Patents

Literature

92results about How to "Realize automatic adjustment control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

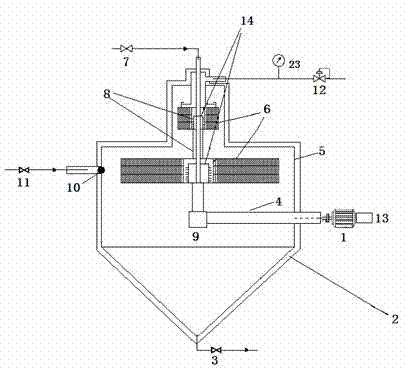

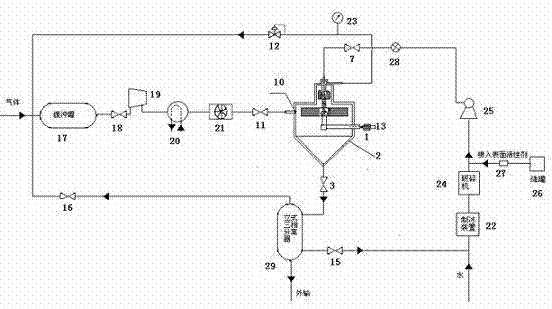

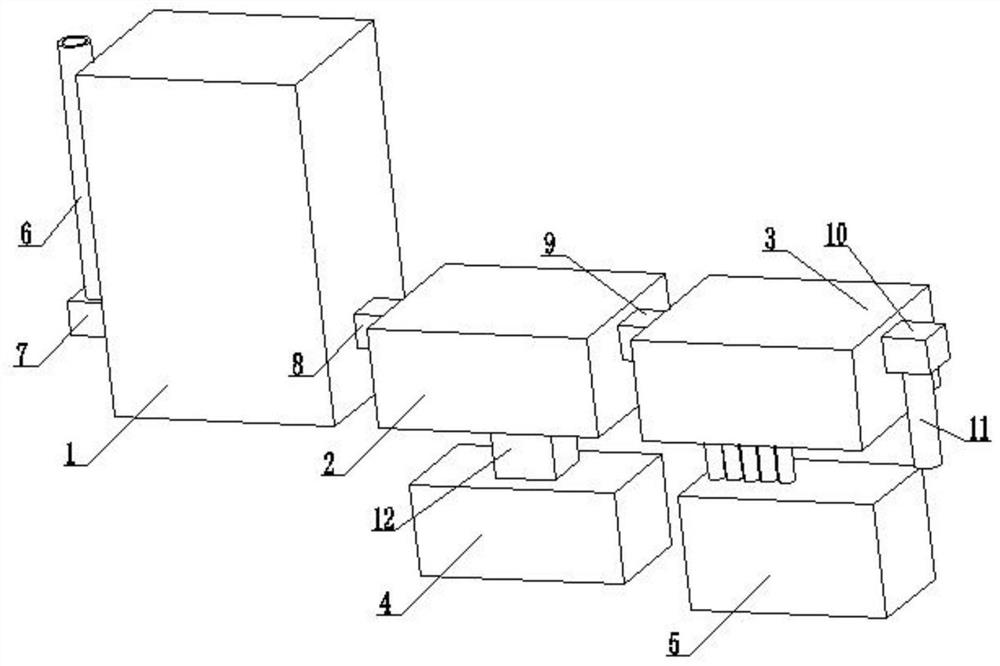

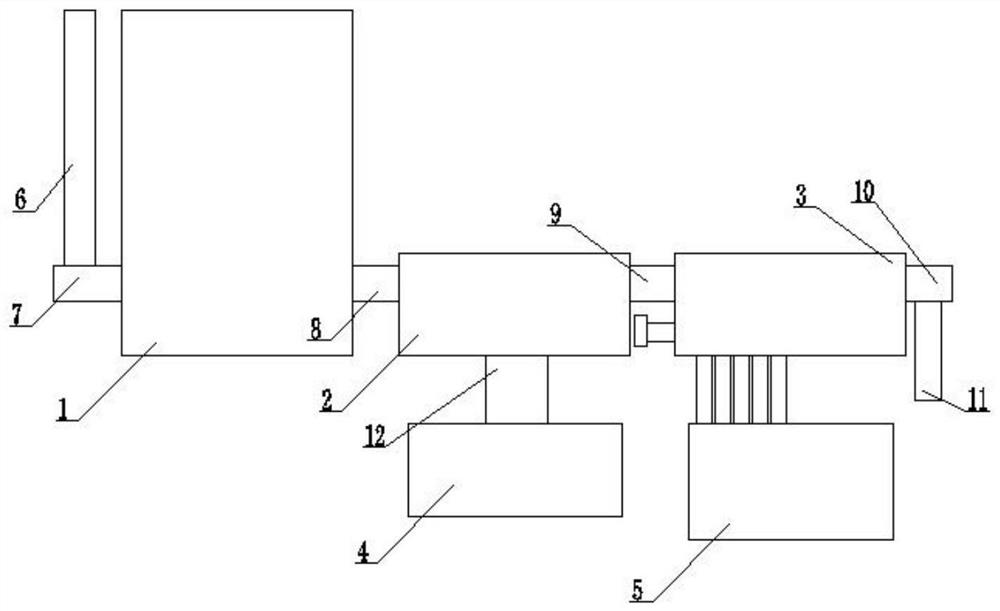

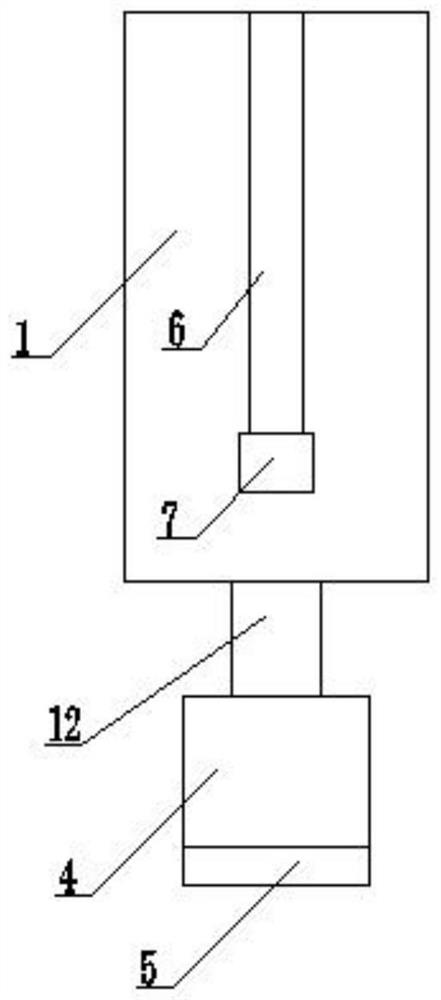

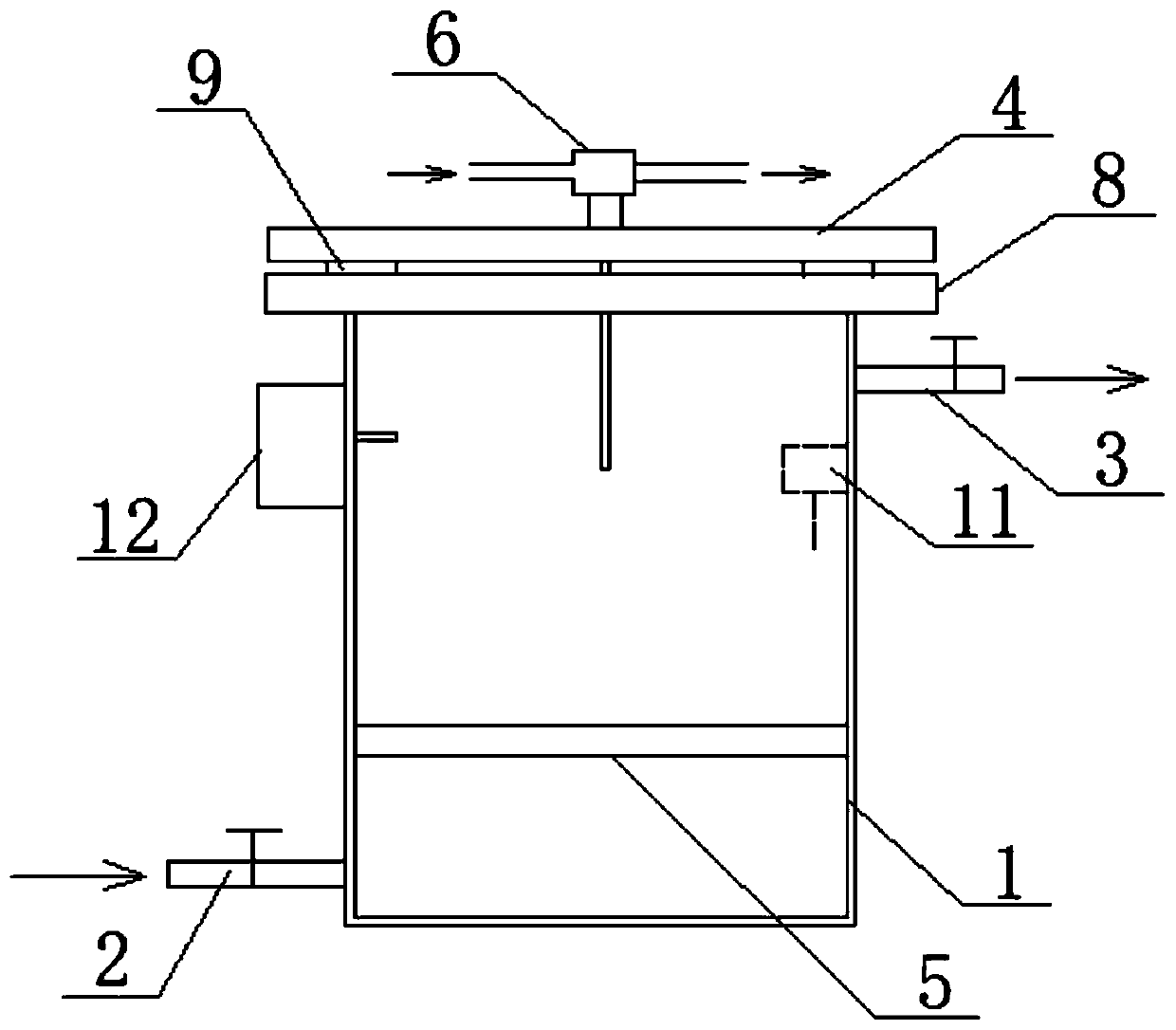

Supergravity hydrate synthesis device

ActiveCN103285781AUniform inflowHigh synthesis efficiencyChemical/physical processesBuffer tankThree-phase

The invention relates to the technical field of hydrate synthesis, storage and transportation and particularly relates to a supergravity hydrate synthesis device. The supergravity hydrate synthesis device comprises a cut-off valve, a one-way liquid valve, a nozzle, a one-way gas valve, a pressure regulating valve, a gas buffer tank, a compressor, a condenser, a turbine flowmeter, an ice maker, a pressure gauge, a pulping machine, a slurry pump, a surfactant storage tank, a Laval spraying valve, a mass flowmeter, a vertical three-phase separator and a supergravity reactor. The supergravity hydrate synthesis device adopts a supergravity technology for enhancing the heat transfer and mass transfer in a hydrate synthesis process, so that the reaction time is shortened, the equipment size decreases, the production cost is reduced, and a tapered outlet is formed so as to be helpful to the outflow of generated hydrates.

Owner:南通东湖国际商务服务有限公司

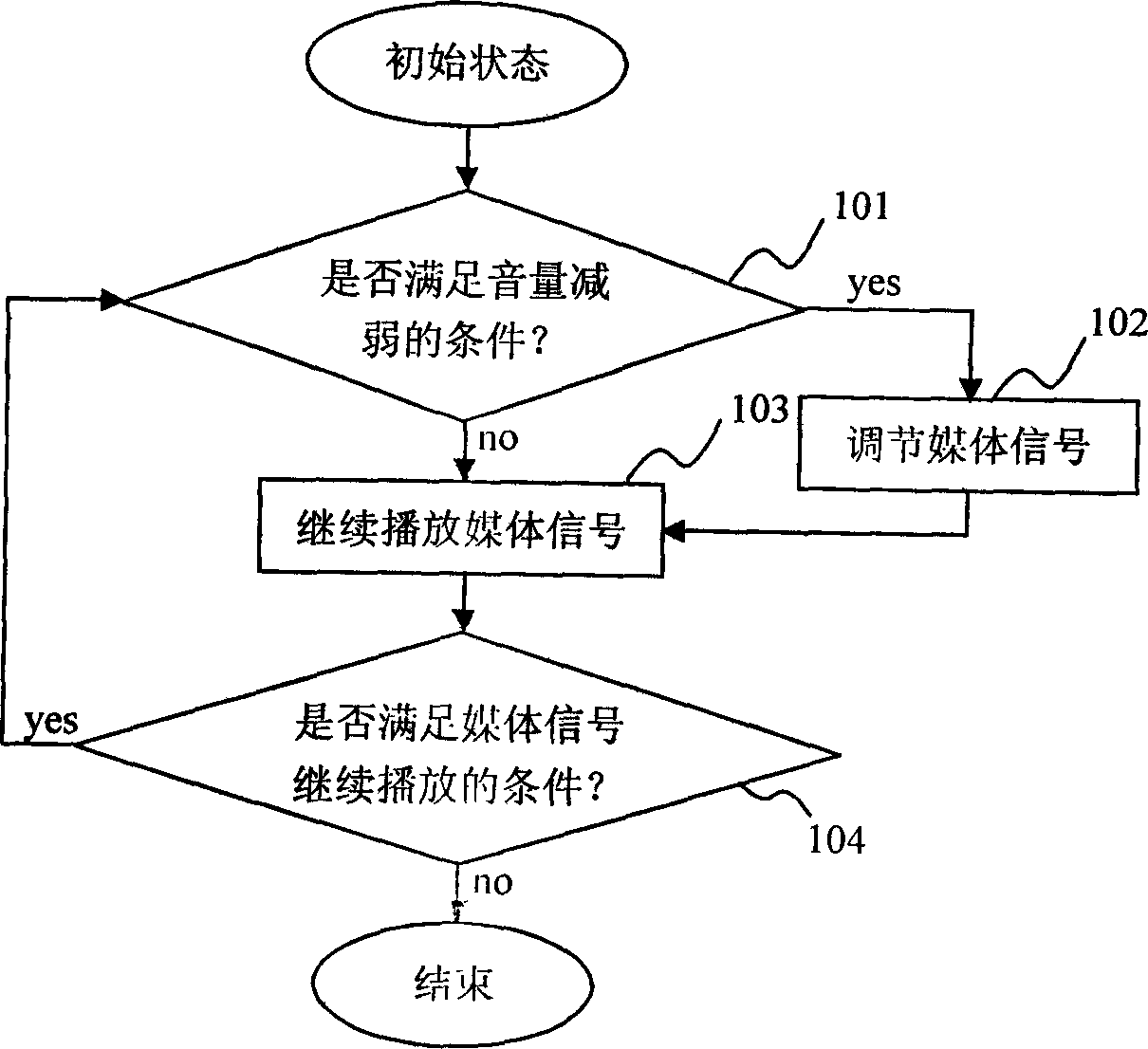

Method for protecting hearing by adjusting volume based on medium player

The invention can automatically tunes the volume of playing sound signal to meet a volume weaken condition and includes the follow steps: when the signal meets the sound volume weaken condition, after tuning down the sound volume, the media signals are played again; when the signal doesn't meet the volume weaken condition, the current signal is directly played; deciding if the played signal meets the condition of continuing play; if yes, then returning to the initial state of the program, and then deciding if the signal still meets the sound volume weaken condition.

