Patents

Literature

134results about How to "Accurate cut" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

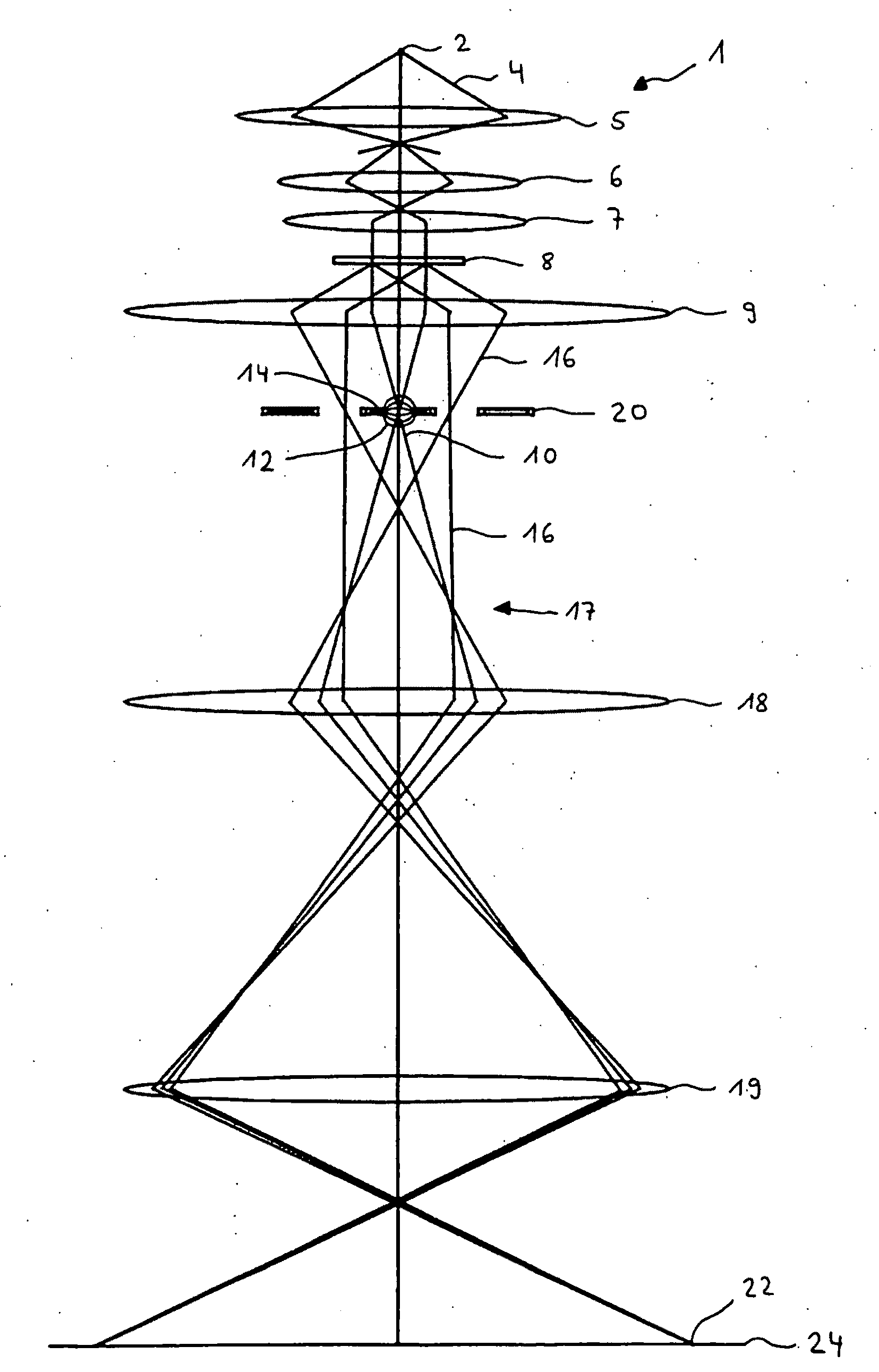

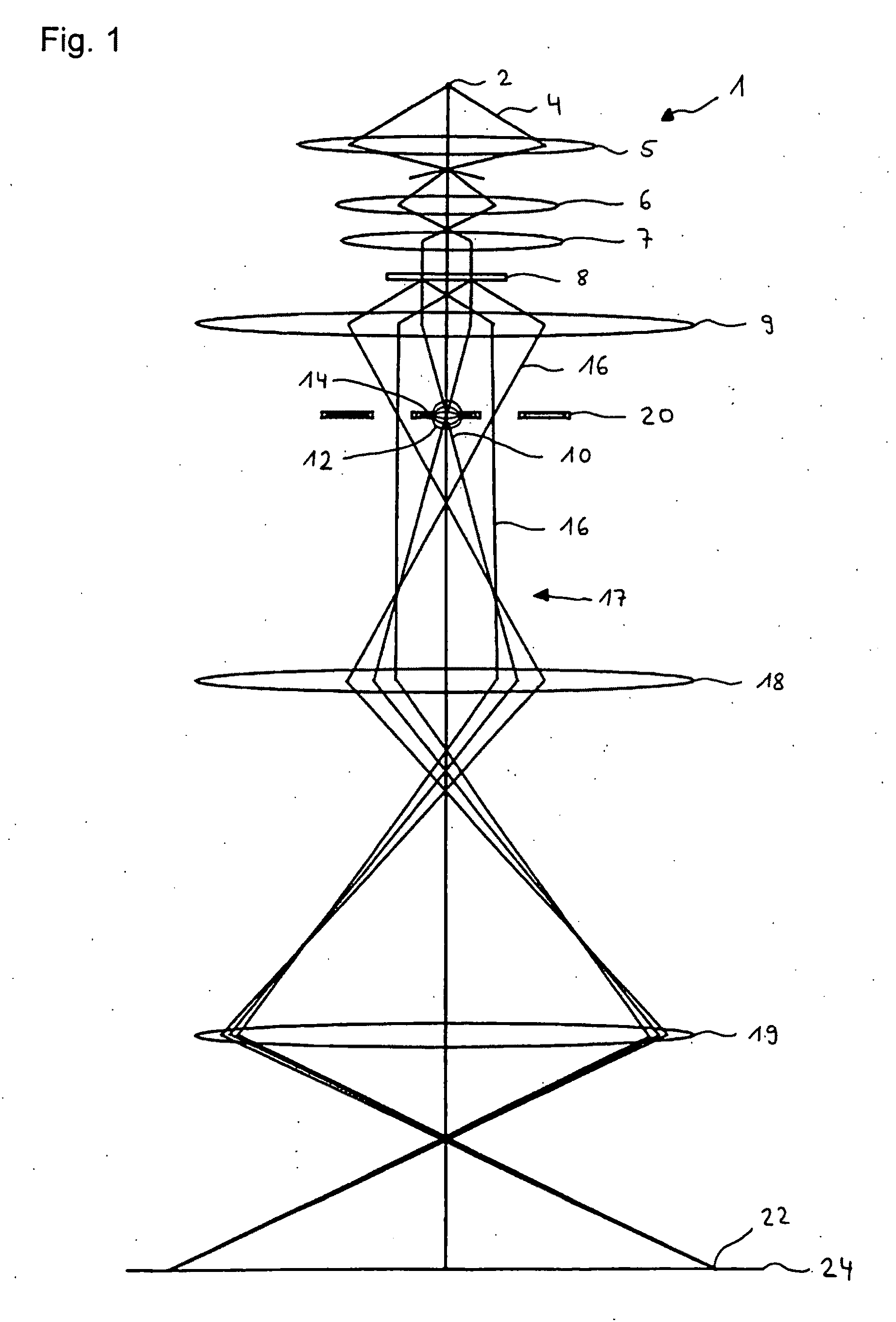

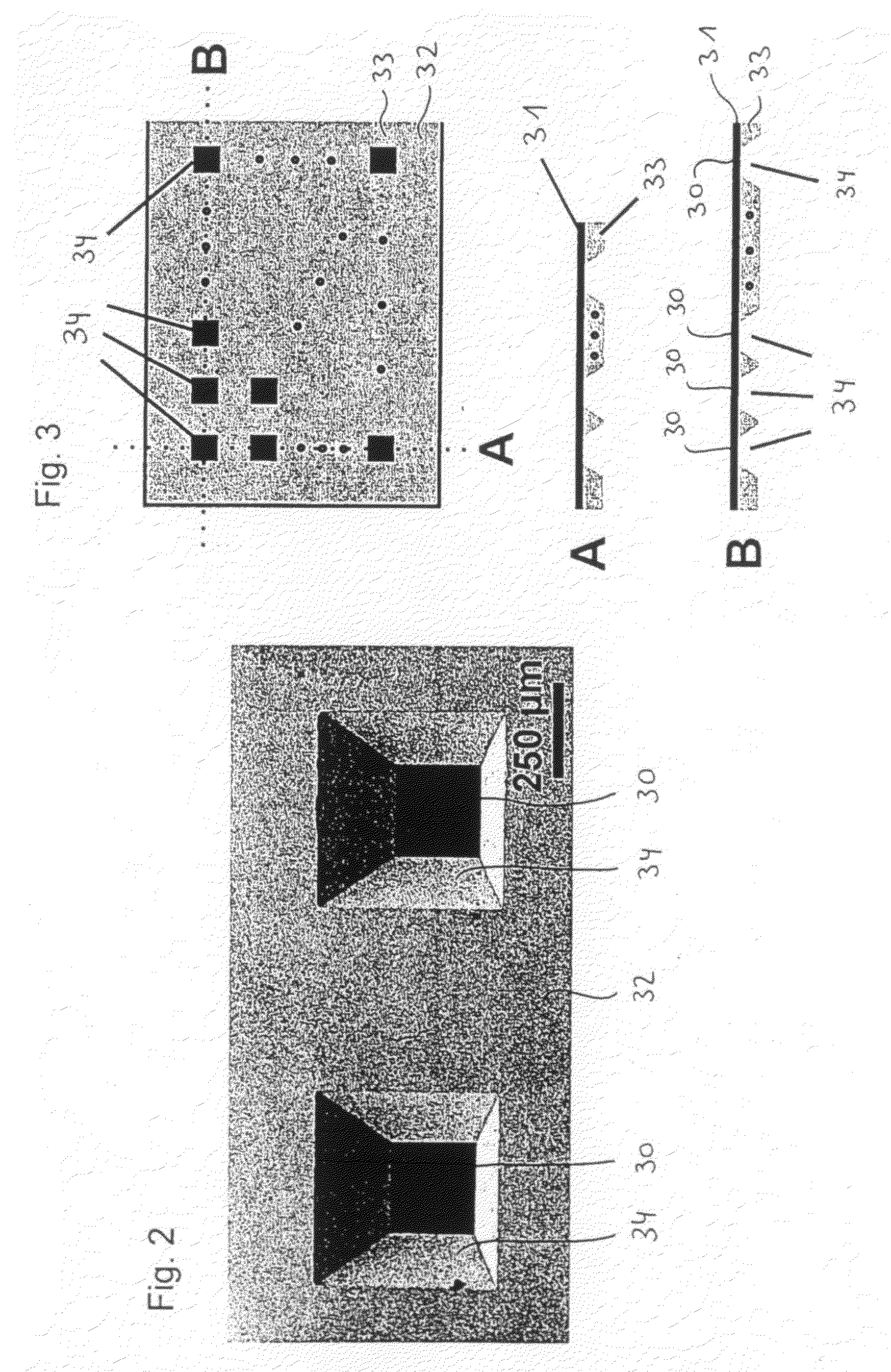

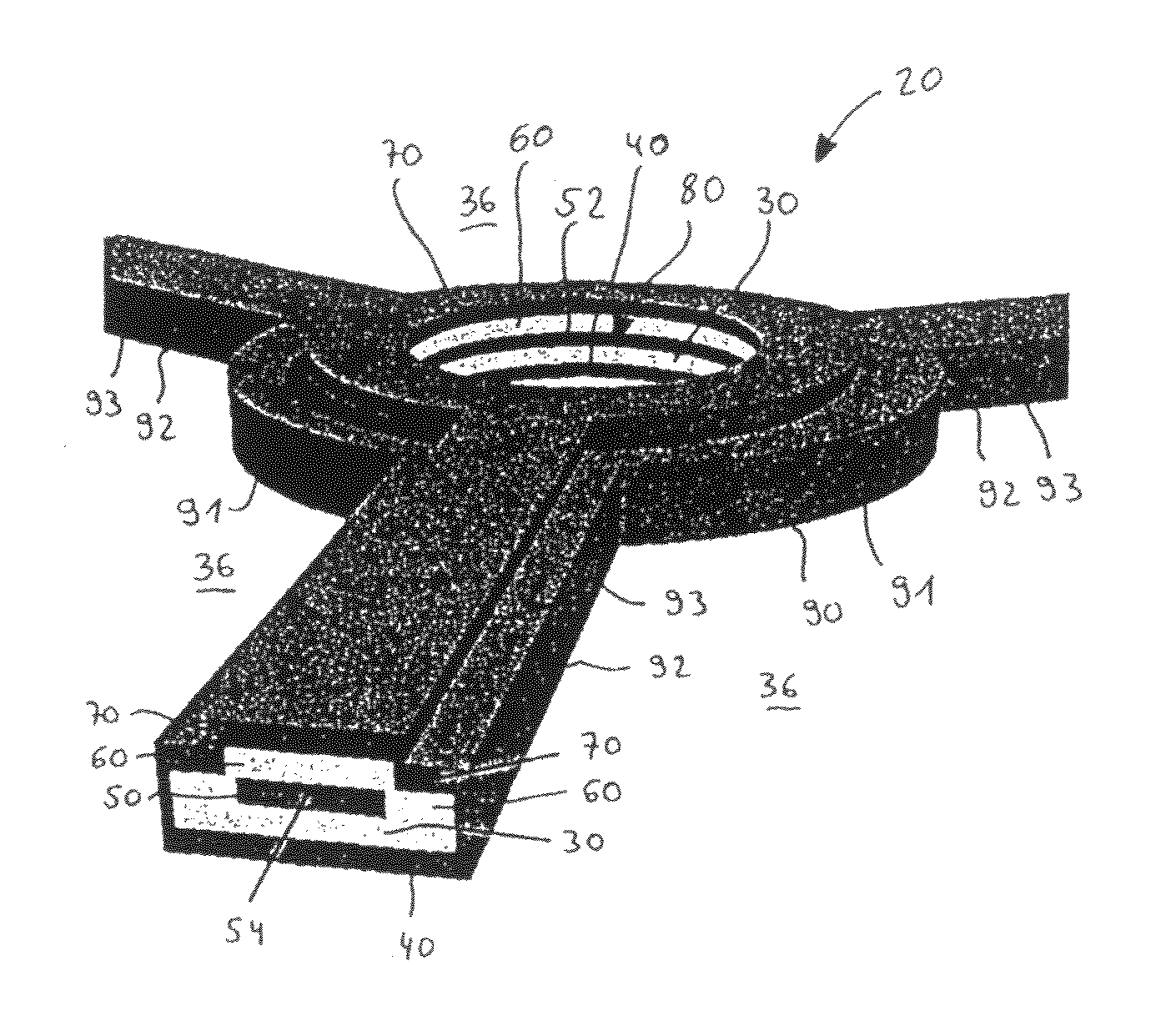

Method For The Production Of Multiplayer Electrostatic Lens Array

InactiveUS20100065741A1Simple and cost-effective methodHigh yieldLine/current collector detailsMaterial analysis using wave/particle radiationElectron microscopeOptoelectronics

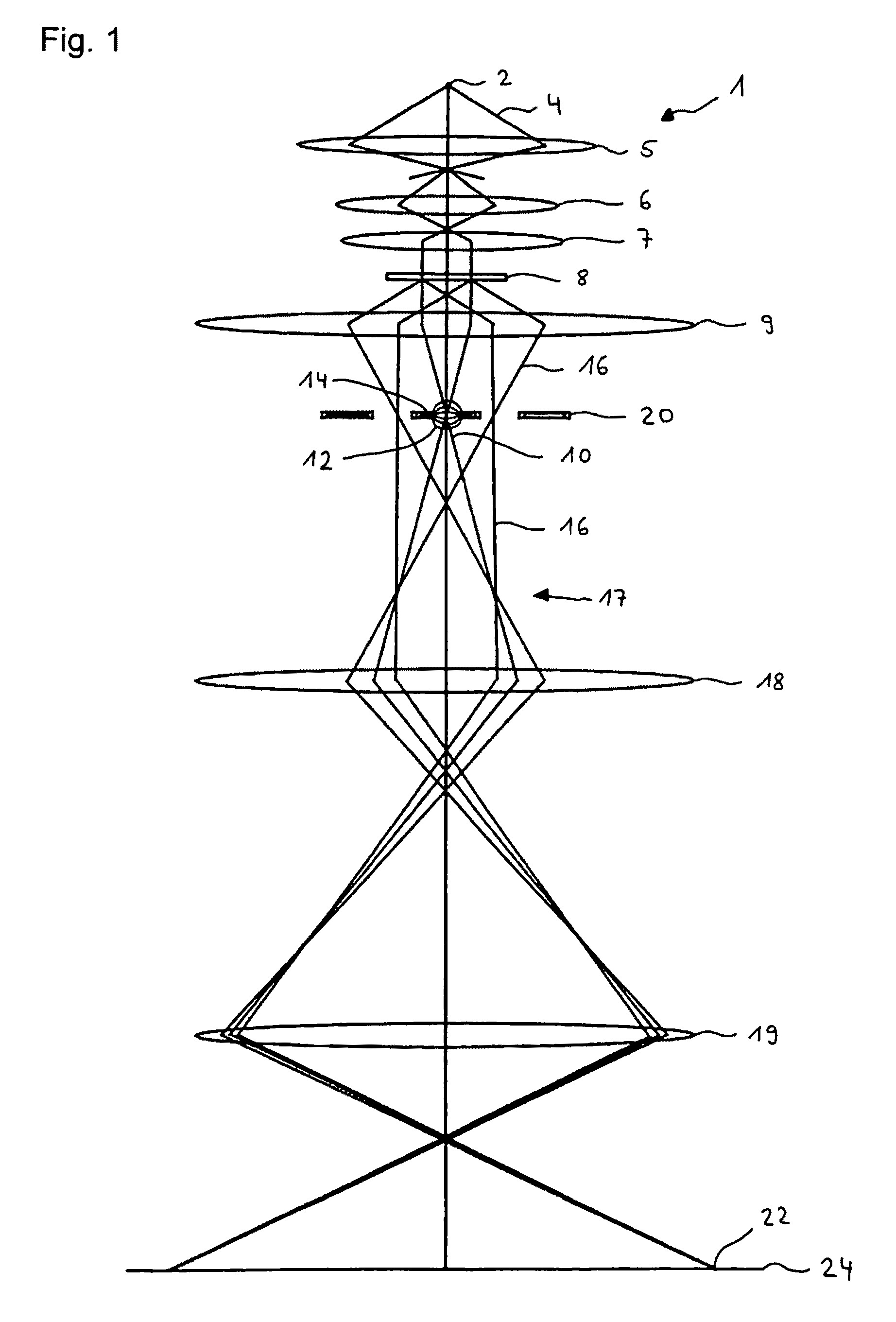

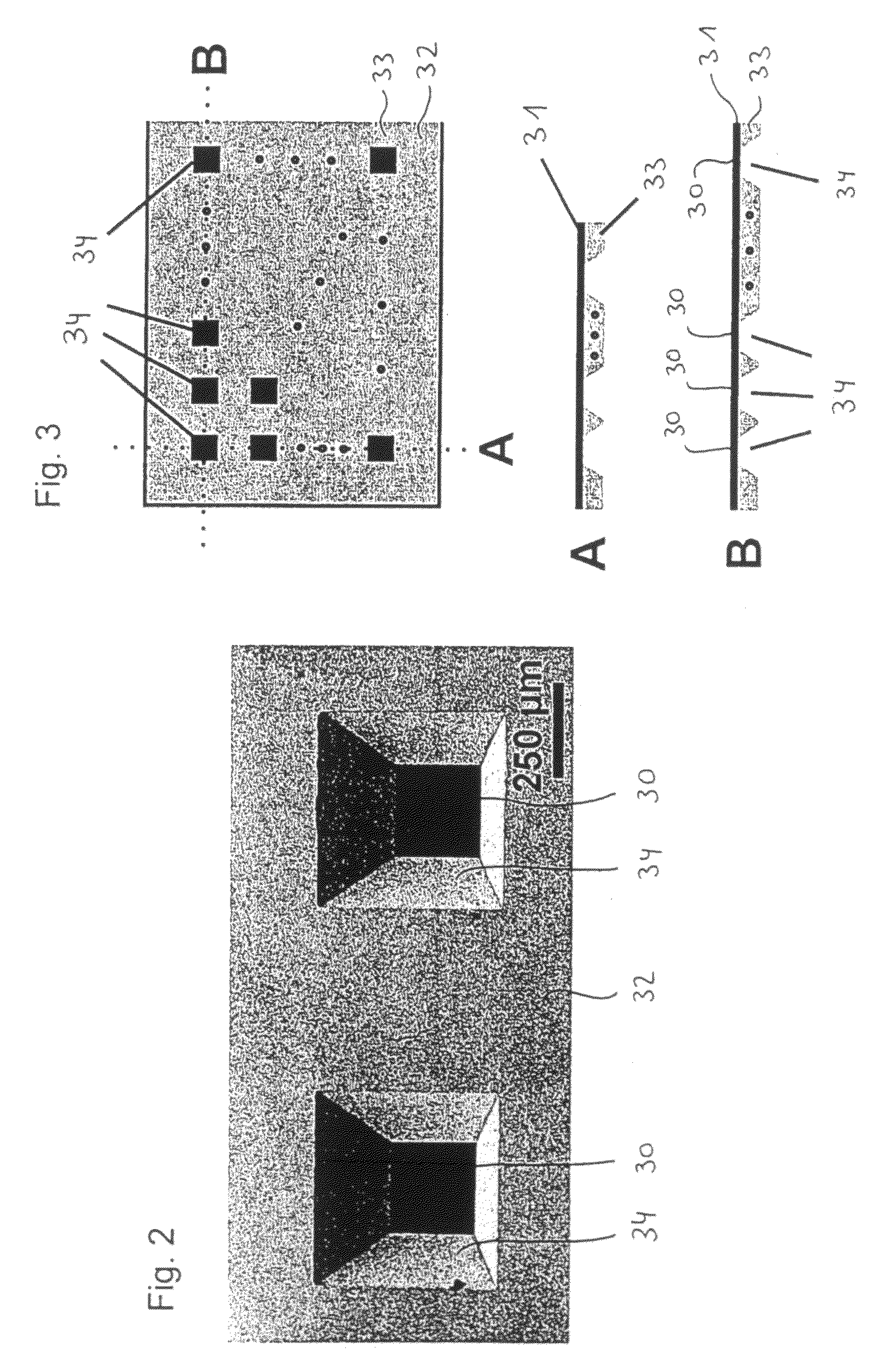

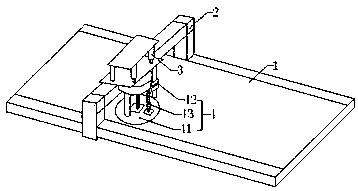

The invention relates to a method for the production of a multilayer electrostatic lens arrangement with at least one lens electrode in general, a method for the production of a phase plate in particular as well as the lens arrangement, the phase plate and a transmission electron microscope with the phase plate.The lens arrangement or the phase plate is produced from a thin self-supporting silicon nitride membrane which is fixed in a macroscopic chip with deposition of further layers. beam.The central bore as well as the aperture opening are milled out by means of an ion

