Semiconductor laser aging clamp

A technology of lasers and semiconductors, applied in the direction of semiconductor lasers, lasers, laser components, etc., can solve problems such as difficulty in probe alignment, small electrode area, damage to lasers, etc., to achieve power management and communication, simple fixture design , the effect of reducing the difficulty of alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention adopts a new idea of replacing vertical contact with surface contact. Aiming at the two limitations of the traditional method: vertical contact and small contact area, the new method adopted by the present invention mainly includes the following aspects.

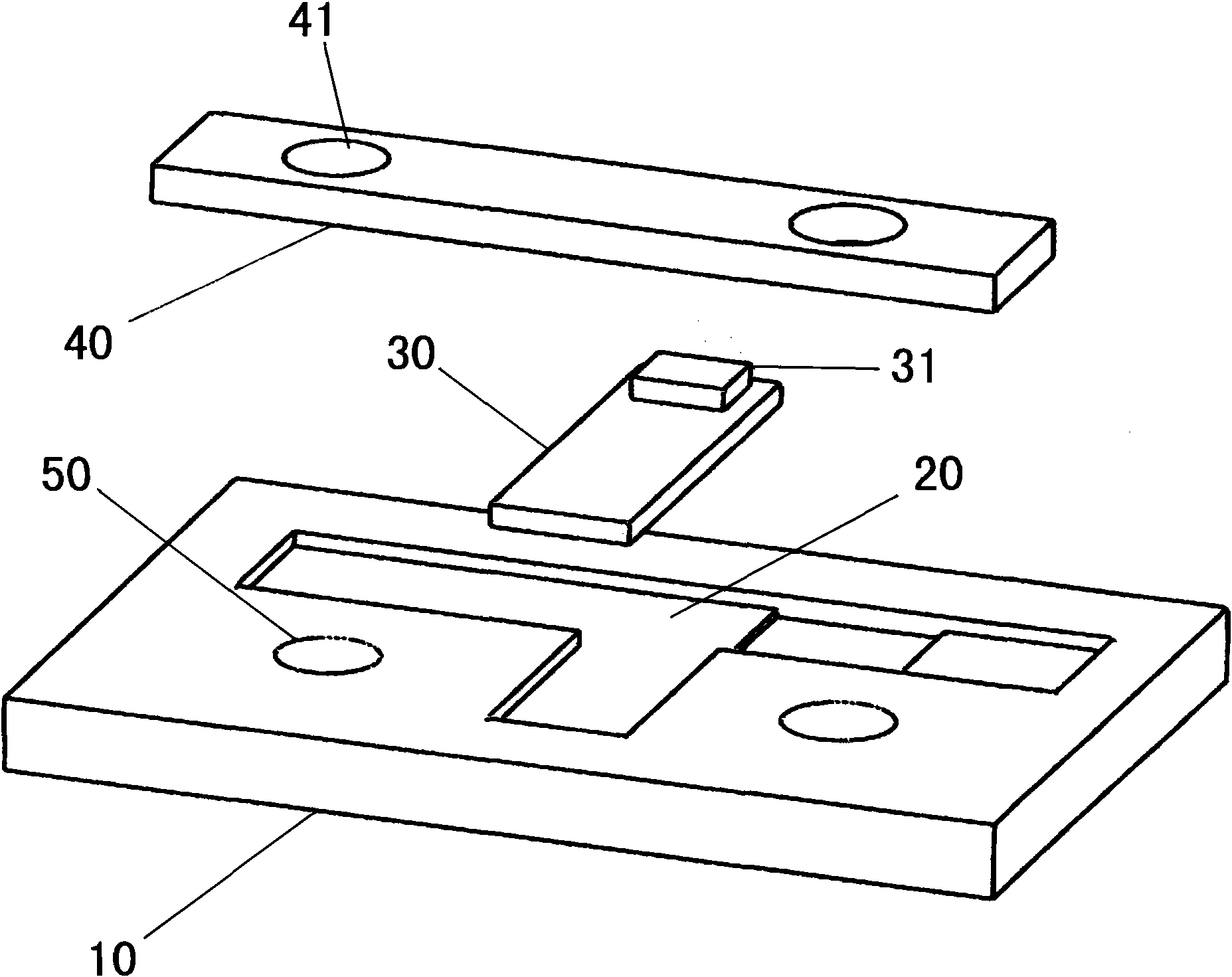

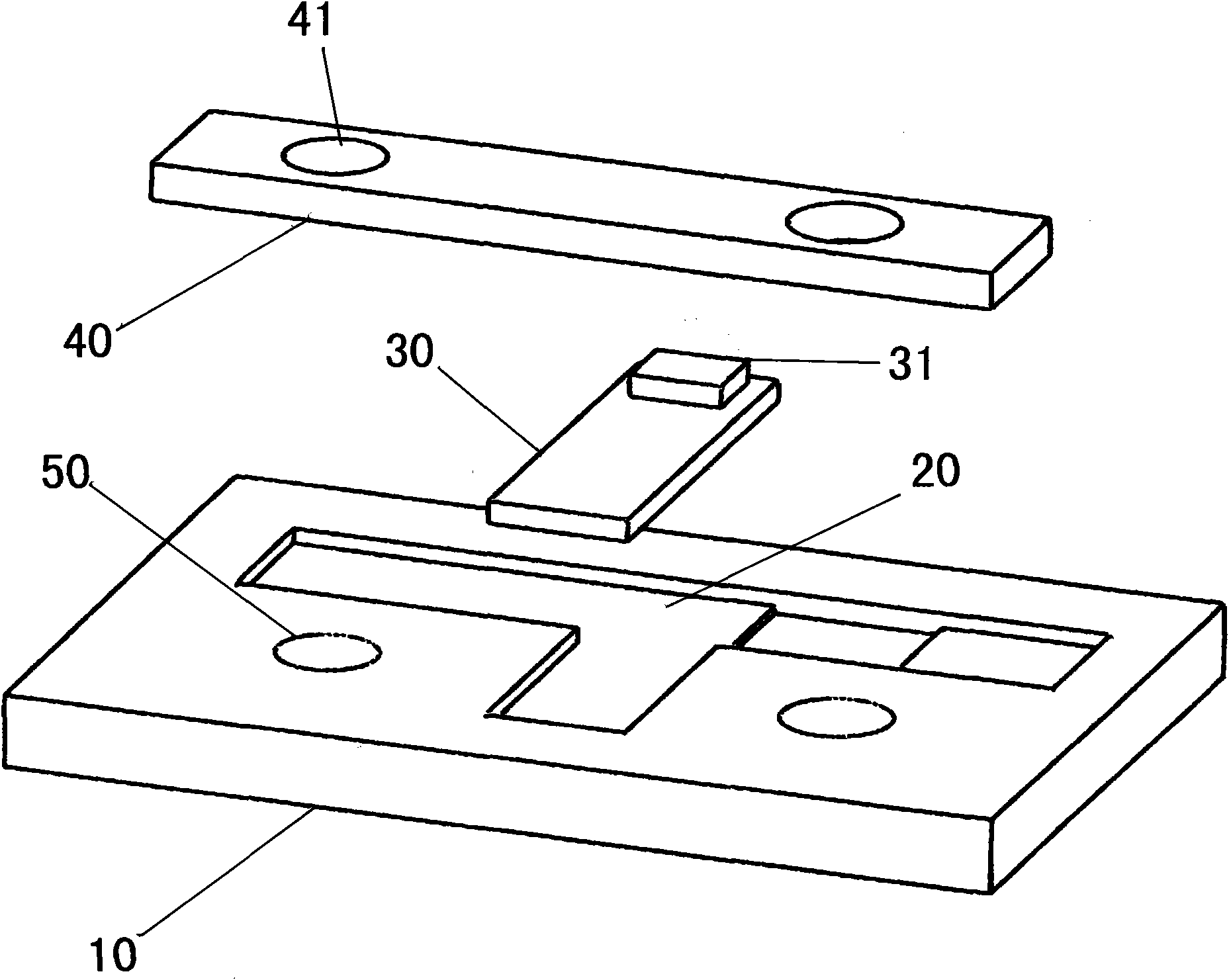

[0022] see figure 1 As shown, the present invention provides an aging fixture suitable for semiconductor lasers, which includes: a main body 10, which can adopt a three-layer printed circuit board, and the thickness of the surface layer is equal to the depth of the groove 20. The depth of the groove 20 should be designed according to the thickness of the heat sink 30 used, so that the heat sink 30 can be submerged in the groove 20 without being blocked by the groove 20 from the optical path of the laser 31 on the heat sink 30 . Therefore, the electrode sinking process can be used to form a groove 20 structure with a required depth, and limit the spatial position of the heat sink 30 while ensur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com