Patents

Literature

253 results about "Particle processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

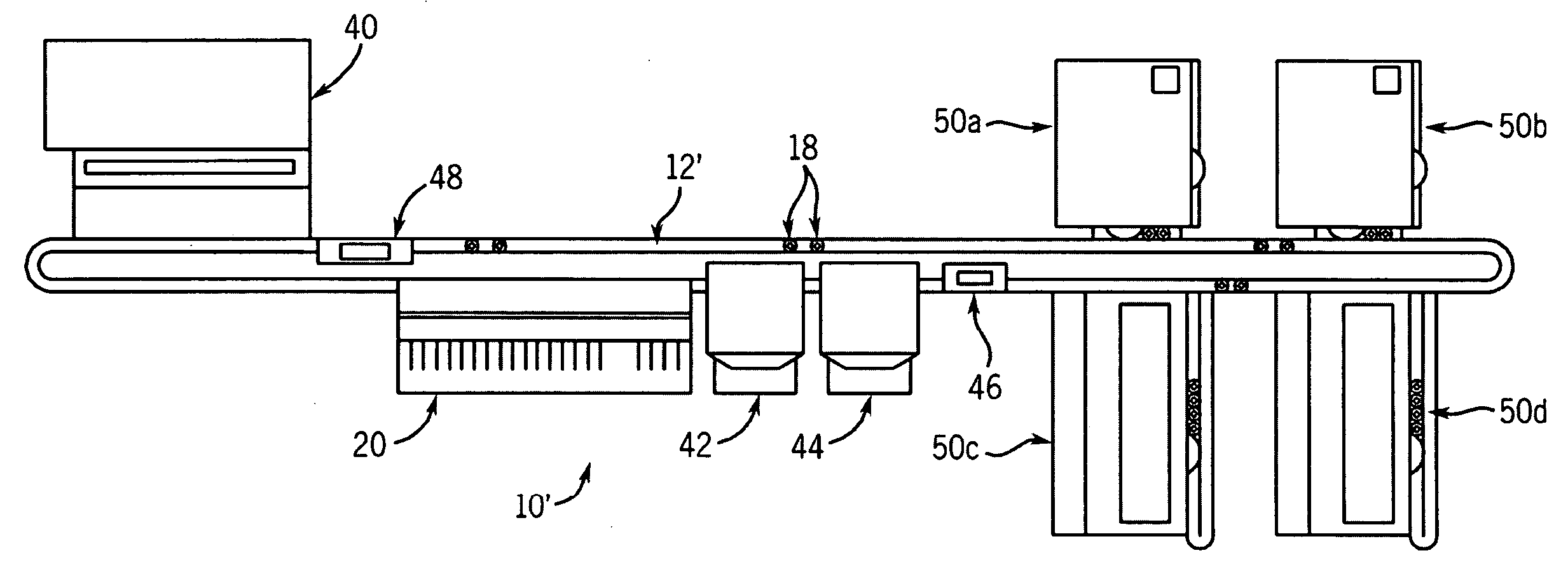

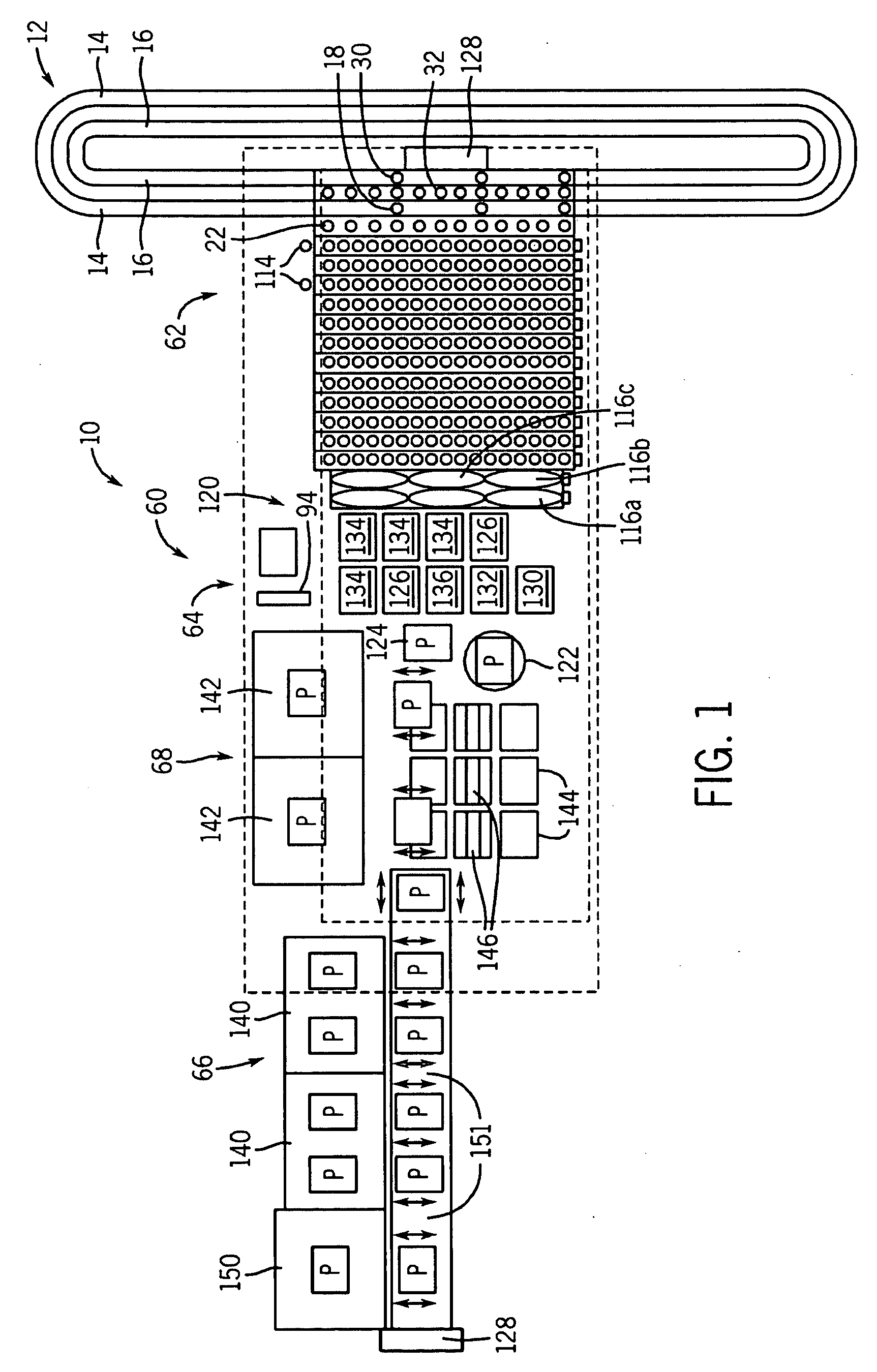

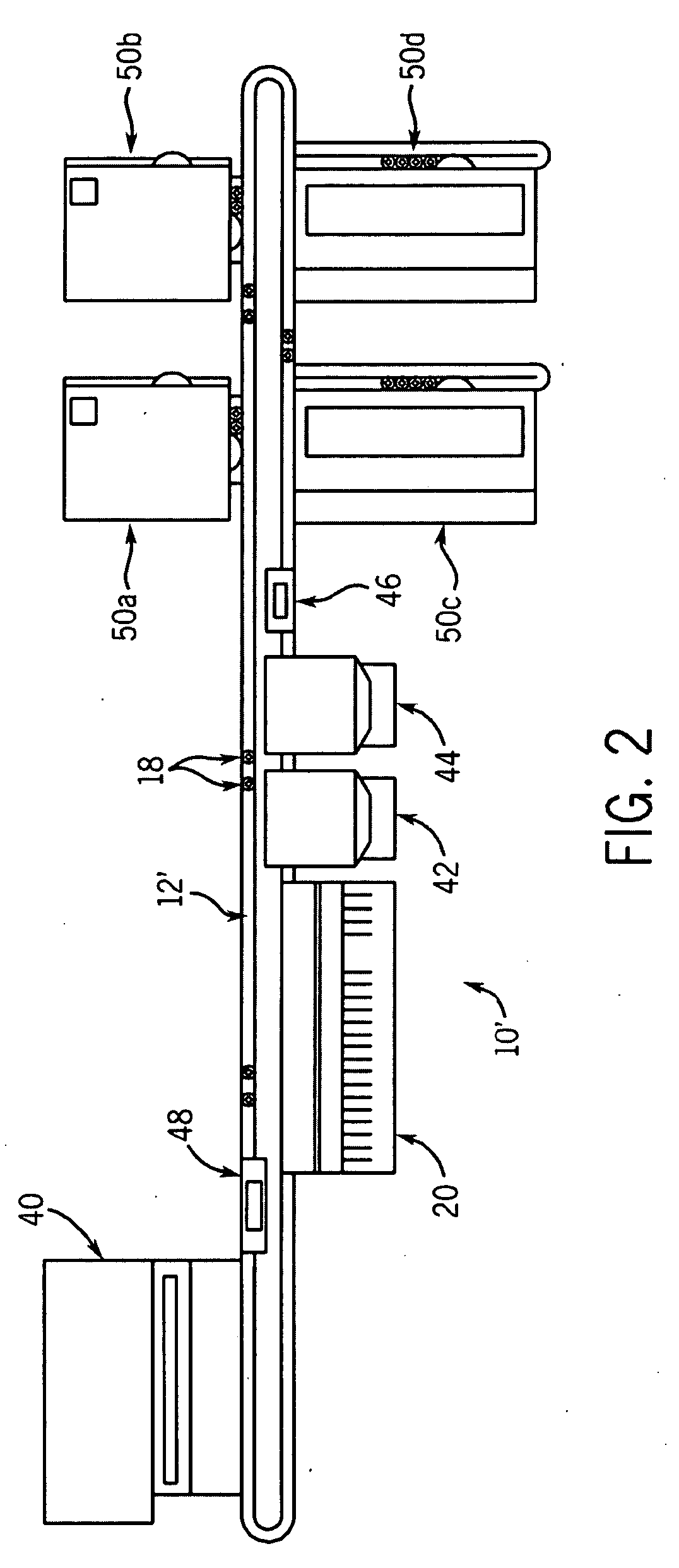

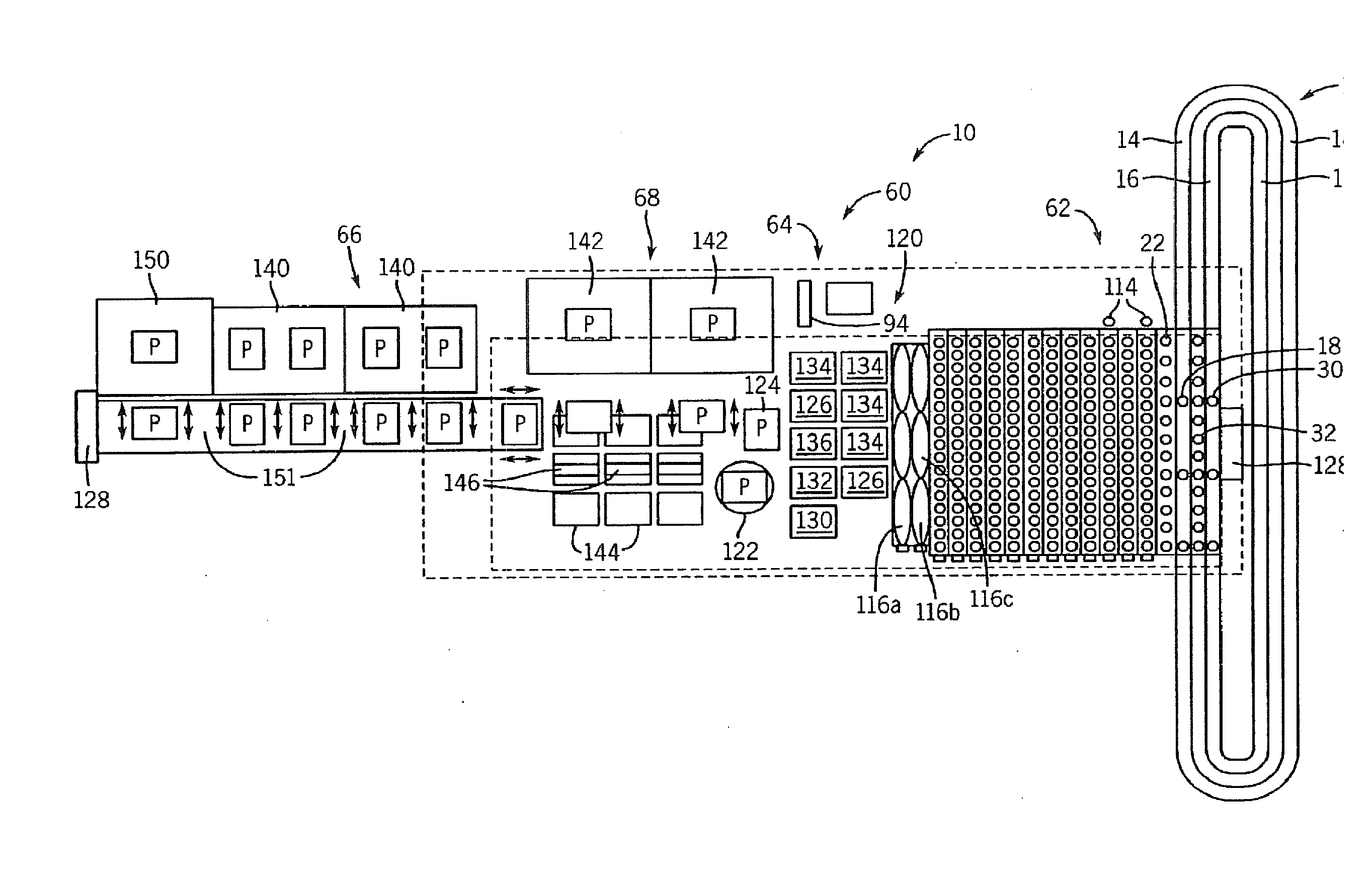

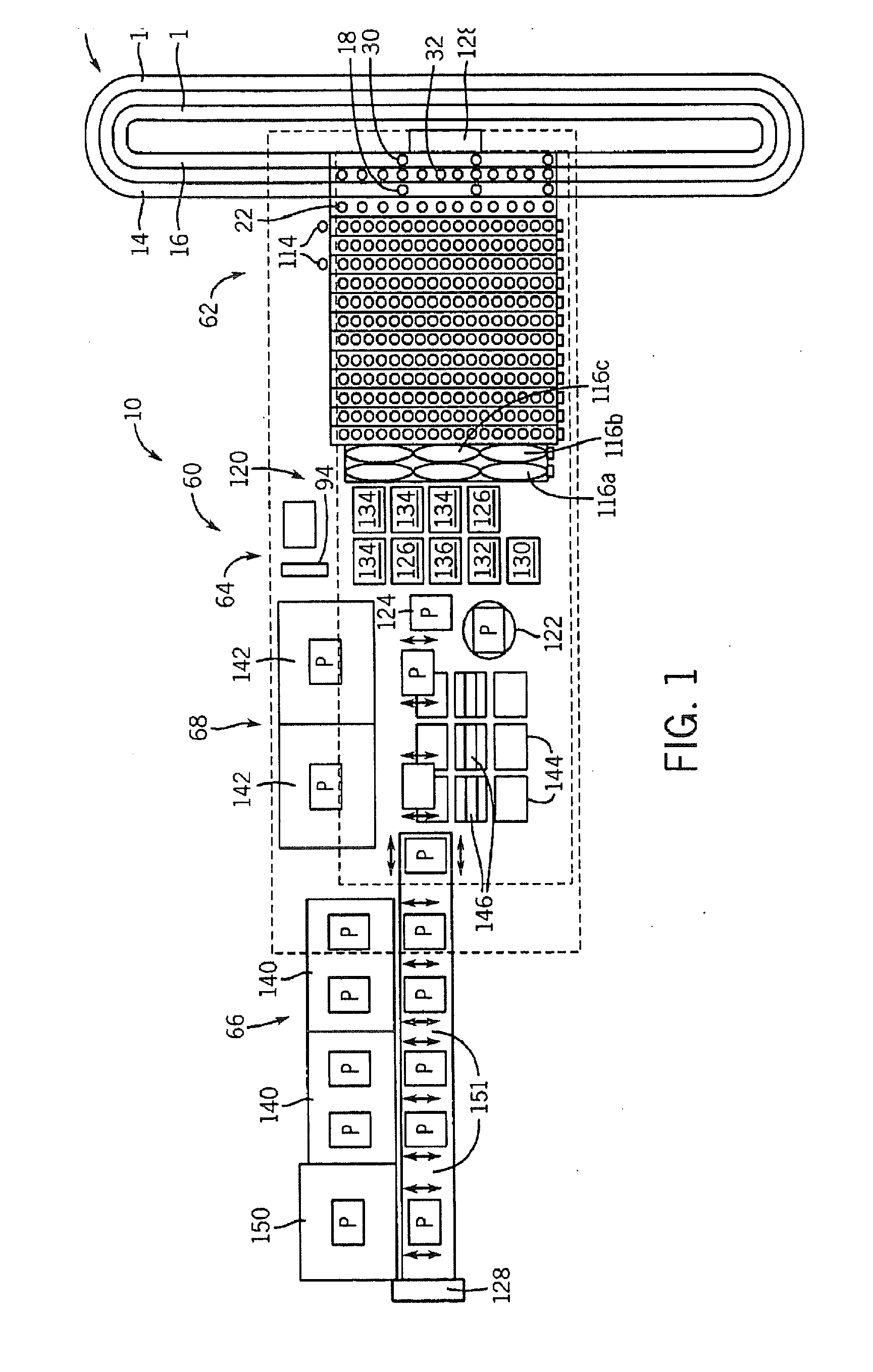

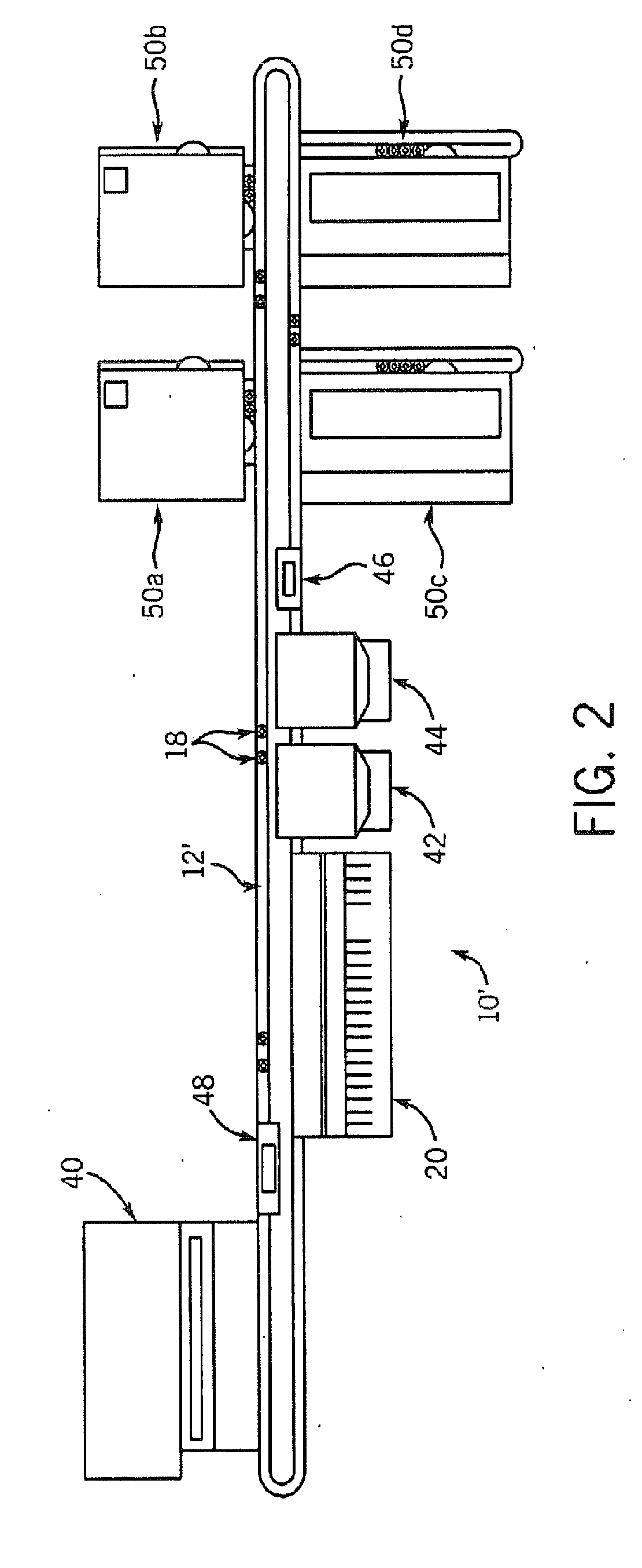

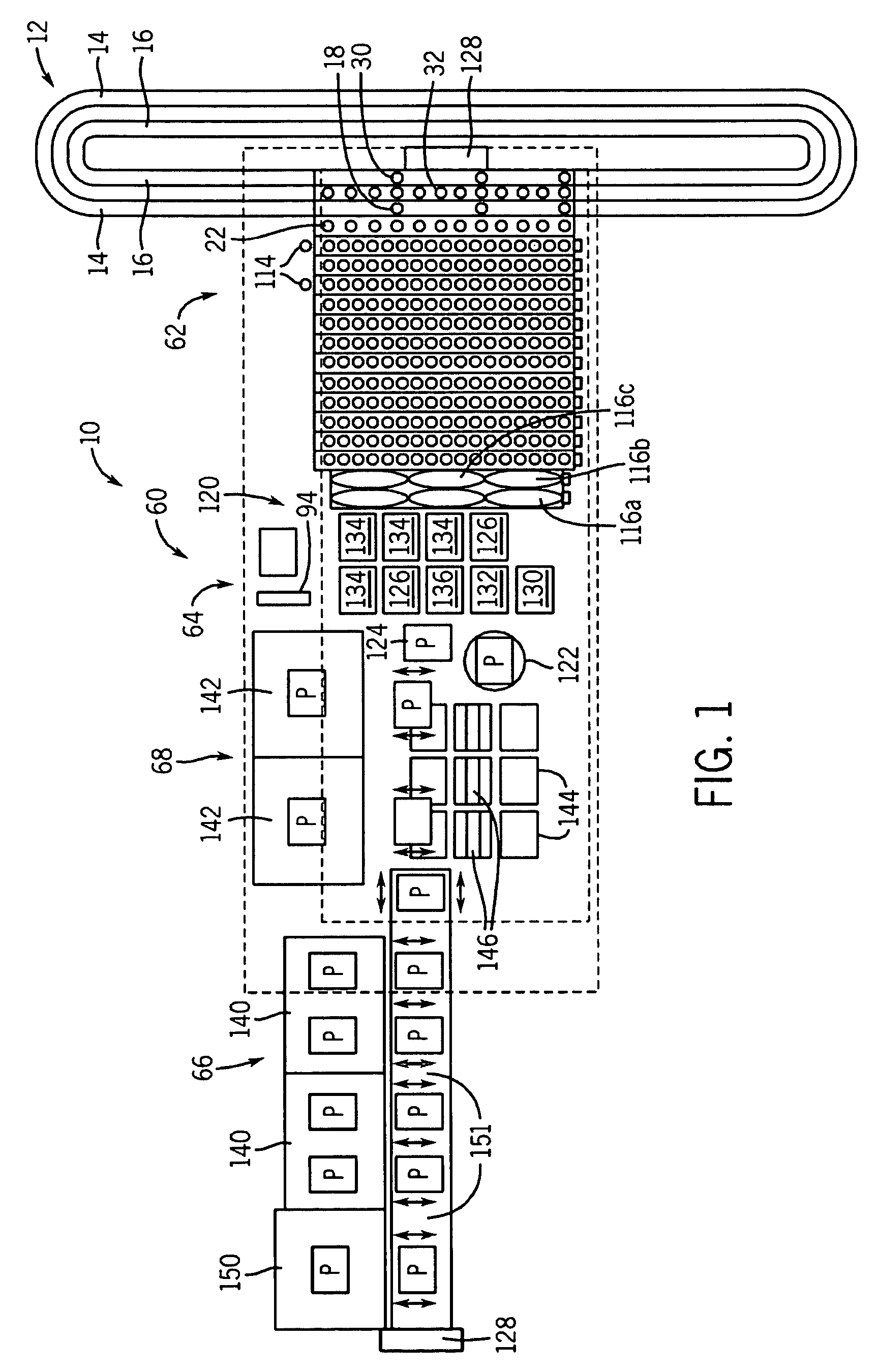

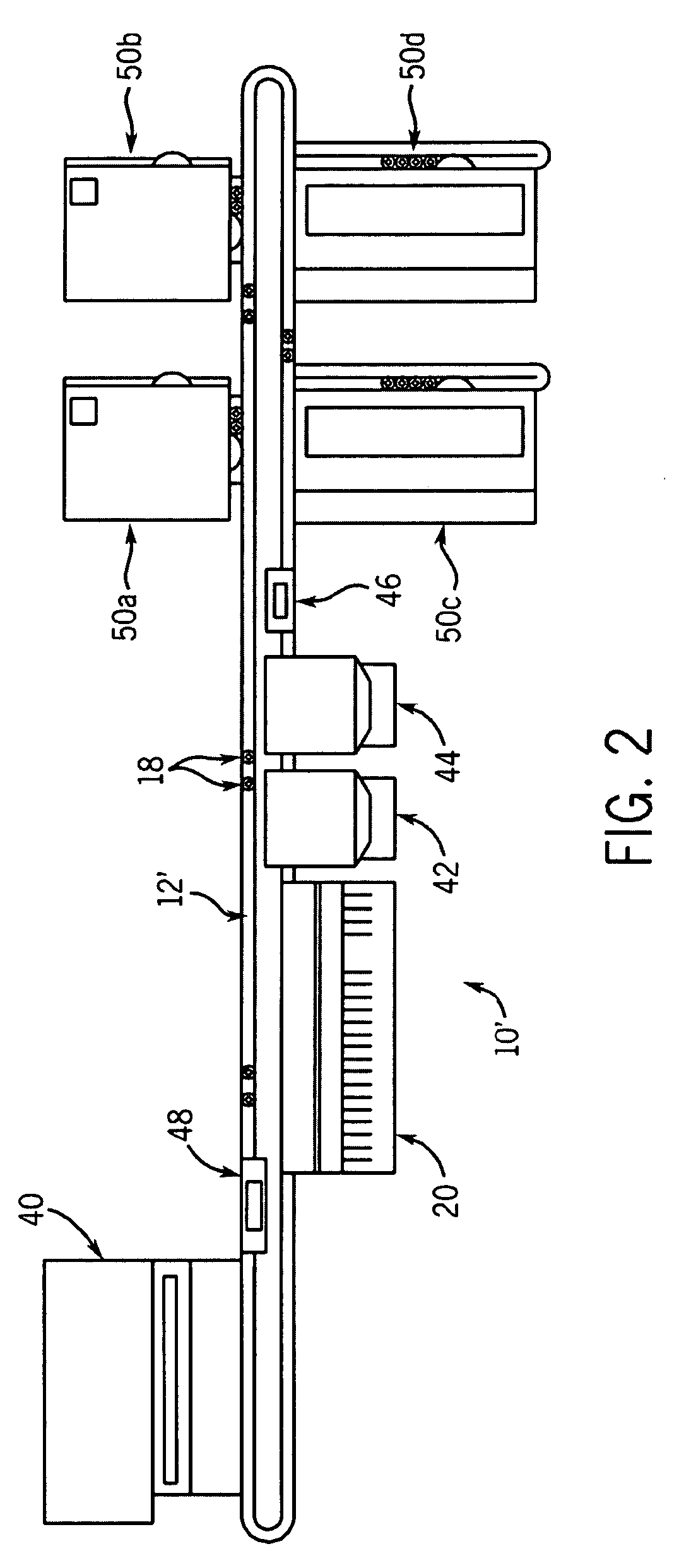

Automated analyzer for clinical laboratory

InactiveUS20090117620A1Manual loadingBioreactor/fermenter combinationsBiological substance pretreatmentsClinical chemistryMicro perforated plate

A laboratory automation system that is capable of carrying out clinical chemistry assays, immunoassays, amplification of nucleic acid assays, and any combination of the foregoing, said laboratory automation system employing at least one of micro-well plates and deep multi-well plates as reaction vessels. The use of micro-well plates as reaction vessels enables the laboratory automation system to assume a variety of arrangements, i.e., the laboratory automation system can comprise a variety of functional modules that can be arranged in various ways. In order to effectively carry out immunoassays by means of micro-well plates, a technique known as inverse magnetic particle processing can be used to transfer the product(s) of immunoassays from one micro-well of a micro-well plate to another.

