Automatic liquid material metering machine

An automatic metering and liquid material technology, which is applied in the field of plastic granule processing, can solve the problems of low manual batching efficiency and inaccurate liquid batching, and achieve the effects of high strength, waste reduction, and slow flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

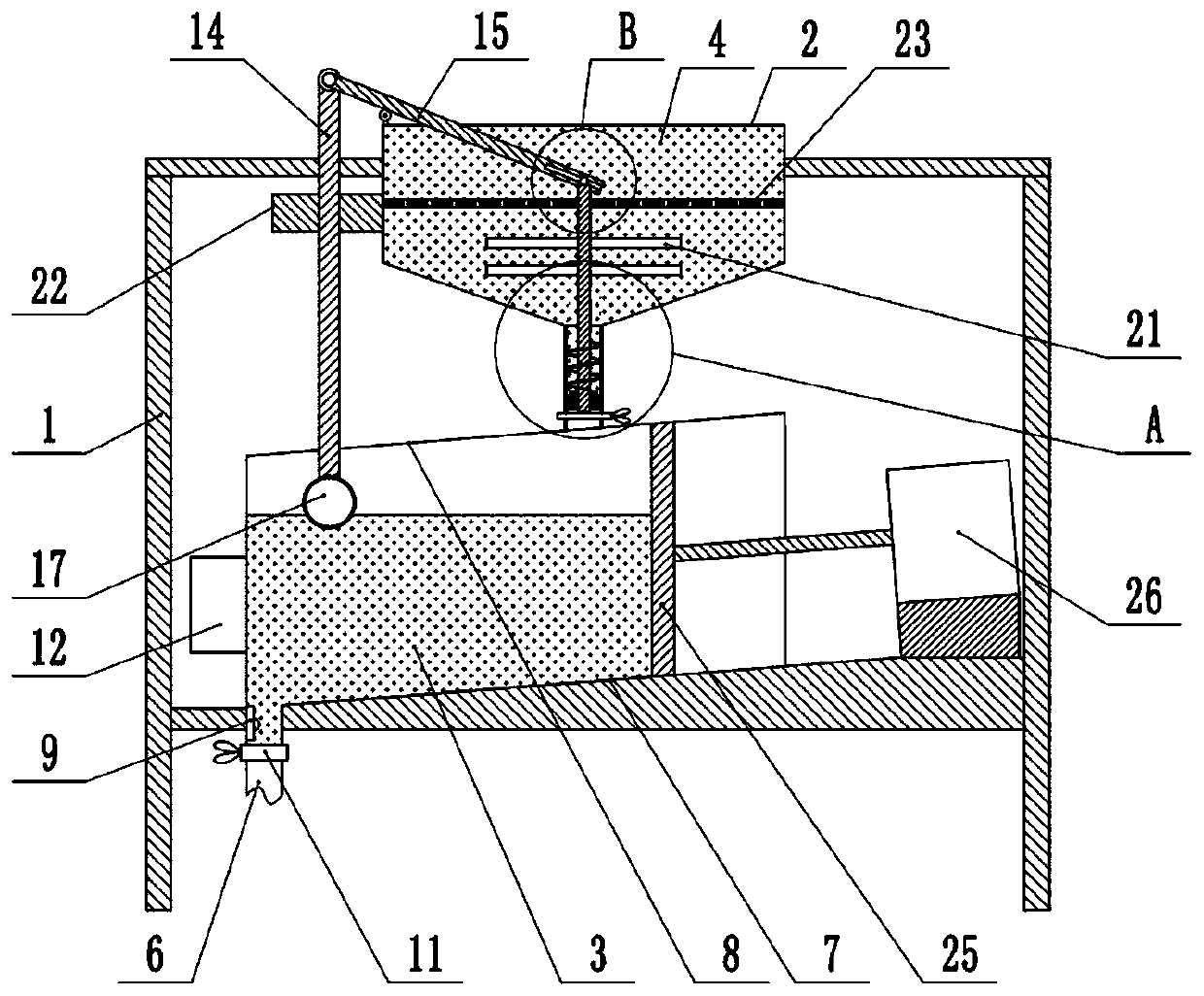

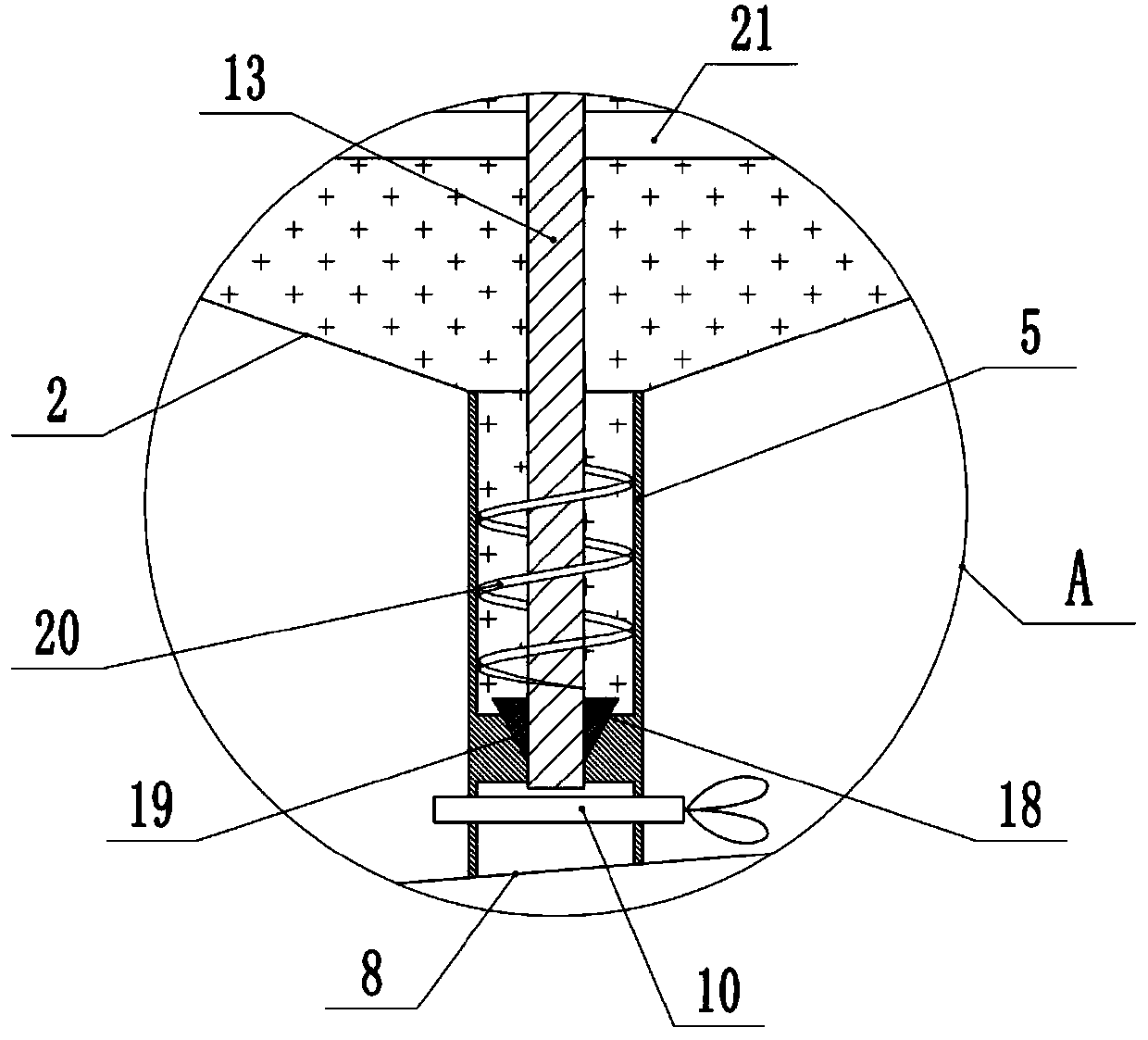

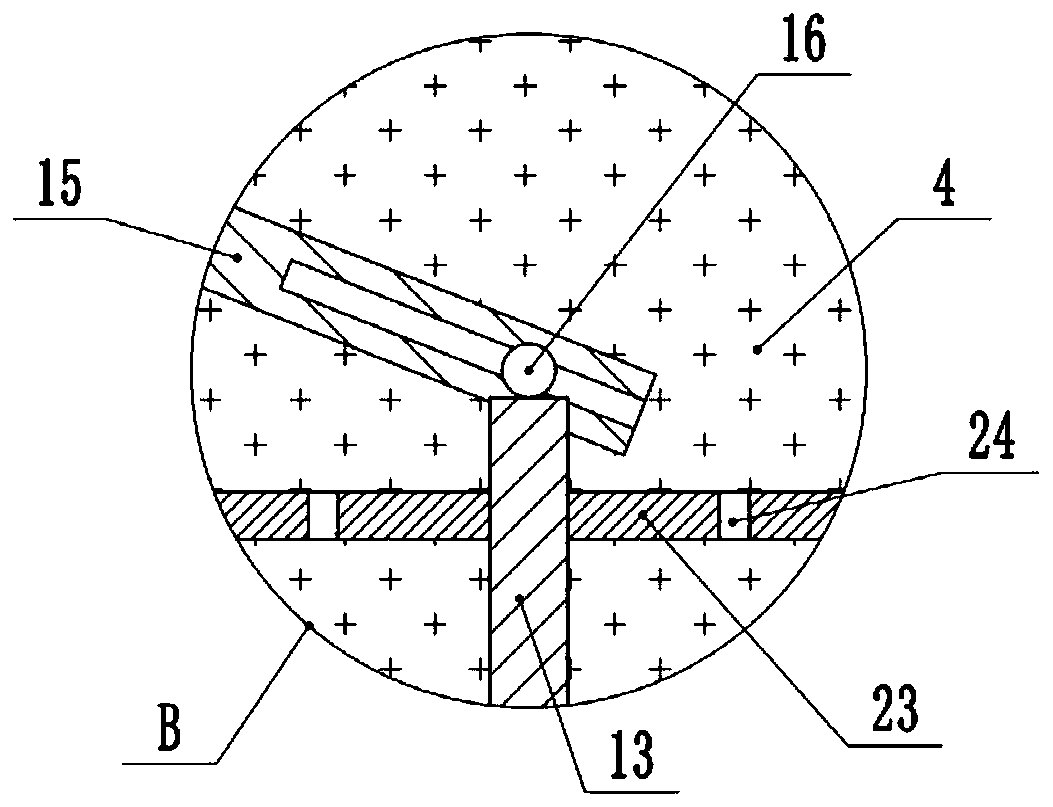

[0036] Embodiment one is basically as figure 1 , figure 2 with image 3 As shown, the liquid material automatic metering machine includes a support frame 1, and the support frame 1 is fixedly connected with a storage bin 2 and a metering bin 3 by screws from top to bottom in turn, and a liquid ingredient 4 is stored in the storage bin 2. The bin 2 