Patents

Literature

207results about How to "Reduced Alignment Difficulty" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

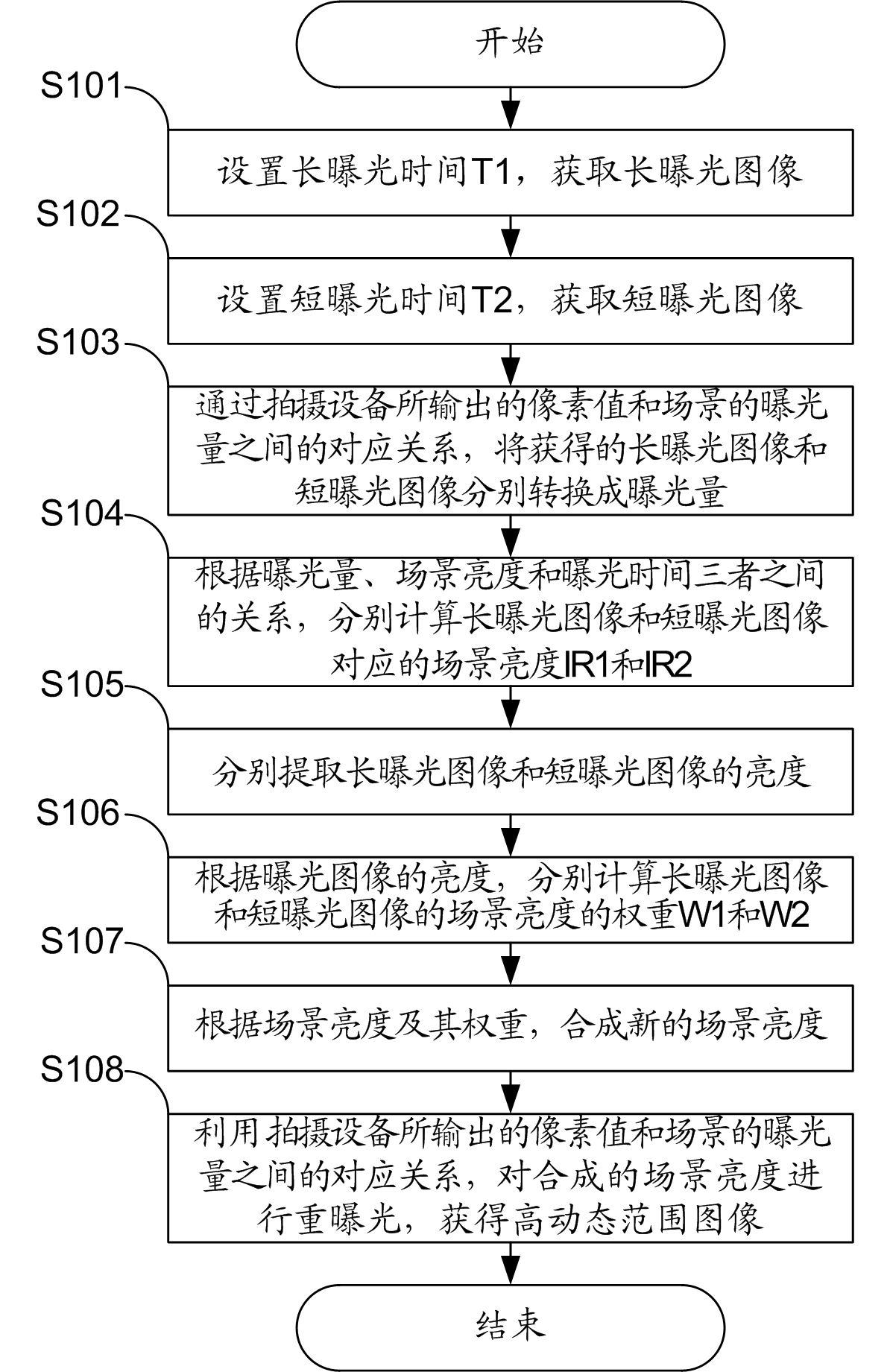

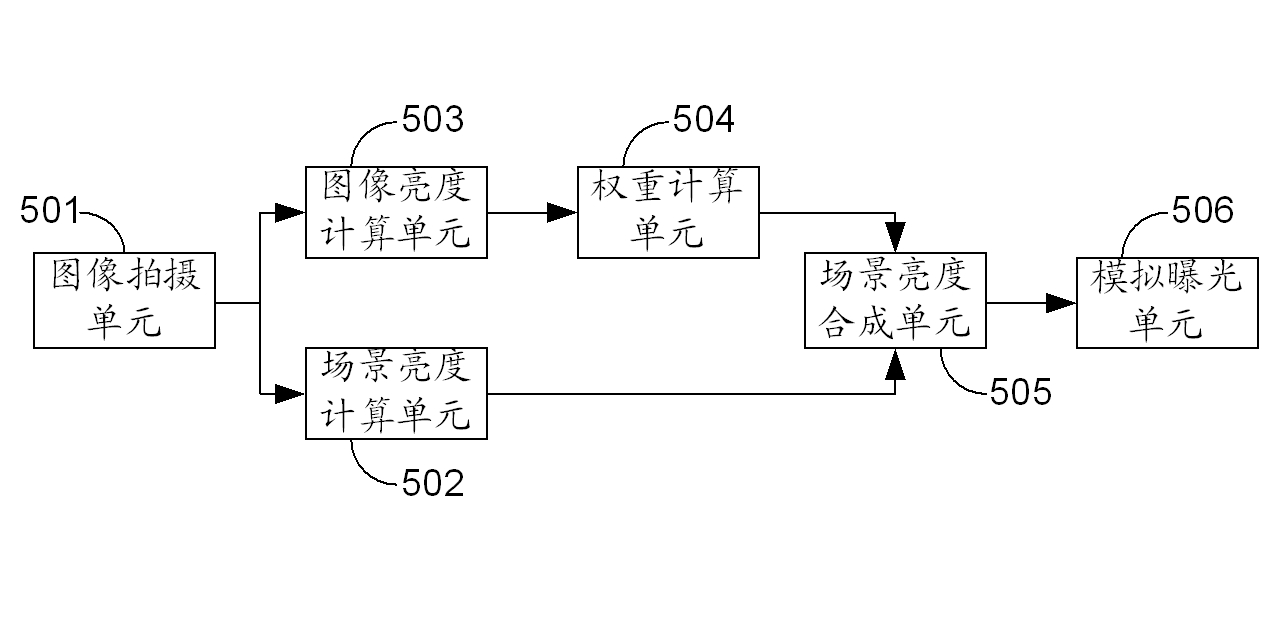

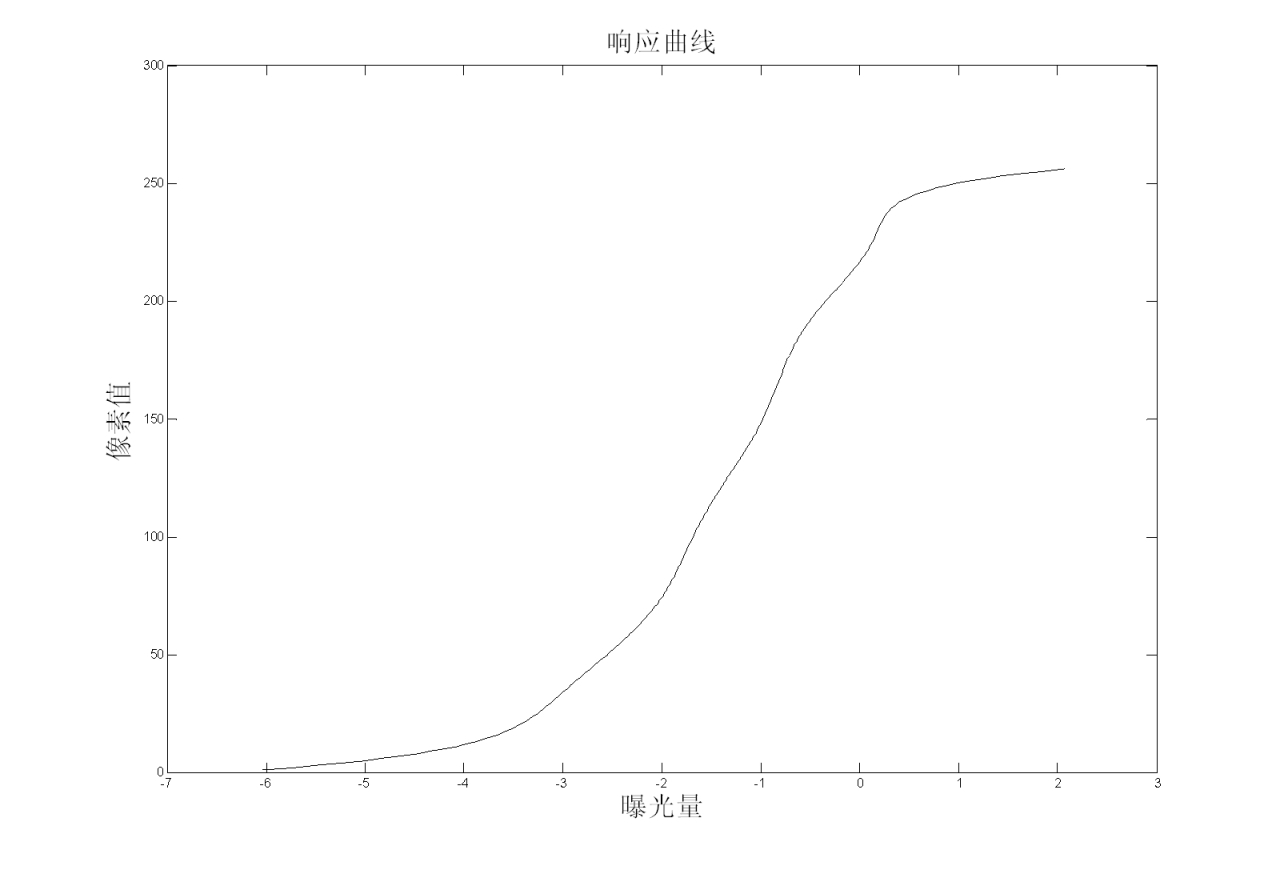

High dynamic-range image synthesis method and device

ActiveCN102420944AReduce difficultyReduce the number of imagesTelevision system detailsColor television detailsImage alignmentImage synthesis

The invention discloses a high dynamic-range synthetic imaging method and device, aiming at providing a method for synthesizing two pieces of images with lower dynamic ranges into a piece of image with higher dynamic range. The high dynamic-range synthetic imaging method comprises the steps of: shooting a same scene at different exposure time to obtain two pieces of different exposed images; respectively converting the two different exposed images to be in exposure value spaces according to response curves of a shooting device; weighted-synthesizing scene brightness which is calculated by utilizing exposure value and exposure time according to brightness of the two pieces of images; and simulated-exposing the synthesized scene brightness through the response curves to obtain the image with high dynamic range. According to the invention, two pieces of different exposed images are synthesized, and thus the difficulty of image alignment is reduced; moreover, the operand and the required storage space in the processing procedure are reduced, so that the high dynamic-range synthetic imaging method and device can be applied to a small-sized handheld device; and at the same time, the image with high dynamic range is rich in details at light parts and shadow parts, and the color and the details of the image are in conformity with those of the original scene.

Owner:芯鑫融资租赁(厦门)有限责任公司

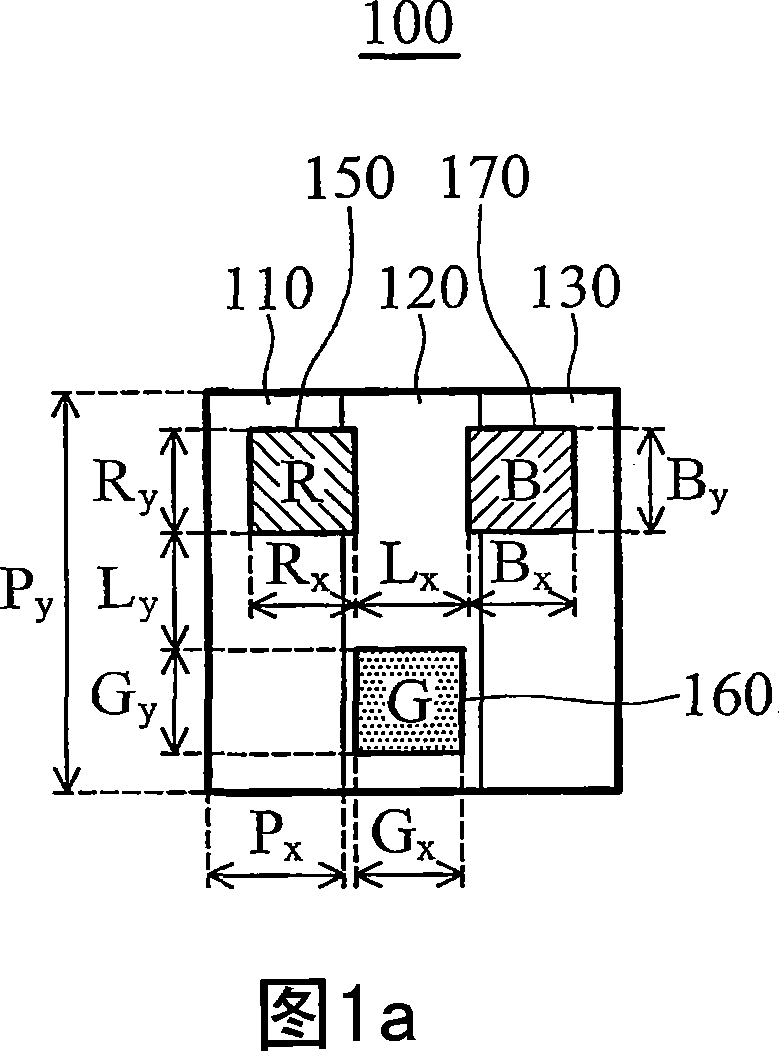

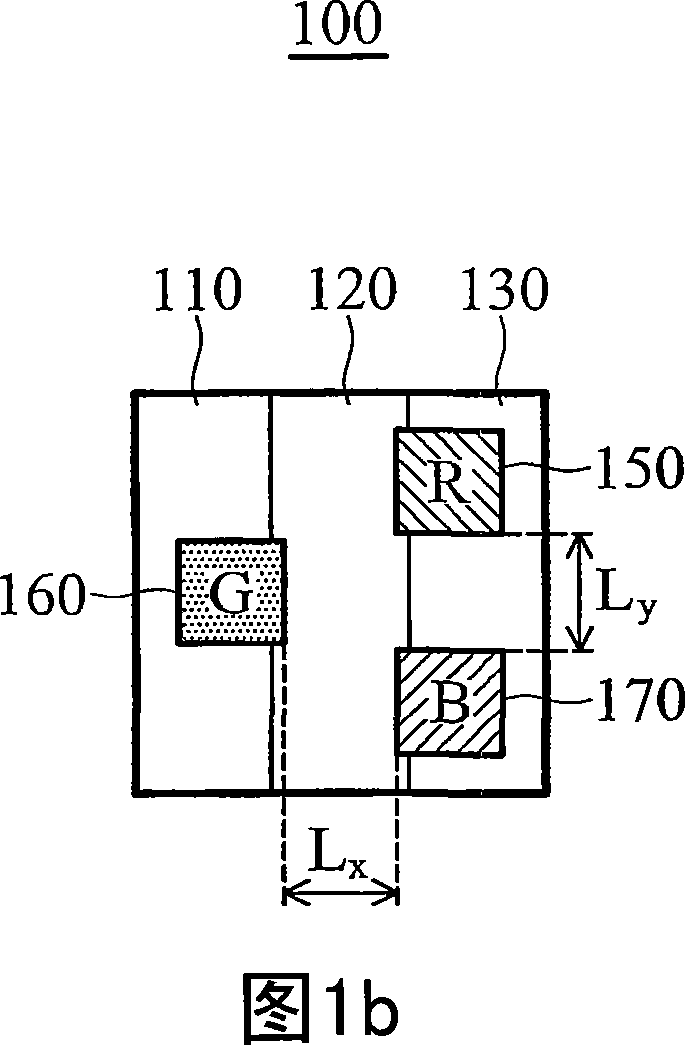

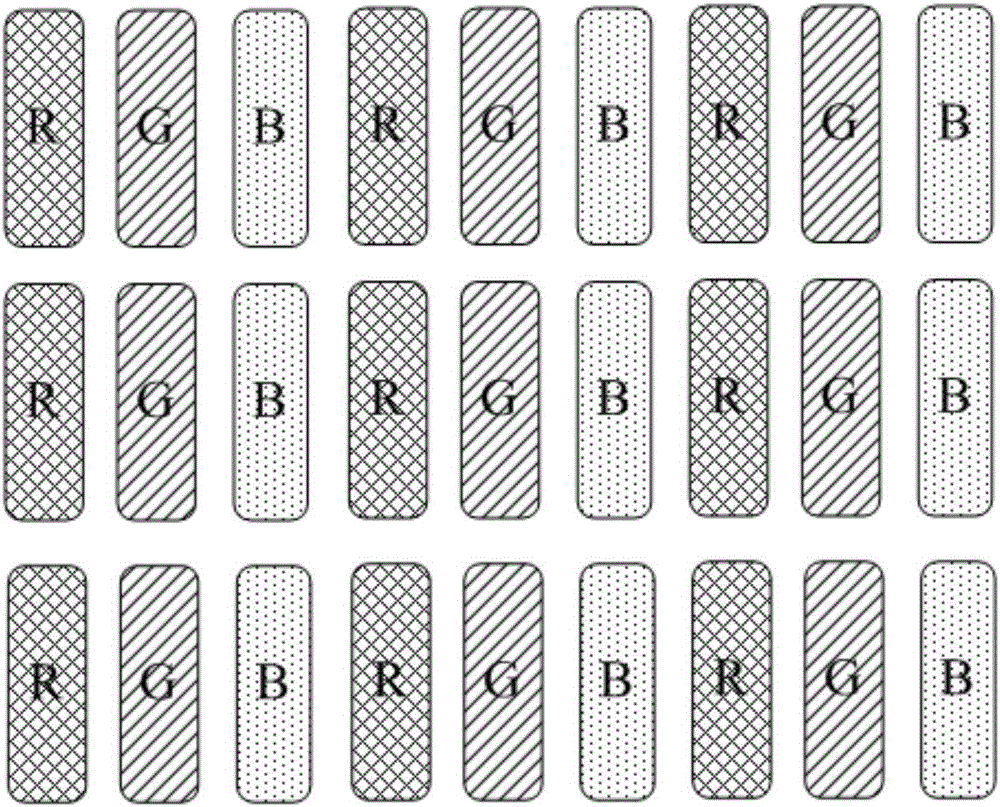

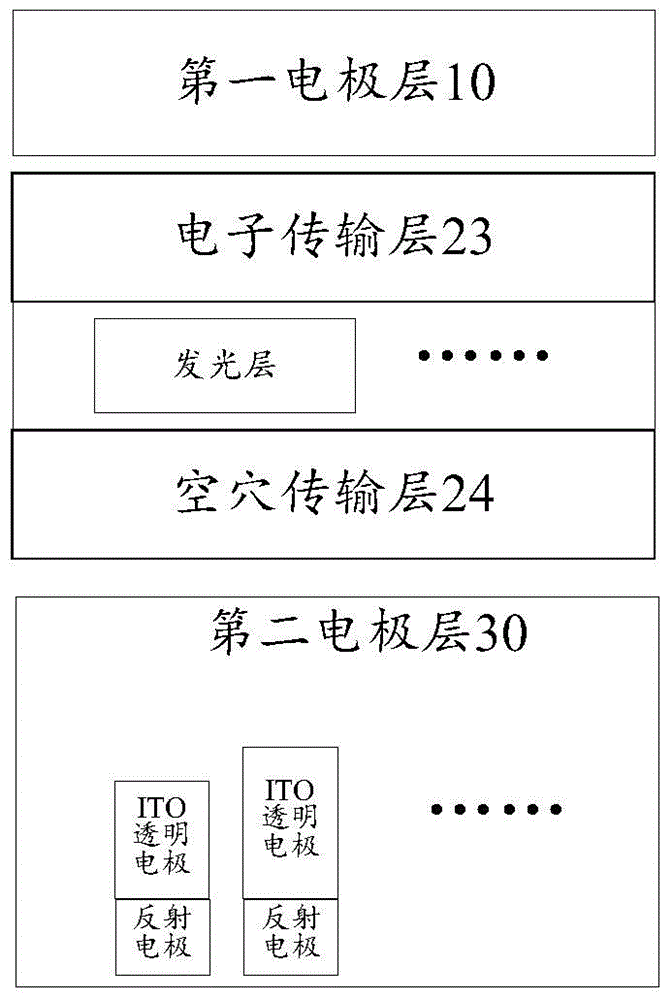

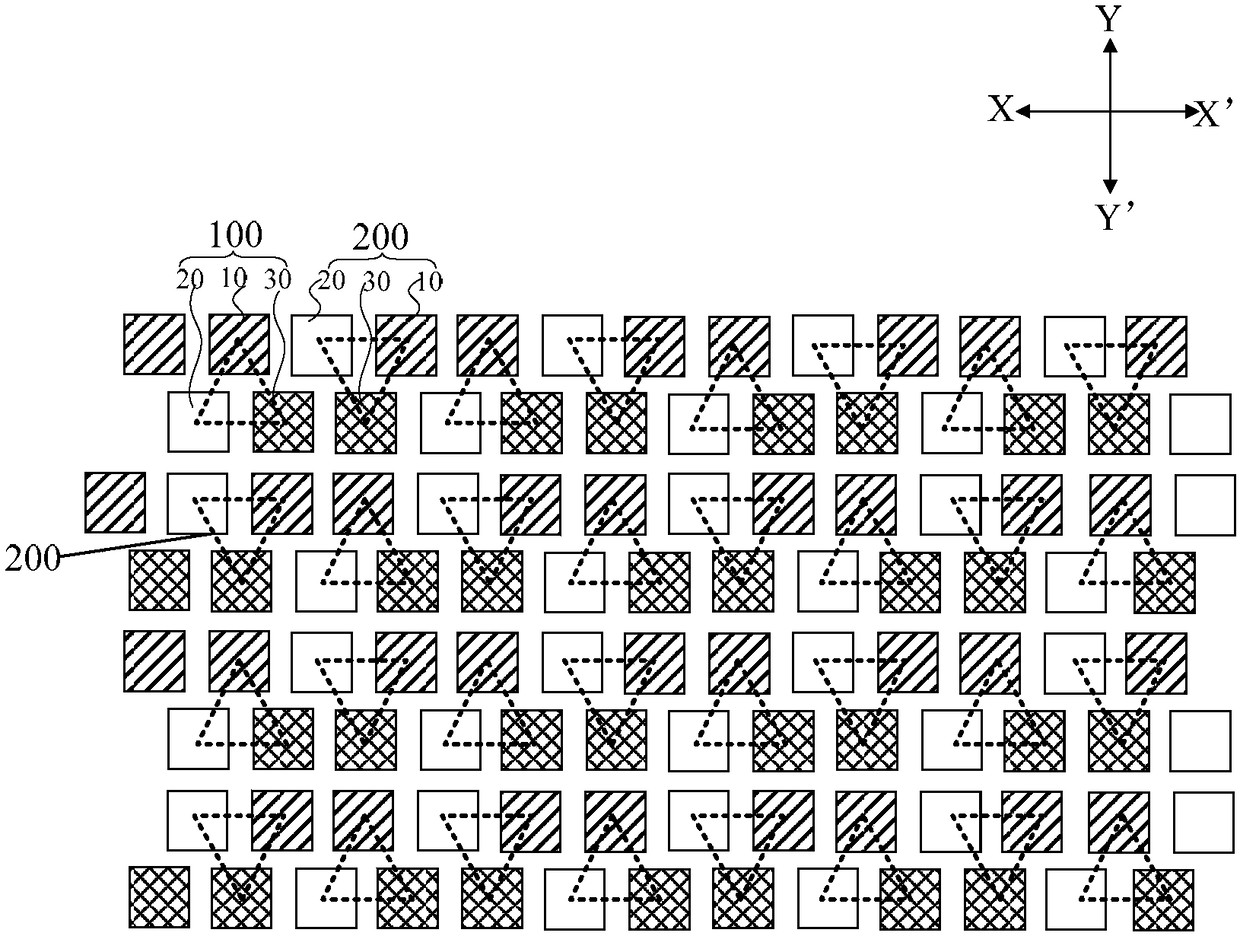

Organic lighting element color pixel array mode and its forming method

InactiveCN101051648AIncrease opening ratioReduced Alignment DifficultySolid-state devicesSemiconductor/solid-state device manufacturingEffect lightLuminescence

A color display panel has an array with a plurality of pixels, each pixel comprises a first sub pixel, a second sub pixel and a third sub pixel, and a red luminescence zone, green luminescence zone and blue luminescence zone. The display panel comprises pixel arrangement of the red luminescence zone, green luminescence zone and blue luminescence zone, which forms a triangle, geometry center of each luminescence zone is positioned at different vertexes of the triangle, such that a side of the triangle substantially is in parallel with on of row direction and column direction, arbitrary luminescence zones bothering with different colors of the row direction are defined to have a distance gap, and arbitrary luminescence zones bothering with different colors of the column direction are defined to have a distance gap, the two gaps distance is substantially or almost equal. The invention can reduce the contraposition difficulty of mask manufacturing technique, besides can increase the opening ratio of the luminescence area of sub pixel, to avoid the color blending circumstance of full color OLED display panel.