Owner:ABBOTT LAB INC

Automated analyzer for clinical laboratory

ActiveUS20120282684A1Bioreactor/fermenter combinationsBiological substance pretreatmentsMicro perforated plateClinical chemistry

A laboratory automation system that is capable of carrying out clinical chemistry assays, immunoassays, amplification of nucleic acid assays, and any combination of the foregoing, said laboratory automation system employing at least one of micro-well plates and deep multi-well plates as reaction vessels. The use of micro-well plates as reaction vessels enables the laboratory automation system to assume a variety of arrangements, i.e., the laboratory automation system can comprise a variety of functional modules that can be arranged in various ways. In order to effectively carry out immunoassays by means of micro-well plates, a technique known as inverse magnetic particle processing can be used to transfer the product(s) of immunoassays from one micro-well of a micro-well plate to another.

Owner:ABBOTT LAB INC

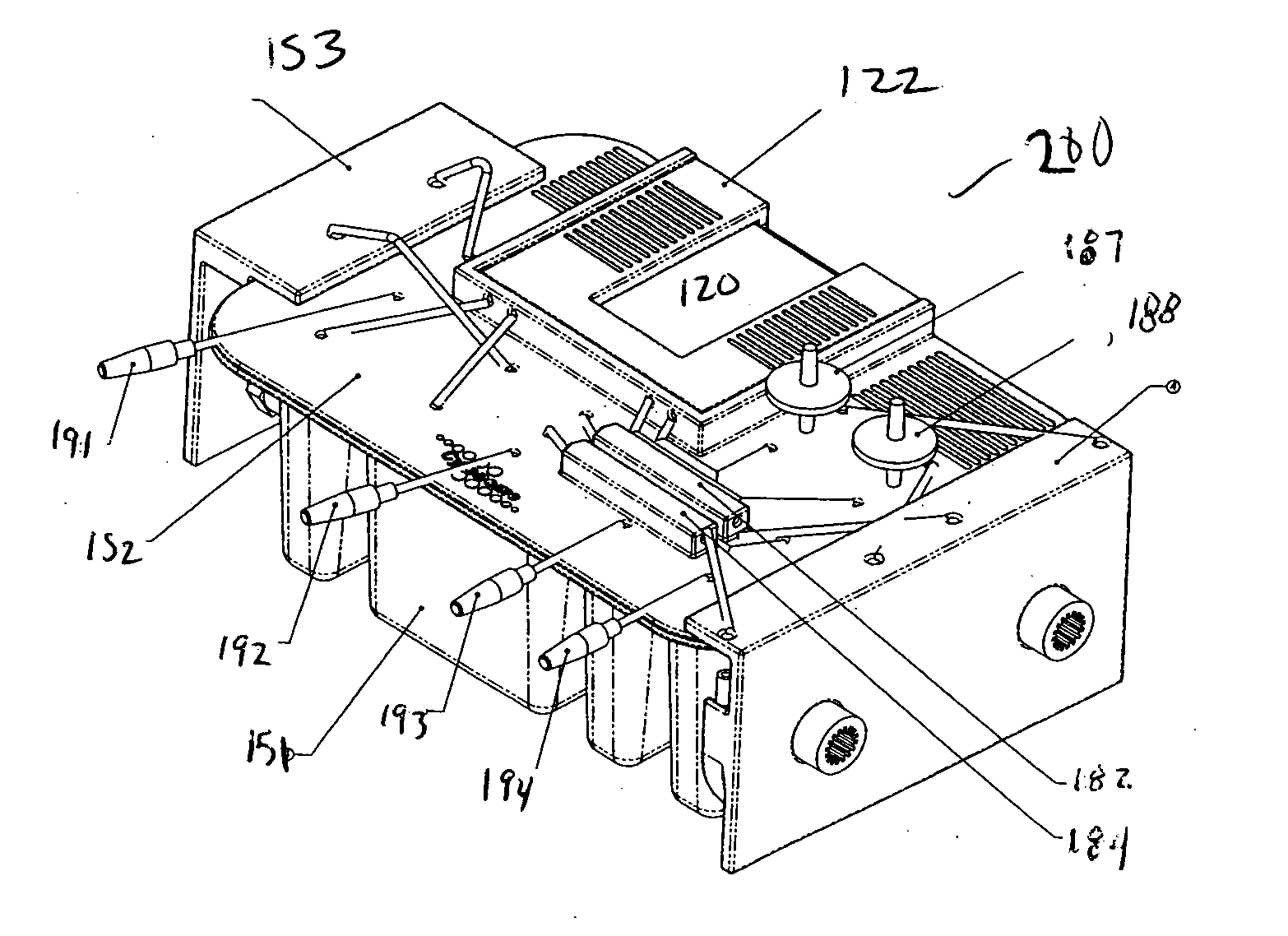

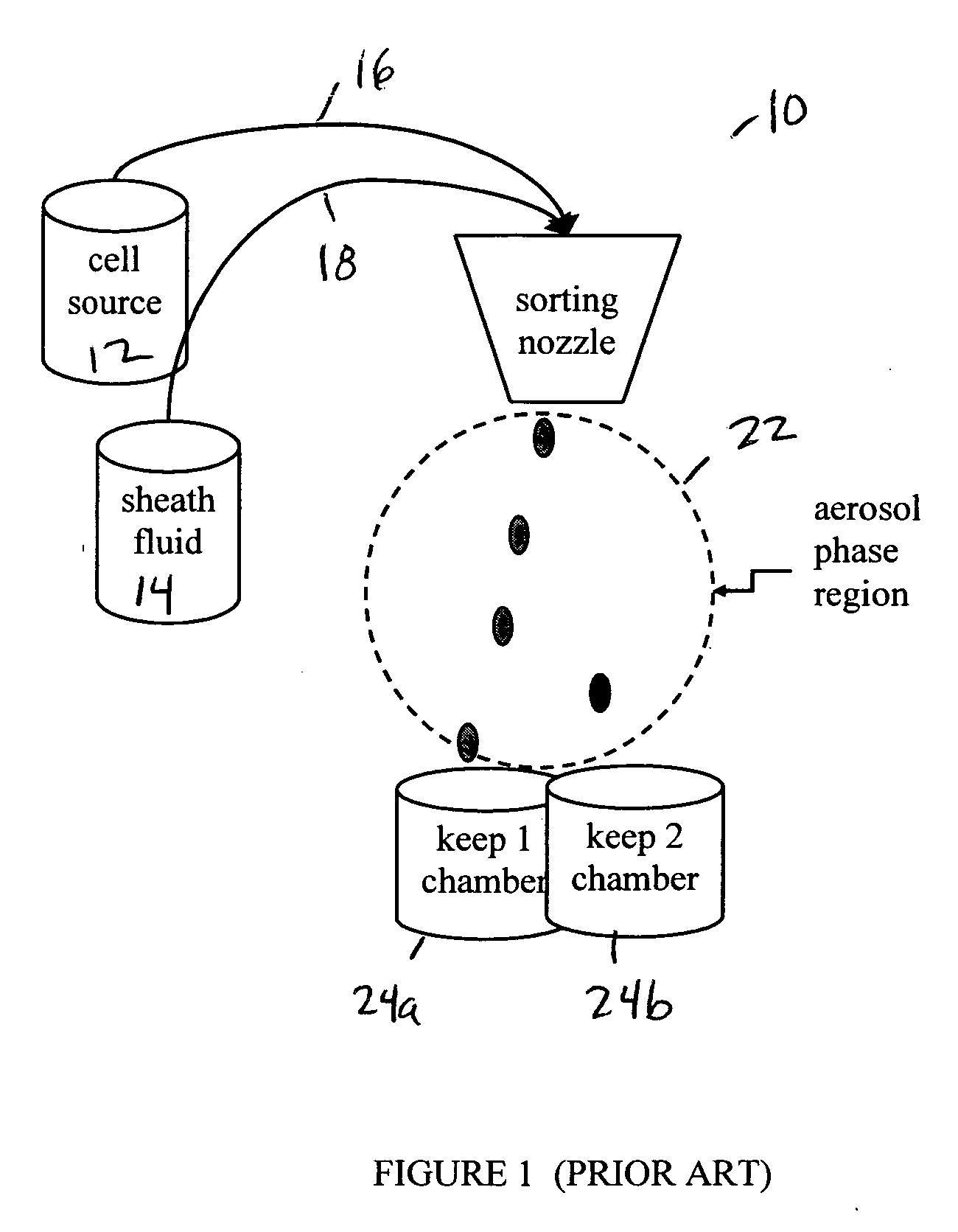

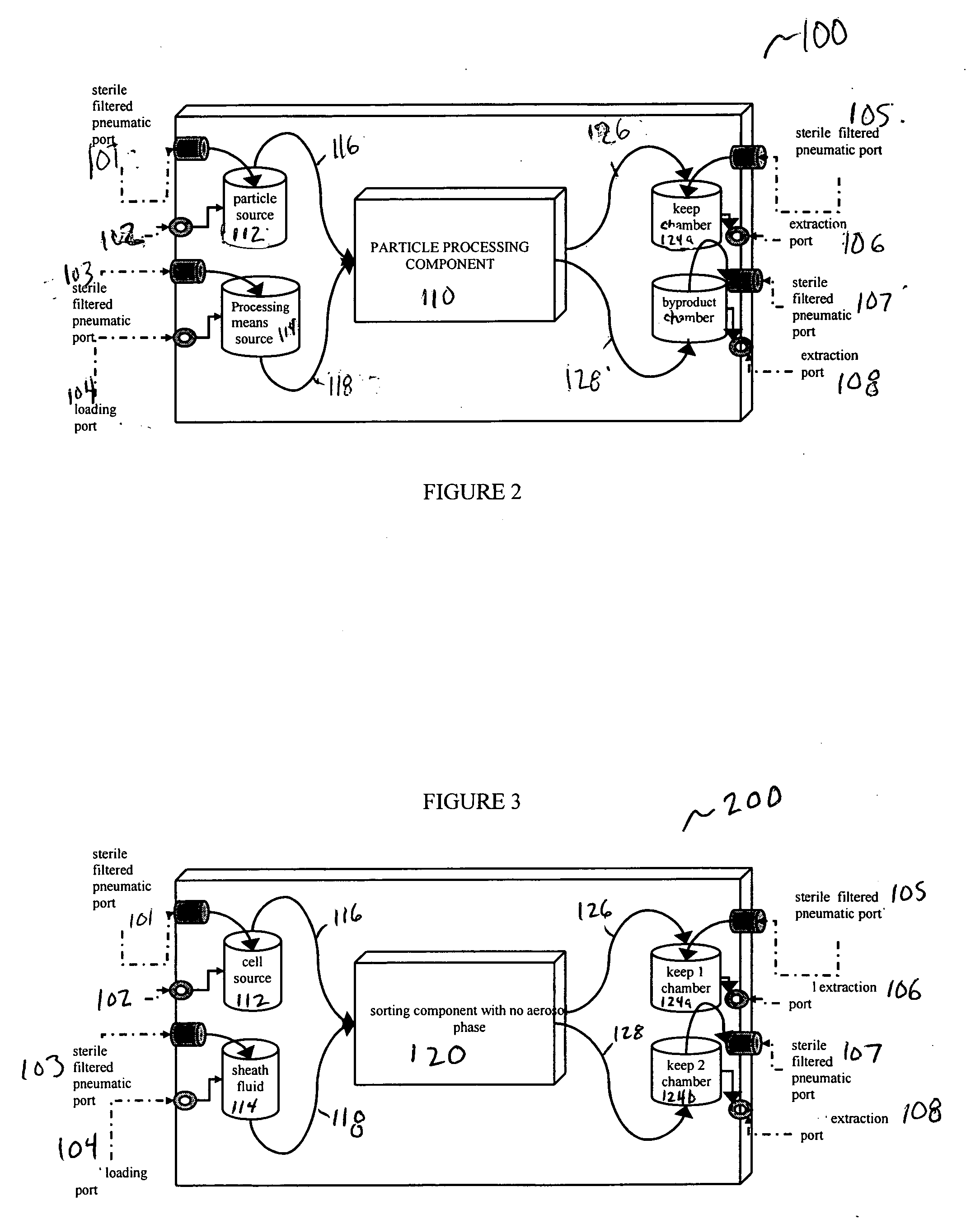

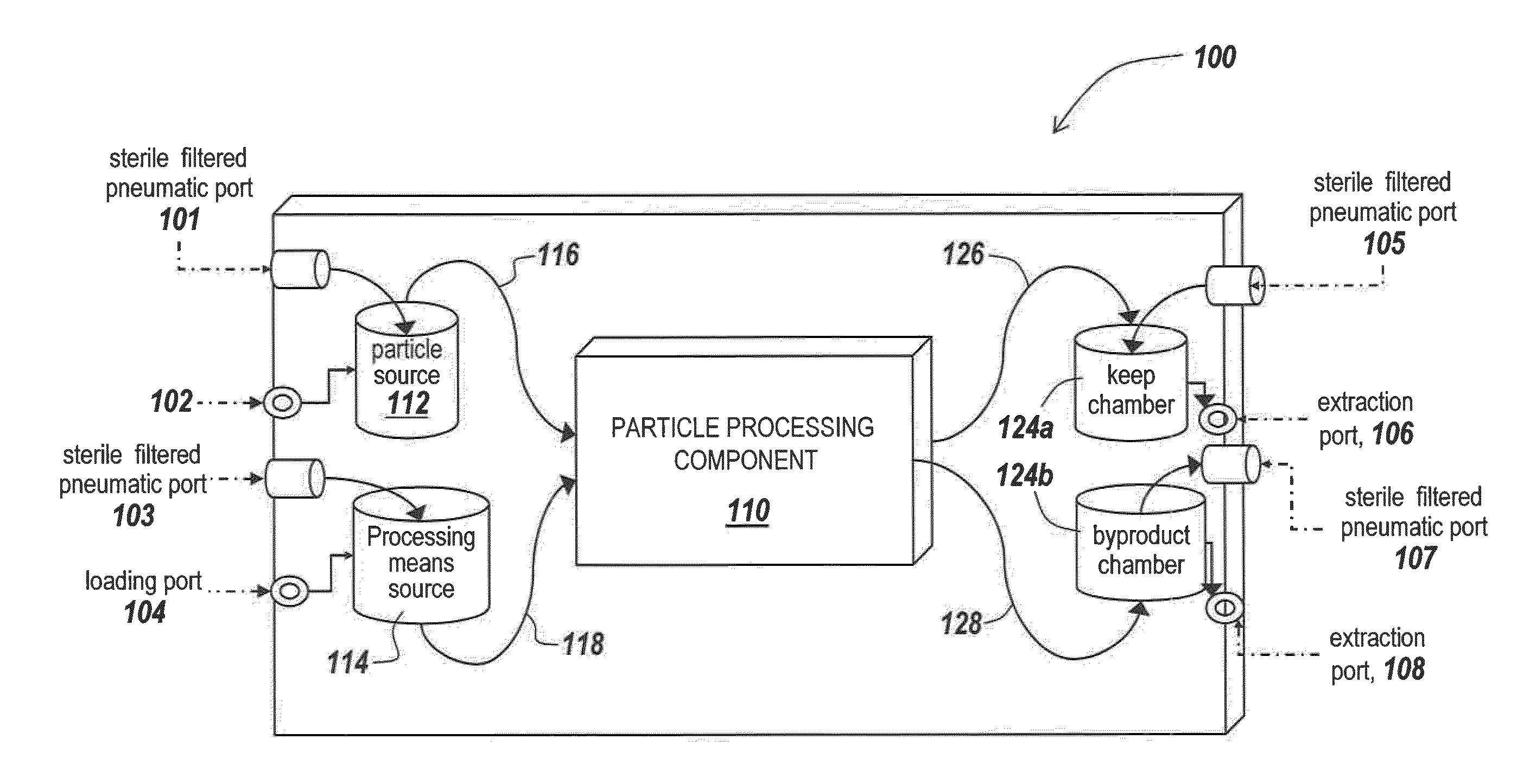

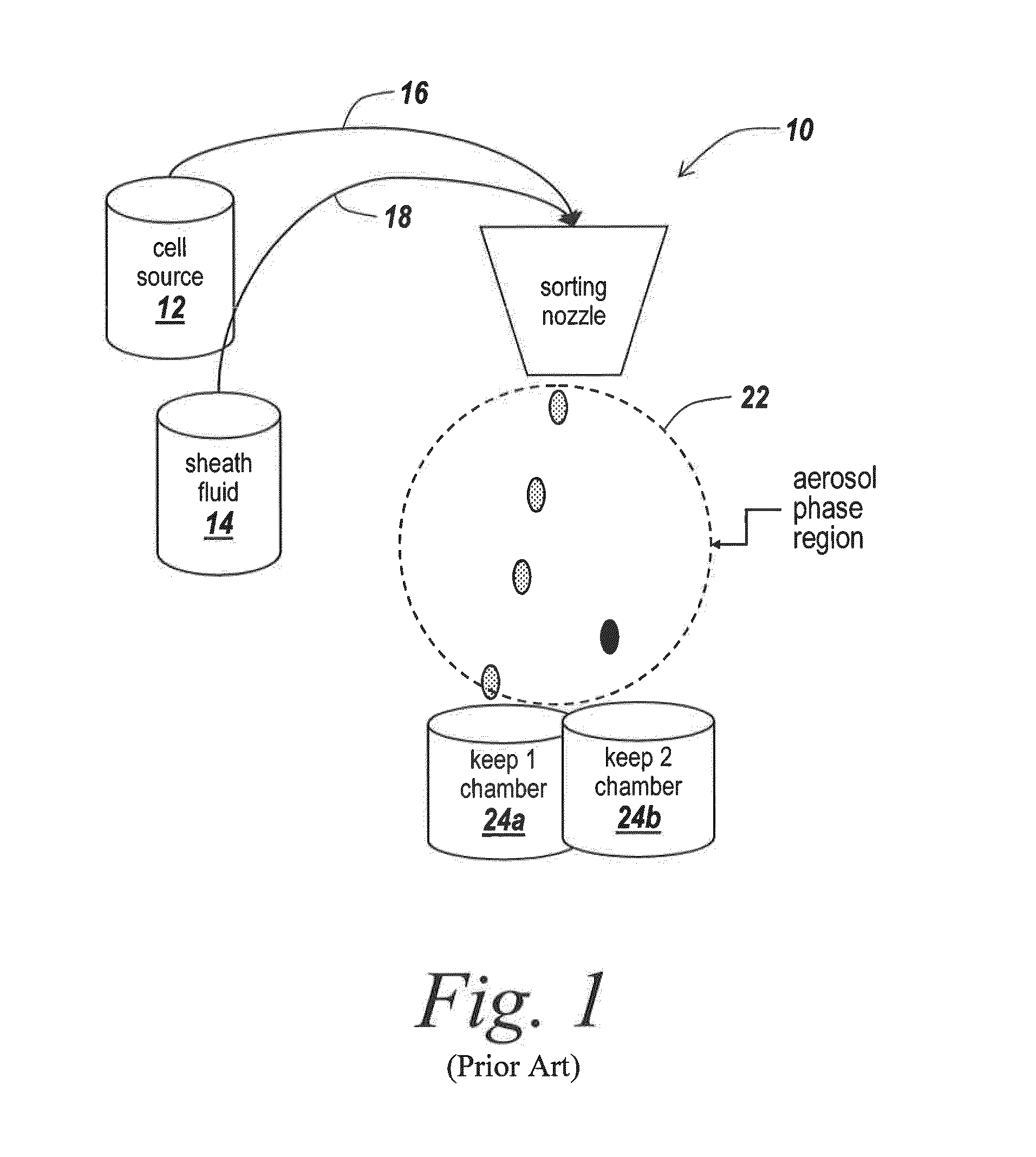

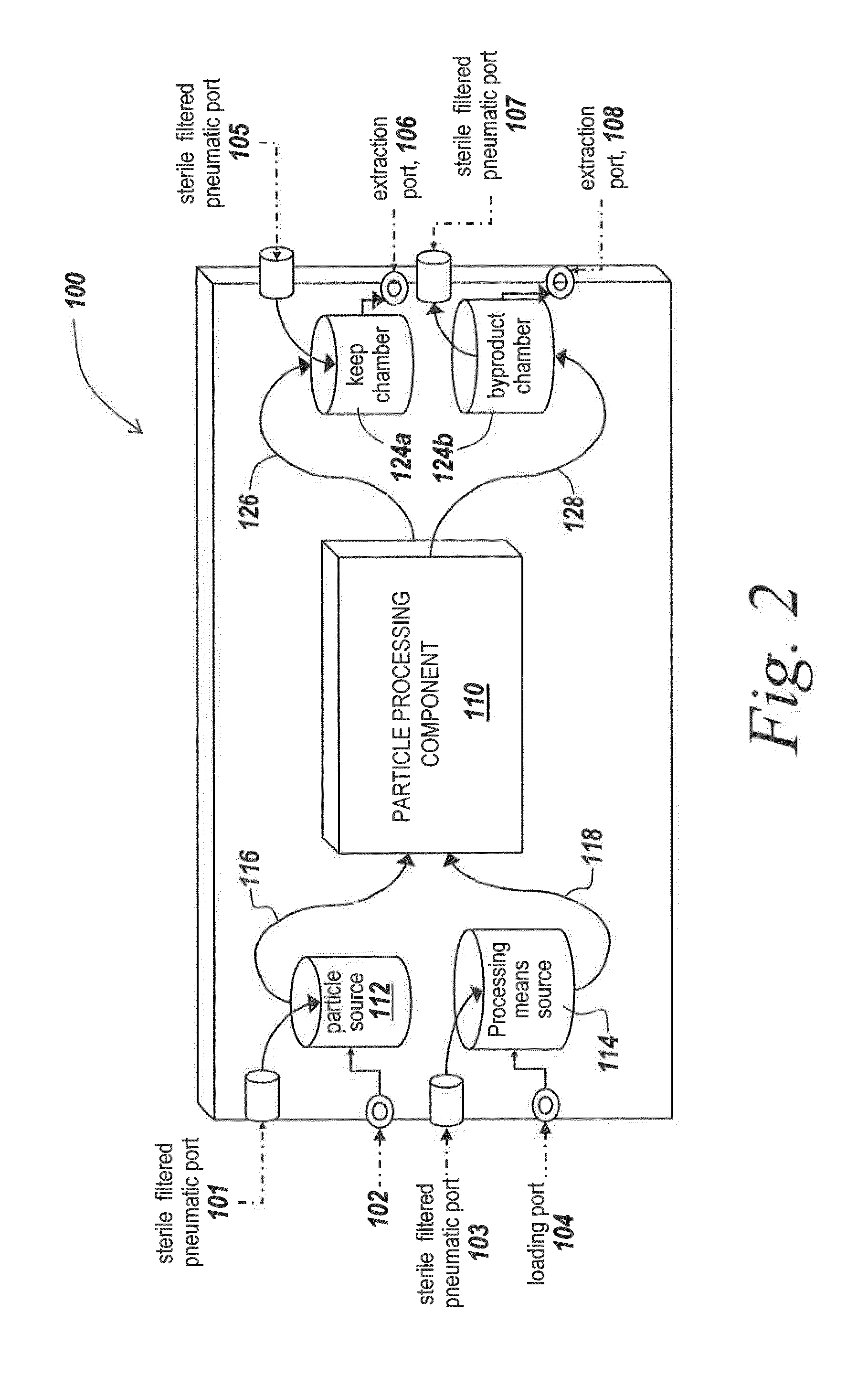

Unitary cartridge for particle processing

ActiveUS20060269446A1Improves or promotes operator isolation and/or product isolationBioreactor/fermenter combinationsBiological substance pretreatmentsOperational systemParticle sorting

A single disposable cartridge for performing a process on a particle, such as particle sorting, encapsulates all fluid contact surfaces in the cartridge for use with microfluidic particle processing technology. The cartridge interfaces with an operating system for effecting particle processing. The encapsulation of the fluid contact surfaces insures, improves or promotes operator isolation and / or product isolation. The cartridge may employ any suitable technique for processing particles.

Owner:CYTONOMEST

Automated analyzer for clinical laboratory

InactiveUS8222048B2Bioreactor/fermenter combinationsBiological substance pretreatmentsClinical chemistryMicrowell Plate

Owner:ABBOTT LAB INC

Unitary cartridge for particle processing

ActiveUS20120009619A1Improves or promotes operator isolation and/or product isolationBioreactor/fermenter combinationsBiological substance pretreatmentsParticle sortingEngineering

A single disposable cartridge for performing a process on a particle, such as particle sorting, encapsulates all fluid contact surfaces in the cartridge for use with microfluidic particle processing technology. The cartridge interfaces with an operating system for effecting particle processing. The encapsulation of the fluid contact surfaces insures, improves or promotes operator isolation and / or product isolation. The cartridge may employ any suitable technique for processing particles.

Owner:CYTONOMEST

Aftertreatment method for liquid disperse dye

InactiveCN101724298ANot easy to settleImprove stabilityOrganic dyesDyeing processSocial benefitsDisperse dye

The invention provides an aftertreatment method for a liquid disperse dye. The aftertreatment method for the liquid disperse dye comprises the following steps: adding water to dissolve a filter cake containing the liquid disperse dye, which is obtained by diazotization, coupling and filtering, to obtain slurry with a solid content of 30 to 50 percent; adding polyglyceryl fatty acid ester surfactants of which the mass is 0.1 to 10 percent of that of the slurry and phenyl amines compounds of which the mass is 0.2 to 2 percent of that of the slurry; stirring and pulping for 1 to 5 hours; raisingthe temperature to between 80 and 110 DEG C and keeping the temperature for 1 to 7 hours; cooling to the normal temperature; adding a dispersing agent or dispersing agent of which the mass is 0.3 to 1 time of that of the dry weight of the filter cake; performing particle processing for 1 to 10 hours by a breaking device, and obtaining slurry; adding a thickening agent of which the mass is 0.1 to 0.3 percent of that of the slurry to the slurry with stirring; continuing to stir for 1 to 2 hours after finishing material addition; and filtering to obtain the liquid disperse dye. The method for preparing the liquid disperse dye has the advantages of low cost, simple operation, active role in environmental protection, and greater economic and social benefits.

