Patents

Literature

73results about How to "Improve metering efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

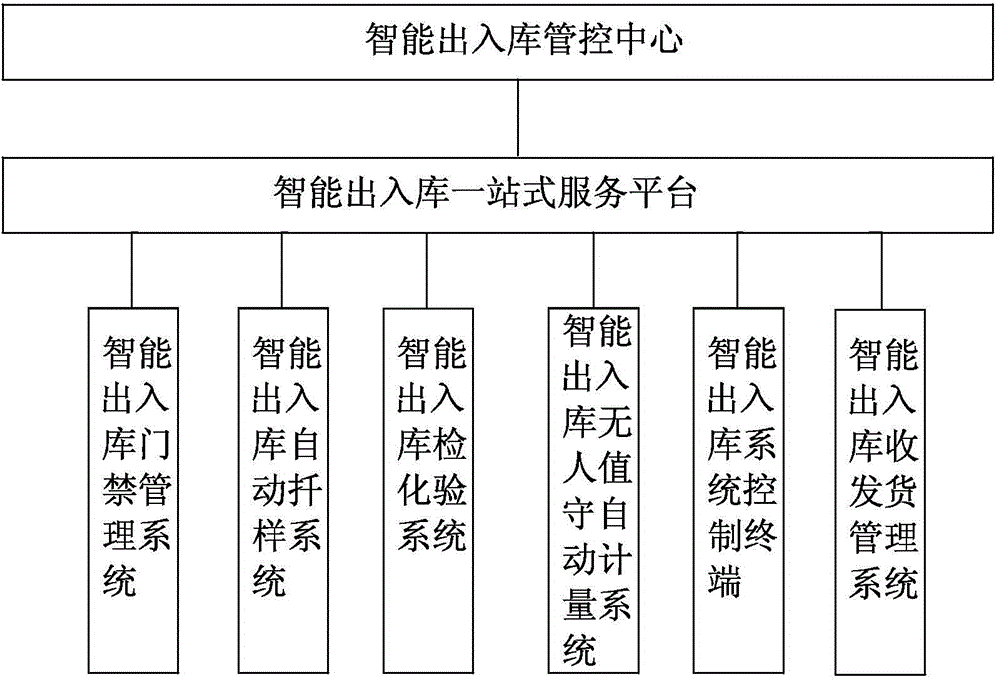

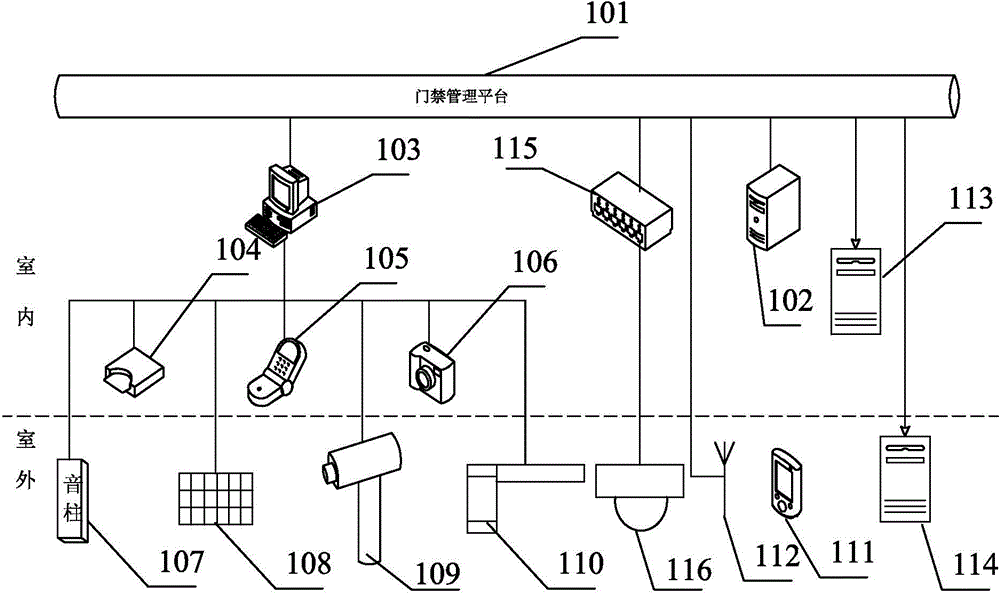

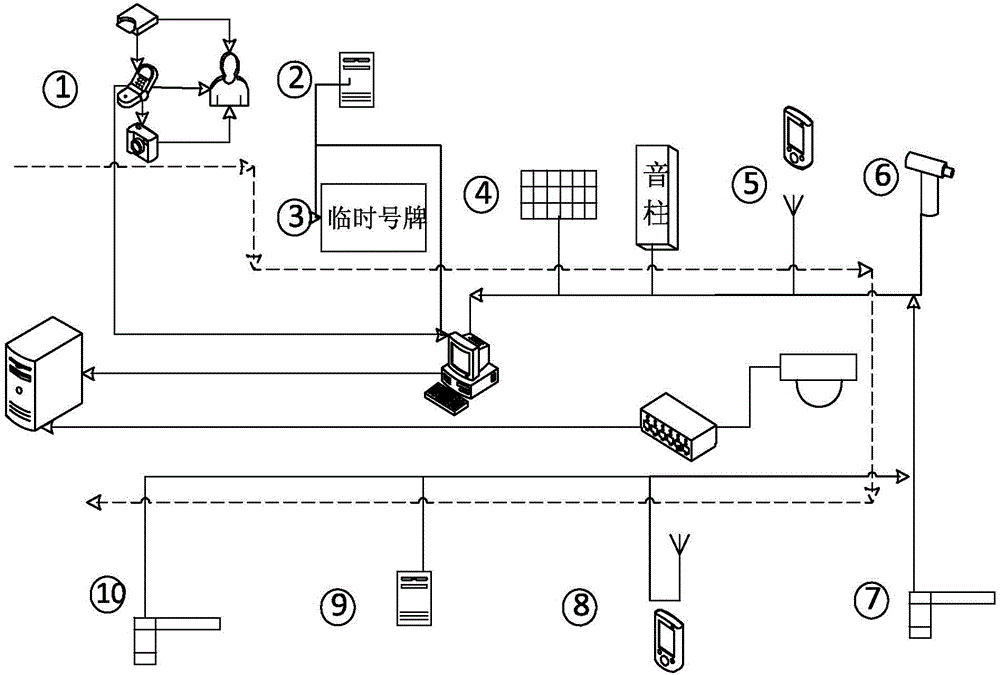

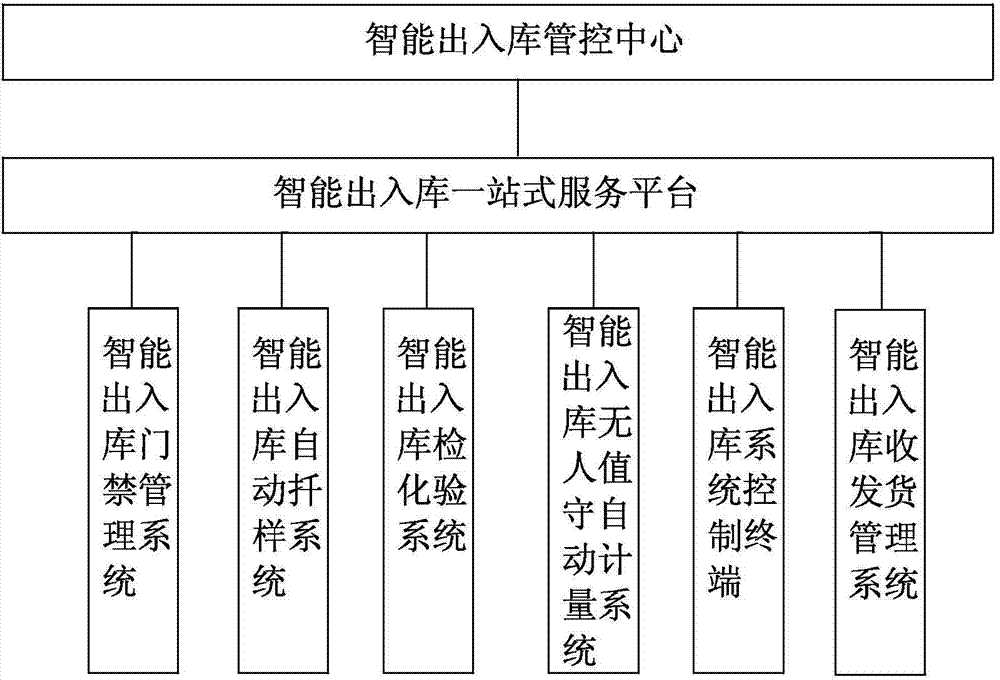

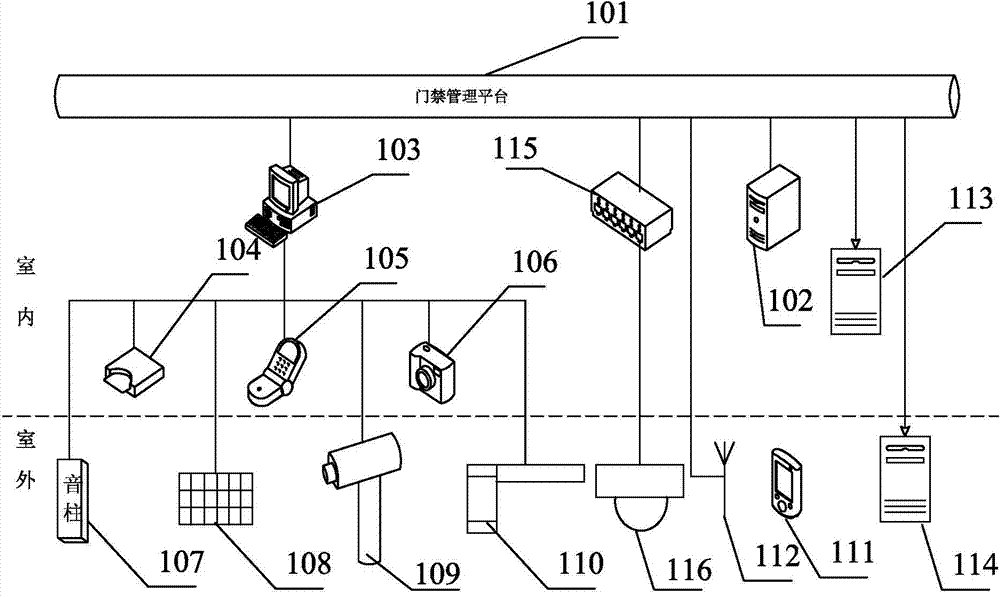

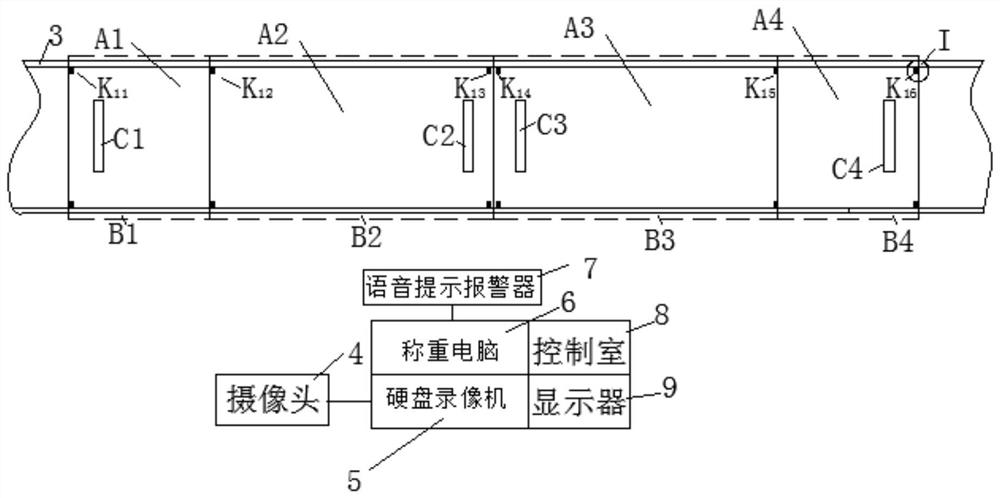

Intelligent depot output-input system of digital grain depot

ActiveCN103559605ASimplify business processesRealize paperless managementIndividual entry/exit registersLogisticsIntelligent managementComputer science

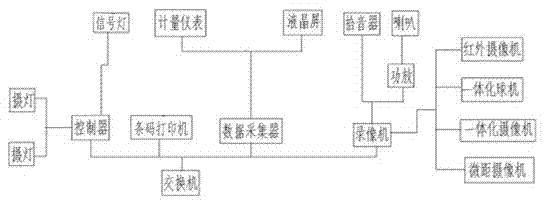

The invention discloses an intelligent depot output-input system of a digital grain depot. The intelligent depot output-input system of the digital gain depot comprises an intelligent depot output-input access control system, an intelligent depot output-input automatic sampling system, an intelligent depot output-input examination assay system, an intelligent depot output-input unattended operation automatic metering system, an intelligent depot output-input system control terminal, an intelligent depot output-input goods receiving-sending management system, an intelligent depot output-input system one-stop service platform and an intelligent depot output-input system control center. The intelligent depot output-input access control system, the intelligent depot output-input automatic sampling system, the intelligent depot output-input examination assay system, the intelligent depot output-input unattended operation automatic metering system, the intelligent depot output-input system control terminal, the intelligent depot output-input goods receiving-sending management system and the intelligent depot output-input system control center are connected with the intelligent depot output-input system one-stop service platform. According to the intelligent depot output-input system of the digital grain depot, a computer, the RFID internet of things technology, the communication technology and the information technology are converged together, networking, automation and intelligent management of the depot output and input are achieved, and labor participation is reduced.

Owner:JINAN JINZHONG ELECTRONICS SCALE +1

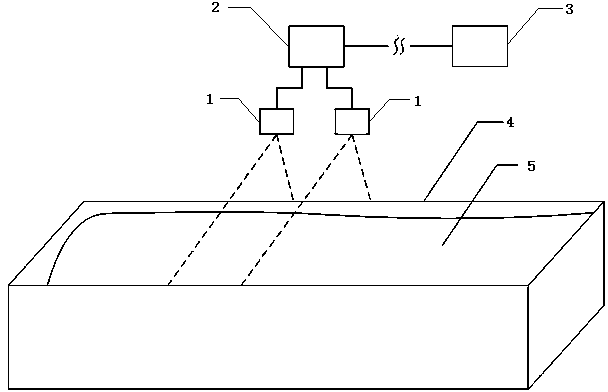

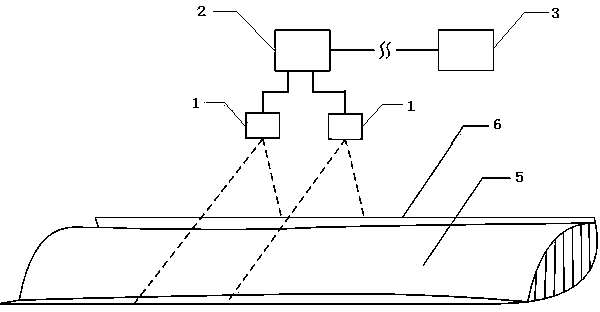

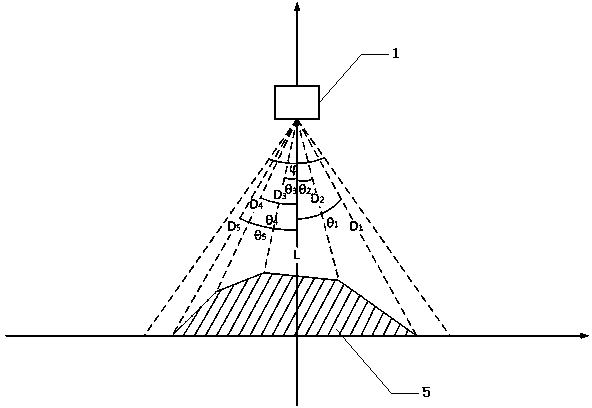

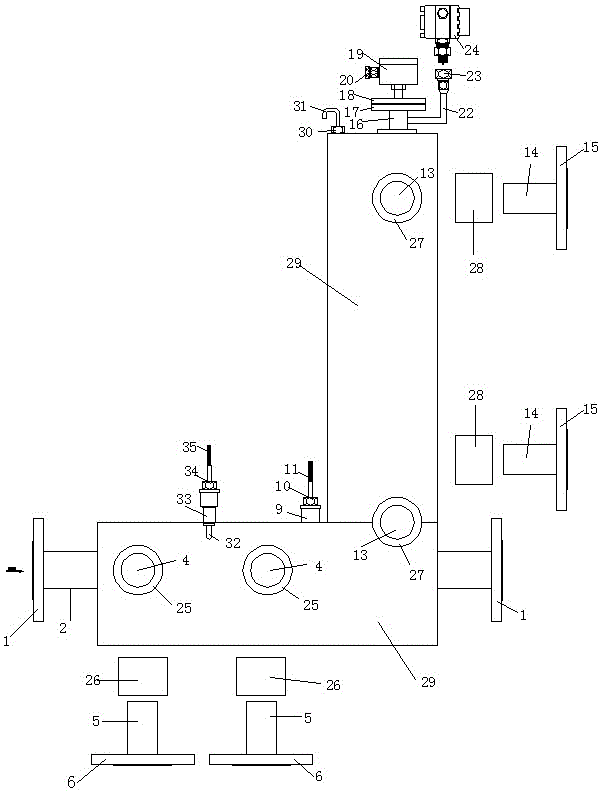

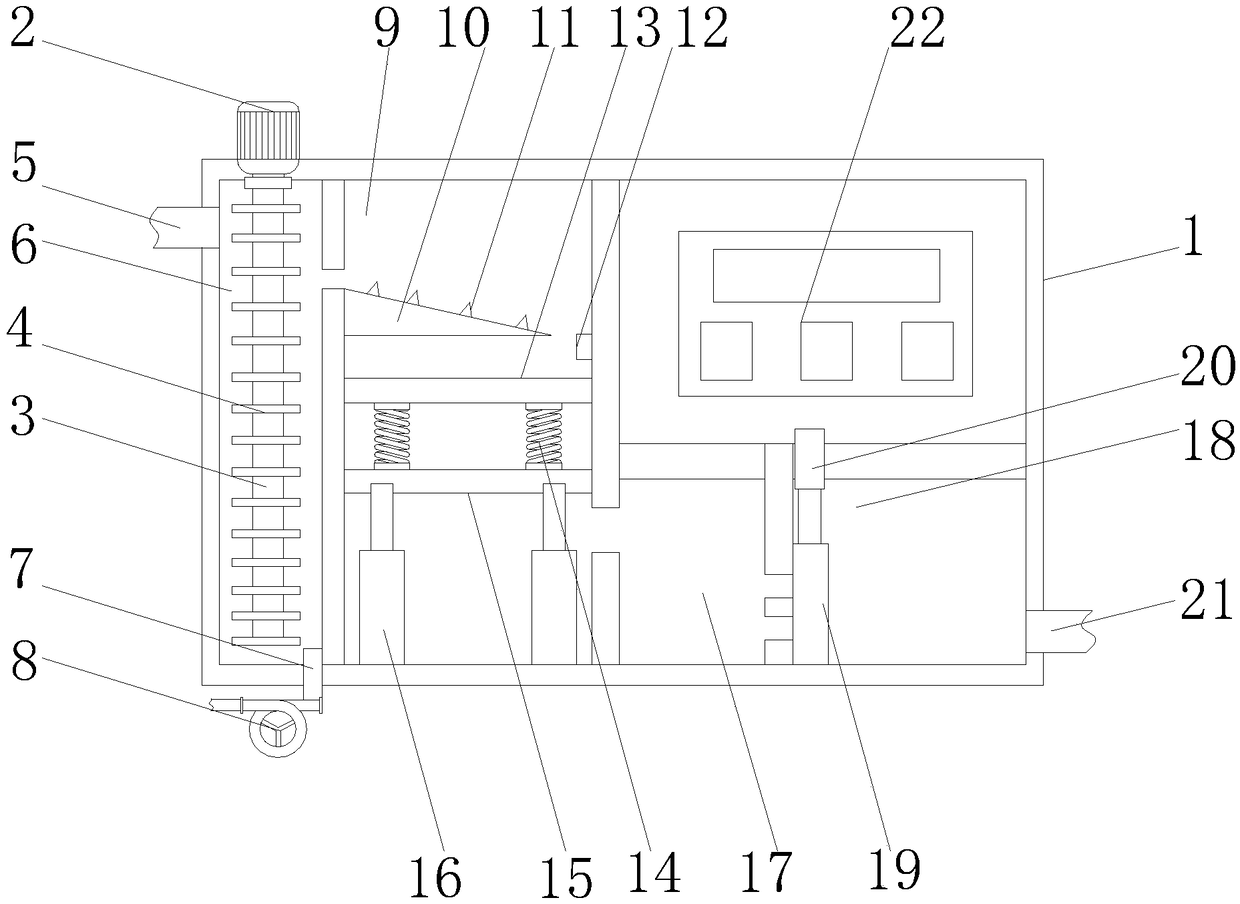

Movable material stack automatic metering system

InactiveCN104019873AHigh measurement accuracyImprove metering efficiencyWeighing apparatus for continuous material flowLaser rangingData acquisition

The invention relates to a movable material stack automatic metering system which comprises two high-speed laser ranging scanners which are installed right above the center line of a measured material stack. The installation height is the width that enables the scanning cross-section to completely cover a carrier of the material stack. The high-speed laser ranging scanners are also connected through an equipment control and data acquisition unit to a background computer provided with calculation programs. The system is reasonably designed, is convenient to install and simple to operate, can be used to ceaselessly detect a measured object, will not be contacted with the measured object, and will not interfere with or get involved in user normal business processes. Measurement accuracy and measurement efficiency are raised. Meanwhile, equipment quantity also can be reduced, and maintenance cost can be lowered.

