Patents

Literature

355results about How to "Accurate realization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

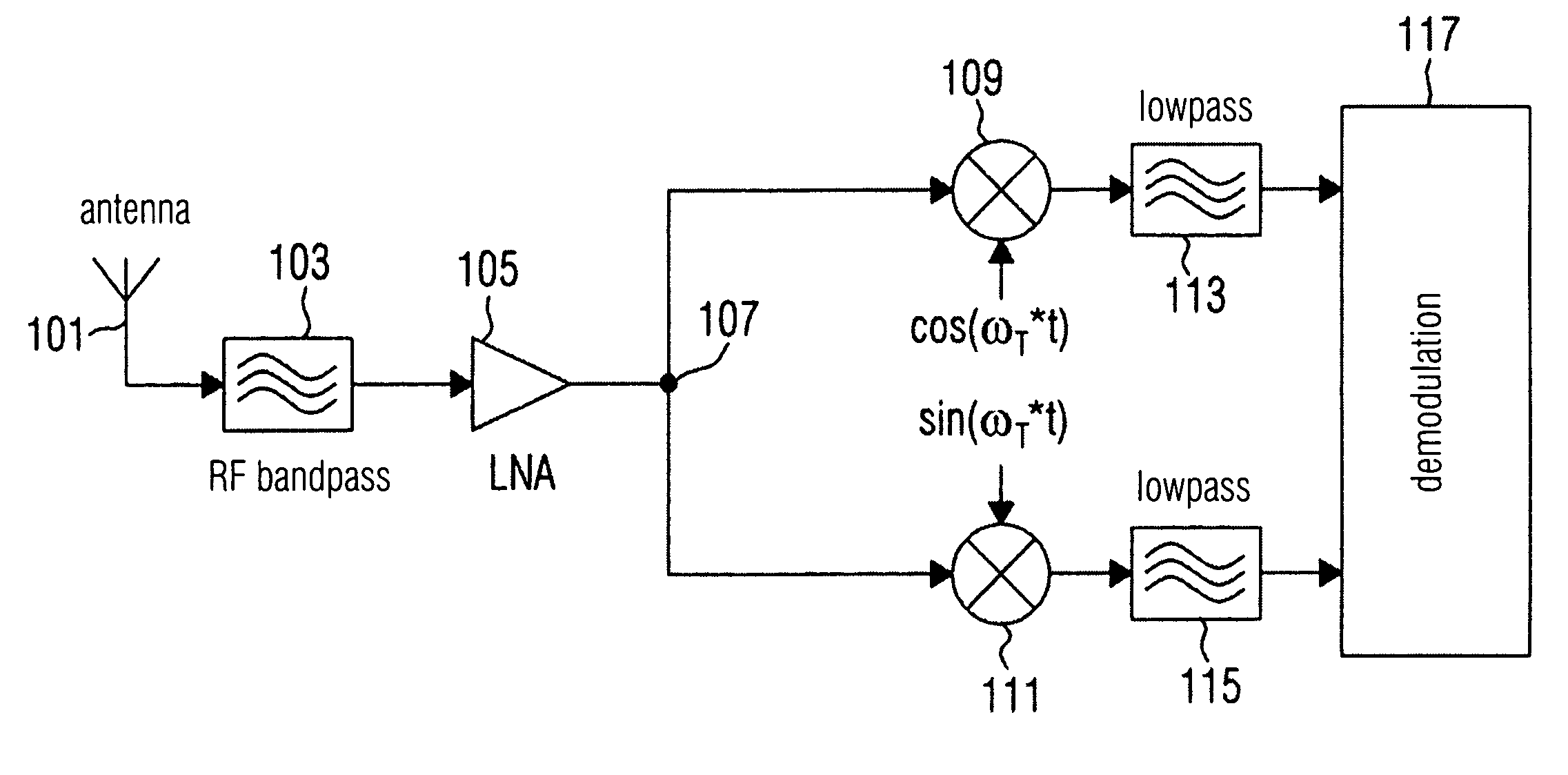

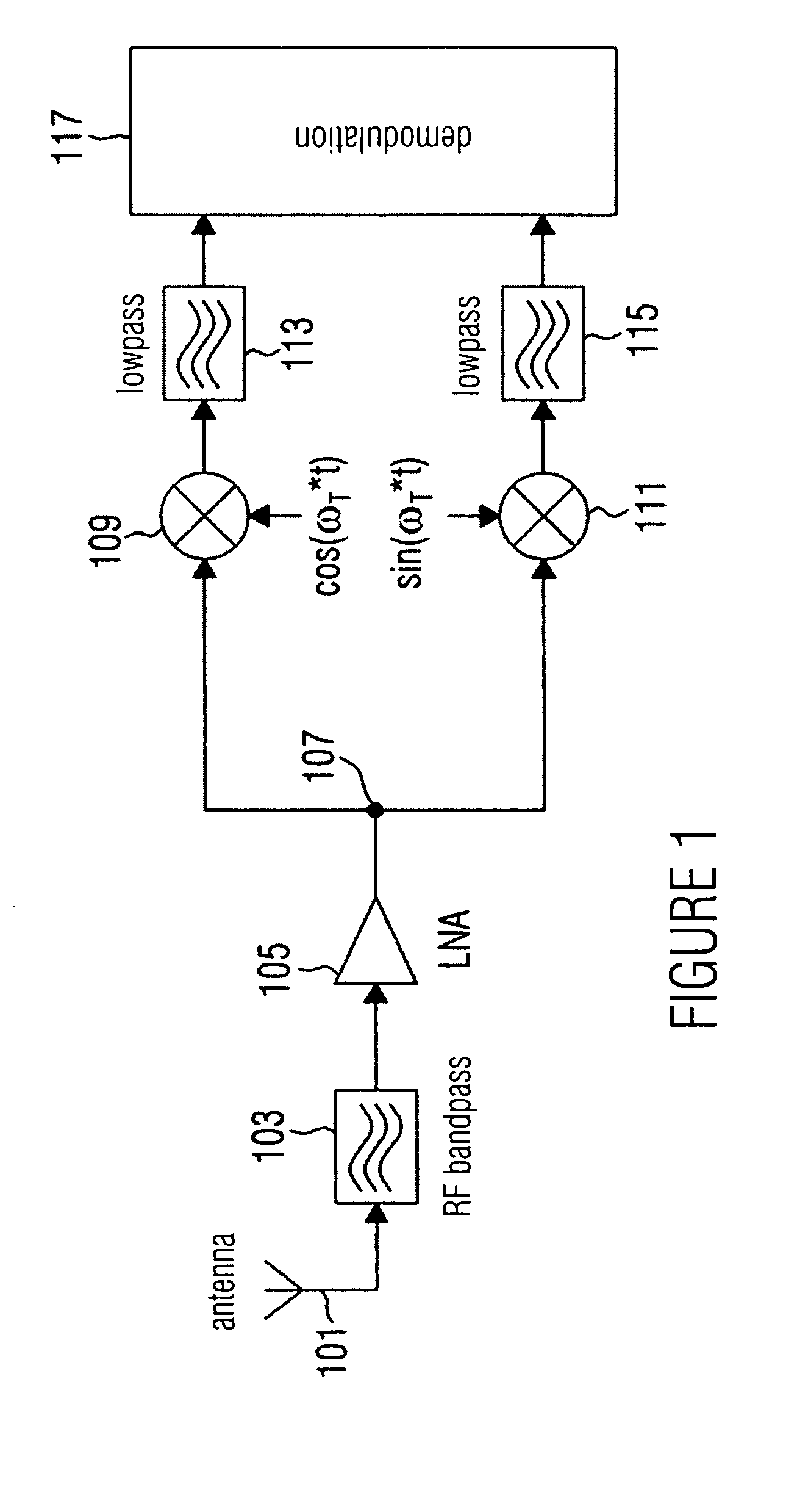

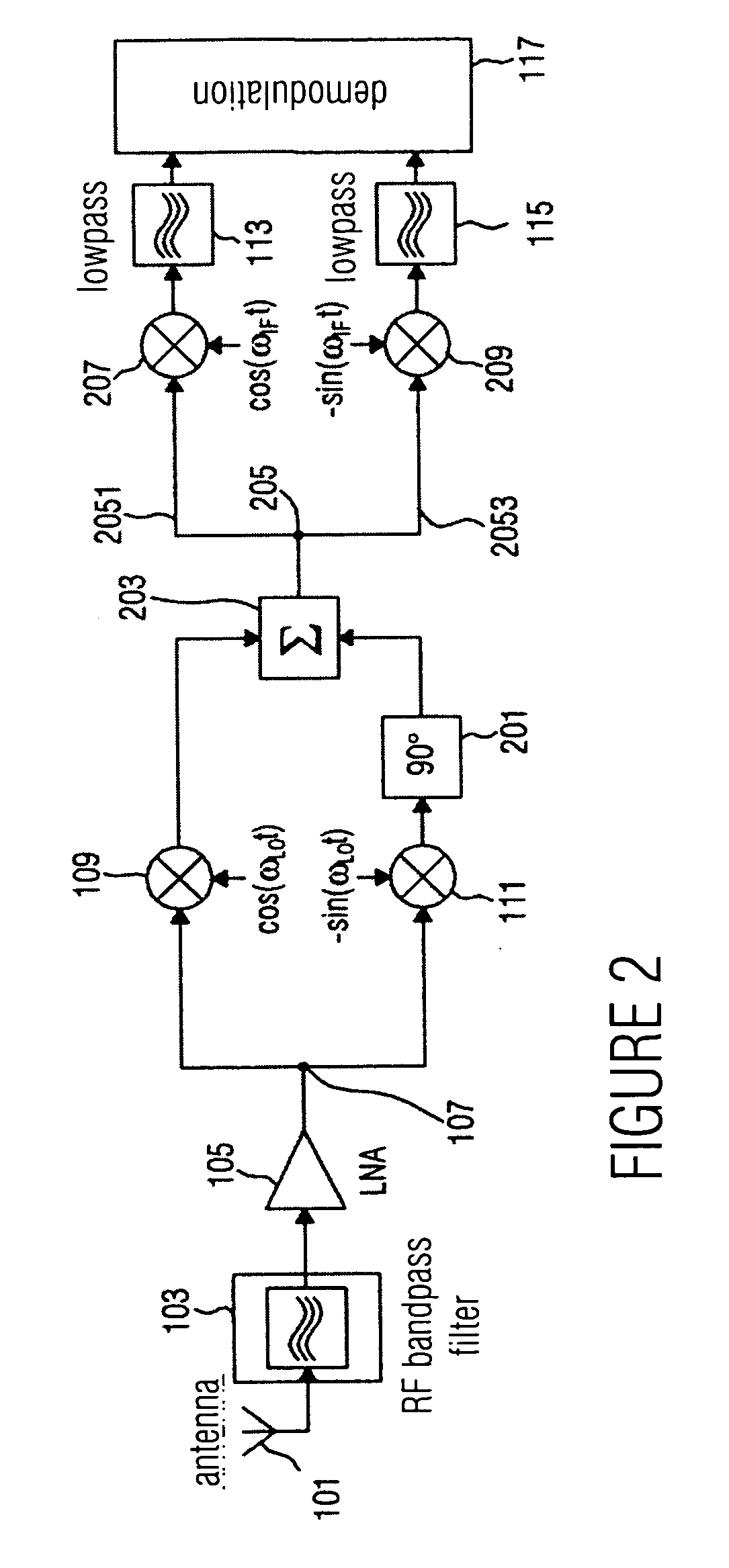

Apparatus and method for downward mixing an input signal into an output signal

InactiveUS20060025099A1Ensure correct executionReduce consumptionTransmission noise suppressionMulti-frequency-changing modulation transferenceIntermediate frequencySignal on

Device for downward mixing an input signal into an output signal includes means for generating a first receive signal and a second receive signal on a first intermediate frequency, a converter means for analog / digital converting the first and the second receive signals on the first intermediate frequency, a phase detection means for detecting a phase difference between a digital representation of the first receive signal and the second receive signal, a first mixer means and a second mixer means for converting the respective digital representations onto a second intermediate frequency, a mixer control means and a summation means, wherein the phase detection means is implemented in order to control means for generating and / or mixer control means so that the output signals of the first and the second mixer means are in a predetermined phase relation to each other, so that an image frequency rejection occurs after a summation. By this it is achieved that the device for downward mixing is basically integrable and that an efficient image frequency rejection is obtained.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

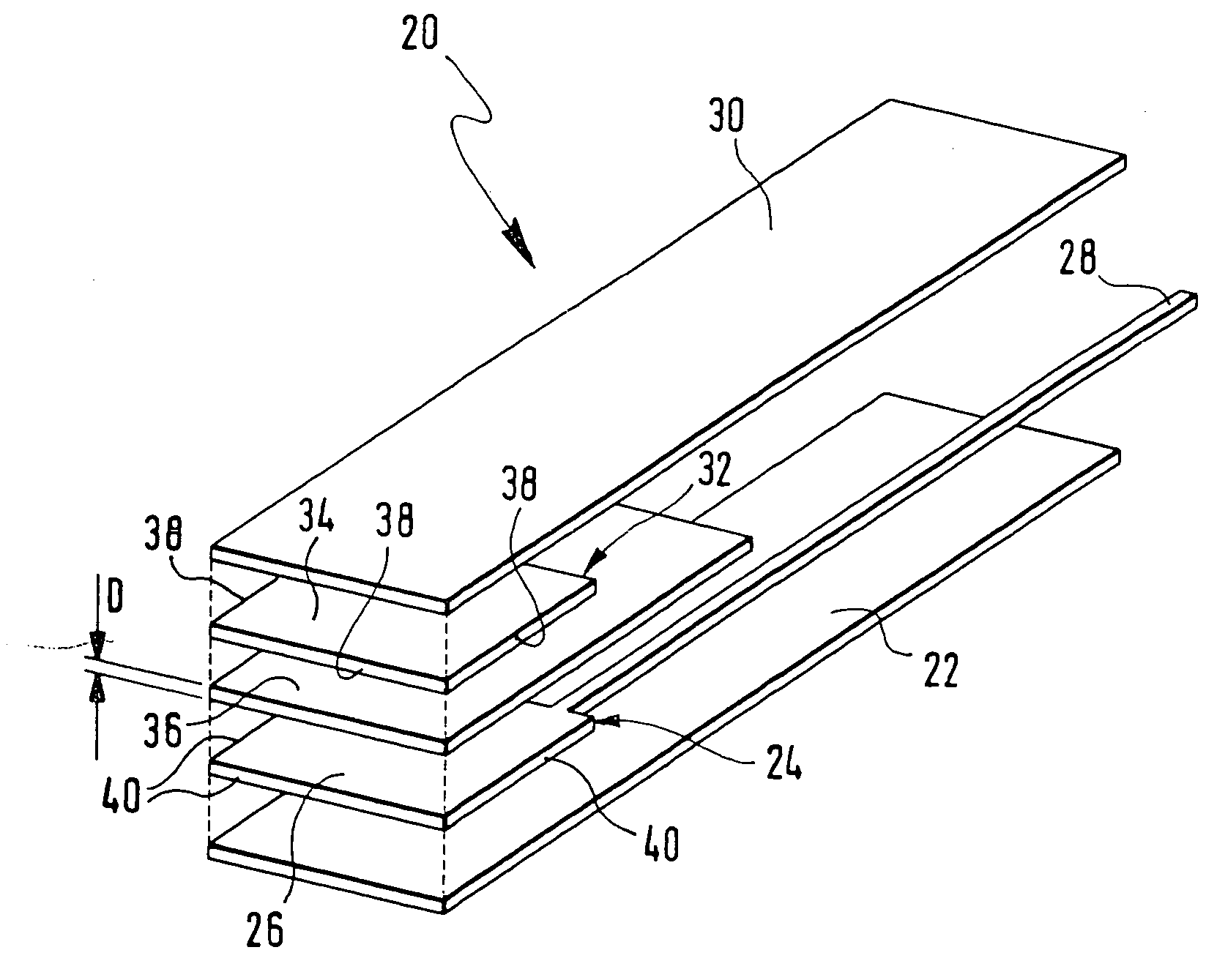

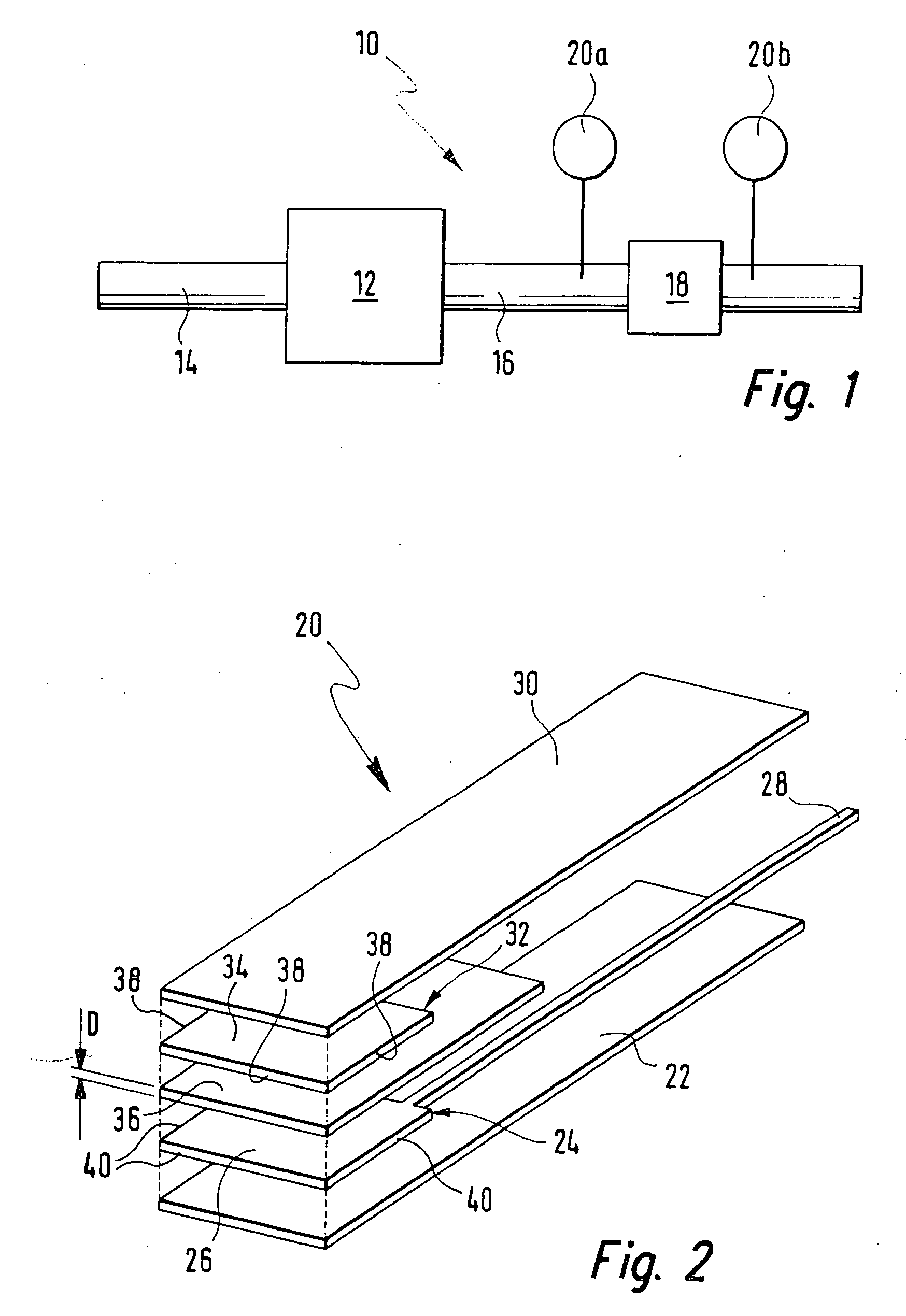

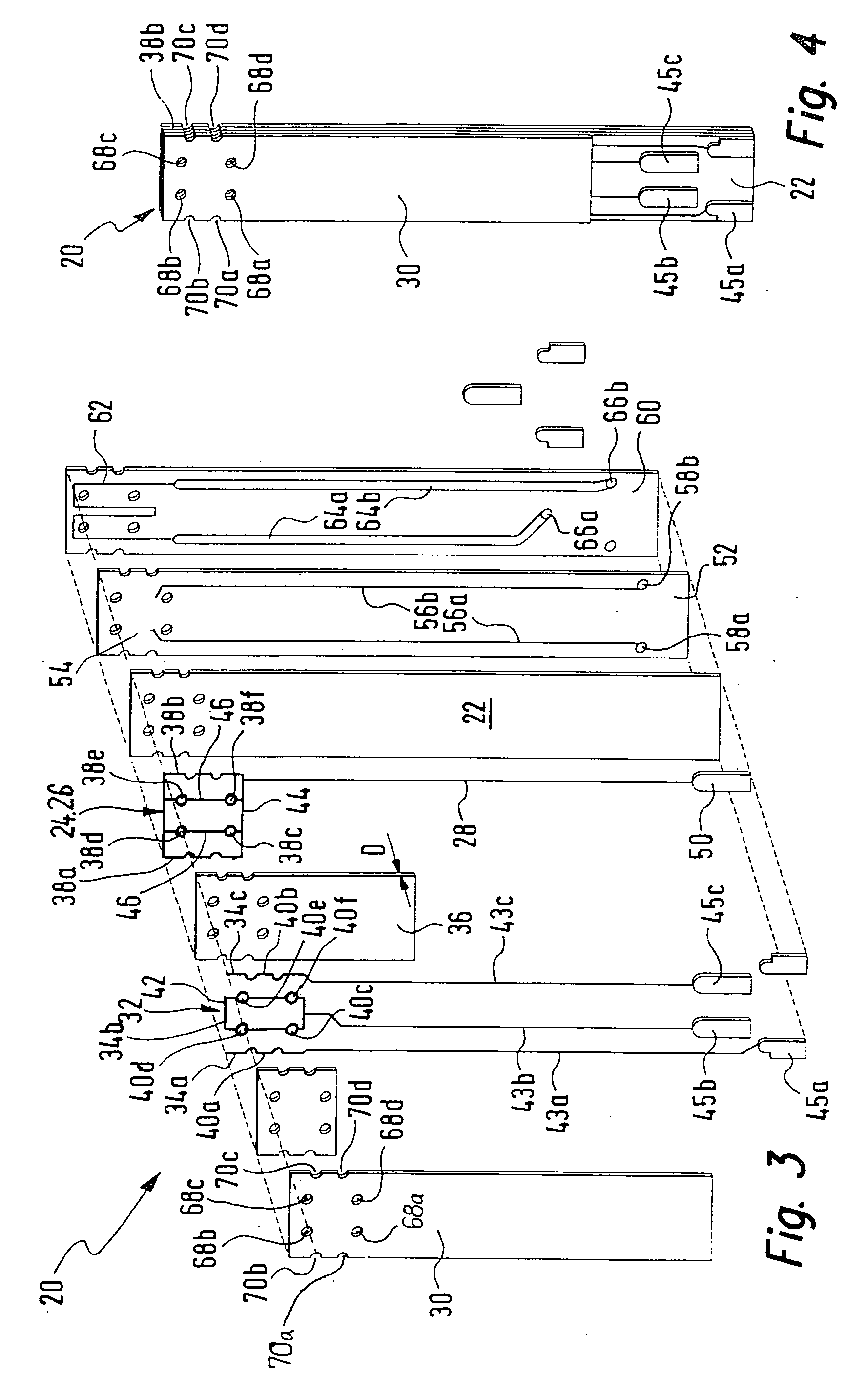

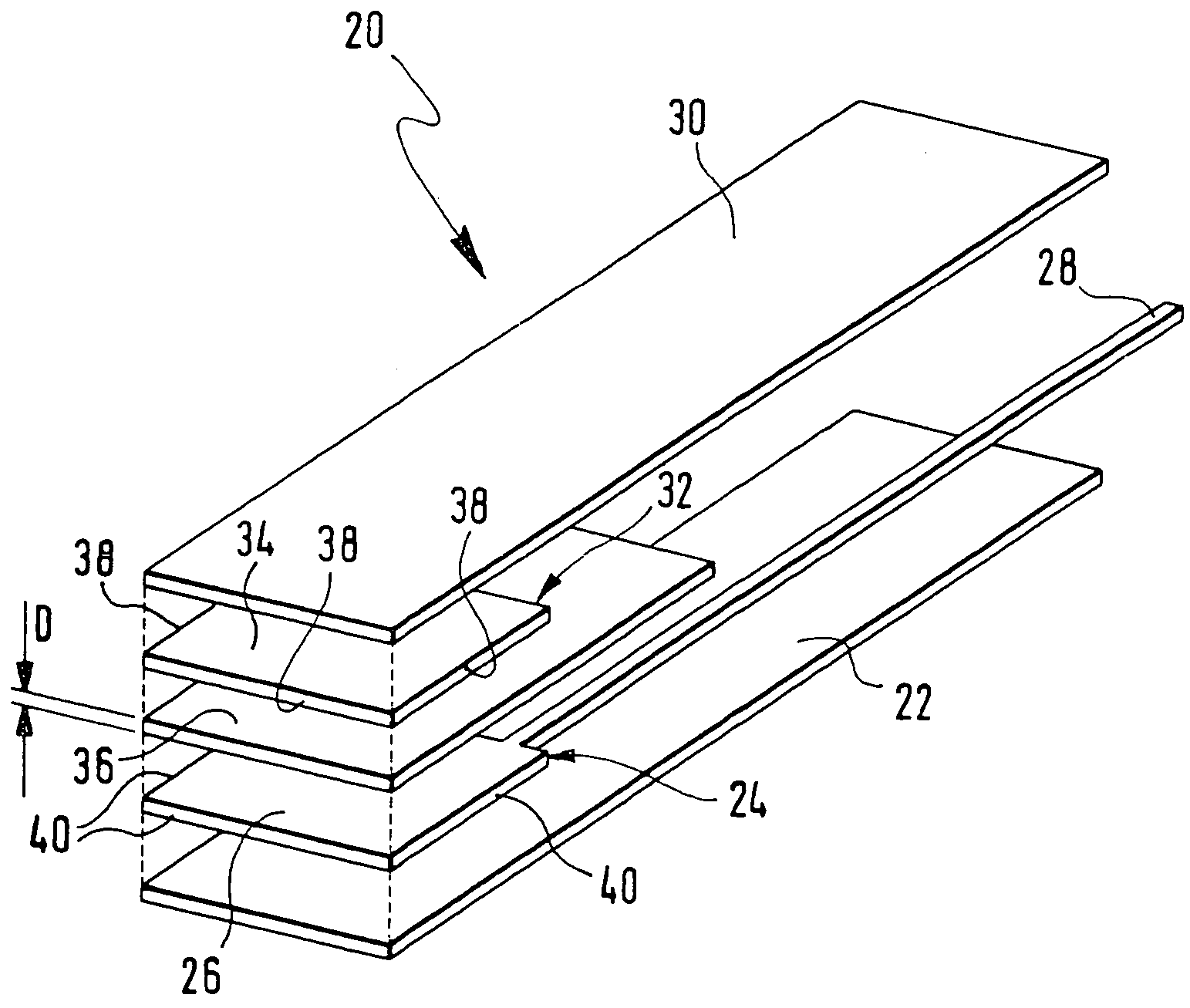

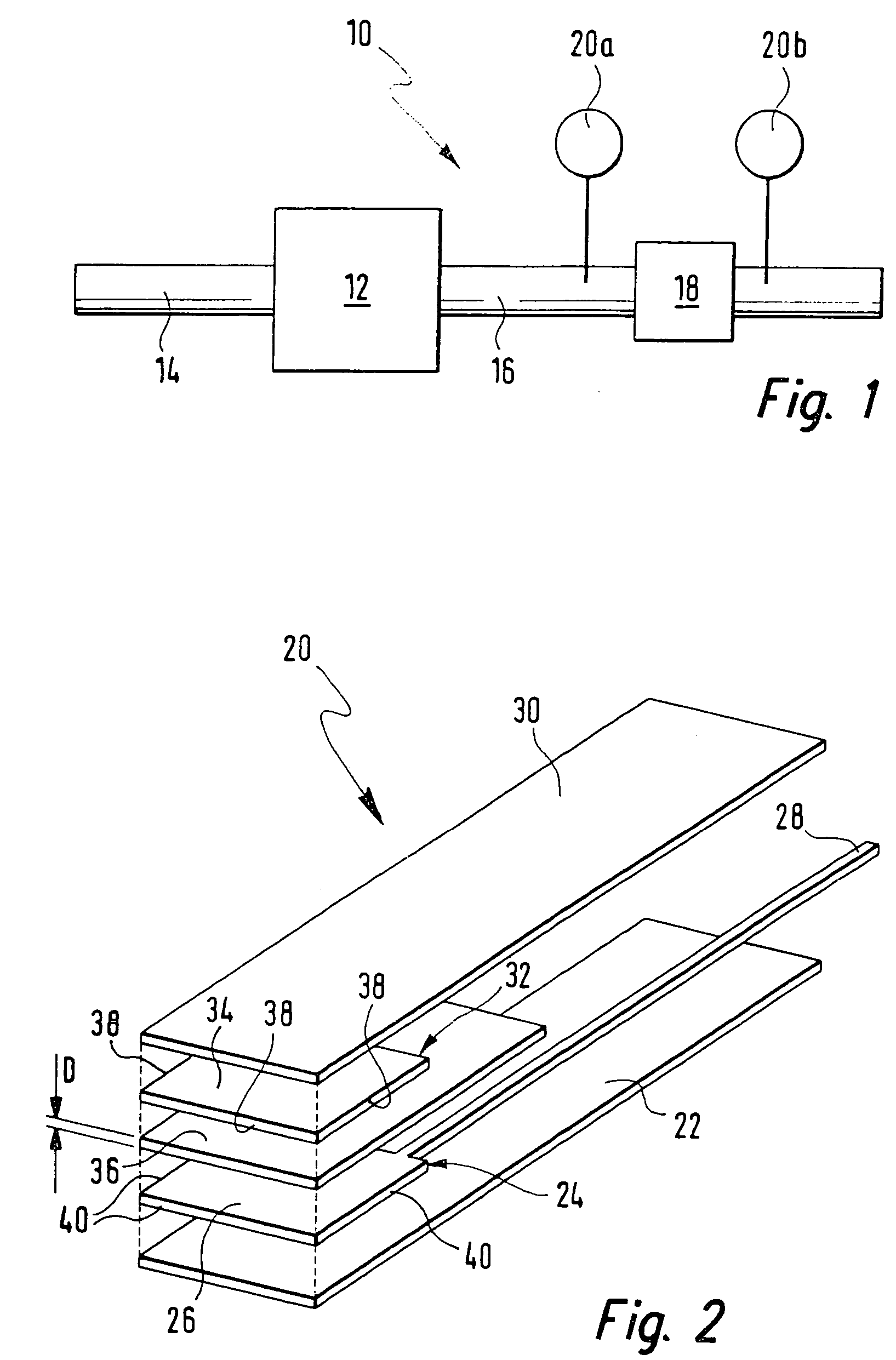

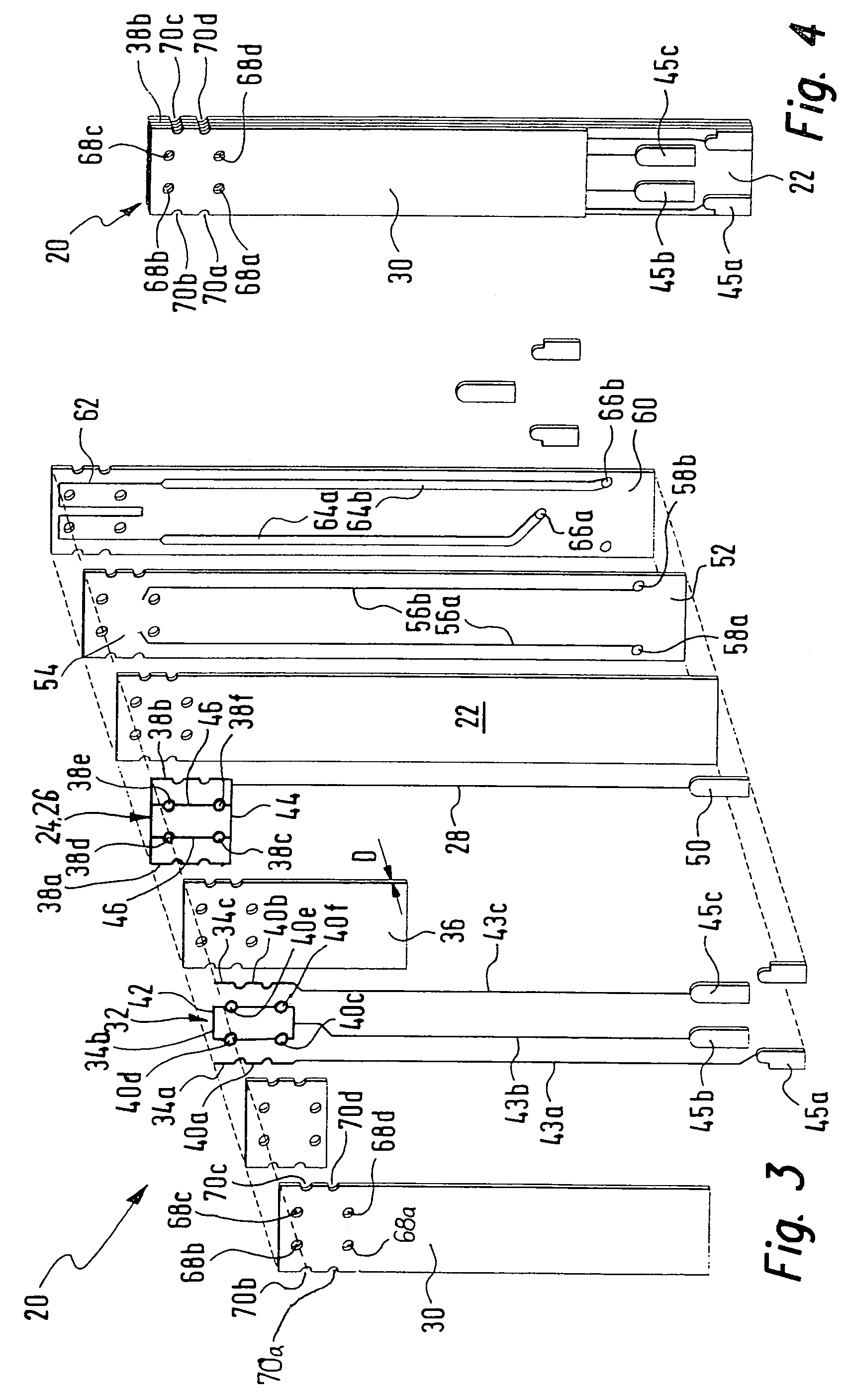

Sensor for detecting particles in a gas stream and method for its manufacture

ActiveUS20070119233A1Fast and inexpensiveEasy to introduceManufacture of electrical instrumentsMaterial impedanceElectricityEngineering

A soot particle sensor for an exhaust system of an internal combustion engine includes a first electrode device and a second electrode device. The electrode devices are situated at a distance from one another and are able to be exposed to the gas stream, at least in some areas. It is provided that the electrode devices are separated from each other by an intermediate layer made of an electrically insulating material, and the electrode devices have free edges that are set apart from each other by the thickness of the intermediate layer and are able to be exposed to the gas stream.