Owner:INVENTEC MULTIMEDIA & TELECOM (TIANJIN) CO LTD

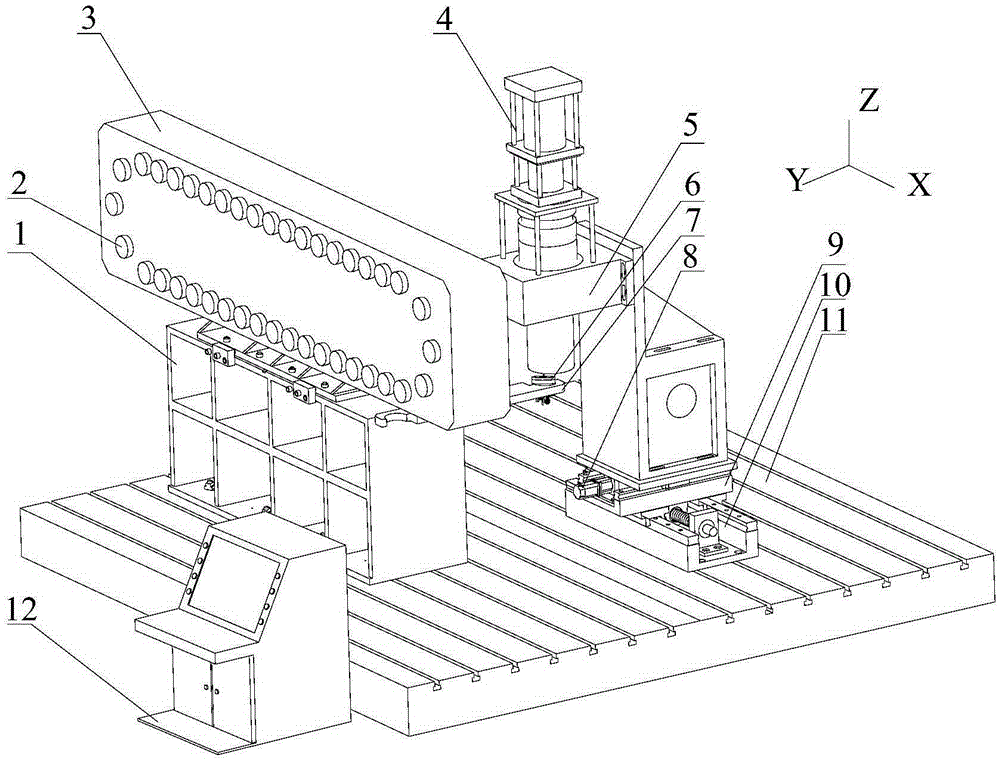

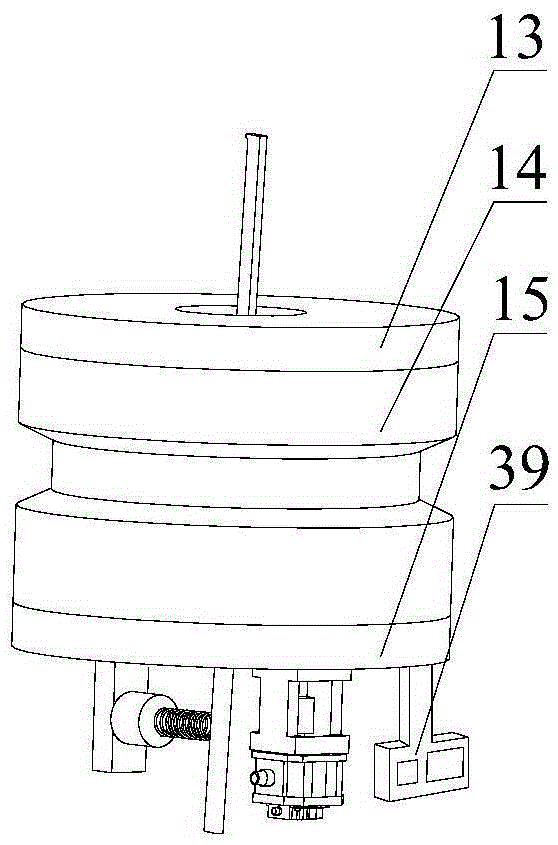

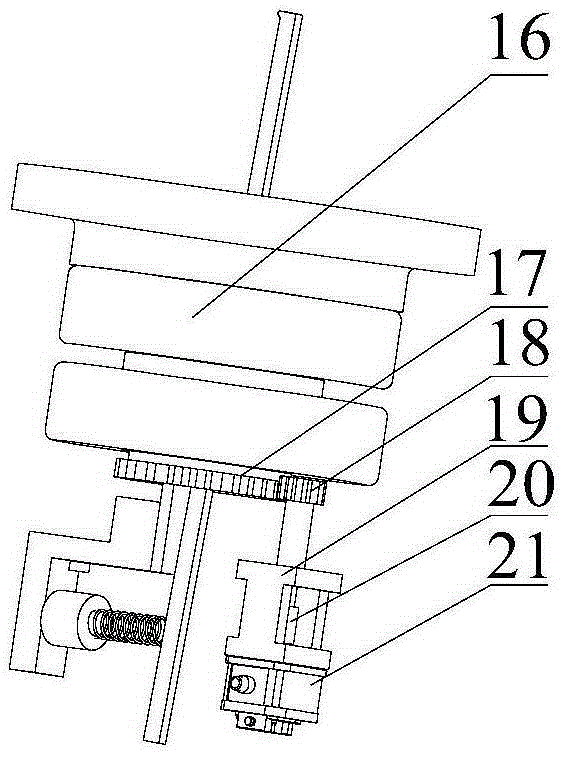

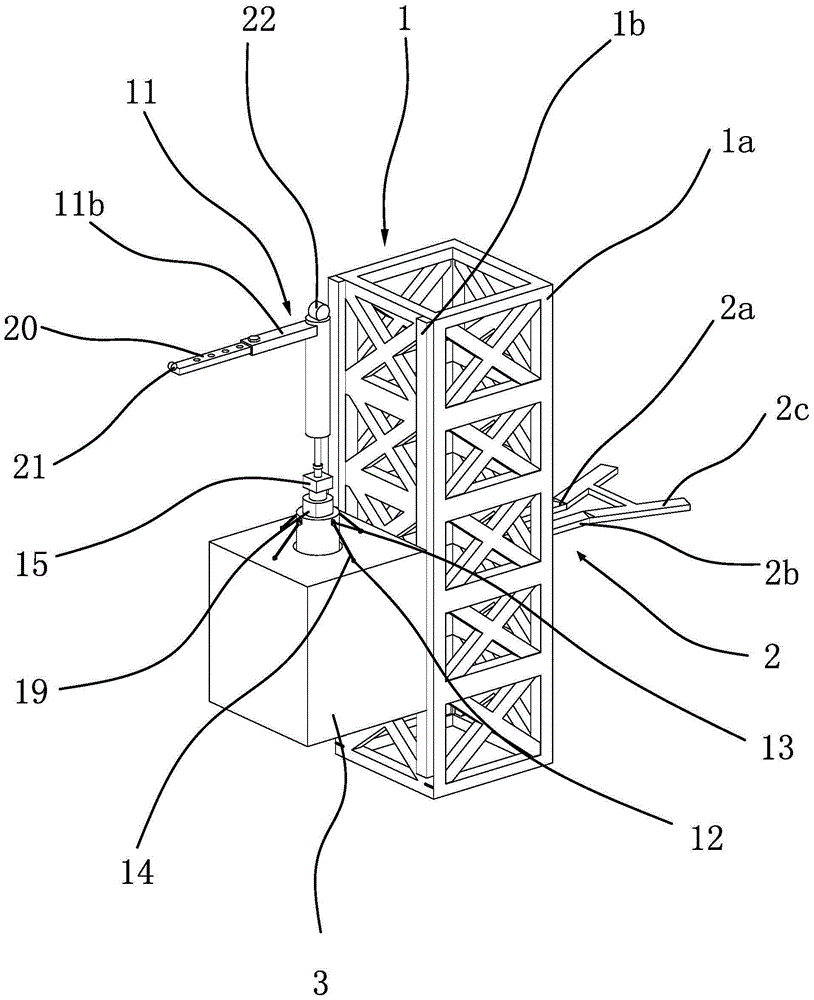

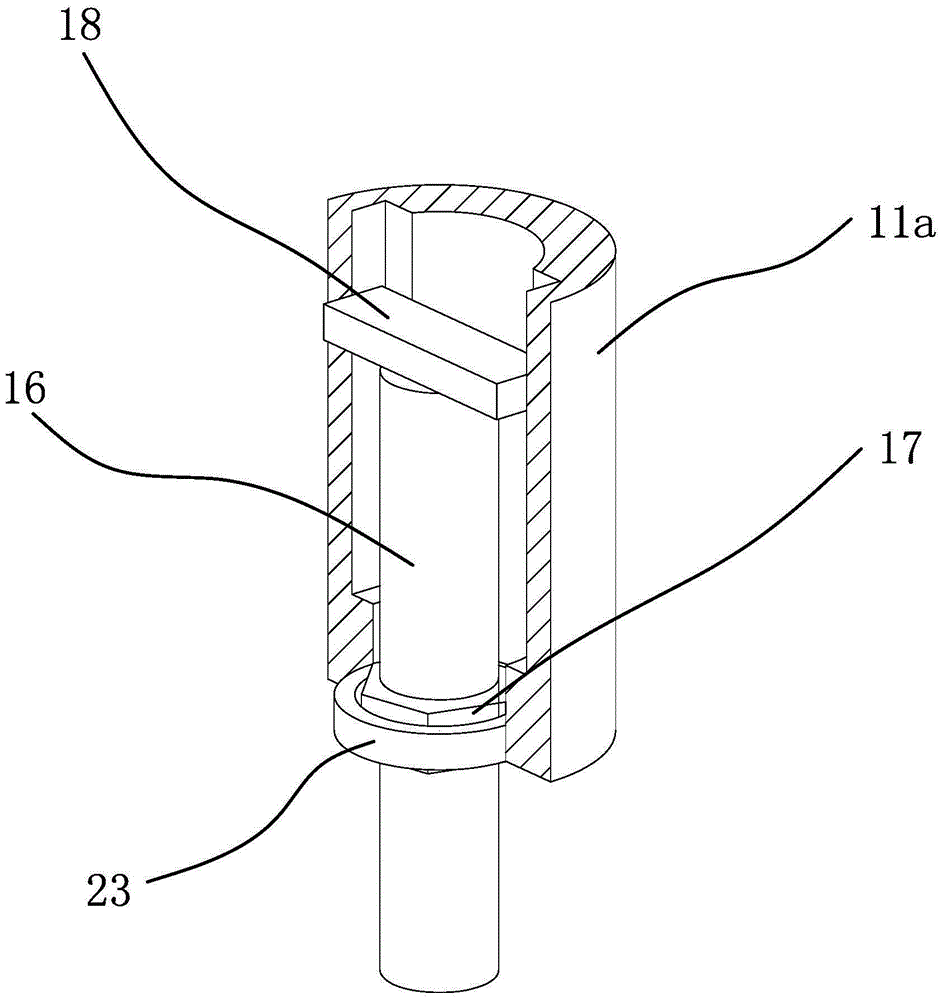

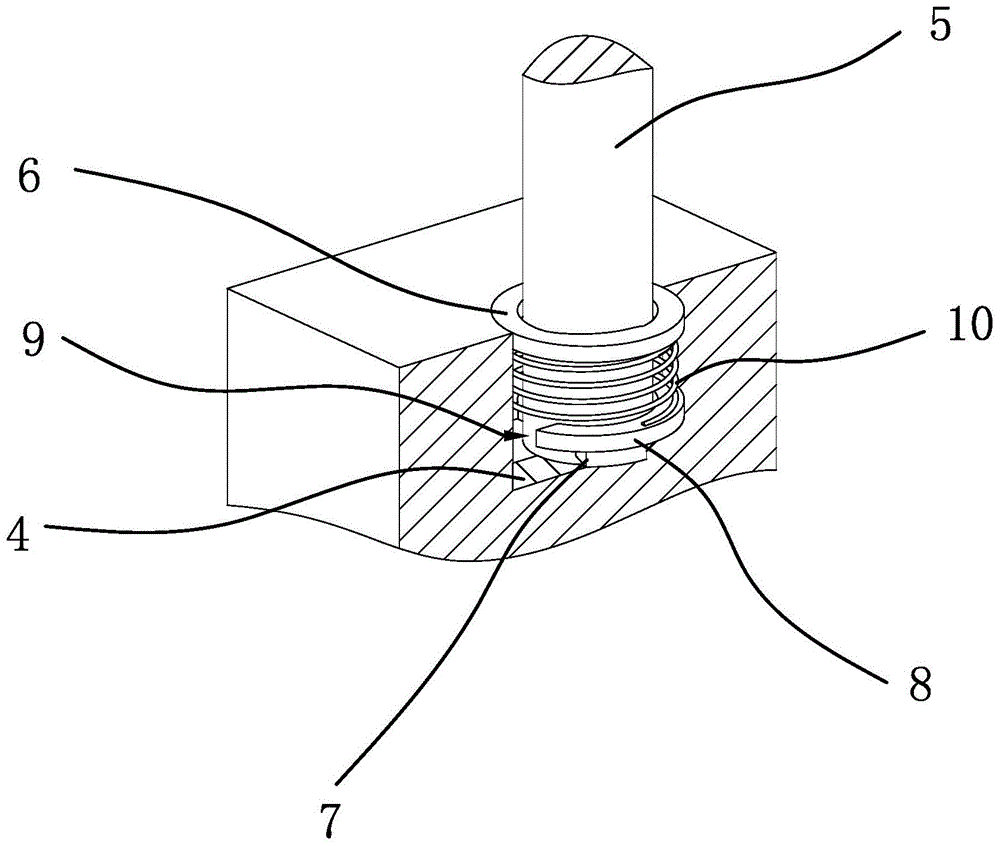

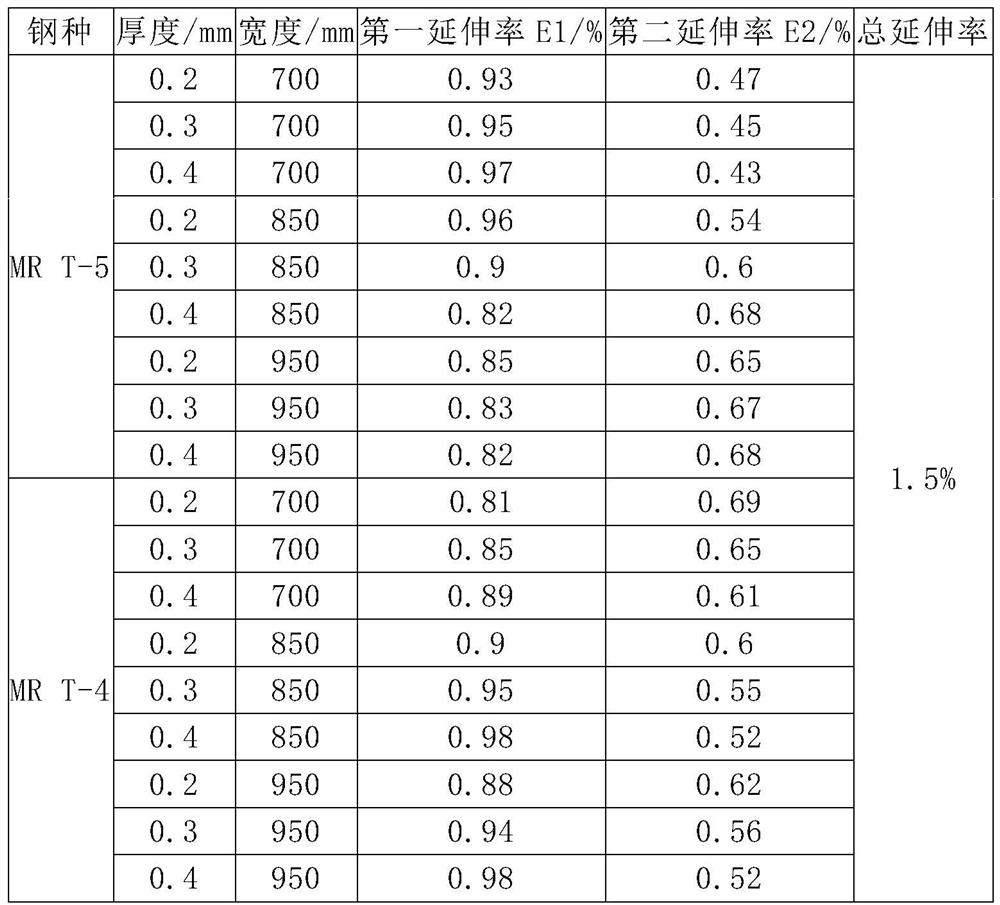

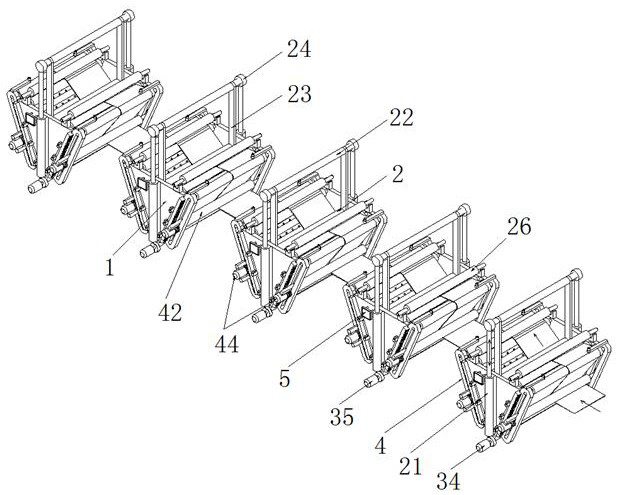

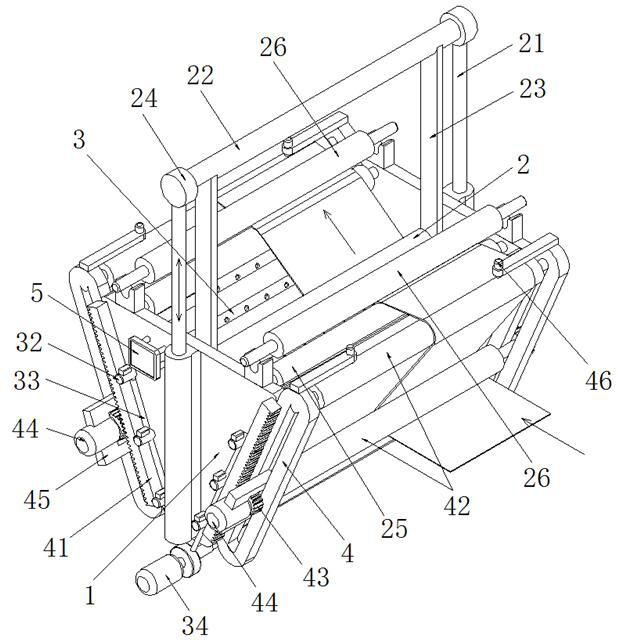

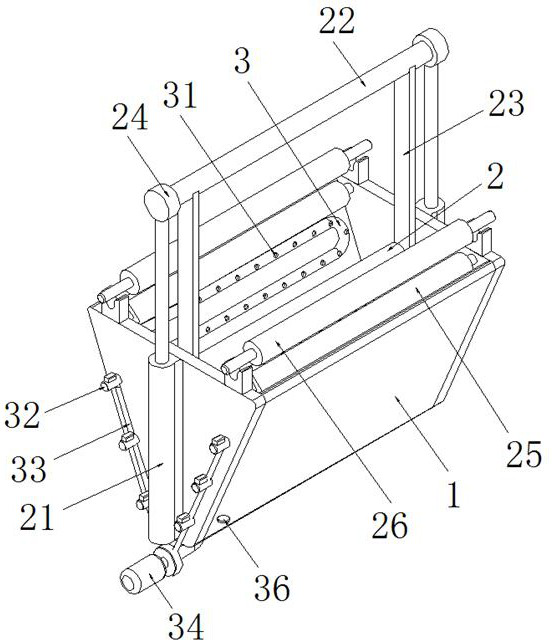

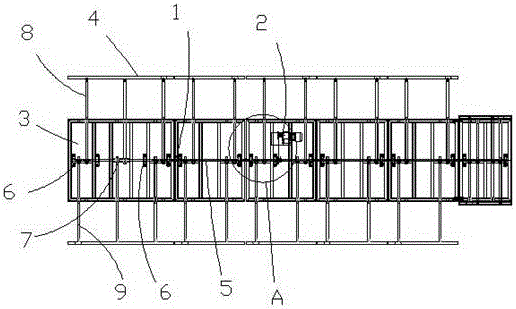

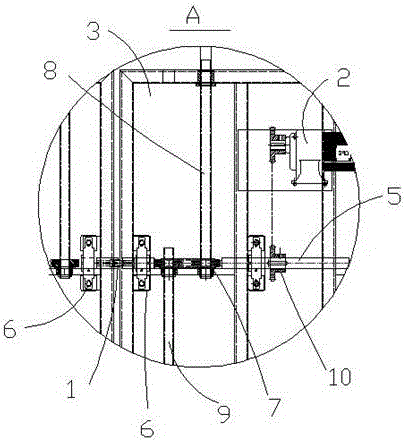

Tool magazine reliability test bench tool change position adaptive centering adjustment device and method

ActiveCN105372091AHigh precisionImprove real-time performanceStructural/machines measurementEngineeringChange positions

A tool magazine reliability test bench tool change position adaptive centering adjustment device and method belong to the mechanical adaptive adjusting field, and aim to solve the problems of low adjusting precision and complex operation and the time-consuming and labor-consuming problems in the prior art. The device comprises a measurement taper shank, an automatic mechanical detection device and a main-shaft bottom feeding unit; and a drive gear and a driven gear in the automatic mechanical detection device are integrally disposed in a tool-grabbing disc, a servo motor A drives the drive gear to rotate, a positioning adjusting rod is connected with the lower end face of a driven gear shaft through an adjusting screw, a measuring rod is connected with the upper part of the positioning adjusting rod through a positioning pin, the positioning pin is located on the axis of the driven gear shaft, a force sensor is fixed to the lower part of the positioning adjusting rod, and the force sensor is connected to the lower part of the measuring rod through a connecting spring. The measurement taper shank is coaxially installed on a mechanical main shaft, the tool-grabbing disc of the automatic mechanical detection device is clamped through a manipulator, and a control unit of a tool magazine reliability test bench controls a motion of the main-shaft bottom feeding unit according to a signal acquired by the force sensor.

Owner:JILIN UNIV

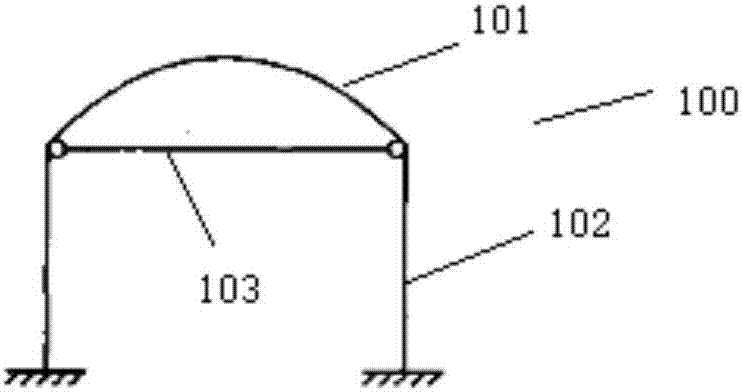

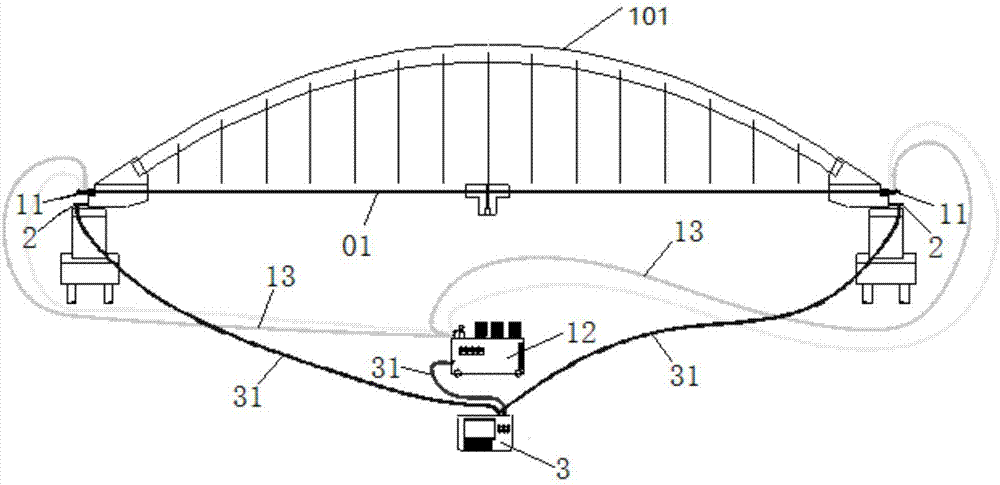

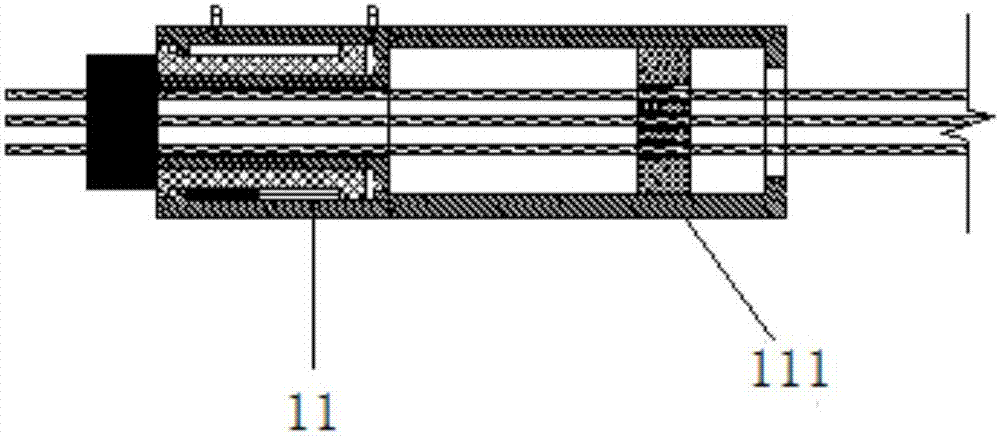

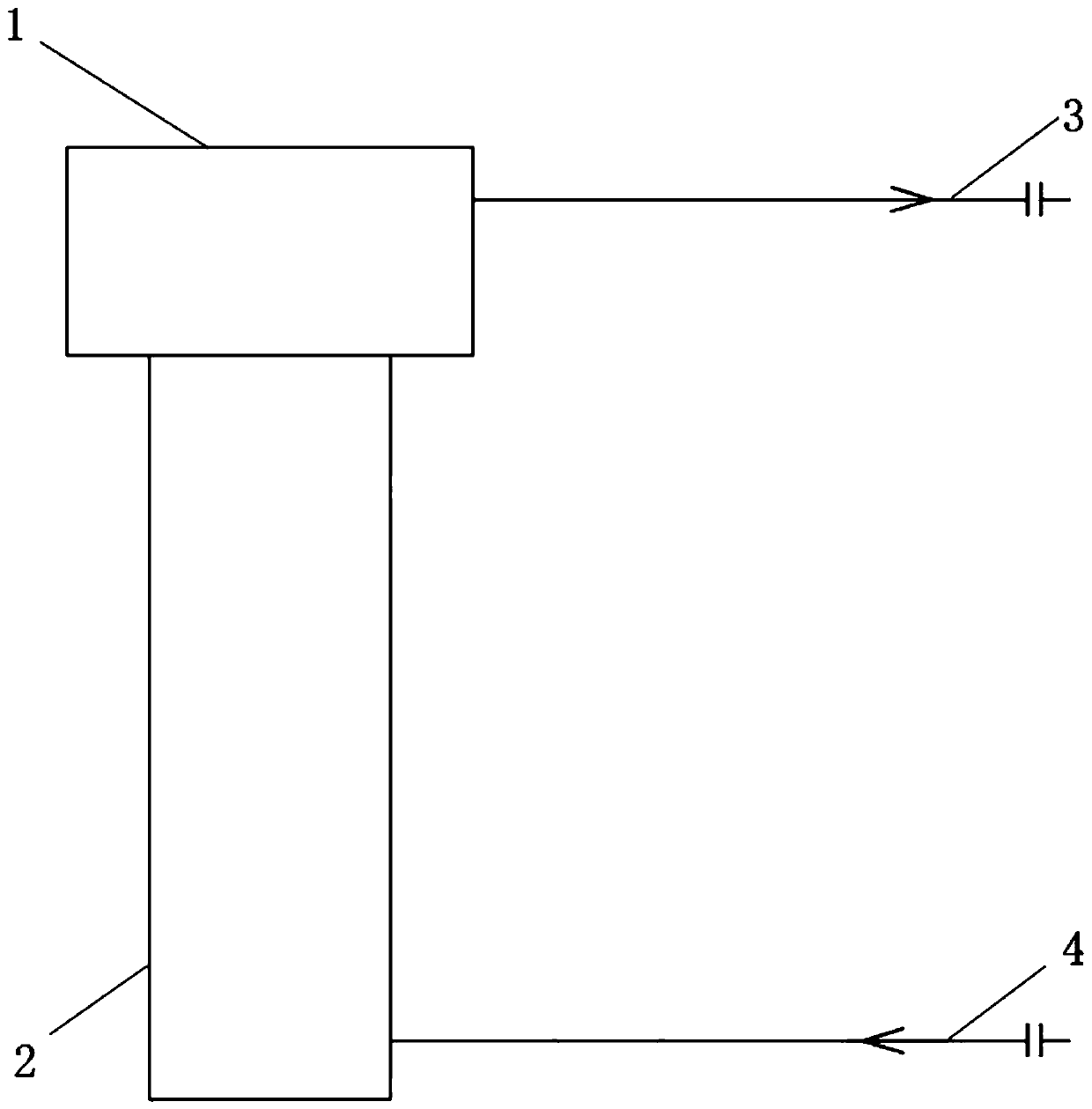

Arch bridge construction tie rod regulating system

PendingCN107313354ARealize automatic adjustment controlReduce internal forceBridge erection/assemblyArch-type bridgeData controlHydraulic pump

The invention provides an arch bridge construction tie rod regulating system. The system comprises a hydraulic system, a displacement sensor and a console; the hydraulic system comprises a hydraulic terminal and a hydraulic pump station, and the hydraulic pump station supplies hydraulic oil for the hydraulic terminal so as to regulate the hydraulic pressure output by the hydraulic terminal; the hydraulic system is used for applying acting force to an arch rib; the displacement sensor is used for measuring the end displacement of the arch rib; the console is connected with the hydraulic pump station and the displacement sensor through a data line; the hydraulic terminal is used for applying acting force to an end of the arch rib, the displacement sensor is used for measuring the displacement of the end of the arch rib and transmitting the result of measurement to the console, and the console is used for controlling the quantity of the hydraulic oil supplied by the hydraulic pump station for the hydraulic terminal according to the data of the displacement sensor.

