Patents

Literature

139results about How to "Reduce alignment accuracy requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

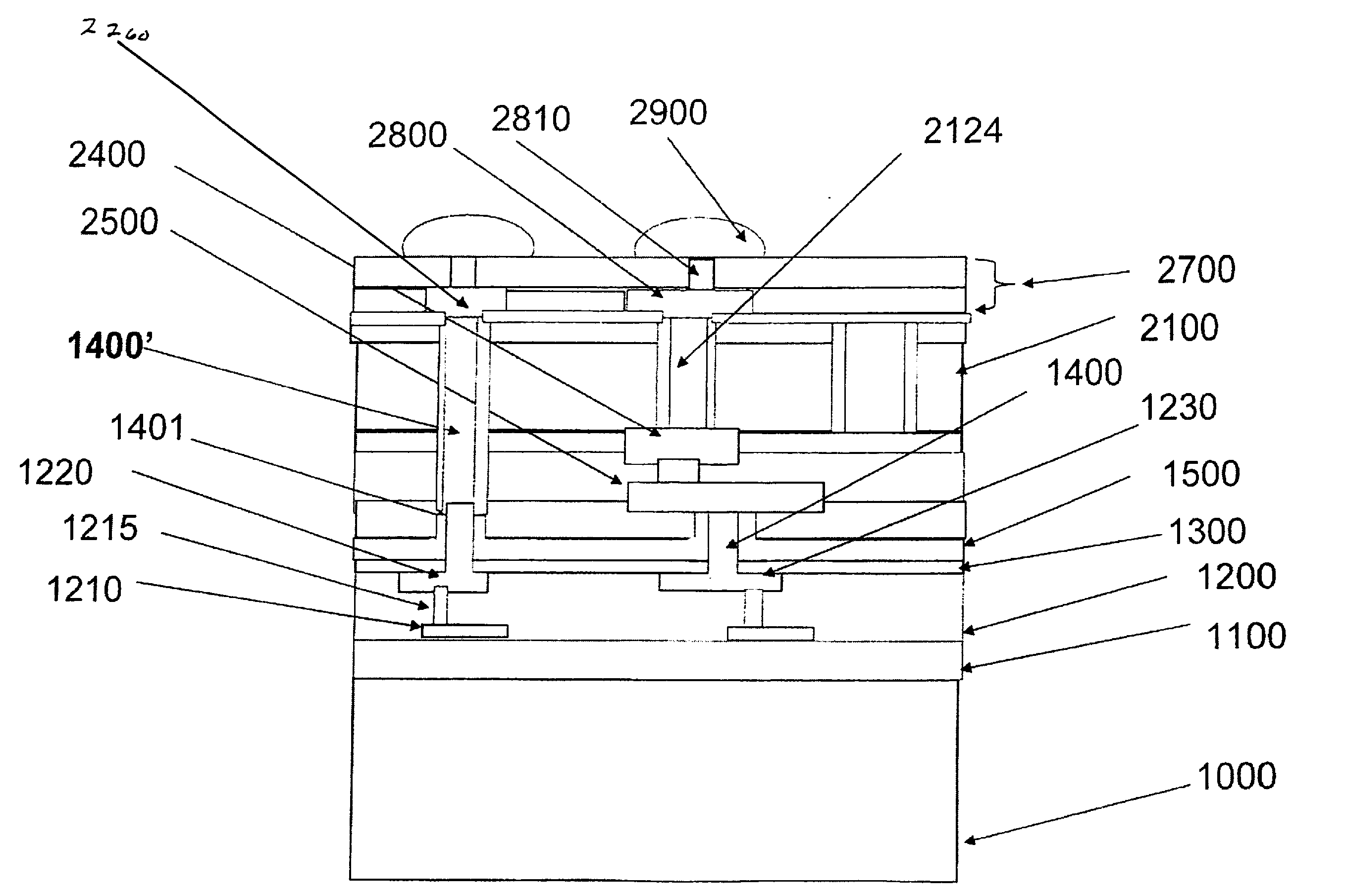

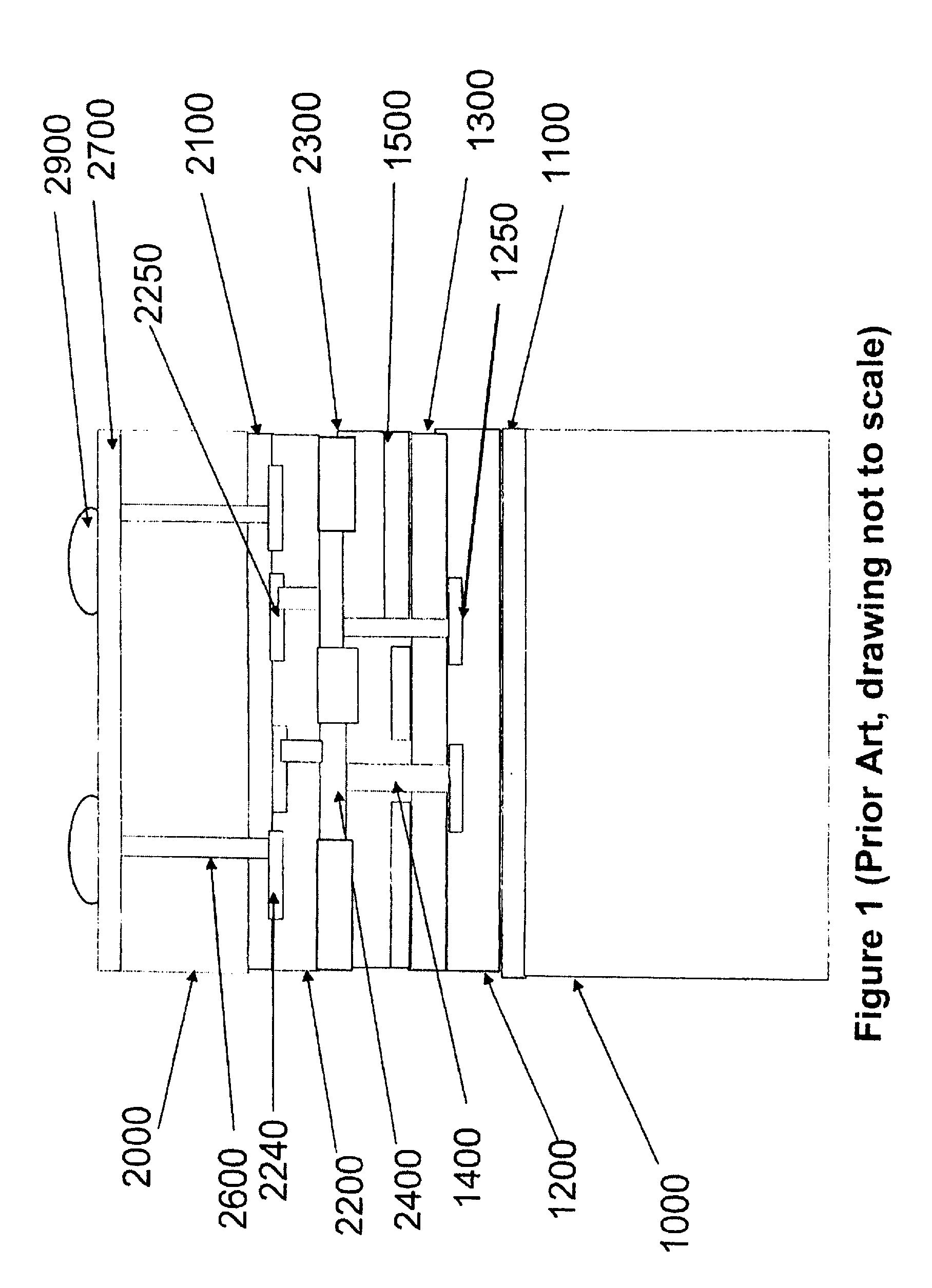

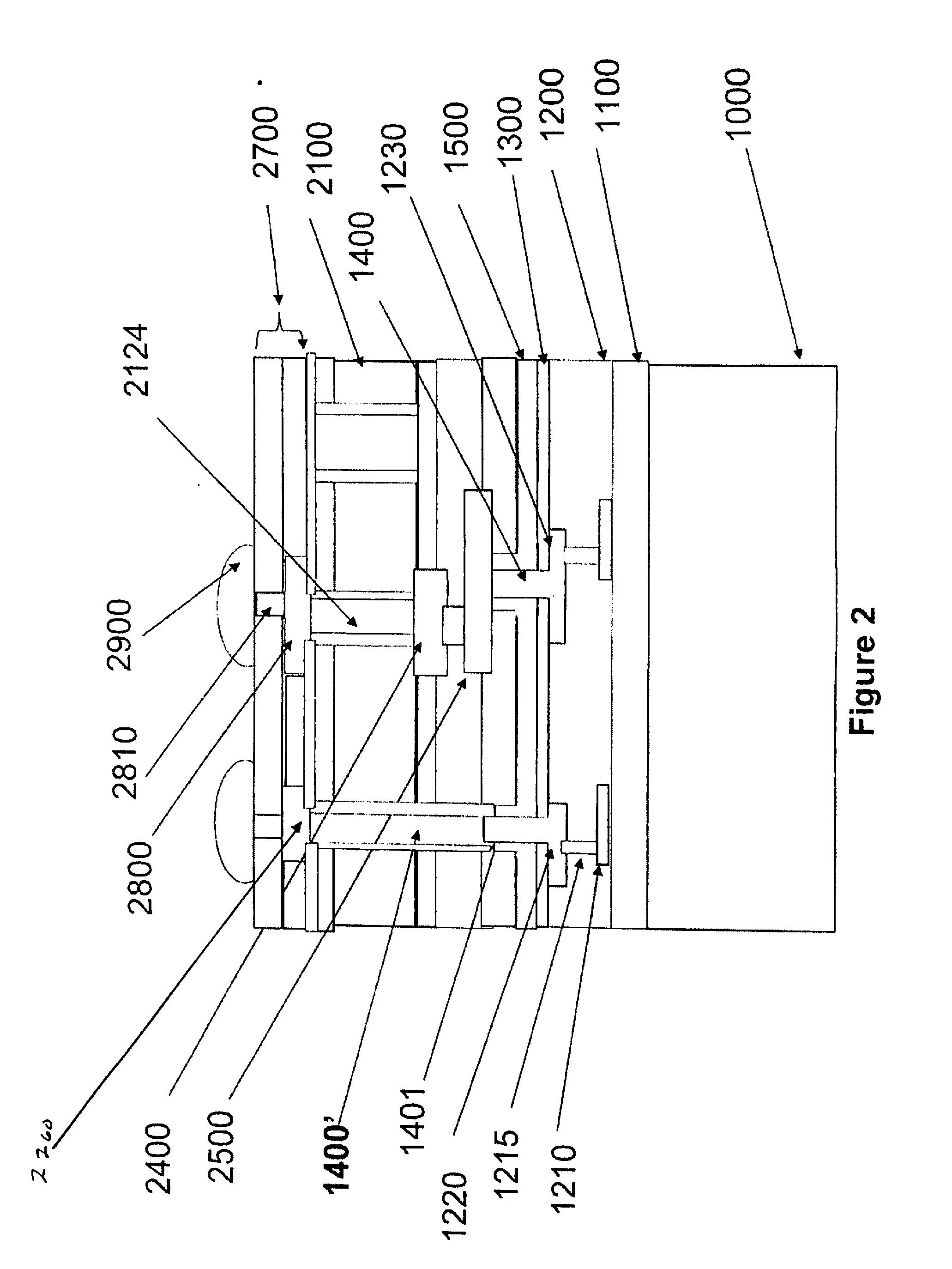

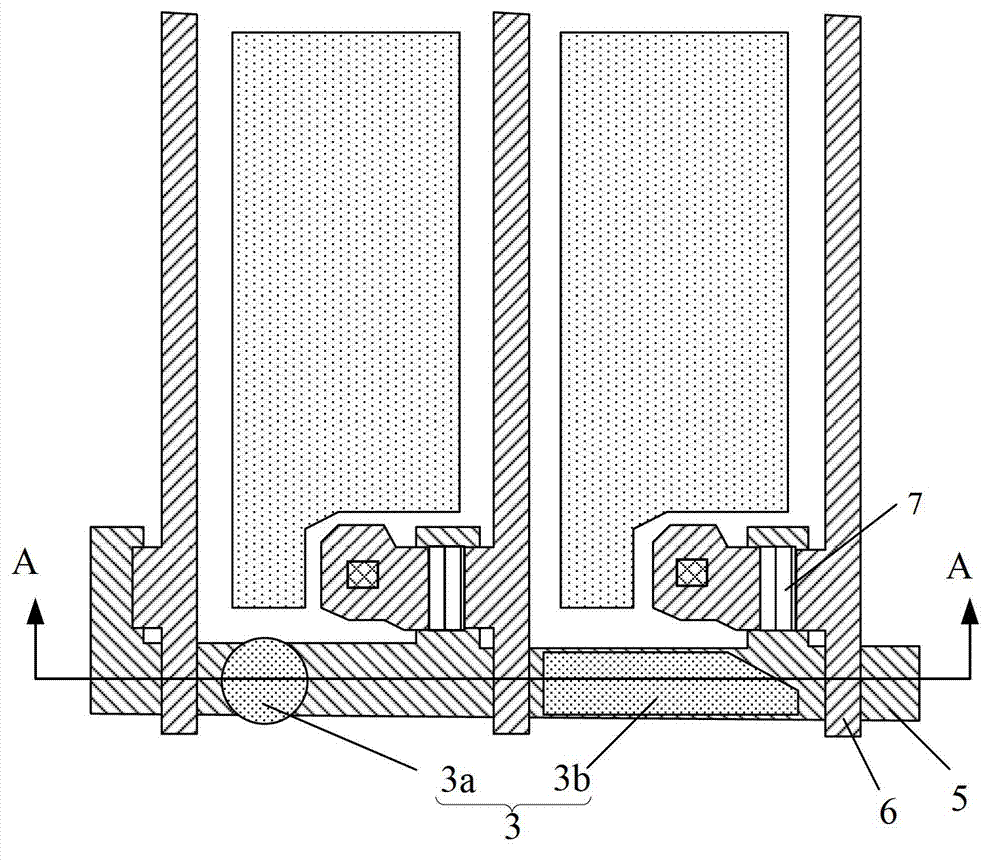

Lock and Key Through-Via Method for Wafer Level 3D Integration and Structures Produced

InactiveUS20100200992A1High yieldFirmly connectedSemiconductor/solid-state device detailsSolid-state devicesState of artEngineering

A three dimensional device stack structure comprises two or more active device and interconnect layers further connected together using through substrate vias. Methods of forming the three dimensional device stack structure comprise alignment, bonding by lamination, thinning and post thinning processing. The via features enable the retention of alignment through the lamination process and any subsequent process steps thus achieving a mechanically more robust stack structure compared to the prior art.

Owner:ALSEPHINA INNOVATIONS INC

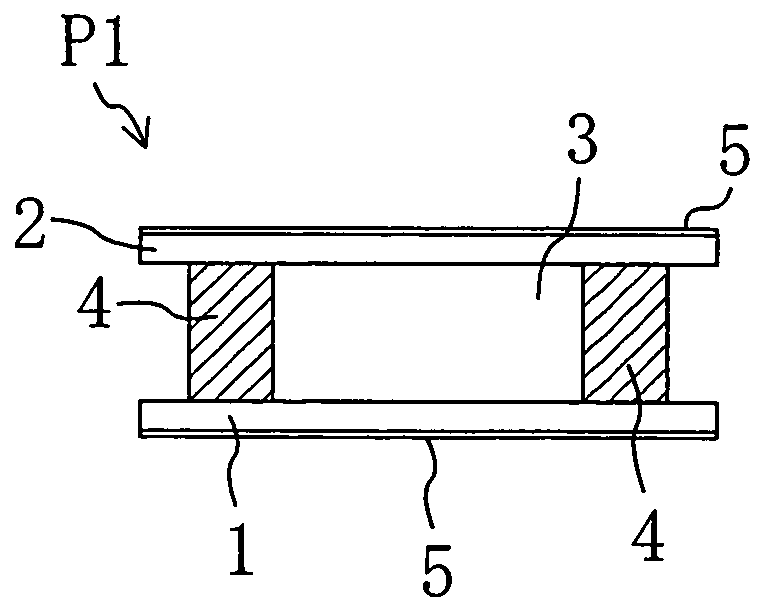

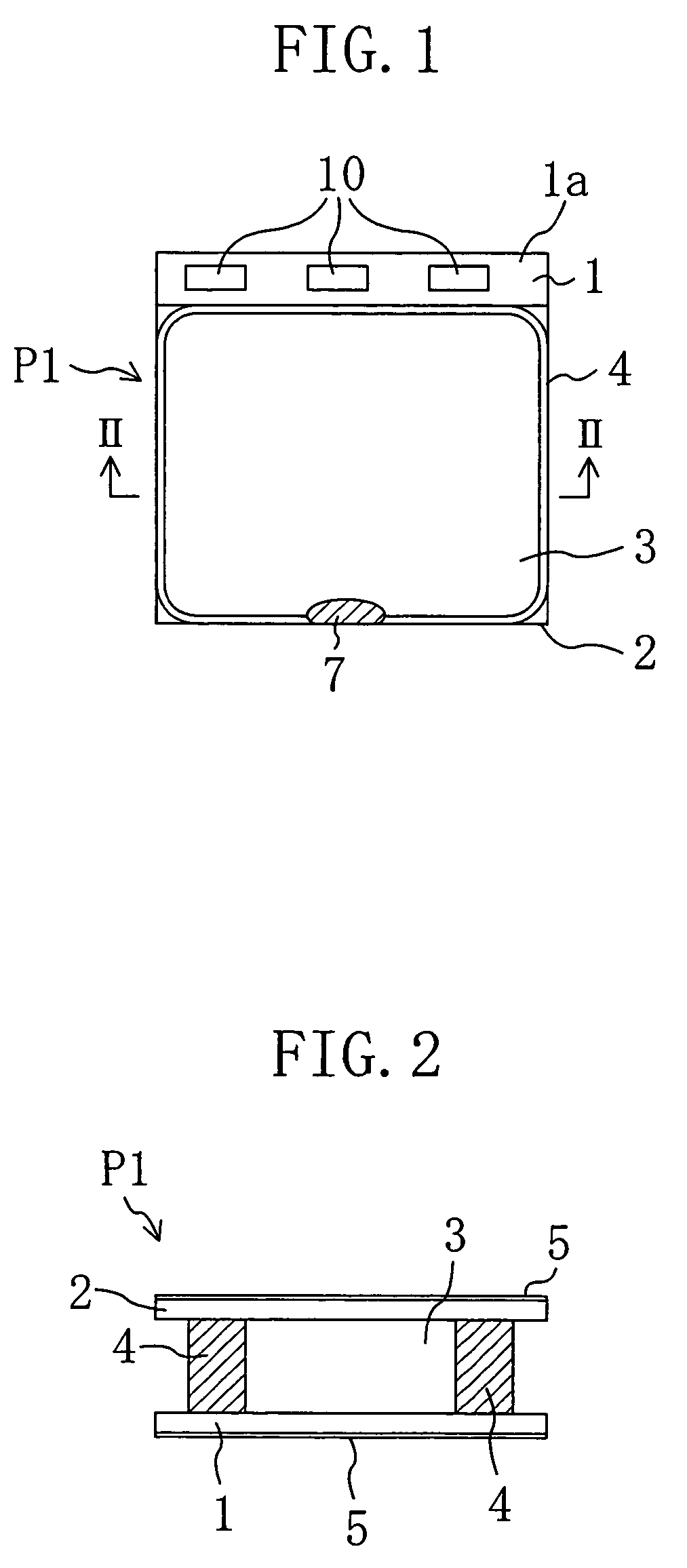

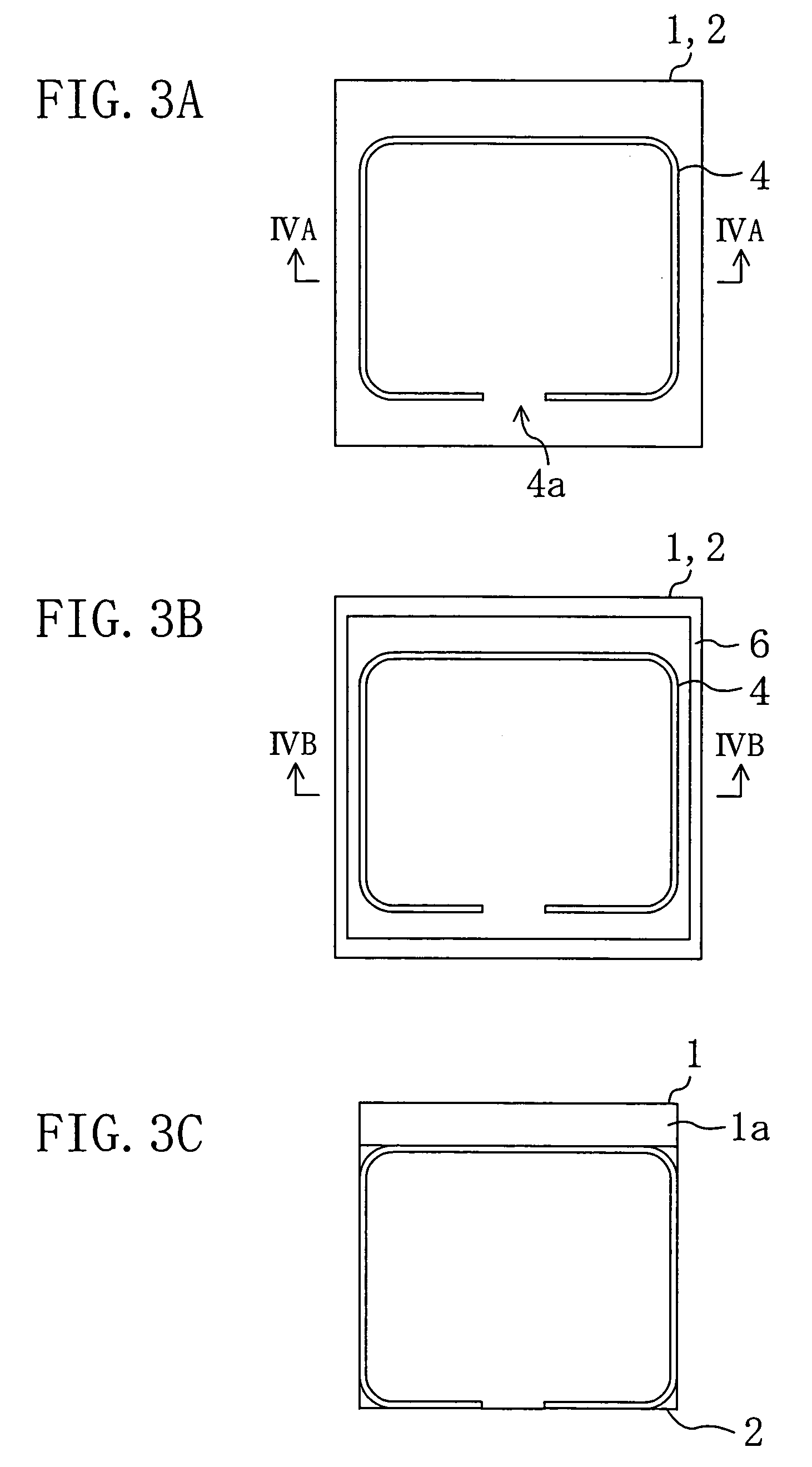

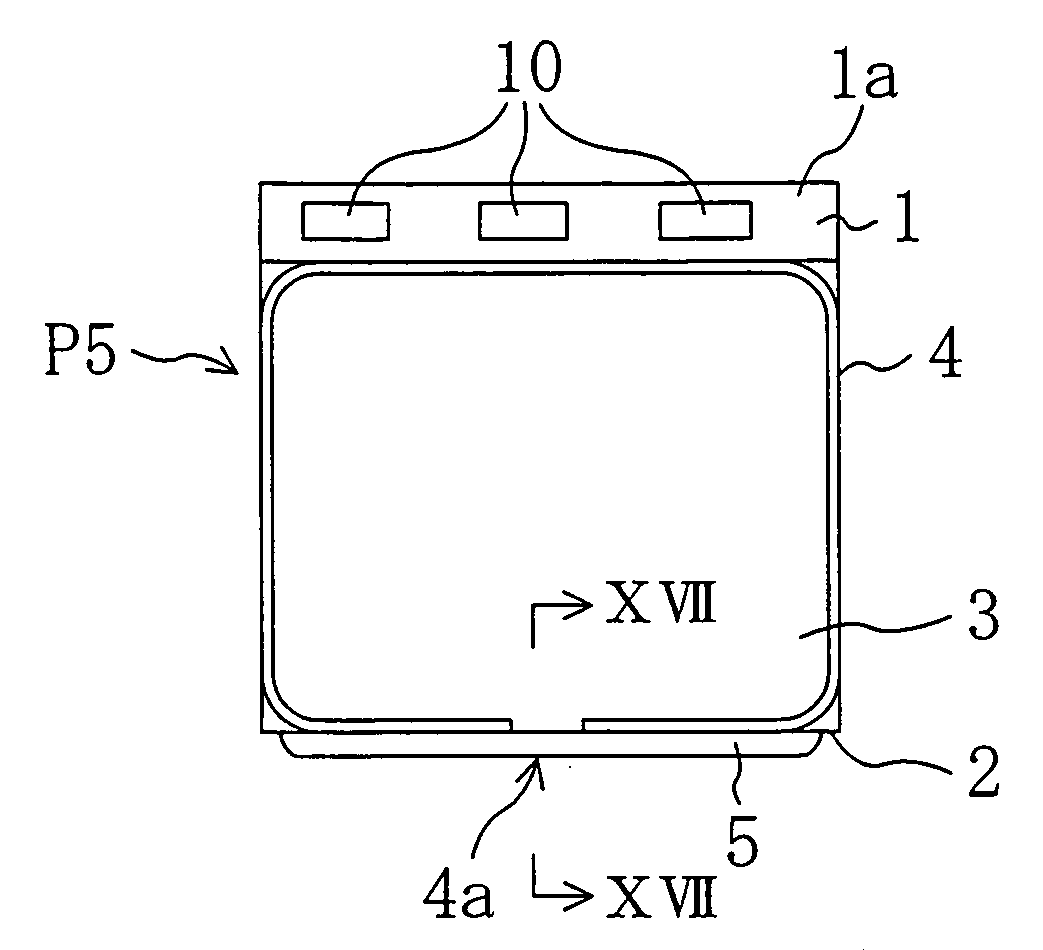

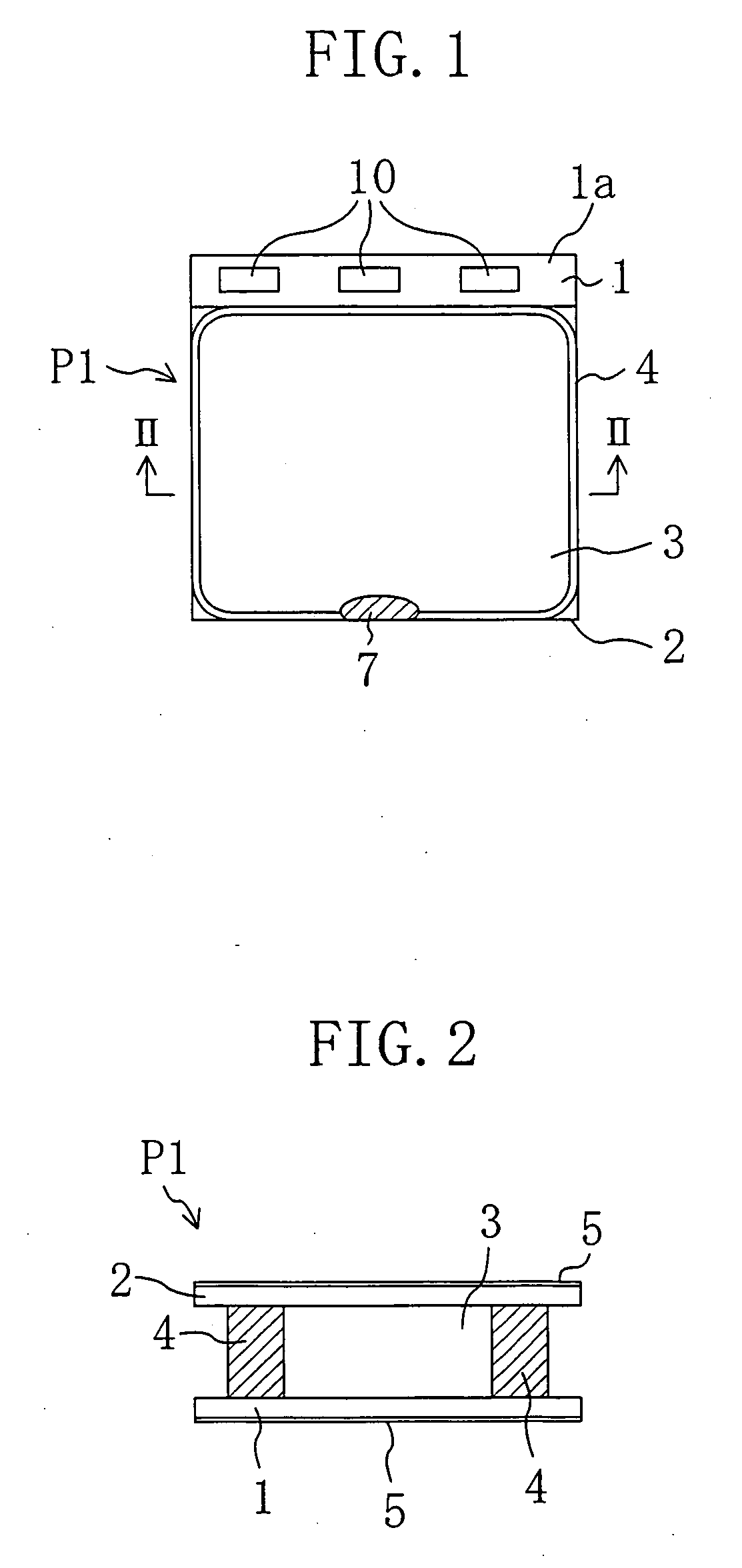

Display panel and method for fabricating the same

InactiveUS7359021B2High mechanical strengthSufficient strength against external stressSolid-state devicesSemiconductor/solid-state device manufacturingComposite materialSurface plate

