Pixel drive circuit of OLED (Organic Light Emitting Diode) display and drive method thereof

A pixel driving circuit and driving method technology, applied in static indicators, instruments, etc., can solve the problems affecting the use of large-screen high-resolution displays, and the long charging time of current-programmed pixel driving circuits, so as to improve the aperture ratio and circuit Simple and reliable, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

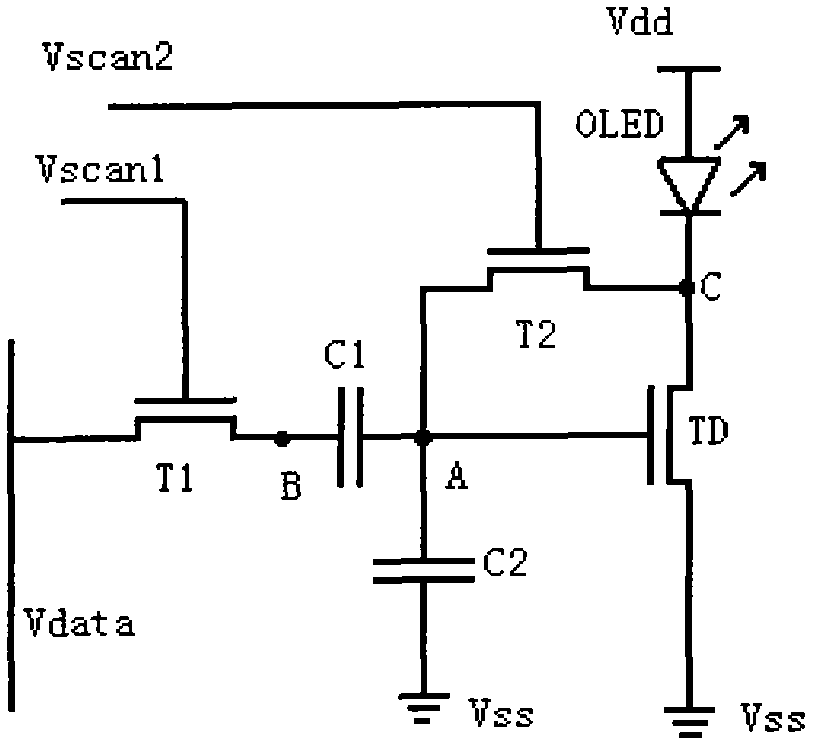

[0029] Such as image 3 As shown, the pixel driving circuit of the OLED display of the present invention includes a first switching transistor T1, a second switching transistor T2, a driving transistor TD, and an OLED light emitting diode. The drain of the first switching transistor T1 is connected to the data line Vdata, the gate is connected to the first scanning control line Vscan1, and the source is connected to the B terminal of the coupling capacitor C1. The first switching transistor T1 controls the coupling capacitor C1 to write to the gate of the drive transistor. Enter the grayscale data voltage.

[0030] The drain of the second switching transistor T2 is connected to the A terminal of the storage capacitor C2 and the coupling capacitor C1, the gate is connected to the second scanning control line Vscan2, the source is connected to the drain of the driving transistor TD, and is connected to the power line Vdd through the organic light emitting diode. connected, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com