Owner:SHANGHAI PUDONG NEW DISTRICT ROAD CONSTR DEV

Automatic telescopic water control spur dike

ActiveCN105780720AAvoid water damageSatisfy navigation and flood protection requirementsBreakwatersQuaysFlood controlEngineering

The invention discloses an automatic telescopic water control spur dike. The automatic telescopic water control spur dike comprises a dike body, wherein the overall dike body is vertically arranged. The automatic telescopic water control spur dike is characterized in that an outer end section of the dike body extends out of a river way; an inner end section of the dike body is concavely arranged on a river bank through a sliding chute and is connected with a telescopic transmission mechanism; the telescopic transmission mechanism is connected with a power machine, then the outward telescopic movement of the dike body is implemented. The automatic telescopic water control spur dike has the advantages that the channel water level can be automatically adjusted, the navigation and flood control requirements of the rivers can be effectively met, the flood control protection of the dike body can be implemented, and the dike is applicable to the rivers with great water level change in flood and drought periods.

Owner:CHONGQING JIAOTONG UNIVERSITY

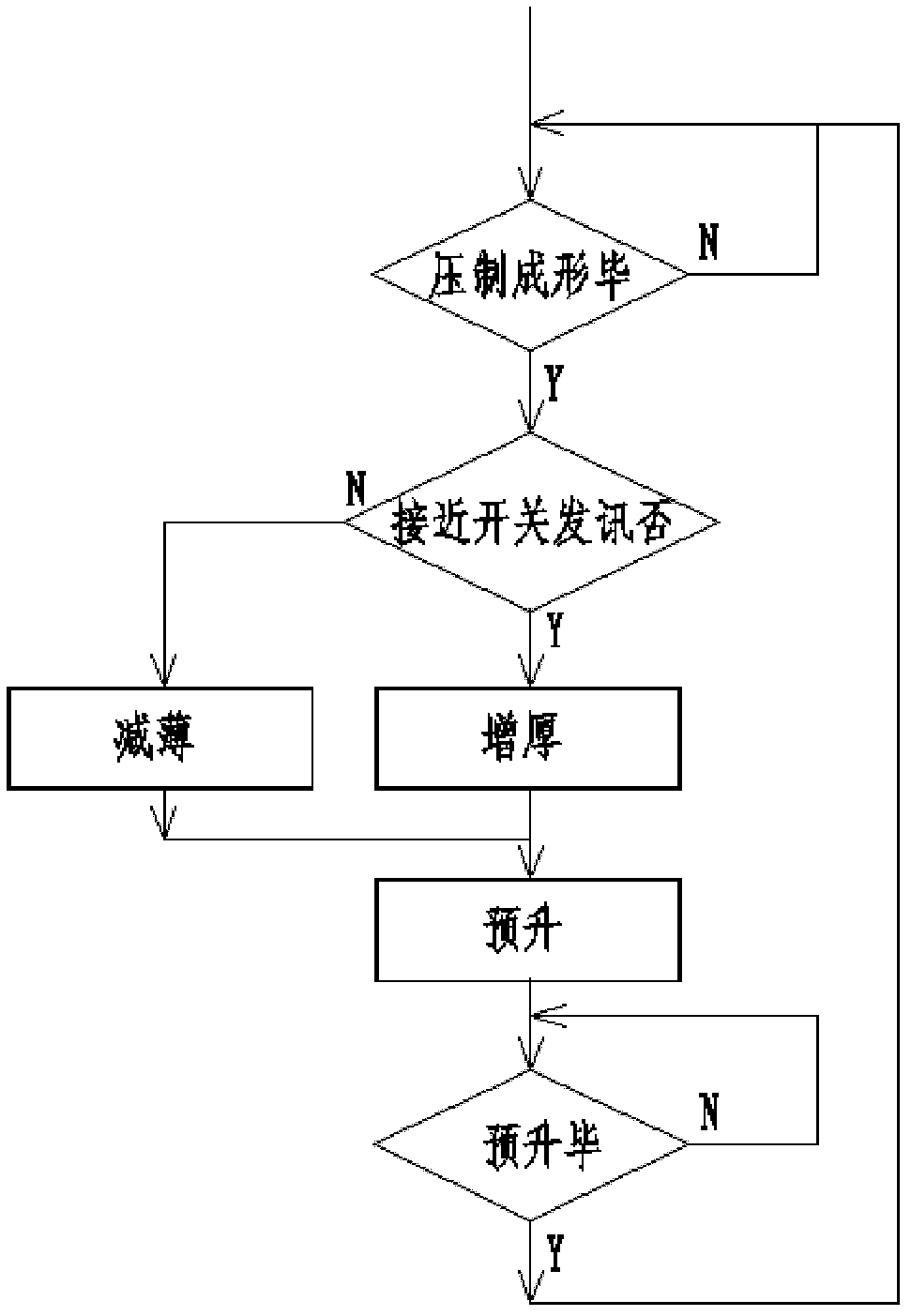

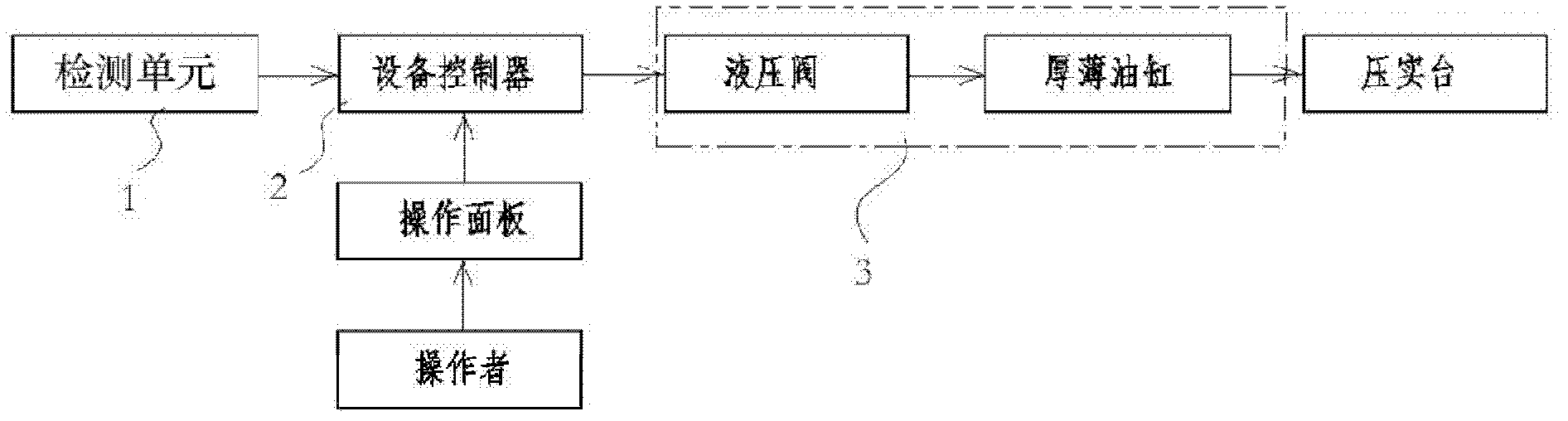

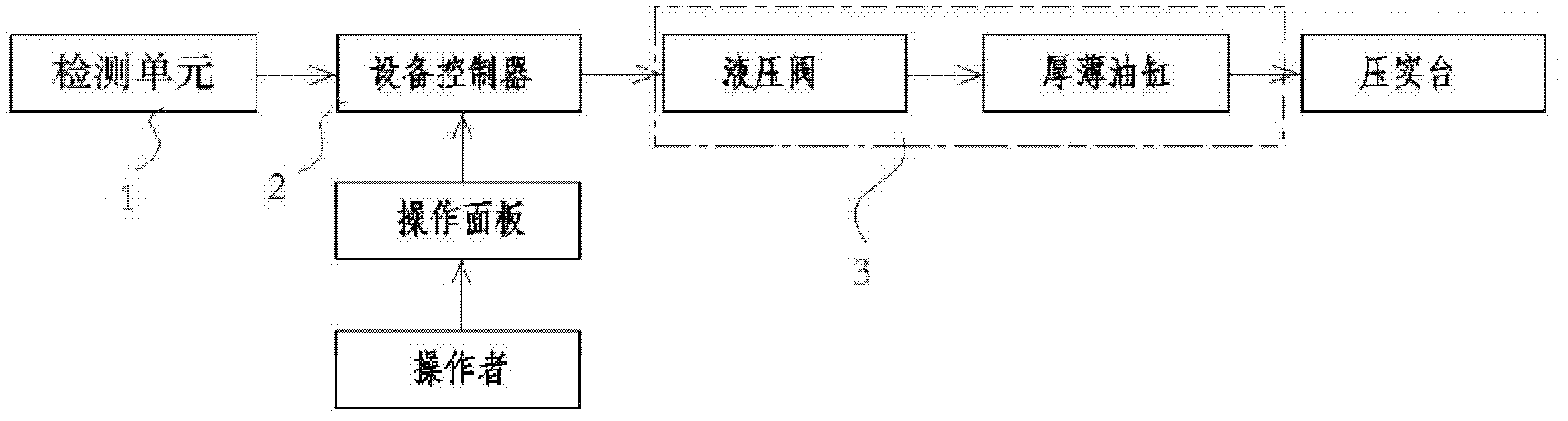

Method and system for controlling thickness of sand mold of piston ring three-station molding machine

InactiveCN102615250ARealize automatic adjustment controlIngenious designMoulding machinesNumerical controlMolding machinePiston ring

The invention discloses a method and a system for controlling the thickness of a sand mold of a piston ring three-station molding machine. The method comprises the following steps of: 1, in the process of manufacturing the sand mold, detecting the lifting magnitude of a compaction platform to determine the thickness of the sand mold which is obtained by press molding; 2, transmitting a correction instruction to a lifting adjusting mechanism of the compaction platform by an equipment controller according to a determination result; and 3, adjusting a pre-lifting in-place position of the compaction platform in real time by the lifting adjusting mechanism of the compaction platform according to the correction instruction, and performing the manufacturing process of the next sand mold. The method is skillfully designed, and by the method, the automatic adjustment and control of the thickness of the sand mold can be realized through mutual cooperation of a few components, defects existing in the conventional production process are overcome, the yield of the sand molds is increased, and the cost for reconstruction of the whole system is low, so the method is suitable for popularization.

Owner:CMCU ENG

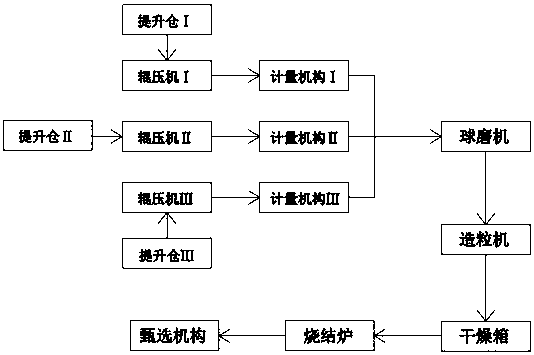

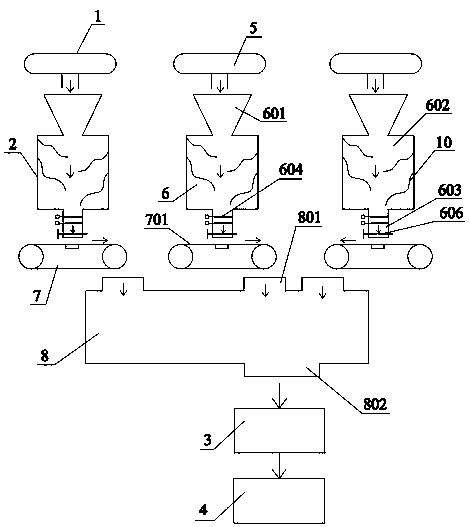

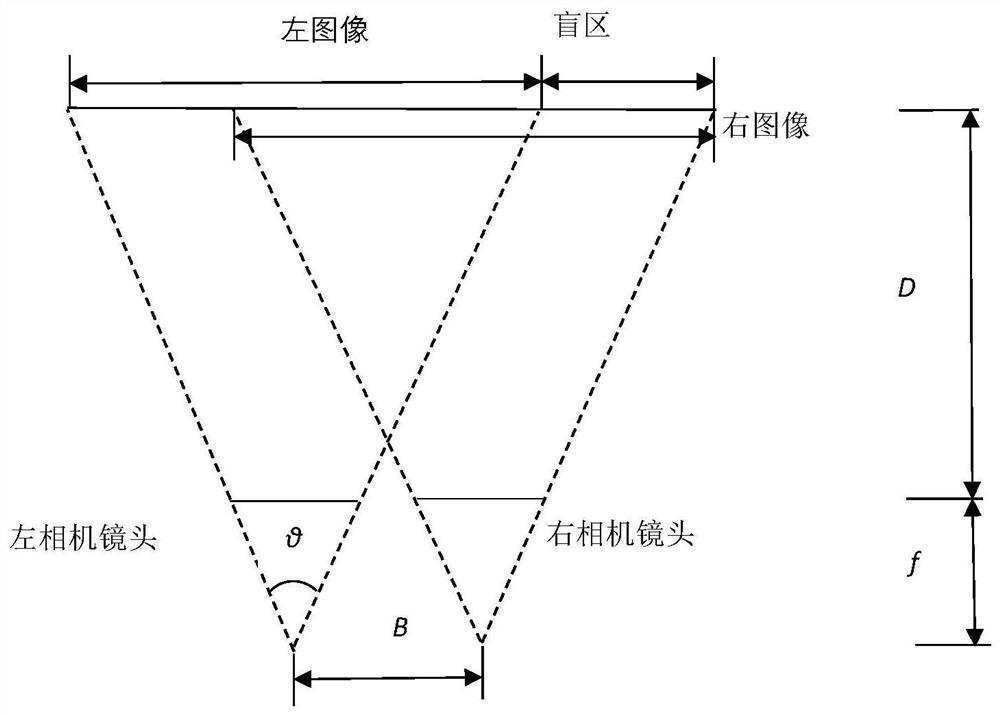

Aggregate production intelligent control system and method

ActiveCN108483962ARealize automatic adjustment controlPlay the role of buffer diversionSievingScreeningEngineeringControl valves

The invention provides an aggregate production intelligent control system and method. The aggregate production intelligent control system comprises a grinding mechanism, a metering mechanism, a molding sintering mechanism, a screening mechanism and a control system; the grinding mechanism comprises a lifting compartment, a rolling machine and a ball mill; the metering mechanism comprises a cone feeding pipe, a storage box, a material guiding pipe and belt scale; a flow dividing plate is arranged in the material guiding pipe, a control valve is arranged at the lower end, the feeding port of theball mill is connected with the discharging end of the belt scale, the discharging port is communicated with the molding sintering mechanism, and the molding sintering mechanism comprises a pelletizer, a drying box and a sintering furnace; the screening mechanism comprises a vibration screening box and a feeding hopper, a screening plate is arranged in the vibration screening box, and a hydrauliccolumn is arranged below the screening plate; and a processor of the control system receives the signals emitted by a temperature sensor I and a temperature sensor II, a weighing sensor I and a weighing sensor II and a velocity sensor on single machine equipment through a communication module, and processes and sends commands. By combining the single machine equipment with intelligent control, automation of the production process is achieved, and the failure processing capability and production efficiency are improved effectively.

Owner:洛阳大华智能科技有限公司

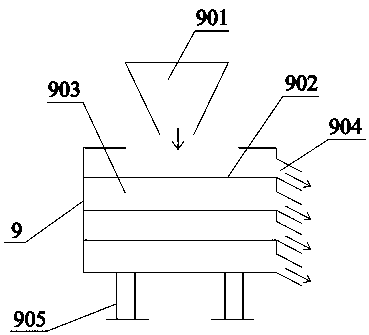

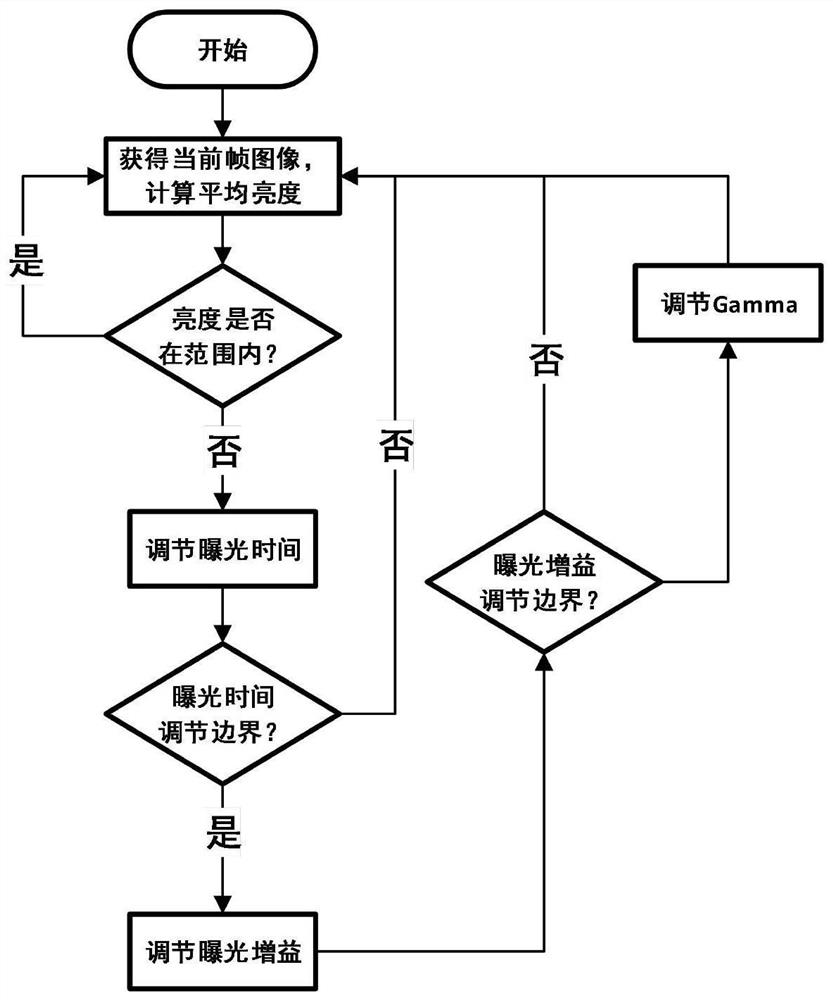

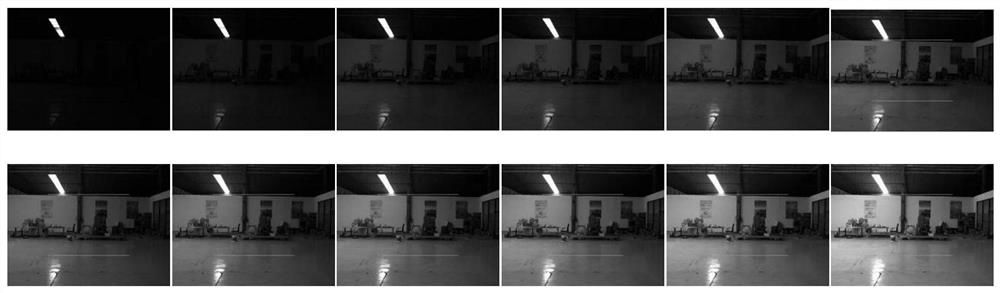

Automatic exposure adjusting method for binocular camera of fire-fighting robot

ActiveCN113382143AQuality improvementGuaranteed uptimeTelevision system detailsColor television detailsStereo matchingOphthalmology

The invention relates to an automatic exposure adjusting method for a binocular camera of a fire-fighting robot. The automatic exposure adjusting method is suitable for being used in underground extreme environments. The method comprises the steps: shooting and acquiring multi-sample image data of the binocular camera in the complex scene in an extreme environment according to a mode that the exposure time is gradually increased from small to large according to the fixed exposure gain and the exposure gain is gradually increased from small to large according to the fixed exposure time; in consideration of a special structure of a binocular camera and information overlapping of a binocular imaging system, carrying out the effective mutual information entropy analysis on multi-sample image data of the binocular camera, and carrying out the disparity map quality analysis on binocular image stereo matching by using a disparity map quality analysis factor; determining an image brightness target of automatic exposure adjustment of a binocular vision system of the fire-fighting robot; performing automatic exposure control on the camera according to the variable step exposure adjustment time obtained by comparing the calculated brightness information of the current frame image with the target brightness information. The device is simple in structure, effective in using method, high in practicability and convenient to transplant and expand.