Owner:NANJING LUOLIAN MEASUREMENT & CONTROL TECH

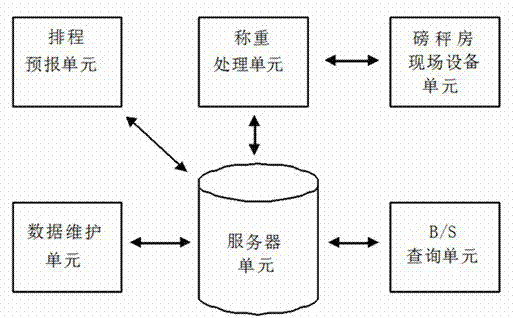

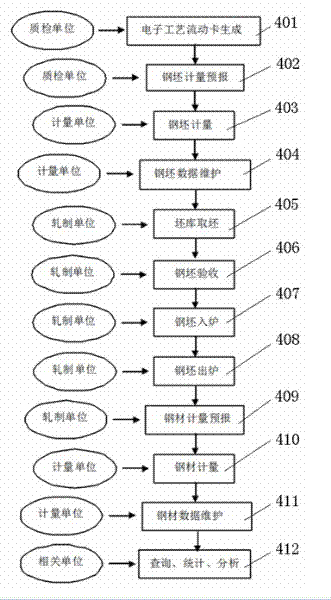

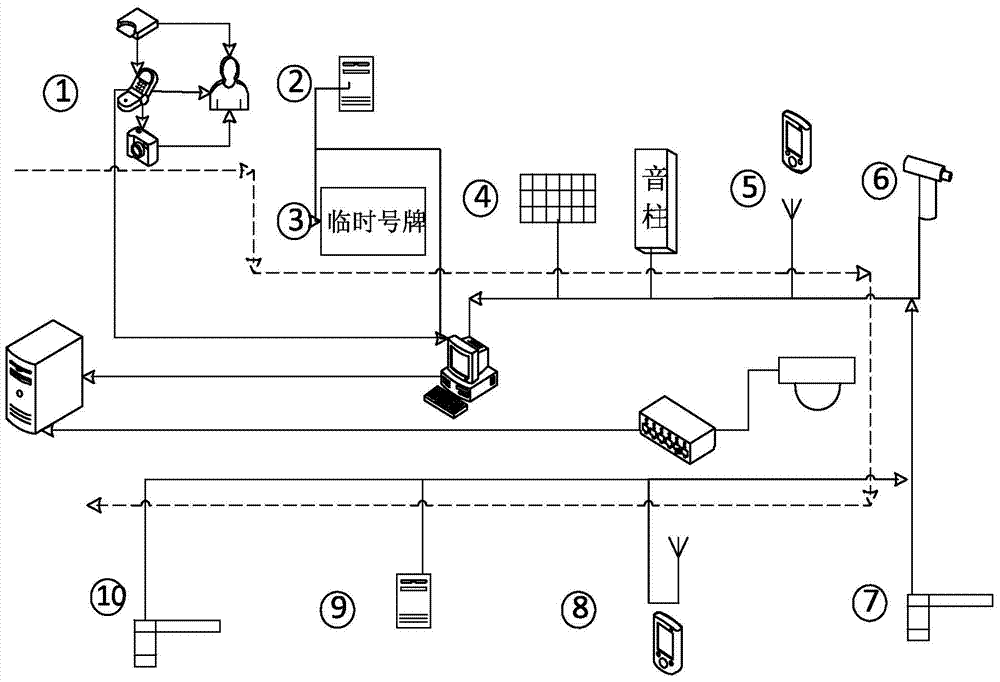

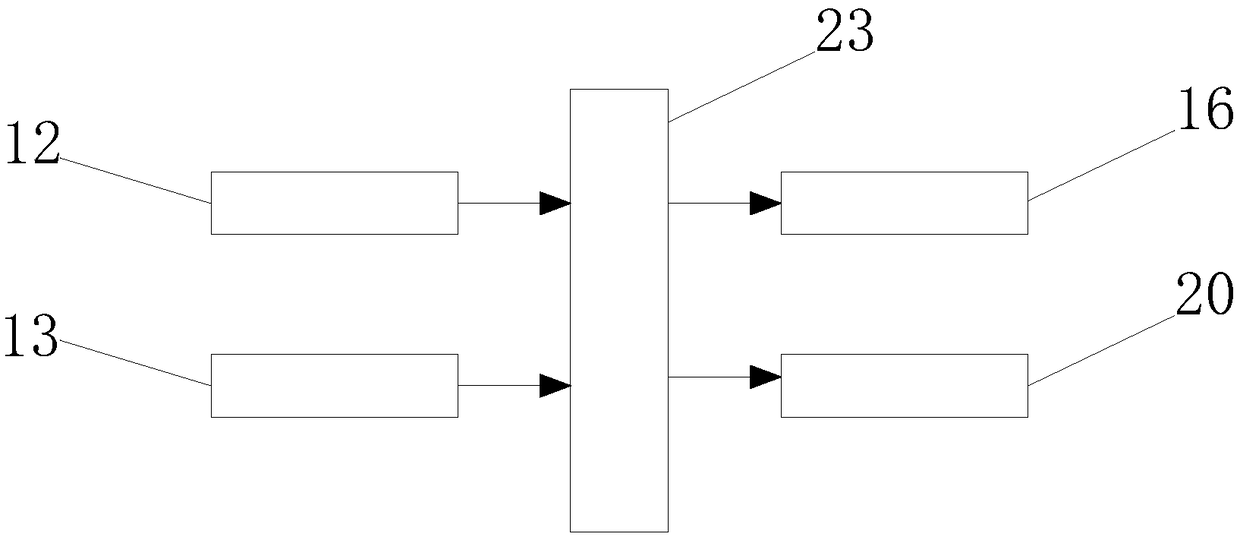

Unattended remote automatic measuring system for steel billets and steel products, and method of the same

ActiveCN102496093AImprove metering efficiencyIncrease productivityLogisticsData transmissionEngineering

The invention discloses an unattended remote automatic measuring system for steel billets and steel products, particularly relates to an on-site unattended weighing measurement system for weighing the steel billets and the steel products on the scales. The unattended remote automatic measuring system is composed of a schedule forecasting unit, a weighing unit, a scale room field apparatus, a data maintaining unit, a B / S inquiry unit and a server unit, and has the functions of schedule forecasting, multi-scale integration, automatic measuring, remote label printing, voice intercom and the like; the scale room filed apparatus unit is connected with the weighing unit, and the weighing unit, the schedule forecasting unit, the data maintaining unit and the B / S inquiry unit are respectively in data transmission connection with the server unit. In the aspect of flow path, the system of the invention is not limited to implementation of pure measuring function, but implements unattended remote automatic measuring for the steel billets and the steel products and control and tracking on the whole flow from the steel billets to the steel products by converting paper bills, such as a technology moving card and the like, into electronic bills, so that level of informatization is improved greatly, and support for scientific management is provided.

Owner:WUKUN STEEL

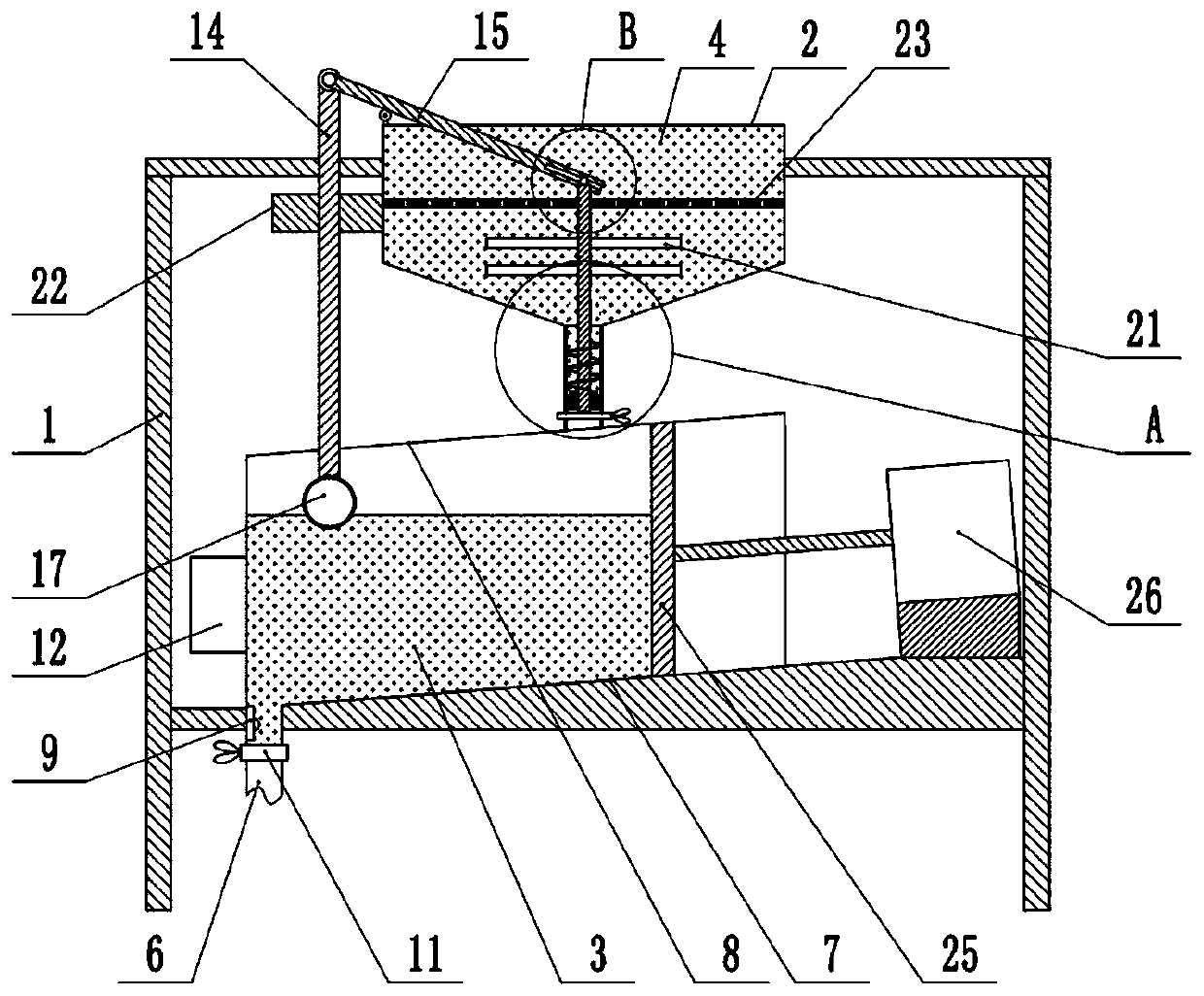

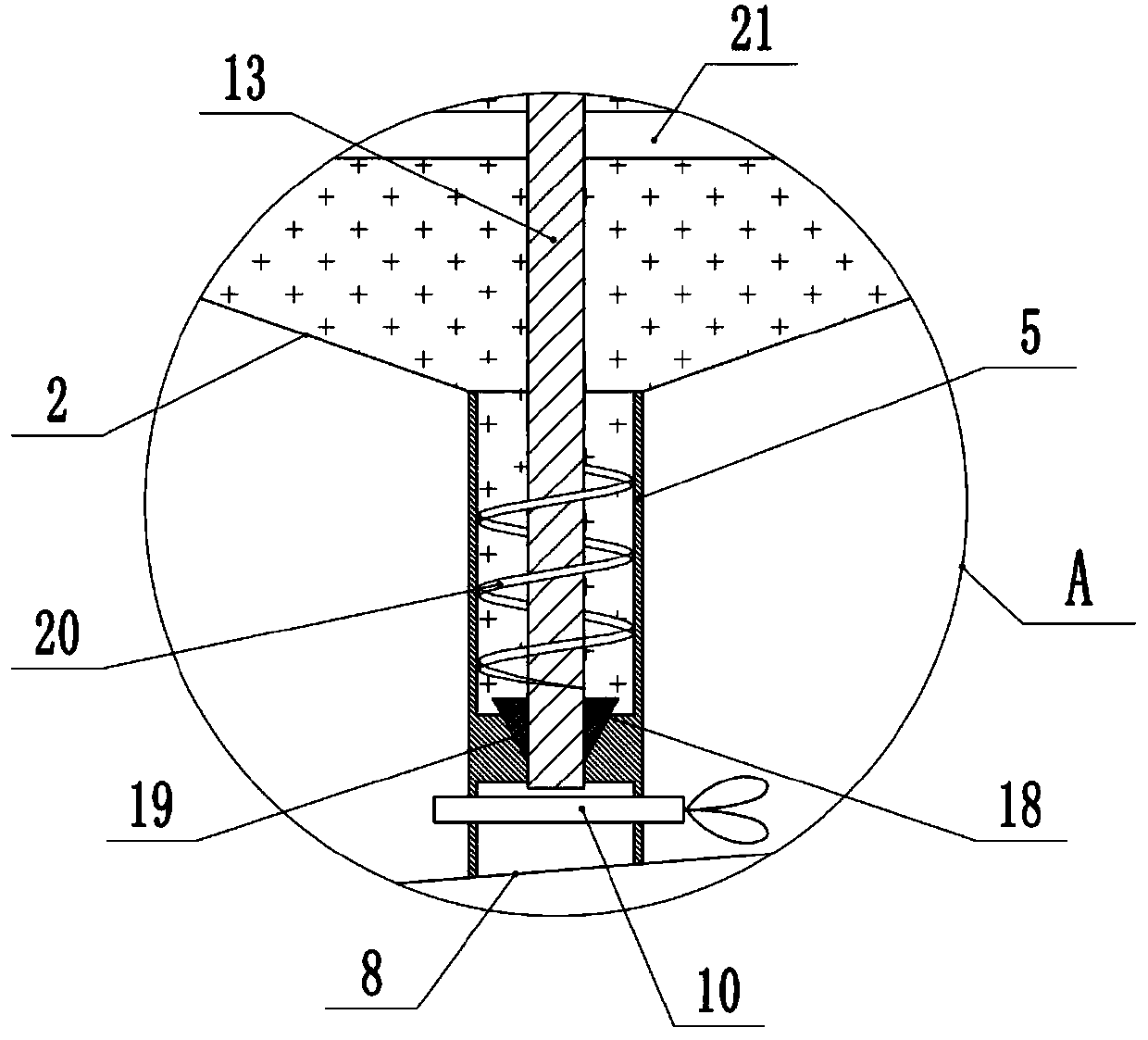

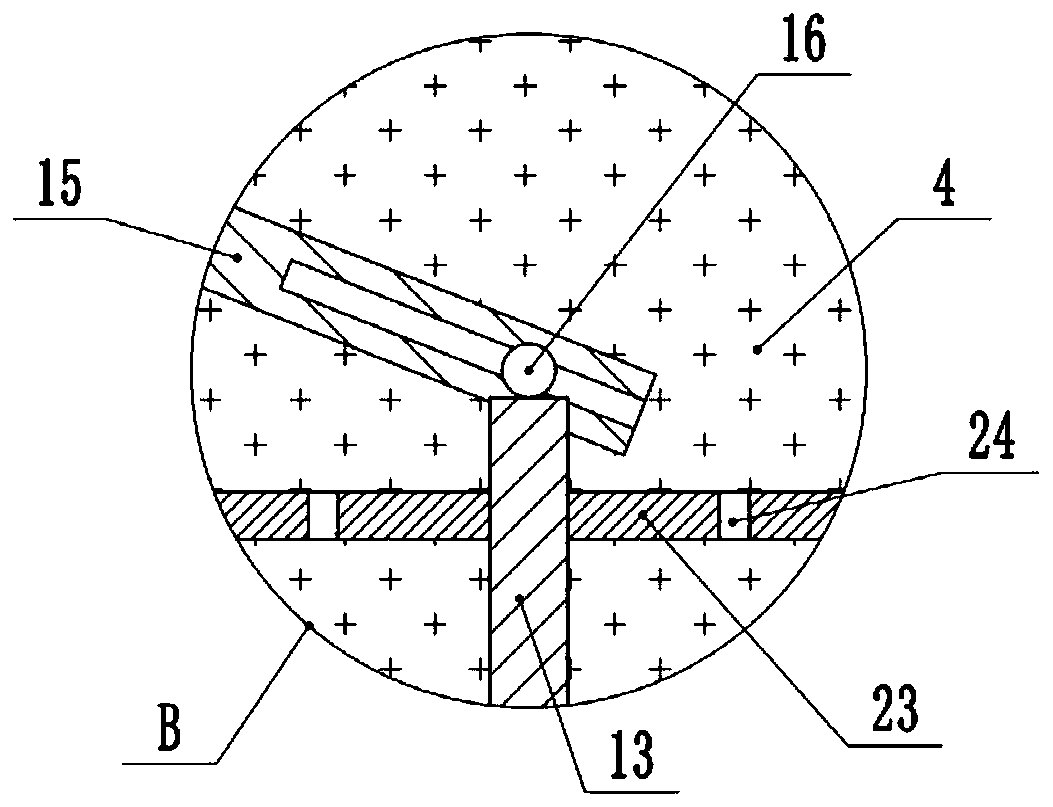

Automatic liquid material metering machine

The invention relates to the technical field of plastic particle processing, in particular to an automatic liquid material metering machine. The automatic liquid material metering machine comprises asupporting frame, wherein a storage bin and an electric cabinet are fixedly connected to the supporting frame; a metering bin is connected below the storage bin through a feeding pipe, and a discharging pipe is arranged at the bottom of the metering bin; a pressure sensor is fixedly connected to the inner bottom end of the metering bin; a feeding electromagnetic valve for controlling feeding is arranged on the feeding pipe; a discharging electromagnetic valve for controlling discharging is arranged on the discharging pipe; the feeding electromagnetic valve, the discharging electromagnetic valve and the pressure sensor are all electrically connected with the electric cabinet; and a flow controller for controlling the feeding speed of the feeding pipe is arranged in the feeding pipe. According to the automatic liquid material metering machine, the weight of liquid ingredients in the metering bin is accurately detected through the pressure sensor, and after the weight of the liquid ingredients reaches a preset value, the metering bin automatically stops feeding and the metered liquid ingredients are fed into a stirrer to be mixed with raw materials, so that the problems that manual weighing of the liquid ingredients is inaccurate and high in labor intensity are solved.

Owner:CHONGQING JINGBANG HIGH MOLECULAR MATERIAL CO LTD

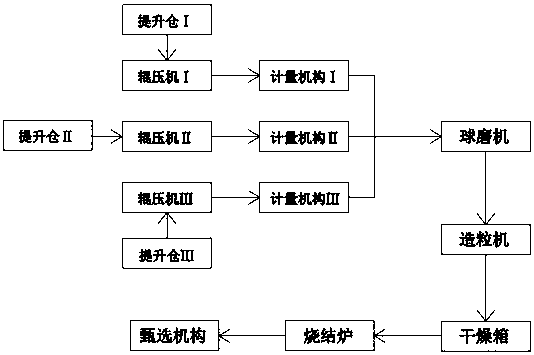

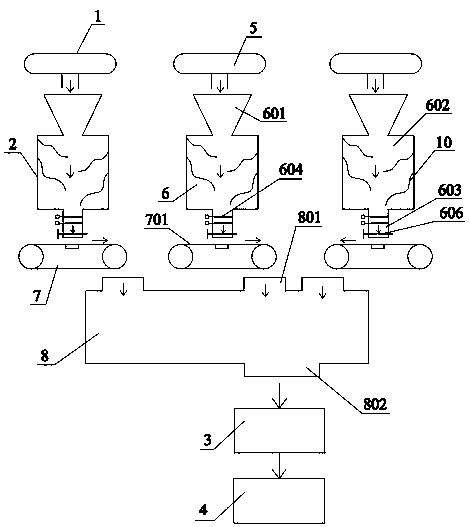

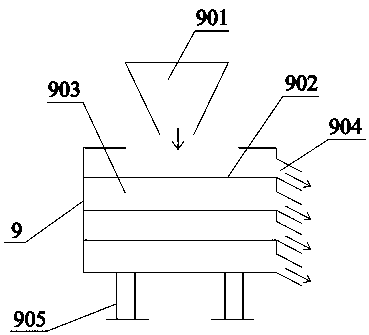

Aggregate production intelligent control system and method

ActiveCN108483962ARealize automatic adjustment controlPlay the role of buffer diversionSievingScreeningEngineeringControl valves

The invention provides an aggregate production intelligent control system and method. The aggregate production intelligent control system comprises a grinding mechanism, a metering mechanism, a molding sintering mechanism, a screening mechanism and a control system; the grinding mechanism comprises a lifting compartment, a rolling machine and a ball mill; the metering mechanism comprises a cone feeding pipe, a storage box, a material guiding pipe and belt scale; a flow dividing plate is arranged in the material guiding pipe, a control valve is arranged at the lower end, the feeding port of theball mill is connected with the discharging end of the belt scale, the discharging port is communicated with the molding sintering mechanism, and the molding sintering mechanism comprises a pelletizer, a drying box and a sintering furnace; the screening mechanism comprises a vibration screening box and a feeding hopper, a screening plate is arranged in the vibration screening box, and a hydrauliccolumn is arranged below the screening plate; and a processor of the control system receives the signals emitted by a temperature sensor I and a temperature sensor II, a weighing sensor I and a weighing sensor II and a velocity sensor on single machine equipment through a communication module, and processes and sends commands. By combining the single machine equipment with intelligent control, automation of the production process is achieved, and the failure processing capability and production efficiency are improved effectively.

