Delivery spray nozzle, polytetrafluoroethylene fine particle processing method and apparatus using the spray nozzle

A technology of polytetrafluoroethylene and conveying nozzles, applied in lighting and heating equipment, conveyors, transportation and packaging, etc., can solve the problems of environmental pollution, limited application range, and low crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

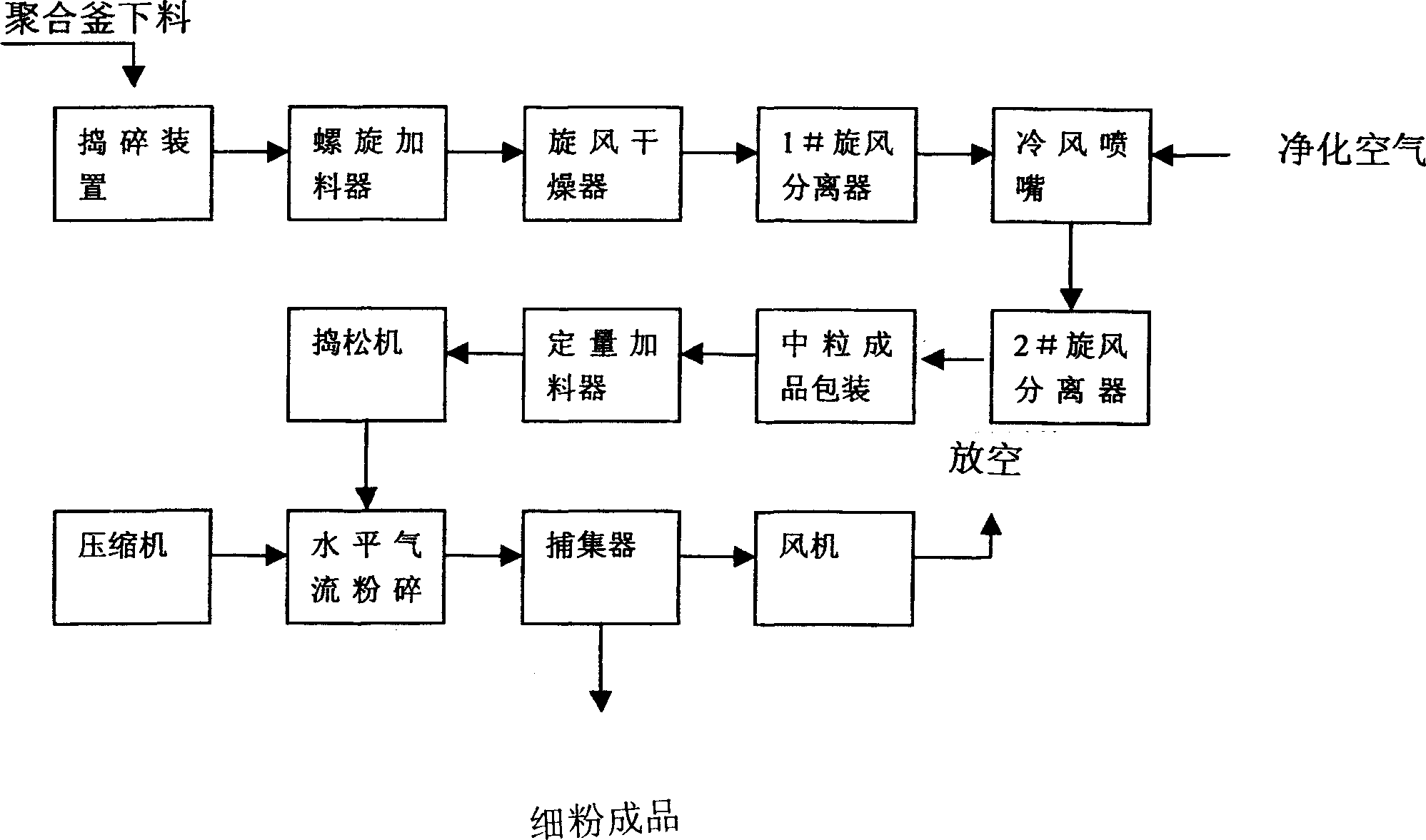

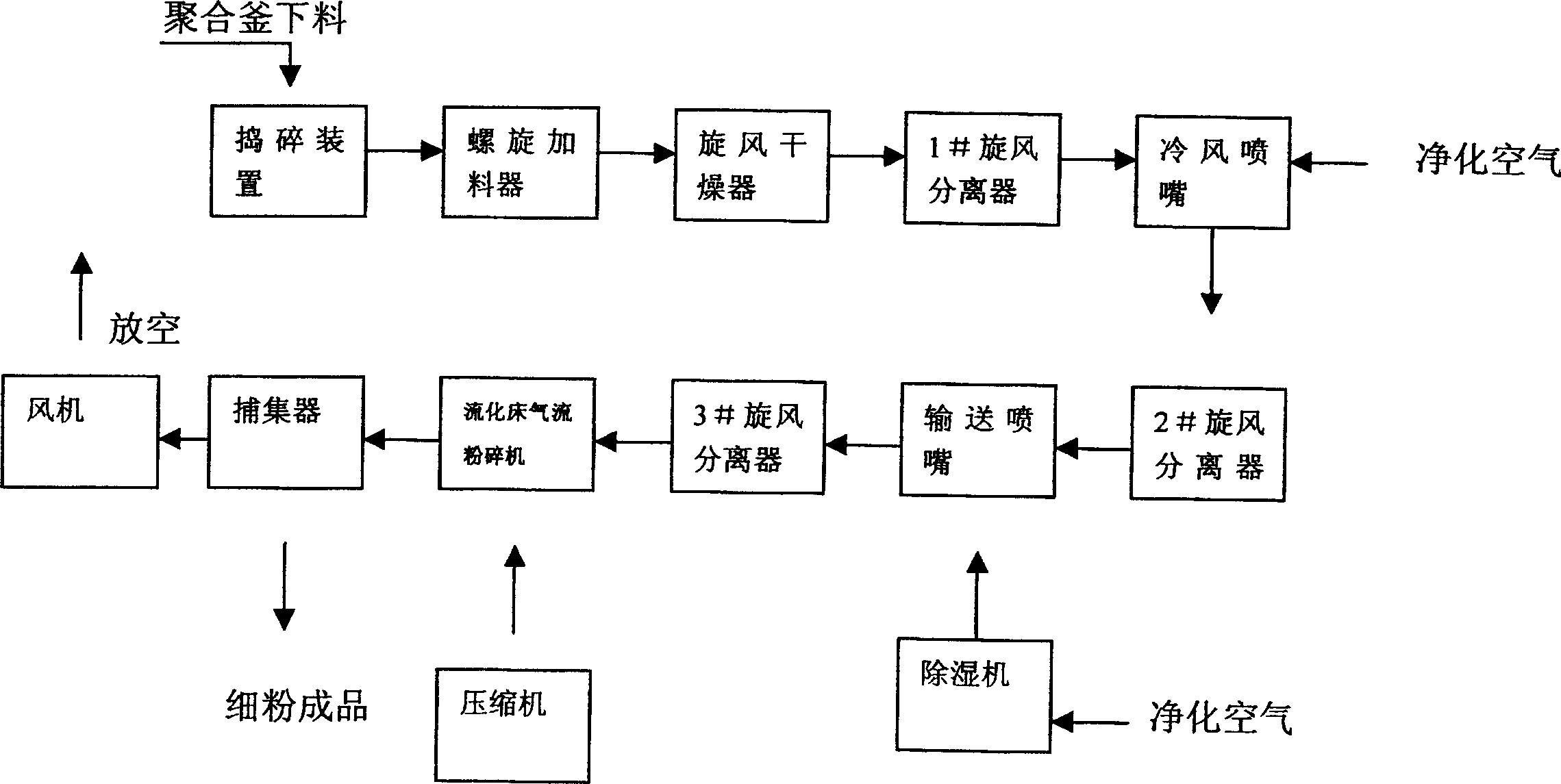

[0136] After the polymerized polytetrafluoroethylene coarse particles are smashed, washed and separated, they are then quantitatively sent to the cyclone dryer through the screw feeder. The speed of the screw feeder is 6r / min. The average particle size of the granular material is 249 μm, and the moisture content is 0.02%.

