Automatic cloth cutting and discharging equipment and control method thereof

A cloth and cutting technology, applied in the cutting of textile materials, textile and papermaking, metal processing, etc., can solve the problems of low work efficiency, burn marks, inaccurate dimensions, etc., achieve reasonable structure design, prevent selvage curl, The effect of avoiding cropping errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

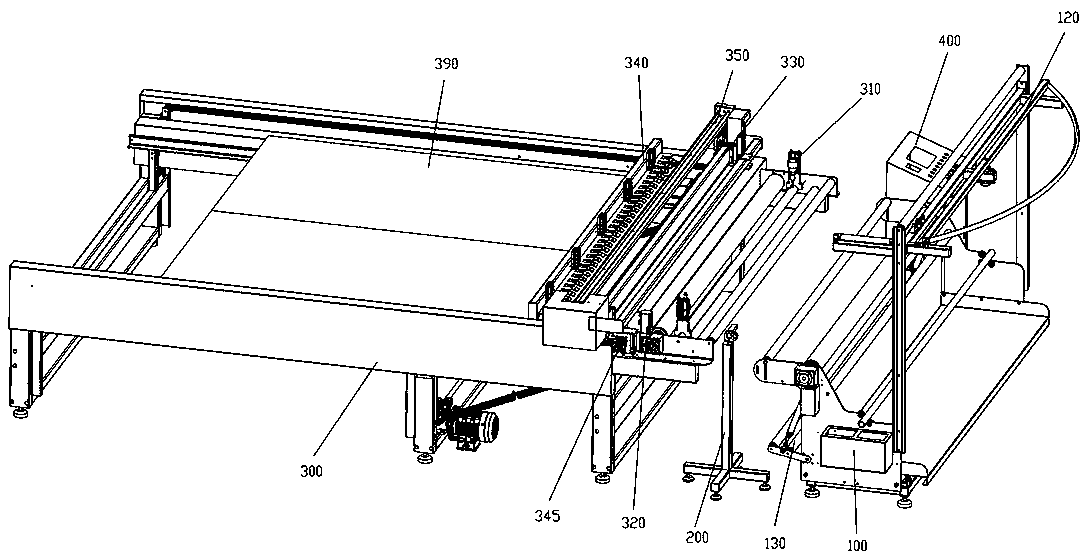

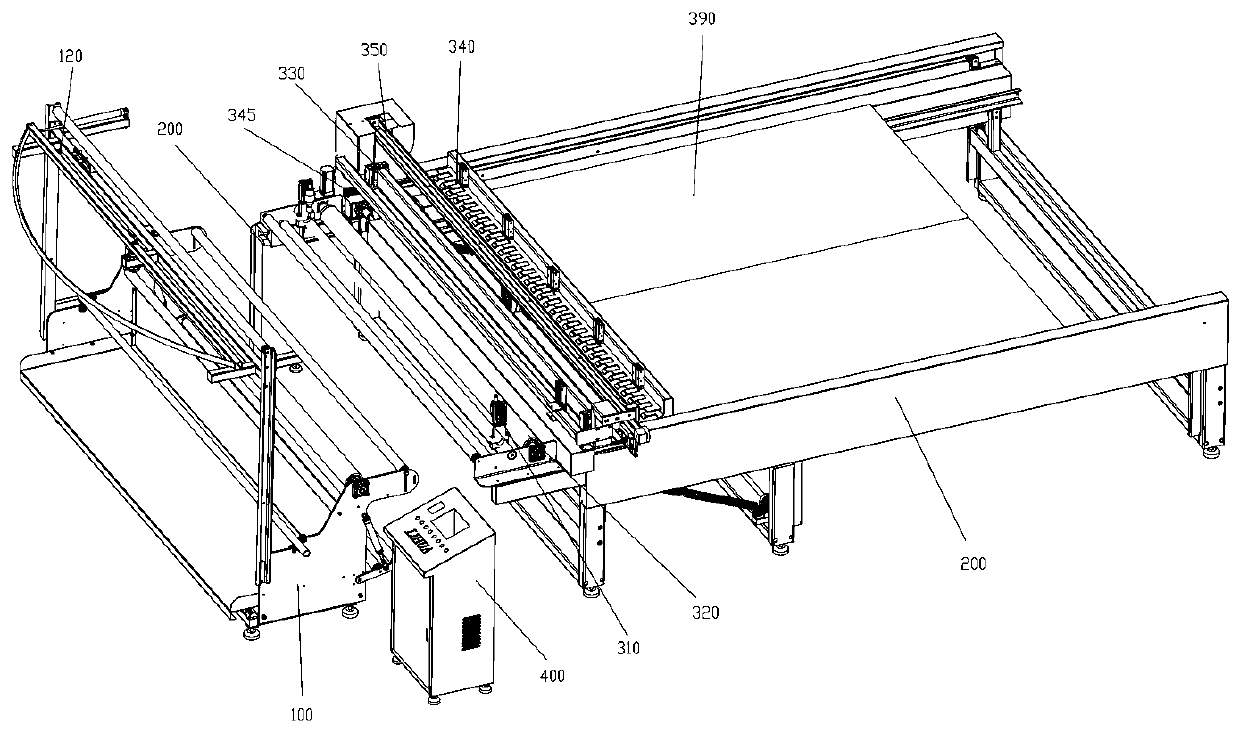

[0074] refer to figure 1 , figure 2 As shown, the present invention discloses a cloth automatic cutting and blanking device, which includes a feeding platform, a tension adjustment feeding mechanism 130, a side-to-side deviation correction mechanism 200, a cloth edge cutting