Owner:浙江龙盛染料化工有限公司 +1

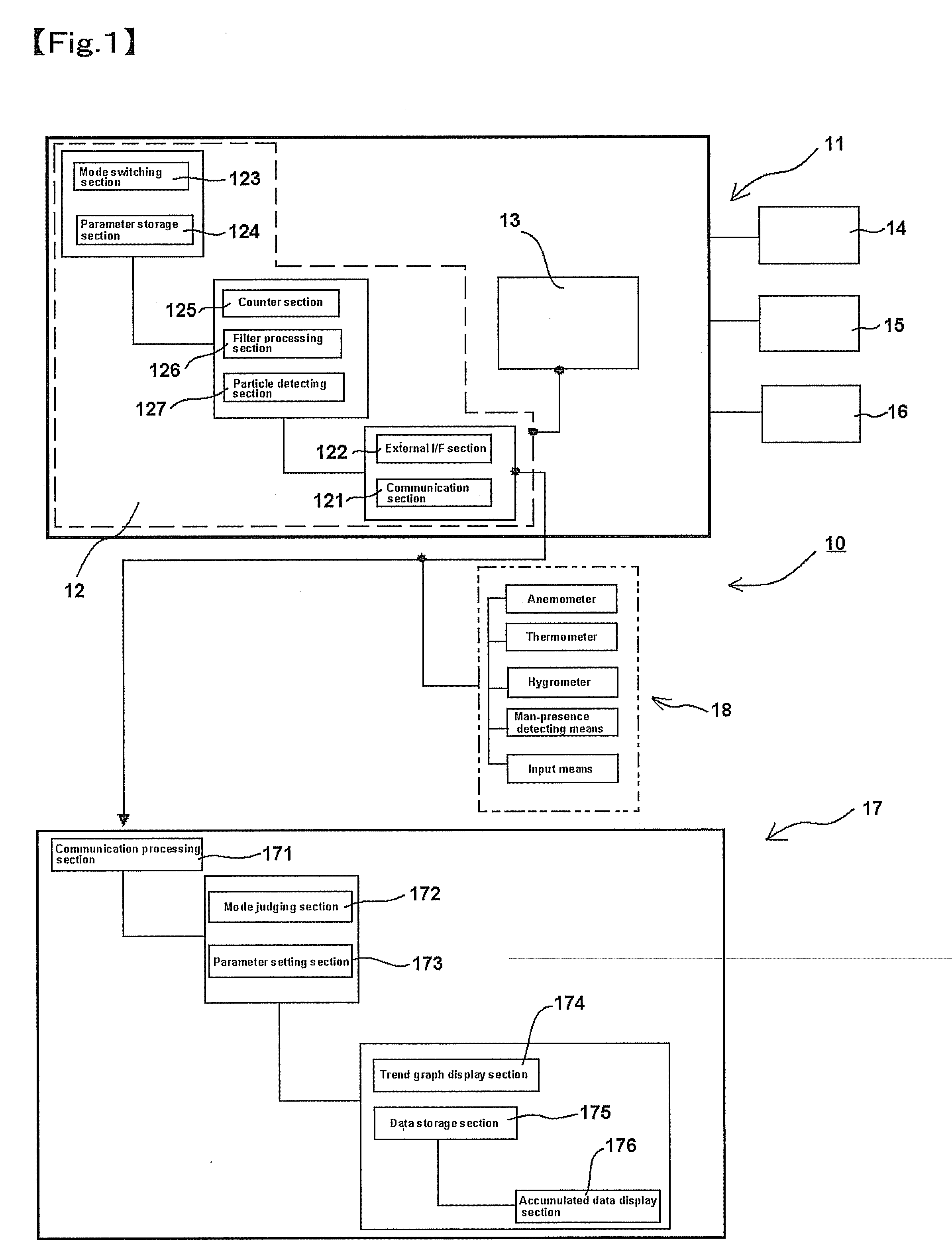

Particle counter and particle counting device having particle counter, and particle counting system and its use method

InactiveUS20100045982A1Low costShort measurement timeMaterial analysis by optical meansIndividual particle analysisInformation processingComputational physics

A particle counting device 11 for detecting and counting particles in a fluid to be measured comprises a measuring section 13 for detecting particles and a control section 12 for processing the output signal from the measuring section 13. When an abnormality occurs, a signal to issue a warning is generated. With this, a constant monitoring or observation is possible. Also, a particle counting system comprising a plurality of particle counting devices 11 and an information processing device 17 for processing the results of the counting by the particle processing devices 11 is also provided. The plurality of particle counting devices 11 are electrically connected to the information processing device 17 in multiple and in parallel. Alternately, a particle counting system comprising a plurality of particle counting devices 11 for detecting and counting particles in a fluid to be measured is also provided. To one of the plurality of particle counting devices 11, the other particle counting devices 11 are electrically connected in multiple and in parallel. Therefore, a particle counting system, the measurement time of which can be shortened while maintaining the accuracy of the measurement results, and its use method are provided relatively inexpensively.

Owner:NIDEC SANKYO CORP

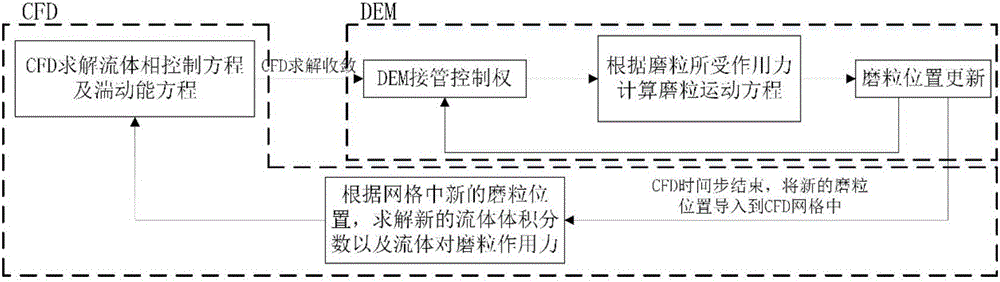

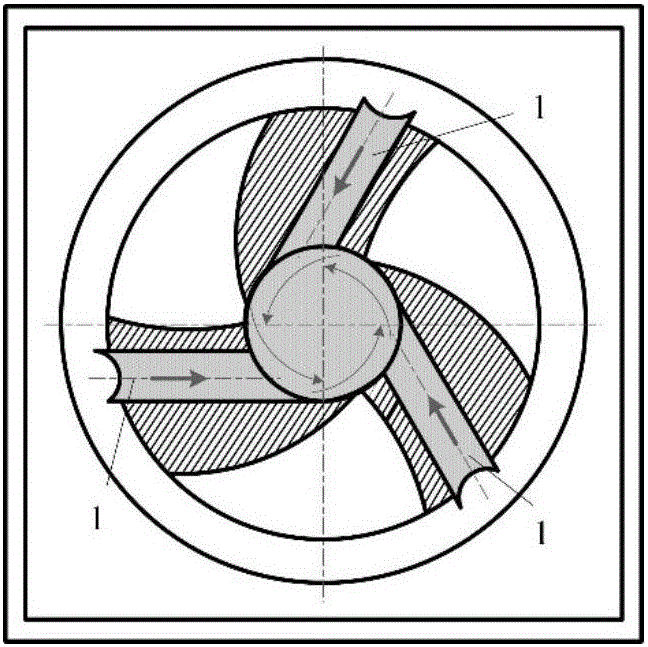

Abrasive particle flow field analysismethod based on CFD-DEM coupling model

ActiveCN106598912AIntuitive abrasive particle movement trajectoryLow costDesign optimisation/simulationComplex mathematical operationsParticle flowTheory model

The invention discloses an abrasive particle flow field analysis method based on a CFD-DEM coupling model. The method comprises the following steps of (1) building and solving an abrasive particle processing-oriented fluid phase control equation set, (2) solving an abrasive particle motion equation through a DEM theory according to a solution result achieved in the (1) step, (3) updating a position of the abrasive particles in a flow path according to the abrasive particle motion equation, and solving a new volume fraction and action force applied to the abrasive particles, (4) substituting a new fluid volume fraction and the action force applied to the abrasive particles to the (1) step for a new round calculation, continuously updating speed and position of each abrasive particle in a circulating way according to the above calculation process to evolving the whole abrasive particle flow processing system to achieve an abrasive particle flow motion rule. A method combining a computational fluid mechanics model and a discrete element theory model is introduced to the abrasive particle flow processing field; precise analysis can be conducted to abrasive particle movements; and abrasive particle processing technology parameters can be accurately adjusted and controlled.

Owner:ZHEJIANG UNIV OF TECH

Orally-disintegrating-tablet-type smokeless tobacco product containing tobacco ultra-micro powder and preparation method thereof

ActiveCN103549646AIncrease dissolution rateImprove absorption rateTobacco treatmentSodium bicarbonateOrally disintegrating tablet

The invention relates to an orally-disintegrating-tablet-type smokeless tobacco product containing tobacco ultra-micro powder and a preparation method thereof, belonging to the technical field of smokeless tobacco processing. The smokeless tobacco product is made of the following raw materials by weight percentage: 30-70 percent of tobacco ultra-micro powder with grain size being smaller than or equal to 10mum, 20-50 percent of xylitol, 1-10 percent of water-soluble starch, 1-10 percent of bonding agent, 0.5-10 percent of composite vitamin, 1-10 percent of plant extract, 0.01-2 percent of edible essence, 3-10 percent of sodium hydrogen carbonate, 2-5 percent of citric acid and 0.3-5 percent of magnesium stearate. The preparation method comprises the steps of micro powder processing, raw material component mixing, soft material preparation and drying, particle processing and tablet pressing after the particles are uniformly mixed with the citric acid, the sodium hydrogen carbonate, the edible essence and the magnesium stearate. After tobacco is micro-powdered, the dissolution rate of active components is improved; the product melts in the mouth, the taste is fine, the human body absorption rate is improved and the cost is saved; the product is naturally disintegrated in the mouth during chewing, a unique pleasant sense can be produced during disintegration and the taste is refreshing and fine.

Owner:YUNNAN RES INST OF TOBACCO SCI

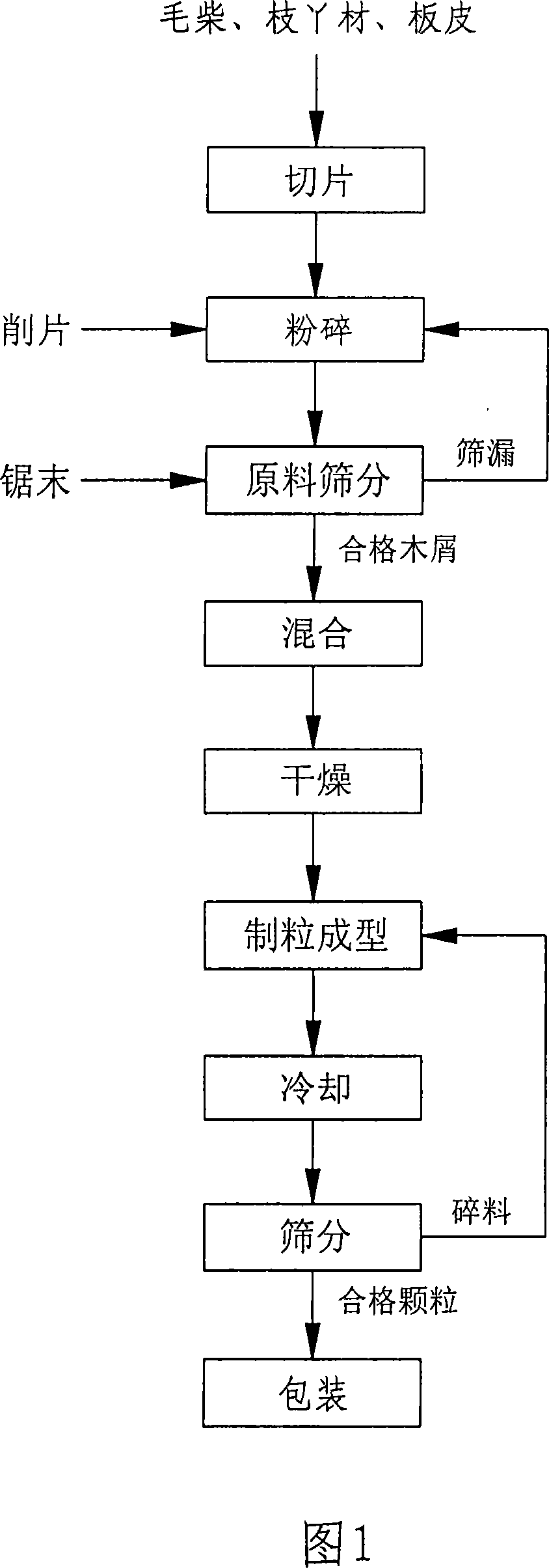

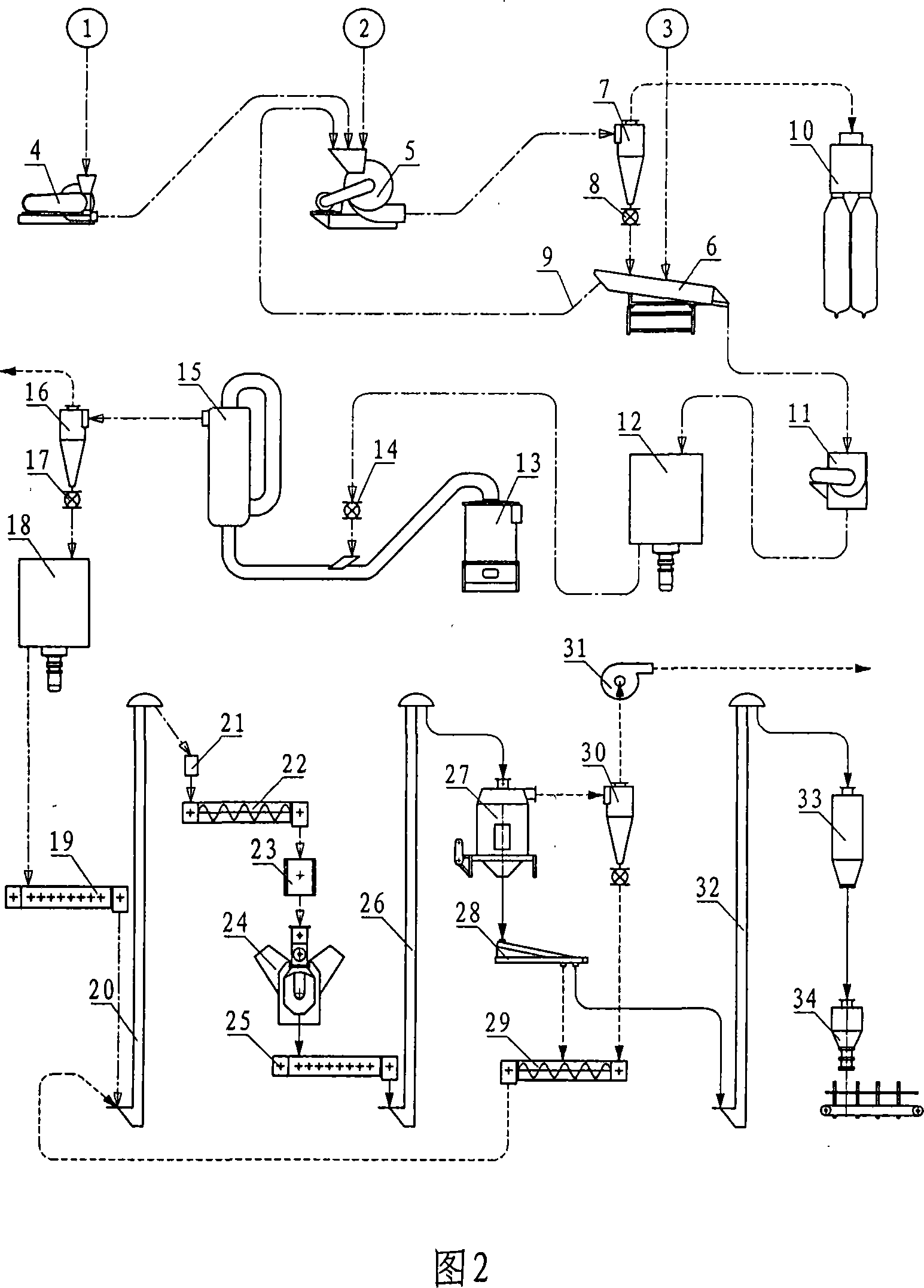

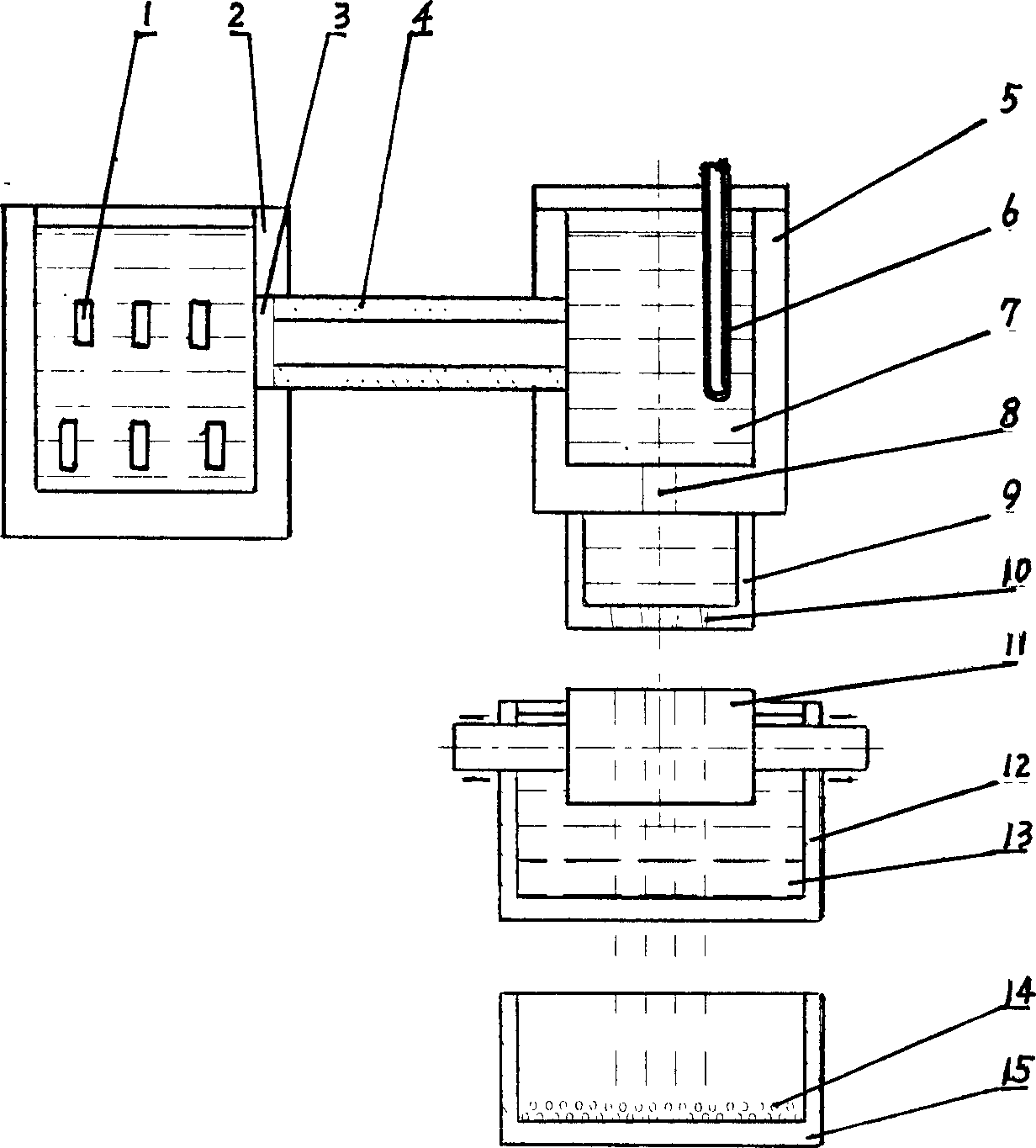

General wood substance grain processing technique and system

ActiveCN101195234AReduce total powerReduce energy consumptionDrying solid materials with heatDomestic articlesGeneral purposeWood machining

The invention discloses a process of general-purpose wood particles, which employs remains of tending and cutting of forest and wood-curing waste as materials which are processed into wood chippings and crashed into wood particles. Crashed wood particles are screened, and wood particles with qualified size are passed to next process and wood particles with unqualified size are crashed again. Heat produced in forming process is used to vaporize contained water to soften the powder materials, and then the powder materials are compressed into particles under the effect of extrusion force. The formed particles which have high temperature and include a small amount of crushed aggregates must be cooled and screened. Screened crushed aggregates returns to the particle processing and forming process and the finished products of particles enters the final package process. Compared with prior art, the energetic consumption of specific yield of the invention can be remarkably reduced, and gross investment can be greatly decreased. The invention discloses a process for producing wood particles, which is on the premise that products quality is met, changes the order of processing technique, reduces gross investment of device, decreases energetic consumption of specific yield, and has low manufacture cost and simple process.

Owner:吉林宏日新能源股份有限公司 +1

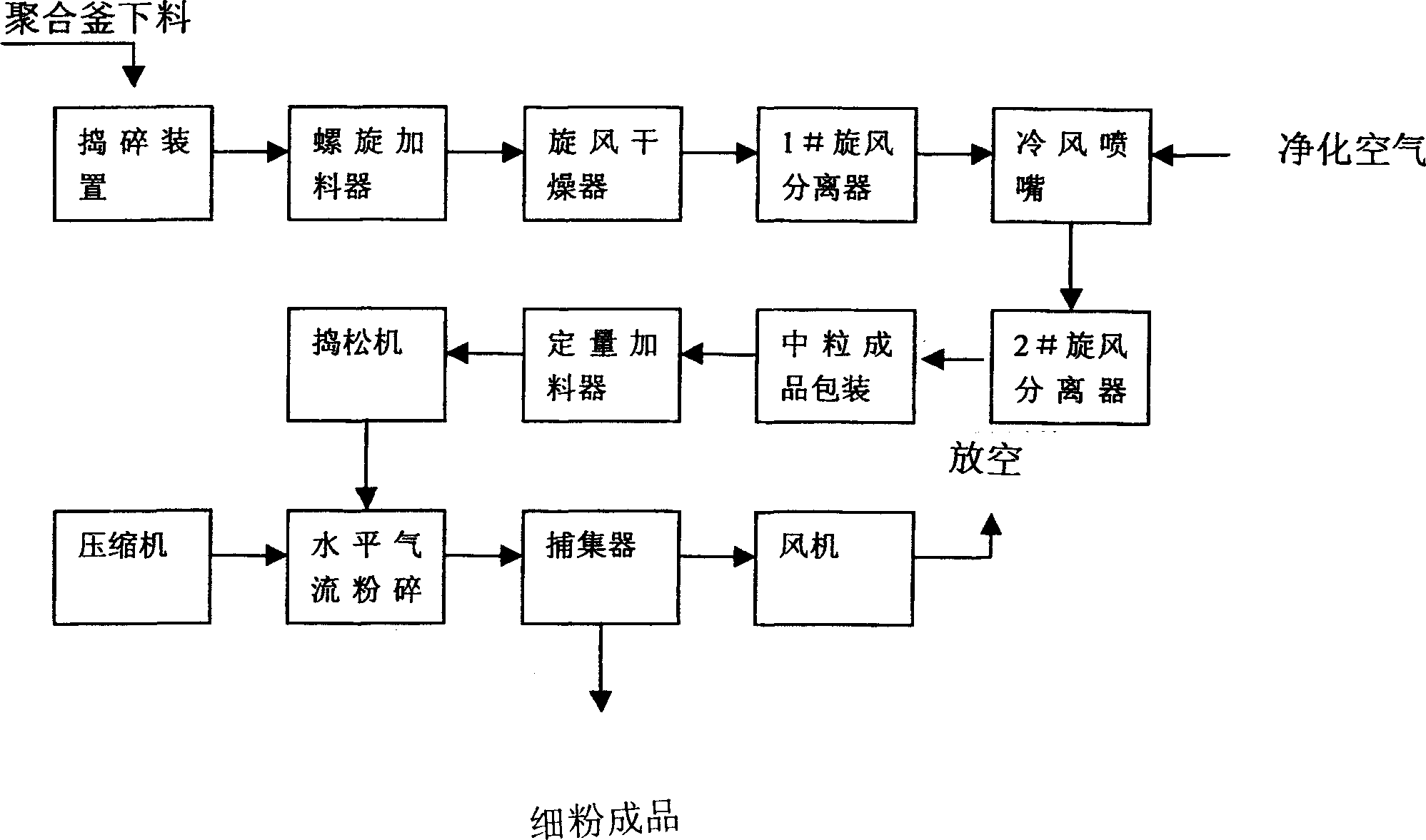

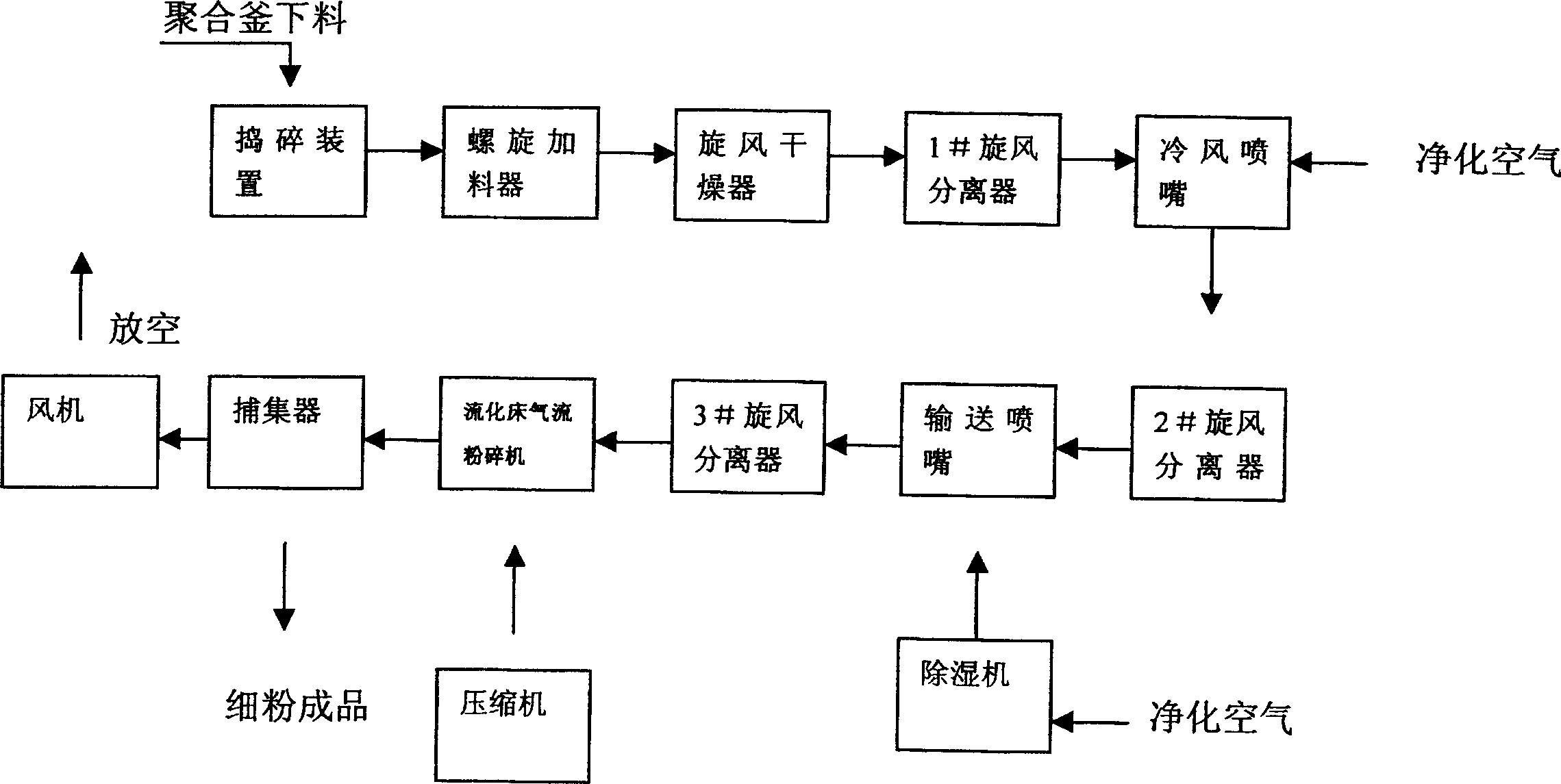

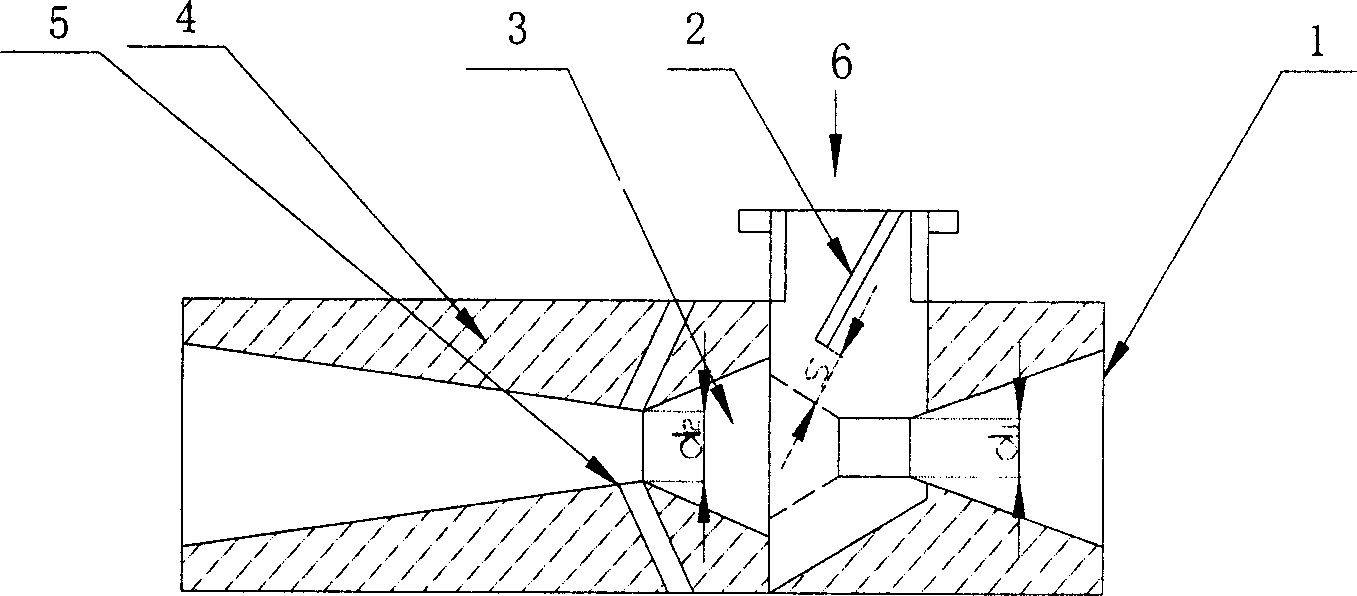

Delivery spray nozzle, polytetrafluoroethylene fine particle processing method and apparatus using the spray nozzle

ActiveCN1876530AReduce lossReduce labor intensityDrying solid materials without heatBulk conveyorsFluidized bedSpray nozzle

The invention relates to a method for continuously preparing politef via suspension method, wherein said method breaks, washes, separates, dries and cools the polymerized politef, to obtain middle particles to be mixed with purified dry air; via cyclone separator, entering into the airflow breaker of fluid bed to be broken and classified; then the fine powder is collected in the collector to generate dry politef powder. The inventnion can continuously and automatically supply politef powder at high quality, in sealed tube.