Owner:GERTHSEN DAGMAR +2

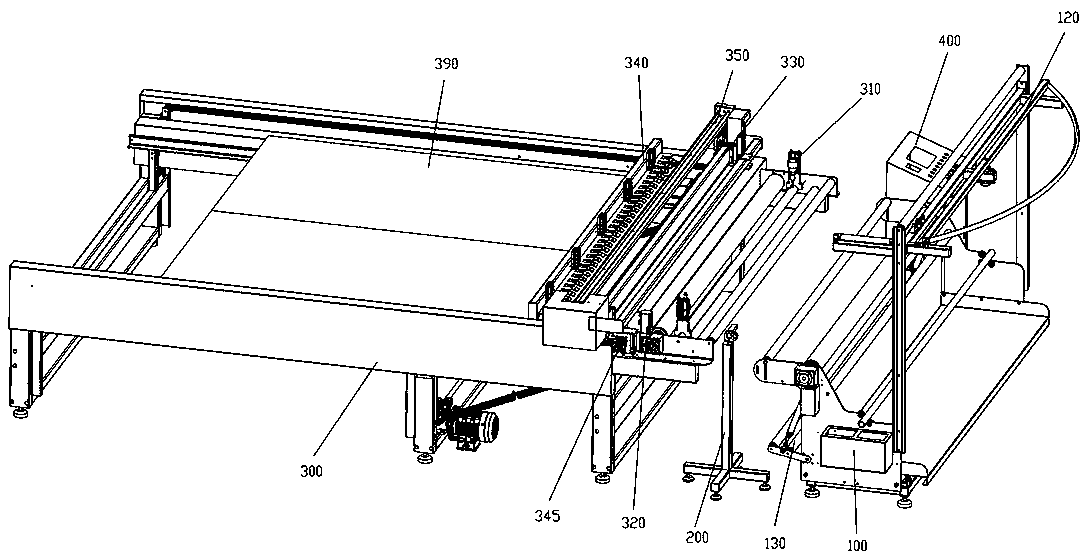

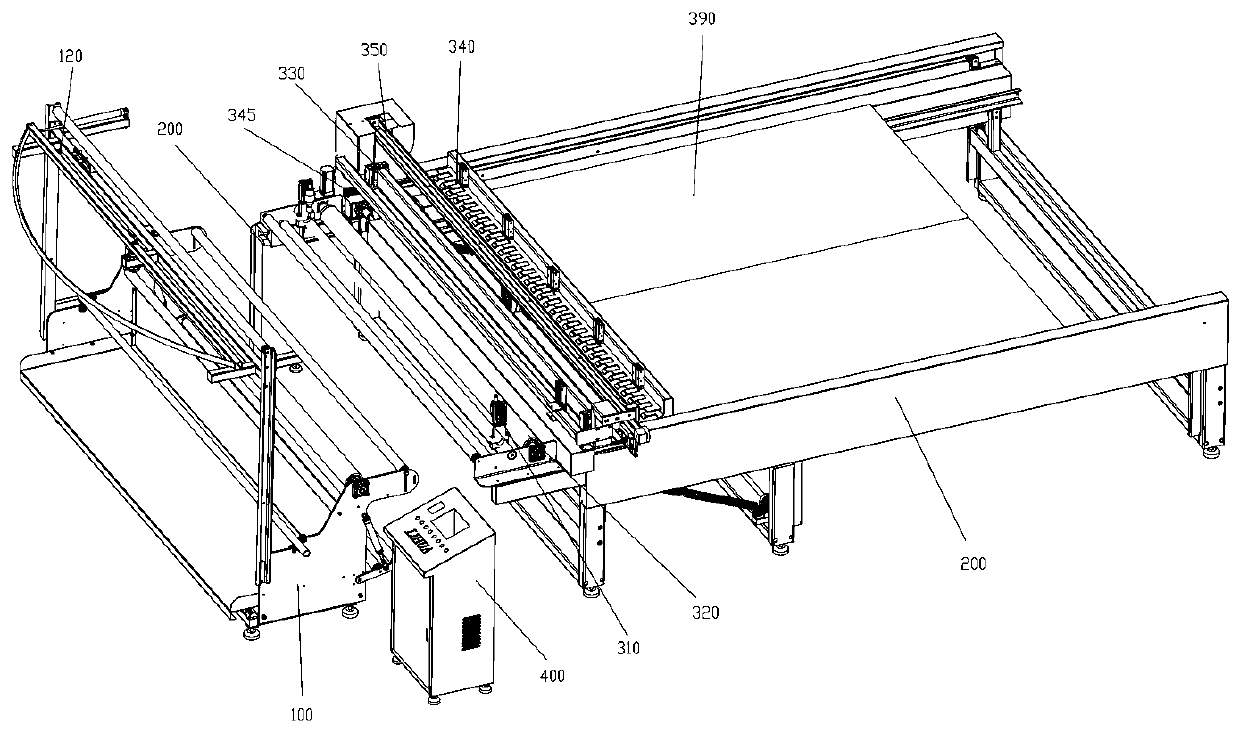

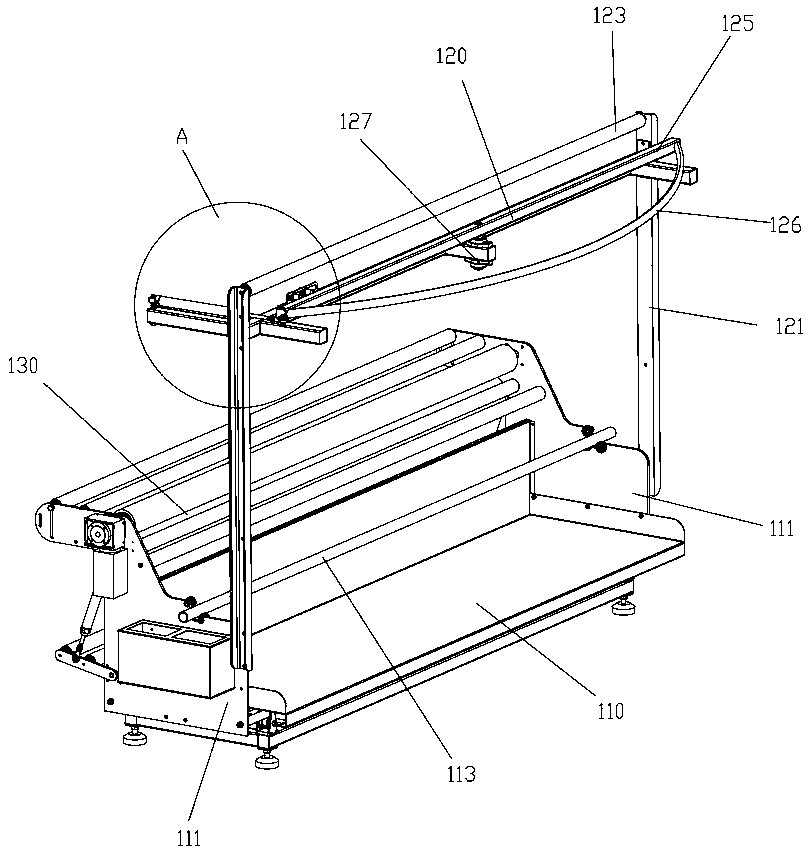

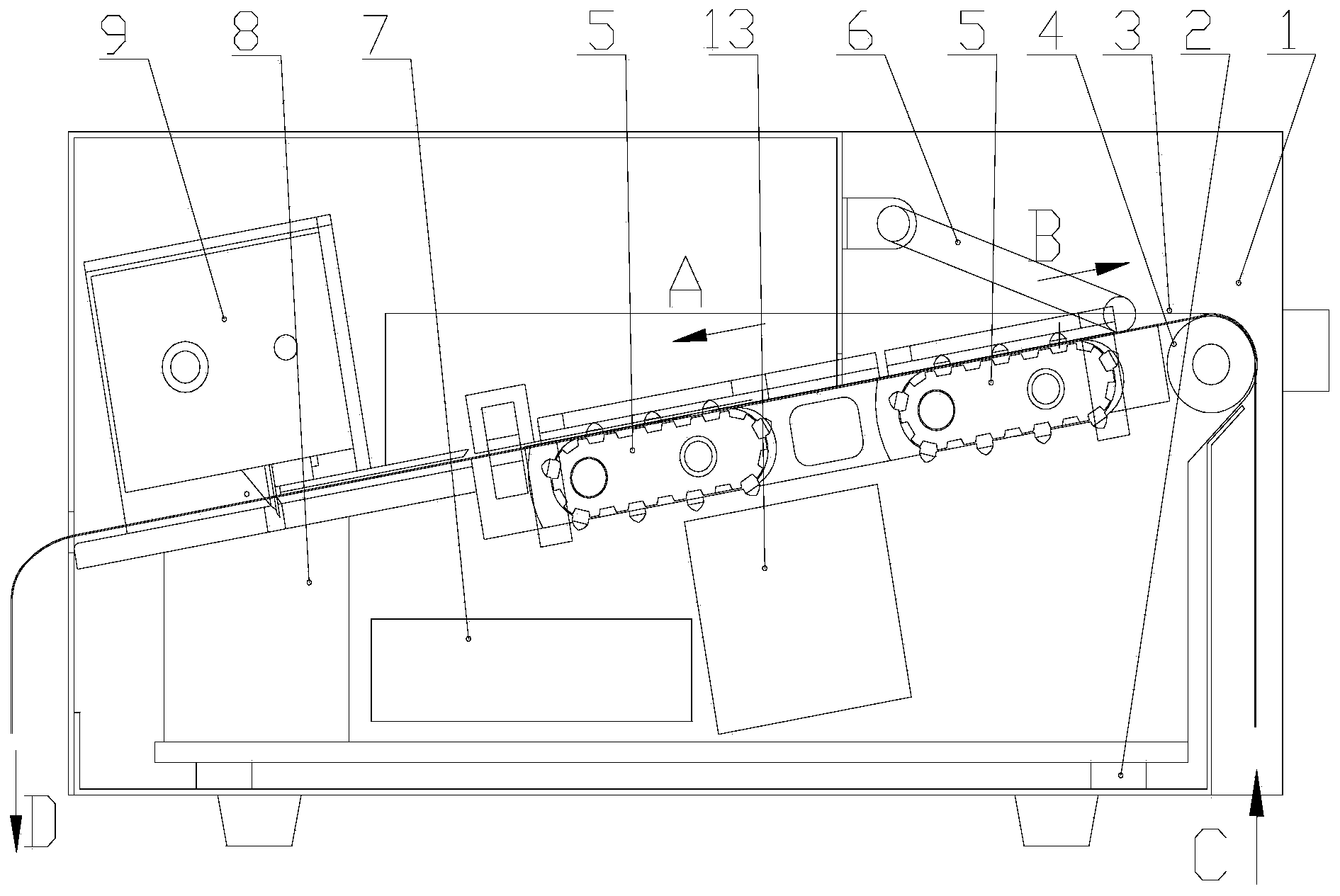

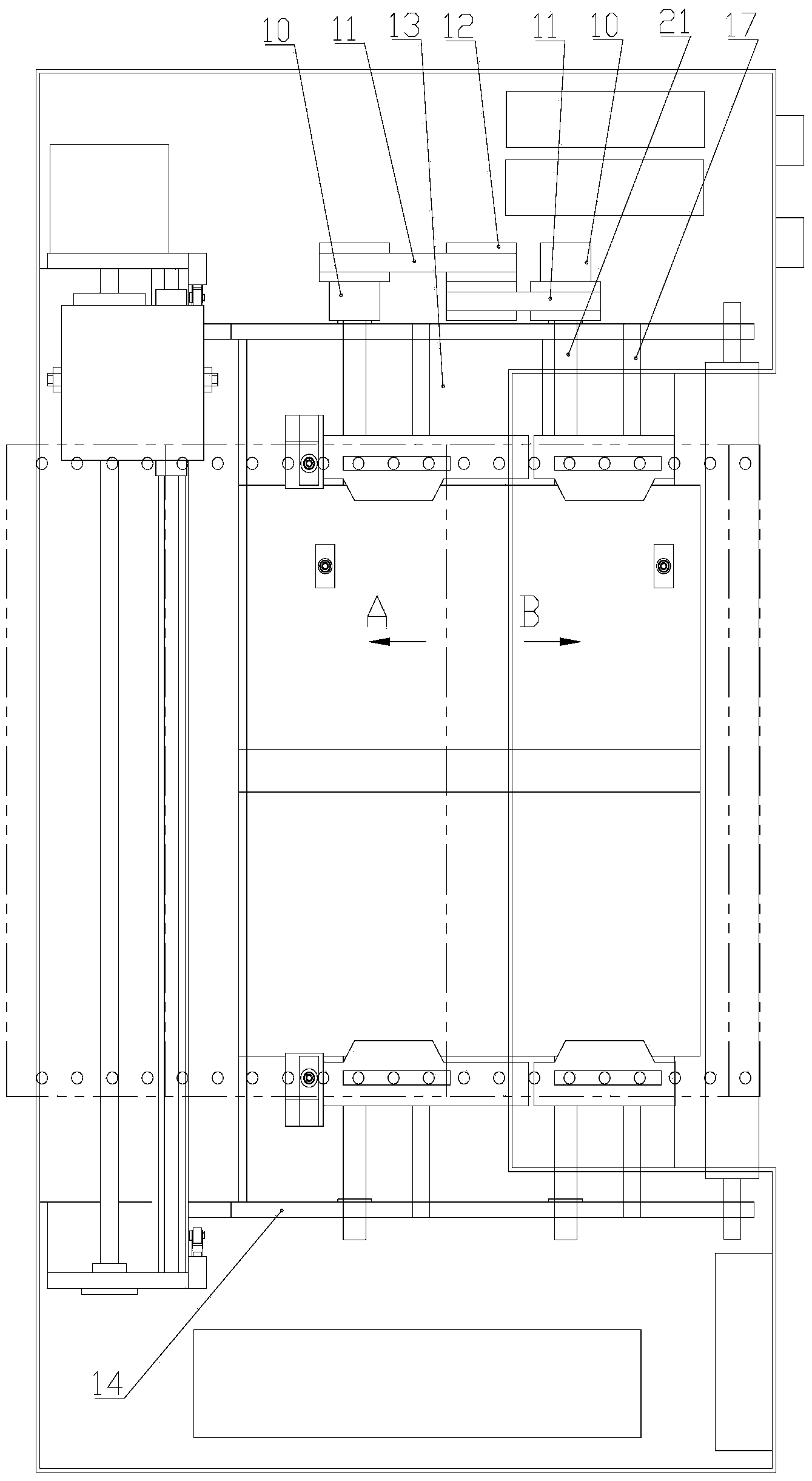

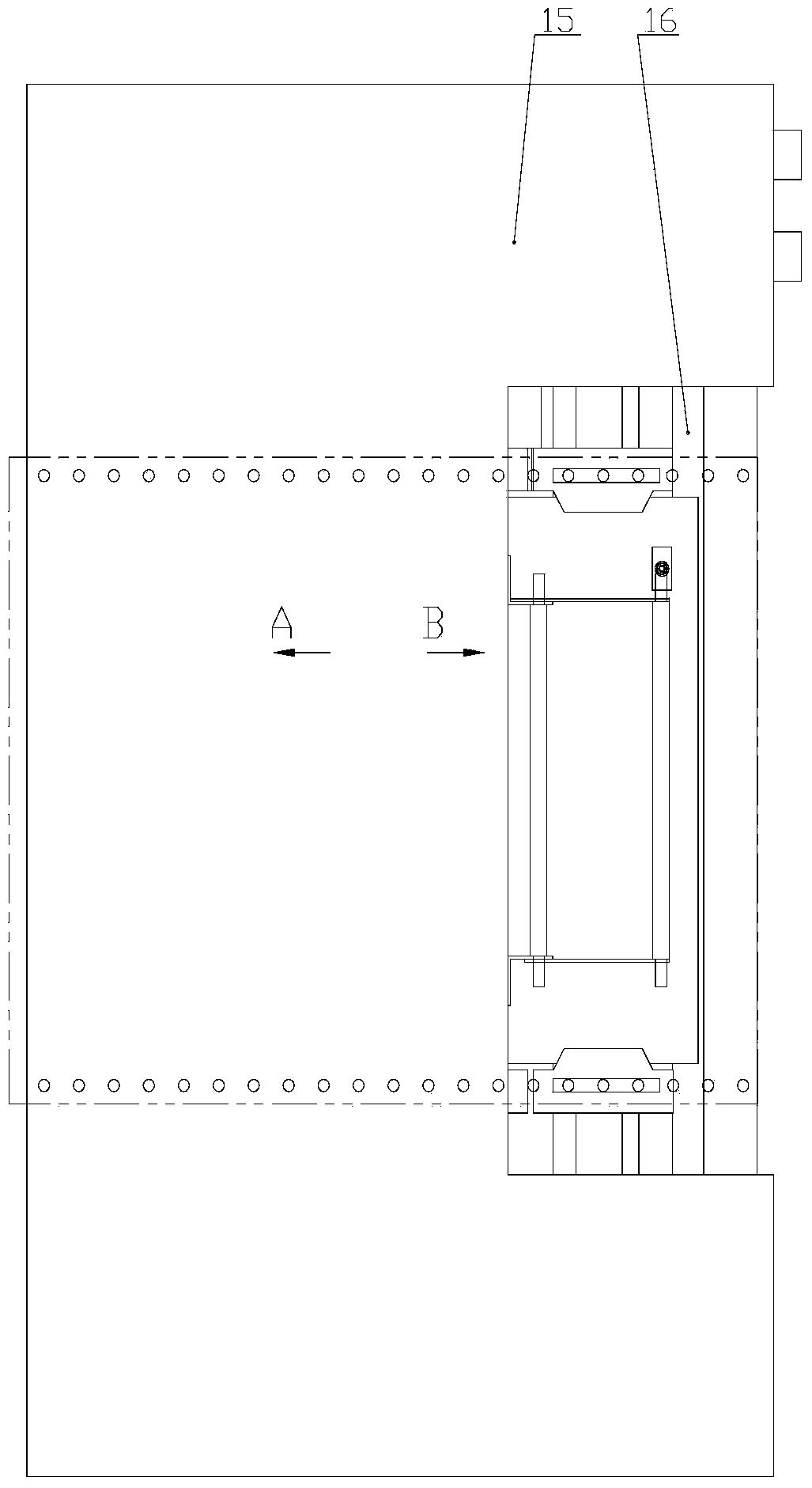

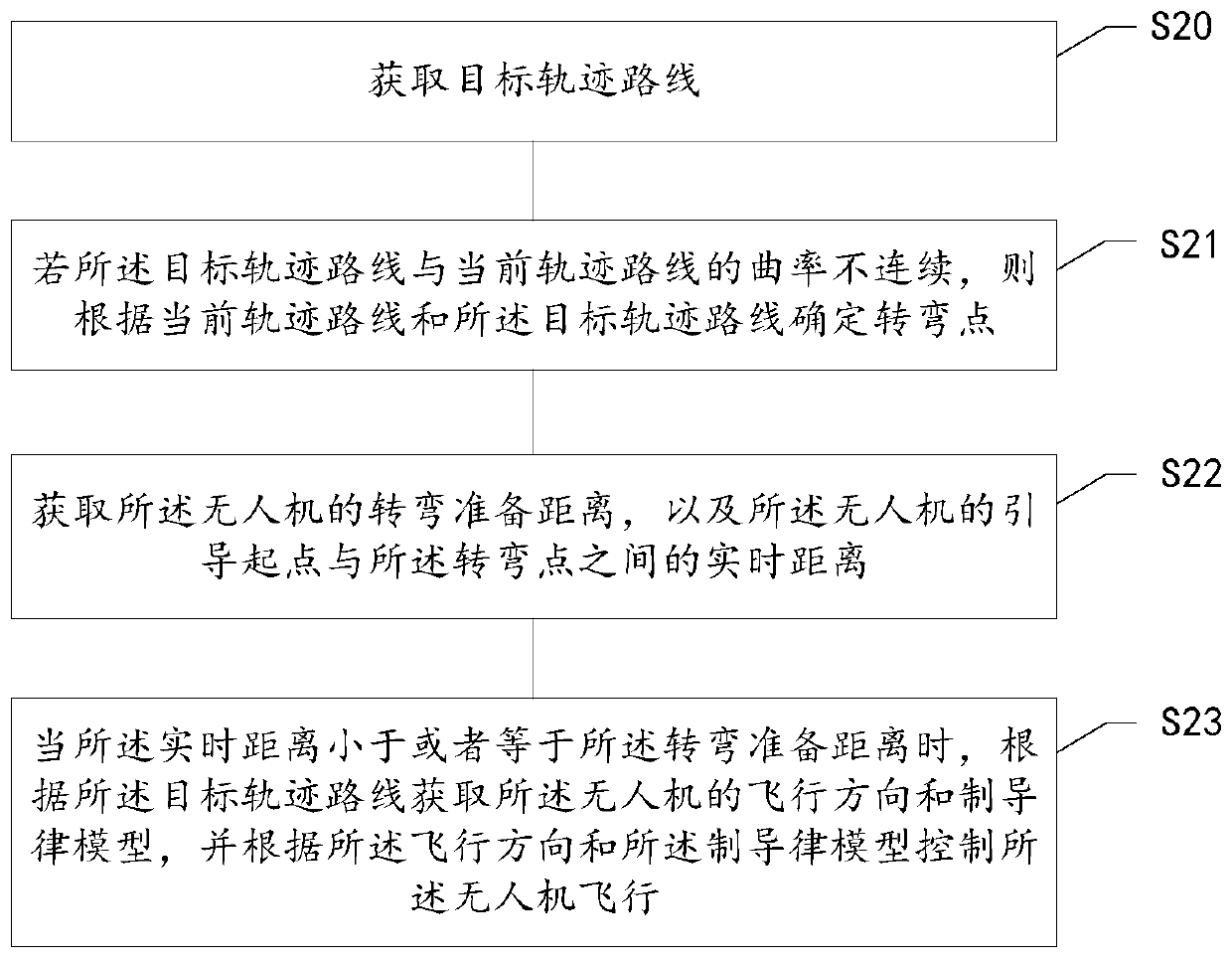

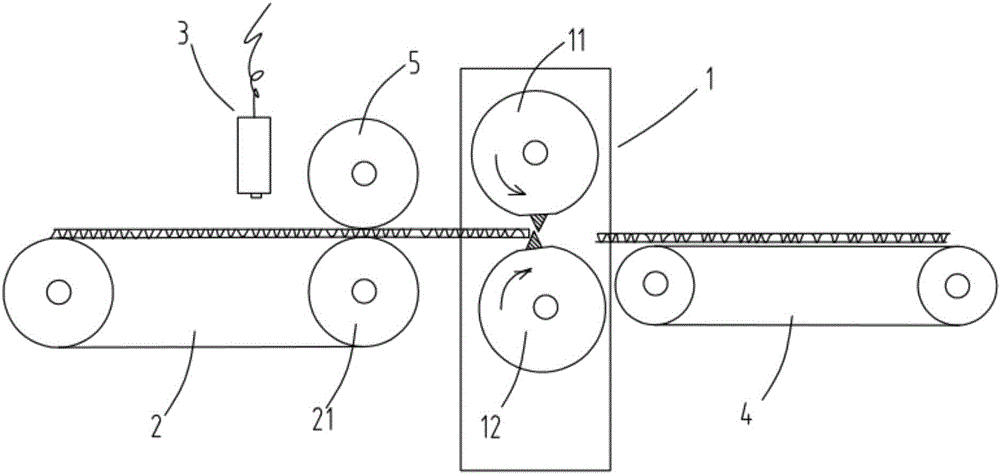

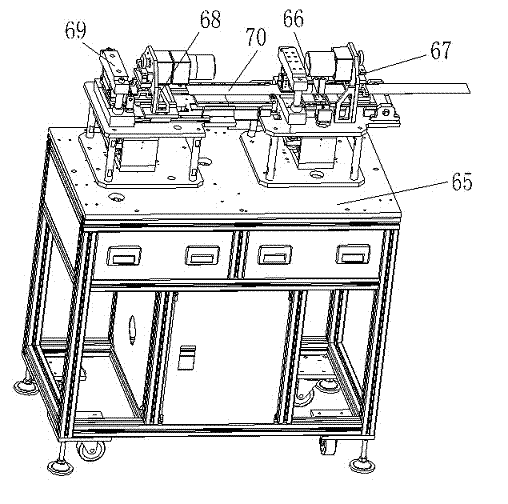

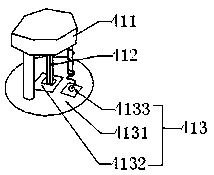

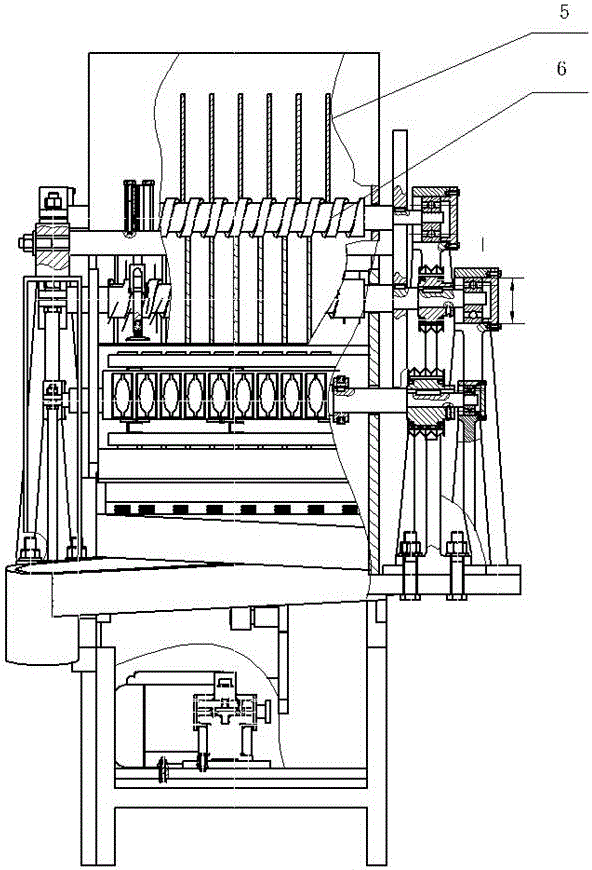

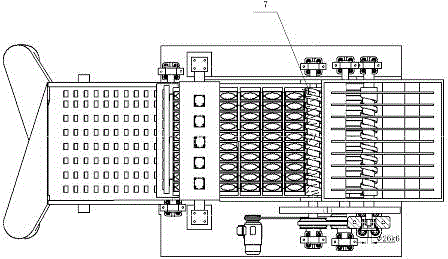

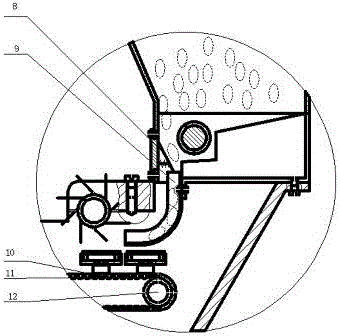

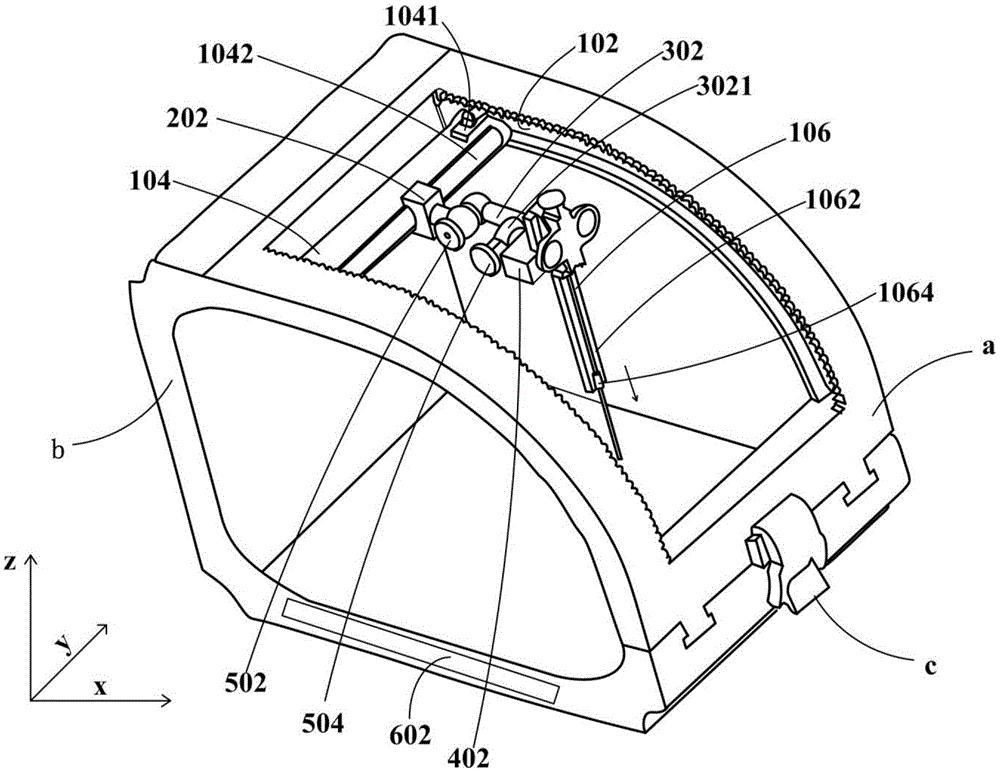

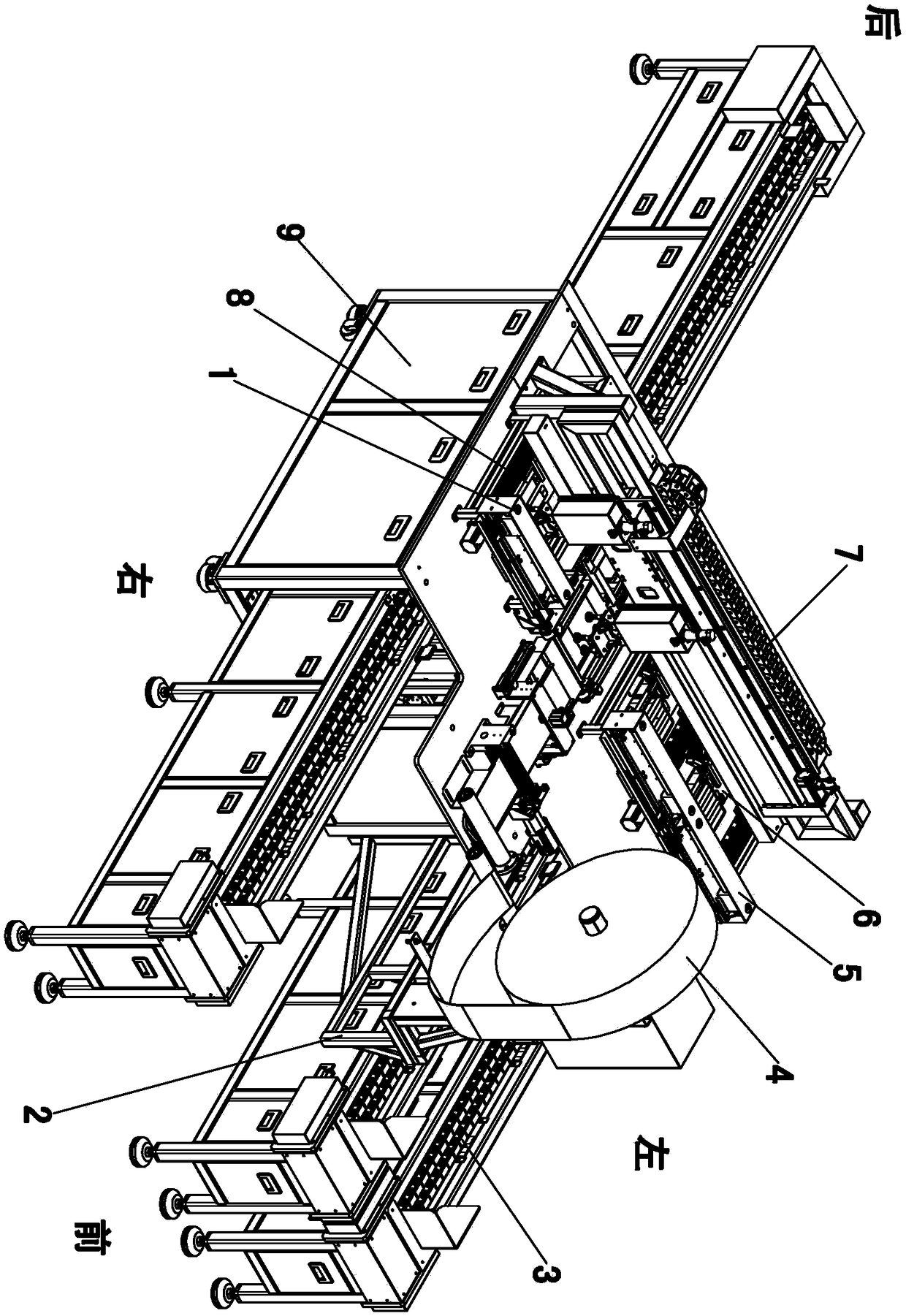

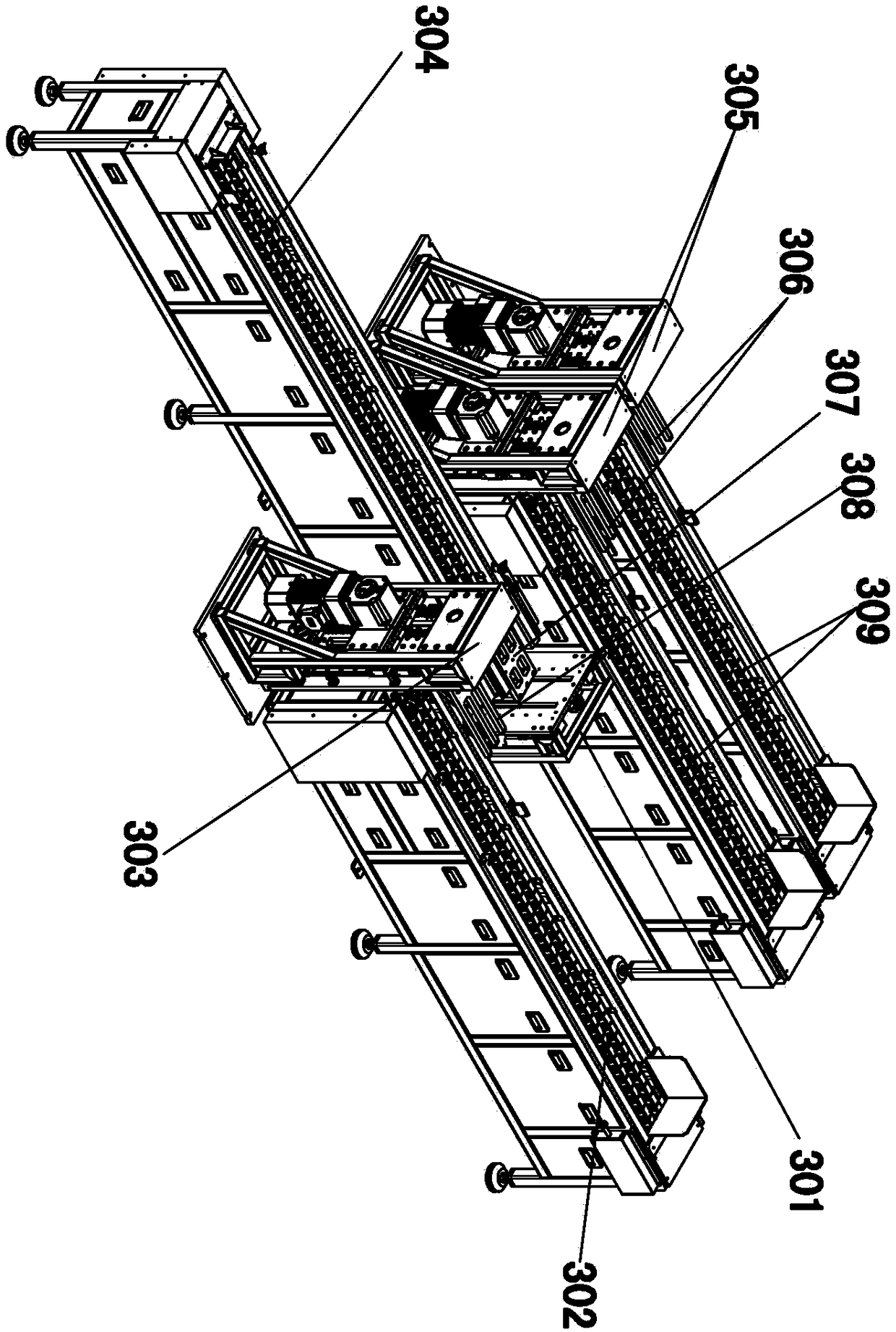

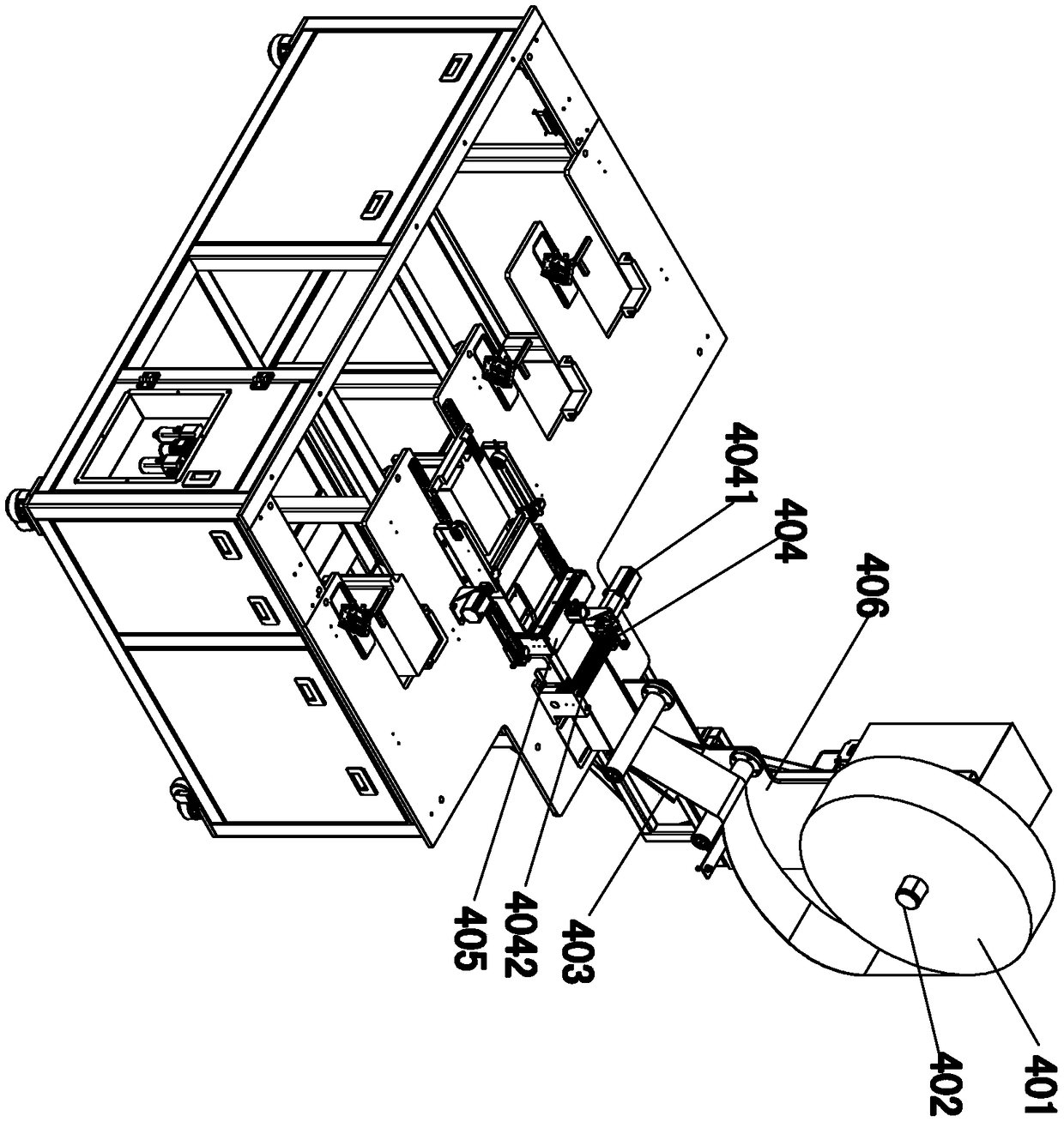

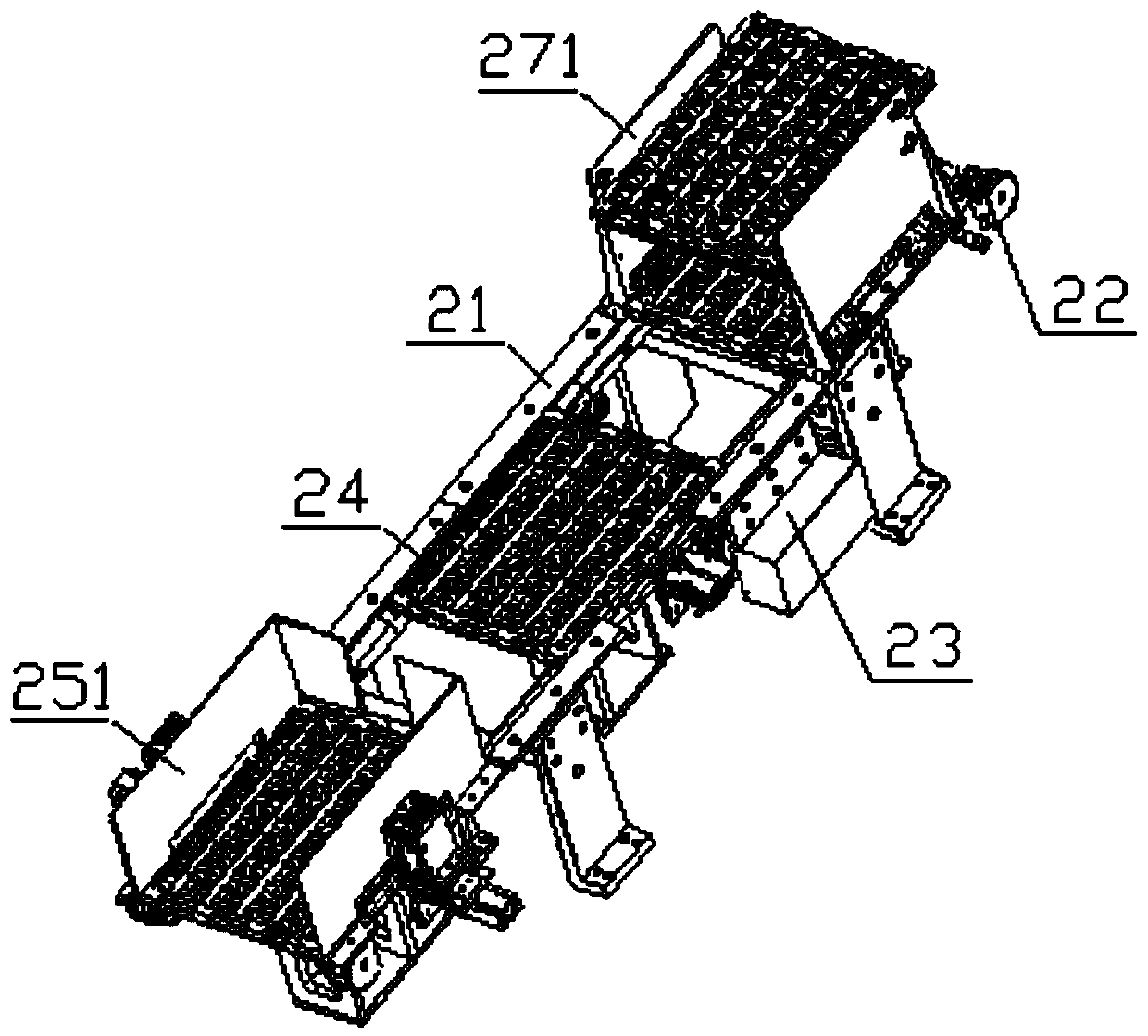

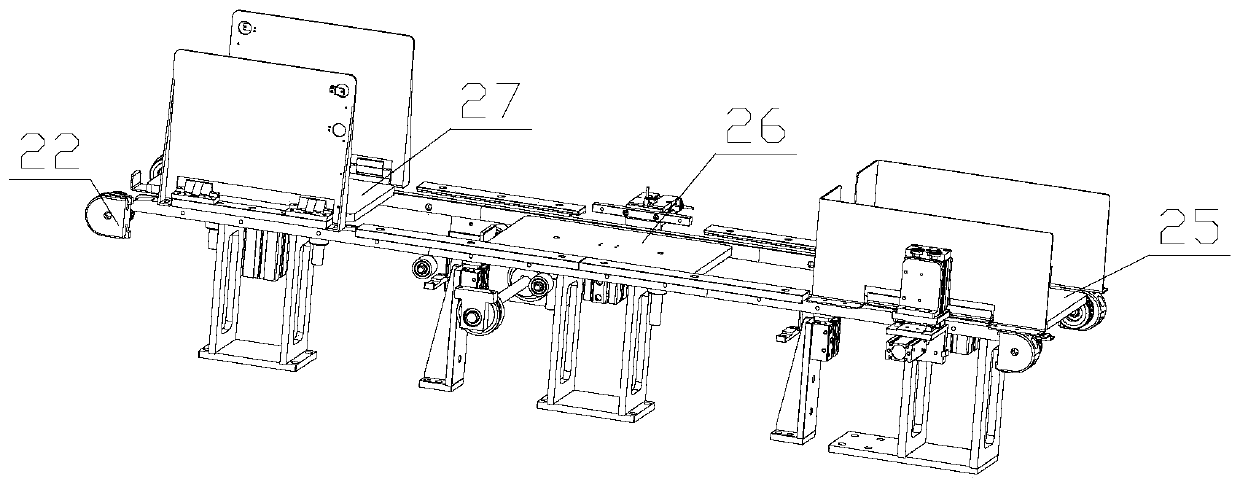

Automatic cloth cutting and discharging equipment and control method thereof

InactiveCN110860935ARealize horizontal deviation correction positioningConsistent cutting tensionSevering textilesMetal working apparatusDistribution controlEngineering

The invention provides automatic cloth cutting and discharging equipment and a control method thereof. The automatic cloth cutting and discharging equipment comprises a feeding platform, a tension adjusting feeding mechanism, an opposite edge deviation rectifying mechanism, a cloth edge cutting mechanism, an automatic cutting and discharging mechanism and a discharging platform which are arrangedin sequence along the advancing direction of cloth; and the equipment further comprises a power distribution control box, wherein the control box realizes control of the whole equipment. The automaticcloth cutting and discharging equipment has the advantages of being reasonable in structural design, quick and accurate in cloth cutting and capable of being applied to various cloth cutting.

Owner:中缝(厦门)自动化科技有限公司

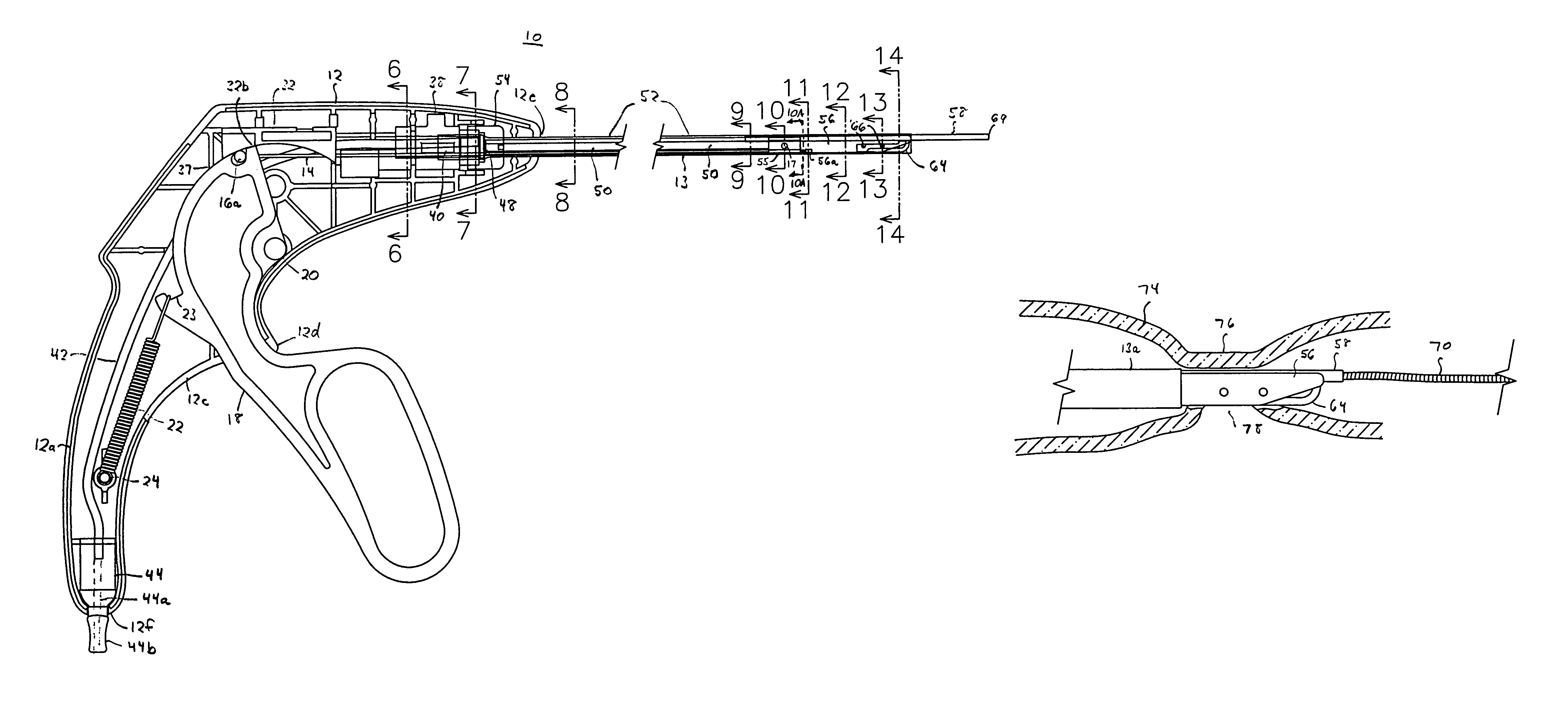

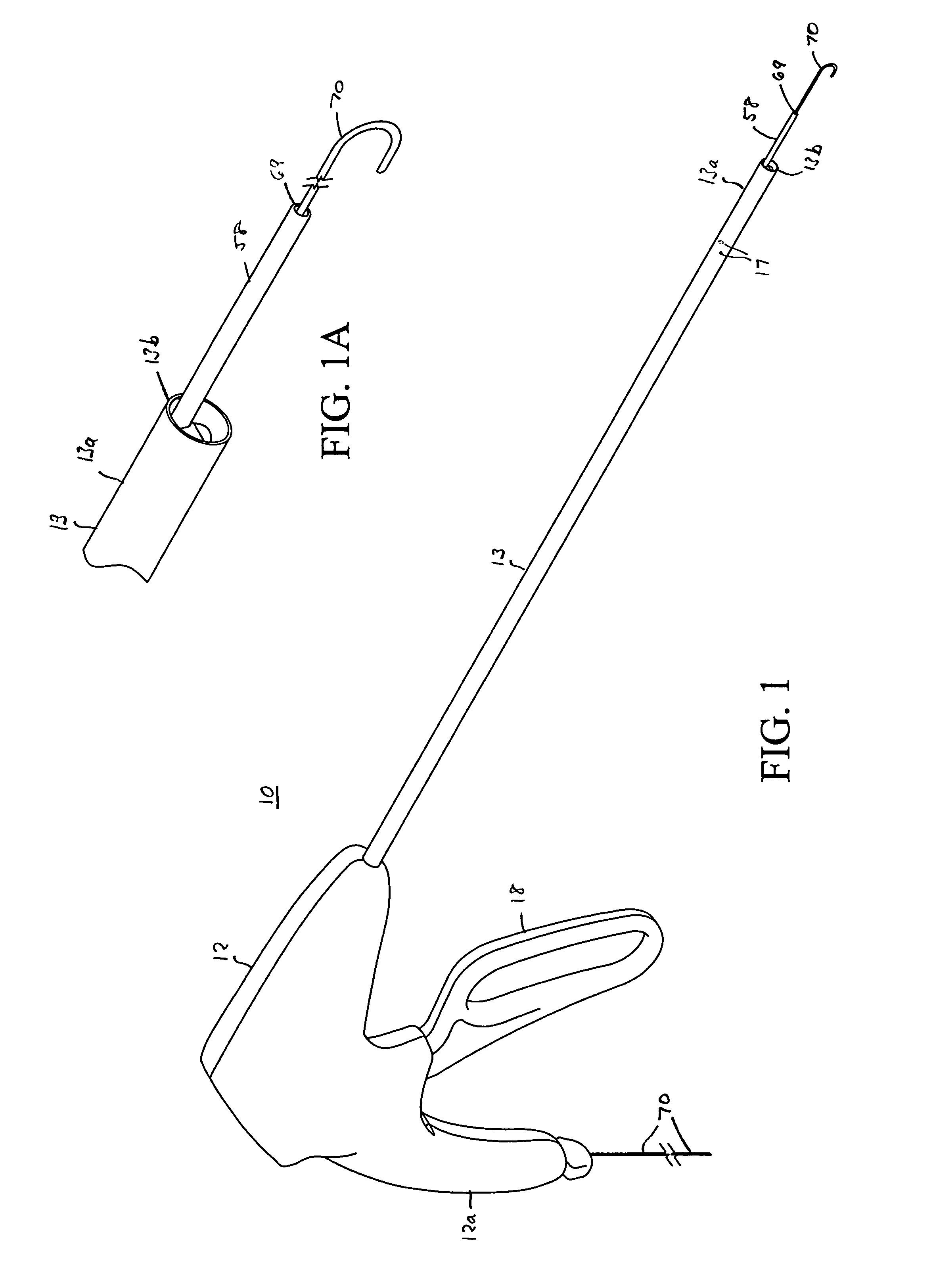

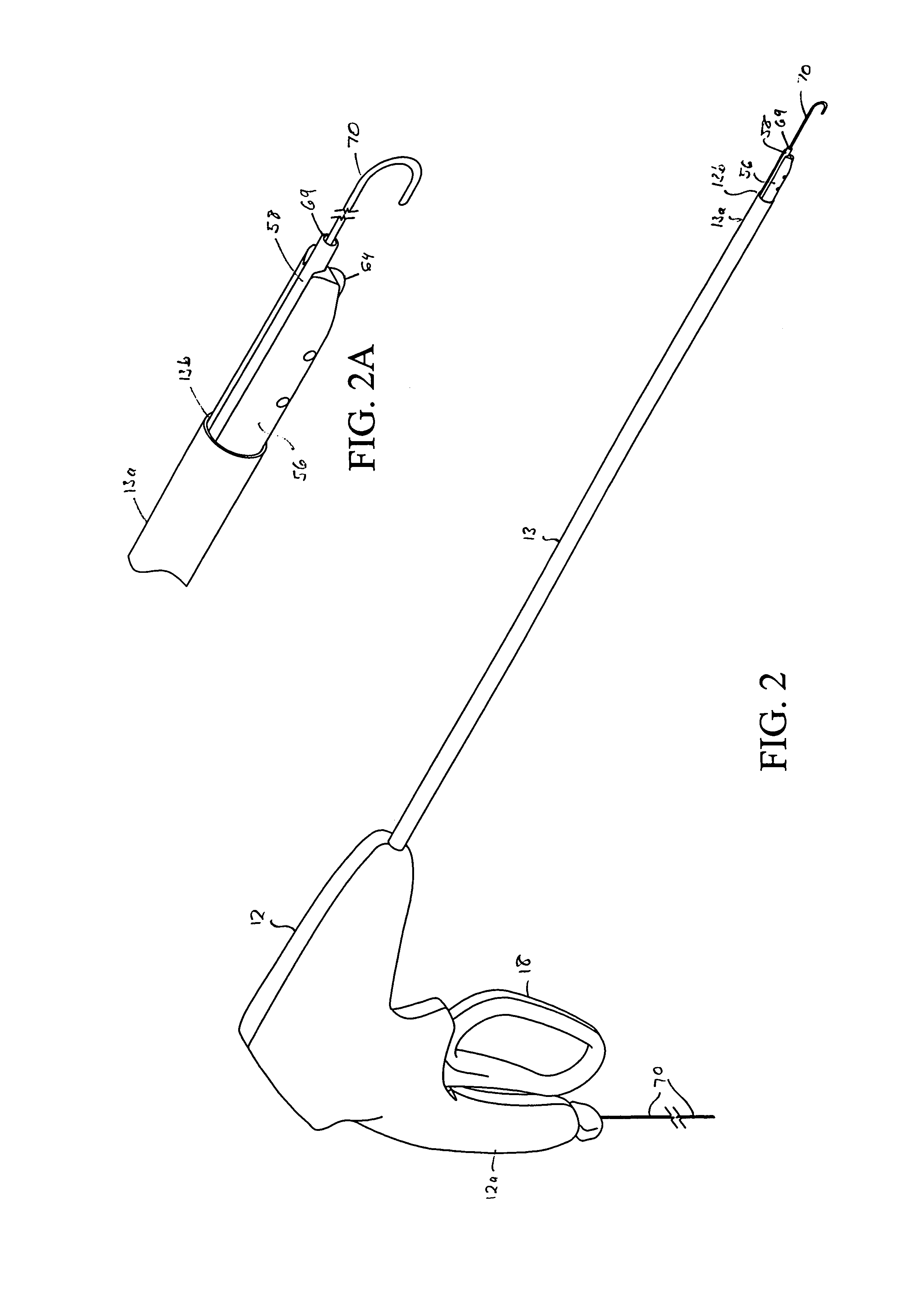

Instrument for guiding the surgical cutting of tissue and method of use