Owner:ROBERT BOSCH GMBH

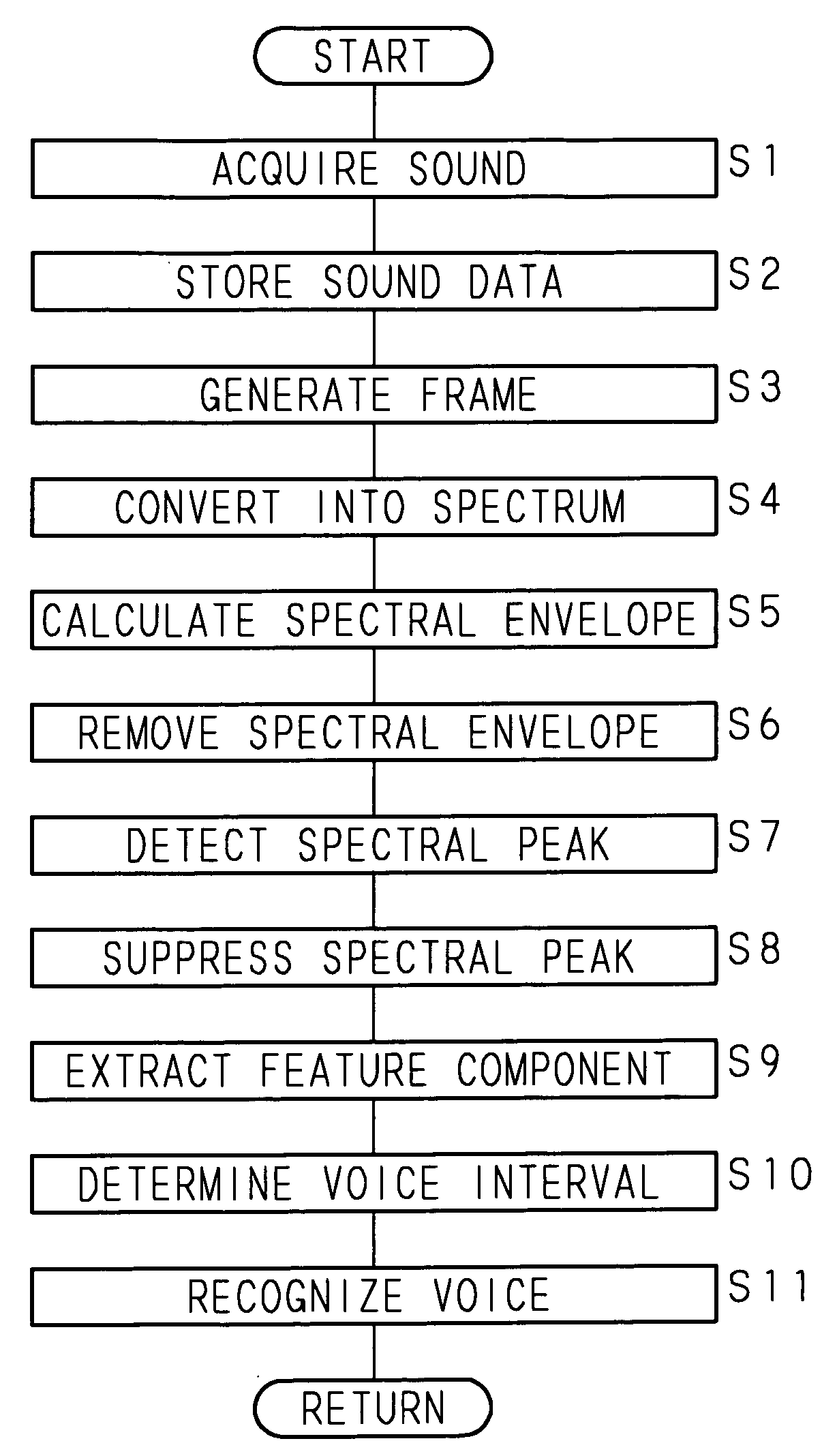

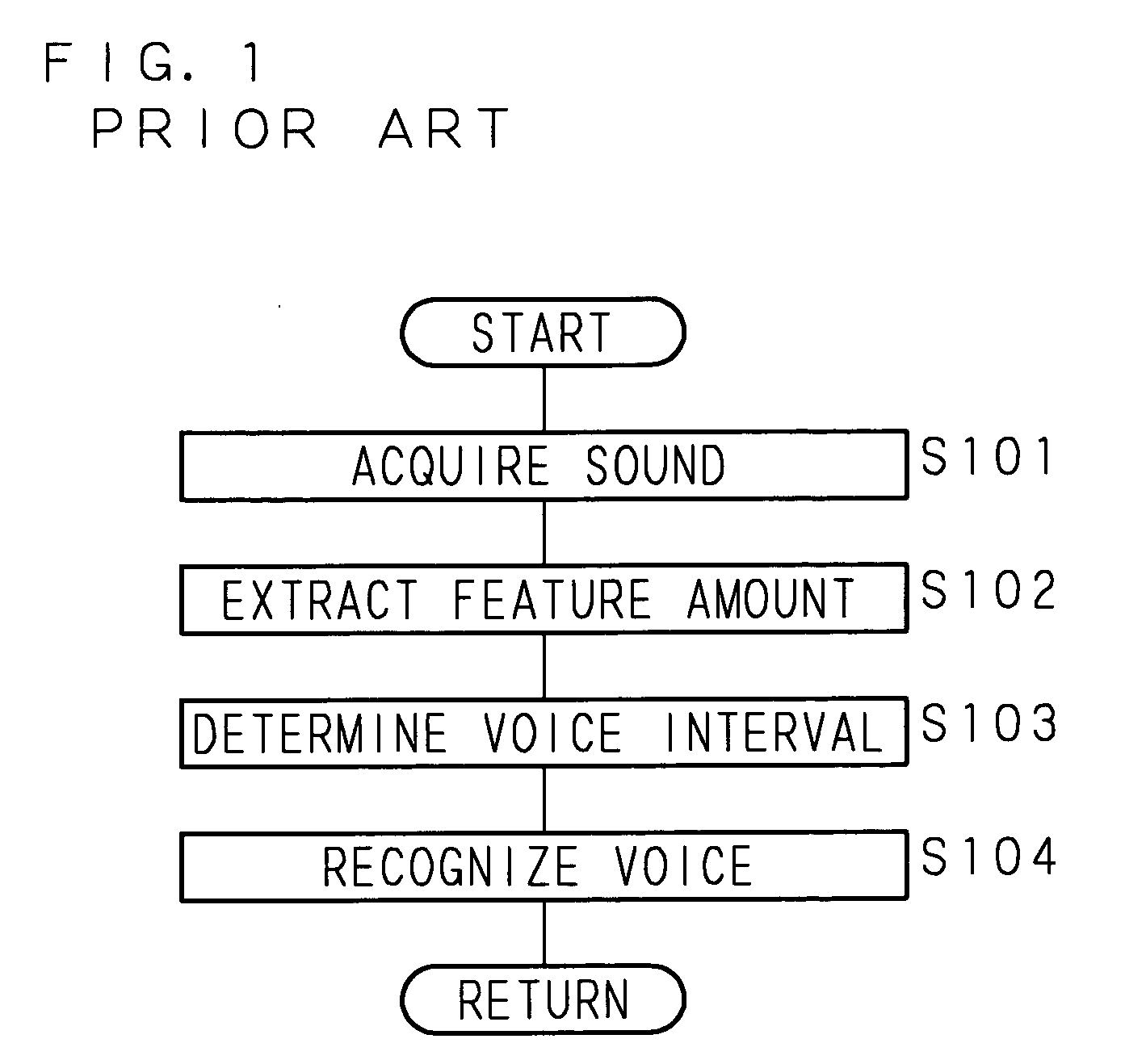

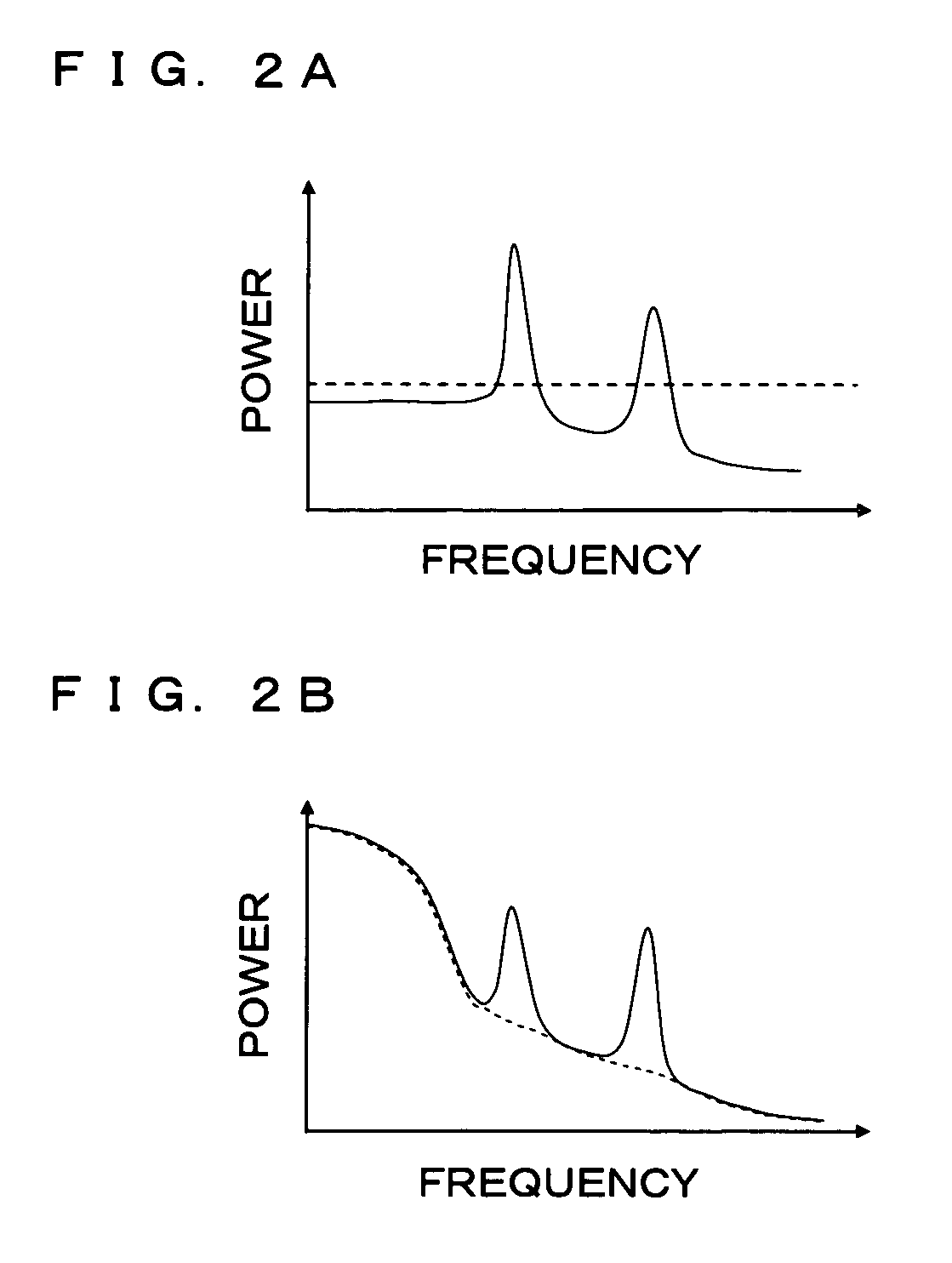

Sound signal processing method, sound signal processing apparatus and computer program

InactiveUS20080069364A1Improve accuracyAccurate detectionStereophonic circuit arrangementsSpeech recognitionFrequency spectrumPeak value

A sound signal processing apparatus creates frames from acquired sound data, and converts a sound signal into a spectrum on a frame-by-frame basis. Then, the sound signal processing apparatus calculates a spectral envelope based on the spectrum, removes the spectral envelope from the spectrum, detects a spectral peak in the spectrum obtained by the removal of the spectral envelope, and suppresses the detected spectral peak. The sound signal processing apparatus determines a voice interval from the spectrum with the suppressed spectral peak, and executes voice recognition processing based on the spectrum with the suppressed spectral peak in a frame determined to be a voice interval.

