Novel automatic plate wrapping equipment for large lead-acid storage battery pole group

A lead-acid battery, large-scale technology, applied in the direction of lead-acid battery electrodes, lead-acid battery construction, lead-acid battery, etc., can solve the problems of endangering the health of employees, large demand for artificial labor, dust pollution and other problems, to save time and energy, high positioning accuracy, and precise cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

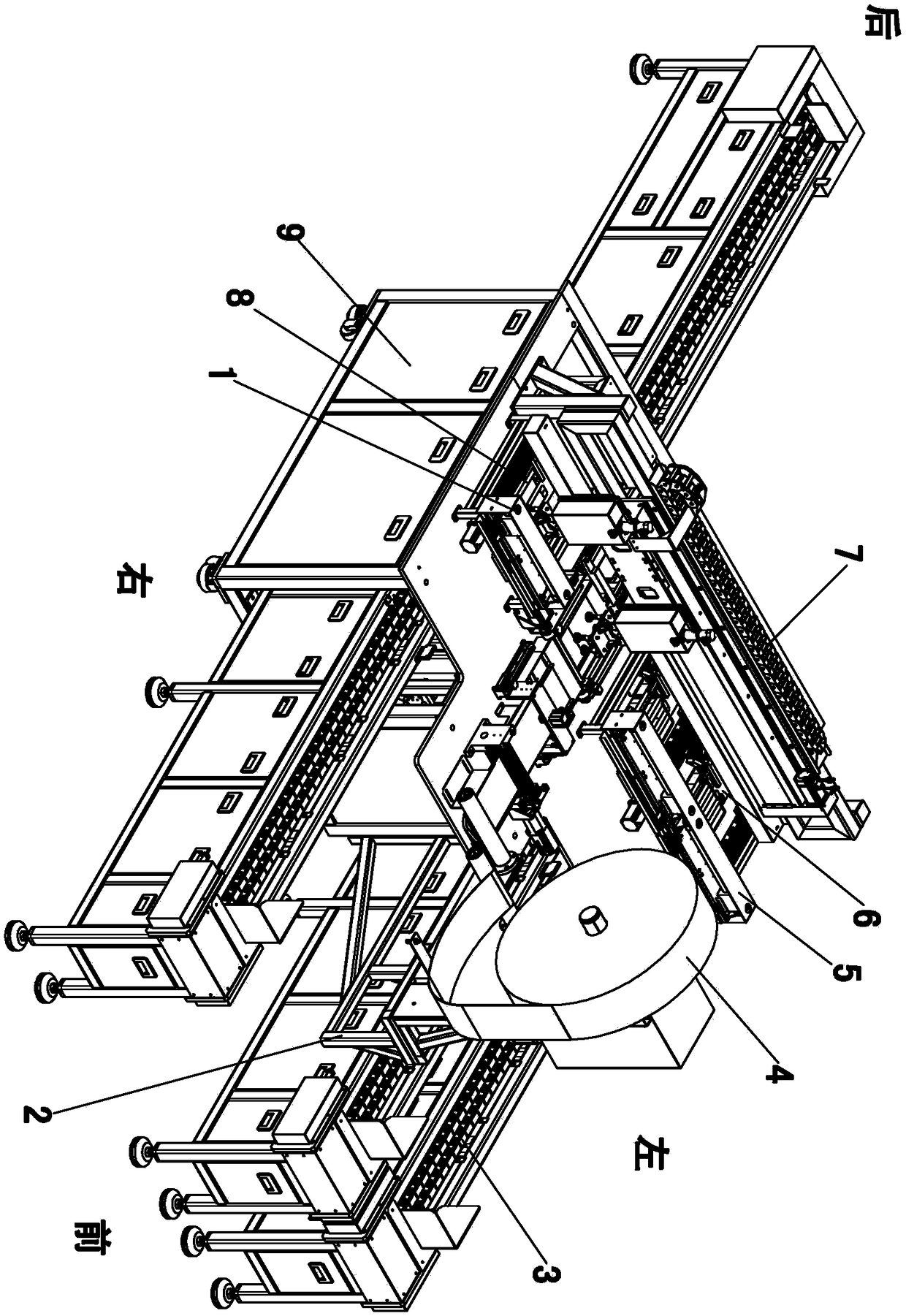