Owner:SHARP KK

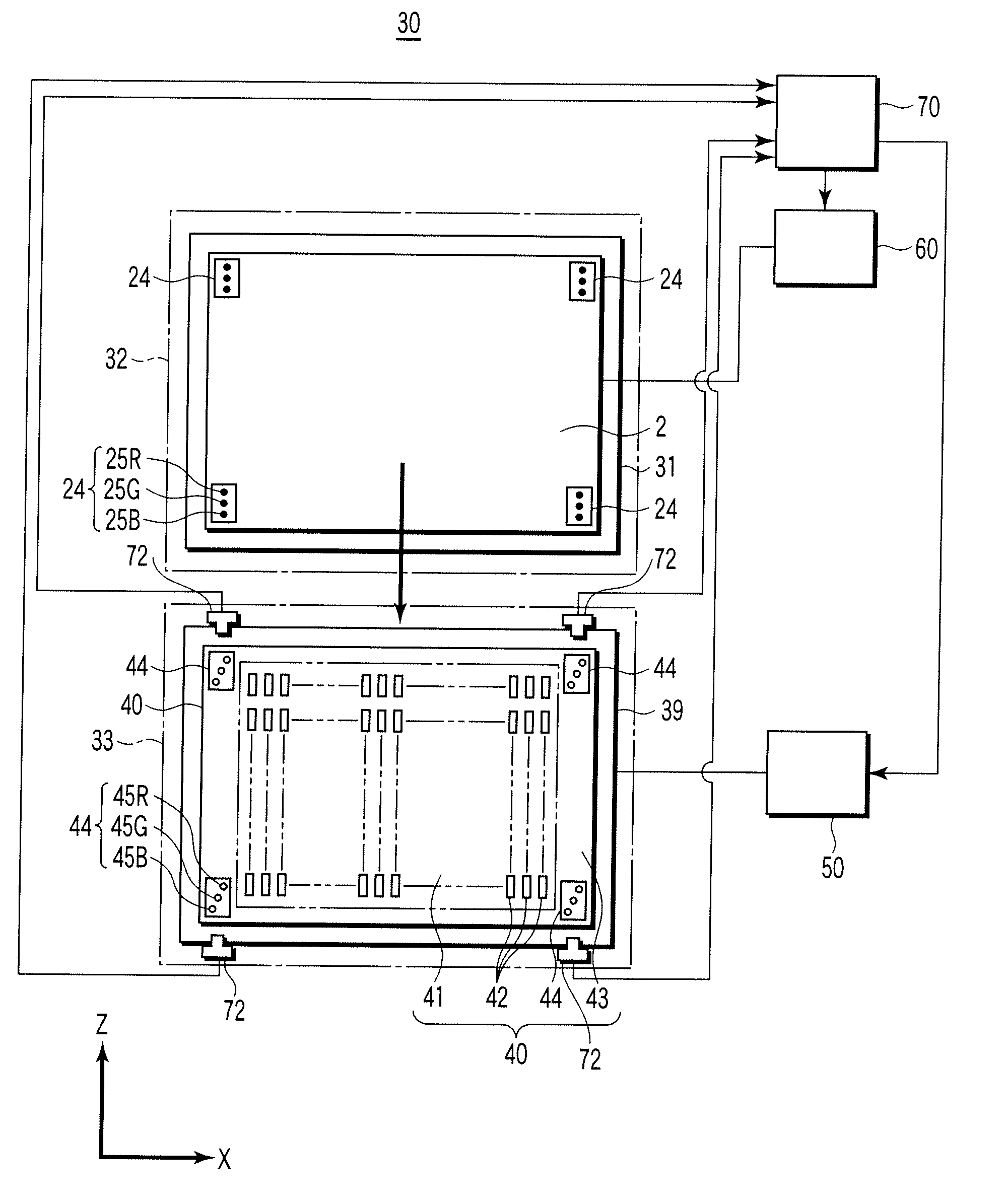

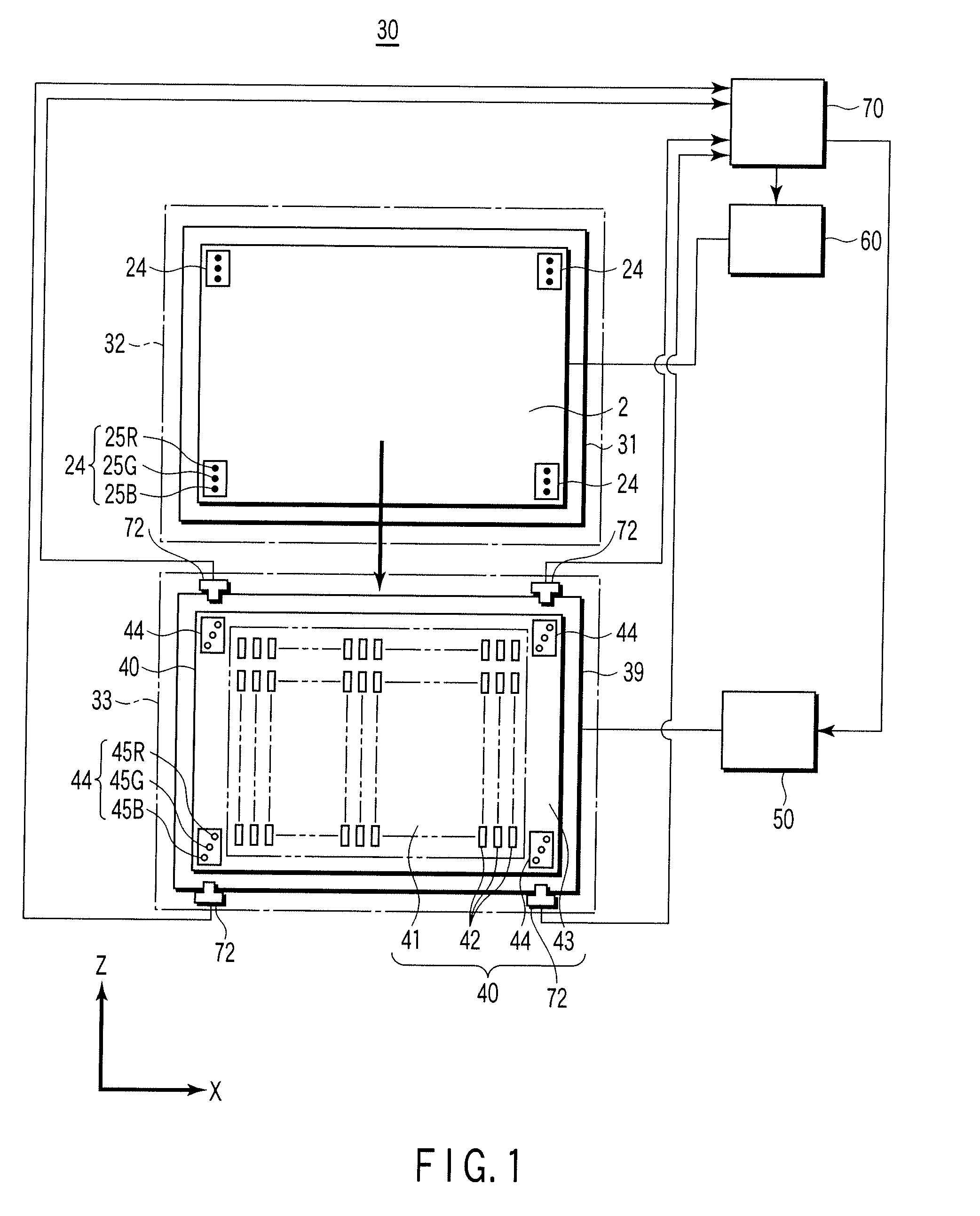

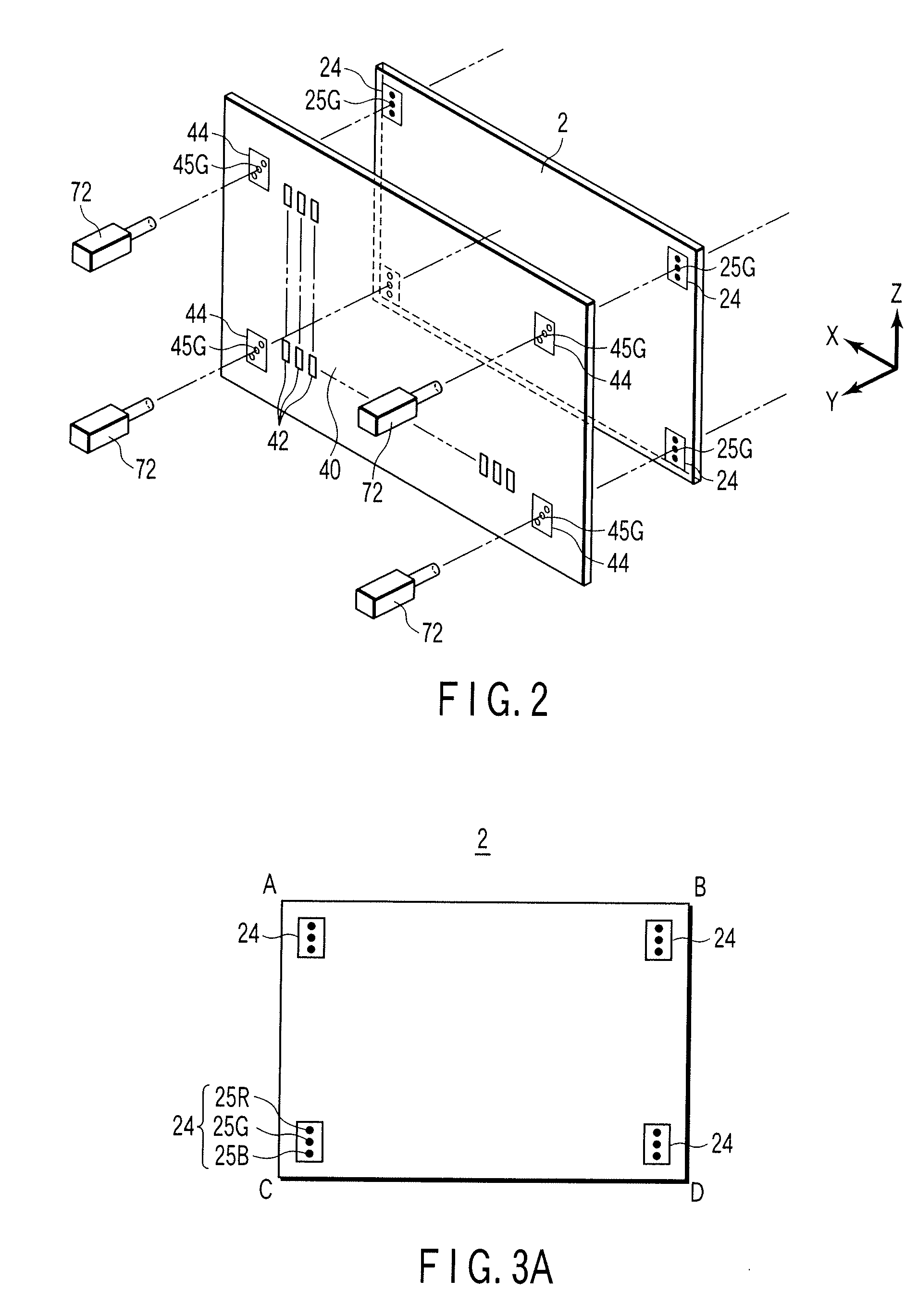

Image display unit, and method of manufacturing the same

InactiveUS20070126334A1Increase productivityQuality improvementDischarge tube luminescnet screensLamp detailsFluorescenceElectron

An image display unit having a back-side substrate on which a number of electron emission elements are arranged, and a front-side substrate which is opposed to a back-side substrate and has fluorescent patterns and light-shielding patterns arranged at positions corresponding to electron emission elements, wherein a marking area is provided at least two locations in an ineffective part of the inside of the front-side substrate, corresponding to alignment marks of a dry plate, and each marking area has three alignment marks. According to the present invention, it is unnecessary to change R, G, B masks whenever three color fluorescent patterns are exposed, and realignment between a mask and a substrate is unnecessary.