Owner:FUJITSU LTD

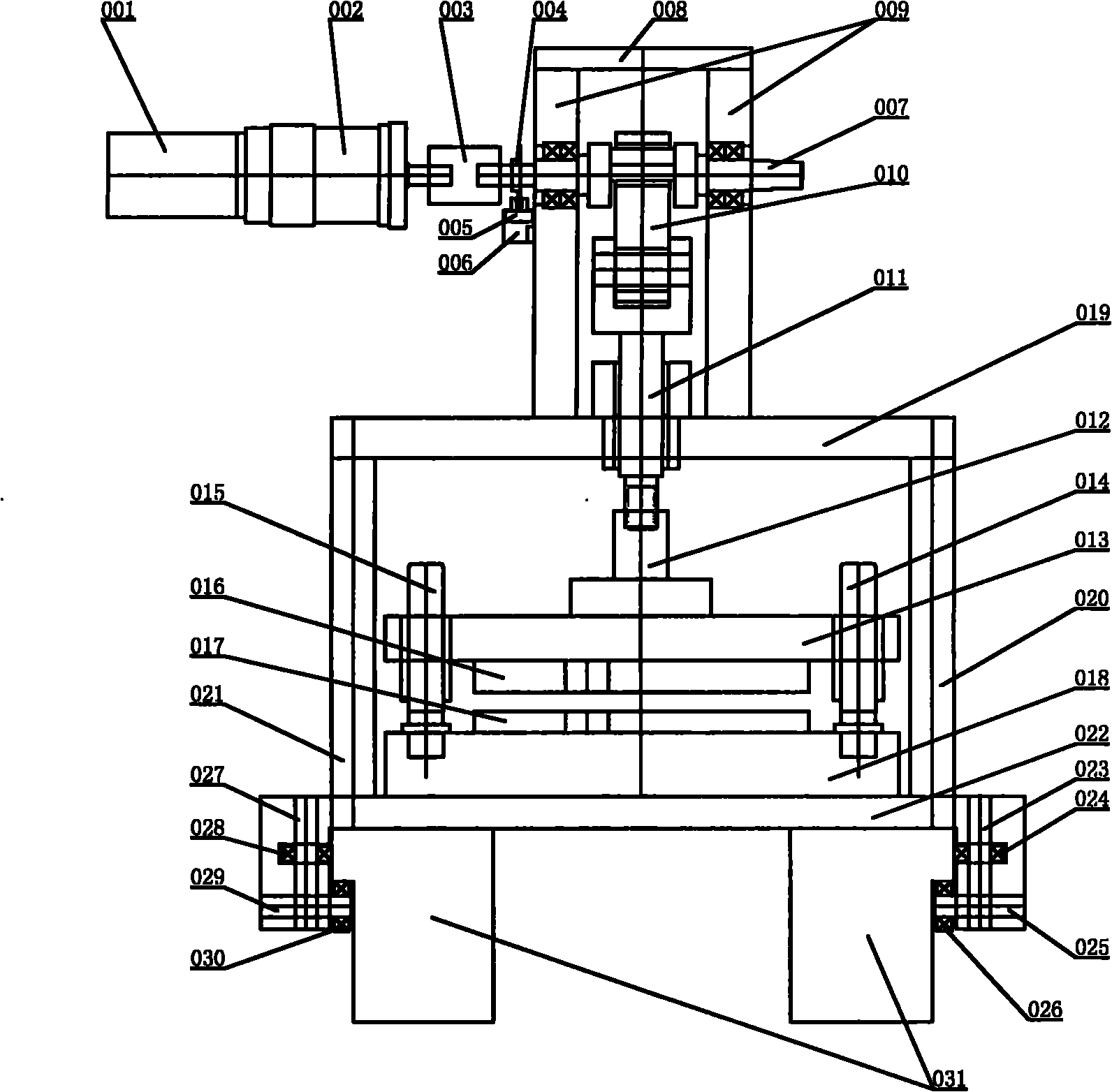

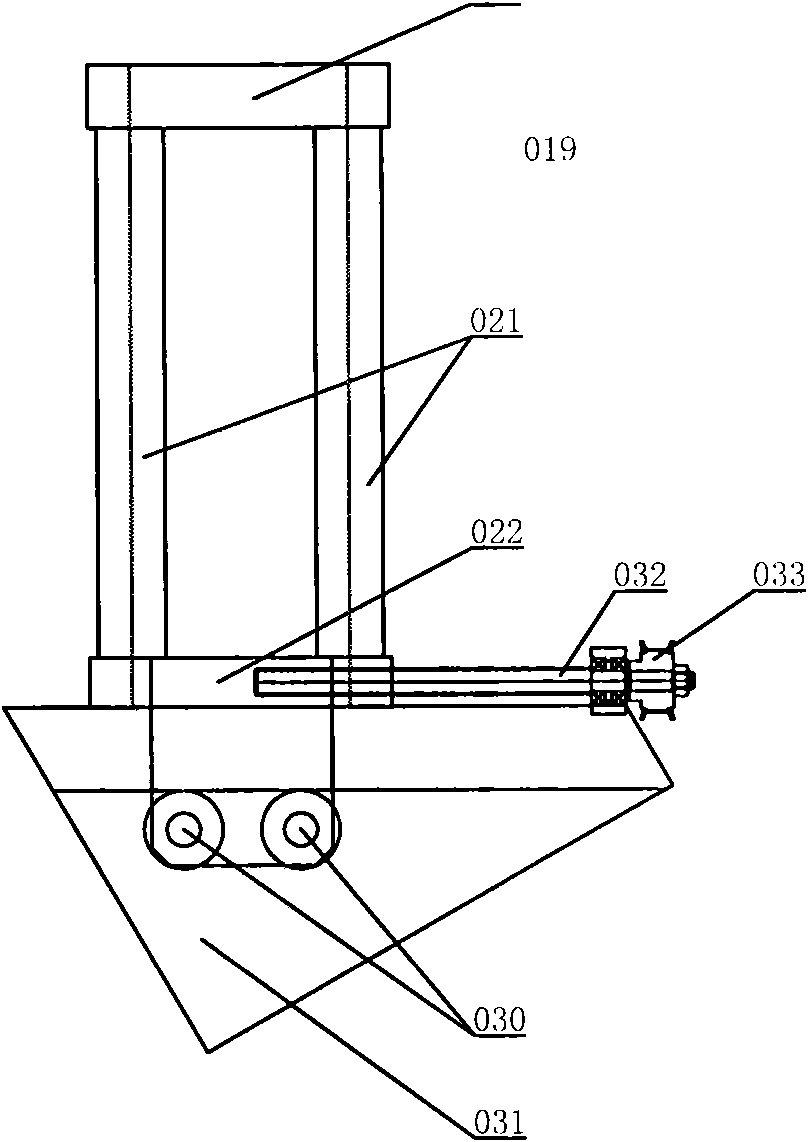

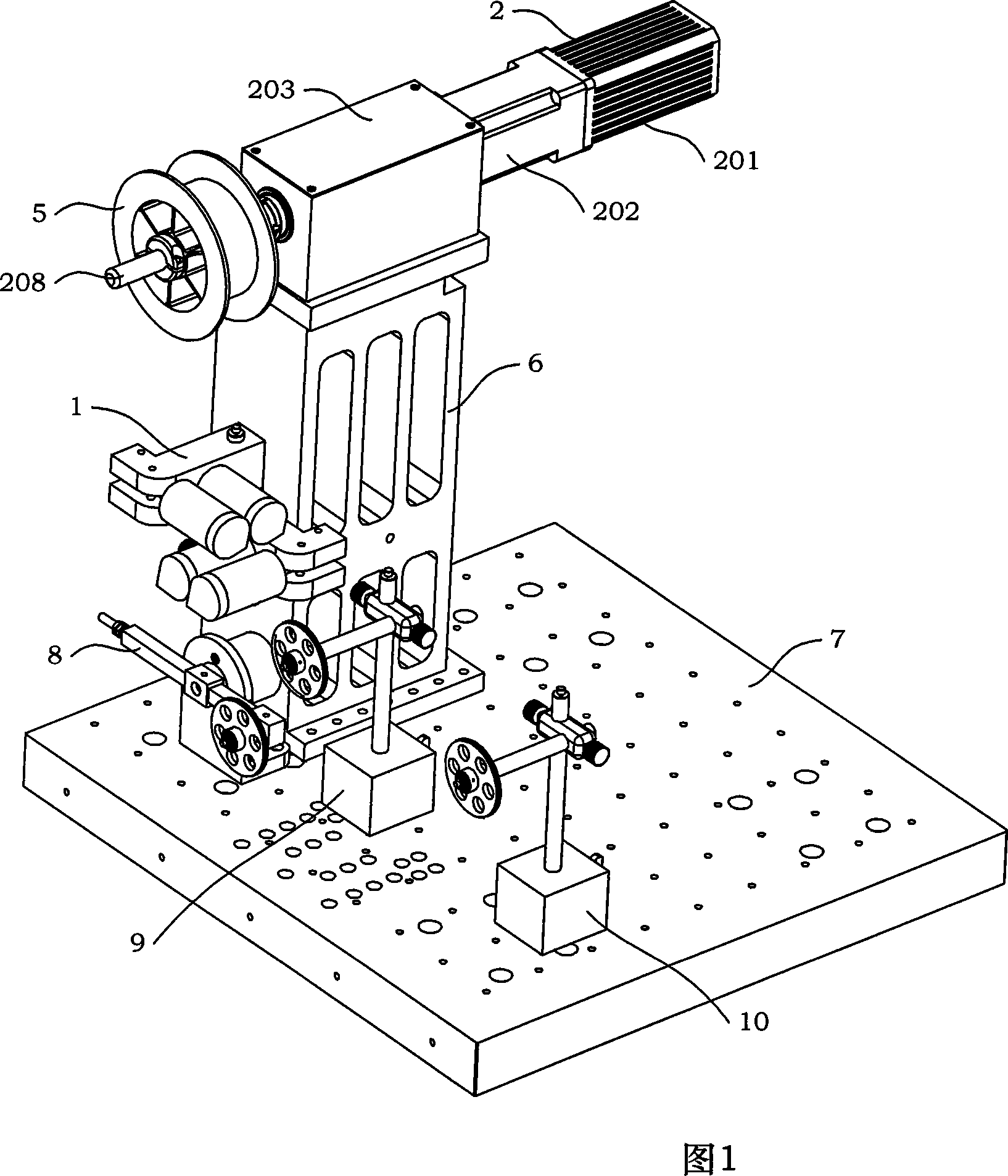

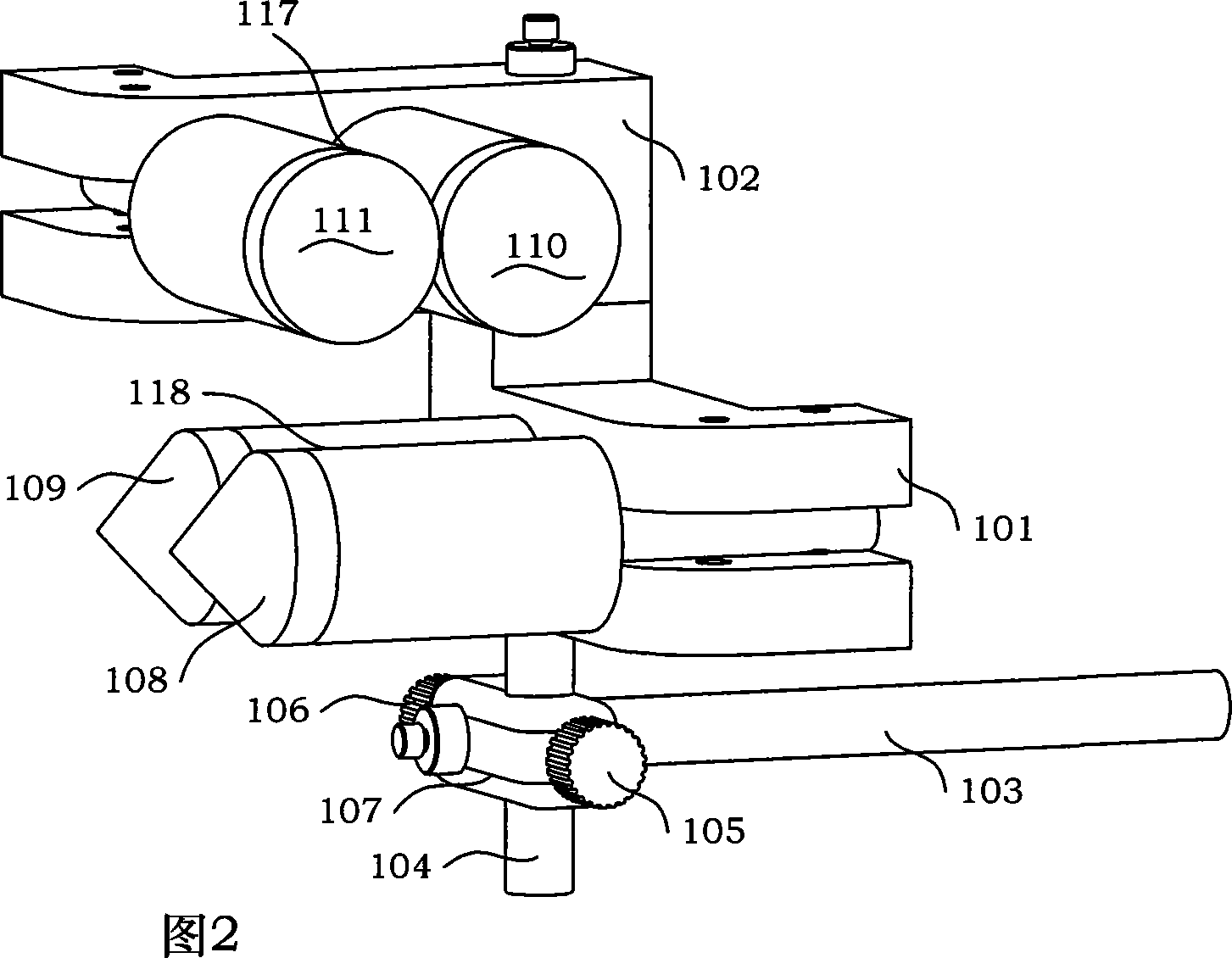

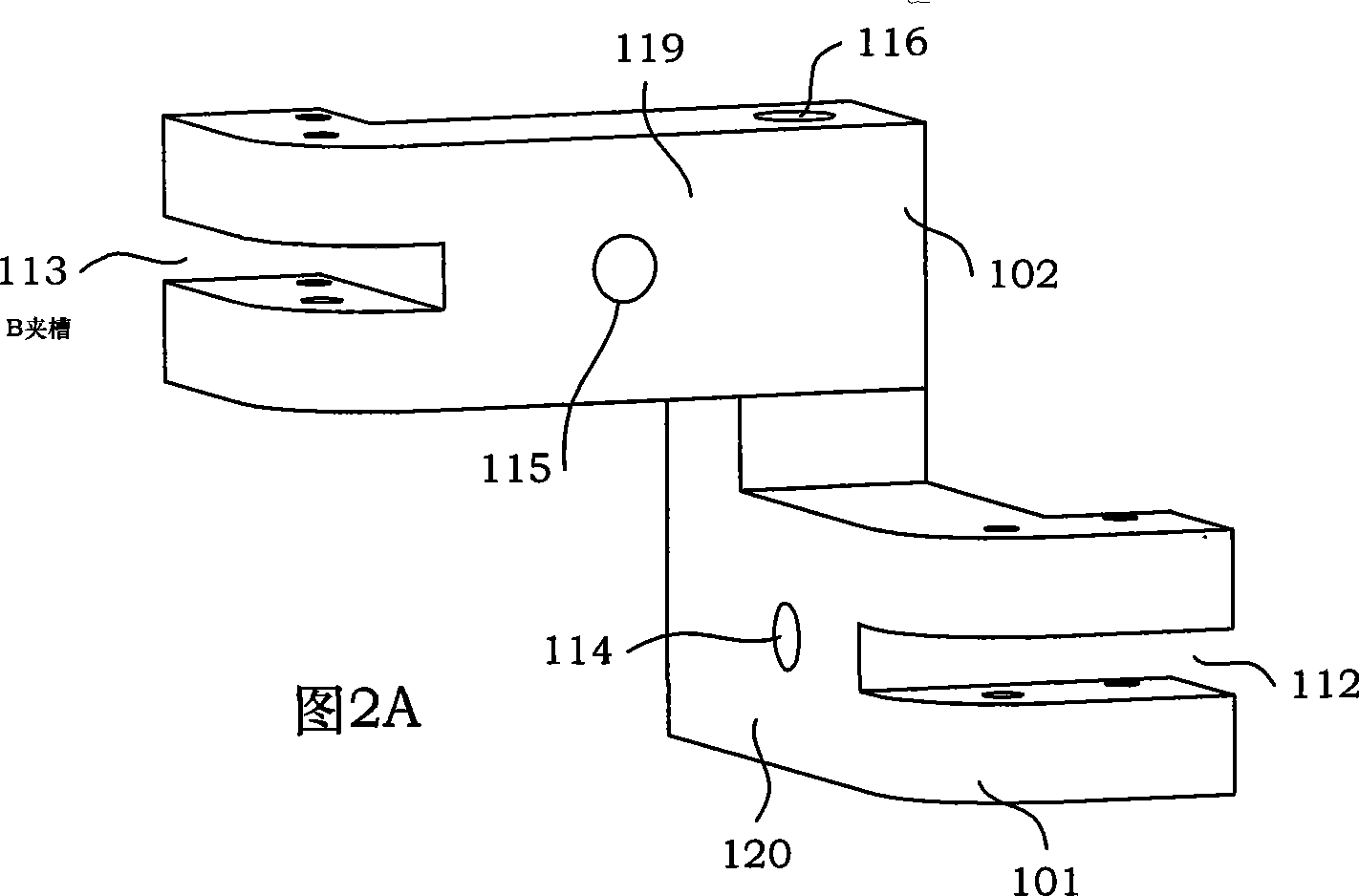

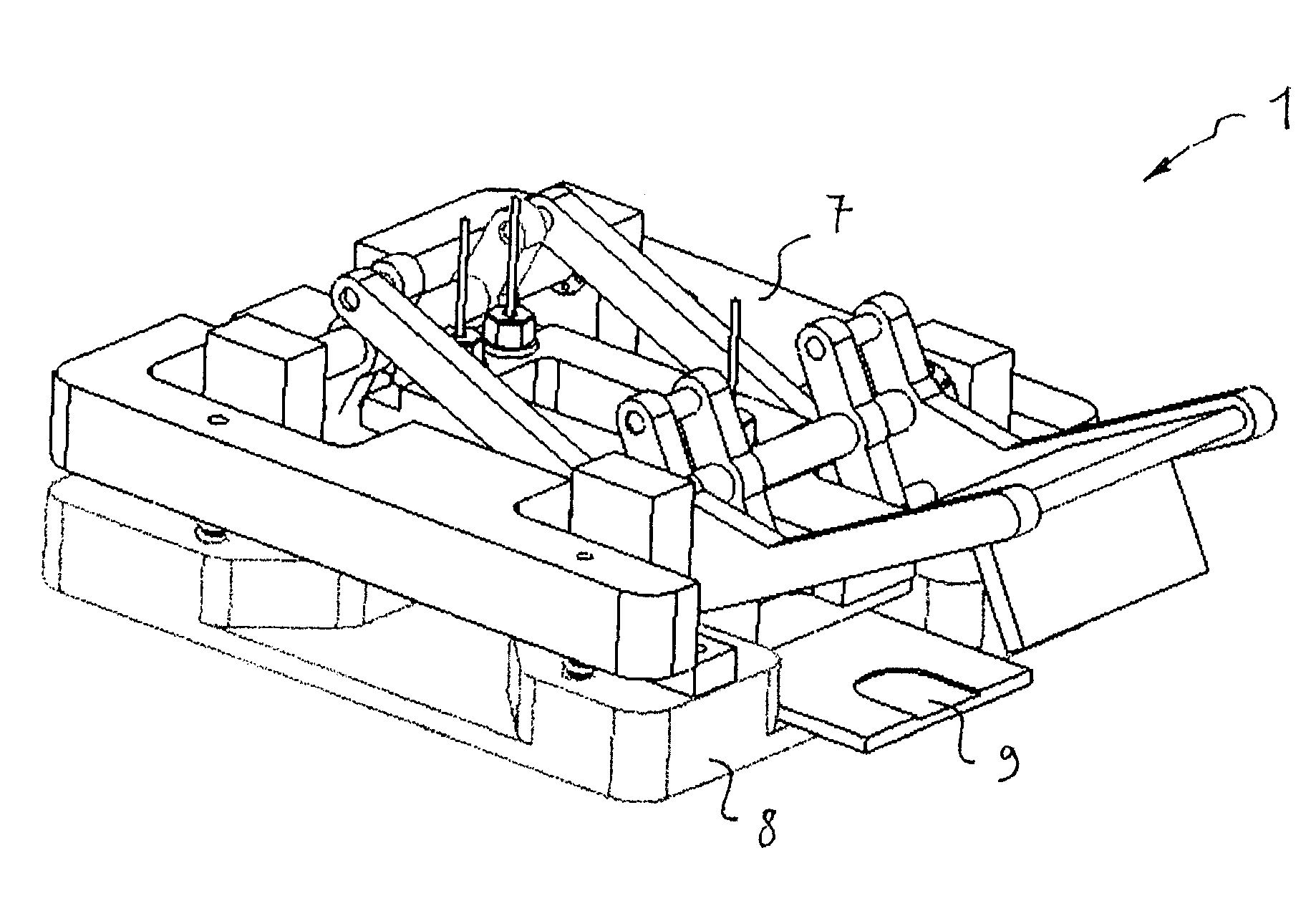

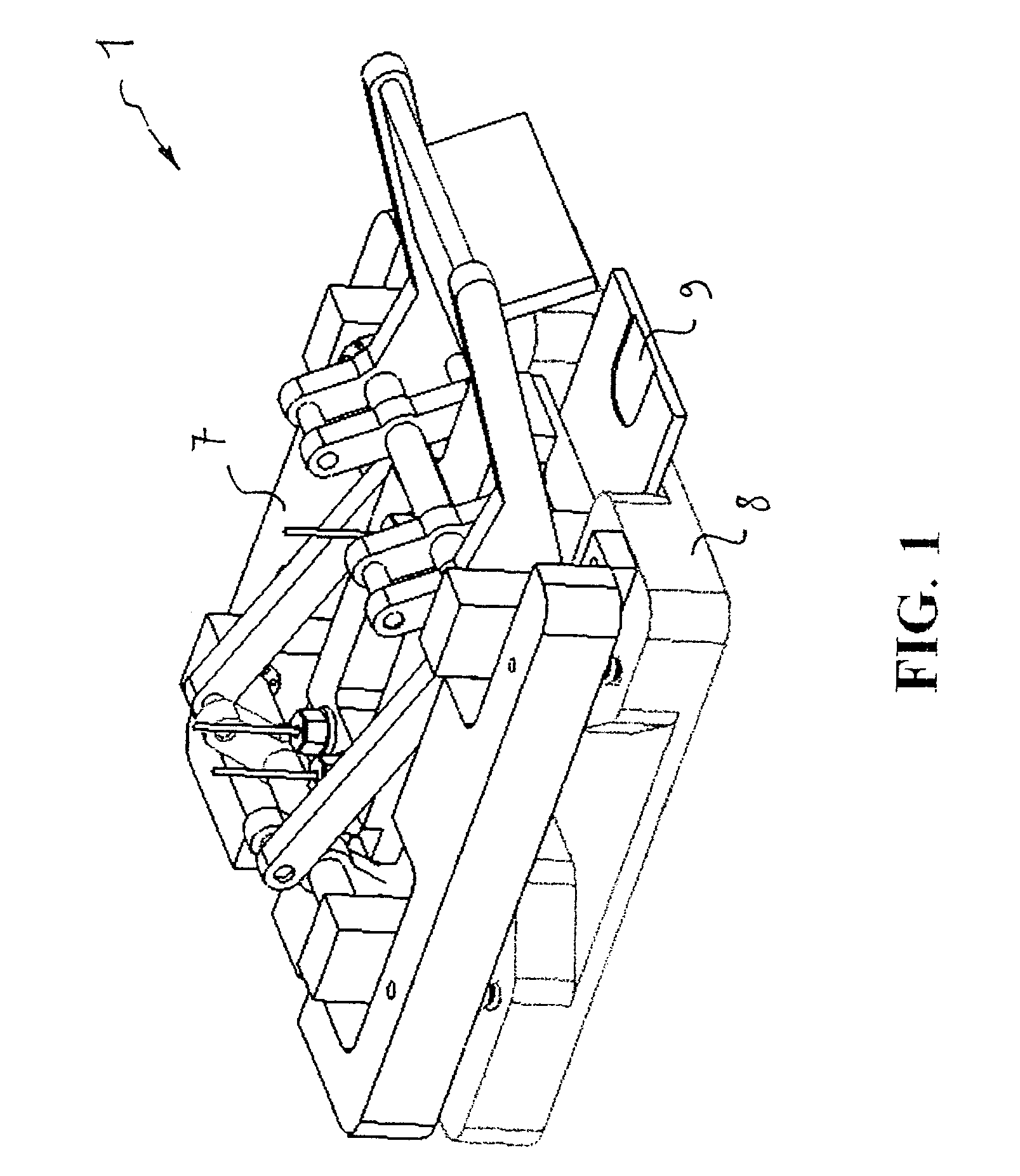

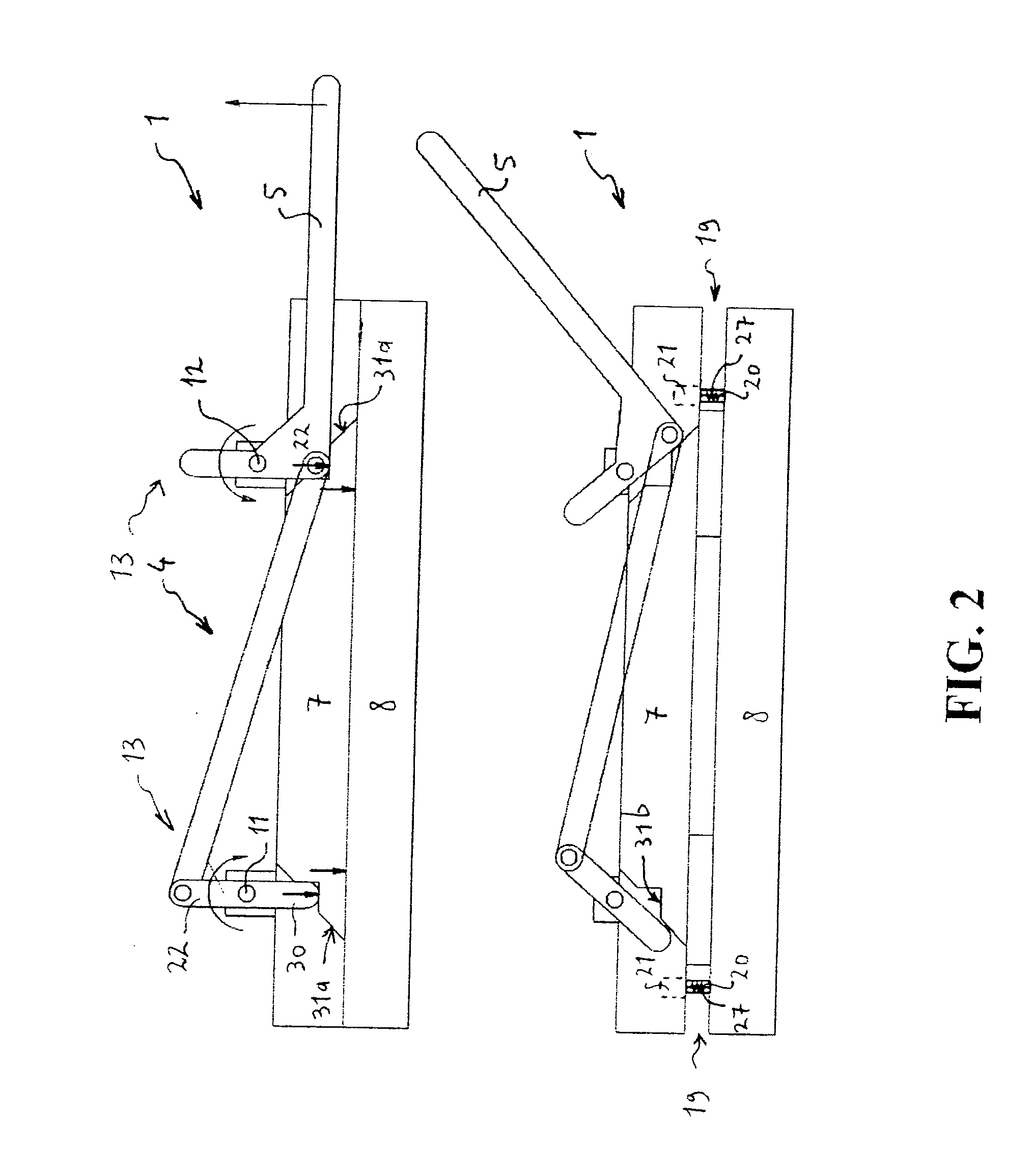

Tab cutting device

ActiveCN101774041AEffective and uniform cutting forceAvoid side stabsShearing machinesMotor driveEngineering

The invention discloses a tab cutting device, which comprises a driving mechanism and a cutting mechanism, wherein the cutting mechanism comprises an upper cutter and a lower cutter; the driving mechanism is coupled with the upper cutter and comprises a motor, a cam and an in-situ detection device; the output shaft of the motor is coupled with the upper cutter by the cam; the motor drives the cam to rotate synchronously; the cam rotates to drive the upper cutter to move relative to the lower cutter to cut a tab. The device can ensure that the upper cutter can achieve an excellent tab cutting effect.

Owner:SHENZHEN YINGHE TECH

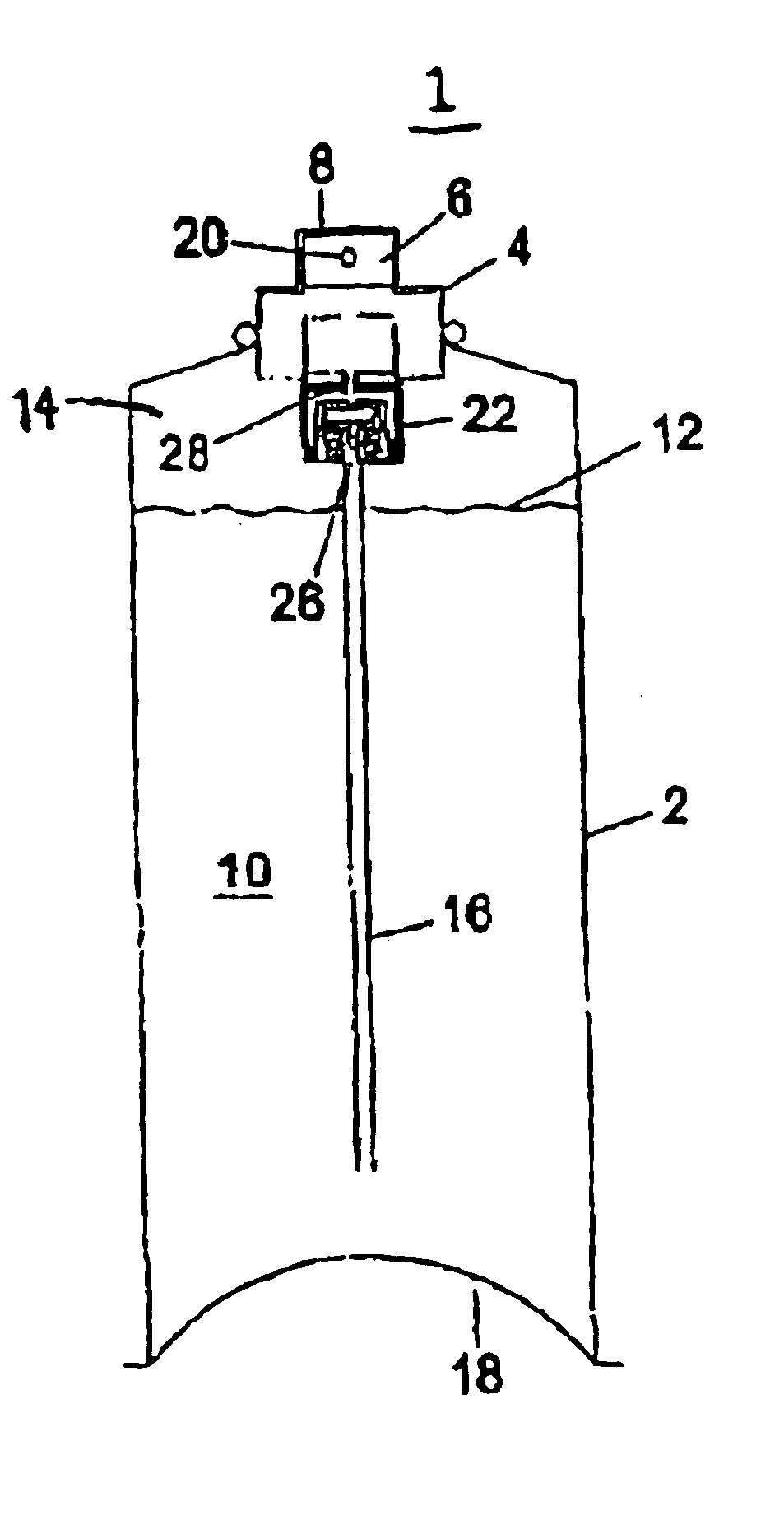

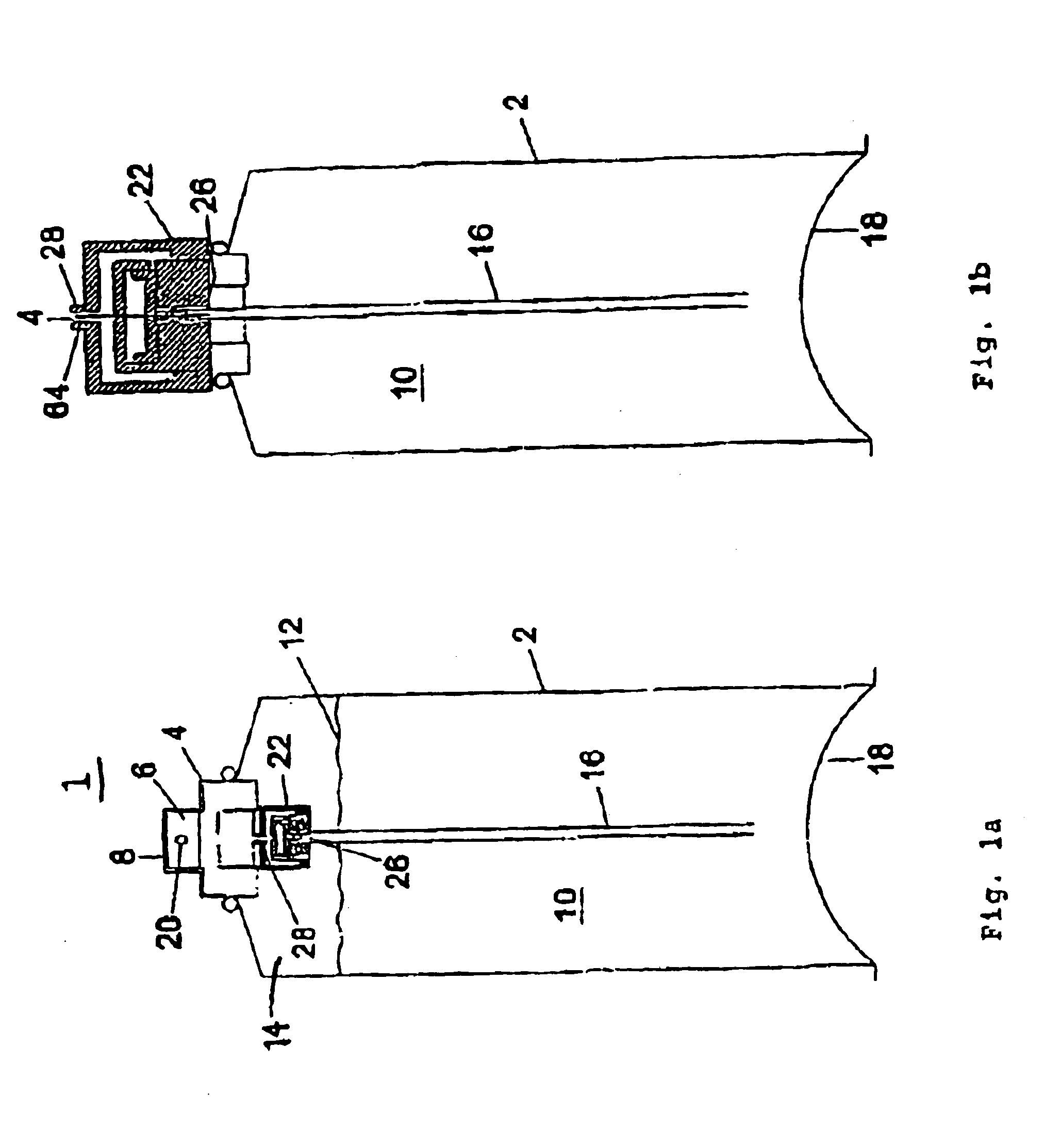

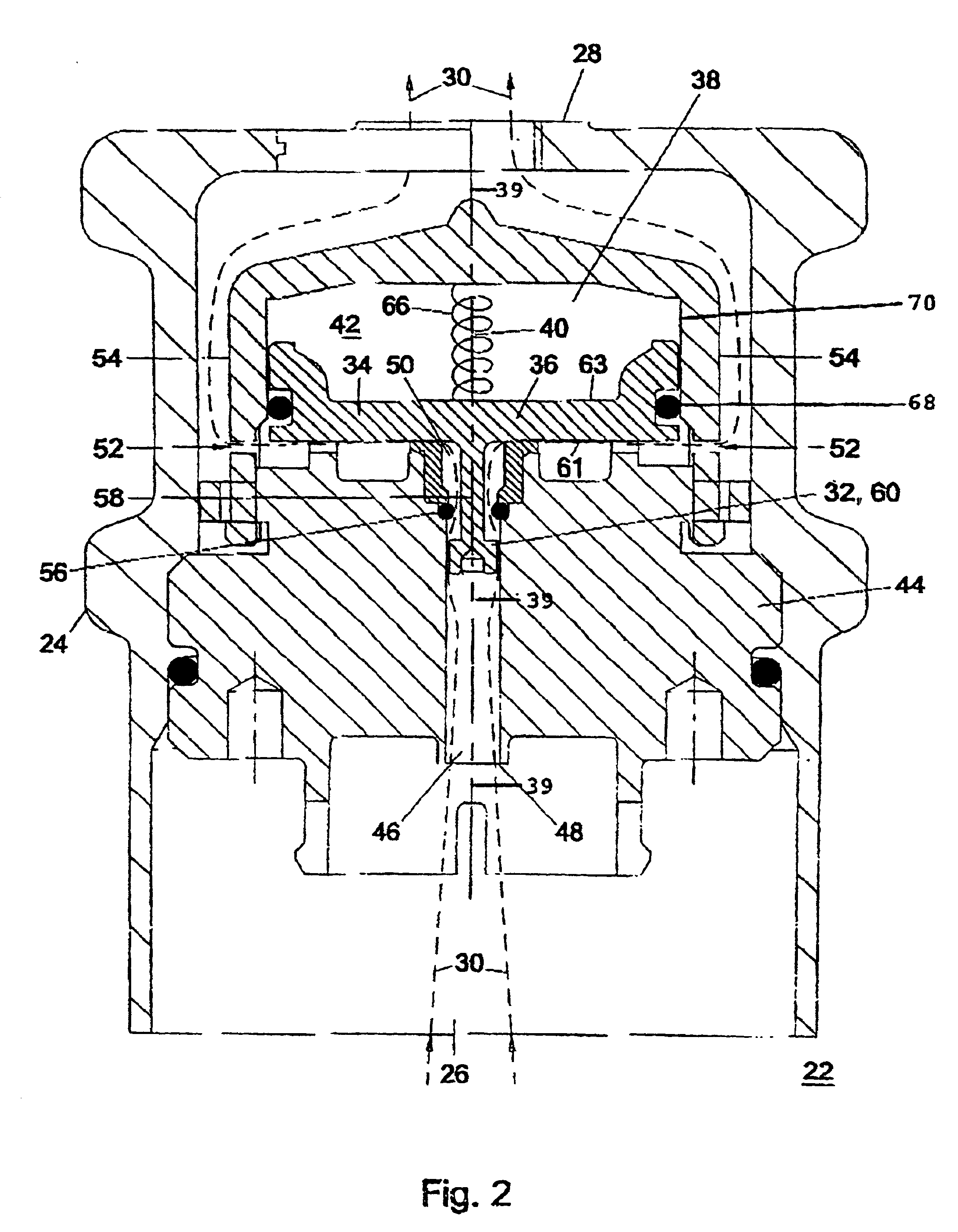

Pressurized package comprising a pressure control device

InactiveUS6851575B2Reduce frictionEasy to controlEqualizing valvesPipe elementsEngineeringPressure controlled ventilation

A pressurized package assembly includes a package having an least one outlet. In use, an inner space of the package is filled with a fluid that is dispensed via the outlet. In the inner space of the package, there prevails a pressure which can vary. The assembly also includes a pressure control device for feeding to the outlet, via the pressure control device, the fluid at a predetermined constant pressure.

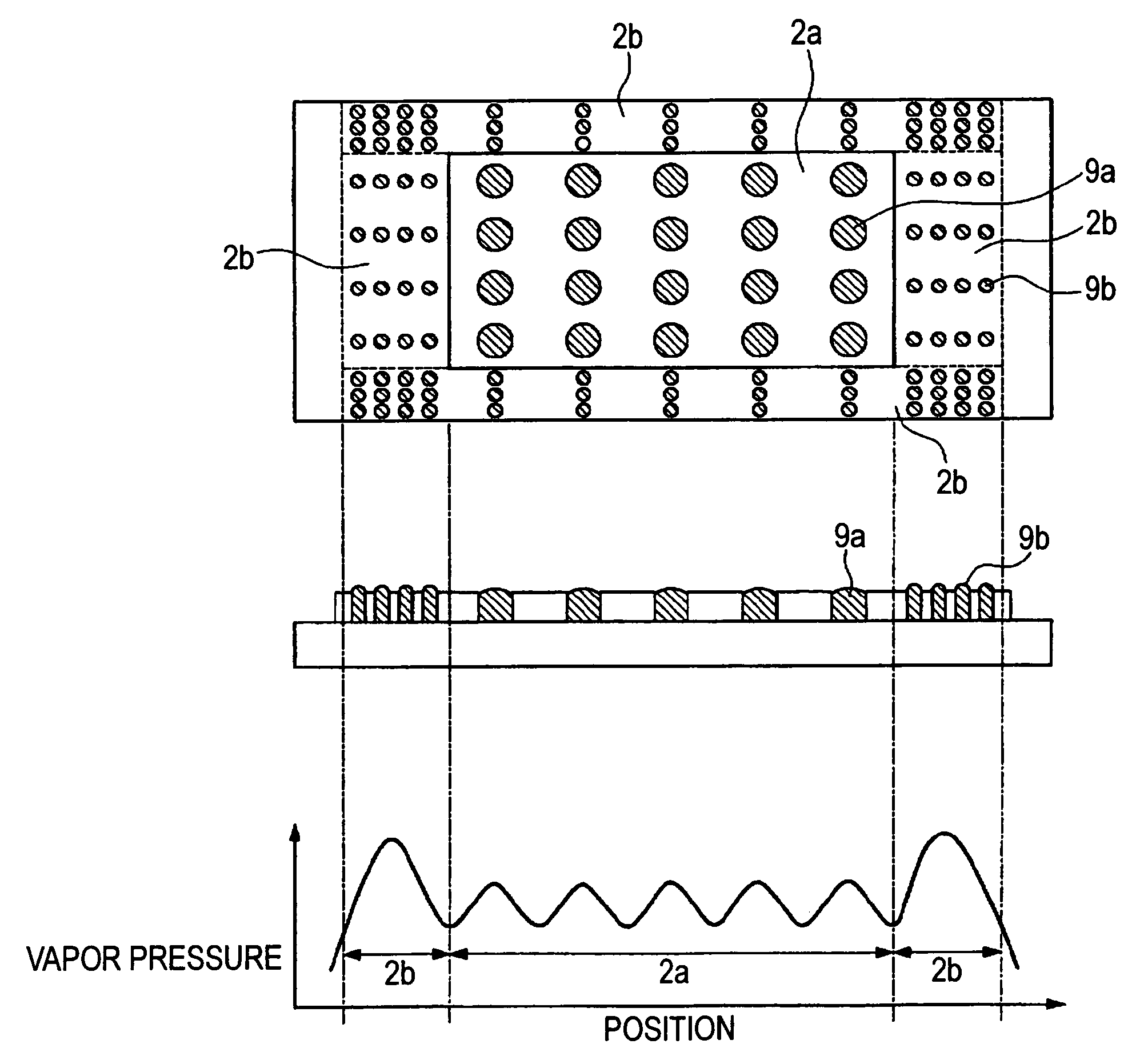

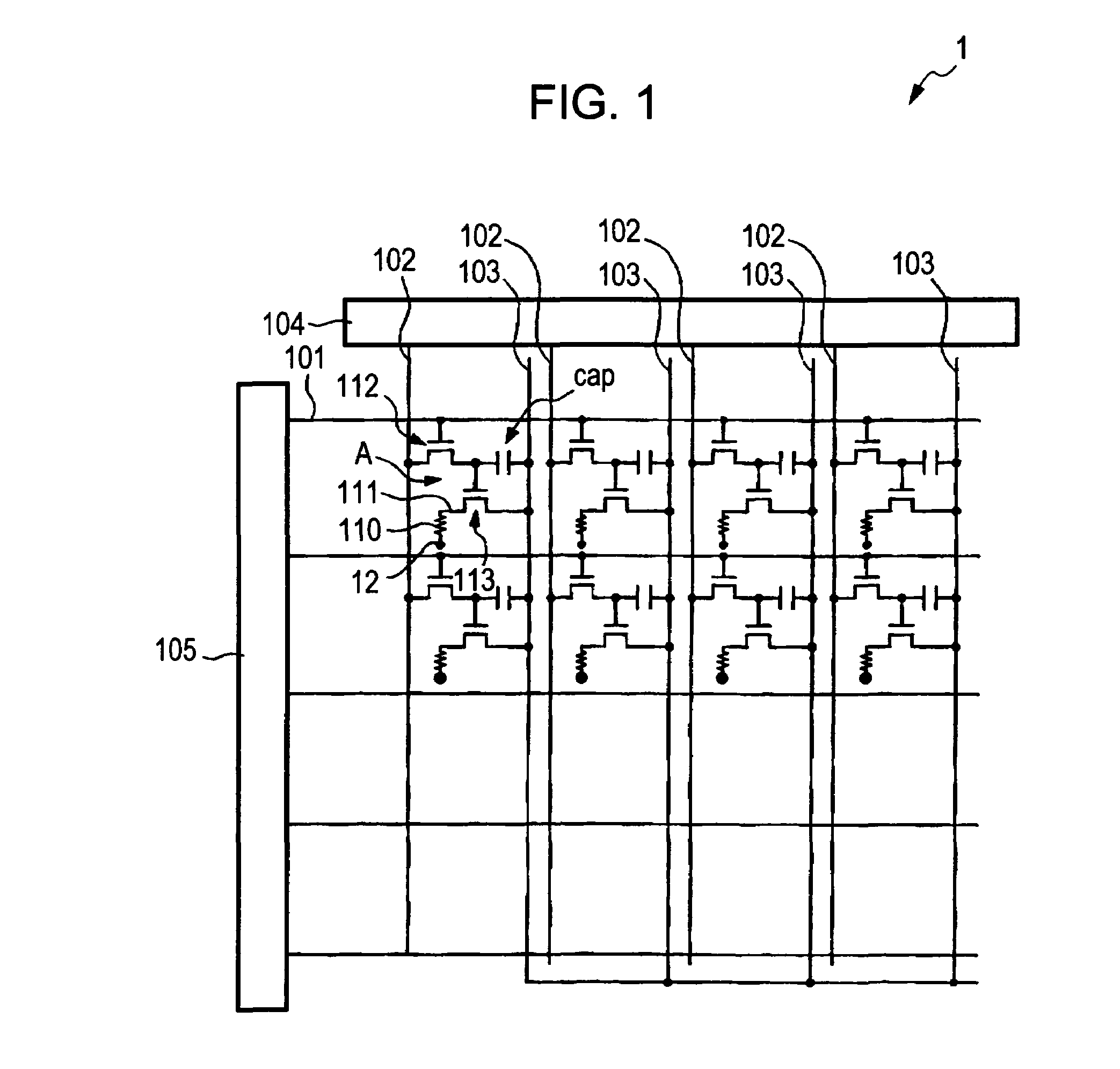

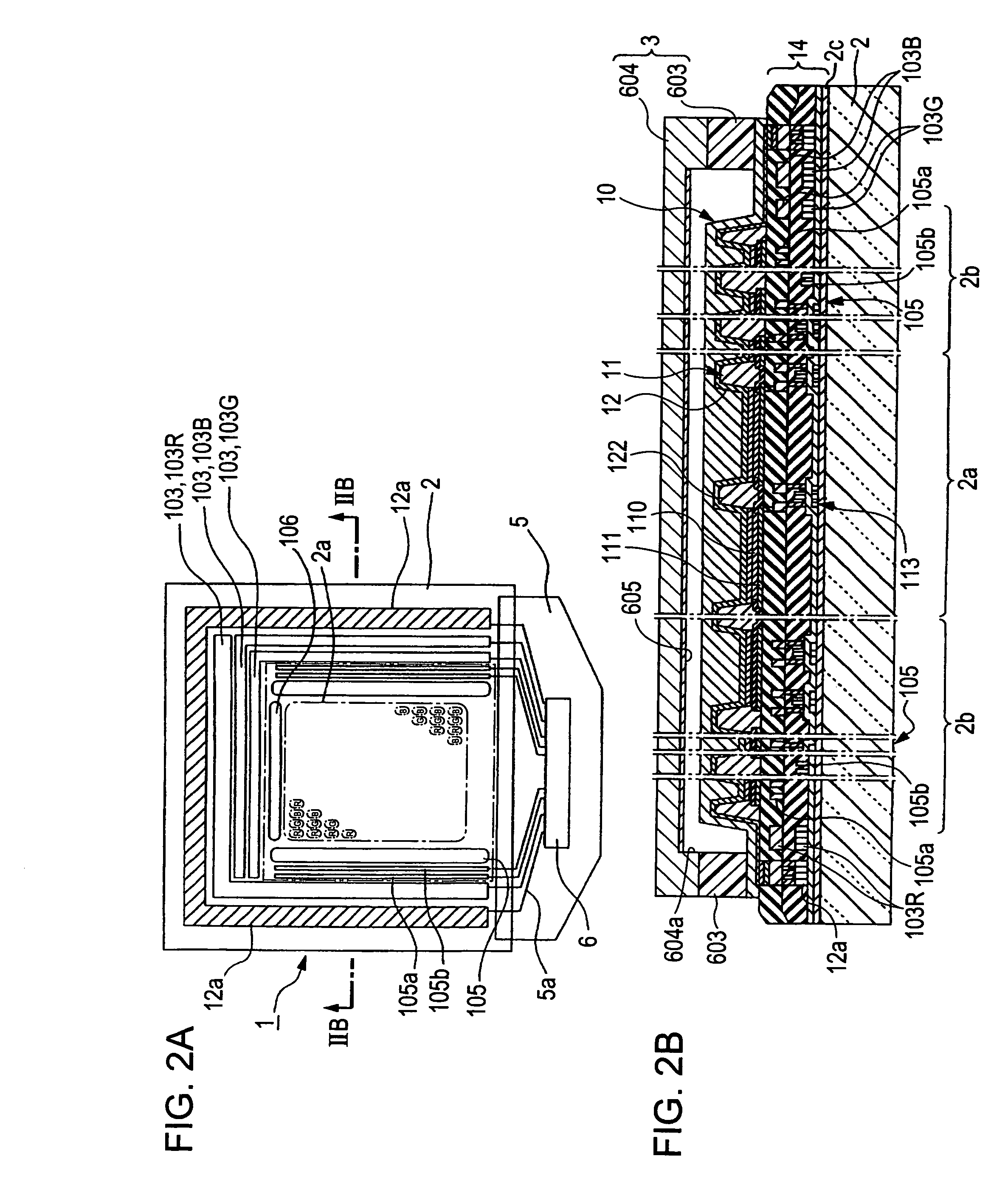

Method of manufacturing color filter substrate, method of manufacturing electro-optical device, electro-optical device, and electronic apparatus

InactiveUS7459177B2Uniform film thicknessA large amountDomestic cooling apparatusLighting and heating apparatusEngineeringSolvent

The color filter substrate has a functional region which includes a plurality of colored layers and which functions as a color filter selectively transmitting predetermined color light components and a non-functional region other than the functional region. The method includes discharging, onto a substrate, a liquid material, in which coloring materials constituting the colored layers are dissolved or dispersed into a solvent, with a liquid droplet discharge method. In the discharging of the liquid material, the liquid material is discharged onto the functional region and the liquid material or the solvent is discharged onto the non-functional region. The amount of the solvent discharged onto the non-functional region per unit area is larger than the amount of the solvent discharged onto the functional region per unit area.