Owner:AU OPTRONICS CORP

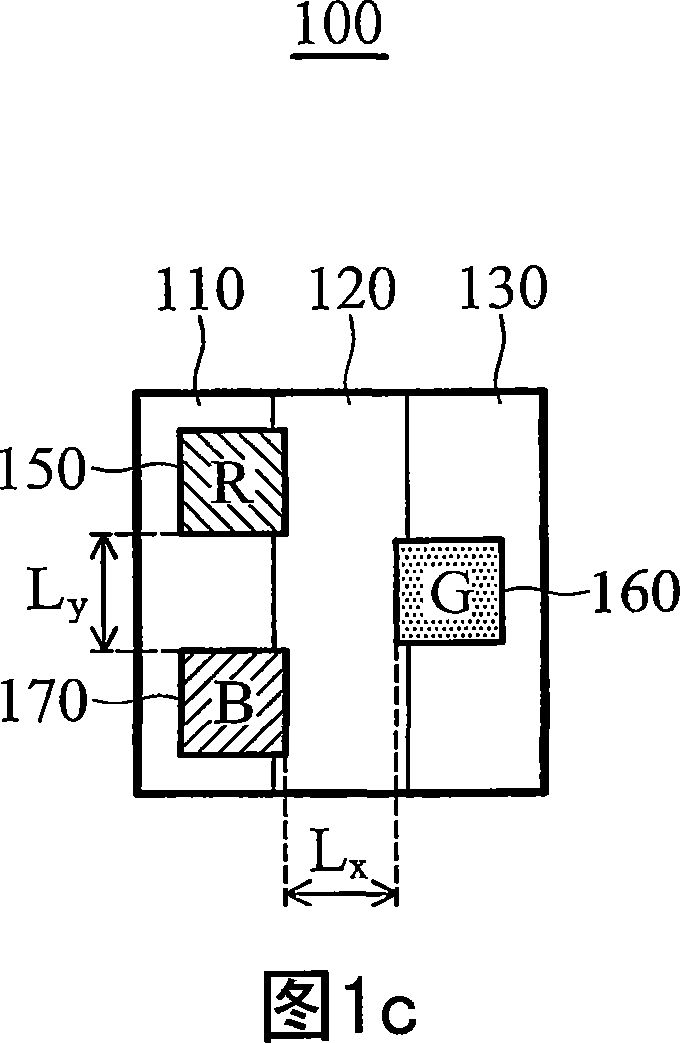

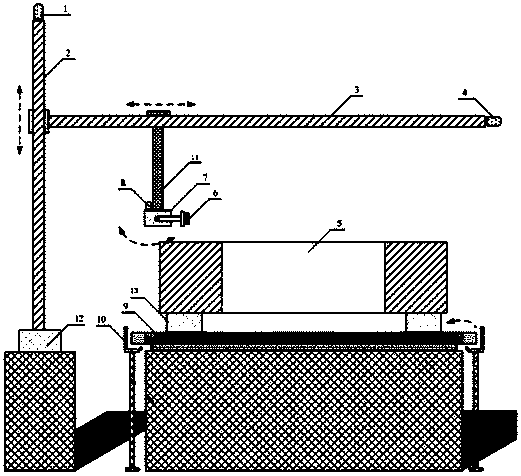

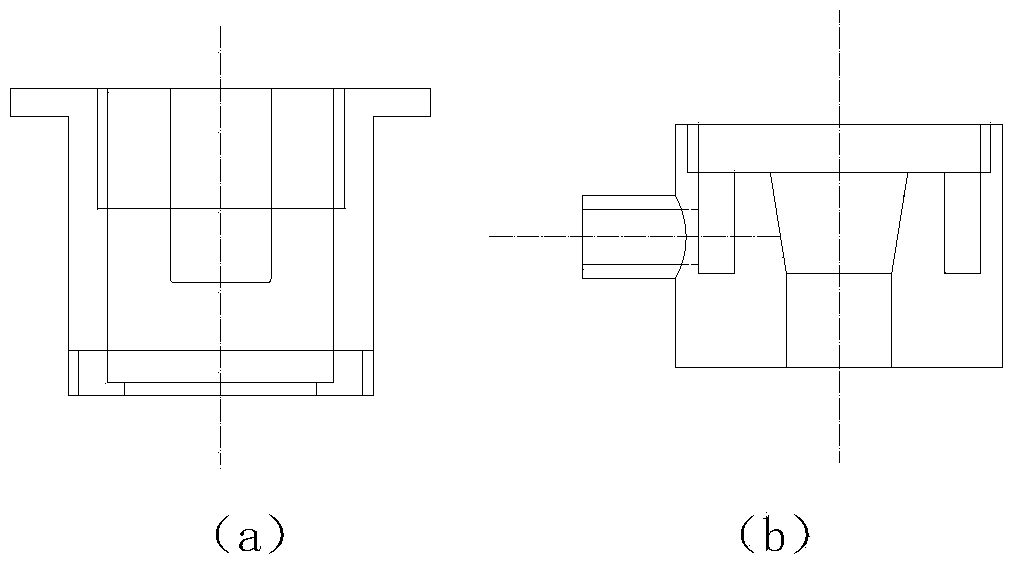

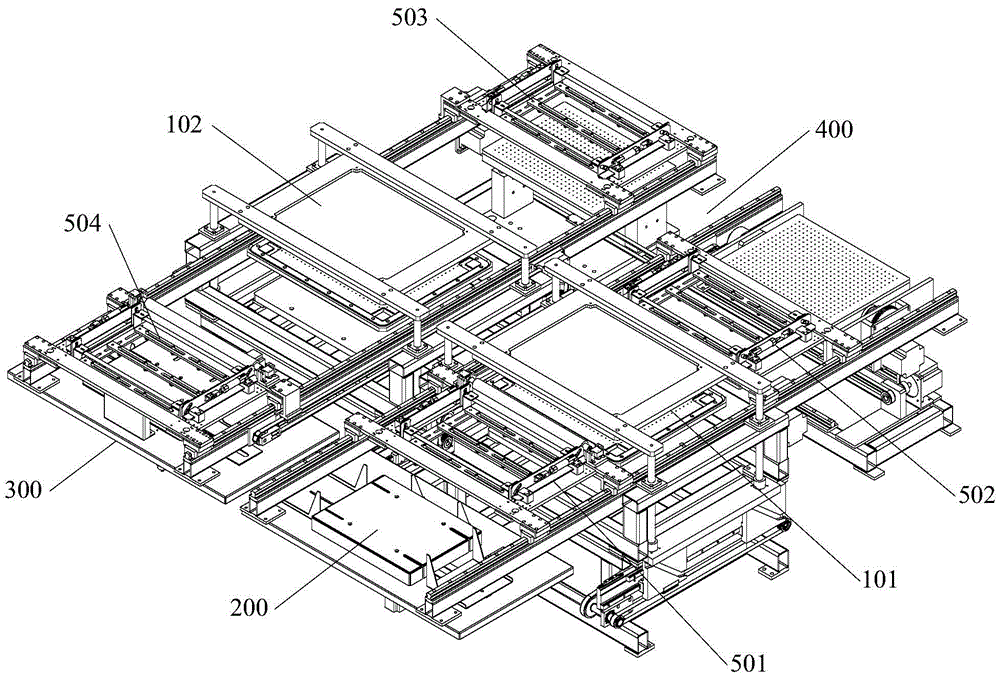

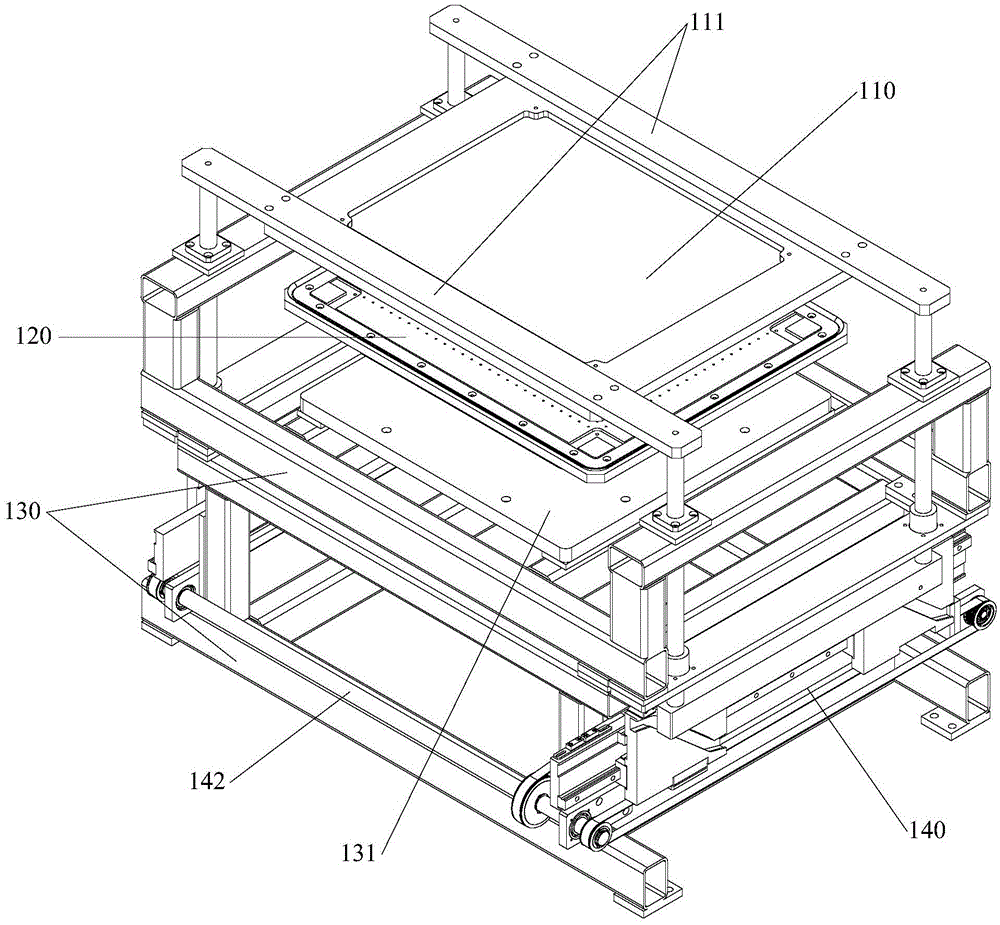

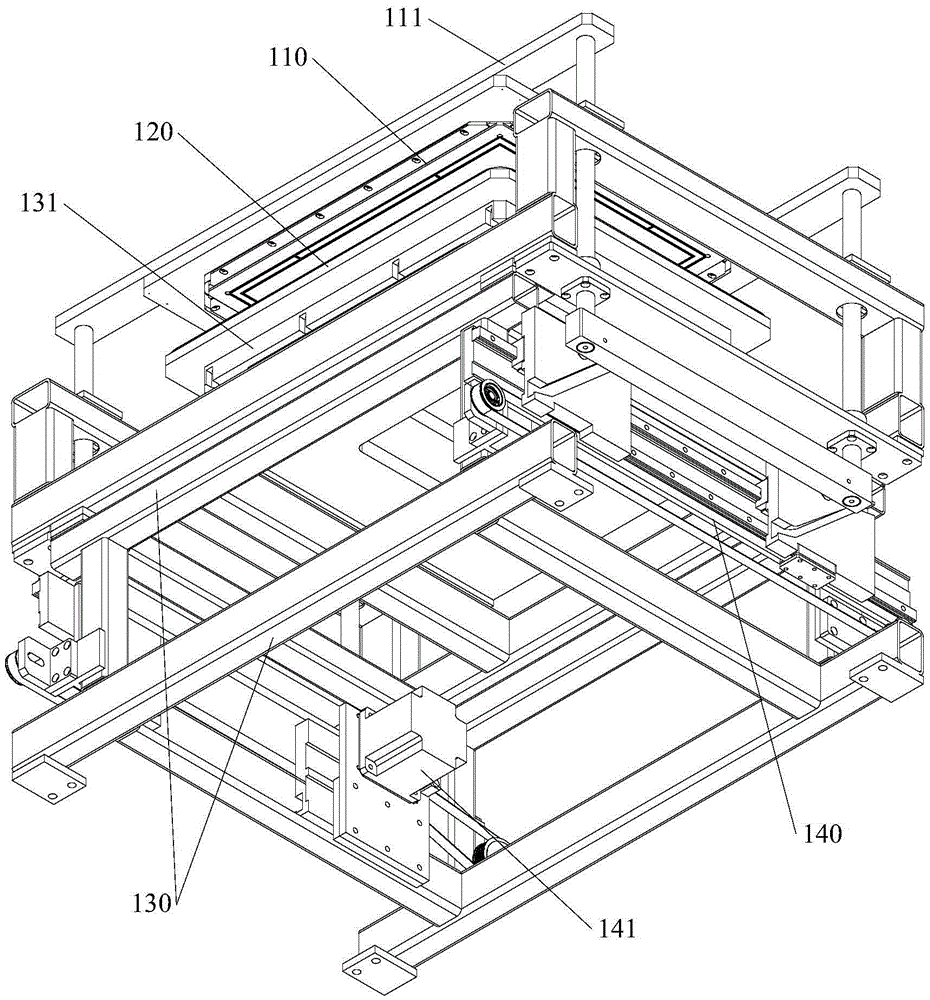

Automatic ultrasonic C scanning detection system for annular forging

ActiveCN104076089AImprove detection efficiencyReduced Alignment DifficultyAnalysing solids using sonic/ultrasonic/infrasonic wavesAutomatic controlData acquisition

The invention discloses an automatic ultrasonic C scanning detection system for an annular forging. The detection system comprises a mechanical scanning control unit, an automatic control mechanical scanning device, a rotary work platform, a water supply and drainage device, a water spray coupling device, an ultrasonic detection probe, an ultrasonic flaw detector and a communication unit thereof, data acquisition equipment and a C scanning nondestructive measurement unit, wherein the mechanical scanning control unit provides synchronous signals for the C scanning nondestructive measurement unit and controls the motions of the mechanical scanning device and the rotary work platform so as to drive the detection probe mounted in the water spray coupling device to scan; the water supply and drainage device is arranged on the edge of the rotary work platform so as to supply and drain water in real time; the ultrasonic flaw detector transmits and receives pulses through the detection probe and conveys detected echo information to the C scanning nondestructive measurement unit through the data acquisition equipment to perform imaging analysis. By adopting the system disclosed by the invention, the problems in ultrasonic detection of the annular forging with a complicated structure can be solved so that the imaging is accurate and visual.

Owner:NANJING CHENGUANG GRP

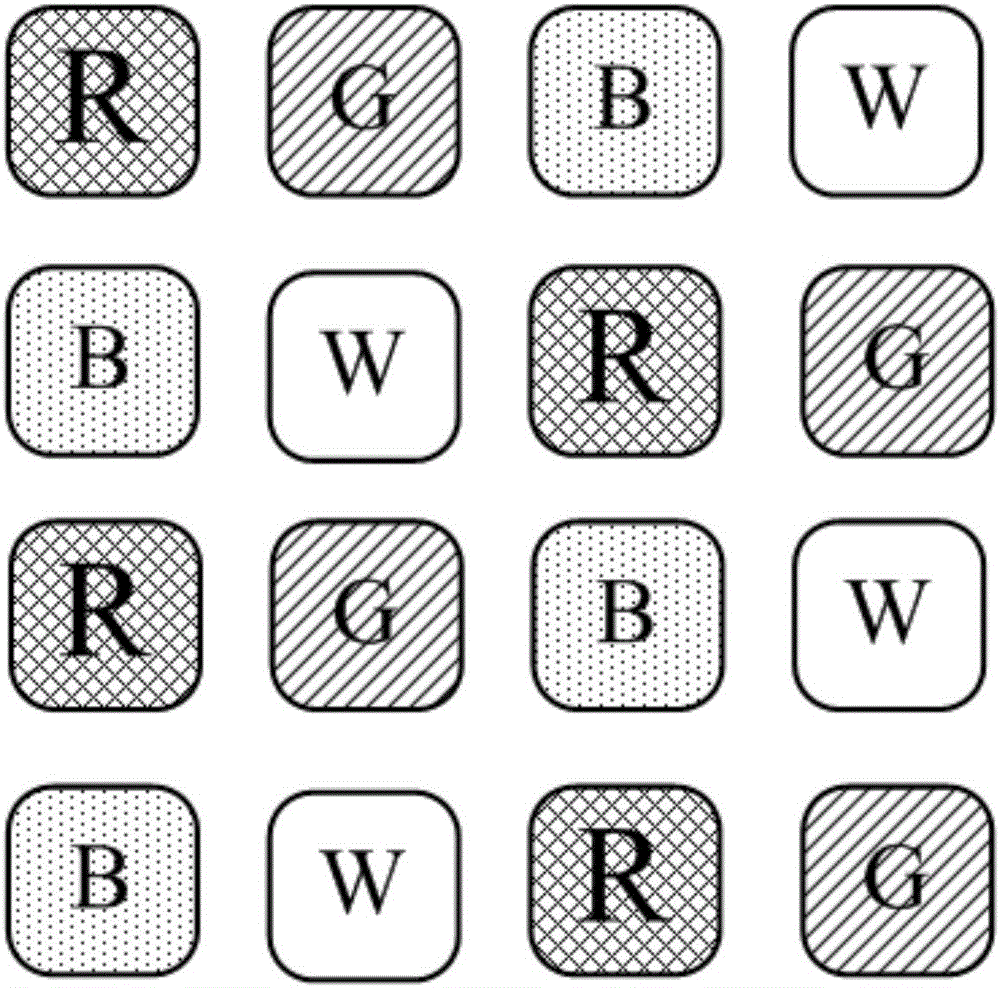

OLED display device

ActiveCN106653804AReduce the difficulty of manufacturing processCrafting Difficulty ImprovementStatic indicating devicesSolid-state devicesEvaporationDisplay device

The invention provides an OLED display device, and the device comprises a first pixel unit, a second pixel unit, a third pixel unit and a fourth pixel unit, wherein the first, second, third and fourth pixel units are repeatedly arranged. Each pixel unit comprises four subpixels, and the four subpixels are shaped like the same pentagon and can form a hexagon. Through the arrangement of the four pixel units, the device enables the pixels with the same color in different pixel units to form a pentagon. During the manufacturing of a mask plate, the pentagons formed by the pixels with the same color can be made into mask plate openings. The mask plate openings and the interval between the openings are increased, thereby reducing the manufacturing difficulty of the mask plate. Meanwhile, during evaporation of pixel colors, the size of the mask plate is increased, and the alignment difficulty of the mask plate is reduced, and the evaporation color mixing is also improved. Because the manufacturing difficulty of the mask plate is reduced and the evaporation color mixing in an evaporation process is also improved, the resolution of a display panel can be further improved.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD +2

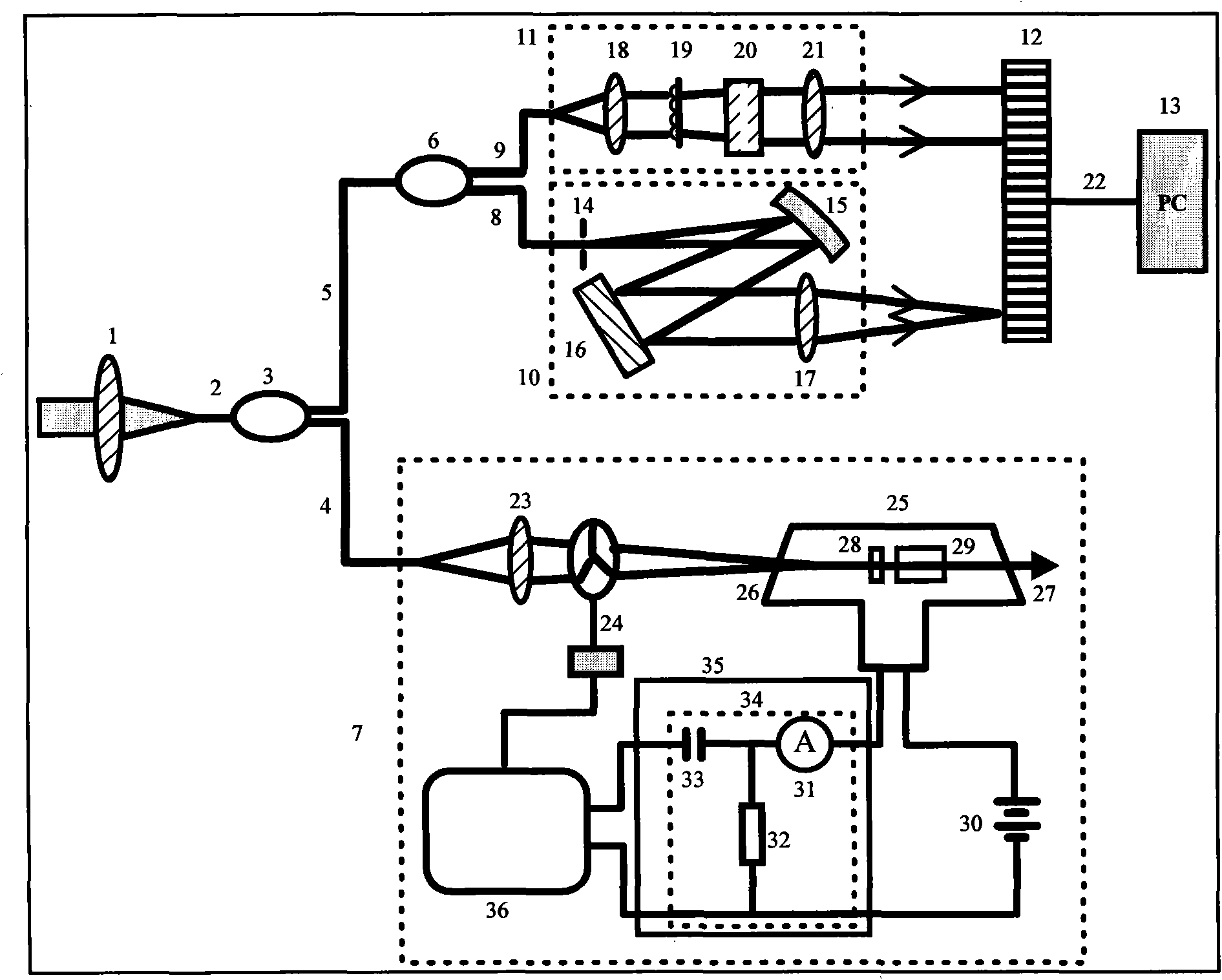

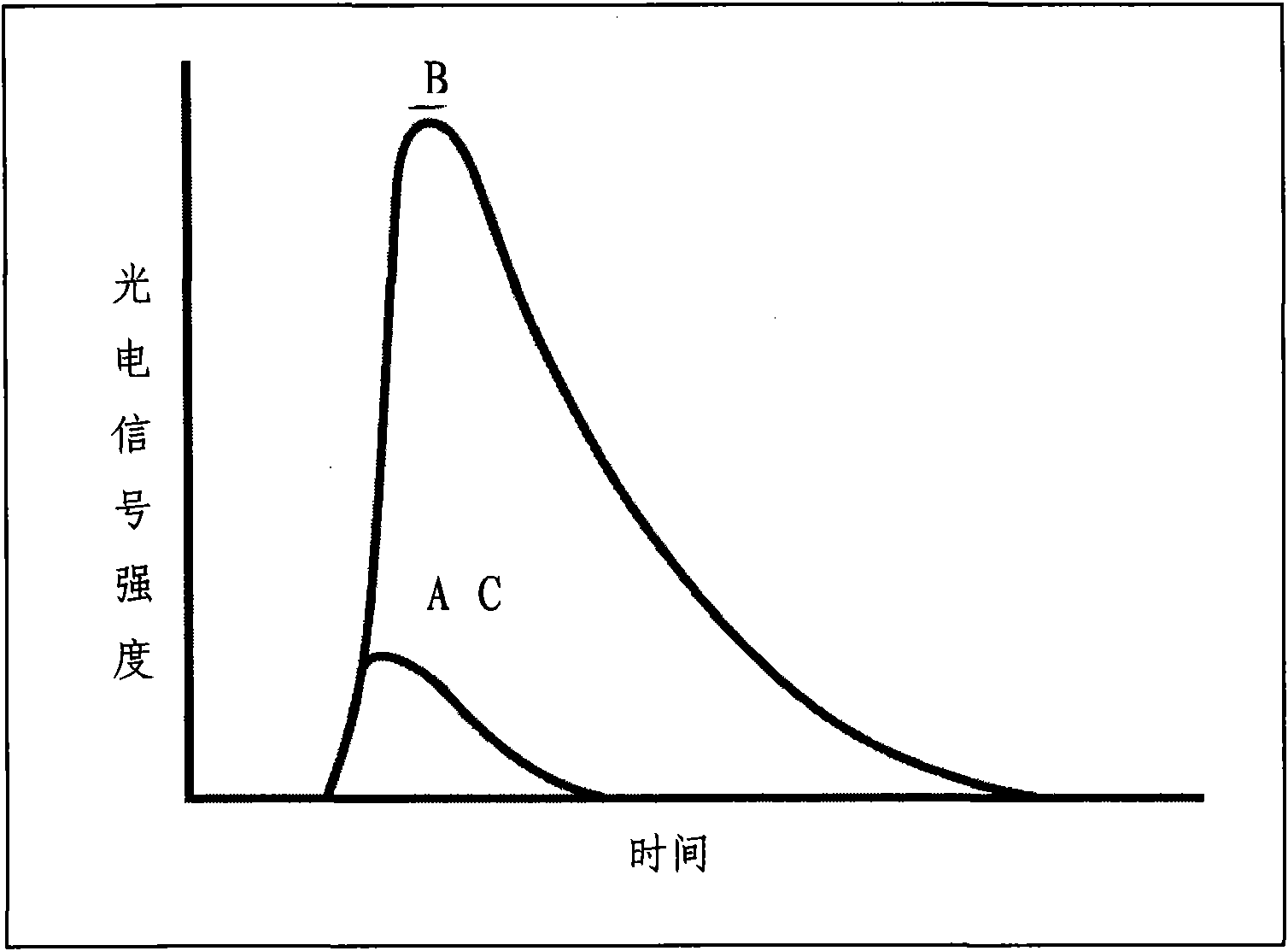

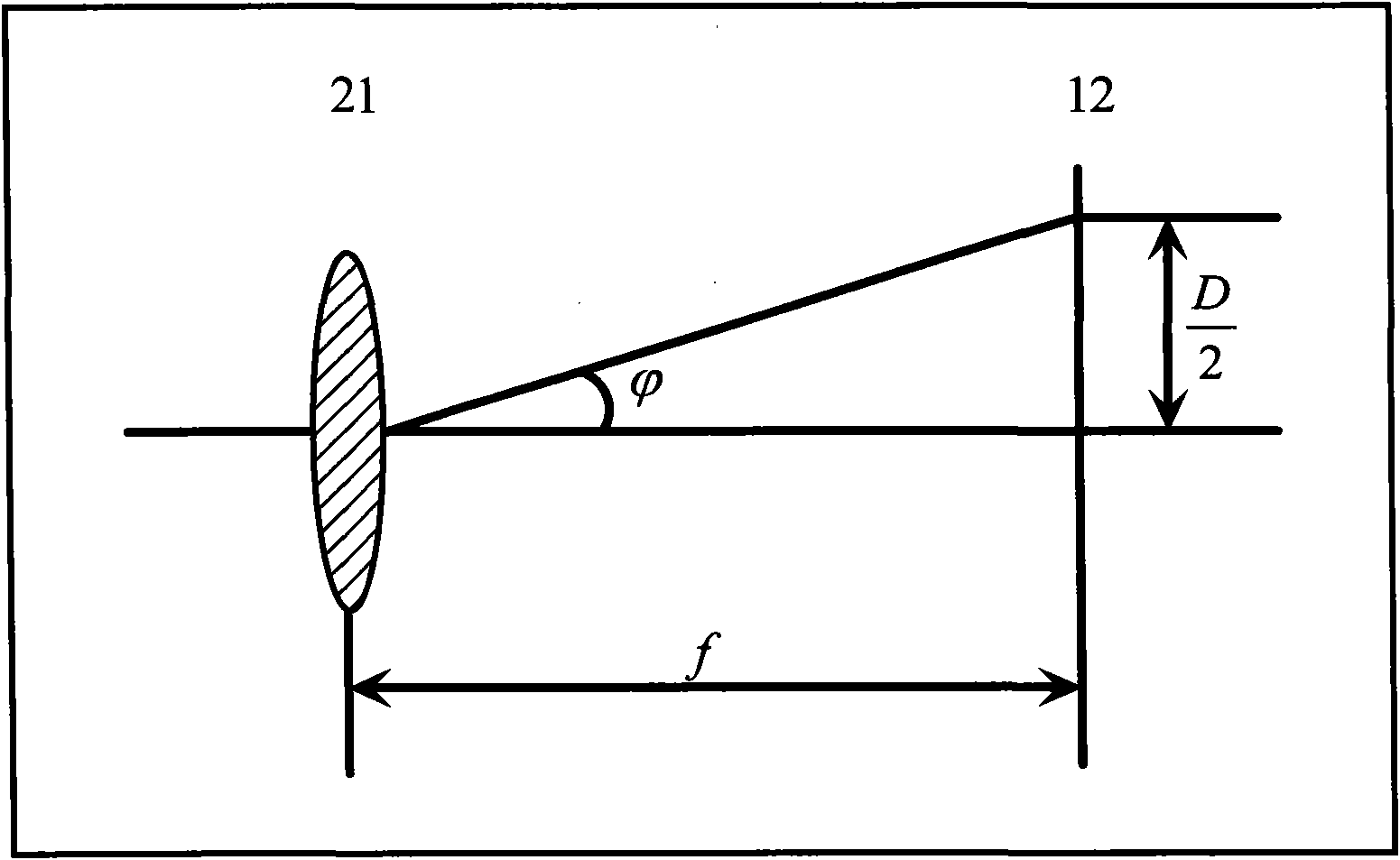

Optical-fiber type laser wavemeter

ActiveCN102155997AReduce mirrorReduced Alignment DifficultyOptical measurementsGratingMeasurement device

The invention provides an optical-fiber type laser wavemeter that consists of a lens, fusing quartz optical fiber, an optical fiber coupler, a wavelength calibrating device, a grating monochromator, a wavelength precise measurement device, a linear CCD (Charge Coupled Device), a signal processor and a data wire. In the invention, the fusing quartz optical fiber is used for guiding light and the optical fiber coupler is used for splitting beam so that the spatial dimension and complexity of the wavemeter can be effectively reduced; and the calibration, coarse measurement and precise measurement of the wavelength are effectively combined so as to realize high-precision real-time measurement on the central wavelength and spectrum bandwidth of the laser. In the invention, the linear width and the central wavelength of the continuous laser and the pulse laser can be measured precisely and conveniently at high speed, and the optical-fiber type laser wavemeter is particularly used for measuring the laser wavelength of an excimer laser.