An instrument is provided for cutting tissue having a housing, a shaft extending from the housing to a distal end with an opening, and a guide tube extending from the distal end through the opening for receiving a guide wire through the shaft and housing. A movable blade shuttle having a blade is provided at the distal end. The blade shuttle's travel is guided by the guide tube when the blade shuttle and blade is extended from the distal end opening to cut tissue and retracted back through the distal end opening. The housing has a pivotal actuator member mechanically coupled to the blade shuttle to remotely control movement of the blade shuttle at the instrument's distal end. The instrument may be used for longitudinal cutting of tissue at remote sites in the body of a patient to provide incisions of precise depth and length over a controlled path of a guide wire.

Owner:LSI SOLUTIONS

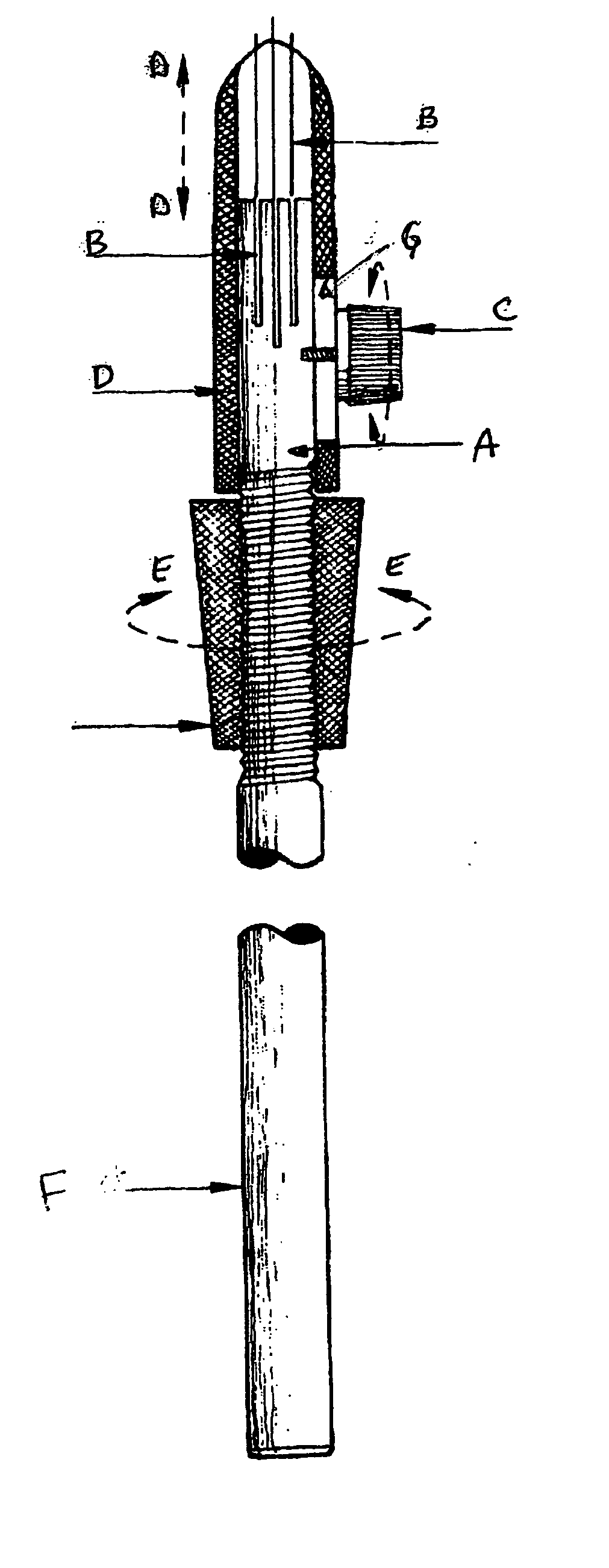

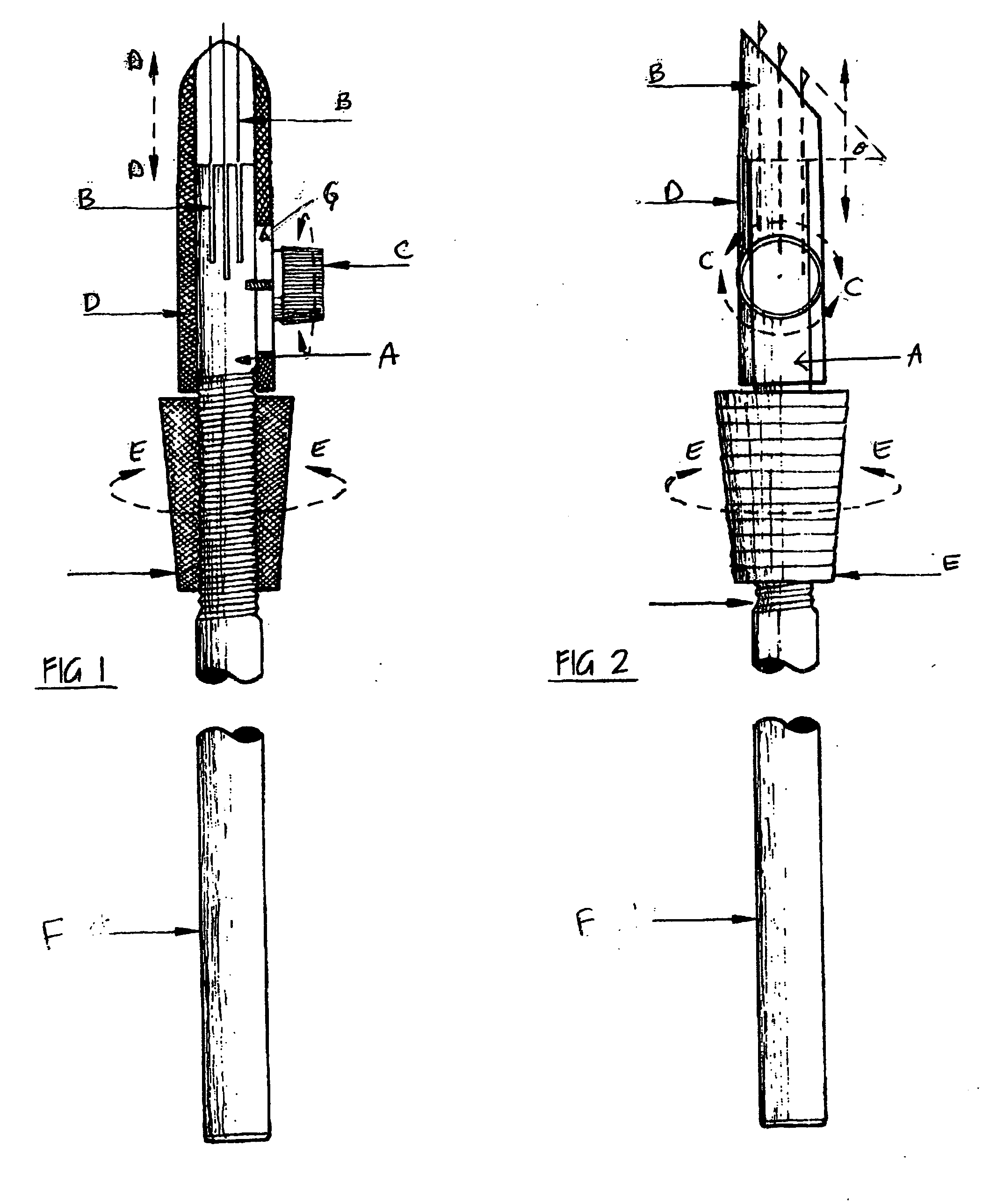

Multi-bladed surgical scalpel

InactiveUS20050049622A1Reduce manufacturing costReduce hand fatigueSkin implantsIncision instrumentsSurgical departmentSmall incision

This multi-bladed scalpel addresses the problem of making many small incisions in very close proximity to each other, to facilitate hair transplantation. With this device, it is possible to make multiple incisions in such proximity. With the blades mounted parallel to each other, at the desired spacing, each incision does not intersect neighboring incisions, so the follicles placed in each incision will be surrounded by the maximum amount of undisturbed tissue to promote revascularization—capillary growth to provide a blood supply to each transplanted follicle. CNC machining techniques are used to create the blade holders with blade mounting sites created at the desired proximity. Medical grade epoxy is used to mount the blades, which are mounted parallel to each other. Blade mounting holes are drilled so the tips of the blade group form a planar array of interdigitated and offset blades at an angle with respect to the handle.

