Method for controlling elongation of double-rack wet temper mill

A control method and elongation rate technology, applied in the field of metallurgy, can solve problems such as limiting the expansion of unit product diversification, affecting product quality, inability to adjust distribution and independent control, etc., to ensure uniform wear, reduce roll consumption, and improve stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0020] The elongation control method of the double-frame wet tempering machine in this embodiment adopts a double-frame four-roller wet tempering machine for thin gauge annealed tin (chrome) substrate rolls with a thickness of 0.2-0.4 mm and a width of 700-950 mm. Carry out a leveling treatment with an elongation rate of 1.5±0.2%, the leveling process is wet leveling, and the leveling liquid concentration is 3±0.5%; the entrance section, middle section and exit section of the two-stand four-roller wet leveling machine are all provided with The velocimeter is output to the two frames of the two-frame four-roller wet-leveling machine through the tester to perform closed-loop control independently, including the following steps:

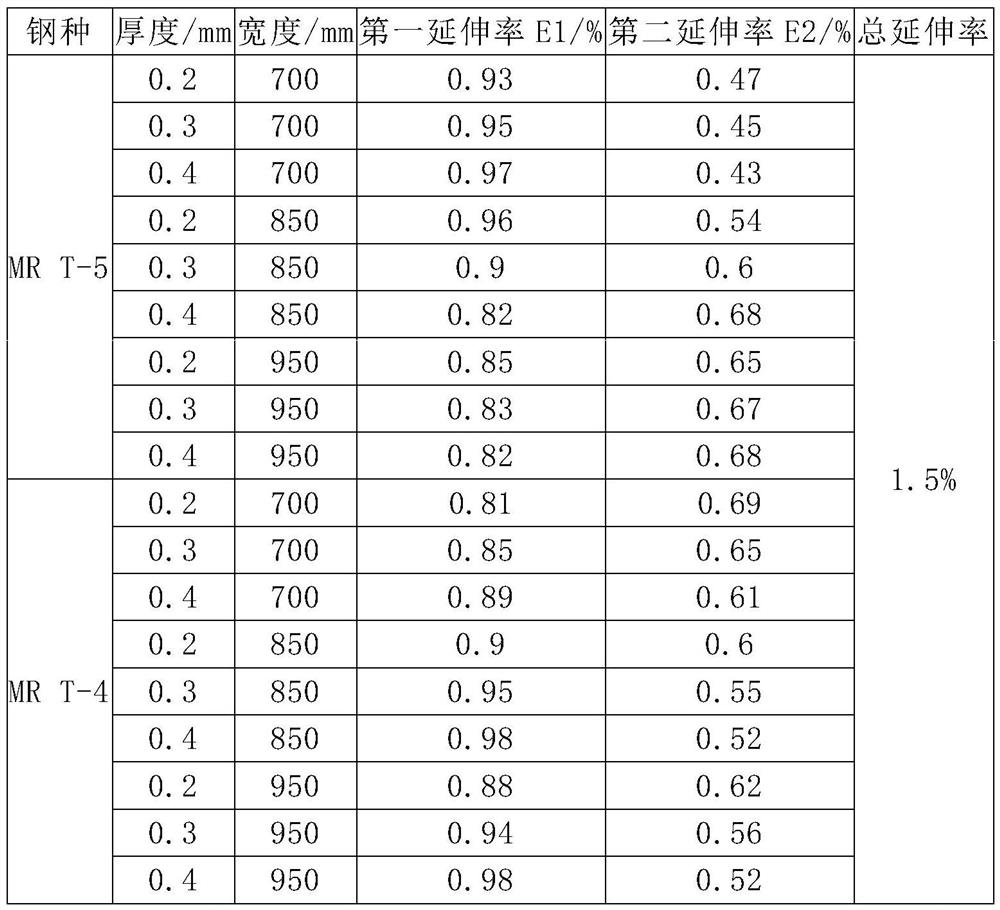

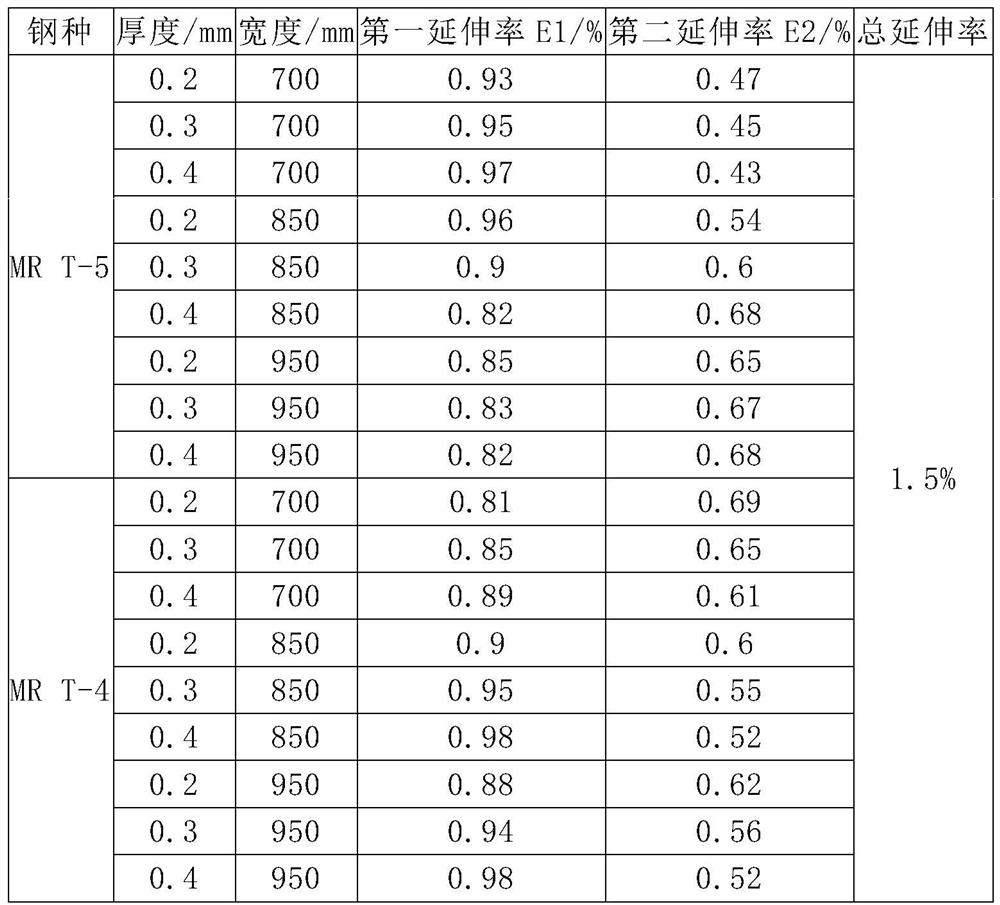

[0021] (1) Formulate the optimal allocation rule table of two rack elongation ratios of different steel types, thicknesses and widths:

[0022]

[0023] Wherein, the first elongation rate is the setting value of the elongation rate of the first frame...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com