Owner:KATEEVA

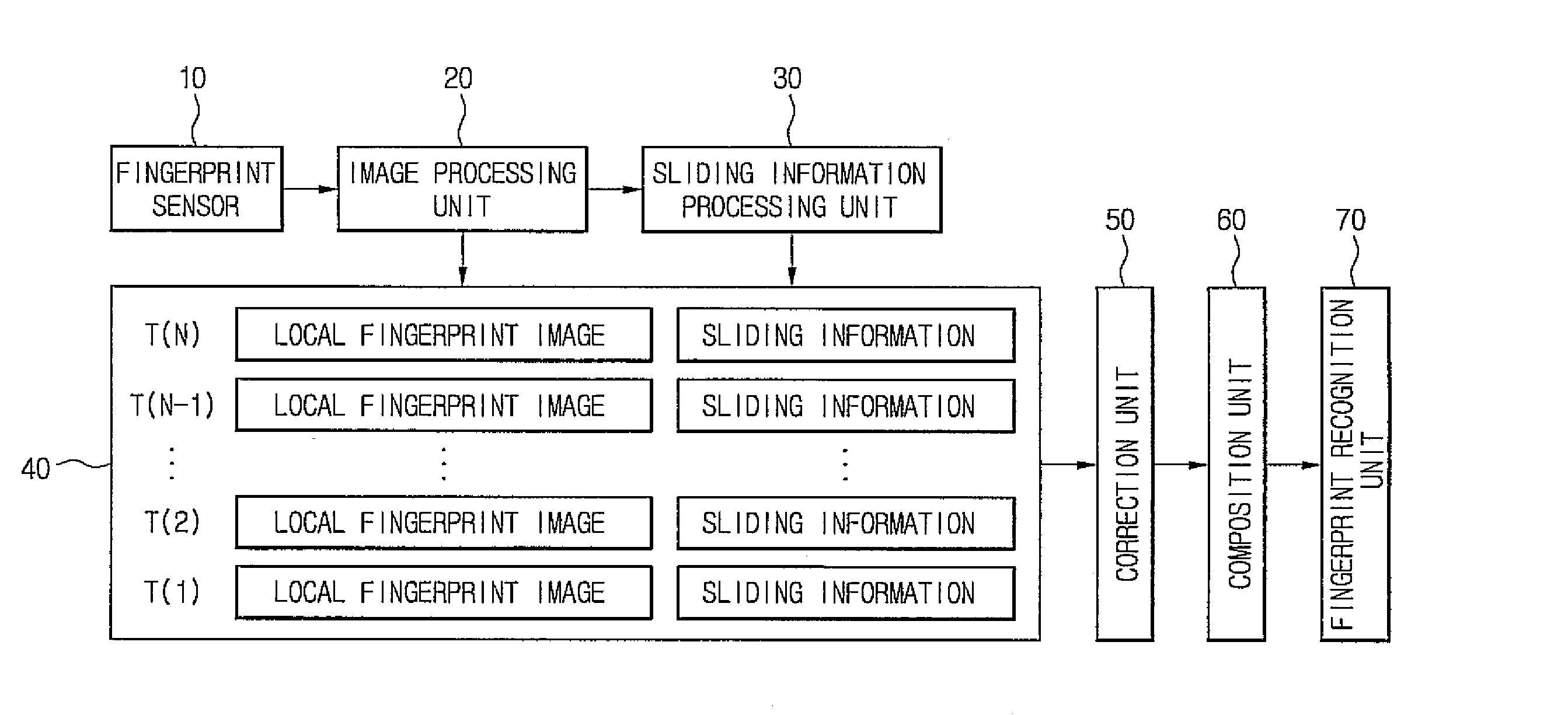

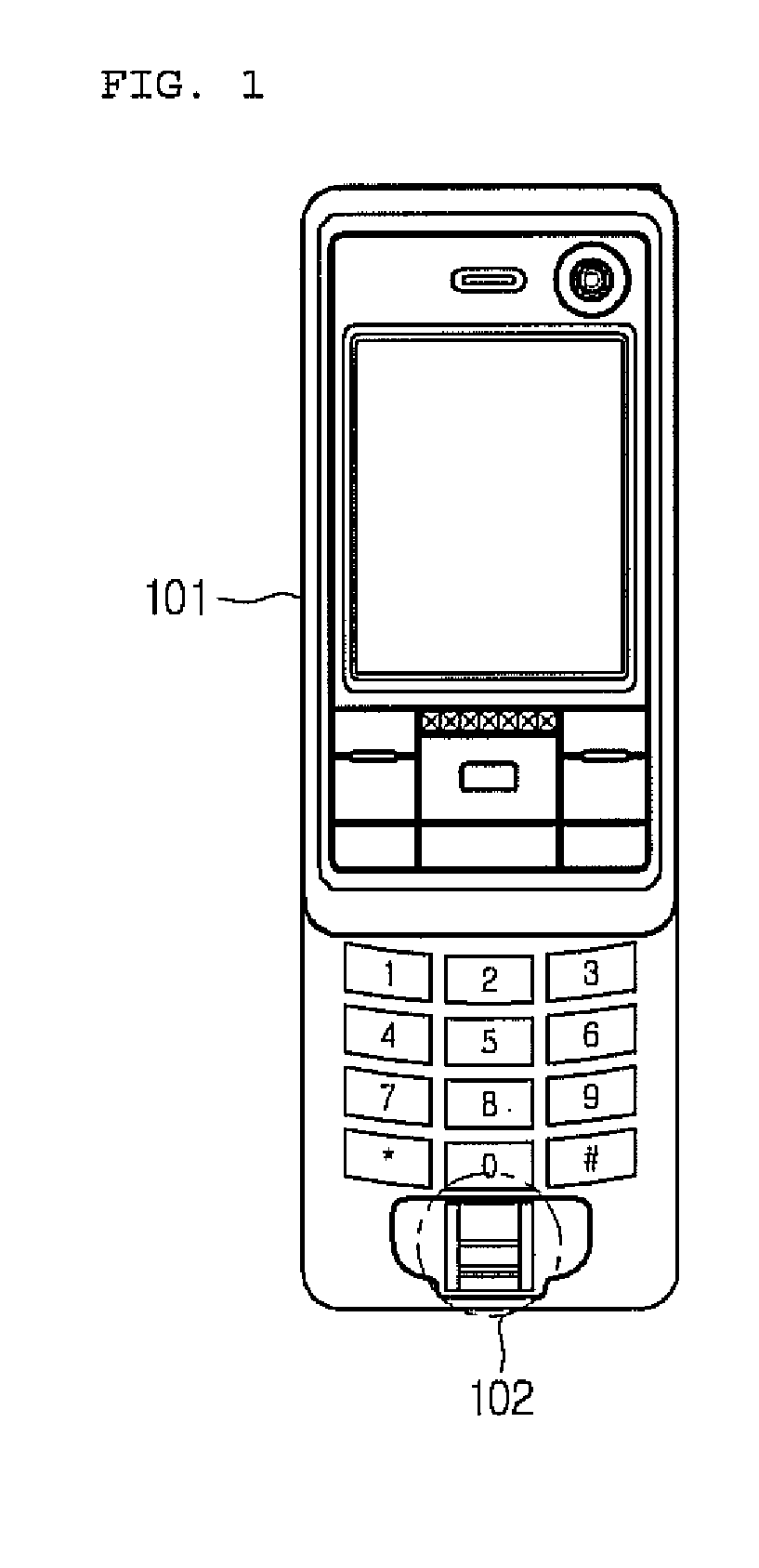

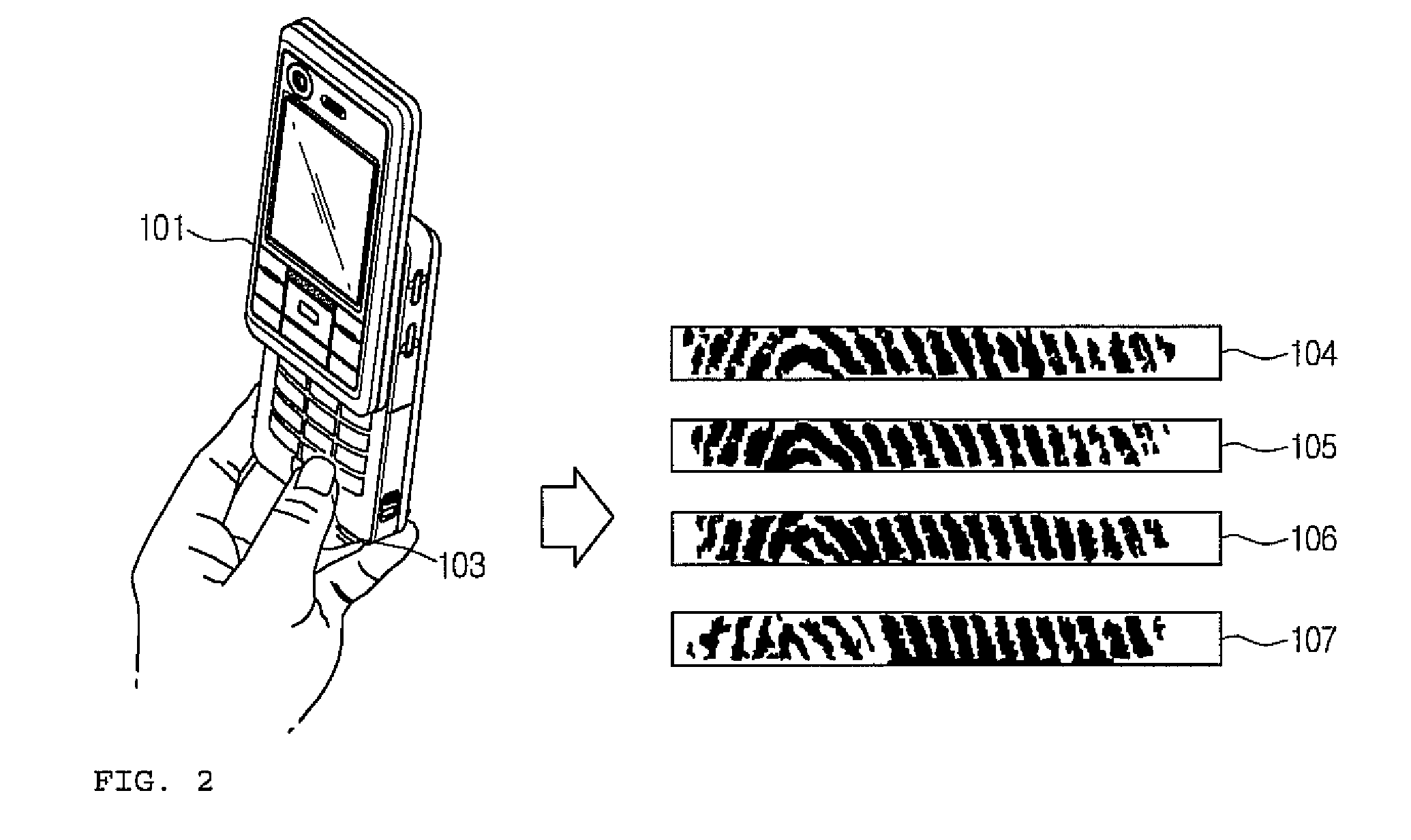

Fingerprint recognition system and method

InactiveUS20060285729A1Effectively correctedWithout increasing calculation timeCharacter and pattern recognitionFingerprint imagePattern recognition

A fingerprint recognition method and system for recognizing a fingerprint by storing local fingerprint images inputted from a fingerprint sensor and compositing the stored local fingerprint images into an effective single fingerprint image. The method includes obtaining relative sliding speed and directional information between the local fingerprint images, correcting sliding speed and directional values of the local fingerprint images using the obtained sliding speed and directional information, and compositing the local fingerprint images into the effective single fingerprint image using the corrected sliding speed and directional values.

Owner:LG ELECTRONICS INC

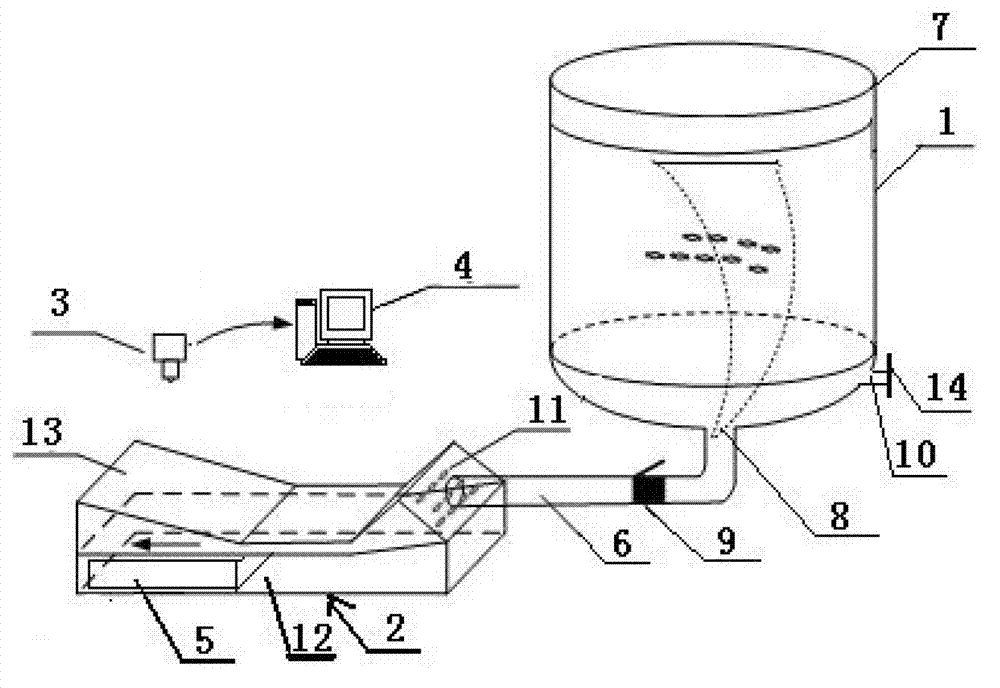

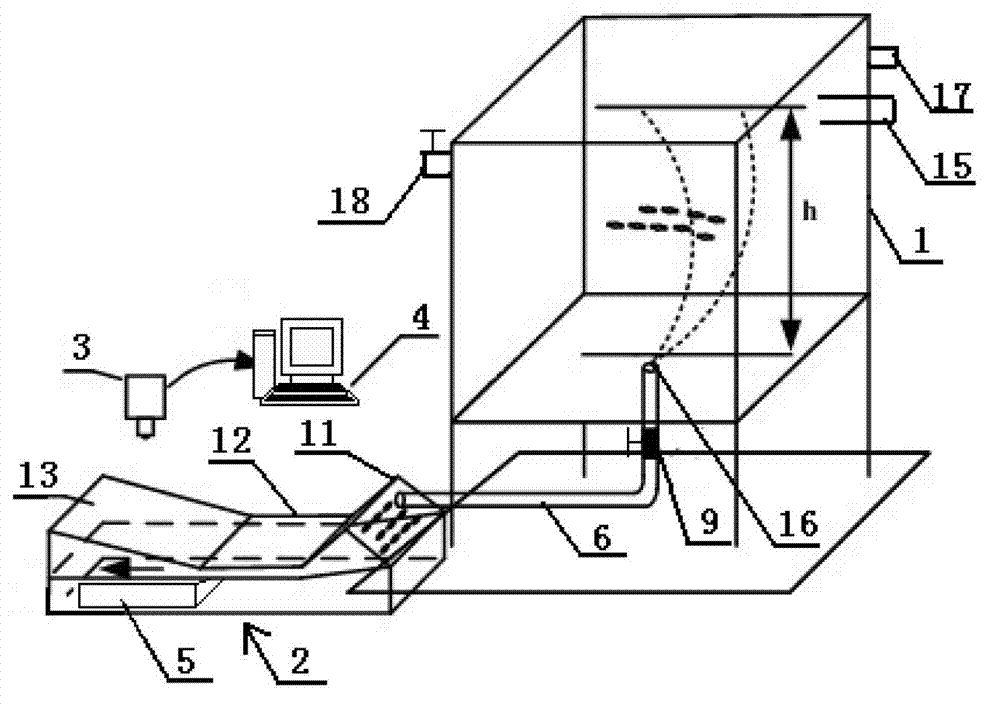

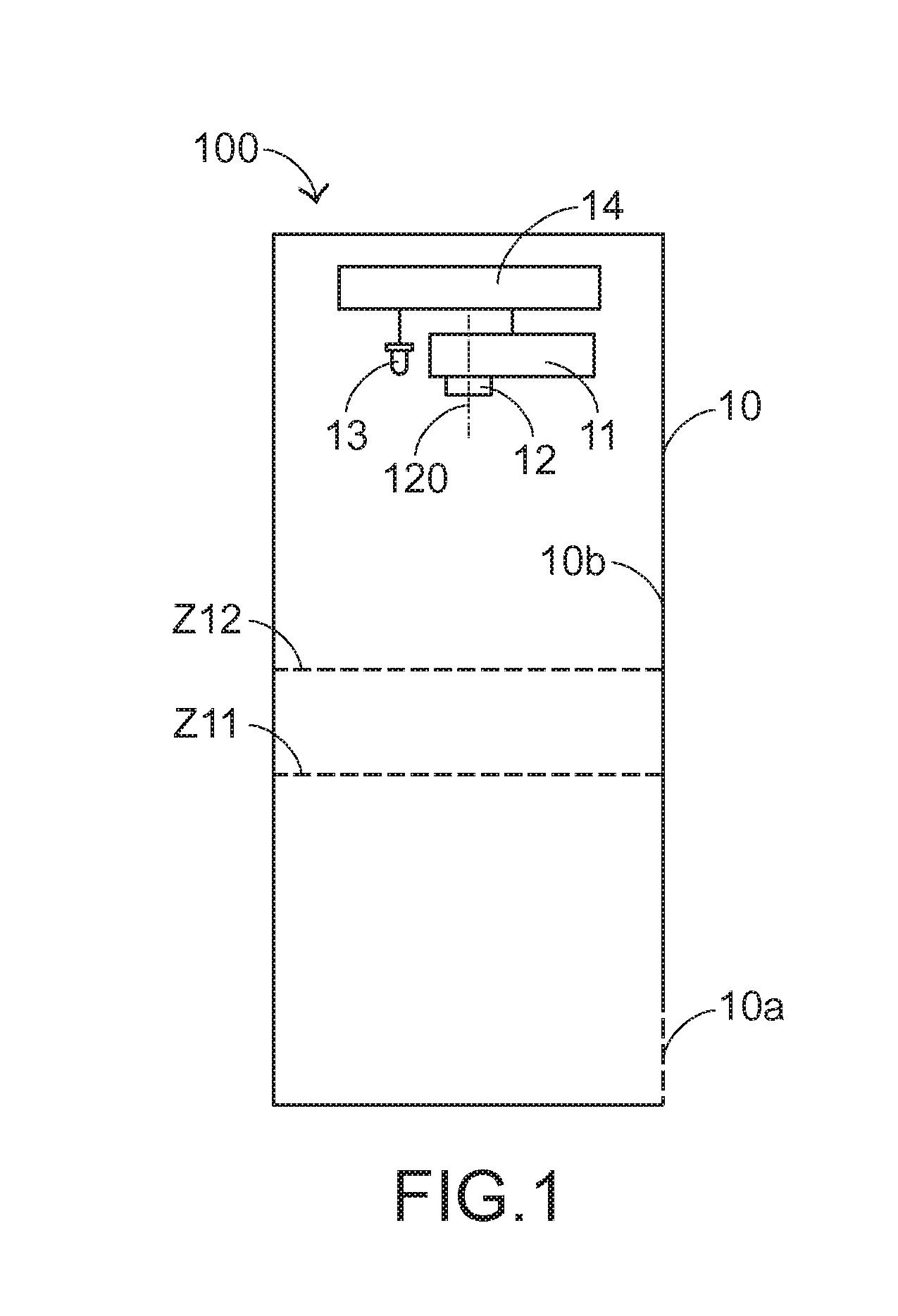

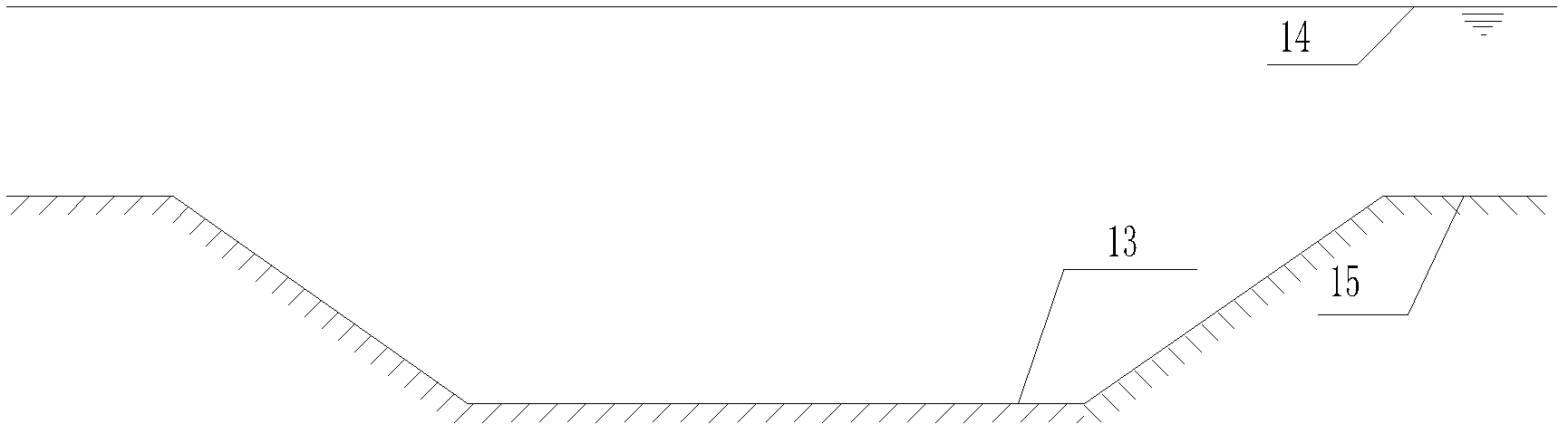

Fish, shrimp and crab seed automatic counting device and method based on computer video processing

InactiveCN102805044AEasy to countAccurate countClimate change adaptationPisciculture and aquariaComputer graphics (images)Water flow

The invention discloses a fish, shrimp and crab seed automatic counting device based on computer video processing and a fish, shrimp and crab seed automatic counting method based on computer video processing. The invention is characterized in that the device comprises a seed body outflow water tank, a counting through tank body, a camera, a backlight source and a computer; wherein the seed body outflow water tank is communicated with the counting through tank body; the camera and the backlight source are positioned above and below the counting through tank body respectively; and the camera is connected with the computer. A counting process comprises the following steps of: pouring a water body containing fish, shrimp and crab seeds into the seed body outflow water tank; allowing the water body to flow into the counting through tank body at a constant flow rate; shooting the seeds with the camera and acquiring video images; preprocessing the video images via computer image processing technologies; working out the number of seeds M in every frame of image; multiplying the number of seeds M in every frame of image by a corresponding weighting coefficient r; and working out the total number of fish, shrimp and crab seeds through accumulation. Parameters such as the size of a single seed body can also be obtained. The device and the method have the advantage that the aim of counting the number of seed bodies accurately, quickly, conveniently and timely is fulfilled.

Owner:NINGBO UNIV

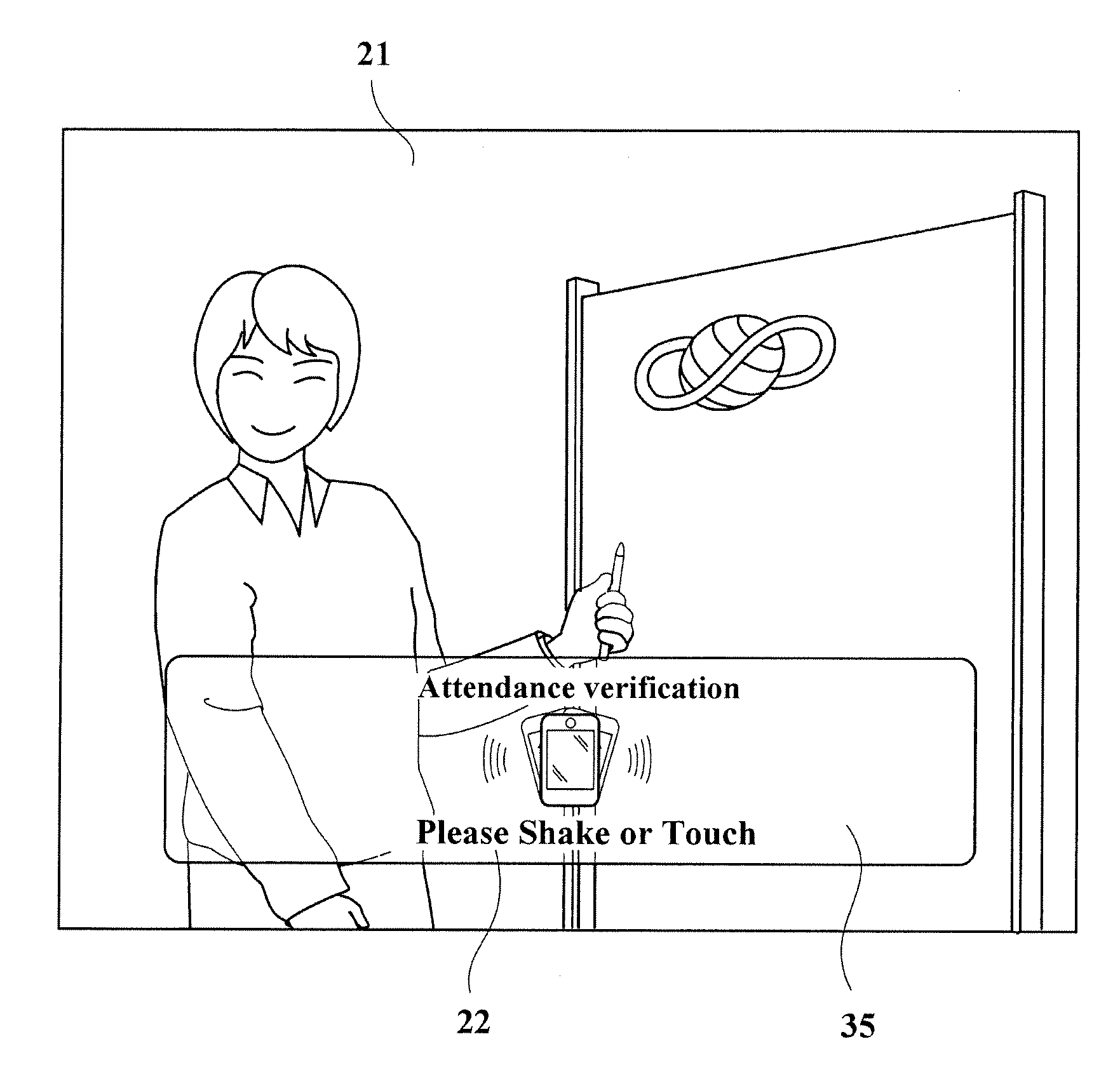

Audio-visual terminal, viewing authentication system and control program

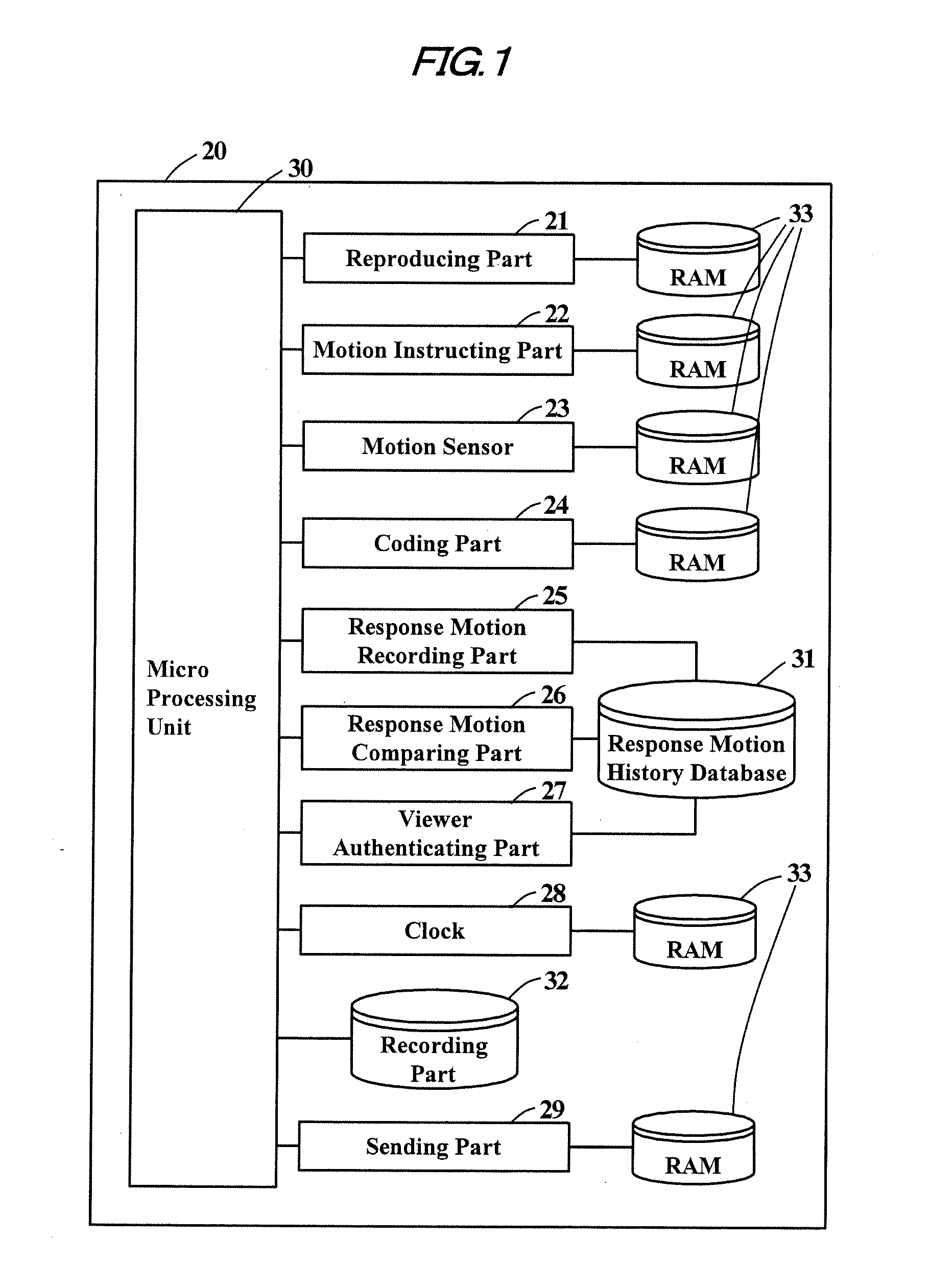

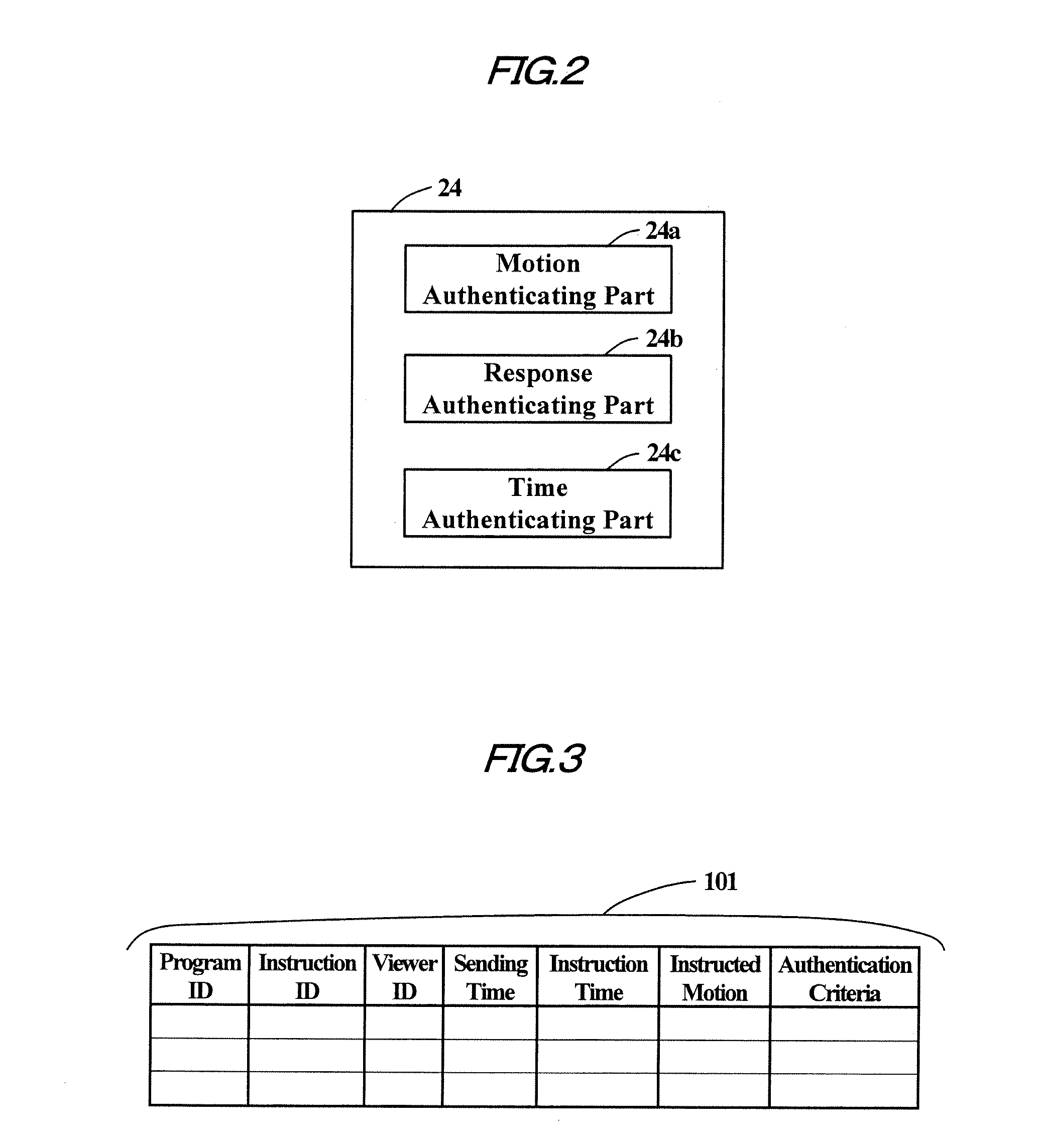

ActiveUS20120182380A1Easy to operateAccurate realizationTwo-way working systemsSelective content distributionComputer hardwareAuthentication system

An audio-visual terminal and a viewing authentication system and control programs therefor are provided. The audio-visual terminal includes a reproducing part for reproducing the audio-visual program, a motion instructing part for instructing, a motion sensor for detecting a response motion of the viewer made by the viewer for transmission to a viewing authenticating principal, a sending part for sending information output from the audio-visual terminal to a viewing authentication system of the viewing authenticating principal, and a coding part for coding information about the response motion of the viewer obtained from a detection result detected by the motion sensor into a signal sendable by the sending part.