Owner:MITTELSTAEOT MARK KEVIN

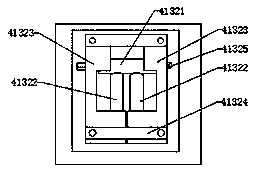

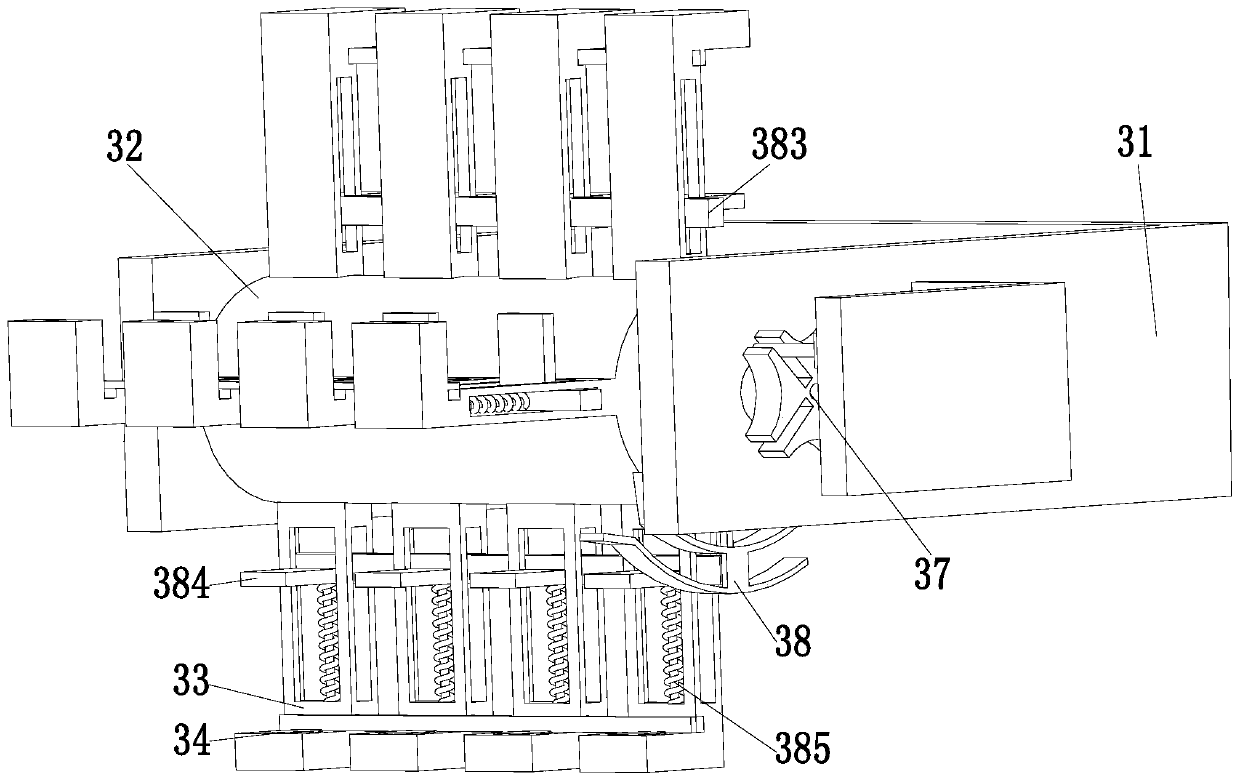

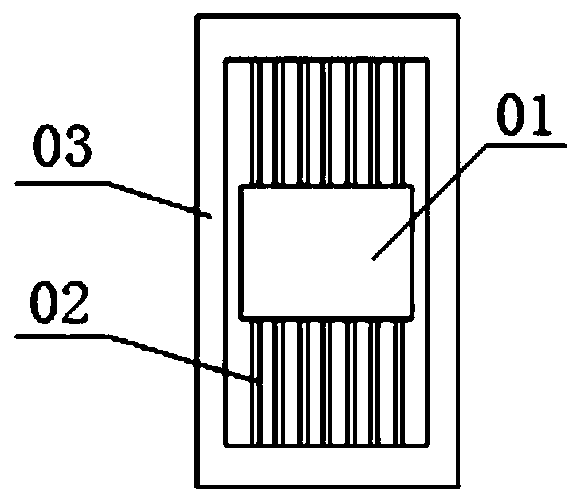

Sheet invoice delivery core for intelligent self-service invoice selling tax terminal

The invention discloses a sheet invoice delivery core for an intelligent self-service invoice selling tax terminal, which comprises a box body, a paper feeding transmission mechanism, paper cutting mechanisms and a paper pressing mechanism, wherein a bottom plate is arranged in the box body, a left side plate and a right side plate are mounted on the bottom plate, and paper support wheels are mounted at the front ends of the left side plate and right side plate; a support shaft and a transmission shaft of the paper feeding transmission mechanism are mounted between the left side plate and the right side plate; the paper cutting mechanisms are mounted at the rear ends of the left side plate and right side plate, a drive motor is mounted below the left side plate, and an output shaft end of the drive motor is connected with a duplex synchronous belt wheel; a support block and a control plate are also mounted on the bottom plate, one end of the support block is connected with the bottom plate, and the other end of the support block is connected with the paper cutting mechanism; the paper pressing mechanism is mounted at the outer part of the box body. The sheet invoice delivery core disclosed by the invention has the advantages of flat delivered invoices, accurate counting of invoice sheets, flat cut and no invoice damage.

Owner:GUANGZHOU MECHANICAL & ELECTRICAL TECH RES INST +1

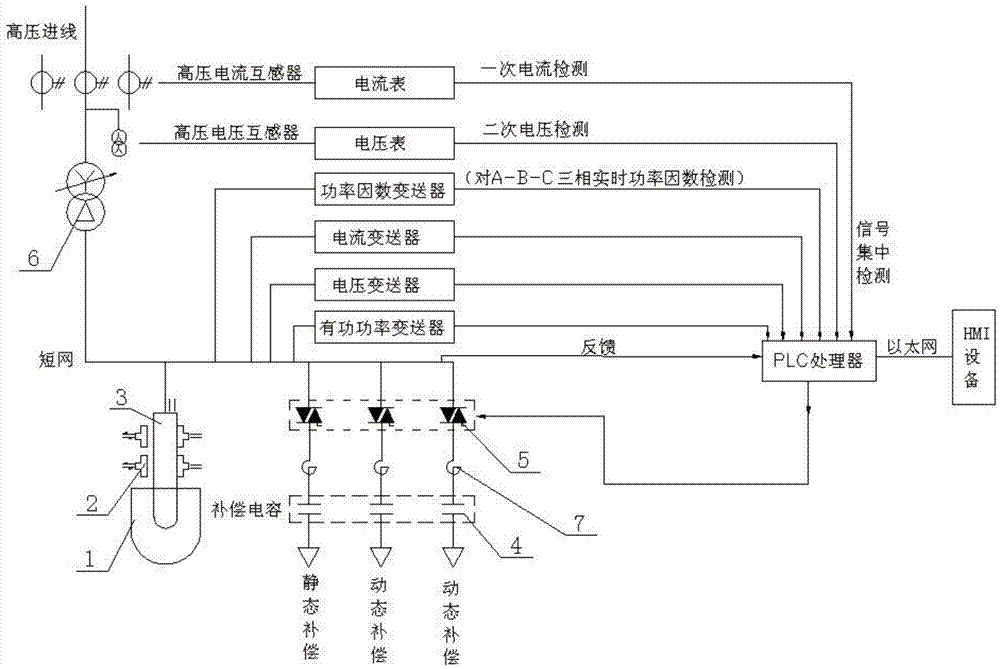

Submerged arc furnace reactive power compensation system and method with static state and dynamic state combined

InactiveCN103618318AAccurate detectionControl switchingReactive power adjustment/elimination/compensationReactive power compensationPower factorEngineering

The invention provides a submerged arc furnace reactive power compensation system and method with the static state and the dynamic state combined. The reactive power compensation system comprises a PLC processor, a high-voltage current transformer, a high-voltage voltage transformer, a transformer, a power coefficient transmitter, a current transmitter, a voltage transmitter, an active power transmitter, static state compensation branch circuits and dynamic state compensation branch circuit. Each compensation branch circuit is formed by connecting a silicon-controlled switching switch and a compensation capacitor in series. The output end of the power coefficient transmitter, the output end of the current transmitter, the output end of the voltage transmitter and the output end of the active power transmitter are electrically connected with an input port of the PLC processor, an output port of the PLC processor is electrically connected with the input end of the silicon-controlled switching switch and feedback signals of the silicon-controlled switching switch are all output to the PLC processor. By means of the method, the compensation system can efficiently and accurately control switching of the compensation branch circuits and the purposes that the power coefficient is balanced, strong phase overcompensation or weak phase undercompensation is avoided and the utilization rate of active loads is improved are achieved.

Owner:四川伟力得能源股份有限公司

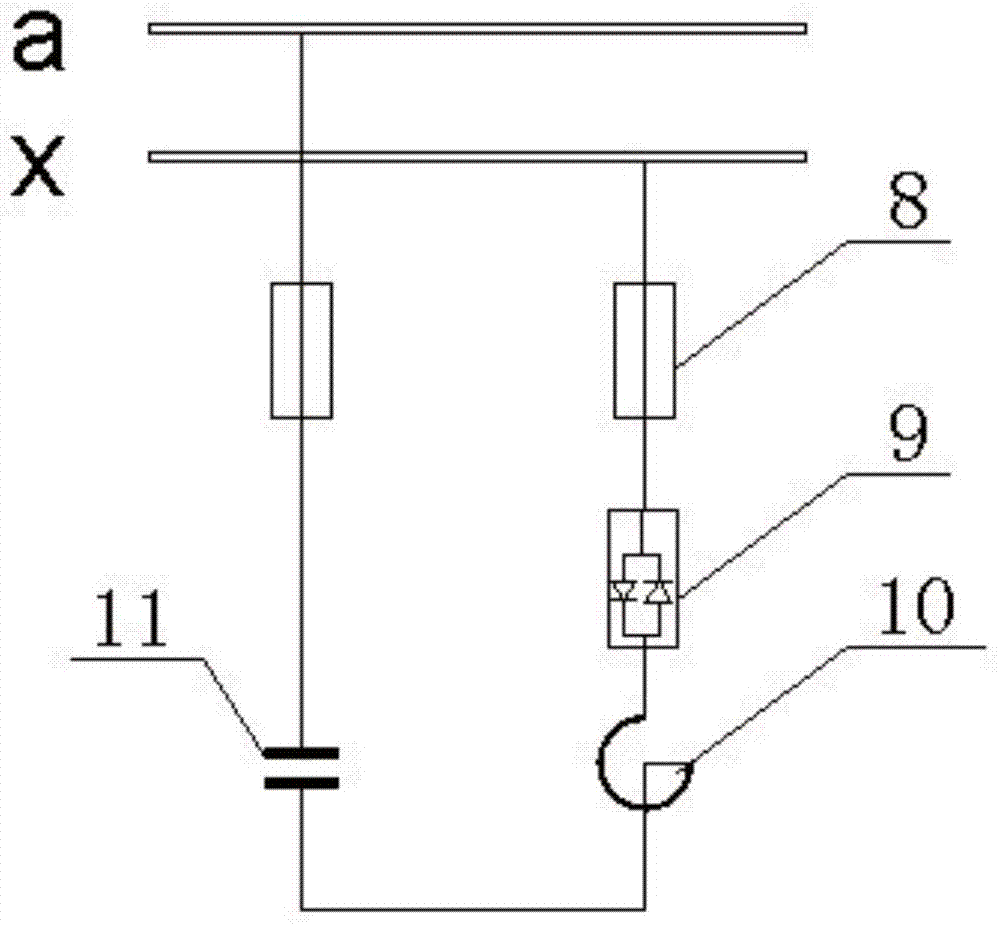

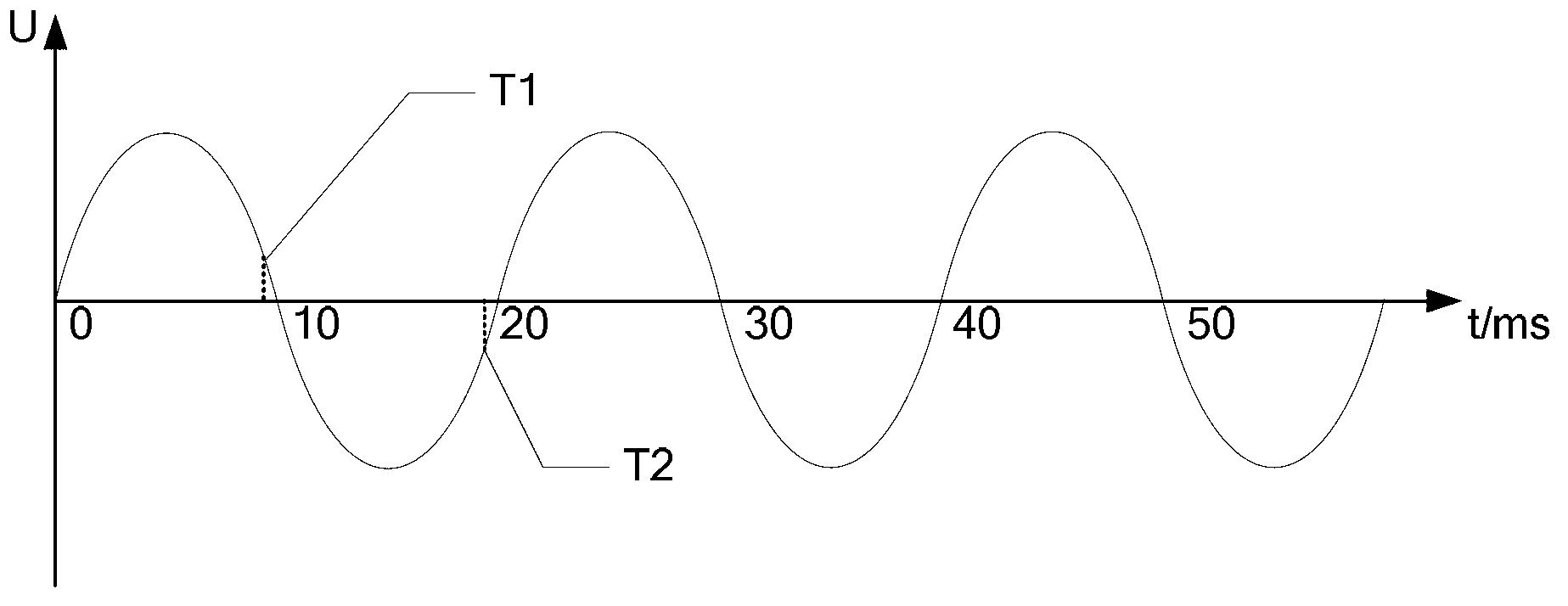

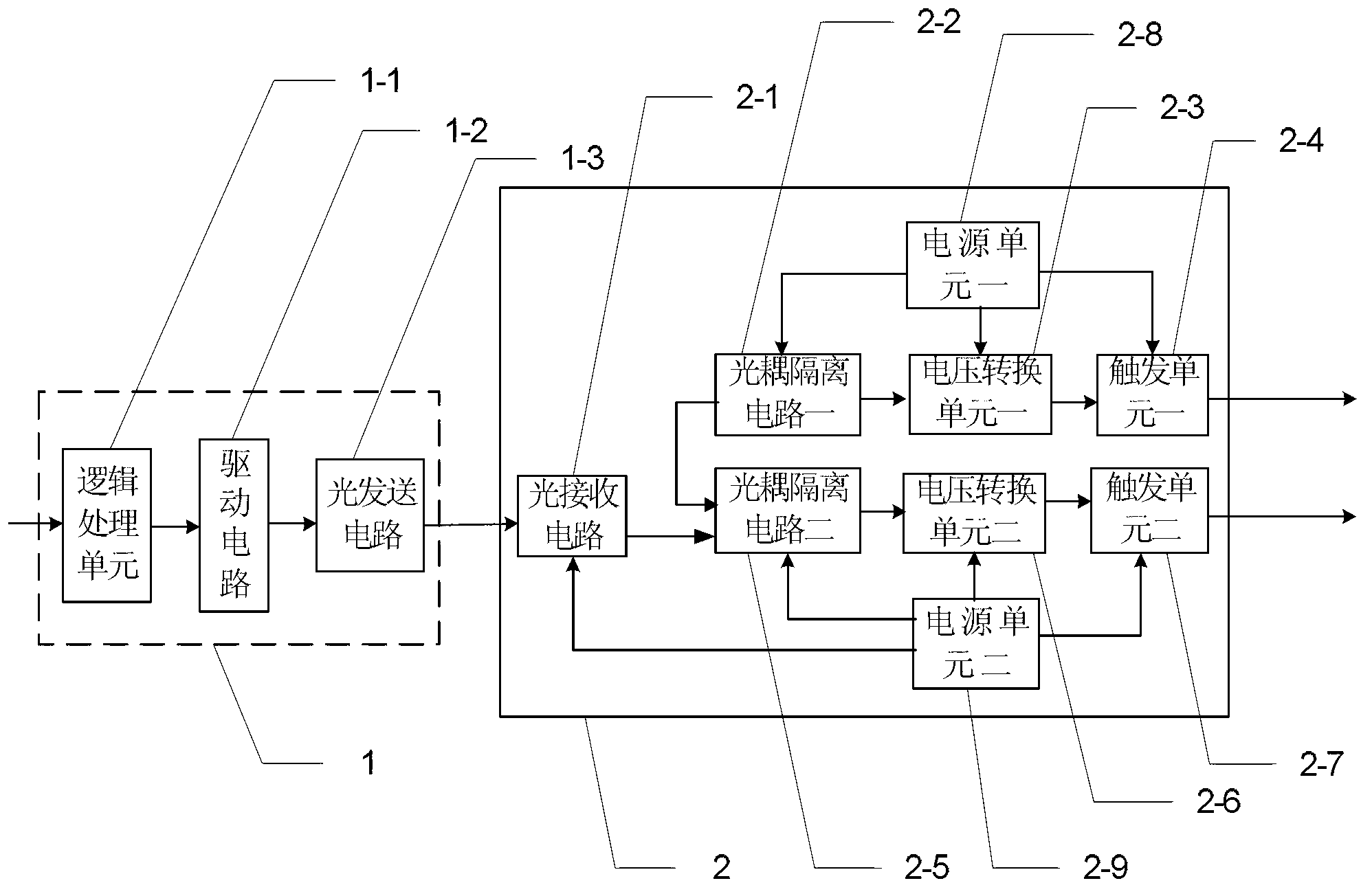

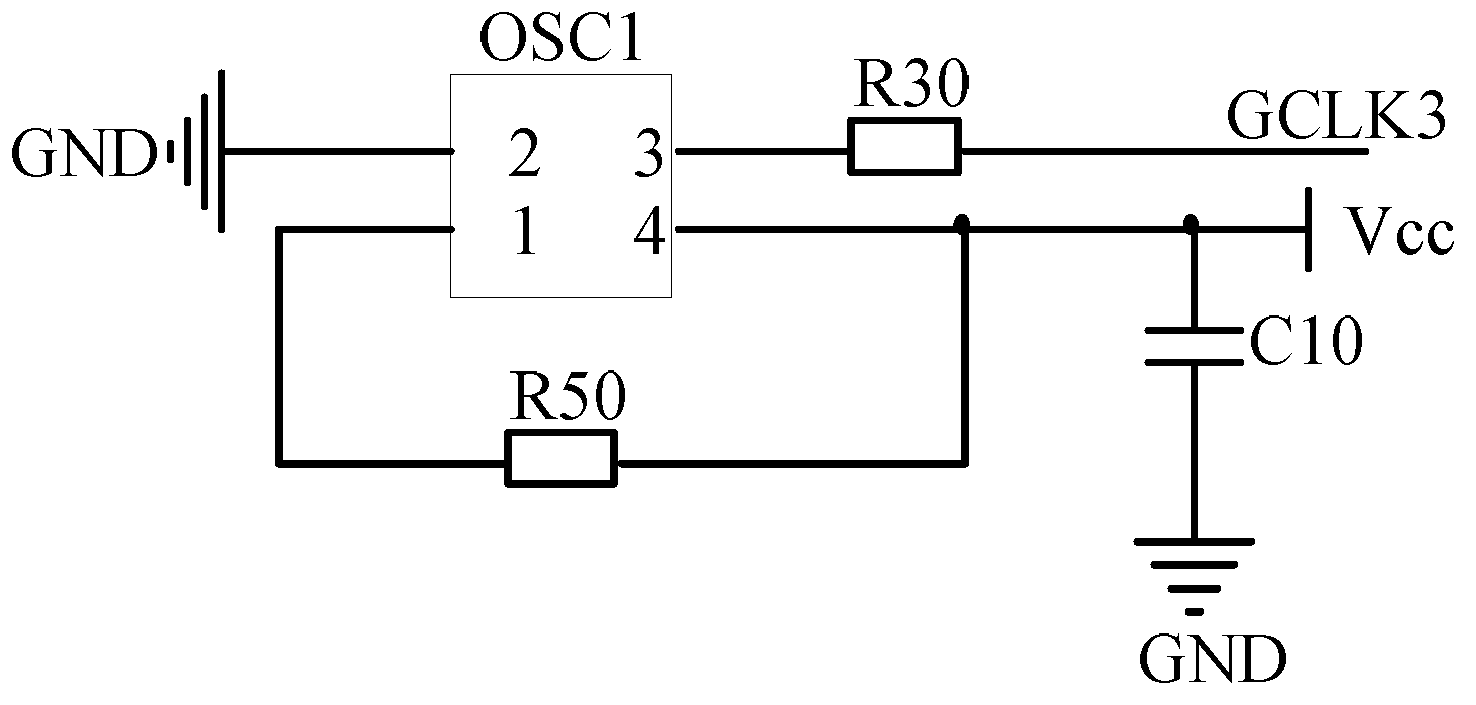

Triggering device and triggering control method for thyristor valve block of high-voltage TSC (thyristor switched capacitor)

ActiveCN103236701AReduce complexityAvoid tedious steps such as sampling comparisonFlexible AC transmissionElectronic switchingElectric power systemIndustrial systems

The invention discloses a triggering device and a triggering control method for a thyristor valve block of a high-voltage TSC (thyristor switched capacitor), and belongs to the field of electric system controllers. With the triggering device and the triggering control method, the problems of complex structures of existing triggering devices and complexity of existing triggering control methods are solved. A control unit is connected with the triggering device. The triggering control method includes that an external clock circuit is adopted to provide clock signals to a logical processing unit, collected SIN signals are judged to acquire switching time, switching signals are outputted according to the switching time, and the switching signals are converted to optical signals through a light transmission circuit to be outputted to a light receiving circuit after being amplified by a driving circuit; and the light receiving circuit outputs electric pulse signals to an optical-coupling isolation circuit II, and input sides of two optical-coupling isolation circuits are switched on simultaneously when the electric pulse signals are of low levels, so that two triggering signals are outputted by two triggering units to gate poles of the thyristor valve block of the high-voltage TSC simultaneously. The triggering device and the triggering control method are applicable to electric systems and industrial systems.

Owner:黑龙江特通电气股份有限公司

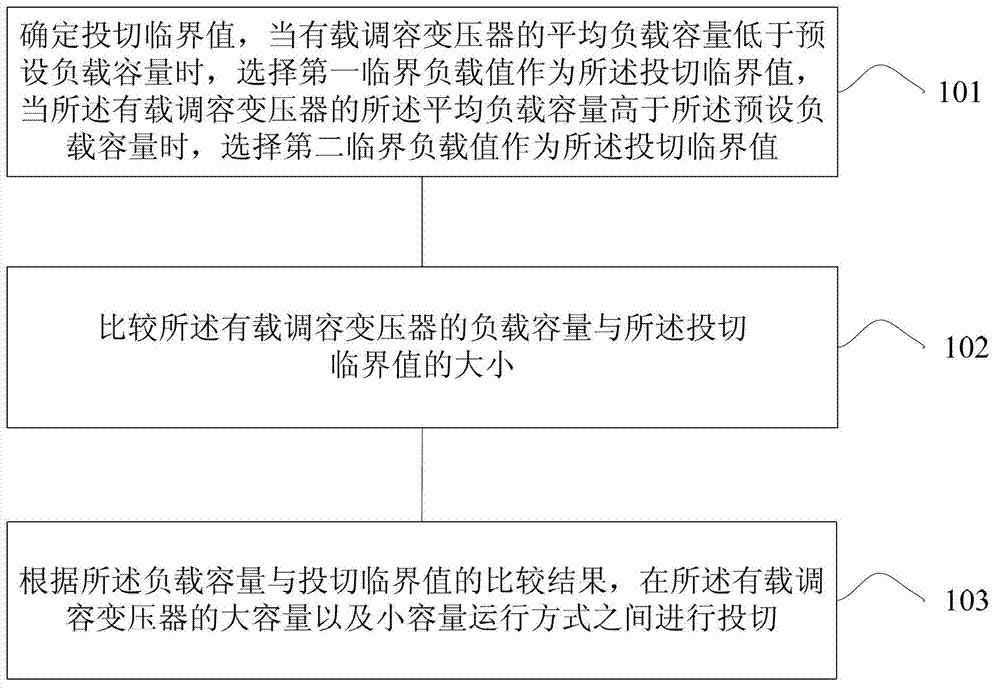

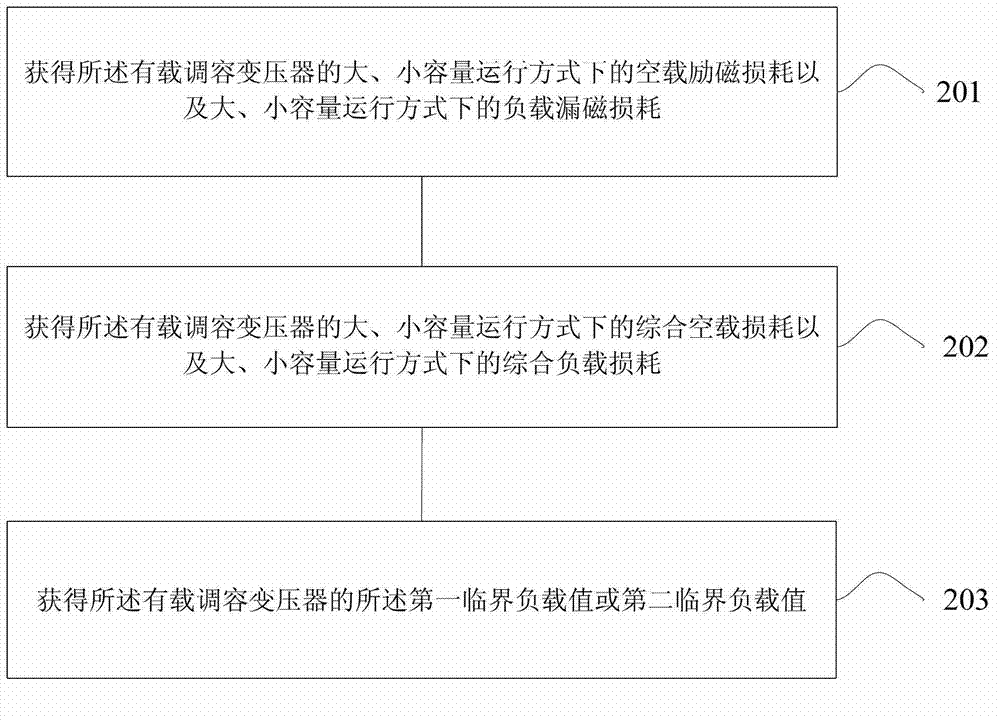

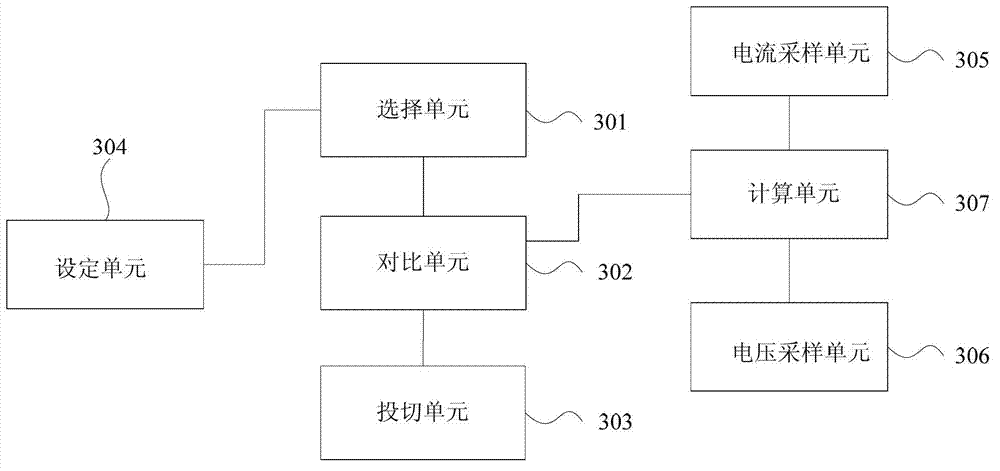

Method and device for regulating capacitance of on-load capacitance regulating transformer

ActiveCN102832622AAvoid lossAvoid wastingPower network operation systems integrationAc network voltage adjustmentCapacitanceTransformer

The invention relates to the field of capacitance regulation control, and in particular relates to a method and a device for regulating the capacitance of an on-load capacitance regulating transformer. The method disclosed by the embodiment of the invention comprises the steps of determining a switching critical value; selecting a first critical load value as the switching critical value when the average load capacity of the on-load capacitance regulating transformer is less than a preset load capacity, and selecting a second critical load value as the critical value when the average load capacity of the on-load capacitance regulating transformer is larger than the preset load capacity; comparing the load capacity of the on-load capacitance regulating transformer with the switching critical value; and switching between large capacity and small capacity operation modes of the on-load capacitance regulating transformer according to the comparison result of the load capacity and the switching critical value. According to the embodiment of the invention, two switching critical values can be alternated, and the on-load capacitance regulating transformer can select a more reasonable switching critical value to carry out the switching of the capacity at different power utilization regions and different power utilization periods, so that the switching is more accurate, and the electric energy is saved effectively.