Owner:洛阳大华智能科技有限公司

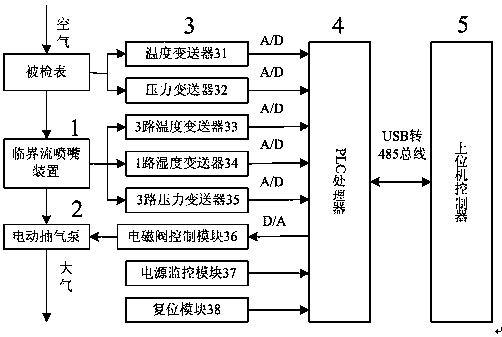

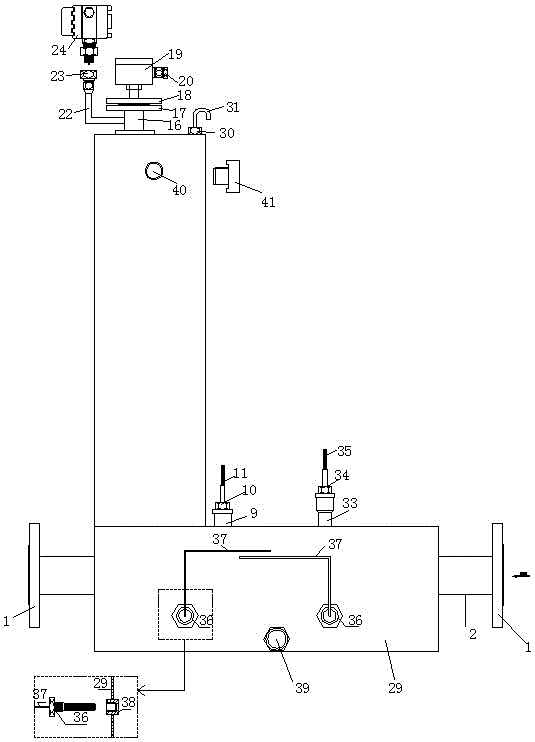

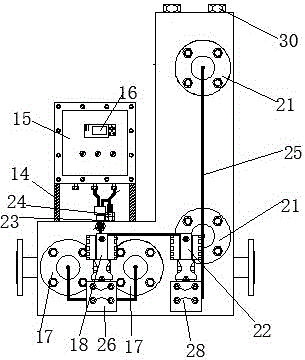

Natural gas flowmeter verification system

InactiveCN107677342AImprove metering accuracyImprove metering efficiencyTesting/calibration apparatusSpray nozzleEngineering

The invention provides a natural gas flowmeter verification system. A critical flow nozzle device is a measurement standard device, and transmits a measured value to a module combination. An electricsucking pump provides a gas source, and extracts gas of a stagnation container, to make the container have certain vacuum degree. The module combination acquires temperature, pressure, and humidityof the position of the stagnation container, and temperature and pressure of the position of a natural gas flowmeter examined meter, and transmits signals to a PLC processor to process and takes partin flow error calculation. The PLC processor transmits processed temperature, pressure, and humidity values, and a corrected measured value of the critical flow nozzle device to an upper computer controller. The upper computer controller displays information transmitted by the PLC processor. The natural gas flowmeter verification system is flexible and universal, and is advantaged by high reliability, good anti-interference capability, simple use, good function, and small volume.

Owner:CHINA PETROLEUM & CHEM CORP +1

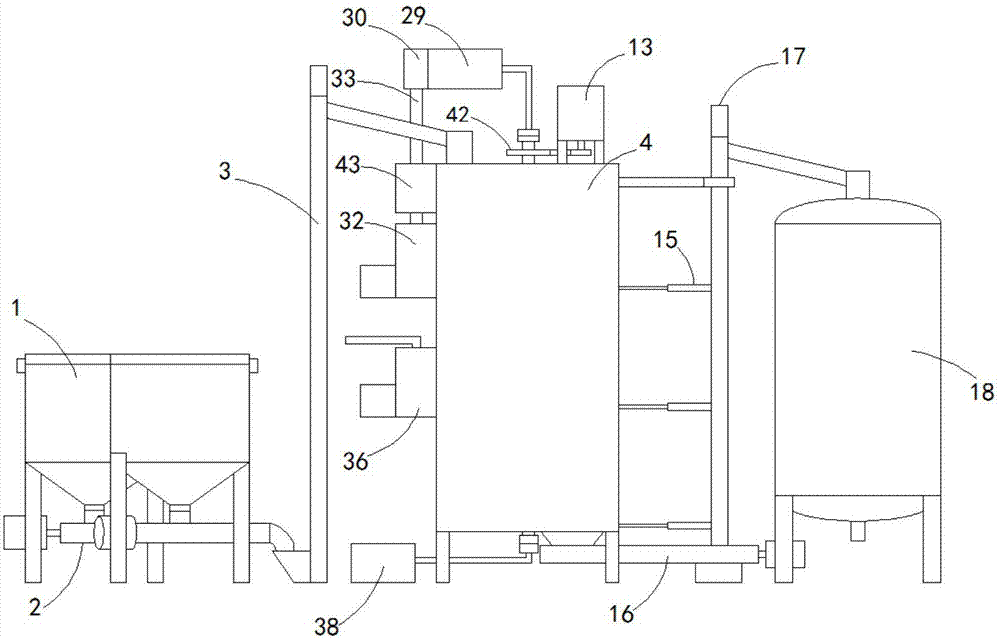

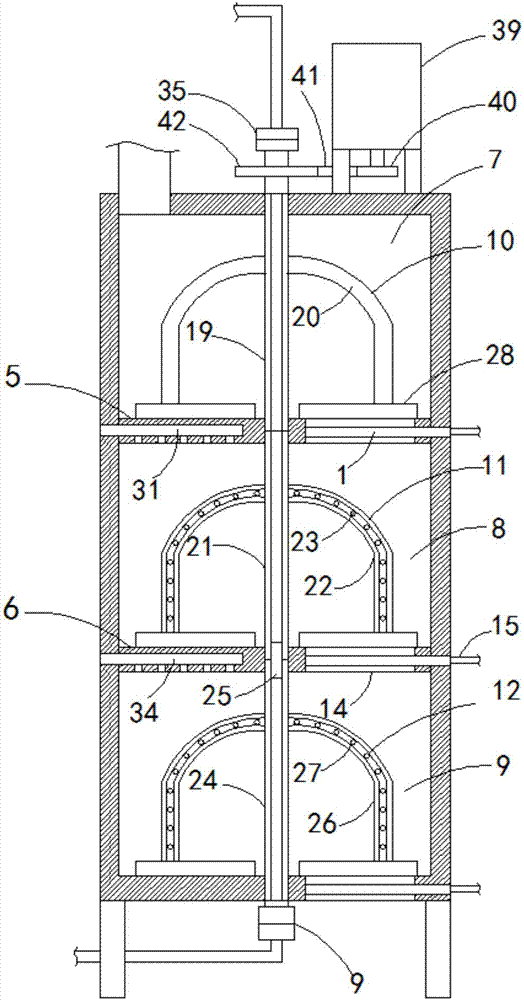

PVC profile raw material automatic metering, mixing, conveying, storing and feeding process

The invention belongs to the technical field of PVC production and machining, and particularly relates to a PVC profile raw material automatic metering, mixing, conveying, storing and feeding process.The process comprises a metering procedure, a mixing procedure and a conveying storage procedure; the metering procedure comprises multiple raw material bins, the discharging ends of the raw materialbins are connected with a spiral constant weight feeder, the spiral constant weight feeder is connected with a mixing tank in the mixing procedure through a first vertical lifting machine, the interior of the mixing tank is sequentially divided into a pre-stirring chamber, a heating stirring chamber and a cooling stirring chamber from top to bottom through a first partition board and a second partition board, a first stirring mechanism, a second stirring mechanism and a third stirring mechanism are arranged in the pre-stirring chamber, the heating stirring chamber and a cooling stirring chamber, in the conveying storage procedure, a spiral conveyor connected with an opening in the bottom face of the mixing tank is included, and the discharging end of the spiral conveyor is connected withthe storage tank through a second vertical lifting machine. The process has the beneficial effects that the PVC profile raw material production and machining efficiency is improved, and the productionand machining cost is reduced.

Owner:新疆志成兴管业有限公司

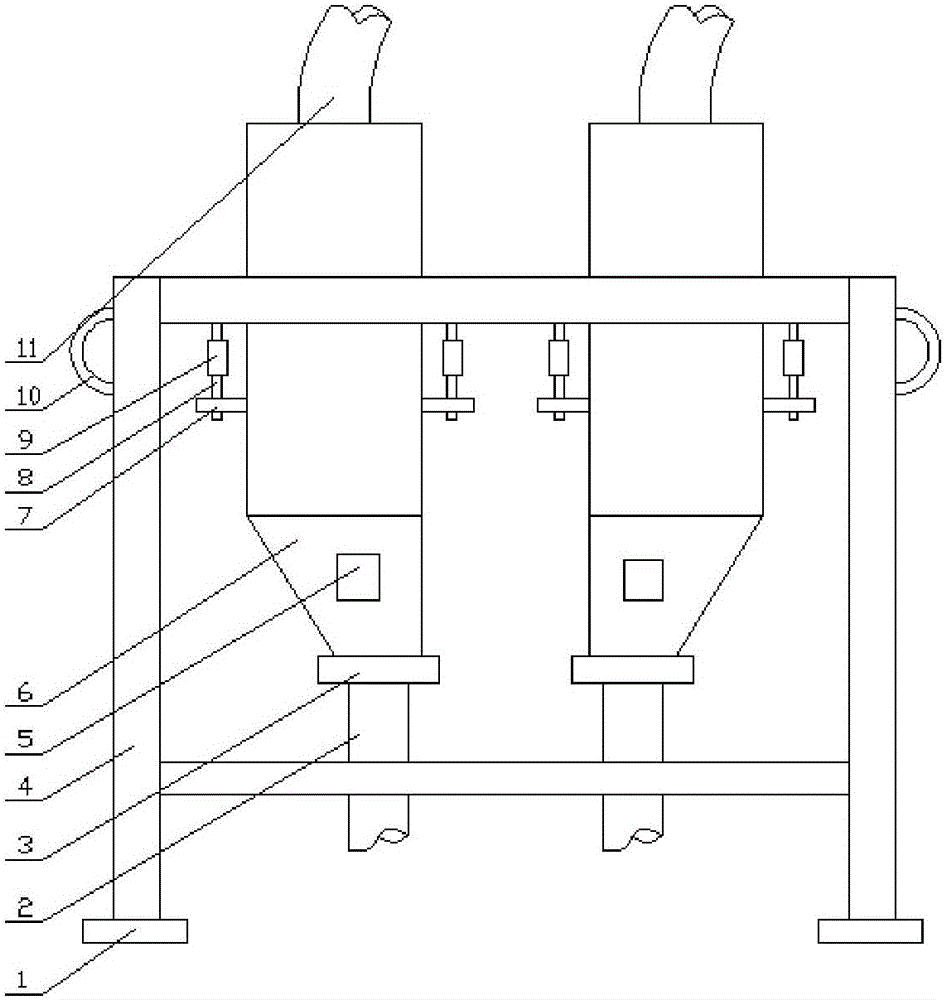

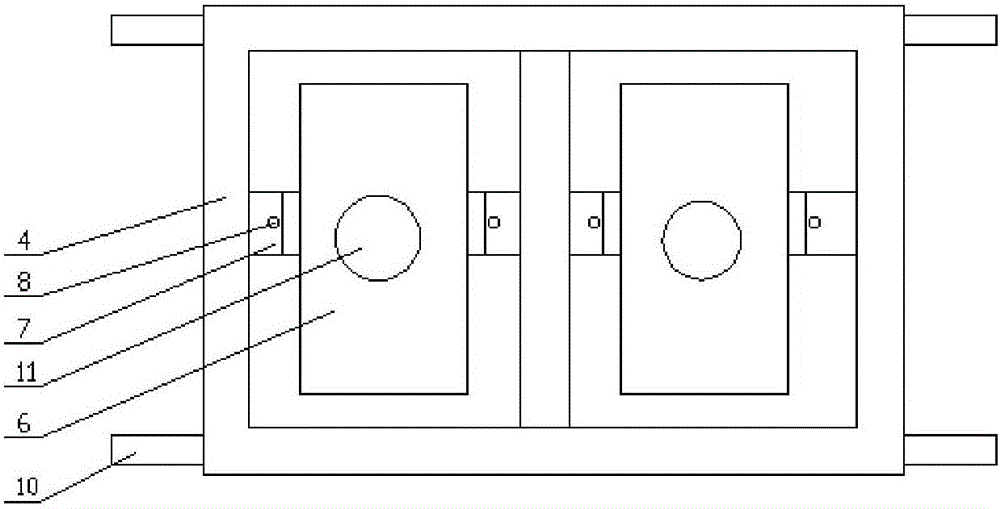

Automatic weighing type main material discharging device

The invention discloses an automatic weighing type main material discharging device. The automatic weighing type main material discharging device comprises a material collecting bin. The bottom of the material collecting bin is fixedly connected with a material collecting hopper. A discharging port is formed in the bottom of the material collecting hopper and provided with a discharging valve capable of controlling opening and closing of the discharging port. A vacuum feeder is arranged on the top of the material collecting bin and can convey main materials in a main material storage tank into the material collecting bin. The material collecting bin is arranged on the rack in a supporting manner, and at least two weighing sensors are arranged between the material collecting bin and the rack. The automatic weighing type main material discharging device has the beneficial effects that the vacuum feeder is utilized for conducting feeding on the material collecting bin, and the whole process is efficient, fast and free of raise dust; after feeding in the material collecting bin is over, the weighing sensors can transmit mass signals of the main materials in the material collecting bin outwards to a controller, and therefore automatic metering of the mass of the main materials in the material collecting bin is achieved; and by means of the metering manner, accuracy can be improved, the metering efficiency is also greatly improved, and therefore the plastic profile or pipe extrusion production efficiency is improved in an assisting manner.

Owner:张家港市繁昌机械有限公司

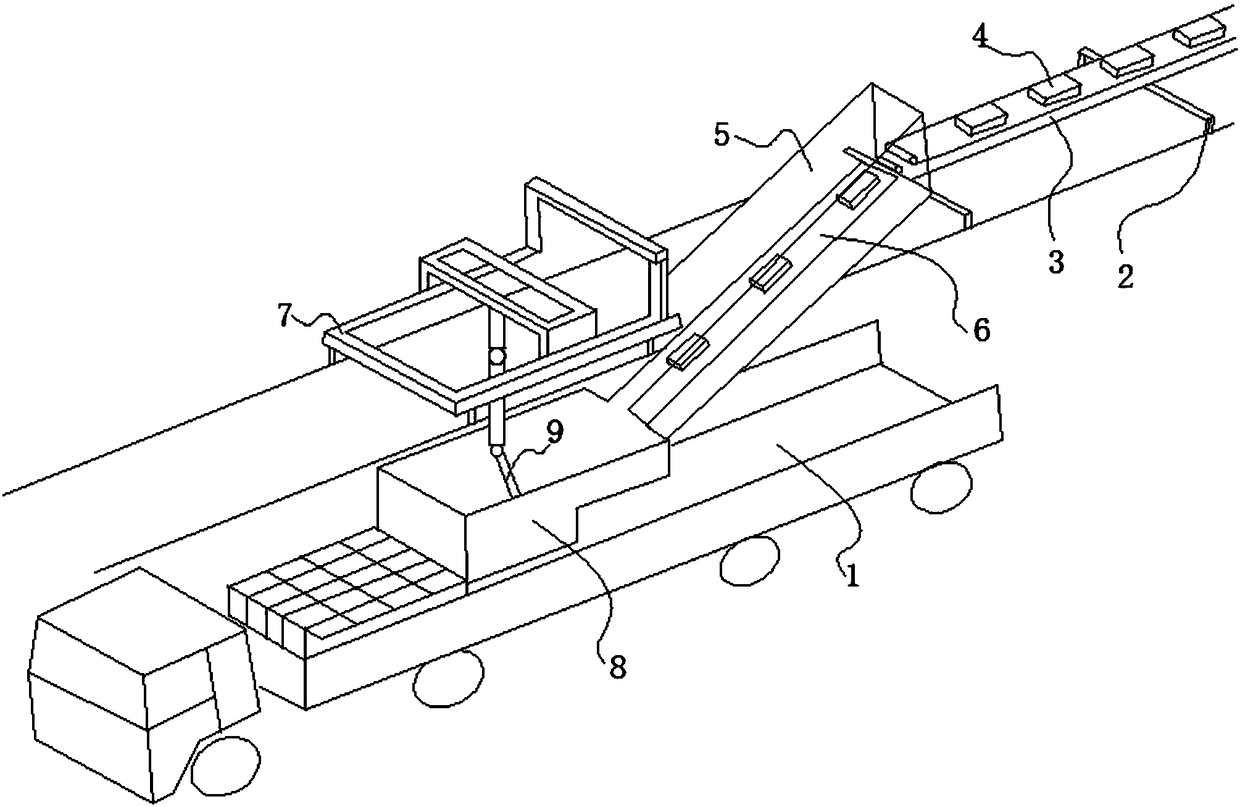

Automatic truck loading system for bagged cement

InactiveCN108190553AIncrease job securityEnsure safetyStacking articlesDe-stacking articlesEngineeringManipulator

The invention discloses an automatic truck loading system for bagged cement, and belongs to the field of automatic truck loading. The automatic truck loading system comprises a truck warehouse and further comprises a supporting frame and a conveying belt; the conveying belt is arranged on the supporting frame; an inclined conveying belt which is matched with the conveying belt for usage is arranged in front of the conveying belt; the end of the inclined conveying belt is provided with a stock bin; the bagged cement conveyed on the inclined conveying belt falls into the stock bin; a supportingseat is above the stock bin, and the middle of the supporting seat is provided with a mechanical hand. Through the automatic truck loading system for the bagged cement, the bagged cement can be automatically loaded into a truck, manual intervention is reduced, the packing, dispatching and calculating efficiency and accuracy are improved, the delivery field environment and the service quality are improved, a safe operation guarantee is provided, manual operation is reduced to the greatest extent, and the safety of staff is ensured.

Owner:ANHUI CONCH GRP +2

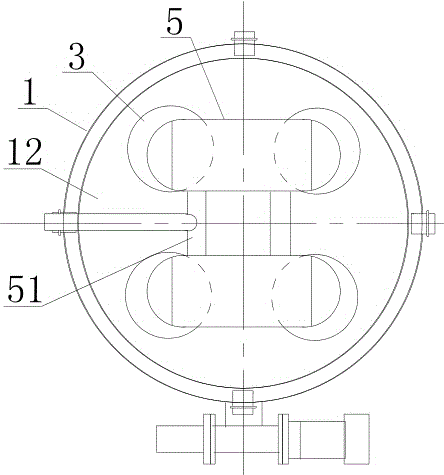

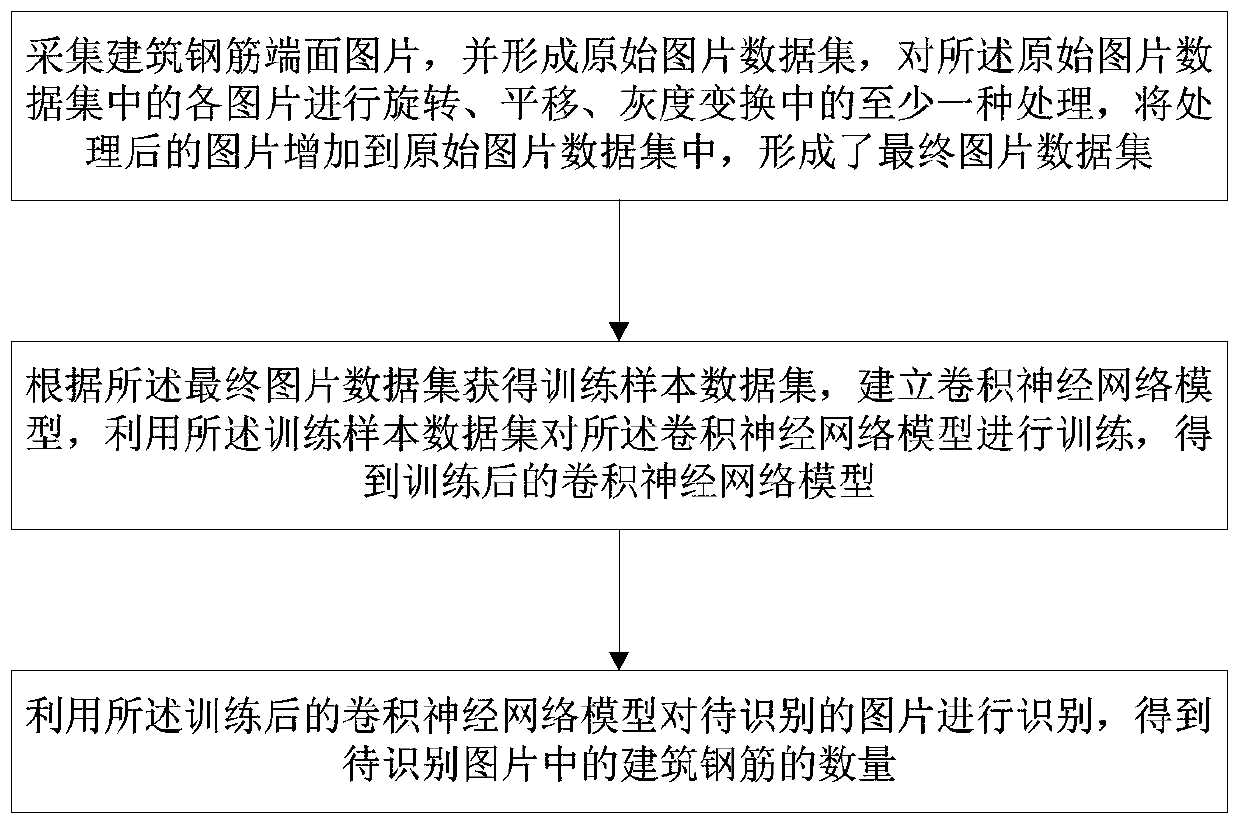

Construction steel bar intelligent recognition metering method and system

PendingCN110781755ATo achieve accurate identificationImprove metering efficiencyCharacter and pattern recognitionNeural architecturesData setAlgorithm

The invention discloses an intelligent recognition and metering method and system for construction steel bars, belongs to the technical field of construction steel bar metering, and solves the problems of relatively low construction steel bar metering accuracy and relatively low efficiency. An intelligent recognition and metering method for construction steel bars comprises the following steps that end face pictures of the construction steel bars are collected, an original picture data set is formed, at least one of rotation, translation and gray scale transformation is carried out on all thepictures in the original picture data set, and a final picture data set is formed; obtaining a training sample data set according to the final picture data set, establishing a convolutional neural network model, and training the convolutional neural network model by using the training sample data set to obtain a trained convolutional neural network model; and identifying a to-be-identified pictureby using the trained convolutional neural network model to obtain the number of the construction steel bars in the to-be-identified picture. Accurate recognition quantity of the construction steel bars is achieved, and metering efficiency of the construction steel bars is improved.