Owner:SHANGHAI 3F NEW MATERIAL TECH CO LTD

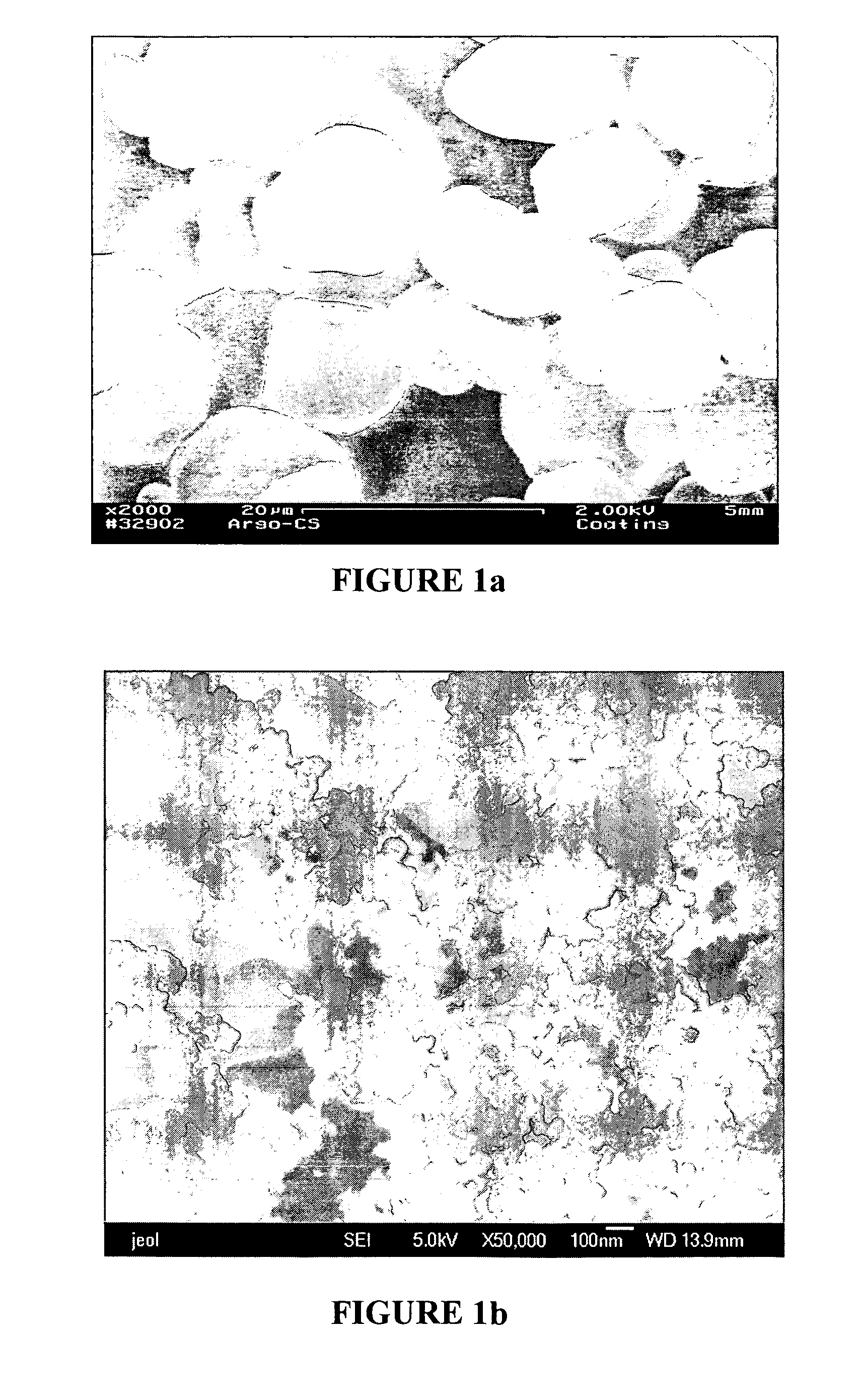

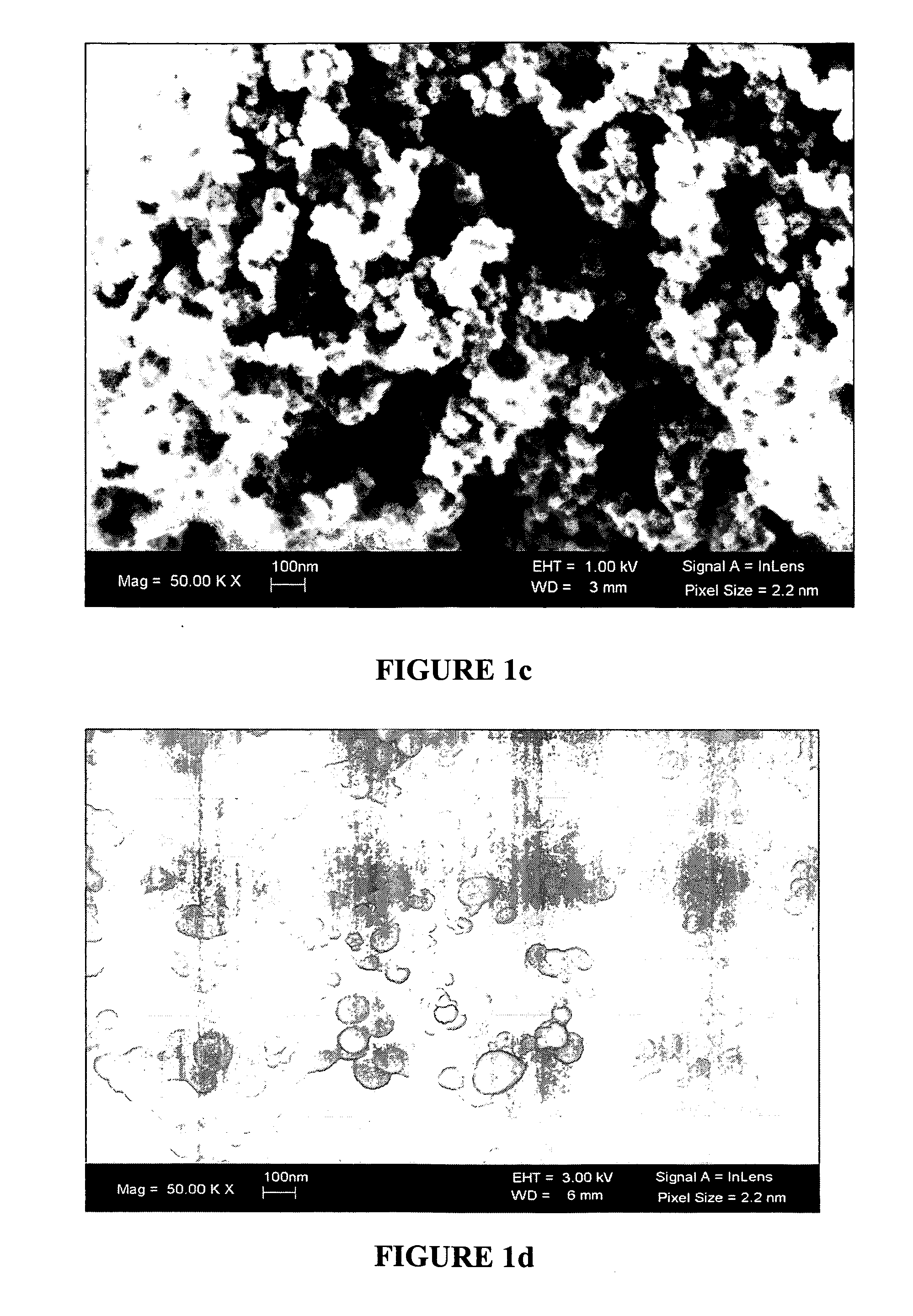

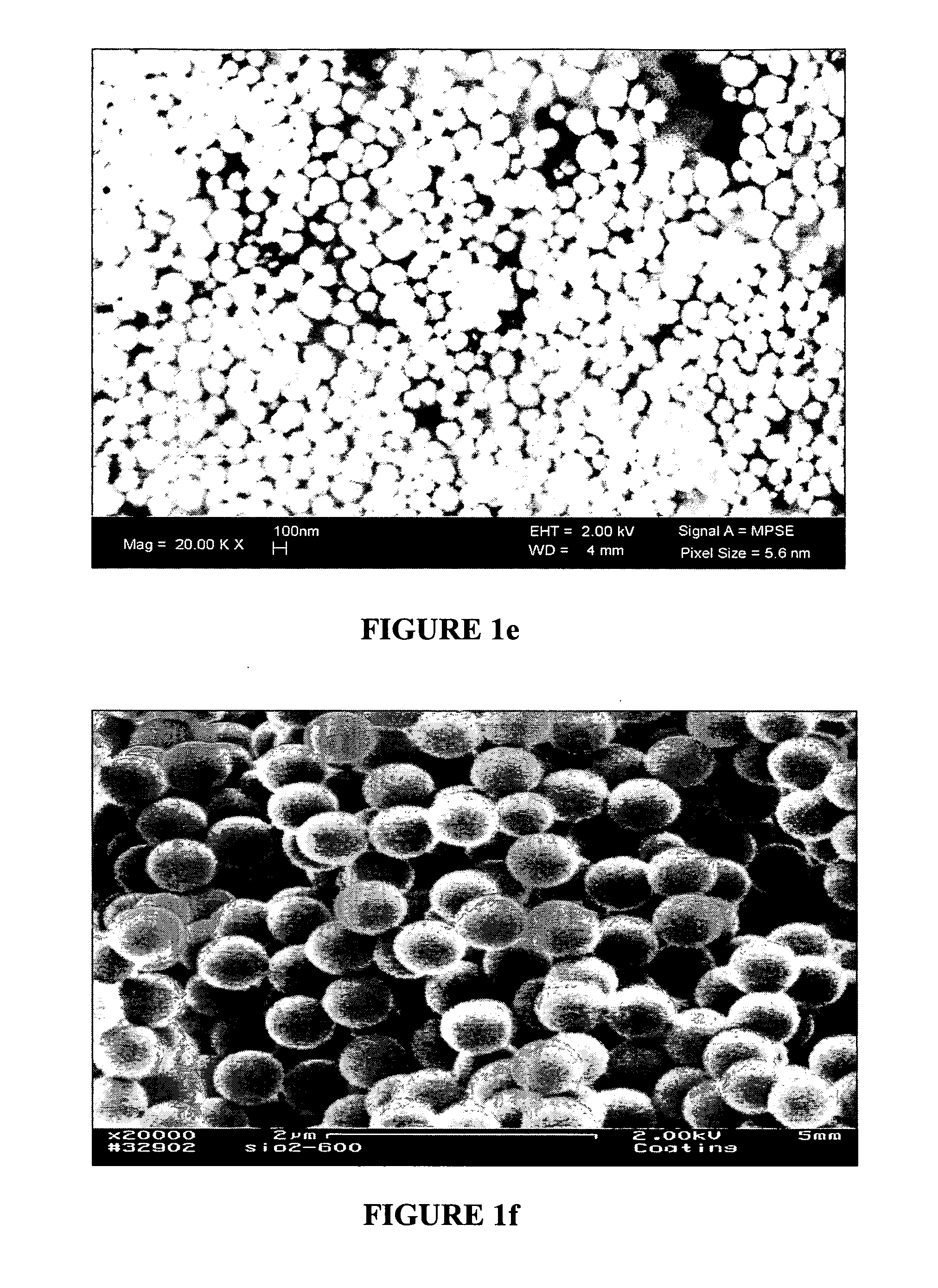

Dry coating and downstream processing of cohesive powders

InactiveUS20070053846A1Improve cohesionEasy to processPowder deliveryTransportation and packagingDownstream processingIngested food

The present disclosure is directed to systems and methods for dry particle coating of cohesive powders, and to the dry coated particles / powders produced thereby. The present disclosure is further directed to systems and methods for dry coating of cohesive particles, particularly nanosized particles, to provide enhanced flowability and other advantageous physical and / or functional properties. The disclosed systems and methods offer downstream processing advantages, e.g., for purposes of subsequent fluidization, coating, granulation and / or other particle processing operations, and have applicability in wide ranging industries, including specifically paint-related applications, pharmaceutical applications, food-related applications, cosmetic applications, defense-related applications, electronics-related applications, toner and ink-related applications, and the like.