Owner:BUSINESS BREAKTHROUGH

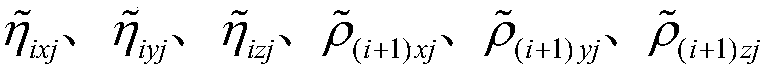

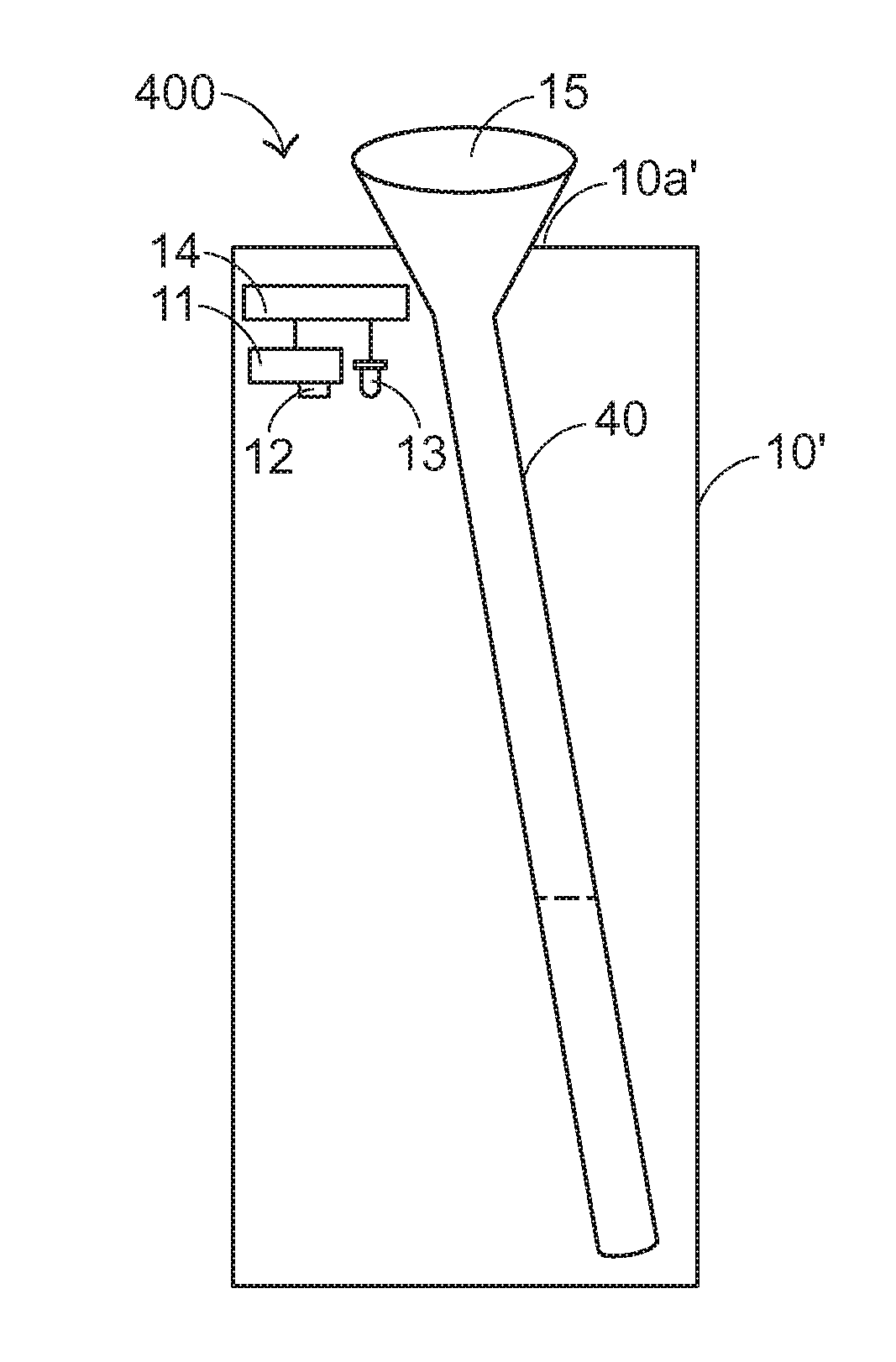

Industrial robot geometric parameter calibration method based on position vector method

ActiveCN107866823ANumerical difference is largeShorten the timeUsing optical meansManipulatorComputer visionGenetic algorithm

The invention discloses an industrial robot geometric parameter calibration method based on a position vector method. The industrial robot geometric parameter calibration method based on the positionvector method comprises the steps that a robot position vector model based on a basis coordinate system oxyz is established, and nominal values of a direction vector and a connection vector in a zerostate of a robot are found from a robot manual; groups of joint angles of the robot are randomly set on a demonstrator according to movement ranges of all joints given by the robot manual, and all thejoints of the robot are controlled to move to the groups of joint angle values qij which have been set; a laser tracker is used for detecting a target which is installed at the tail end G of the robot, and a tail end posture and position data of a measured robot are obtained; and an objective function Ej of the geometric parameter calibration of the robot is established, and a genetic algorithm is used for solving the objective function Ej so as to obtain an optimal solution of the direction vector and the connection vector of the measured robot. According to the industrial robot geometric parameter calibration method based on the position vector method, the problem of singularity caused by parallel and vertical adjacent joints is solved, and meanwhile, an industrial robot geometric parameter calibration error optimization objective function is built based on the model.

Owner:NANJING INST OF TECH

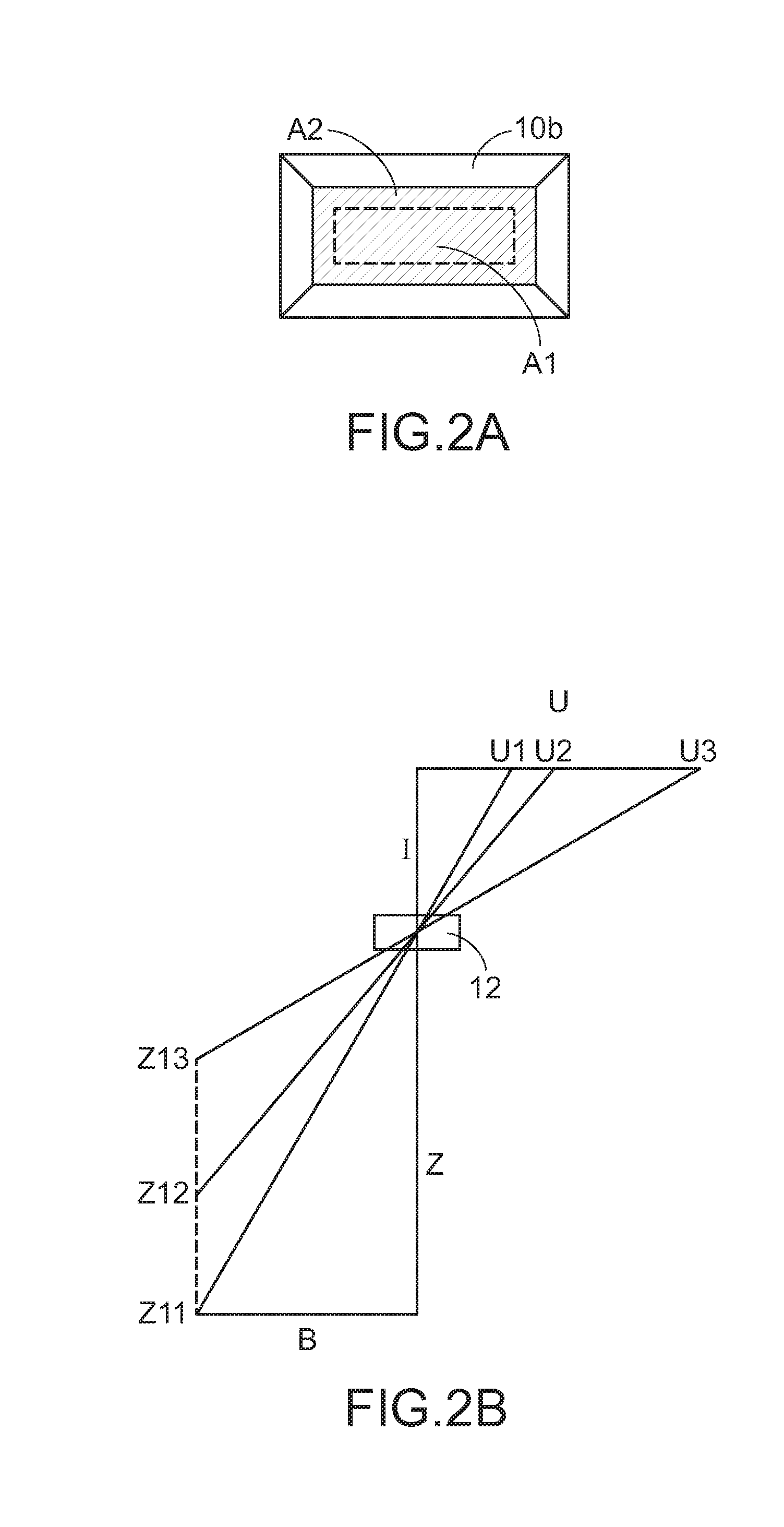

Liquid level measuring device

InactiveUS20150002658A1Accurate realizationReduce installation costsColor television detailsMachines/enginesOptical axisLevel measurement

A liquid level measuring device includes a container and a digital electronic device. The container is located at a detection region. The container has an opening, so that a liquid is permitted to flow into the container through the opening. The digital electronic device is combined with the container. The digital electronic device includes a lens, and an optical axis of the lens is directed to and perpendicular to a detection plane. A light source illuminates the detection plane. The lens is operated in a fixed-focus mode to shoot the detection plane to acquire an image stream. Each image frame of the image stream contains a corresponding liquid surface image. After an image analyzing operation is performed on the corresponding liquid surface image to calculate the corresponding liquid surface image, a liquid level of the liquid is realized.

Owner:NATIONAL TAIWAN OCEAN UNIVERSITY

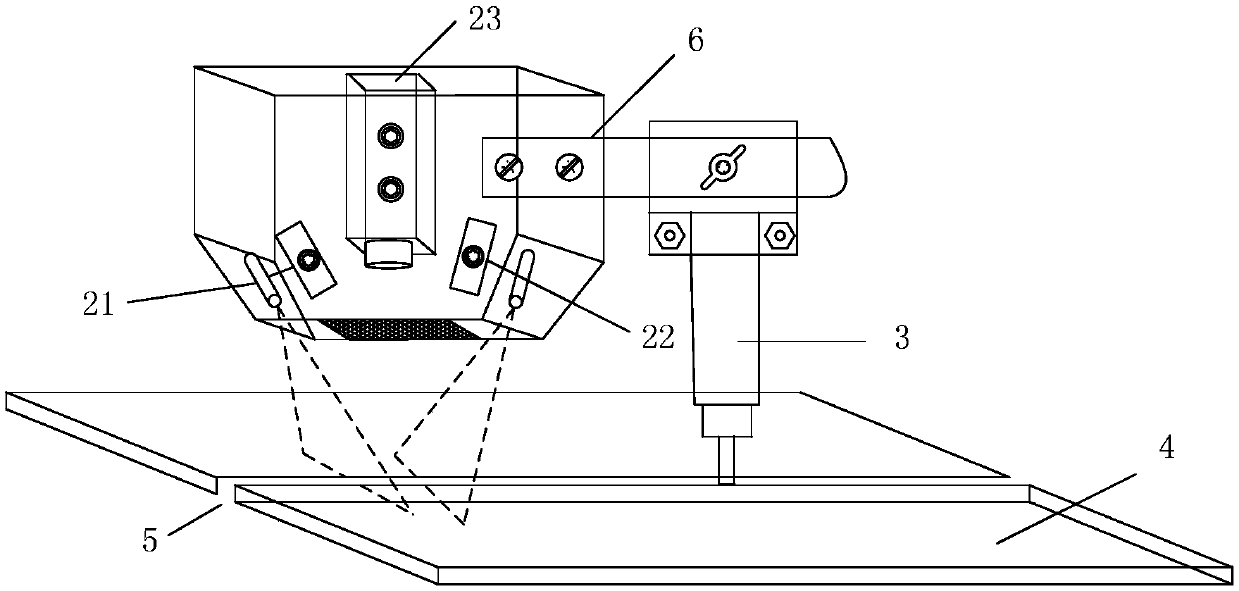

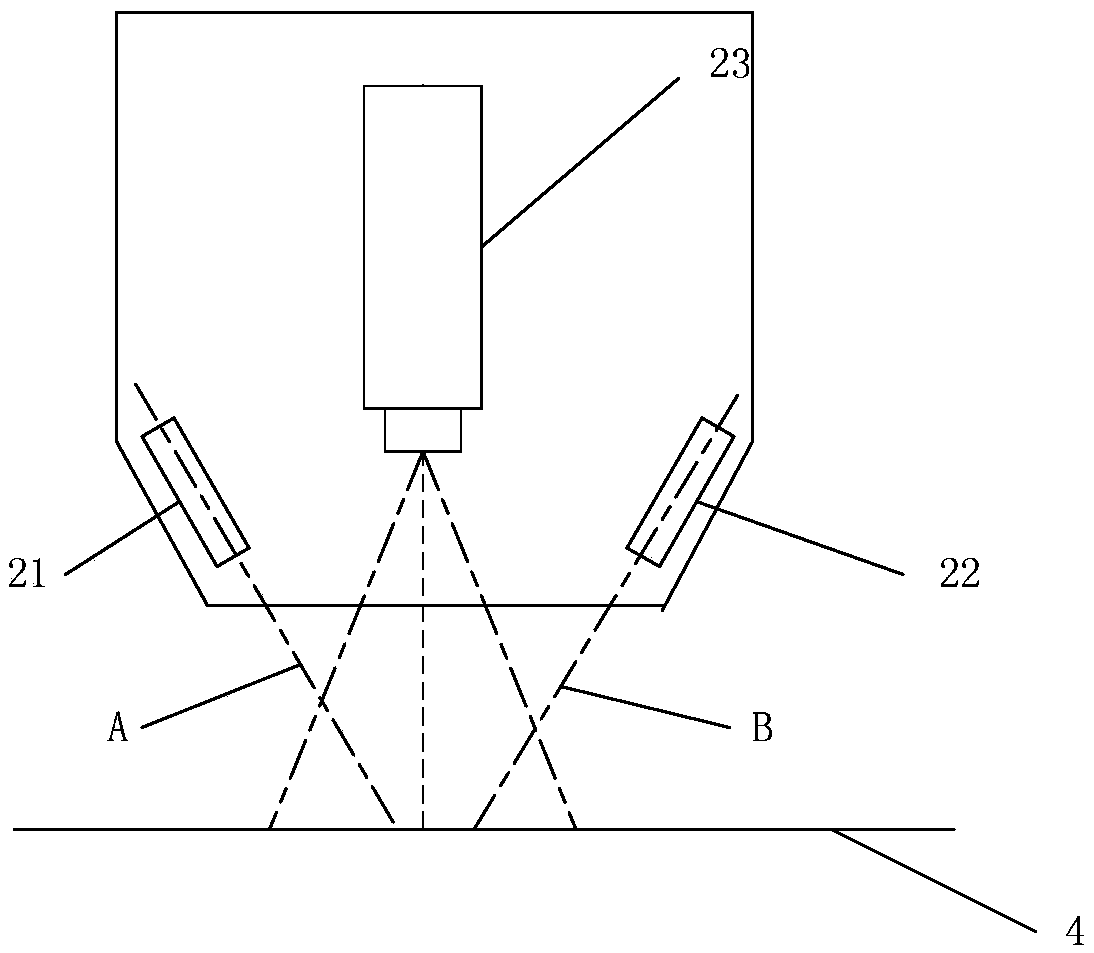

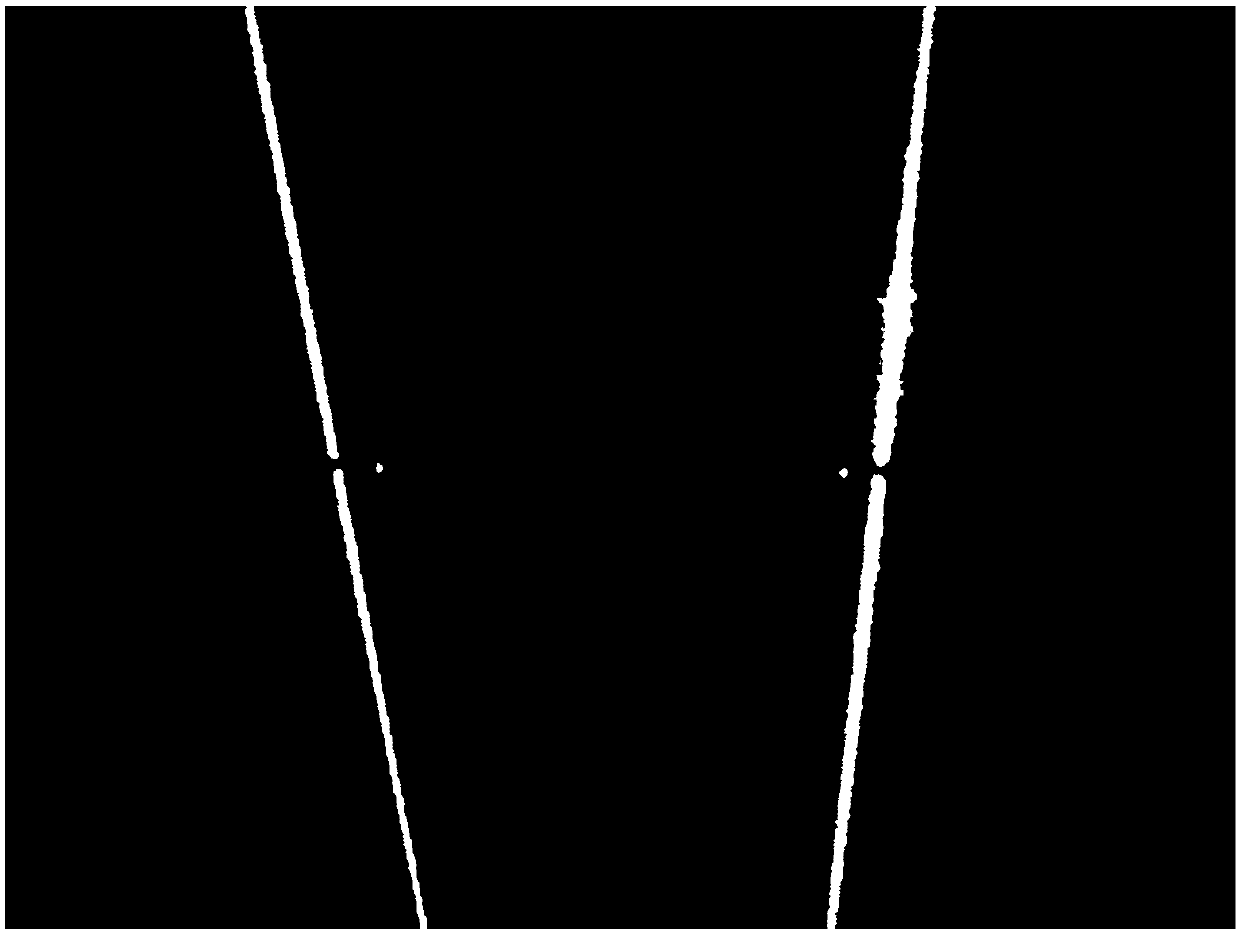

System and method based on double-line-laser structure light and used for welding joint identification and tracking

InactiveCN109676243AControl Depth of FocusAccurate realizationWelding/cutting auxillary devicesAuxillary welding devicesLaser transmitterEngineering

The invention discloses a system and a method based on double-line-laser structure light and used for welding joint identification and tracking. The system comprises a laser emitter, an industrial camera, an industrial lens, a light filter, a welding gun, a motor and a computer, wherein the laser emitter comprises double laser generators installed at the two sides of the industrial camera and generating two structure light planes by projecting laser onto the surface of a workpiece, so that two laser stripes are formed on the surface of the workpiece; an image acquisition system is composed ofthe industrial camera, the industrial lens and the light filter, and used for acquiring a welding joint image containing the laser stripes; image processing is carried out on the acquired welding joint image through a computer to obtain the position of a welding joint in the image; calibration is carried out on the camera and the laser planes to obtain the internal and external parameters of the camera and the space equations of the line laser planes, and the three-dimensional space attitude of the welding joint is calculated; and the motor controls the welding gun and receives data, and thenwelding is carried out at a corresponding position. The system and method realize correction for a welding process, control the focal depth of the welding gun, and realize control over a defocusing amount.

Owner:苏州实创德光电科技有限公司 +1

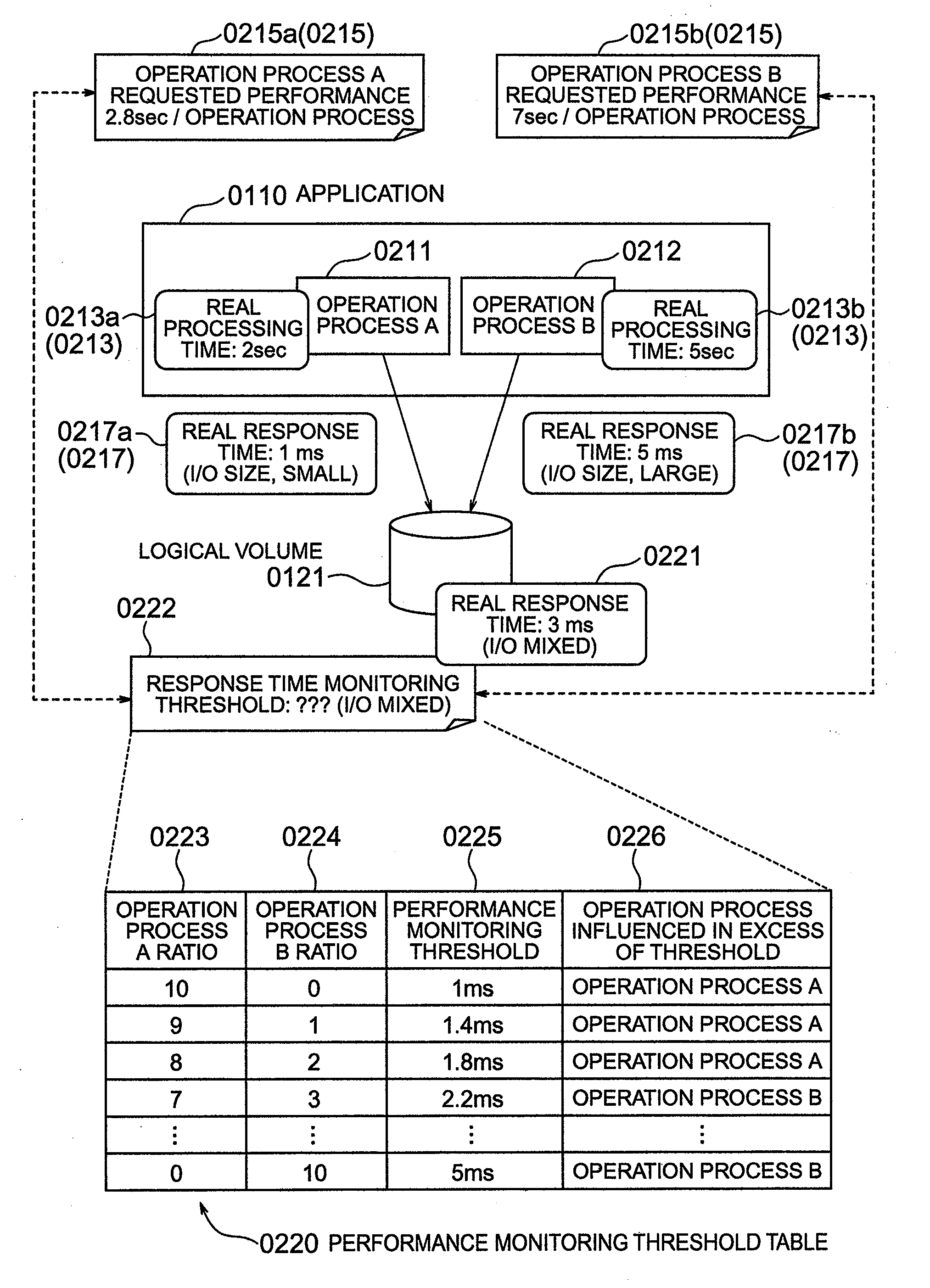

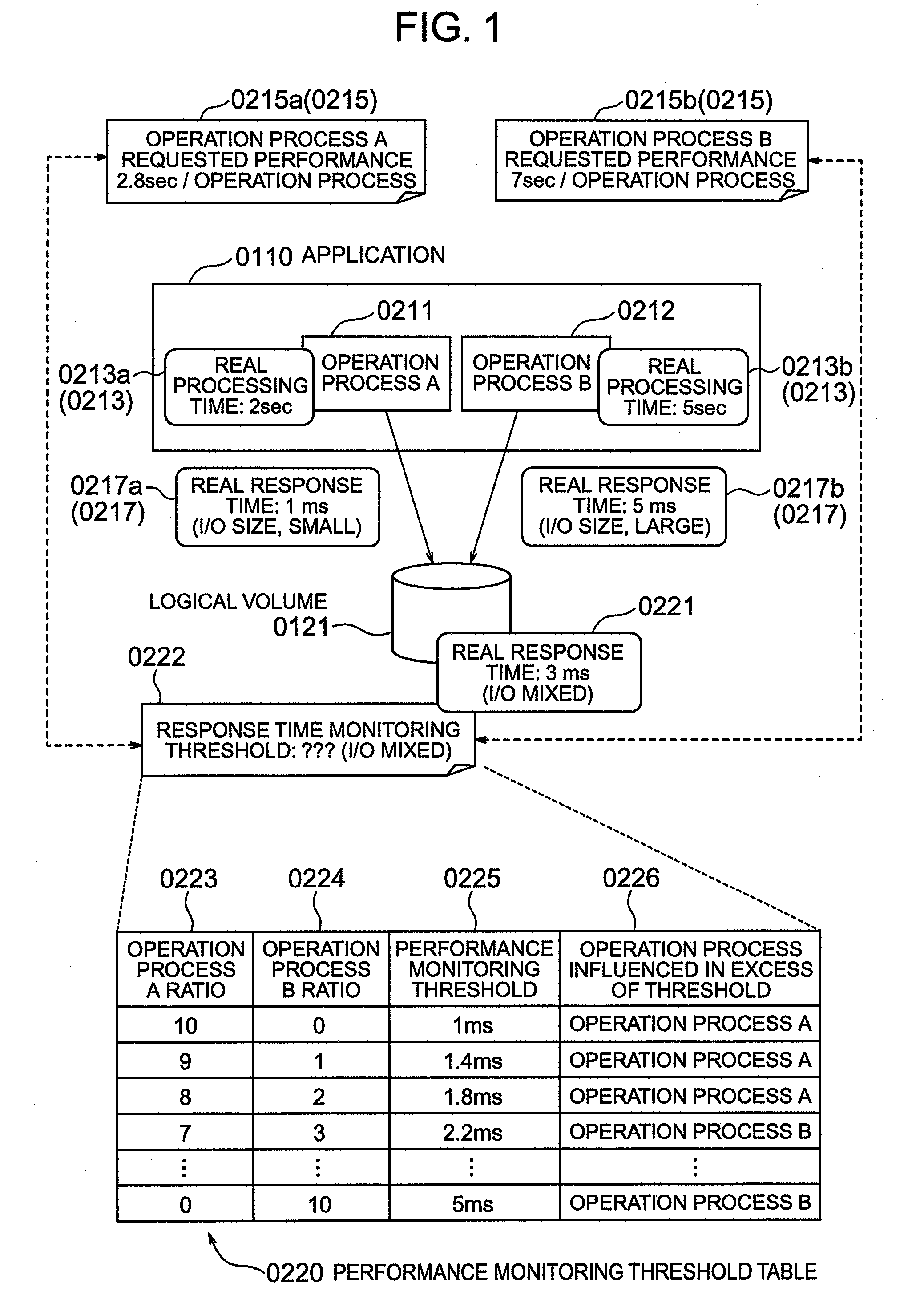

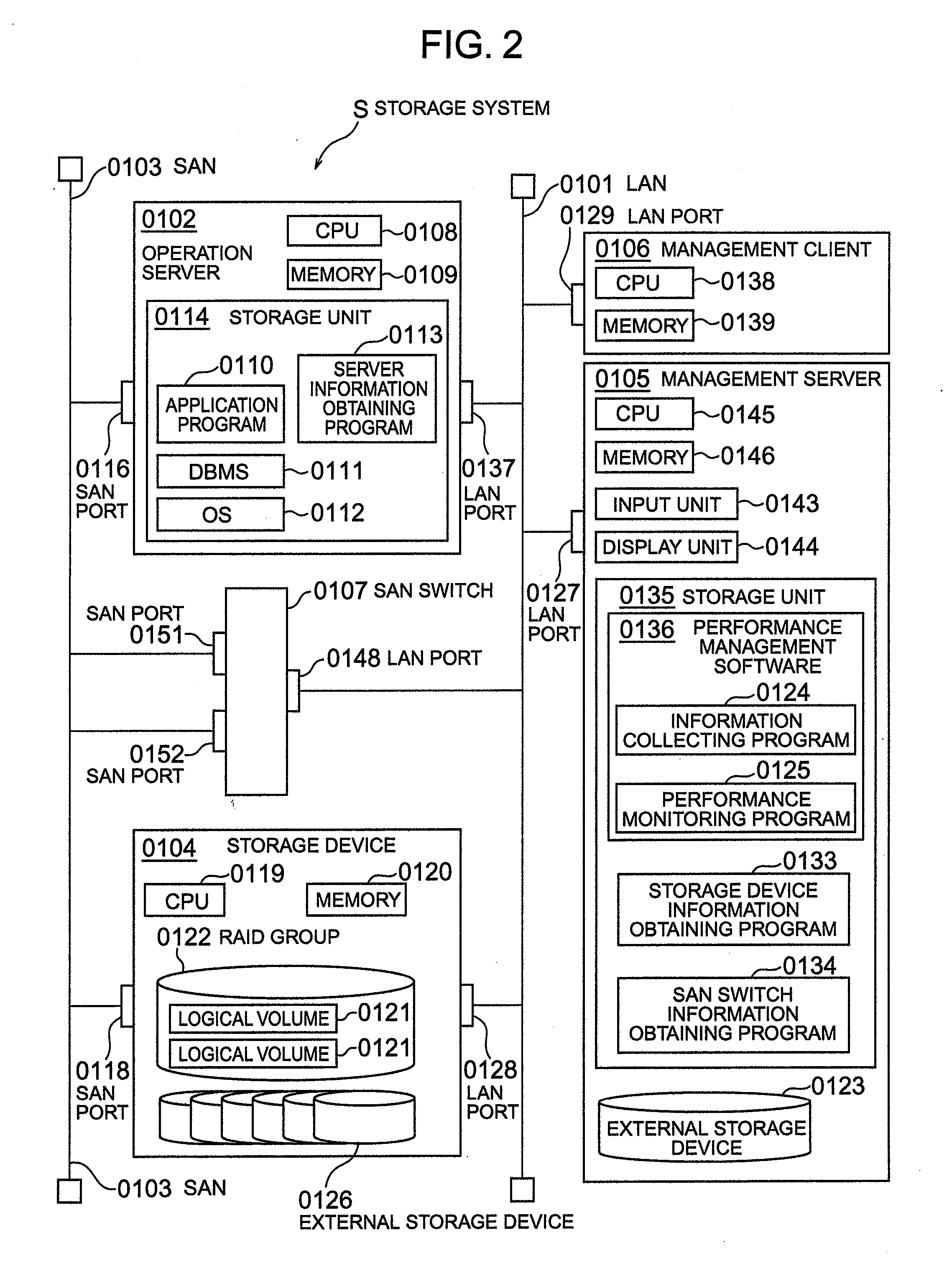

Storage management system, a method of monitoring performance and a management server

InactiveUS20090138884A1Accurate realizationError detection/correctionMultiprogramming arrangementsResource basedStorage management

A storage management system provides a capability of properly setting a performance monitoring threshold and monitoring a performance of a storage resource in the SAN environment with respect to the operation process being executed. The storage management system includes a management server, a storage device, a storage network, and a management server. The management server is arranged to have a performance information collecting unit for collecting the current performance value of a storage resource, a composition section determining unit for determining a composition section corresponding with a composition ratio of the operation processes, a threshold information storage unit for storing a performance monitoring threshold corresponding with the composition section with respect to one or more storage devices, and a performance determining unit for determining a performance of the storage resource based on the current performance value and the performance monitoring threshold.

