Tab cutting device

A cutting and tab technology, used in shearing devices, shearing machines, metal processing equipment, etc., can solve the problems of inability to rectify and adjust, the cutting tool is fixed, and the quality of the tabs is affected, so as to improve the cutting quality, Effective and uniform cutting force, avoiding edge burrs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below through embodiments in conjunction with the accompanying drawings.

[0023] In one embodiment, the tab cutting device includes a driving mechanism and a cutting mechanism.

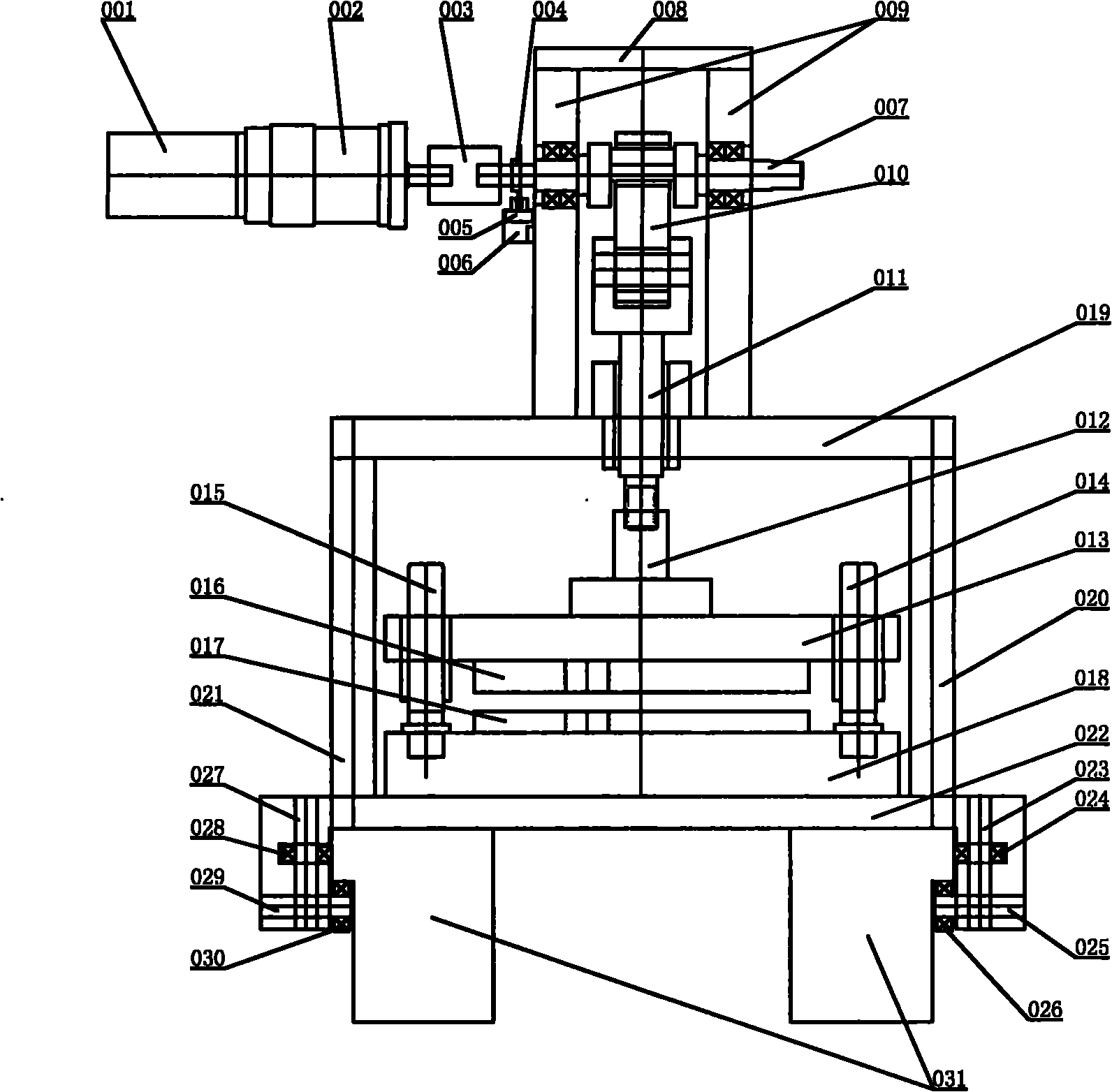

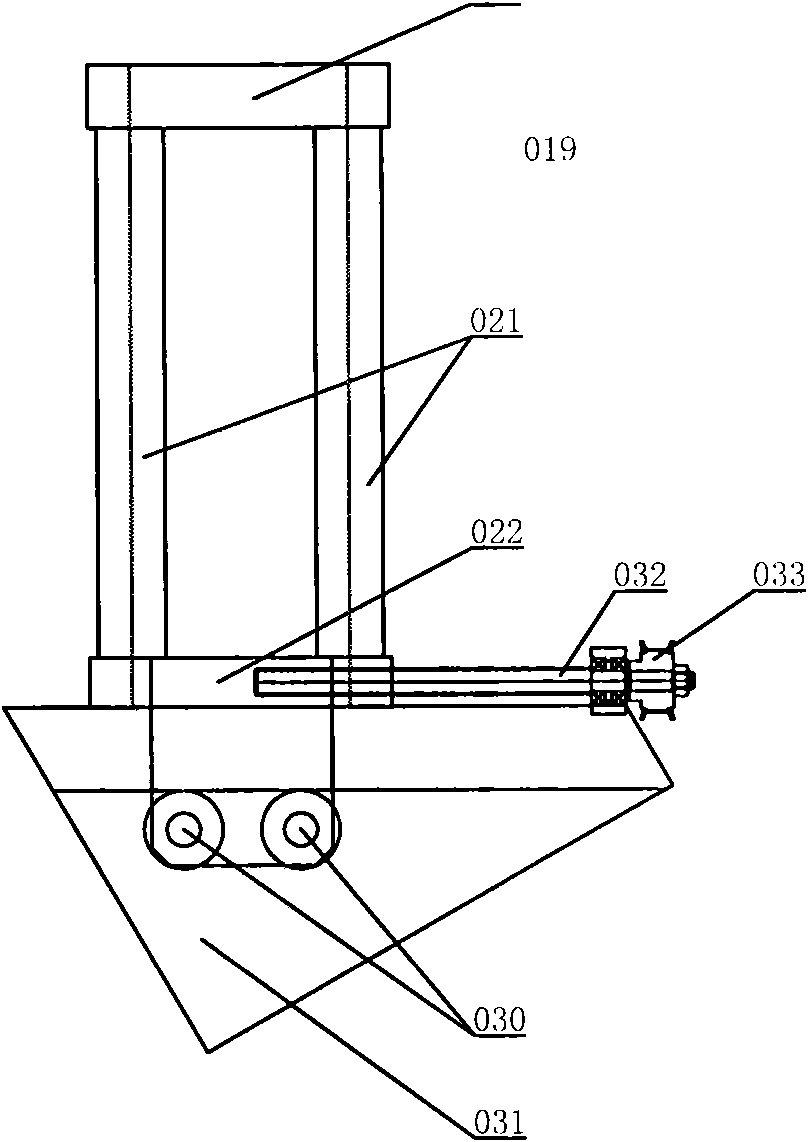

[0024] Please refer to figure 1 , the driving mechanism includes a motor 001, a reducer 002, a shaft coupling 003, an optical code disc 004, an inductor 005, an inductor bracket 006, a rotating shaft 007, a fixed block 008, a connecting block 009, a cam 010, and a first connecting rod 011.

[0025] Wherein, the output shaft of the motor 001 is fixedly connected with the rotating shaft 007 through the reducer 002 and the coupling 003, so that the rotating shaft 007 is driven by the motor 001 to rotate synchronously. The optical code disc 004, the sensor 005, and the sensor bracket 006 constitute an origin detection device. The optical code disc 004 is fixedly installed on the rotating shaft 007, and a gap is provided on the optical cod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com