Owner:NEW JERSEY INSTITUTE OF TECHNOLOGY

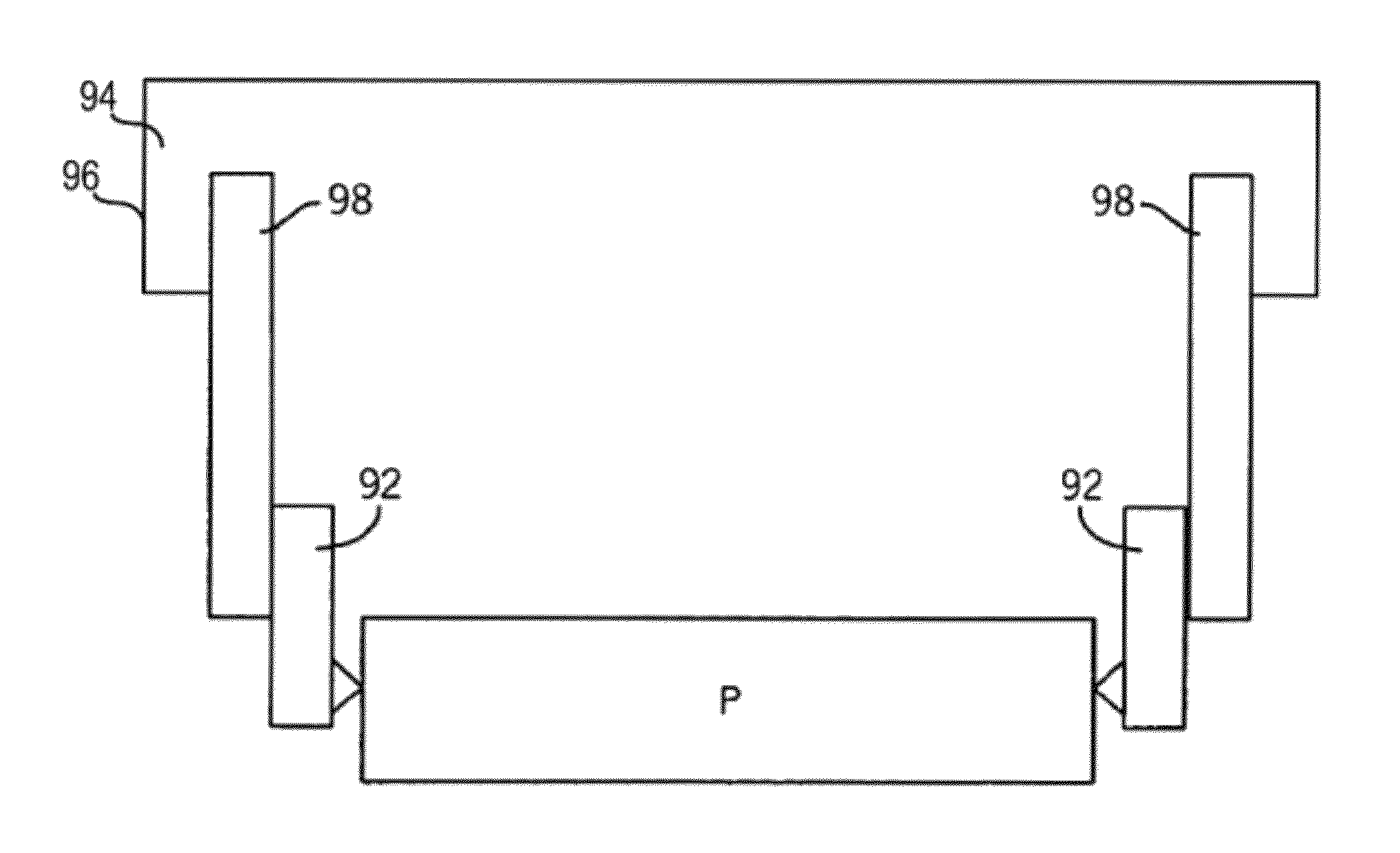

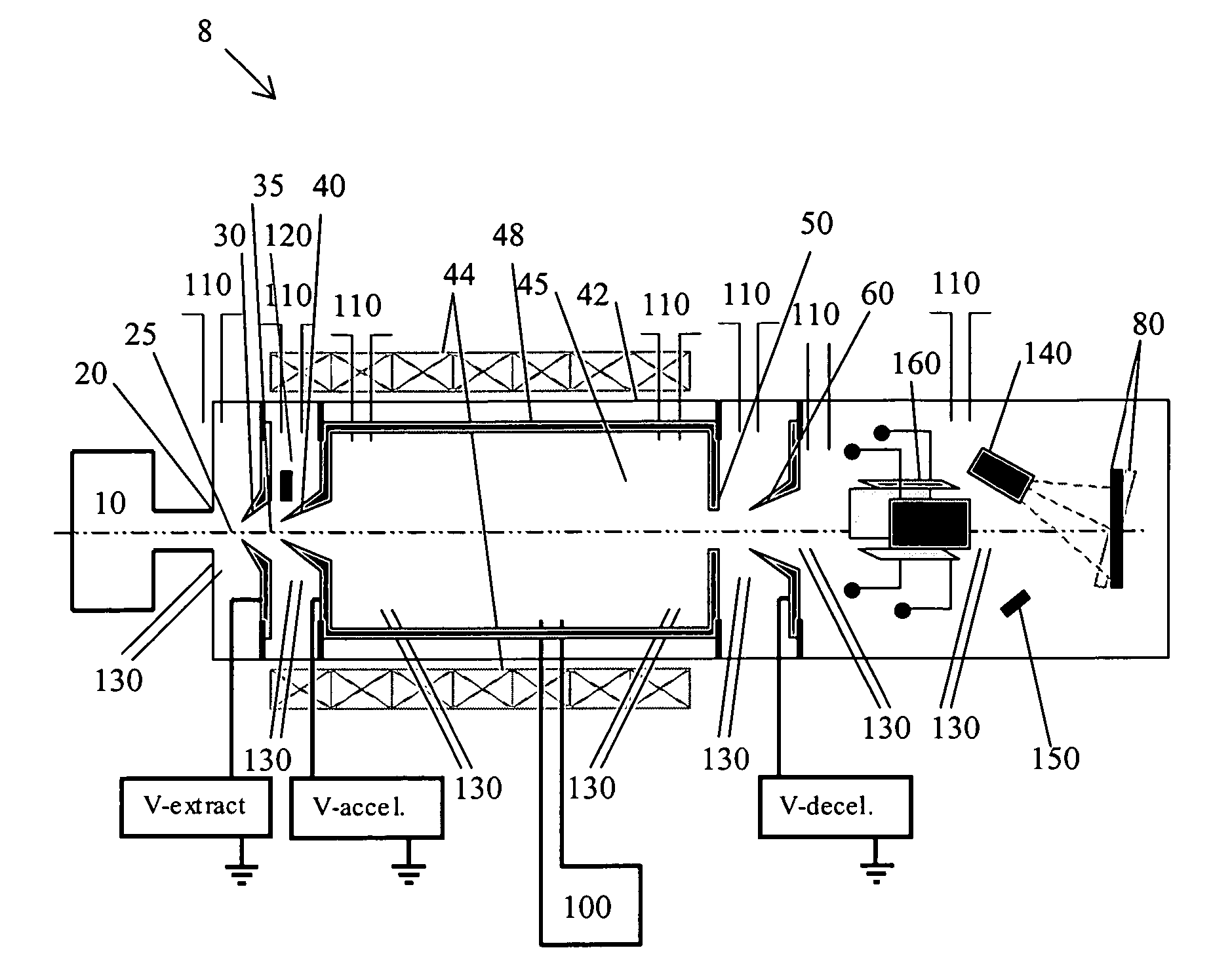

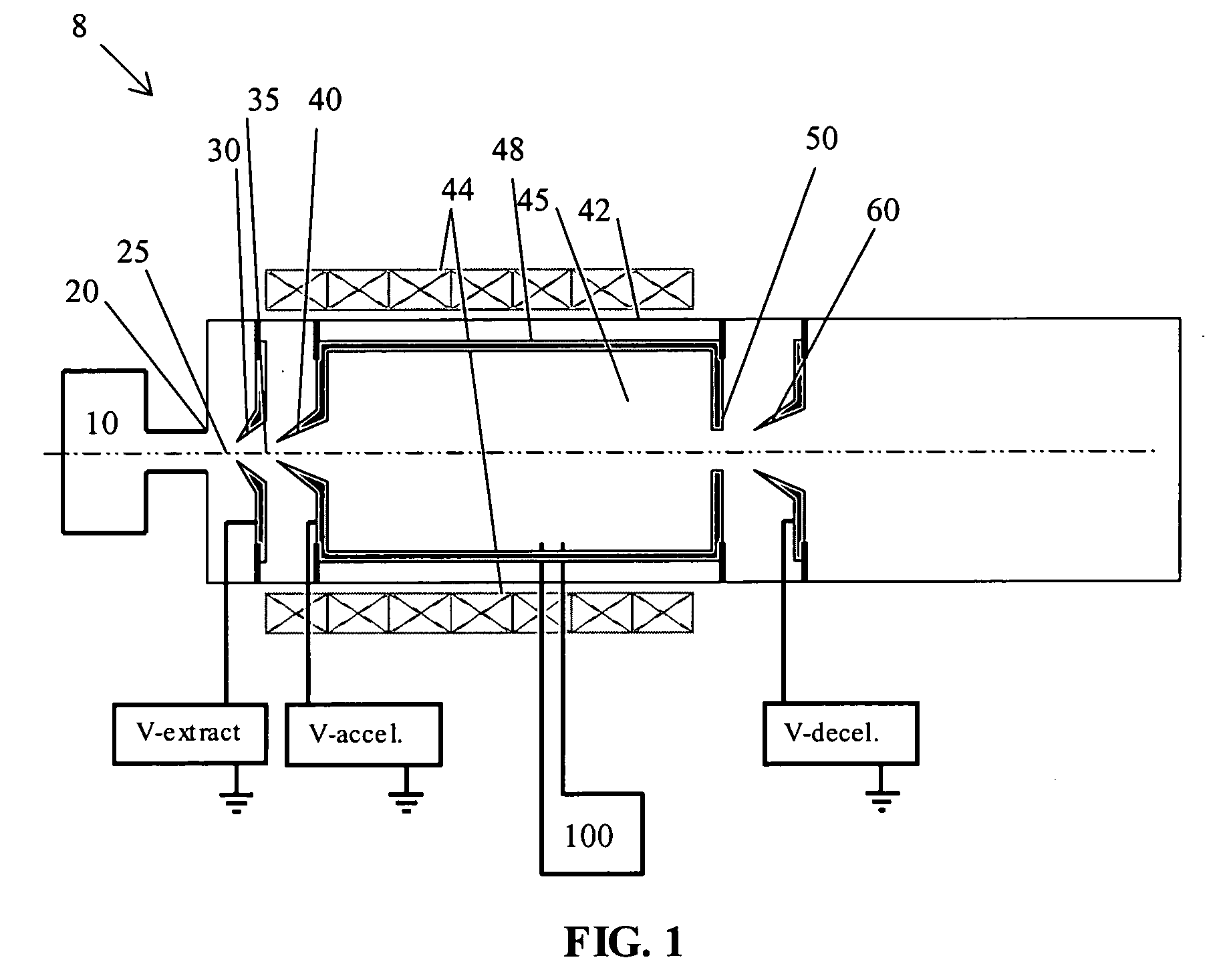

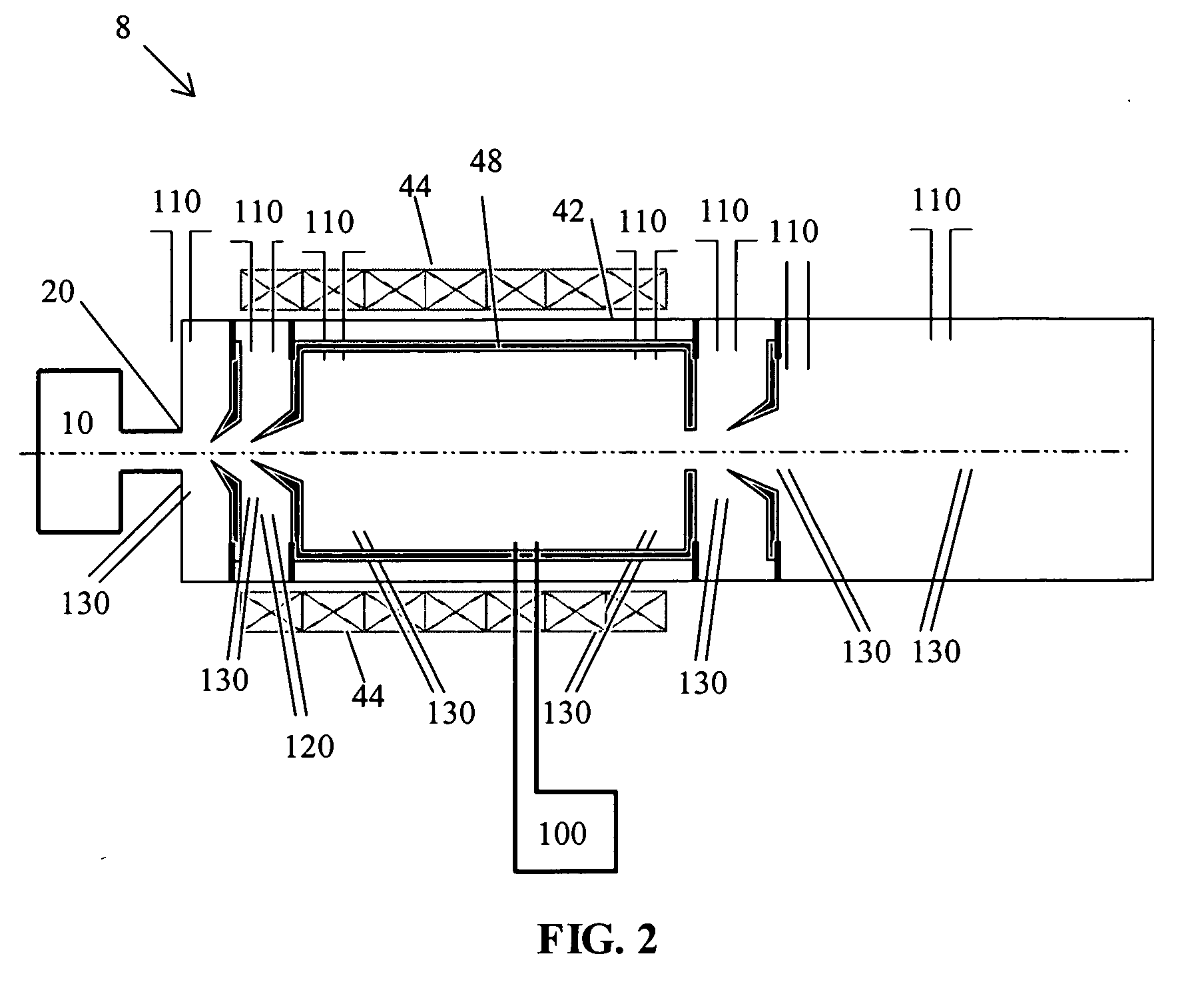

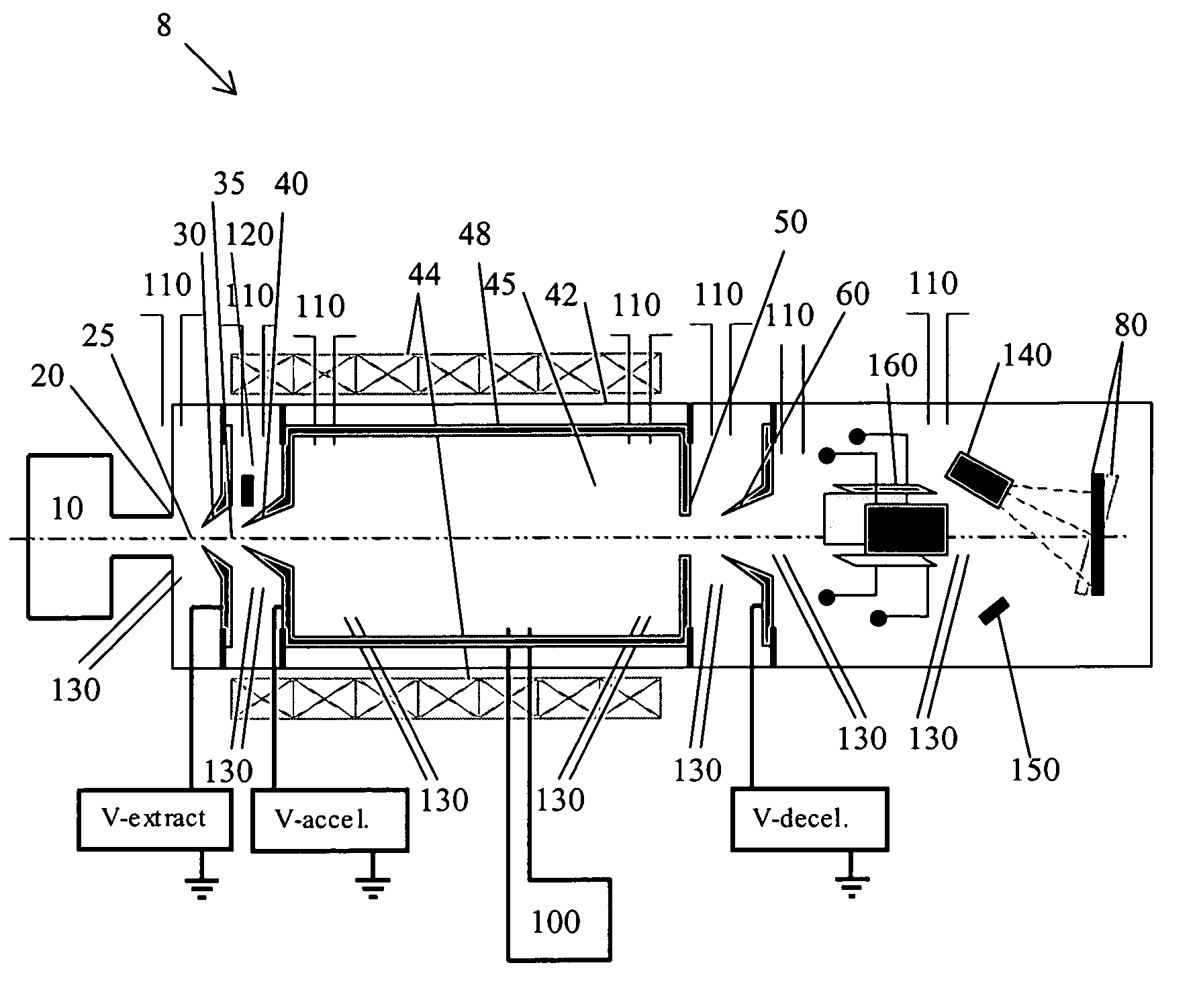

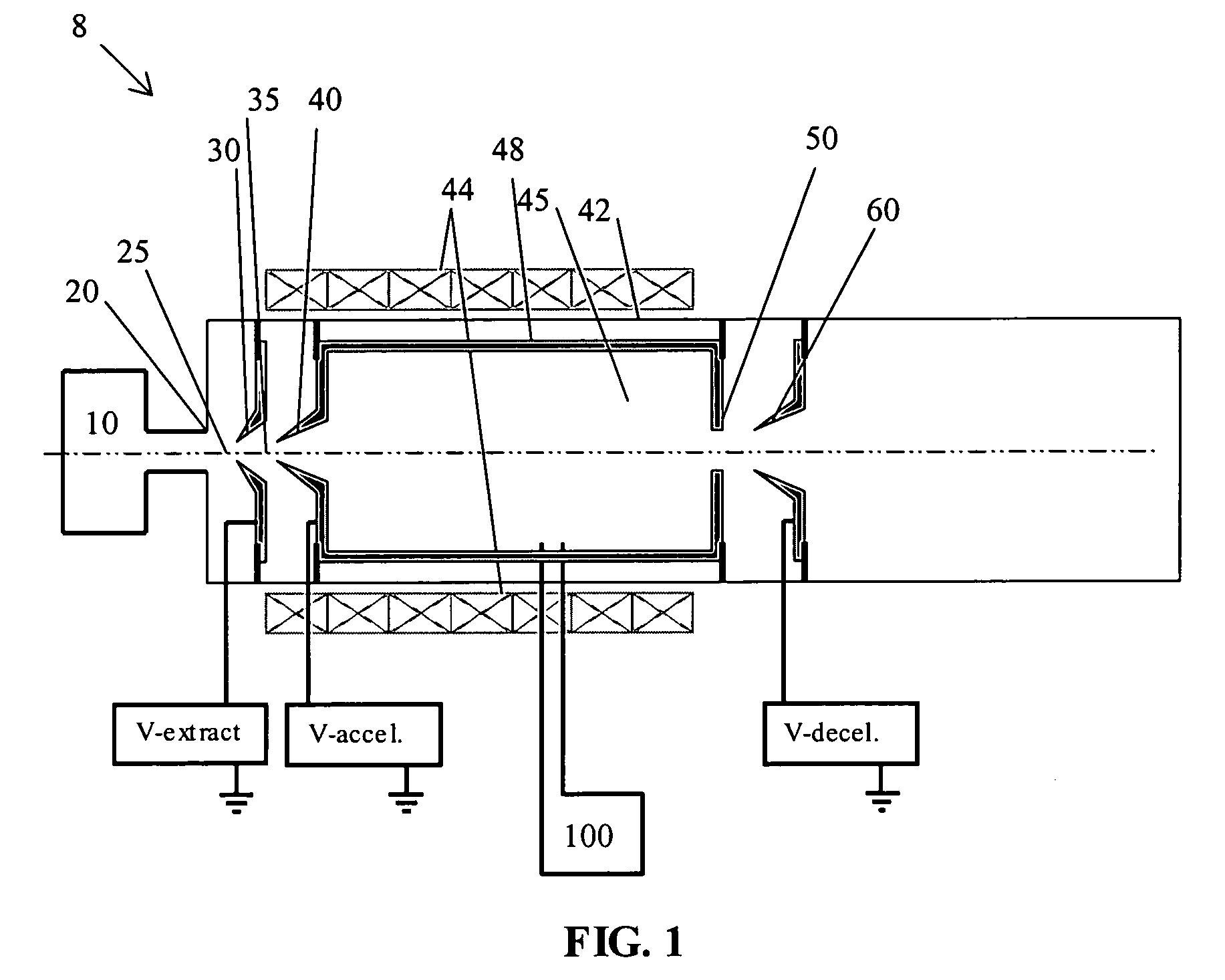

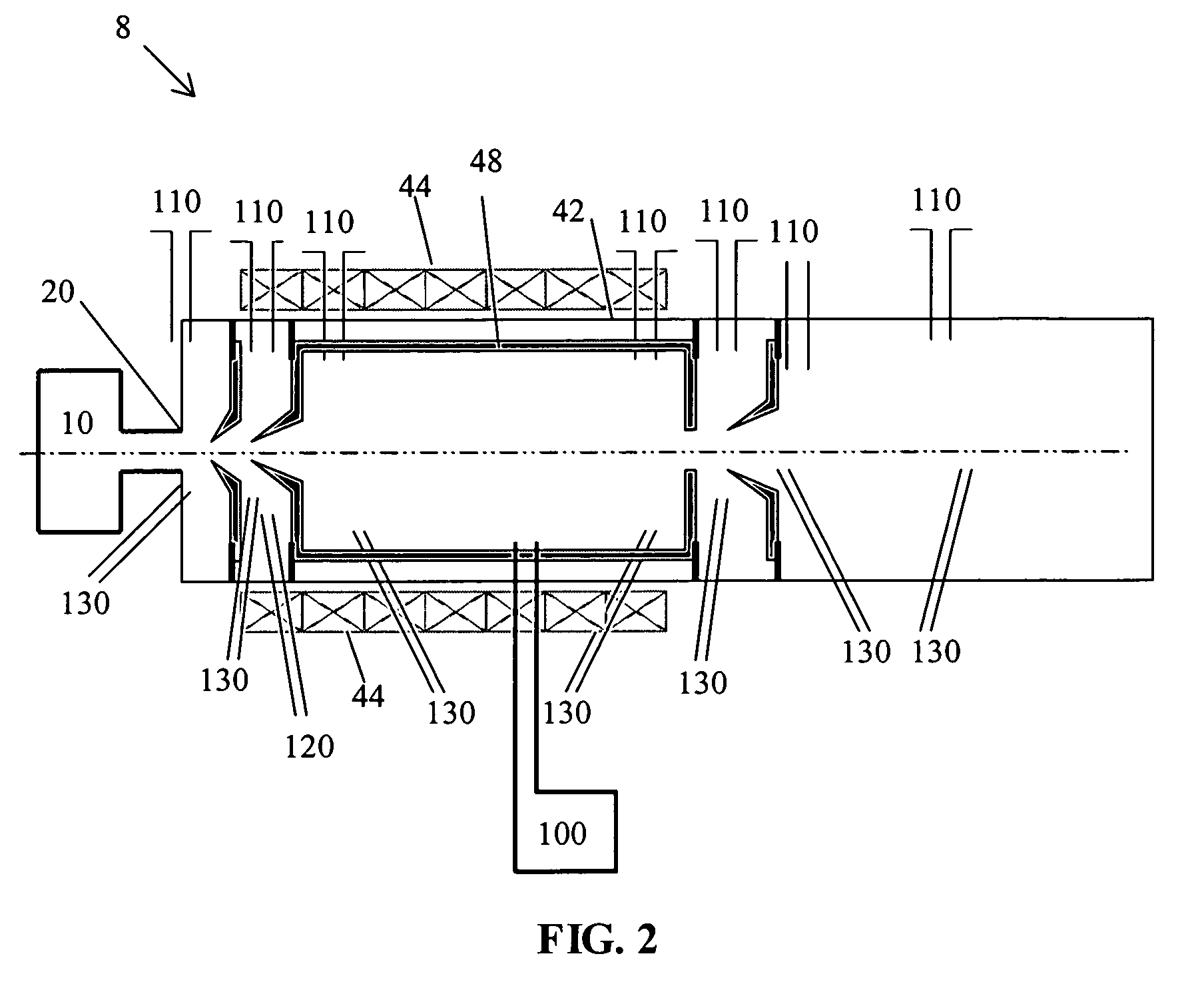

Particle processing apparatus and methods

InactiveUS20040238753A1Stability-of-path spectrometersMaterial analysis using wave/particle radiationAcceleration UnitPhysics

This invention relates to an apparatus for processing particles. The apparatus comprises a particle source having an exist aperture; an extraction electrode located at the exist aperture; an acceleration electrode adjacent to the extraction electrode; a processing compartment adjacent to the acceleration electrode; and a deceleration electrode located adjacent to the processing compartment. The invention also relates to methods of processing particles and to particles processed by the apparatus and methods of the invention.

Owner:CABOT MICROELECTRONICS CORP

Particle processing apparatus and methods

InactiveUS7196337B2Stability-of-path spectrometersMaterial analysis using wave/particle radiationAcceleration UnitPhysics

This invention relates to an apparatus for processing particles. The apparatus comprises a particle source having an exist aperture; an extraction electrode located at the exist aperture; an acceleration electrode adjacent to the extraction electrode; a processing compartment adjacent to the acceleration electrode; and a deceleration electrode located adjacent to the processing compartment. The invention also relates to methods of processing particles and to particles processed by the apparatus and methods of the invention.

Owner:CABOT MICROELECTRONICS CORP

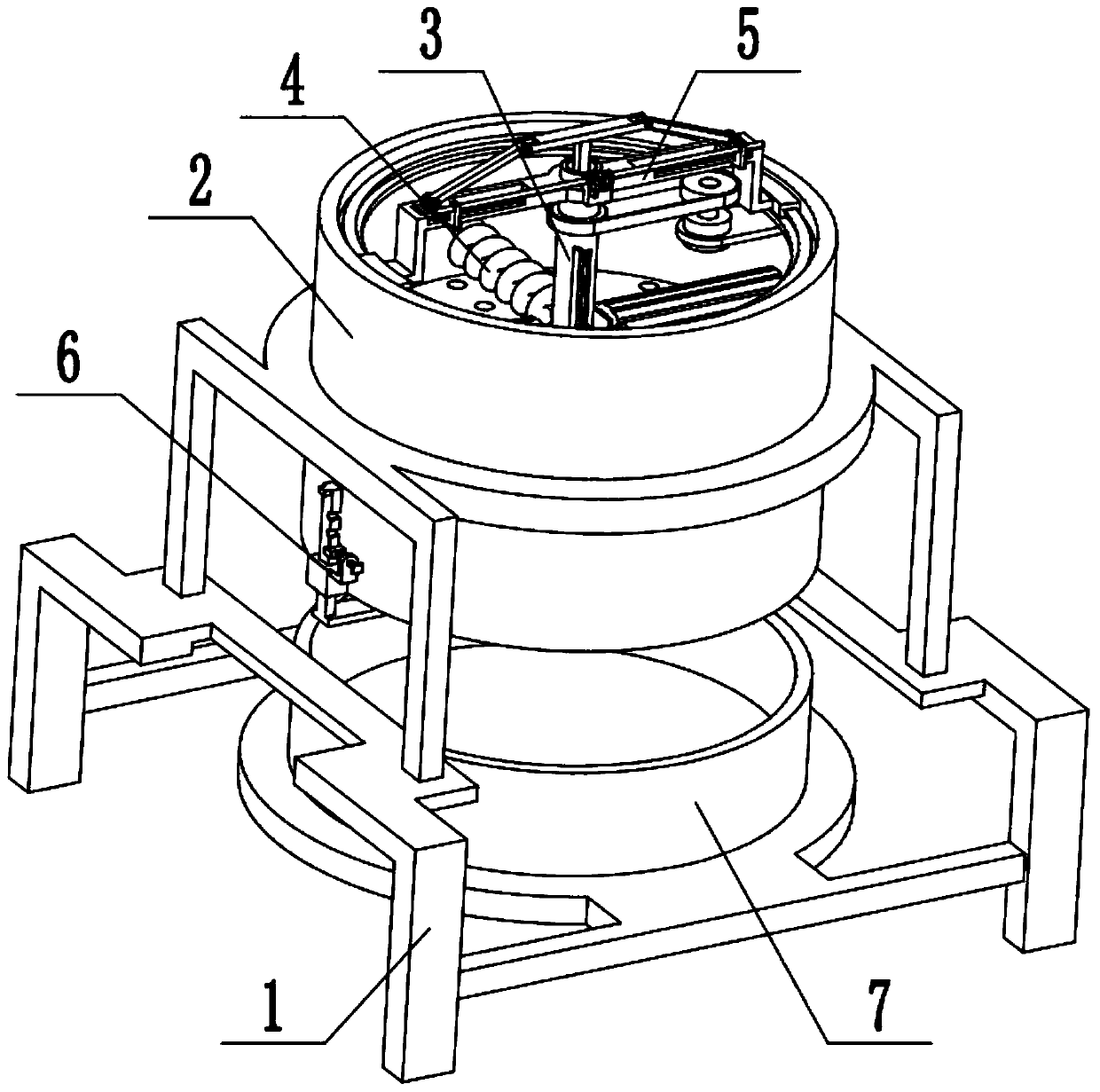

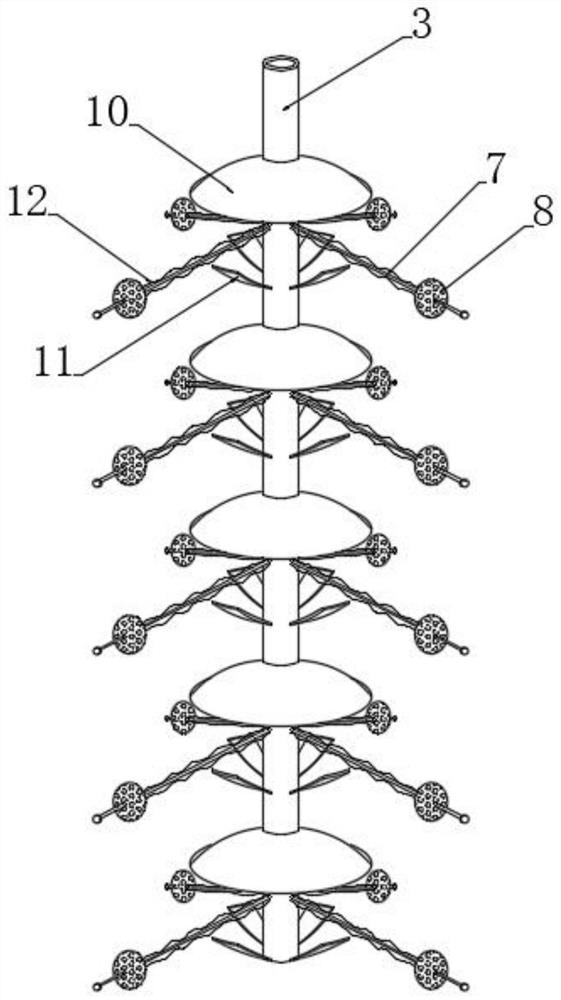

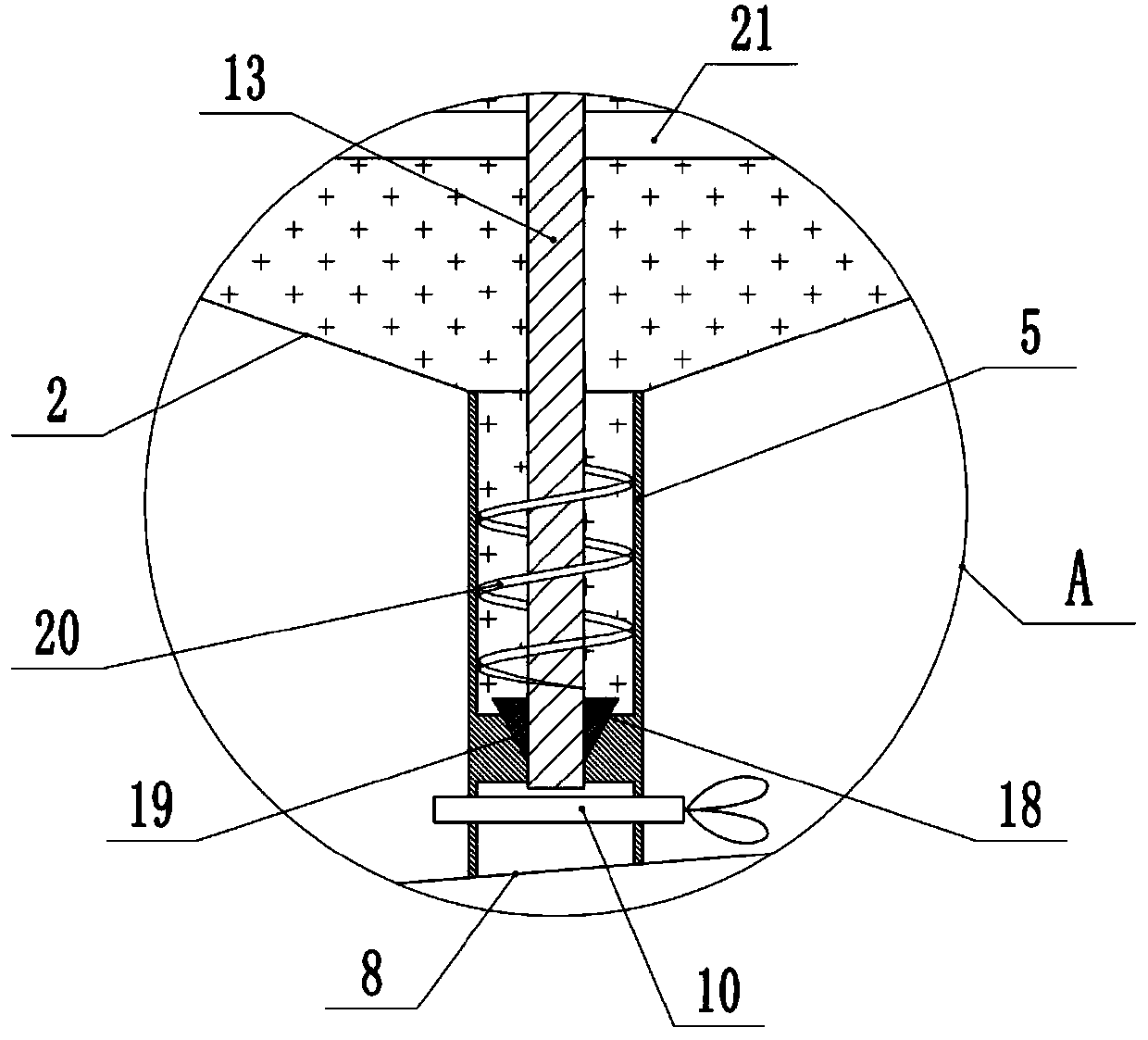

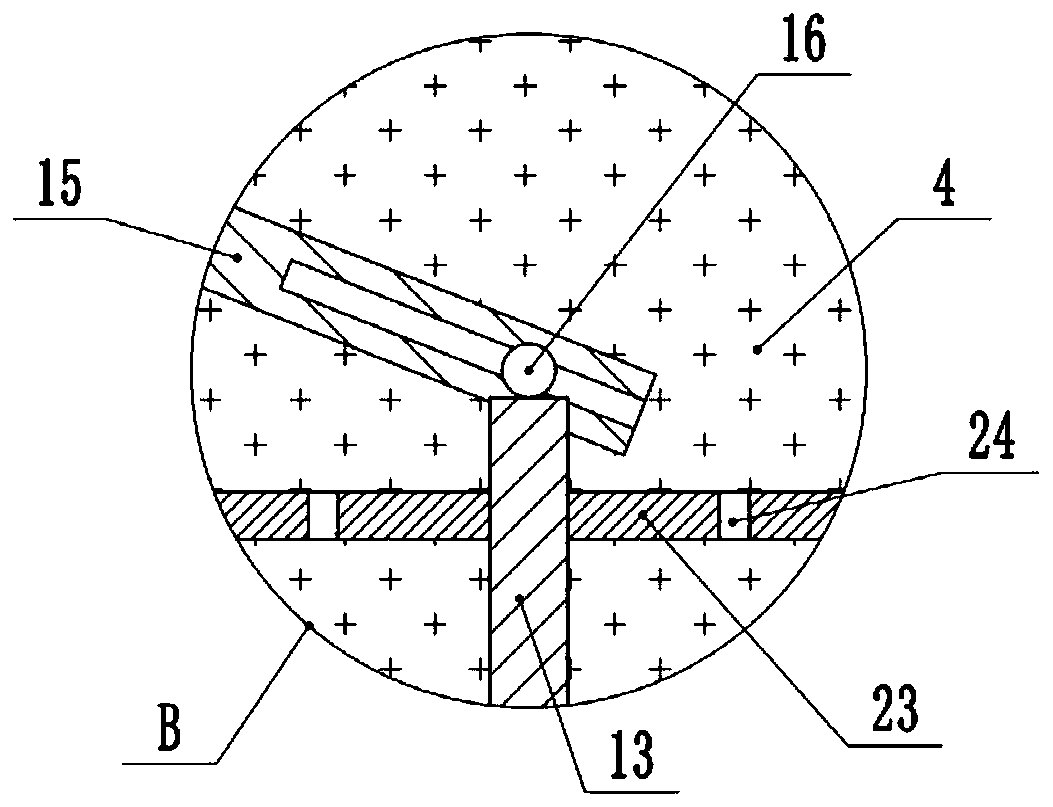

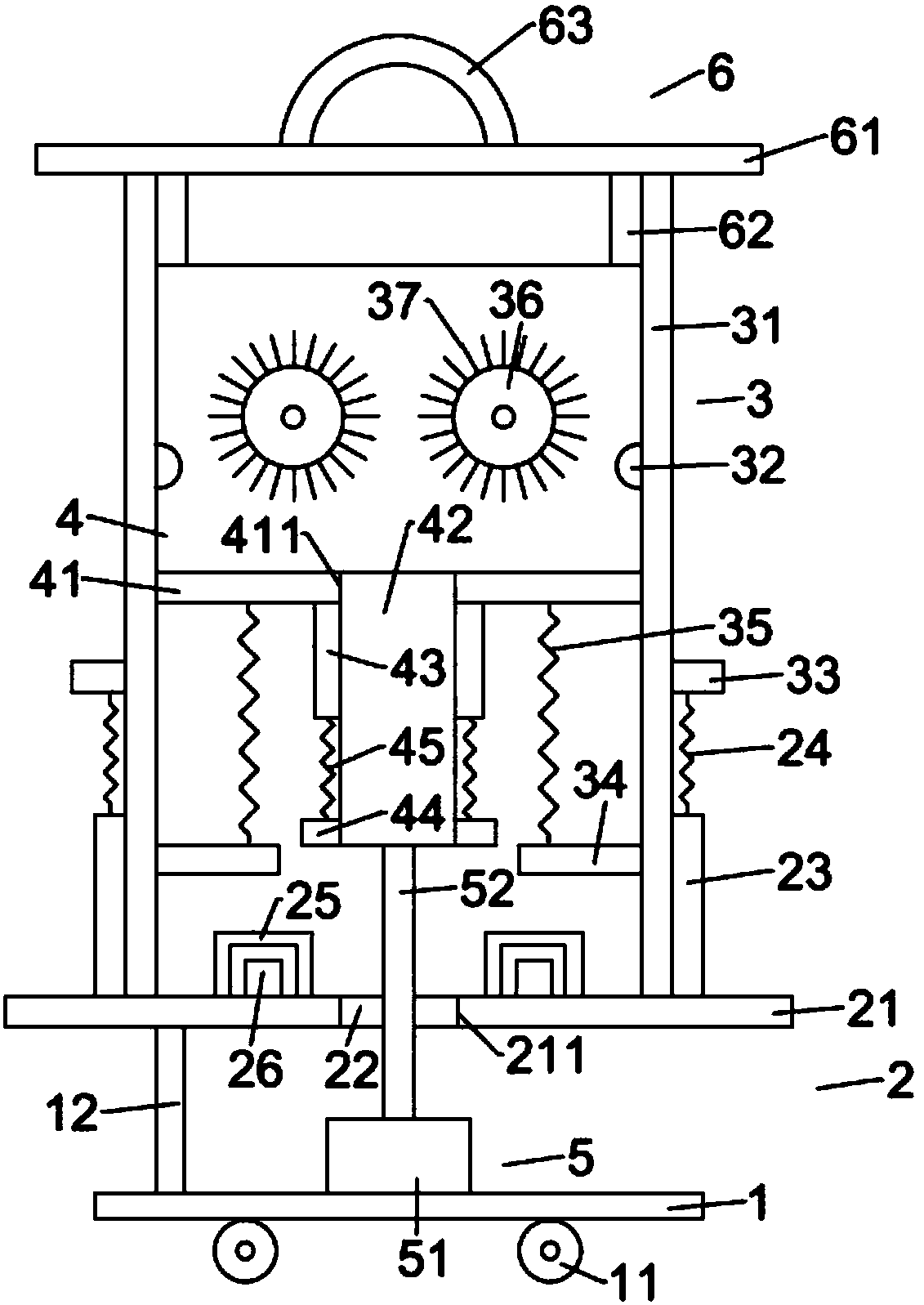

Biomass fuel particle and processing device and method thereof

ActiveCN110791349APrevent coagulationImprove the suppression effectShaking/oscillating/vibrating mixersTransportation and packagingProcess engineeringMechanical engineering

The invention relates to a biomass fuel particle and a processing device and method thereof. The biomass fuel particle is prepared from the components: 15 parts of rice husks, 25 parts of straw, 10 parts of wood scraps, 3 parts of corn cobs, 35 parts of rice and wheatgrass, 5 parts of tree roots, 35 parts of wood chips, 10 parts of bagasse, 5 parts of cottonseed shells, 3 parts of a dehydrator, 1part of pecan shells and 1 part of bamboo chips. The processing method includes the following steps that step 1, biomass fuel is put into a fuel processing cylinder; step 2, a reciprocating drive assembly starts to drive a stirring plate and a spiral stirring blade move up and down in a reciprocating mode, and the biomass fuel is rotated and stirred up and down in a reciprocating mode; step 3, a particle processing driving part starts to drive two pressing rollers to rotate, and the two pressing rollers extrude the biomass fuel from a circular through hole by the cooperation with a round holeseat plate; step 4, the particle processing driving part drives a cutting knife mechanism to rotate, and the rotary cutting knife mechanism cuts the extruded column-shaped biomass fuel into grain shape; and step 5, biomass fuel particles fall into a material receiving box to be collected.