Owner:南京海莱特激光科技有限公司

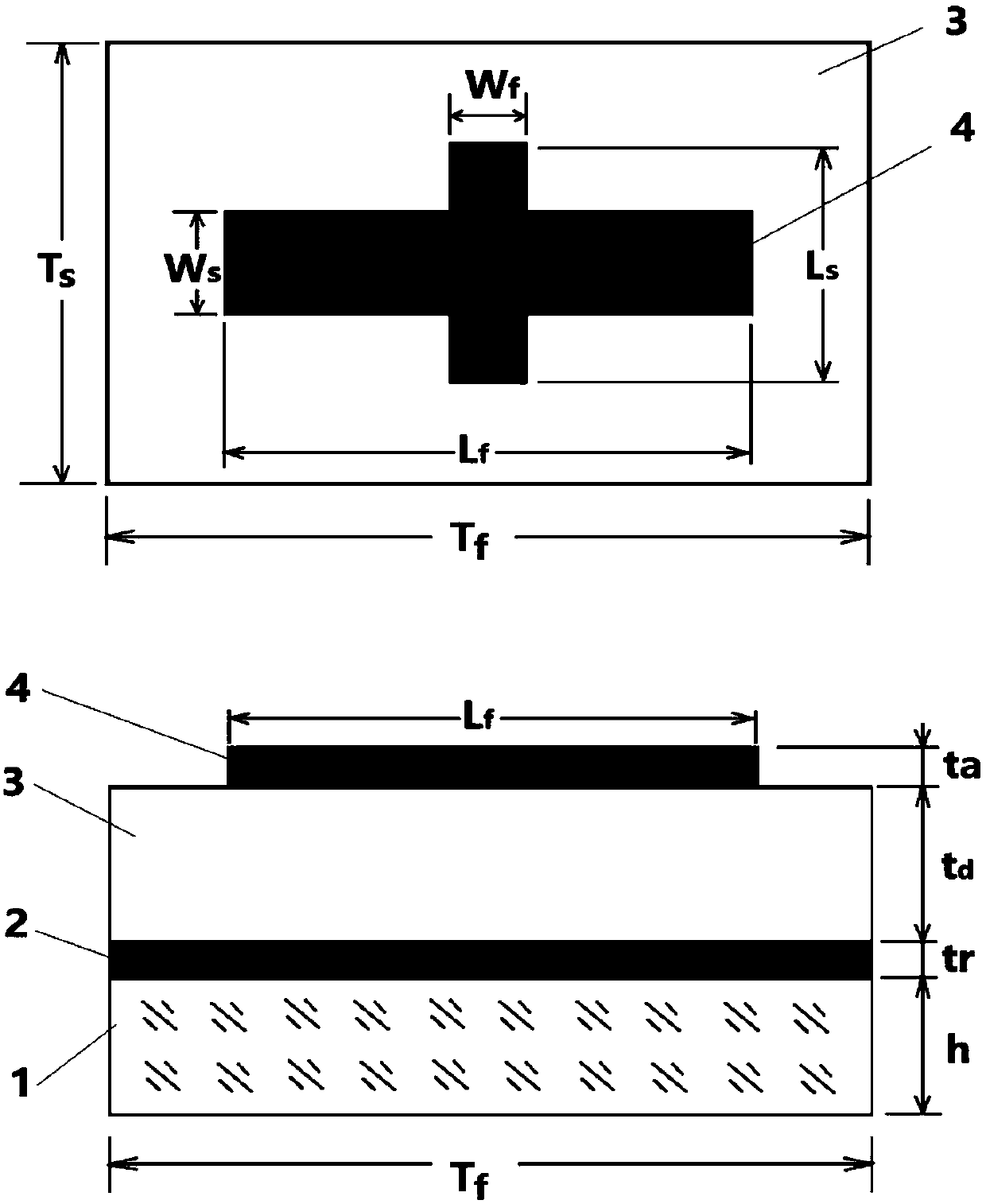

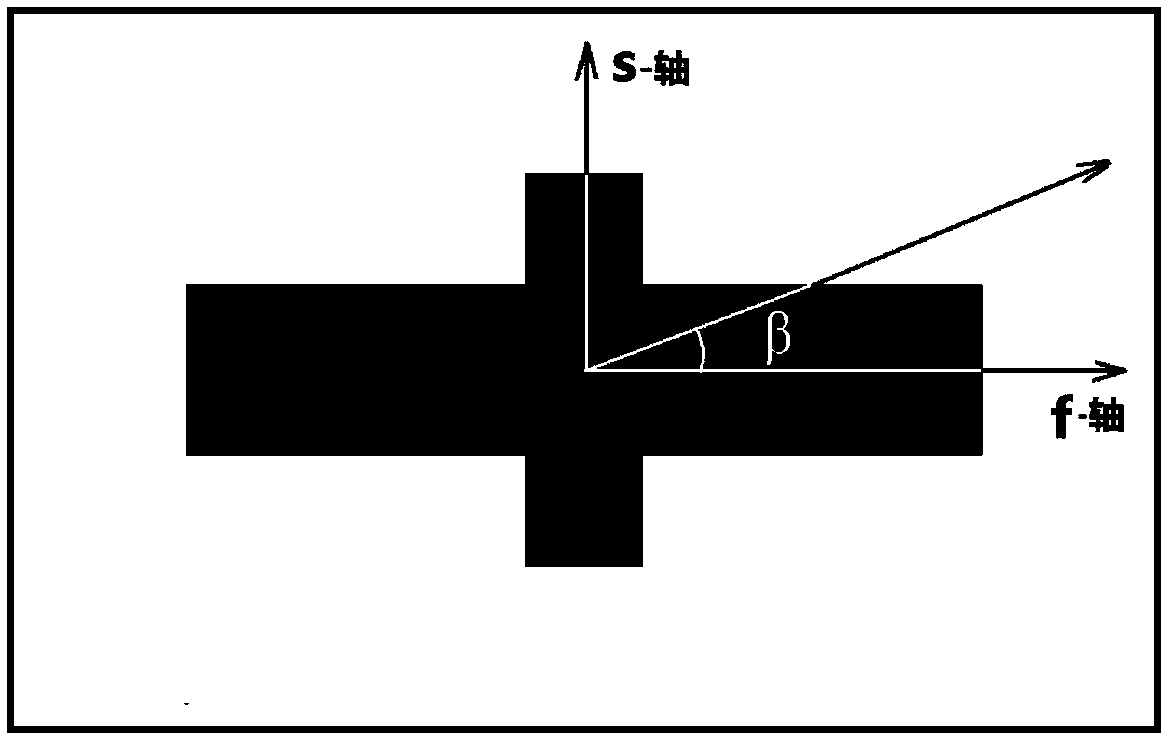

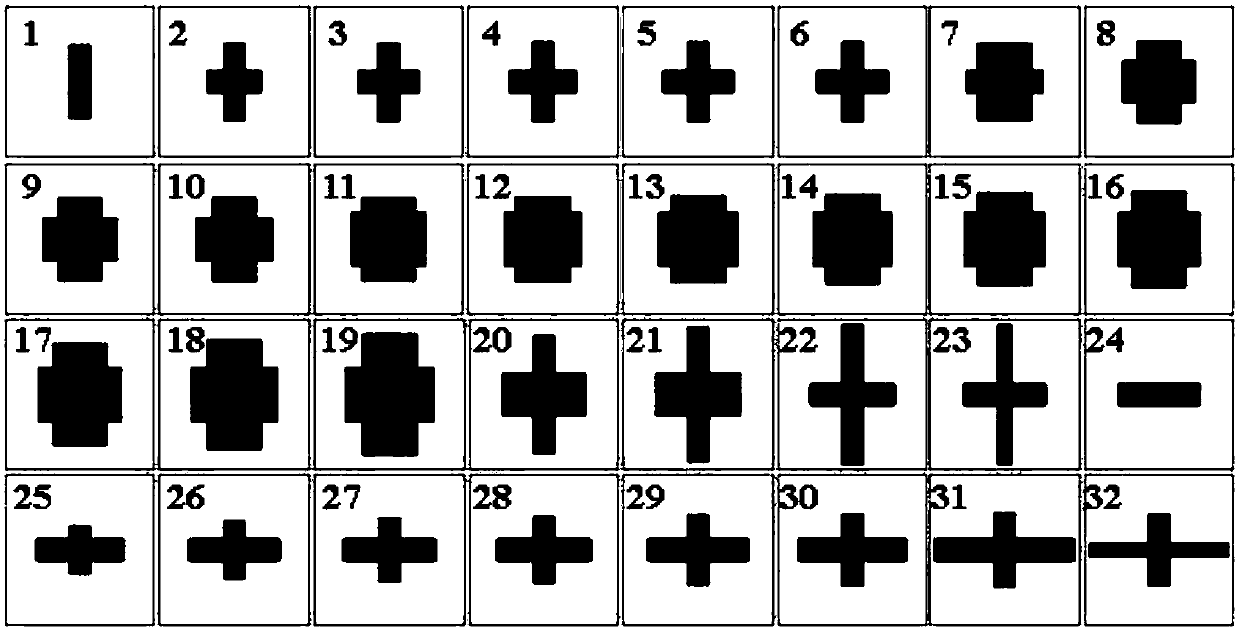

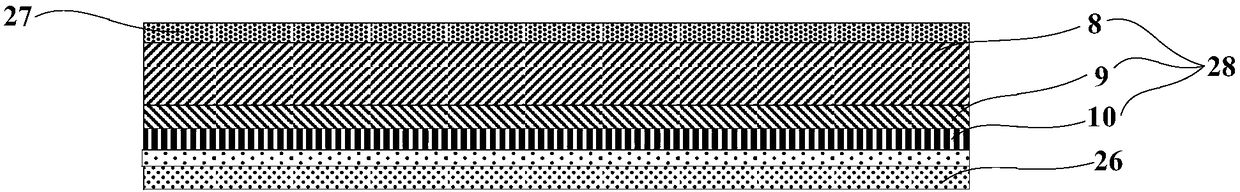

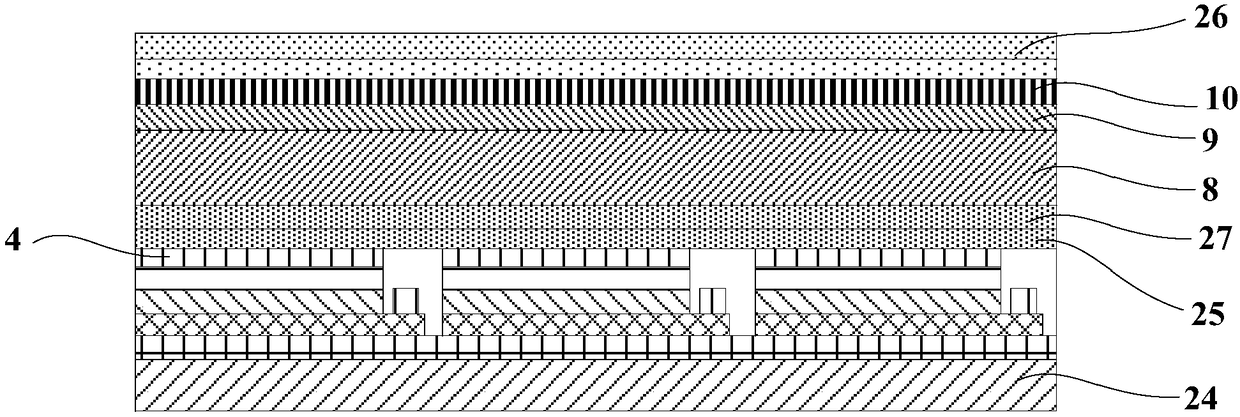

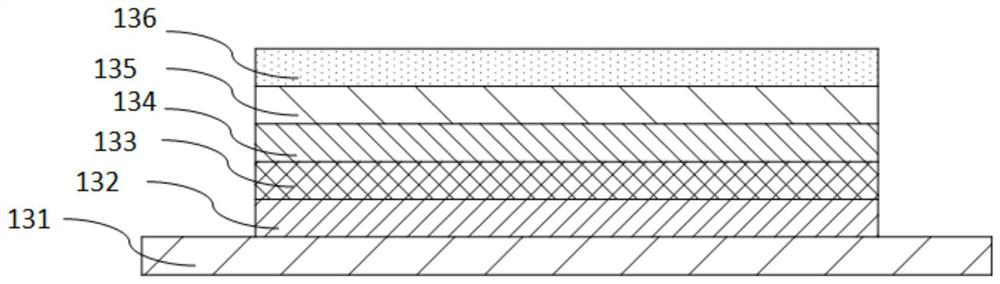

Birefringent phase control super-surface unit and broadband polarization and phase control array and device

The invention discloses a broadband polarization and phase control array based on a birefringent super-surface structure. The broadband polarization and phase control array comprises a substrate, a metal reflection film, a medium layer, a cross sub-wavelength optical antenna unit, a birefringent phase control super-surface structure unit and a birefringent phase control super-surface structure array. According to a reasonable design, the birefringent phase control super-surface structure unit has a birefringent effect and a phase control function, and under incident conditions of circularly polarized light, the reflected light further has polarization control and phase control functions of space sub-wavelength resolution; and with respect to the circularly polarized incident light, the birefringent phase control super-surface structure units are arranged to form a birefringent phase control super-surface structure array according to the needed space polarization and phase distributionin order to obtain a special optical field with any polarization and phase distribution. Moreover, the birefringent phase control super-surface structure unit and the birefringent phase control super-surface structure array have wide operating wavelength ranges.

Owner:CHONGQING UNIV

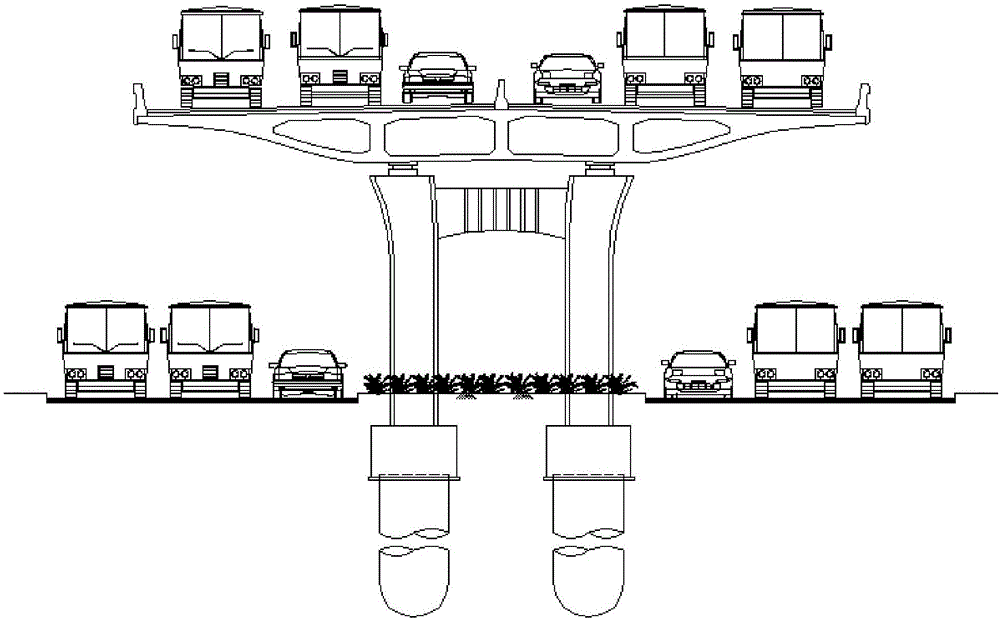

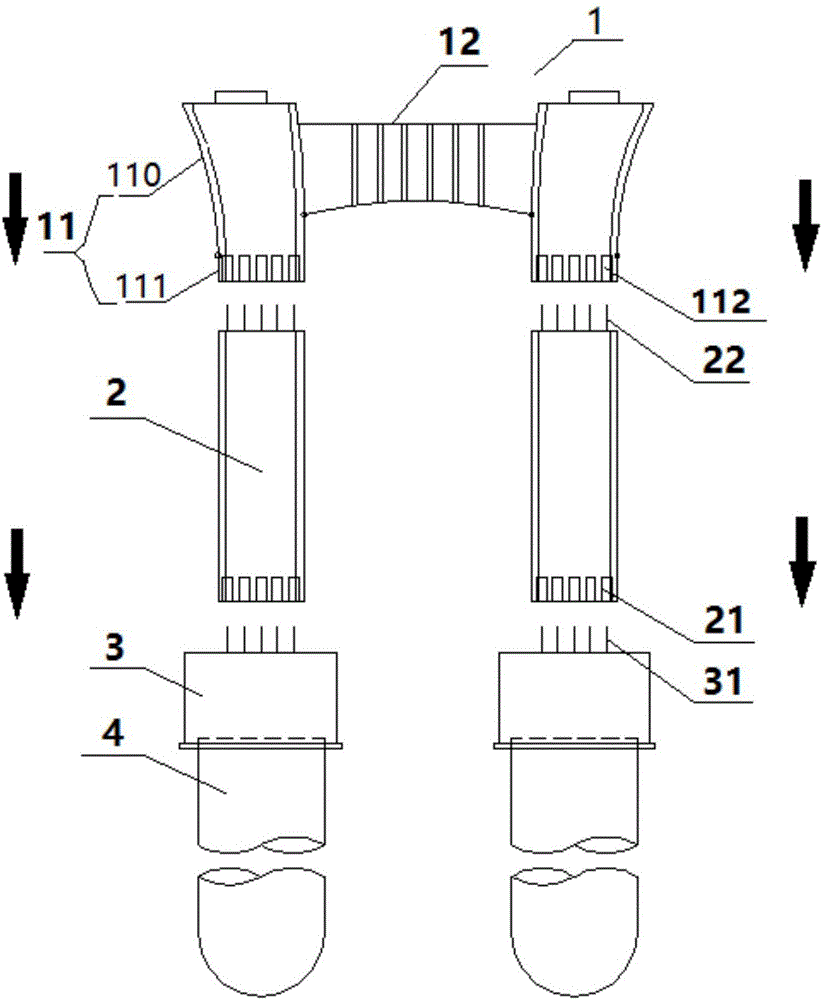

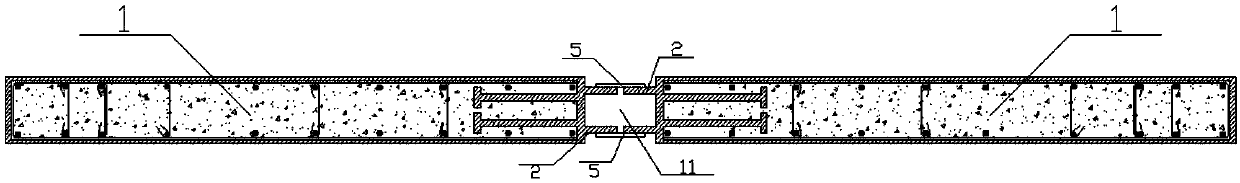

Prefabricated double-column vase bridge pier and assembling construction method thereof

InactiveCN106677056AReduce pollutionReduce the difficulty of on-site construction alignmentBridge structural detailsBridge erection/assemblyBuilding constructionLower degree

The invention discloses a prefabricated double-column vase bridge pier and an assembling construction method thereof. The prefabricated double-column vase bridge pier comprises two pier body sections and one pier cap section, the pier body sections are bridge pier straight main sections, the pier cap section is a joint of two bridge pier straight and curve transition sections and one tie beam, the two bridge pier straight and curve transition sections are positioned at two ends of the tie beam respectively, and a bridge pier curve section is arranged on the upper portion of each bridge pier straight and curve transition section and gradually transits downwards into a bridge pier straight end section. The double-column vase bridge pier is prefabricated and divided into the pier body sections and the pier cap section, the assembling direction of the bridge pier is uniformly vertical, site construction alignment difficulty is reduced, site construction time is shortened, pollution of site construction to surrounding environments is relieved, and the influence of construction on surround traffic is minimized.

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD

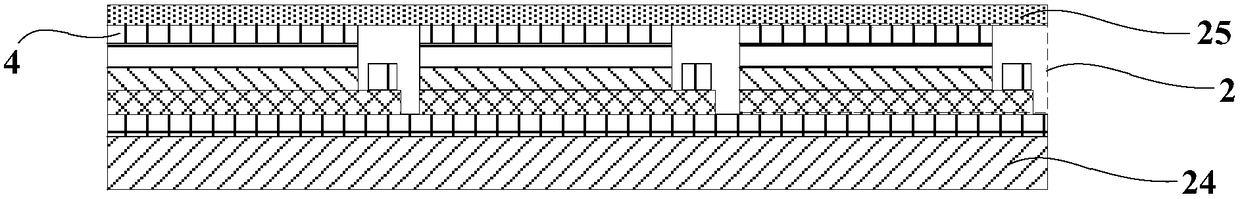

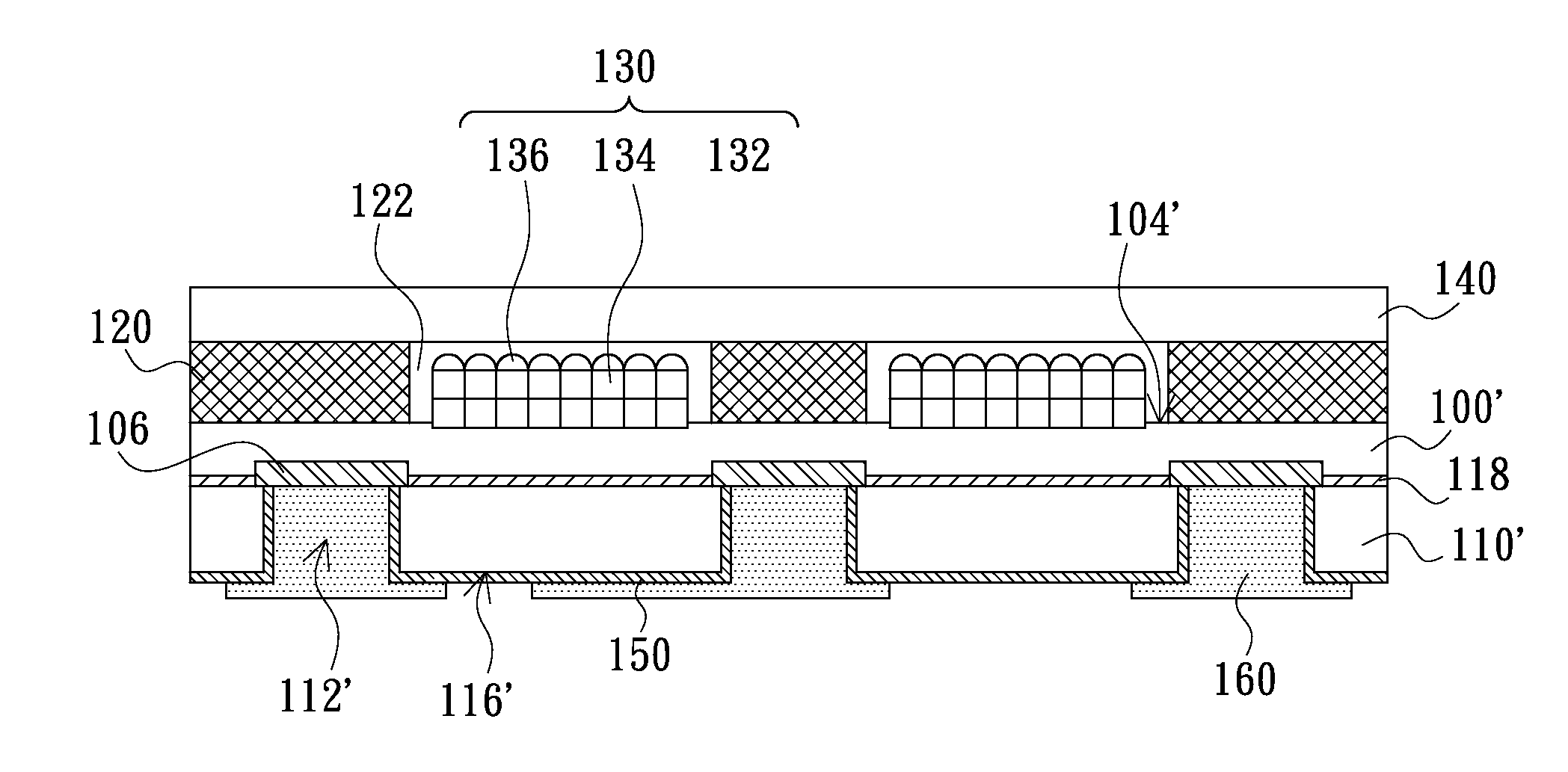

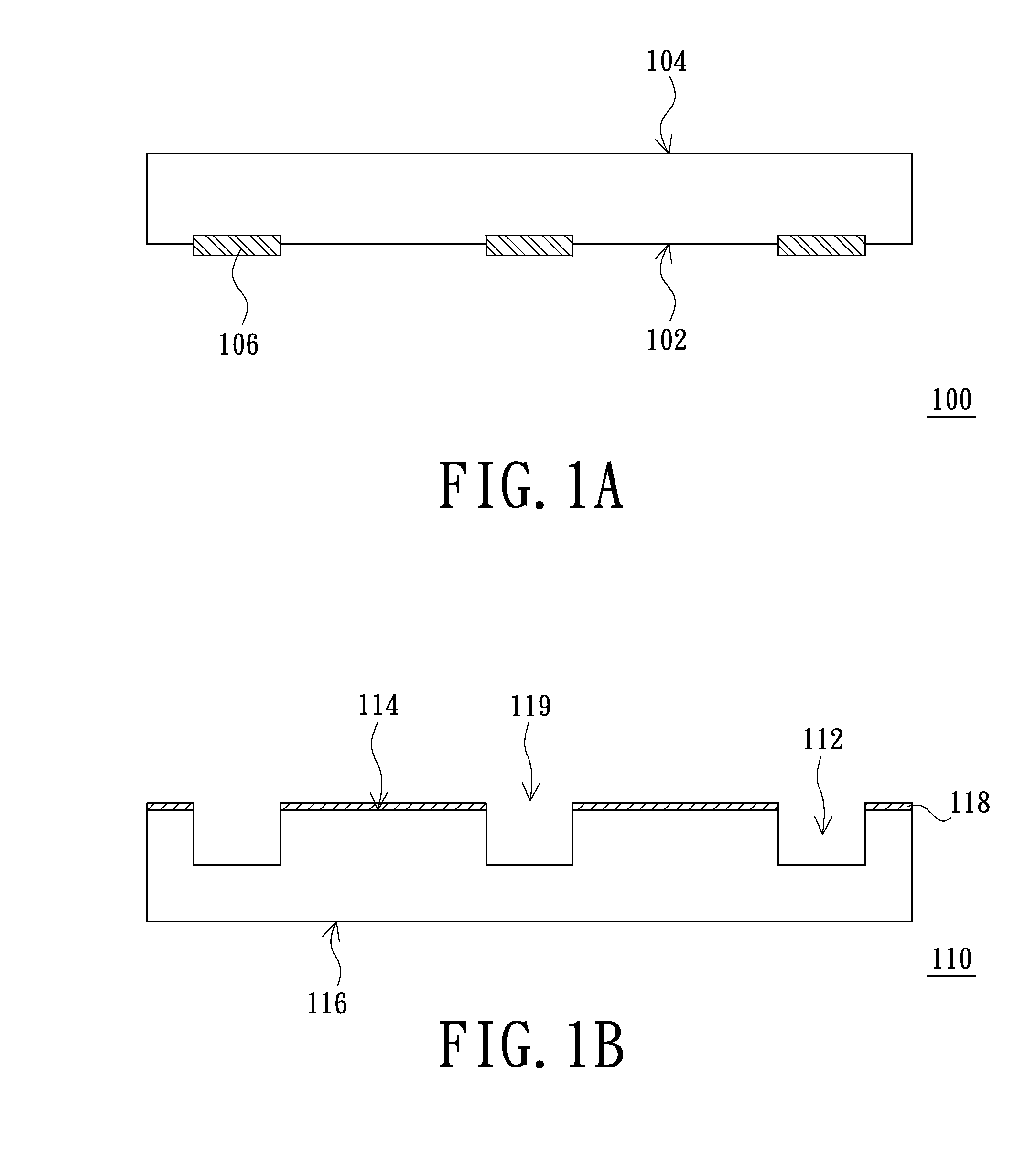

Display substrate, display device and production method of display substrate

ActiveCN108493209ASmall sizeAvoid lostSolid-state devicesSemiconductor devicesImage resolutionDisplay device

The invention discloses a display substrate, a display device and a production method of the display substrate. According to the display substrate, the display device and the production method, the product yield of the display substrate and the resolution ratio of the display device are increased. The display substrate comprises a substrate and a plurality of pixel units arrayed on the substrate,wherein the pixel units include a light-emitting diode, a connecting metal and a thin film transistor which are sequentially arranged along the direction far from the substrate; the connecting metal is electrically connected with a top electrode of the light-emitting diode; and an active layer of the thin film transistor is isolated from the connecting metal, and a drain electrode of the thin filmtransistor is conductively connected with the connecting metal.

Owner:BOE TECH GRP CO LTD

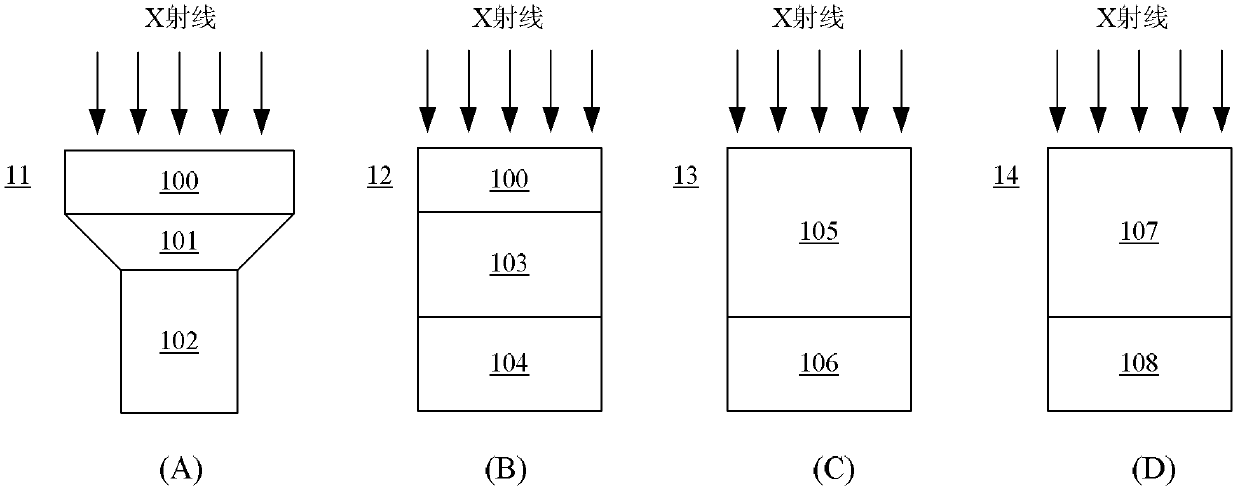

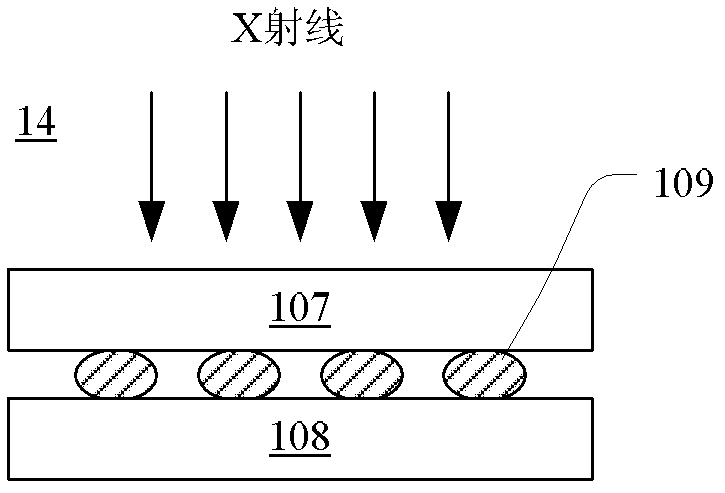

X-ray detector and manufacturing method thereof

ActiveCN103296036AImprove yieldLittle cross effectRadiation controlled devicesRadiation intensity measurementCmos pixelsInterconnection

The invention discloses an X-ray detector and a manufacturing method thereof. The X-ray detector comprises an interconnection substrate, bonding interconnection, a photovoltaic conversion device chip and a CMOS pixel reading chip, wherein the bonding interconnection penetrates through the interconnection substrate and is exposed out of the two main surfaces of the interconnection substrate, the photovoltaic conversion device chip is bonded with one main surface of the interconnection substrate, the CMOS pixel reading chip is bonded with the other main surface of the interconnection substrate, and a bonding pad of the photovoltaic conversion device chip is electrically connected with a bonding pad of the CMOS pixel reading chip through the bonding interconnection. According to the X-ray detector, working processes can be simplified, and reliability and yield can be improved.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

