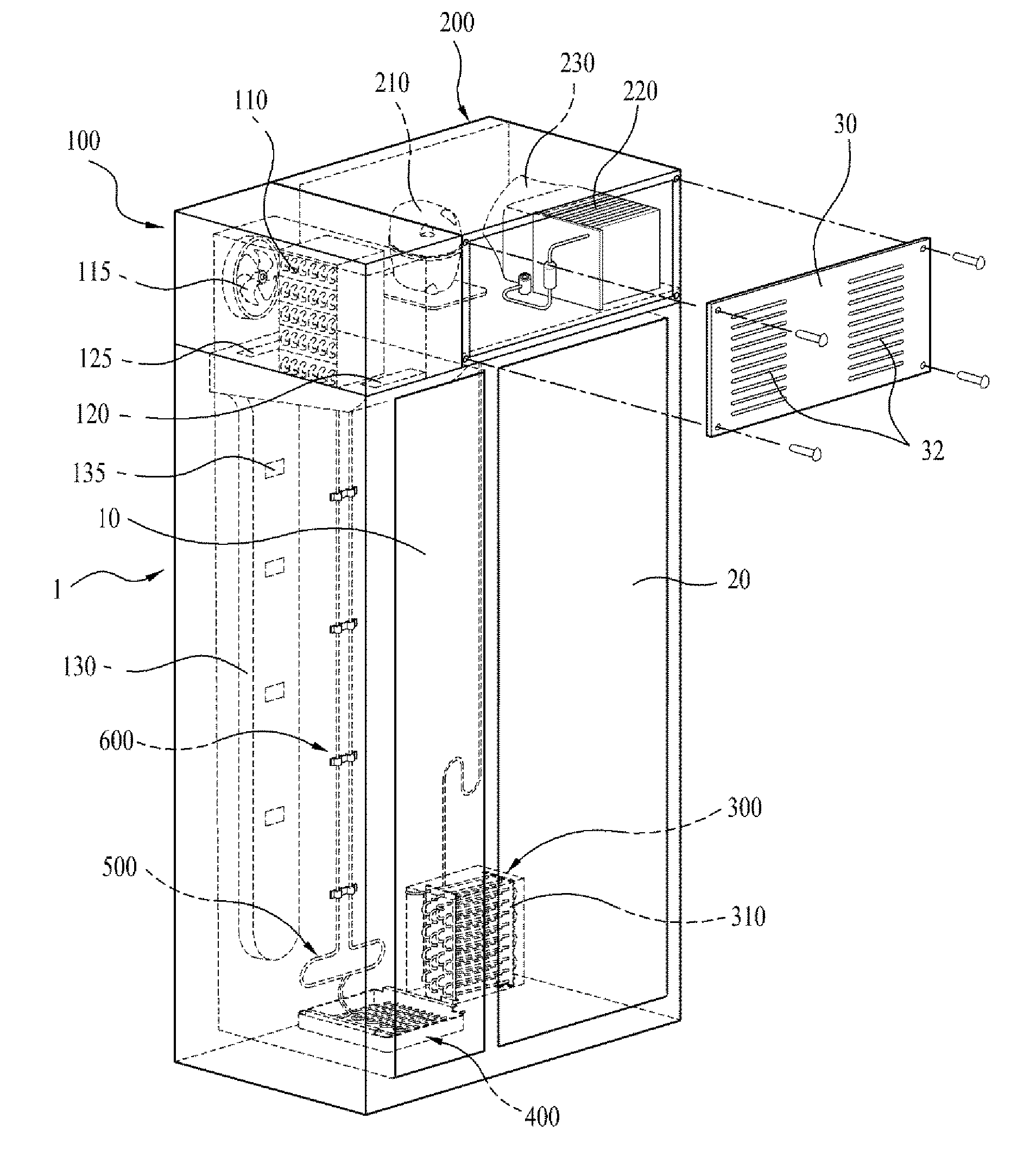

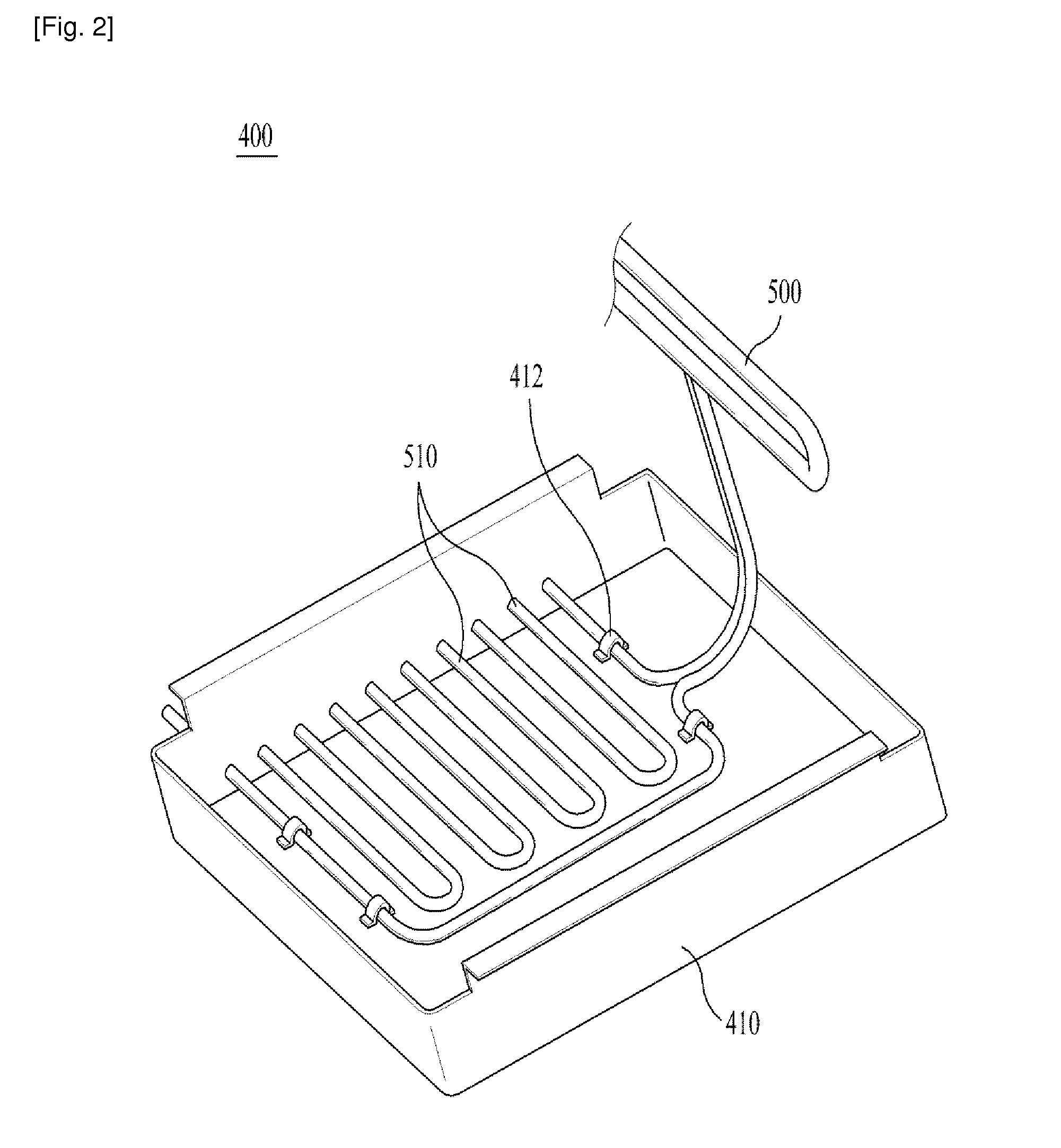

Refrigerator

InactiveUS20120117999A1Improve satisfactionEfficiency of consumption of be maximizeRefrigeration componentsCooling fluid circulationEvaporatorEngineering

A refrigerator is disclosed. The refrigerator includes a cabinet comprising a freezing compartment and a refrigerating compartment, a cold air generation chamber for the freezing compartment provided in an upper portion of the cabinet, in communication with the freezing compartment, the cold air generation chamber configured to accommodate an evaporator for the freezing compartment, a machine room provided in an upper portion of the cabinet, a cold air generation chamber for the refrigerating compartment independently provided from the cold air generation chamber for the freezing compartment, the cold air generation chamber for the refrigerating compartment configured to accommodate an evaporator for the refrigerating compartment, and a defrosted-water treating part configured to receive defrosted-water generated from the evaporator for the freezing compartment and the evaporator for the refrigerating compartment.