Owner:KK TOSHIBA

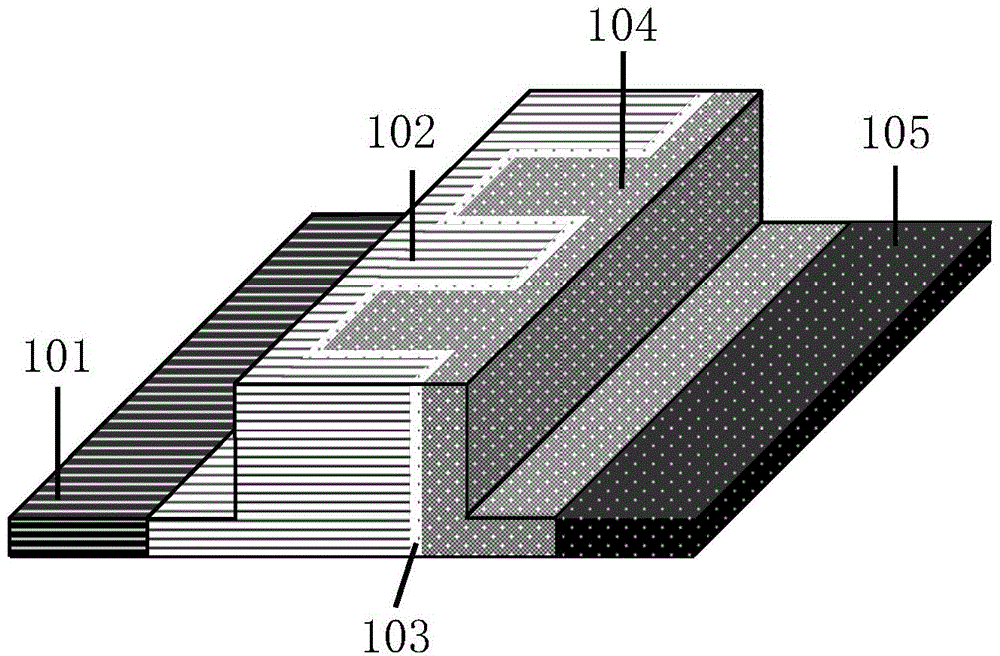

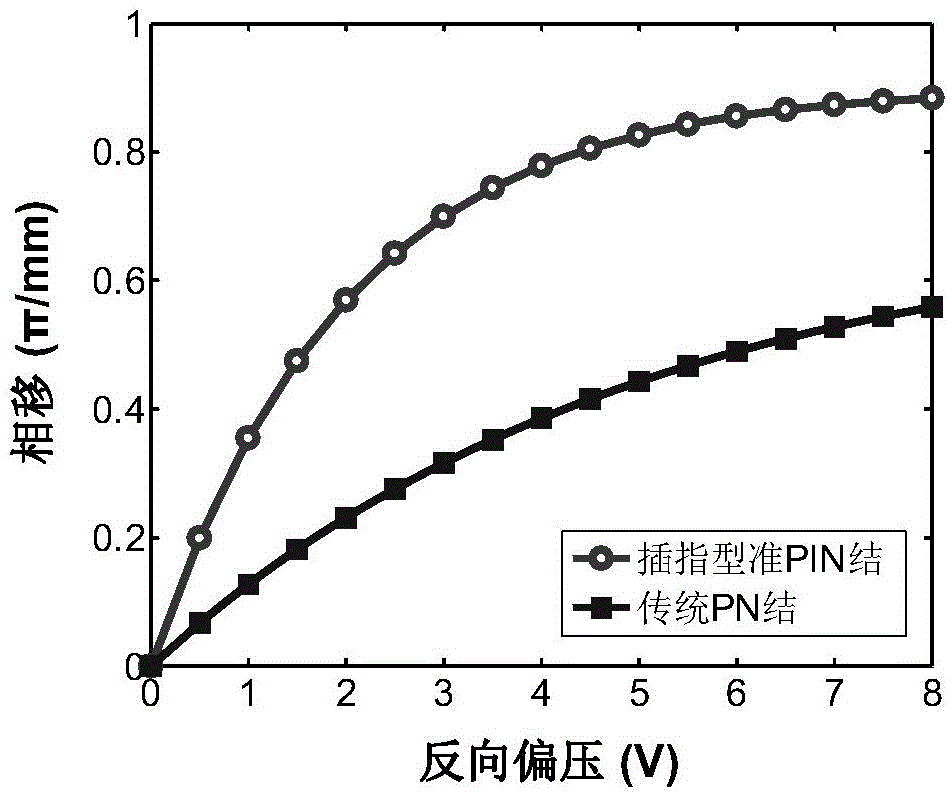

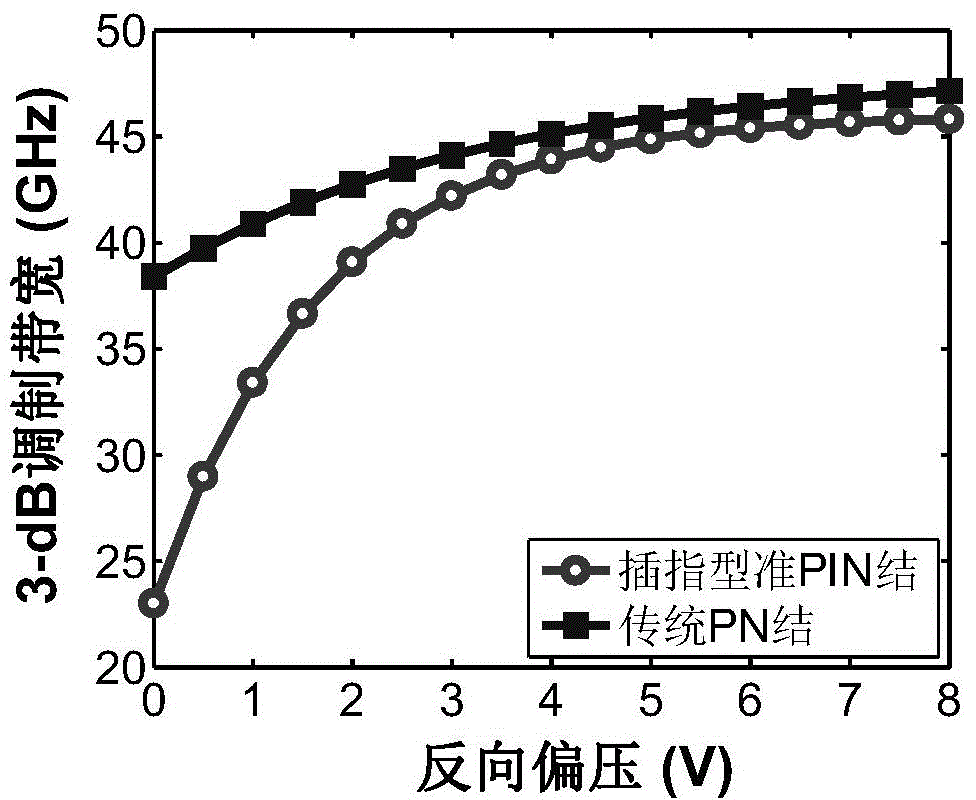

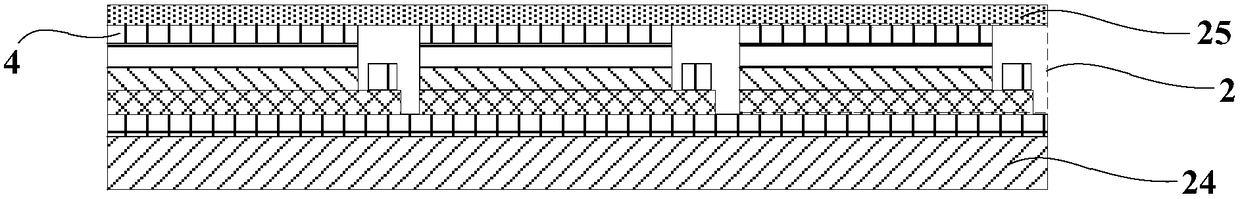

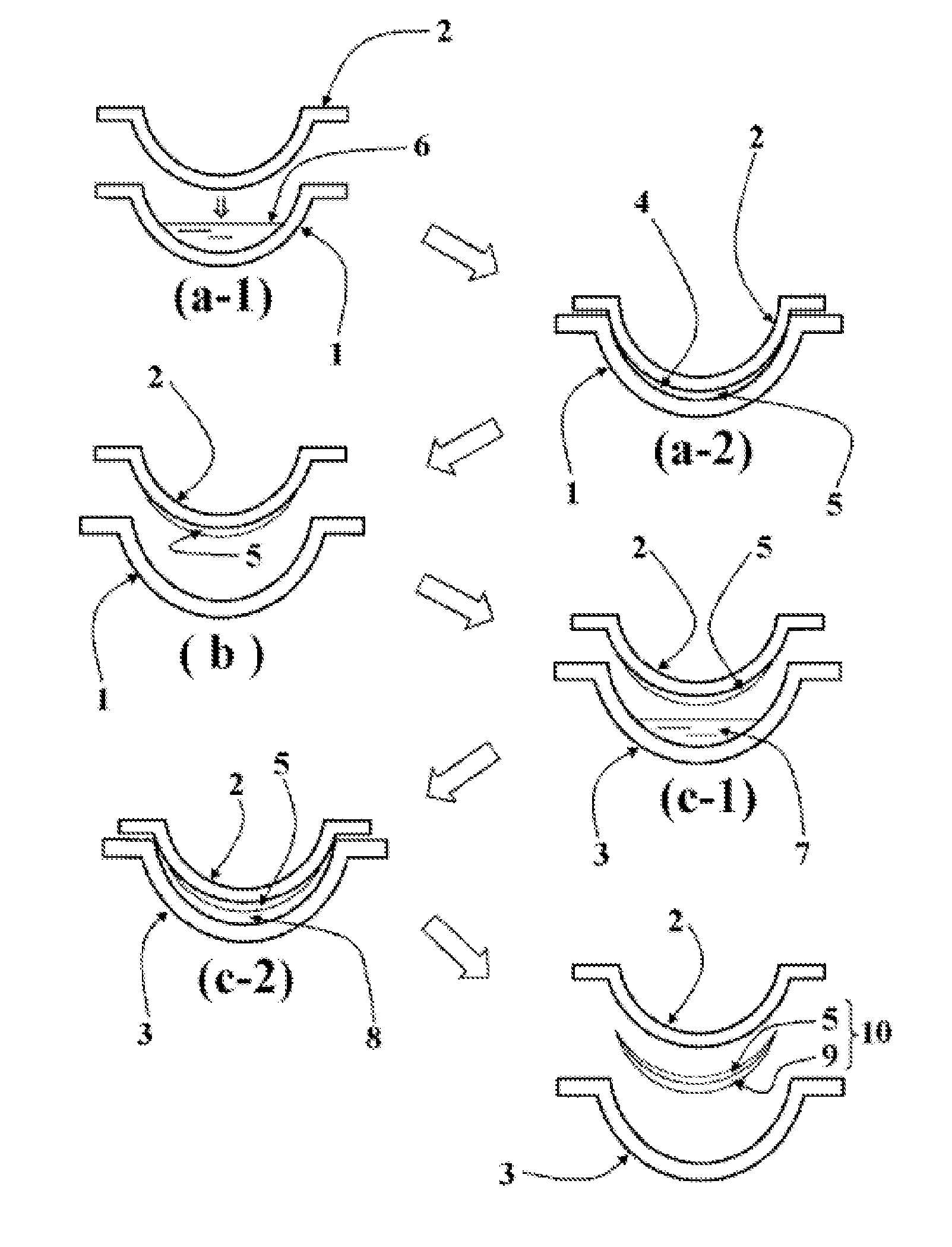

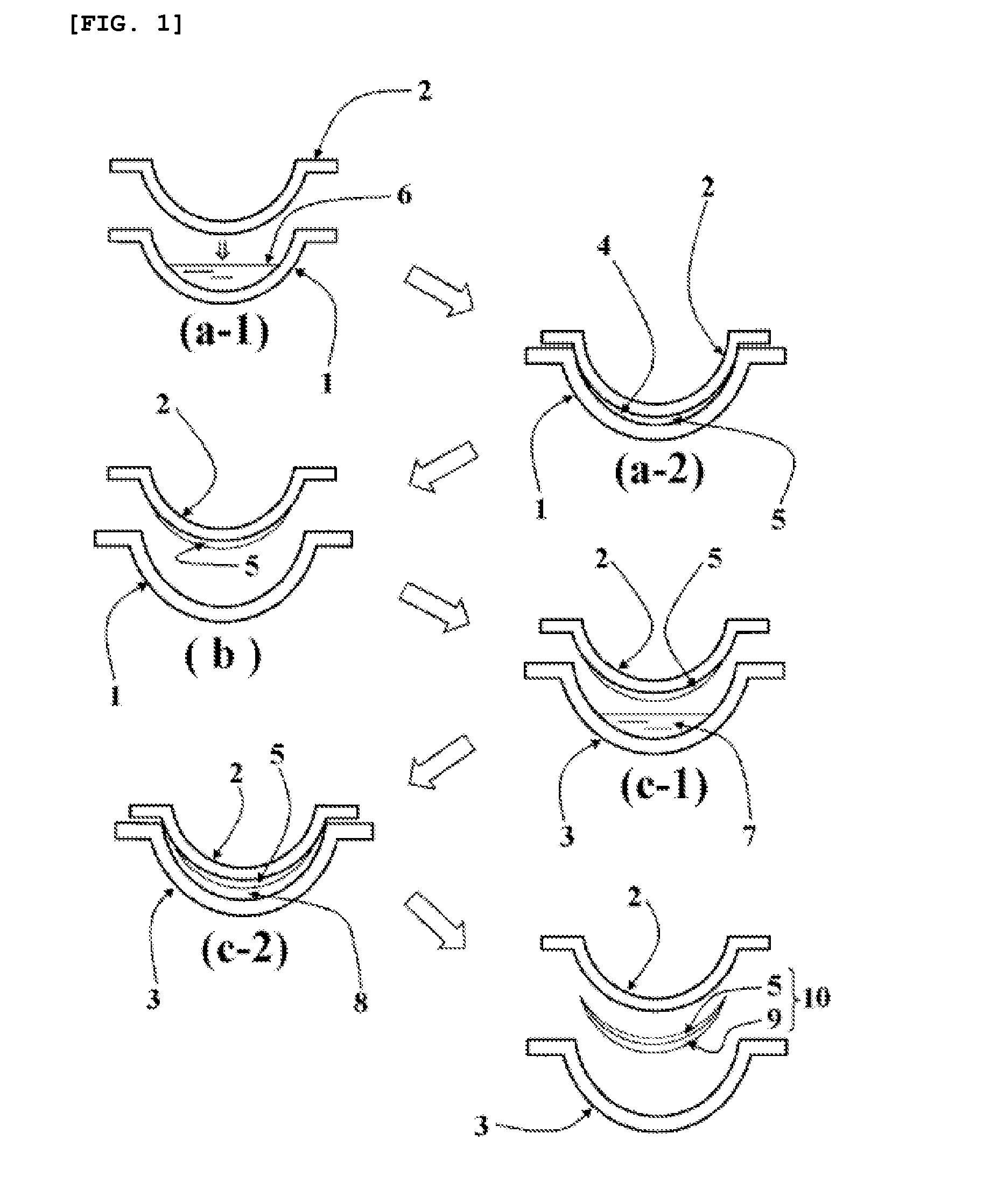

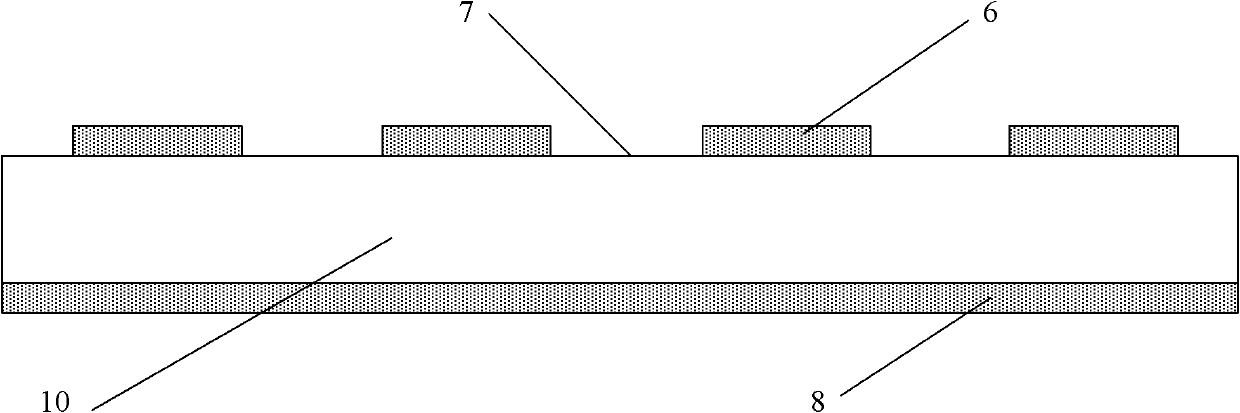

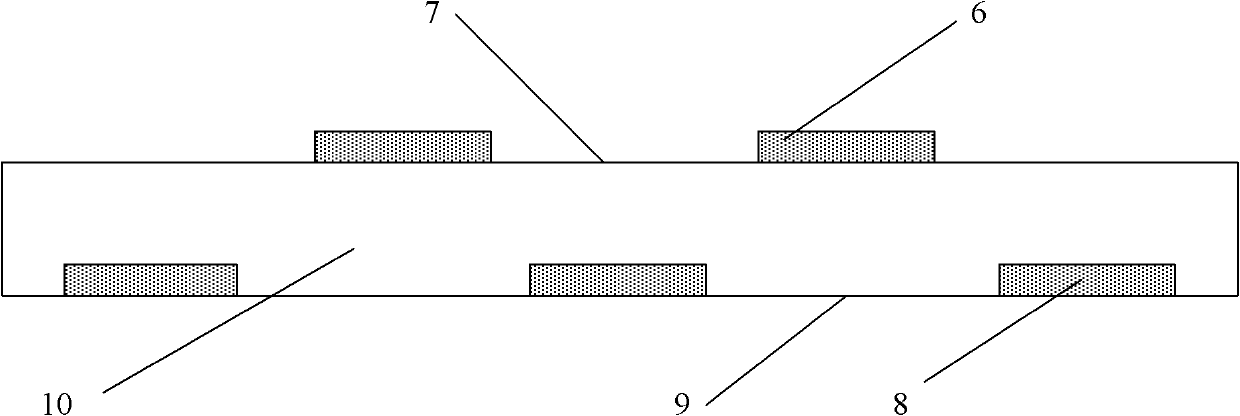

Doping structure for improving efficiency and bandwidth of silicon-based electro-optic tuning device

ActiveCN104393133AIncreased intrinsic electrical bandwidthIncrease tuning speedNon-linear opticsSemiconductor devicesP type dopingInsertion loss

The invention discloses a doping structure for improving efficiency and bandwidth of a silicon-based electro-optic tuning device. The doping structure comprises a P+ type doping area arranged on the outer ridge area on one side close to the edge and is in ohmic contact with the above metal; A P type doping area is arranged on the outer ridge area connected with the P+ type doping area and extends to the inner ridge area; An N+ type doping area is arranged on the outer ridge area on the other side close to the edge and is in ohimic contact with the above metal; A N-type doping area is arranged on the outer ridge area connected with the N+ type doping area and extends to the inner ridge area and is complementary with the P type doping area; An almost-I type doping area is arranged between the P type doping area and the N type doping area and forms an almost PIN knot with the P type doping area and the N type doping area. By means of the doping structure, the silicon-based electro-optic tuning device is improved in the aspects of the modulator speed, efficiency and insertion loss, the cost is reduced, the requirement of the ion implantation process for the mask alignment accuracy is reduced, and large-scale manufacture of the device is facilitated.

Owner:WUHAN POST & TELECOMM RES INST CO LTD

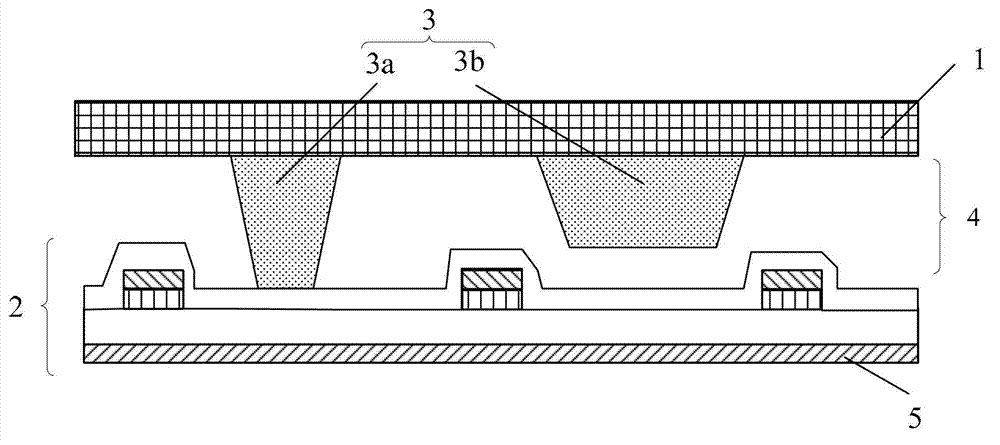

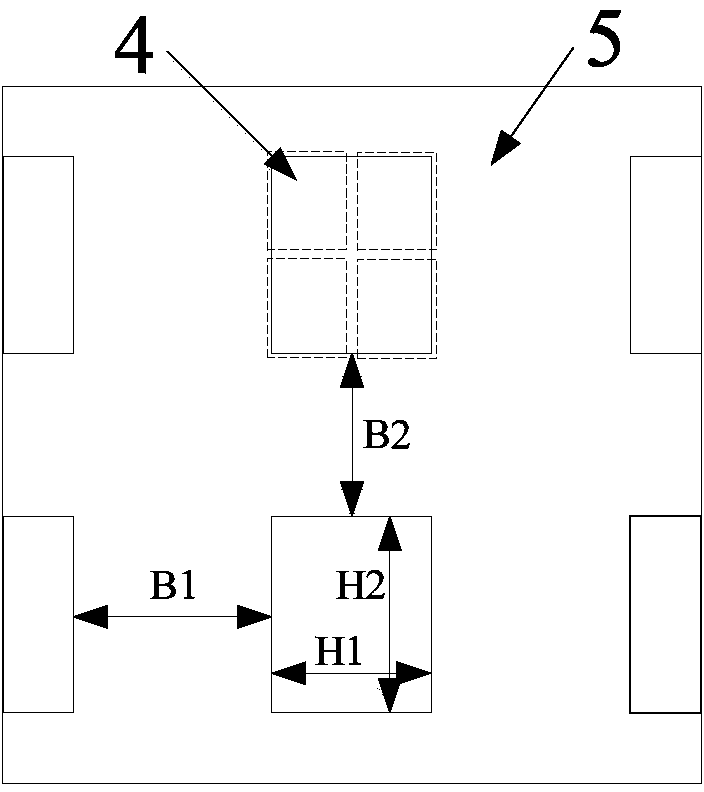

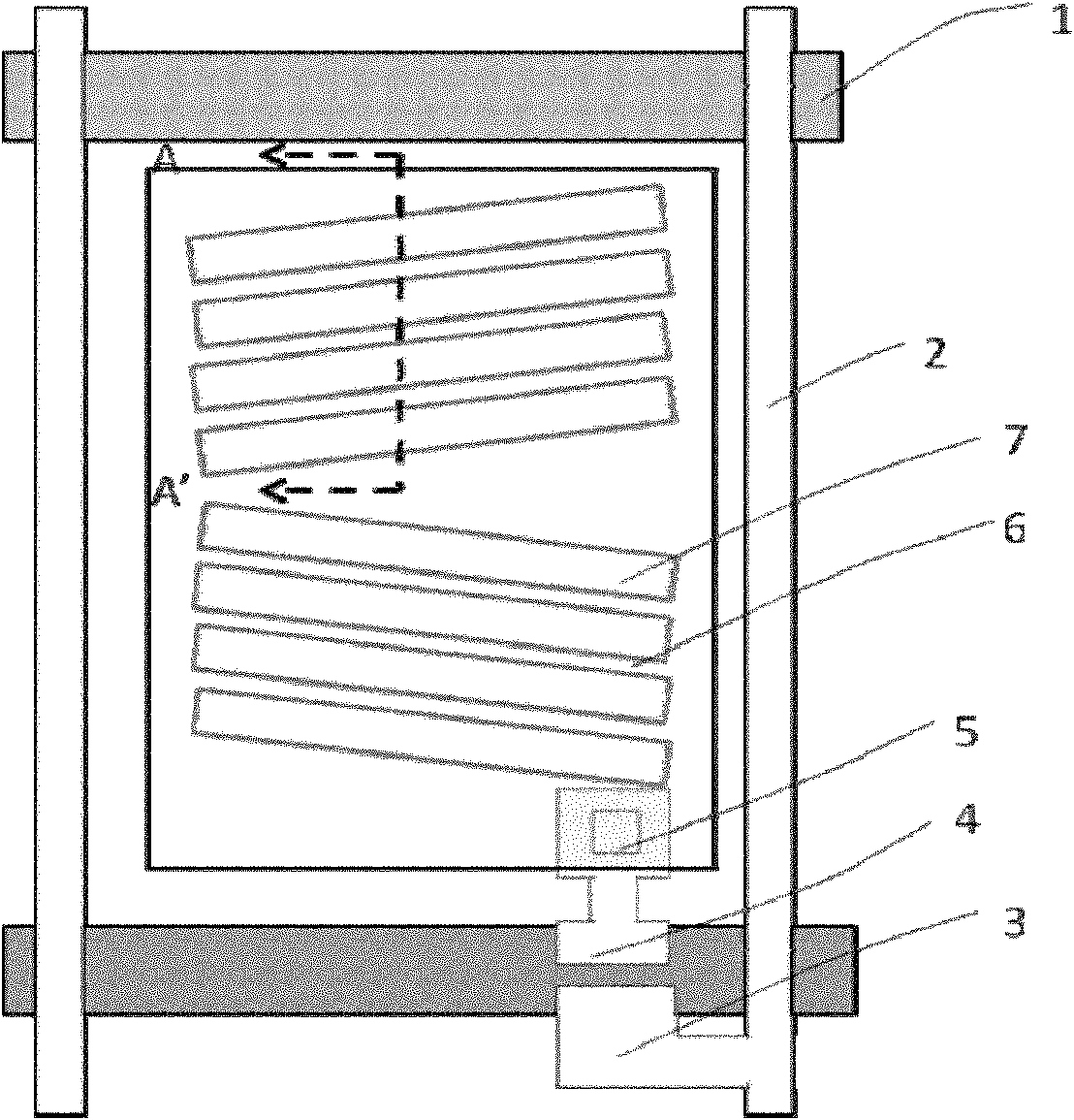

Liquid crystal display panel and manufacturing method thereof

ActiveCN102955297AGuaranteed compression performanceIncrease marginNon-linear opticsLiquid-crystal displayLiquid crystal

The embodiment of the invention provides a liquid crystal display panel and a manufacturing method thereof, relating to the display field. The problem of low-temperature bubbles of the display panel can be effectively solved; and the anti-pressure capability of the display panel can be ensured, so that the quality of a display picture can be ensured. The liquid crystal display panel comprises an upper substrate, a lower substrate, a liquid crystal layer and a spacer, wherein the liquid crystal layer and the spacer are arranged between the upper substrate and the lower substrate; and the liquid crystal display panel is characterized in that the spacer is arranged in an area corresponding to a grid line in the liquid crystal display panel. The liquid crystal display panel provided by the embodiment of the invention is applied to manufacturing of liquid crystal displays.

Owner:BOE TECH GRP CO LTD +1

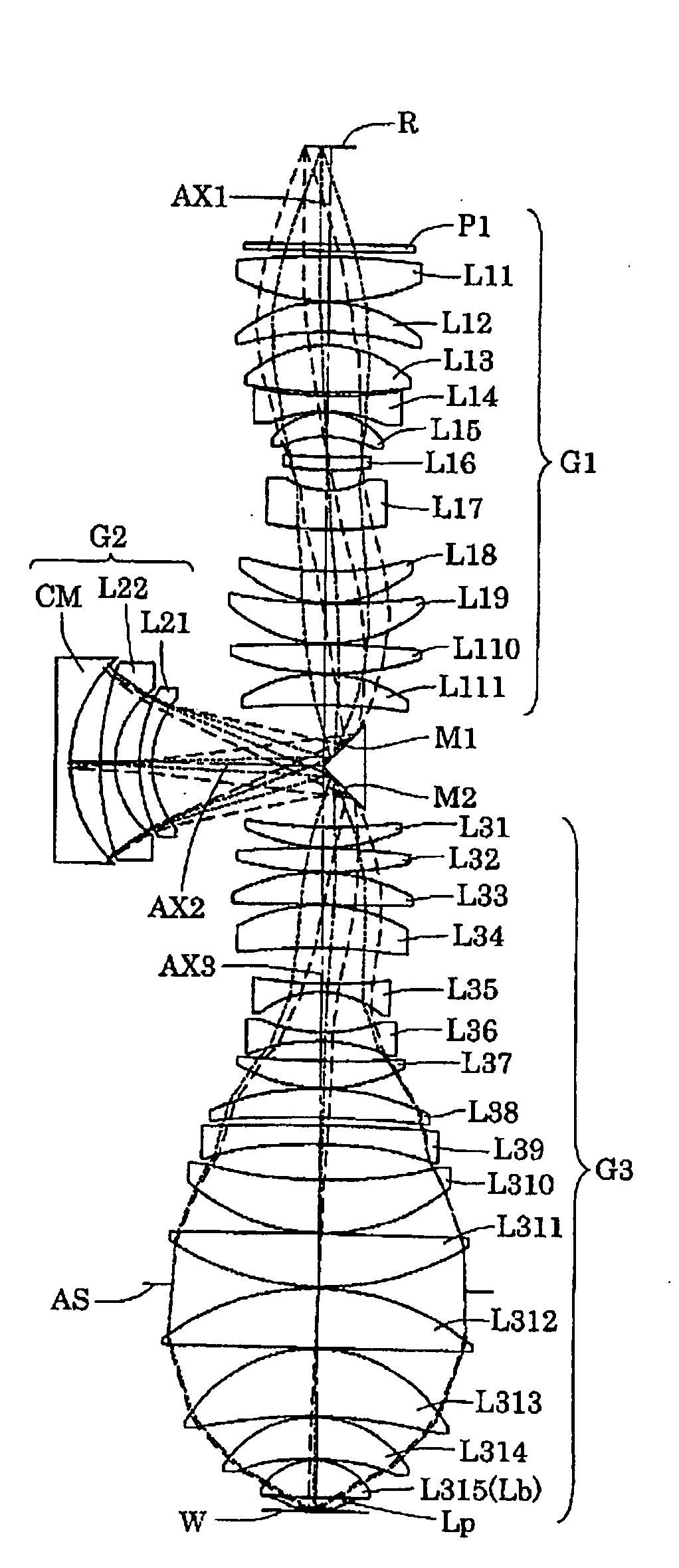

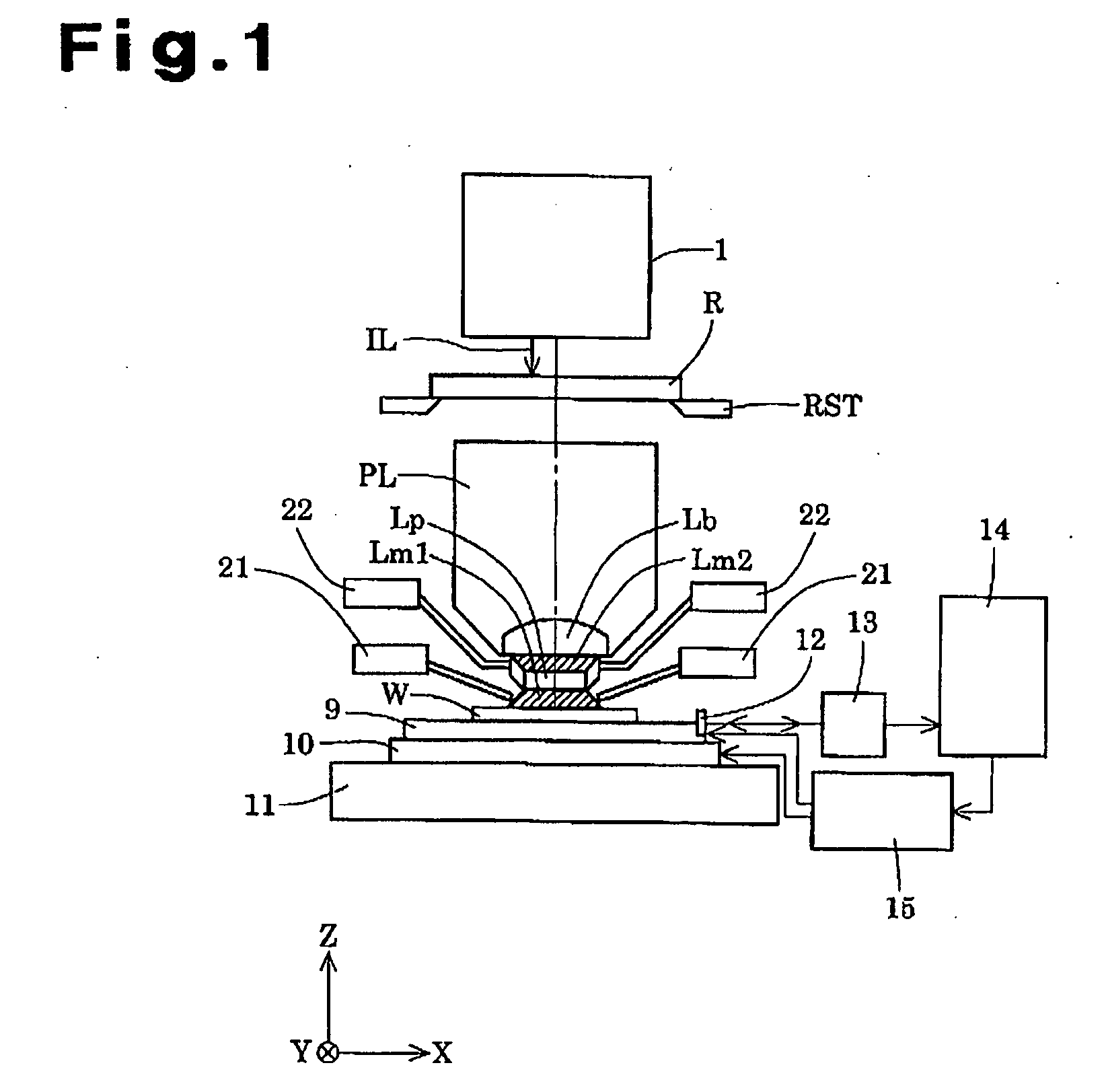

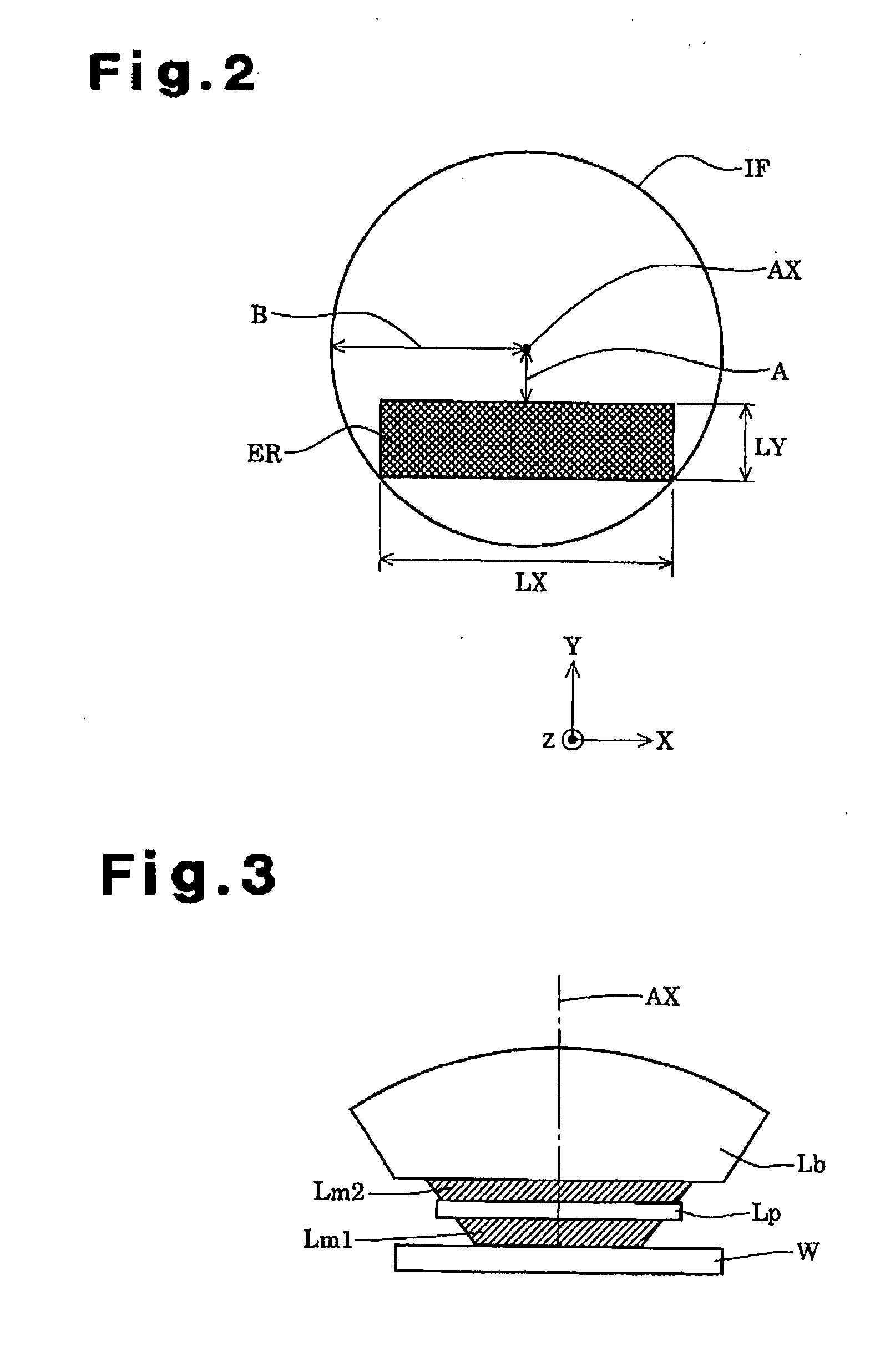

Projection optical system, exposure apparatus, and exposure method

InactiveUS20090046268A1Improve accuracyReduce alignment accuracy requirementsPhotomechanical apparatusSemiconductor/solid-state device manufacturingOptical axis

An immersion projection optical system having, for example, a catadioptric and off-axis structure, reduces the portion of an image space filled with liquid (immersion liquid). The projection optical system, which projects a reduced image of a first plane onto a second plane through the liquid, includes a refractive optical element (Lp) arranged nearest to the second plane. The refractive optical element includes a light emitting surface (Lpb) shaped to be substantially symmetric with respect to two axial directions (XY-axes) perpendicular to each other on the second plane. The light emitting surface has a central axis (Lpba) that substantially coincides with a central axis (40a) of a circle (40) corresponding to a circumference of a light entering surface (Lpa) of the refractive optical element. The central axis of the light emitting surface is decentered in one of the two axial directions (Y-axis) from an optical axis (AX).