Owner:HITACHI LTD

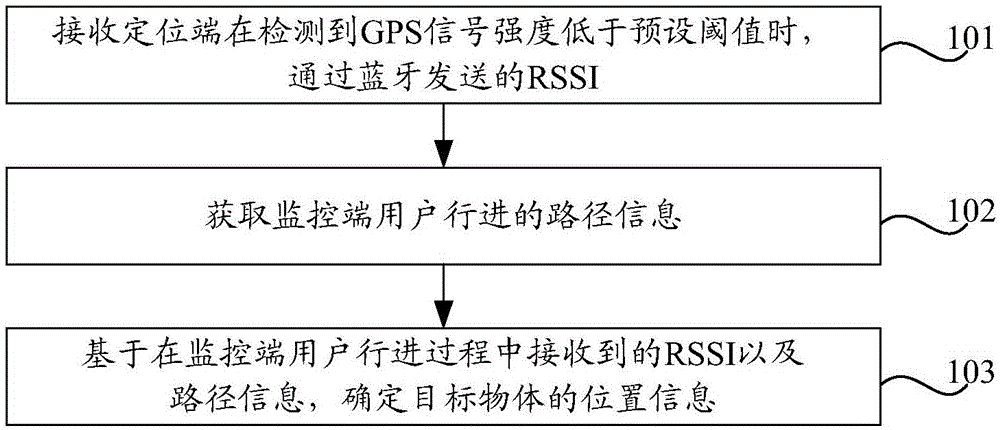

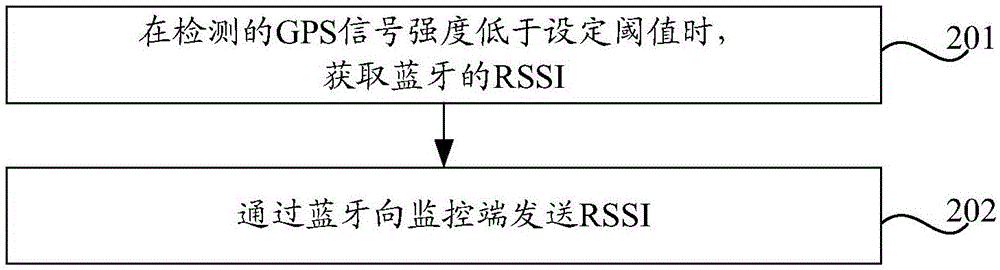

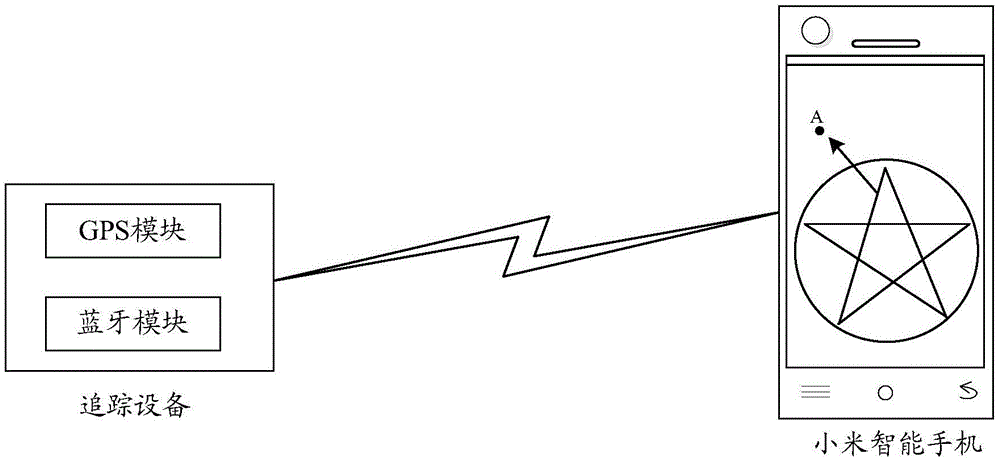

Positioning method, device and terminal

ActiveCN105101404AAchieve precise positioningReduce positioning errorsLocation information based serviceReceived signal strength indicationComputer terminal

The present disclosure relates to a positioning method, device and terminal. The positioning method comprises: receiving Received Signal Strength Indication (RSSI) sent through Bluetooth when a positioning end detects that the signal strength of a Global Positioning System (GPS) is lower than a preset threshold; obtaining path information about the travel of a user at a monitoring end; and determining the position information of a target object on the basis of the RSSI and the path information received in the travelling process of the user at the monitoring end. Through the application of the embodiment of the present disclosure, a GPS positioning error is corrected through the RSSI; accurate positioning on the target object can be realized; positioning precision can be within 5 meters; and the present disclosure is especially suitable for places with dense obstacles and weak GPS signals such as buildings, underground garages, indoor shopping squares and the like.

Owner:ANHUI HUAMI INFORMATION TECH CO LTD +1

Sensor for detecting particles in a gas stream and method for its manufacture

ActiveUS7574895B2High sensitivityLower average response timeManufacture of electrical instrumentsParticle suspension analysisElectricityEngineering

A soot particle sensor for an exhaust system of an internal combustion engine includes a first electrode device and a second electrode device. The electrode devices are situated at a distance from one another and are able to be exposed to the gas stream, at least in some areas. It is provided that the electrode devices are separated from each other by an intermediate layer made of an electrically insulating material, and the electrode devices have free edges that are set apart from each other by the thickness of the intermediate layer and are able to be exposed to the gas stream.

Owner:ROBERT BOSCH GMBH

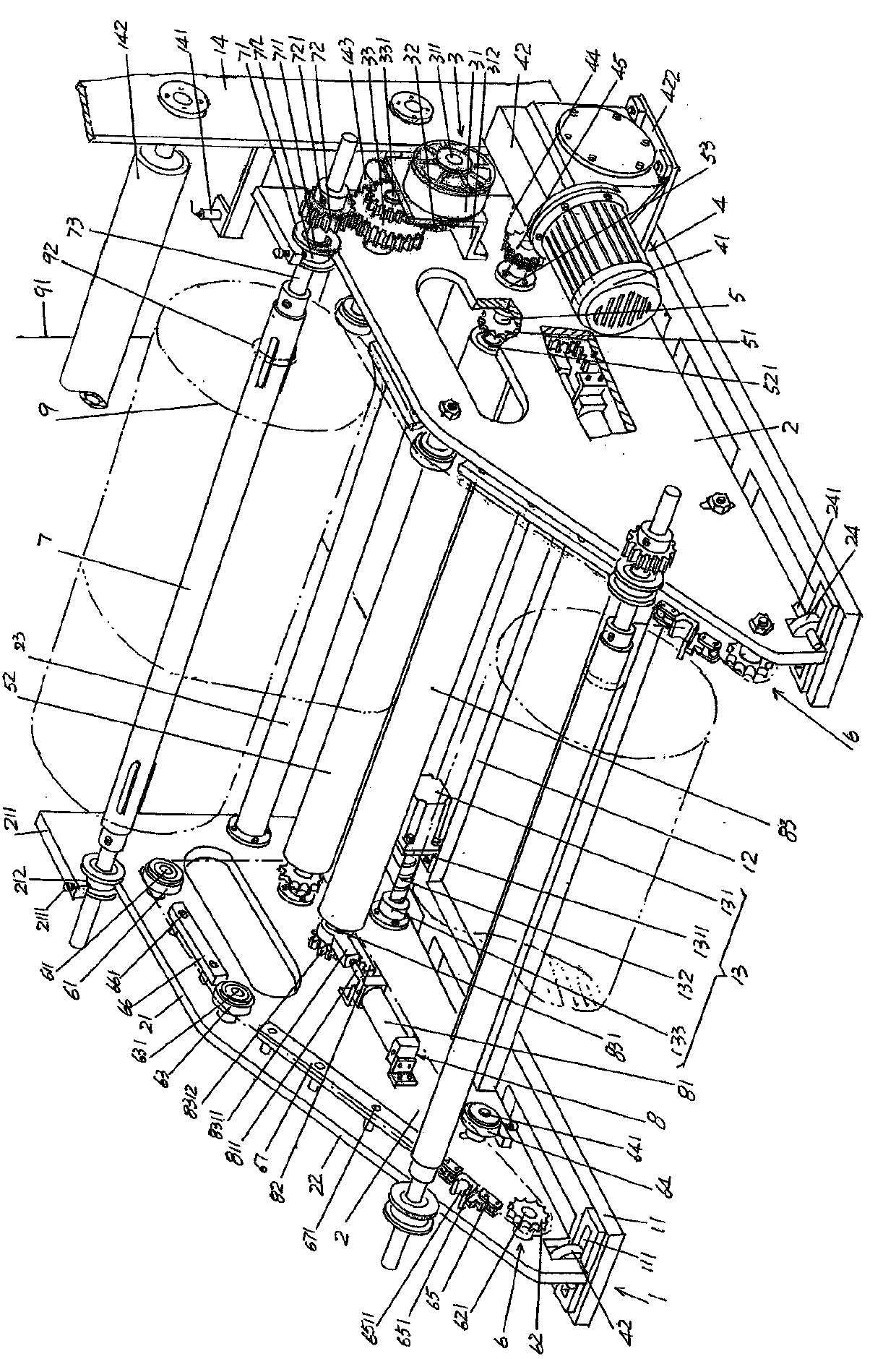

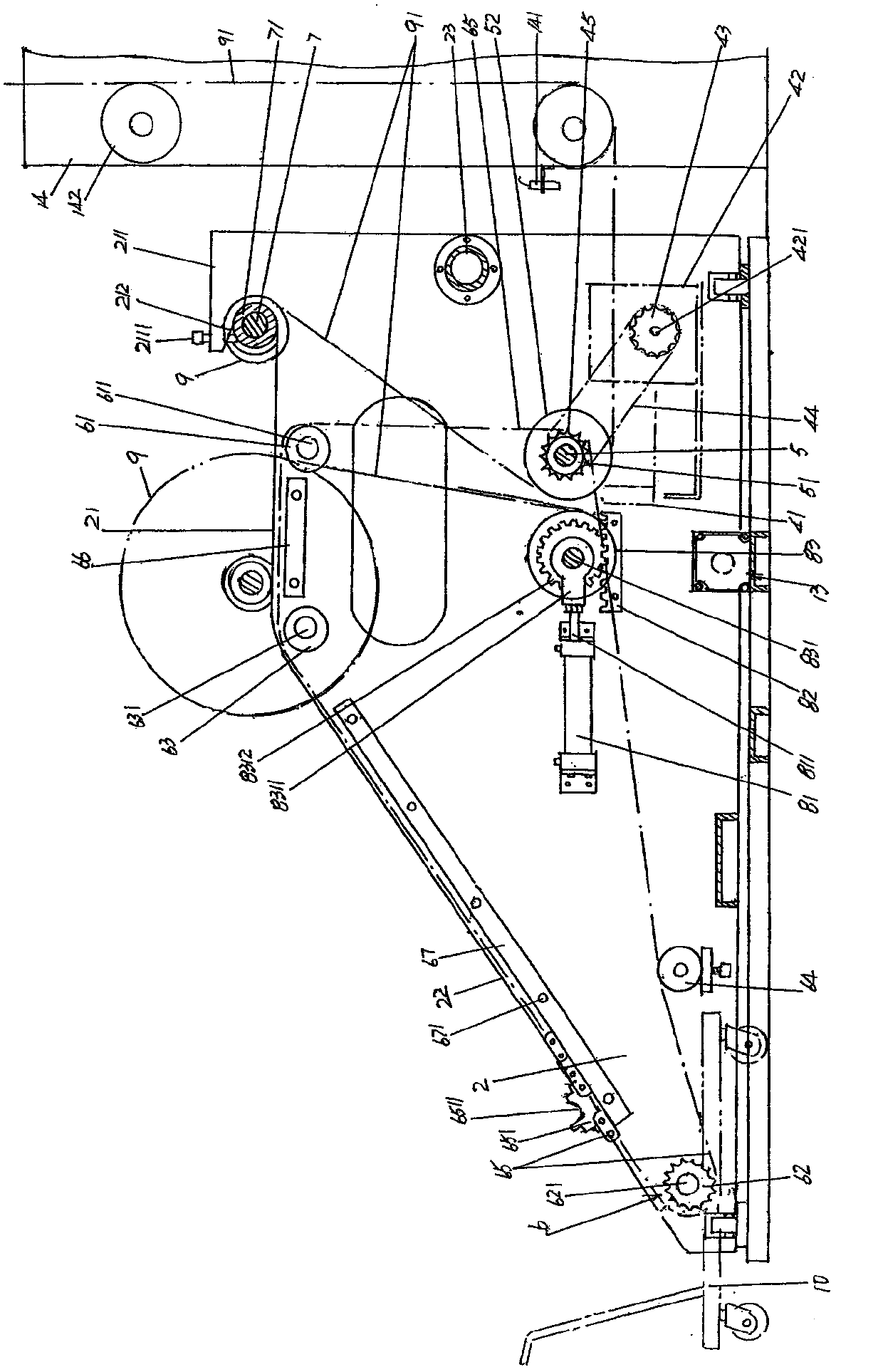

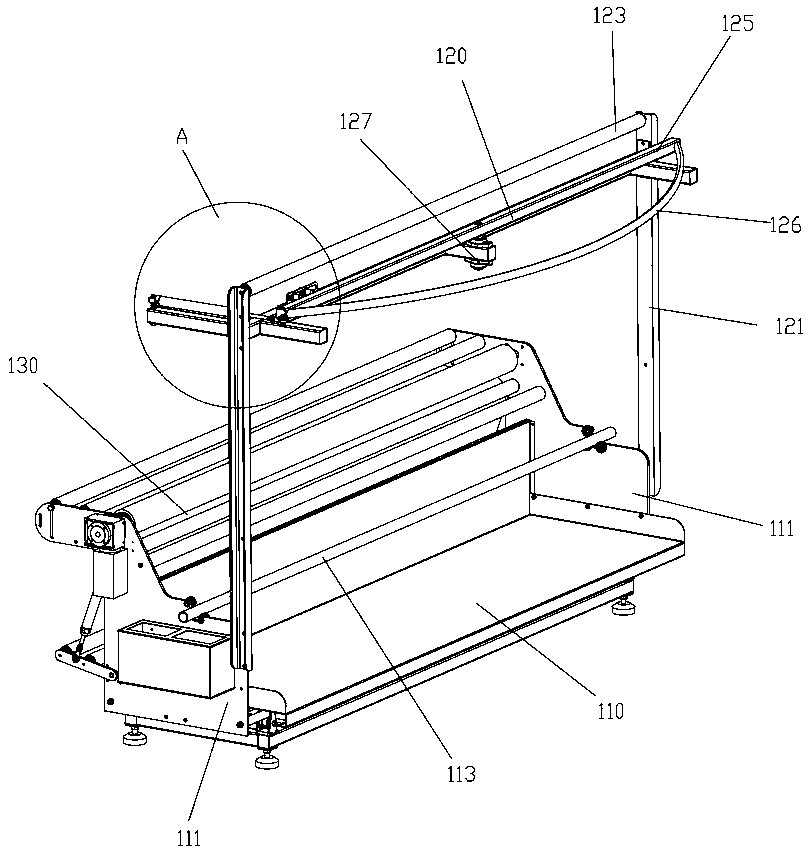

Film uncoiling machine having automatic deviation rectifying function

The invention provides a film uncoiling machine having an automatic deviation rectifying function and belongs to the field of special devices for film adhesive tape production. The film uncoiling machine comprises a machine base, wherein the machine base comprises a pair of base arms, a base arm connecting beam, a film guiding frame, a pair of wall boards, a supporting roller driving mechanism, a supporting roller lifting power mechanism, a traction transmission shaft, a supporting roller traction mechanism and a supporting roller. The film uncoiling machine is characterized in that wall board rolling wheel grooves are respectively formed at the front ends and the rear ends of a pair of base arms. Wall board rolling wheels are respectively arranged at the front ends and the rear ends of a pair of wall boards and correspond to the wall board rolling wheel grooves and matched with the wall board rolling wheel grooves. A deviation rectifying execution mechanism is arranged on the base arm connecting beam and connected with one inward side of one wall board. A film deviation signal acquirer is arranged on the film guiding frame. When a film deviates, the film deviation signal acquirer acquires signals, the deviation rectifying execution mechanism drives the wall board rolling wheels on a pair of wall boards to perform displacement along the wall board rolling wheel grooves so as to achieve deviation rectification, and a phenomenon that two ends of each split film roll protrude.

Owner:SUZHOU BAIQI ELECTRONICS MATERIAL

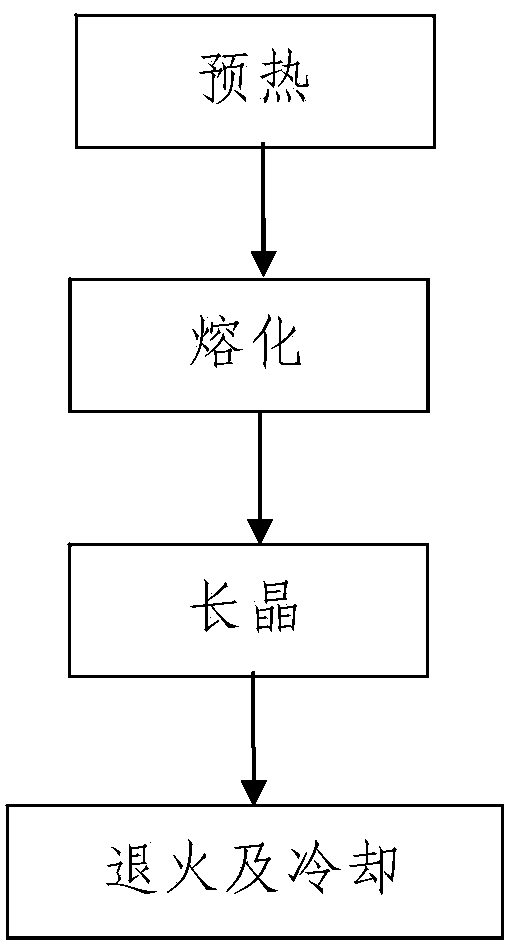

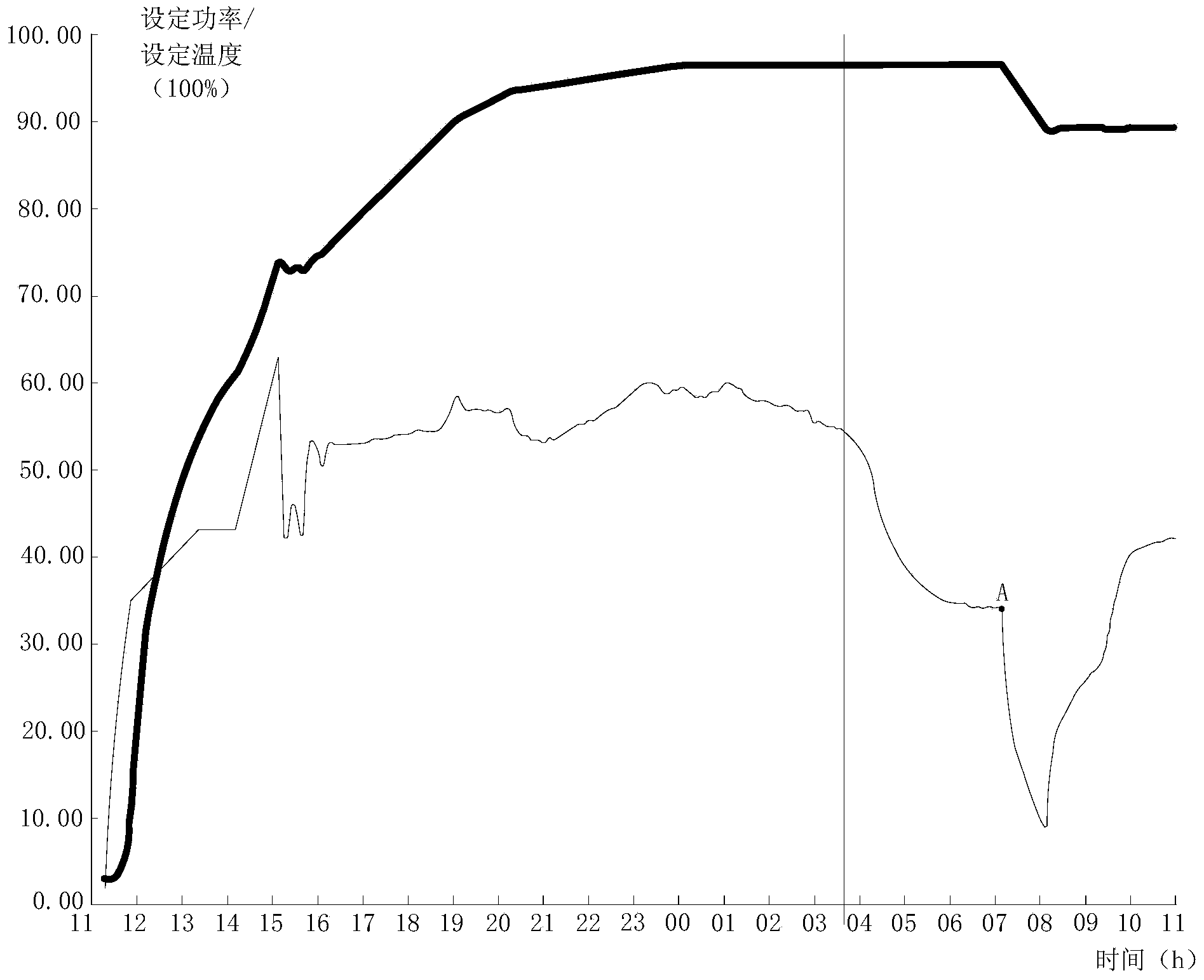

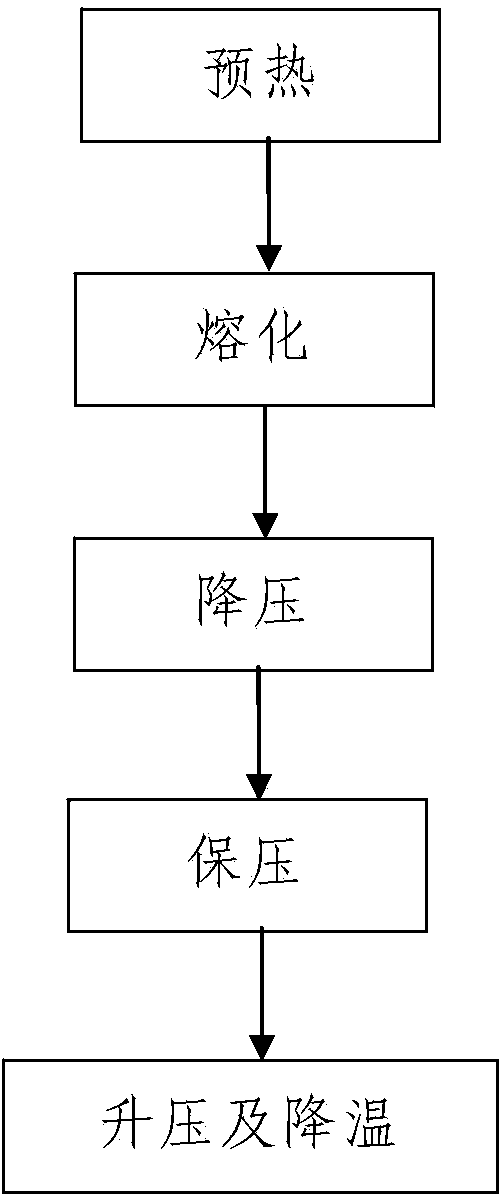

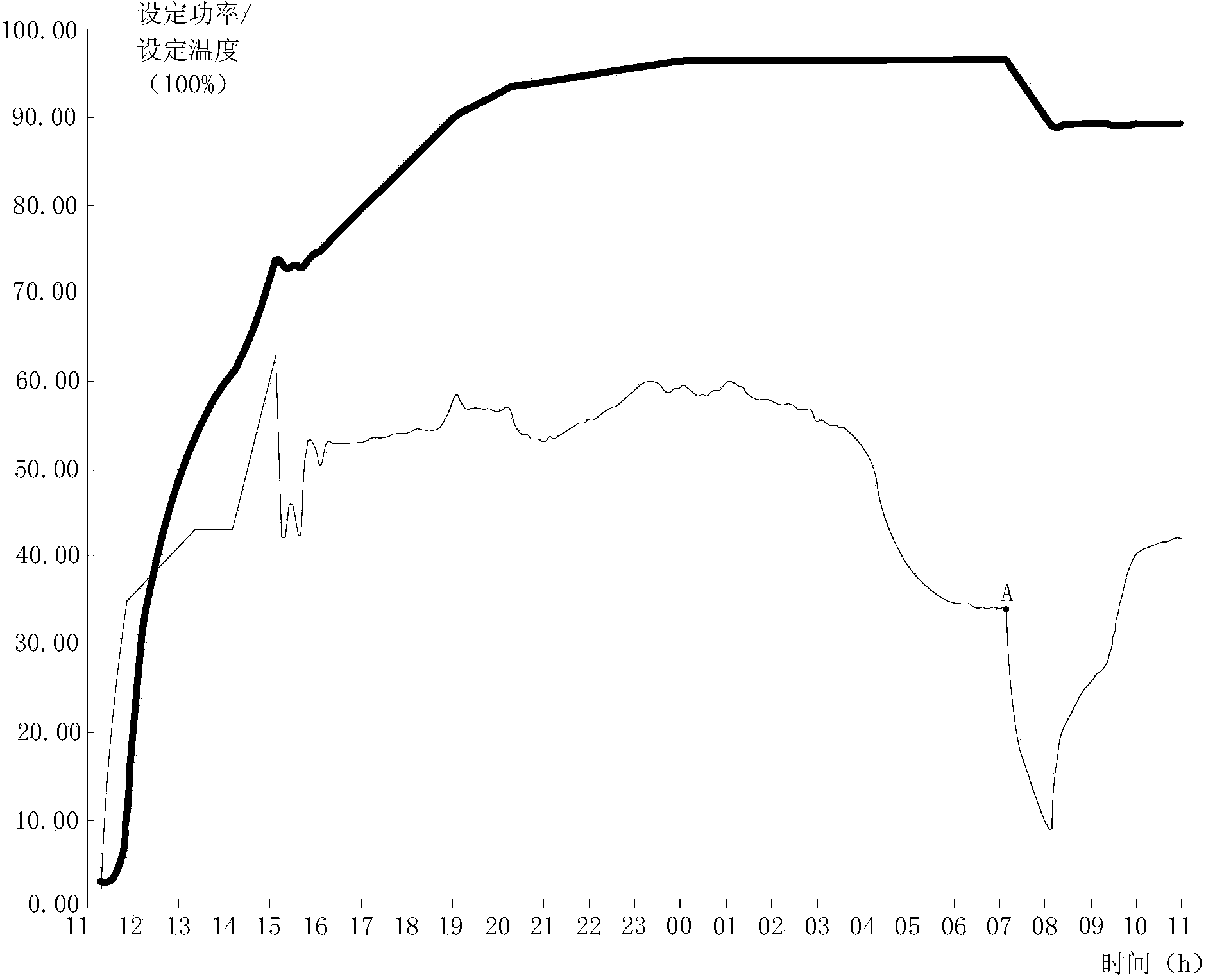

Polycrystalline silicon ingot casting process

InactiveCN103741214AReasonable designSimple processing stepsPolycrystalline material growthSingle crystal growth detailsPolycrystalline siliconMetallurgy

The invention discloses a polycrystalline silicon ingot casting process. The process comprises the following steps: 1, preheating; 2, melting; 3, growing crystal: the temperature is controlled to T6 and is preserved for 1h, and T6=1420 DEG C; the hoisting height of a heat insulation cage is 90mm; the temperature is controlled to T6 and is preserved for 2h, and the hoisting height of the heat insulation cage is not changed; the temperature is controlled to T6 and is preserved for 3h, and the hoisting height of the heat insulation cage is 110mm; the temperature is gradually lowered from T6 to T7, the temperature lowering time is 7-9h, and the hoisting height of the heat insulation cage is 210mm; T7=1405 DEG C; the temperature is controlled to T7 and is preserved for 7-9h, and the hoisting height of the heat insulation cage is not changed; the temperature is controlled to T7 and is preserved for 7-9h, and the hoisting height of the heat insulation cage is not changed; the temperature is gradually lowered from T7 to T8, and the hoisting height of the heat insulation cage is not changed; T8=1395 DEG C; 4, annealing and cooling. The polycrystalline silicon ingot casting process has the advantages of simple steps, reasonable design, convenience in realization, easiness in grasp and good using effect and can reasonably control the ingot casting crystal growth process.

Owner:XIAN HUAJING ELECTRONICS TECH

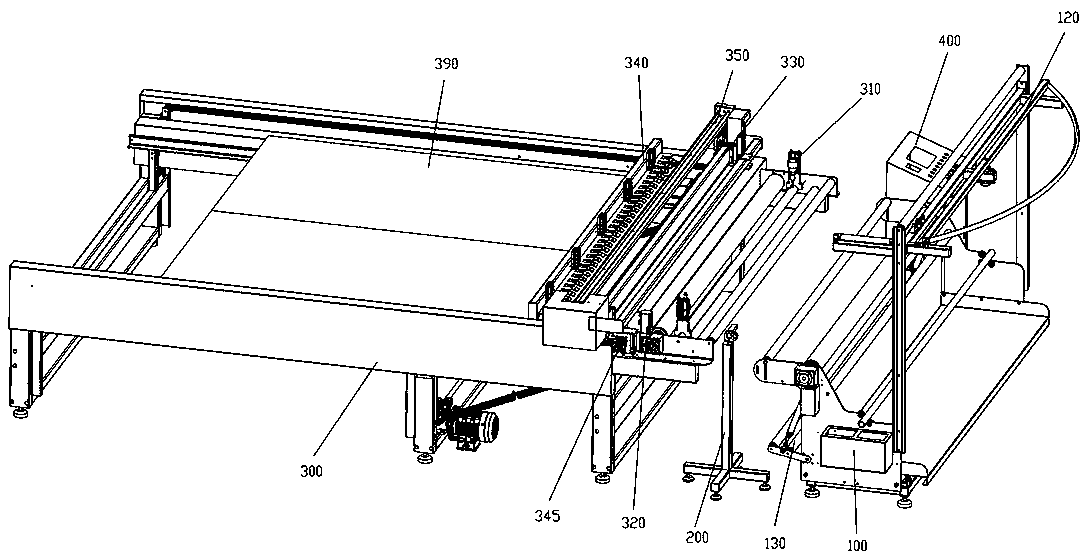

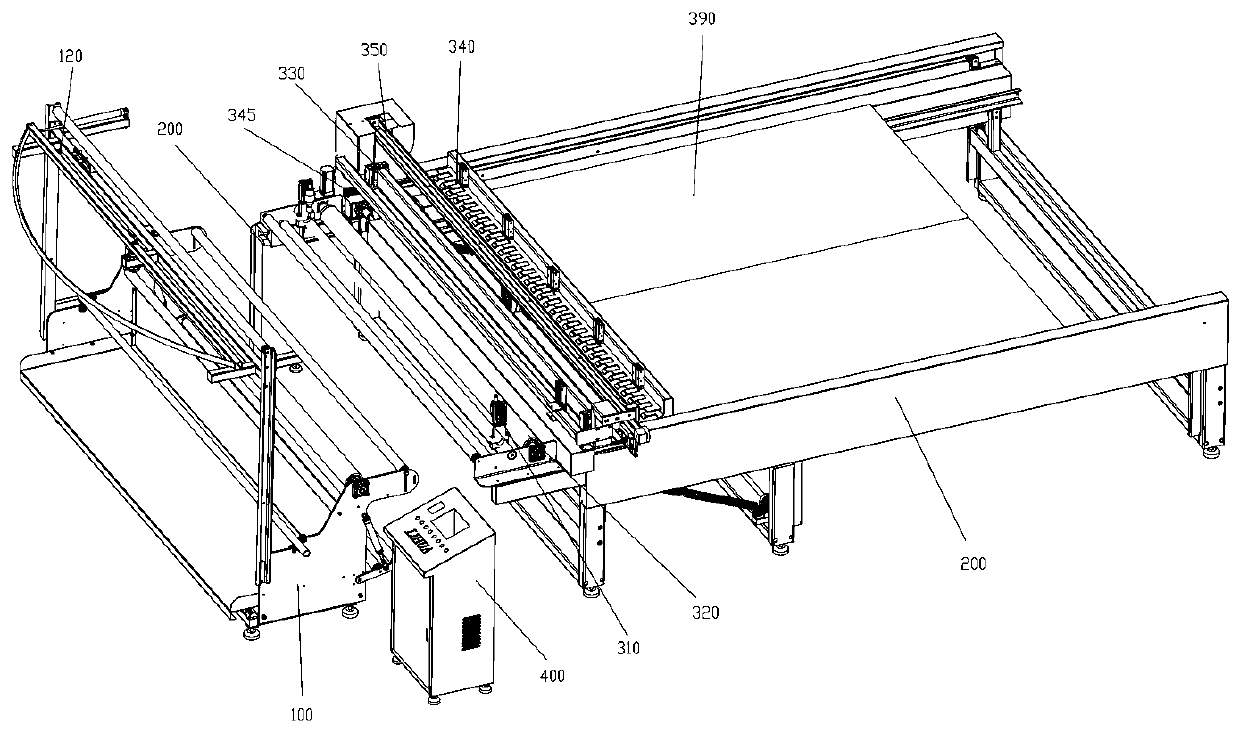

Automatic cloth cutting and discharging equipment and control method thereof

InactiveCN110860935ARealize horizontal deviation correction positioningConsistent cutting tensionSevering textilesMetal working apparatusDistribution controlEngineering

The invention provides automatic cloth cutting and discharging equipment and a control method thereof. The automatic cloth cutting and discharging equipment comprises a feeding platform, a tension adjusting feeding mechanism, an opposite edge deviation rectifying mechanism, a cloth edge cutting mechanism, an automatic cutting and discharging mechanism and a discharging platform which are arrangedin sequence along the advancing direction of cloth; and the equipment further comprises a power distribution control box, wherein the control box realizes control of the whole equipment. The automaticcloth cutting and discharging equipment has the advantages of being reasonable in structural design, quick and accurate in cloth cutting and capable of being applied to various cloth cutting.