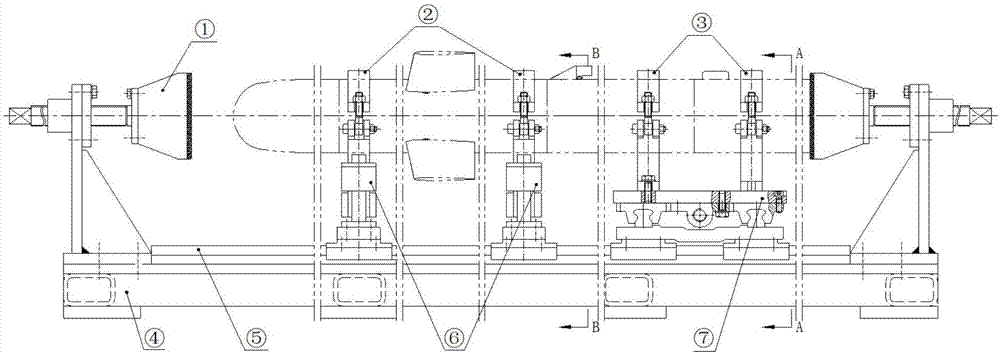

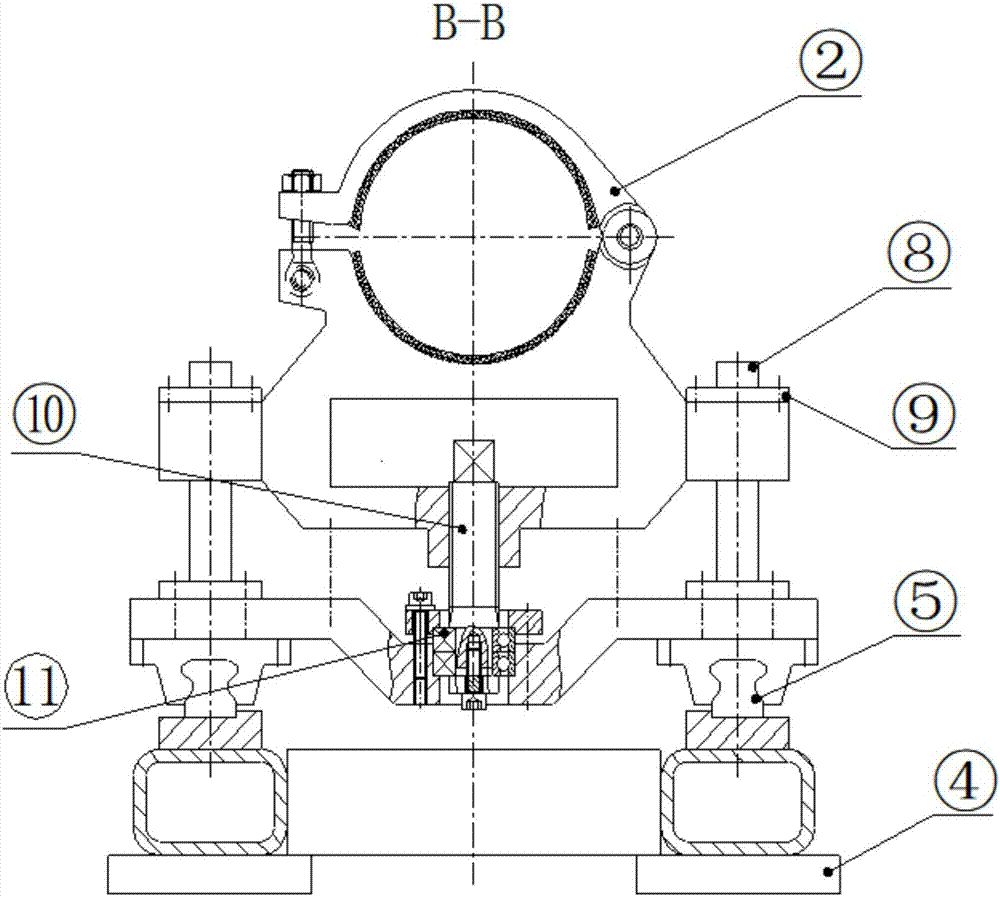

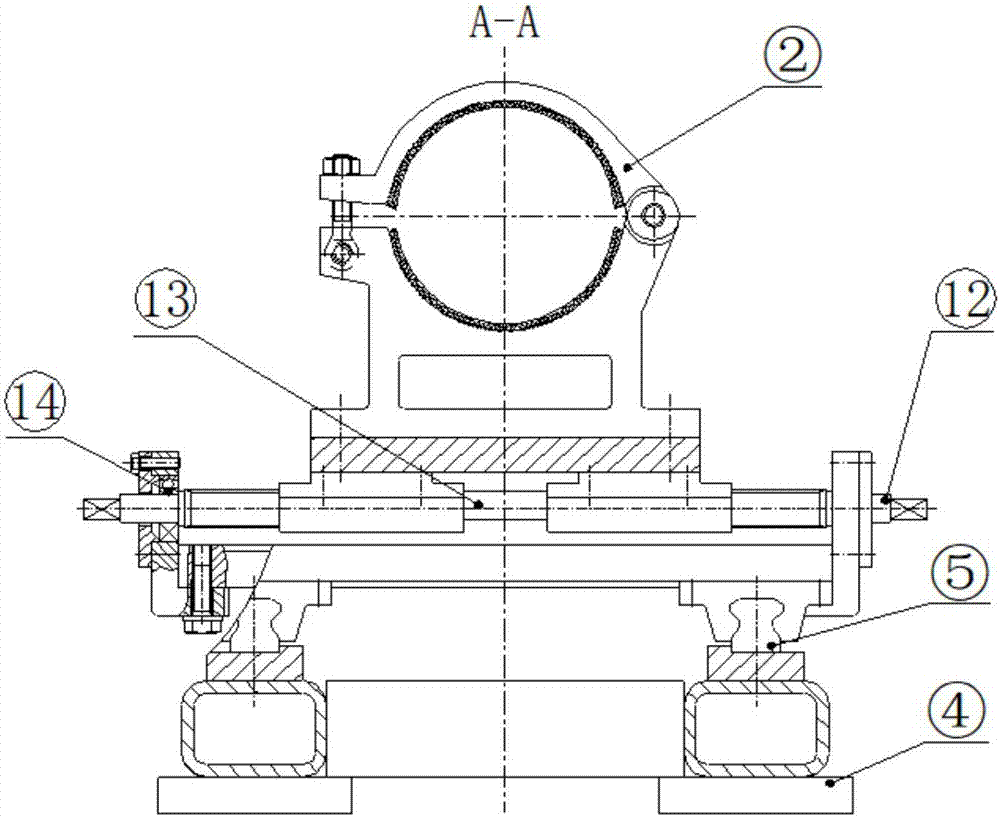

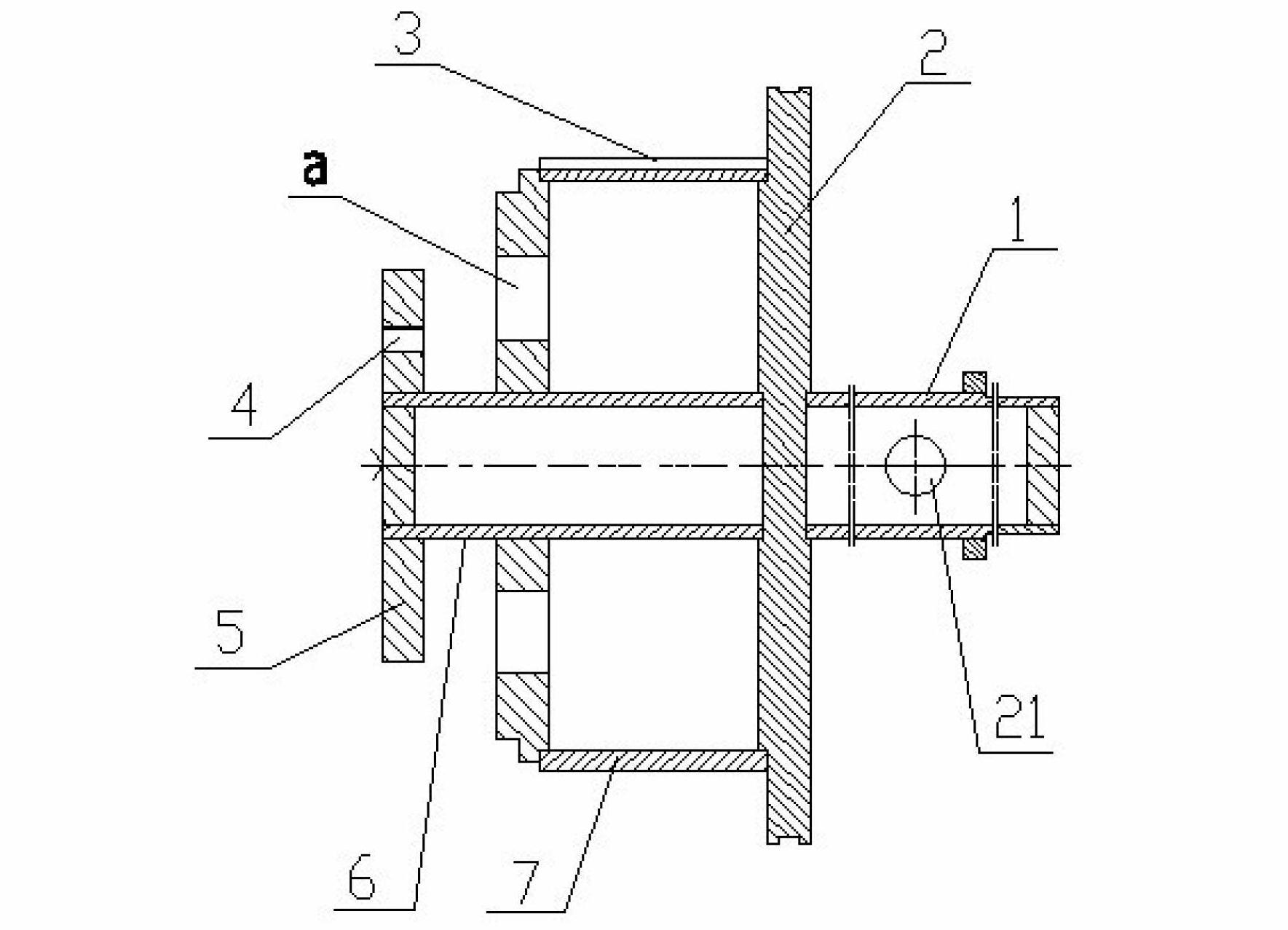

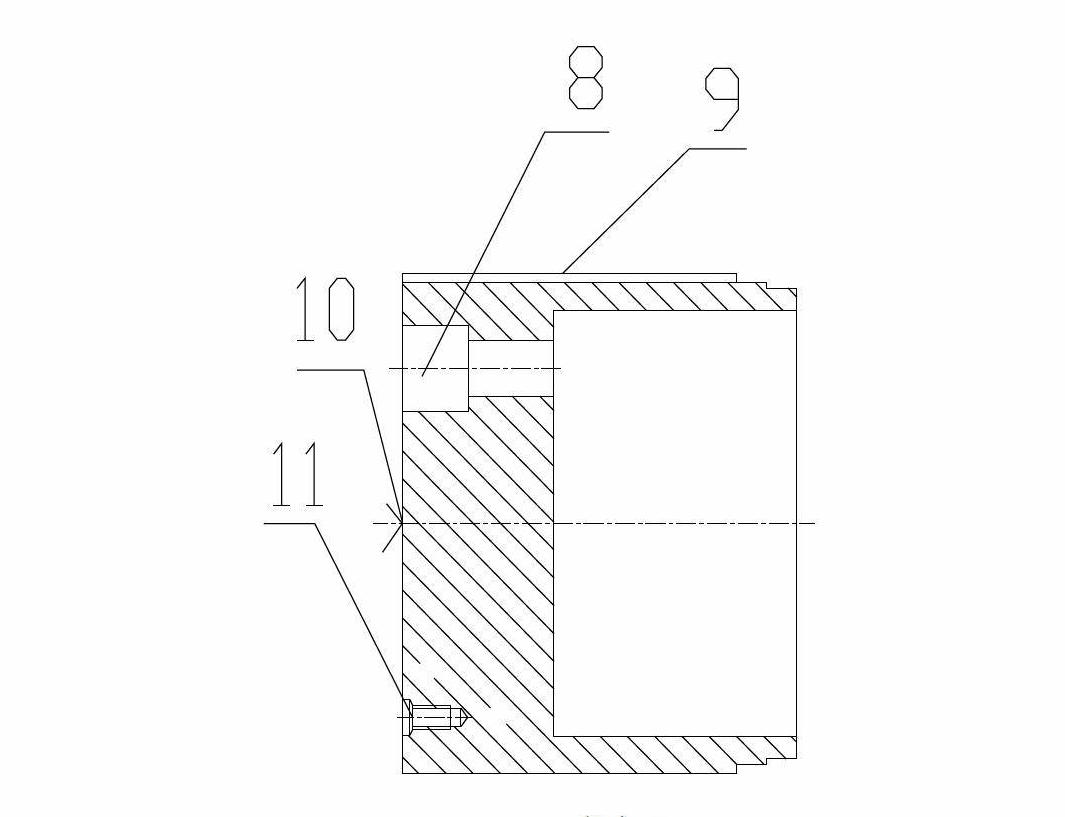

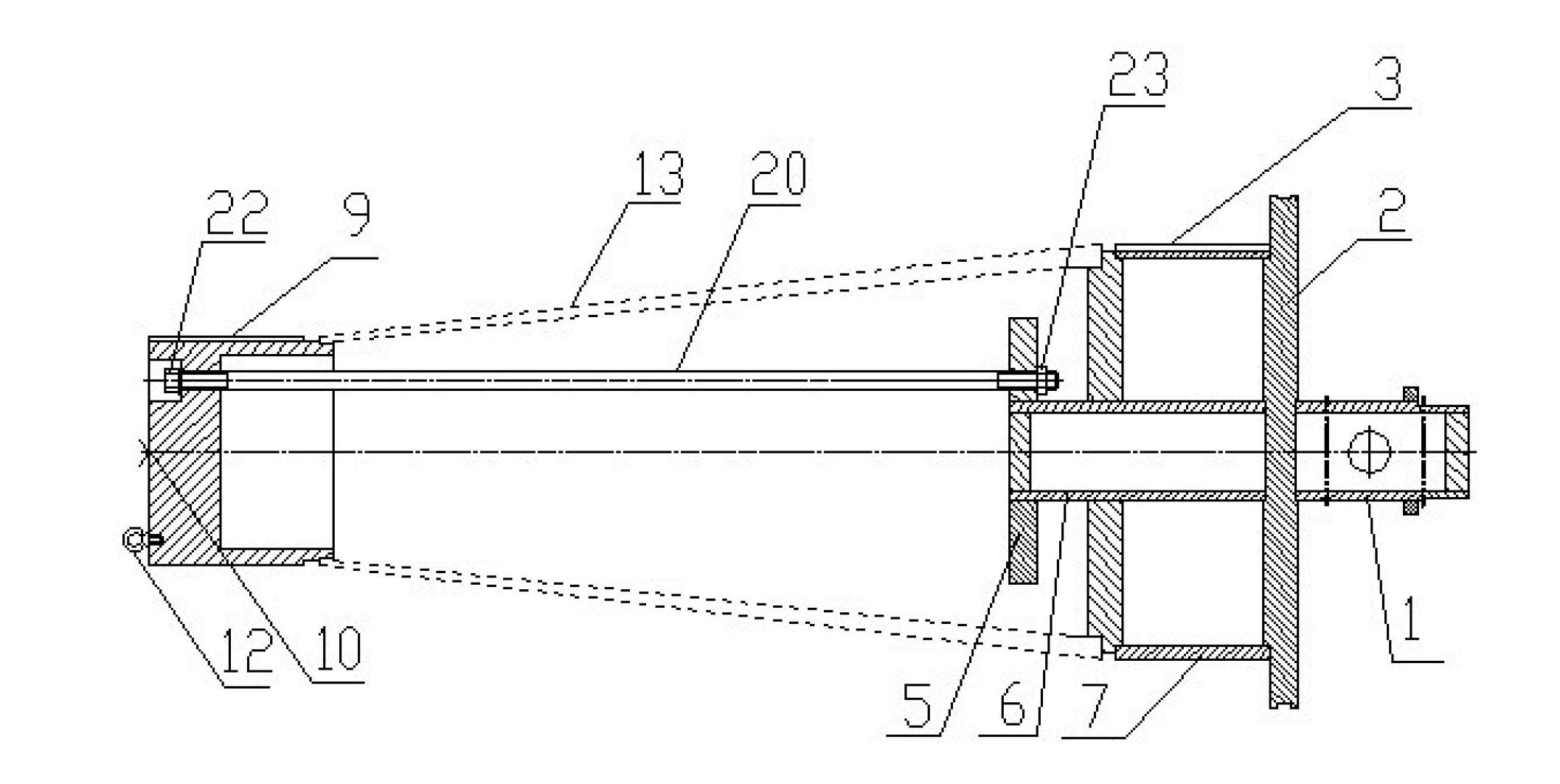

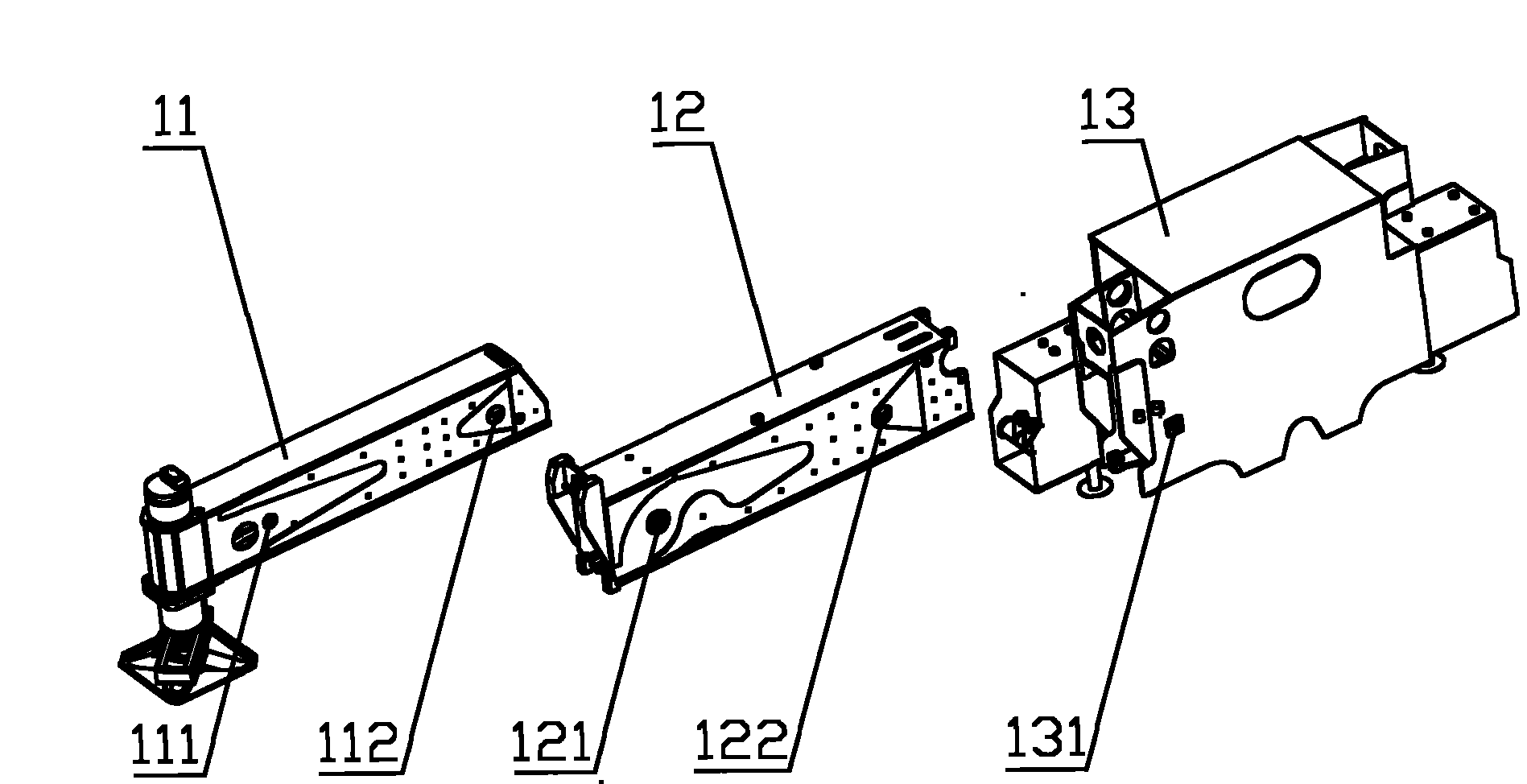

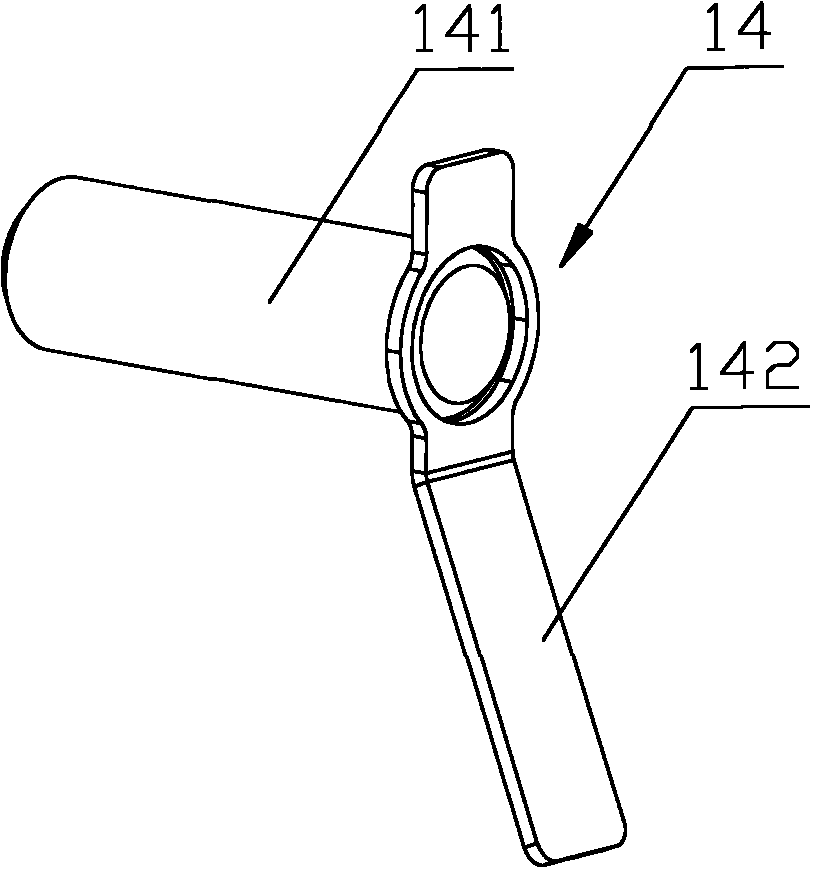

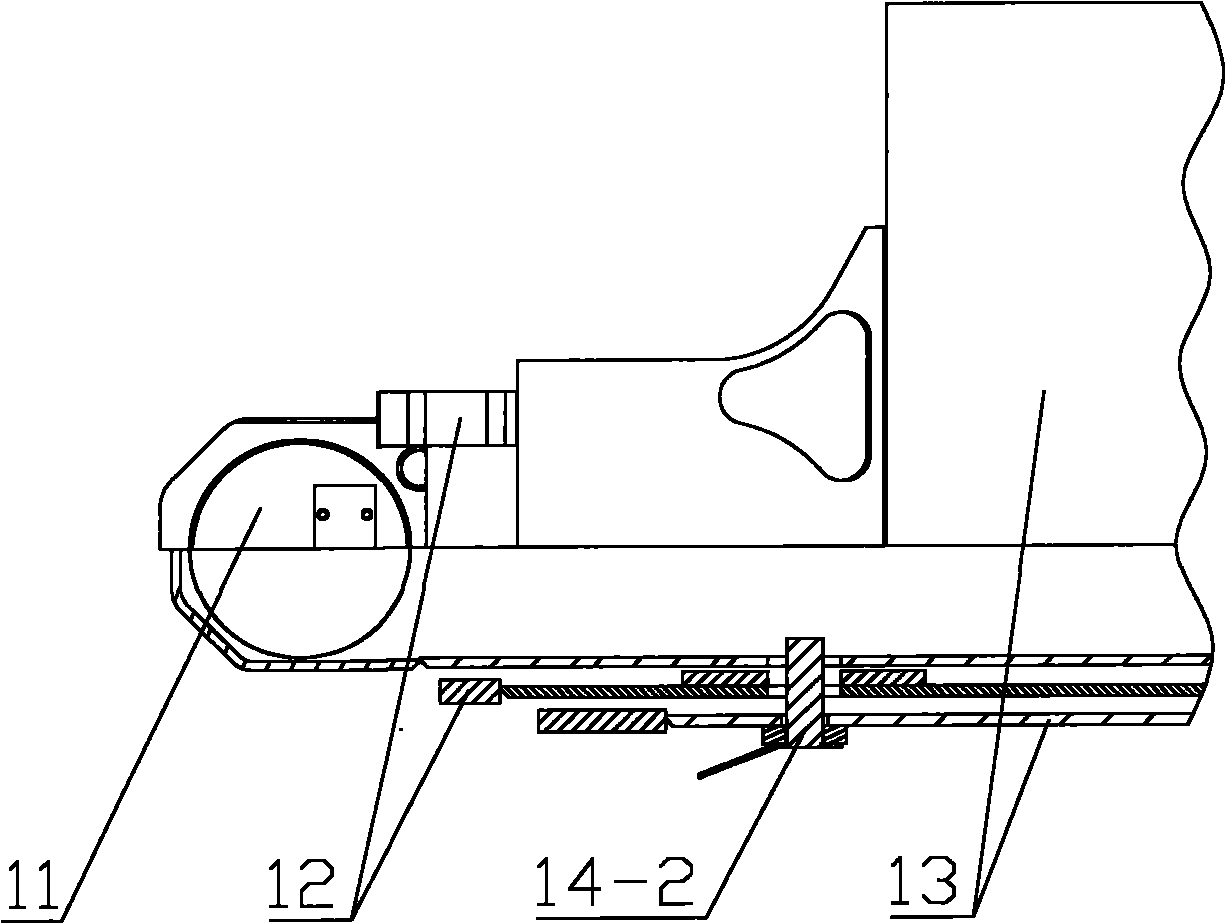

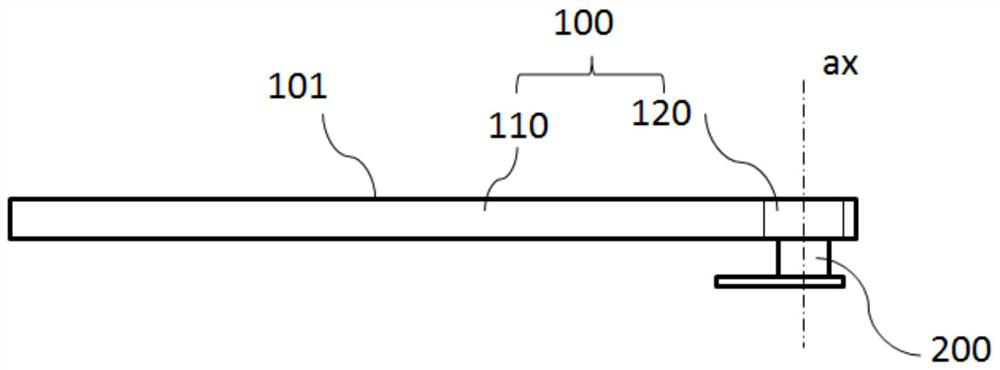

Butt tool for cabin sections of small missile

InactiveCN107953106AReduce the difficulty of alignmentImprove assembly efficiency and qualityMetal working apparatusMissileAxial force

The invention provides a butt tool for cabin sections of a small missile. The butt tool comprises a bottom frame, an axial rail, a lifting fine adjustment mechanism, a transverse fine adjustment mechanism and an axial force application mechanism. The butt tool adopts an integrally assembled structure form, and is convenient to carry, operate and maintain; and an upper arc seat and a lower arc seatwhich are used for clamping a missile body are connected through hinges, so that assembling, disassembling and clamping of each cabin section are facilitated, and the working efficiency is improved.The butt tool has the advantages that each cabin section can be freely adjusted in the X, Y and Z directions, so that the difficulty of centering and alignment of the cabin sections is greatly lowered, and the assembly efficiency and quality are improved; the defect that manual assembly is not stable and low in efficiency is overcome, meanwhile, the labor intensity of operators is greatly reduced,and the phenomenon of collision and scratch of the missile body is effectively avoided; and the coaxiality of the cabin sections of the missile can be guaranteed to be less than 0.3mm through precisemechanical assembly.