Owner:南瑞智能配电技术有限公司 +1

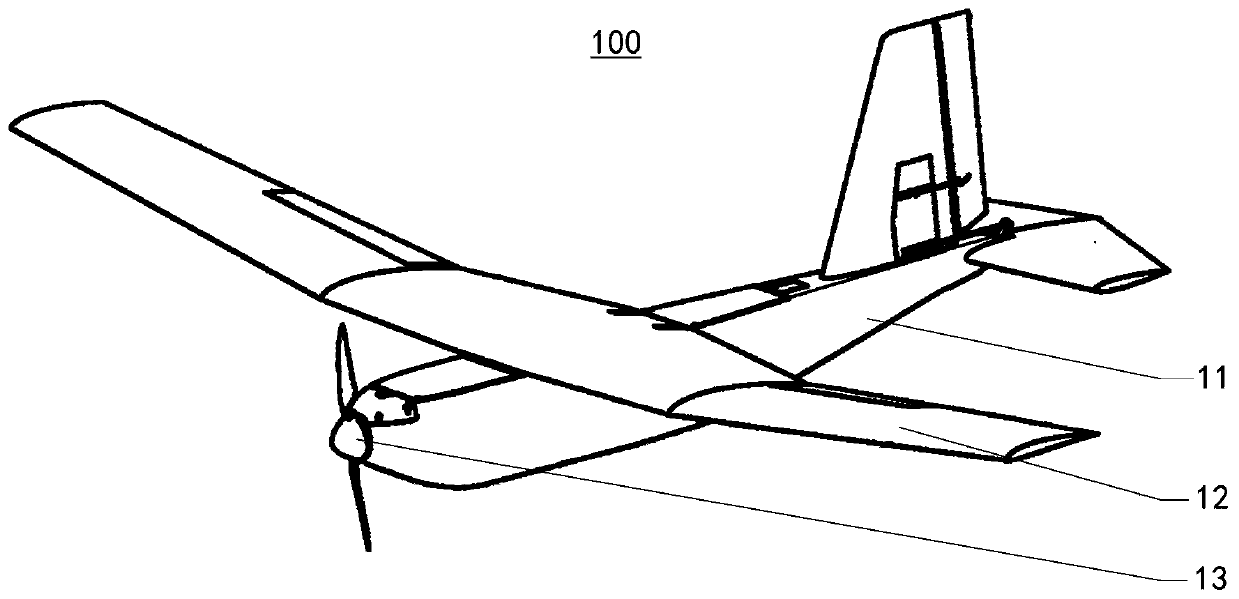

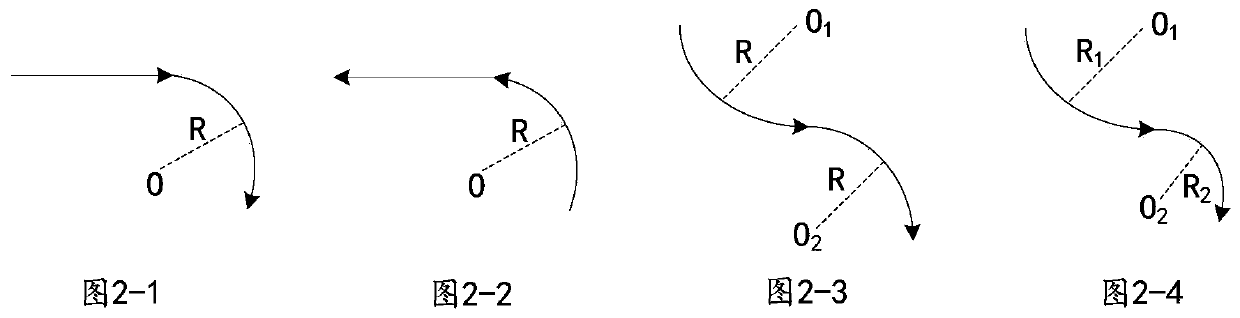

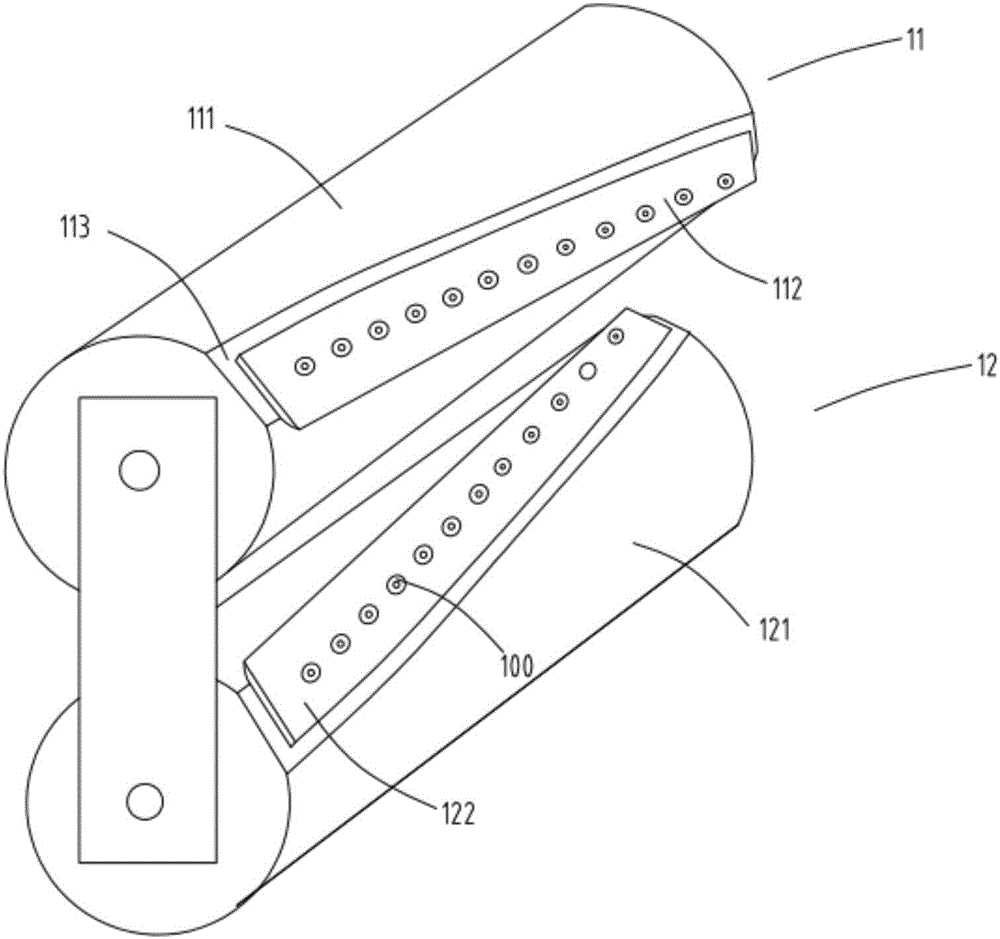

Unmanned aerial vehicle guidance method, unmanned aerial vehicle and storage medium

ActiveCN111522353AAccurate cutImprove tracking accuracyAttitude controlPosition/course control in three dimensionsFlight directionUncrewed vehicle

The invention relates to the field of unmanned aerial vehicles, and discloses an unmanned aerial vehicle guidance method, an unmanned aerial vehicle and a storage medium. The method comprises: obtaining target trajectory route acquiring; if the curvature of the target track route is not equal to that of the current track route, determining a turning point according to the current track route and the target track route; acquiring a turning preparation distance and a real-time distance of the unmanned aerial vehicle; when the real-time distance is smaller than or equal to the turning preparationdistance, obtaining the flight direction and guidance law model of the unmanned aerial vehicle according to the target trajectory route, and controlling the unmanned aerial vehicle to fly; calculating a turning preparation distance according to the current flight state of the unmanned aerial vehicle. Therefore, when the unmanned aerial vehicle enters the turning preparation distance, the flight direction and the guidance law model are switched in time to control the flight of the unmanned aerial vehicle, so as to ensure that the unmanned aerial vehicle accurately cuts into the target trajectory route at the turning point, and then the unmanned aerial vehicle flies on the target trajectory route, thereby improving the tracking precision of the unmanned aerial vehicle on the target trajectory route.

Owner:SHENZHEN AUTEL INTELLIGENT AVIATION TECH CO LTD

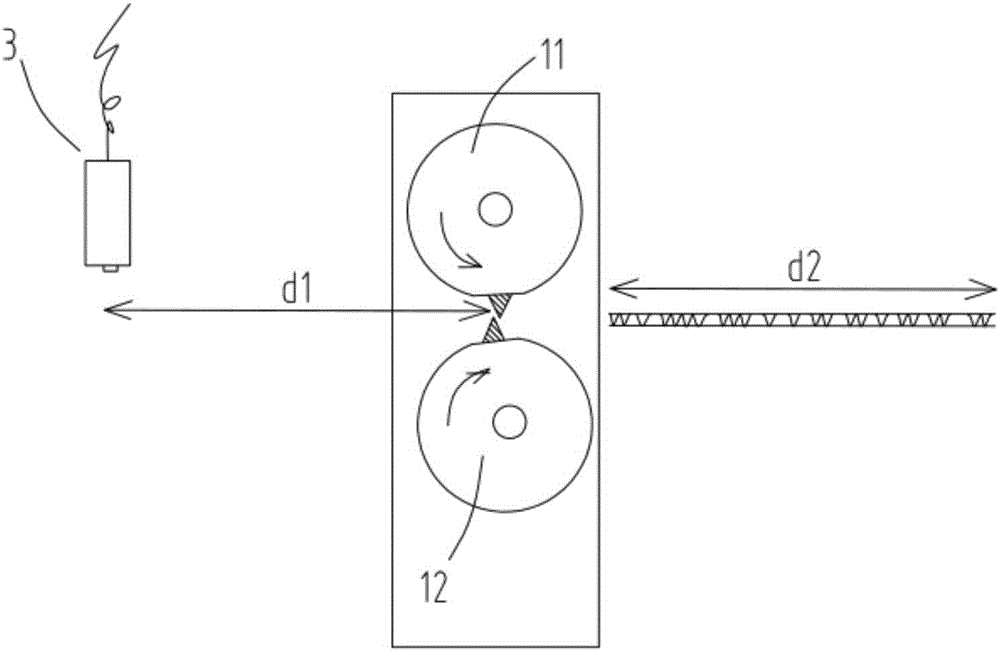

Paperboard cutting device

InactiveCN106426353AImprove cutting effectGuaranteed to be verticalMetal working apparatusCardboardEngineering

The invention relates to a paperboard cutting device. The paperboard cutting device comprises a transverse cutting machine, a paperboard feeding belt used for feeding a paperboard into the transverse cutting machine and a sensor controlling working of the transverse cutting machine. The paperboard feeding belt is arranged at the front end of the transverse cutting machine. The sensor is arranged at the front end of the transverse cutting machine and the upper end of the paperboard feeding belt. The paperboard cutting device overcomes the problems that the corrugated board cutting effect is not good, the cutting length is not precise enough, and cutting affects the paperboard conveying stability.

Owner:CHANGXING SIAN MINFENG COLOR PRINTING FACTORY

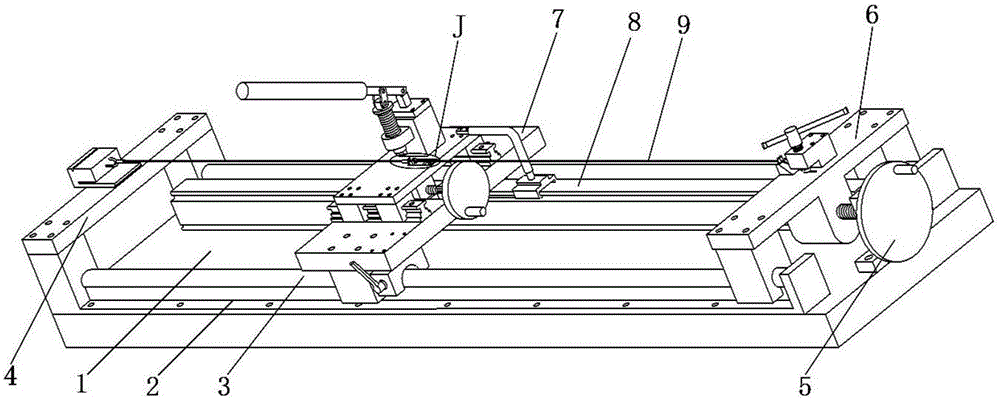

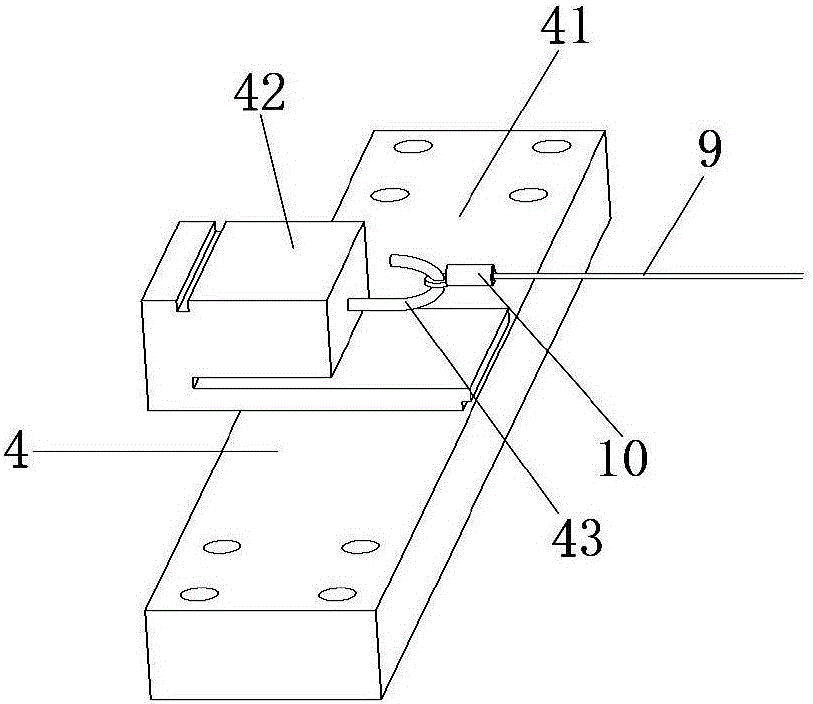

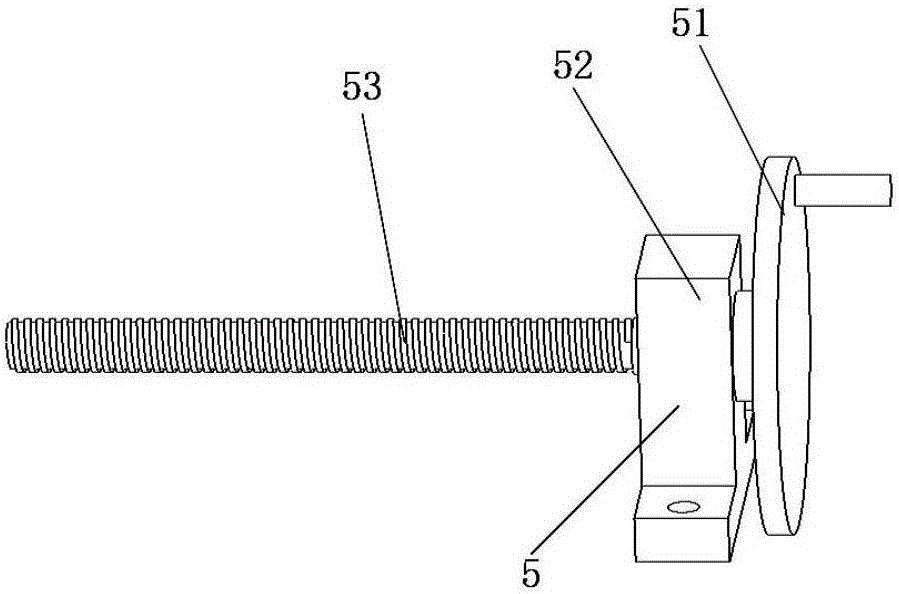

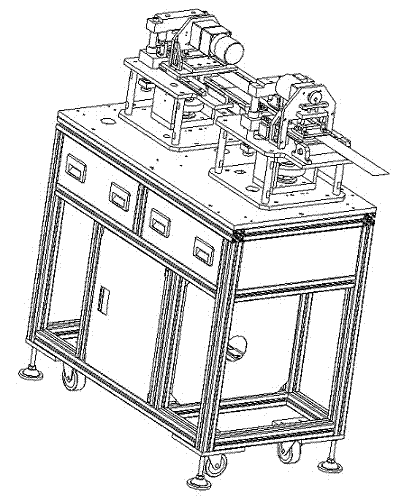

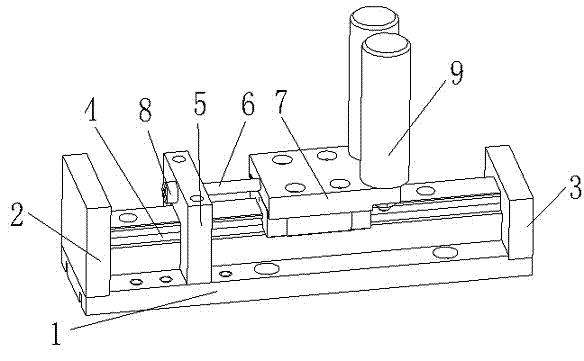

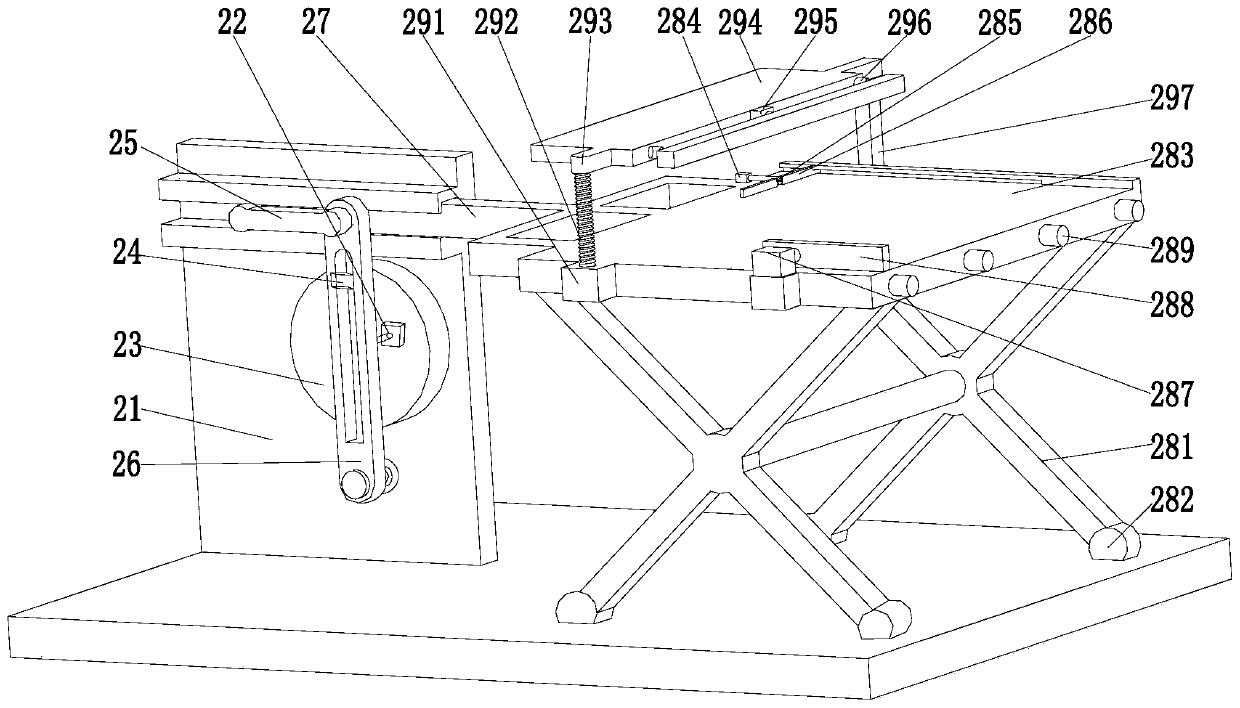

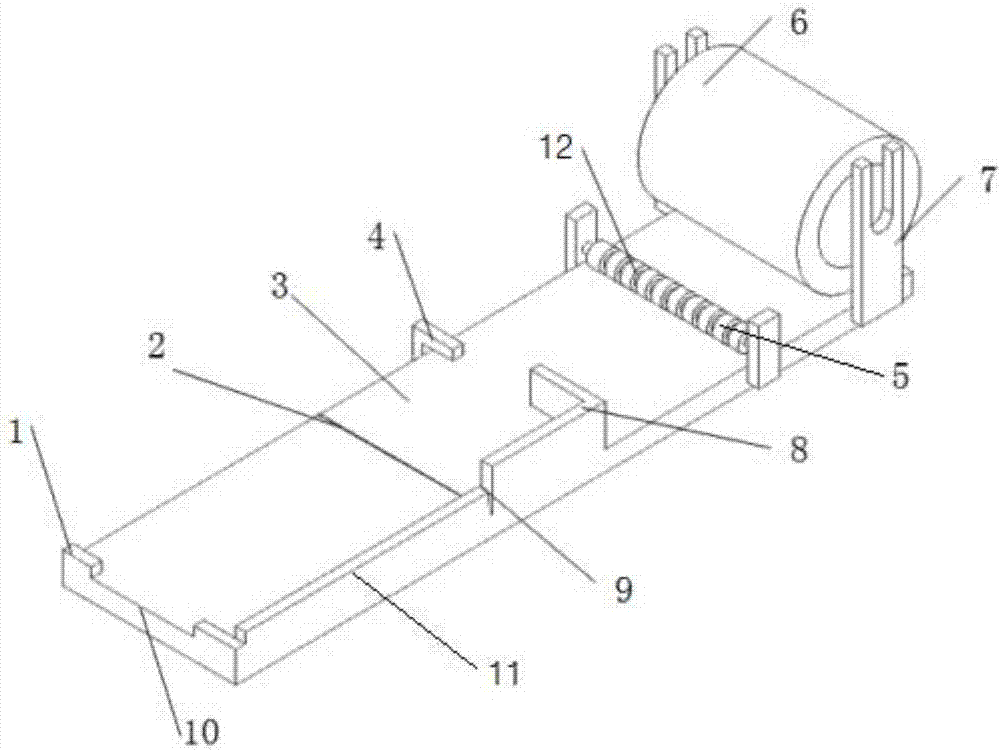

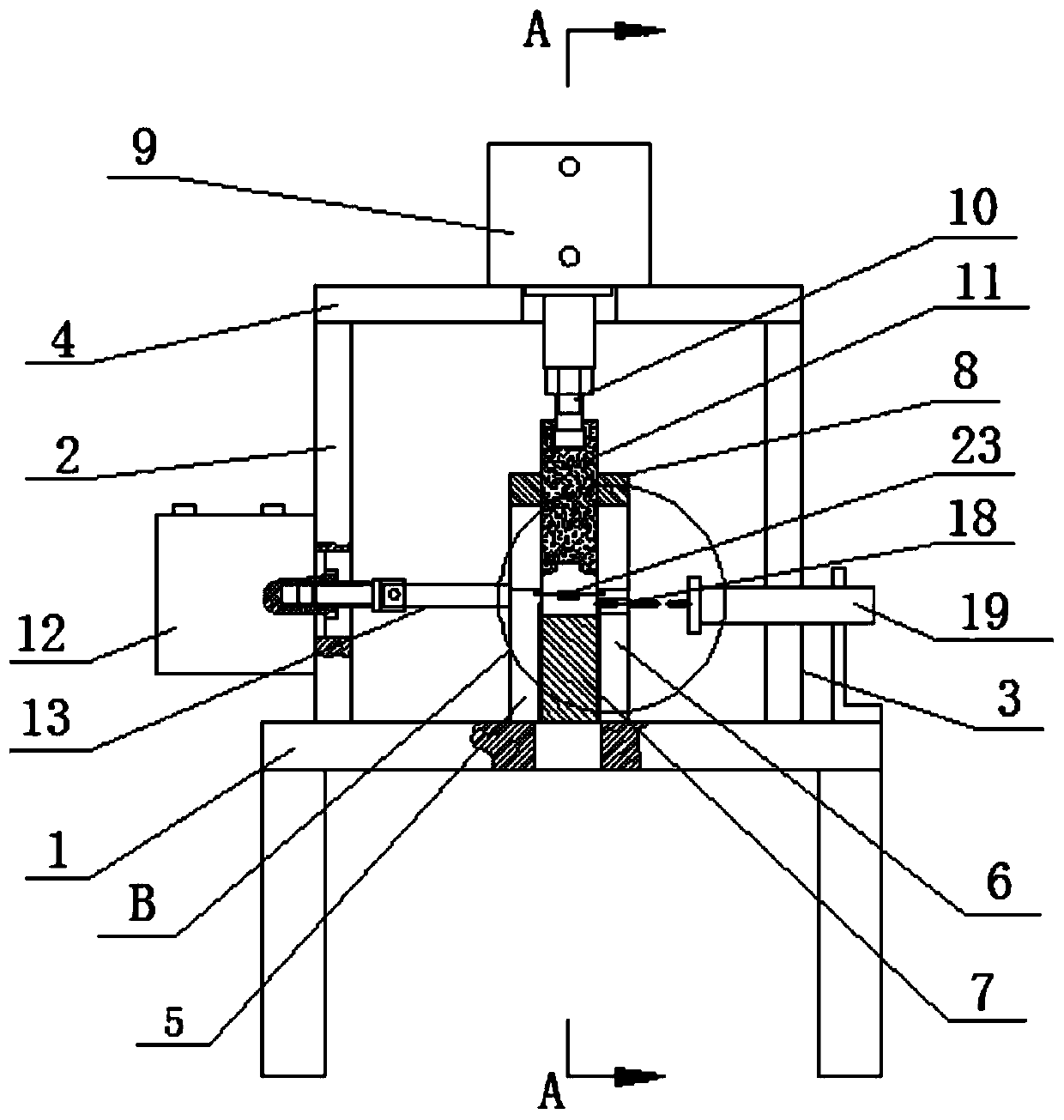

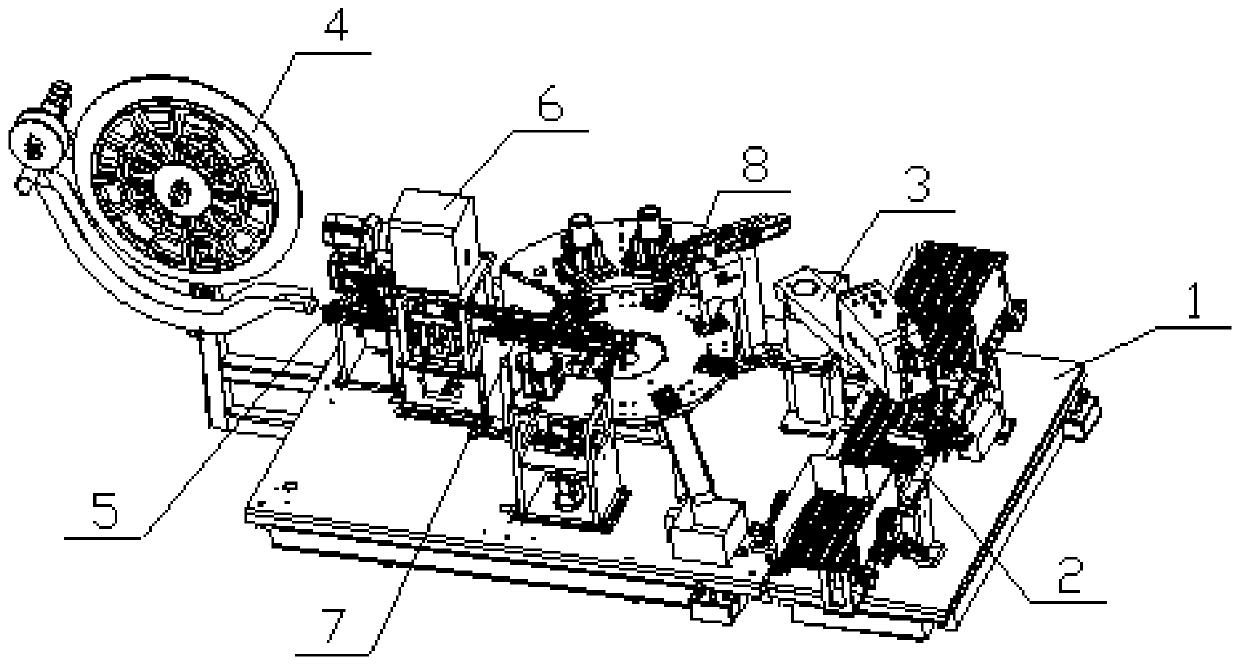

Cable cutting device for flexible cable net of cable antenna

ActiveCN106180486AAvoid force instabilityAccurately control the lengthMetal working apparatusEngineeringFlexible cable

The invention discloses a cable cutting device for a flexible cable net of a cable antenna. The cable cutting device is provided with a base; two guiding rail bases are fixed on the left side and the right side of the base through threads correspondingly; and first connecting guiding rails are fixed on the two guiding rail bases correspondingly. A force measuring device is installed at one end of the base. A tension adjusting device is installed on the other end of the base. A sliding table cable pressing device is slidably connected with the first connecting guiding rails arranged on the other end of the base; and a sliding table cable cutting mechanism is slidably connected with the first connecting guiding rails and located between the force measuring device and the sliding table cable pressing device. A sliding block expansion displacement sensor is arranged on the base. According to the cable cutting device for the flexible cable net of the cable antenna, the machining errors of a cable of the cable antenna are effectively reduced, and the working tension which the cable needs can be accurately controlled when the cable is tensioned; the stress on the cable is not affected by the operations of the sliding table cable cutting mechanism when a connector arranged on the other end of the cable is manufactured; and the lengths of needed cables can be precisely controlled through a sliding table cable cutting female table and a sliding table cable cutting table.