Owner:LG ELECTRONICS INC

Nickel alloy wire and production method thereof

InactiveCN105220017APay attention to sciencePay attention to technicalityWire rodNon-metallic inclusions

The invention discloses a nickel alloy wire. An alloy comprises the following components in percentage by mass: 7-10% of Si, 2-3% of Cu, 1-2% of Mg, 0.1-0.2% of Ag, 0.4-0.6% of Mo, 0.01-0.02% of Ti, 0.02-0.03% of La, 0.01-0.03% of Co, 0.01-0.02% of Mn, 0.03-0.04% of Sn, and the balance of nickel and inevitable non-metallic inclusions. The invention also provides a corresponding preparation method. Products are novel and unique new products with a scientific and reasonable formula, not only have an outstanding intrinsic quality, but also have a good appearance quality; and the effect of easy operation and the capability of improving the working efficiency, reducing the pollution, and saving the cost can be achieved.

Owner:WUXI QINGYANG MACHINERY MFG

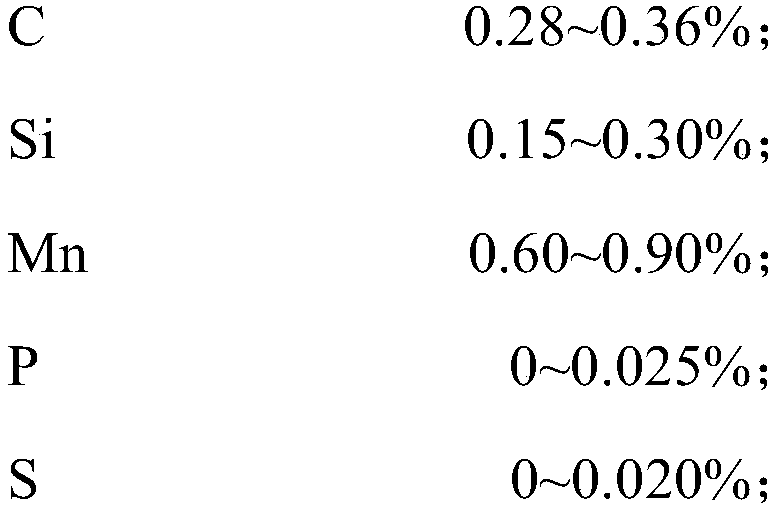

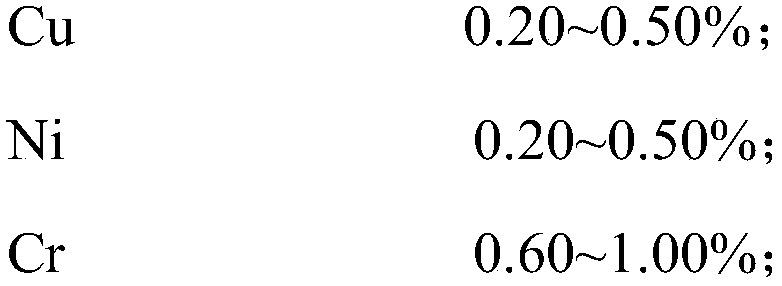

Continuous-cast steel billet with optimized surface quality and manufacturing method of such continuous-cast steel billet

The invention relates to the field of metal machining, in particular to a manufacturing method of a continuous-cast steel billet with the optimized surface quality. The manufacturing method includes transferring molten steel with the specific elements into a middle ladle, and enabling the molten steel to flow into a crystallizer via a submerged nozzle, wherein a distance between the submerged nozzle and an outer arc side of the crystallizer is greater than that between the submerged nozzle and an inner arc side of the crystallizer. The manufacturing method has the advantage that the solidifying thickness of the molten steel in the crystallizer is evener through change on a nozzle position in the prior art, and the stress gradient of a billet shell caused by thermal contraction is decreased, so that longitudinal recesses or cracks formed in the surface of the billet shell are avoided.