Owner:XIAN AEROSPACE PROPULSION TESTING TECH RES INST

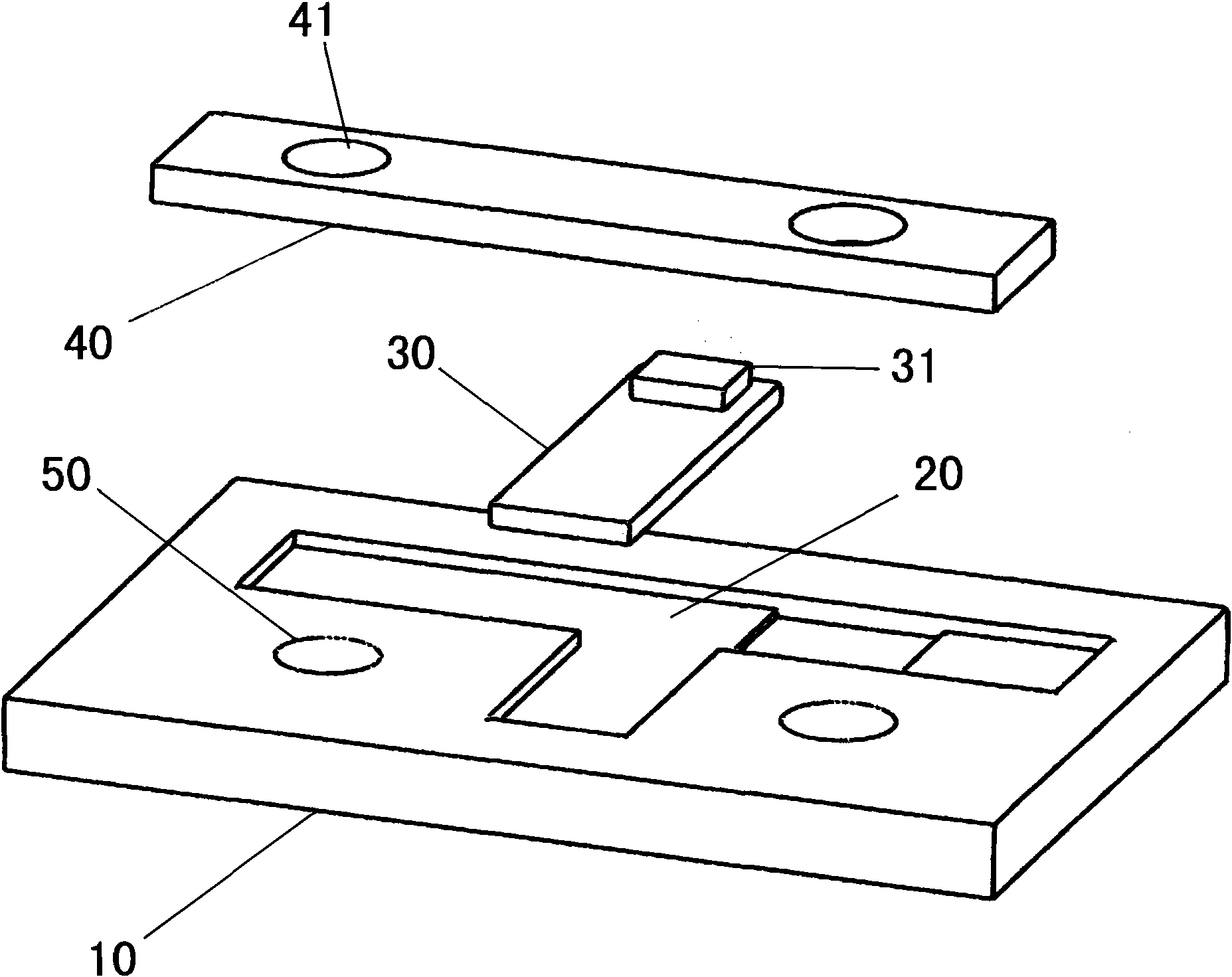

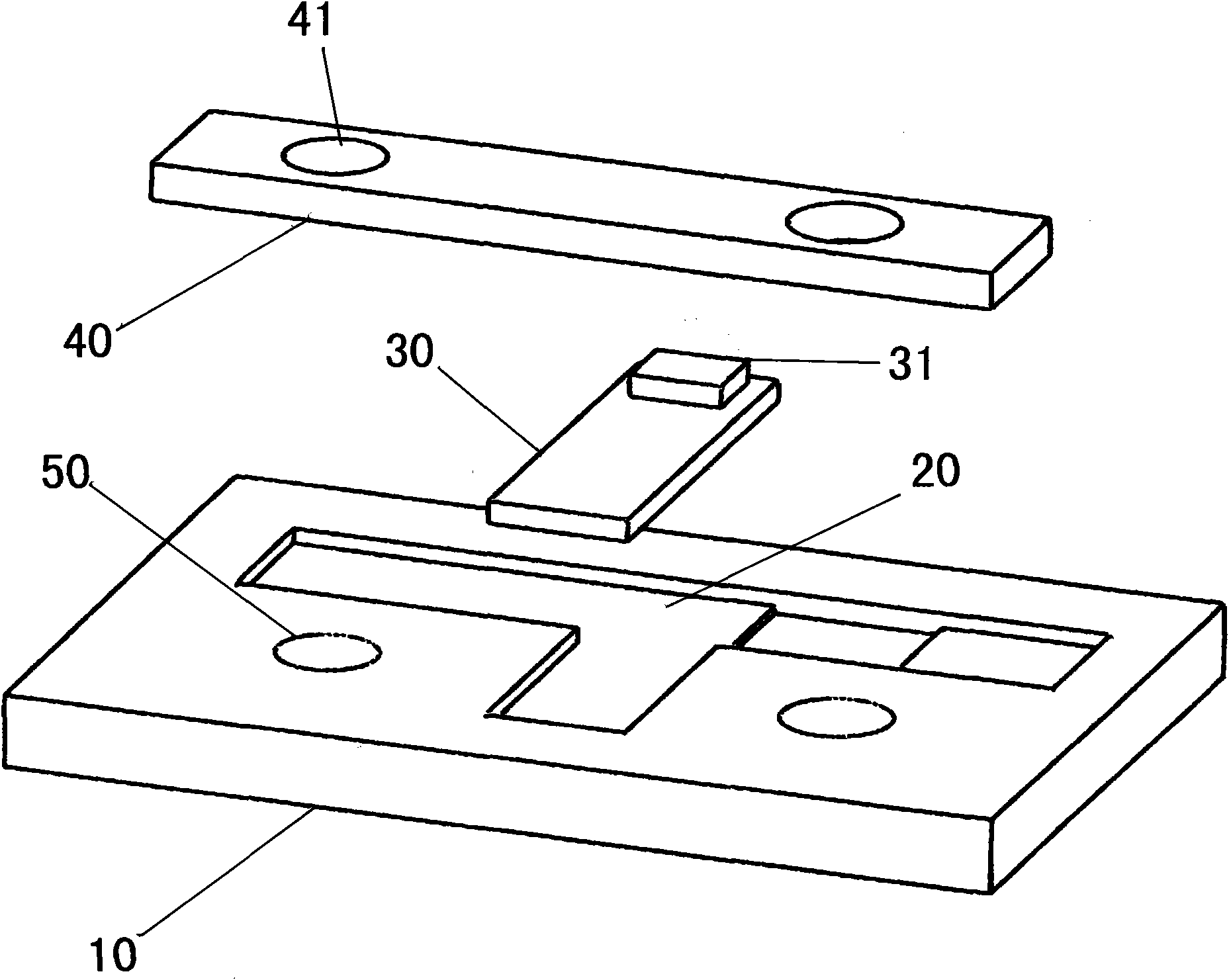

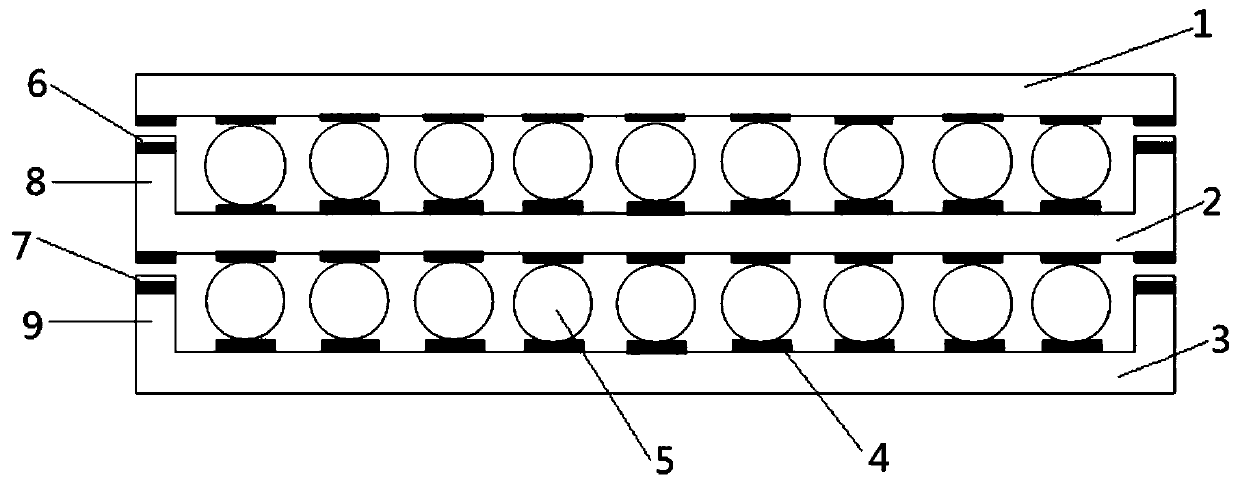

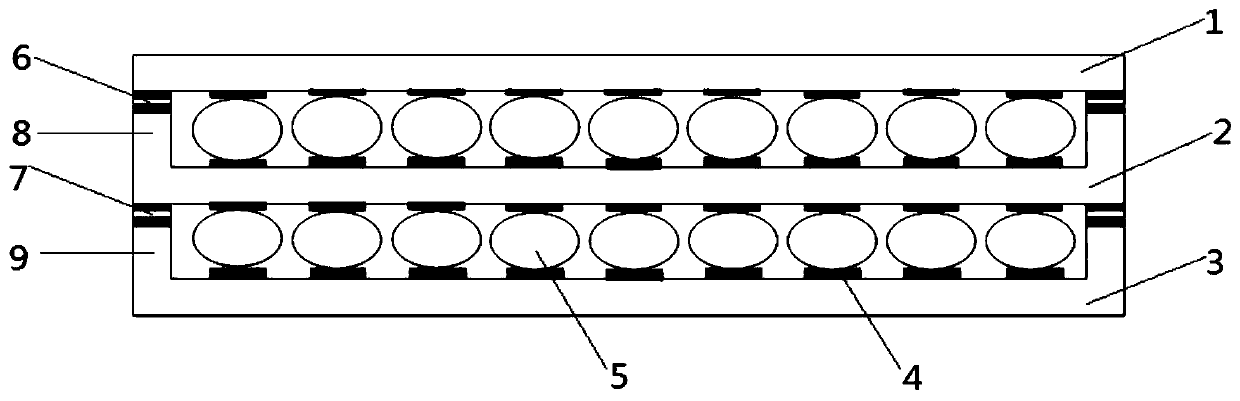

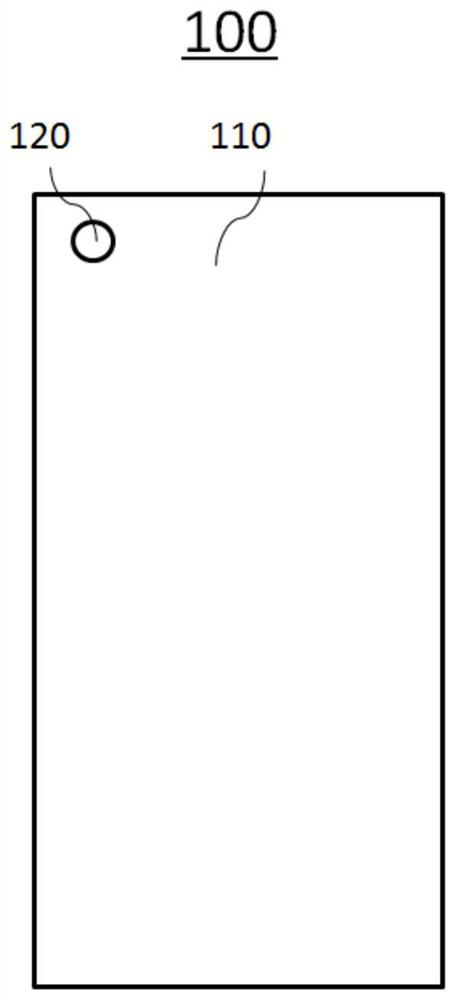

Semiconductor laser aging clamp

InactiveCN101872936ASimple designReduced Alignment DifficultyLaser detailsSemiconductor lasersSemiconductor packageEngineering

The invention provides a semiconductor laser aging clamp which comprises a main body, a heat sink and a cover plate, wherein the main body is a printed circuit board, a square, bar-shaped or T-shaped groove is arranged in the middle of the main body, and screw holes are arranged at two sides of the groove on the main body and correspond to circular holes on the cover plate; the heat sink with a laser is positioned in the groove; and the cover plate is used for covering the heat sink, and the circular holes are arranged at two sides on the upper surface of the cover plate and used for fixing the cover plate on the main body through screws.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Turning method for winding heat-proof layer on metal shell cabin section and device thereof

ActiveCN102658467AImprove resection rateImprove the clamping methodEngineeringUltimate tensile strength

The invention relates to the technical field of nonmetal material cutting processing, and discloses a turning method for winding a heat-proof layer on a metal shell cabin section and a winding core mould. In the invention, the parameters of the turning method are controlled, and the phenomena of splitting, cracking, scrap falling, block drop and fracture easily caused by the existing machining turning of the heat-proof layer are effectively improved, thus the qualified rate of finished products is improved; by changing the clamping mode, the clamping deformation of parts in processing is reduced, and the alignment difficulty is reduced; and through the improvement of the manufacturing method of the heat-proof layer, the heat-proof layer can be directly wound on the metal shell cabin section, the manufacturing and assembling processes of the heat-proof layer are simplified, the labor intensity is lowered, and the connection between the heat-proof layer and the metal shell cabin section is tighter. The processing method disclosed by the invention is universal, realizes low rejection rate of the parts, and is safe and reliable to use; and the provided winding core mould has a simple structure and is easy to manufacture and convenient to use.

Owner:HUBEI SANJIANG AEROSPACE GRP HONGYANG ELECTROMECHANICAL

Automatic exposure machine for flexible printed circuit board

ActiveCN105607430AImprove Exposure AccuracyImprove stabilityPhotomechanical exposure apparatusMicrolithography exposure apparatusEngineeringSlide plate

The invention relates to an automatic exposure machine for a flexible printed circuit board. The automatic exposure machine comprises a first exposure mechanism and a second exposure mechanism, a material feeding stacking mechanism and a material receiving stacking mechanism, a plate overturning mechanism and a sucking disc assembly, wherein the first exposure mechanism and the second exposure mechanism are arranged side by side for exposing both sides of the flexible printed circuit board respectively; the material feeding stacking mechanism and the material receiving stacking mechanism are respectively arranged in front of the first exposure mechanism and in front of the second exposure mechanism; the plate overturning mechanism is arranged at the back of the two exposure mechanisms; the sucking disc assembly is used for conveying the flexible printed circuit board among the mechanisms; the plate overturning mechanism comprises an overturning assembly capable of rotating the flexible printed circuit board by 180 degrees and a sliding plate assembly for driving the flexible printed circuit board to move left and right corresponding to the first exposure mechanism and the second exposure mechanism; each exposure mechanism comprises a supporting assembly, exposure glass arranged above the supporting assembly, an aligning platform surface which is positioned below the exposure glass and can be matched with the exposure glass to clamp the flexible printed circuit board between the aligning platform surface and the exposure glass and a glass opening and closing assembly for driving the exposure glass to move up and down, and an aligning mechanism for driving the flexible printed circuit board to slide or rotate on the plane is arranged on the bottom surface of the aligning platform surface. According to the automatic exposure machine for the flexible printed circuit board, exposure for both sides of the flexible printed circuit board can be completed once, and the problems of the flexile printed circuit board such as aligning difficulty and easy deflection are avoided, so that the production efficiency is improved.

Owner:深圳市研宝工业科技有限公司

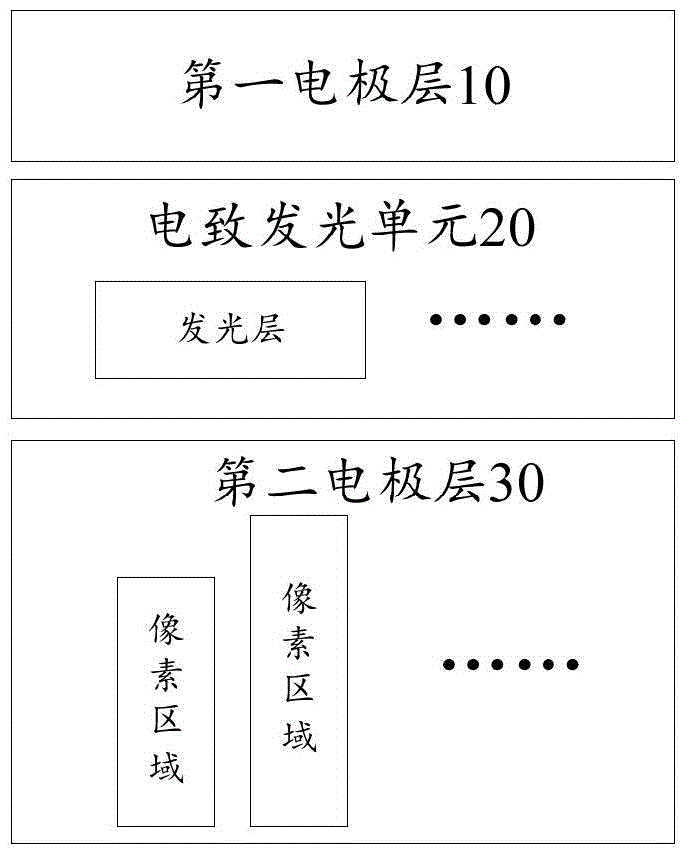

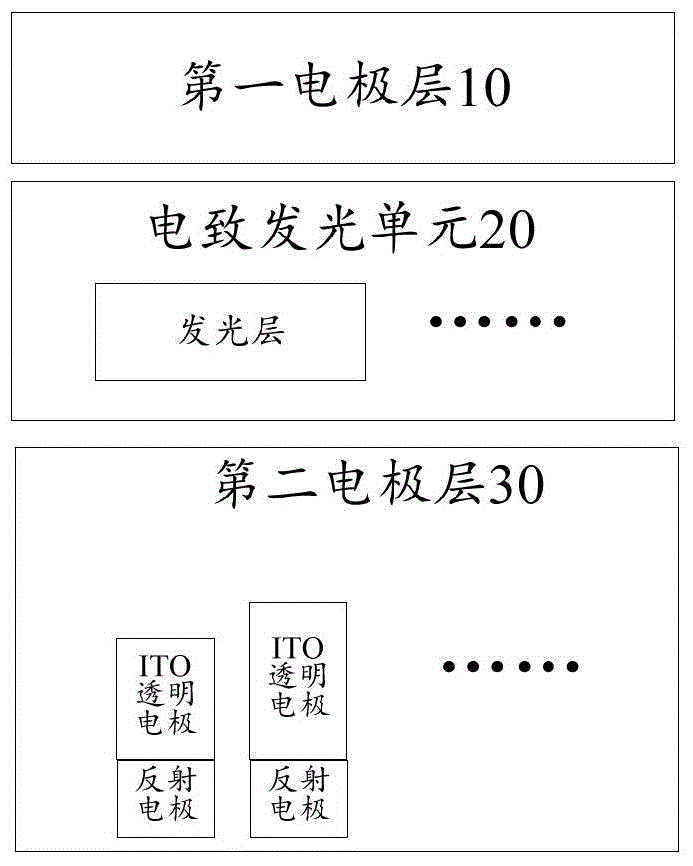

OLED (Organic Light Emitting Diode) unit, manufacturing method of OLED unit and display panel

InactiveCN104681736AAvoid color mixingReduce in quantitySolid-state devicesSemiconductor/solid-state device manufacturingElectricityLight-emitting diode

The invention discloses an OLED (Organic Light Emitting Diode) unit, a manufacturing method of the OLED unit and a display panel and belongs to the technical field of display. The OLED unit comprises a first electrode layer, an electroluminescent unit and a second electrode layer, wherein the electroluminescent unit is located between the first electrode layer and the second electrode layer and comprises at least one luminous layer; each luminous layer corresponds to two pixel areas; the second electrode layer comprises the pixel areas; and each luminous layer is overlapped with the two pixel areas corresponding to a projection area in the second electrode layer. According to the unit, each luminous layer can correspond to the two pixel areas, the quantity of the luminous layers in the OLED unit is reduced, and the area of the luminous layers is increased, so that the alignment difficulty between the luminous layers and the pixel areas is reduced, and a color mixture phenomenon of the display panel is avoided.

Owner:BOE TECH GRP CO LTD

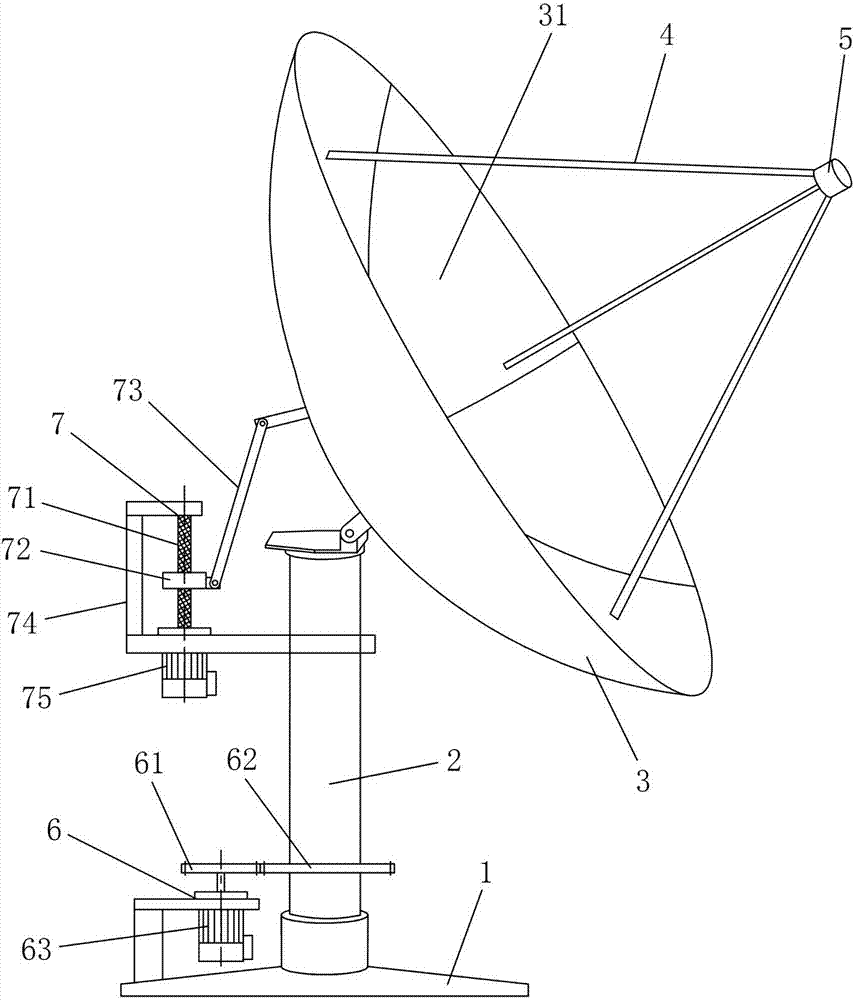

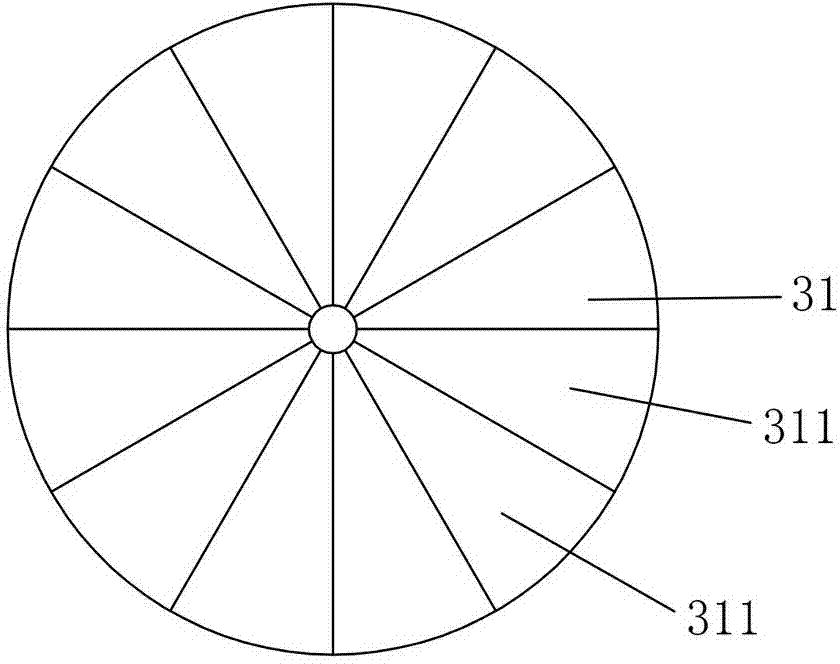

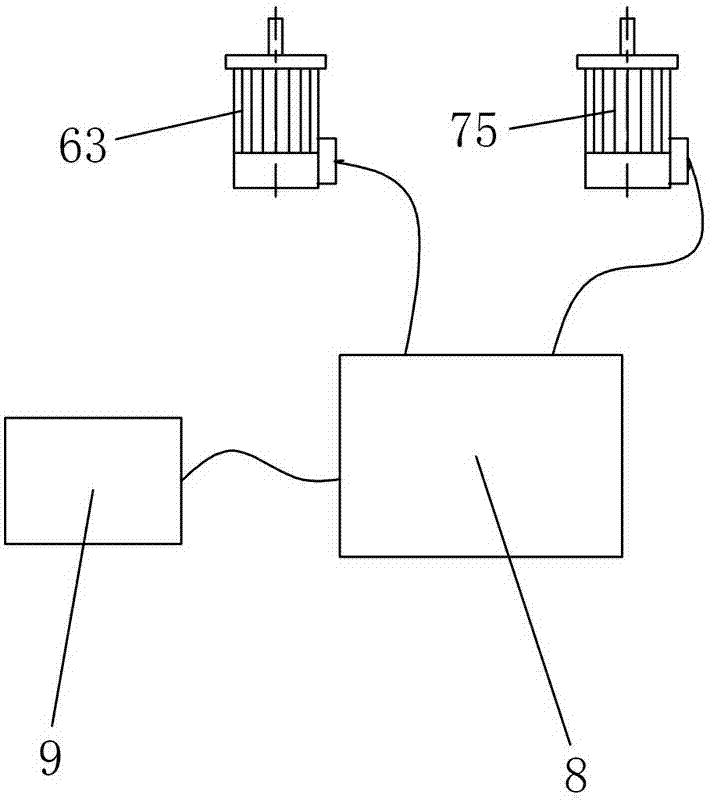

Geosynchronous satellite wide area power grid wildfire remote sensing signal receiving device

The invention discloses a geosynchronous satellite wide area power grid wildfire remote sensing signal receiving device comprising a pedestal, a stand column and a receiving pot. A feed source is installed in front of the spherical reflection surface of the receiving pot via a support. The stand column is arranged on the pedestal via a rotating mechanism and can rotate around the vertical axis. The receiving port is hinged on the stand column round the horizontal axis. The receiving device also comprises a rotating driving assembly which is used for driving the stand column to rotate and a pitching driving assembly which is used for driving the receiving pot to perform pitching movement. The geosynchronous satellite wide area power grid wildfire remote sensing signal receiving device has advantages that a power grid wildfire geosynchronous satellite wide area weak signal can be accurately received, monitoring range is wide, and detection real-time performance and reliability are high.

Owner:HUNAN XIANGDIAN POWER TEST & RES TECH LTD

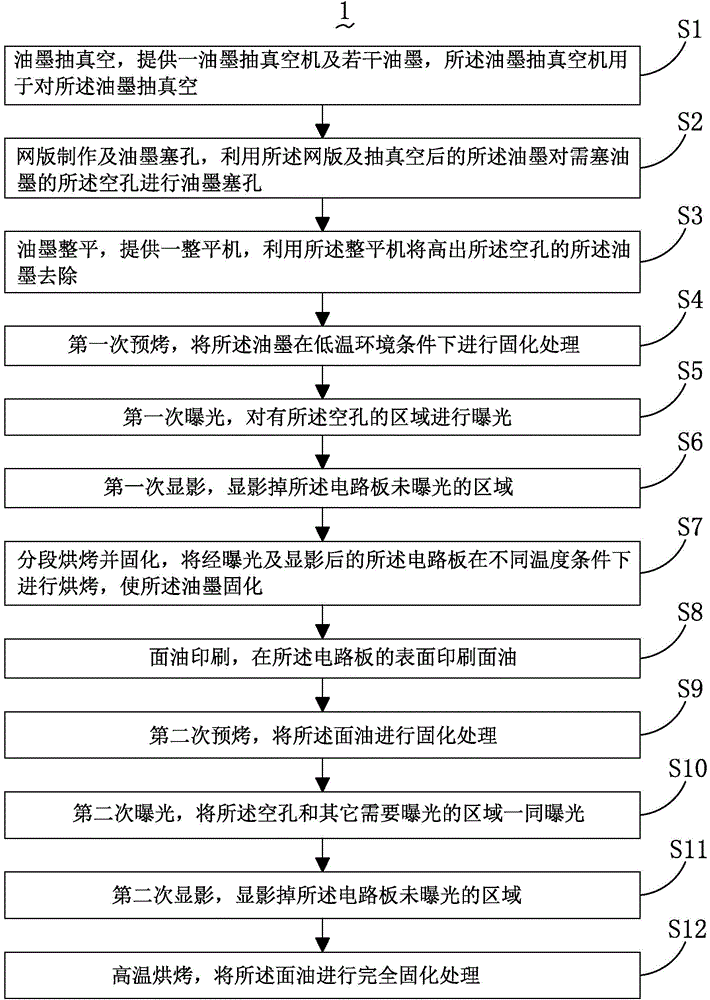

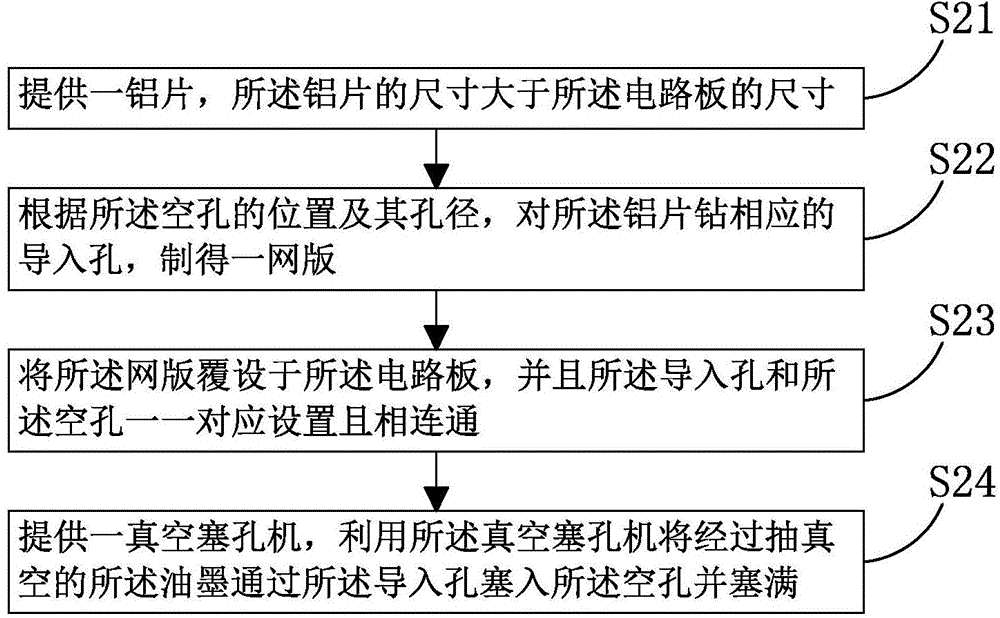

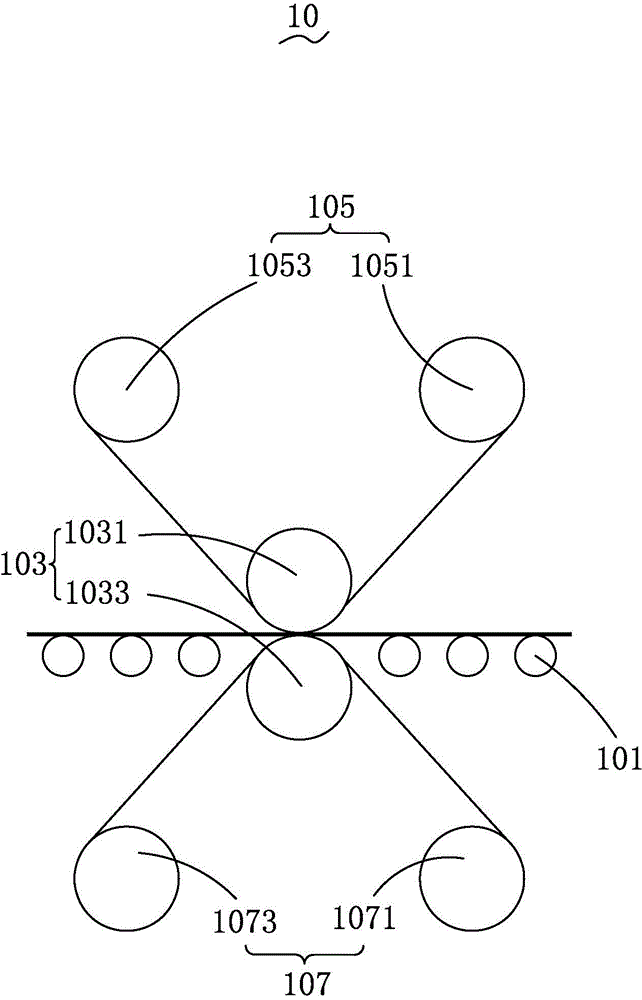

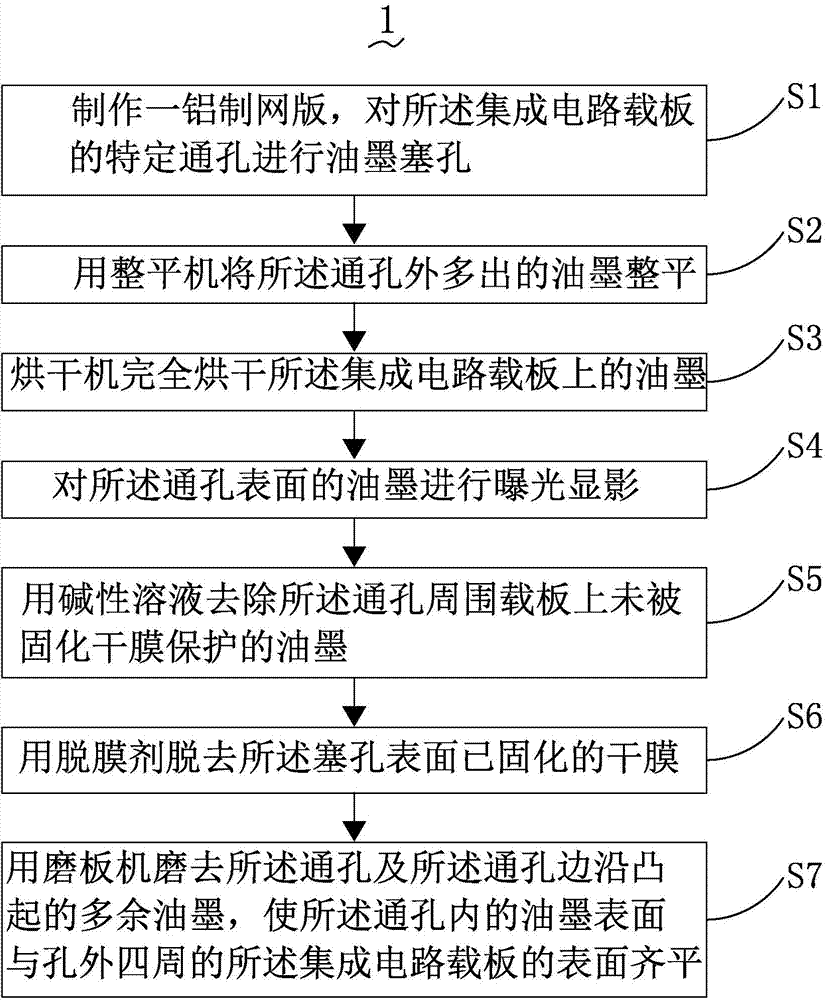

Printing ink hole plugging process method for circuit boards

InactiveCN104486913AImprove the effectReduce the difficulty of alignmentPrinted element electric connection formationPrinting inkEngineering

The invention provides a printing ink hole plugging process method for circuit boards. The printing ink hole plugging process method comprises the following steps: printing ink vacuumizing; screen printing plate production and printing ink hole plugging; printing ink leveling; pre-baking for the first time; exposing for the first time; developing for the first time; subsection baking and curing; surface oil printing; pre-baking for the second time; exposing for the second time; developing for the second time; high-temperature baking. The printing ink hole plugging process method reduces the probability that cracks exist in printing ink, improves the effect of printing ink hole plugging, and avoids the phenomenon that chemicals and humidity in the follow-up process can permeate into empty holes as the cracks exist in the cured printing ink.

