Organic lighting element color pixel array mode and its forming method

A pixel and element technology, applied in the field of color display panels, can solve the problems of mask etching manufacturing difficulties, difficulty in manufacturing high-resolution OLED displays, misalignment and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

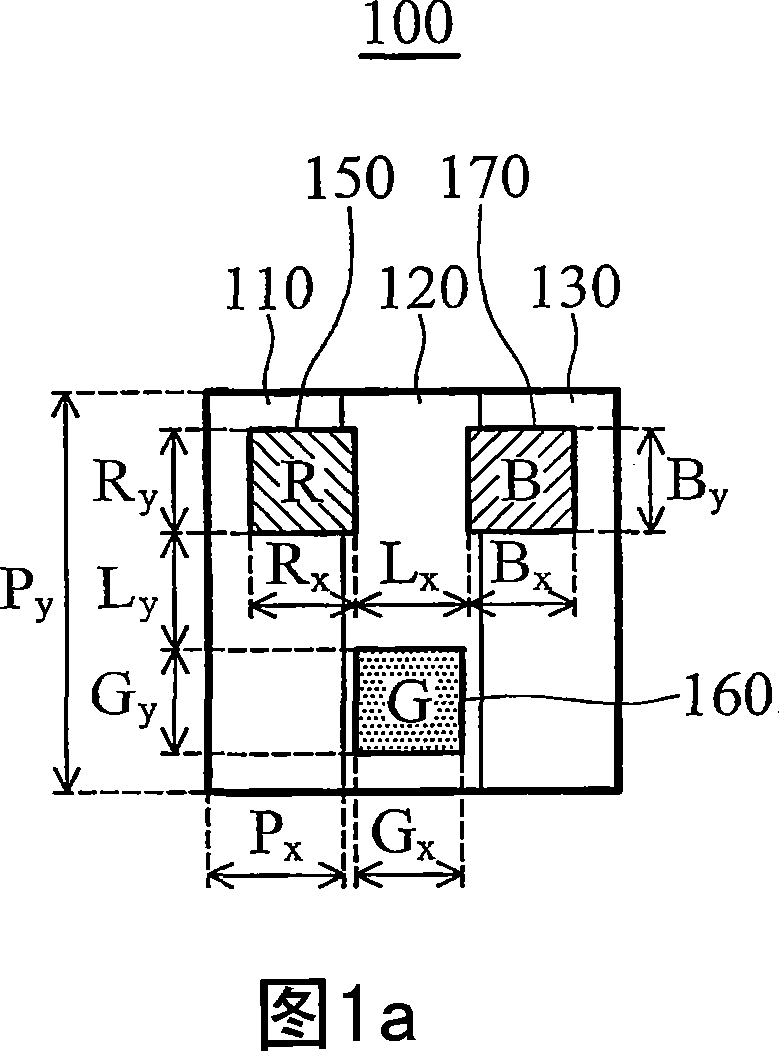

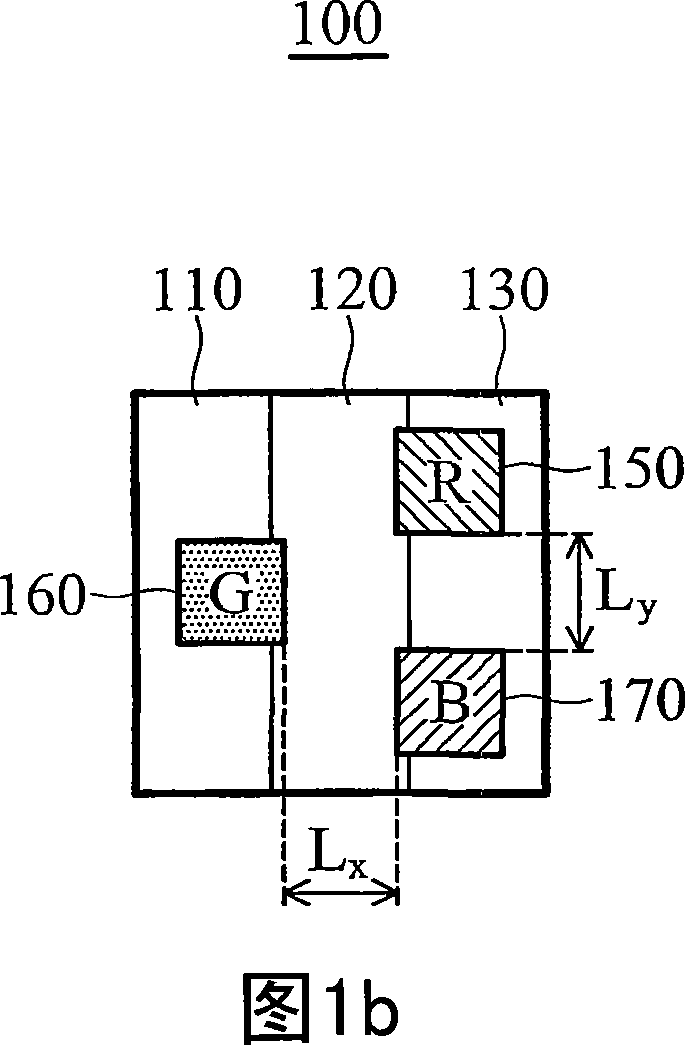

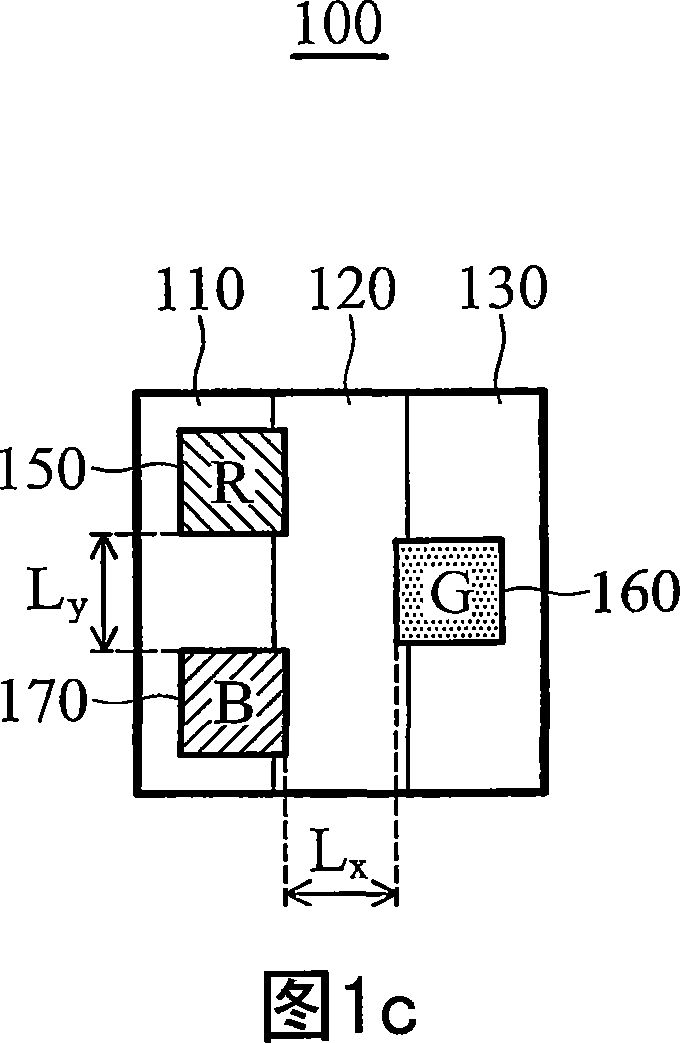

[0069] The full-color display panel of the present invention has a plurality of pixels arranged in a matrix in a row direction and a column direction perpendicular to the row direction. Referring to FIGS. 1 a to 1 c , each pixel 100 includes a first sub-pixel 110 , a second sub-pixel 120 and a third sub-pixel 130 , which are adjacent to each other and arranged along the row direction of the pixel matrix. Each sub-pixel ( 110 , 120 , 130 ) is substantially equal, and has a sub-pixel pitch Px in a row direction and a sub-pixel pitch Py in a column direction. The sub-pixel pitch Px in the row direction and the sub-pixel pitch Py in the column direction together define the sub-pixel area, that is, (Px×Py).

[0070] In addition, each pixel 100 has a red (sub-pixel) light-emitting area 150, a green (sub-pixel) light-emitting area 160 and a blue (sub-pixel) light-emitting area 170, which are arranged in a triangle, and each sub-pixel light-emitting area ( 150, 160, 170) have their g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com