Owner:吉林省尚心能源有限责任公司

Dynamic dehumidification device for drying plastic particles

InactiveCN112212623AImprove dehumidification effectPlay a magnetic roleDrying gas arrangementsDrying chambers/containersMoisture absorptionMagnetic shield

The invention discloses a dynamic dehumidification device for drying plastic particles, and belongs to the technical field of plastic particle processing. Moisture on the plastic particles is absorbedand dried through magnetic dehumidification balls, and before the magnetic dehumidification balls absorb the moisture, magnet layers can magnetically absorb hollow magnetic balls, and after the magnetic dehumidification balls absorb the moisture to a certain degree, outer moisture absorption expansion layers absorb water and expands to extrude inner elastic magnetic shielding layers, inner elastic magnetic shielding layers are extruded to be tightly attached to the hollow magnetic balls, so that a certain magnetic shielding effect on the hollow magnetic balls is achieved; and the magnetic dehumidification balls are reset inwards under the action of extension springs, and after a drying part is dried and the outer moisture absorption expansion layers lose water, the inner elastic magneticshielding layers expand outwards to weaken the shielding effect on the hollow magnetic balls, when the magnetic attraction force of the magnet layers to the hollow magnetic balls is larger than the tensile force of the extension springs, the magnetic dehumidification balls are pulled to move outwards, reciprocating dynamic movement is matched with a rotating dehumidification cylinder, and the gooddehumidification effect on the plastic particles is effectively achieved.

Owner:林建金

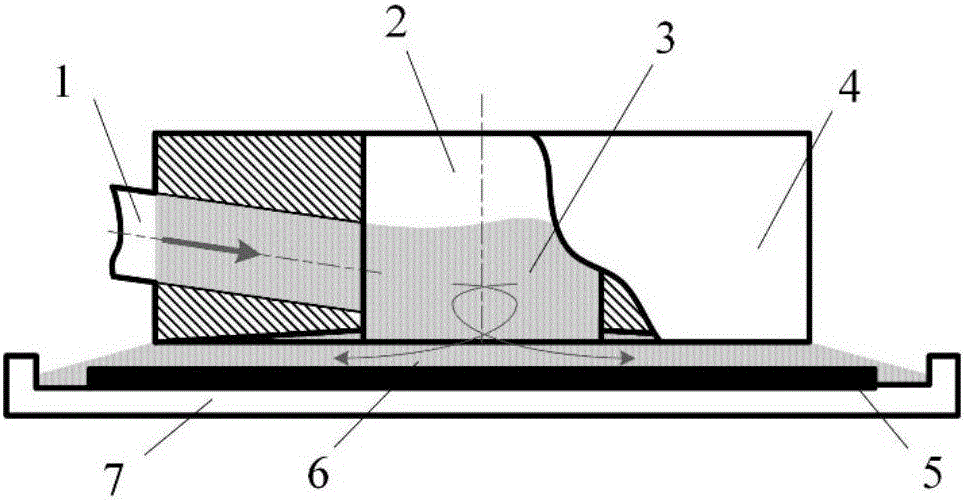

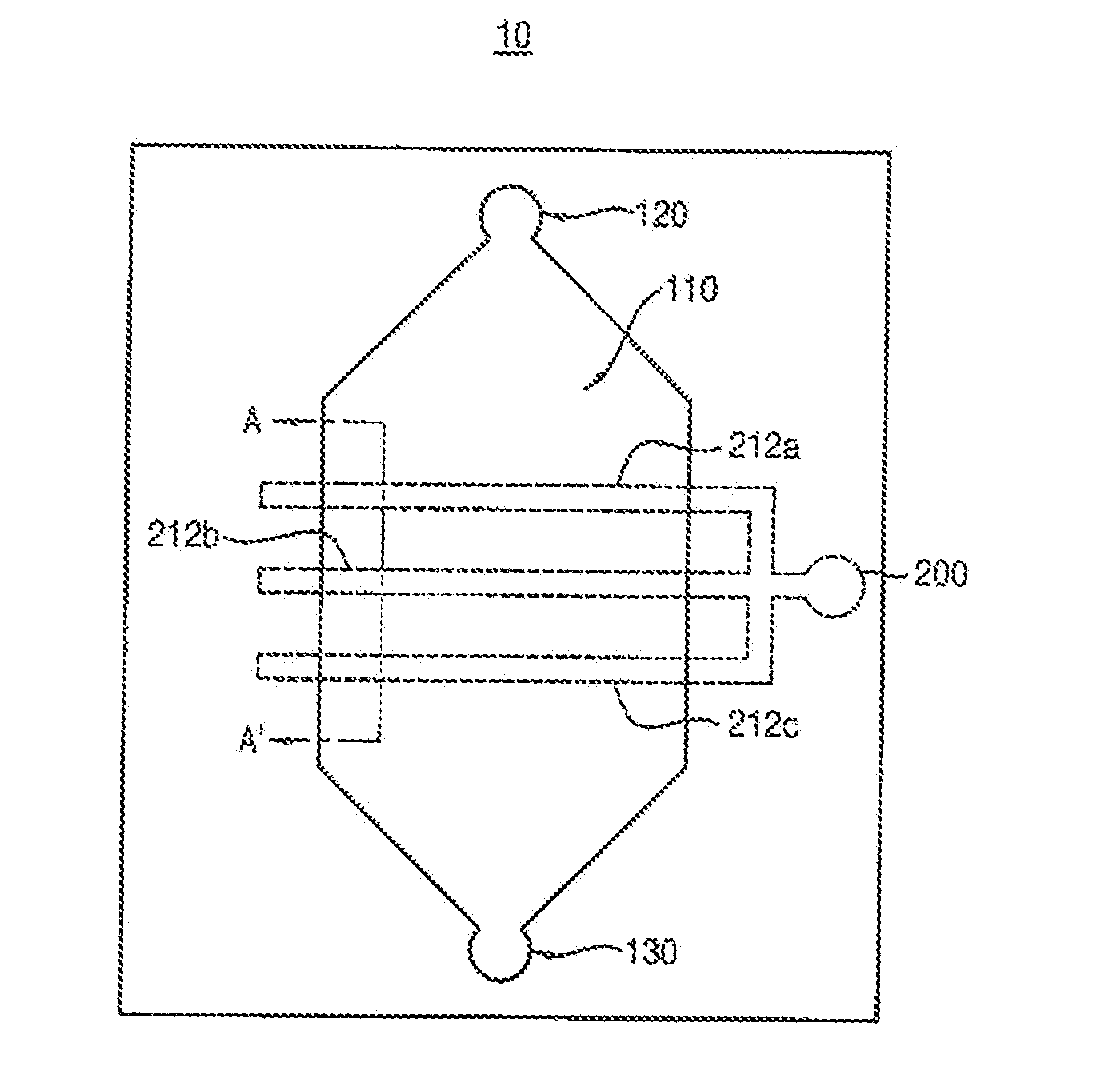

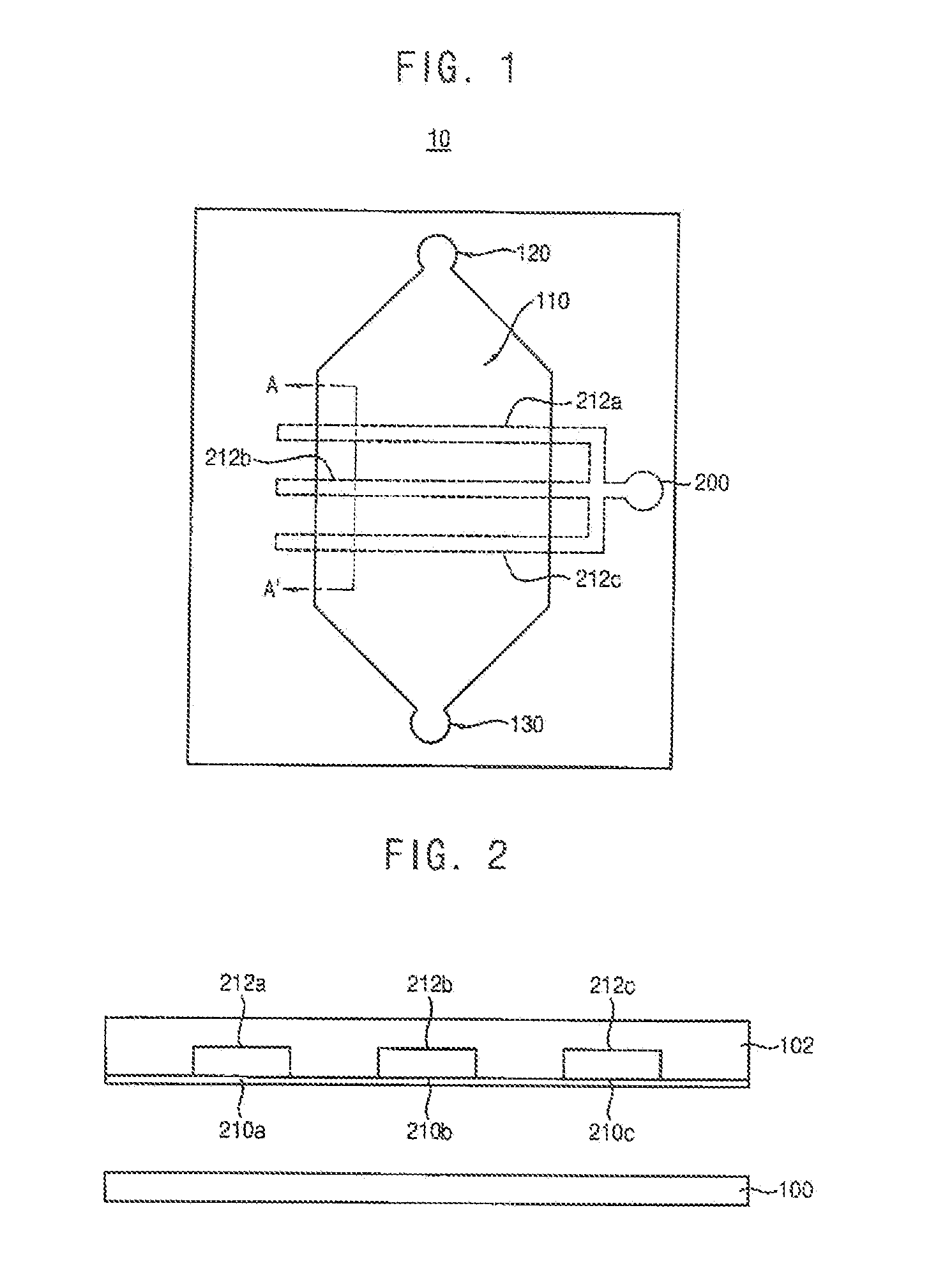

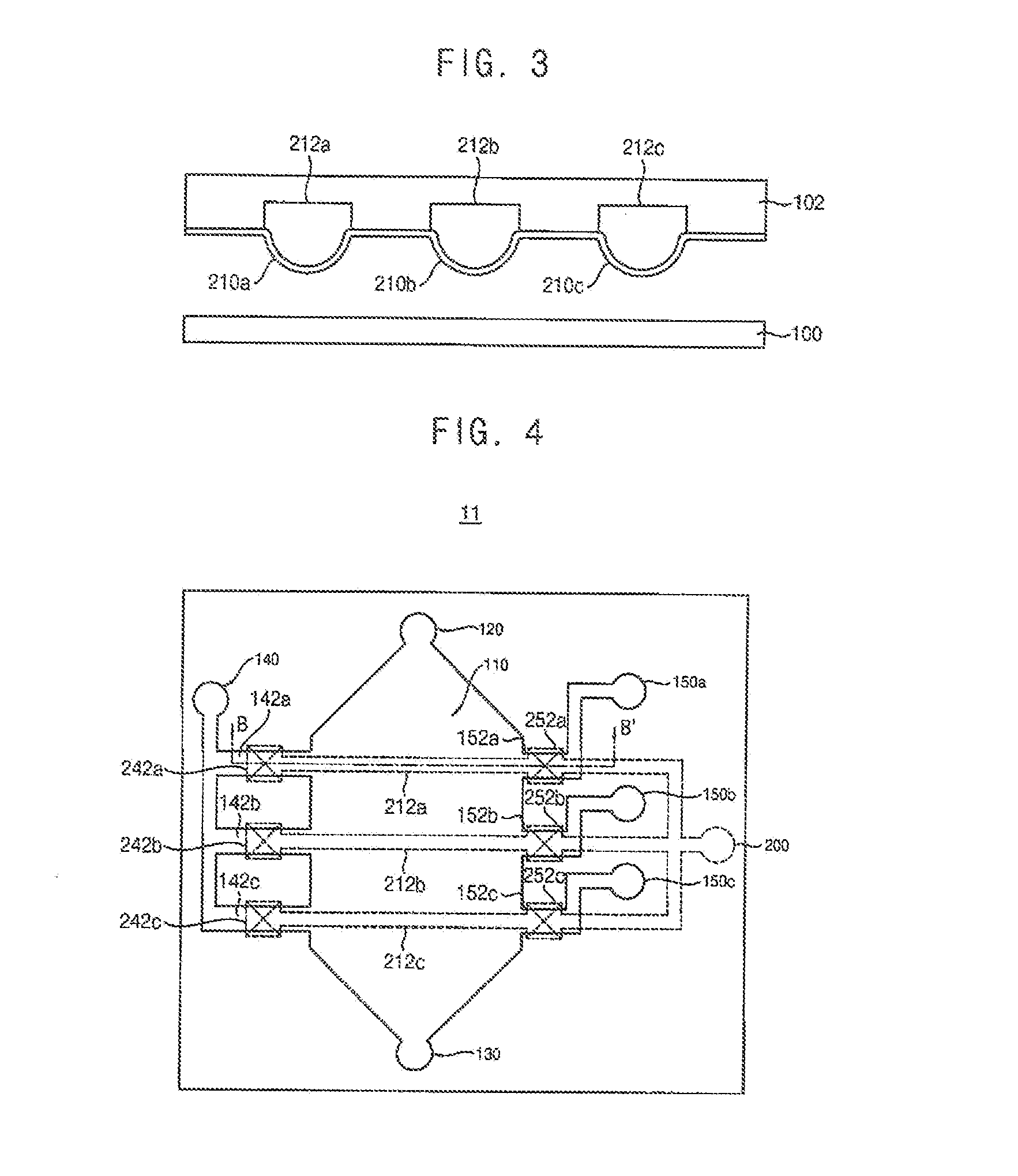

Particle Processing Device Using Membrane Structures

ActiveUS20150192504A1Easy to collectBioreactor/fermenter combinationsBiological substance pretreatmentsControl lineEngineering

A particle processing device includes a chamber including an input portion and an output portion and providing a space for flowing of a fluid having a particle, at least two deformable membrane structures sequentially arranged in the chamber and controlling a sectional area of a fluid path through which the fluid flows, and at least two membrane control lines respectively applying pressure to the deformable membrane structures.

Owner:KOREA ADVANCED INST OF SCI & TECH

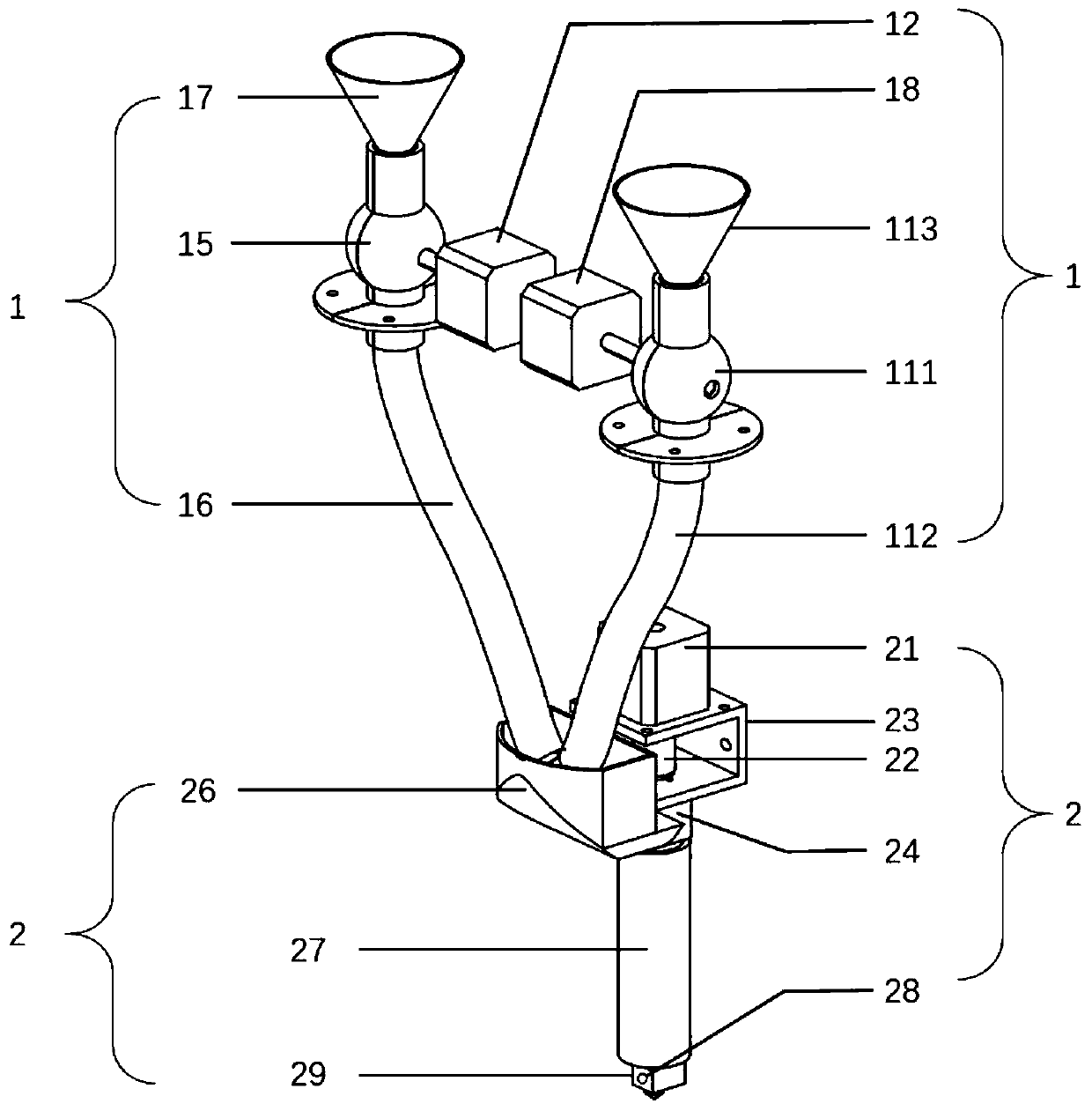

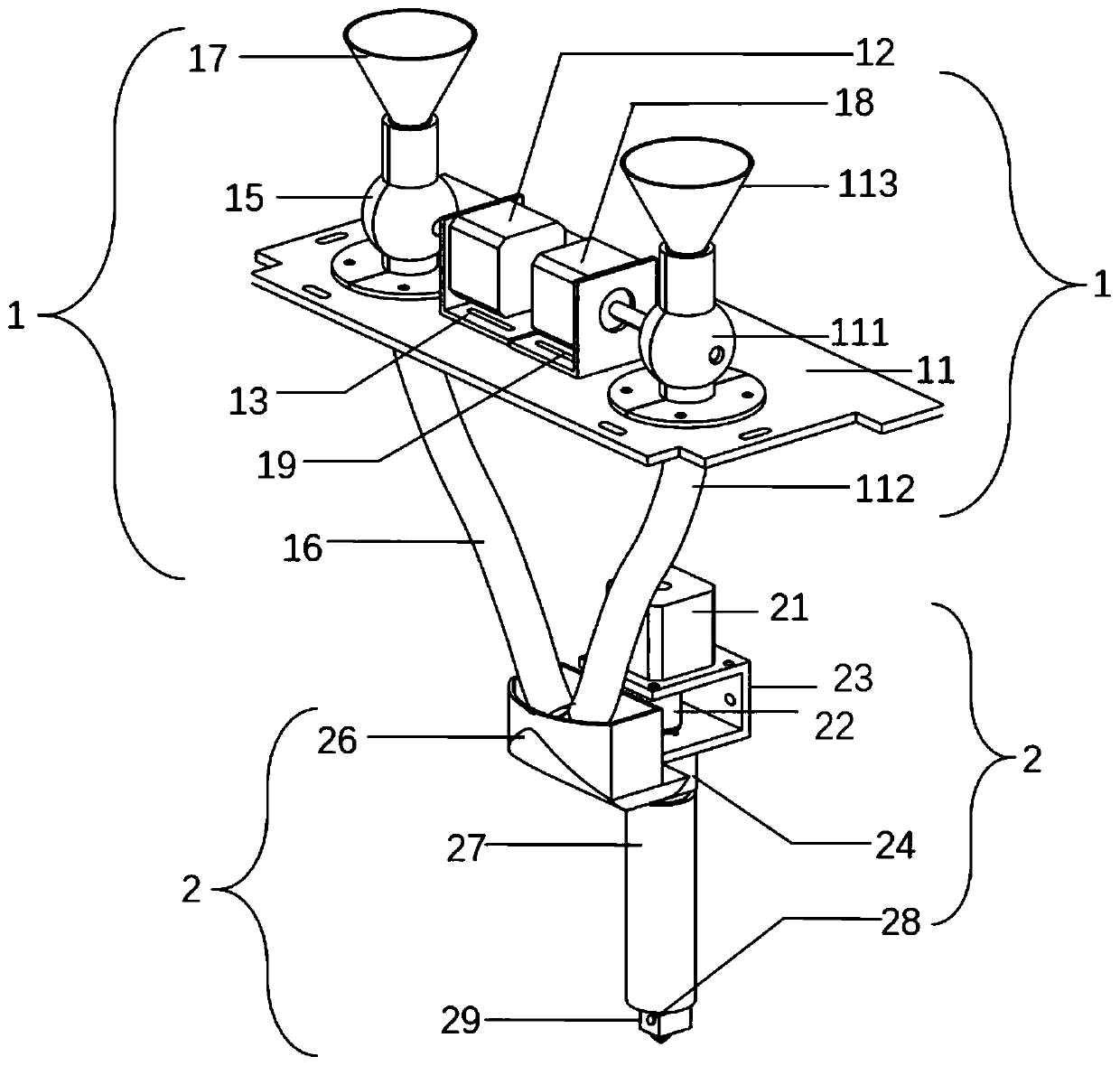

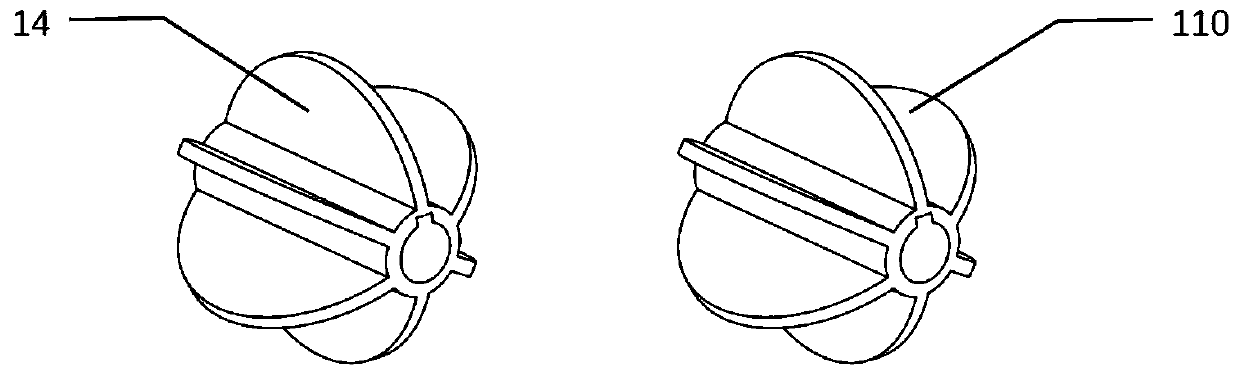

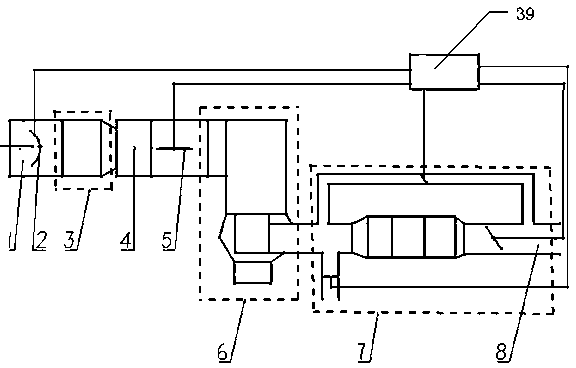

Multi-material gradient forming fusion extrusion system for 3D printing

PendingCN110014643AReduce processReduce the possibilityAdditive manufacturing apparatus3D object support structuresMulti materialDifferential transmission

The invention belongs to the field of material machining, and discloses a multi-material gradient forming fusion extrusion system for 3D printing. The multi-material gradient forming fusion extrusionsystem for 3D printing comprises two parts of a particle differential transmission mechanism and a particle fusion extrusion mechanism. According to the multi-material gradient forming fusion extrusion system for 3D printing, the gradient forming of heterogeneous multi-materials is realized by controlling the feeding amount of different kinds of particles in the forming process; and by adopting the system, the wire material machining can be changed into particle processing, and the 3D printing of composite polymer materials can be supported by mixing two kinds of polymer particles together. The composition control of two kinds of polymer mixed particles is realized, and the composition proportion of printing materials is enabled to be controllable so as to realize 3D printing of the functionally gradient heterogeneous multi-materials; and the range of usable materials is expanded by flexible machining,the production cost is reduced, and the occurrence of the problems of wire breaking,blockage of a spray headand the like in wire machining is avoided.