Owner:CHINA UNIV OF MINING & TECH +1

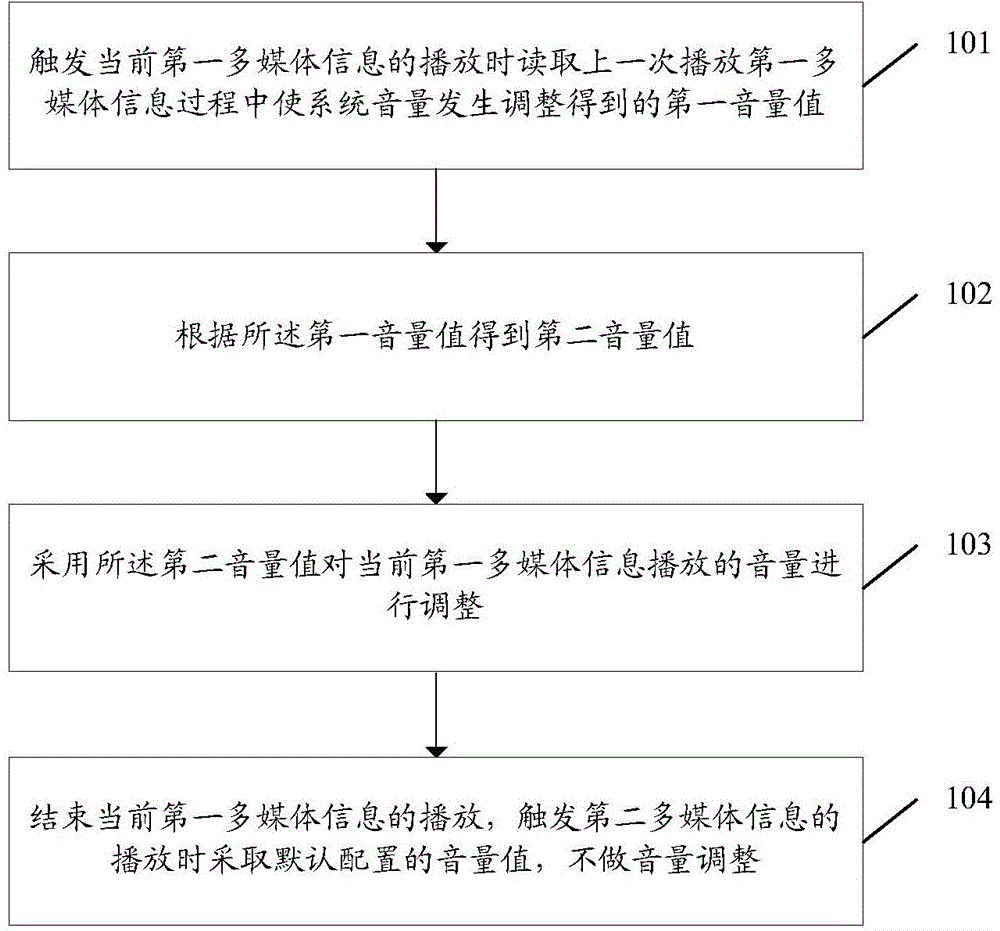

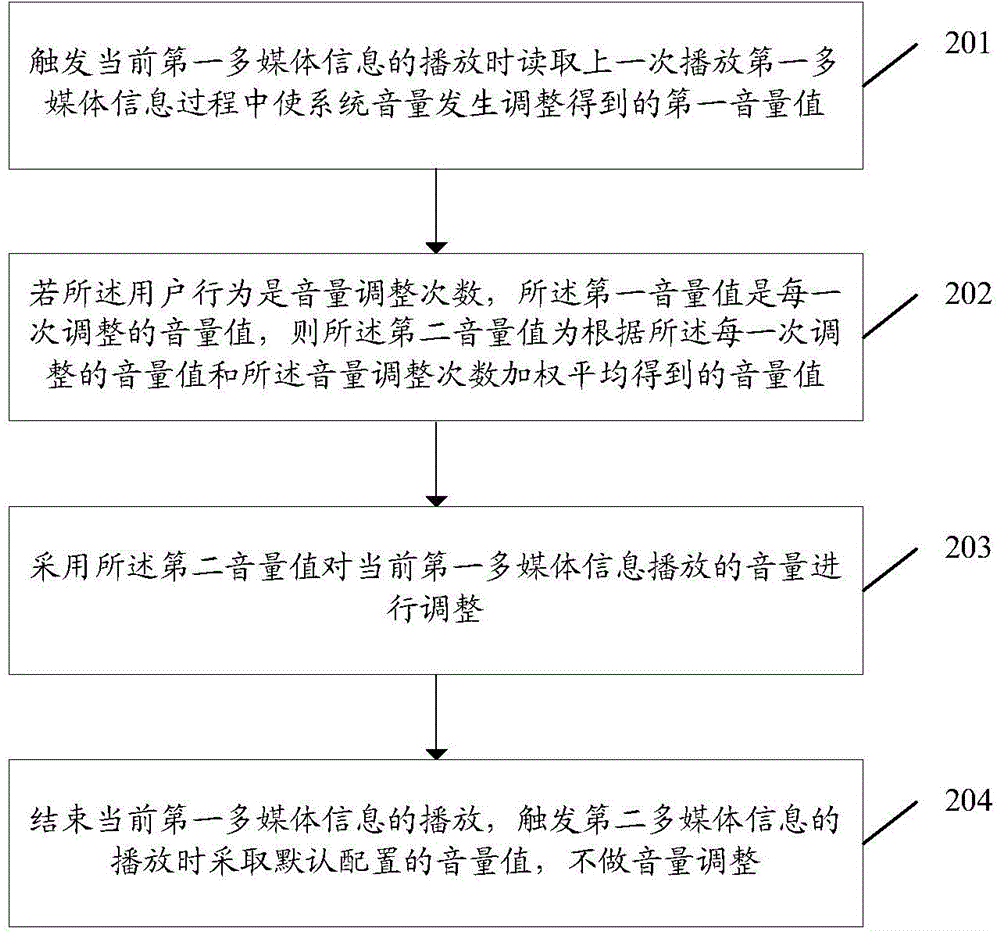

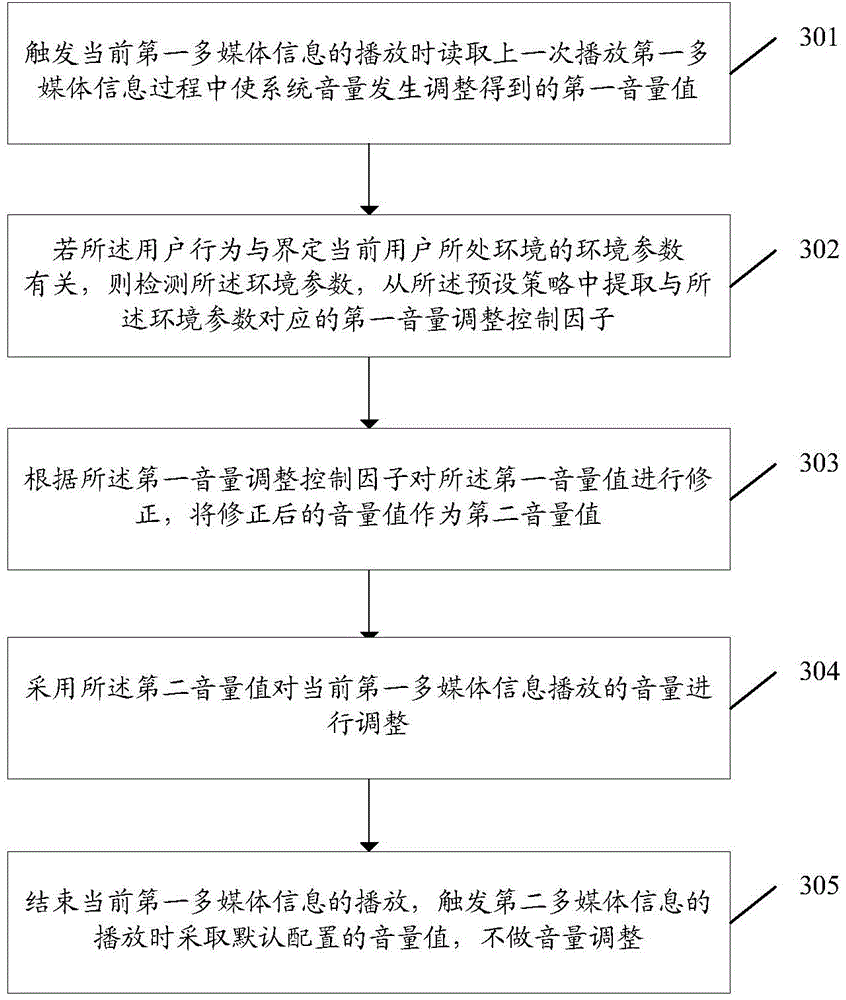

Volume control method of multimedia information and client terminal thereof

ActiveCN104617901ARealize automatic adjustment controlNo manual intervention involvedGain controlSoftware engineeringVolume control

The invention discloses a volume control method of multimedia information and a client terminal thereof, wherein the method comprises the following steps: reading a first volume value obtained by the adjustment of the system volume during the process of playing the first multimedia information last time while triggering the play of the existing first multimedia information; obtaining a second volume value based on the first volume value; using the second volume value to adjust the volume of playing the existing first multimedia information; ending the play of the existing first multimedia information, using a default volume value when triggering the play of the second multimedia information without the volume adjustment.

Owner:TENCENT TECH (BEIJING) CO LTD

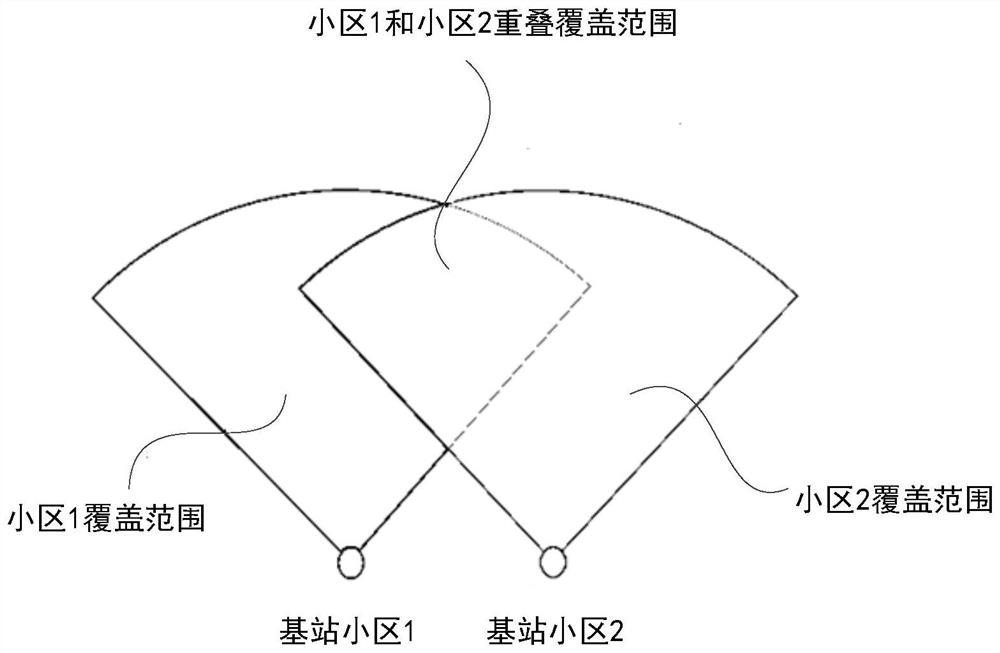

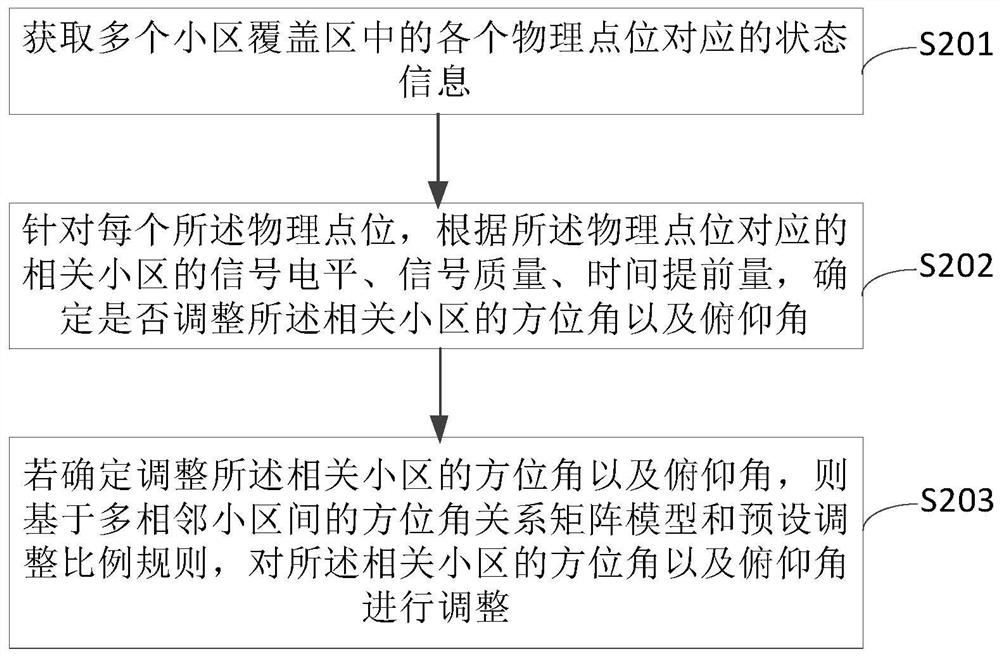

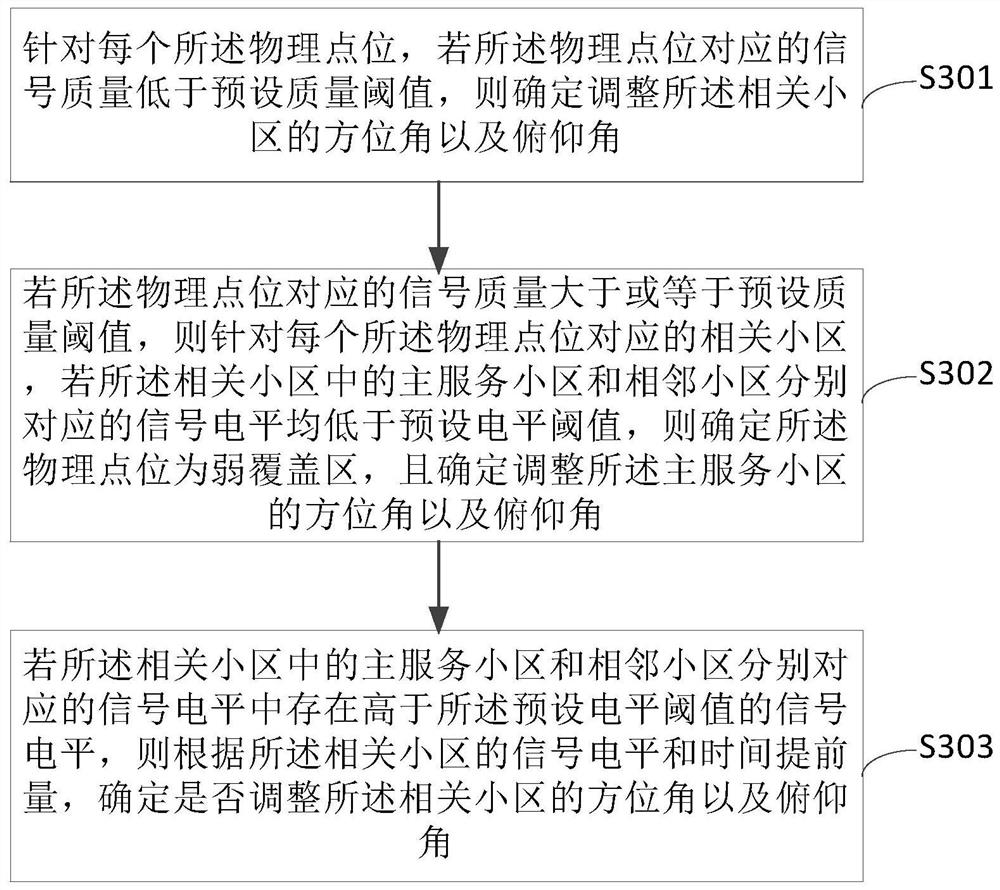

Control method and device for adjusting cell coverage area, equipment and storage medium

ActiveCN111654870AImplement the control methodRealize automatic adjustment controlNetwork planningSignal qualityEngineering

The embodiment of the invention provides a control method and device for adjusting a cell coverage area, equipment and a storage medium. The method comprises the following steps: acquiring state information corresponding to each physical point location in a plurality of cell coverage areas; for each physical point location, determining whether to adjust the azimuth angle and the pitch angle of therelated cell according to the signal level, the signal quality and the time advance of the related cell corresponding to the physical point location; and if it is determined that the azimuth angle and the pitch angle of the related cell are adjusted, adjusting the azimuth angle and the pitch angle of the related cell based on an azimuth angle relation matrix model between multiple adjacent cellsand a preset adjustment proportion rule. According to the method provided by the embodiment of the invention, rapid and accurate adjustment and a good coverage effect in the coverage area of the multi-base station cell can be realized.

Owner:CHINA UNITED NETWORK COMM GRP CO LTD

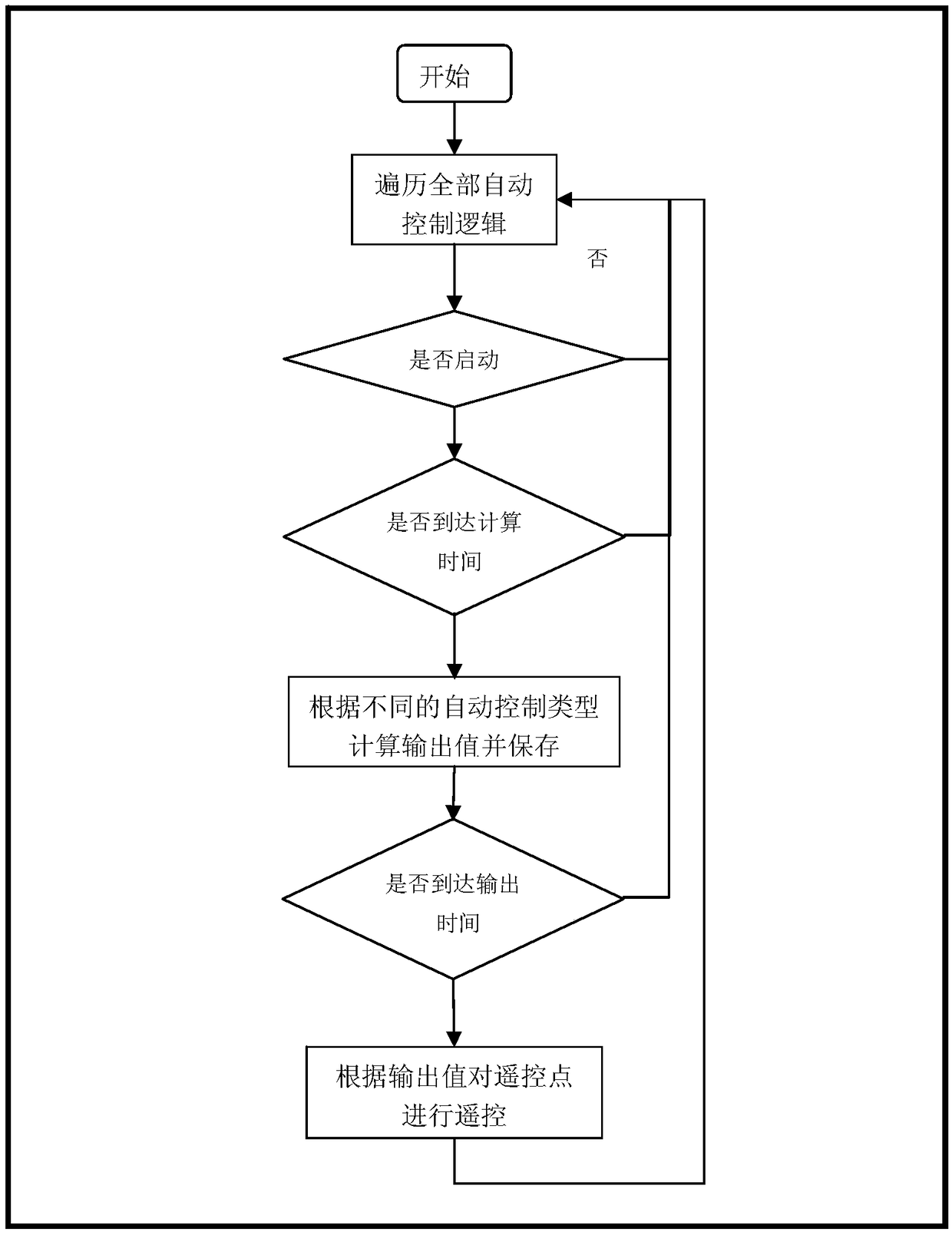

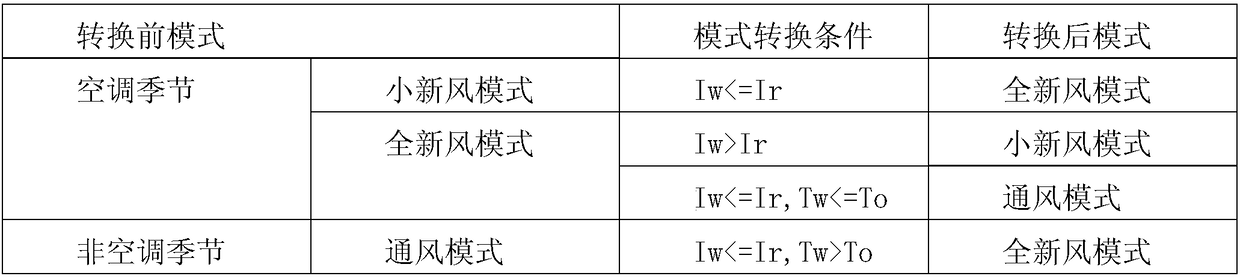

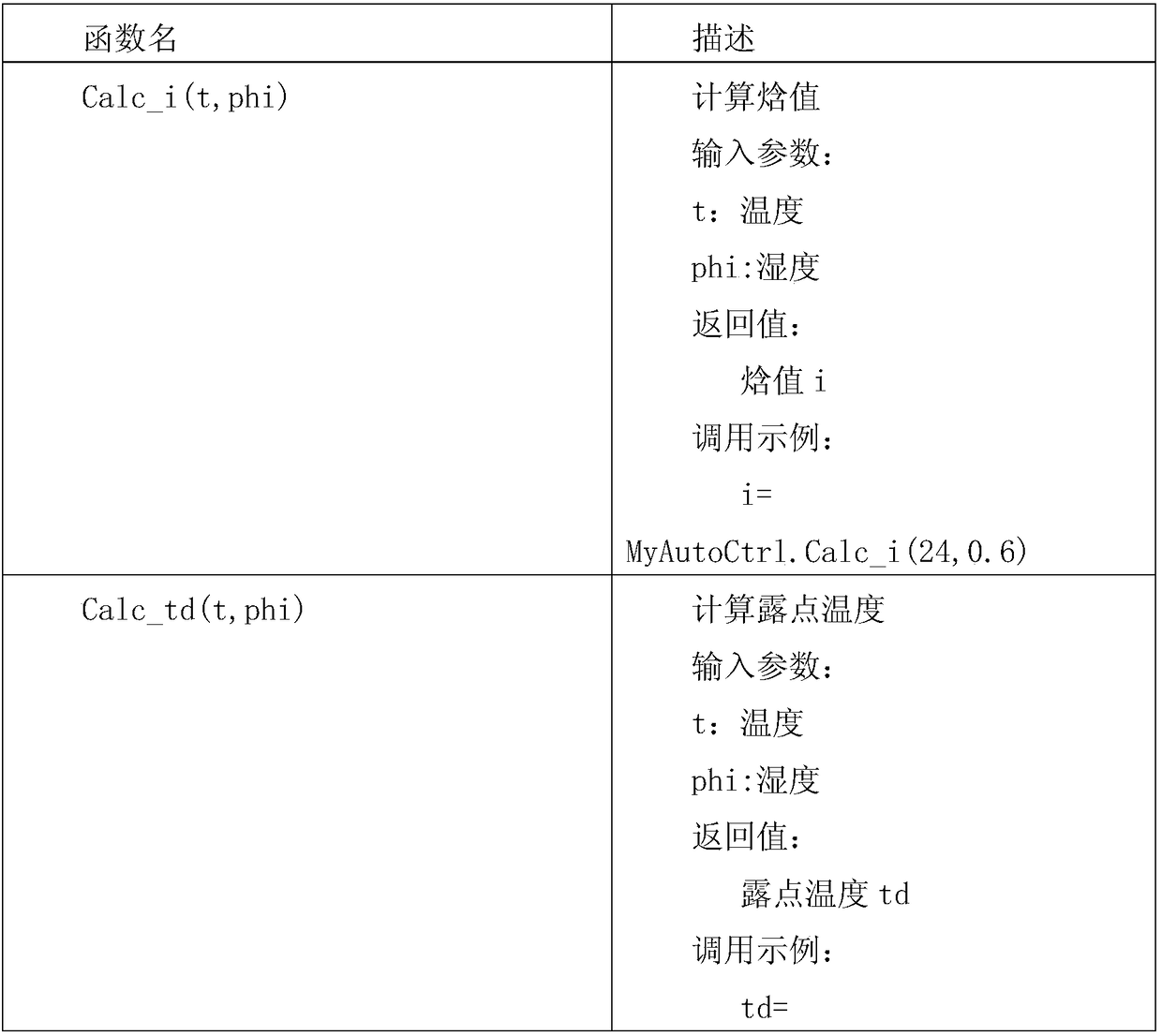

Method for realizing automatic adjustment of BAS professional equipment of integrated monitoring system