communicates with the metering bin 3 through a feed pipe 5, and the bottom of the metering bin 3 is connected with a discharge port 6 for discharging.

[0037] Such as figure 1 As shown, the bottom plate 7 and the top plate 8 of the metering bin 3 are all in an inclined state of low left and high right, and the discharge port 6 is located at the low end of the left side of the bottom plate 7, and the inner wall of the bottom plate 7 near the discharge port 6 is fixedly connected by screws. Pressure sensor 9, pressure sensor 9 is used for measuring the size of the pressure at the discharge port 6 places. combine figure 1 with ...

Embodiment 2

[0052] Such as Figure 4 As shown, the difference between Embodiment 2 and Embodiment 1 is that a temporary storage bin 27 is connected to the bottom of the discharge port 6, and each time the metering bin 3 completes a metering work, all liquid ingredients 4 are discharged to the temporary storage bin 27 for further processing. Temporary storage, when it is necessary to put the liquid ingredients 4 in the mixer, when it is necessary to discharge the liquid ingredients 4 in the metering chamber 3 to the mixer, there is no need to wait for the liquid ingredients 4 in the metering chamber 3 to gradually flow down into the mixer, but directly open the temporary The storage bin 27 allows the liquid ingredients 4 inside the temporary storage bin 27 to be discharged to the mixer at one time, thereby reducing the time for the liquid ingredients 4 to be discharged from the metering bin 3 to the mixer, and improving feeding efficiency.

[0053] Simultaneously, in order to ensure stable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com