Owner:NIKON CORP

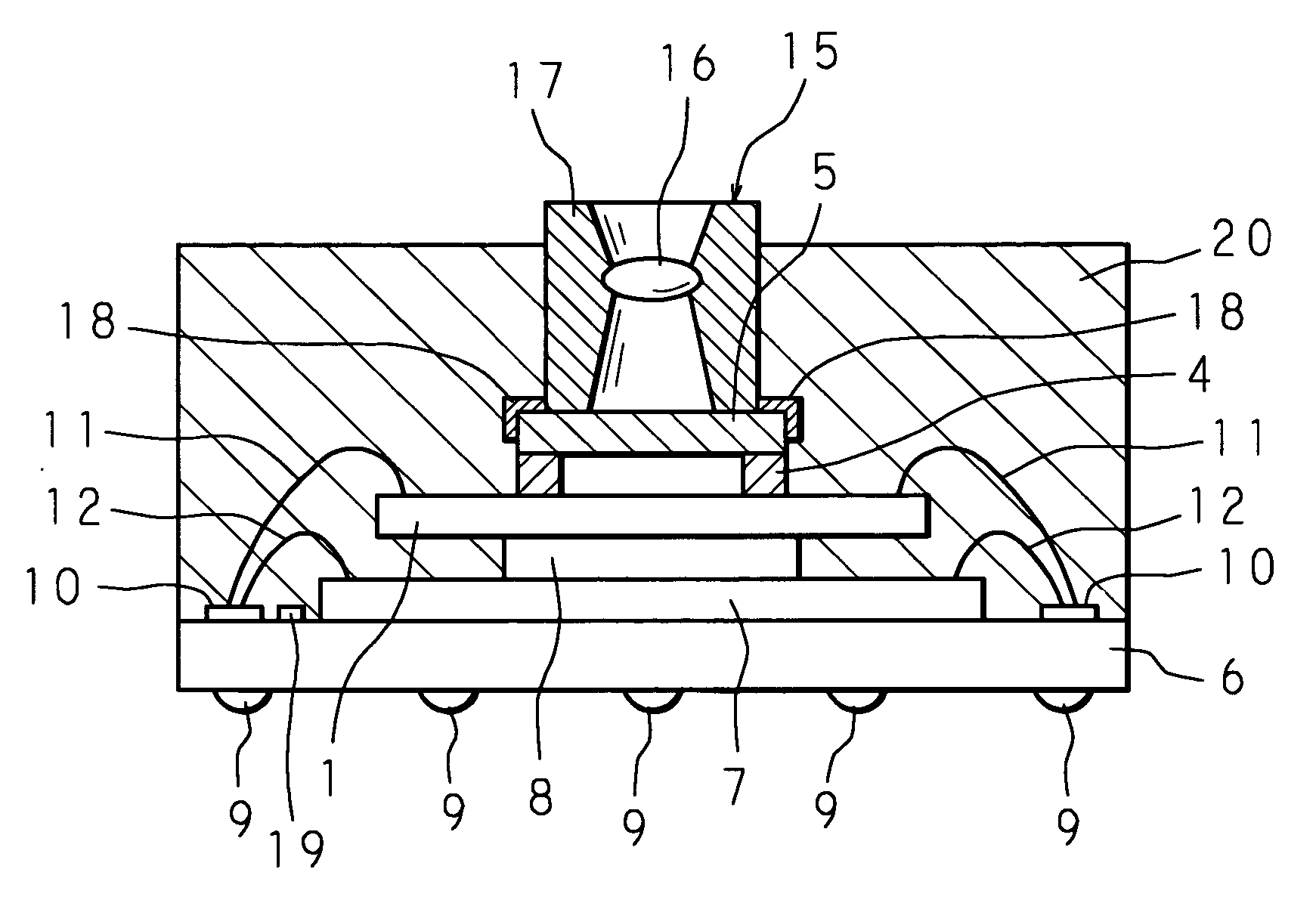

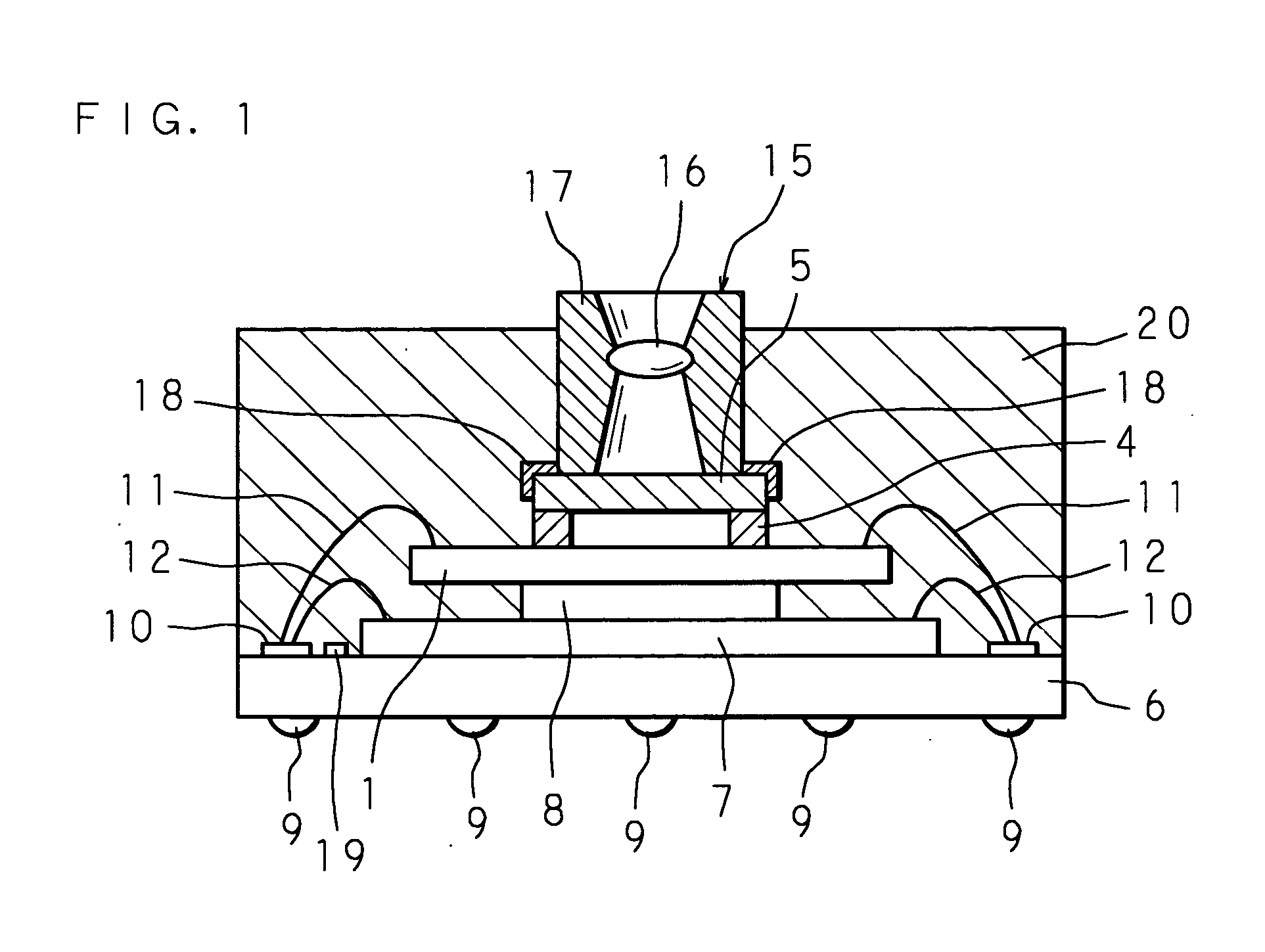

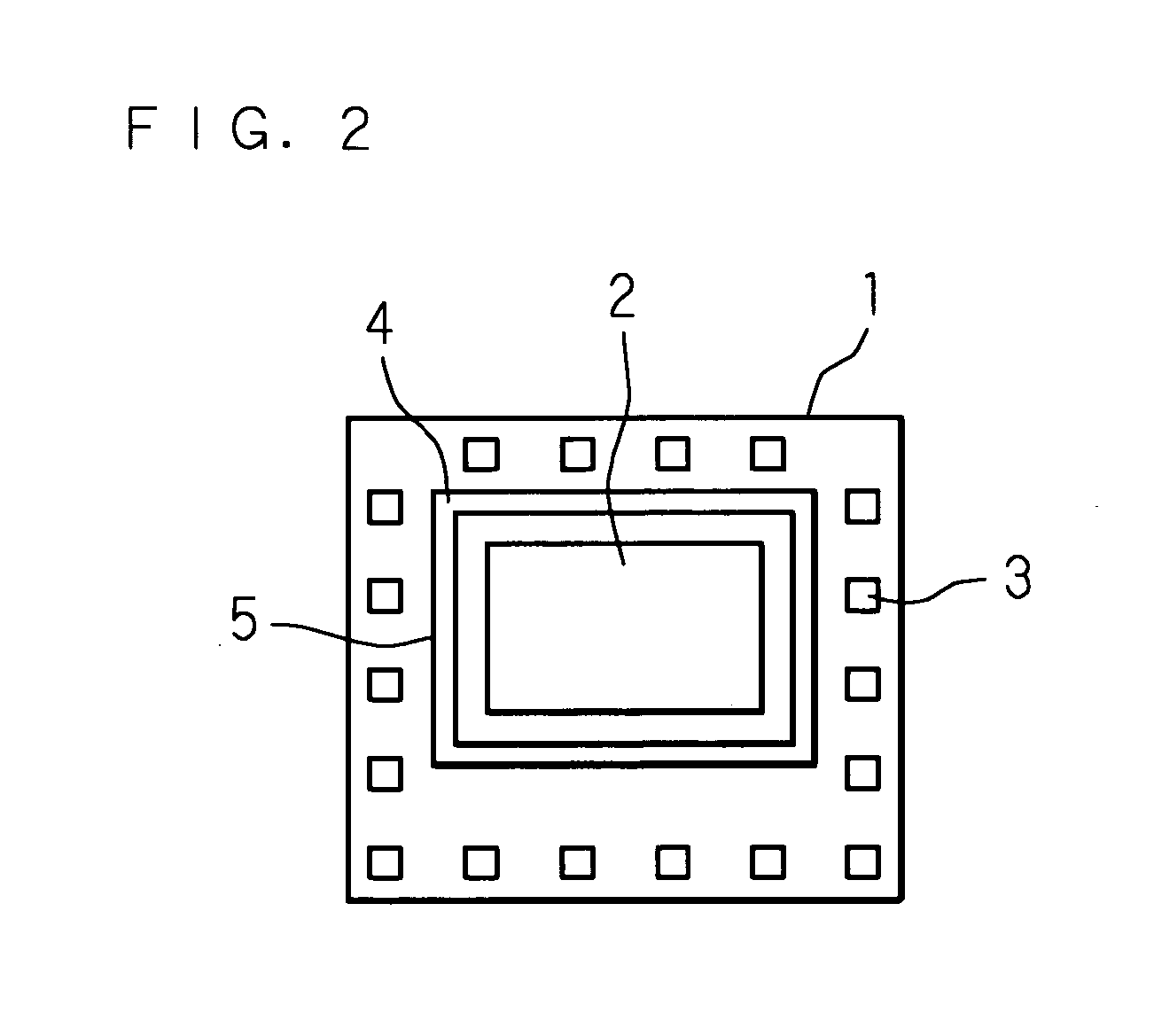

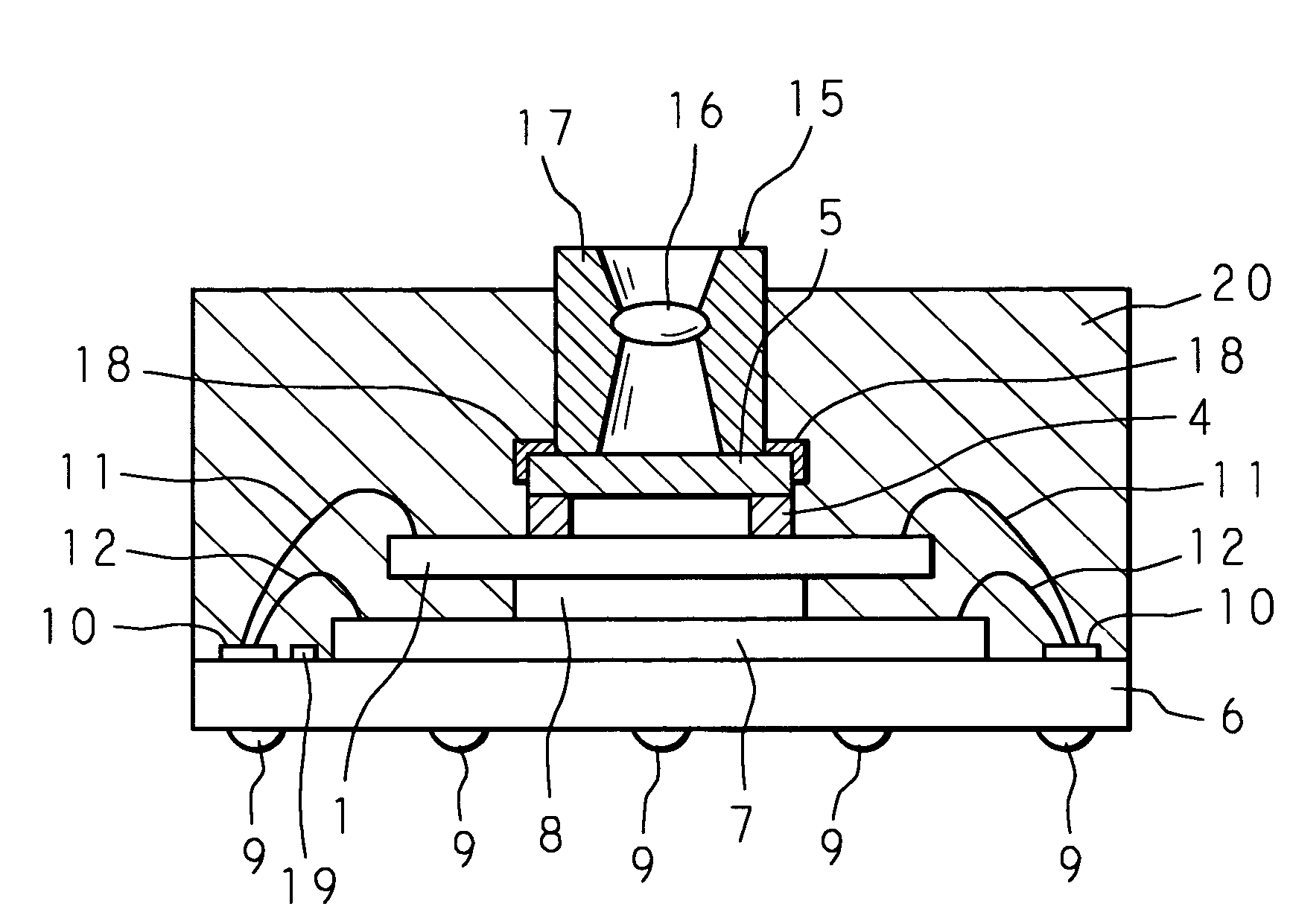

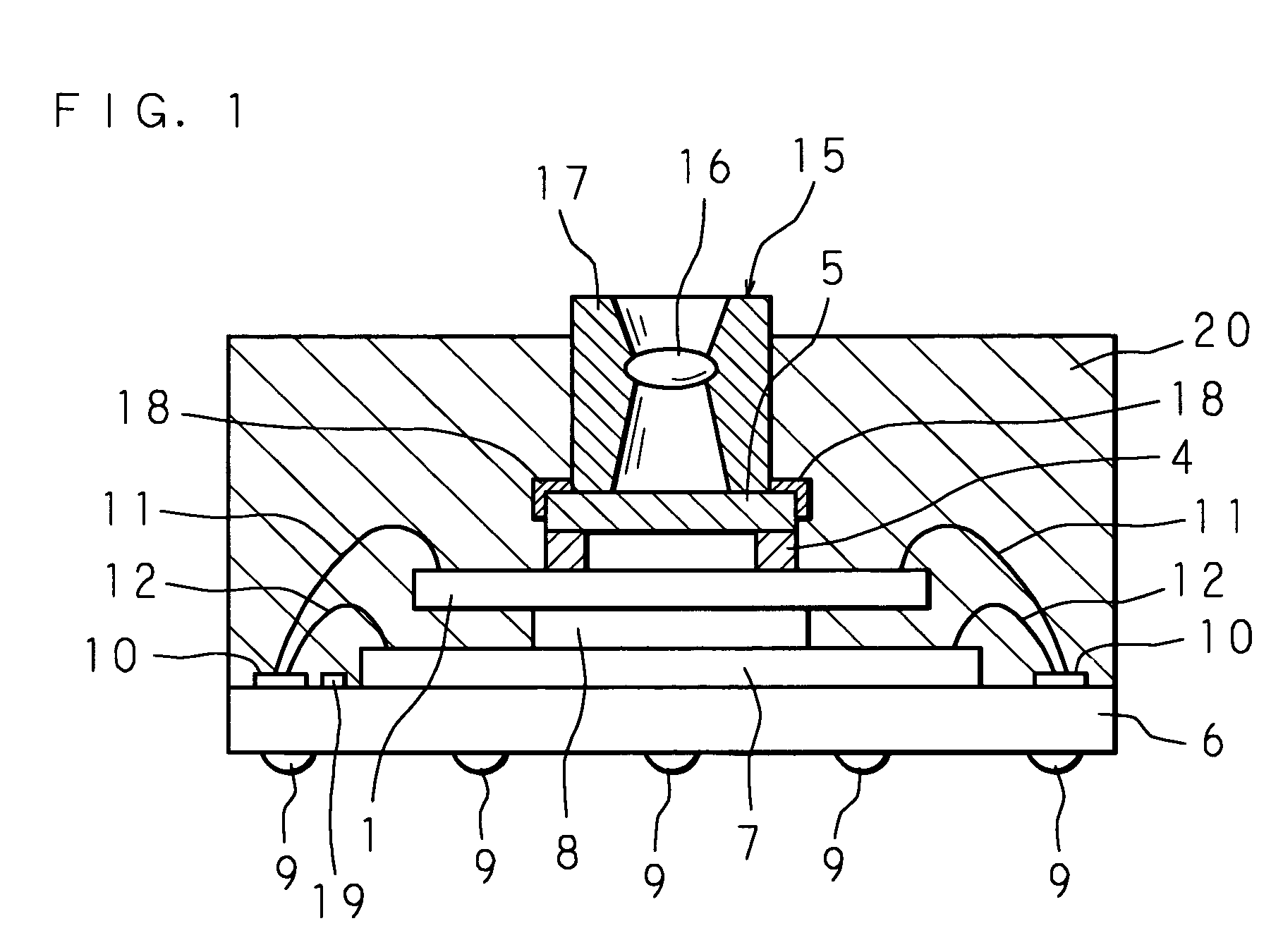

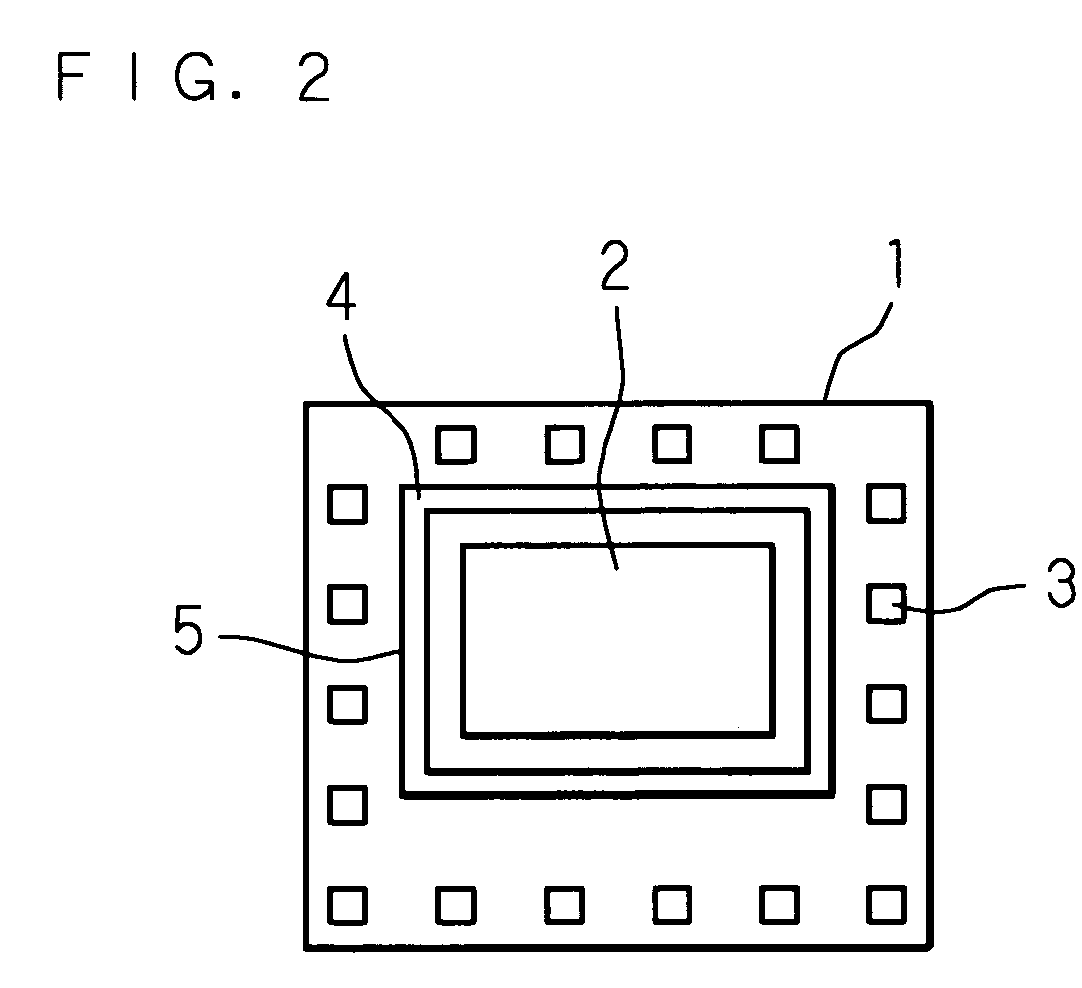

Optical device module, and method of fabricating the optical device module

InactiveUS20060219884A1Reduce alignment accuracy requirementsImprove accuracySolesSpurEngineeringSynthetic resin

An optical path delimiter having a lens is disposed so as to be in contact with a transparent lid bonded to a surface of a solid-state image sensor, and is fixed without bonded. Further, the solid-state image sensor to which the transparent lid is bonded, the optical path delimiter disposed so as to be in contact with the transparent lid without bonded, a DSP serving as a signal processor, a circuit part and a wiring board are fixed by being sealed in a synthetic resin. Even when distortion occurs due to warpage, flexure or the like on a board where the solid-state image sensor is disposed, the accuracy of the alignment of the lens with respect to the solid-state image sensor never decreases. In addition, the solid-state image sensor or the signal processor is never damaged by an external shock.