InactiveCN109343339ARealize automatic adjustment controlConvenient to call each otherAdaptive controlIntegrated monitoringAutomatic control

The invention discloses a method for realizing the automatic adjustment of the BAS professional equipment of the integrated monitoring system, and the automatic monitoring and control of the BAS professional equipment is realized by the integrated monitoring system, and the PLC of the traditional BAS system only plays the role of uploading the collected information and directly controlling the adjustment. The LUA script is used to realize the automatic control operation of the enthalpy value, and of the fan frequency conversion speed adjustment; the enthalpy value calculation and the operationalgorithm library of the frequency conversion speed are provided in the form of C++ dynamic library, and is called with the LUA script in the form of C function; The configuration definition tool ofthe comprehensive monitoring system has to be used to define the input parameters and LUA scripts of different automatic adjustment calculations; then, the operation cycle control with the backgroundbeing integrately monitored for an automatic control service is designed for the delivery of the adjustment control commands after the calculation is implemented.

Owner:NARI TECH CO LTD

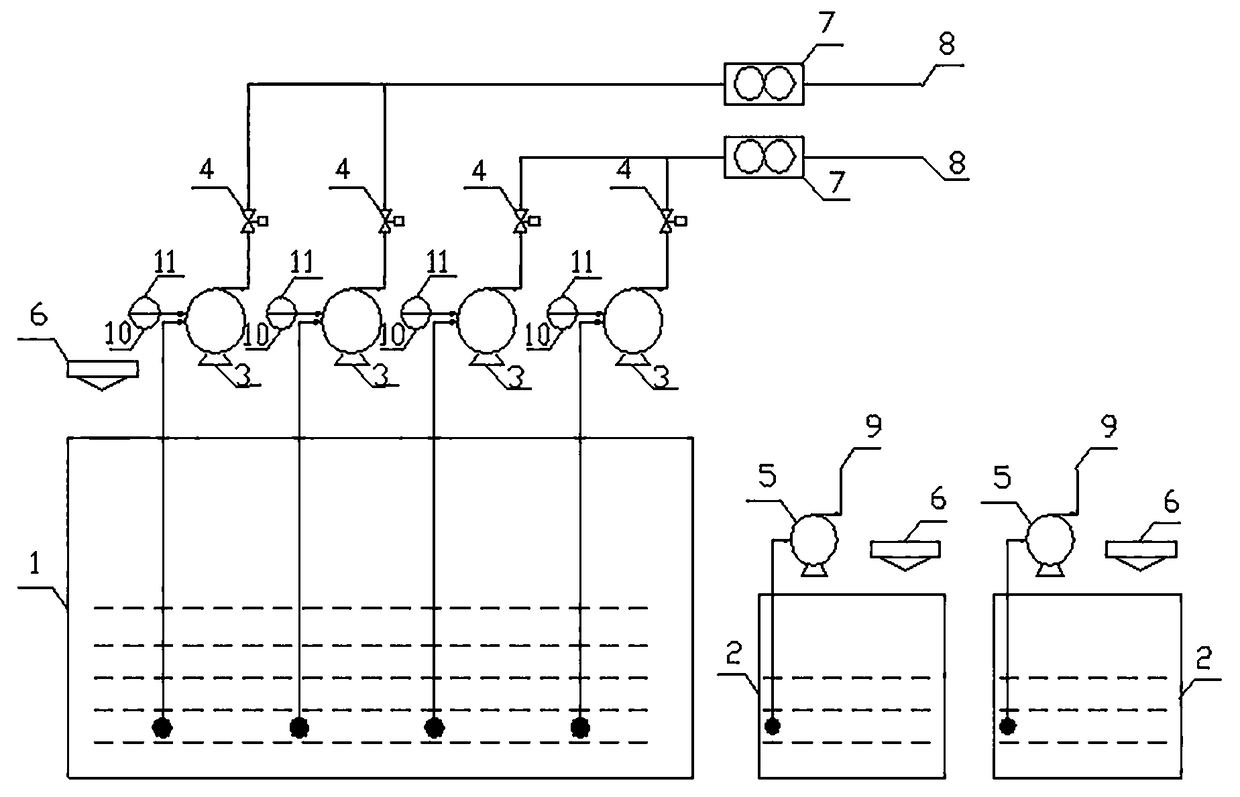

Remote control system of underground pump station

PendingCN109356835ARealize automatic adjustment controlImprove automationPump controlPump installationsControl systemRemote control

The invention discloses a remote control system of an underground pump station, The remote control system is used for controlling the interlocking control of underground pump station equipment and anelectric valve, automatic adjustment and control of ore pulp conveying and waste water discharging are realized, the automation of a production system is improved, the labor intensity of workers is reduced, and meanwhile, the operation stability and operation efficiency of the equipment are improved; and the system specifically has the beneficial effects that the operation condition of an ore pulpconveying pump is automatically judged by the system, an alarm signal if given out when a fault is encountered, and a standby pump is automatically started; according to multiple parameters such as the temperature, the vibration, a pipeline flow, the running state of the ore pulp conveying pump is judged, and starting and stopping of the ore pulp conveying pump are controlled according to the comprehensive conditions. According to the system, the operation process is simple, and the system is suitable for modern management.

Owner:JINCHUAN GROUP LIMITED

Damper adjusting device of gas range

InactiveCN107036133AIncrease air volumeImprove sufficiencyDomestic stoves or rangesLighting and heating apparatusSpray nozzleElectricity

The invention discloses a damper adjusting device of a gas range. The damper adjusting device of the gas range comprises a sensor, a driving device, a spray nozzle, a damper sheet assembly and a control device, wherein the sensor is fixedly installed on a gas range and used for detecting the temperature of fire, the driving device is used for adjusting the opening degree of a damper of the gas range, the spray nozzle is used for providing gas, and the control device is electrically connected with the sensor and the driving device. The spray nozzle is arranged at an air inlet of a gas stove. The damper sheet assembly comprises a plurality of damper sheets fixedly installed on the spray nozzle. The damper sheets are sequentially provided with ventilation openings with areas being gradually increased in the air inlet direction of the gas stove from outside to inside. The driving device comprises a motor and a lead screw. The spray nozzle is in transmission connection with the lead screw in a threaded manner. An output shaft of the motor is fixedly connected with the lead screw and drives the spray nozzle to slide in the air inlet direction of the gas stove. The motor is electrically connected with the control device. The damper adjusting device of the gas range has the beneficial effects of automatic detection and adjustment, and high accuracy, safety and reliability.

Owner:GUANGDONG UNIV OF TECH

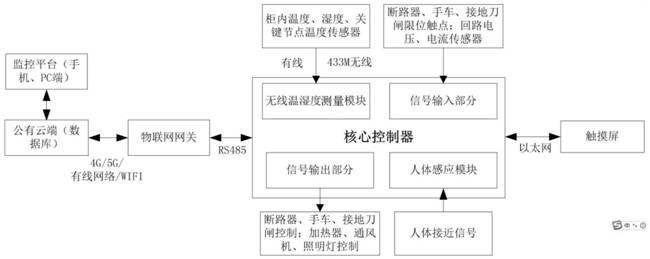

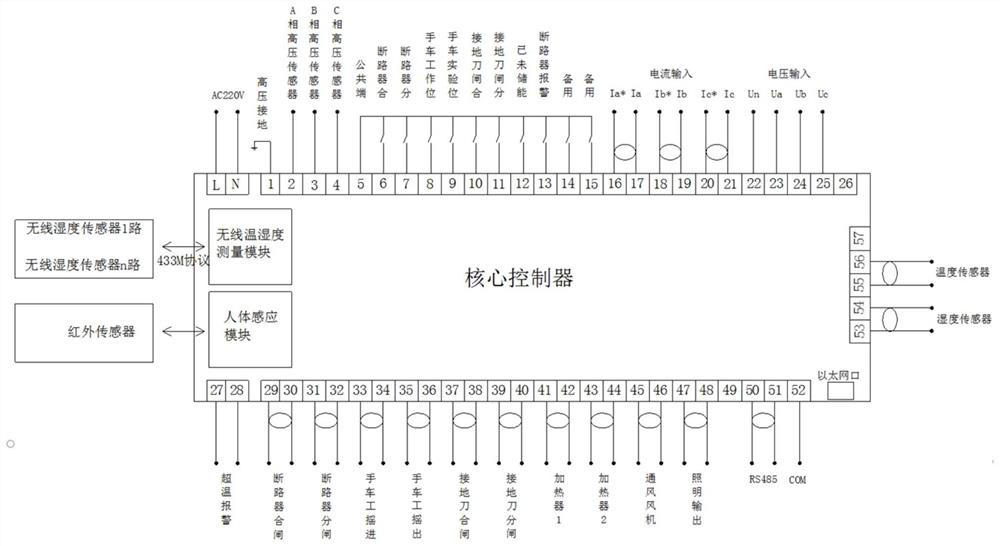

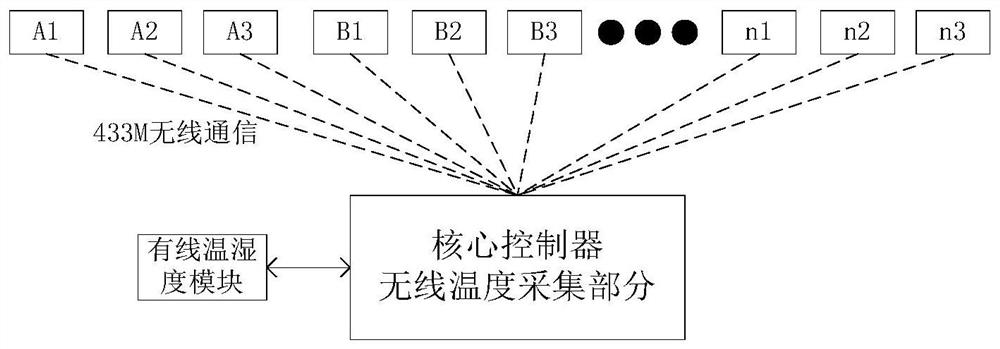

Internet of Things cloud configuration switch cabinet intelligent monitoring system

InactiveCN112987828ARealize automatic adjustment controlEasy to operateSimultaneous control of multiple variablesModbusIot gateway

An Internet of Things cloud configuration switch cabinet intelligent monitoring system comprises a switch cabinet local monitoring device and an Internet of Things monitoring software system, the switch cabinet local monitoring device comprises a core controller, a touch screen, an Internet of Things gateway, a public cloud end (database) and a monitoring platform, and the touch screen is interactively connected with the core controller through the Ethernet. The Internet of Things gateway communicates with the core controller through a Modbus, supports a wired network / WIFI / 4G / 5G mode to upload information to a public cloud end (database) and realizes a cloud configuration function, the monitoring platform comprises a mobile phone and a PC end, and the monitoring platform can access and read the public cloud end (database) and publish a WEB webpage monitoring picture and an APP monitoring interface. According to the invention, convenient operation and scientific management of daily operation and maintenance of the medium-high voltage switch cabinet can be realized, the automation level and intelligent upgrading are realized, and finally, unattended operation of a transformer substation system is realized.

Owner:BEIHUA UNIV

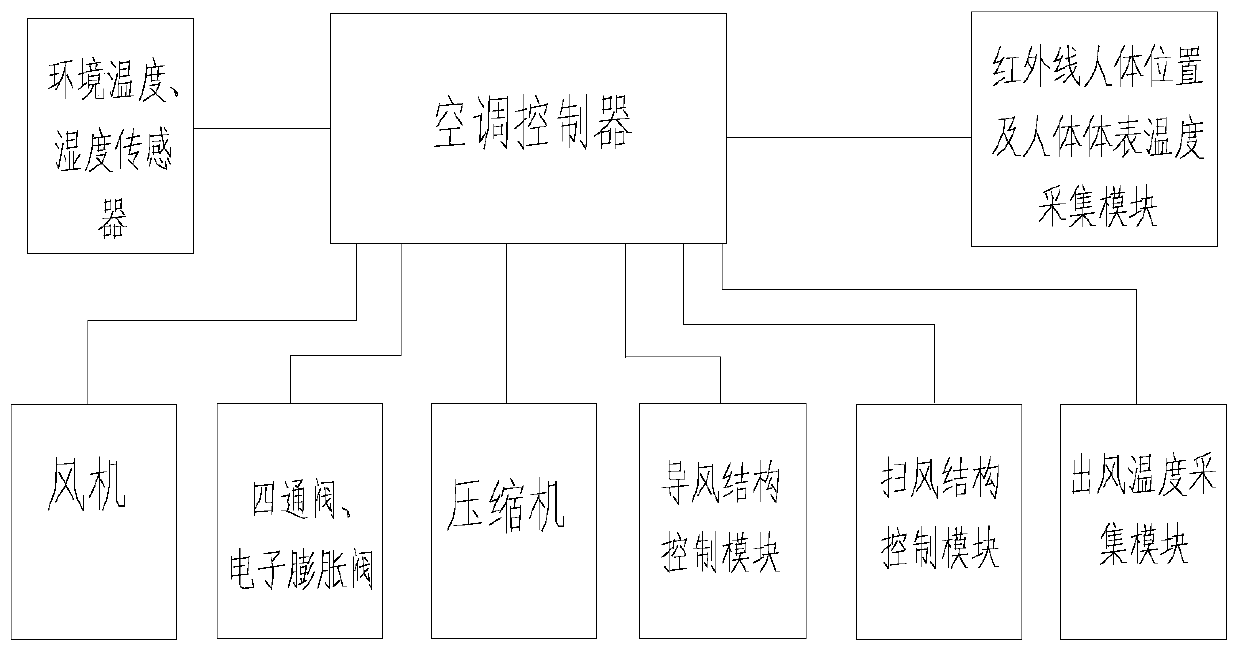

Blowing area adjusting method, air outlet assembly and air conditioner

PendingCN110595011ARealize automatic adjustment controlImprove comfortMechanical apparatusSpace heating and ventilation safety systemsEngineering

The invention provides a blowing area adjusting method, an air outlet assembly and an air conditioner and relates to the technical field of air conditioners and solves the technical problem that the blowing areas of the air conditioner cannot be adjusted independently according to demands of people. The blowing area adjusting method comprises the following steps: S100, starting a blowing device; S200, pressing a control button electrically connected to a control module to start a comfort mode of the blowing device; S300, acquiring information of an area of a human body by a human body detection device and transferring a signal of the information of the area of the human body to the control module; and S400, controlling a blowing assembly to move by the control module according to the information of the area of the human body, wherein blown air blows to a space out of the area of the human body. According to the invention, forms of the air outlets of the air conditioner are diversified,and the air outlet area can be adjusted automatically as needed. By combining an infrared detection system, the air outlet angle of the air conditioner is adjusted automatically, so that air conditioner air-out is adjusted and controlled automatically without air feeling, and the comfort of the air conditioner is improved.