Owner:深圳中物智建科技有限公司

Flow metering system for oilfield production fluid

InactiveCN105890698AGuaranteed measurement accuracyGuarantee the safety of useVolume variation compensation/correction apparatusVolume/mass flow by differential pressureSystems designOil field

The invention discloses a flow metering system for oilfield production fluid. The flow metering system consists of a flow measurement mechanism, a compensation mechanism and a data calculation mechanism which are connected integrally. The system is very suitable for measuring liquid, such as mud, slurry, slurry oil, fuel oil, residual oil, coal tar and other fluids with high viscosity as well as suspended, easy-to-crystallize and dirty fluids, which is difficult to measure by a conventional flowmeter, to keep extremely high measurement precision and measurement stability. The metering system is novel in design and high in functionality; the difficulty in accurate metering of mixed media of oilfield production fluid, particularly medium oil / water components can be accurately metered, so that the efficiency of the metering system is improved, the investment for meters is reduced, and the demands of the metering system for various environments are met; the system is not required to be cleaned and maintained by a worker, so that human resources are saved, and the production efficiency is improved; the application prospect is considerable.

Owner:王燕

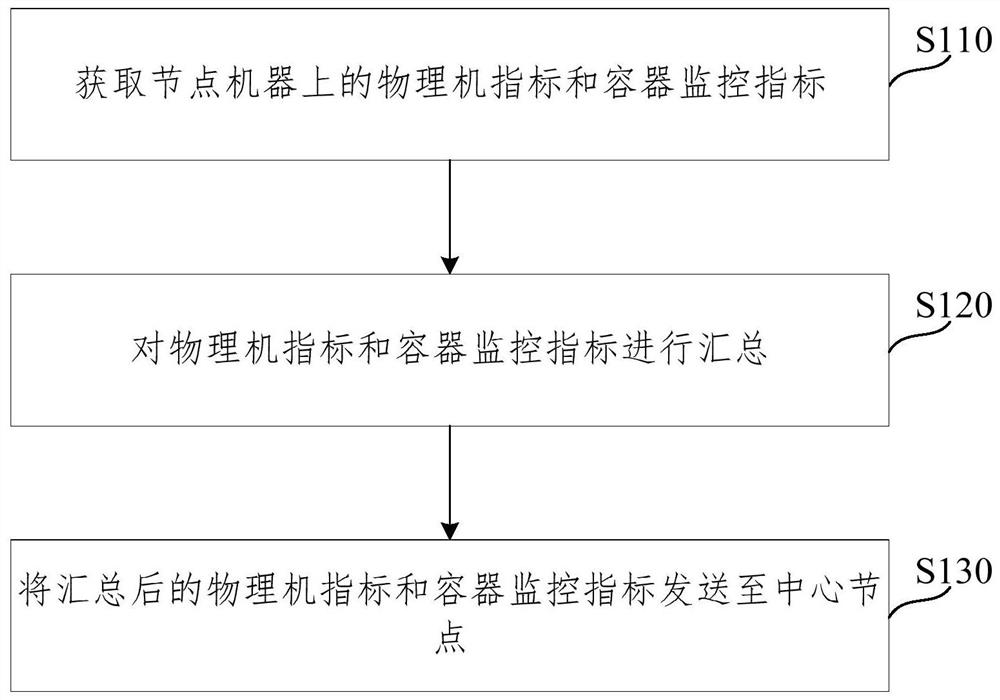

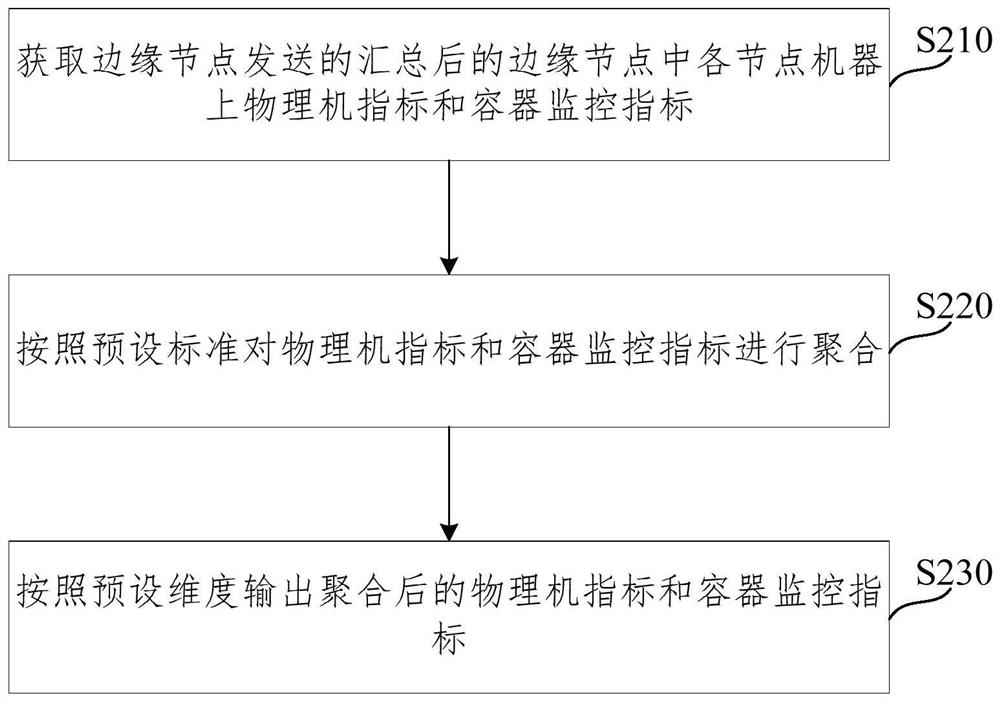

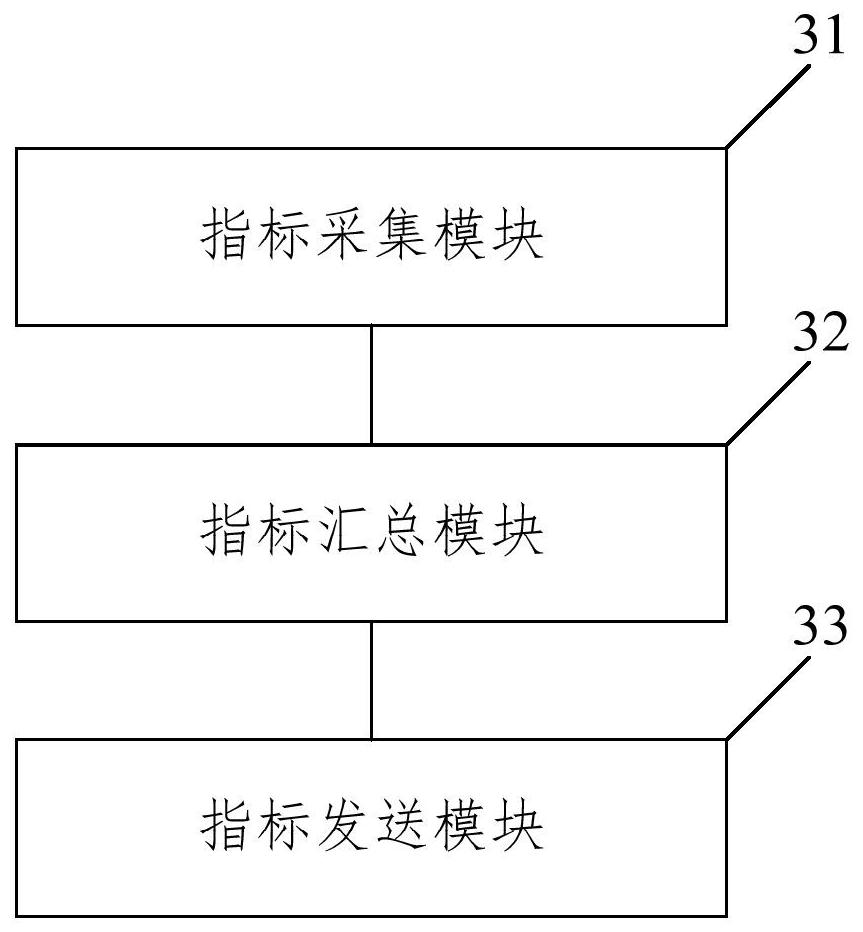

Edge node data processing method, device and system, equipment and storage medium

ActiveCN112671602AAvoid backlogAvoid delayResource allocationHardware monitoringEdge nodeComputer engineering

The invention relates to an edge node data processing method, device and system, equipment and a storage medium. The data processing method of the edge node is applied to a node machine of the edge node, and comprises the following steps: acquiring a physical machine index and a container monitoring index on the node machine; summarizing the physical machine indexes and the container monitoring indexes; and sending the summarized physical machine indexes and container monitoring indexes to a central node. According to the embodiment of the invention, independent collection of respective physical machine indexes and container monitoring indexes by each node machine at the midpoint of the edge node is realized, overstock of collection tasks is avoided, the collection efficiency of the metering indexes is improved, and the metering indexes are gathered and then sent to the central node; and the center node completes index measurement based on the physical machine indexes and the container monitoring indexes.

Owner:BEIJING KINGSOFT CLOUD NETWORK TECH CO LTD

Intelligent depot output-input system of digital grain depot

ActiveCN103559605BSimplify business processesRealize paperless managementLogisticsIntelligent managementComputer science

Owner:JINAN JINZHONG ELECTRONICS SCALE +1

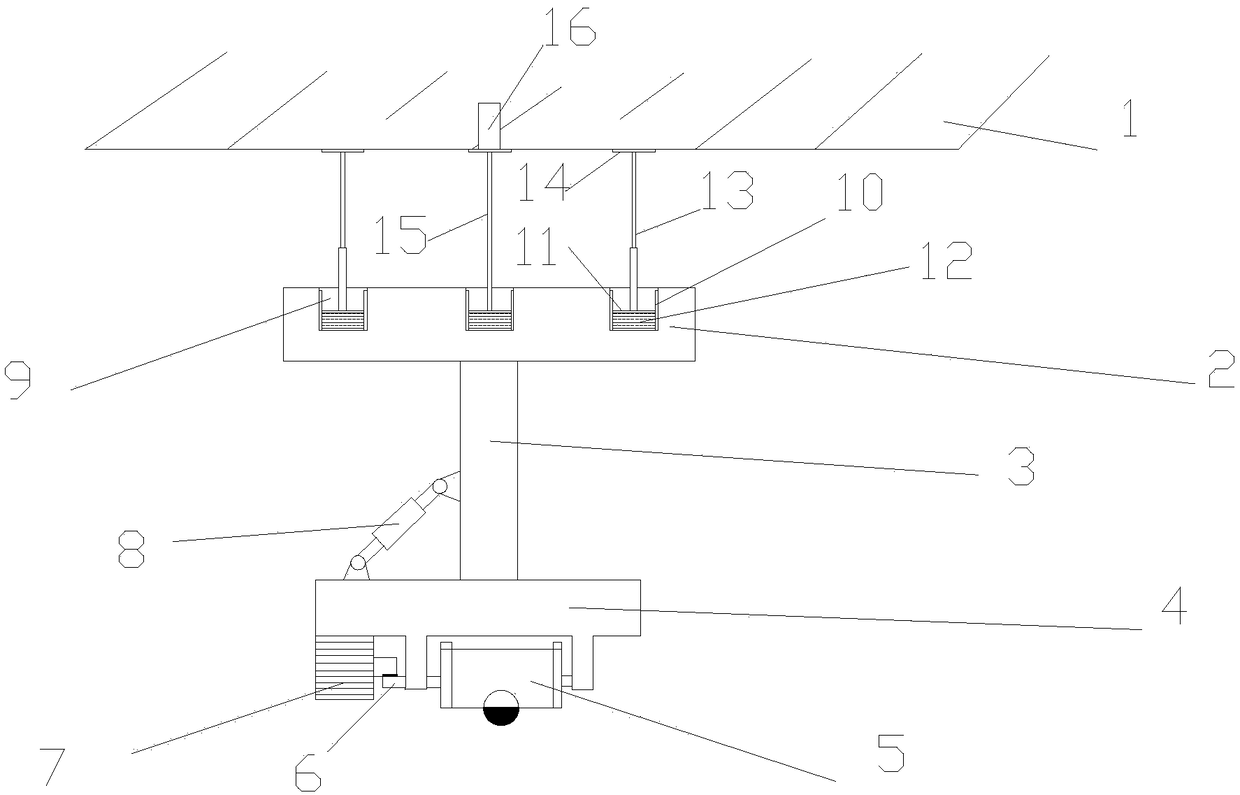

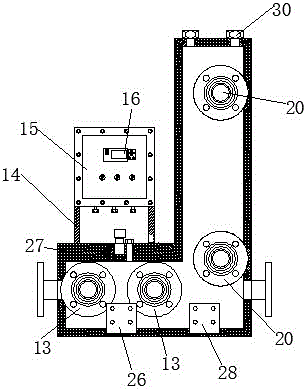

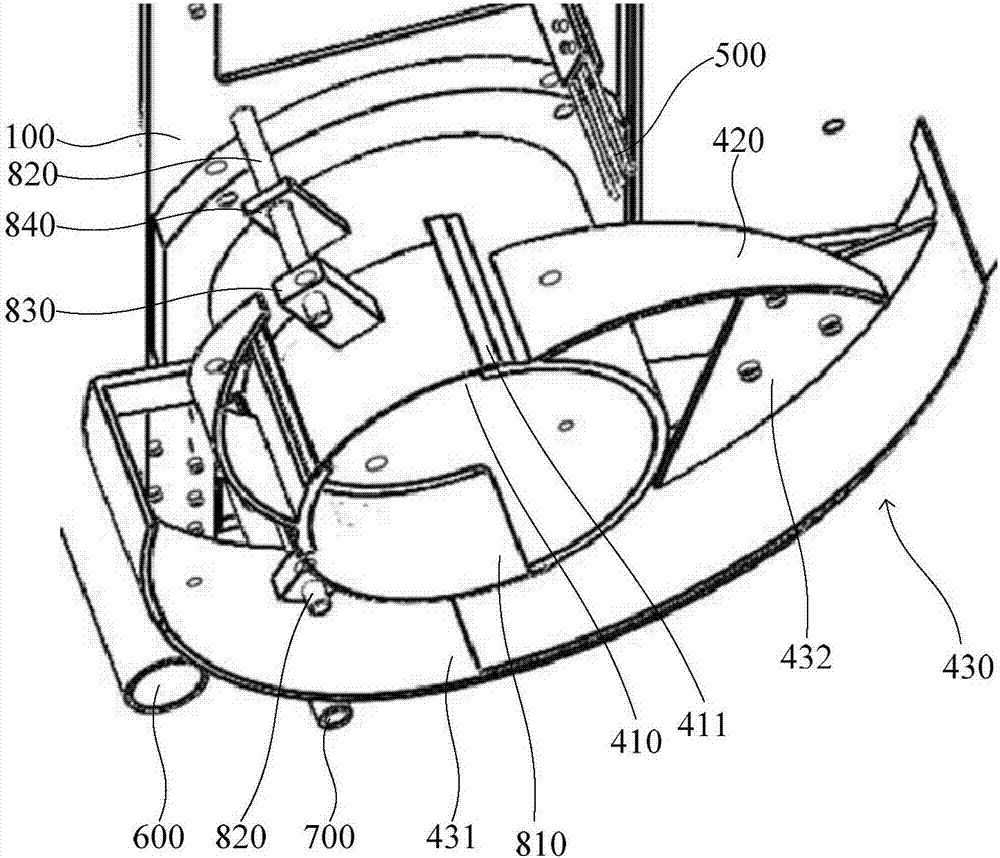

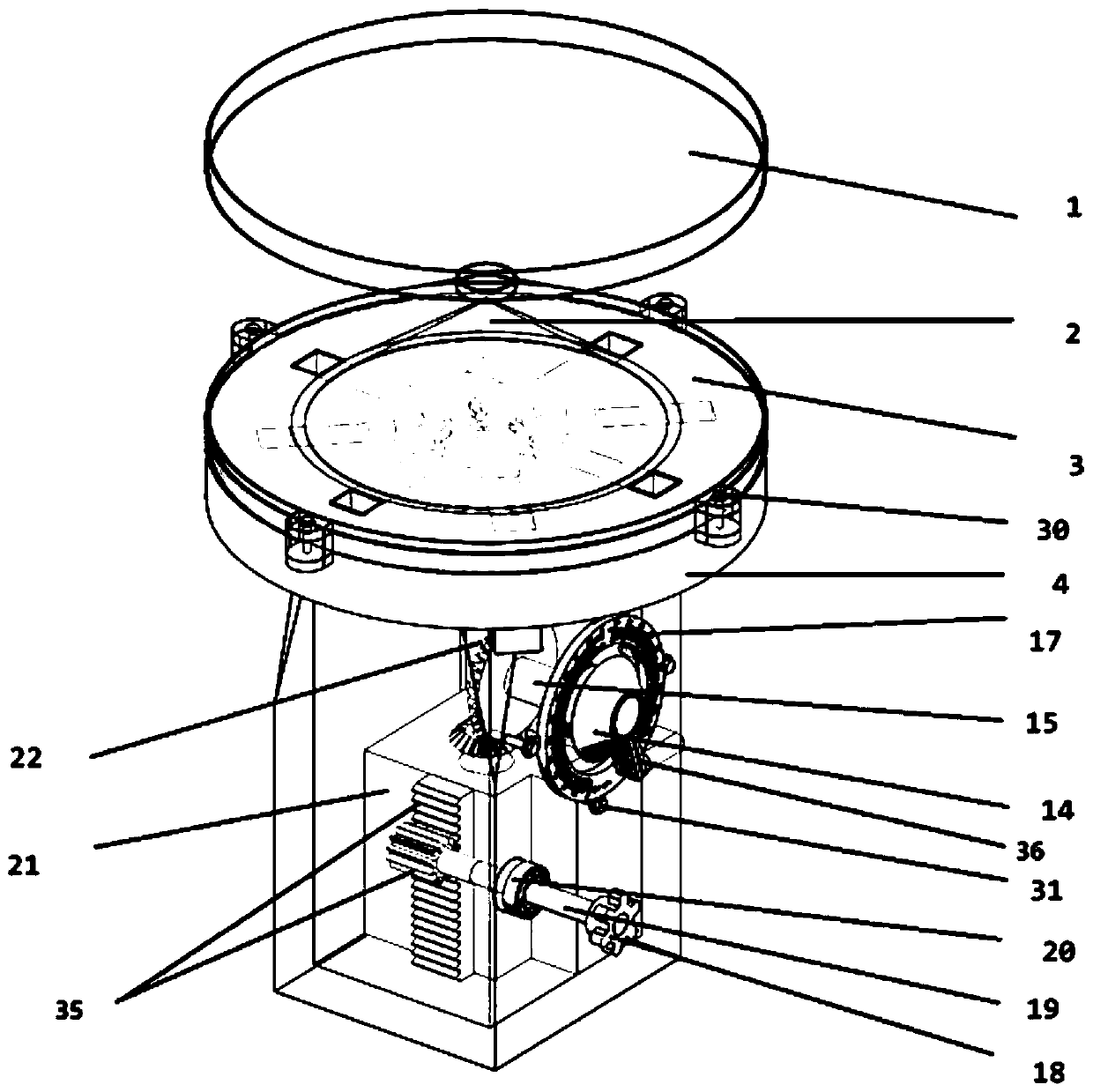

Granary food stock number monitoring device

InactiveCN109001749AImprove metering efficiencyAccurate data conclusionsOptical rangefindersPhotogrammetry/videogrammetryLaser rangingHydraulic pump

A granary food stock number monitoring device comprises a fixed seat, a connecting rod, a support, an infrared high-definition camera and an electric-hydraulic pusher. The fixed seat is fixedly connected with a bin top through a bolt, one end of the connecting rod is welded with the fixed seat, the other end of the connecting rod is connected with the support, the outer wall of the middle portionof the connecting rod is hinged with one end of the electric-hydraulic pusher, the other end of the electric-hydraulic pusher is hinged with one side of the support, the lower portion of the support is provided with the infrared high-definition camera, the infrared high-definition camera sleeves a gear shaft, one end of the gear shaft is in transmission connection with a motor at one side of the infrared high-definition camera, the other end of the gear shaft is rotationally connected with the support, and the infrared high-definition camera is internally provided with a laser distance measurement sensor. The granary food stock number monitoring device is accurate in data conclusion, small in error and automatic in monitoring process, can save manpower resource and can reduce the management cost.