Owner:SHARP KK

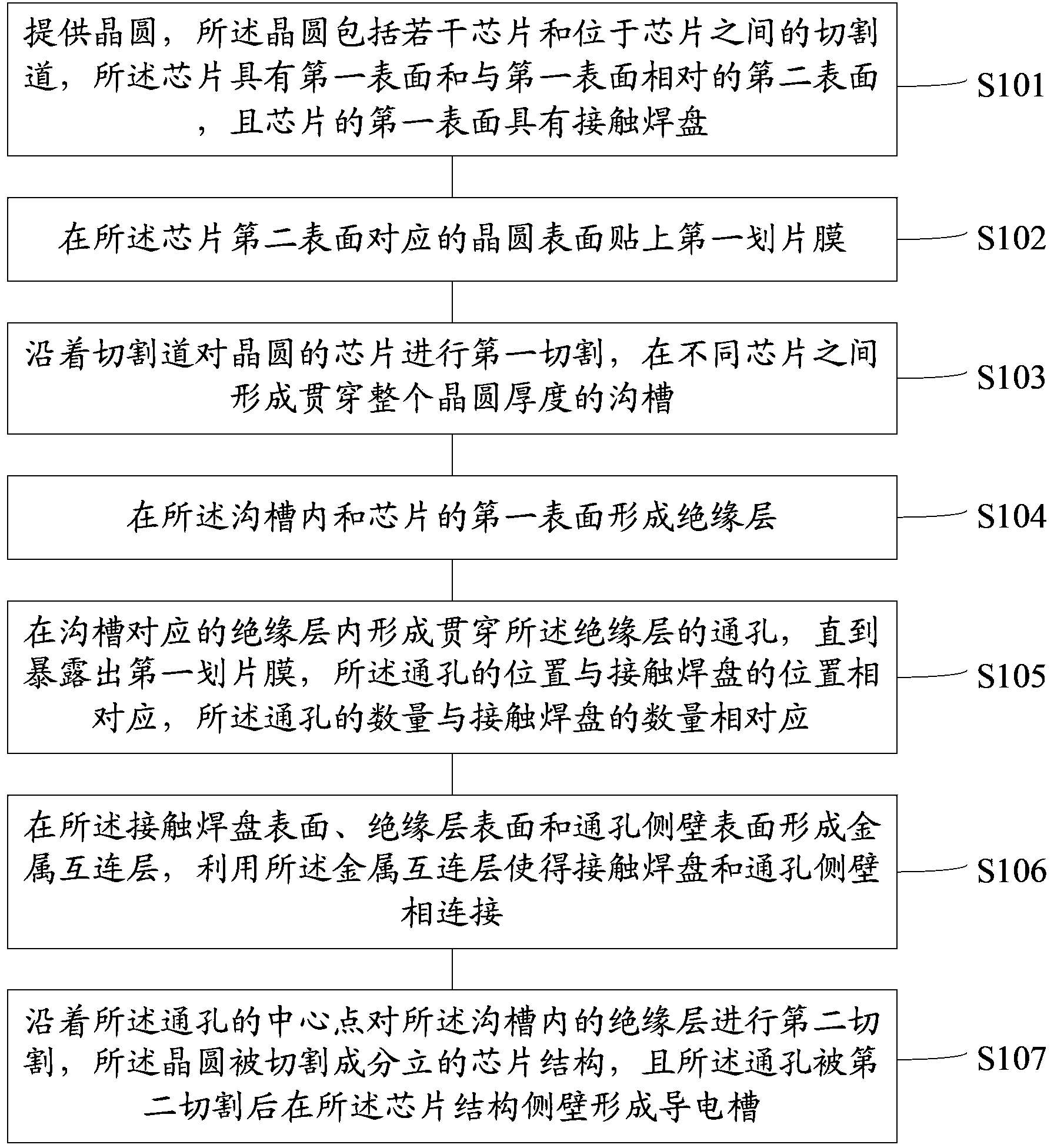

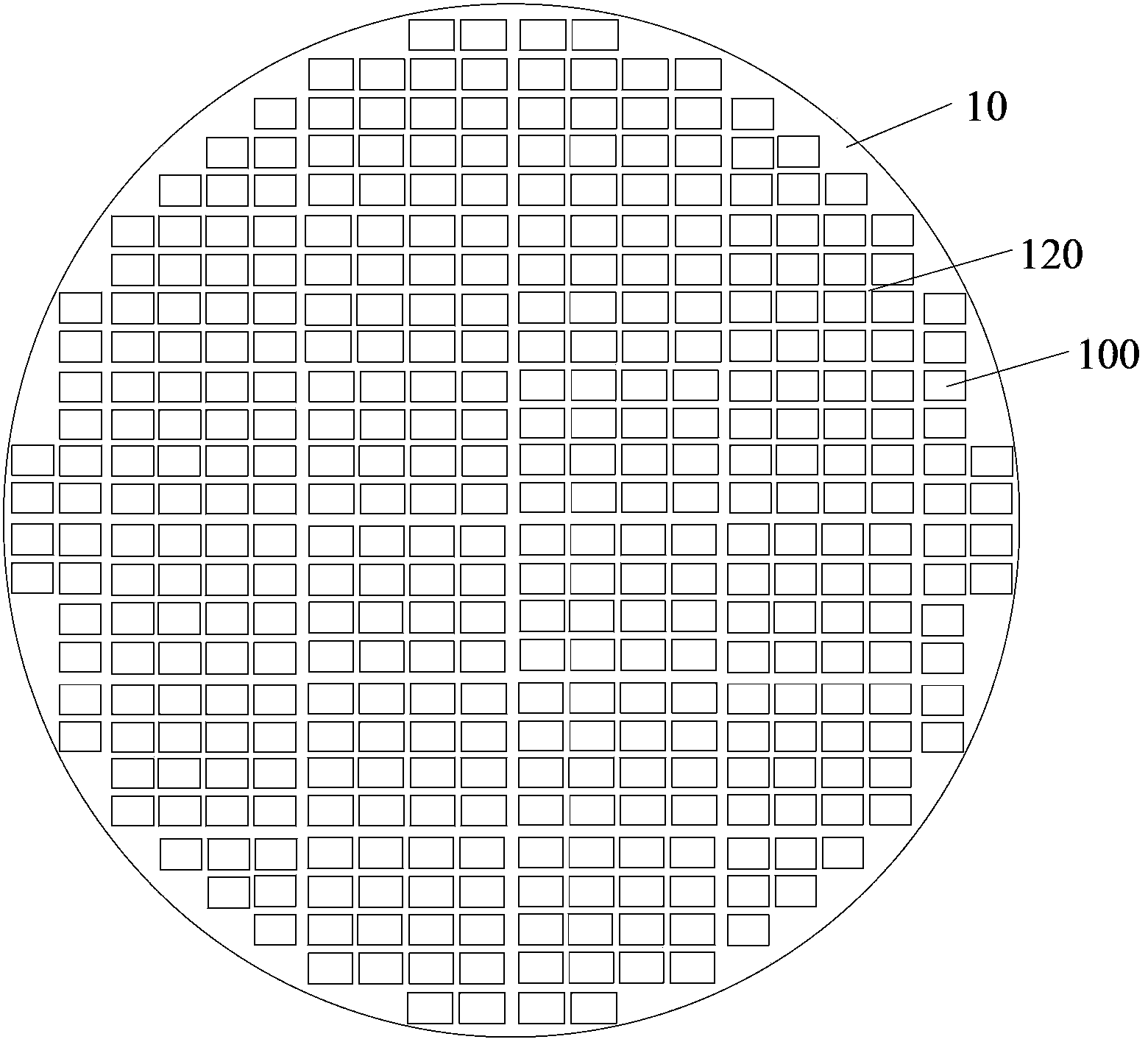

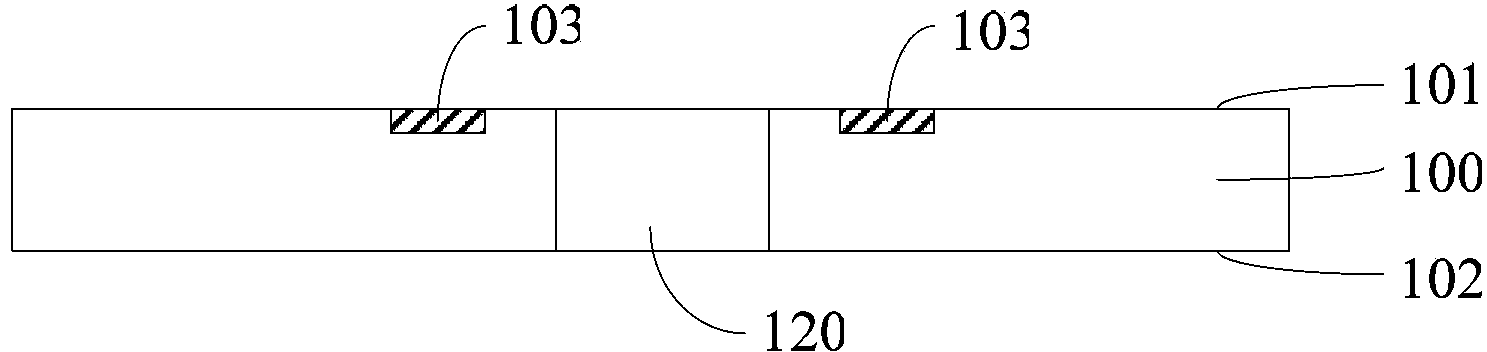

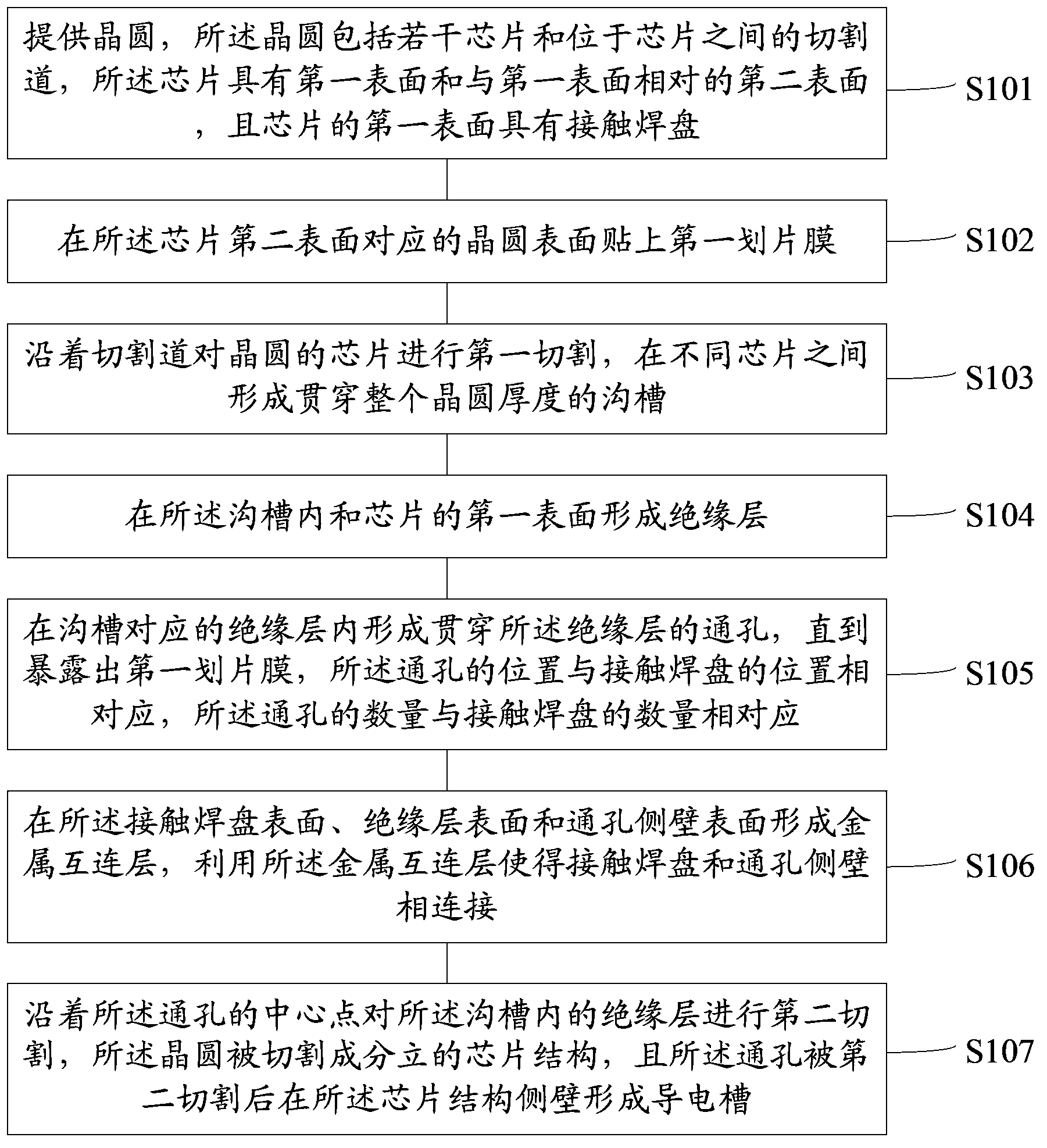

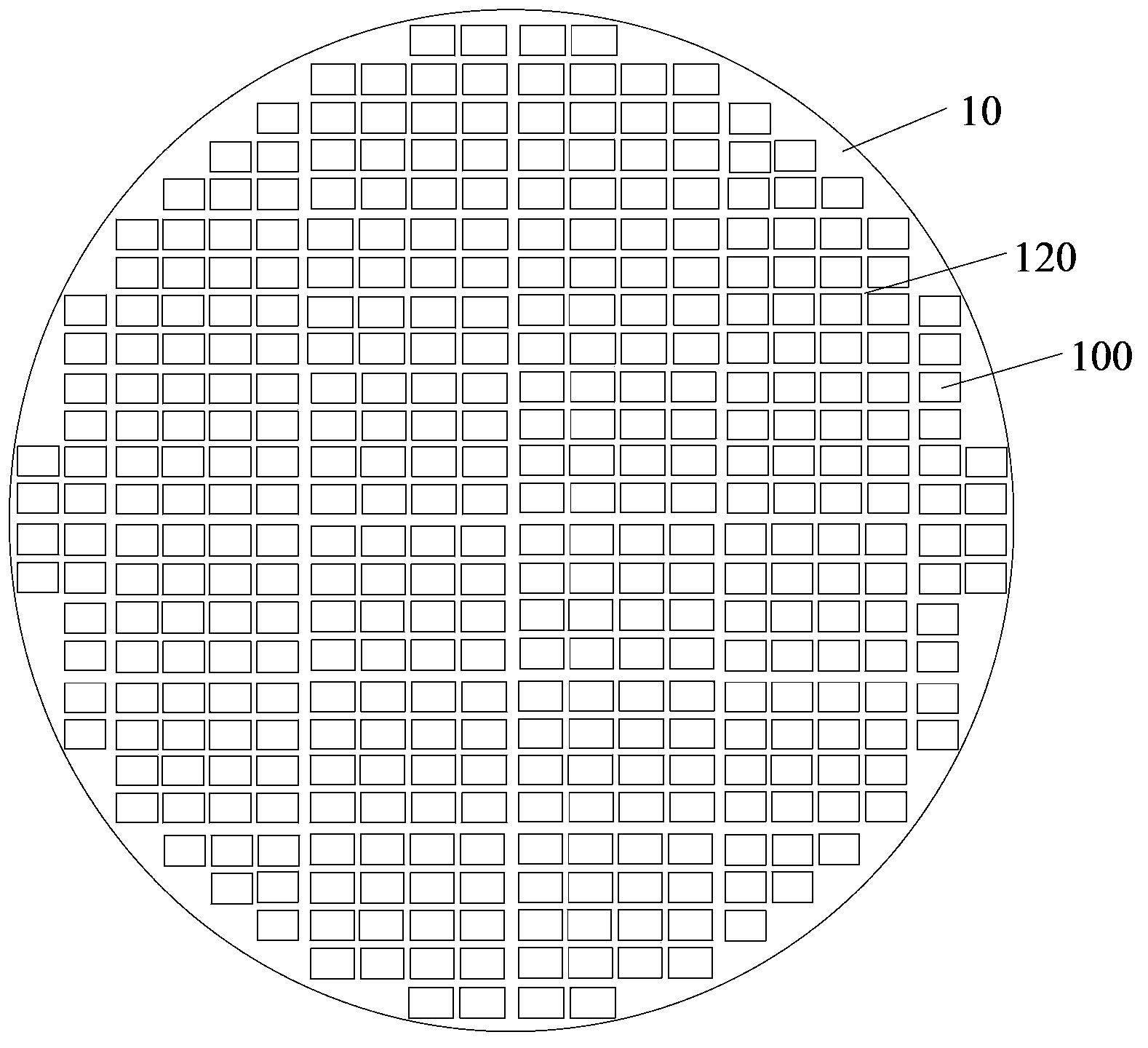

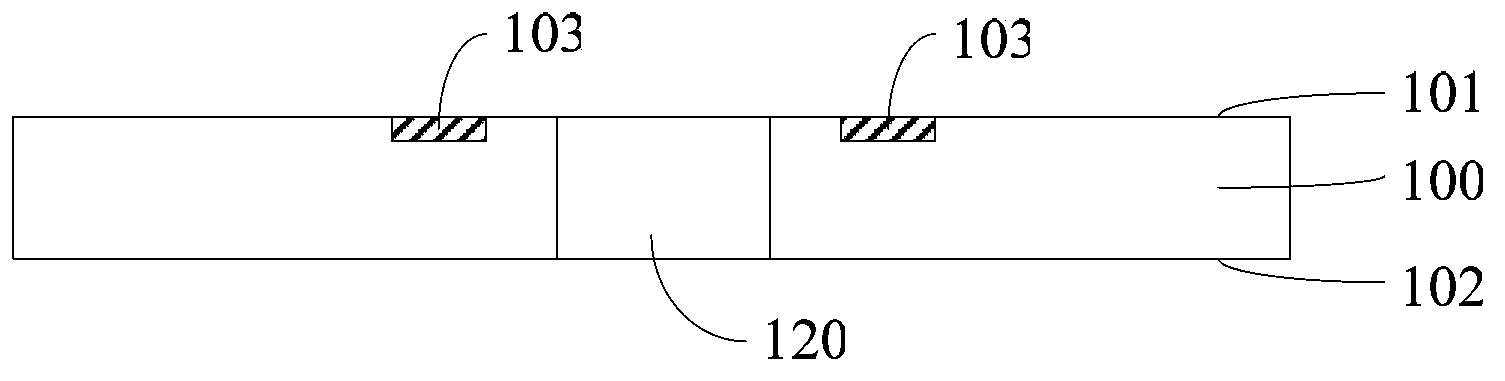

Chip cutting method and chip packaging method

ActiveCN103413785AReduce areaNo short circuitSolid-state devicesSemiconductor/solid-state device manufacturingAdhesiveInterconnection

Provided are a chip cutting method and a chip packaging method. The chip packaging method includes the steps that at least two chip structures are provided, wherein each chip structure comprises a chip and an insulating layer at least located on the side wall of the chip, the side wall of the insulating layer of each chip structure is provided with a conductive groove, the chip structures are stacked, and the conductive grooves of the different chip structures correspond to each other in position; the insides of the conductive grooves are filled with conductive adhesives, wherein circuits in the different chip structures are electrically connected through the conductive adhesives. Due to the fact that the conductive grooves are formed in the side walls of the insulating layers, the conductive adhesives formed in the conductive grooves cannot be in direct contact with the chips, and short-circuit phenomena cannot occur; due to the fact that the conductive grooves and contact welding plates are connected through metal interconnection layers on the surfaces of the insulating layers, the insulating layers cannot influence layout design of other metal interconnection structures in the chips, the chip area occupied by the metal interconnection structures can be saved, and the component integration degree of the chips can be beneficially improved.

Owner:NANTONG FUJITSU MICROELECTRONICS

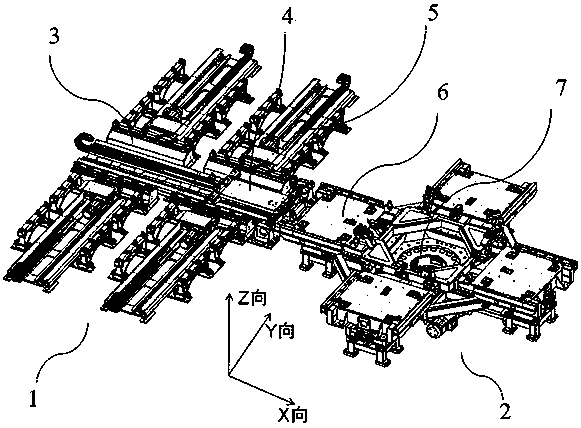

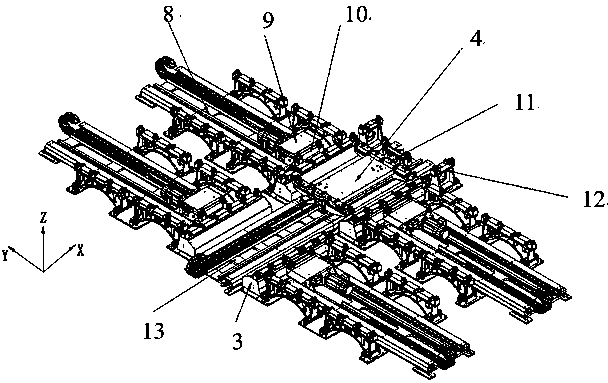

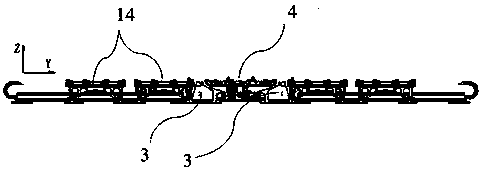

Intelligent fixture switching system

PendingCN107931937ARealize linkageShort switching timeWelding/cutting auxillary devicesAuxillary welding devicesIntelligent lightingRobotic systems

The invention provides an intelligent fixture switching system. The system comprises a storage location and a rotating table and is characterized in that the storage location comprises Z-direction lifting devices, an X-direction transferring platform and Y-direction storage locations; the rotating table comprises a plurality of switching platforms and a rotating table driver; a motor driving partof the storage location is controlled by the robot system; the storage location is docked with one of the switching platforms; and the other switching platforms continuously work. Compared with the prior art, the system provided by the invention has the advantages that the system is based on robot control and used for conveying, storing and switching fixtures to cooperate with an industrial robotfor grasping, welding and painting; the mechanical structure is flexible and the intelligent flexible production can be realized in combination with intelligent control; and therefore, the requirements for the universality, the automation and the intelligent switching of the fixtures are met, the production efficiency is greatly increased and the production cost is effectively reduced.

Owner:SHANGAHI SHOW KYOEL AUTOMOTIVE EQUIP +1

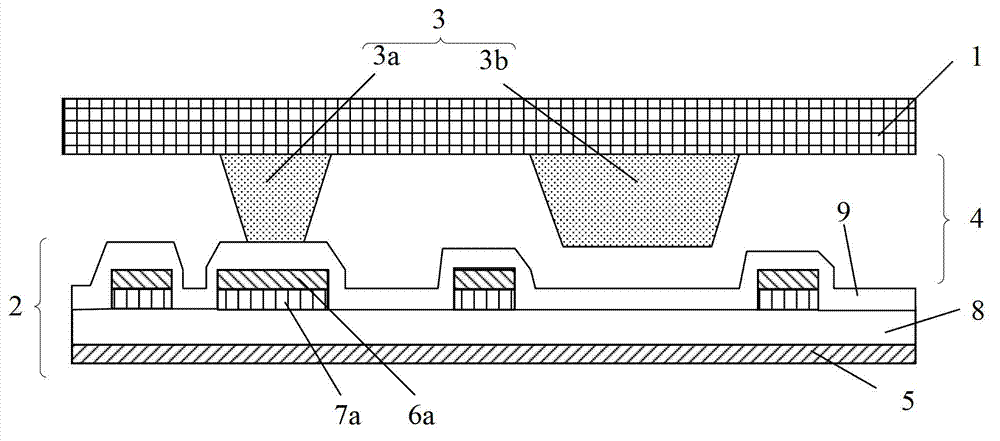

Display substrate, display device and production method of display substrate

ActiveCN108493209ASmall sizeAvoid lostSolid-state devicesSemiconductor devicesImage resolutionDisplay device

The invention discloses a display substrate, a display device and a production method of the display substrate. According to the display substrate, the display device and the production method, the product yield of the display substrate and the resolution ratio of the display device are increased. The display substrate comprises a substrate and a plurality of pixel units arrayed on the substrate,wherein the pixel units include a light-emitting diode, a connecting metal and a thin film transistor which are sequentially arranged along the direction far from the substrate; the connecting metal is electrically connected with a top electrode of the light-emitting diode; and an active layer of the thin film transistor is isolated from the connecting metal, and a drain electrode of the thin filmtransistor is conductively connected with the connecting metal.

Owner:BOE TECH GRP CO LTD

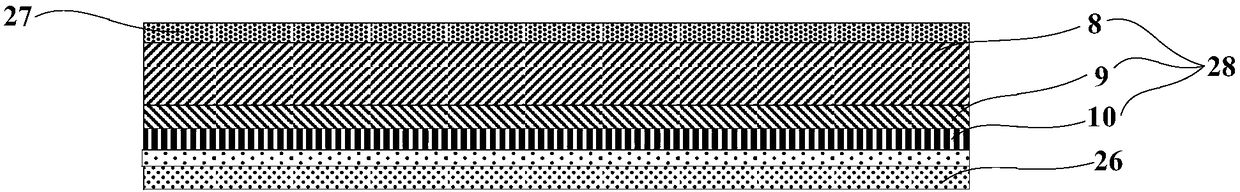

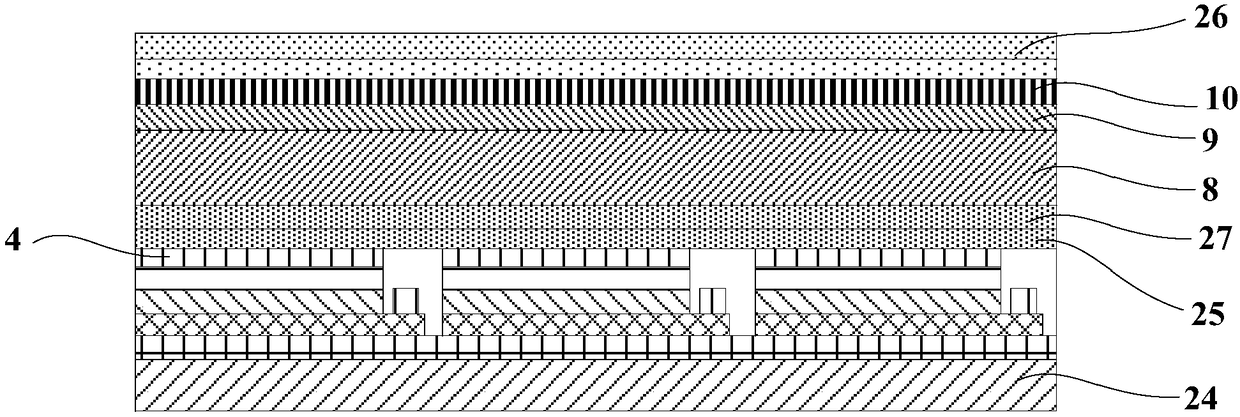

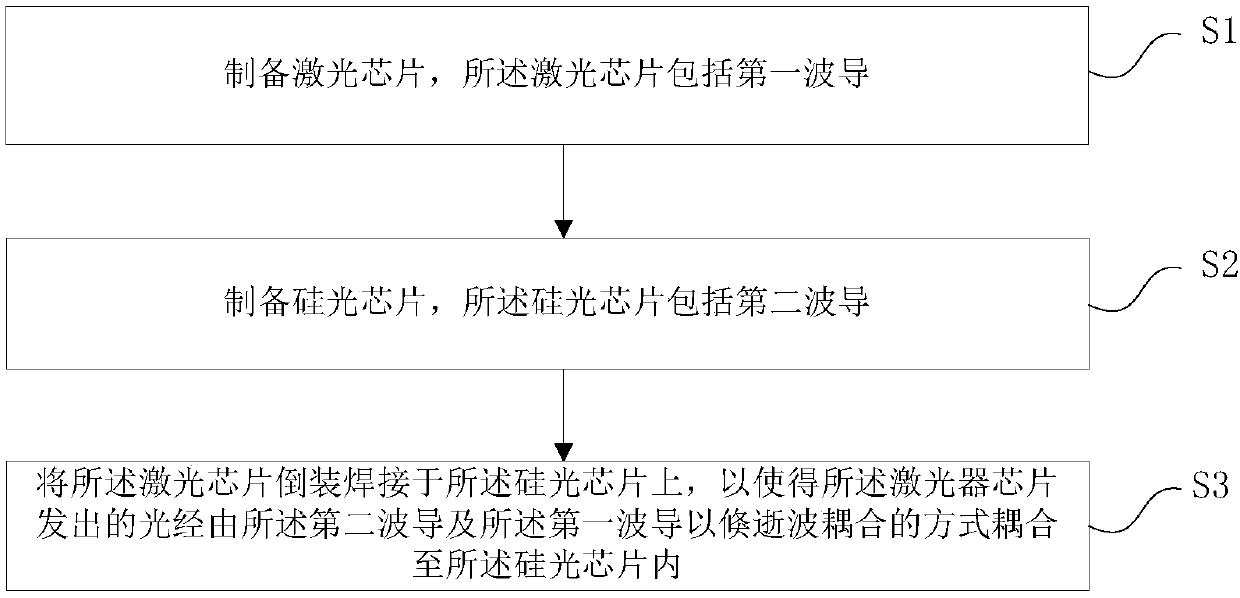

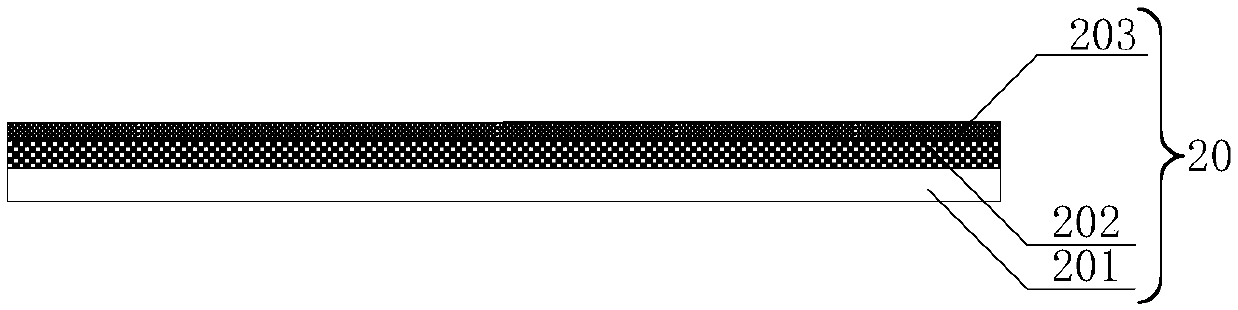

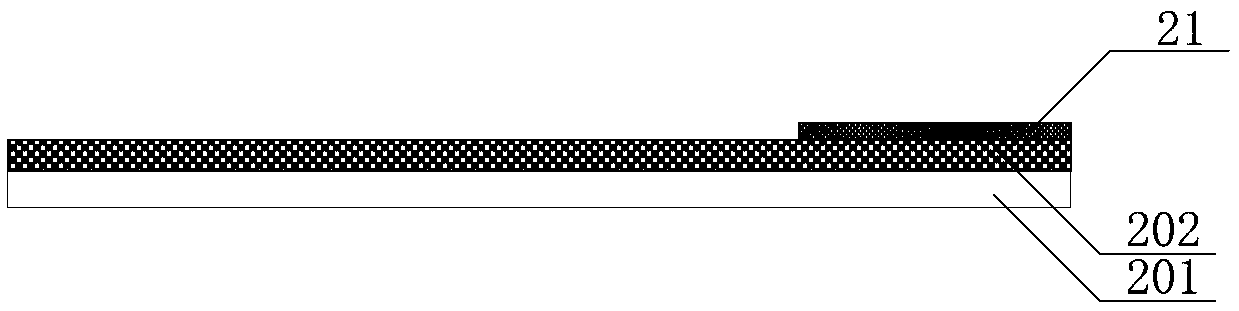

Laser and silicon optical chip integrated structure and preparation method thereof

ActiveCN110954998AReduce alignment accuracy requirementsImprove coupling efficiencyCoupling light guidesEngineeringErbium lasers

The invention provides a laser and silicon optical chip integrated structure and a preparation method thereof. The laser and silicon optical chip integrated structure comprises a laser chip which comprises a first waveguide, and a silicon optical chip which comprises a second waveguide, wherein the second waveguide and the first waveguide couple the light emitted by the laser chip into the siliconoptical chip in an evanescent wave coupling manner. According to the laser and silicon optical chip integrated structure prepared by the invention, the first waveguide in the laser and the second waveguide in the silicon optical chip couple the light emitted by the laser into the silicon optical chip in the evanescent wave coupling manner, compared with the end face coupling in the prior art, thecoupling mode has lower requirement for alignment accuracy in the flip-chip bonding process, and still has higher coupling efficiency even under the actual process condition that alignment has errors.