Owner:GREE ELECTRIC APPLIANCES INC

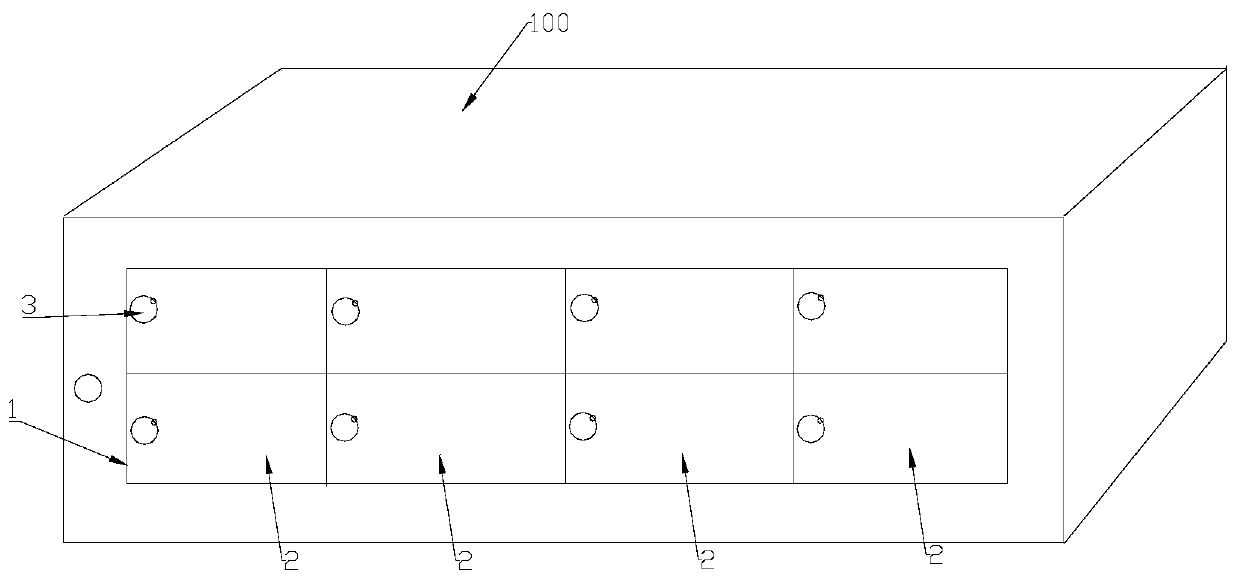

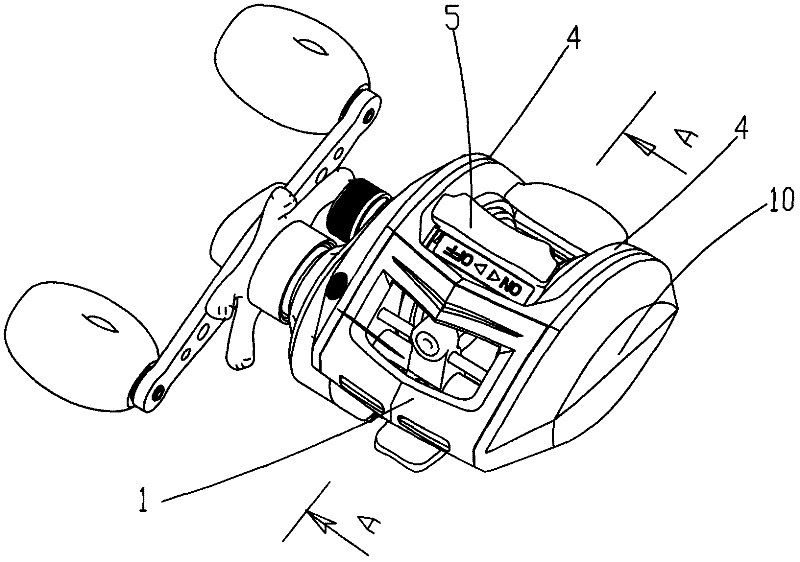

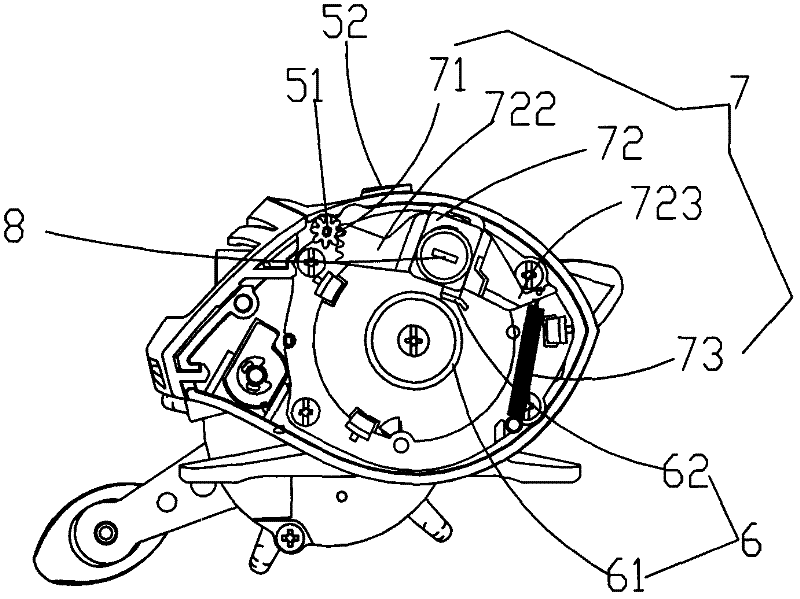

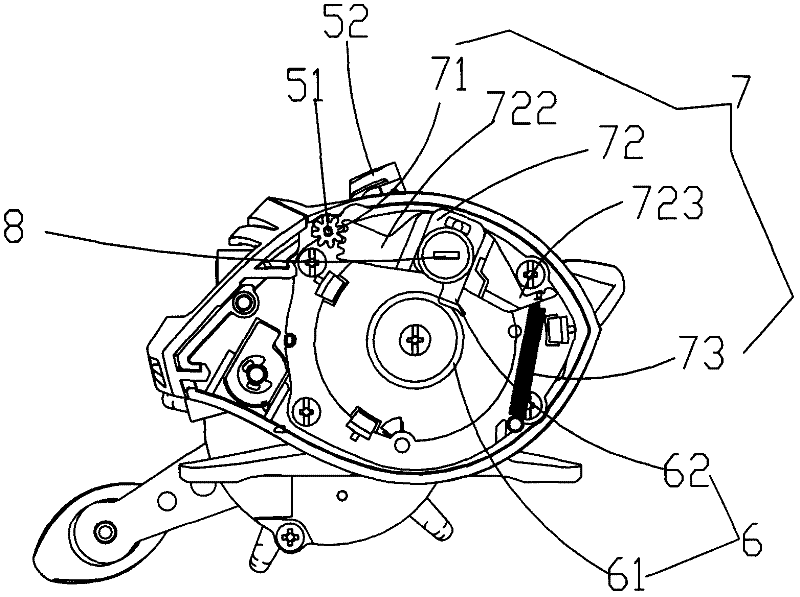

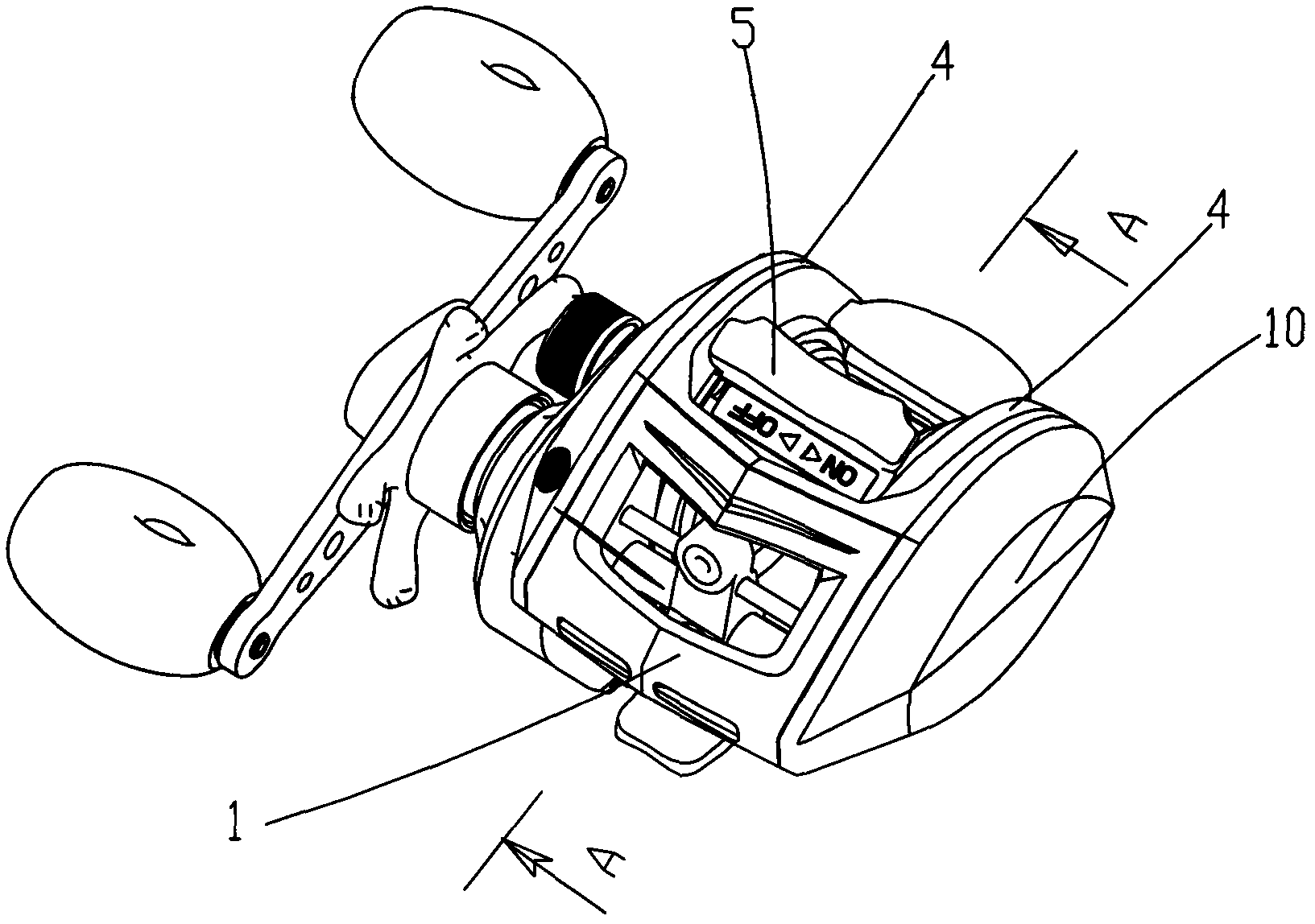

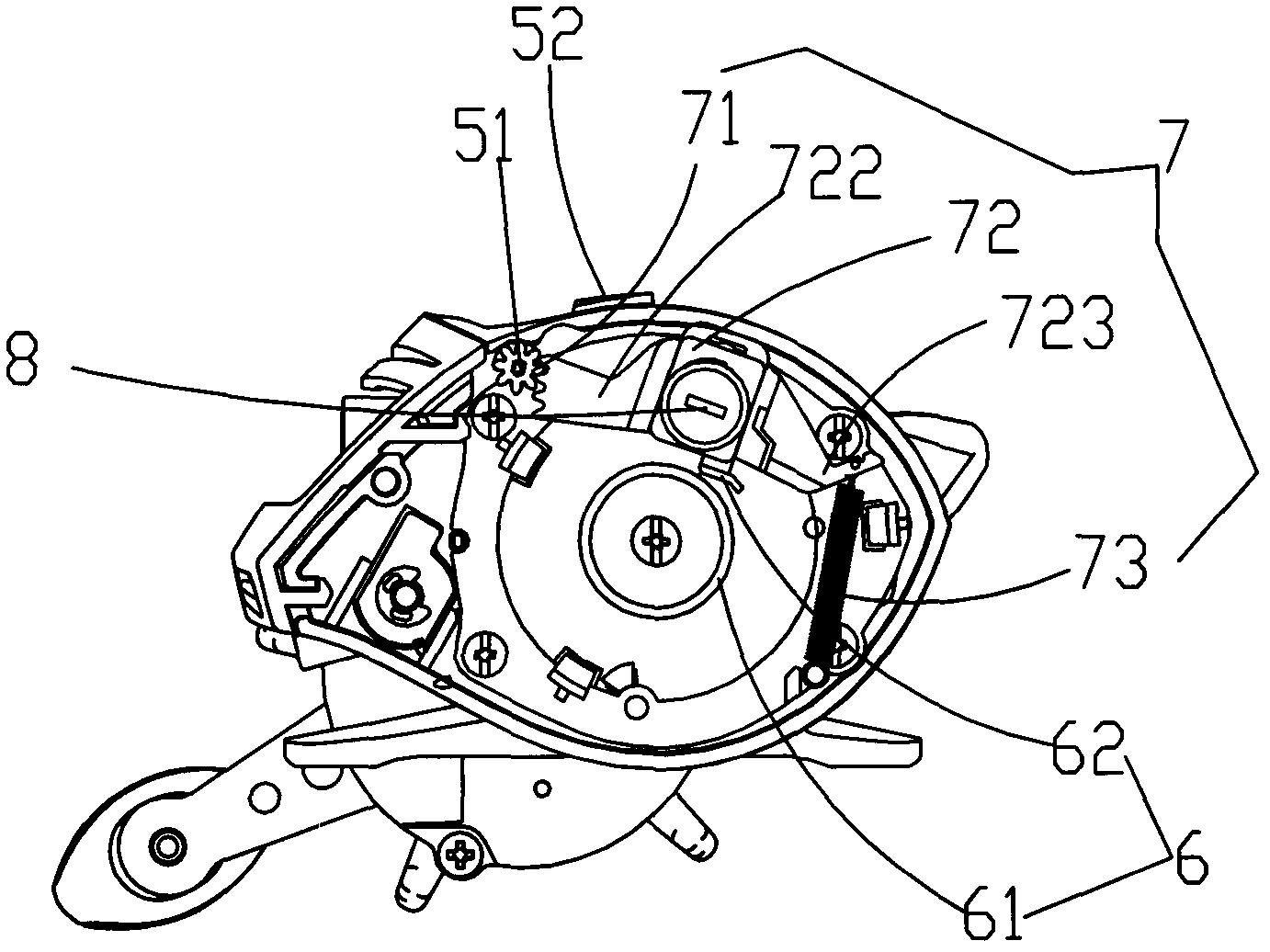

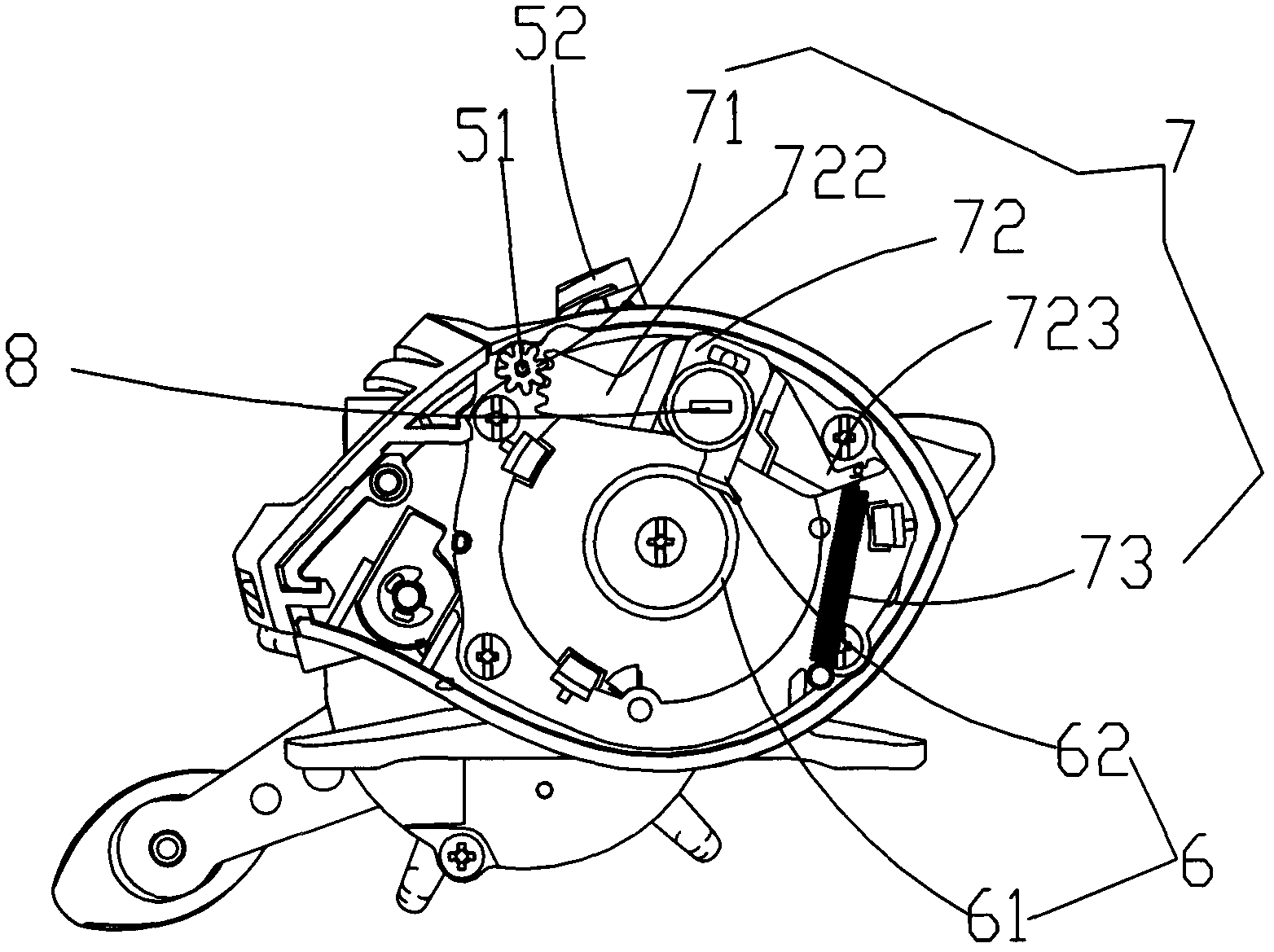

Line mess preventing fishing reel

The invention relates to a fishing reel which comprises a support, a line reel arranged in the support and used for loading a fishing line and two opposite line mess preventing plates located on both sides of the support and at both ends of the line reel. The fishing reel is characterized by also comprises a pressure sensing snob, a transmission mechanism, a friction mechanism and a rebound elastic element, such that the fishing reel has the function of stopping the line reel to rotate as soon as the bait enters water, and automatic adjusting control is realized. No matter beginners or old and new fishermen can freely throw the line without messing, so the fishermen have a happy mood to participate in leisure or competitive activities.

Owner:FOSHAN NANHAI GLOBALINO FISHING TACKLE LTD

Pulling-down-preventing limiting construction lifter

ActiveCN105197743ARealize automatic adjustment controlAchieve normal startupElevatorsBuilding liftsArchitectural engineeringBuilding construction

The invention provides a pulling-down-preventing limiting construction lifter and belongs to the technical field of construction, solving the problem that in the prior art, safety potential hazard is caused by the incompletely insertion of a suspender. The pulling-down-preventing limiting construction lifter comprises a controller, a guide rail frame and a wall attaching frame, wherein the guide rail frame comprises standard sections and a guide rail, and the wall attaching frame comprises a connecting rod I, a connecting rod II and a positioning piece; the guide rail is also provided with a suspension cage in a sliding manner, a groove is formed in the suspension cage, the groove is provided with a travel switch, an installation column is correspondingly arranged in the groove, the installation column is fixedly provided with a limiting block I, the lower end of the installation column is fixedly provided with a clamping block, a limiting block II is fixed in the groove, a clamping groove is formed in the limiting block II, and a retractable spring is also arranged between the limiting block I and a clamping block; the upper end of the installation column is provided with a suspender, the suspender comprises a vertical rod and a transverse rod, and a lifting positioning mechanism is arranged between the vertical rod and the installation column. The pulling-down-preventing limiting construction lifter has advantage that the lifter can be started only when the suspender is installed in place.

Owner:HAINING HUBA HEAVY IND

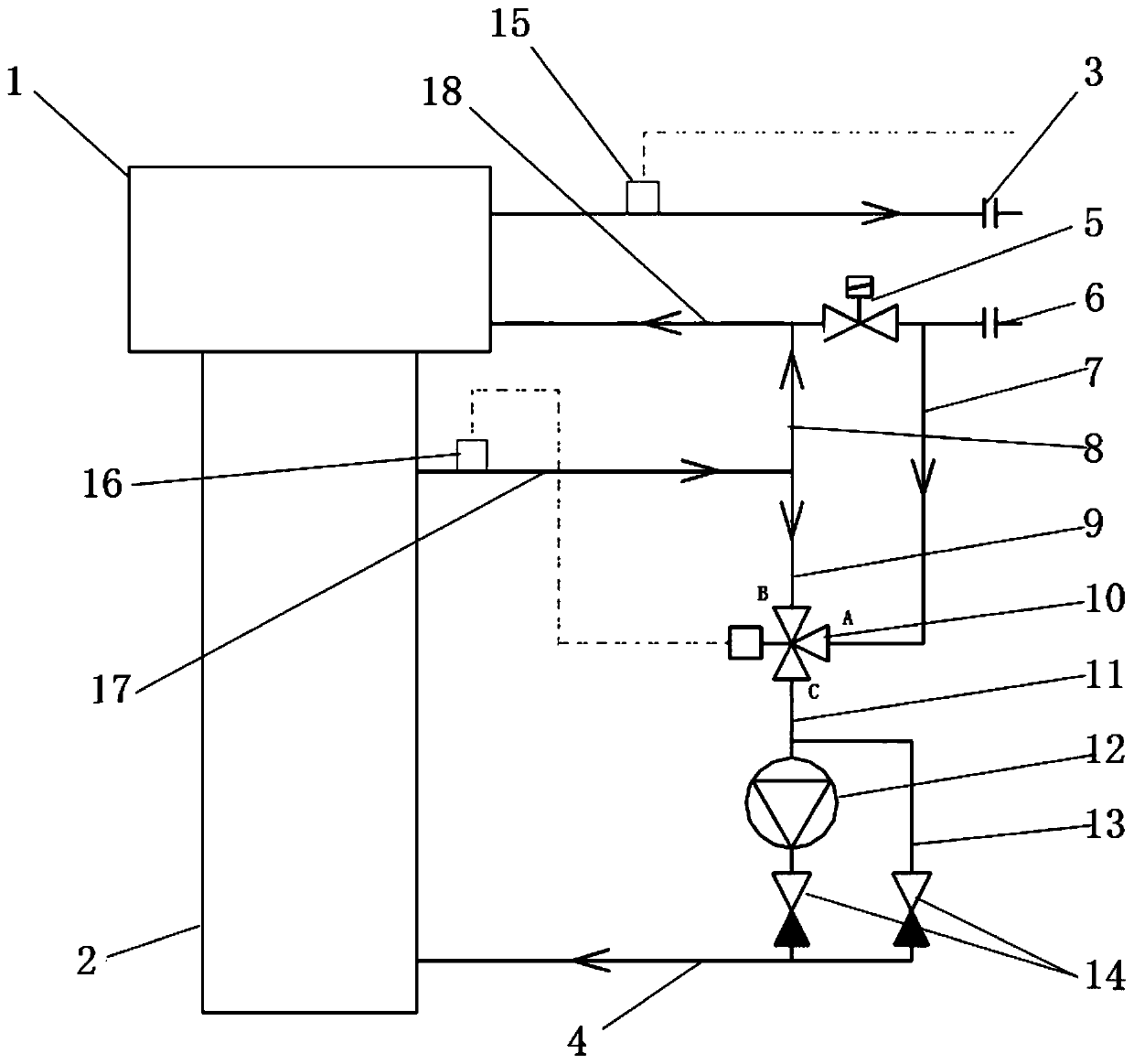

Cylinder sleeve cooling water system and method for low-speed diesel engine for dual-fuel ship

ActiveCN110714832ARealize control regulationRealize automatic adjustment controlCoolant flow controlInternal combustion piston enginesTemperature controlCombustion chamber

The invention discloses a cylinder sleeve cooling water system and method for a low-speed diesel engine for a dual-fuel ship. The cylinder sleeve cooling water system comprises a temperature control valve, a circulating pump, an electromagnetic valve, two check valves, a cylinder cover water outlet temperature sensor and a cylinder sleeve water outlet temperature sensor, wherein the cylinder coverwater outlet temperature sensor and the cylinder sleeve water outlet temperature sensor are used for monitoring the water outlet temperature of a cylinder cover and the water outlet temperature of acylinder sleeve in real time respectively, and transmitting the water outlet temperatures to the temperature control valve to realize automatic control and adjustment of the temperature of cooling water, so that a cooling water cavity of the cylinder sleeve can be kept at a proper temperature, cold corrosion of the cylinder sleeve is avoided, and the cooling water supply requirements of the low-speed diesel engine for the dual-fuel ship in two different operation modes, namely a fuel oil mode and a fuel gas mode, are met. According to the fuel oil mode and the fuel gas mode of a main engine, the temperature of the cooling water is automatically controlled and adjusted, so that a cooling cavity of a combustion chamber is automatically adjusted to be kept at a proper temperature, the problemof cold corrosion of the cylinder sleeve is solved, and the requirements of the dual-fuel main engine for the cooling water in the two different operation modes are met.

Owner:CSSC MES DIESEL

Line mess preventing fishing reel

Owner:FOSHAN NANHAI GLOBALINO FISHING TACKLE LTD

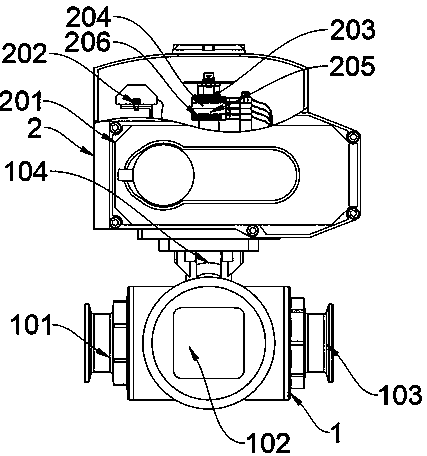

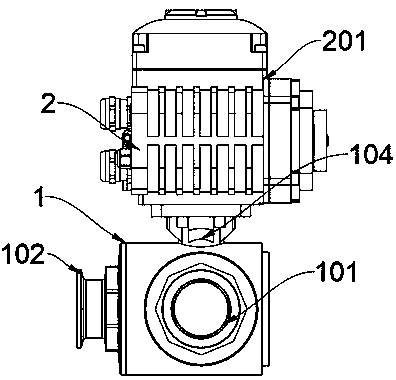

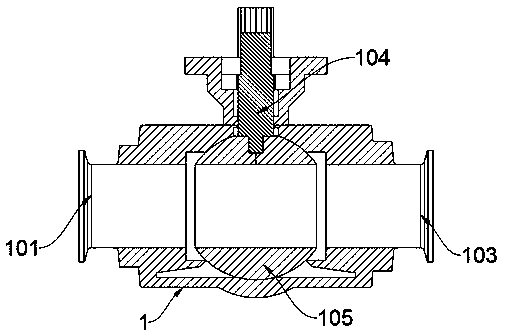

Multi-flowing-direction three-position electric three-way valve

PendingCN110425309ARealize automatic adjustment controlCompact structureOperating means/releasing devices for valvesMultiple way valvesExecution unitEngineering

The invention discloses a multi-flowing-direction three-position electric three-way valve, and relates to the field related to novel electric valves; and the multi-flowing-direction three-position electric three-way valve can achieve all functions in both L type flowing direction and T type flowing direction, can generate a straight flowing direction, and also can generate a two-elbow flowing direction to achieve multi-flowing-direction intelligent functions. An electric execution mechanism comprises a closing limiting cam, a middle upper section limiting cam, a middle lower section limiting cam and an opening limiting cam; an output shaft is arranged among the closing limiting cam, the middle upper section limiting cam, the middle lower section limiting cam and the opening limiting cam; awiring terminal is mounted on one side of the execution unit; a valve rod is mounted at the lower end of the output shaft; a valve ball is mounted at the lower end of the valve rod; a three-way ballvalve body comprises a first inlet, a second inlet and a third inlet; and the electric execution mechanism further comprises an execution mechanism outer shell.

