Display substrate, display device and production method of display substrate

A technology for display substrates and substrates, applied in electrical components, electrical solid devices, circuits, etc., can solve the problems of high epitaxial layer requirements, loss of precision, unfavorable high-resolution panels, etc. The effect of small position and alignment difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

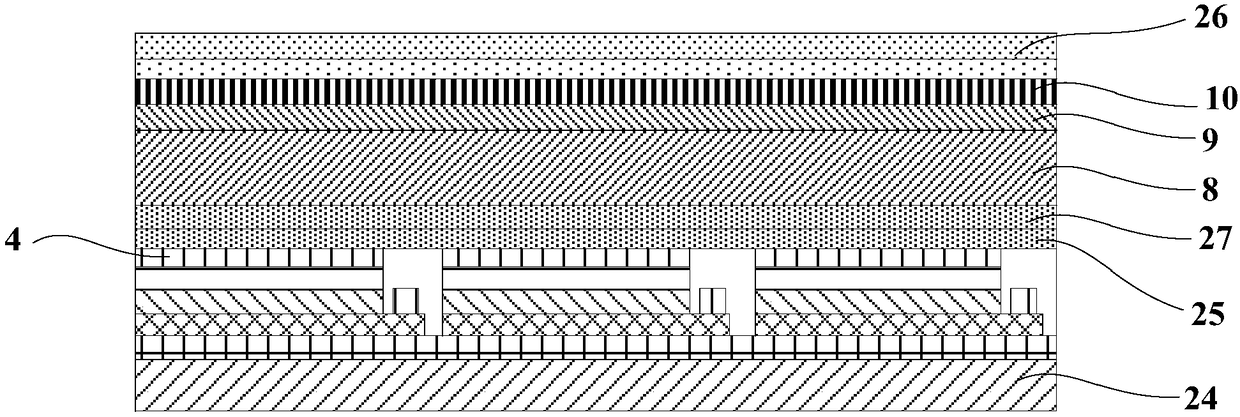

[0081] In order to improve the product yield of the display substrate and the resolution of the display device, embodiments of the present invention provide a display substrate, a display device, and a method for manufacturing the display substrate. In order to make the purpose, technical solution and advantages of the present invention clearer, the following examples are given to further describe the present invention in detail.

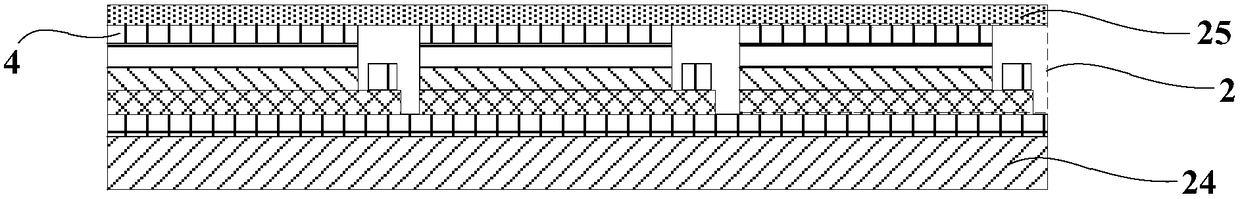

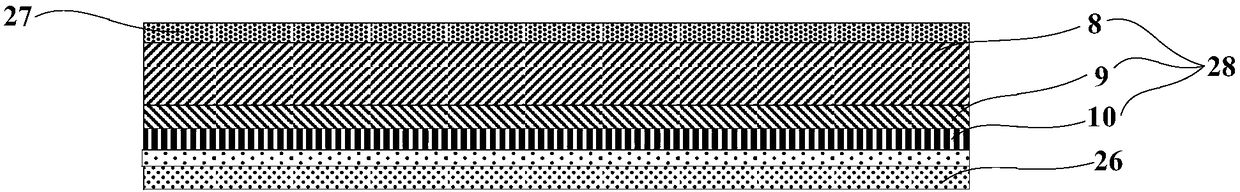

[0082] Such as Figure 7 and Figure 12 As shown, the display substrate provided by the embodiment of the present invention includes: a substrate 1 and a plurality of pixel units arranged in an array arranged on the substrate 1, wherein:

[0083] The pixel unit includes a light emitting diode 2, a connection metal 3 and a thin film transistor 5 arranged in sequence along the direction away from the substrate 1;

[0084] The connecting metal 3 is conductively connected with the top electrode 4 of the light emitting diode 2;

[0085] The active lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com