Preparation method of display substrate, display substrate and display device

A technology for display substrates and array substrates, applied in semiconductor/solid-state device manufacturing, diodes, semiconductor devices, etc., can solve problems such as the decrease in aperture ratio, achieve the effects of eliminating the decrease in aperture ratio, increasing the aperture ratio, and avoiding preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

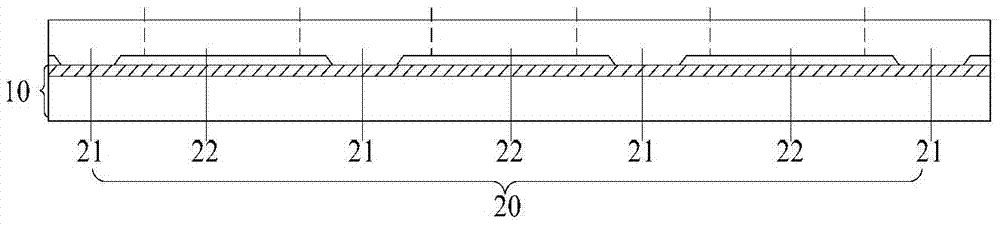

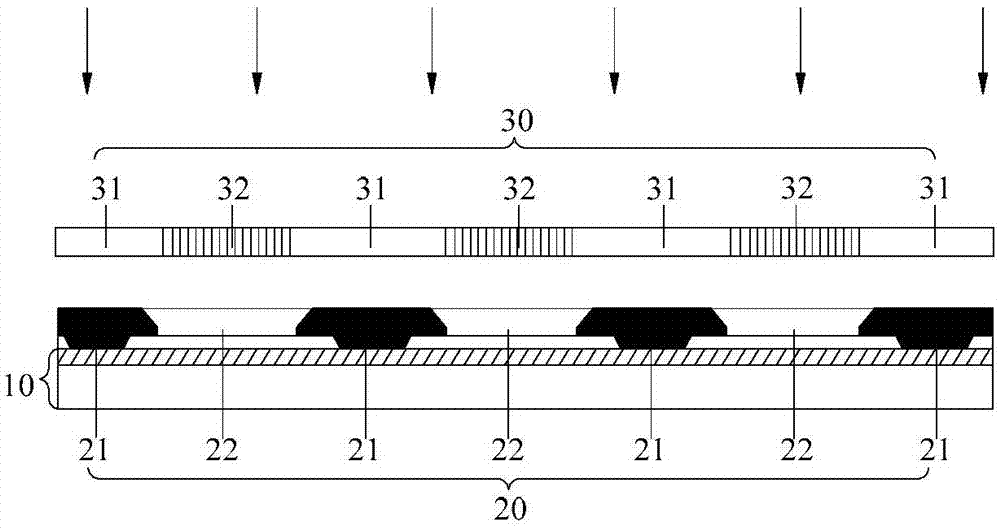

[0026] As mentioned in the background art, in the prior art, the color filter is directly prepared on the array substrate, which complicates the film layer structure of the display substrate, and further reduces the aperture ratio to a certain extent. In order to solve this problem, the inventor thought that: since the pixel defining layer on the array substrate is located in its non-pixel area, and when the color filter is prepared on the array substrate, the black matrix of the color filter is also located on the array substrate. In the non-pixel area, therefore, a pixel-defining layer with light-shielding properties can be prepared to replace the black matrix to play a light-shielding function, so that the black matrix can be removed from the substrate. Starting from this idea of the invention, the inventors of the present invention consider that the pixel defining layer is generally formed by patterning process, and the forming material of the pixel defining layer mainly ...

Embodiment 2

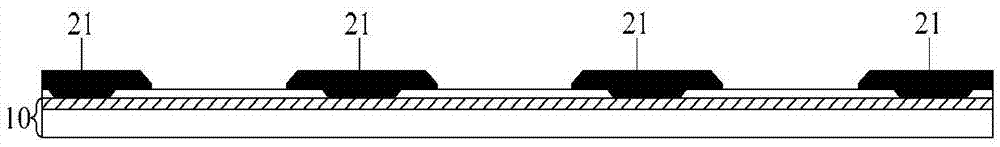

[0061] An embodiment of the present invention provides a display substrate, see Figure 7 and Figure 8 , the display substrate includes an array substrate 10 and a pixel defining layer 40 uniformly distributed with a photochromic material, the pixel defining layer 40 is arranged on the non-pixel area of the array substrate 10, and the photochromic material can be transmitted by light under the action of light The light becomes light-shielding, so that the pixel defining layer containing the photochromic material can change from light-transmitting to light-shielding under the action of light, and the transformation of the pixel defining layer from light-transmitting to light-shielding is irreversible.

[0062] Since the photochromic material is evenly distributed in the pixel defining layer 40 of the above display substrate, the photochromic material can change from light transmission to light shielding under the action of light, so when preparing the pixel defining layer of...

Embodiment 3

[0068] An embodiment of the present invention provides a display device, which includes the display substrate in the second embodiment above.

[0069] In the display substrate of the above-mentioned display device, the photochromic material is evenly distributed in the pixel defining layer, and the photochromic material can change from light transmission to light shielding under the action of light, so that only by exposure, light, etc., the formation of The pixel defining layer has the effect of shading. Therefore, the above-mentioned display device can prepare a light-shielding pixel defining layer through a simple patterning process, and replace the black matrix with the light-shielding pixel defining layer, which simplifies the film layer structure of the display substrate, thereby solving the problem of color filter preparation. On the array substrate, the problem of decreasing the aperture ratio is caused, and the aperture ratio of the display device is improved. At the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com