Owner:HUAZHONG UNIV OF SCI & TECH

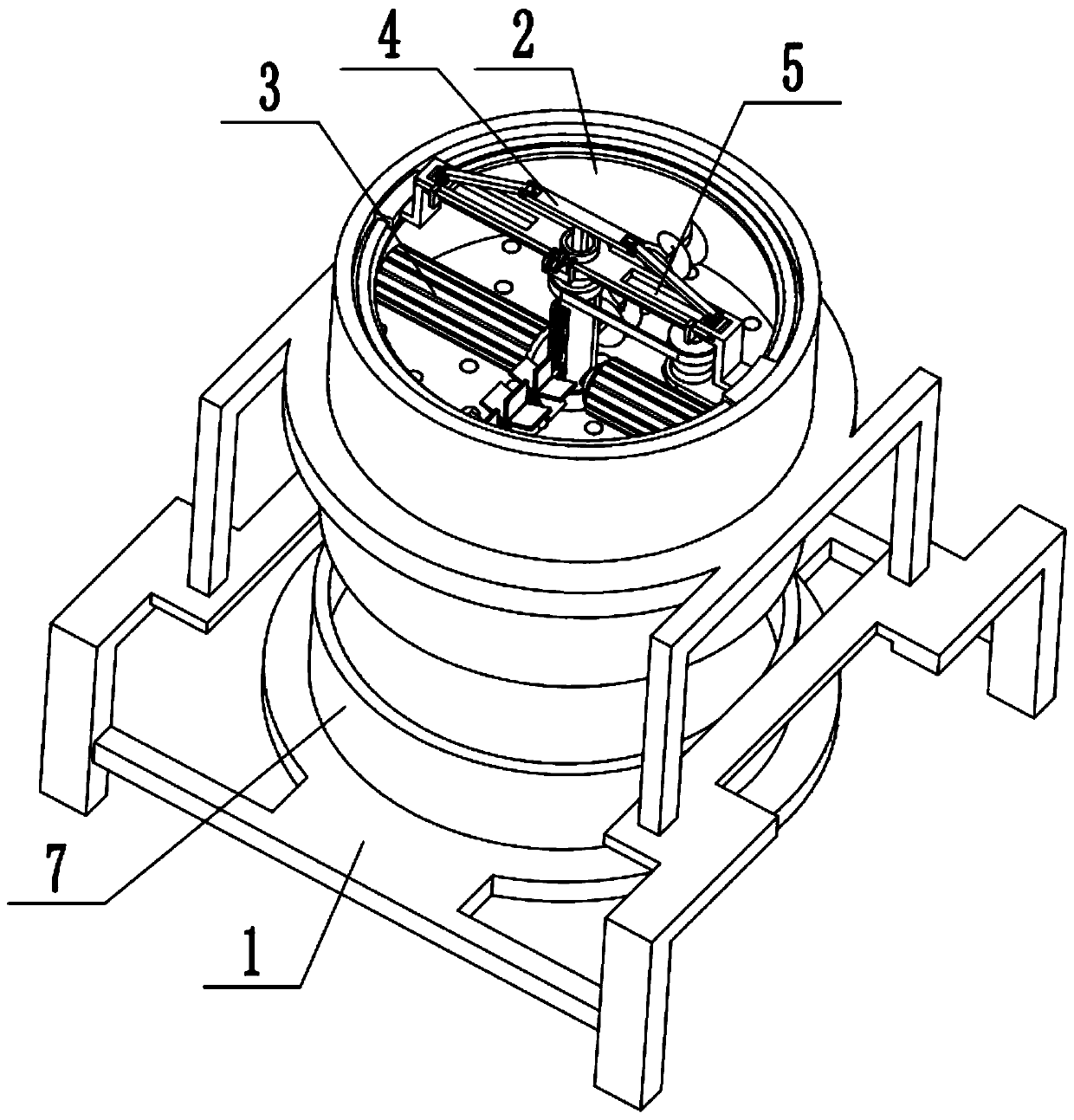

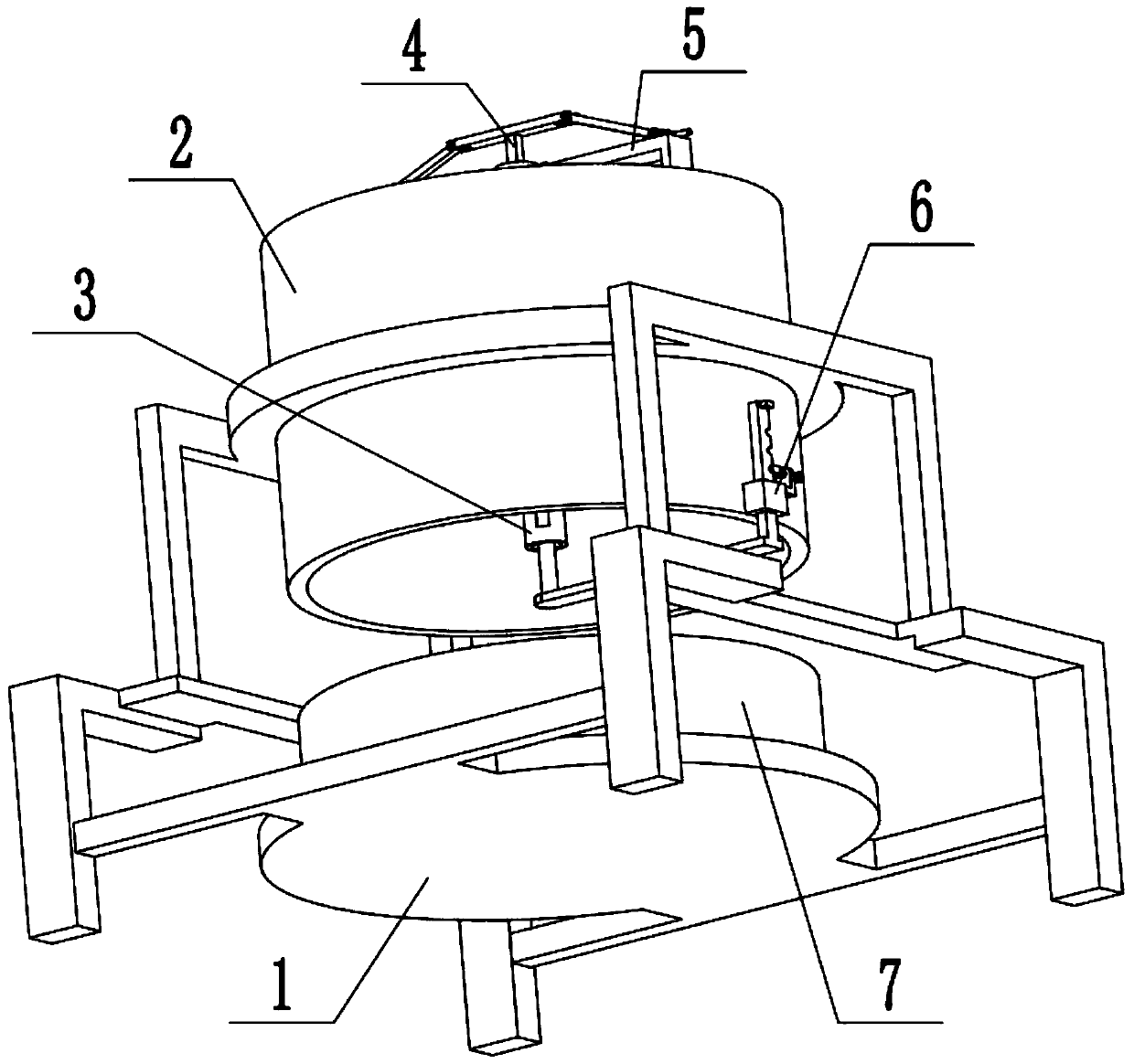

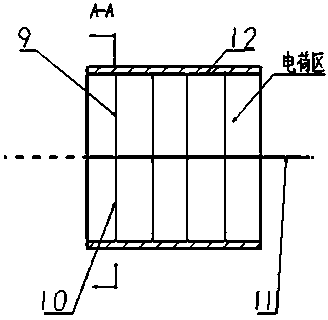

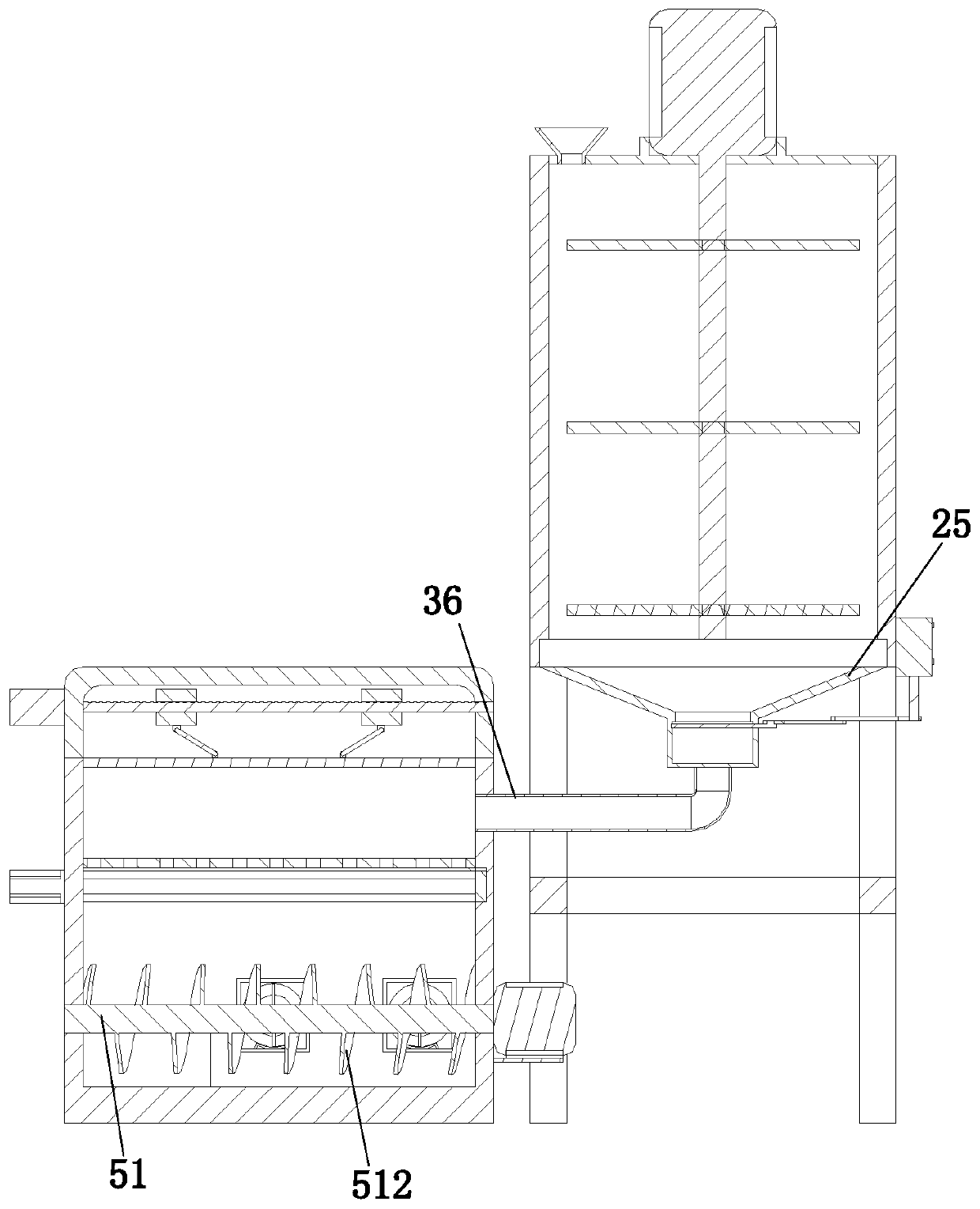

Haze particle collection processing device

InactiveCN104963746AImprove collection efficiencyMake up for deficienciesExhaust apparatusSilencing apparatusFine particulateEngineering

The invention aims to provides a haze particle processing device; the device can effectively collect and process fine particles in waste gas, and can directly collect and process PM2.5 (fine particle with particle size less than or equal to 2.5 micrometers) massively existing in the atmosphere. A power device can pump the air containing haze particles into the haze particle collection processing device through an air inlet for purification, and the air flowing outside an air outlet complies with a national standard. The haze particle collection processing device is strong in versatility, can be applied to the industrial field, and can be applied to a waste gas exhaust port of a diesel engine device; the haze particle collection processing device is applied to the industrial production so as to greatly reduce waste gas particle and charcoal smog content without causing secondary airborne dust pollution; the haze particle collection processing device is applied to a diesel car so as to greatly improve particle collection and processing efficiency when compared with a conventional method, so the diesel car can be small in exhaust backpressure, small in pressure drop, high in particle collection efficiency, and complete in particle after-treatment.

Owner:SHENYANG LIGONG UNIV

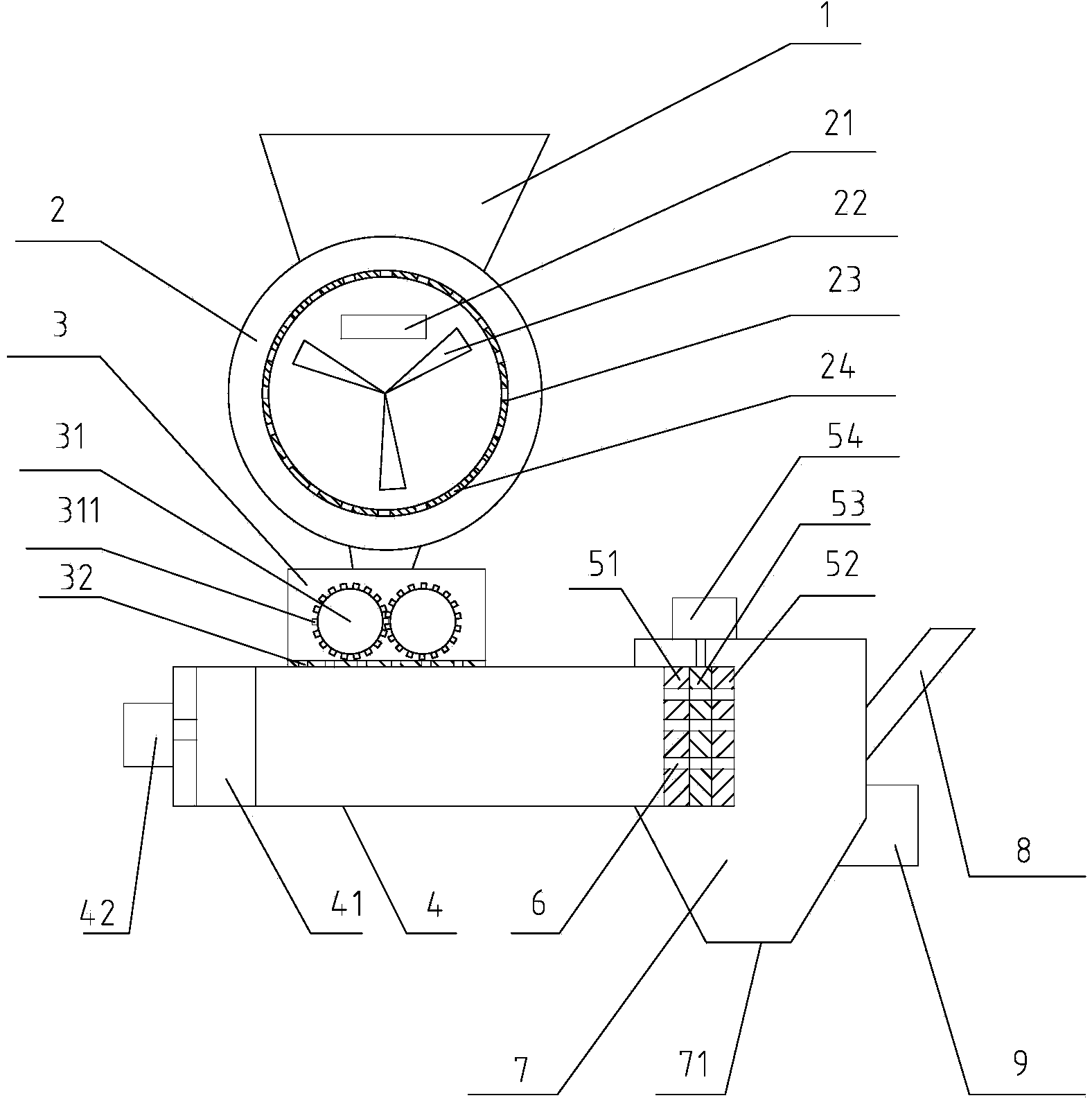

Feed processing machine

InactiveCN104106835AReduce pressure requirementsExcellent pellet feedFeeding-stuffDrive motorEngineering

The invention discloses a feed processing machine and relates to the field of husbandry. The feed processing machine solves the problems that feed particle processing efficiency is low and quality is poor in the prior art. The feed processing machine comprises a hopper, a crushing device, a grinding device and an extruding device. A material opening of the hopper is connected with a feeding opening of the crushing device. A crushing cutter and a driving motor for driving the crushing cutter to rotate are arranged on the crushing device, and a discharging opening of the crushing device is connected with a feeding opening of the grinding device. The grinding device is internally provided with grinding rollers and a rotating motor for driving the grinding rollers to rotate, and the bottom of the grinding device is provided with a plurality of discharging holes. The discharging holes are connected with a feeding opening of the extruding device, and the extruding device is internally provided with an extruding part, an extruding piston and a driving cylinder for driving the extruding piston to move towards the extruding part. The feed processing machine is applied to processing of particle feed.

Owner:长兴丰盛畜禽食品有限公司

Preparation method and application of copper (II) ion imprinting polyurethane

ActiveCN105646827AFast adsorption rateHigh adsorption selectivityOther chemical processesWater contaminantsFiberPhysical chemistry

The invention provides a preparation method of a polyurethane base copper (II) ion imprinting polymer with high adsorption capacity, high selectivity and quick adsorption rate. Copper (II) ion imprinting polyurethane serves as a solid phase adsorber, and an effective method is provided for removing copper (II) ions in various water systems and aided detection, separation and enrichment on the copper (II) ions in the various water systems. The copper (II) ion imprinting polyurethane can be formed by foam, diaphragm plate, spun fiber, coating, package or particle processing.

Owner:HUAIHAI INST OF TECH

Automatic liquid material metering machine

The invention relates to the technical field of plastic particle processing, in particular to an automatic liquid material metering machine. The automatic liquid material metering machine comprises asupporting frame, wherein a storage bin and an electric cabinet are fixedly connected to the supporting frame; a metering bin is connected below the storage bin through a feeding pipe, and a discharging pipe is arranged at the bottom of the metering bin; a pressure sensor is fixedly connected to the inner bottom end of the metering bin; a feeding electromagnetic valve for controlling feeding is arranged on the feeding pipe; a discharging electromagnetic valve for controlling discharging is arranged on the discharging pipe; the feeding electromagnetic valve, the discharging electromagnetic valve and the pressure sensor are all electrically connected with the electric cabinet; and a flow controller for controlling the feeding speed of the feeding pipe is arranged in the feeding pipe. According to the automatic liquid material metering machine, the weight of liquid ingredients in the metering bin is accurately detected through the pressure sensor, and after the weight of the liquid ingredients reaches a preset value, the metering bin automatically stops feeding and the metered liquid ingredients are fed into a stirrer to be mixed with raw materials, so that the problems that manual weighing of the liquid ingredients is inaccurate and high in labor intensity are solved.

Owner:CHONGQING JINGBANG HIGH MOLECULAR MATERIAL CO LTD

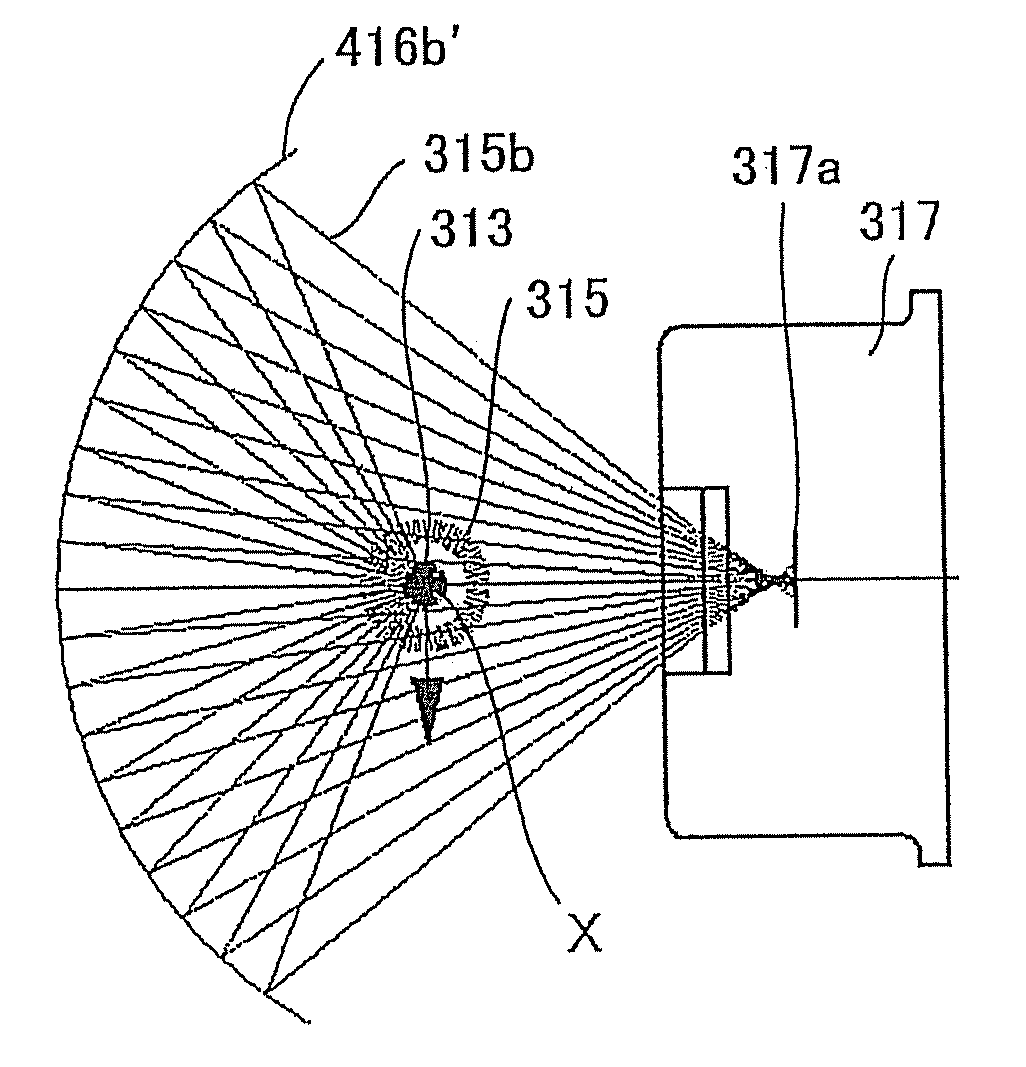

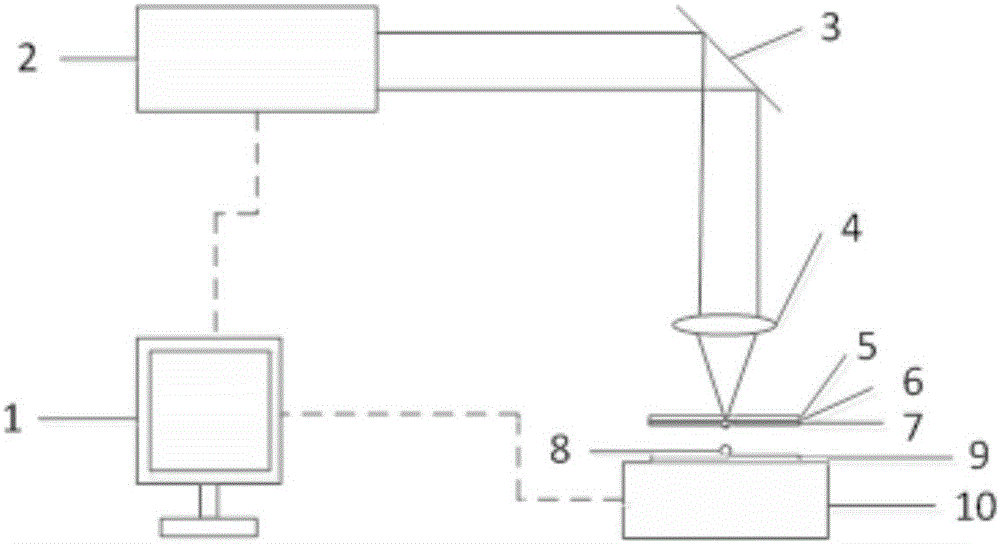

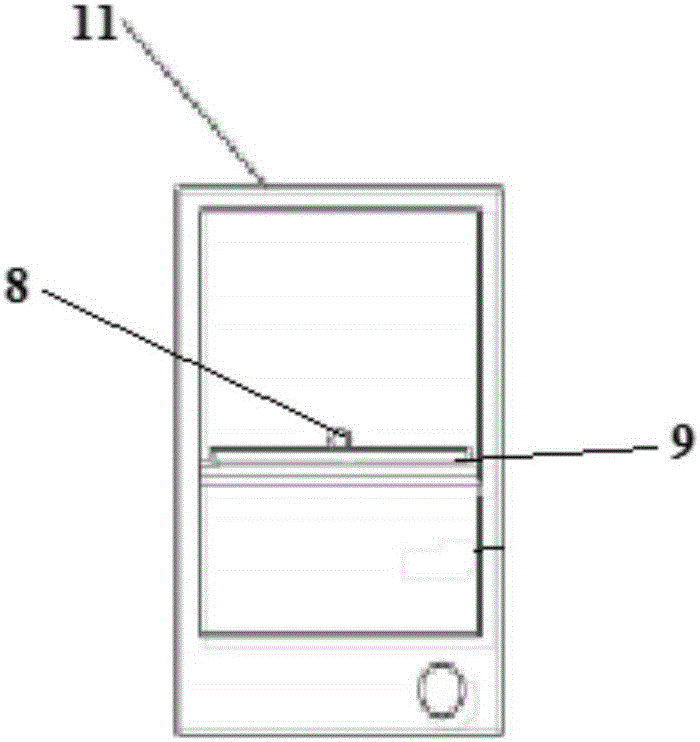

Particle manufacturing equipment and application thereof

InactiveCN105855726ASolution rangeSolve the accuracy problemLaser beam welding apparatusSputteringOptoelectronics

The invention belongs to the field of micro-nano processing, and in particular relates to a particle manufacturing device and its application. The invention provides a particle manufacturing equipment, comprising: a laser, a reflector, a convex lens, a carrier and a receiver; after the laser generates laser light, the laser passes through the reflector and the convex lens in turn and reaches the carrier, After the sacrificial layer placed on the bearing member is acted on by the laser, an energy wave is generated, so that the liquid low surface energy material is sputtered to generate particles, and the generated particles reach the receiving member. The present invention also provides an application of the above particle manufacturing equipment in the preparation of low surface energy material particles. In the technical solution provided by the present invention, the types of raw materials are not limited, and particles of different sizes can be obtained by adjusting the laser to generate laser light with different energies, with high precision. The invention solves the technical defects of narrow particle preparation application range and poor particle size precision in the prior art.