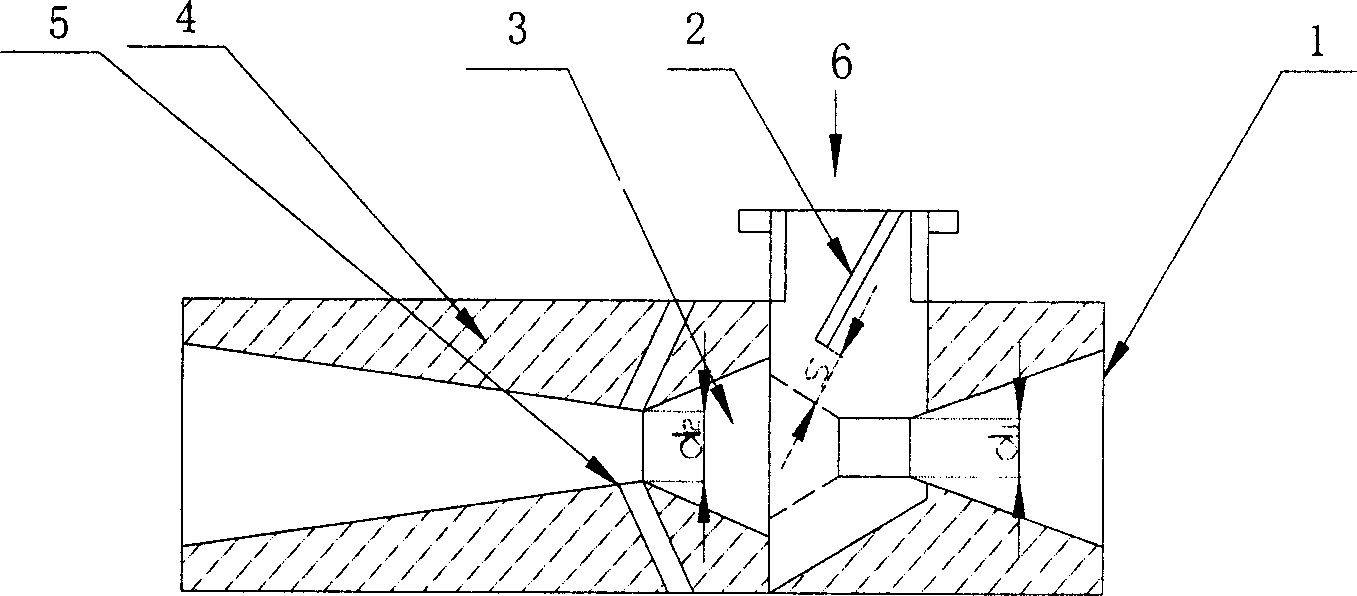

[0137] Pass the purified air at room temperature through a dehumidifier with a moisture content of 0.09g / m 3 , the distance s from the lower part of the baffle to the boundary of the jet flow is 15mm, the ratio d2 / d1 of the outlet diameter d1 of the jet pipe to the outlet diameter d2 of the shrinkage pipe is 1.9, and the ratio of the inlet diameter R of the medium-sized material inlet pipe 6 to the outlet diameter r The 3:1 conveying nozzle attracts the medium-sized material into the 3# cyclone separator, and the medium-sized material enters the chamber of the fluidized bed jet mill through the butterfly valve with the airflow. The opening and closing frequ...

Embodiment 2

[0140] After the polymerized polytetrafluoroethylene coarse particles are crushed, washed and separated, they are then quantitatively sent to the cyclone dryer through the screw feeder, and the speed of the screw feeder is 10r / min. The average particle size of the granular material is 212 μm, and the moisture content is 0.02%.

[0141] The purified normal temperature air passes through the dehumidifier with a moisture content of 0.12g / m 3 , the distance s from the lower part of the baffle to the boundary of the jet flow is 18mm, the ratio d2 / d1 of the outlet diameter d1 of the jet pipe to the outlet diameter d2 of the shrinkage pipe is 2.0, and the ratio of the inlet diameter R of the medium-sized material inlet pipe 6 to the outlet diameter r 3:2 conveying nozzles attract medium-grained materials into 3 # In the cyclone separator, the medium-grained material enters the cavity of the fluidized bed jet mill through the butterfly valve with the airflow. The opening and closing ...

Embodiment 3

[0144] The polytetrafluoroethylene coarse particles after the polymerization reaction are crushed, washed and separated, and then quantitatively sent to the cyclone dryer through the screw feeder. The rotation speed of the screw feeder is 18r / min. The average particle size of the granular material is 284 μm, and the moisture content is 0.02%.

[0145] The purified normal temperature air passes through the dehumidifier with a moisture content of 0.10g / m 3 , the distance s from the lower part of the baffle to the jet flow boundary is 17mm, the ratio d2 / d1 of the outlet diameter d1 of the injection pipe to the outlet diameter d2 of the shrinkage pipe is 2.3, and the ratio of the inlet diameter R to the outlet diameter r of the medium-sized material inlet pipe 6 The conveying nozzle is 3:1.5 to attract medium-grained materials into 3 # Cyclone separator, the medium-grained material enters the chamber of the fluidized bed jet mill through the butterfly valve with the airflow, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com