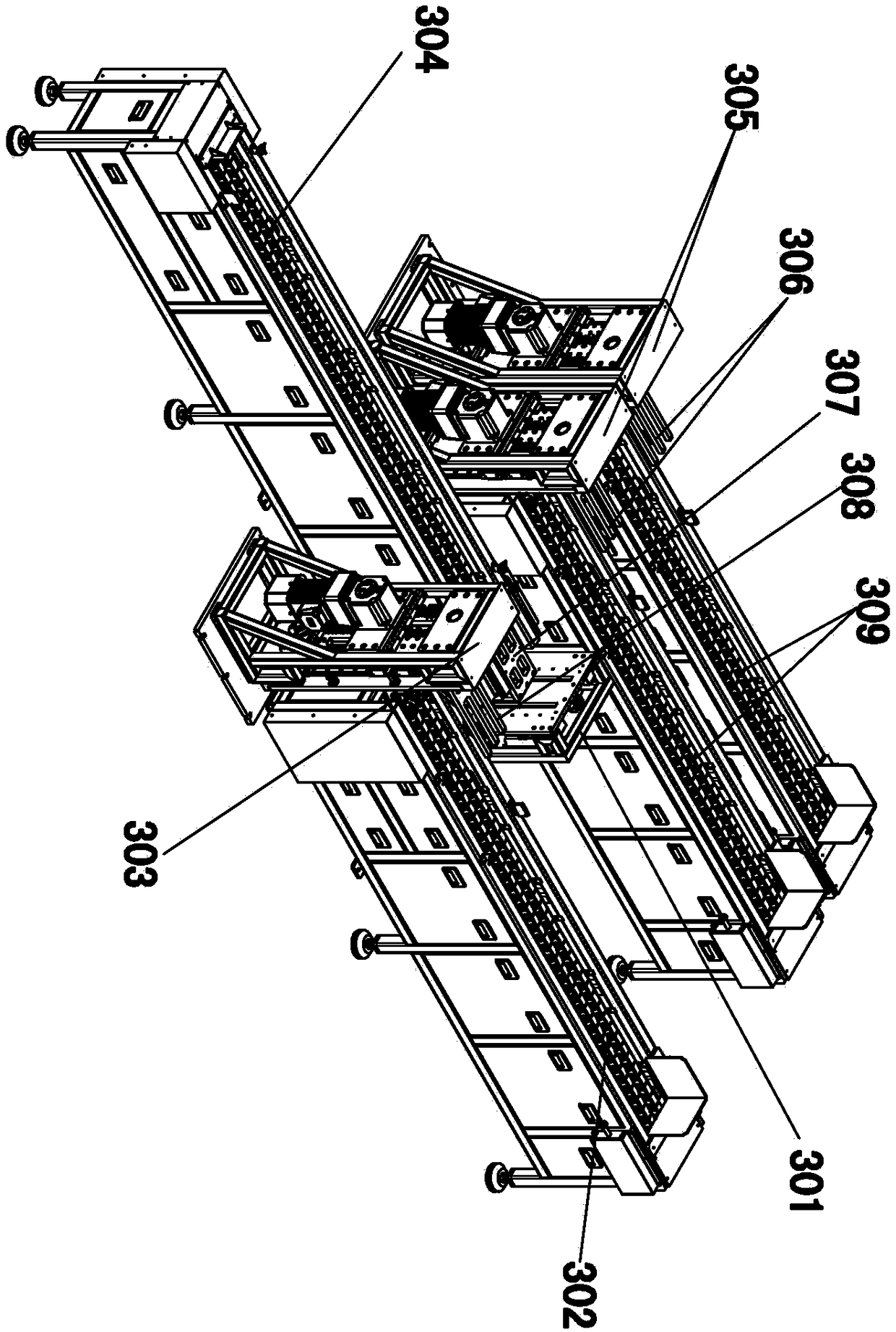

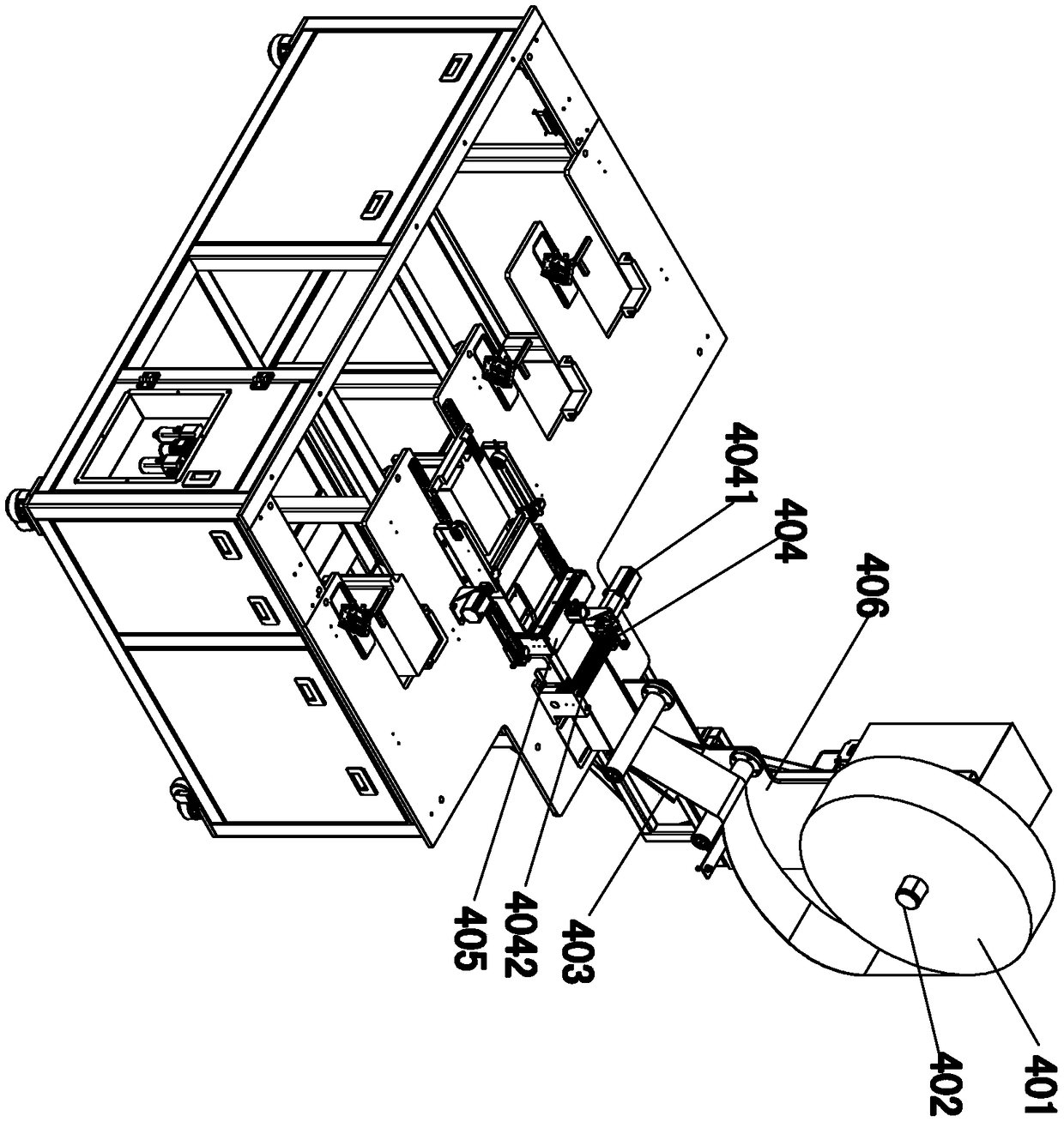

[0019] Such as Figure 1 to Figure 8 As shown, a new type of large-scale lead-acid battery electrode group automatic plate wrapping equipment, including a frame 9, a finished product lifting and conveying mechanism 3, a separator coil material discharging mechanism 4, a negative electrode finishing cylinder 6, a positive and negative electrode plate transfer mechanism 7 and Positive finishing cylinder 8; the finished product lifting and conveying mechanism 3 is fixedly connected with the frame 9 by bolts, the positive finishing cylinder 8 and two negative finishing cylinders 6 are all fixed on the frame 9, and the positive finishing cylinder 8 is arranged on the finished lifting Above the positive pole lifting mechanism 303 of the conveying mechanism 3, the negative electrode sorting cylinder 6 is arranged above the two negative pole lifting mechanisms 305 of the finished product lifting conveying mechanism 3, and the separator coil material discharging mechanism 4 is fixedly i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com