Owner:SHANGHAI JULIANG VALVE GRP CO LTD

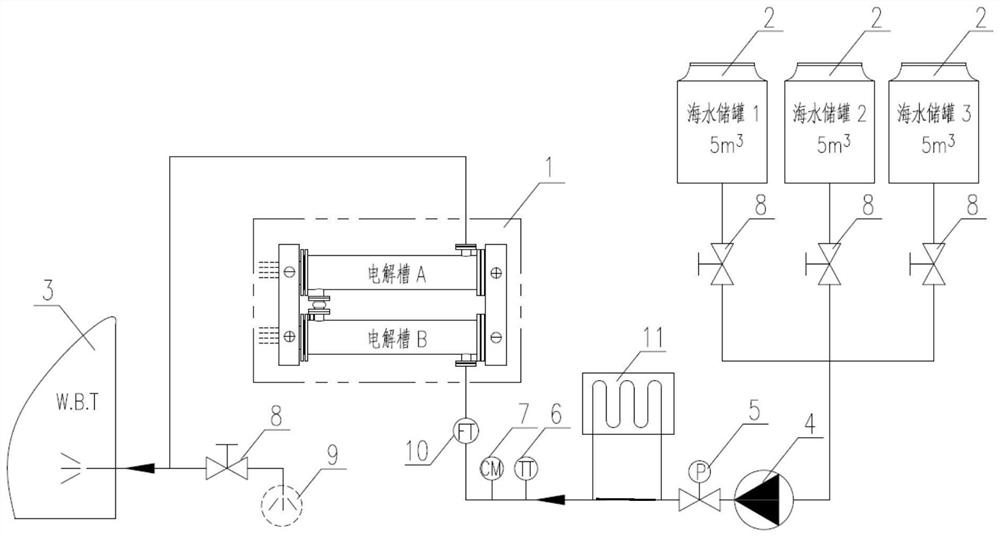

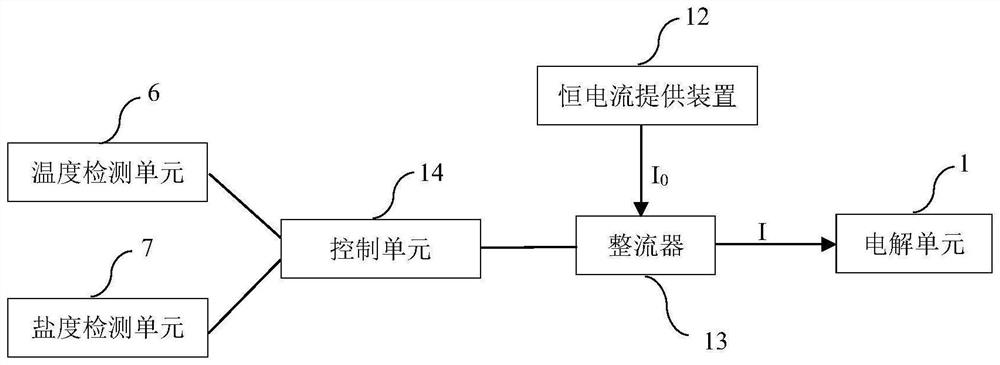

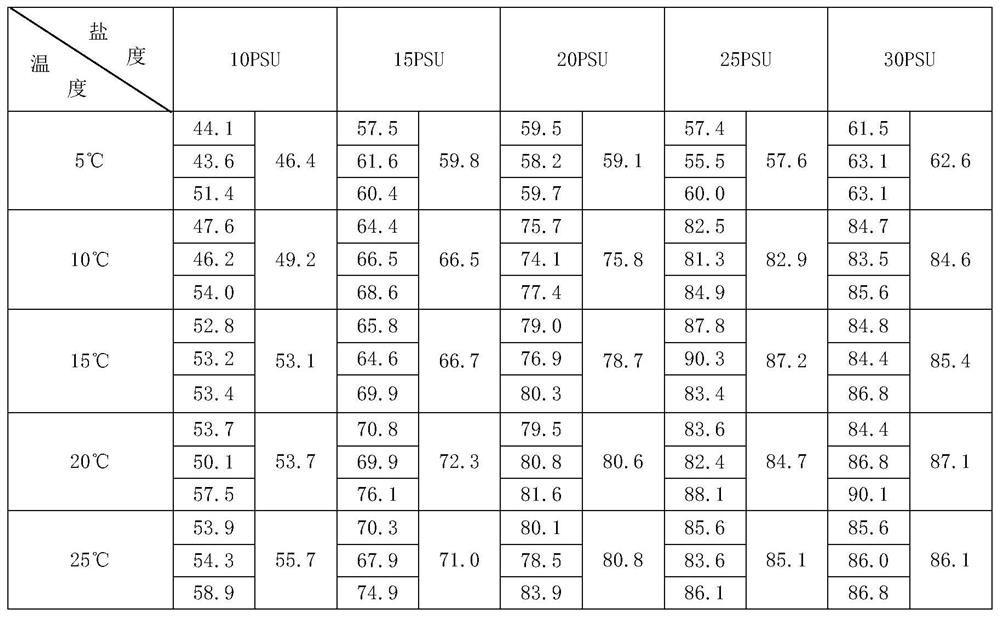

Ship ballast water treatment method and system

ActiveCN112939153ARealize automatic adjustment controlAvoid downtimeWater treatment parameter controlNature of treatment waterElectrolysisBallast water treatment

The invention provides a ship ballast water treatment method and system. The ship ballast water treatment system comprises an electrolysis unit, a constant current supply device, a temperature detection unit, a salinity detection unit, a control unit and a rectifier. When the system works, according to the temperature and salinity of the ballast water measured in real time, the electrolytic current I currently required by the electrolysis unit is calculated by combining the electrolytic efficiency eta of the electrolysis unit and the relational data of the temperature and salinity of the ballast water, and automatic adjustment and control of the required electrolytic current are achieved. The system gets rid of a commonly used method for detecting residual chlorine through a residual chlorine concentration analyzer and reversely controlling electrolytic current, system shutdown caused by faults of the residual chlorine concentration analyzer is avoided, and the practicability and reliability of the system are improved.

Owner:SUNRUI MARINE ENVIRONMENT ENG

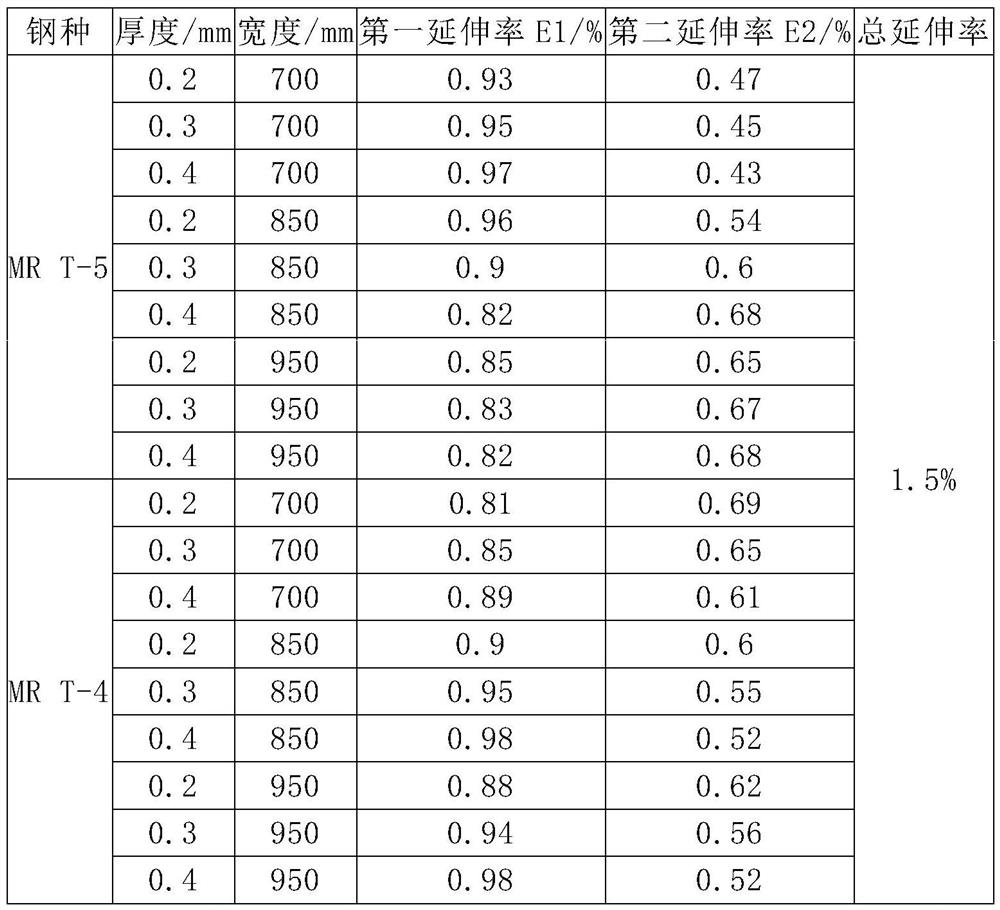

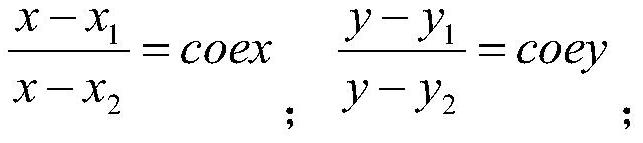

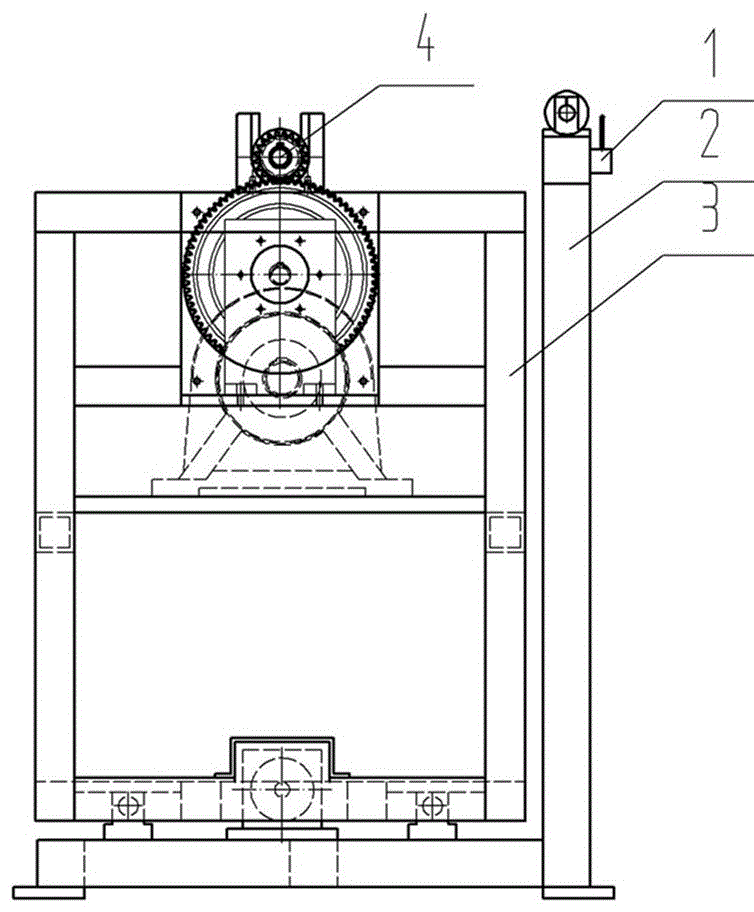

Method for controlling elongation of double-rack wet temper mill

ActiveCN112139255ARealize automatic adjustment controlUniform wearMetal rolling arrangementsElongation control deviceProcess engineeringBending force

The invention relates to a method for controlling the elongation of a double-rack wet temper mill. The method for controlling the elongation of the double-rack wet temper mill comprises the steps of making a rule table, establishing a model, adjusting and the like. According to the method for controlling the elongation of the double-rack wet temper mill, when a steel type, a thickness and a widthare changed in a production process, elongation set values of two racks are calculated and adjusted in real time by using an elongation set value calculation model, so that the optimal adjustment setting for the elongation of the two racks in the production process of different materials is achieved, and automatic adjustment control for elongation modeling is achieved; and meanwhile, according tothe elongation of the two racks, real-time automatic matching adjustment is carried out on a roll bending force and tension according to existing process rules.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Deviation-correcting automatic discharge tension braking device

InactiveCN106219299AAccurate realizationRealize automatic adjustment controlWebs handlingSynchronous motorDrive wheel

Disclosed is a deviation-correcting automatic discharge tension braking device. The deviation-correcting automatic discharge tension braking device mainly comprises a light deviation sensor, a deviation-correcting feeder lower frame, a deviation-correcting adjusting frame body, a bearing roll shaft, a magnetic powder brake, a brake wheel, a driven wheel, a cycloidal pin gear speed reducer, a driving wheel, a synchronous motor driving device, a linear bearing guide device and a transverse rolling wheel. The working state of a brake is controlled through a master control computer according to a blanking cycle, automatic braking is achieved, the brake is connected with the bearing roll shaft through gear transmission, and the control precision is high.

Owner:YANCHENG XIONGYING PRECISION MACHINERY

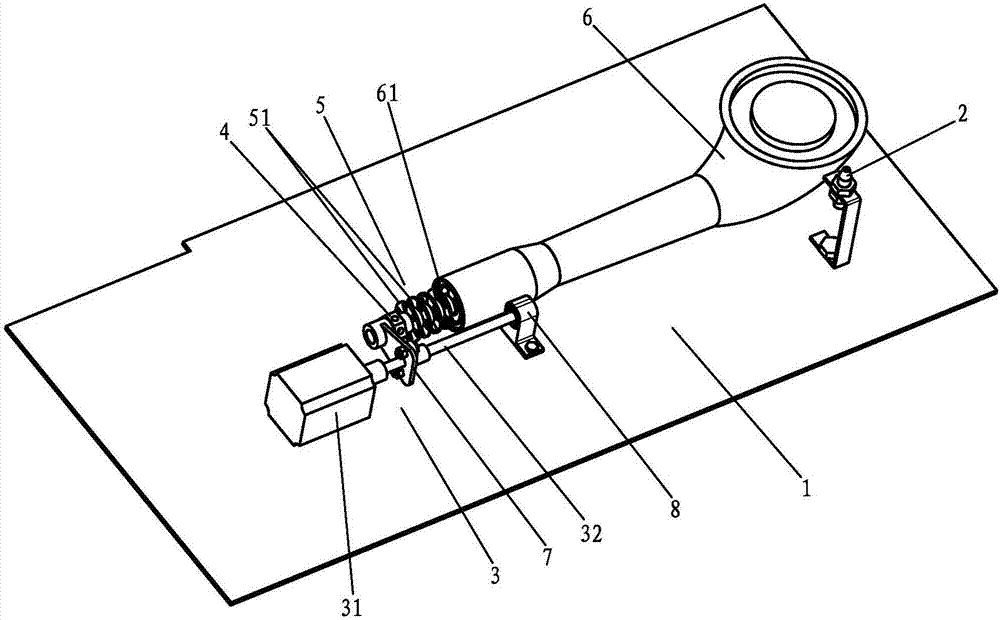

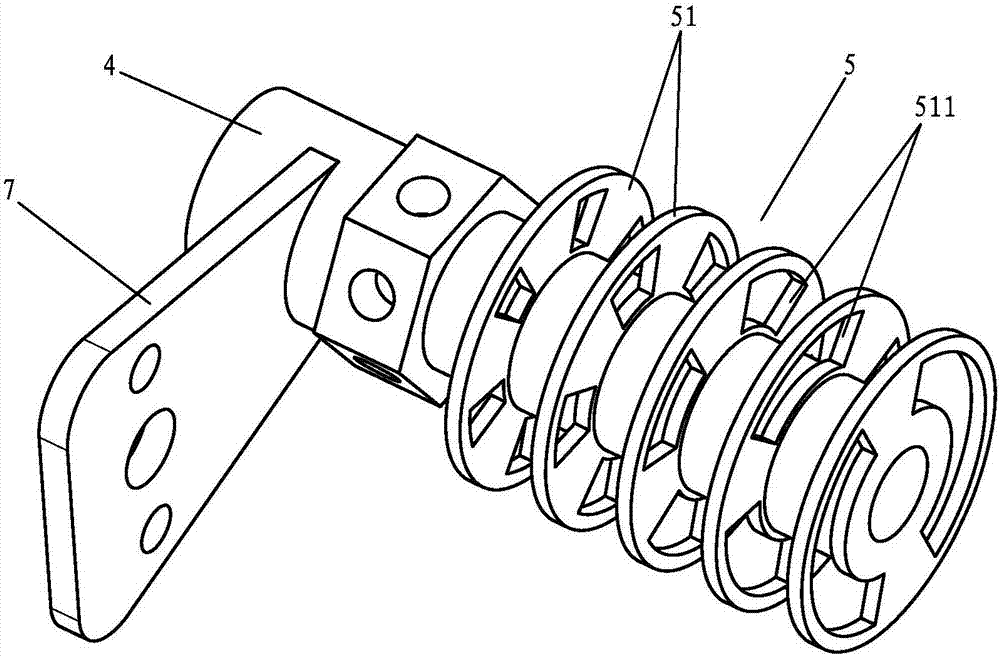

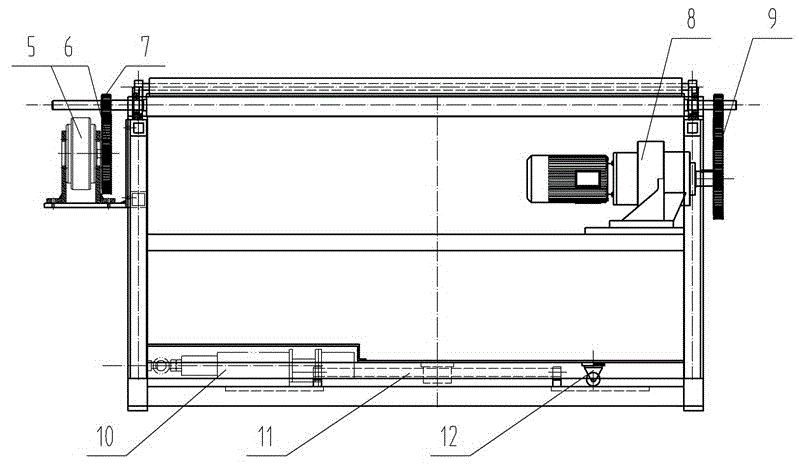

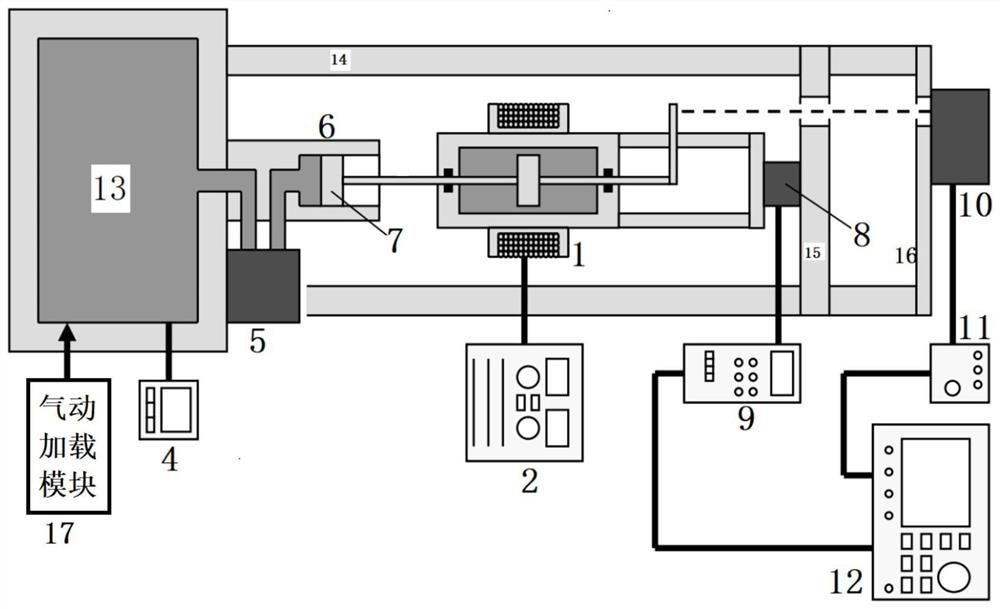

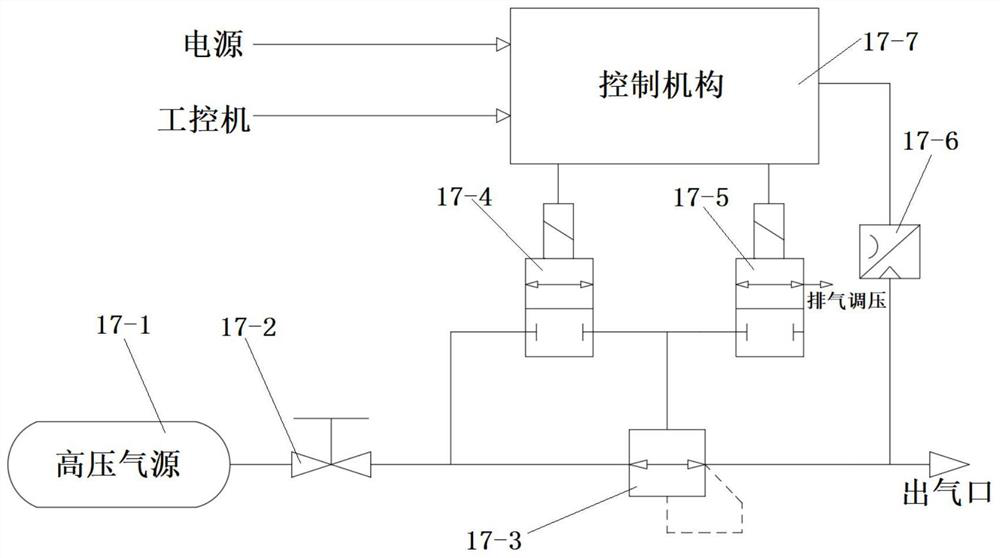

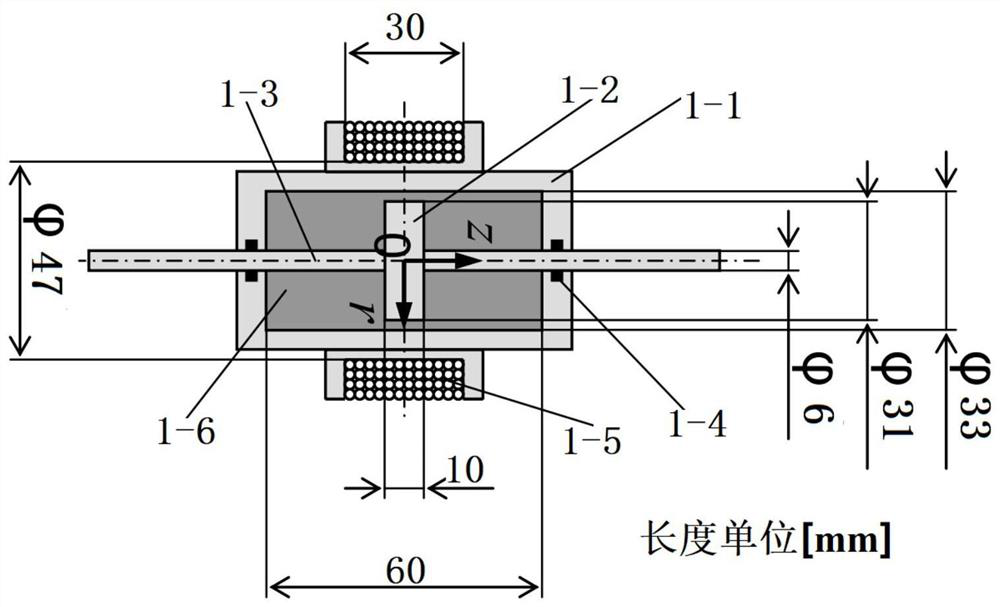

Test bed

PendingCN112255579AImprove technical effectFacilitates automated analysisOptical rangefindersMagnetic property measurementsInlet valveClassical mechanics