Owner:吕梁建龙实业有限公司

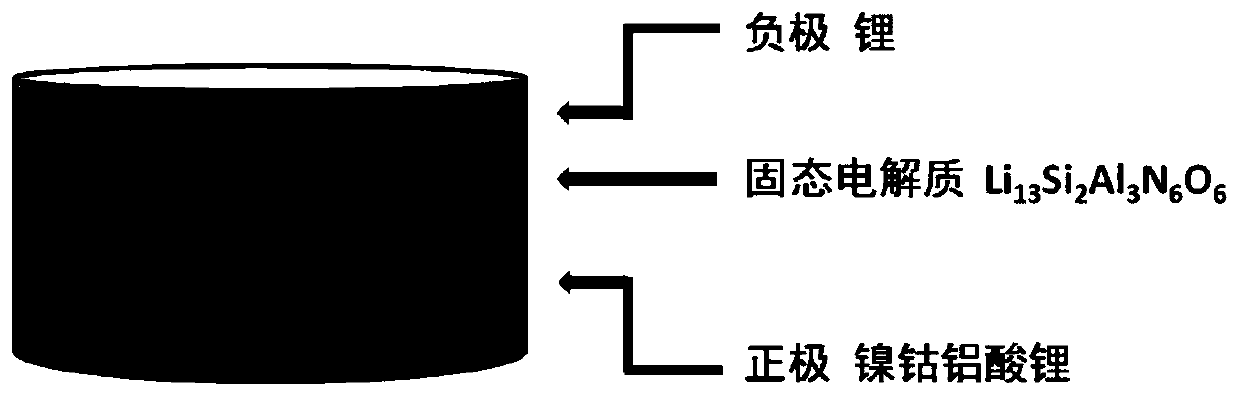

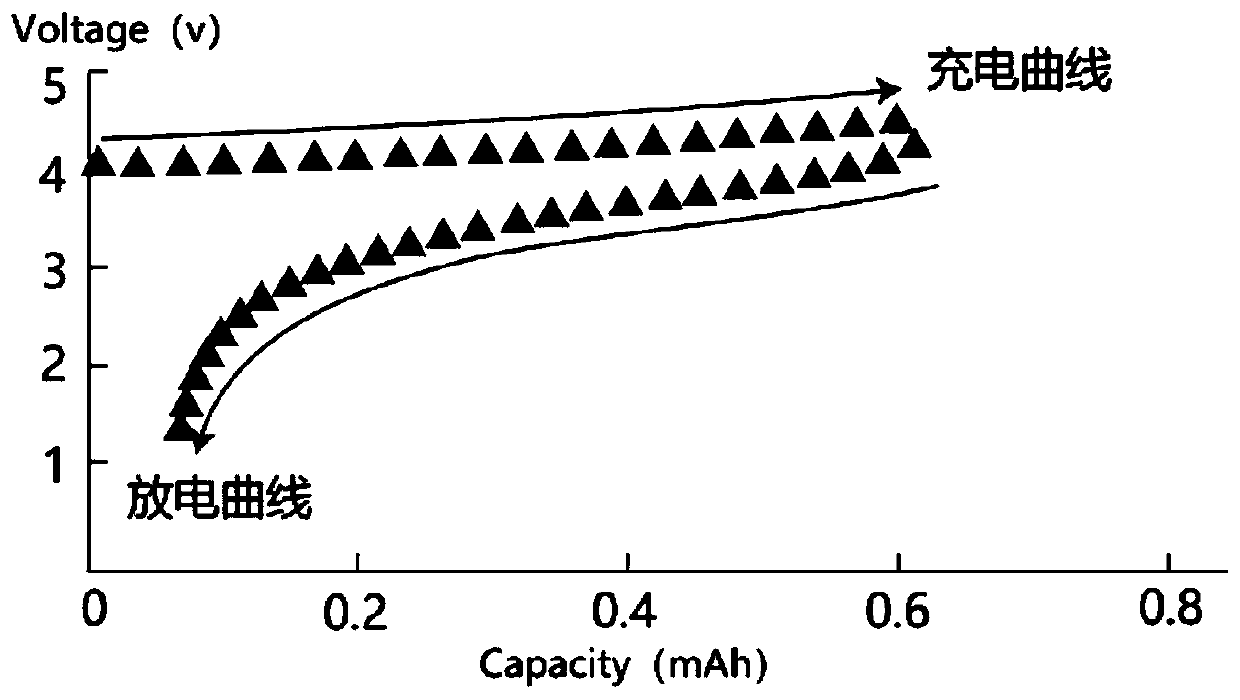

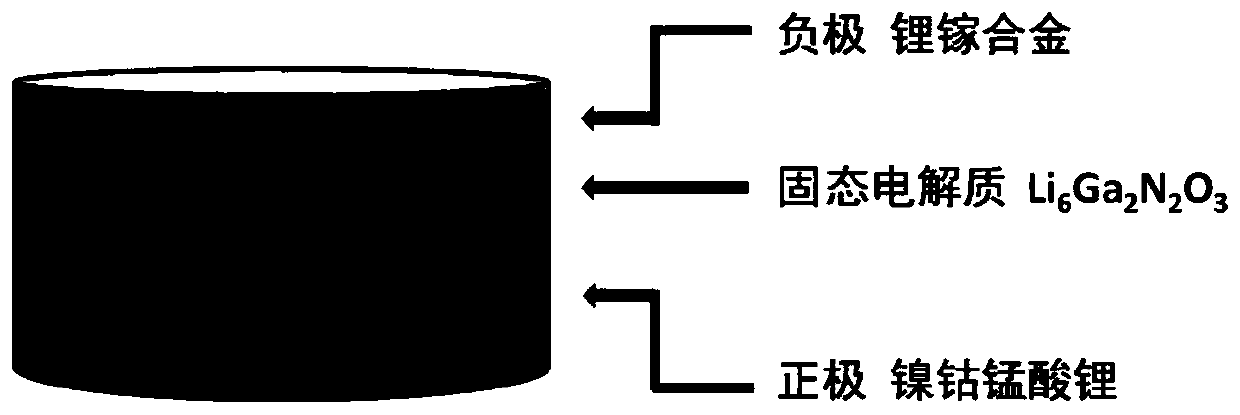

All-solid-state battery and preparation method thereof

InactiveCN110380116AImprove intrinsic performanceImprove electrochemical performanceFinal product manufacturePositive electrodesAll solid stateSolid state electrolyte

The invention relates to the technical field of all-solid-state batteries, and specifically discloses an all-solid-state battery and a preparation method thereof. The all-solid-state battery comprisesa positive plate, a negative plate and a solid-state electrolyte plate located between the positive plate and the negative plate, wherein the solid-state electrolyte plate is made of a first solid-state electrolyte material, and the positive plate is made of a positive electrode material and a second solid-state electrolyte material. The all-solid-state battery improves the intrinsic properties and electrochemical performance of the battery, and improves the ion conductivity of the solid-state electrolyte. In addition, the all-solid-state battery is simple in preparation process, has repeatability and mass production and has great application and popularization values.