Owner:中缝(厦门)自动化科技有限公司

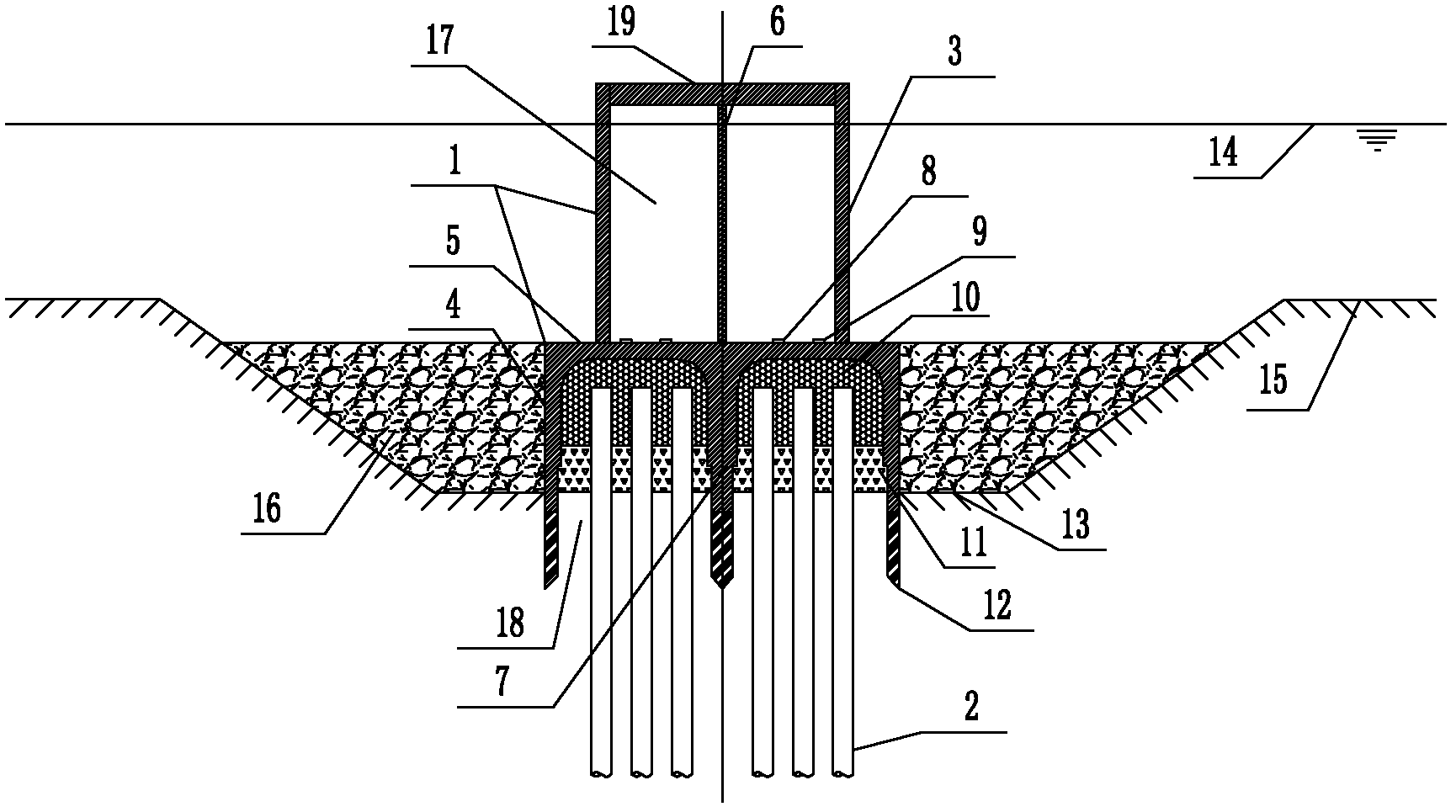

Pile foundation bucket foundation and construction method thereof

ActiveCN102644293AWith air stabilityAir flotationFoundation engineeringOffshore constructionBuilding construction

The invention discloses a construction method of the pile foundation bucket foundation. The foundation consists of a bucket body and a pile foundation; the bucket body comprises an upper wall body, a lower wall body, a cover plate, an upper baffle and a lower baffle. The cover plate is arranged at the upper part of the lower wall body, and the lower baffle is arranged inside the lower wall body, so as to form a lower wall body cavity. The upper wall body is arranged on the cover plate, the upper baffle is arranged inside the cover plate, so as to form an upper wall body cavity. A water-air valve and a concrete pouring valve which are communicated with the upper wall body cavity and the lower wall body cavity are arranged on the cover plate. The bucket body is sunk after the construction of the pile foundation, injecting water into the upper wall body cavity and absorbing water by the lower wall body cavity are main sinking means, and when the bucket body reaches a designed penetrating depth, bottom sealing concrete and in-bucket concrete are poured into the lower wall body cavity, so that a pile is connected with the bucket body. The pile foundation bucket foundation is suitable for being served as a deep-water bridge foundation on the condition of a thick covering layer, gives full play to the characteristics of high vertical bearing capability of the file foundation and convenience in construction of the bucket foundation, has high applicability, simple construction technology, small post-construction settlement, and lower requirement on offshore construction equipment, does not require the building of large construction auxiliary facilities, and is low in construction cost.

Owner:CCCC SECOND HARBOR ENG

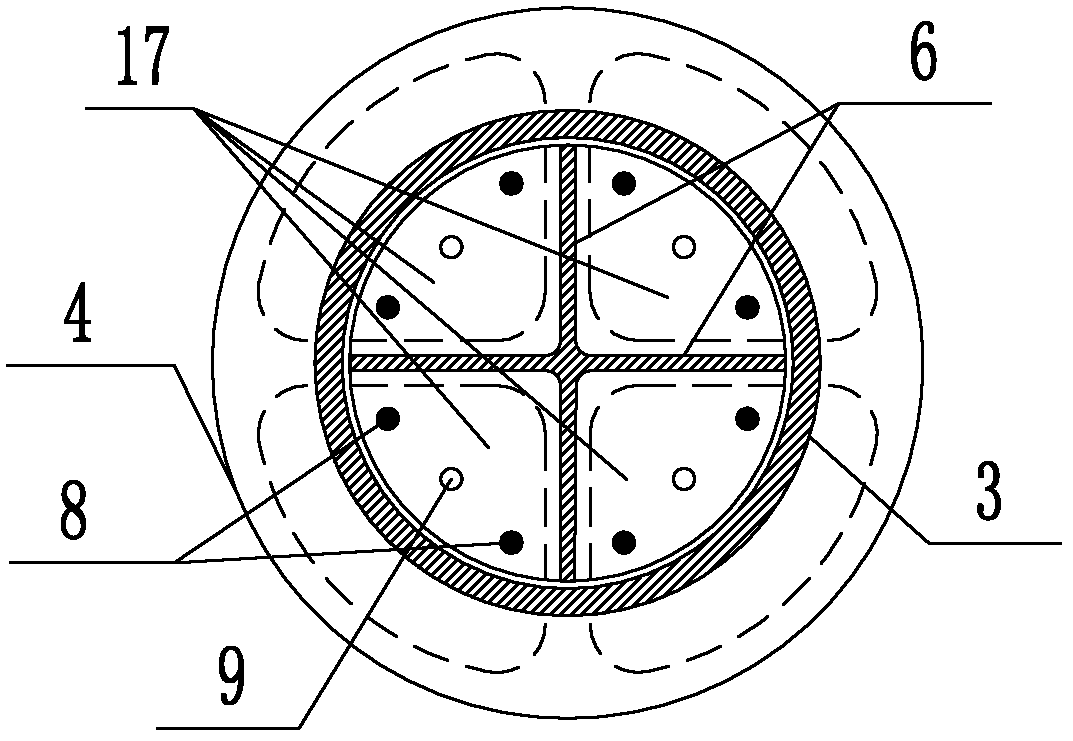

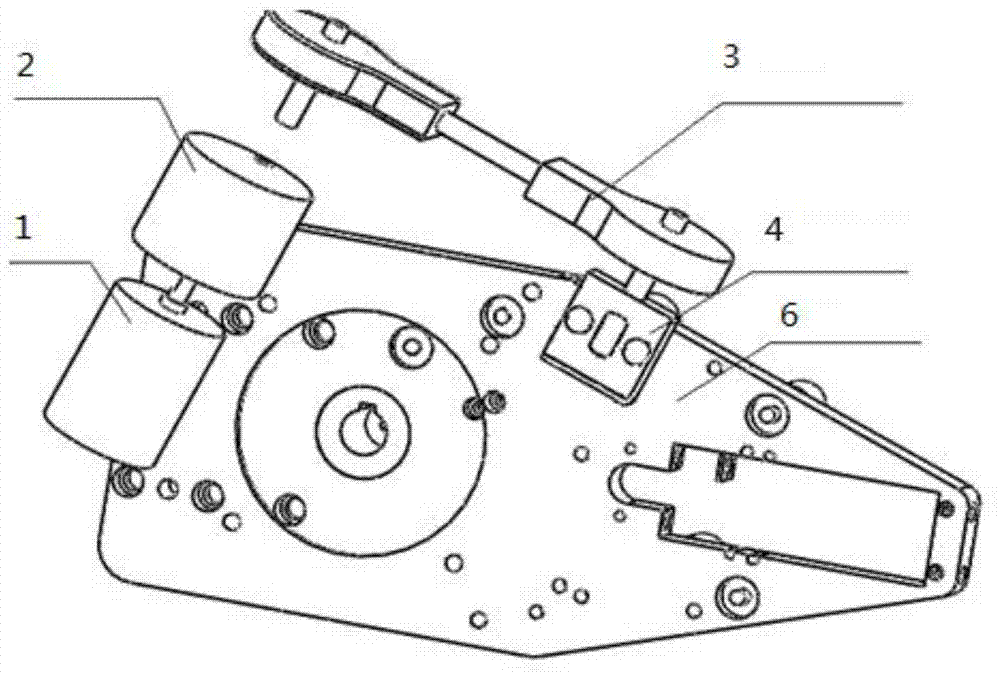

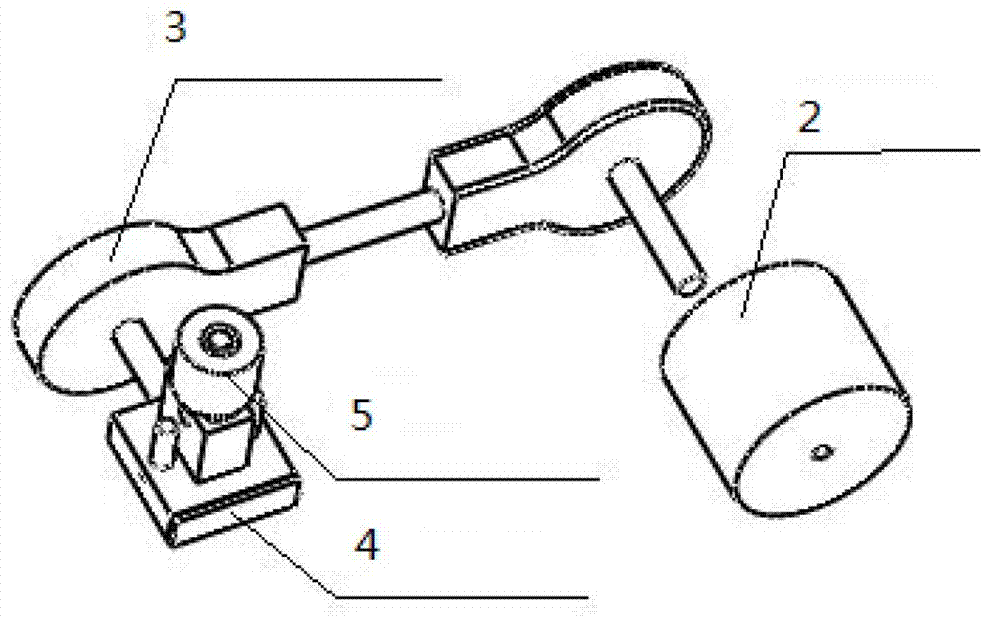

Tension mechanism adapted for automatic optical fiber winding machine

InactiveCN101059582ACompact designNo reverse dead zoneFilament handlingSagnac effect gyrometersWinding machineFiber

The invention discloses a tension structure used in automatic fiber coiler, composed of a fiber collector, a driver, a transmit box, a fiber discharge wheel, a support base, and a sliding table tension element, a first fiber guider and a second fiber guider, wherein the lower end of the support base via nut and screw is mounted on the sliding table, while the upper end is mounted with the transmit box, the driver is on the transmit box, while a motor and a speed reducer are mounted at the outer back of the transmit box, the accurate shaft of the driver is suspended at the outer front of the transmit box, which is mounted with the fiber discharge wheel, the fiber collector is at one side of the support base, vertically with the fiber discharge wheel, the sliding table is arranged with a plurality of mounting holes for fixing and mounting devices, the tension element, the first and the second fiber guiders via nut and screw are fixed on the sliding table, which guide grooves are in one plane. The inventive tension device has reasonable, compact and simple structure, without reverse dead area, but with stable transmission control, accurate tension control, non-zero-bias in force measurement, digit and closed tension control.

Owner:BEIHANG UNIV

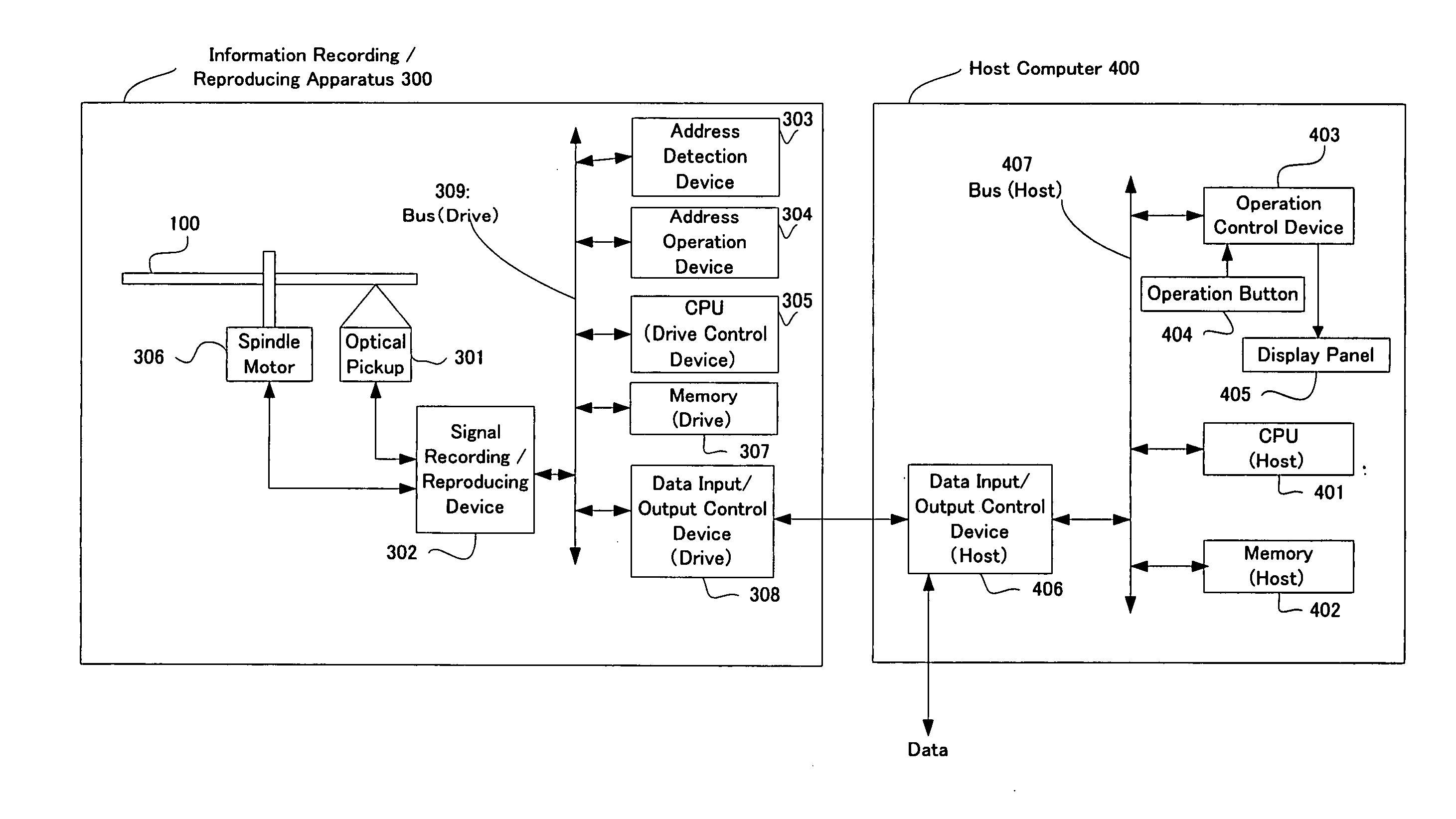

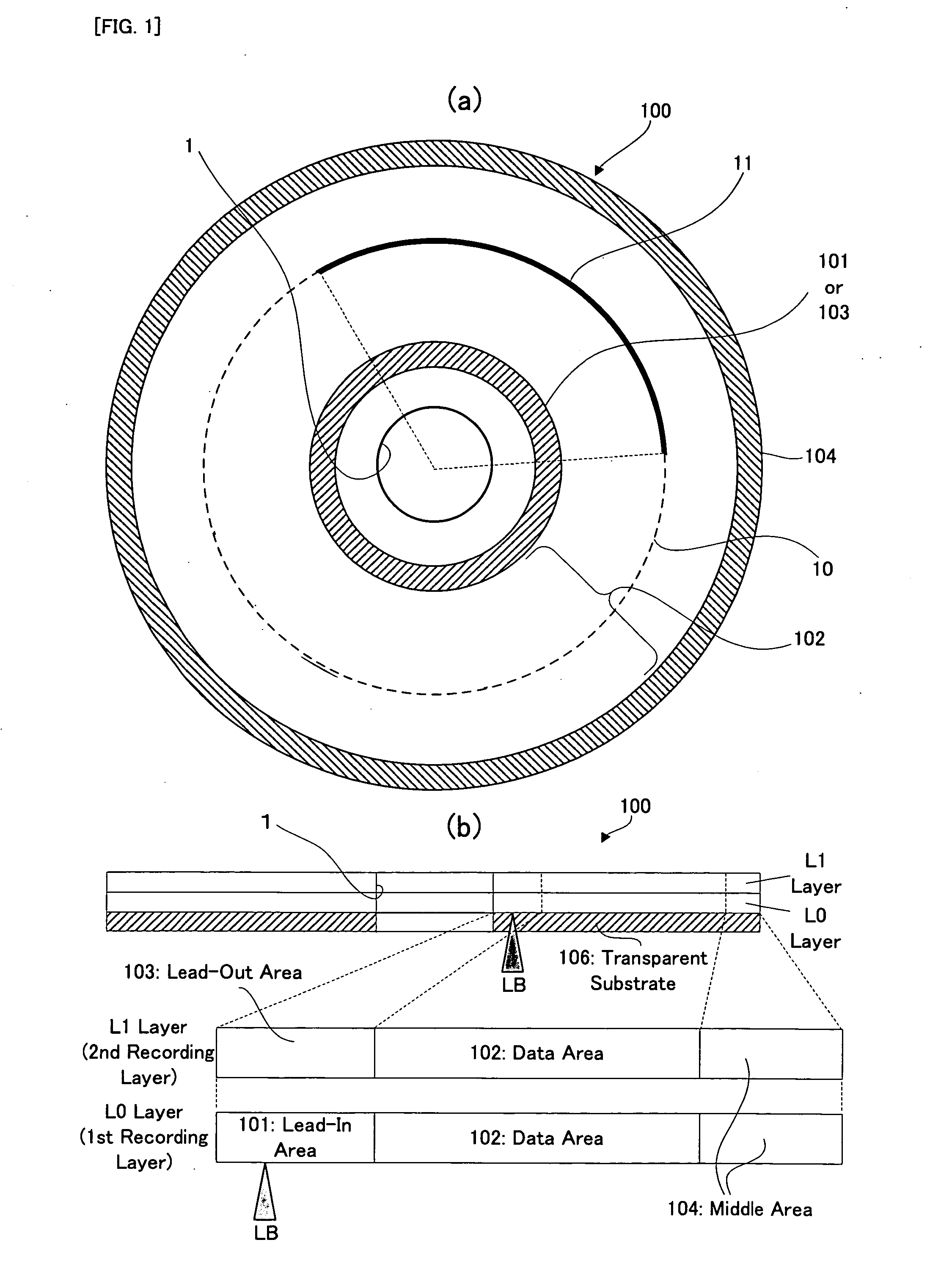

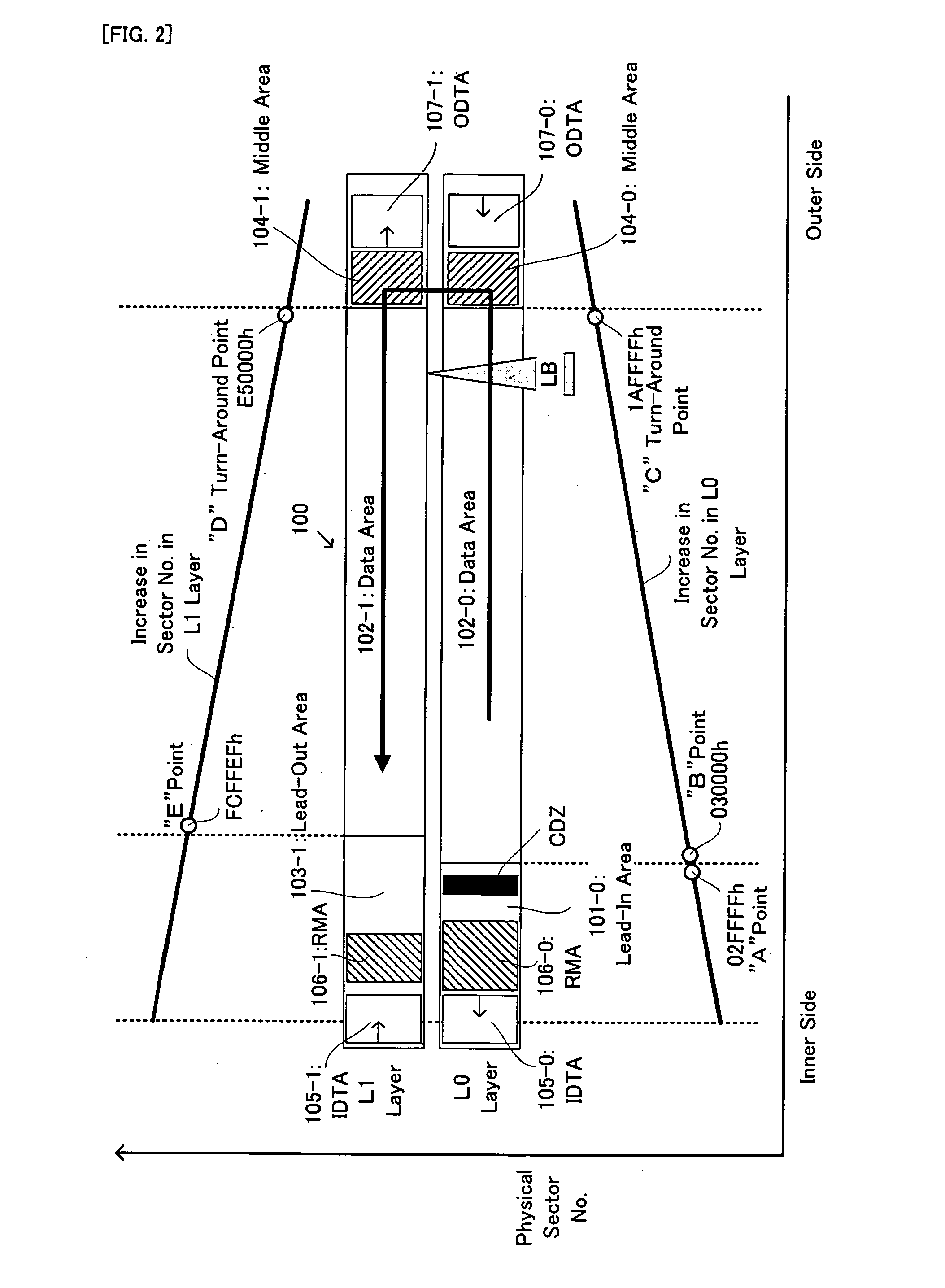

Information recording apparatus and method, and computer program for recording control

ActiveUS20070177472A1Learn accuratelyRealize the operationFilamentary/web record carriersRecord information storageRelative shiftRecording layer

An information recording device is used for recording record information in an information recording medium at least including a first recording layer capable of forming a first recording area and a second recording layer capable of forming a second recording area. The information recording device includes: write elements; acquisition elements for acquiring offset information indicating a relative shift; calculation elements for calculating an address (“Y′=Inv Y−α”) indicating a second boundary point opposing to a first boundary point according to the offset information; and control elements for controlling the write elements so as to write record information (i) while making the first boundary point a recording end or start position and (ii) making the second boundary point indicated by the calculated address a recording start or end position.

Owner:PIONEER CORP

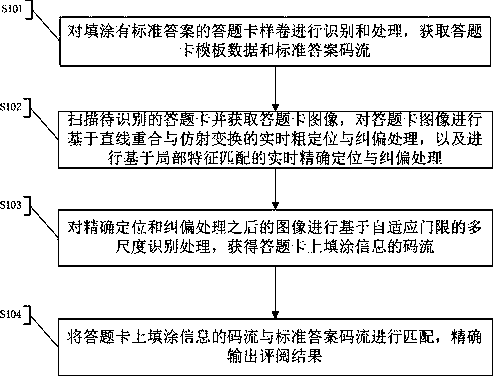

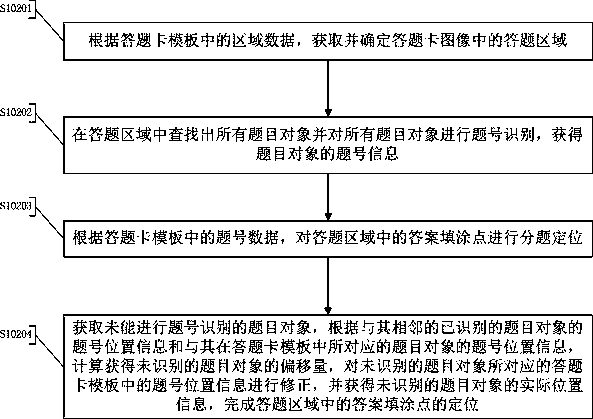

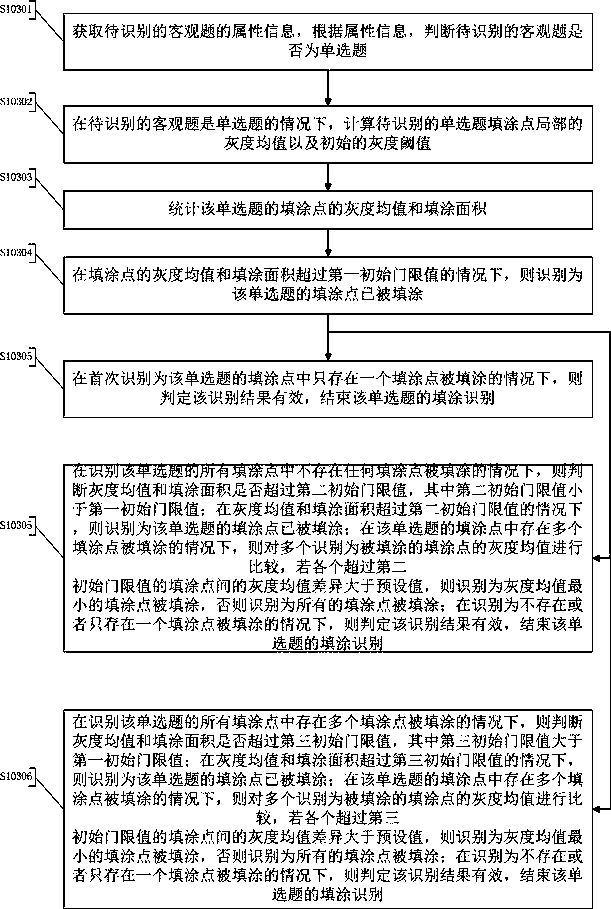

Recognition processing method and device for answer sheet

ActiveCN108537218AAchieve positioningAccurate realizationImage analysisGeometric image transformationPattern recognitionFeature matching

The invention provides a recognition processing method for an answer sheet. The method comprises the following steps: performing recognition and processing on answer sheet sample test paper filled with standard answers, and obtaining answer sheet template data and standard answer code stream; scanning an answer sheet to be scanned and obtaining an answer sheet image, performing real-time coarse positioning based on linear superposition and affine transformation and correction processing on the answer sheet image, and performing real-time accurate positioning based on local feature matching andcorrection processing; performing multi-scale recognition processing based on an adaptive threshold on the image subjected to accurate positioning and correction processing, so as to obtain code stream of filled information on the answer sheet; and matching the code stream of the filled information on the answer sheet with the standard answer code stream, and accurately outputting review results.Correspondingly, the invention further provides a recognition processing device for the answer sheet. The method has the advantages that the answer card can be accurately positioned, single choices,multiple choices and indefinite choices can be recognized and processed, and the recognition precision is high.