Owner:SHANGHAI IND U TECH RES INST

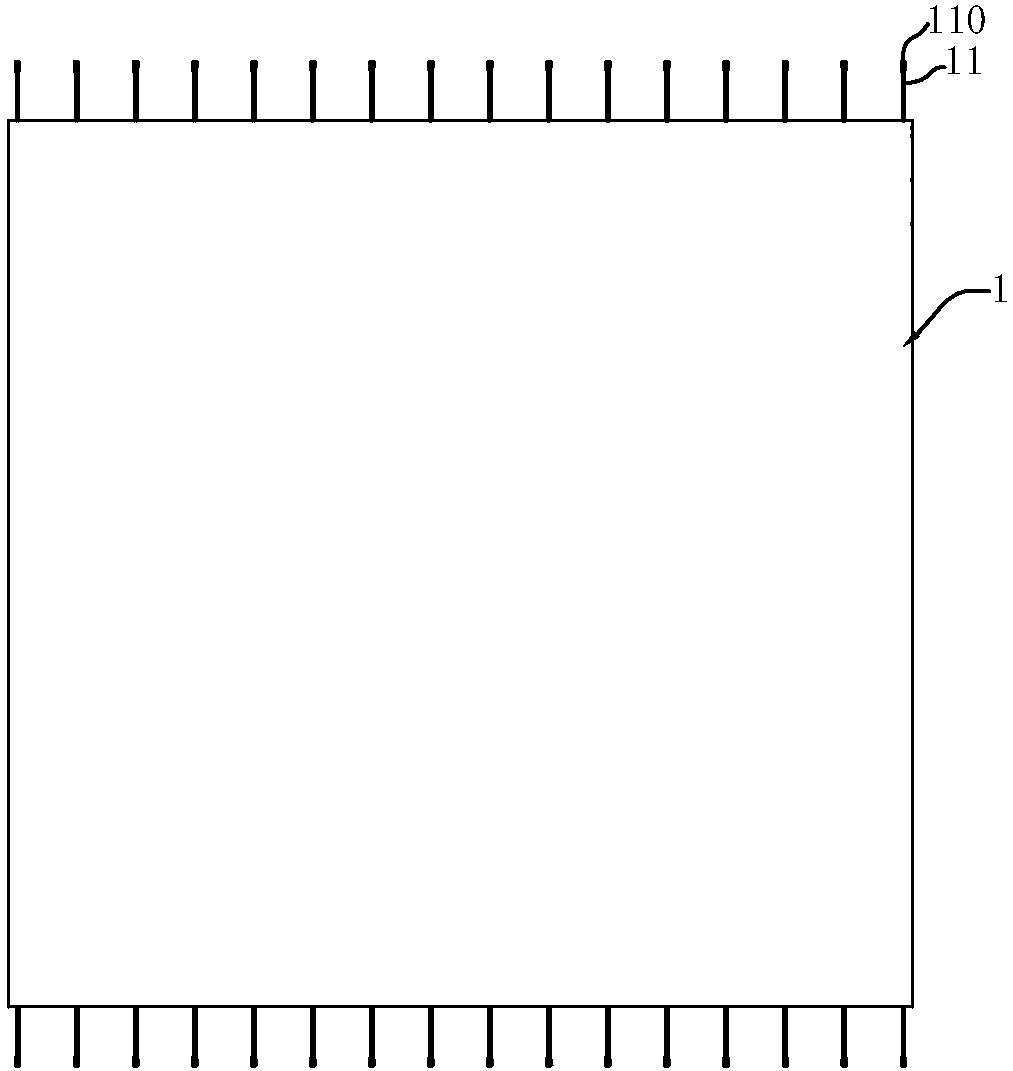

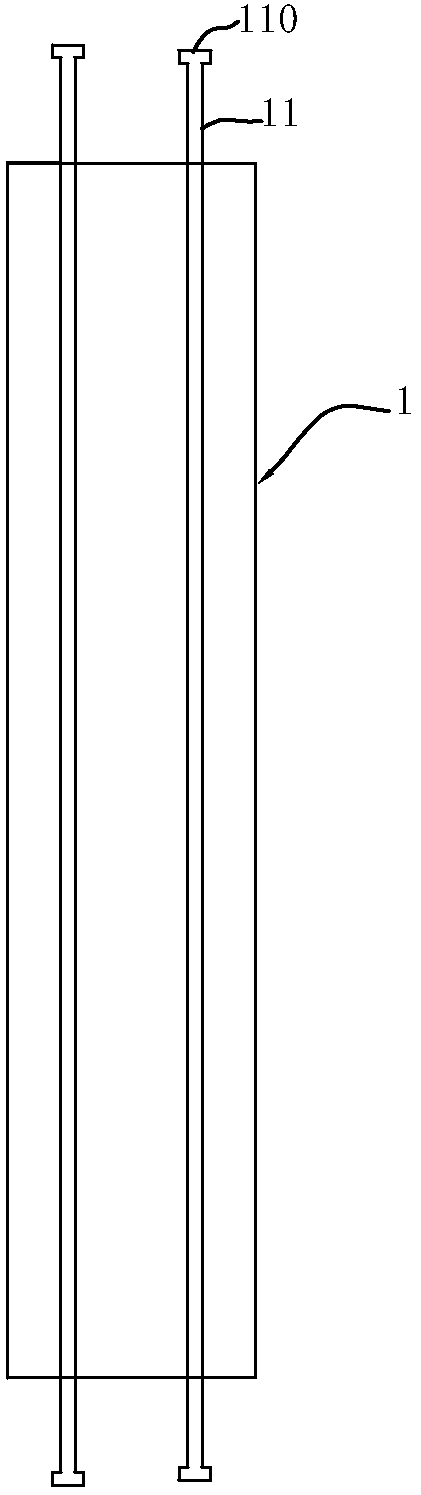

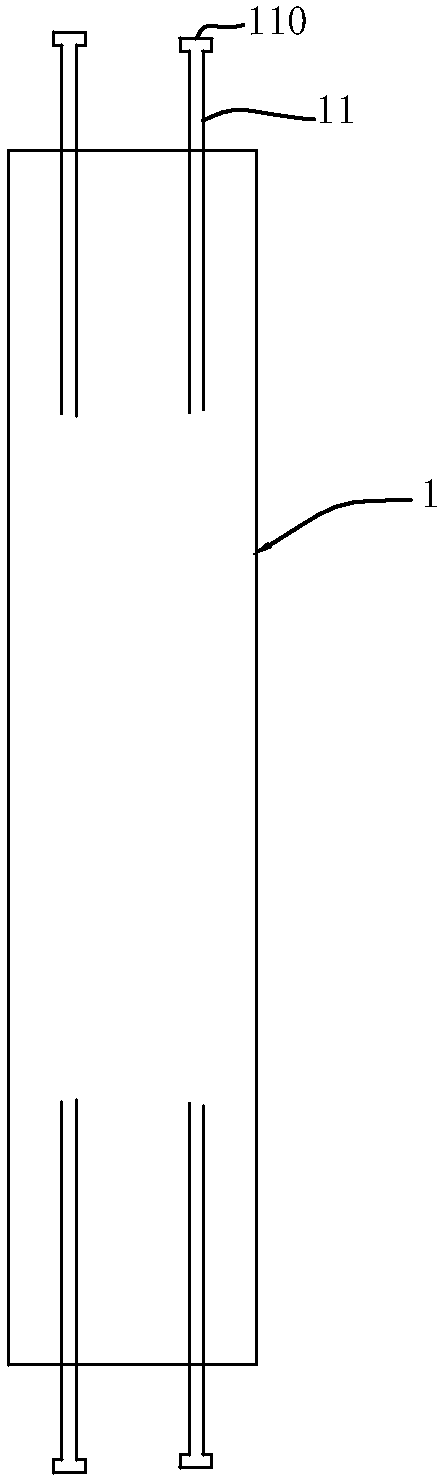

Prefabricated wall panel and connecting structure and construction method thereof

The invention relates to a prefabricated wall panel and a connecting structure and a construction method thereof. The prefabricated wall panel comprises a wall panel die block, connecting steel bars are pre-embedded in the upper and lower end surfaces of the wall panel die block, expanded feet are fixed at the ends, extending out of the wall panel die block, of the connecting steel bars, and the sizes of the expanded feet are greater than the outer diameters of the connecting steel bars. The prefabricated wall panels, adjacent to each another in the horizontal direction, of the multiple prefabricated wall panels are spliced to form to be in the shape of a line, T, L or cross, and vertical post-pouring belts are formed at the joints of the prefabricated wall panels. The construction methodcomprises the steps that lower prefabricated wall panels are pre-installed, the lower precast wall panels are installed, supported and located, so that horizontal post-pouring belt space is reserved between the upper and lower prefabricated wall panels; the connecting steel bars of the upper and lower prefabricated wall panels are connected with sleeves; and horizontal post-pouring concrete is poured, so that cement slurry flows into the sleeves. The prefabricated wall panel obtained by the construction method has good connecting integrity and high seismic resistance.

Owner:李藏柱

Chip structure and chip packaging structure

ActiveCN103413798AReduce areaNo short circuitSemiconductor/solid-state device detailsSolid-state devicesAdhesiveInterconnection

Provided are a chip structure and a chip packaging structure. The chip packaging structure comprises at least two chip structures and conductive adhesives located in conductive grooves, wherein the side walls of the chip structures are provided with the conductive grooves, the chip structures are stacked, the conductive grooves of the stacked chip structures correspond in position, and circuits in the stacked chip structures are electrically connected through the conductive adhesives. Due to the fact that the conductive grooves are formed in the side walls of insulating layers, the conductive adhesives formed in the conductive grooves later cannot be in direct contact with chips, and short-circuit phenomena cannot occur; due to the fact that the conductive grooves and contact welding plates are connected through metal interconnection layers on the surfaces of the insulating layers, the insulating layers cannot influence layout design of other metal interconnection structures in the chips, the practice that extra metal interconnection structures are designed due to positions of the contact welding plates is needless, the chip area occupied by the metal interconnection structures can be saved, and the component integration degree of the chips can be beneficially improved.

Owner:NANTONG FUJITSU MICROELECTRONICS

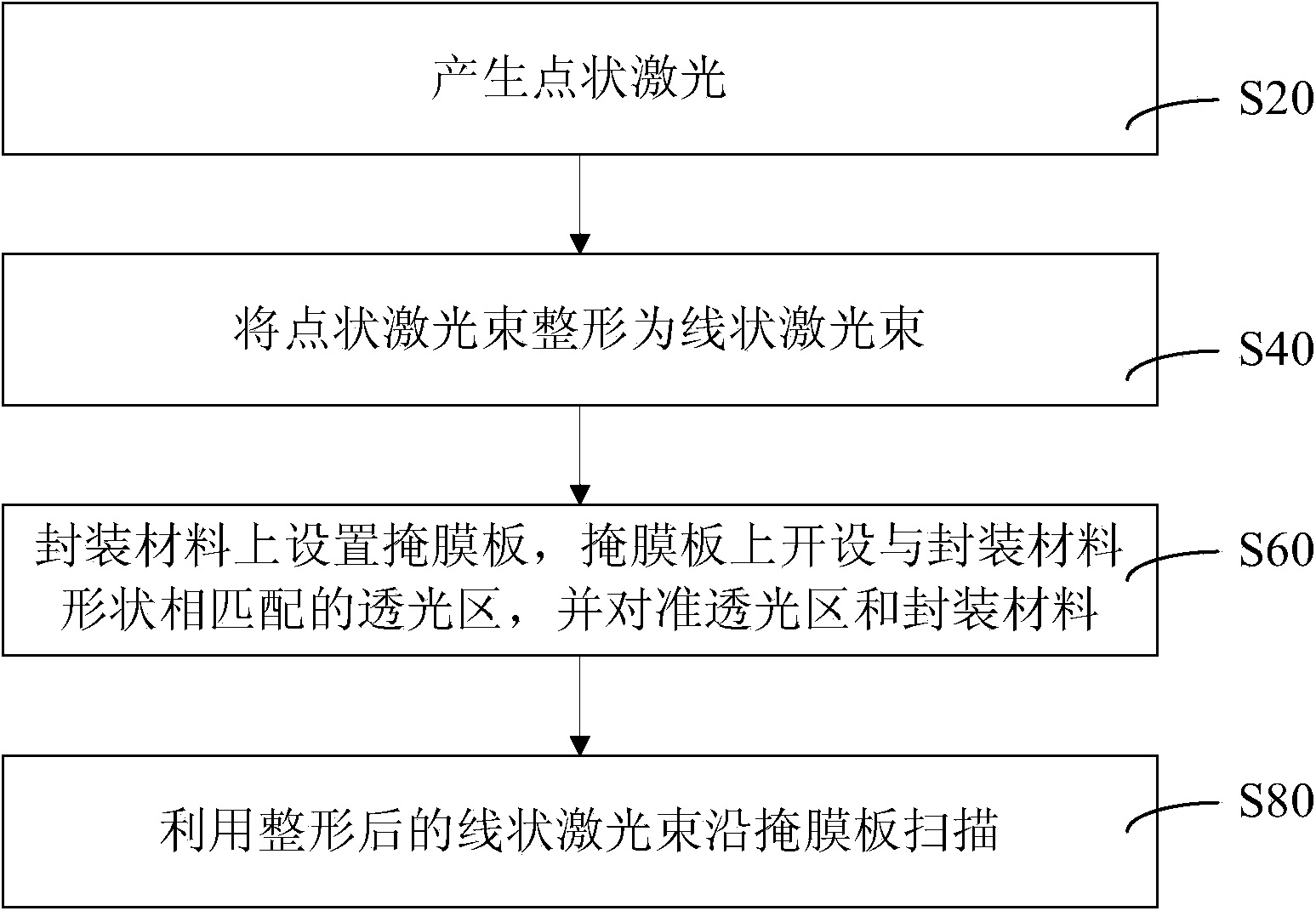

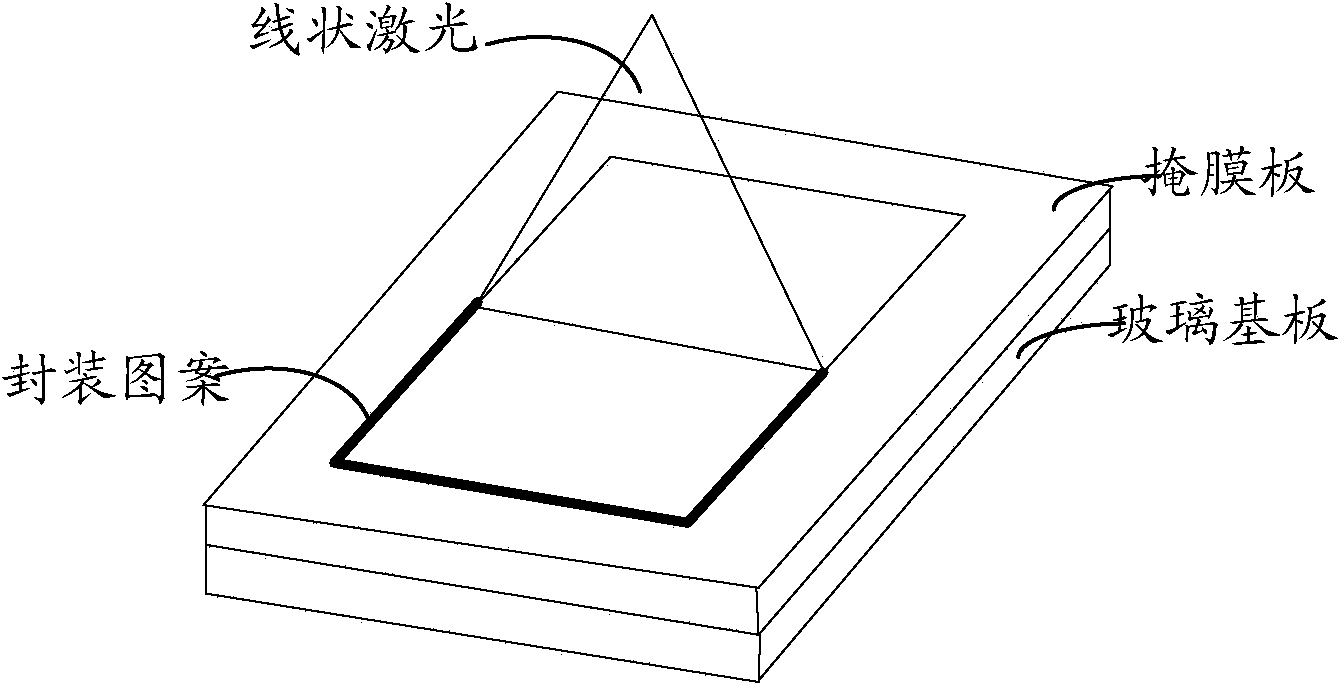

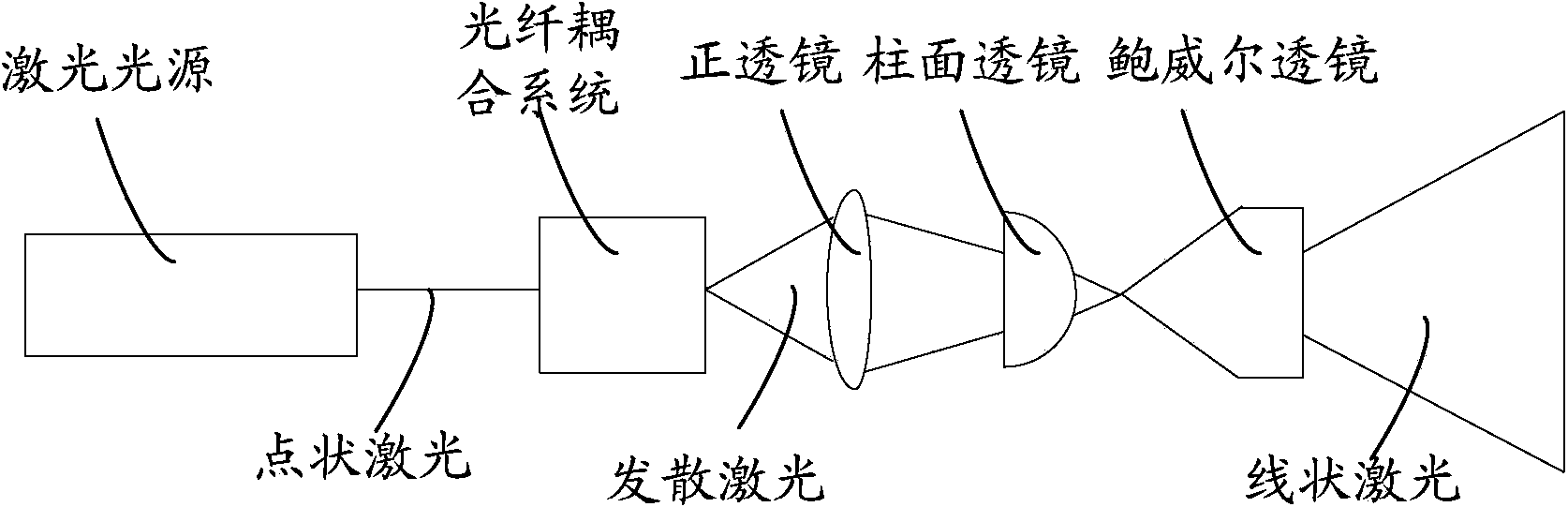

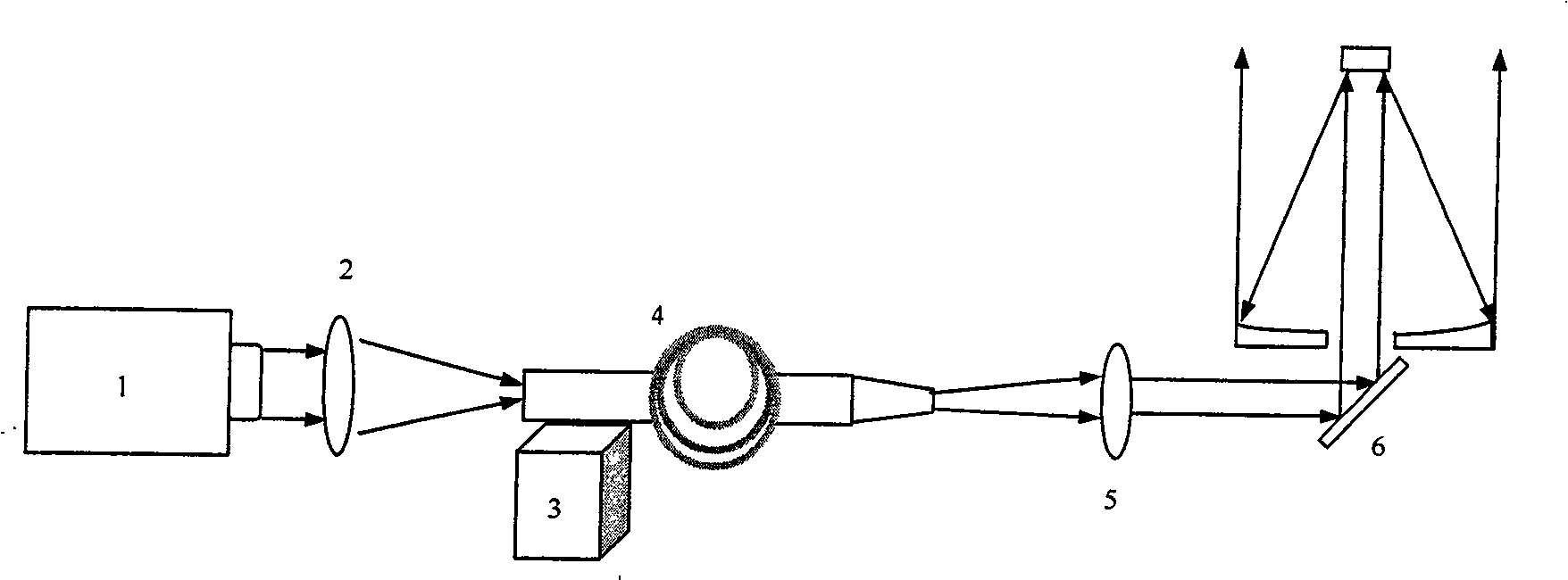

Laser packaging method and equipment

ActiveCN103466922AAchieve irradiationReduce alignment accuracy requirementsGlass reforming apparatusLight beamOptoelectronics

A laser packaging method includes the steps of generating dotted laser beams, shaping the dotted laser beams into linear laser beams, arranging a mask plate on a packaging material, forming a light transmitting zone of which the shape is matched with the shape of the packaging material on the mask plate, aligning the mask plate to the light transmitting zone and the packaging material, and utilizing the linear laser beams to scan the mask plate. By the adoption of the laser packaging method, after the mask plate and sealing patterns are aligned, the linear laser beams scan and irradiate the mask plate, irradiation and hot melting of the whole sealing patterns can be achieved, and the packaging efficiency is improved. After the mask plate and sealing patterns are aligned, laser can accurately irradiate a packaging zone, and the requirement for aligning accuracy of the laser beams is reduced.

