Method and system for controlling thickness of sand mold of piston ring three-station molding machine

A thickness control, three-station technology, applied in the direction of molding machine, digital control, casting molding equipment, etc., to achieve the effect of low cost, high pass rate, and ingenious design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, but not for limiting the protection scope of the present invention.

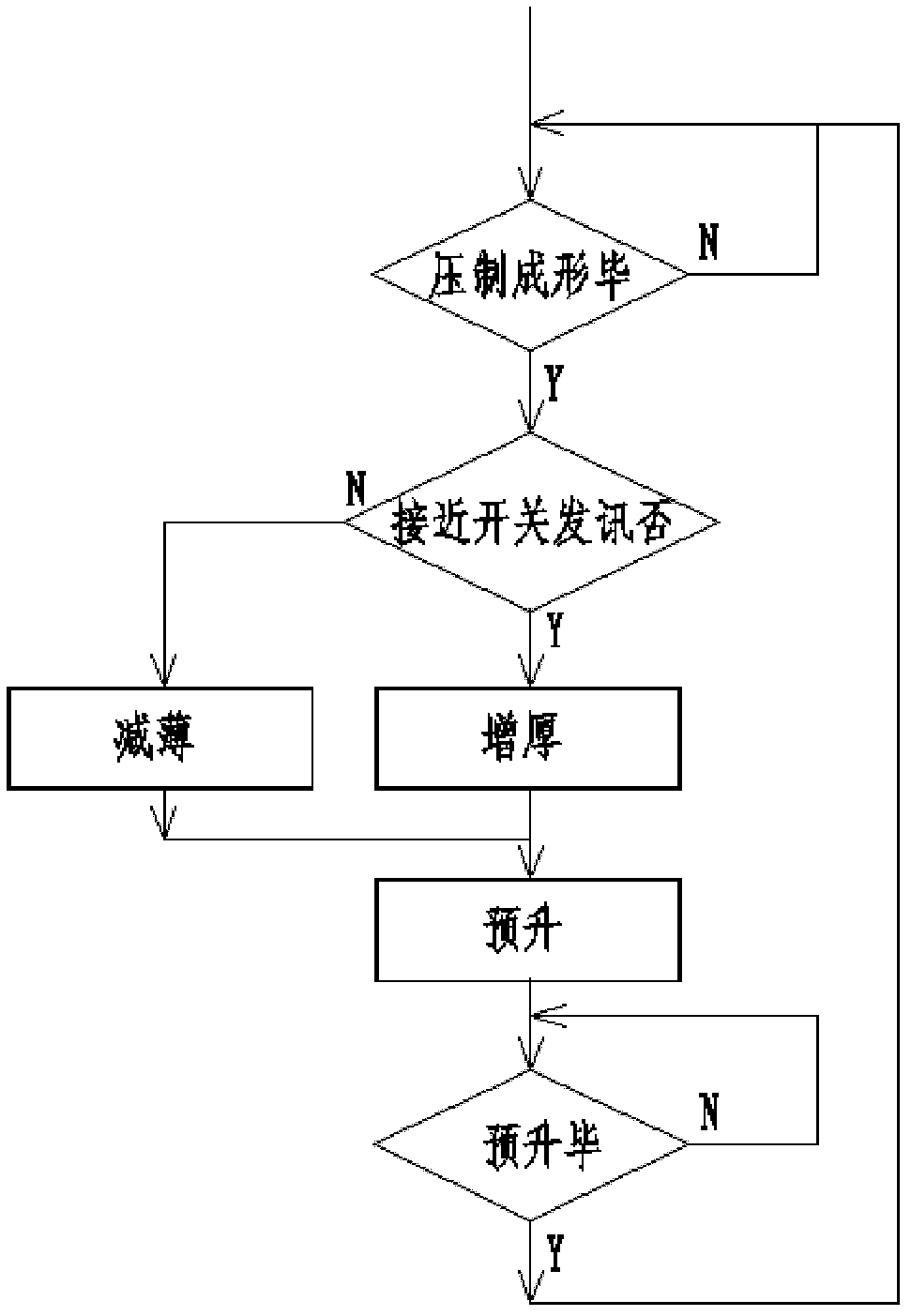

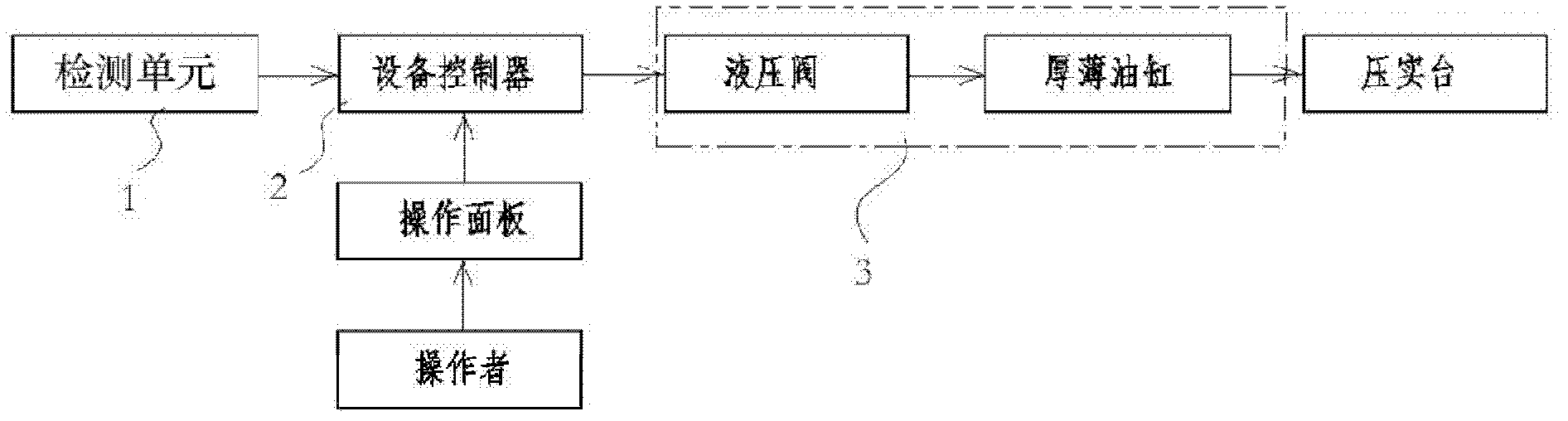

[0028] In order to solve the problem of automatic adjustment of sand mold thickness, the core is to solve how to make the pre-lifting position of the compaction table automatically adjust with the change of the composition of the molding sand. Slow or small changes in the composition of the molding sand should have sufficient adaptive capacity. In view of this design idea, the sand mold thickness control method of the three-station piston ring molding machine of the present invention includes the following steps:

[0029] Step 1: In the process of making the sand mold, judge the thickness of the pressed sand mold as "too thick" or "too thin" by detecting the lifting r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com