Method for carrying out 10kV charged wire connecting operation by CO2 laser cable peeling device

A technology of CO2 and lead wires, which is applied in the direction of cable installation device, cable installation, overhead line/cable equipment, etc., can solve the problems of high risk factor, impossibility of popular use, current overload and heat generation, etc., and meet the requirements of safety and manufacturability Requirements, realize remote all-round monitoring, and increase the effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0041] A use of CO 2 The laser cable peeling device performs 10kV live wire connection operation method, including the following steps:

[0042] 1) Operators should wear insulating and protective equipment, and provide reliable insulation and shielding for charged and grounded bodies within the scope of work;

[0043] 2) Make sure that the line to be connected has no ground short circuit and is well insulated;

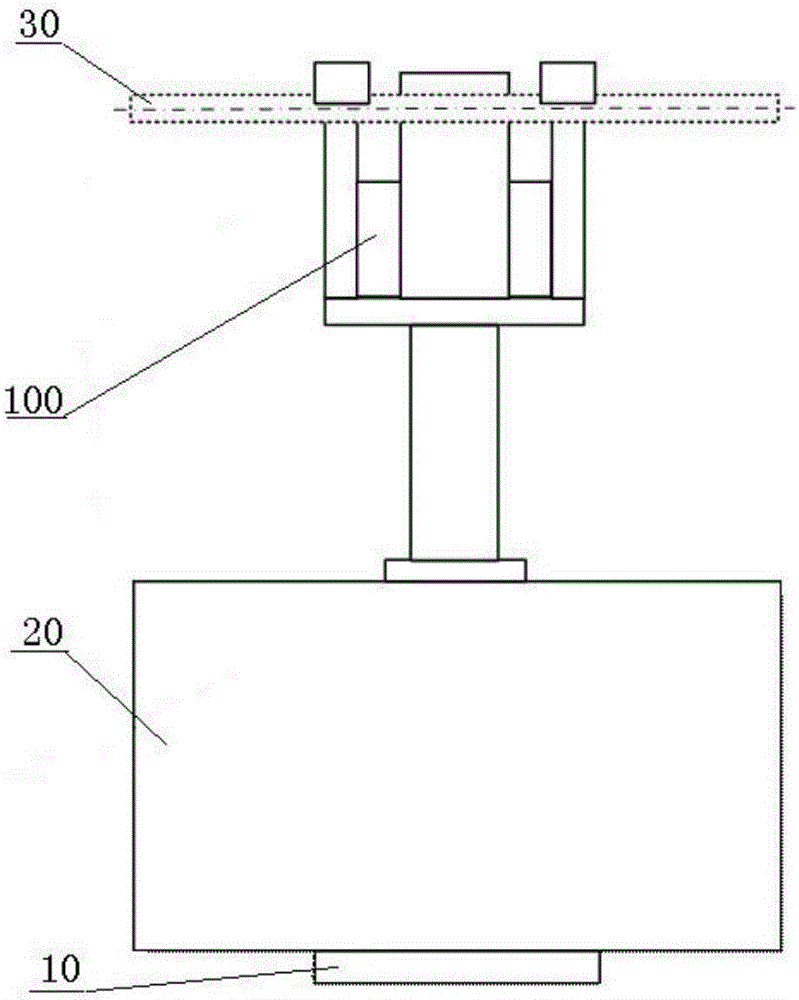

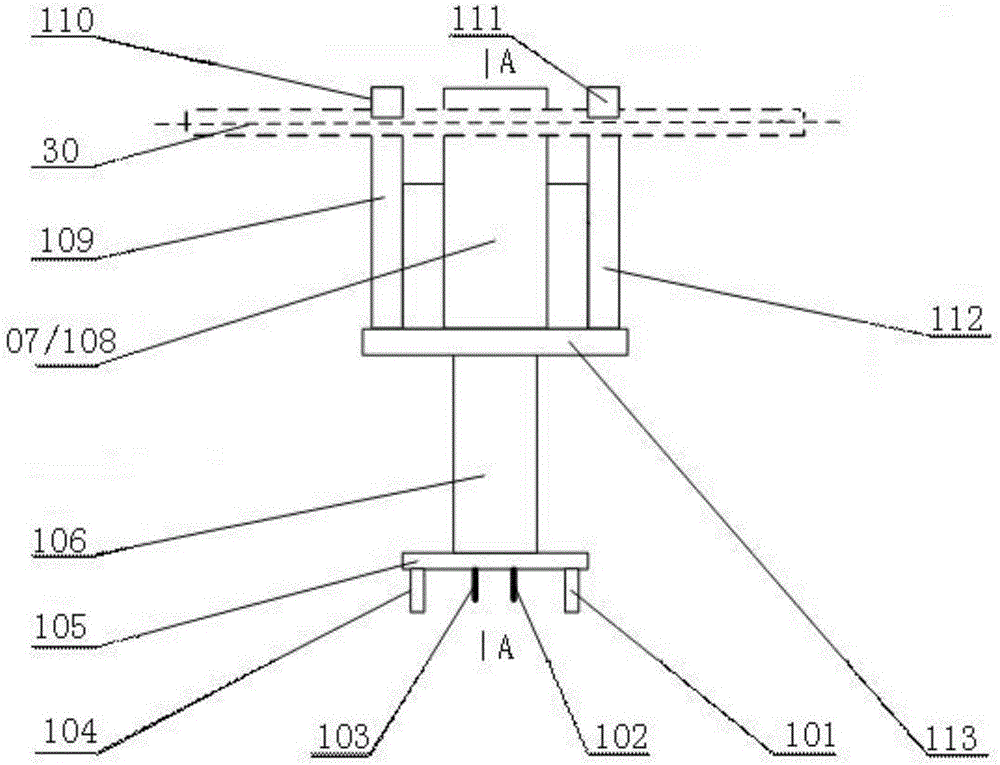

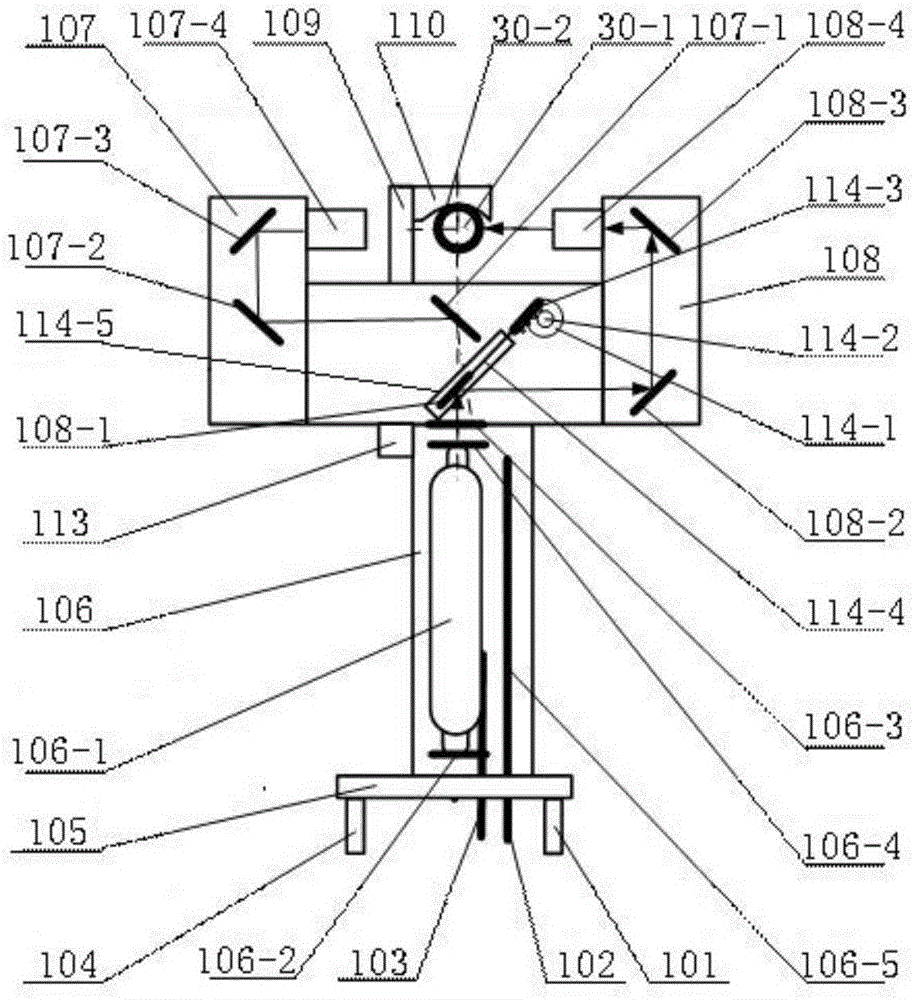

[0044] 3) CO 2 The laser cable peeling device 100 is lifted to the operating point of the live lead wire by an insulated bucket truck, and the CO 2 The laser cable peeling device 100 is suspended on the live wire 30, and its cutting laser beam emission positions are respectively located on both sides of the live wire 30;

[0045] 4) start CO 2 The laser cable peeling device 100 cuts out "H"-shaped incisions on both sides of the live w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com