Owner:SHANGHAI UNIV

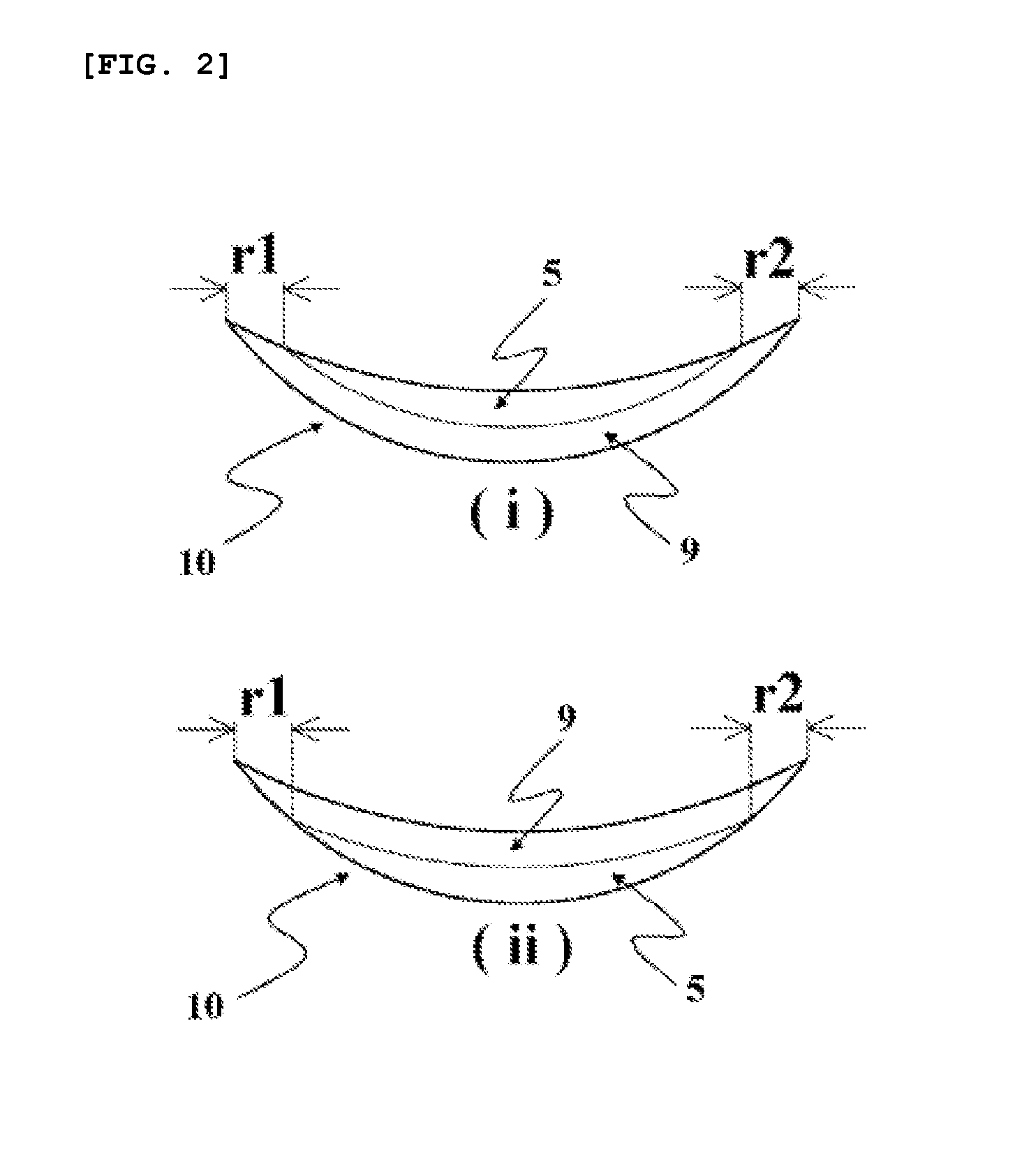

Multilayer contact lens and production process therefor

InactiveUS20150137397A1Reduce alignment accuracy requirementsLow costSpectales/gogglesOptical articlesEngineeringWork in process

A method for manufacturing a contact lens having a multilayer structure using a mold, includes: (a) charging a first polymerizing composition into a space formed by combining a first mold with a second mold, and polymerizing a first semi product having a thinner thickness and a smaller outer diameter than those of a contact lens immediately before being removed from the molds after all polymerizing processes; (b) opening the first and second molds; and (c) charging a second polymerizing composition into a space formed by combining a third mold with one of the first and second mold, the first semi product fixed onto the one of the first and second molds, and polymerizing the second polymerizing composition.

Owner:MENICON NECT

Image sensor module with optical path delimiter and accurate alignment

InactiveUS7397023B2Reduce alignment accuracy requirementsImprove accuracySolesPrintersEngineeringSynthetic resin

Owner:SHARP KK

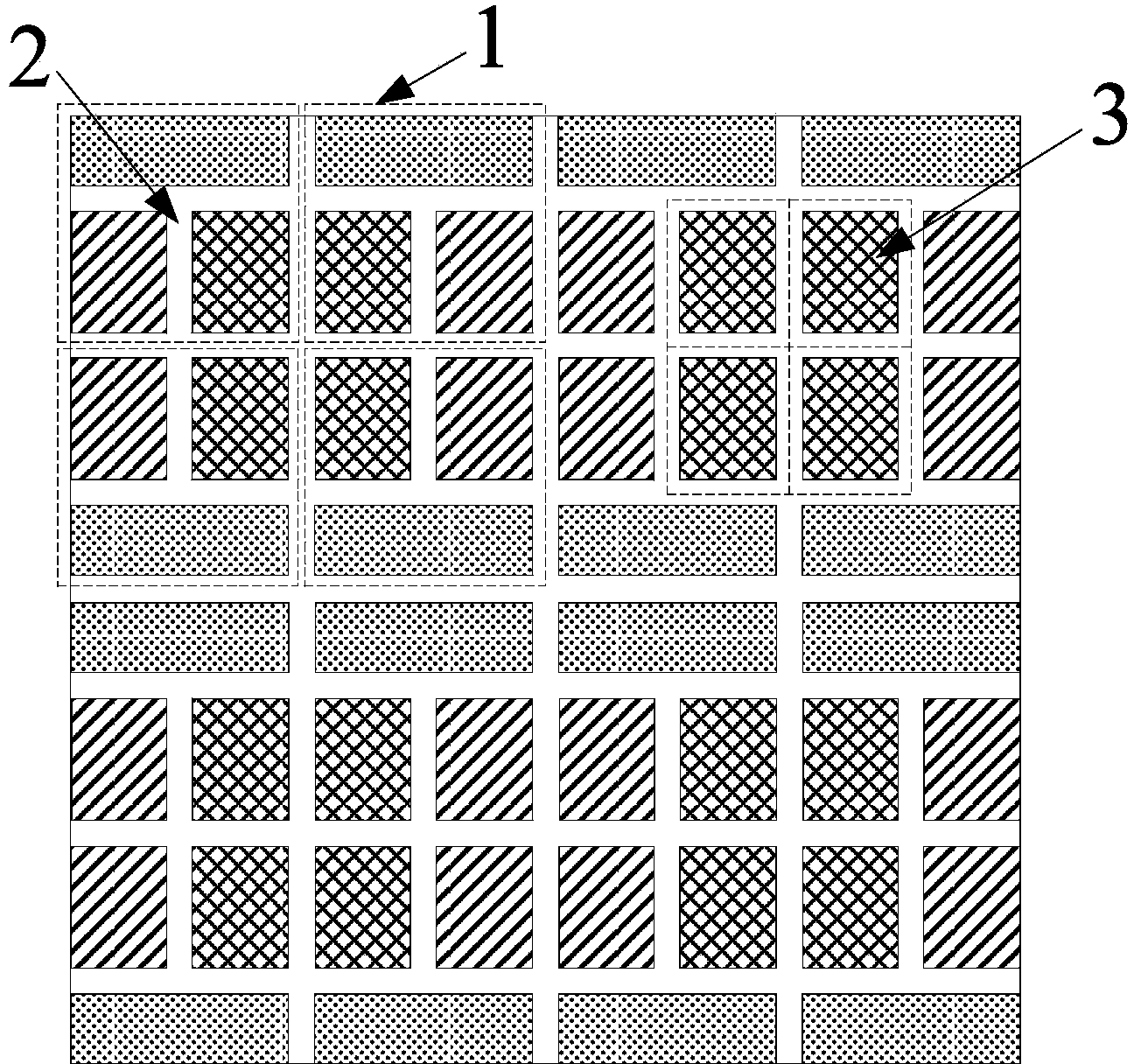

High-resolution OLED device and masking plate for manufacturing same

InactiveCN104393012AImprove resolutionSmall sizeSolid-state devicesVacuum evaporation coatingChinese charactersComputer science

A high-resolution OLED device comprises pixel units which are distributed into matrixes, each pixel unit comprises four pixels, and each pixel comprises a red sub-pixel, a green sub-pixel and a blue sub-pixel; each red sub-pixel, the corresponding green sub-pixel and the corresponding blue sub-pixel are distributed in a shape like a Chinese character 'pin' in the corresponding pixel, and the red sub-pixels, the green sub-pixels and the blue sub-pixels of every two adjacent pixels in each pixel unit are symmetrical with respect to the public edge of the corresponding pixels. The high-resolution OLED device has the advantages that a manufacturing method is based on the proven FMM technique in the industry, but according to the special pixel distribution mode, a MASK evaporated with organic light-emitting materials is in a mesh shape, and each open hole corresponds to four sub-pixels. Under the situation of the same resolution, sizes of the open holes and sizes of connection bridges of the MASK are larger. A high-resolution OLED display screen can be manufactured on the basis the proven FMM technique in the industry; alternatively under the situation of the same resolution, the requirement for MASK processing and OLED display screen manufacturing processes can be reduced, and improvement on the product yield is facilitated.

Owner:SICHUAN CCO DISPLAY TECH

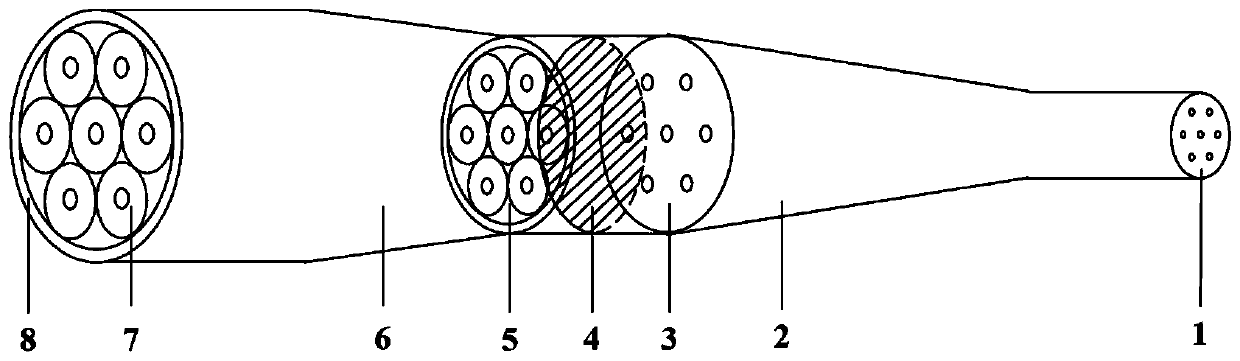

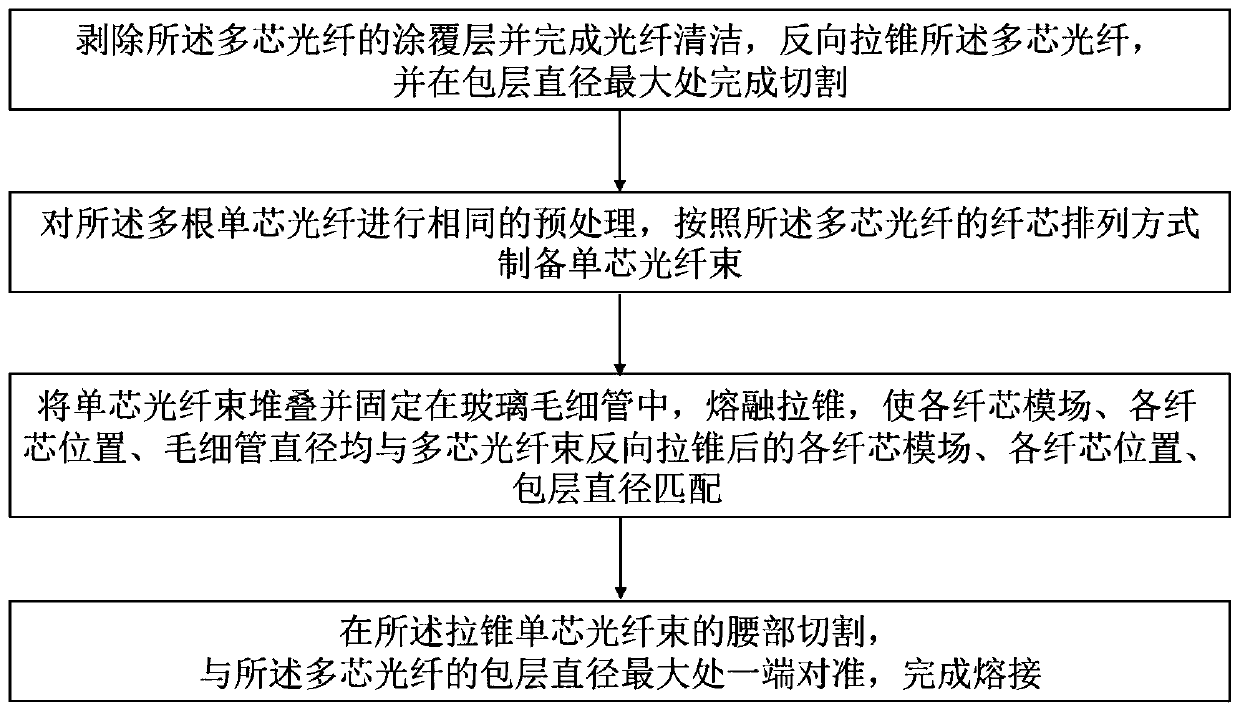

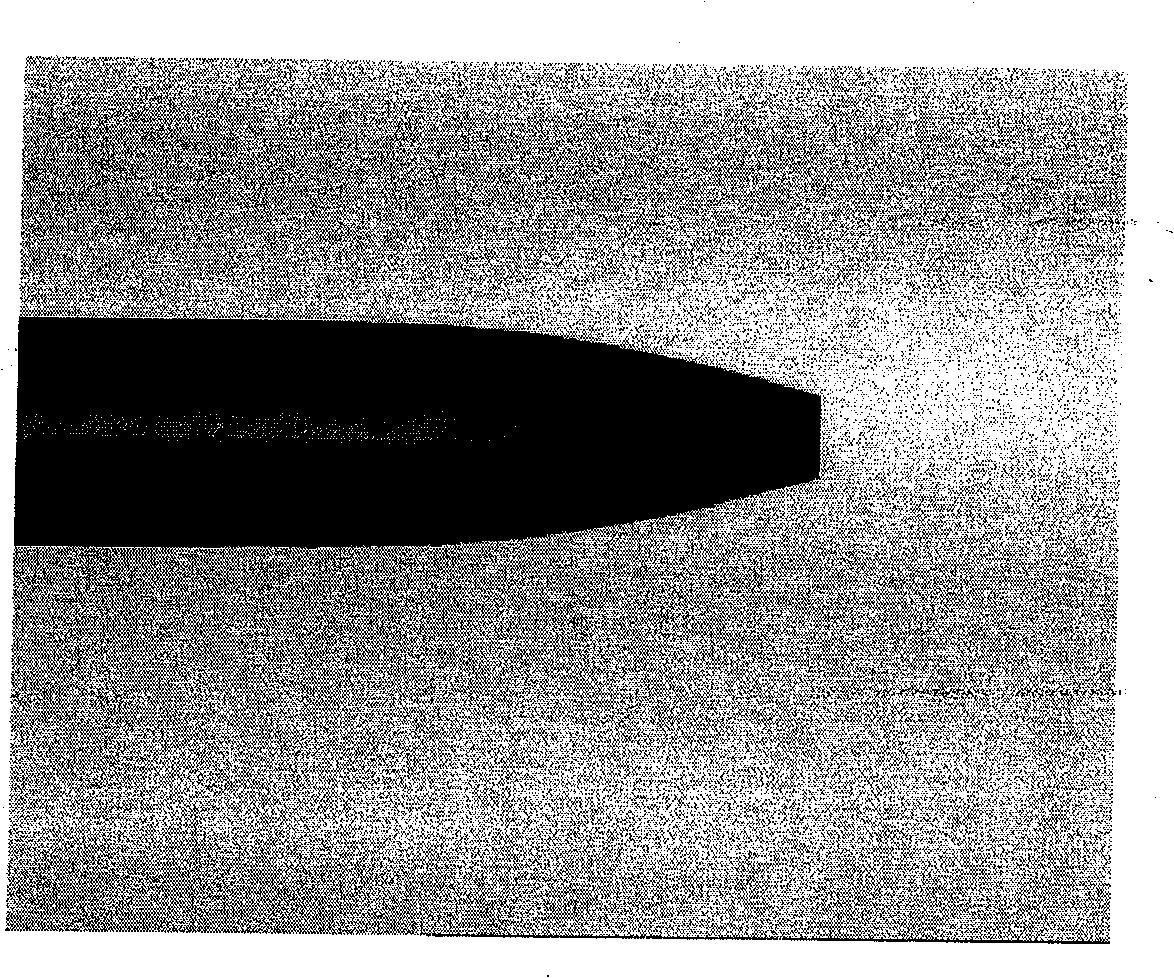

Multi-core optical fiber coupler preparation method based on reverse tapering technology

ActiveCN110488417AReduce sensitivityLarge mode field diameterCoupling light guidesFiberWeld strength

The invention belongs to the technical field of optical fiber communication, and particularly relates to a multi-core optical fiber coupler preparation method based on reverse tapering technology. Themethod comprises the following steps: stripping a coating layer of a multi-core optical fiber, reversely tapering the multi-core optical fiber, and finishing cutting at the position with the maximumcladding diameter; preprocessing the plurality of single-core optical fibers, and preparing a single-core optical fiber bundle according to a fiber core arrangement mode of the multi-core optical fibers; stacking and fixing the single-core optical fiber bundle in a glass capillary tube, and performing fused biconical taper to enable each fiber core mode field, each fiber core position and the diameter of the capillary tube to be matched with each fiber core mode field, each fiber core position and the cladding diameter after reverse biconical taper of the multi-core optical fiber bundle; and cutting the waist of the tapering single-core optical fiber bundle, and aligning with one end of the maximum cladding diameter of the multi-core optical fiber to finish welding. According to the method, the alignment precision requirement can be reduced, and the optical coupling efficiency between multiple single-core optical fibers and each core of the multi-core optical fiber can be effectively improved; inter-core crosstalk during coupling is effectively suppressed, and meanwhile, the welding strength is improved.

Owner:FUDAN UNIV

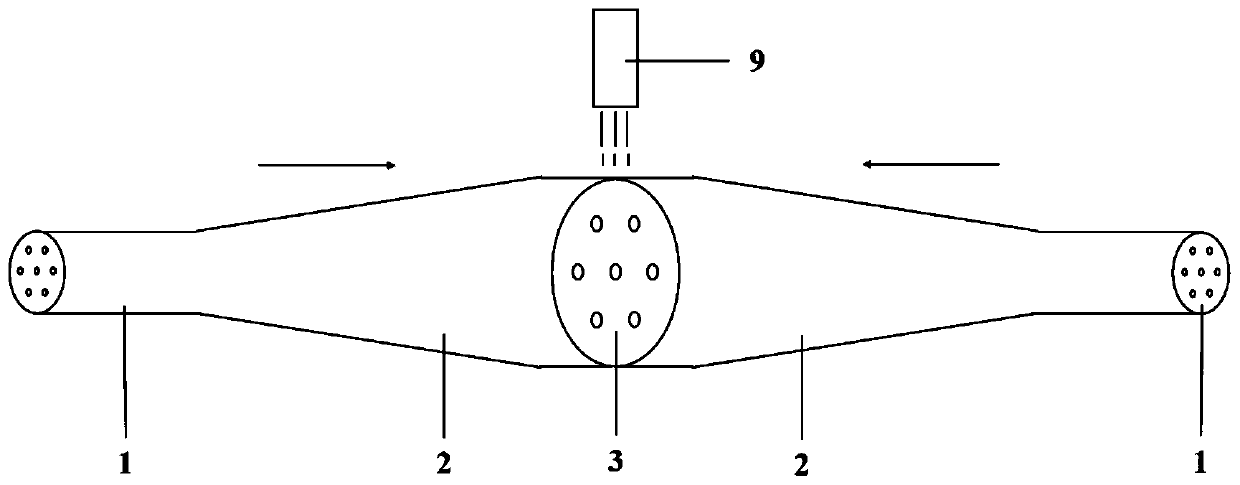

Laser beam optical fiber transmission device in laser sodium guiding technology

InactiveCN101271176AImprove power conversion efficiencyLarge core diameterGlass making apparatusCladded optical fibreFiberLight beam

A laser beam optical fiber transmission device of a laser sodium guide star technology is characterized in that: the device uses a cylindrical multimode optical fiber for producing a conical shape by adopting the melt-pulling method for pulling, then a table is formed by grinding, the device comprises: a cylindrical multimode optical fiber part and a conical table optical fiber part, the conical table optical fiber part is formed at the tail end of the cylindrical multimode optical fiber by direct processing, the other end of the cylindrical multimode optical fiber is an input end of a laser beam, the other end of the conical table optical fiber is an output end of the laser beam, the length of the cylindrical multimode optical fiber is equal to 1 to 1.2 times of the distance from a laser to a transmitting telescope; the radius of a fiber core of the conical table optical fiber which is arranged at the thick end is equal to the radius of the fiber core of the cylindrical multimode optical fiber, and the radius of the fiber core of the conical table optical fiber which is arranged at the thin end meets the single-mode condition for transmitting the laser by the optical fiber. The optical fiber transmission device has the advantages of simple and flexible structure and low cost, the quality of the output light beam is close to the diffraction limit, at the same time, the optical fiber transmission device can effectively overcome the non-linear scattering and other effects during the optical fiber transmission, thus achieving the purpose of transmitting the higher laser power.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

Display panel and method for fabricating the same

InactiveUS20080160871A1High mechanical strengthSufficient strength against external stressSolid-state devicesSemiconductor/solid-state device manufacturingSurface plate

Owner:SHARP KK

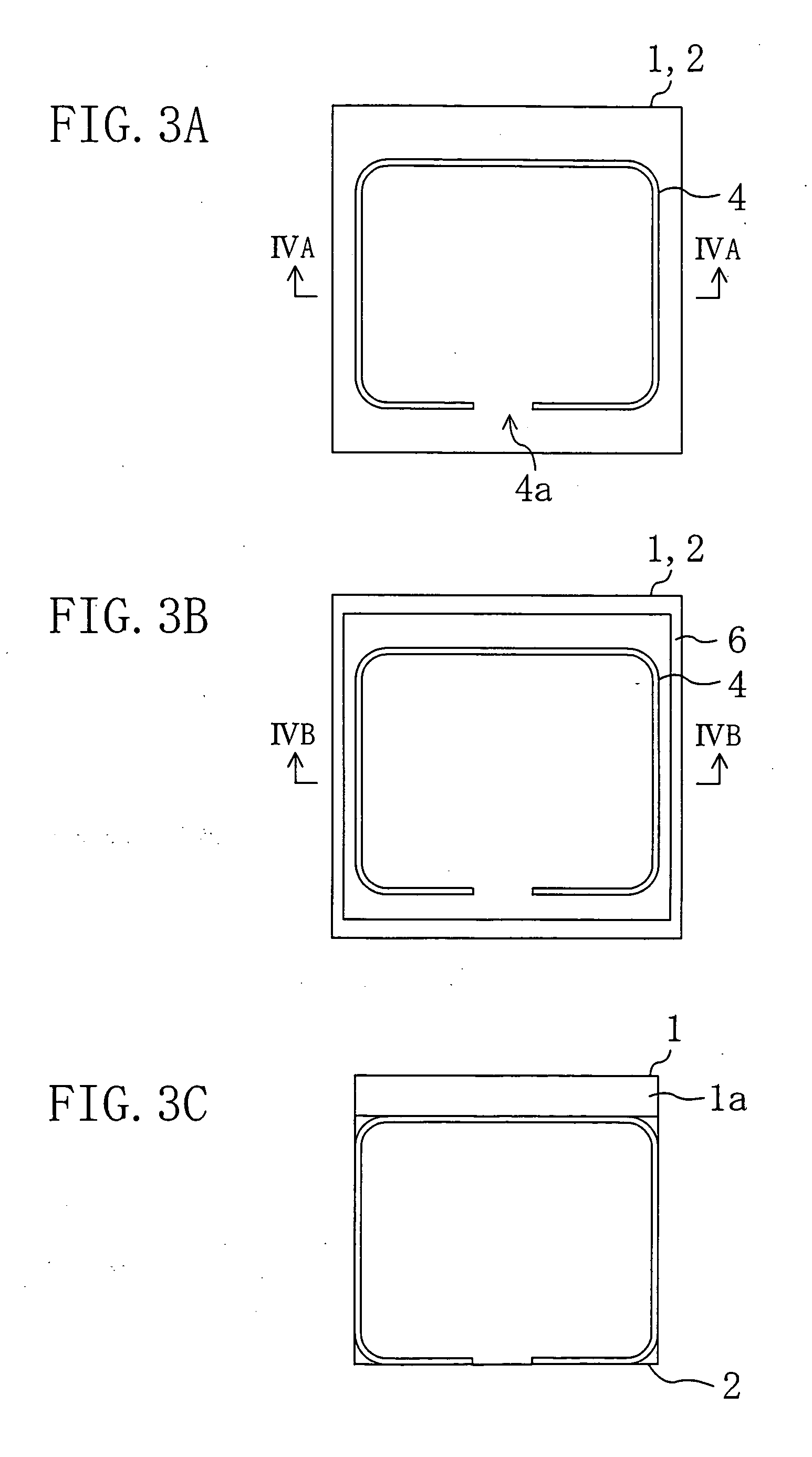

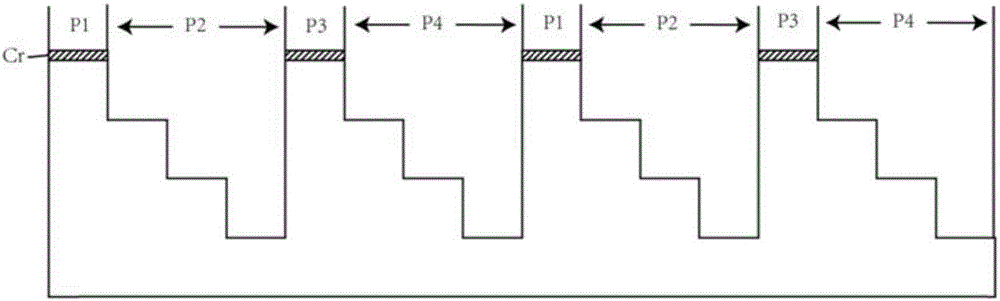

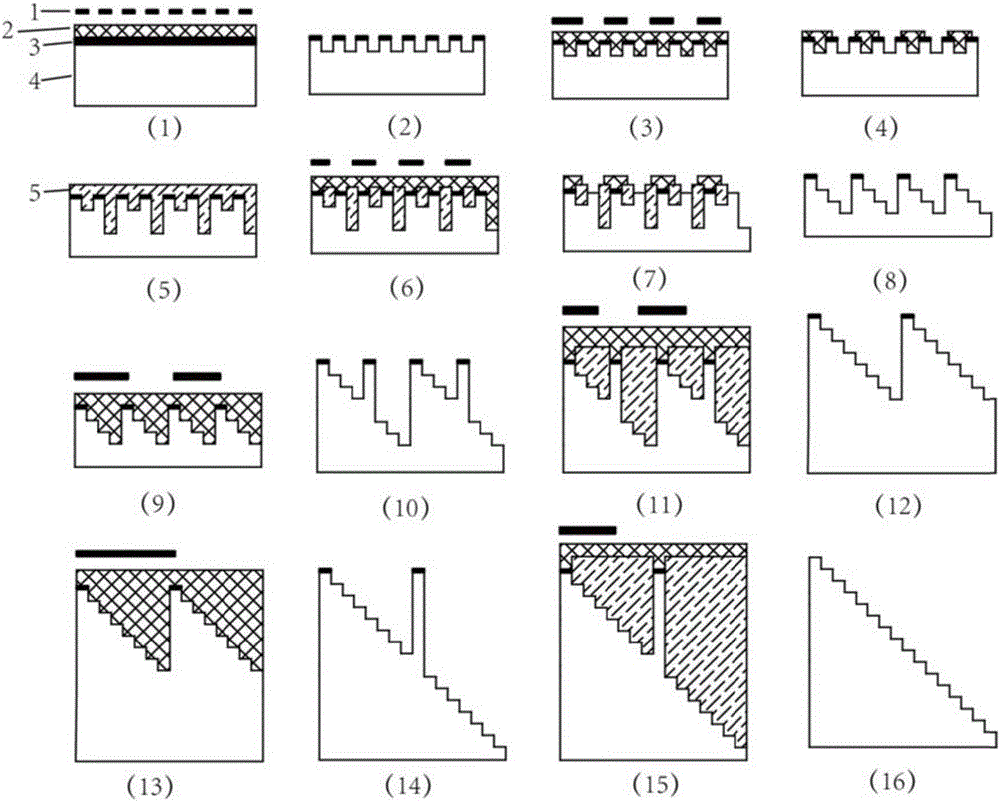

Making method of large-caliber film diffraction element with high diffraction efficiency

ActiveCN106154382AReduce alignment accuracy requirementsGood repeatabilityDiffraction gratingsChemistryCaliber

The invention provides a making method of a large-caliber film diffraction element with high diffraction efficiency to solve technical problems existing in a present preparing process of large-caliber film diffraction elements. The method includes the first step of making of a multi-step relief structure quartz substrate, the second step of polymer solution coating, the third step of polymer solution curing and film forming, the fourth step of film and substrate separating, and the fifth step of film splicing. The method has the advantages of being low in cost, high in repeatability, simple and efficient. The diffraction efficiency of the element made with the method is not lower than 7%.