Owner:SHENZHEN WUZHU TECH

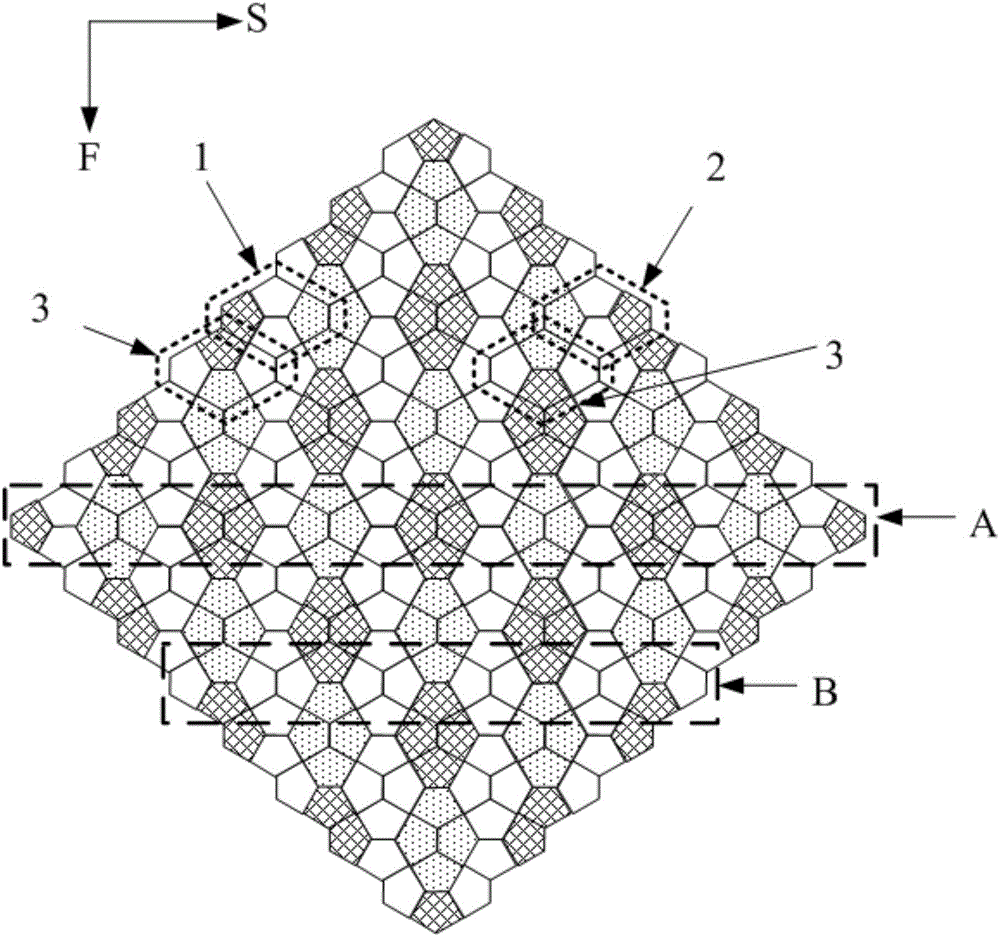

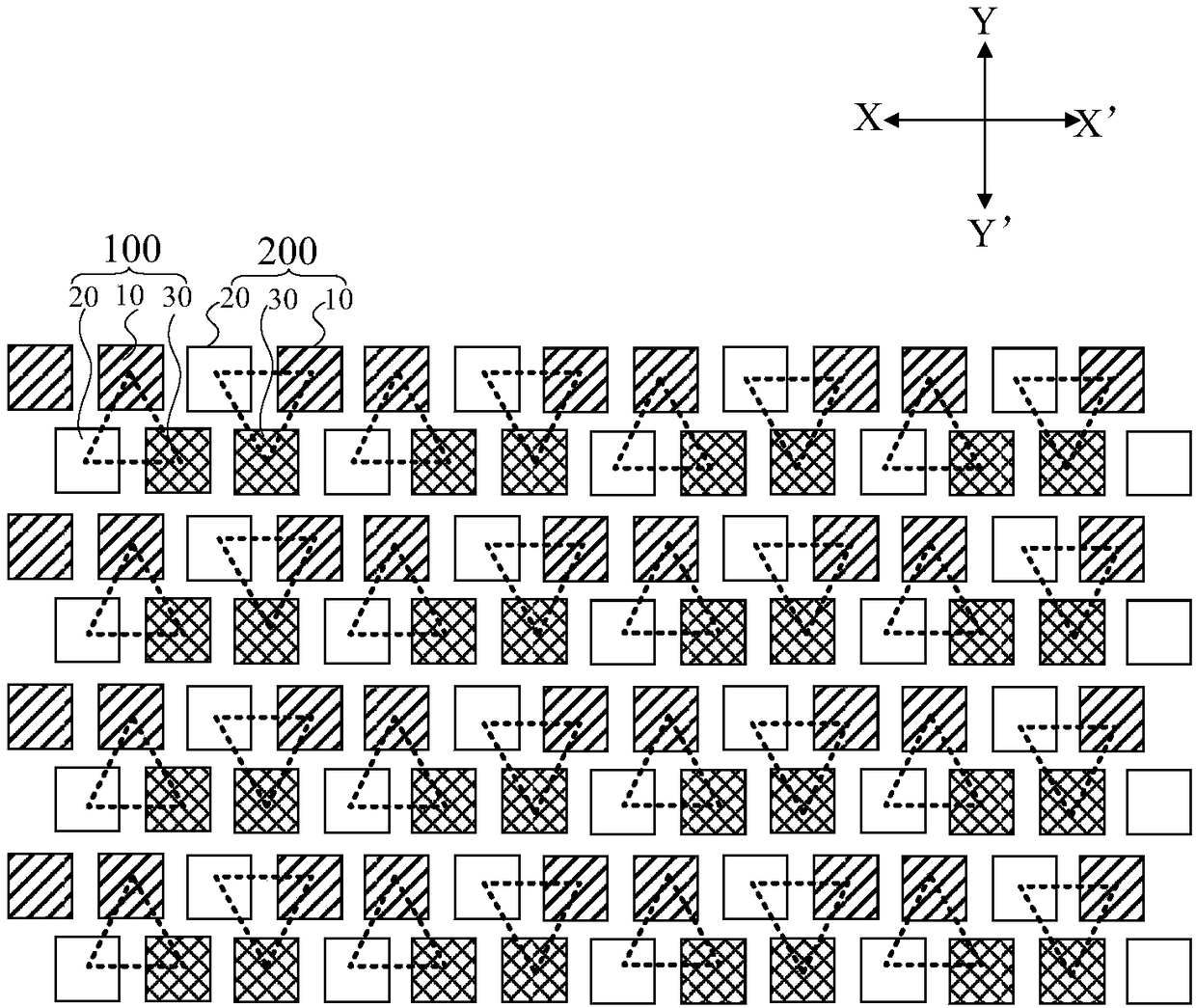

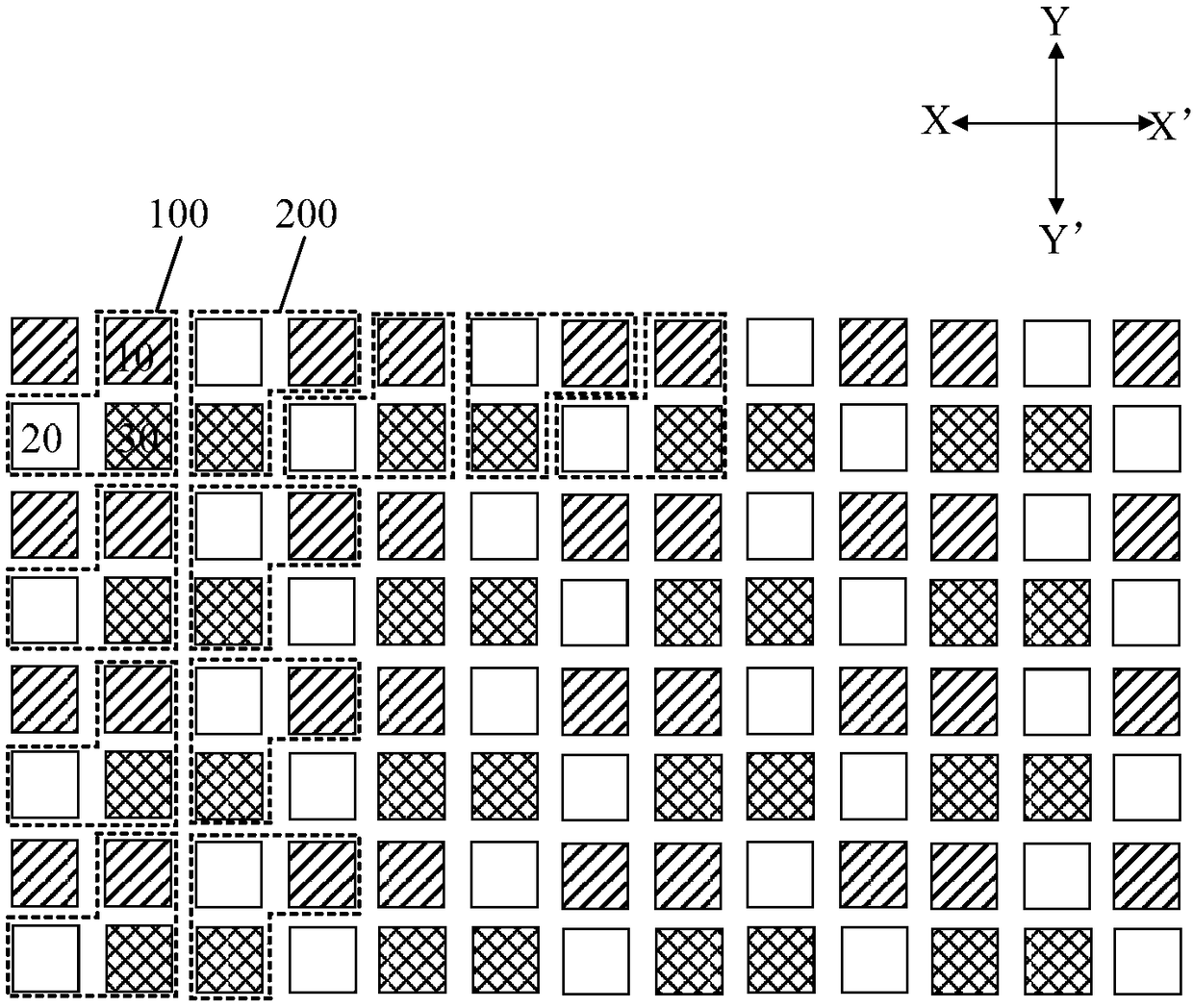

Pixel arrangement structure, display panel, display device, and mask plate

ActiveCN108493224AImprove the uniformity of arrangementLow manufacturing process requirementsSolid-state devicesSemiconductor devicesColor mixingDisplay device

The embodiment of the invention, which relates to the field of display technology, provides a pixel arrangement structure, a display panel, a display device, and a mask plate so that problems of highalignment difficulty, color mixing, and low sub-pixel arrangement uniformity caused by the small opening dimension of the FMM in the prior art can be solved. The pixel arrangement structure comprisesfirst display units and second display units, wherein the first display units and the second display units are arranged in an array and are arranged alternately and successively along a row direction.Each display unit consists of a first sub pixel, a second sub pixel, and a third sub pixel that have three kinds of different colors and are distributed at two adjacent rows. For one group of first display units and one group of second display units adjacent to the first display units in a first direction, the first sub pixels in the first display units and the first sub pixels and the second subpixels in the second display units are arranged at the same row; and the second sub pixels and the third sub pixels in the first display units and the third sub pixels in the second display units arearranged at the same row.

Owner:BOE TECH GRP CO LTD +1

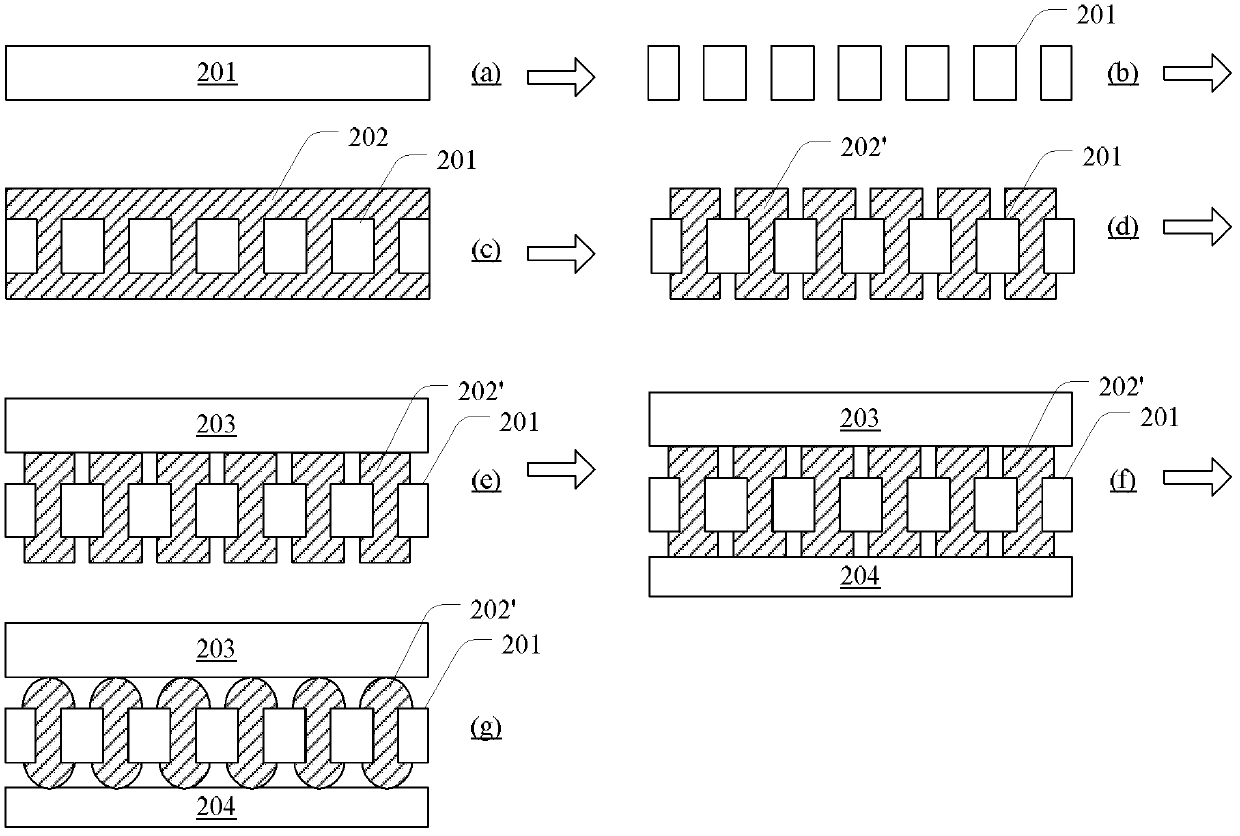

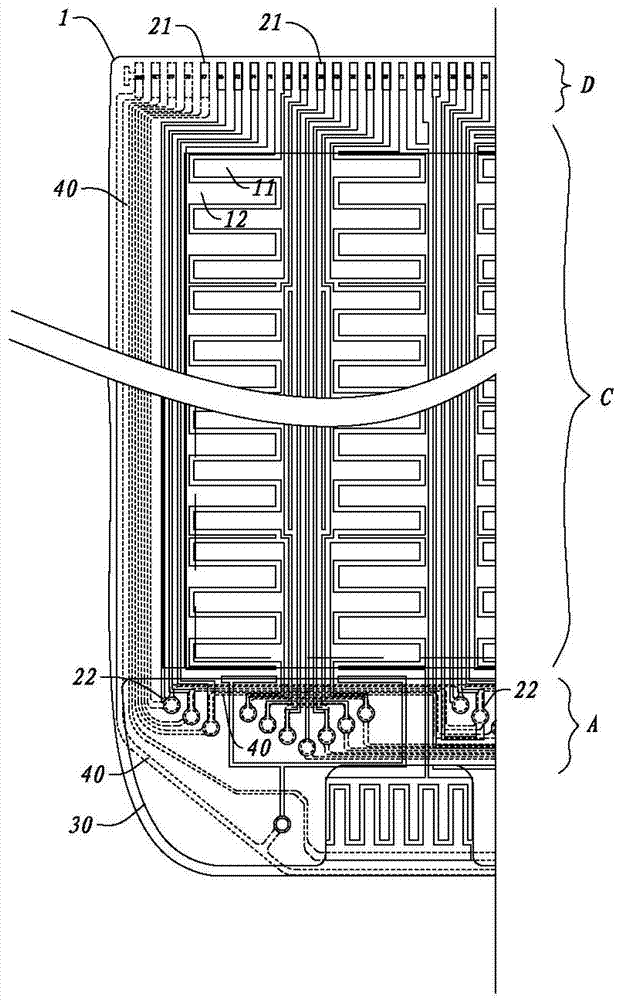

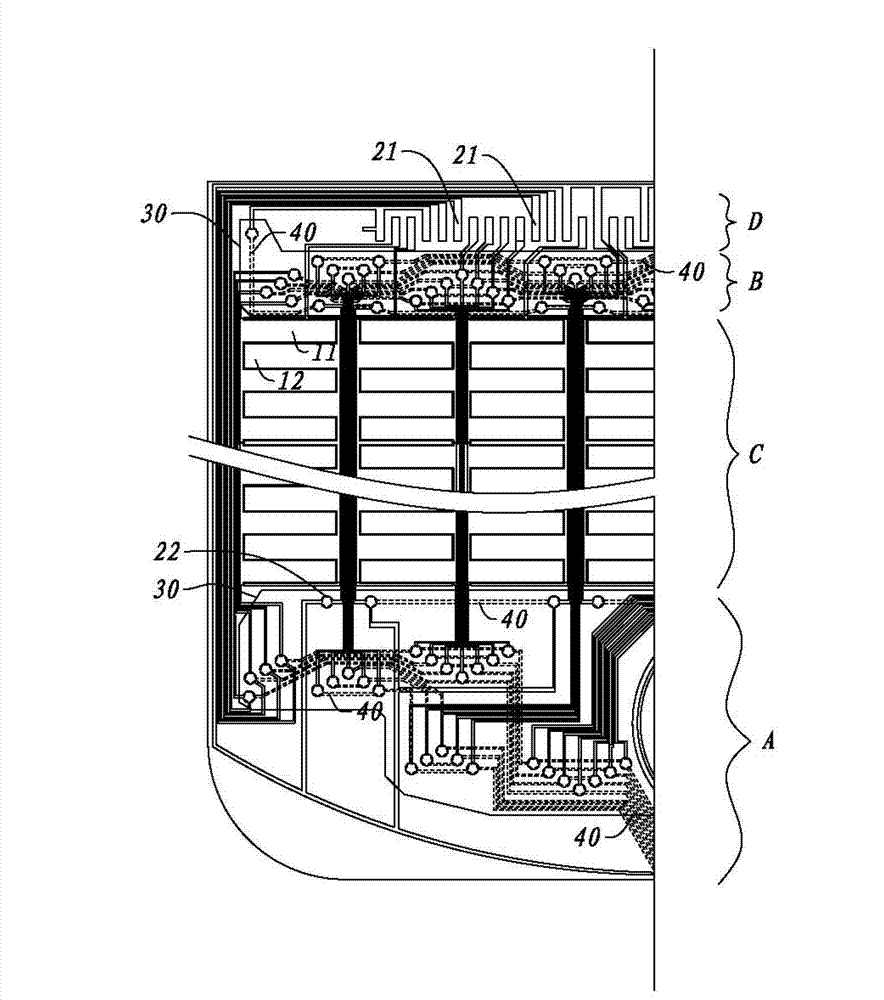

Self-alignment integrated package method of high-density three-dimensional lamination layer

PendingCN110211884AReduced Alignment DifficultyReduce failure rateSemiconductor/solid-state device detailsSolid-state devicesHigh densityInter layer

The invention discloses a self-alignment integrated package method of a high-density three-dimensional lamination layer, and aims to provides an integrated package method which employs a BGA welding ball as an interlayer mechanical support for multi-layer substrate self-alignment three-dimensional stack and also can be a signal interconnection passage among high-density layers. The self-alignmentintegrated package method is implemented according to the technical scheme that bonding pads are arranged on a lower surface of a top-layer substrate, an upper surface and a lower surface of an intermediate-layer substrate and an upper surface of a bottom-layer substrate and are used for welding micro BGA welding balls, the micro BGA welding balls are attached onto the upper surface of the intermediate-layer substrate and the upper surface of the bottom-layer substrate, the micro BGA welding balls on the upper surface of the intermediate-layer substrate are corresponding to the lower surface of the top-layer substrate, the micro BGA welding balls on the upper surface of the bottom-layer substrate are corresponding to the lower surface of the intermediate-layer substrate, vertical and interconnection rectangular array micro BGA ball welding is formed, a hollow square boss cavity box body is arranged at the peripheries outside an upper cavity surface of the intermediate-layer substrate 2and an upper cavity surface of the bottom-layer substrate 3, the cavity box body is stacked and placed in a backflow welding furnace by a tool, and self-alignment lamination layer welding is performed to form a package body.

Owner:10TH RES INST OF CETC

Mobile construction machinery and outrigger locking mechanism thereof

InactiveCN102079297AEffective lockingAchieve lockingVehicle fittings for liftingCranesEngineeringBuilding construction

The invention discloses an outrigger locking mechanism used for mobile construction machinery. In the invention, an outrigger of the mobile construction machinery comprises a first movable outrigger (2), a second movable outrigger (3) and a fixed outrigger (4); the outrigger locking mechanism comprises a locking part (6) and a first locking hole (21) which is matched with the locking part (6) and arranged at the outer end of the first movable outrigger (2); a first mounting hole (41) is arranged at the outer end of the fixed outrigger (4); and when both the first movable outrigger (2) and the second movable outrigger (3) are retracted into the fixed outrigger (4), the locking part (6) is inserted into the first locking hole (21) and the first mounting hole (41) and has a scheduled distance from the second movable outrigger (3). The outrigger locking mechanism is easy to operate and can effectively enhance locking efficiency. The invention also provides the mobile construction machinery comprising the outrigger locking mechanism and then the reliability is enhanced.

Owner:XUZHOU HEAVY MASCH CO LTD

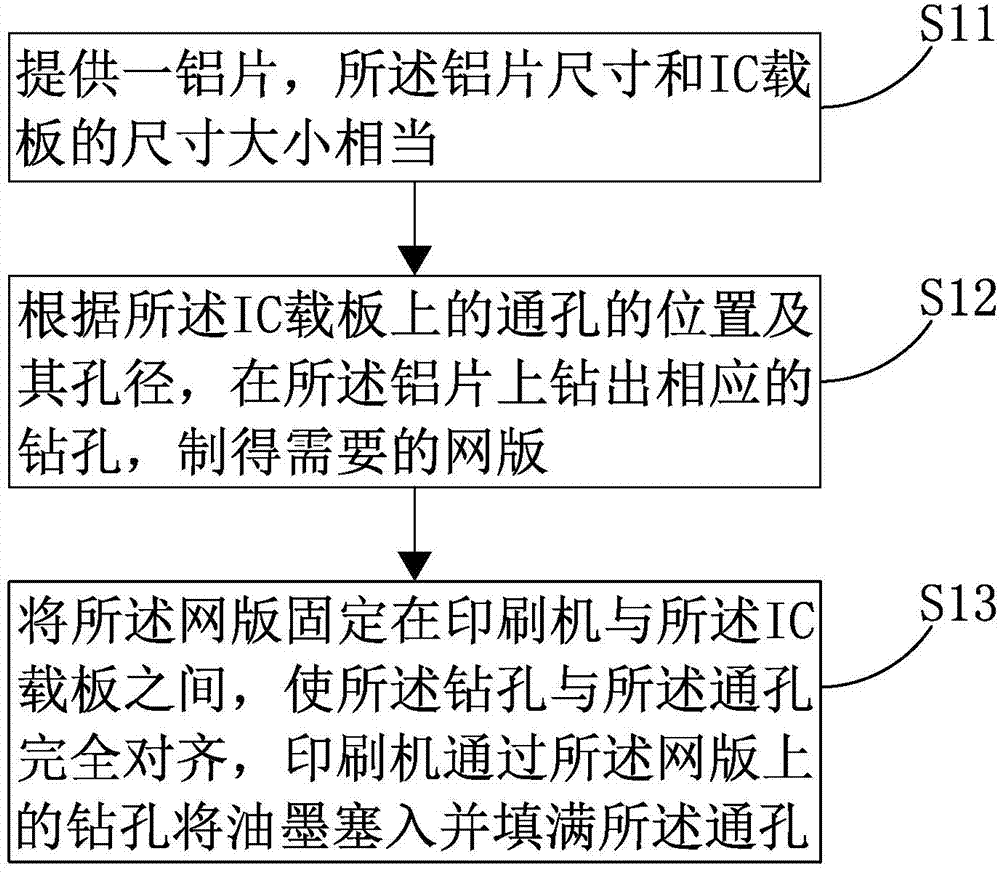

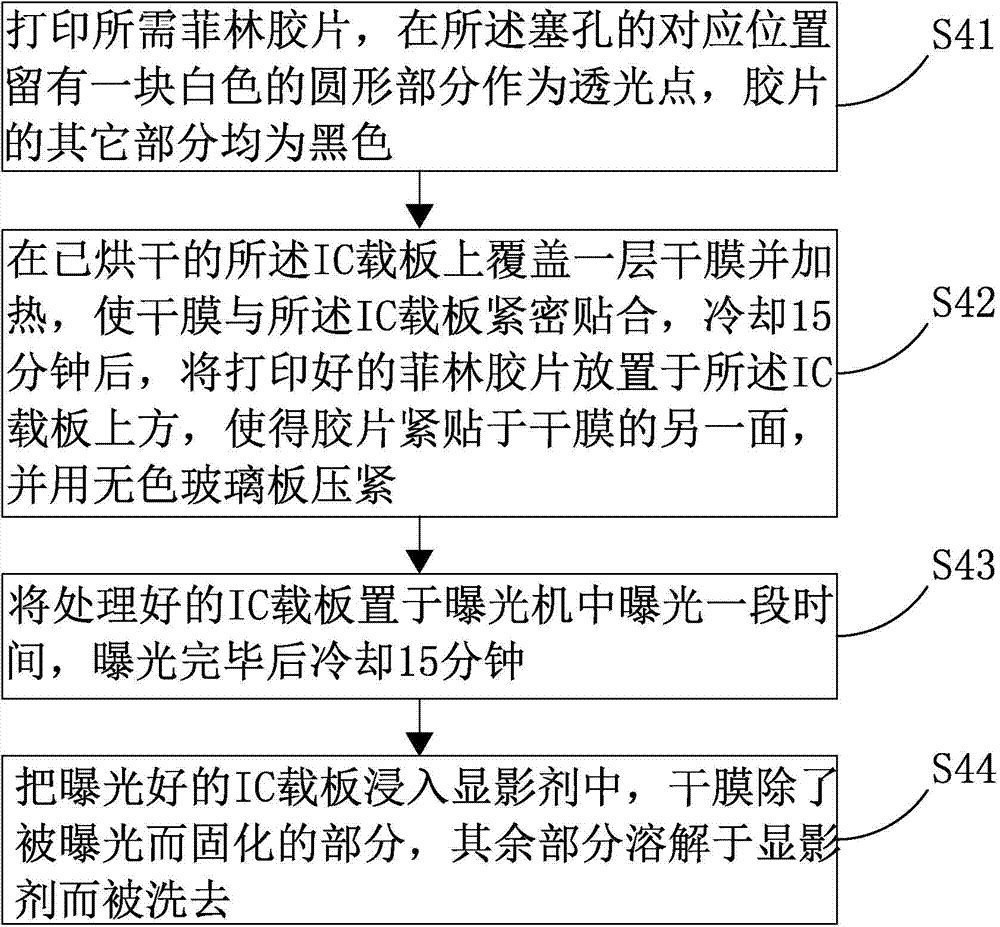

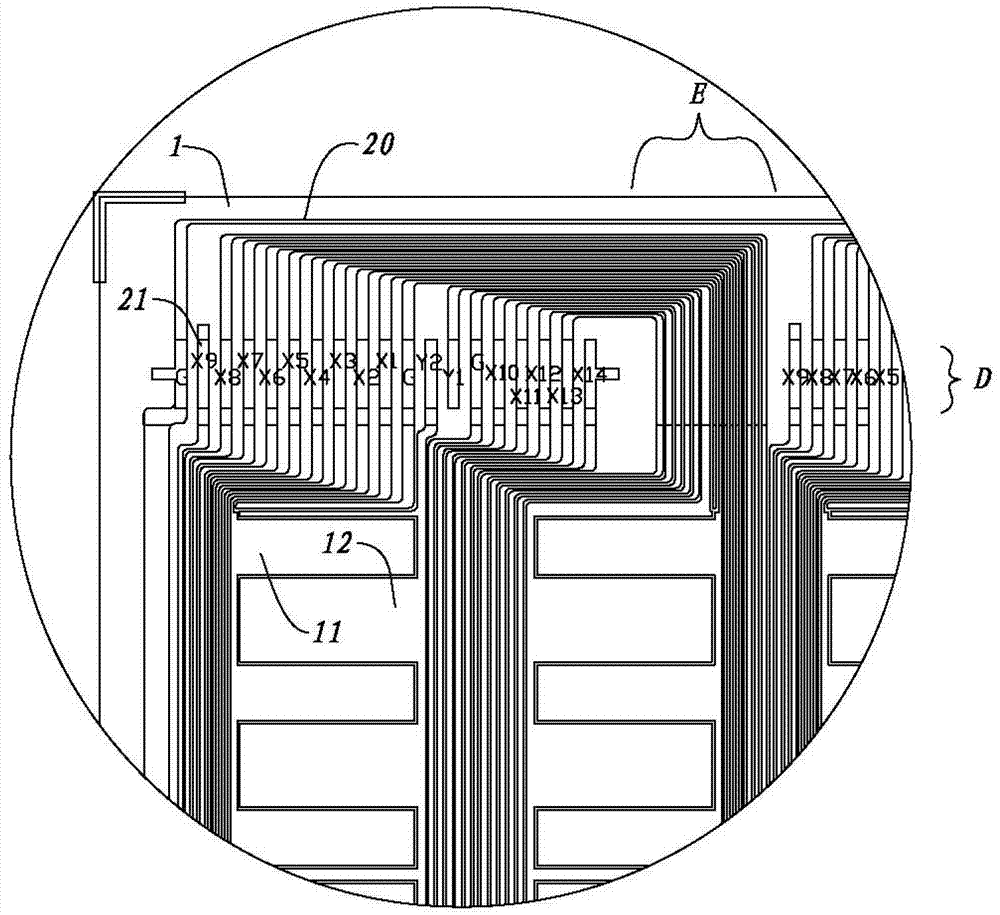

Process method for integrated circuit carrying plate plug hole

InactiveCN104507274AImprove fullnessReduced Alignment DifficultyPrinted element electric connection formationScreen printingIntegrated circuit

The invention provides a process method for an integrated circuit carrying plate plug hole. The process method for the integrated circuit carrying plate plug hole comprises the following steps that an aluminum screen printing plate is manufactured, and a specific through hole of the integrated circuit carrying plate is subjected to ink hole plugging; a leveling machine is used for leveling excessive ink outside the through hole; a drying machine completely dries ink on the integrated circuit carrying plate; the ink on the surface of the through hole is subjected to exposure development; an alkaline solution is used for removing uncured dry film protection ink on the carrying plate around the through hole; a demolding agent is used for removing a dry film cured on the surface of the plug hole; the ink projected out of the through hole and projected at the edge of the through hole are ground away by a plate grinding machine, so that the surface of the ink inside the through hole is aligned with the surface of the integrated circuit carrying plate. The process method for the integrated circuit carrying plate plug hole provided by the invention has the advantages that the operation is simple and convenient, the recessed phenomenon of the ink in the through hole can be avoided, the flatness of the surface of a product is ensured, and the output rate of inferior-quality products and the loss due to the reason are reduced.