Owner:ANHUI KEJIE LIANGBAO STORAGE EQUIP

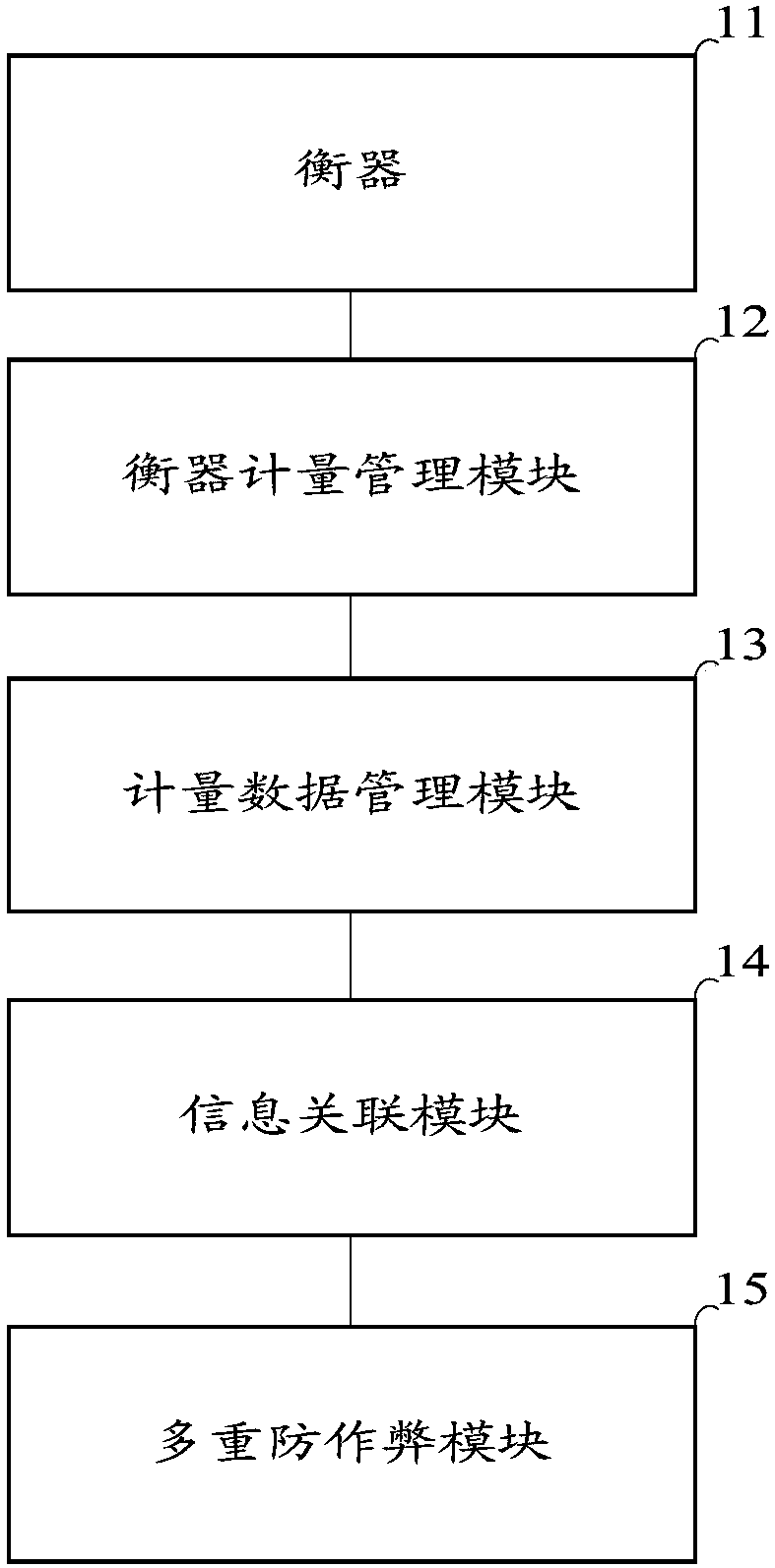

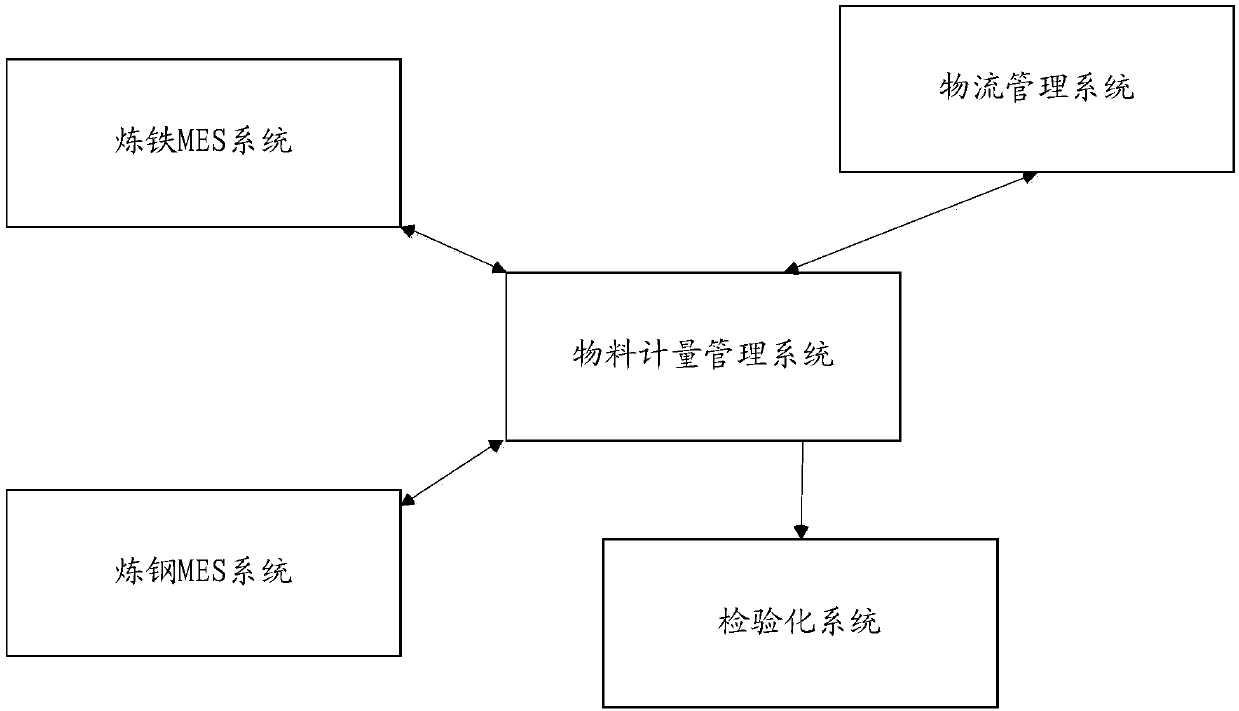

Material measurement management system

InactiveCN107609822ARealize online automatic meteringImprove metering efficiencyLogisticsManagement systemLogistics management

The invention discloses a material measurement management system. The system is realized through the following steps of: automatically measuring a to-be-measured object through at least one weighing apparatus; carrying out remote monitoring management on the automatic measurement operation of the weighing apparatus by a weighing apparatus measurement management module; acquiring measurement data of the weighing apparatus by a measurement data management module and managing the measurement data; associating the measurement data with material logistics information, material inspection information and material production information by an information association module; and judging whether measurement cheating exists in a material acceptance check process carried out according to a preset material acceptance check process or not by a multiple anti-cheating module by utilizing a plurality of preset anti-cheating ways. According to the system, multiple preset anti-cheating ways are utilizedto judge whether measurement cheating exists in the acceptance check process or not, so that the measurement cheating is effectively prevented and the measurement management risk is relatively low; and the measurement data is associated with the logistics information, the inspection information and the production information, and acceptance check is carried out according to the reasonable presetmaterial acceptance check process, so that the online automatic measurement of materials is realized and the measurement efficiency is improved.

Owner:攀钢集团西昌钢钒有限公司

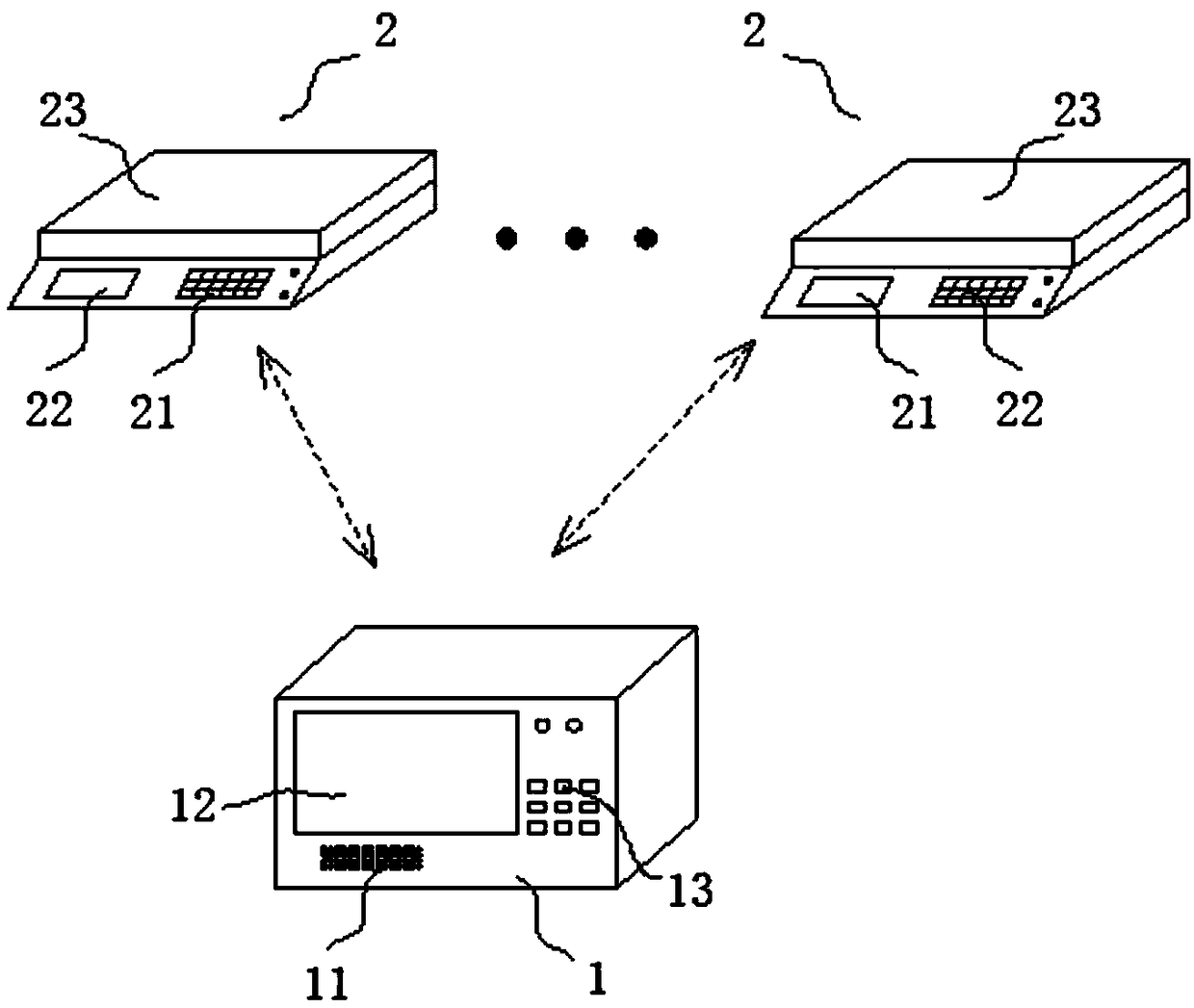

Medical metering equipment capable of intelligently summarizing and real-timely broadcasting

PendingCN109448837AImprove accuracyImprove metering efficiencyEnemata/irrigatorsDiagnosticsElectricityComputer module

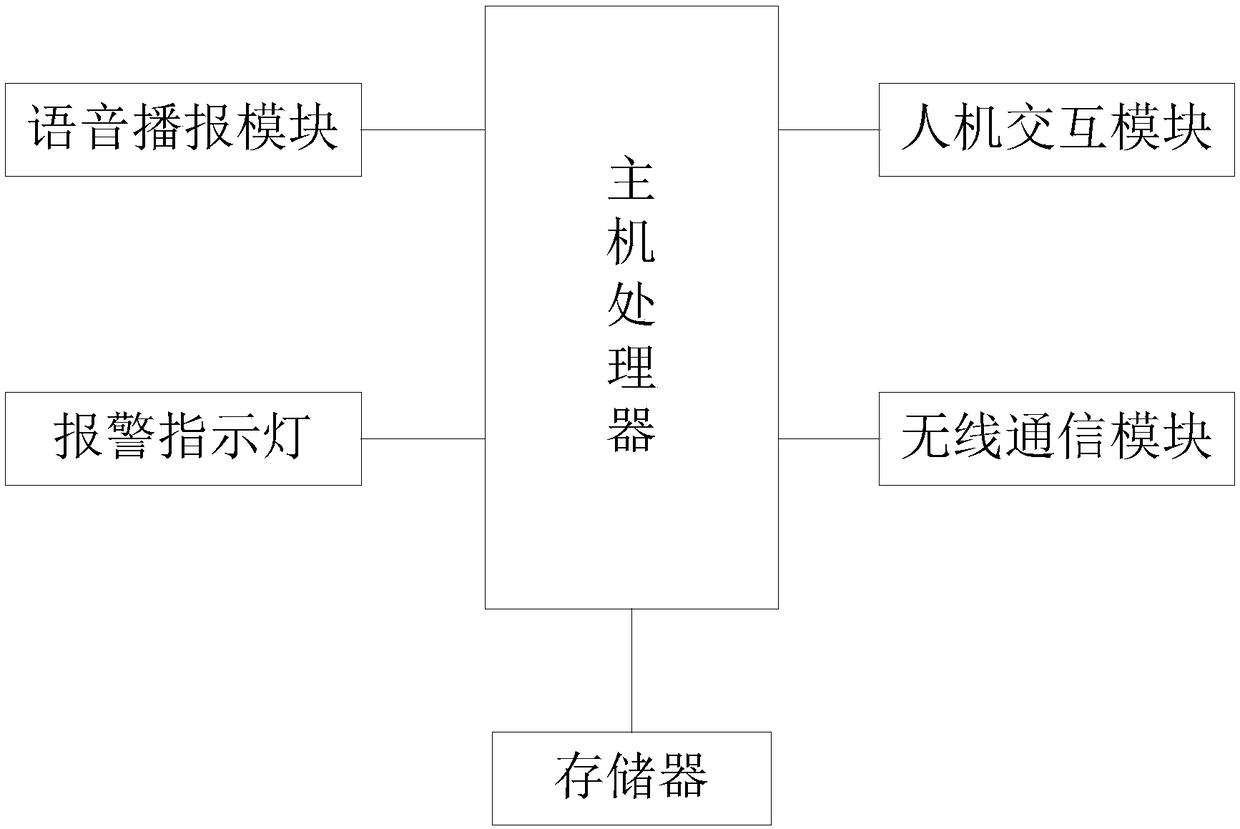

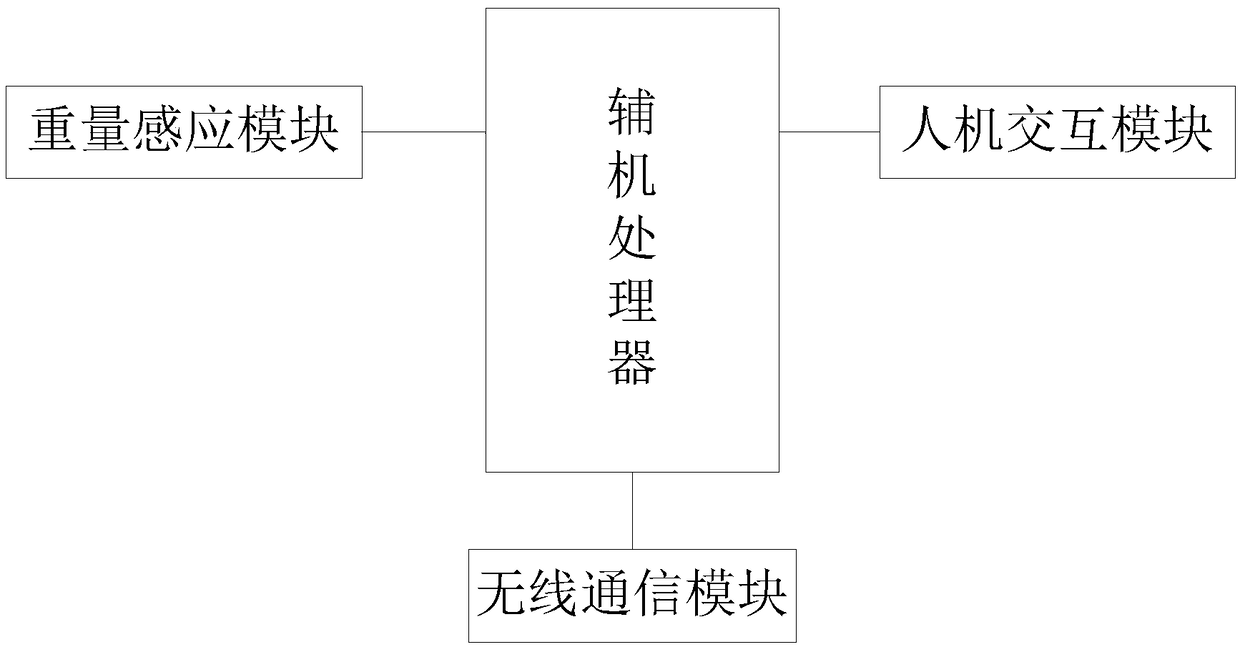

The invention relates to medical metering equipment capable of intelligently summarizing and real-timely broadcasting. The medical metering equipment comprises a host machine, a solid collection container and auxiliary machines, wherein the host comprises a host machine processor, a voice broadcast module, a memory and a human-computer interaction module, the auxiliary machine comprises a processor, a human-computer interaction module and a weight sensor, and the solid connection container is provided with an infrared counter capable of electrically connected to the auxiliary machine processorand used for measuring the amount of solids. According to the present invention, the host machine is wirelessly communicated to the auxiliary machines, and can receive the data transmitted by one, two or multiple auxiliary machines, and perform real-time display and summarizing analysis, and the summarizing conditions comprise addition, subtraction, addition-subtraction mixing and the like, suchthat the accuracy and the metering efficiency of the metering of the amount of input and output are substantially improved, the pathogenetic condition delay caused by the metering error is avoided, and the risk of medical errors is reduced; and the host machine performs the periodical and / or quantitative sound broadcasting and alarming on the current metering results according to the preset conditions so as to avoid frequent metering, repeated metering and other problems and reduce the labor intensity of medical staff.

Owner:THE WEST CHINA SECOND UNIV HOSPITAL OF SICHUAN

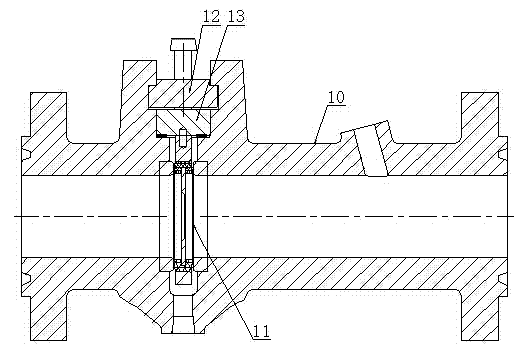

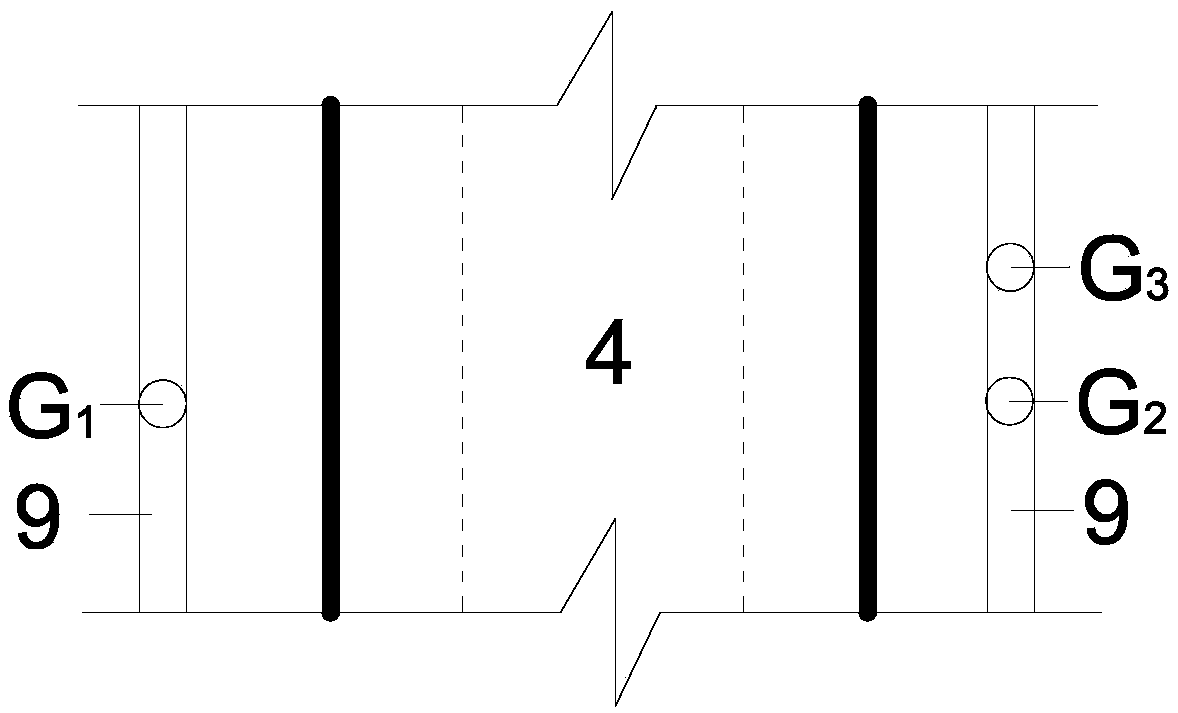

Critical speed flow metering system

ActiveCN104713603AAutomatic and accurate measurementQuick measurementVolume/mass flow by differential pressureData acquisitionComputer module

The invention discloses a critical speed flow metering system. The system comprises a throttle mechanism and a data acquiring measurement system, wherein the throttle mechanism comprises a valve body and a pore plate arranged in the valve body, the data acquiring measurement mechanism comprises a PC, a control cabinet, a temperature sensor and two pressure transmitters; the temperature sensor and the two pressure transmitters are fixed on the valve body, one pressure transmitter is located at the downstream side of the pore plate, and the other pressure transmitter and the temperature sensor are located at the upstream side of the pore plate; a data acquiring module and a communication module are arranged in the control cabinet, the temperature sensor and the two pressure transmitters are connected with the data acquiring module, and the data acquiring module is used for transmitting acquired data to the PC by the communication module. The system disclosed by the invention is capable of automatically, accurately and quickly measuring the flow of fluid at the critical speed according to the acquired data, and the aim of integrating data acquisition, transmission and metering is realized.