Owner:XIDIAN UNIV

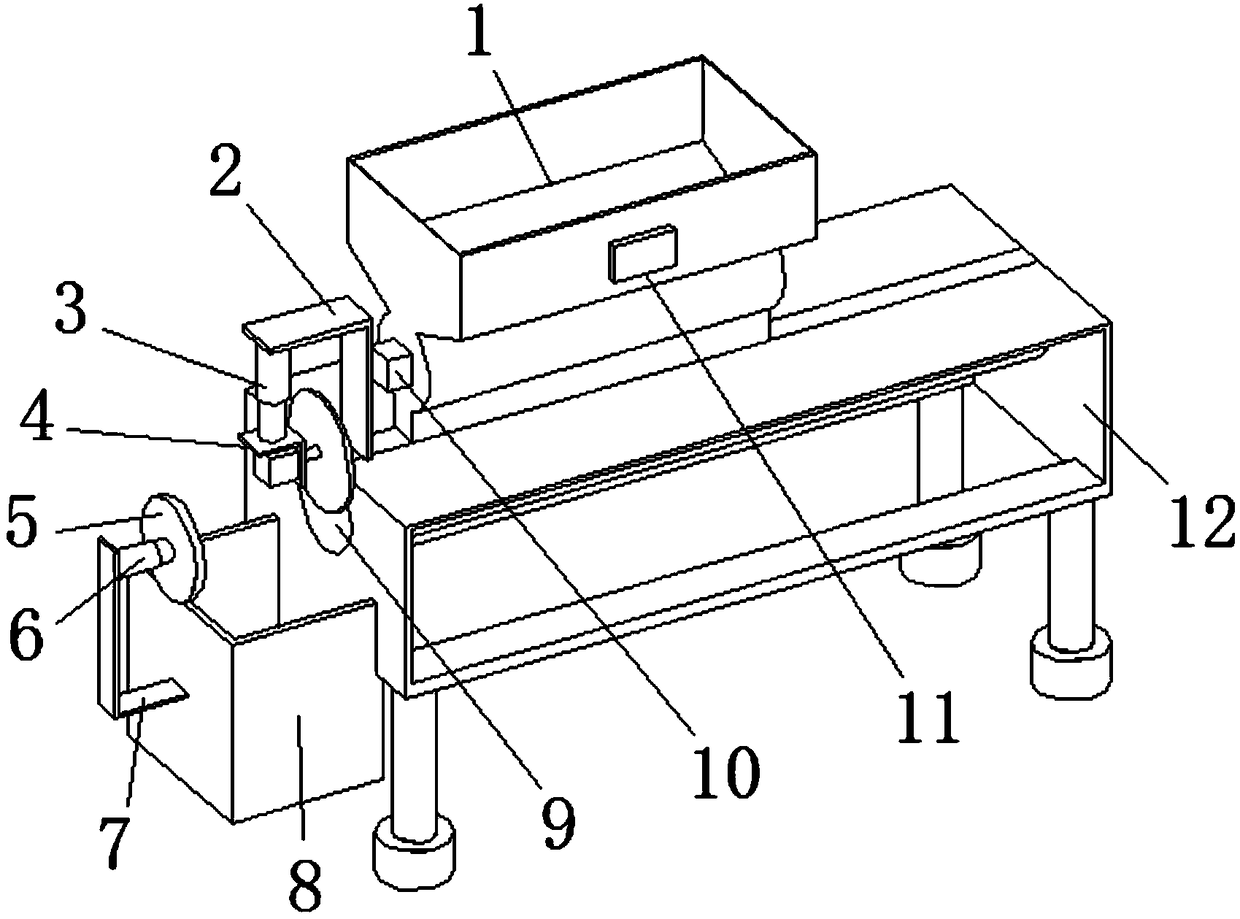

Light-absorbing-piece cutting machine

InactiveCN103112026AEasy to limitGuaranteed qualityMetal working apparatusWebs handlingEngineeringMechanical engineering

The invention discloses a light-absorbing-piece cutting machine. The light-absorbing-piece cutting machine comprises a working table and is characterized by further comprising a limiting mechanism, a delivery mechanism, a piece pressing mechanism, a feeding mechanism and a cutting mechanism, wherein the delivery mechanism which is used for conveying light absorbing pieces to the piece pressing mechanism is installed beside the working table, the limiting mechanism which is used for limiting conveying positions of the light absorbing pieces is installed at the rear end of the piece pressing mechanism, the feeding mechanism which is used for delivering the light absorbing pieces to the cutting mechanism is installed at the rear end of the limiting mechanism, and the cutting mechanism is installed at the rear end of the feeding mechanism. The light-absorbing-piece cutting machine is simple in structure, and good in cutting effect.

Owner:KUNSHAN FOR EASIER AUTOMATION TECH

Method for the production of multiplayer electrostatic lens array

InactiveUS8487268B2Simple and cost-effective methodHigh yieldStability-of-path spectrometersLine/current collector detailsIon beamElectron microscope

The invention relates to a method for the production of a multilayer electrostatic lens arrangement with at least one lens electrode in general, a method for the production of a phase plate in particular as well as the lens arrangement, the phase plate and a transmission electron microscope with the phase plate.The lens arrangement or the phase plate is produced from a thin self-supporting silicon nitride membrane which is fixed in a macroscopic chip with deposition of further layers.The central bore as well as the aperture opening are milled out by means of an ion beam.

Owner:GERTHSEN DAGMAR +2

Automatic cutting device for automobile trim skin and cutting method

PendingCN109531641AAvoid makingAvoid backlogGrinding machine componentsOther manufacturing equipments/toolsDrive shaftEngineering

The invention discloses an automatic cutting device for automobile trim skin. The automatic cutting device comprises a cutting bed worktable, a cross beam, an air cylinder and a cutting machine head.The cross beam is fixed in a bestriding manner to the cutting bed worktable, and the cutting machine head is mounted on the cross beam; the cutting machine head comprises a tool bit frame, a tool bitelectric sharpening system and a cooling system. The tool bit frame comprises a TG transmission shaft, a fixed plate, a cutter and a cutterhead; the TG transmission shaft is connected to the power output end of the air cylinder, the top end of the cutter is fixed to the TG transmission shaft and the bottom end of the cutter penetrates the cutterhead; the tool bit electric sharpening system is rotatably mounted at the lower end of the machine head to polish the cutter; and the cooling system communicates to the cutterhead. According to the automatic cutting device disclosed by the invention, preparation and overstock of molds are avoided, input of accessories is reduced, and the cost is saved. According to the cutting method, the off-cut gap and the off-cut direction are optimized by meansof software, and based on digital processing, the cut products are diversified, thereby meeting the processing demands of conventional PVC and 3D composite material processing. The automatic cutting device achieves automatic production and improves the production efficiency.

Owner:常熟安通林汽车饰件有限公司

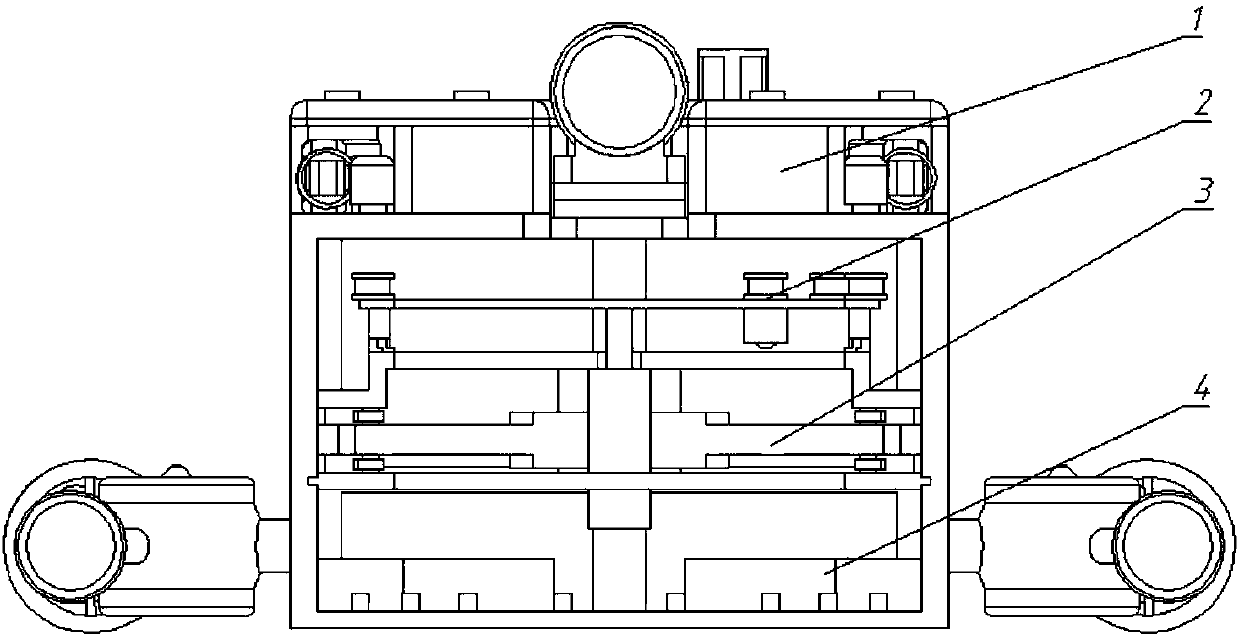

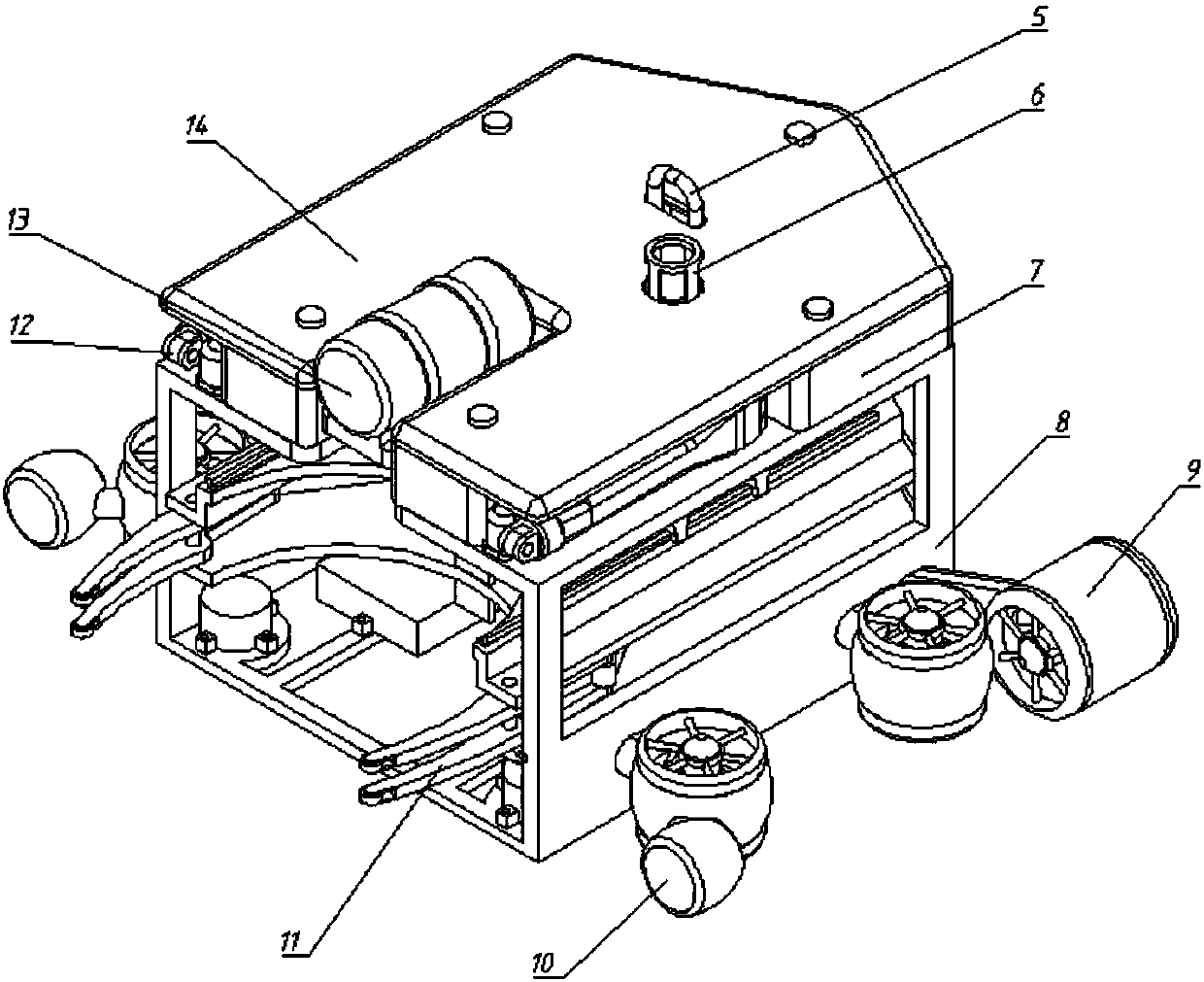

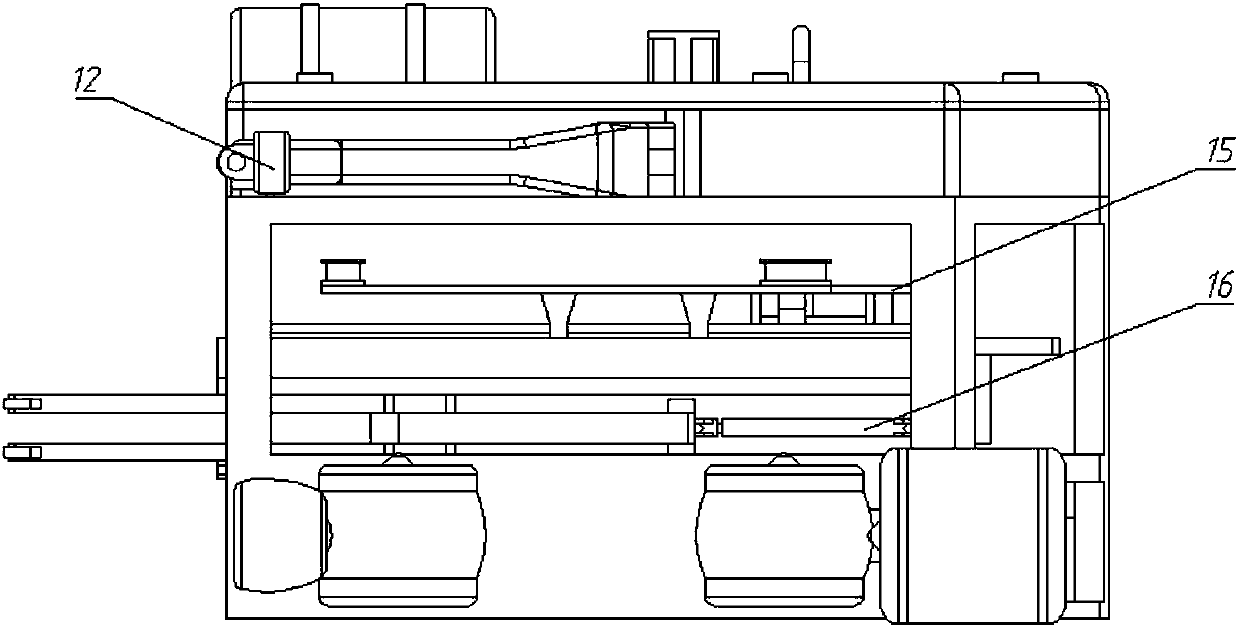

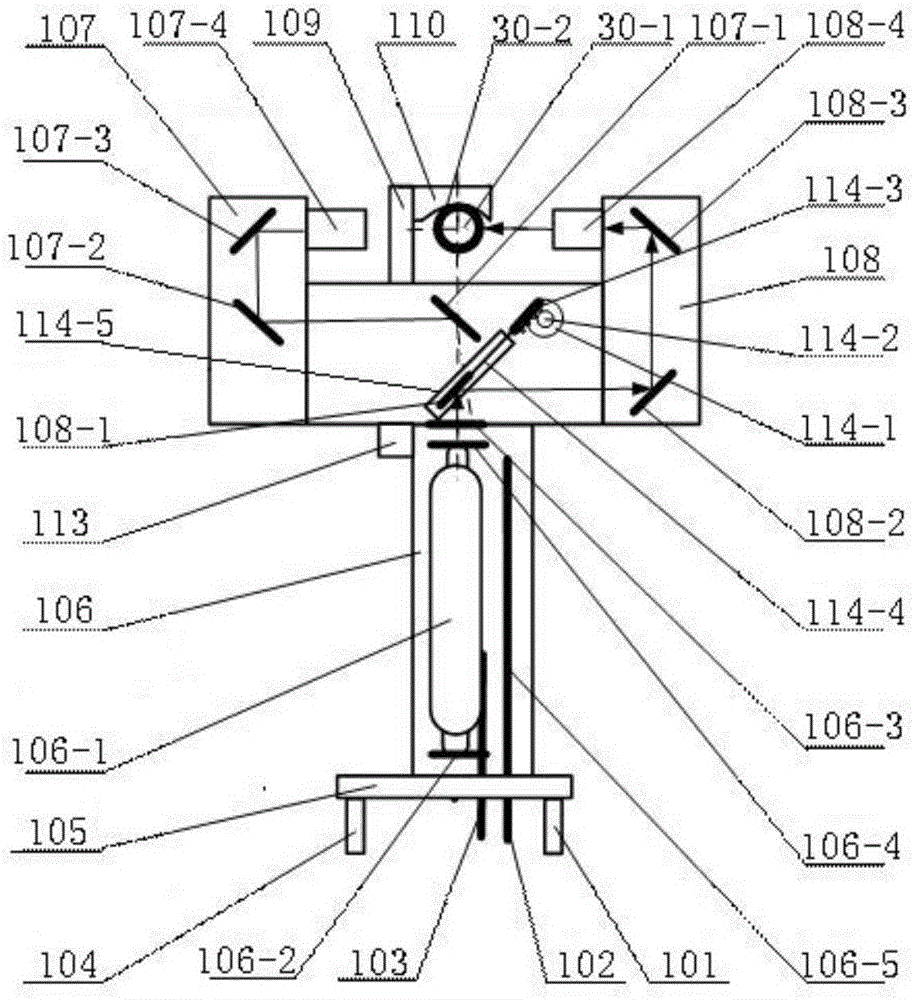

Submarine pipeline cutting robot

InactiveCN107900455AImprove efficiencyImprove securityMetal sawing devicesMetal sawing accessoriesOcean bottomHydraulic cylinder

Disclosed is a submarine pipeline cutting robot. The submarine pipeline cutting robot is mainly used for cutting treatment of submarine damaged pipelines. The submarine pipeline cutting robot is composed of an operation carrier body, a pushing device, a cutting device and a clamping device. The carrier body comprises a carrier frame, a buoyancy block, a propeller, a five-degree-of-freedom manipulator, a lighting lamp, a camera pan-tilt and a hydraulic device. A pushing mechanism is connected to the carrier frame through a hydraulic cylinder and can slide along a rail on the frame. A set of cutting mechanism is arranged above the pushing device and can slide along a rail on the pushing device, so that the cutting purpose is achieved. The manipulator is located in the center of the pushing device. A manipulator base is connected with the pushing device through the hydraulic device. A manipulator clamp hand is connected with the pushing device through pin nails. The state of the manipulator is controlled through combined action of the hydraulic device, so that the purpose of holding the pipelines is achieved. According to the submarine pipeline cutting robot, the submarine pipelines which are located within 1000 meters of the underwater depth and have the size no more than 500 millimeters can be cut.

Owner:NORTHEAST GASOLINEEUM UNIV

Method for forging bearing ring

The invention provides a method for forging a bearing ring, and relates to the field of manufacturing of mechanical metal, in particular to a technology for bearing forging production. The method comprises the steps of material preparation: blanking 600g of each section of a round steel long bar; forging forming: heating the material section by a heating furnace, hammering the material section by high-speed hammering equipment, automatically conveying a hammered blank while cooling, performing spraying cooling to remove a thin oxide layer generated on a semi-finished ball track under high temperature in time, then performing cutting and final annealing, and performing forging on press machine equipment; treatment after forging: removing waste products and repairing reprocessed products by detection; jacking: performing combined cutting in a punching hole to obtain a coarse bearing ring blank. In the forging process, precise temperature control is adopted, so that the manufactured ring is extremely high in intensity, and a finally manufactured bearing is anti-abrasion and long in service; meanwhile, the oxide layer can be removed in time in the forging process, and cutting can be precisely carried out.

Owner:WUHU JINLONG MOLD FORGING

Areca nut slicing mechanism and slicing method

ActiveCN105904493AImprove quality and efficiencyIncrease productivityMetal working apparatusSlide plateAreca

Provided are an areca nut slicing mechanism and slicing method. The areca nut slicing mechanism comprises a vibration screen, an areca template, an air cylinder, a V-shaped collector hopper, a partition plate, a spiral rubber roller, a brush roller, a spring baffle, a U-shaped sliding plate, a rubber skin layer, a synchronous belt and the like, wherein the partition plate is welded in the V-shaped collector hopper; the spiral rubber roller penetrates through the V-shaped collector hopper under the support of a bearing and a bearing block; the spring baffle is installed on the front portion of the V-shaped collector hopper; the U-shaped sliding plate is installed below the V-shaped collector hopper through a bolt; the areca template is installed on the rubber skin layer (10) of the synchronous belt; the air cylinder is connected with a suction cup through a T-shaped rod, and a spring is installed on the suction cup through a bolt; and a cutter clamped by an n-shaped clamp is arranged inside the suction cup and used for slicing areca nuts. After the areca nuts are sliced, areca slices and seeds fall into the vibration screen under the turning action of the synchronous belt, so that vibrating screening is completed, and preparations are made for the next procedure.

Owner:CHANGSHA UNIVERSITY

Plain glass cutting auxiliary processing device

InactiveCN110422997AAccurate cutImprove crop qualityGlass severing apparatusCutting glassPulp and paper industry

The invention relates to a plain glass cutting auxiliary processing device. The plain glass cutting auxiliary processing device comprises a bottom plate, a pushing device, a rotating receiving device,and a waste material collecting device; the pushing device is fixedly arranged on the left end of the bottom plate; a support plate is arranged on the right end of the bottom plate; the rotating receiving device is arranged on the support plate; and the waste material collecting device is arranged on the bottom plate. The plain glass cutting auxiliary processing device is capable of solving difficult problems in the prior art in plain glass cutting process: 1, in artificial cutting of glass, displacement is easily caused, cutting precision is not high, and operators are easily damaged by cutting glass waste materials; 2, in glass cutting process using conventional machines, cutting precision is not high, glass cutting quality is influenced, in time collecting of cut off glass and recycling of cut off glass are impossible to realize. The plain glass cutting auxiliary processing device is capable of realizing intelligent plain glass cutting, is excellent in cutting effect, and high in working efficiency.

Owner:定州市亮鑫玻璃制品有限公司

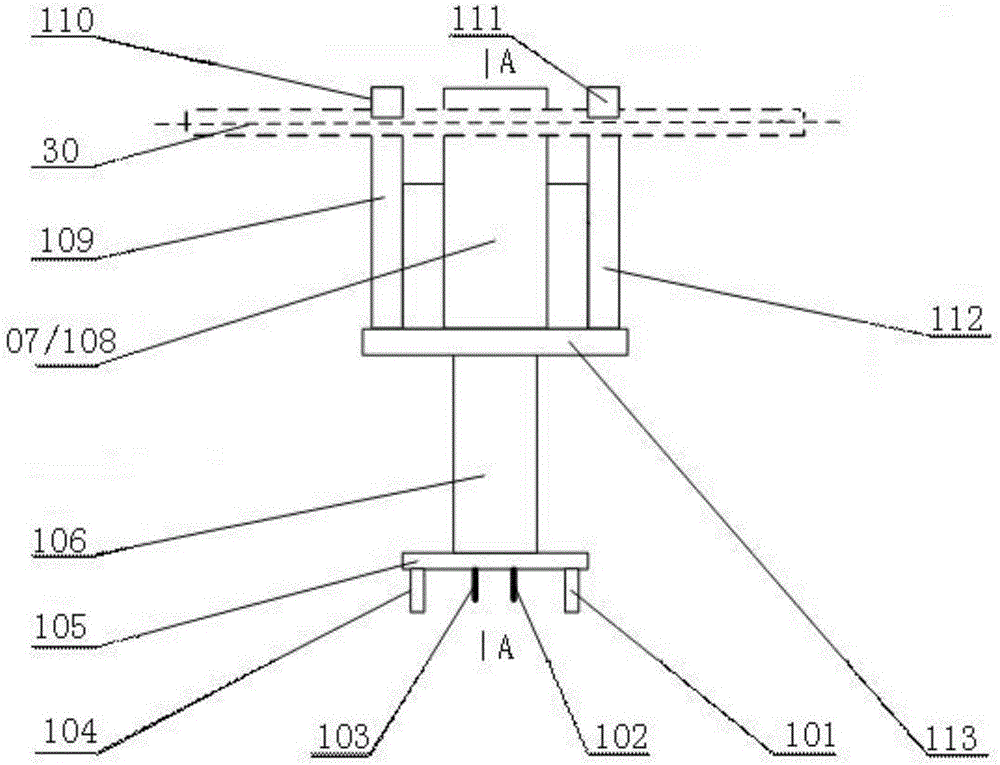

Multifunctional puncture instrument

The invention discloses a multifunctional puncture instrument, which includes a bracket and a positioning device. The positioning device includes: two arc-shaped rails, a positioning rod and a puncture needle frame, wherein the two ends of the positioning rod are respectively movably connected to the The two arc-shaped rails are connected, the puncture needle holder is connected with a puncture needle holder installation seat, and the puncture needle holder installation seat is connected with the positioning rod through a connecting arm. The present invention realizes arbitrary directional adjustment of the puncture needle through the connection mode between the connecting arm, the spherical joint and the puncture needle holder mounting seat, so that the optimal path from the puncture point to the lesion target can be determined through simple operations. And accurately cut the puncture needle into the target point.