Owner:SHENZHEN WUZHU TECH

Bridging and wire-leading sensor of monolayer multi-point touch screen and forming process thereof

InactiveCN103116427AIncrease widthExpand line spacingInput/output processes for data processingLine sensorIndium tin oxide

The invention discloses a bridging and wire-leading sensor of a monolayer multi-point touch screen and a forming process thereof. The forming process is characterized by comprising the following steps: firstly, providing an insulating and transparent substrate, and etching one surface of the substrate into an induction electrode and an indium tin oxide (ITO) leading wire which extends out, wherein contacting points and bridging points for bridging connection are arranged at the tail end of the leading wire, then, keeping on forming a transparent insulating layer on the surface of the substrate, wherein the insulating layer covers all bridging points in the plane and presetting through holes at positions of the bridging points, and at last, forming a bridging layer on the substrate, the insulating layer of which is processed, wherein the bridging layer is positioned on the surface of the insulating layer or comprises the surface of the substrate, the bridging layer is communicated with the bridging points through the through holes, and the bridging and wire-leading sensor is got. Due to the fact that bridging wires exist, the contacting points of the monolayer multi-point touch screen are distributed evenly, the phenomena that the contacting points are blocked and crossed by the leading wire are avoided, the widths of the contacting points and wire distance are enlarged, binding difficulty between the contacting points and flexible printed circuit (FPC) is reduced, and yield is increased.

Owner:来宾市永典木业有限公司

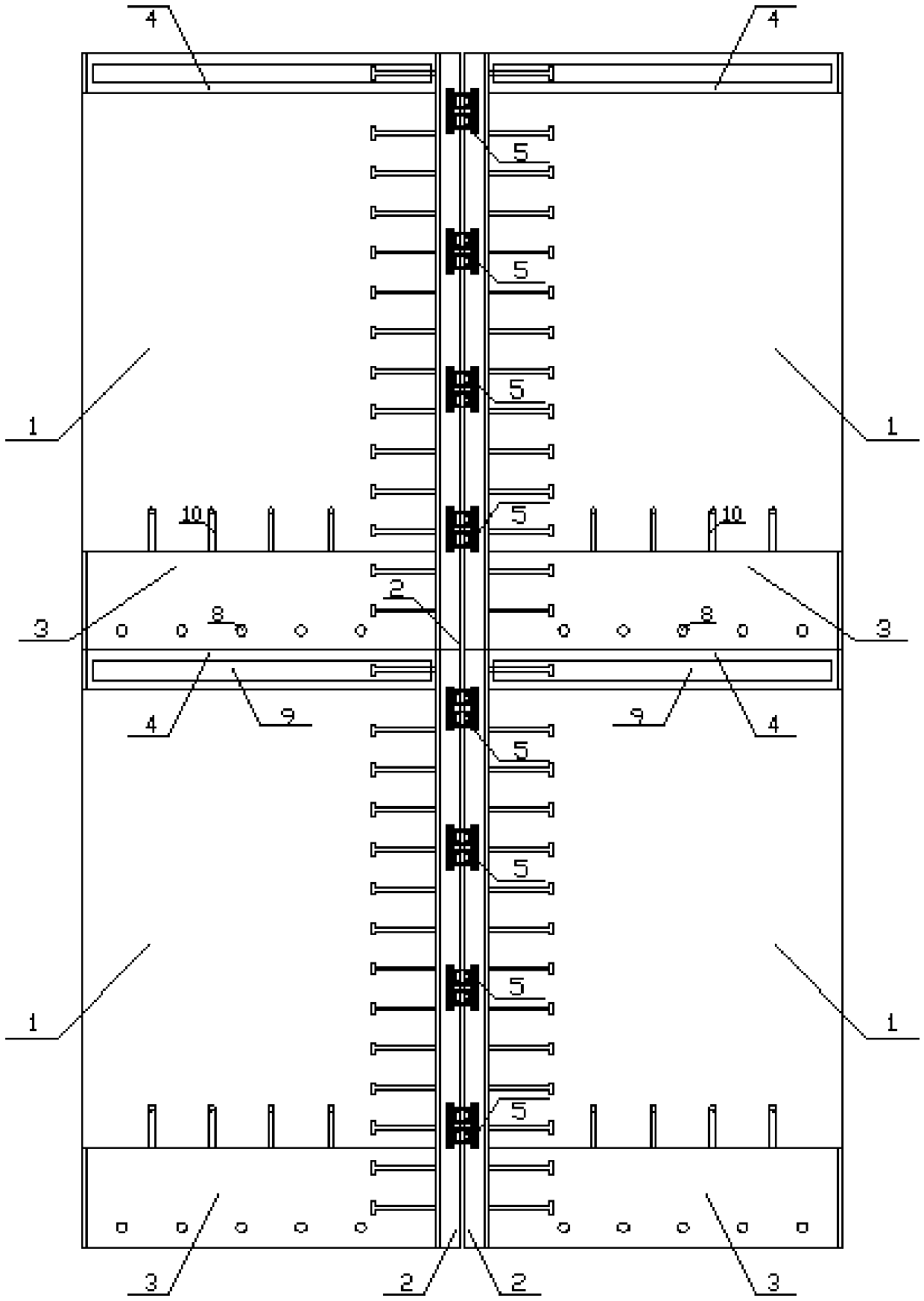

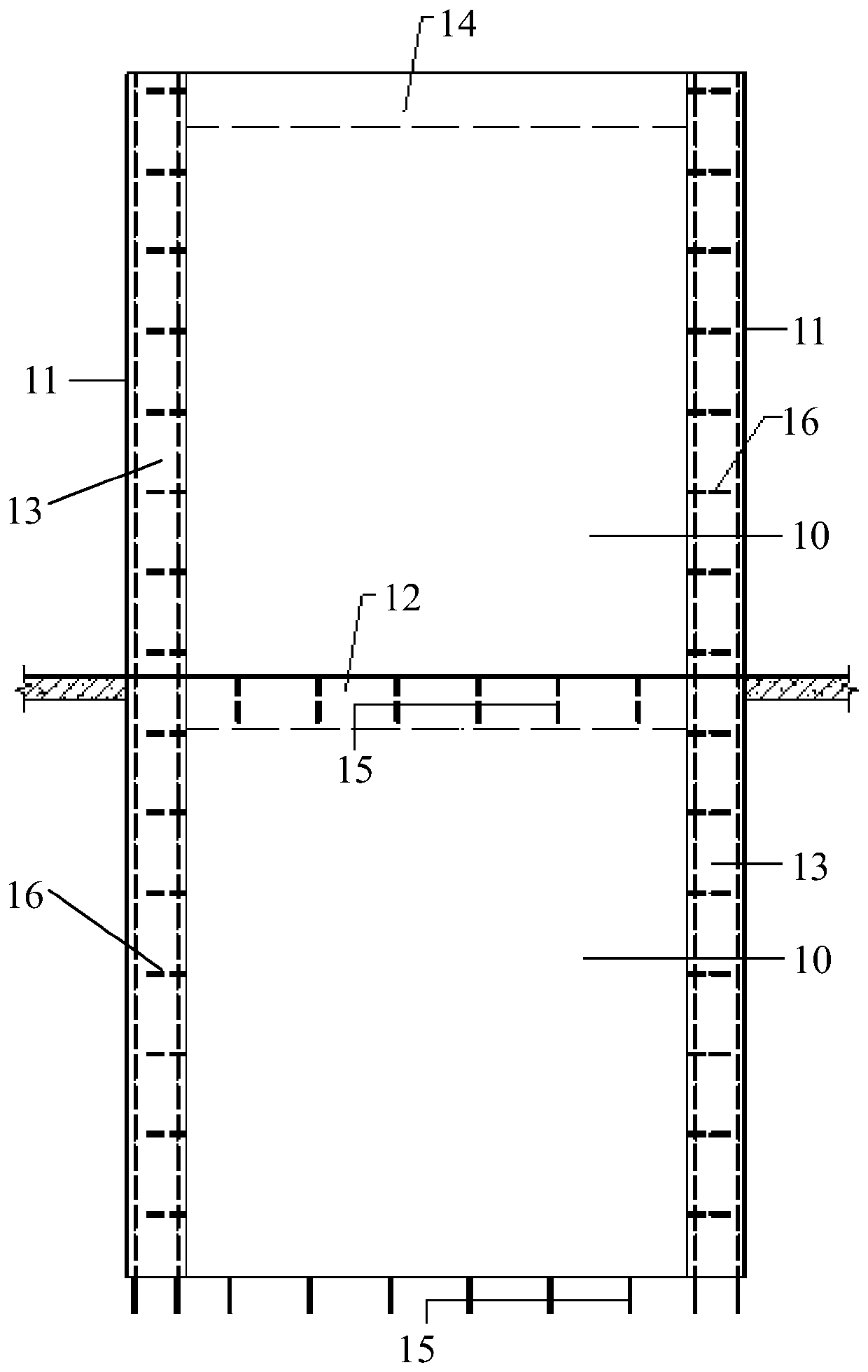

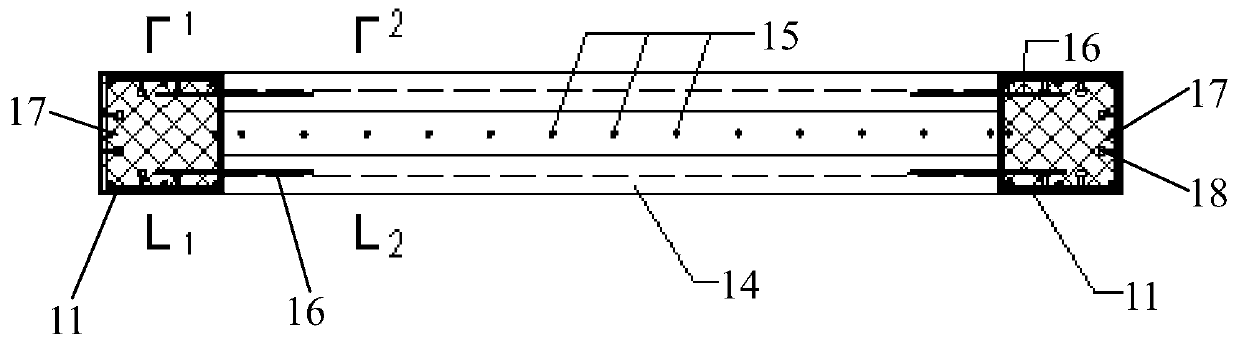

Assembly connection structure and assembly connection construction method of fabricated shear wall structure

PendingCN109667366AReduced Alignment DifficultyImprove reliabilityWallsProtective buildings/sheltersKeel structureRebar

The invention relates to an assembly connection structure of a fabricated shear wall structure. The structure comprises shear walls; section steel keels are respectively pre-buried at the connecting parts of the left and right shear walls to be connected horizontally; the section steel keels of the two shear walls are connected by means of damping devices; a bottom connection steel mold and a topconnection steel mold are respectively pre-embedded at the connecting parts of the upper and lower layer shear walls to be connected vertically; a hollow grouting filling area is formed between the bottom connection steel mold and the top connection steel mold; by grouting in the grouting filling area, the connection between the bottom connection steel mold and the top connection steel mold is realized. The steel molds are locally pre-embedded so as to realize the vertical connection of the shear walls, so that the alignment difficulty of a reinforcing steel bar and a sleeve during on-site hoisting of a prefabricated wall is greatly reduced, the construction quality is effectively guaranteed, and the reliability of the connection position is improved; a section steel keel structure is adopted by the horizontal connection of the shear walls, so that additional connecting ribs at connecting parts are omitted, the field installation difficulty is effectively reduced, and the constructionefficiency is increased.

Owner:SHENYANG JIANZHU UNIVERSITY

Under-screen camera shooting assembly, corresponding organic light emitting diode display screen and terminal equipment

ActiveCN111863868AReduce processing difficultyIncrease productivityTelevision system detailsSolid-state devicesTerminal equipmentEngineering

The invention provides an organic light emitting diode display screen. The organic light emitting diode display screen comprises a substrate, a buffer layer, a first electrode layer, a pixel layer, asecond electrode layer, a packaging layer, a polarizing layer and a cover plate, wherein the pixel layer comprises a main display area and a light-transmitting area; the polarizing layer is provided with a polarizing layer through hole; the part, which is located under the polarizing layer through hole, of the pixel layer forms the light-transmitting area, the main display area and the light-transmitting area are not separated through a packaging material, and the packaging layer packages the pixel layer by covering the upper surface of the main display area and the upper surface of the light-transmitting area. The invention further provides a corresponding under-screen camera shooting assembly and terminal equipment. According to the invention, the production efficiency of the under-screen camera shooting assembly based on the hole digging screen is improved, and the production cost is reduced; and the size of a hole of the hole digging screen is reduced while the light incoming amount of the under-screen camera shooting module is ensured.

Owner:NINGBO SUNNY OPOTECH CO LTD

Package process of backside illumination image sensor

ActiveUS20120009716A1Reduced Alignment DifficultyImprove packaging efficiencySolid-state devicesSemiconductor/solid-state device manufacturingEngineeringThinning

In a package process of backside illumination image sensor, a wafer including a plurality of pads is provided. A first carrier is processed to form a plurality of blind vias therein. The first carrier is adhered to the wafer so that the blind vias face to the pads correspondingly. A spacing layer is formed and a plurality of sensing components are disposed. A second carrier is adhered on the spacing layer. Subsequently, a carrier thinning process is performed so that the blind vias become the through holes. An insulating layer is formed on the first carrier. An electrically conductive layer is formed on the insulating layer and filled in the though holes to electrically connect to the pads. The package process can achieve the exact alignment of the through holes and the pads, thereby increasing the package efficiency and improving the package quality.

Owner:XENOGENIC DEV LLC

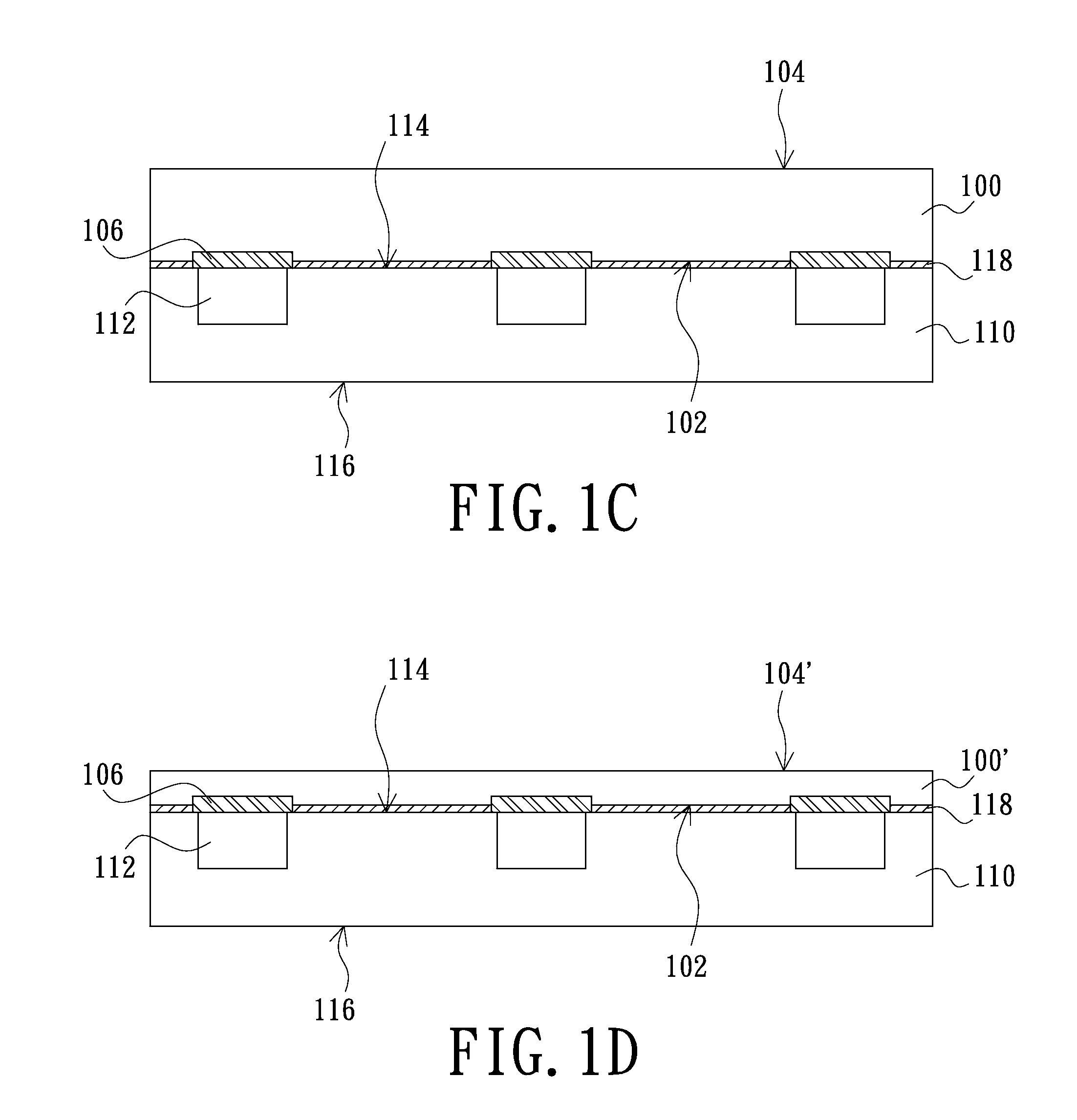

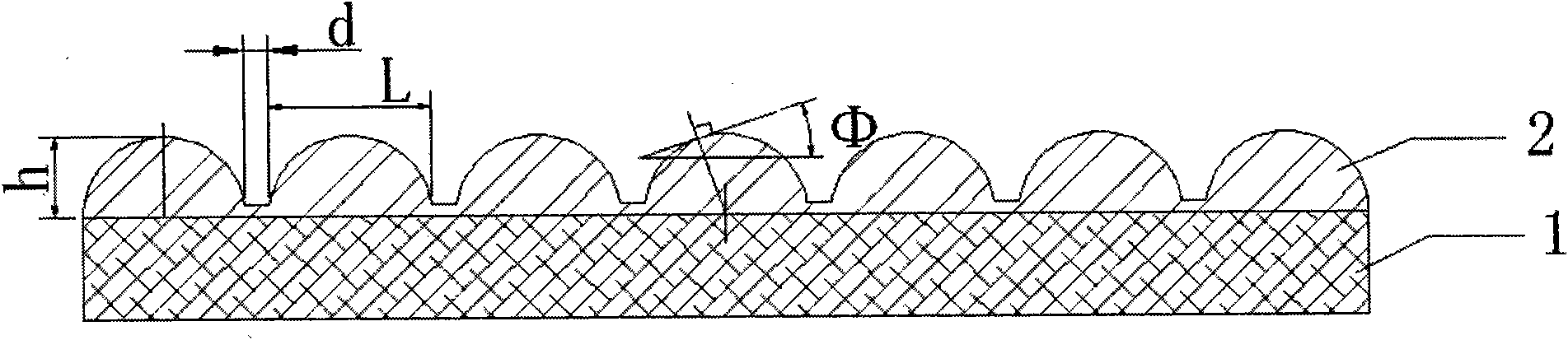

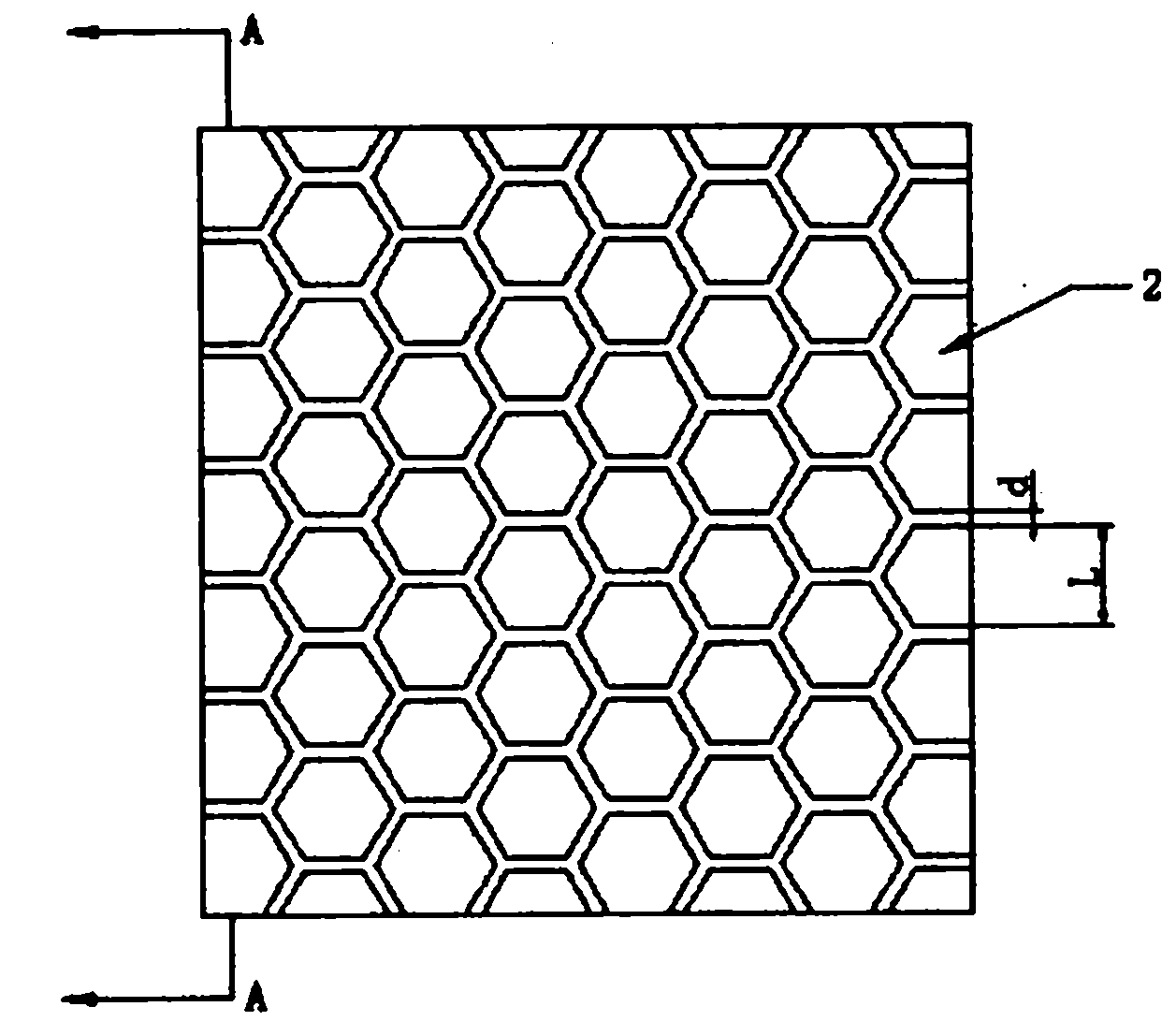

Method for expressing three-dimensional visual effect of image text

InactiveCN102371838AIncrease productivityReduce pollutionThree-dimensional effectsPattern printingHot stampingGrating

The invention discloses a method for expressing a three-dimensional visual effect of an image text, and relates to a method for expressing an image-text stereoscopic vision effect directly without backlight. The two problems to be solved are to improve production benefit by reducing the counterpoint difficulty of gratings formed by hot pressing and three-dimensional pictures and enhance the three-dimensional visual effect of the image text and to improve the rough sense of a picture by improving the accuracy of the gratings formed by the hot pressing. In order to solve the technical problems, the invention adopts a technical scheme that the method comprises the following steps of: printing a synthesized three-dimensional image text on a printed material 1, and manufacturing a grating die matched with the three-dimensional image text in advance in an ironing head of hot stamping equipment; and bonding a transparent membrane on the surface of the image text, and performing the hot pressing to form an equidistant orthohexagonal spherical grating 2, so that the image text has the three-dimensional visual effect. The method is mainly used for product packages, books, advertising and the like which express the three-dimensional visual effect of the image text directly without the backlight.

Owner:罗俊平 +1

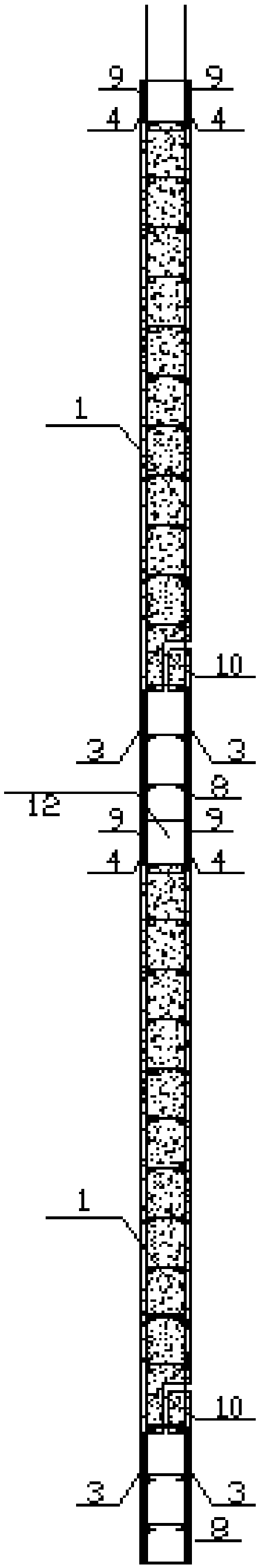

Connecting structure and construction method of fabricated shear wall structure

PendingCN110939212AAvoid misalignment problemsReduced Alignment DifficultyWallsArchitectural engineeringRebar

The invention discloses a connecting structure and a construction method of a fabricated shear wall structure. The connecting structure comprises a prefabricated shear wall, steel structure connectingparts, a horizontal connecting unit and vertical connecting units, wherein a notch is reserved at the top of the lower-layer prefabricated shear wall, the horizontal connecting unit is arranged in the notch in a poured mode, vertical anchor ribs are reserved at the bottom of the upper-layer prefabricated shear wall, the vertical anchor ribs are inserted into and anchored in the horizontal connecting unit, horizontal connecting ribs are reserved at the ends of the two sides of the lower-layer prefabricated shear wall and the upper-layer prefabricated shear wall correspondingly, the steel structure connecting parts are installed at the ends of the two sides of the lower-layer prefabricated shear wall and the upper-layer prefabricated shear wall, the horizontal connecting ribs are anchored with the steel structure connecting parts, the steel structure connecting parts define vertical pouring spaces at the ends of the two sides of the lower-layer prefabricated shear wall and the upper-layer prefabricated shear wall, and the vertical connecting units are poured in the vertical pouring spaces. According to the connecting structure, the cast-in-place or grouting mode is adopted in the connection of the prefabricated shear wall, so that the problem that steel bars cannot be aligned is solved, the alignment difficulty between the steel bars and a sleeve during field hoisting of the prefabricated shear wall is greatly reduced, and the reliability and the construction speed of the connection position are improved.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