Owner:DEYANG DIXINJIA VALVE MFR

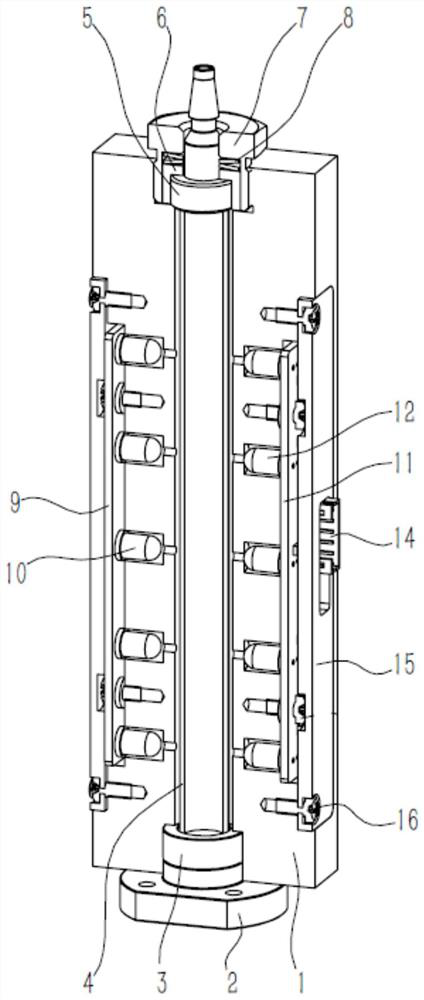

Dye metering device for spinning

InactiveCN105823542AQuick purgeImprove metering efficiencySpecial purpose weighing apparatusEngineeringButterfly valve

The invention relates to the field of textiles, in particular to a textile dye metering device, which can simultaneously meter multiple dyes and has high metering accuracy and fast metering speed. Its structure includes a metering rack; the metering rack hangs a number of metering buckets through a number of lifting lugs and a number of screw rods, the metering bucket is a hollow structure, and the lower part of the metering bucket is a tapered structure; The upper surface of the metering hopper is provided with a feed pipe, and the feed pipe is connected to the inside of the metering hopper; the outer surface of the tapered structure of the metering hopper is provided with a vibrator; the lower end of the metering hopper is provided with a discharge pipe, The feed pipe is connected to the inside of the metering hopper; the end of the discharge pipe close to the metering hopper is sleeved with a butterfly valve; the textile dye metering device is convenient and quick to use, low in use cost, and maintenance-free, and is suitable for measuring and weighing textile dyes.

Owner:SUZHOU HUACE TEXTILE SCI & TECH

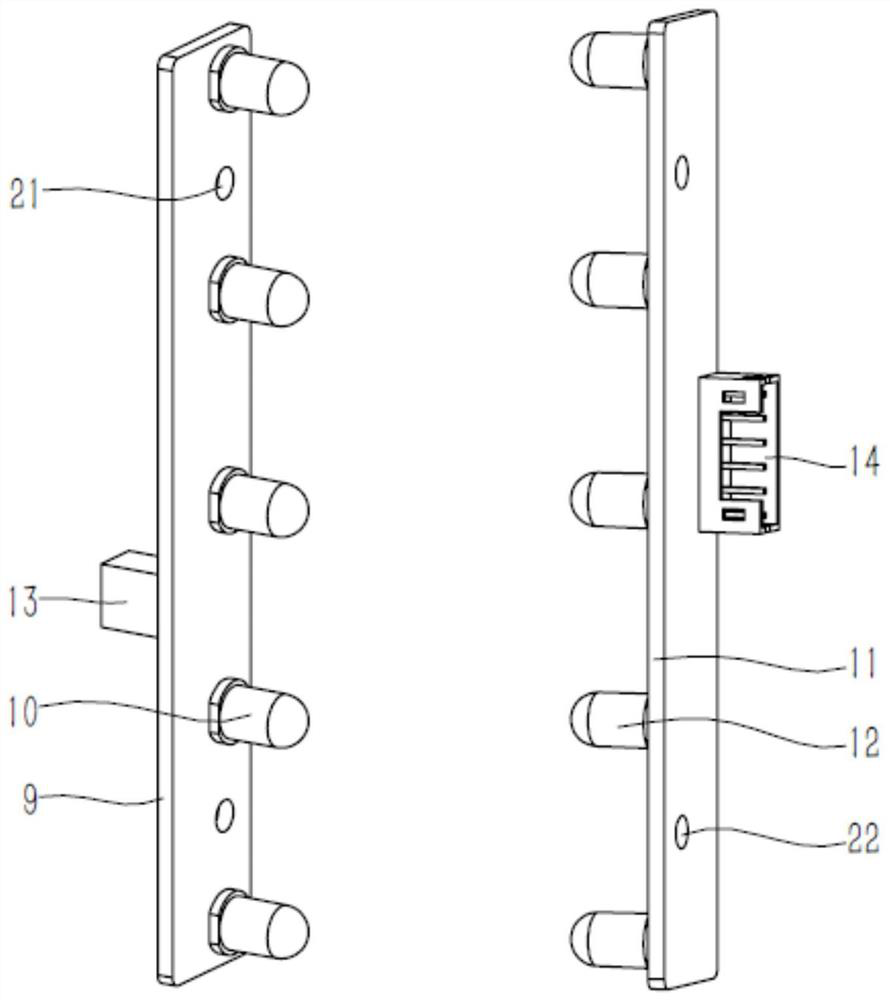

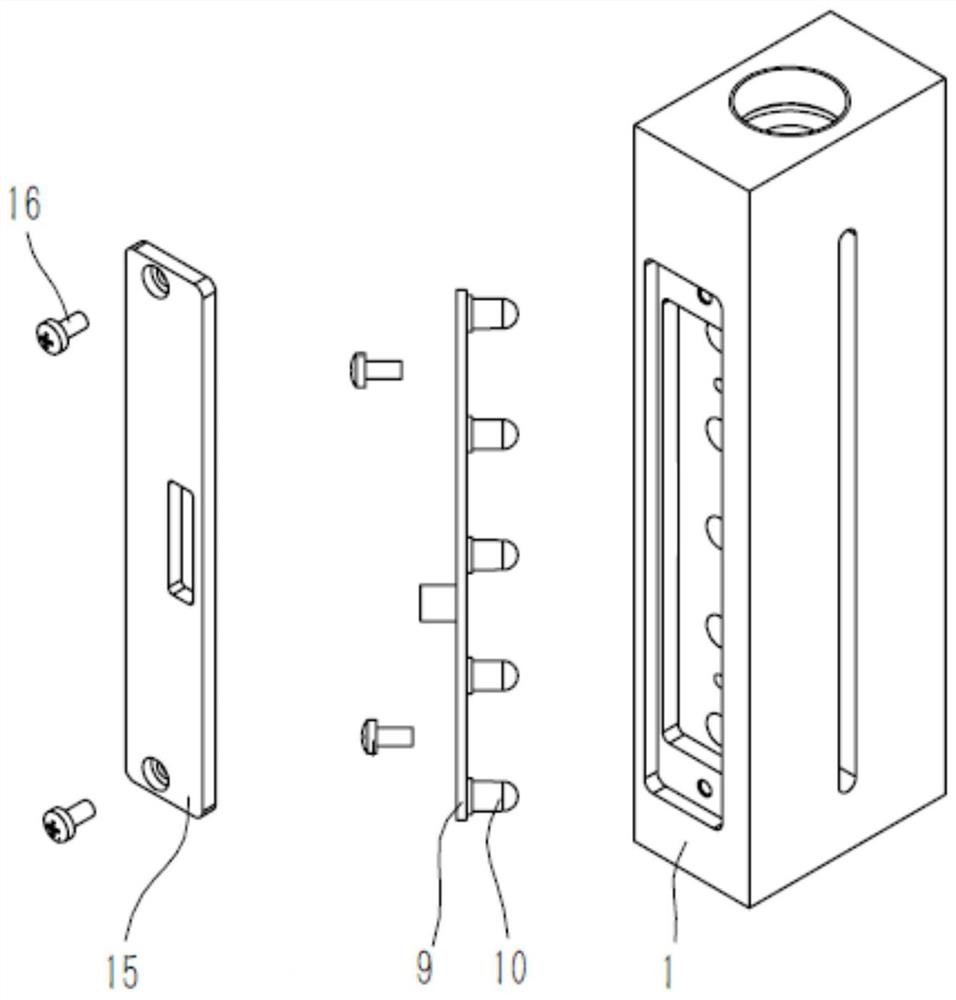

Novel metering device of water quality on-line monitoring equipment

InactiveCN113109263AIncrease flexibilityCorrectly designedMaterial analysis by optical meansTesting waterWater qualityEnvironmental engineering

The invention provides a novel metering device of water quality on-line monitoring equipment, and belongs to the technical field of water quality detection equipment. The novel metering device of the water quality on-line monitoring equipment comprises a frame, the upper end and the lower end of the frame are provided with a top installation step and a bottom installation step respectively, and the left end and the right end of the frame are each provided with a second sinking table; wherein first sinking tables are arranged on the inner walls, close to each other, of the two second sinking tables; the circumferential inner wall of the top mounting step is provided with a connecting thread, and the lower inner wall of the top mounting step is fixedly connected with a limiting step; a plurality of counter bores are formed in the inner walls, close to each other, of the two first sinking tables, and light passing holes are formed in the inner walls, close to each other, of the counter bores; the device also includes a metering pipe that is arranged in the middle of the frame. According to the invention, the height of the liquid level in the metering pipe can be monitored through the light holes, observation is convenient, and use requirements are met.

Owner:储信自动化科技有限公司

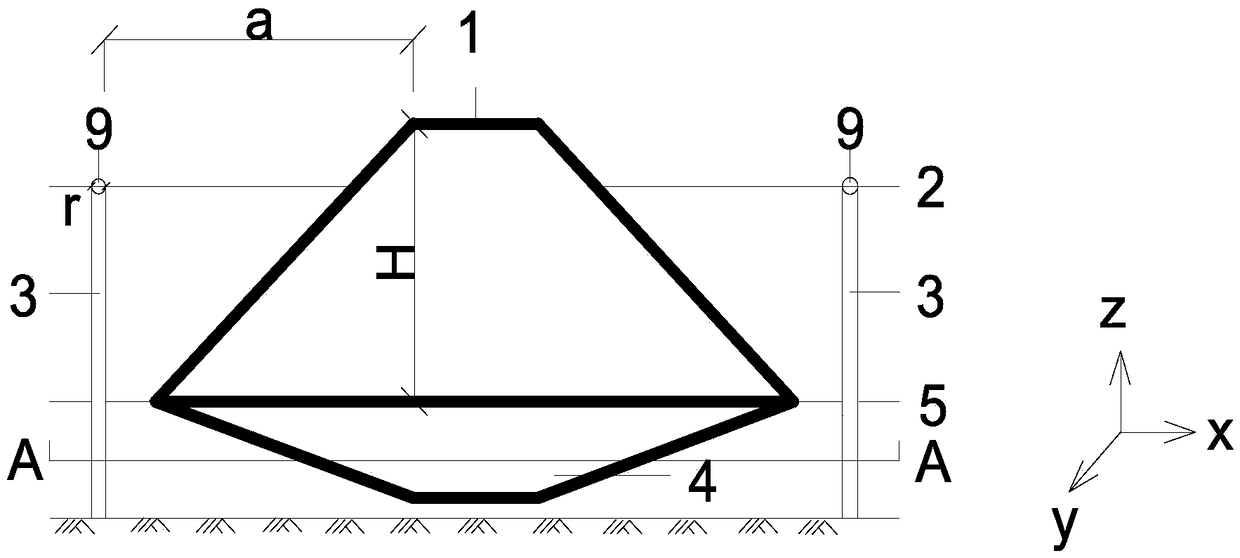

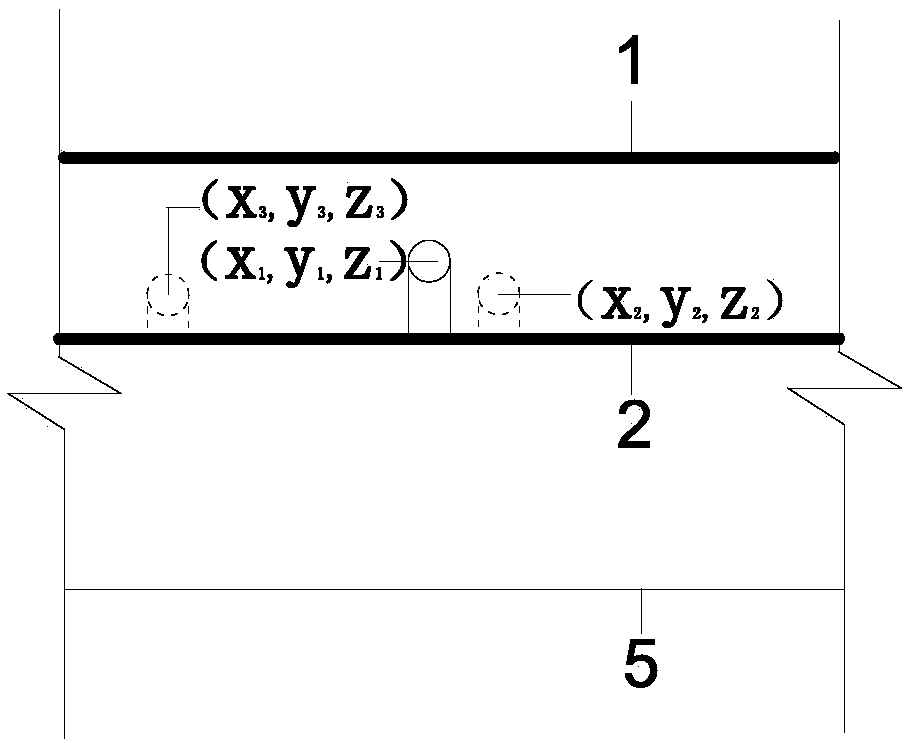

Method for measuring stone throwing and sedimentation packing effect of breakwater

ActiveCN109282737AImprove efficiencyHigh precisionUsing electrical meansElectric/magnetic contours/curvatures measurementsCapacitanceSoil horizon

The invention discloses a method for measuring a stone throwing and sedimentation packing effect of a breakwater. The breakwater is divided based on the principle of equidistant division, and a measurement section is determined according to the height of the bank and the height of the embankment; the whole system is controlled by a virtual orbit; a soil layer, the water and stones are calibrated according to the principle of first-calibration and second-measurement and based on the dielectric properties of the soil, and the capacitance value per unit length of the material is determined; the length of a material region in each layer is calculated by using the law that the capacitance is proportional to the length of the material; according to the calculation result, the stone throwing andsedimentation packing form is drawn, and the stone throwing and sedimentation packing area is calculated; and the method measuring a stone throwing and sedimentation packing effect of a breakwater isestablished by comparing and analyzing the design drawing. The method is simple to implement, is low in cost, and can be widely applied to the evaluation of the stone throwing and sedimentation packing effect of the breakwater.

Owner:HOHAI UNIV

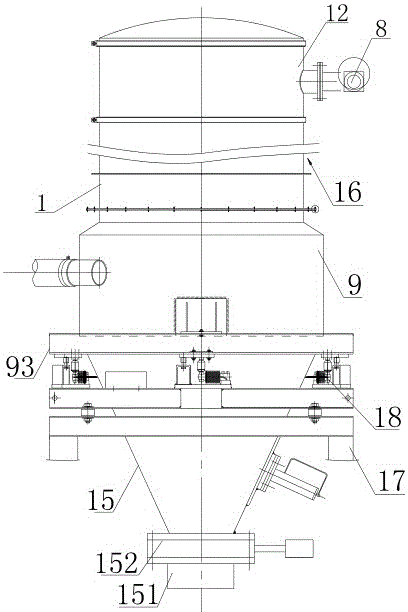

Automatic metering equipment for chemical liquid material feeding

ActiveCN109178377AReduce manual labor intensityImprove metering efficiencyLiquid materialLiquid level sensorAutomatic testing

The invention discloses automatic metering equipment for chemical liquid material feeding. The automatic metering equipment comprises a weighing box. A stirring cavity is arranged in the weighing box.A servo motor is fixedly connected to the inner wall of the stirring cavity. The output end of the servo motor is fixedly connected with a stirring shaft. The surface of the stirring shaft is fixedlyconnected with stirring blades in a sleeved manner. One end of the stirring cavity communicates with a weighing cavity. The inner wall of the weighing cavity is fixedly connected with a flow guide plate. The surface of the flow guide plate is fixedly connected with a stop band. A liquid level sensor is arranged on the inner side wall of the weighing cavity. A weighing plate is movably connected in the weighing cavity. Springs are fixedly connected to the bottom end of the weighing plate. A mounting plate is fixedly connected to the bottom ends of the springs. According to the automatic metering equipment, through the arrangement of first electric push rods and a second electric push rod, automatic weighing and arrangement are carried out in a manner that the first electric push rods and the second electric push rod ascend and descend, the manual labor intensity is reduced, and the metering efficiency is improved.

Owner:浙江零轴智能装备有限公司

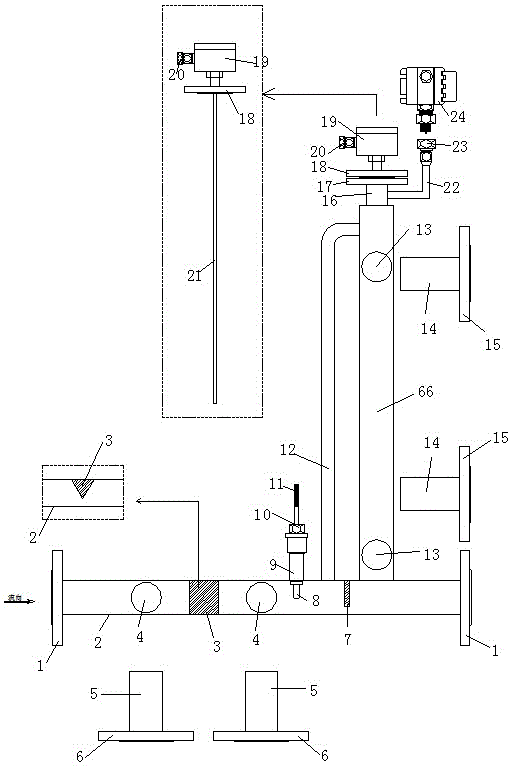

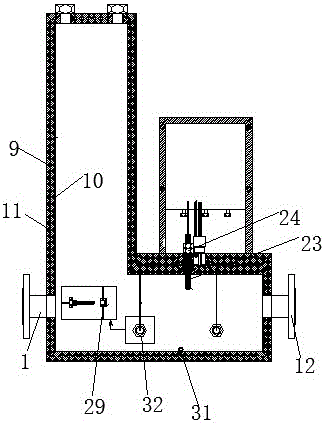

Crude oil single well metering and measuring system

ActiveCN106321063AReduce lossesGuaranteed measurement accuracySurveyConstructionsTransverterEngineering

The invention discloses a crude oil single well metering and measuring system which comprises a shell, a main controller, a receiving terminal, a flow measuring assembly, a density measuring assembly and a temperature measuring assembly. The shell comprises an inner layer shell body and an outer layer shell body, and heat insulation cotton is arranged between the inner layer shell body and the outer layer shell body. A heat guide oil storage chamber is arranged in the inner layer shell body, and an explosion-proof box support is arranged on the outer layer shell body. An explosion-proof box is connected to the explosion-proof box support, and a transverter, an air switch and a tracing ribbon are arranged in the explosion-proof box. The tracing ribbon is located in the transverter. The air switch controls the tracing ribbon to be started and stopped. The flow measuring assembly is arranged in the inner layer shell body, and the density measuring assembly and the temperature measuring assembly are both arranged on the outer layer shell body. The flow measuring assembly, the density measuring assembly and the temperature measuring assembly are all in signal connection with the main controller, and the main controller is in signal connection with the receiving terminal. The metering precision of an oil well is improved, the using cost of an oil well metering instrument is reduced, and the metering efficiency of the oil well is improved.