Owner:赵江民

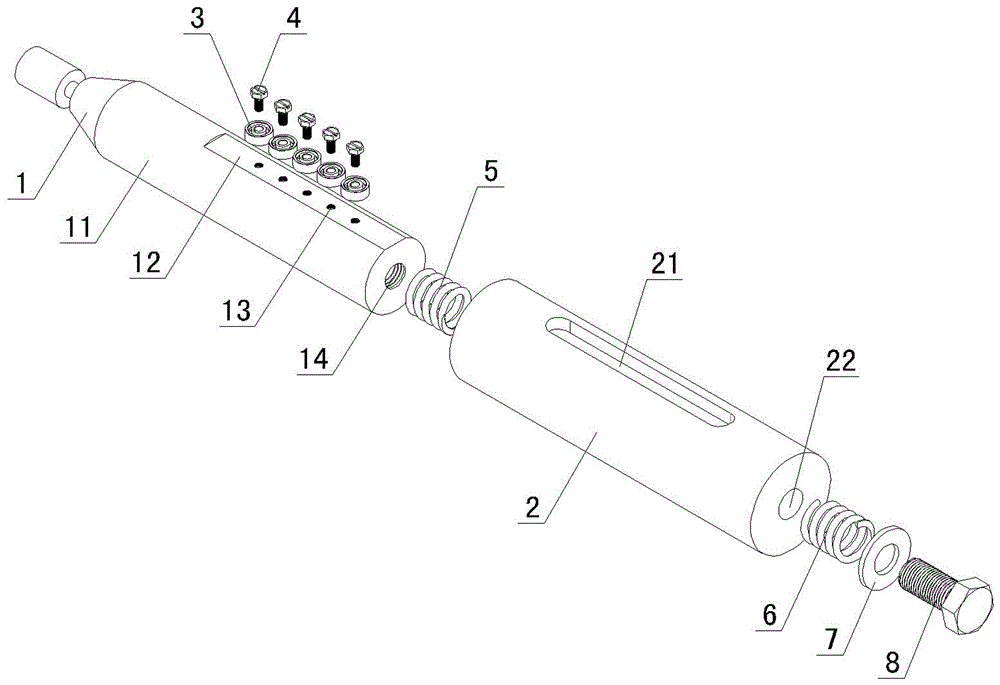

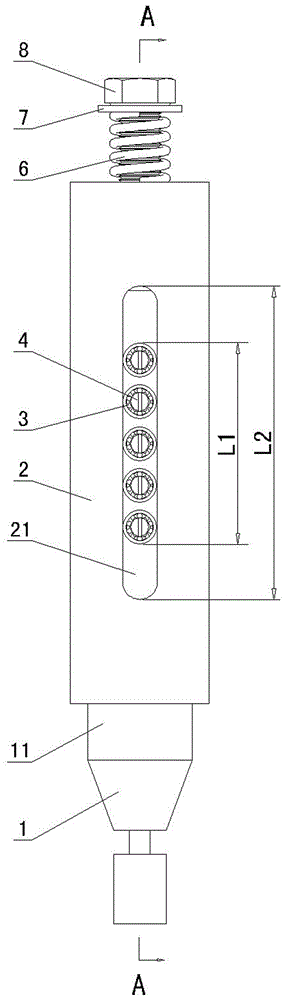

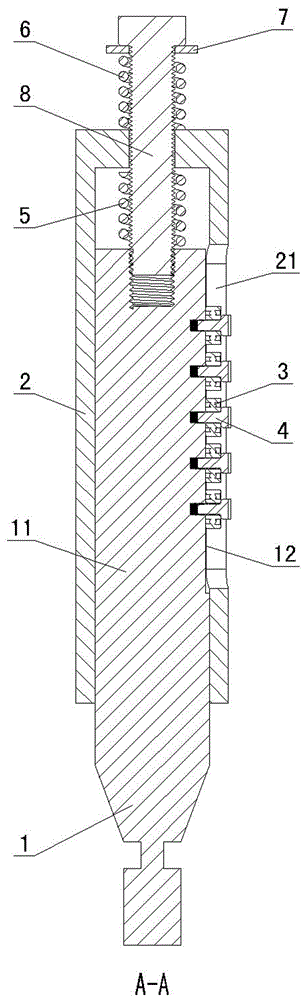

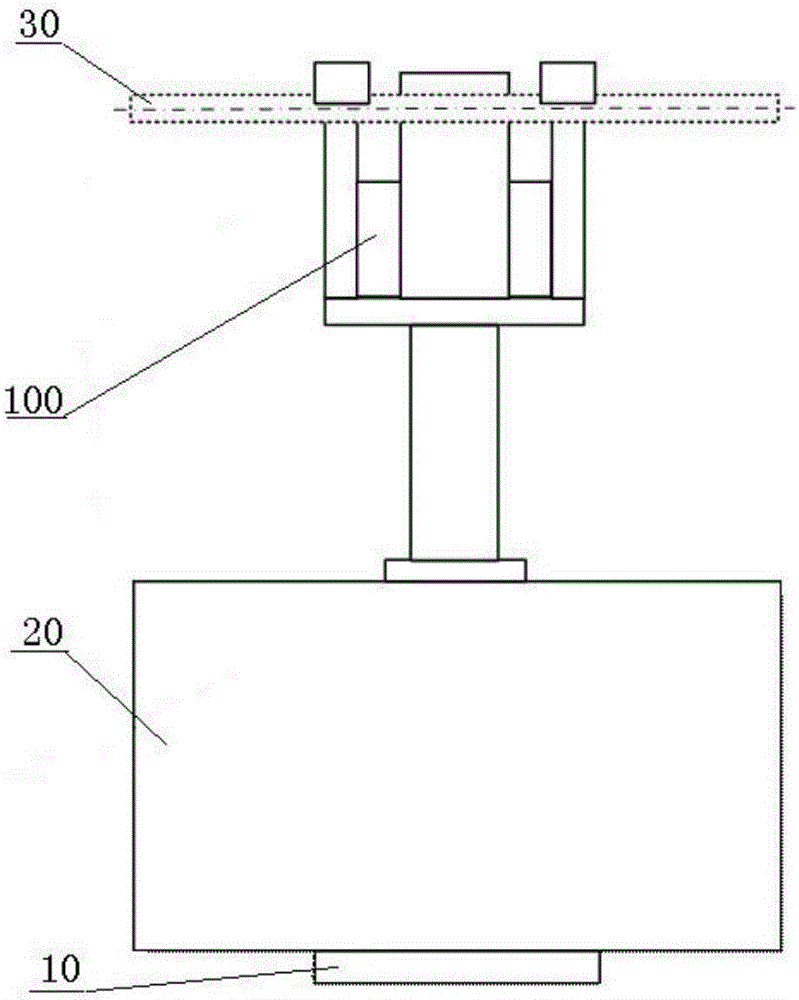

Floating double-shaft shoulder friction stir welding tool and method for space welding

ActiveCN106624340AEasy to slideReduce frictionNon-electric welding apparatusRolling-element bearingEngineering

The invention discloses a floating double-shaft shoulder friction stir welding tool and a method for space welding. The tool comprises a stirring head and a sleeve; at least two rolling bearings are arranged on a connecting shaft of the stirring head; each rolling bearing is connected with the connecting shaft of the stirring head through a locking bolt; U-shaped grooves in clearance fit connection with the rolling bearings are axially formed in the side wall of the sleeve; the length L2 of the U-shaped grooves is larger than the positioning distance L1 of the rolling bearings; an adjusting bolt in threaded connection with the connecting shaft of the stirring head is inserted in the top center of the sleeve; the adjusting bolt is sleeved with a first limiting spring and a second limiting spring; the first limiting spring is positioned in the sleeve; the second limiting spring is positioned out of the sleeve; and the adjusting bolt is screwed to change relative positions of the connecting shaft of the stirring head and the sleeve so as to realize adjustment of the pressing degree of the first limiting spring and the second limiting spring. The tool is simple and reliable in structure, easy to manufacture and excellent in use effect, and can effectively realize floating welding and space all-position welding.

Owner:CHINA-UKRAINE INST OF WELDING GUANGDONG ACAD OF SCI

Method for carrying out 10kV charged wire connecting operation by CO2 laser cable peeling device

ActiveCN105743018ANo damageSatisfy securityApparatus for removing/armouring cablesApparatus for overhead lines/cablesElectricityCo2 laser

The invention relates to a method for carrying out 10kV charged wire connecting operation by a CO2 laser cable peeling device. The CO2 laser cable peeling device is suspended on a live wire; H-shaped notches are cut out at two sides of the live wire respectively; the H-shaped notches at two sides are accurately butted and then form two annular notches at two sides and two coherent longitudinal notches between the two annular notches on the live wire; a cut insulating sheath is peeled off from the live wire; one end of a drainage wire is locked by a lock bar; the drainage wire is sent to a live wire connection position; a round mouth screw type drainage wire clamp is suspended on the live wire with a drainage wire clamp operating rod; a bolt is tightened; and the drainage wire clamp and the wire are tightly fixed. Online peeling is carried out on the live wire by the CO2 laser cable peeling device; a metal cable core is not damaged; the peeling efficiency is high; the notches are accurate; and the reliability of 10kV charged wire connection is greatly improved.

Owner:ANSHAN POWER SUPPLY COMPANY OF STATE GRID LIAONING ELECTRIC POWER COMPANY +2

Wheat straw preprocessing cutting device

The invention discloses a wheat straw preprocessing cutting device. The device comprises a connection support, a straw sliding barrel is welded to the upper end of the connection support, an opening is formed in one end of the straw sliding barrel and connected with a through hole, corresponding to the opening of the straw sliding barrel, of one side of the connection support, and a third electricretractable rod is connected to the right end in the straw sliding barrel through bolTS; a push plate can be driven to move through the third electric retractable rod, wheat straw can be pushed out of the opening of the straw sliding barrel through the push plate, a cutting blade can be driven to move up and down through a first electric retractable rod, the cutting sheet can be driven to rotatethrough a second motor, and accordingly the wheat straw is cut more conveniently; an adjustment baffle can be driven to move left and right through a second electric retractable rod, and the cutting length can be adjusted through the adjustment baffle. The wheat straw preprocessing cutting device is simple in structure and convenient to operate, cutting is more accurate, convenience is provided for people, and a large amount of labor is saved.

Owner:吾家农场成都农业有限公司

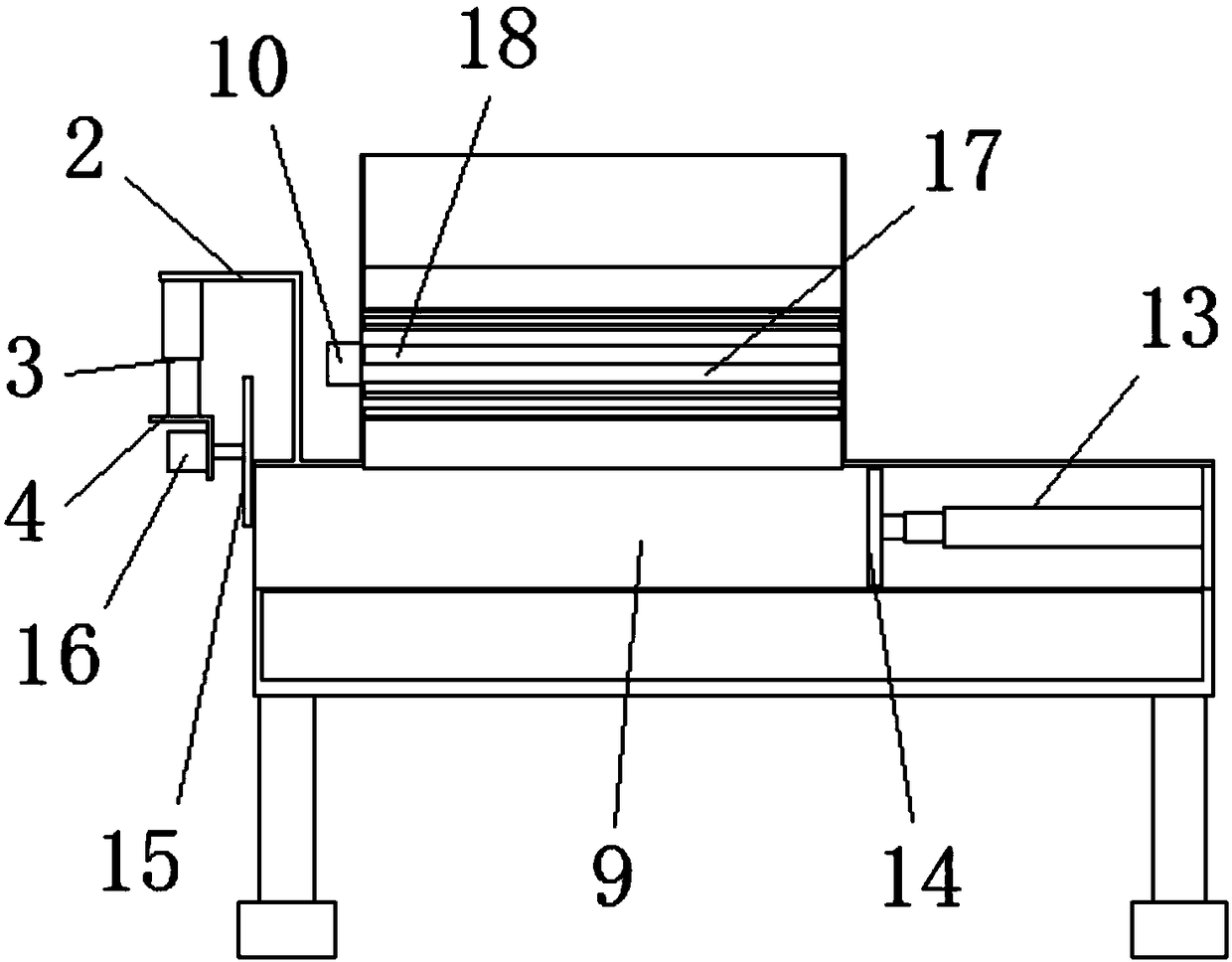

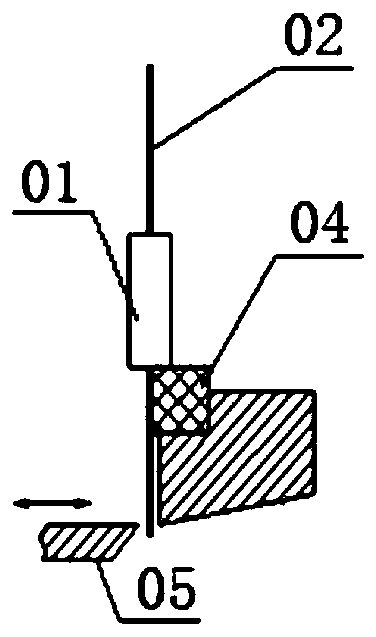

Cutting machine

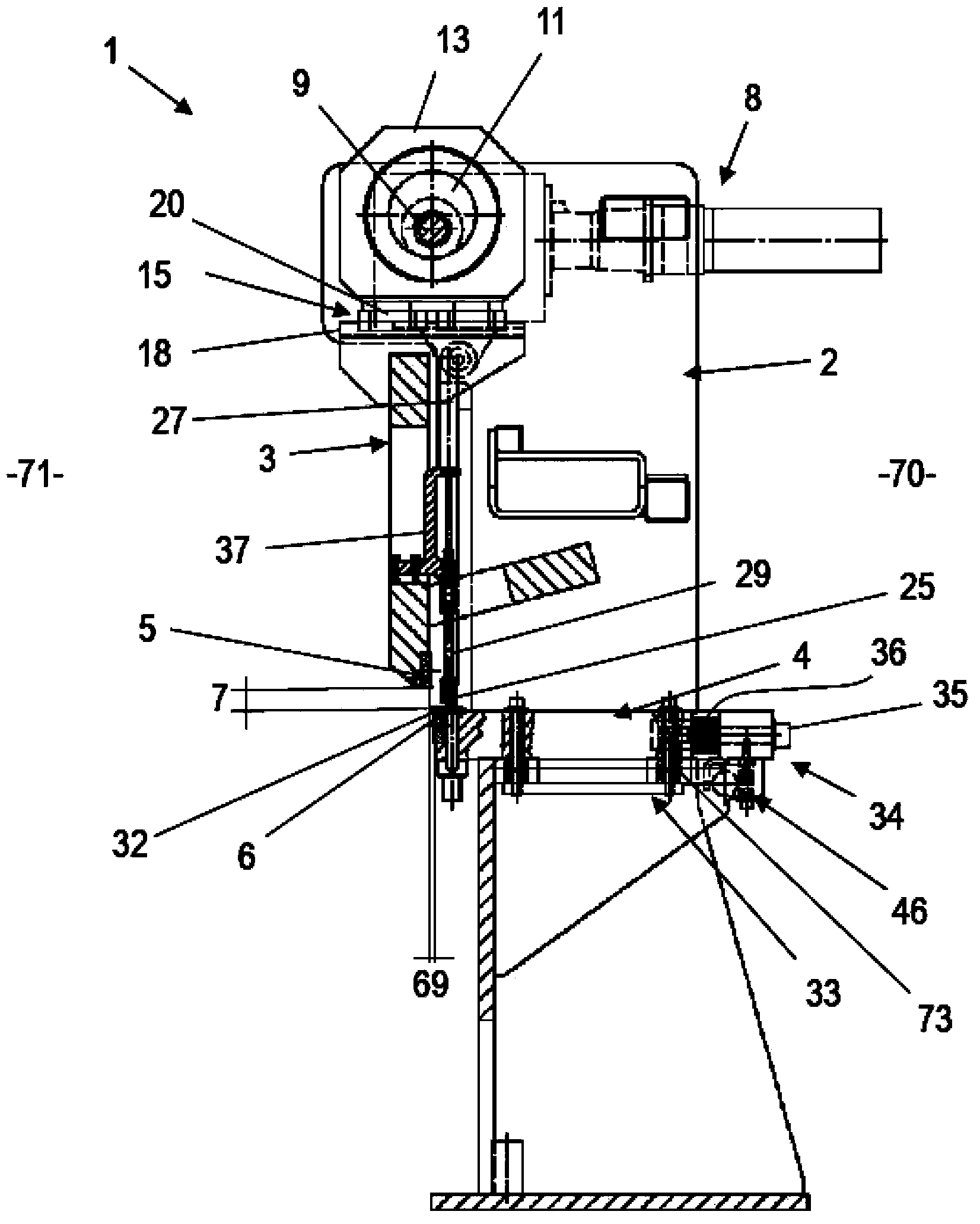

The invention relates to a cutting machine for cutting sticky ribbons, particularly the ribbon comprises sticky thin cord fabric material comprising spinning silk and / or steel wire. The cutting machine comprises a main frame (2), a knife rest (3), a platen (4) with a lower blade (6), and a driving device (8) with a driving shaft (9), wherein the knife rest (3) with an upper blade (5) can vertically move and support on the main frame (2), a knife edge (7) is arranged between the upper blade (5) and the lower blade (6), the driving device (8) is used for driving the knife rest (3) with the upper blade (5) to vertically move relative to the main frame (2). In order to realize high hardness, the driving shaft (9) eccentrically supports in at least one bearing shell (12 or 13), and the bearing shell only can horizontally move and support on the knife rest (3) through linear guide parts (14 and 15).

Owner:KARL EUGEN FISCHER GMBH

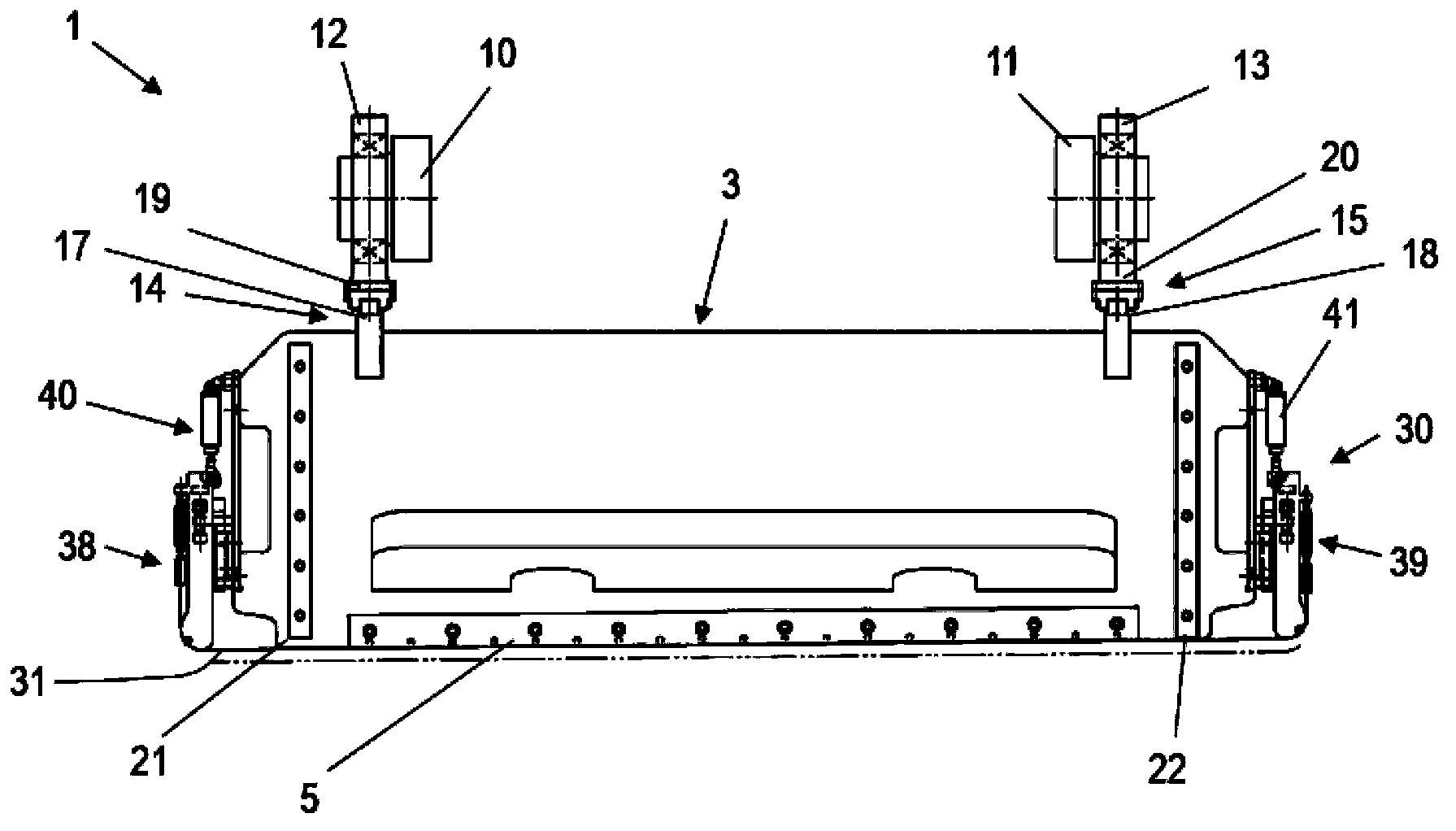

Single aluminum-shell battery encapsulating apparatus

ActiveCN107146912AAccurate cutAvoid wastingAssembling battery machinesFinal product manufactureContinuous operationAluminium

The invention discloses a single aluminum-shell battery encapsulating apparatus. The single aluminum-shell battery encapsulating apparatus comprises a bottom plate, an adhesive-passing roller and a film bracket; the adhesive-passing roller and the film bracket are arranged at one end of the bottom plate, and a film is arranged on the film bracket; a positioning plate and a feeding groove are arranged in the middle position of the bottom plate; the positioning plate is L-shaped, wherein a long plate of the positioning plate is fixedly arranged along one side edge of the bottom plate; a short plate of the positioning plate is parallel to the feeding groove, wherein a certain distance is formed between the bottom of the short plate of the positioning plate and the bottom plate; and the feeding groove is formed in a direction perpendicular to an adhesive tape conveying direction. The single aluminum-shell battery encapsulating apparatus is simple in structure, low in cost, low in requirement on an operator, and capable of accurately completing positioning of the adhesive tape and the surface of a battery, accurately cutting the adhesive tape with the required length, avoiding waste of material and realizing efficient continuous operation, and simple in steps, high in efficiency, and capable of greatly improving encapsulating consistency and avoiding the problems of shell contact, poor subsequent welding and the like caused by encapsulating offset.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

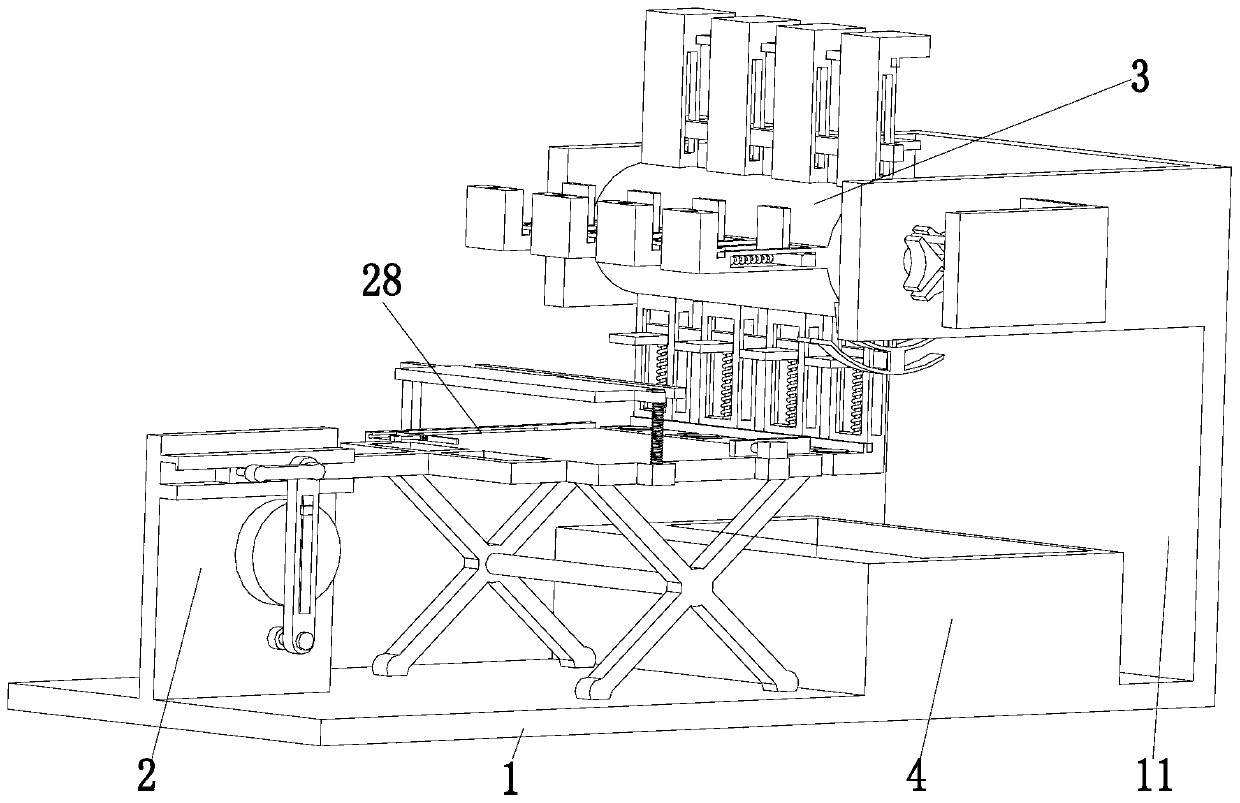

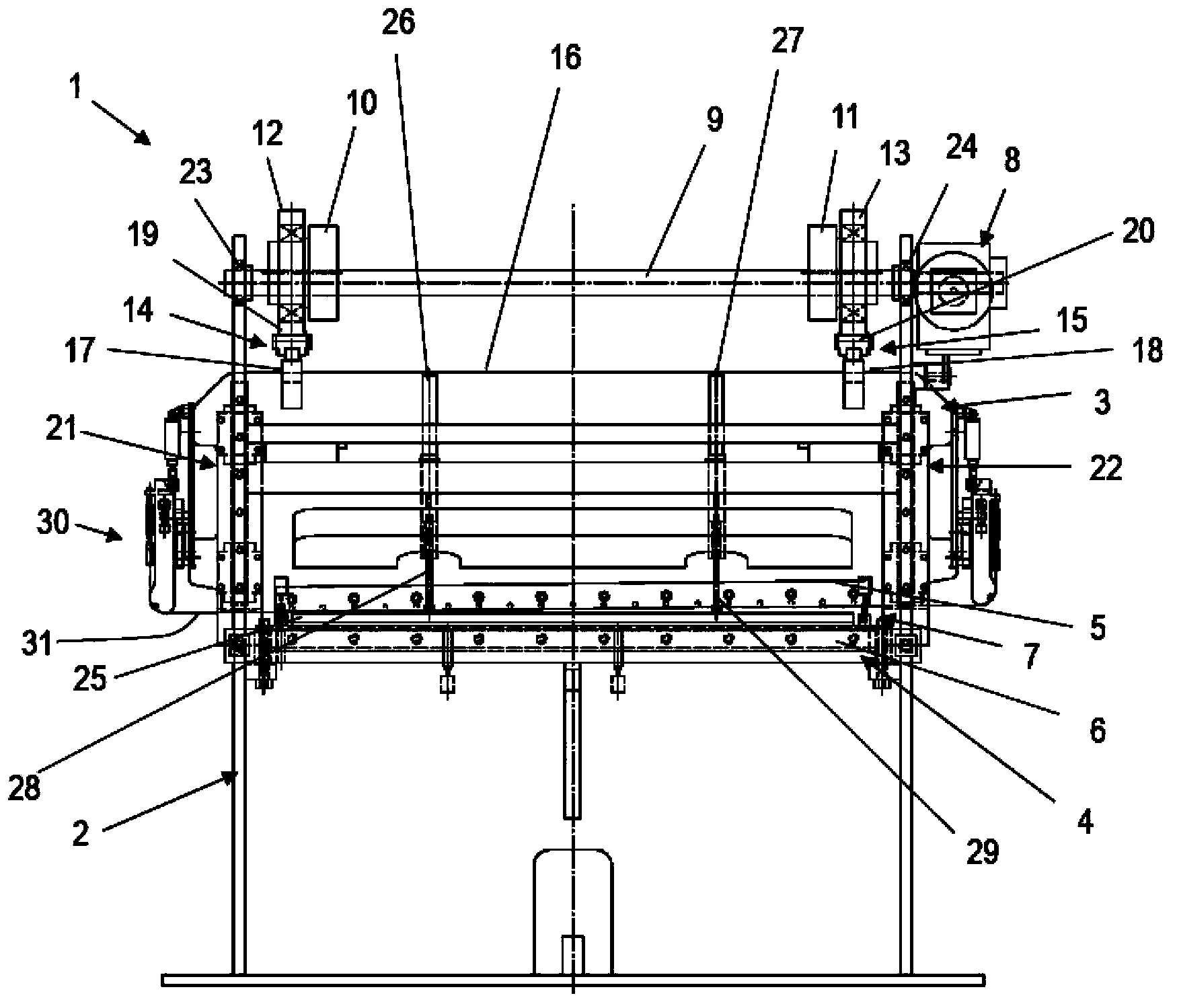

Novel automatic plate wrapping equipment for large lead-acid storage battery pole group

PendingCN108199093ASimple structureShort positioning timeFinal product manufactureLead-acid accumulator electrodesPhysical well beingEngineering

The invention discloses novel automatic plate wrapping equipment for a large lead-acid storage battery pole group and belongs to the technical field of battery production equipment and aims to solve the problems that existing plate wrapping procedures for battery production are performed manually, are low in efficiency and high in labor intensity, require a large quantity of manual labor, cause dust pollution to the environment and ruin body health of relevant employees. A finished product lifting conveying mechanism is fixedly connected with a rack, a positive pole arrangement cylinder and two negative pole arrangement cylinders are fixed on the rack, the positive pole arrangement cylinder is arranged above a positive pole lifting mechanism of the finished product lifting conveying mechanism, the negative pole arrangement cylinders are arranged above two negative pole lifting mechanisms of the finished product lifting conveying mechanism, a diaphragm coiled material discharging mechanism is fixedly mounted on the rack and arranged between the positive pole arrangement cylinder and the negative pole arrangement cylinders, a positive and negative plate transferring mechanism is fixed on the rack and arranged on the rear sides of the positive pole arrangement cylinder and the negative pole arrangement cylinders. The production efficiency is improved.

