Paperboard cutting device

A cardboard and cutting technology, which is applied in metal processing and other directions, can solve the problems of inaccurate cutting length, affecting the stability of cardboard transmission, and poor cutting effect of corrugated cardboard, so as to prevent the effect of obstruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

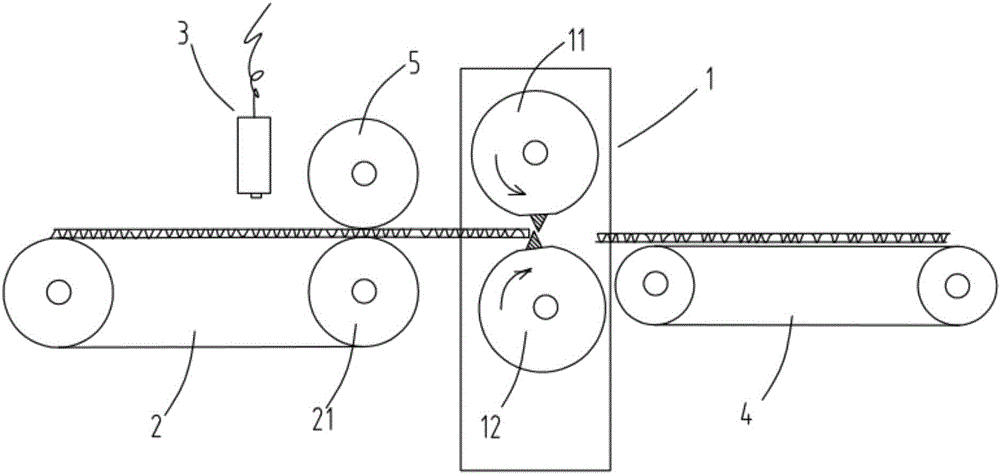

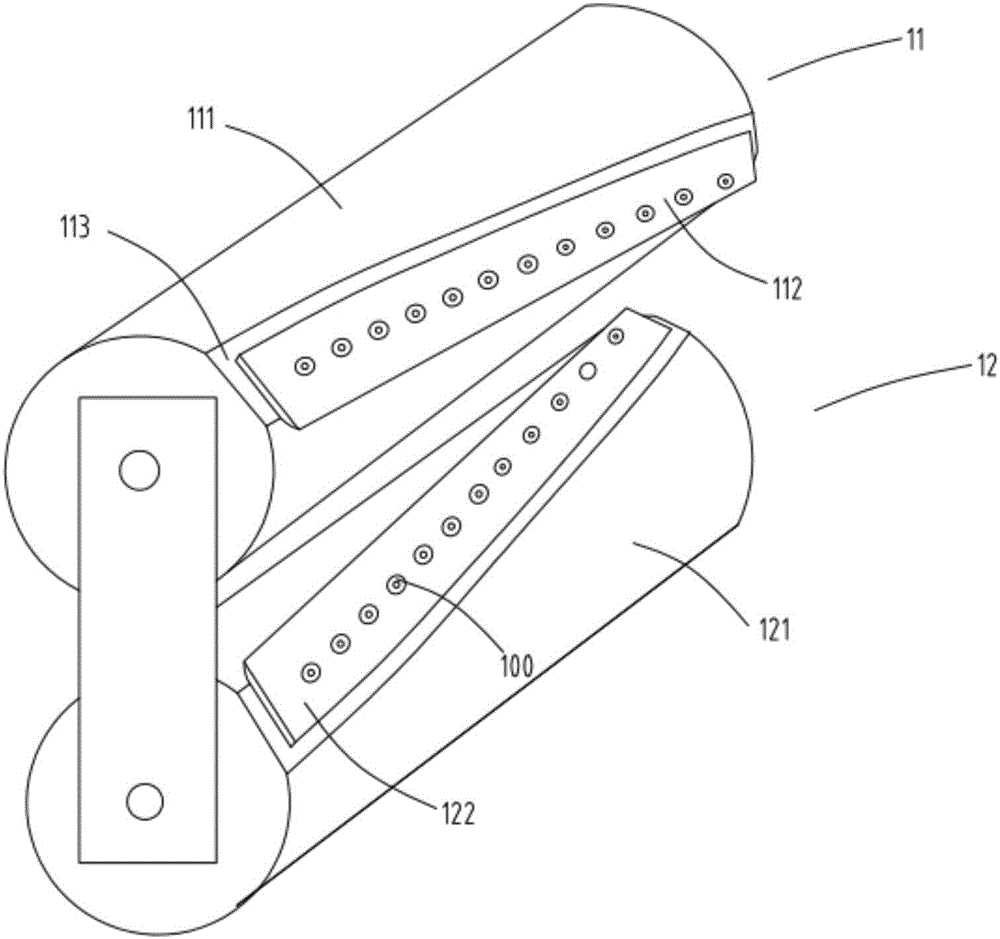

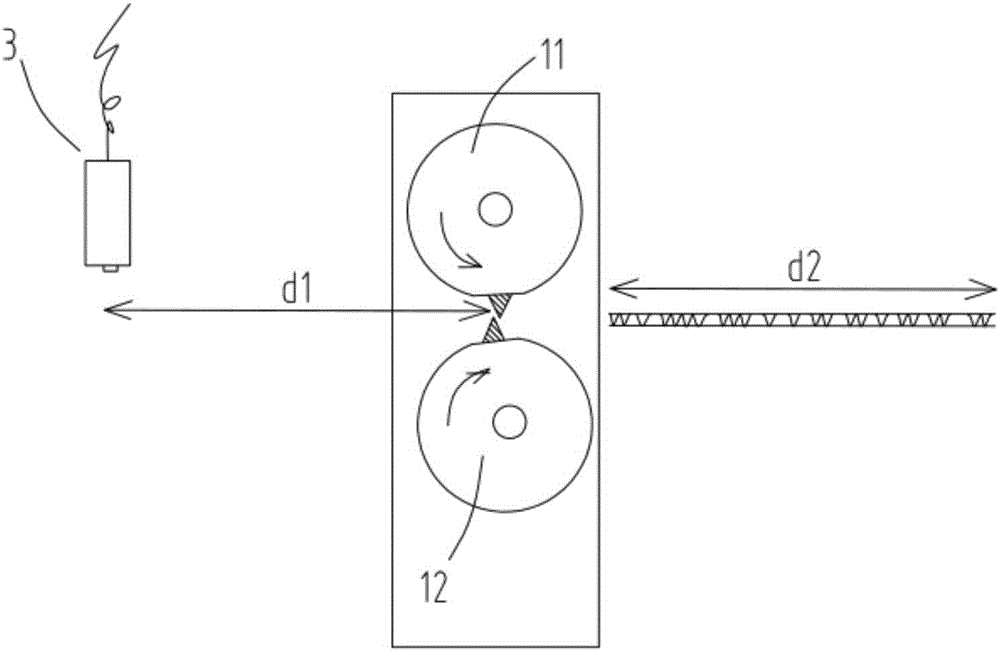

[0022] figure 1 A schematic diagram of the cardboard cutting equipment, figure 2 Schematic diagram of positioning the laminating part for the face paper, image 3 It is a structural schematic diagram of the upper roller knife and the lower roller knife. like figure 1 , figure 2 , image 3 As shown, what is provided in this embodiment is a cardboard cutting device, including a cross-cutting machine 1, a paper feeding belt 2 for feeding cardboard 10 into the cross-cutting machine 1, and a sensor 3 for controlling the operation of the cross-cutting machine 1 The paper feeding belt 2 is arranged on the front end of the cross cutting machine 1; the sensor 3 is arranged on the front end of the cross cutting machine 1 and the upper end of the paper feeding belt 2; the cross cutting machine 1 includes an upper roller knife 11 and a lower roller Knife 12; the upper roller knife 11 includes a counterclockwise-rotating upper roller 111 and a cutter a112 arranged on the upper rolle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com