Automatic cutting device for automobile trim skin and cutting method

An automatic cutting device, a technology for automobile interior decoration, applied in the field of cutting machines, can solve the problems of decreased product stability, low utilization rate of coil materials, increased cost, etc., and achieve the effects of reducing investment, saving labor costs, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

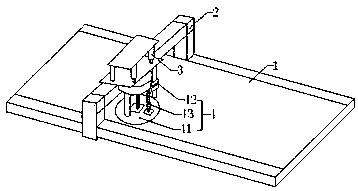

[0028] The invention discloses an automatic cutting device for automobile interior skin, comprising: a cutting table 1, a crossbeam 2, a cylinder 3 and a cutting head 4; the crossbeam 2 is fixed on the cutting table 1, the cylinder 3 is fixed on its top surface, and the cutting machine head 4 is installed on its bottom surface.

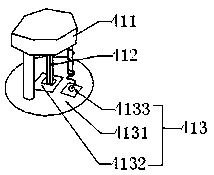

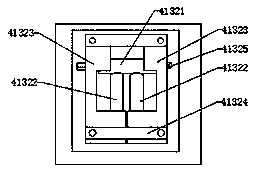

[0029] The cutting head 4 includes a cutter head frame 41, a cutter head electric sharpening system 42 and a cooling system 43; wherein, the cutter head frame 41 is made of aluminum alloy, which is durable and includes a TG transmission shaft (not shown), Fixed disc 411, cutter 412 and cutter disc 413, the TG transmission shaft is connected to the power output end of the cylinder 3, the fixed disc 411 is fixed on the beam 2, the top of the cutter 412 runs through the The fixed disc 411 is fixed on the TG transmission shaft, and its bottom end runs through the cutter disc 413, and moves up and down under the drive of the cylinder 3, thereby driving the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com