Owner:GUANGDONG UNIV OF TECH

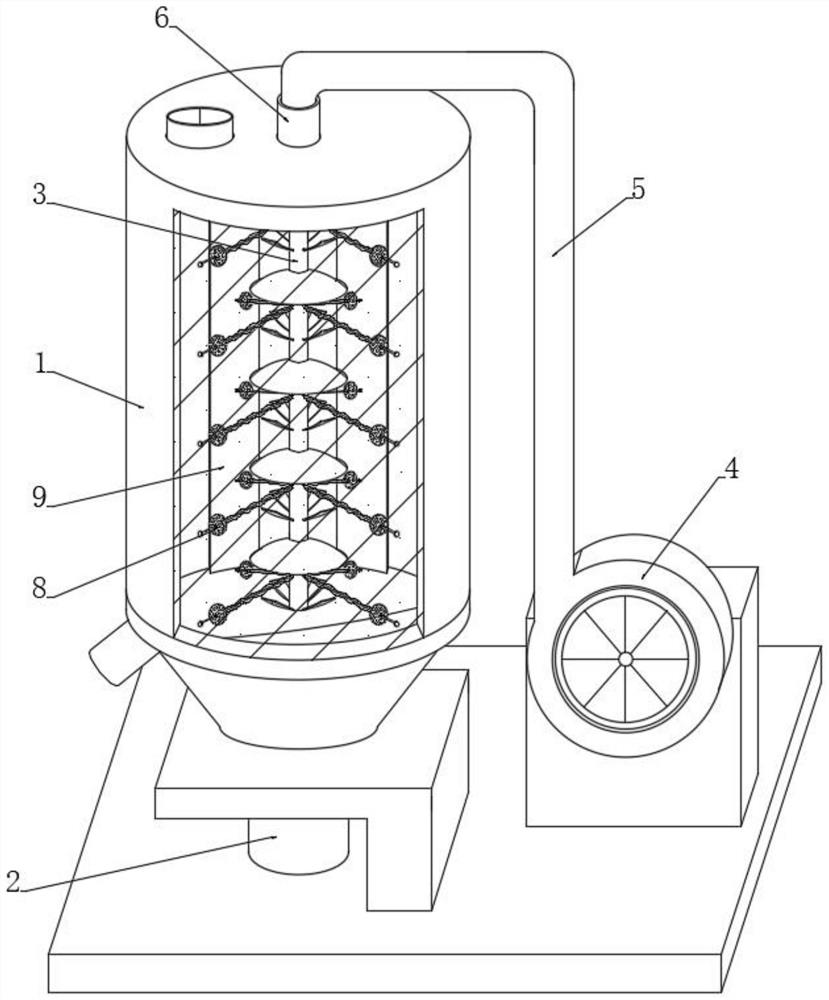

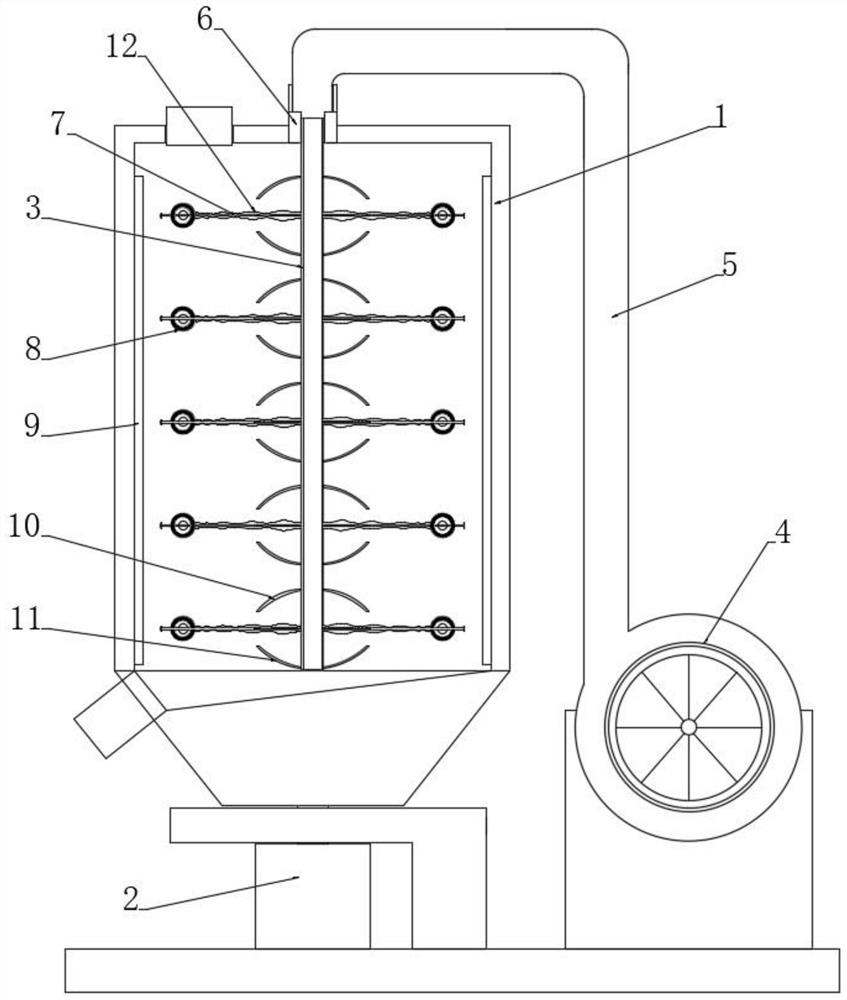

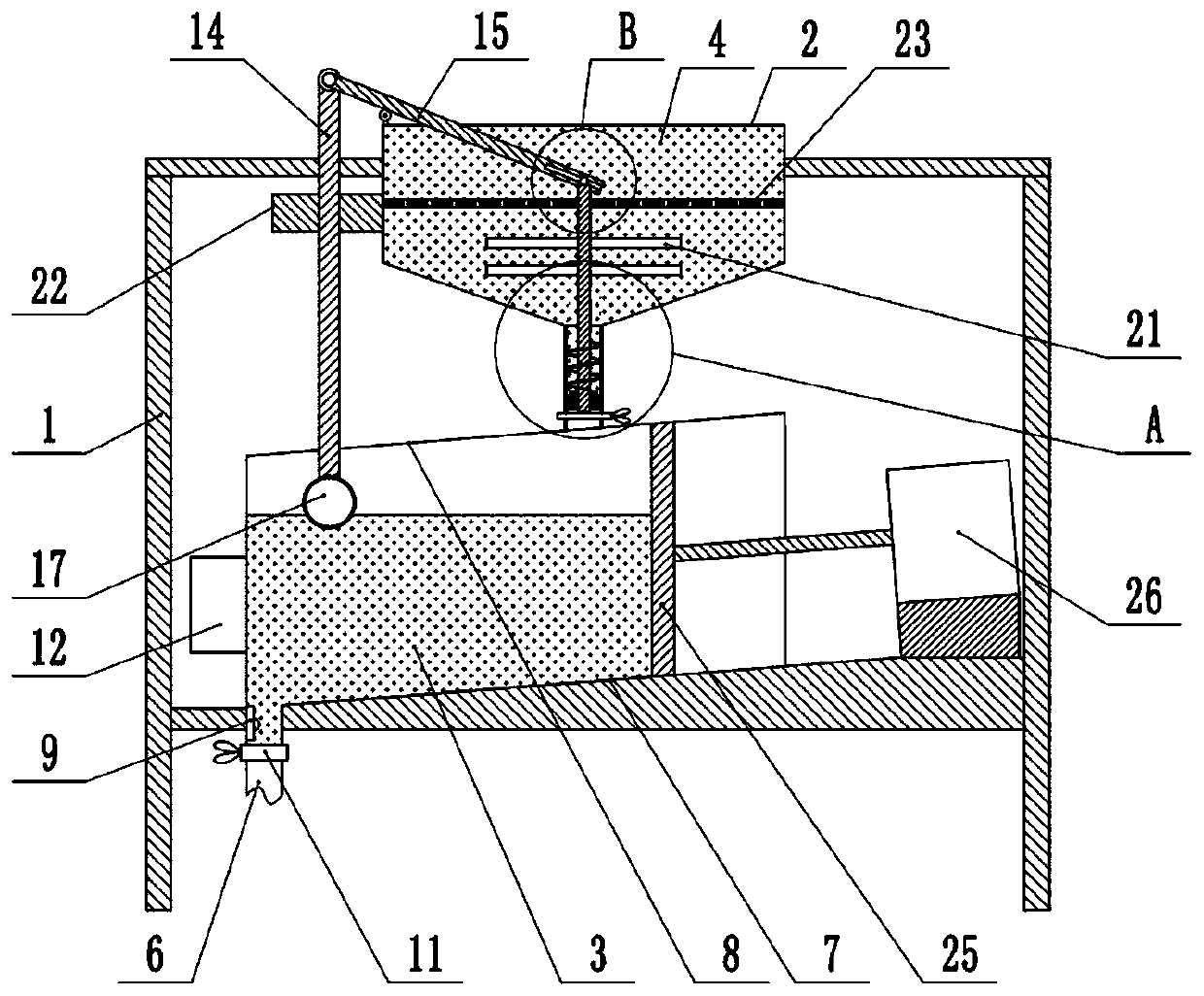

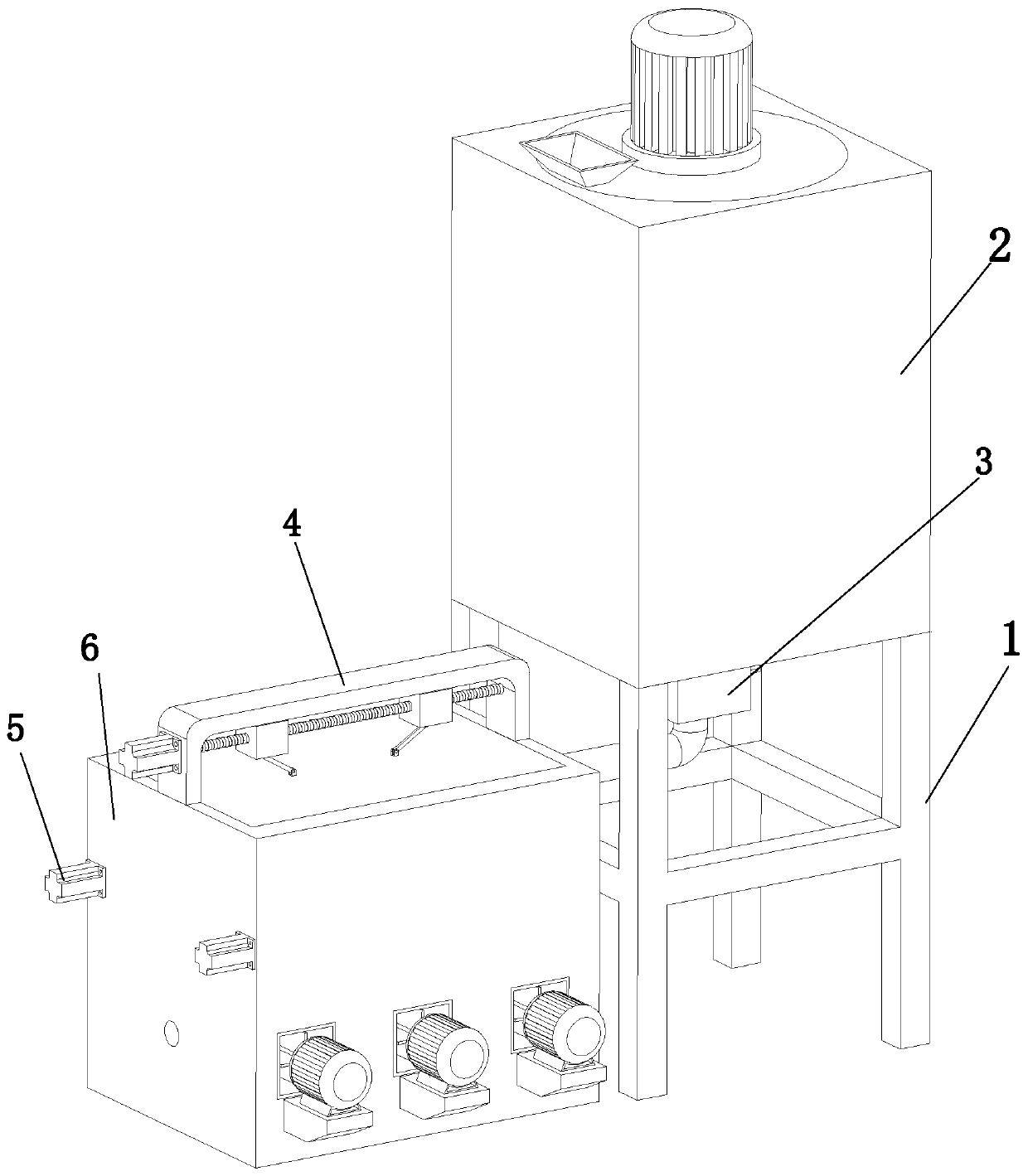

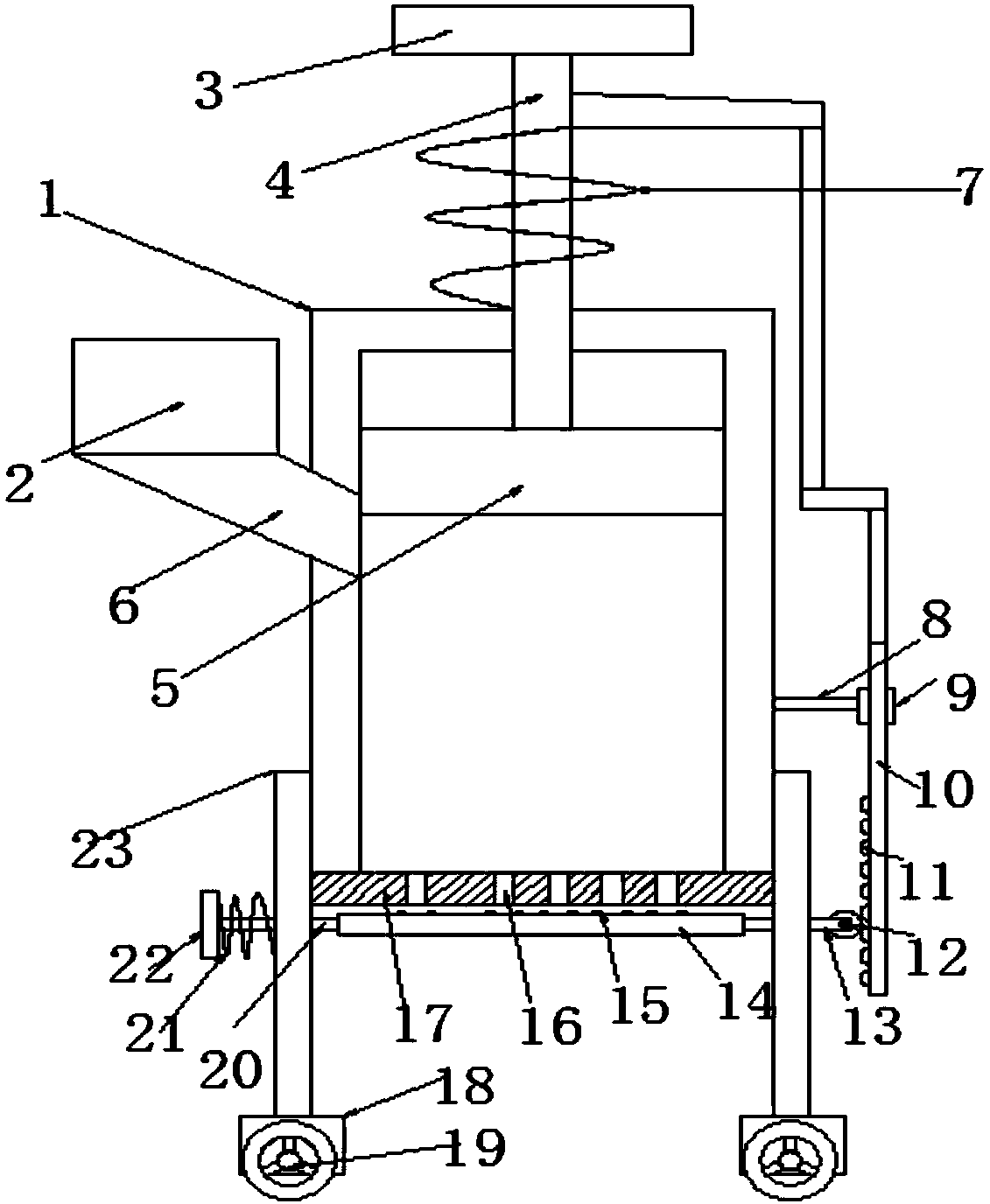

Plastic particle processing treatment equipment for engineering plastic production

InactiveCN108518937AThorough and effective dryingFully dryGranular material dryingDrying chambers/containersEngineering plasticEngineering

The invention discloses plastic particle processing treatment equipment for engineering plastic production. The plastic particle processing treatment equipment comprises a bottom plate, a drying device, a frame device, a lifting device, an electric cylinder device and a cover plate device; the drying device and the frame device are located on the upper portion of the bottom plate, the lifting device is accommodated in the frame device, the electric cylinder device is arranged on the upper portion of the bottom plate, and the cover plate device is arranged on the frame device. According to theplastic particle processing treatment equipment for engineering plastic production, plastic particles can be thoroughly and effectively dried, drying is sufficient and thorough, heating is even, the drying effect is ensured, operation is easy, and using is convenient.

Owner:GUANGZHOU CHANXIN BIOTECH CO LTD

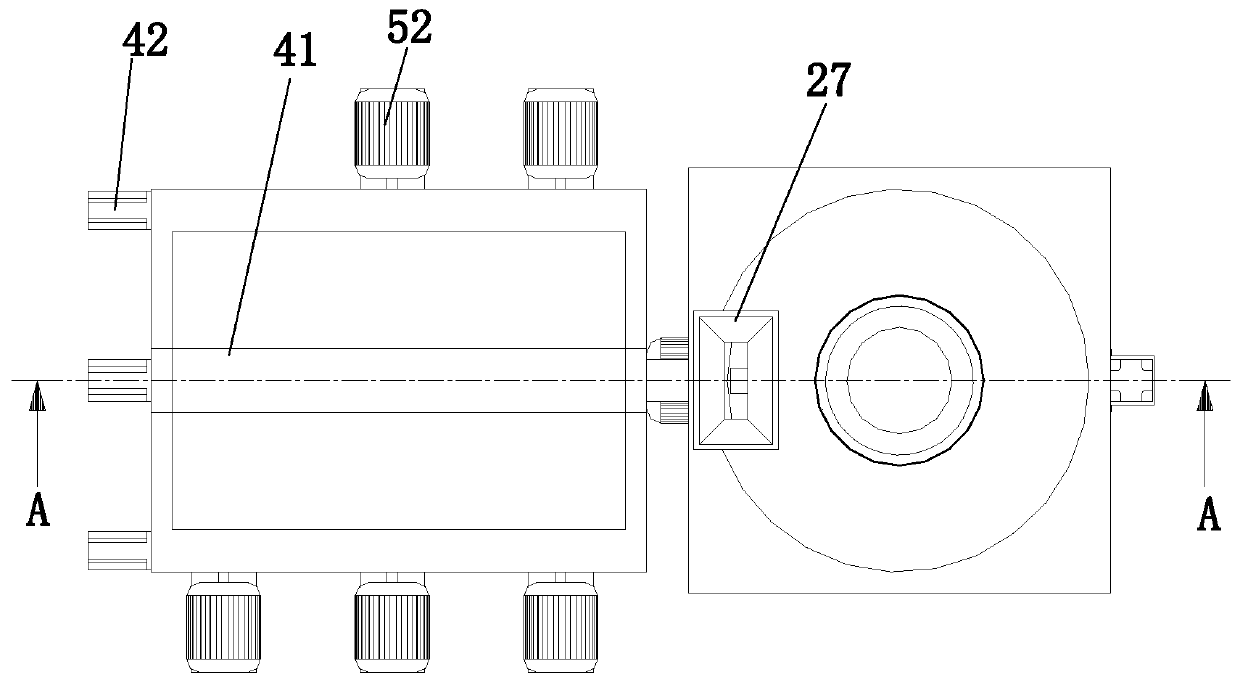

Starch particle processing device

InactiveCN110801776AWon't stickWill not affect later useDrying gas arrangementsGranulation by material expressionProcess engineeringStarch granule

The invention discloses a starch particle processing device, and belongs to the technical field of starch processing. The starch particle processing device comprises a supporting frame, a mixing assembly, a discharging assembly, a processing assembly and a drying assembly. The mixing assembly is arranged at the top of the supporting frame; the discharging assembly is arranged at the bottom of themixing assembly; a processing box is arranged beside the supporting frame; the processing assembly comprises a forming part and a cutting part, the forming part is arranged on the processing box, andthe cutting part is arranged on the processing box; the drying assembly comprises a material mixing part and a plurality of drying parts, the material mixing part is arranged on the processing box, and the drying parts are all arranged on the processing box. Starch particles are conveyed forwards through work of a mixing auger, a drying fan works to output hot air to be conveyed into the processing box through a drying air outlet channel opening while the starch particles are conveyed, the starch particles in the processing box are dried, and after drying is conducted, a box door is opened, and the starch particles are taken out.

Owner:ANHUI SCI & TECH UNIV

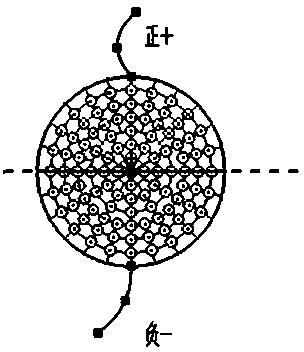

Zinc-particle processing method for making electrogalvanizing steel plate

The production method of zinc granules for making galvanized sheet steel includes: melting zinc pig in melting furnace, feeding the melton zinc into heat-insulating furnace, said heat-insulating furnace adopts heating sleeve in the ceramic to supply heat, when the molten zinc is heat-insulated, the N2 or Ar2 can be used for protection. The temp. of molten zinc in the heat-insulating furnace is controlled in 435-455 deg.C. The lower portion of heat-insulating furnace is equipped with one or more than one through hole. Said through hole is directly connected with batchmeter, the molten zinc is flowed through the batchmeter and drip nozzle, then dripped on the gypsum cooling roller whose rotating speed is 30 rmp-80 rpm, 50%-80% of roller body area of cooling roller can be soaked in the condensated water tank whose internal water temp. is 15 deg.C-45 deg.C, so that the molten zinc can be quickly changed into zinc granules.

Owner:上海宝鹏有色金属制品厂

Road cement concrete rubber particle surface modifier

The invention discloses a rubber particle surface modifier for road cement concrete, which relates to a wasted rubber particle surface modifier used in road-use cement concrete. The mixture ratio of the modifier is as above: the modifier has wild material source, low price and convenient manufacture, which can carry out the modification treatment to the rubber particles in a wasted rubber particle processing plant or a concrete mixing location, the modified rubber particles can be directly packaged in a damp state or be properly dried and packaged to leave the factory. Compared with the unmodified rubber particle one, the cement concrete prepared by modified wasted rubber particles can increase the compressive strength by 20%, the breaking strength by 10%-30% and the flexural toughness by 30%-50% under the condition of the same fluidness, thereby having valuable economic and social benefit.

Owner:TONGJI UNIV

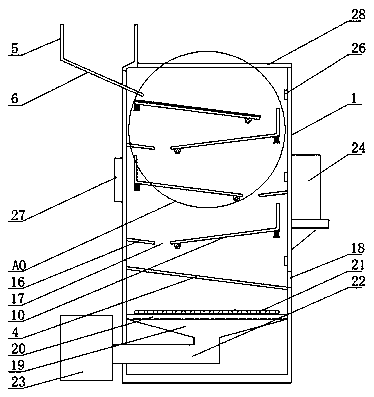

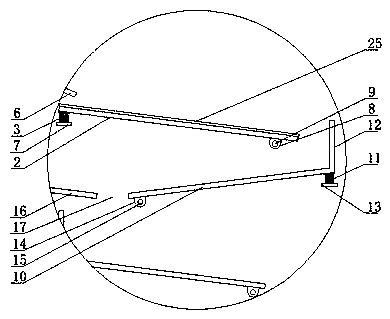

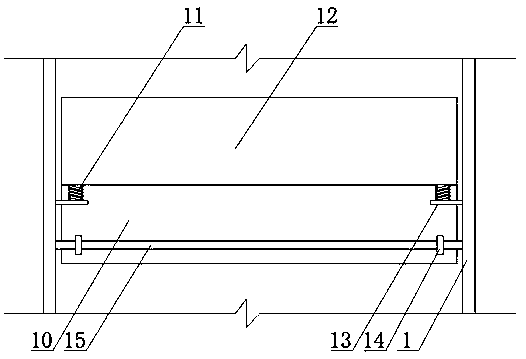

Rapid air-drying equipment for plastic particle processing

InactiveCN110332790AGuaranteed to slipUniform windGranular material dryingDrying gas arrangementsEngineeringSmall footprint

The invention discloses rapid air-drying equipment for plastic particle processing. The rapid air-drying equipment for plastic particle processing comprises an air-drying box, a feeding guide plate, afirst vibrating spring, material guide mechanisms and a discharging guide plate; one side of the top end of the air-drying box is fixedly connected with a feeding hopper; the feeding guide plate is arranged at the upper end of an inner cavity of the air-drying box; multiple groups of material guide mechanisms are arranged at the lower end of the feeding guide plate; the adjacent two groups of material guide mechanisms are arranged reversely; the discharging guide plate is arranged below the material guide mechanism at the bottom; a discharging port is in the inner wall of the air-drying box on one side of the discharging guide plate; an air outlet cavity is formed at the bottom of the inner cavity of the air-drying box; the upper end of the air outlet cavity is fixedly connected with an air outlet plate; the bottom of the air outlet cavity is fixedly connected with a vent pipe; the other end of the vent pipe is fixedly connected with a blast blower; and the outer wall of one side of the air-drying box is fixedly connected with a vibrating machine. The rapid air-drying equipment for plastic particle processing has the beneficial effects of simple structure, small occupied area, high air-drying speed and good effect, and is mainly applied to plastic particle processing drying.

Owner:长兴悦成塑料制品有限公司

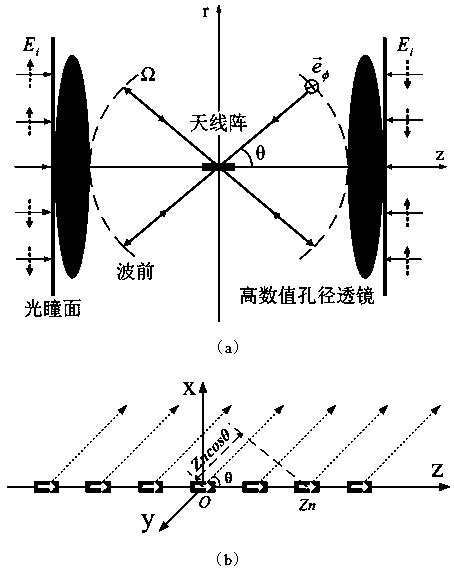

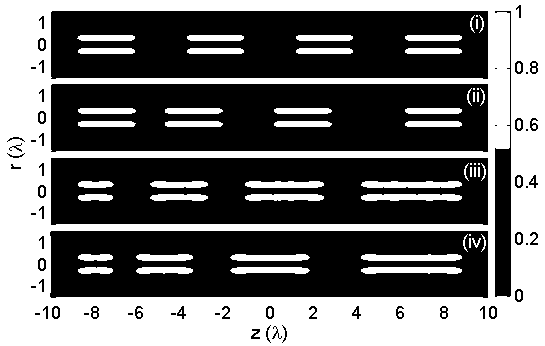

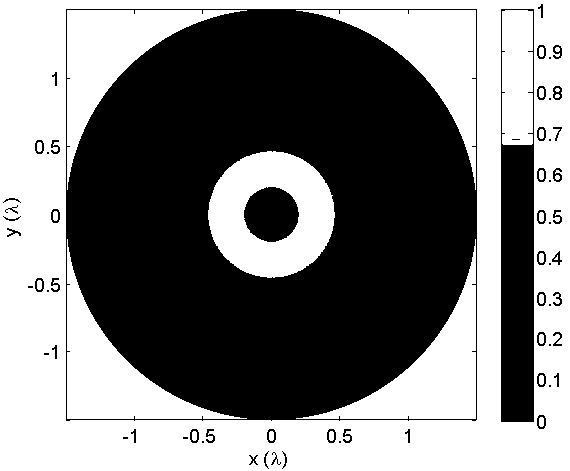

Method for implementing light pipe field array having predetermined characteristic

ActiveCN109240018AOf predetermined natureSimple methodAntenna arrays manufactureIndividually energised antenna arraysMagnetic currentAzimuthal polarization

The invention relates to a method for implementing a light pipe field array having predetermined characteristic. According to the method, a hollow light pipe array is achieved by reversely rotating aradiation field of an isotropic collinear magnetic current antenna array arranged at a focus region. A simulation example shows that the implemented hollow light pipe is in pure azimuthal polarization, the light intensity distribution within the whole focal depth range is hardly maintained unchanged, and the shape and the position of the hollow light pipe are respectively dependent on an element factor and an array factor. The light pipe array having predetermined property, implemented by the method, can be expected to be used for the fields of multi-particle capturing and control, multi-particle processing and photoetching and the like.

Owner:QUANZHOU NORMAL UNIV

Feed particle processing device with polarized cutting function

The invention discloses a feed particle processing device with a polarized cutting function. The device comprises a cylindrical barrel, wherein a piston block is in sliding fit inside the barrel; a piston rod is vertically arranged in the middle of the upper end of the piston block; the upper end of the piston rod penetrates through a through hole in the top of the barrel, and is provided with a handle; the handle and the top of the barrel are connected and fixed through a reset spring I; supporting legs are symmetrically arranged on two sides of the lower end of the barrel; supporting blocksare arranged at lower ends of the supporting legs; rollers are arranged on the supporting blocks, and are used for facilitating device handling; and a movable bottom plate is detachably arranged at the lower port of the barrel. The feed particle processing device has a simple and reasonable structure, is convenient for handling, can be automatically adjusted correspondingly since the shaking frequency of an assembly frame is consistent with the descending speed of the piston rod, so that the feed processing quality can be guaranteed, defects of an existing device can be eliminated, and the device has strong practicality.

Owner:SHENZHEN RUNFENG INVESTMENT CONSULTATION CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com