Owner:GUANGZHOU TINCI MATERIALS TECH

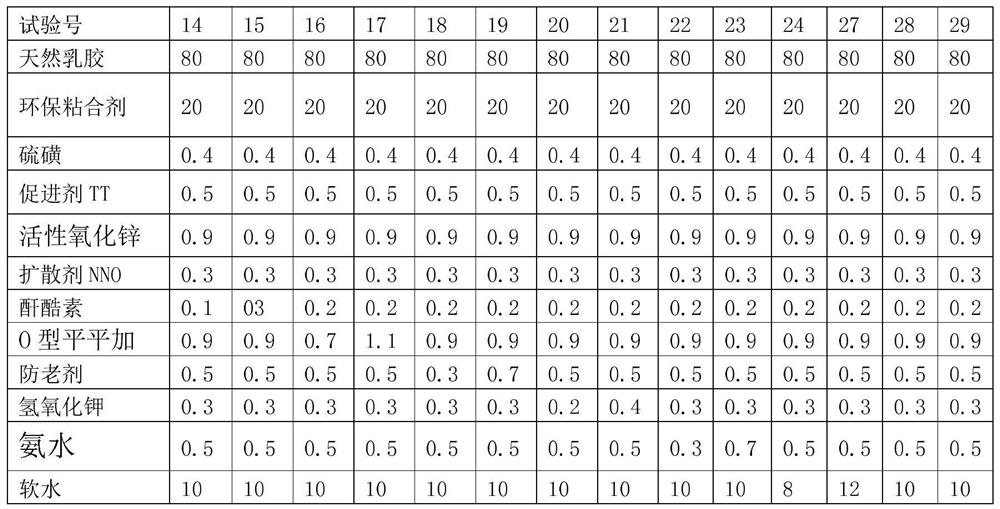

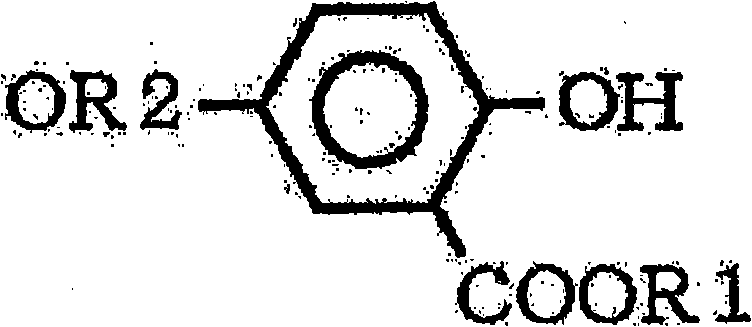

Novel water-based adhesive for polyester filament canvas shoes and preparation method thereof

InactiveCN112341953AEnhance anti-deterioration abilityImprove intrinsic performanceNatural rubber adhesivesNon-macromolecular adhesive additivesPolyesterAdhesive cement

The invention discloses a novel water-based adhesive for polyester filament canvas shoes and a preparation method thereof. A combined body of natural latex and an environment-friendly adhesive is usedas a main body material, and molecules of the latex are basically kept in the original shape, so that the higher initial adhesion capacity of the novel water-based adhesive for the polyester filamentcanvas shoes is ensured; asthe rubber polymer does not change, the vulcanized and cross-linked adhesive and an adhered adhesive part form a high-strength unified body and have relatively high final adhesion strength, so that the requirement on the surface viscosity of the adhered adhesive part is not high, the requirement on the temperature of the adhered adhesive part is low, and the requirementof an adhered adhesive material on the thermal insulation property is reduced. Due to the fact that the initial bonding force and affinity with the adhered adhesive part are improved, plastic flowingof molecules on the bonding surface of the adhesive part in the initial stage of high-temperature vulcanization is prevented, the adhesive part and the upper are firmly bonded together through the adhesive, and therefore the three quality problems of lace delaminating, base cloth disengaging and outsole elastic edges of the rubber shoes are effectively solved.

Owner:JIHUA 3537 SHOE MAKING

Preparation method of high-performance black corundum abrasive

ActiveCN113277837AHigh bonding strengthImprove adhesionOther chemical processesElectric arc furnaceCrusher

The invention discloses a preparation method of a high-performance black corundum abrasive. The preparation method comprises the following steps: (1) proportioning of raw materials: selecting 43-51 parts of high-alumina bauxite, 48-56 parts of high-iron bauxite and 1-2 parts of magnesium oxide as raw materials, respectively crushing the selected raw materials, and then mixing the raw materials through an automatic batching system to enable the mixed raw materials to meet a proportion requirement; (2) electric melting: adding the raw materials mixed in the step (1) into an electric arc furnace for electric melting to prepare liquid black corundum, and then cooling the liquid black corundum to obtain a semi-finished blocky black corundum product; and (3) preparation of a finished product: subjecting the semi-finished blocky black corundum product obtained after electric smelting in the step (2) to crushing, impurity removal, cleaning and sorting through a jaw crusher and a ball mill so as to obtain a finished black corundum abrasive product. According to the invention, the technical problem of increasing the performance of the common-grade black corundum abrasive within limited cost is solved, a traditional technical concept in the field is broken through, and the inherent performance of a common-grade black corundum product is greatly improved.

Owner:ZHENGZHOU YEDA HIGH TECH MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Preparation method and preparation system of 4.5 [mu]m ultrathin copper foil for lithium battery Preparation method and preparation system of 4.5 [mu]m ultrathin copper foil for lithium battery](https://images-eureka.patsnap.com/patent_img/30fd7497-99b7-41ea-af8e-c7f0c378b2ec/200818101554.png)