The invention relates to a test bed which is specially used for testing the resistance characteristic of a shock absorber of a magnetic functional fluid containing micron-scale and nano-scale magneticparticles, namely, testing the influence of different mixing ratios, electromagnetic field intensities and loading loads of micron-scale and nano-scale magnetic particles in the magnetic functional fluid of the shock absorber on the shock absorption resistance of the shock absorber. The test bed measures position change of a measured object in a non-contact mode through using a laser displacementsensor, and achieves the technical effects of high measurement precision, high sensitivity and accurate and efficient signal transmission for the micro displacement change of a shock absorber piston;and a test result is directly displayed through an oscilloscope and is more visual and faster. A pneumatic loading module is designed, through the design of a control mechanism, an air inlet valve, an air outlet valve and a pilot pressure regulating valve, the test bed realizes pneumatic loading, pressure maintaining and automatic adjusting control over loading loads, guarantees the loading accuracy and stability, and has large adjustable range of the loading loads, so that the testable working condition range of the test bed is larger.

Owner:XIHUA UNIV

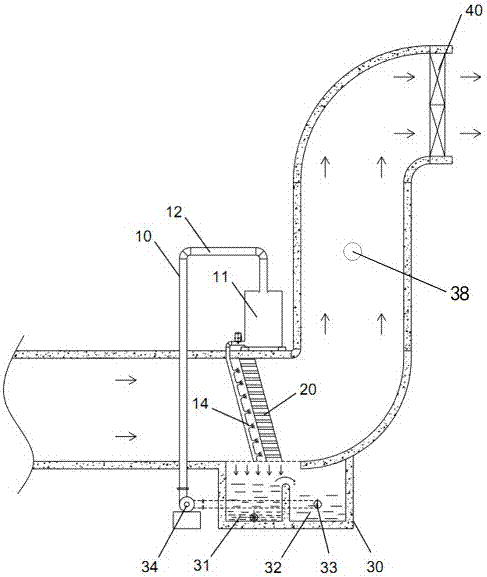

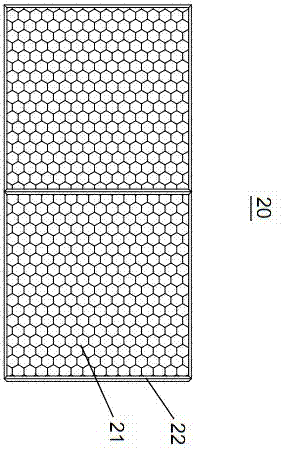

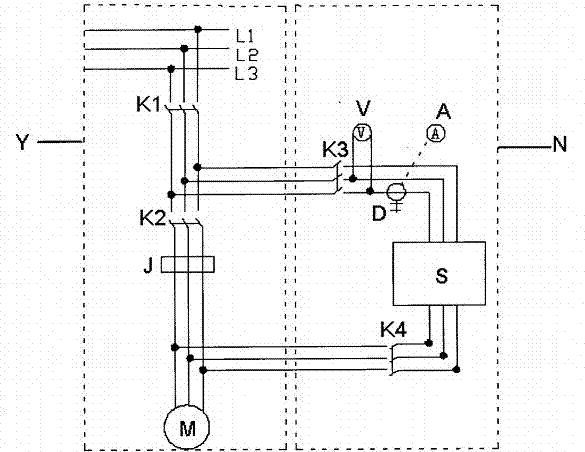

Electrical welding and cutting machine room air purification treatment device

InactiveCN107420985AGuaranteed automatic regulation controlGuarantee pm2.5 up-to-standard emission and realize automatic adjustment controlMechanical apparatusSpace heating and ventilation safety systemsControl systemLiquid state

The invention discloses an electrical welding and cutting machine room air purification treatment device. The electrical welding and cutting machine room air purification treatment device comprises an exhaust pipe. A control system is arranged at an outlet of the exhaust pipe. The control system keeps detecting and controls the air exhaust volume. The electrical welding and cutting machine room air purification treatment device is characterized by further comprising an adsorber mounted at the front end of the control system, a water container and a collection box, wherein the adsorber comprises adsorber cavities and adsorption materials; the adsorption materials are arranged in the adsorber cavities; the water container comprises a water bucket, a water atomizer and a pressurizer; the water atomizer makes liquid-state water change into vaporous water and is connected with the water bucket; the collection box is connected with the water bucket and conveys recovered water to the water bucket. The electrical welding and cutting machine room PM2.5 treatment device comprises the adsorber, the water container and the collection box. The adsorber is mounted at the front end of an exhaust pipe probe. The adsorber and an air channel form a whole. Noise is low. Space is saved. The adsorption effect is good.

Owner:王俊霞

Embroidery dyeing equipment and process thereof

ActiveCN113818162AReduce labor costsDecrease productivityTextile treatment machine arrangementsLiquid/gas/vapor removal by gas jetsProcess engineeringDyeing

The invention belongs to the technical field of embroidery dyeing, and particularly relates to embroidery dyeing equipment and a process thereof. The embroidery dyeing equipment comprises a linearly arranged V-shaped box body, wherein the interior of the V-shaped box body is provided with a cavity or is provided with dye; a liftable depth adjusting mechanism is arranged at the center line of the two ends of the V-shaped box body; a main pressing roller in the depth adjusting mechanism enables embroidery penetrating through the bottom of the main pressing roller to be pressed and adjusted in depth in the V-shaped box body; the inner side wall of the V-shaped box body is fixedly connected with a cyclic heating device; and the cyclic heating device realizes cyclic stepped heating on air or the dye in the V-shaped box body. According to the embroidery dyeing equipment and the process thereof provided by the invention, by combining the embroidery equipment and the embroidery process, an existing single embroidery dyeing process can be integrated, the integrated dyeing effect can be achieved, the labor cost can be reduced, the working efficiency can be improved, the automatic adjustment control can be achieved according to different embroidery dyeing processes, and the production line type automatic control can be achieved.

Owner:东莞市奥普特绣花有限公司

Automatic settling plate of foaming machine

InactiveCN106079224ARealize automatic adjustment controlHigh degree of automationGear driveDrive motor

The invention discloses an automatic settling plate of a foaming machine, and relates to the mechanical field of foaming machines. The automatic settling plate comprise a plurality of settling main plates, worm and worm-gear drive mechanisms, a movable connector and a drive motor; the settling main plates comprise a settling bottom plate and settling side plates which are symmetrically arranged at the two sides of the settling bottom plate; the worm and worm-gear transmission mechanisms are fixedly arranged on the lower part of the settling bottom plate, and are movably connected with the settling side plates; the plurality of the worm and worm-gear transmission mechanisms are movably connected through the movable connector; the drive motor is fixedly arranged on the bottom of the settling bottom plate; and the drive motor drives the worm and worm-gear transmission mechanisms to drive the settling side plates to separately open and close synchronously in the horizontal direction. The automatic settling plate of the foaming machine effectively realizes automatic regulate control on width before settling plate foaming and forming and is high in degree of automation, so that forming efficiency is improved to a greater extent, more manpower and material resources are saved and control precision is improved; and moreover, the automatic settling plate is simple in integral structure, is convenient to manufacture, mount and operate, and is high in practicability.

Owner:苏州恒昇海绵机械制造有限公司

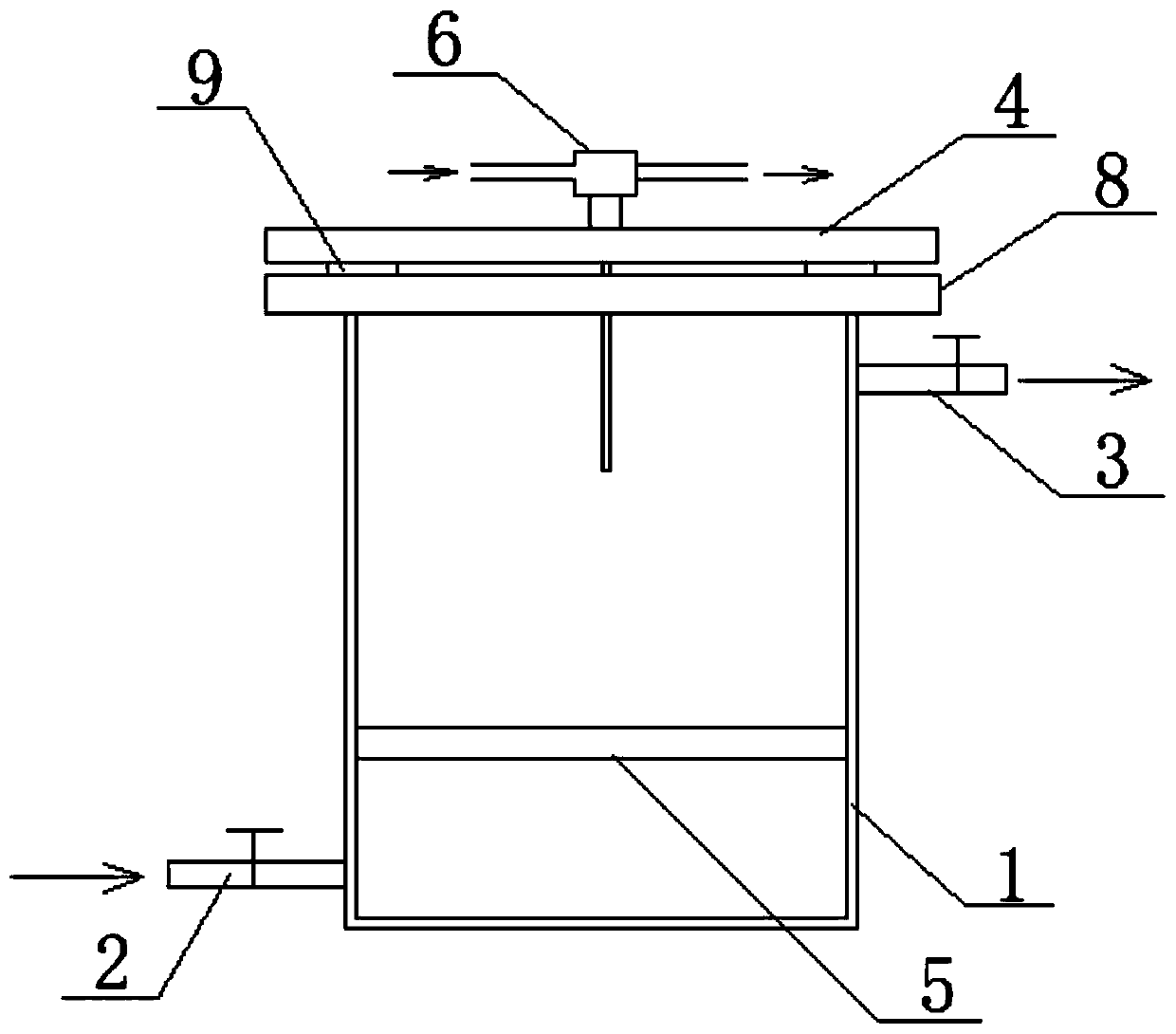

Secondary water supply device

InactiveCN111749305AReliable connectionEasy inspection and maintenanceService pipe systemsWater mainsPondageWater storage tank

The invention provides a secondary water supply device comprising a water storage tank, a filtering box and a pressurizing box. The left side face of the water storage tank is provided with a first transverse through pipe. The top of the first transverse through pipe is provided with a water inlet pipe. The right side face of the water storage pipe communicates with the left side face of the filtering tank through a second transverse through pipe. The bottom of the filtering box is provided with a smashing chamber. A power box is arranged at the bottom of the smashing chamber. The right side face of the filtering box communicates with the left side face of the pressurizing box through a third transverse through pipe. The right side face of the pressurizing box is provided with a fourth transverse through pipe. The bottom of the fourth transverse through pipe is provided with a water outlet pipe. A pressure transmitting box is arranged below the pressurizing box. The left side wall andthe right side wall in the water storage tank are provided with a first electric cylinder base plate and a second electric cylinder base plate correspondingly. The secondary water supply device can effectively solve the technical problems that in the prior art, the functions of automatically controlling the amount of stored water, filtering and smashing impurities, conducting classified pressurization and the like are not achieved, and the secondary water supply device is beneficial for application and popularization.

Owner:贺俊威

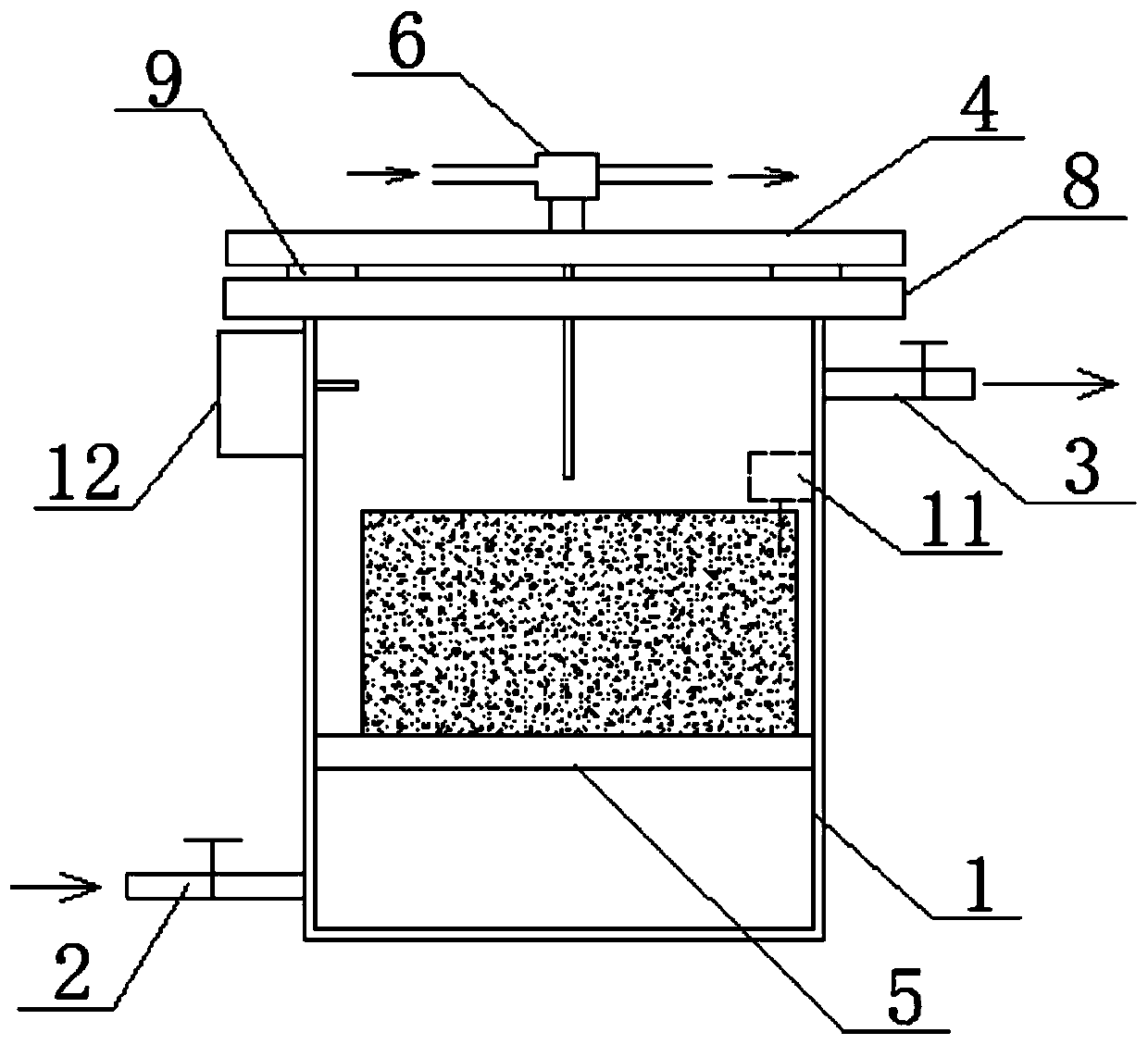

Soil culture device and soil culture and gas collection method based on same

PendingCN110274800ARealize automatic adjustment controlThe test result is accurateWithdrawing sample devicesEarth material testingAir blowerCollection methods

The invention discloses a soil culture device and a soil culture and gas collection method based on the same. The soil culture device comprises a culture cavity and a cover body; the upper end of the culture cavity is open, and the lower end of the culture cavity is sealed; a supporting separation plate is arranged in the culture cavity; a plurality of through holes are formed in the supporting separation plate; an air inlet is formed in the lower portion of the culture cavity; the air inlet is communicated with an air blower air outlet outside the culture cavity; an air outlet is formed in the upper portion of the culture cavity; and the air inlet and the air outlet are respectively provided with valves. The soil culture device further comprises a gas collection structure; the gas collection structure is arranged on the cover body; the gas collection structure comprises a carrier gas inlet, a carrier gas outlet, a greenhouse gas inlet and a greenhouse gas outlet; and after the cover body covers the culture cavity, the carrier gas inlet and the greenhouse gas inlet of the gas collection structure are both located in the culture cavity, and the carrier gas inlet and the greenhouse gas outlet are located outside the culture cavity. With the above structure adopted, measuring results are more accurate, and meanwhile, collected greenhouse gas is closer to a true value.

Owner:CHENGDU INST OF BIOLOGY CHINESE ACAD OF S

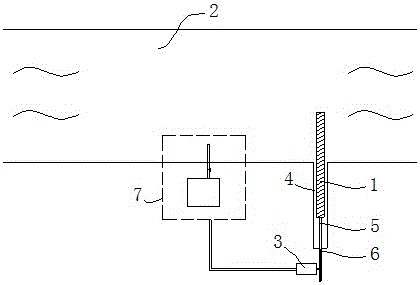

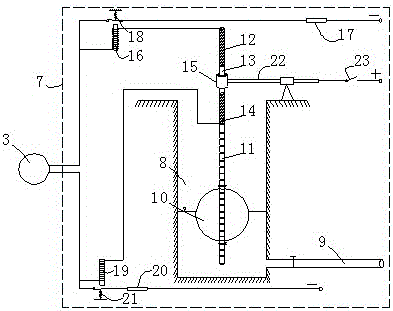

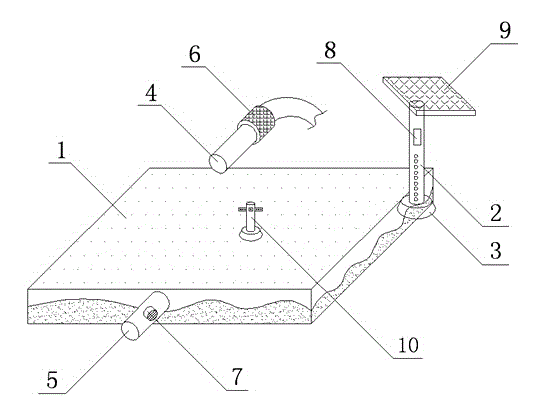

System for enhancing oxygen and adjusting water level for fish pond

InactiveCN106172164ATime-consuming and laborious to solveRealize automatic adjustment controlPisciculture and aquariaSimultaneous control of multiple variablesAutomatic controlEngineering

The invention relates to a system for enhancing oxygen and adjusting a water level of a fish pond. The system comprises a controller (8). The system is characterized in that the controller (8) is mounted at the inner part of the upper end of a perpendicular detection rod (2), the bottom of the perpendicular detection rod (2) is perpendicularly fixed to a detection rod fixing seat (3), the detection rod fixing seat (3) is fixed to the bottom of a fish pond (1), and a plurality of water level detection meters are perpendicularly arranged on the outer side surface of the perpendicular detection rod (2) at equal intervals; and the water level detection meters are separately connected with a signal input end of the controller (8), and a signal output end of the controller (8) is connected with a water inlet pump (6) and a water outlet electromagnetic valve (7). According to the system disclosed by the invention, the controller is mounted at the inner part of the upper end of the perpendicular detection rod, the water level detection meters are perpendicularly arranged on the outer side surface of the perpendicular detection rod at equal intervals, and the water level detection meters are separately connected with the signal input end of the controller, so that the problem that the control of the water level of the fish pond is time-consuming and labor-consuming is effectively solved, the automatic adjustment and automatic control of the water level of the fish pond are realized, and the system is wide in application range.

Owner:童峰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com