Owner:湖南诚壹文化产业有限公司

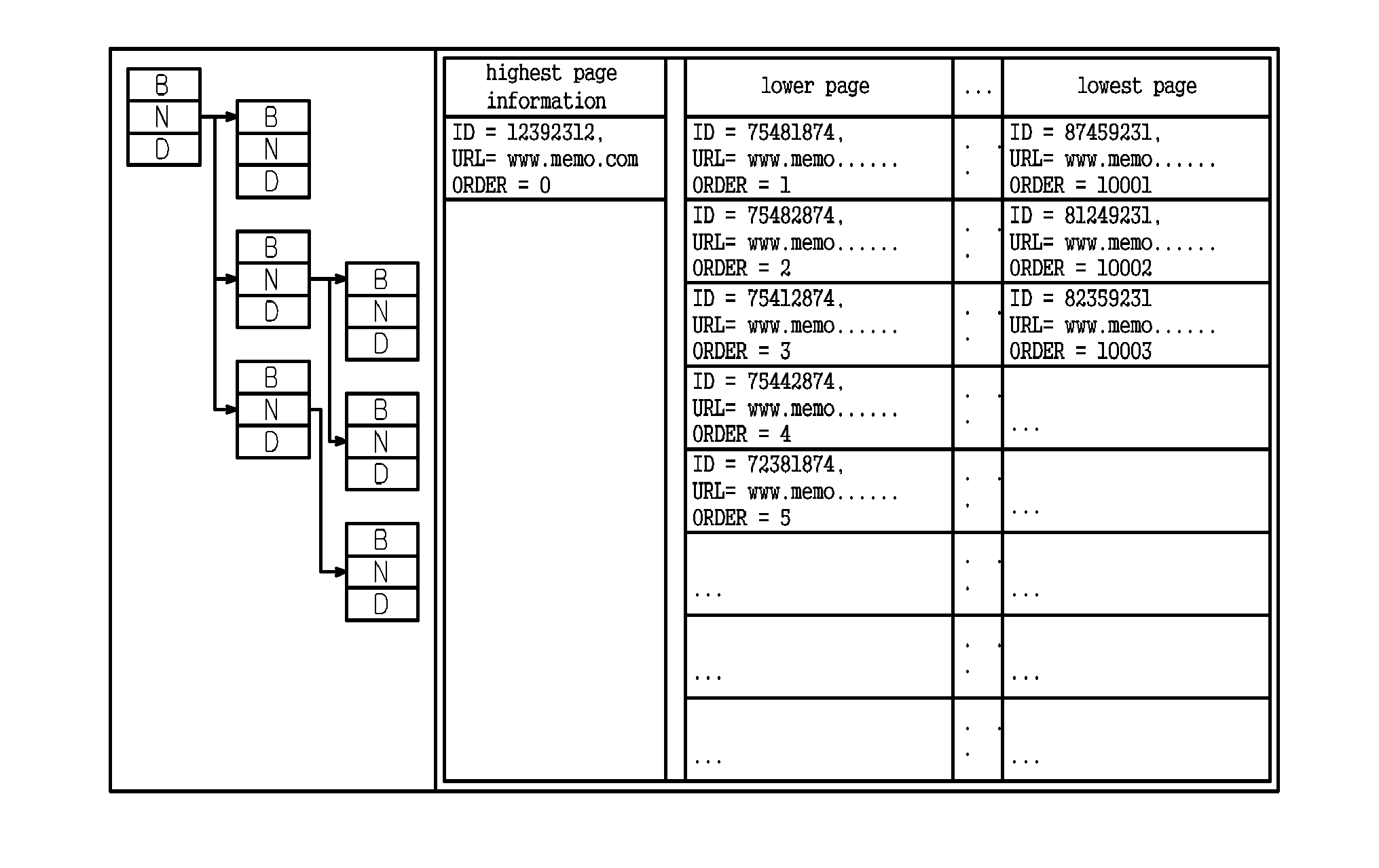

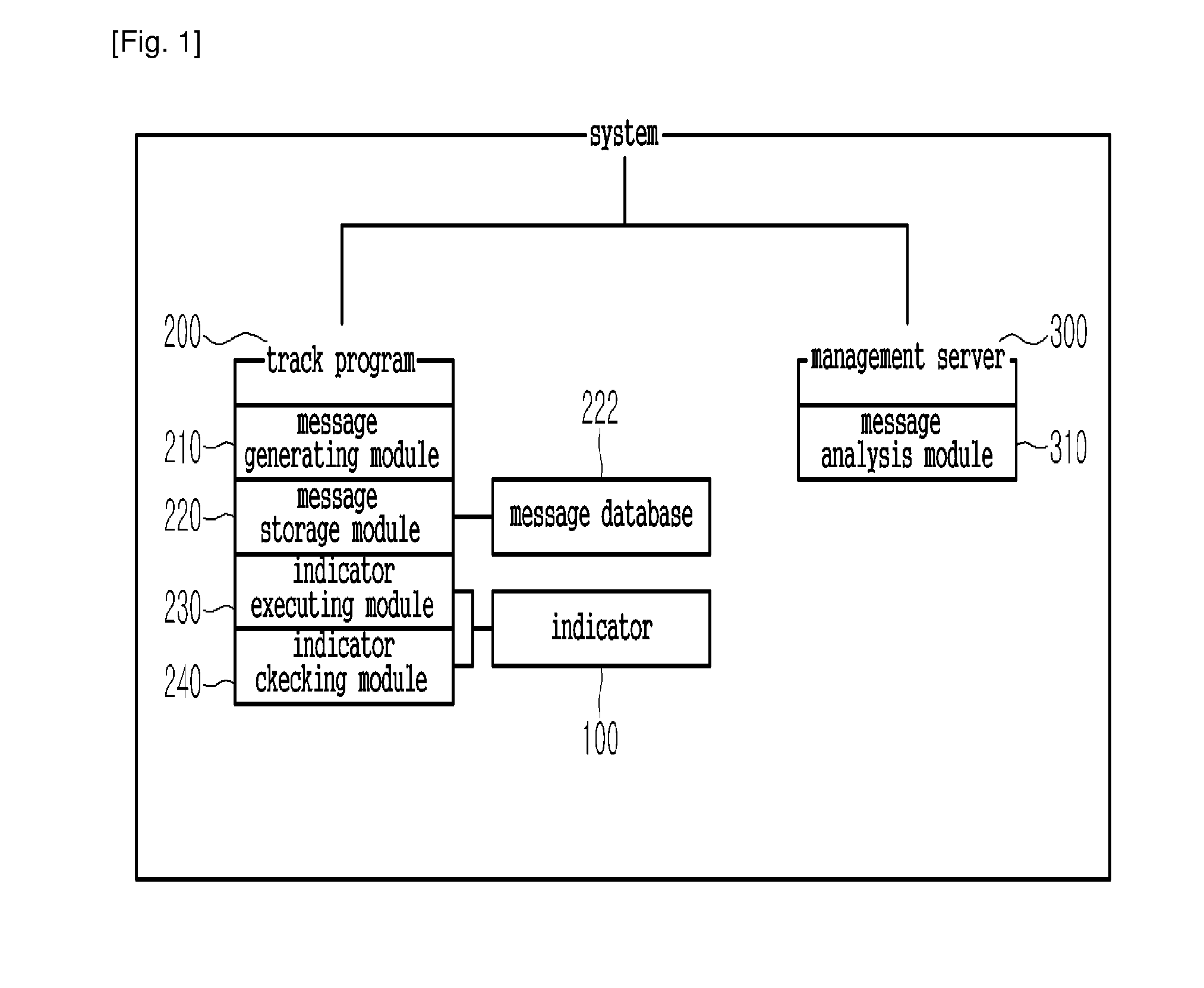

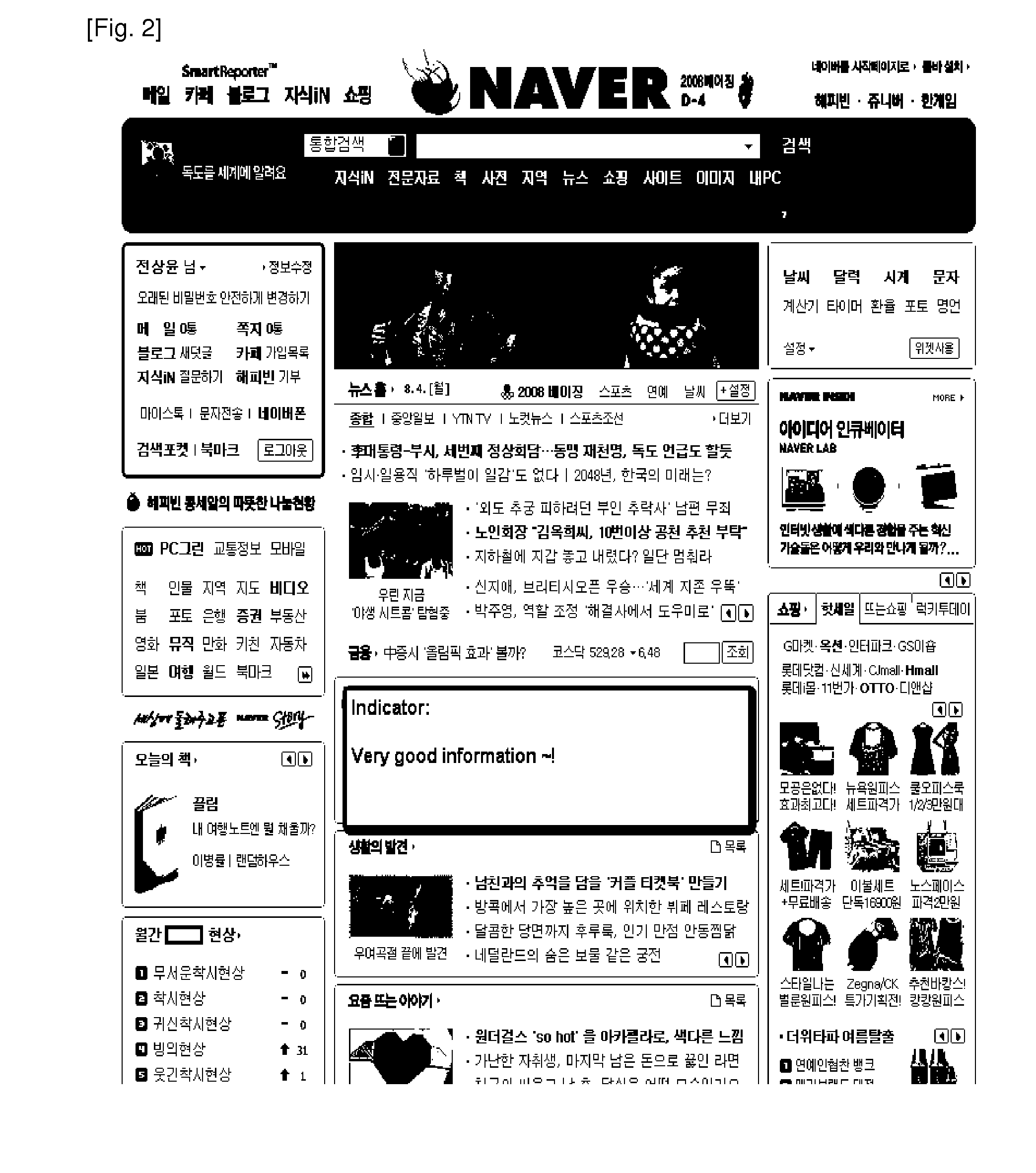

Method for Grasping Information of Web Site Through Analyzing Structure of Web Page

InactiveUS20100235402A1Improve the level ofAccurate realizationDigital data processing detailsDigital computer detailsWeb siteStructure analysis

The present invention provides a method for determining website information through web page structure analysis, including: generating, when a web page starts to move, a movement start message that contains IDs issued to identify respective web pages; generating, when a web page starts to move, a movement terminating message that contains URL information about a corresponding web page and information to determinate whether a corresponding web page is a main page or a subpage through the ID; generating, when all web pages have been loaded, a document terminating message containing information that analyzes which of the web pages has been moved; collecting the messages and generating a message database; and determining the website information of a specific user's visiting state and access states of the website, based on analysis of the message database.

Owner:ISFORU CO LTD

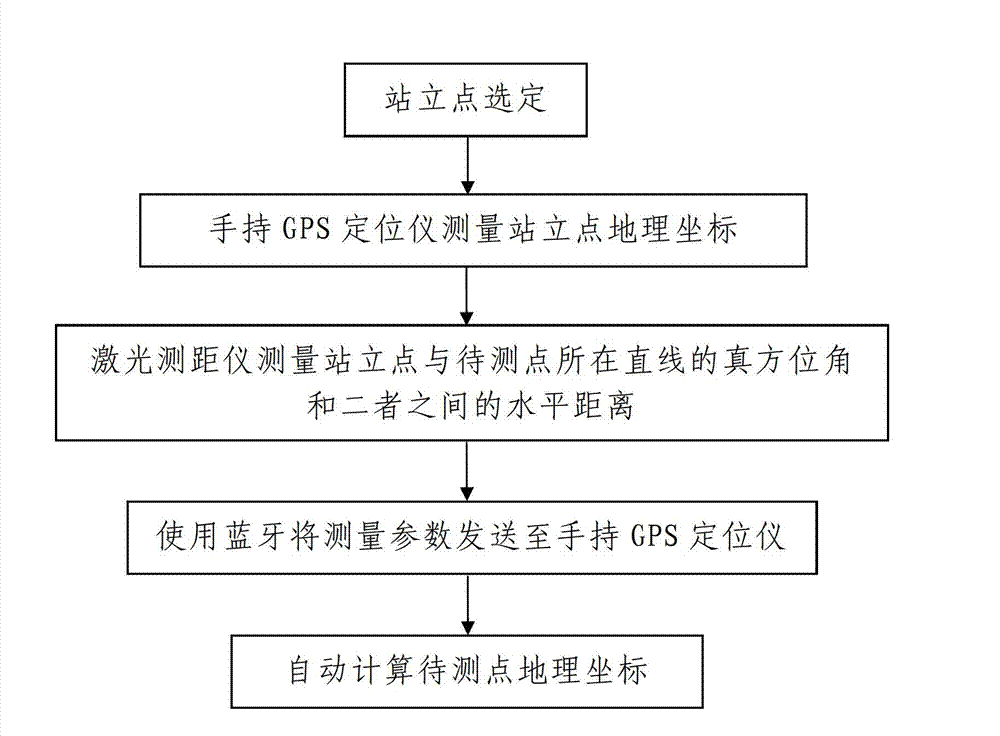

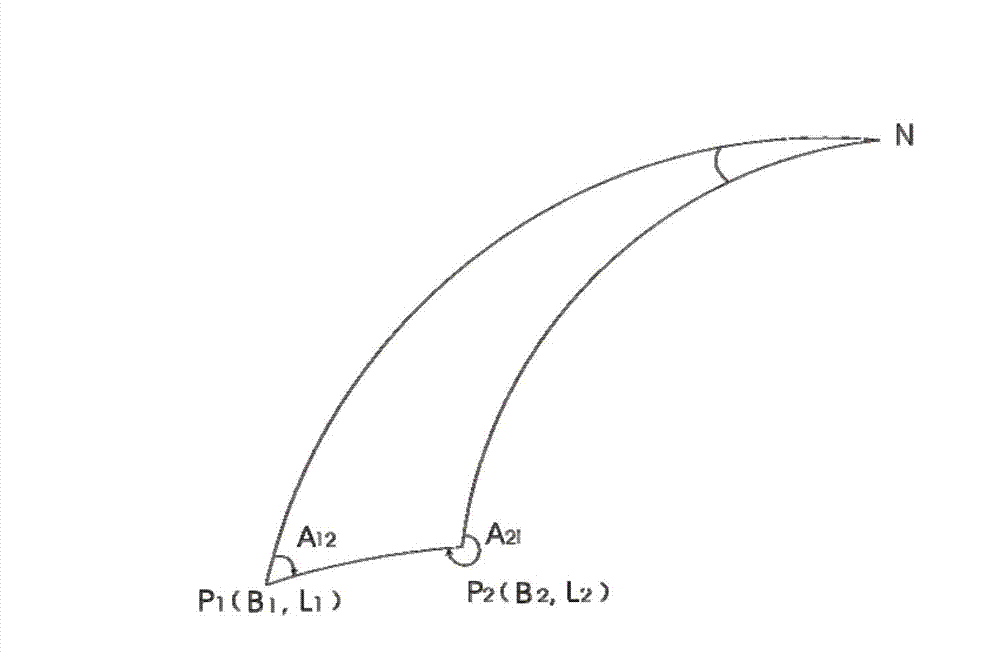

Quick measuring method based on laser ranging device

InactiveCN102829755ASimple stepsSimple and fast operationAngle measurementOptical rangefindersLaser rangingGps measurement

The invention discloses a quick measuring method based on a laser ranging device. The quick measuring method comprises the following steps of: 1, selecting a standing point, that is to say, selecting an observation point, which is beneficial for observation of a GPS (Global Positioning System), as a standing point P1 of a measuring worker; 2, measuring geographical coordinates of the standing point, that is to say, measuring geographical coordinates P1 (B1, L1) of the standing point P1 by utilizing a GPS measuring device; 3, measuring by the laser ranging device, that is to say, measuring horizontal distances s among a true azimuth angle A12 of a straight line of the standing point P1 and a point to be measured P2, the standing point P1 and the point to be measured P2 by utilizing the laser ranging device, wherein the laser ranging device is a laser ranging device provided with an electronic compass; and 4, converting the geographical coordinates of the point to be measured P2. The quick measuring method, provided by the invention, has the advantages of simple operation, convenience for implementation, quick measuring speed, high measuring precision, and capability of really realizing quick and accurate measurement of a detail point, and effectively solving the problems of slow measuring sped and difficulty in measurement of the conventional handheld GPS measuring method.

Owner:XIAN MEIHANG INFORMATION IND

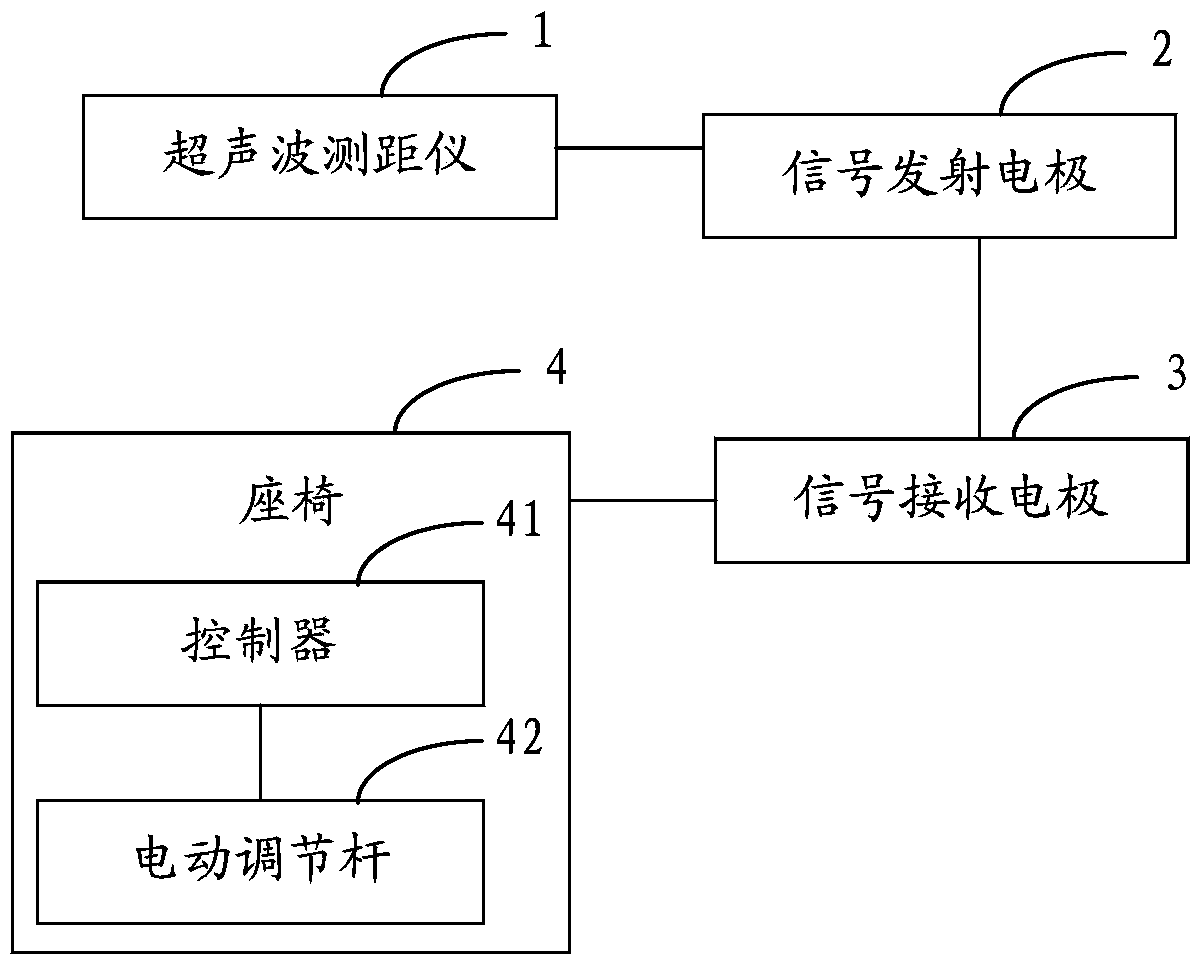

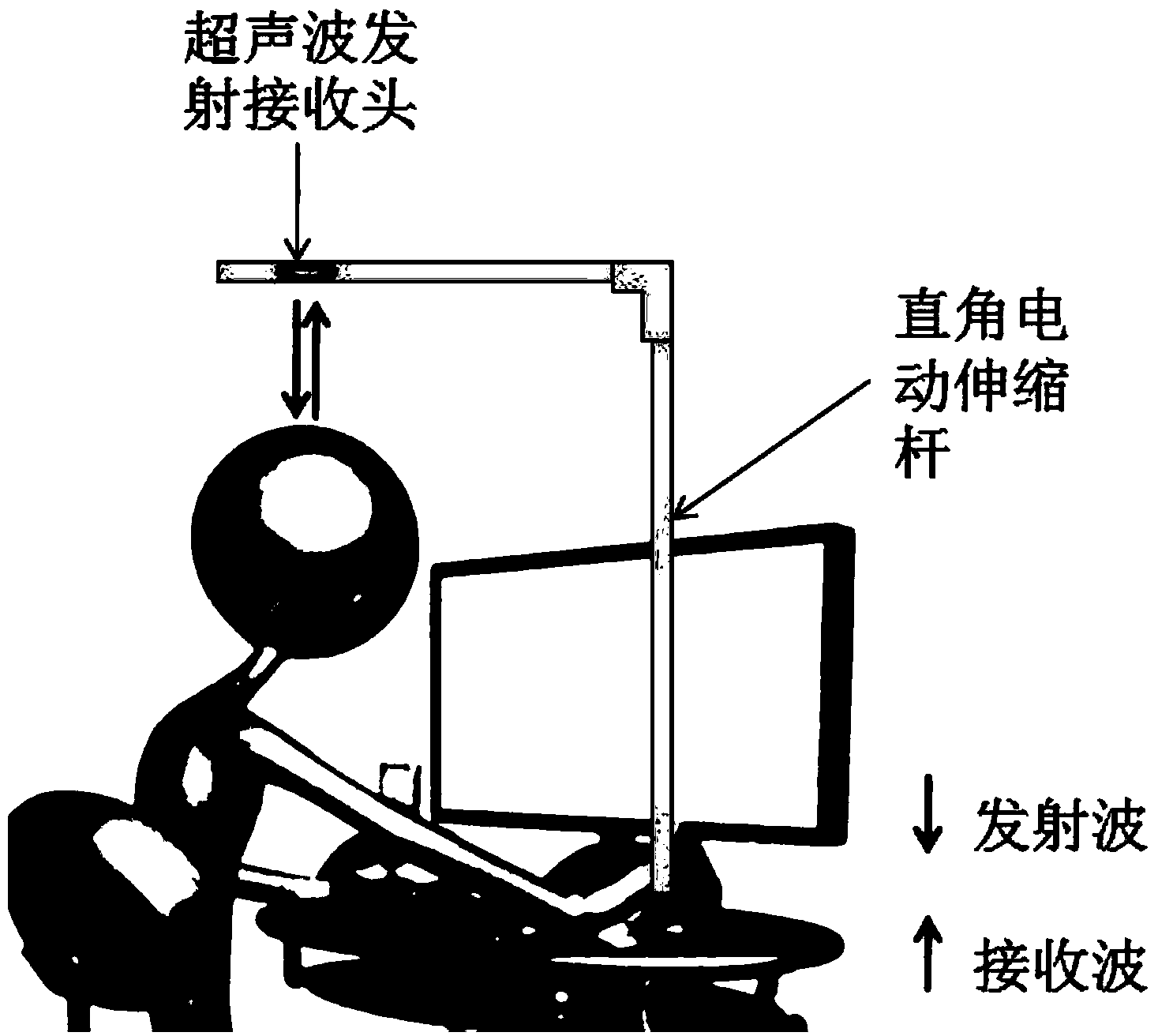

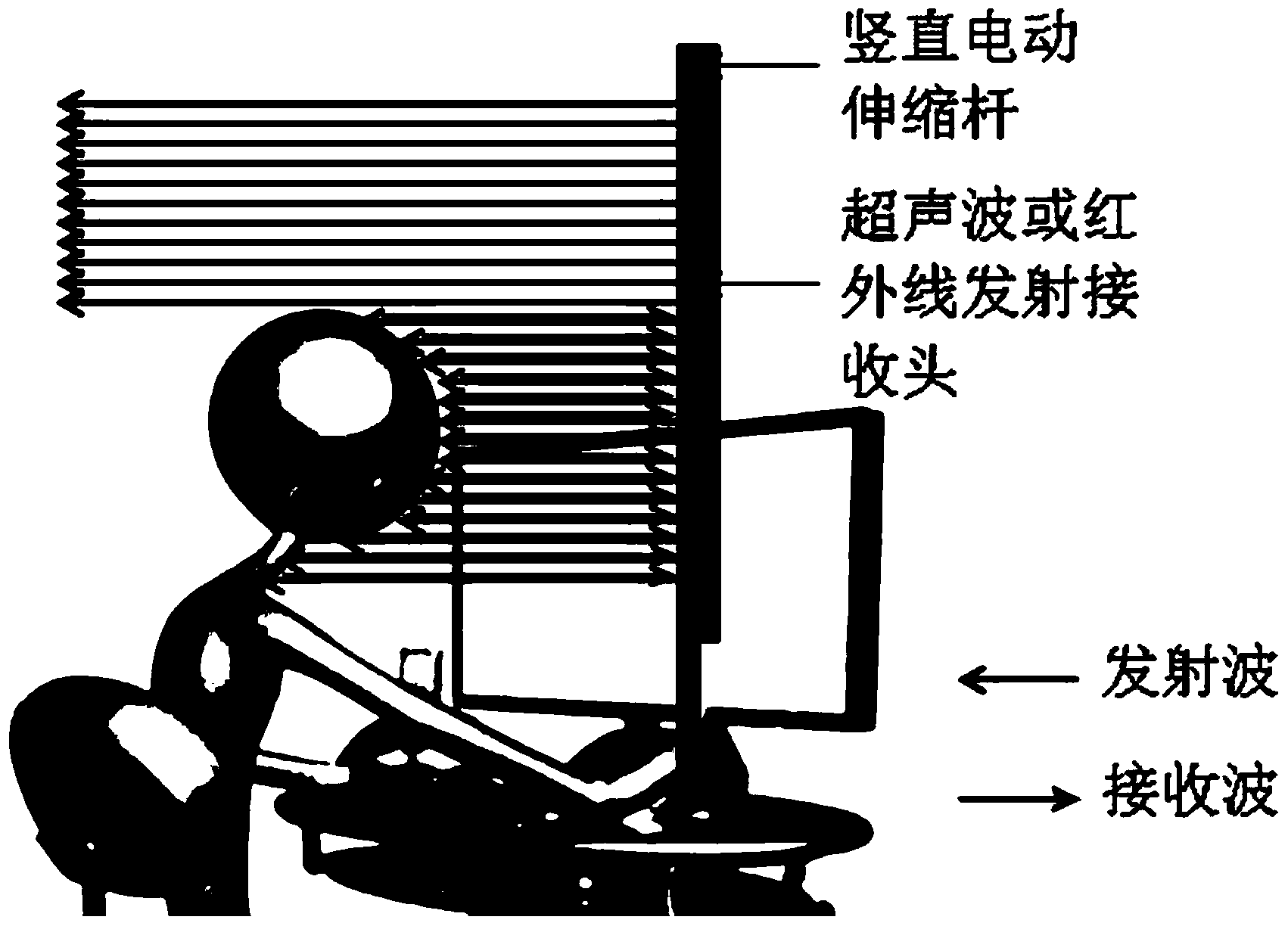

Seat adjustment control method and system

ActiveCN103645741AEasy to implementAccurate realizationPosition/direction controlBody contactEngineering

The invention is applicable to the technical field of seat adjustment, and provides a seat adjustment control method and system. The method comprises acquiring current sitting posture data of a user after an ultrasonic rangefinder is turned on, and transmitting the sitting posture data to each body part of the user via a signal emitting electrode; a signal receiving electrode receiving the sitting posture data and transmitting the sitting posture data to a controller of a current seat of the user; and controlling, by the controller based on the sitting posture data, an electrically controlled adjustment lever of the seat to adjust the seat, wherein the signal emitting electrode is disposed on the surface of the ultrasonic rangefinder and the signal receiving electrode is disposed at a place where the seat is in contact with the user's body. According to the invention, the seat is automatically adjusted to the most reasonable and beneficial state for the user's body in a simple, convenient and accurate manner.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

Device and Method for Fluidic Coupling of Fluidic Conduits to a Microfludic Chip, and Uncoupling Thereof

InactiveUS20100320748A1Way accuratePowerfulLaboratory glasswaresPipe elementsSystem requirementsCoupling

A system for fluidic coupling and uncoupling of fluidic conduits and a microfluidic chip, wherein the fluidic conduits are connected mechanically to a first structural part and the microfluidic chip is carried by a second structural part. The structural parts are moved perpendicularly toward and away from each other by means of a mechanism provided for this purpose. Outer ends of the fluidic conduits can thus be moved over a determined distance substantially perpendicularly to the outer surface of the microfluidic chip and connecting openings in the outer surface of the microfluidic chip. This enables accurate realization of fluidic coupling and uncoupling without the occurrence of undesirable moments of force and with minimal risk of damage to the fluidic conduits or the connecting openings. With such system requirements which can be set in respect of convenience, speed, temperature resistance, sealing, chemical resistance, reproducibility and so forth, can be fulfilled.

Owner:MICRONIT MICROTECHNOLOGIES BV

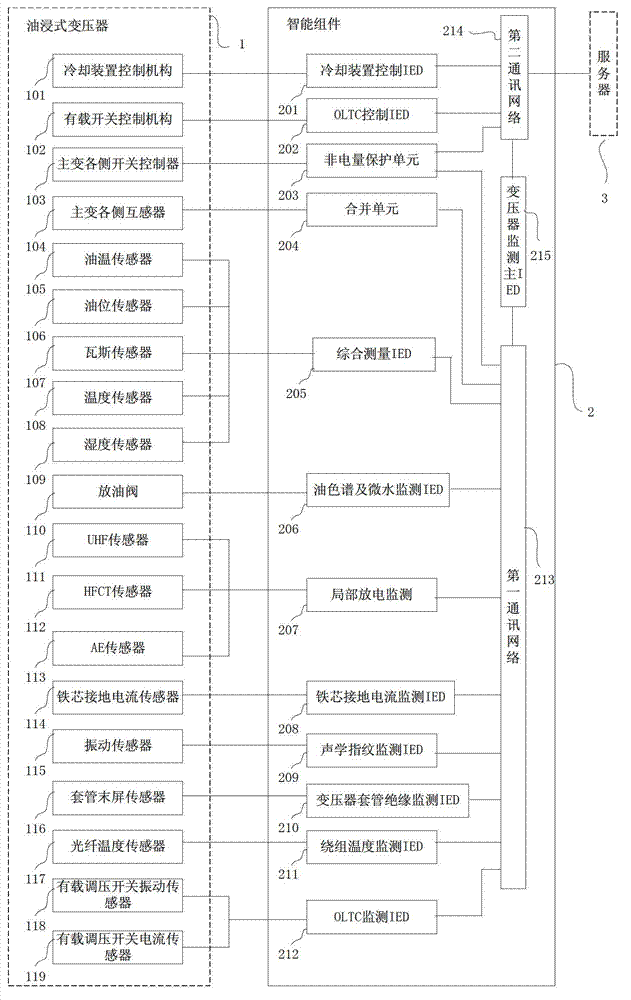

Intelligent component for oil-immersed transformer

InactiveCN103206984AStatus accurateEasy to controlMeasurement devicesProgramme control in sequence/logic controllersTemperature monitoringTap changer

The invention discloses an intelligent component for an oil-immersed transformer. The intelligent component comprises a cooling device control intelligent electronic device (IED), an on-load tap-changer (OLTC) control IED, a non-electric quantity protection unit, a merging unit, a comprehensive measurement IED, an oil chromatography and micro-water monitoring IED, a local discharge monitoring IED, an iron core grounding current monitoring IED, an acoustic fingerprint monitoring IED, a transformer bushing insulation monitoring IED, a winding temperature monitoring IED, an OLTC monitoring IED, a first communication network, a second communication network and a transformer monitoring master IED. According to the intelligent component, aiming at the particularity of the oil-immersed transformer, comprehensive information acquisition is performed, so that the state of the oil-immersed transformer can be monitored and controlled accurately and quickly.

Owner:STATE GRID CORP OF CHINA +1

Polycrystalline silicon ingot casting molten material and impurity removing process

InactiveCN103741206AReasonable designThe process steps are simplePolycrystalline material growthFrom frozen solutionsCrucibleIngot casting

The invention discloses a polycrystalline silicon ingot casting molten material and an impurity removing process. The process comprises the following steps: 1, preheating: adopting an ingot furnace to preheat a silicon material filled in a crucible, and gradually raising the heating temperature of the ingot furnace to T1; the preheating time is 6-10h, and T1=1165-1185 DEG C; 2, melting: the melting temperature is T1-T5; T5=1540-1560 DEG C; in the melting process, filling insert gases into the ingot furnace, and keeping air pressure in the furnace in Q1, and Q1=550-650mbar; 3, removing impurities: the process is as follows: the 11th step, reducing pressure: the air pressure of the ingot furnace is reduced from Q1 to Q2, and the pressure reducing time is 8-12min, and Q2=350-450mbar; the 12th step, maintaining pressure; the 13th step, boosting pressure and lowering temperature. The process has the advantages of simple steps, reasonable design, convenience in realization, easiness in grasp and good using effect, can discharge gas containing carbon in the furnace in time, and increases the polycrystalline silicon ingot casting quality.

Owner:XIAN HUAJING ELECTRONICS TECH

Automatic deviation rectifying mechanism for abrasive belt of polishing machine

InactiveCN102814716AEliminate Surface Quality IssuesSurface quality is stableBelt grinding machinesThin walledEngineering

The invention provides an automatic deviation rectifying mechanism for an abrasive belt of a polishing machine. The polishing condition of the abrasive belt is detected in real time by using a photoelectric sensor; when the abrasive belt deviates, micrometric displacement of deviation is transferred by the photoelectric sensor to a controller, a pulse signal sent by the controller is transferred to a direct current servo motor, an eccentric wheel is driven by the direct current servo motor to rotate, a connecting rod is driven by the eccentric wheel to swing, and then, a swing shaft is driven to rotate to enable a worm gear and worm mechanism to work and realize the linear motion of a worm and a deviation rectifying roller on the worm, so that the deviation rectification of the abrasive belt is realized. The mechanism is simple in structure, easy to realize and capable of realizing automatic deviation rectification in the thin-wall blade polishing process, eliminating the surface quality problem brought by the deviation of the abrasive belt, ensuring the stability of the surface quality of a blade and also improving the polishing effect of the blade.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

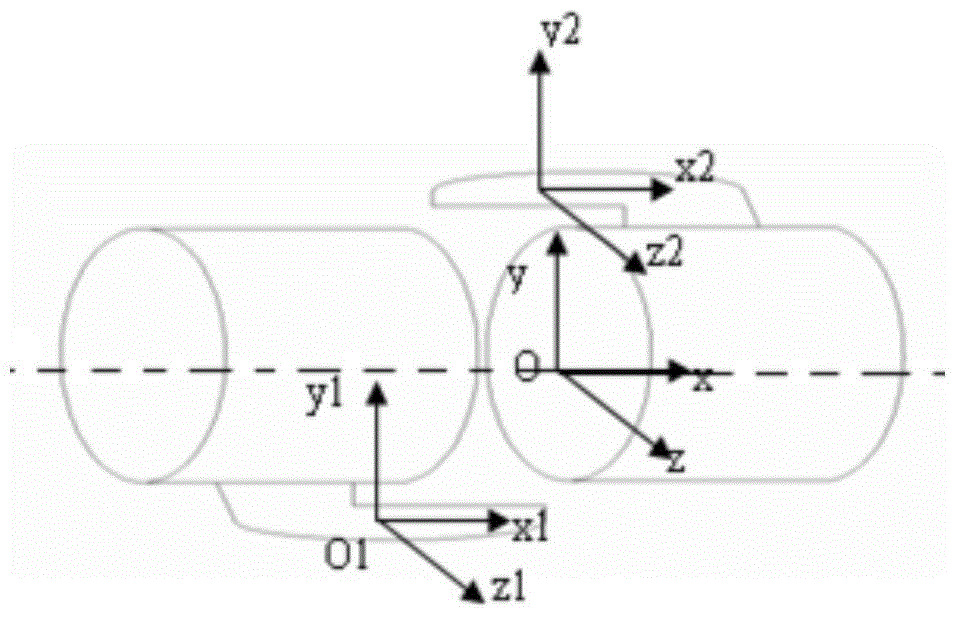

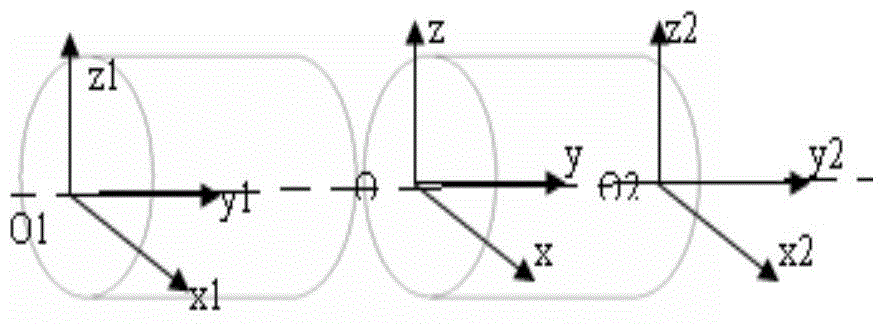

Solving method of kinematics of underwater mechanical arm based on configuration plane

The invention provides a solving method of kinematics of an underwater mechanical arm based on a configuration plane. The calculation method comprises steps of inputting joint parameters of the underwater mechanical arm by carrying out analysis for mechanical arm joints, resolving the known working configuration of a robot according to types of joint modules, resolving the robot joints into corresponding types of basic joints according to movement types and inputting position arrays of target points of the robot; and modeling the basic joints by carrying out kinematical modeling for basic moving joints forming the space mechanical arm, and normalizing the kinematical modeling to form a unified modeling method. According to the invention, disadvantages are solved that solving is complex and it is hard to remove incorrect solution from multiple solutions in a traditional analytic method; problems of poor real-time performance and low precision of the common iteration method are solved; solving for inverse kinematics of the robot can be quickly and precisely achieved; and actual application requirements of the underwater mechanical arm are met.

Owner:HARBIN ENG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com