Owner:JIANGSU HUAERWEI TECH GRP

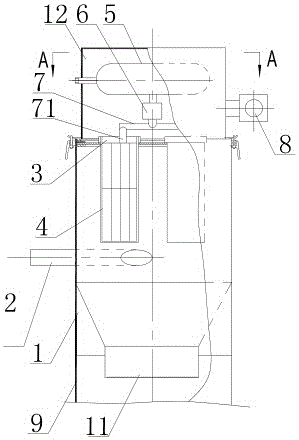

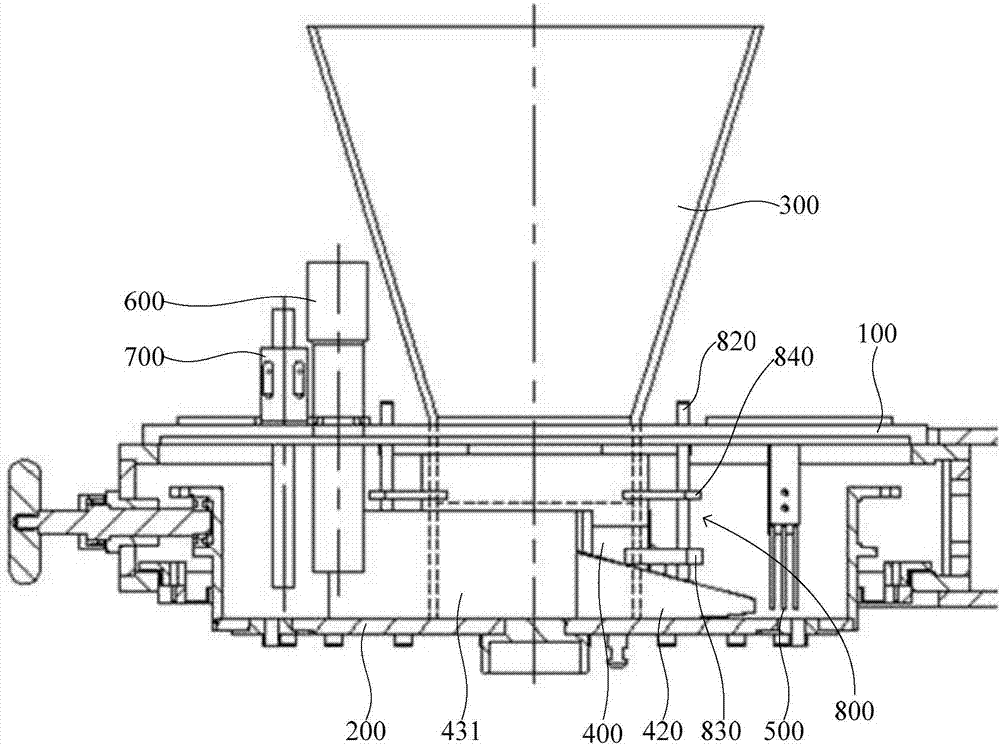

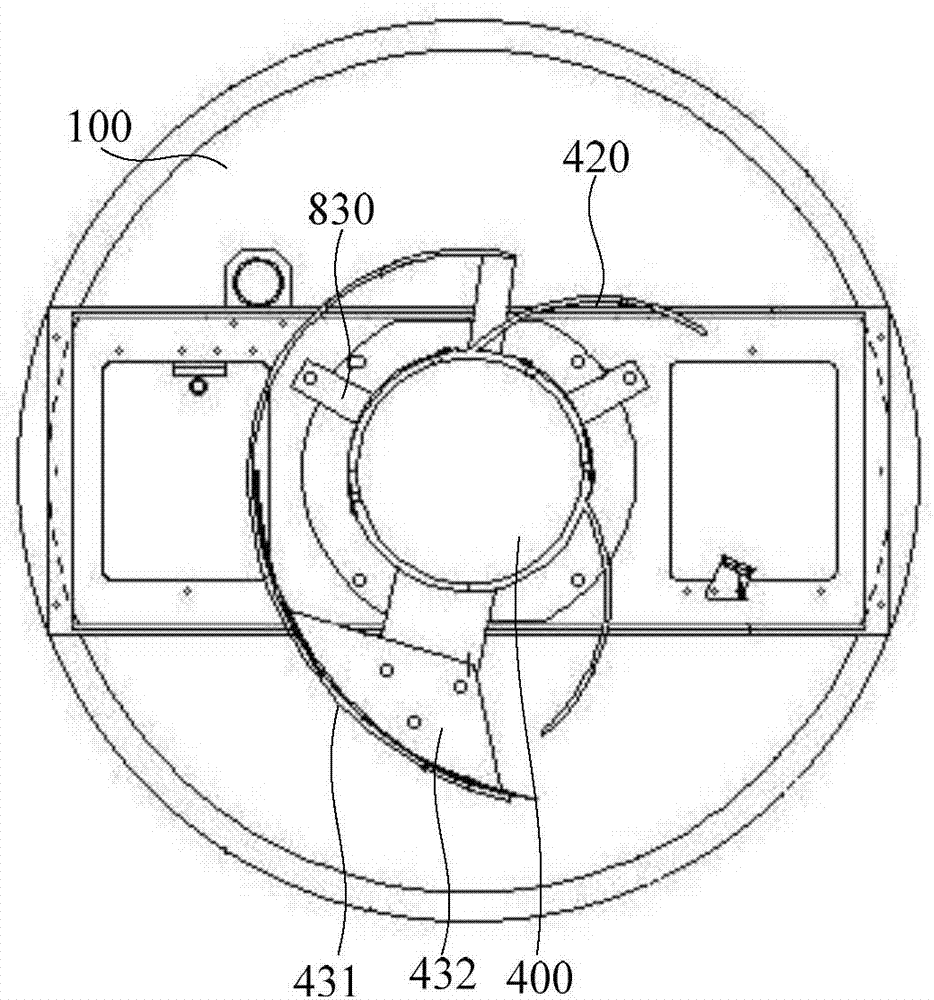

Rotational packing machine and rotary feeding device

The invention discloses a rotary feeding device. The rotary feeding device comprises a rack, a rotary disk, a material bin and a discharging drum. The material bin is fixed on the rack. The material bin communicates with the discharging drum. The rotary disk is rotationally arranged on the rack. The discharging drum and the rotary disk are distributed up and down in the vertical direction. The rotary disk is provided with a plurality of material cups which are distributed around the rotary center of the rotary disk. The discharging drum is provided with a discharging opening. The discharging opening is used for discharging materials to the rotary disk. The discharging drum is provided with a poking part and a leveling part. The poking part is used for guiding materials to fall into the material cups from the surface of the rotary disk. The leveling part is used for scraping the top end of a material stack formed by materials falling into the material cups. The invention further discloses a rotational packing machine. According to the scheme, the problem of the low measurement efficiency of material measuring of a current rotational packing machine by adopting a weighing method is solved.

Owner:BEIJING XINLONGLI TECH CO LTD

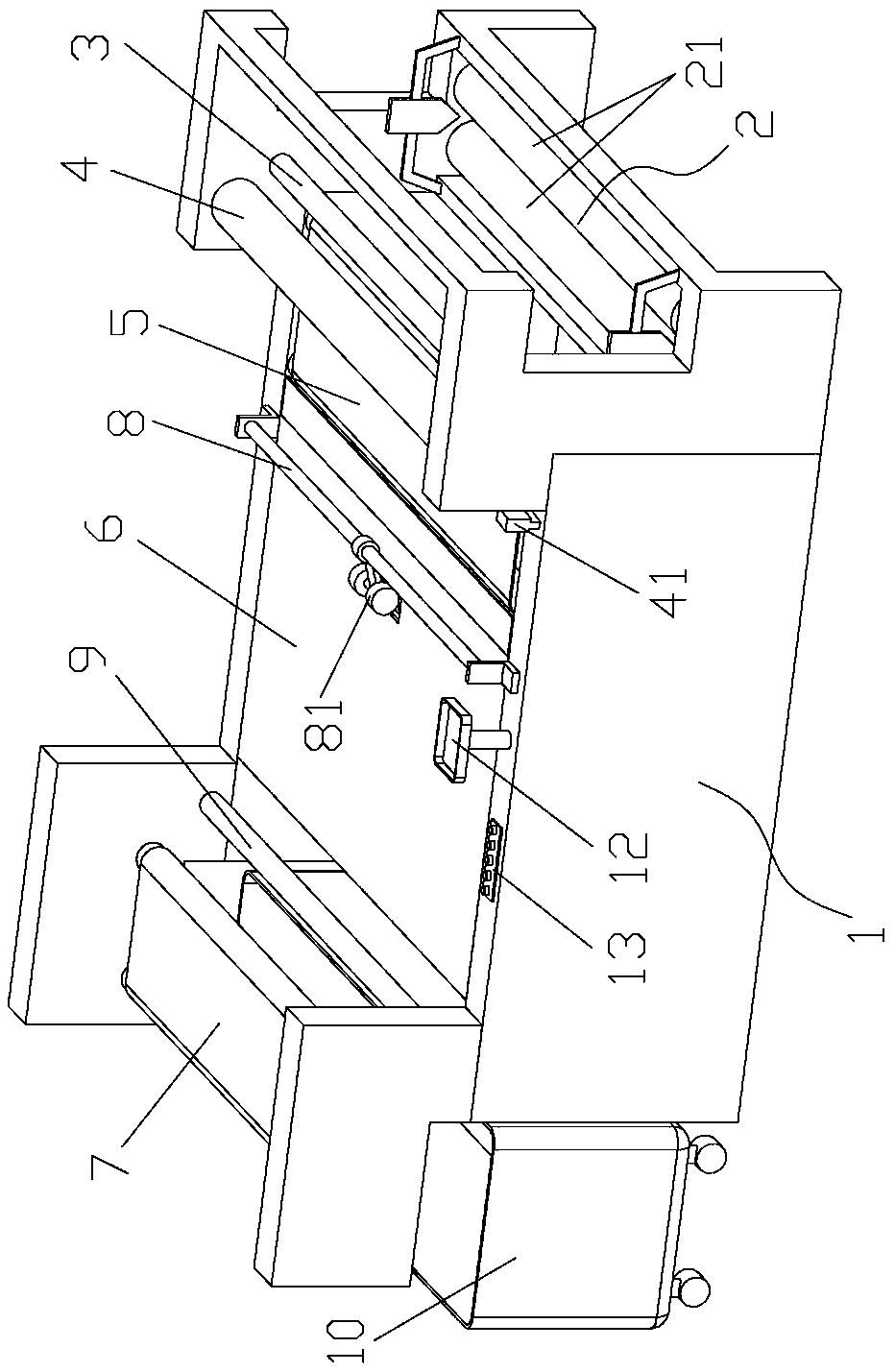

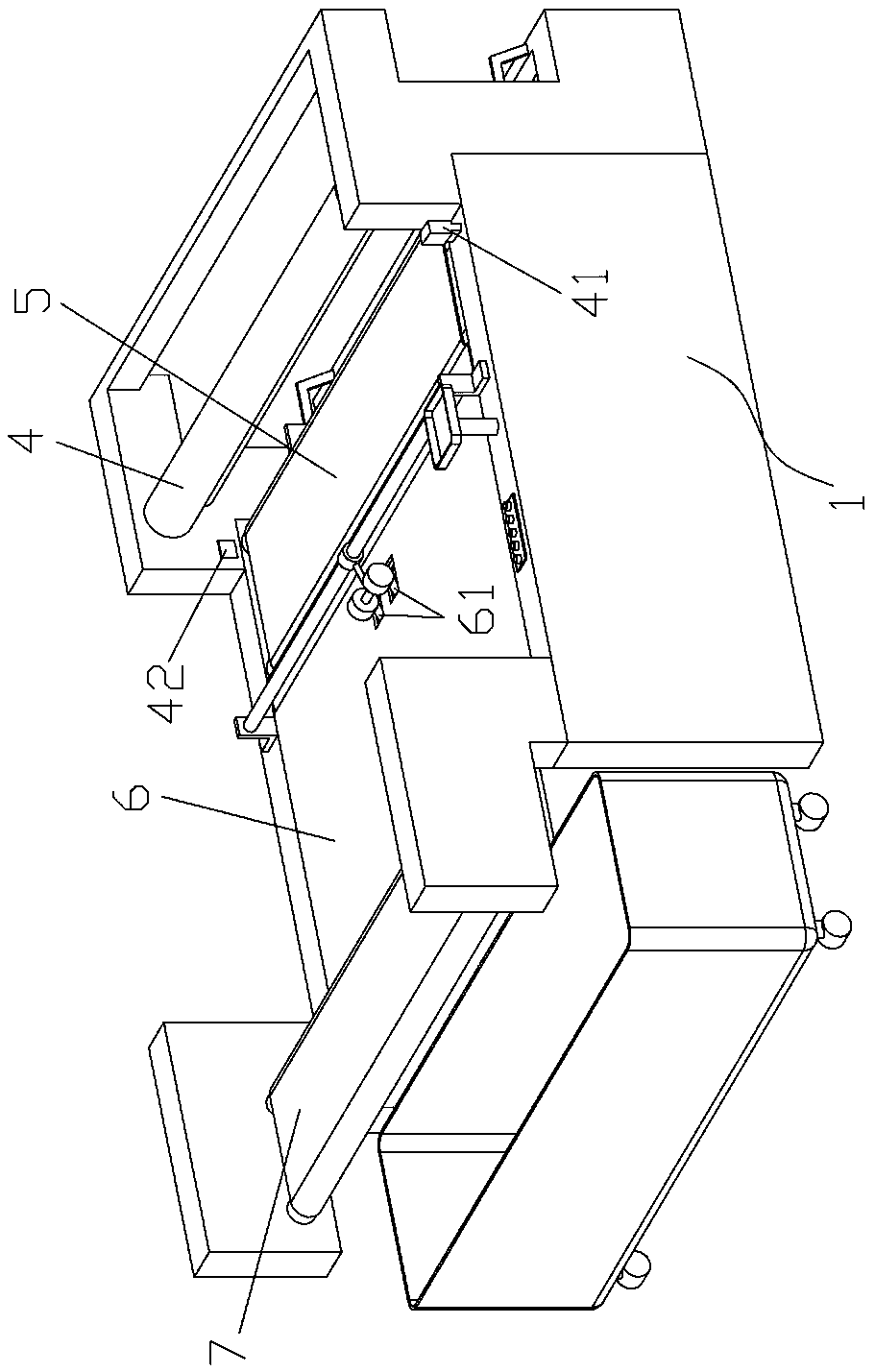

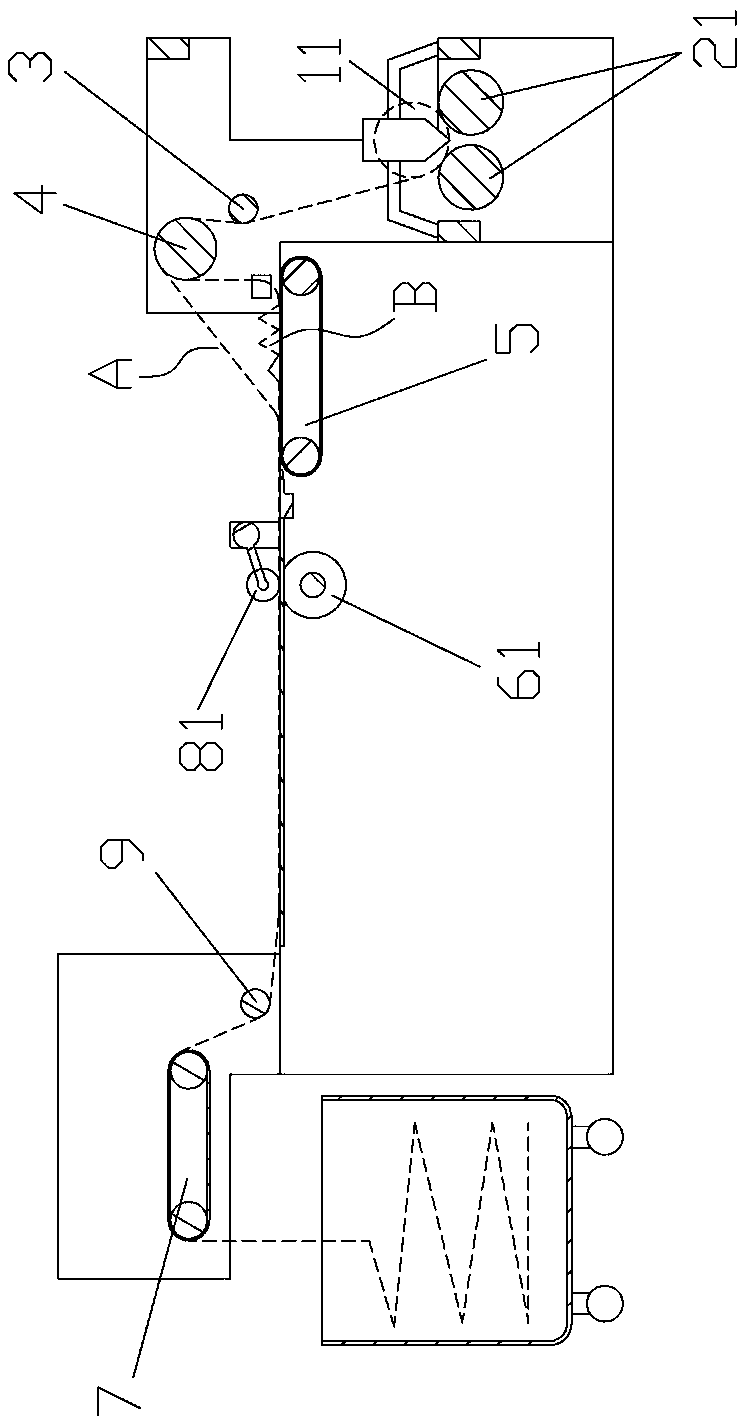

Automatic cloth measuring machine

PendingCN110540093AAccurate measurementEliminate elastic effectsWebs handlingNatural stateEngineering

The invention mainly relates to an automatic cloth measuring machine. The automatic cloth measuring machine mainly comprises a main frame, wherein a cloth returning mechanism, a cloth guiding roller I, a driving roller, a conveying belt device I, a platform board and a conveying belt device II are sequentially arranged on the main frame along the feeding direction of cloth; the cloth returning mechanism comprises two cloth returning rollers, and the two cloth returning rollers are horizontally installed on the main frame; the driving roller is driven by an independent driving device, and the driving roller is used for feeding the cloth and enables the cloth to fall on the conveying belt device I; a photoelectric sensing controller I is arranged on the main frame on the position, on the side of the driving roller, of the main frame, a sensing plate is arranged at the position, corresponding to the photoelectric sensing controller I, on the other side of the main frame, and the photoelectric sensing controller I is obliquely arranged with the sensing plate; and the photoelectric sensing controller I is used for sensing the cloth falling from the driving roller and controlling the feeding speed of the driving roller, the lower end of the platform board is provided with a measuring wheel, the measuring wheel is used for measuring the length of the cloth, and the conveying belt device I and the conveying belt device II are synchronously rotated. The machine has the advantages that the design is ingenious in structure, the cloth can be measured in a natural state, the cloth measuring is accurate, and the metering efficiency is high.

Owner:CODETEX SHAOXING TEXTILE INSPECTION

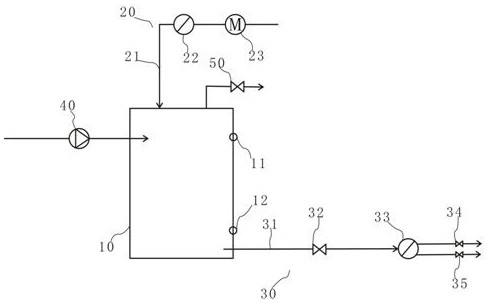

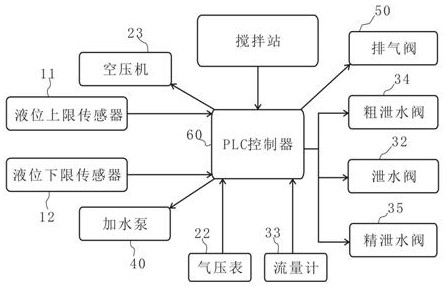

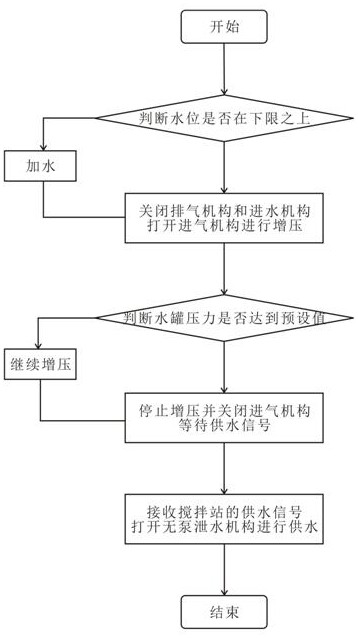

Constant-pressure water supply device and constant-pressure water supply method for concrete dry mixing plant

PendingCN113529847AIncrease humidityAvoid pilling and lumpingService pipe systemsWater mainsDry mixingEngineering

The invention relates to the technical field of liquid ingredient metering in a dry mixing plant, and particularly discloses a constant-pressure water supply device and a constant-pressure water supply method for a concrete dry mixing plant. The method specifically comprises the following steps that whether the water level of a water tank is above the lower limit of the liquid level or not is judged, if not, an air inlet mechanism is closed and an exhaust mechanism and a water inlet mechanism are opened to add water, and if yes, the next step is executed; the exhaust mechanism and the water inlet mechanism are closed, and the air inlet mechanism is opened to pressurize; whether the pressure of the water tank reaches a preset water supply pressure value or not is judged, if not, pressurization continues, if yes, pressurization is stopped, the air inlet mechanism is closed, and a water supply signal is waited; and the water supply signal of the mixing plant is received, and a pump-free water drainage mechanism is opened for water supply. Constant-pressure continuous water supply can be achieved, the water supply amount is accurately metered through a flow meter, the humidity stability of dry mixing materials can be guaranteed, pilling and blocking of the materials caused by water dripping can be avoided, the influence of air existing in a pipeline on the precision of the flow meter can be avoided, the water supply precision can be improved, and the metering efficiency can be improved.

