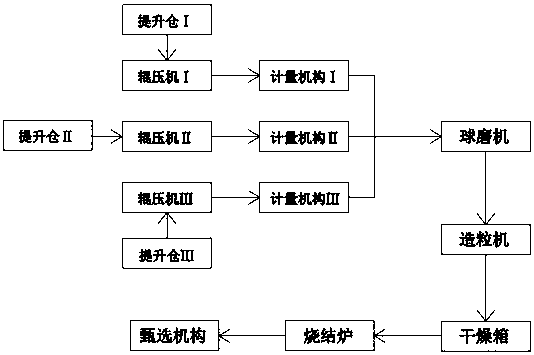

Aggregate production intelligent control system and method

An intelligent control system and control system technology, applied in chemical instruments and methods, solid separation, filtration, etc., can solve problems such as inability to provide feedback to guide staff to adjust, reduce aggregate production efficiency, and weak self-adjusting ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

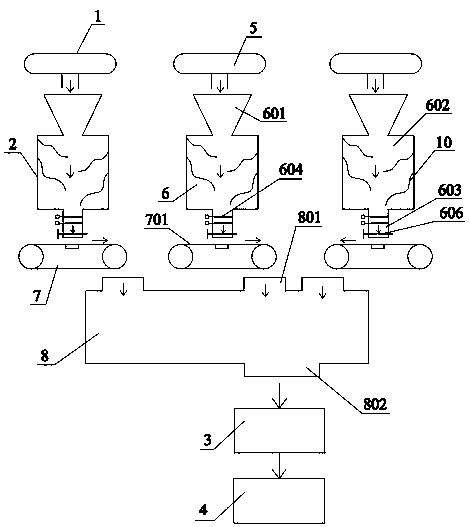

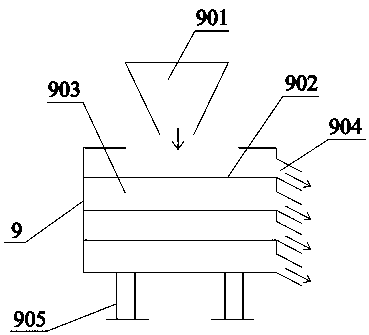

[0030] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions will be clearly and completely described below in conjunction with the embodiments of the present invention. Describe the scheme of the present invention in detail below in conjunction with specific embodiment:

[0031] An intelligent control system for aggregate production, including multiple stand-alone devices and a control system for production, each stand-alone device is provided with a motor, and the control system is provided with an alarm module; the control system includes interconnected communication Module, program setting module and processor, the processor receives the signals from the temperature sensor I, weighing sensor I, weighing sensor II, speed sensor and temperature sensor II set on the stand-alone equipment through the communication module, and Process the received signal and issue instructions;

[0032]The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com