Owner:中山慧能科技有限公司

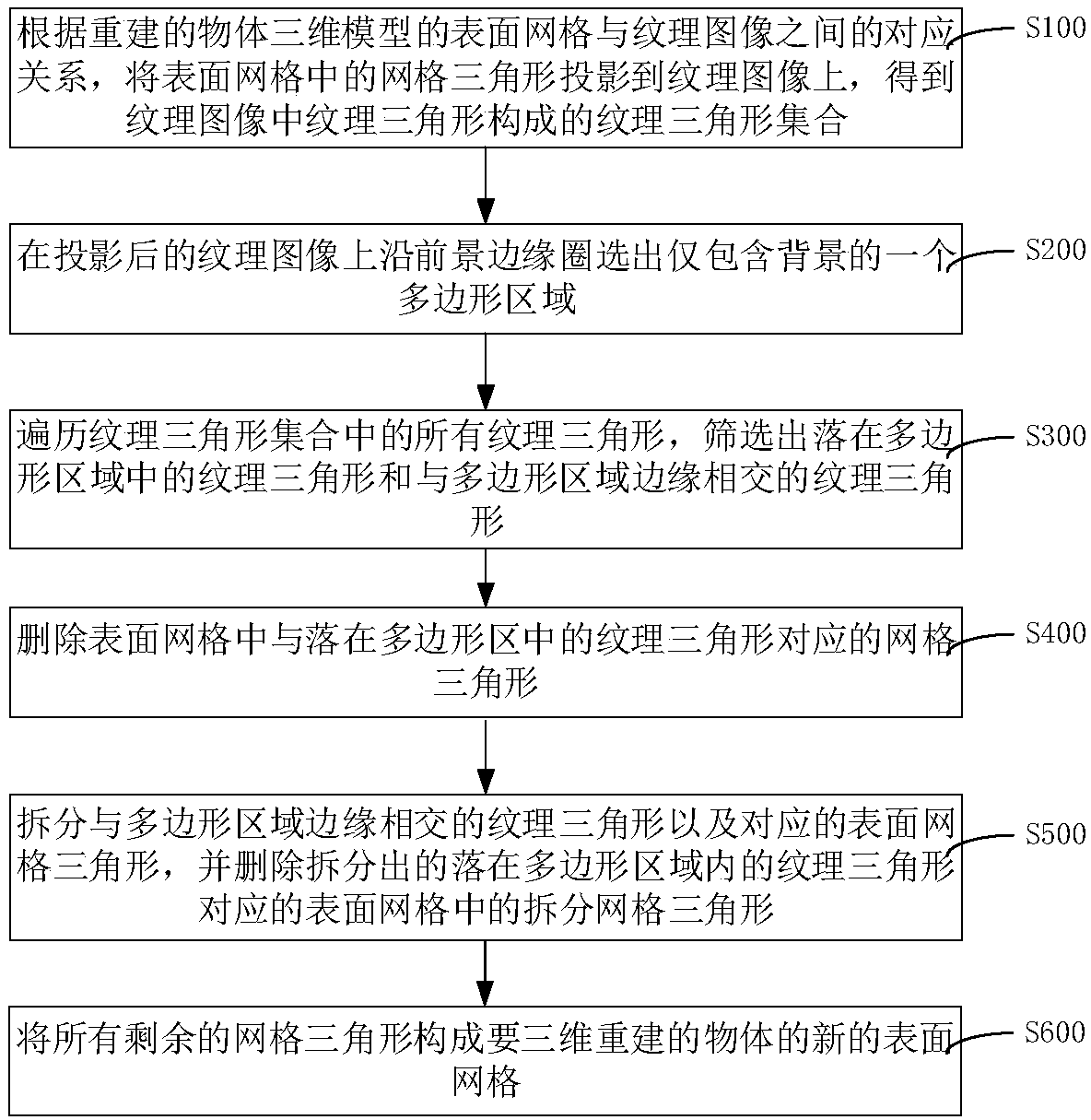

Texture-based interactive mesh model cutting method and device and modeling device

ActiveCN109003333AAccurate cutImprove processing precision3D modellingComputer graphics (images)Mesh model

The invention discloses a texture-based interactive mesh model cutting method and device and modeling device. The method comprises the following steps: according to the correspondence between the surface mesh of the reconstructed object three-dimensional model and the texture image, projecting the mesh triangle in the surface mesh onto the texture image to obtain the texture triangle set formed bythe texture triangle in the texture image; selecting a polygon region containing only the background on the projected texture image; traversing all the texture triangles in the set of texture triangles, and filtering out the texture triangles that fall in the polygon region and intersect with the edges of the polygon region; removing a mesh triangle corresponding to a texture triangle falling ina polygon region; splitting a texture triangle intersecting with the edge of the polygon region and a corresponding surface mesh triangle, and deleting the splitting triangle in the surface mesh corresponding to the texture triangle falling in the polygon region; building a new surface mesh of a newly-built object three-dimensional model.

Owner:浙江景致数据技术有限公司

Automatic cutting equipment of integrated circuit tube shell lead frame

InactiveCN110142331AAccurate cutSmooth cutMetal working apparatusPressesAutomatic test equipmentControl system

The invention discloses automatic cutting equipment of an integrated circuit tube shell lead frame. The automatic cutting equipment comprises a workbench, a male die supporting seat, a female die, a male die driving air cylinder, a male die, an exhaust waste gas cylinder, a positioning push rod and a photoelectric control system, wherein the male die supporting seat and the female die are fixed onthe workbench, the male die driving air cylinder is fixed on the male die supporting seat, the male die is connected with the male die driving air cylinder and faces the female die, the exhaust wastegas cylinder which is fixed on the male die supporting seat and faces the female die, and the positioning push rod is connected to the exhaust waste gas cylinder. According to the automatic cutting equipment, the precise cutting of the integrated circuit tube shell lead frame is realized by adopting pneumatic technology, photoelectric sensing control technology and precise die blanking technology, and the automatic cutting equipment is automatically separated from a waste material, mechanically controlled, and accurately and rapidly cut.

Owner:刘玉琦

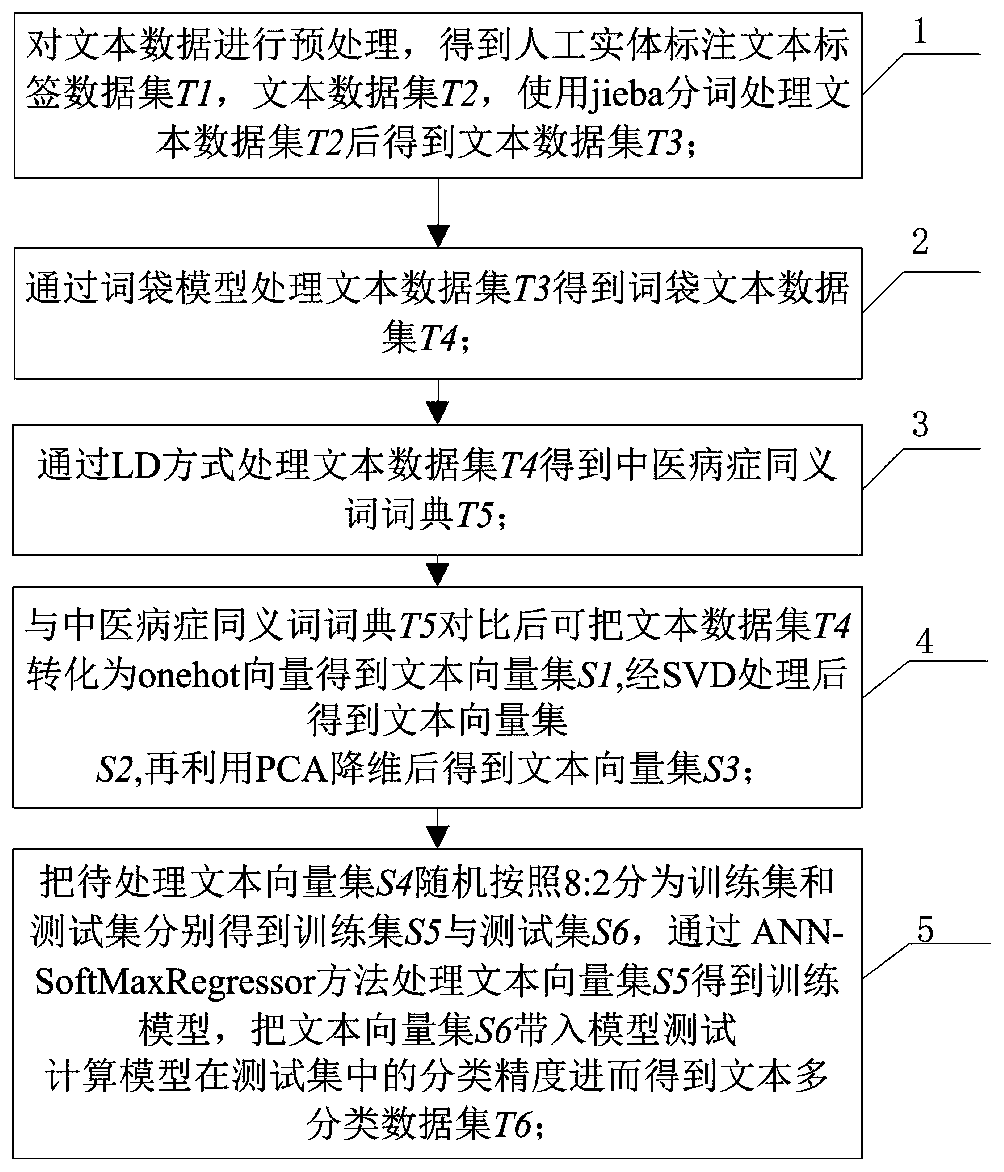

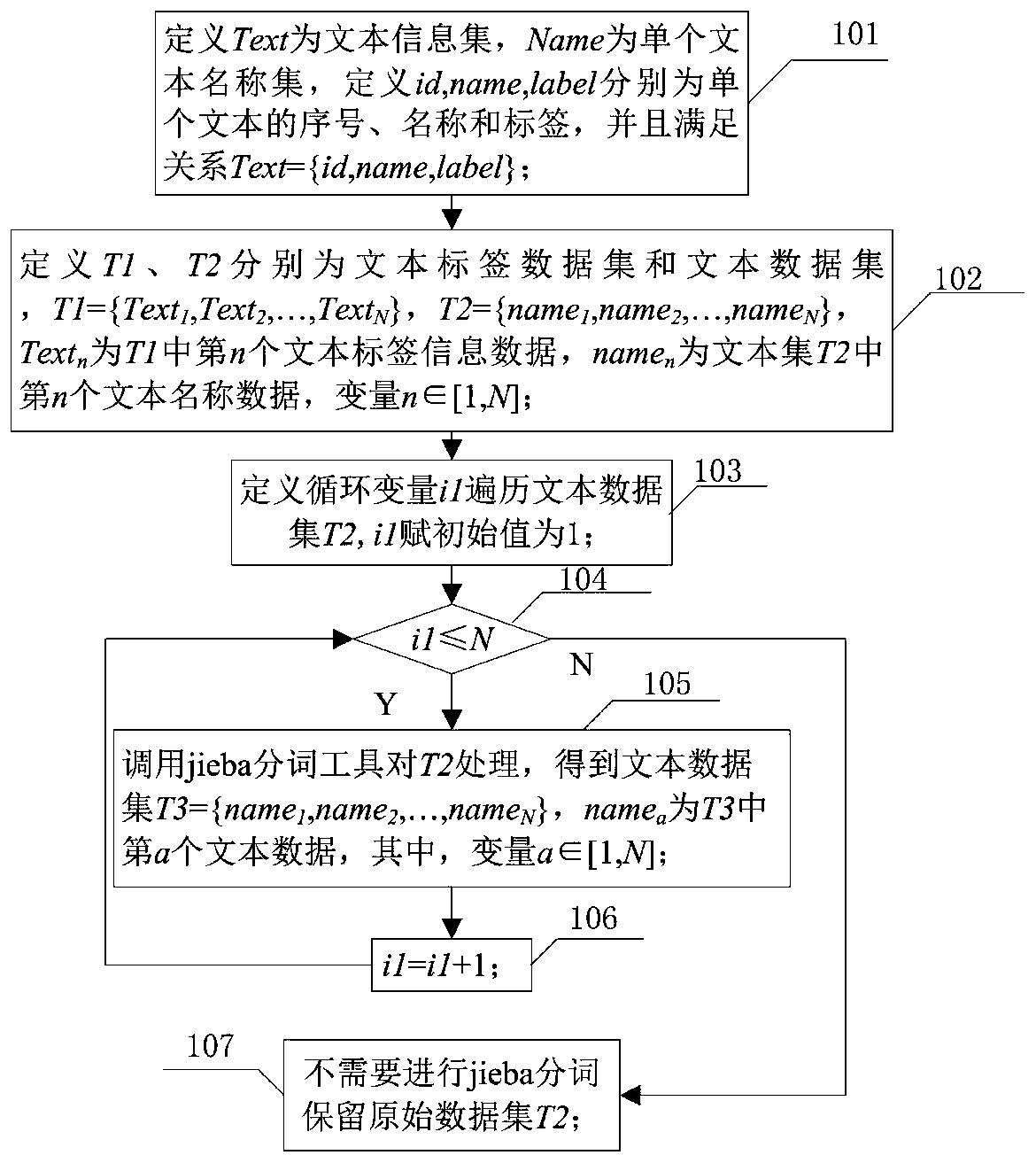

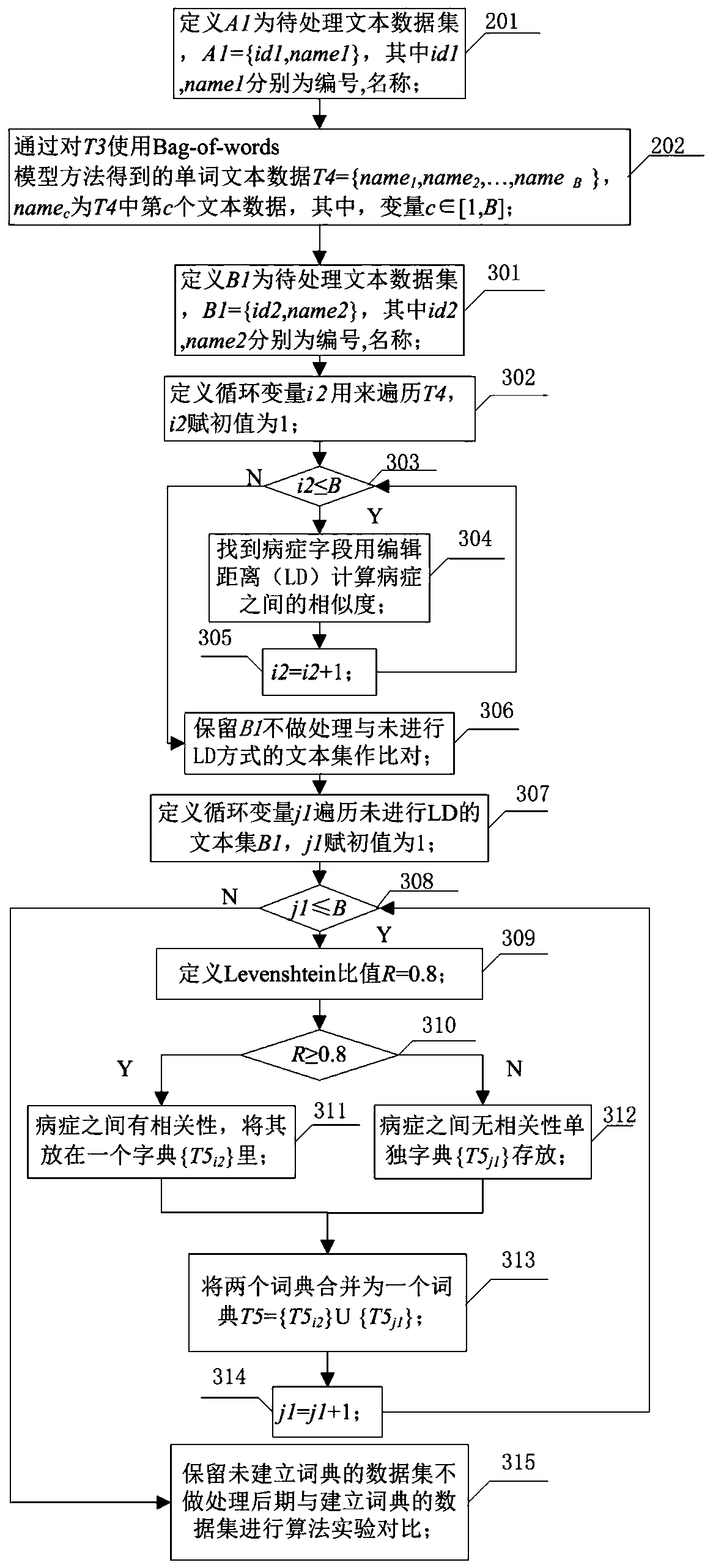

Traditional Chinese medicine short text multi-classification method based on LD and ANN-SoftMax Regressor

ActiveCN110413781AImprove classification accuracyHigh precisionSpecial data processing applicationsNeural learning methodsDiseaseClassification methods

The invention discloses a traditional Chinese medicine short text multi-classification method based on an LD and ANN-SoftMax Regressor. The method is mainly based on constructed text label data labeled by an artificial entity to process data on the traditional Chinese medicine short text data. Firstly, a jaeba word segmentation tool is adopted for word segmentation, and then a Bag-of-Words model is adopted for processing. A symptom synonym dictionary is established in an LD mode to perform dimension reduction processing on text onehot vectorization representation after word bag construction byutilizing SVD and PCA, and then ANN-SoftMax Regressor multi-classification training is performed to finally obtain the traditional Chinese medicine short text multi-classification method. The methodis suitable for the field of traditional Chinese medicine and short text classification, and can effectively enable fuzzy symptom classification of diseases to be more accurate.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

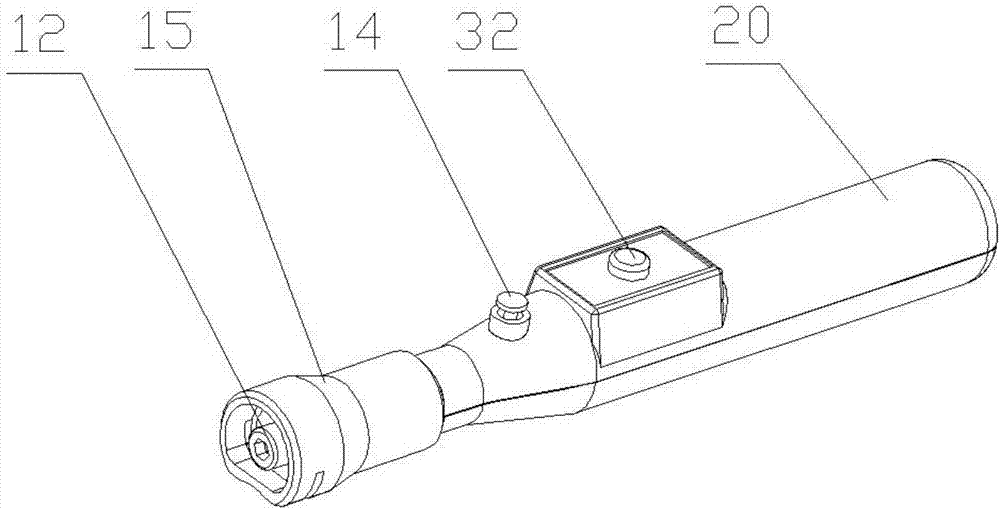

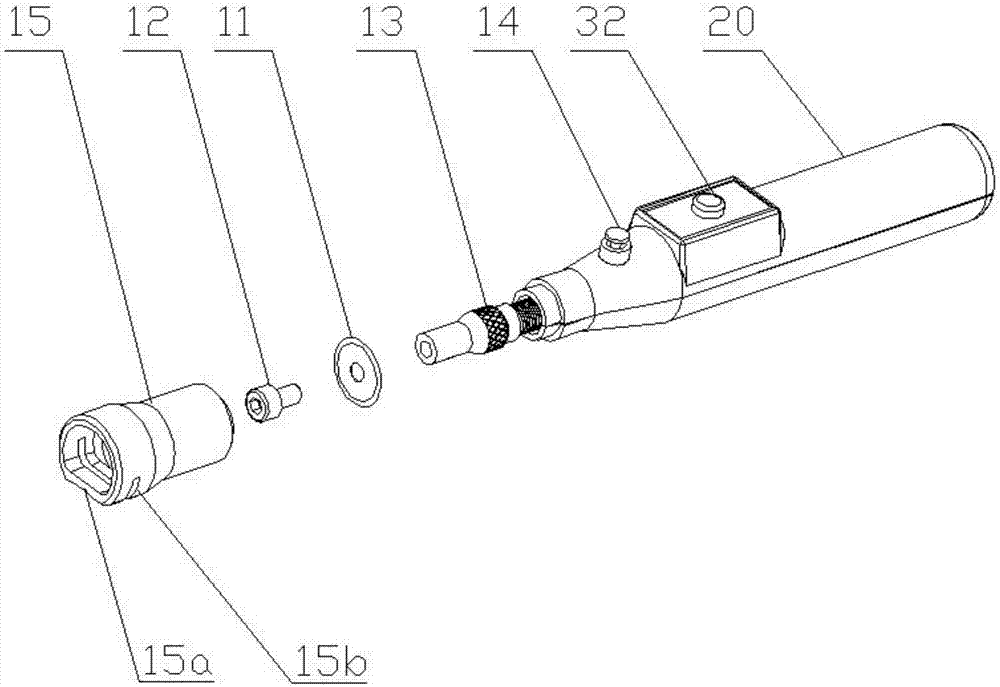

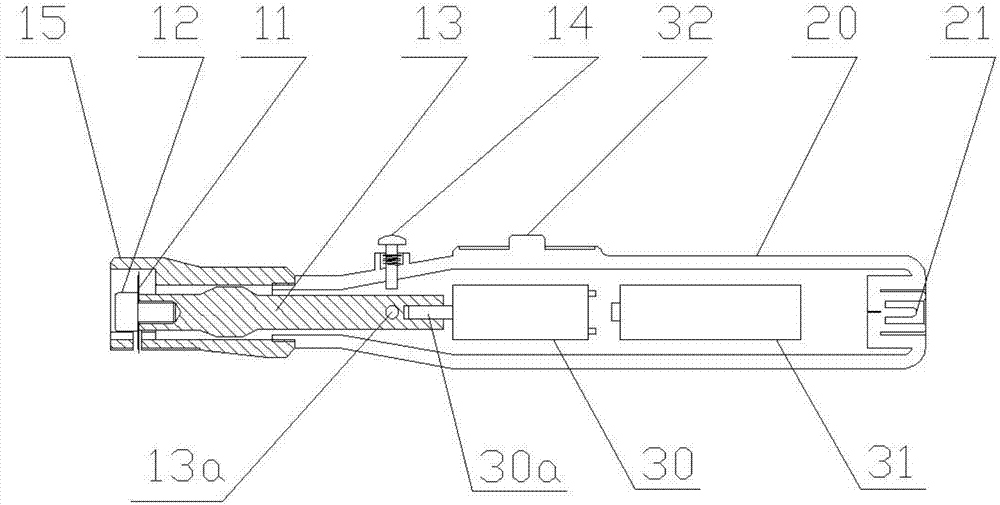

Electric rotary-cutting safe scalpel

PendingCN107496010AHigh precisionSmooth edgeIncision instrumentsExcision instrumentsSurgical knifeEngineering

The invention discloses an electric rotary-cutting safe scalpel. The scalpel comprises a handle and a scalpel head at the front end of the handle, and the scalpel head comprises a circular blade (11) and a protective cover (15); the circular blade (11) is fixed to one end of a rotation shaft (13) through a fastening bolt (12), the other end of the rotation shaft (13) is connected with an output shaft (30a) of a motor (30), and the motor (30) is arranged in a containing cavity (20) of the handle; the protective cover (15) is arranged at the front end of the containing cavity (20) and covers the circular blade (11). The electric rotary-cutting safe scalpel is convenient to use, an operator only needs to place the scalpel edge onto the surface of tissue to be cut and can accurately and rapidly cut the tissue, and the effects are achieve that that the cut size is precisely controlled and smooth and neat incisions are cut; the electric rotary-cutting safe scalpel obviously improves the surgical efficiency and surgical quality, is more ingenious than an ordinary scalpel, is easier and safer to operate, and greatly reduces the psychological burdens of doctors and patients.

Owner:丁允志

High-speed backboard connector backboard assembling equipment and assembling process

PendingCN110783795AFast loading and unloadingSmall footprintContact member assembly/disassemblyBackplaneStructural engineering

The invention relates to high-speed backboard connector backboard assembling equipment and an assembling process. The high-speed backboard connector backboard assembling equipment comprises a bottom plate, a feeding and discharging mechanism, a moving mechanism, a material roll, a feeding mechanism, a cutting mechanism, a carrying mechanism and an assembling mechanism. By using the high-speed backboard connector backboard assembling equipment and the assembling process, through cooperation of the feeding and discharging mechanism and the moving mechanism, rapid feeding and discharging of products can be achieved, and an occupied space is small; through cooperation of the feeding mechanism and the cutting mechanism, accurate feeding and rapid cutting of a material belt can be achieved, cutting precision is high, and quality of material sheets is good; through the carrying mechanism, accurate assembling of the material sheet and a plastic shell can be achieved, and the material sheet canbe prevented from being separated from the plastic shell through pre-pressing; and through the assembling mechanism, the material sheet and the plastic shell can be fixed together, two sides of thematerial sheet can be pressed downwards, and edge warping is prevented.

Owner:昆山三智达自动化设备科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com