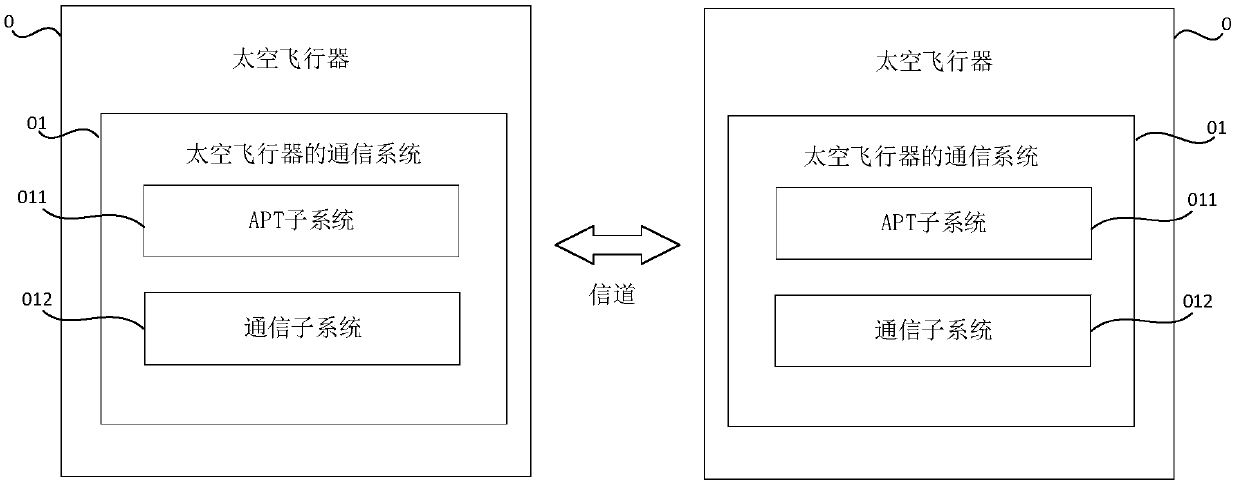

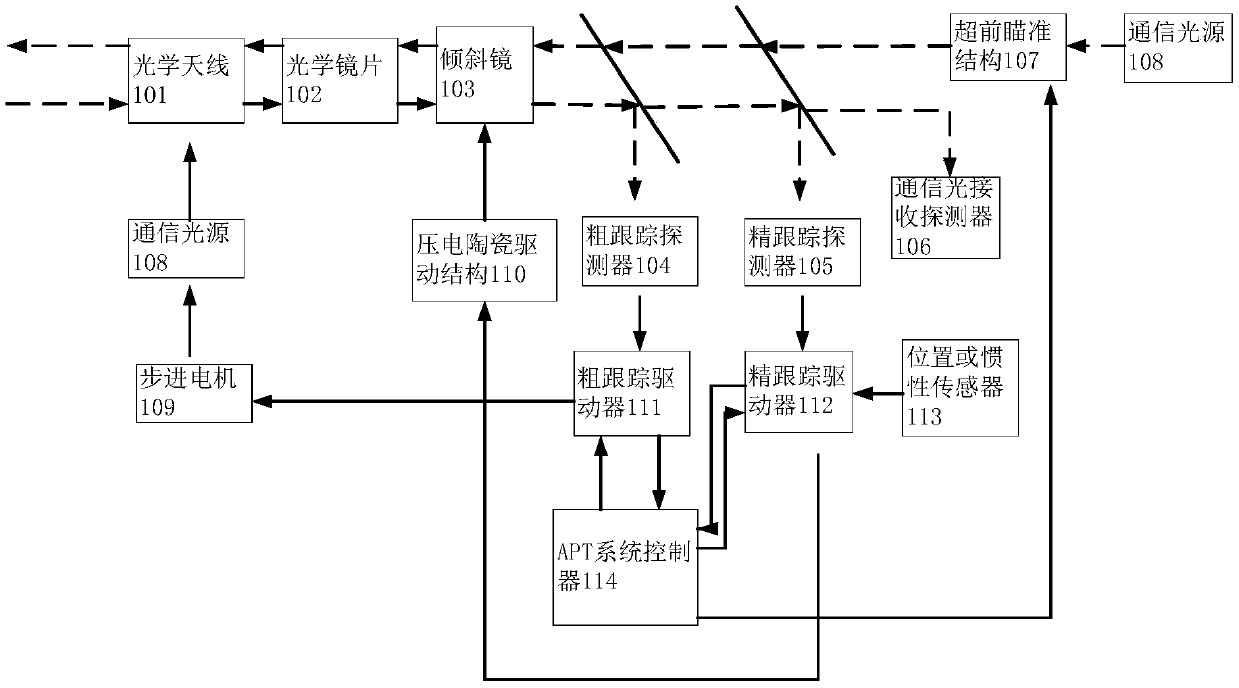

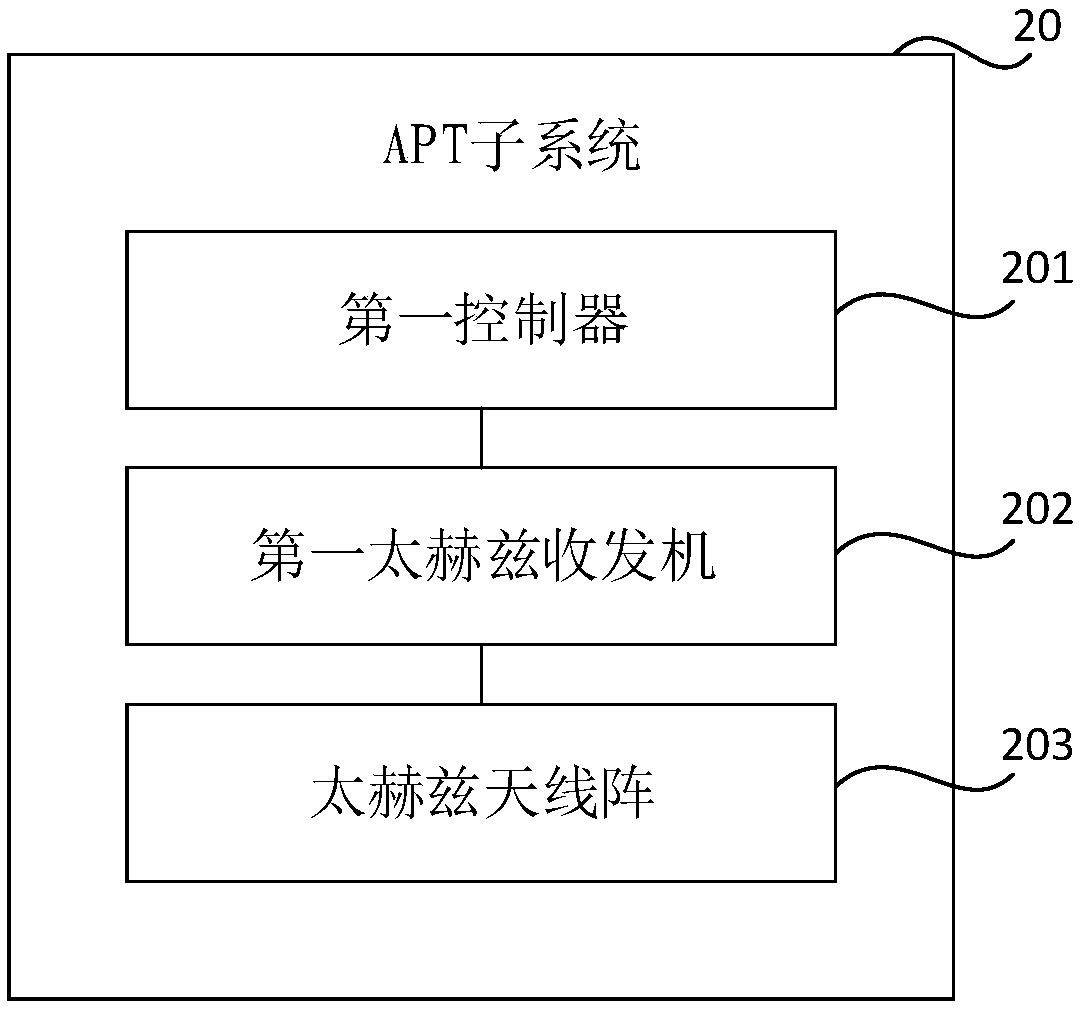

Communication system of APT subsystem and spacecraft

ActiveCN111130615AImprove energy efficiencyIncreased catch chanceSatellite communication transmissionRadio transmissionEmbedded systemSpace vehicle

The invention relates to a communication system of an APT subsystem and a spacecraft, and belongs to the technical field of space communication. The APT subsystem comprises a first controller, a firstterahertz transceiver and a terahertz antenna array which are connected in sequence, wherein the first terahertz transceiver is used for modulating and demodulating terahertz waves; the terahertz antenna array is used for transmitting and receiving terahertz waves; and the first controller is used for controlling the first terahertz transceiver to capture, align and track another APT subsystem through the terahertz antenna array. According to the invention, the capture, alignment and tracking efficiency of the APT subsystem is improved. The communication system is used for communication in space.

Owner:HUAWEI TECH CO LTD

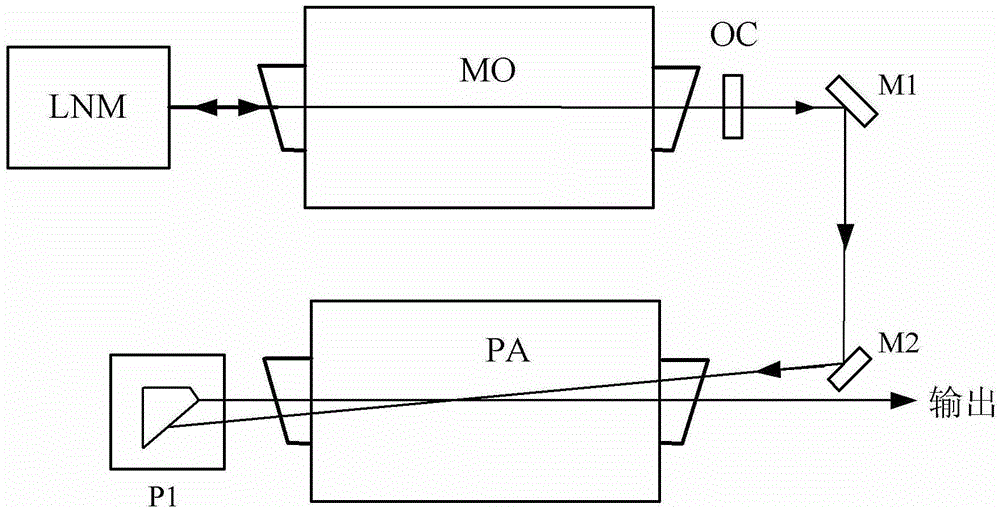

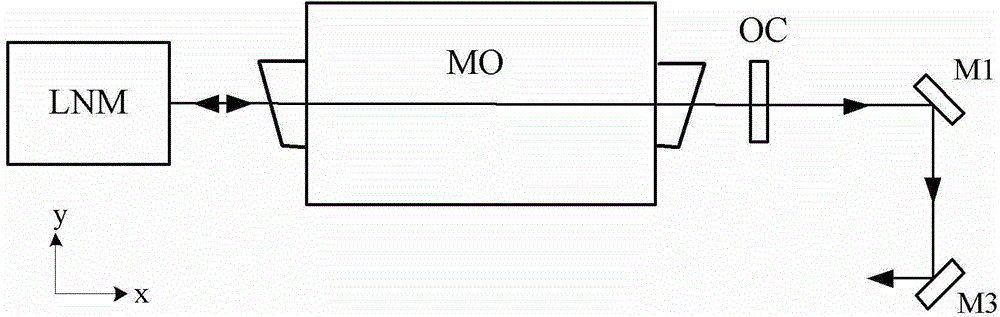

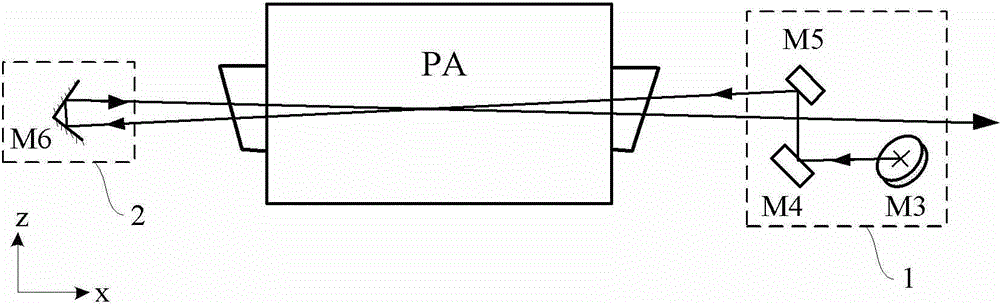

Dual-cavity excimer laser adopting dual-pass structure

ActiveCN104577684AReduced Alignment DifficultyImprove alignment accuracyLaser detailsLine widthComputer module

The invention discloses a dual-cavity excimer laser adopting a dual-pass structure. The dual-cavity excimer laser comprises a main oscillation cavity (MO), a linewidth narrowing module (LNM), an output coupling mirror (OC), a power amplifier (PA), a first high-reflective mirror (M1), a PA light path transmission module (1) and a PA light path transposition module (2), wherein the main oscillation cavity (MO) and the power amplifier (PA) are arranged in a direction perpendicular to a horizontal plane; the PA light path transmission module (1) comprises three high-reflective mirrors; the PA light path transposition module comprises a double-faced reflective mirror; laser coming to the PA from the PA light path transmission module (1) and laser returned from the PA light path transposition module (2) are positioned in the same horizontal plane, and a tiny included angle is formed. According to the dual-cavity excimer laser, the difficulty in light path alignment can be reduced, the alignment precision can be improved, and the element cost also can be reduced; the dual-cavity excimer laser has the advantages of flexible structure and good heat dissipation effect.

Owner:RAINBOW SOURCE LASER RSLASER

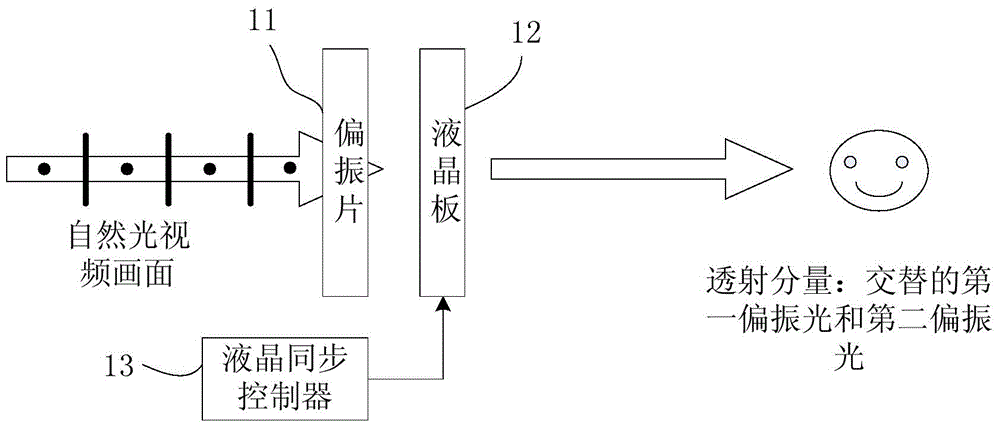

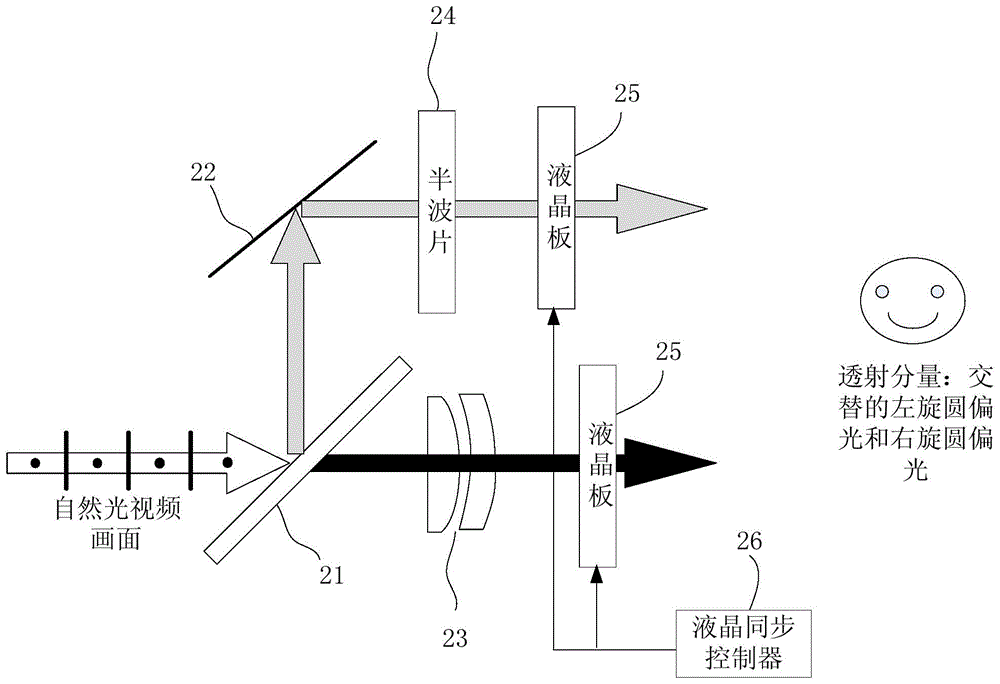

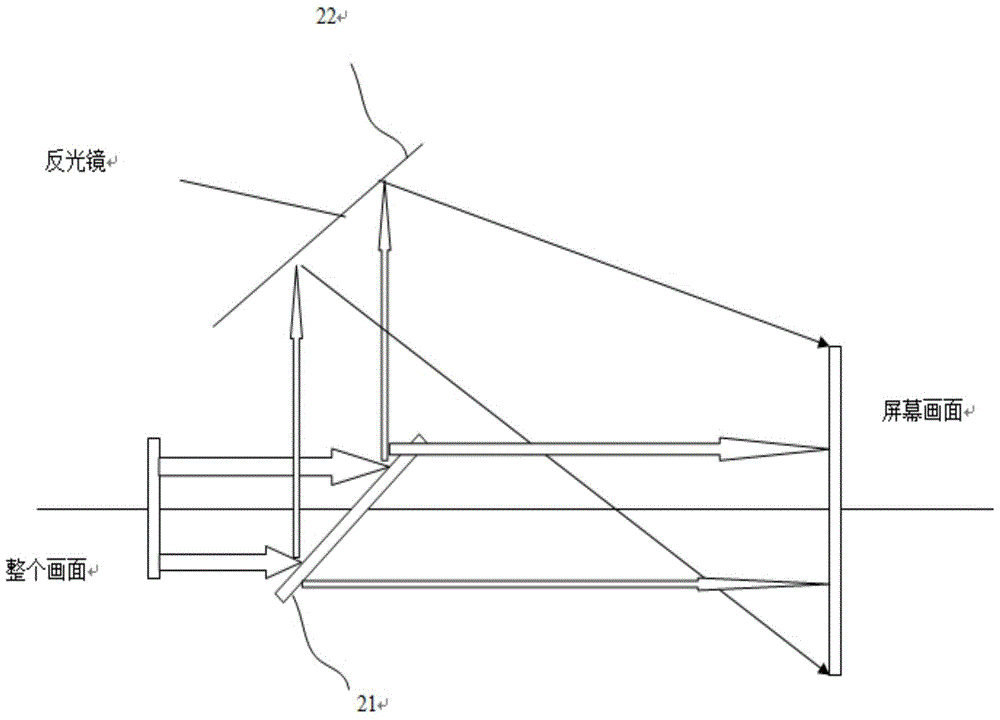

Three-optical-path polarizing light-splitting stereoscopic video conversion system

InactiveCN104954775AReduced Alignment DifficultyHigh light efficiencySteroscopic systemsInstrumentsStereoscopic videoImaging quality

The present invention relates to a three-light path polarized light-splitting stereographic video switching system. The system comprises: a polarized light-splitting device comprising a first polarized light-splitting layer and a second polarized light-splitting layer which are crossed, wherein the first polarized light-splitting layer is used for guiding a received natural light video image to a first side path and a main path, and the second polarized light-splitting layer is used for guiding the received natural light video image to a second side path and the main path; two reflection devices; a compensation mirror arranged on the main path; a half wave plate arranged on the main path or the side path; and a synchronization controller and three identical liquid crystal optical rotation devices electrically connected thereto, wherein the synchronization controller is used for synchronously driving the three liquid crystal optical rotation devices according to a left-right eye synchronization signal to change the polarization state of incident linearly polarized light so as to alternately generate left-handed circular polarized light and right-handed circular polarized light. By means of the the above arrangement, the three-light path polarized light-splitting stereographic video switching system of the present invention can obtain a relatively high light effect, images are easily aligned, and the imaging quality is high.

Owner:SHENZHEN ESTAR DISPLAYTECH

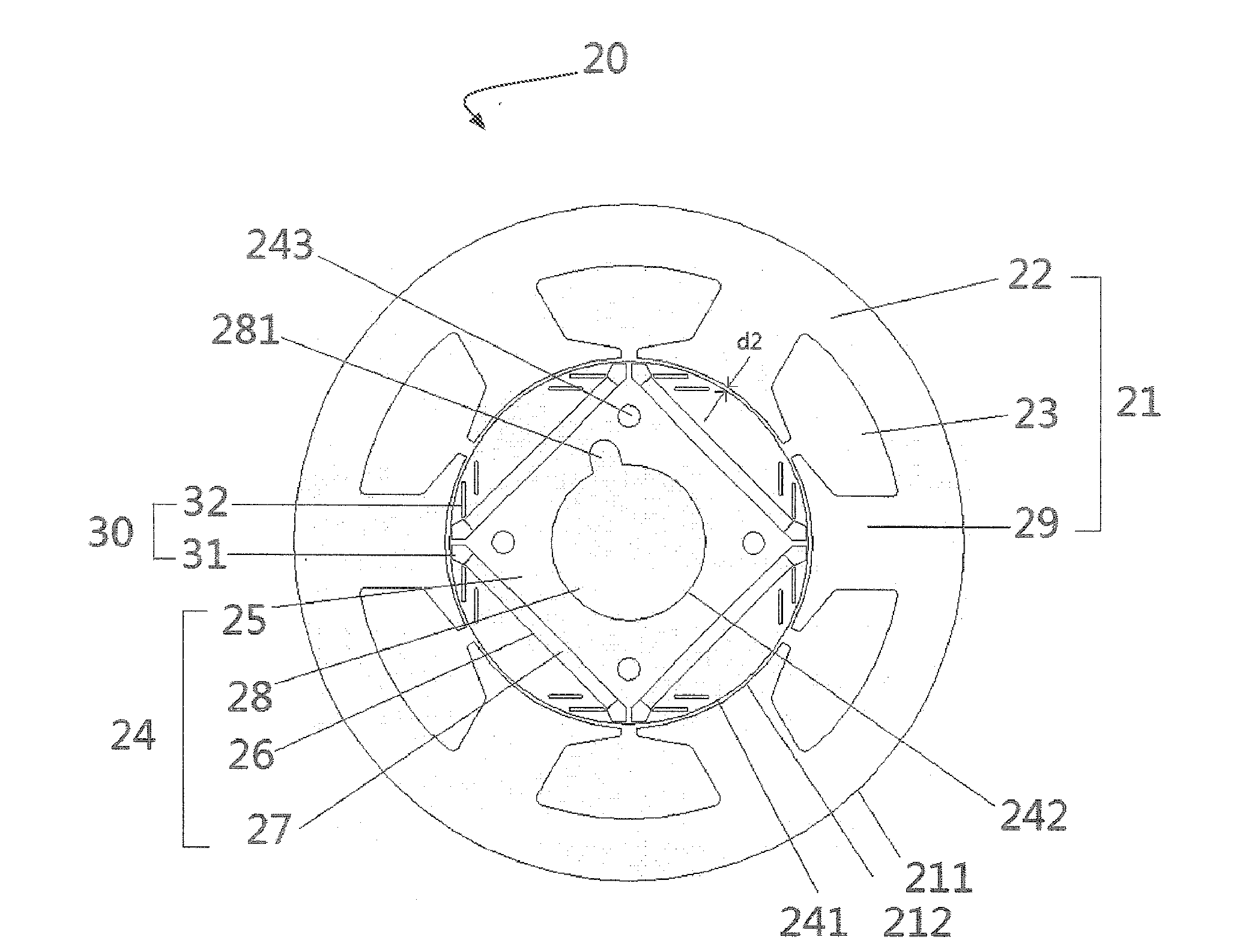

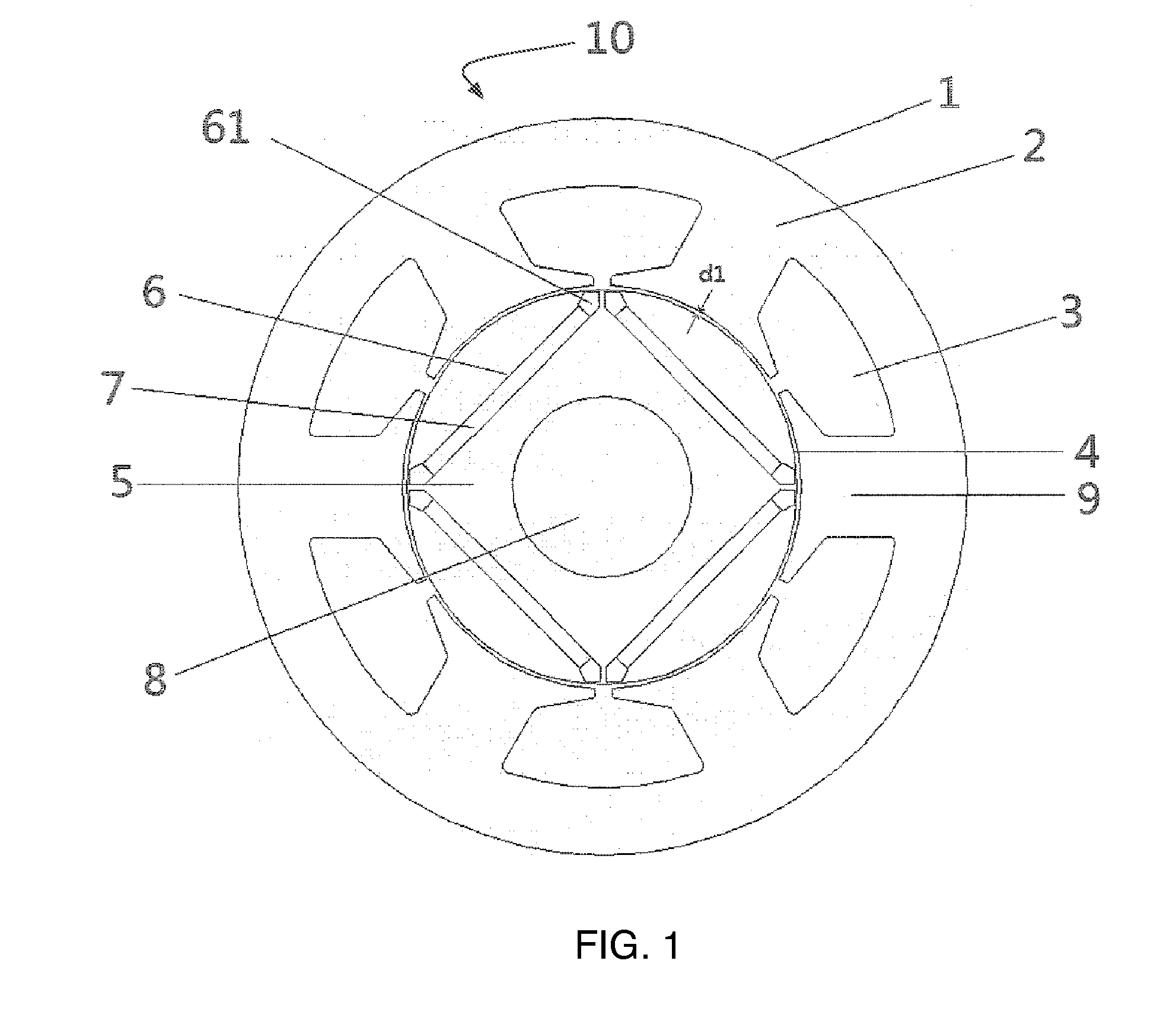

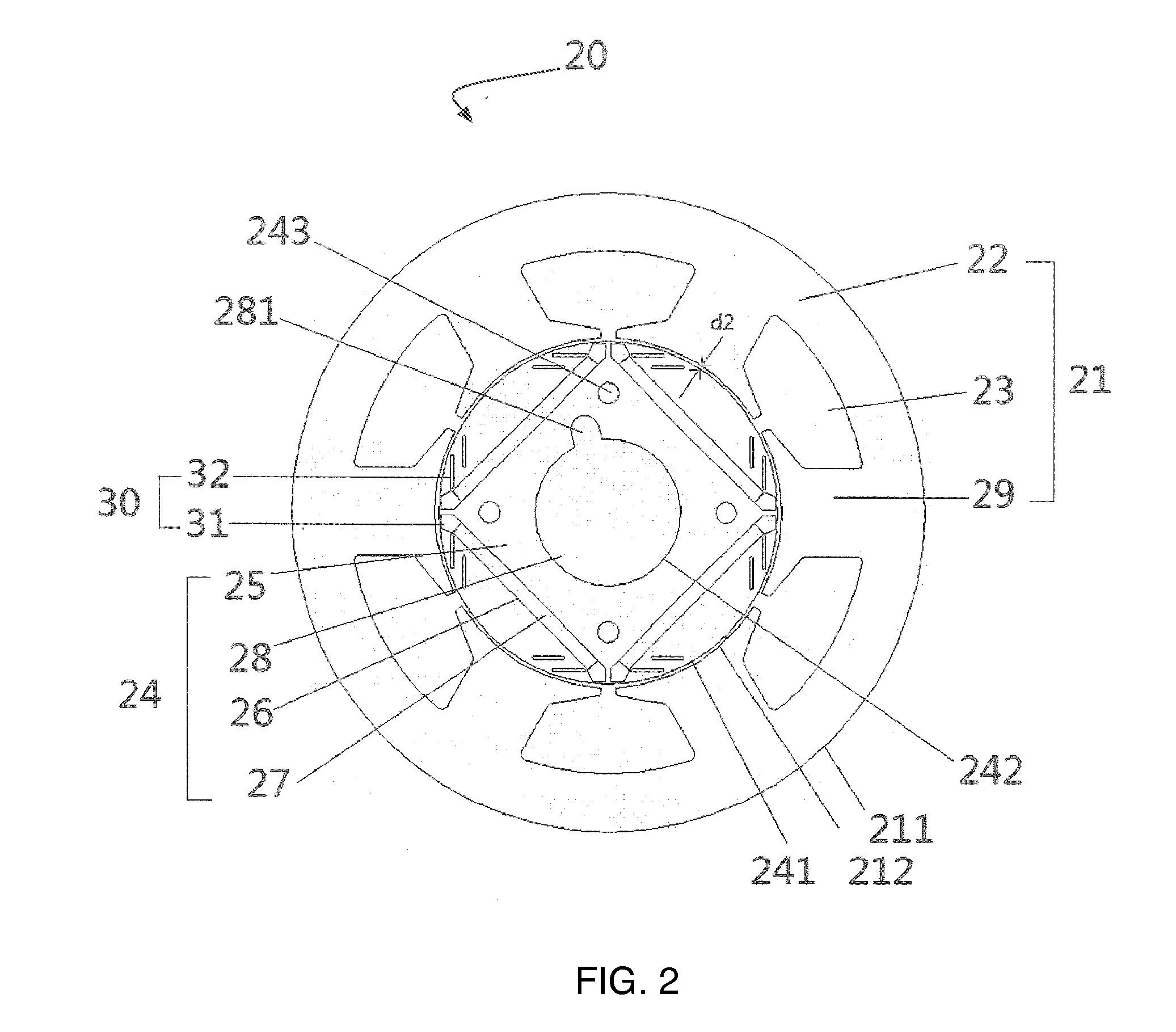

Rotor of built-in permanent magnet motor and built-in permanent magnet motor using same

InactiveUS20150042200A1Convenient and simple machiningImprove toleranceMagnetic circuit rotating partsPermanent magnet motorEngineering

A rotor (24) of an interior permanent magnet motor and an interior permanent magnet motor (20) are disclosed. The rotor (24) of the interior permanent magnet motor includes a rotor iron core (25); a plurality of permanent magnets (27), where the plurality of permanent magnets (27) are spaced apart inside the rotor iron core (25); and a plurality of air slots (30), disposed at end portions of adjacent permanent magnets (27) and close to an outer circumference of the rotor, and adapted to generate air gap flux density between the outer circumference of the rotor and an inner circumference of a stator of the interior permanent magnet motor, and the air gap flux density being in an analogous sinusoidal shape.

Owner:DANFOSS (TIANJIN) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com