mechanism 310, an automatic The cutting and blanking mechanism and the blanking platform 390 define the blanking platform 390 to be located at the rear of the feeding platform, and define the feeding platform to be located in front of the blanking platform 390. The equipment also includes a power distribution control box 400. Device control.

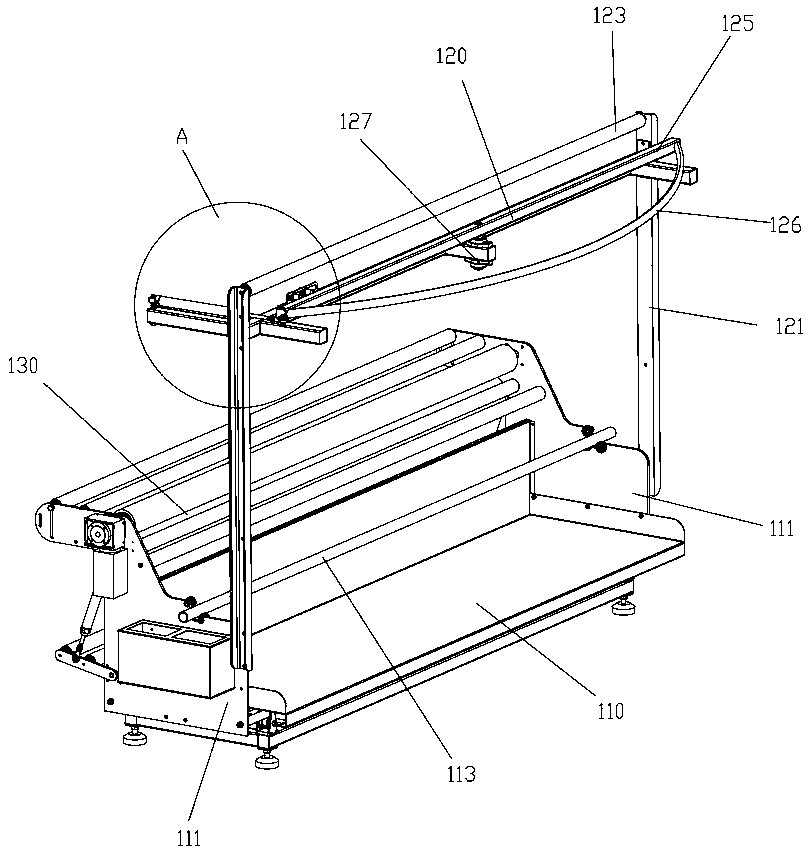

[0075] refer to image 3 , Figure 6 As shown, the feeding platform includes a first frame 100, and the first frame 100 includes a cloth laying platform 110 horizontally arranged for placing cloth to be cut, and both ends of the cloth laying platform 110 are provided with vertical sides. Plate 111, both side plates 111 are provided with bearing group 112 and clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com