Owner:QUANGONG MACHINERY

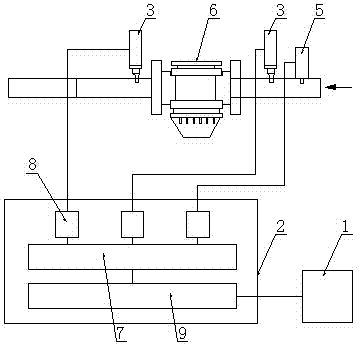

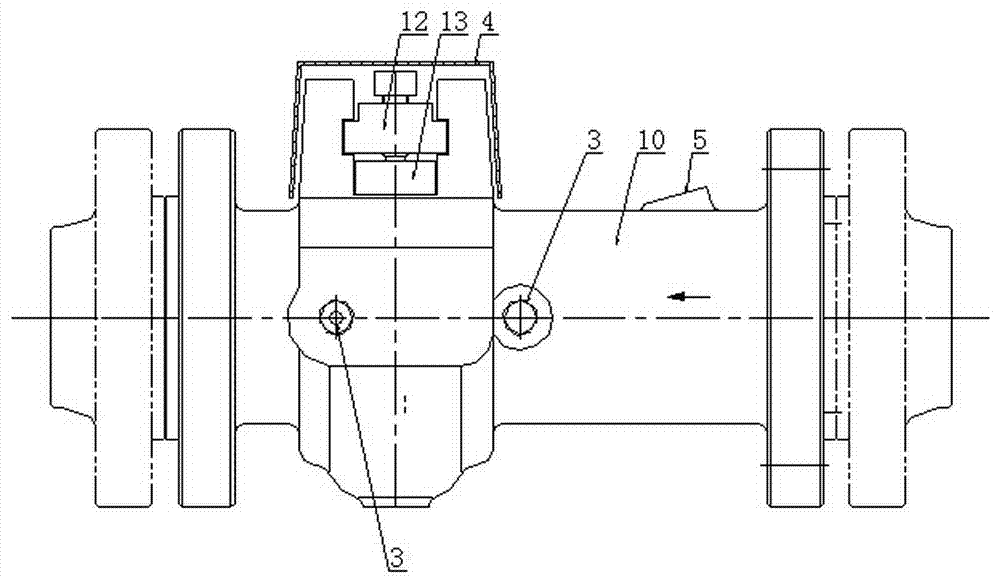

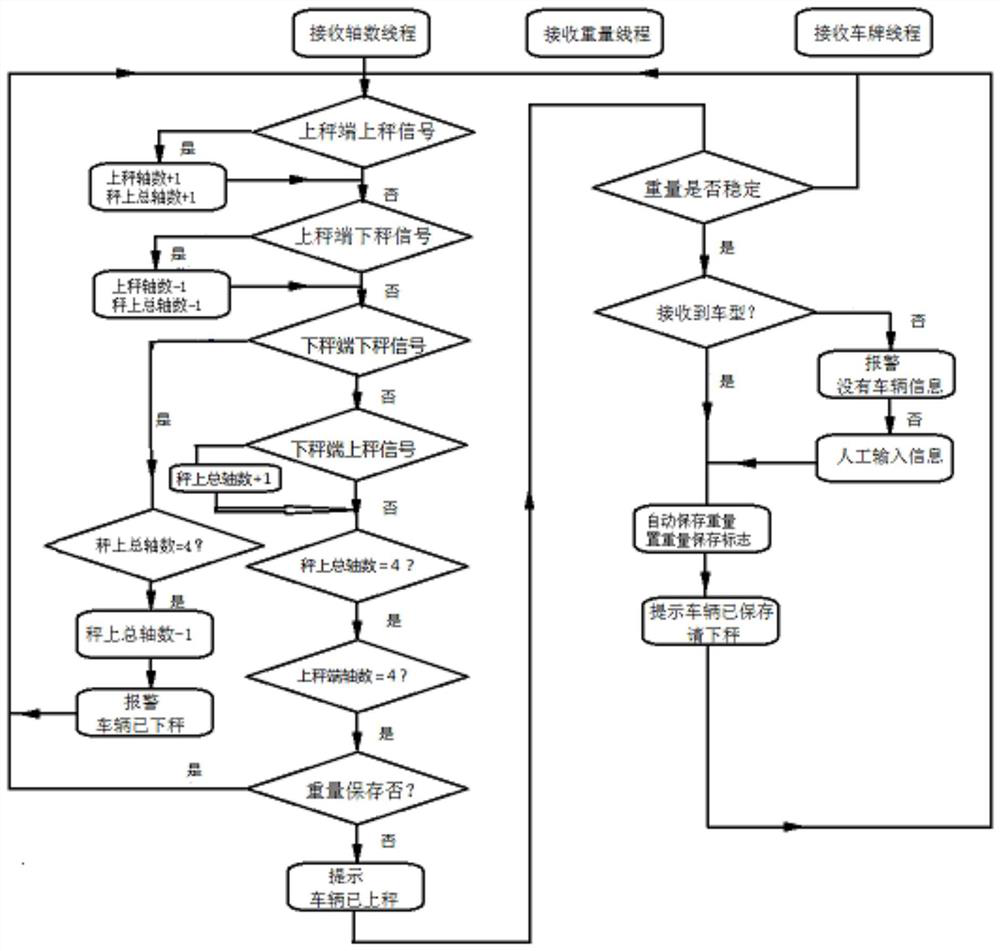

Intelligent judgment method and device for vehicle parking state in static rail weighbridge overbalance

ActiveCN112284503AAccurate weighing and weighingImprove metering efficiencySpecial purpose weighing apparatusControl engineeringParking space

The invention discloses an intelligent judgment method and device for the vehicle parking state in static rail weighbridge overbalance, which can intelligently judge a parking position and give a prompt when the vehicle is loaded and unloaded to realize automatic acquisition of weight, vehicle number, position and vehicle type information by a double-carriage rail weighbridge, and the method and device are accurate in weighing and high in metering efficiency. The method comprises the steps of system construction, driving direction judgment, forward driving receiving axle number and vehicle position judgment and reverse driving receiving axle number and vehicle position judgment. The judgment device comprises a first small platform scale area, a first large platform scale area, a second large platform scale area, a second small platform scale area, a rail weighbridge, first to sixth wheel switch groups, and first to fourth vehicle number recognizers. Each wheel switch set is composed ofa first land wheel switch and a second land wheel switch which are symmetrically distributed along the central axis of the rail.

Owner:锦州中理外轮理货有限公司

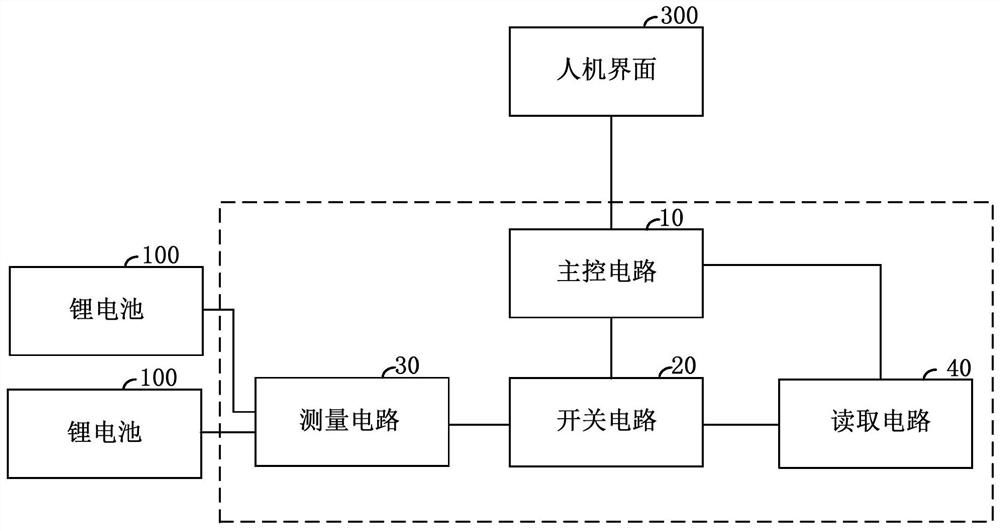

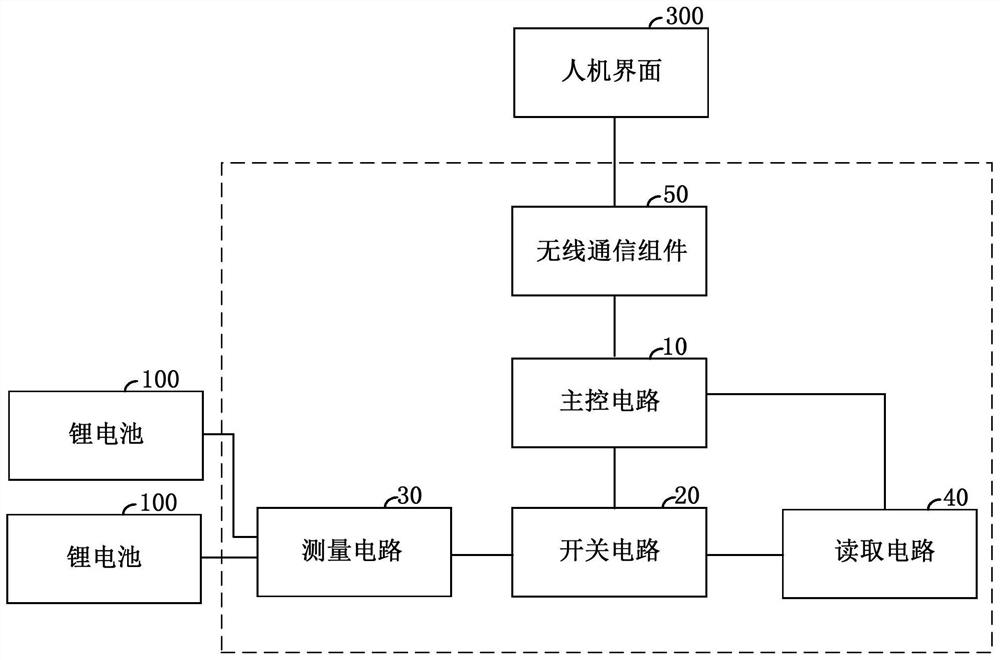

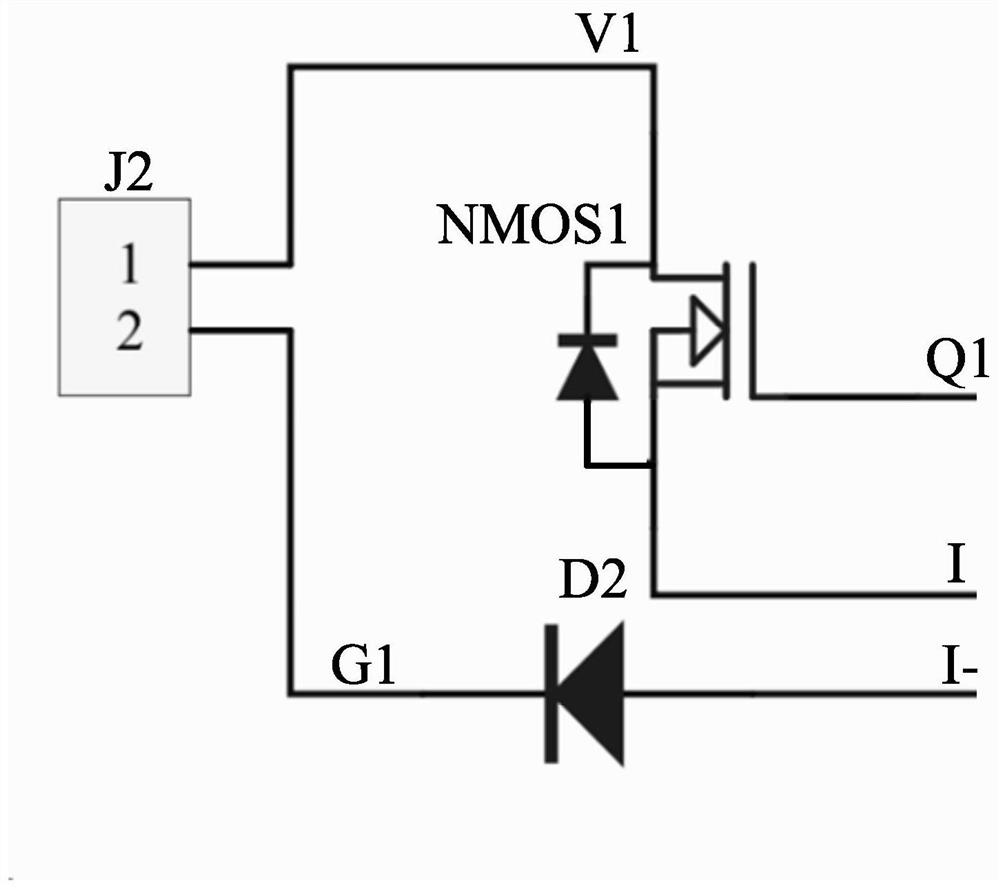

Lithium battery equipment parameter acquisition circuit and system

PendingCN111796188AImprove accuracyShort timeCurrent/voltage measurementElectrical testingControl theoryControl circuit

The invention discloses a lithium battery equipment parameter acquisition circuit and system. The system comprises a measuring circuit, a switching circuit, a reading circuit and a main control circuit. The measuring circuit is connected with at least two lithium batteries, measures the working current and the working voltage of each lithium battery one by one, and outputs corresponding voltage measuring values and current measuring values to the switching circuit; the switching circuit is provided with at least two voltage measuring channels and two current measuring channels, sequentially gates the voltage measuring channels and the current measuring channels to drive the measuring circuit to work, and transmits each voltage measuring value and each current measuring value to the readingcircuit; and the voltage measuring values and the current measuring values are displayed by the reading circuit and fed back to the main control circuit, and the main control circuit stores the voltage measuring values and the current measuring values. According to the lithium battery equipment parameter acquisition circuit and system, the voltage measuring values and current measuring values ofa plurality of lithium batteries can be measured at a time, the operation is convenient and fast, the detection efficiency is high, the consumed time is short, and the problem of high error rate caused by multiple times of manual detection is avoided.

Owner:DONGGUAN CHUANGMING BATTERY TECH

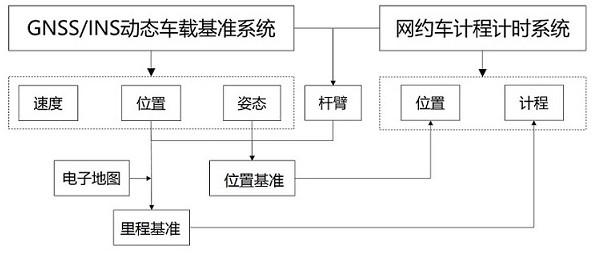

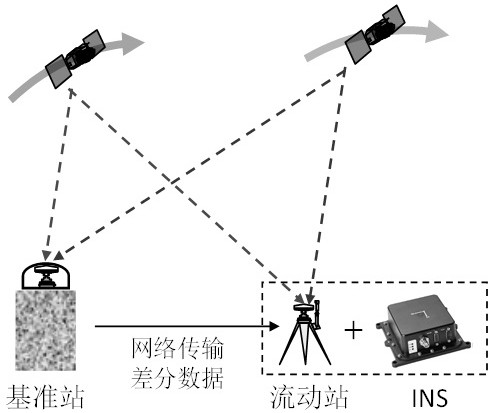

Online car-hailing log detection method, system and device and computer readable storage medium

InactiveCN113686351AGuarantee meter continuity and accuracyImprove metering efficiencySatellite radio beaconingDistance measurementElectronic mapInertial navigation system

The invention discloses an online car-hailing log detection method, system and device and a computer readable storage medium, and the method comprises the steps: carrying out combined positioning based on satellite navigation system GNSS reference receiver differential positioning and an inertial navigation system INS, and solving a high-precision discrete point positioning result of a vehicle carrier in a real environment; by utilizing the high-precision discrete point positioning result and combining with a lane electronic map, carrying out mileage recovery of a vehicle driving track, and obtaining a reference mileage; and comparing the reference mileage with a distance counting result of an online car-hailing terminal to obtain an online car-hailing distance counting error. According to the invention, an accurate comparison reference can be provided for online car-hailing logging, so that logging detection in a real dynamic road test environment is realized; the reference mileage can be directly calculated by importing the combined positioning result file and inputting the distance counting result of the online car-hailing end, so that the distance counting error of the online car-hailing end is obtained; according to the invention, the accuracy and continuity of positioning can be ensured, and the metering efficiency is improved.

Owner:NANJING INST OF MEASUREMENT & TESTING TECH +1

Remote centralized measurement method for steel product

InactiveCN107123059AReduce the number of measurementsImprove metering efficiencyData processing applicationsCo-operative working arrangementsProduction lineMetallurgy

The invention relates to the field of steel product measurement and particularly relates to a remote centralized measurement method for a steel product. According to the method, after a steel product leaves a production line, necessary information for measurement of the steel product comprising a product specification, a packaging material, a weight, and a mass deduced weight is inputted to a control center through a computer, and the necessary information is made to a barcode label to be stuck on the steel product; and the steel product arrives at a specified weighing position through a transportation device, a gauger scans the label through a PDA, a measurement request is sent to the control center, the weight information is checked, whether re-measurement is needed is judged, and if re-measurement is needed, the measurement result is fed back to the control center. The measurement times are reduced, and the measurement efficiency is improved.

Owner:TAIYUAN IRON & STEEL GROUP

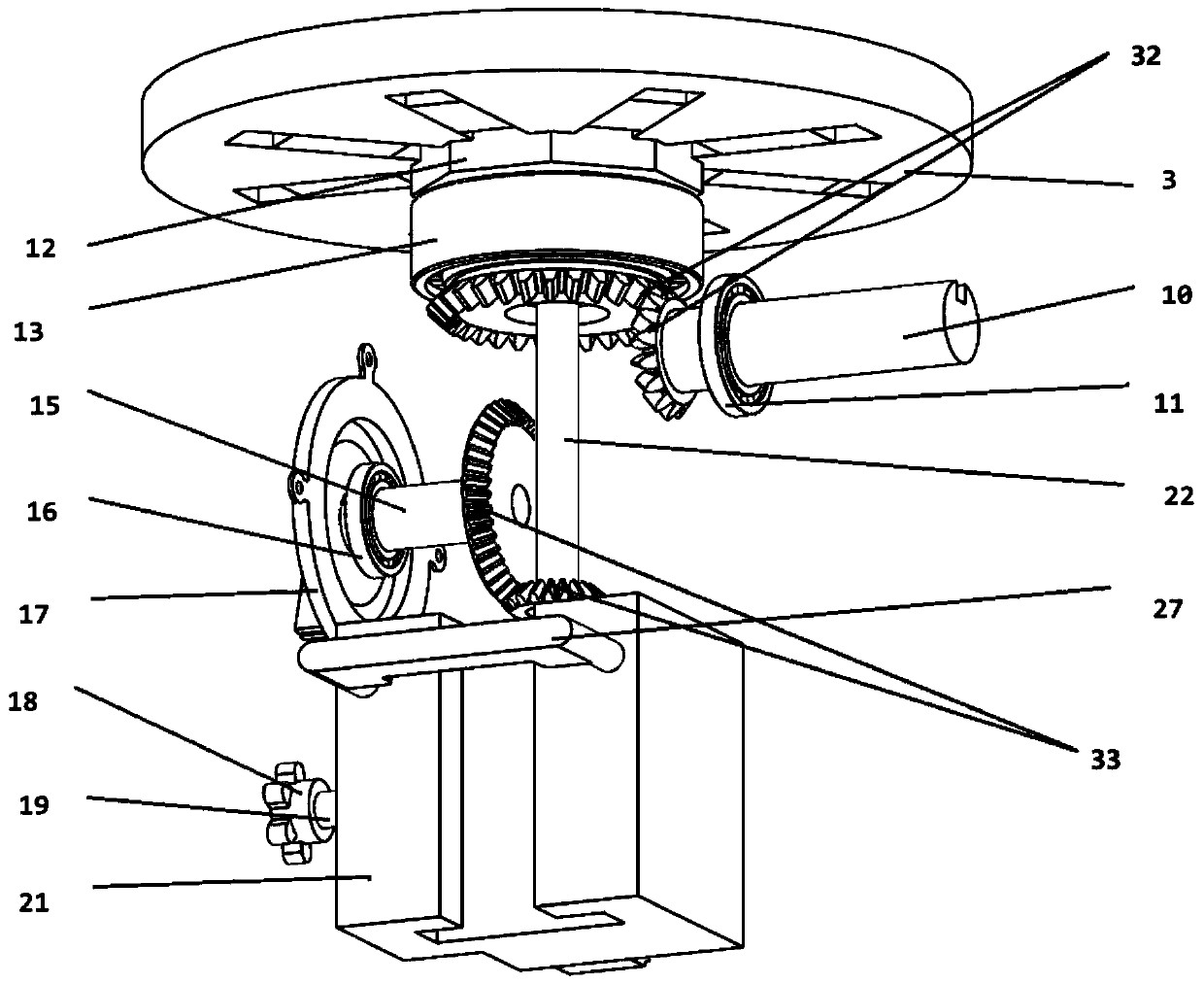

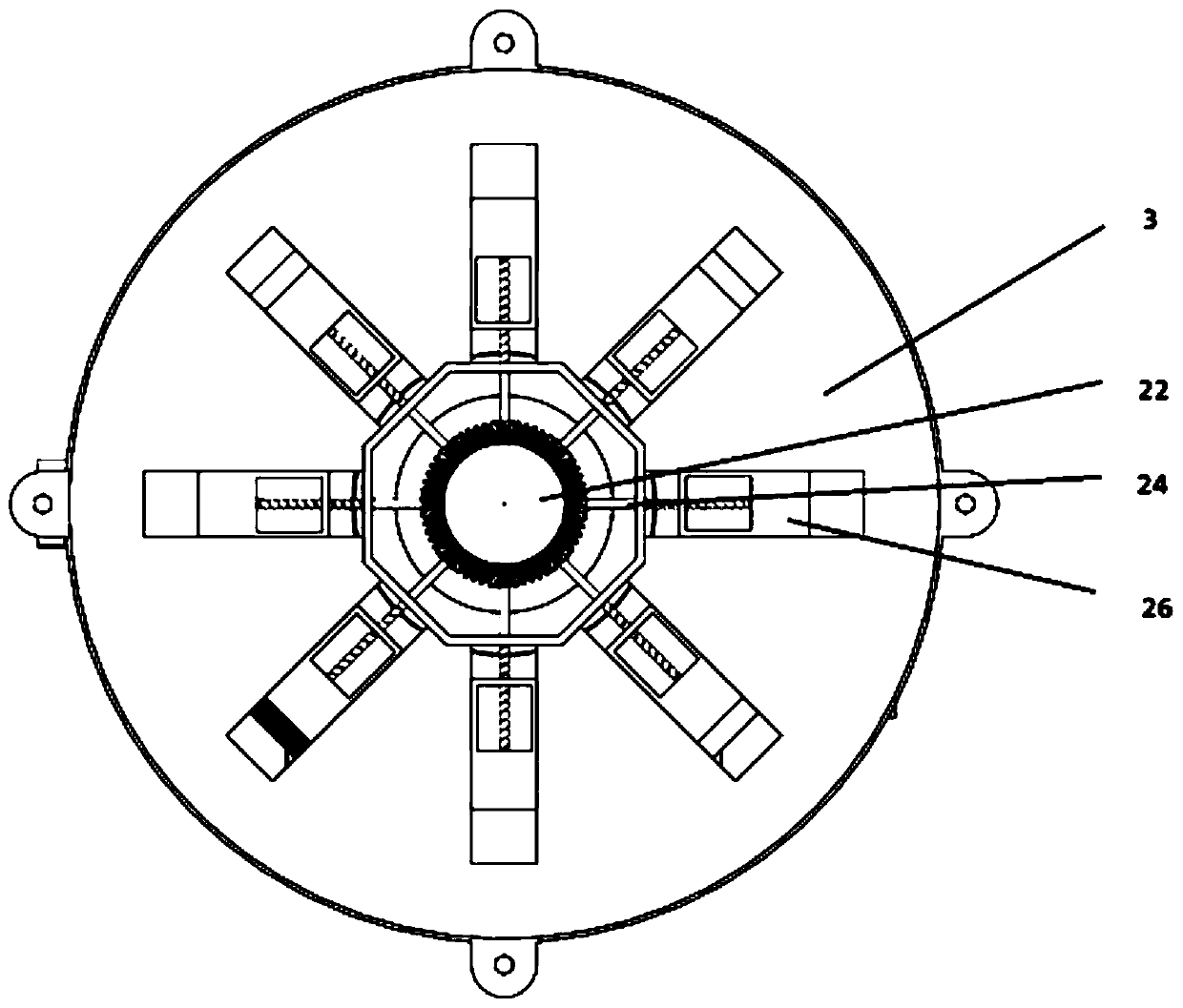

Rotary type volume-adjustable cup metering mechanism

ActiveCN111099069ARealize simultaneous feeding and dischargingImprove the efficiency of metering and dispensingSolid materialControl engineeringControl theory

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com