Owner:UNIV OF SCI & TECH OF CHINA

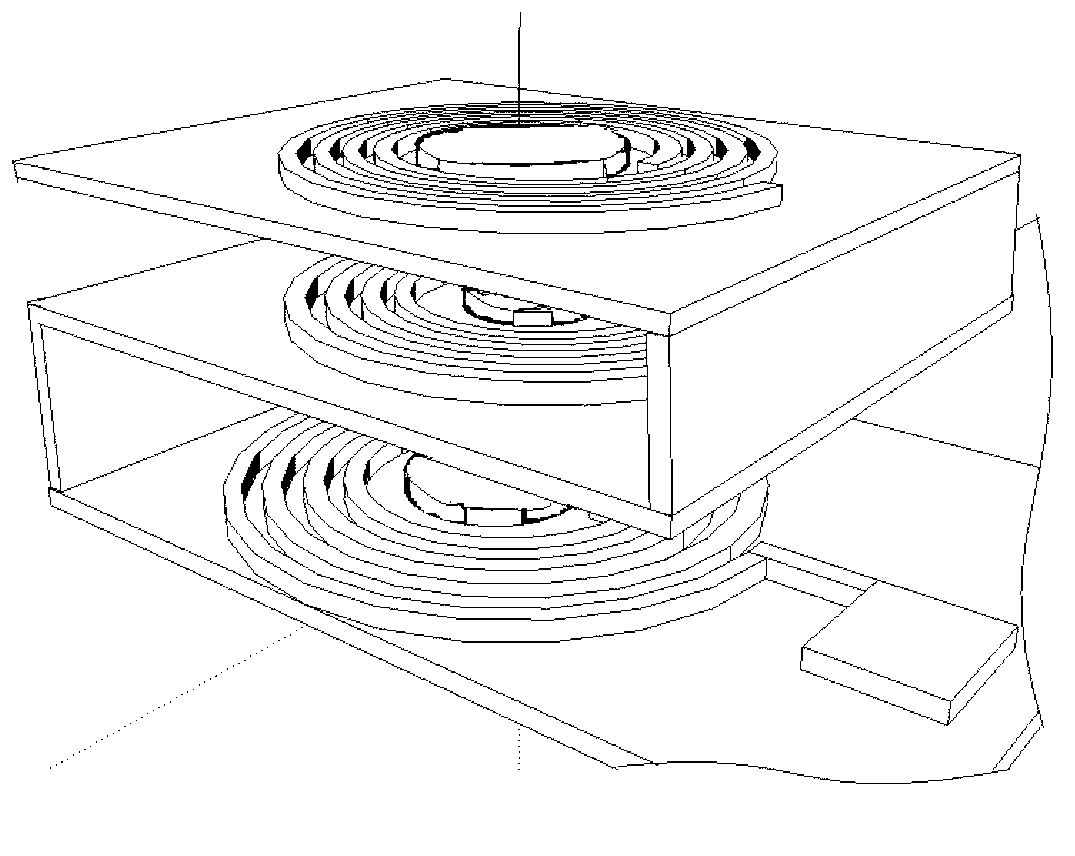

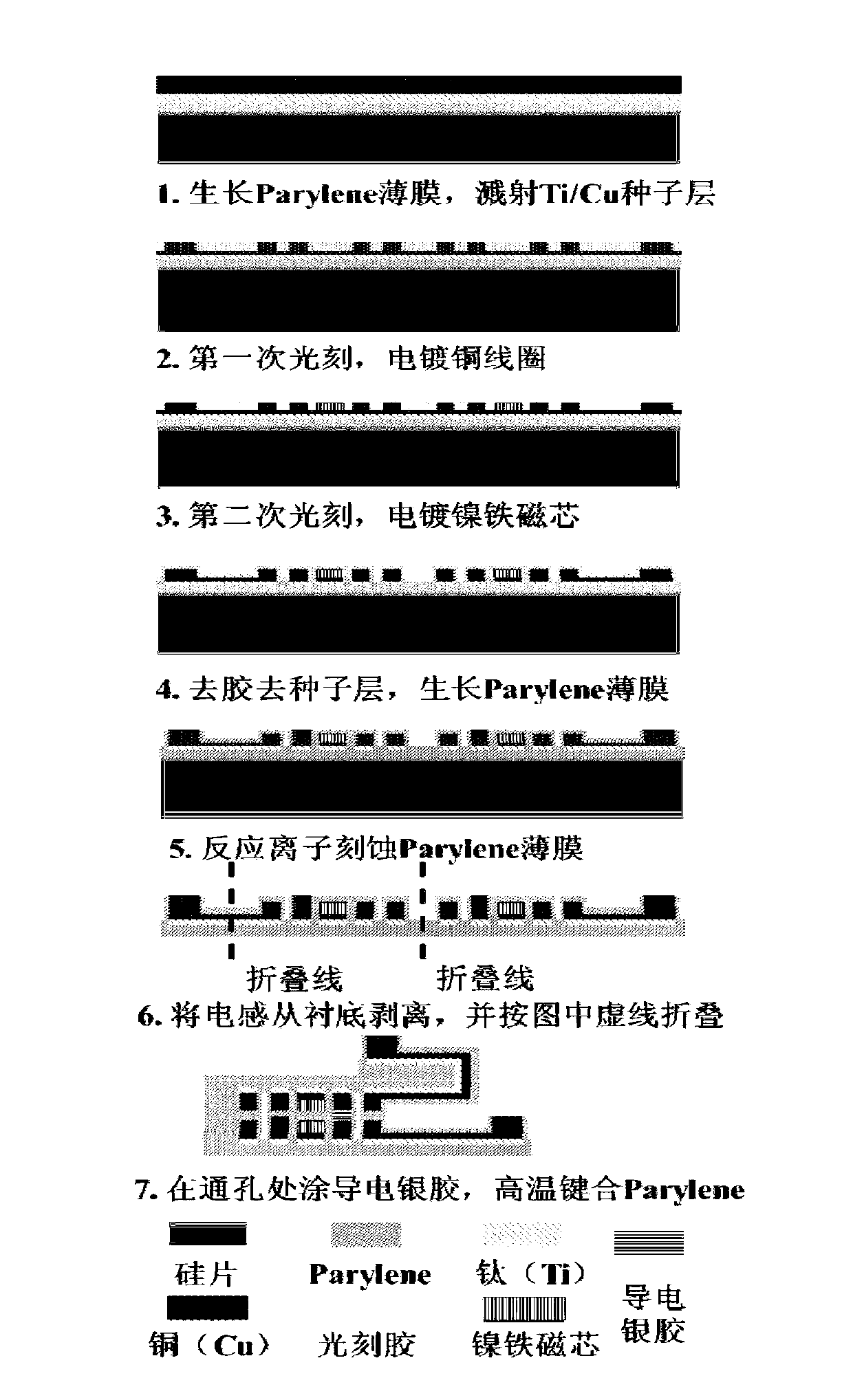

Preparation method of flexible substrate-based folding spiral inductor provided with magnetic core

ActiveCN103000362AReduce manufacturing costReduce defective rateDecorative surface effectsInductances/transformers/magnets manufactureMicro nanoBiochemical engineering

The invention relates to the field of micro-nano machining, and in particular relates to a preparation method of a flexible substrate-based folding spiral inductor provided with a magnetic core; the folding spiral inductor is obtained by combining a preparation method of a plane inductor with folding; compared with the inductor which is not folded, the folding spiral inductor has obviously improved performances; and compared with a three-dimensional inductor prepared by the traditional technology, the folding spiral inductor has the advantages of being simple in processing steps and low in cost. The folding spiral inductor prepared by the method has the characteristics of being good in performances, small in volume, flexible (bended and folded), good in biological compatibility, simple in preparation method and the like, can be widely applied to various biological and non-biological microsystems, and is especially used for an implantable wireless energy transmission system.

Owner:PEKING UNIV

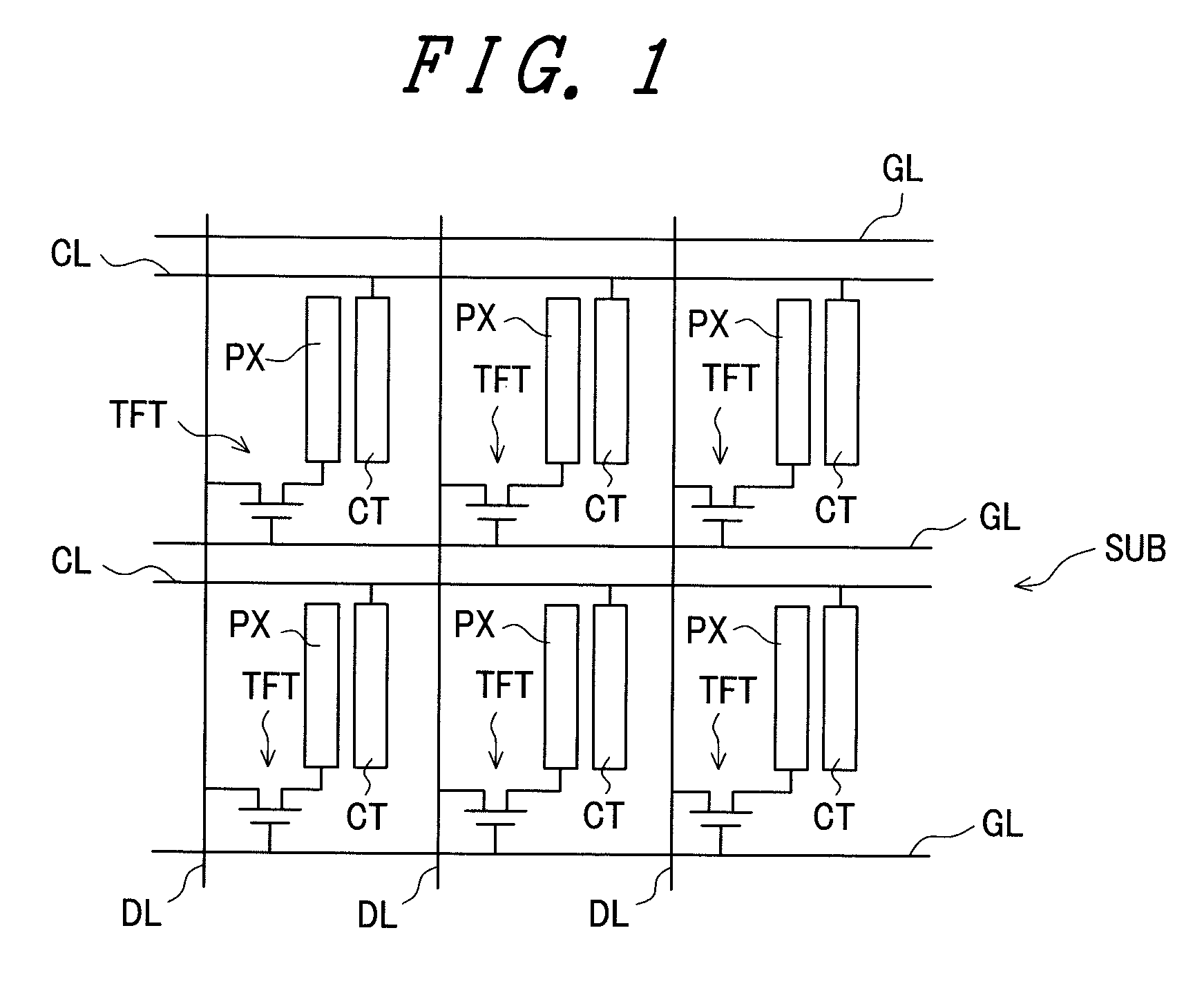

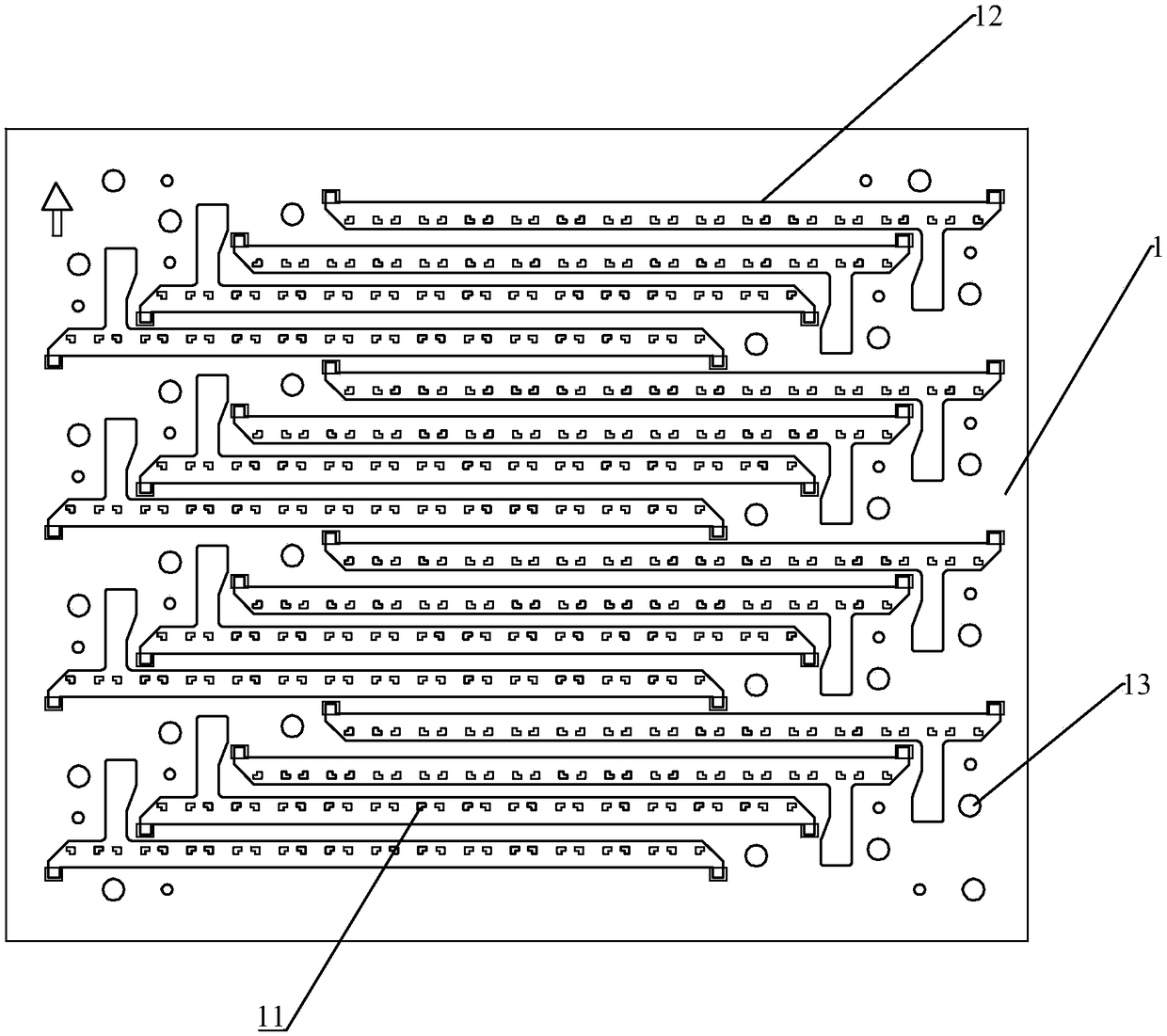

Array substrate of thin film transistor (TFT)-liquid crystal display (LCD) and manufacture method thereof

ActiveCN102566155ASimple arrangementWithout changing the widthSolid-state devicesSemiconductor/solid-state device manufacturingLiquid-crystal displayInsulation layer

An embodiment of the invention discloses an array substrate of a thin film transistor (TFT)-liquid crystal display (LCD) and a manufacture method thereof, which relate to the technical field of liquid crystal displays and can reduce storage capacity when aligning accuracy is not high. The array substrate comprises a substrate, grid lines and data lines, wherein the grid lines and the data lines are arranged on the substrate. Each grid line and each data line intersect to define a pixel unit which comprises the TFT, a pubic electrode, a first pixel electrode layer and a second pixel electrode layer, wherein the first pixel electrode layer and the second pixel electrode layer are separated by an insulation layer. The first pixel electrode layer is connected with the pubic electrode and comprises a plurality of first pixel electrodes separated by first pixel electrode layer openings. The second pixel electrode layer is connected with a drain electrode of the TFT and comprises a plurality of second pixel electrodes separated by second pixel electrode layer openings. The second pixel electrode comprises overlaying-position pixel electrodes completely overlaid on the first pixel electrodes and opening-position pixel electrodes with edges completely in the first pixel electrode layer openings.

Owner:BOE TECH GRP CO LTD +1

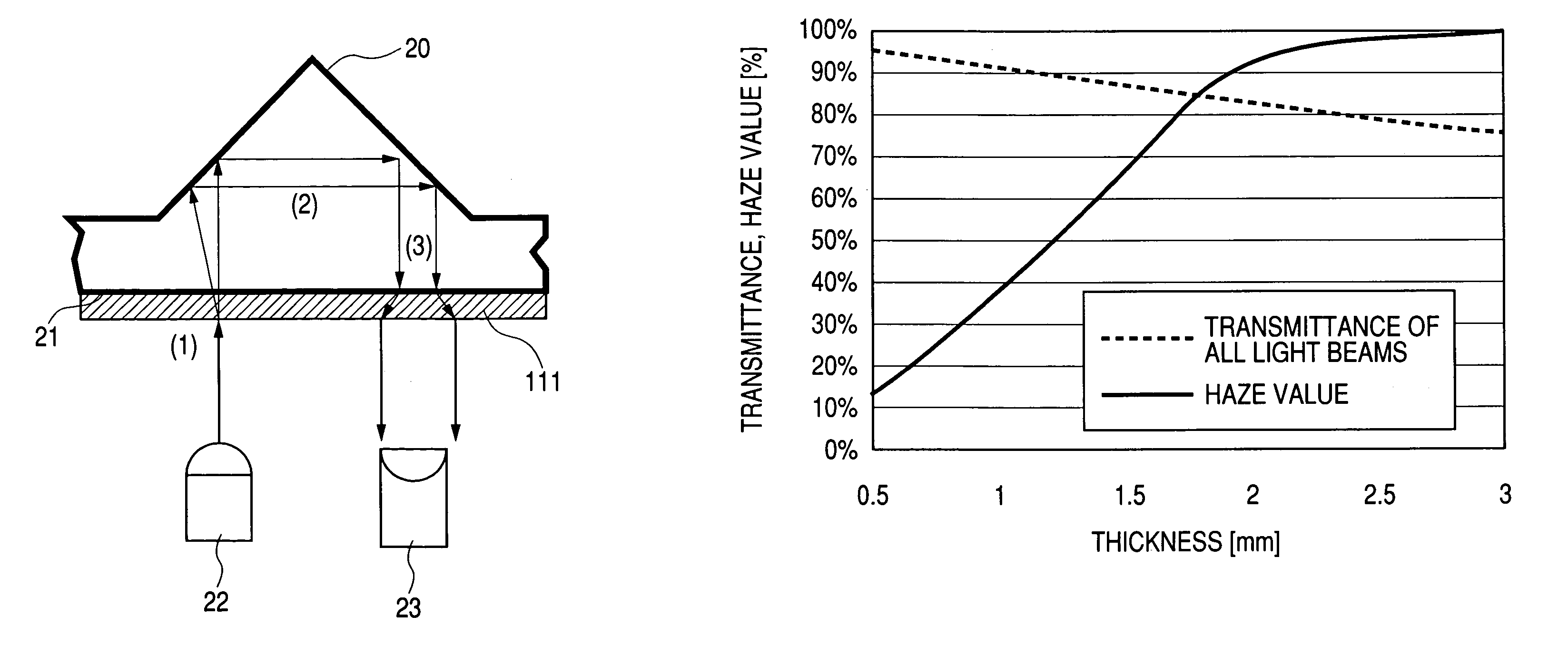

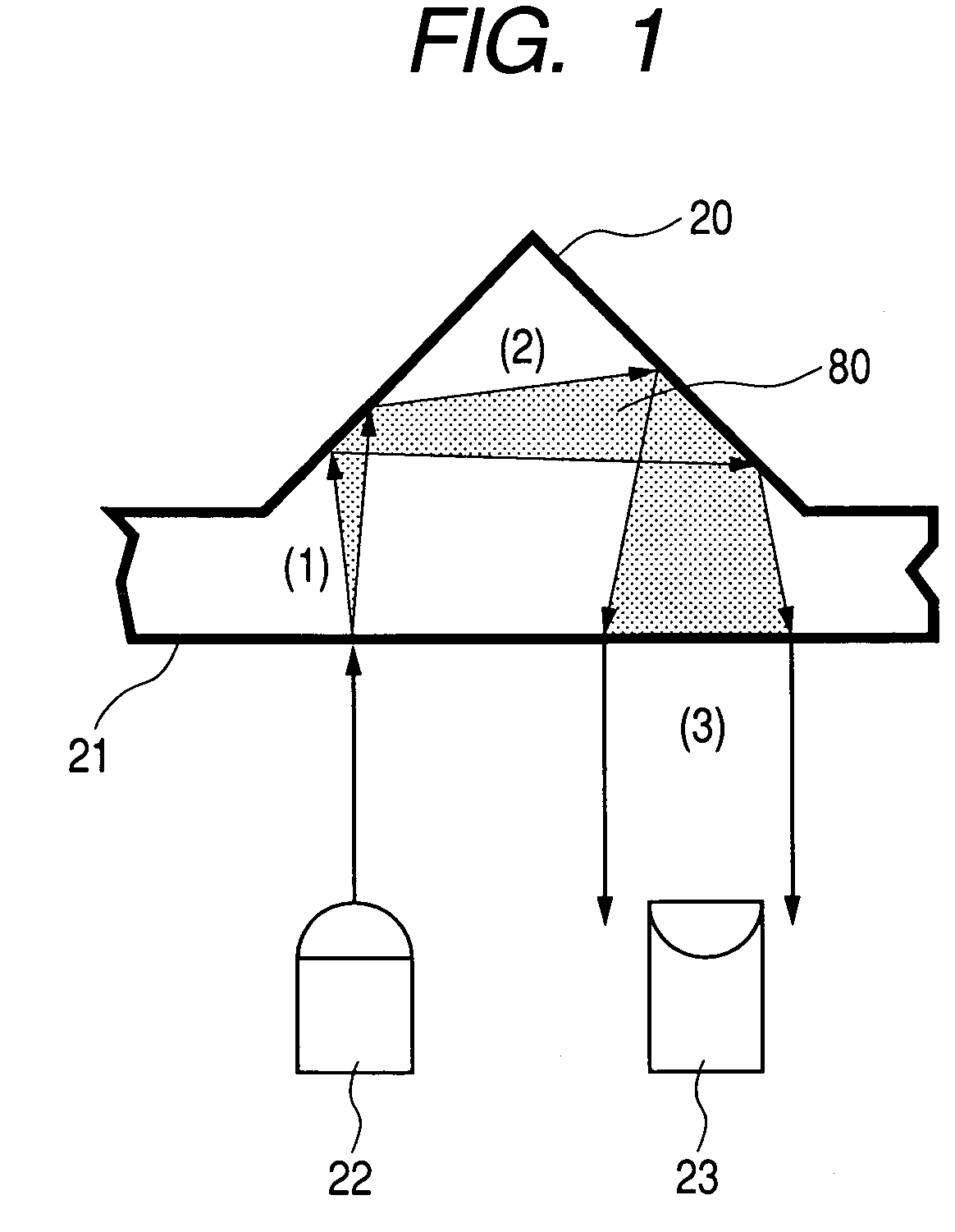

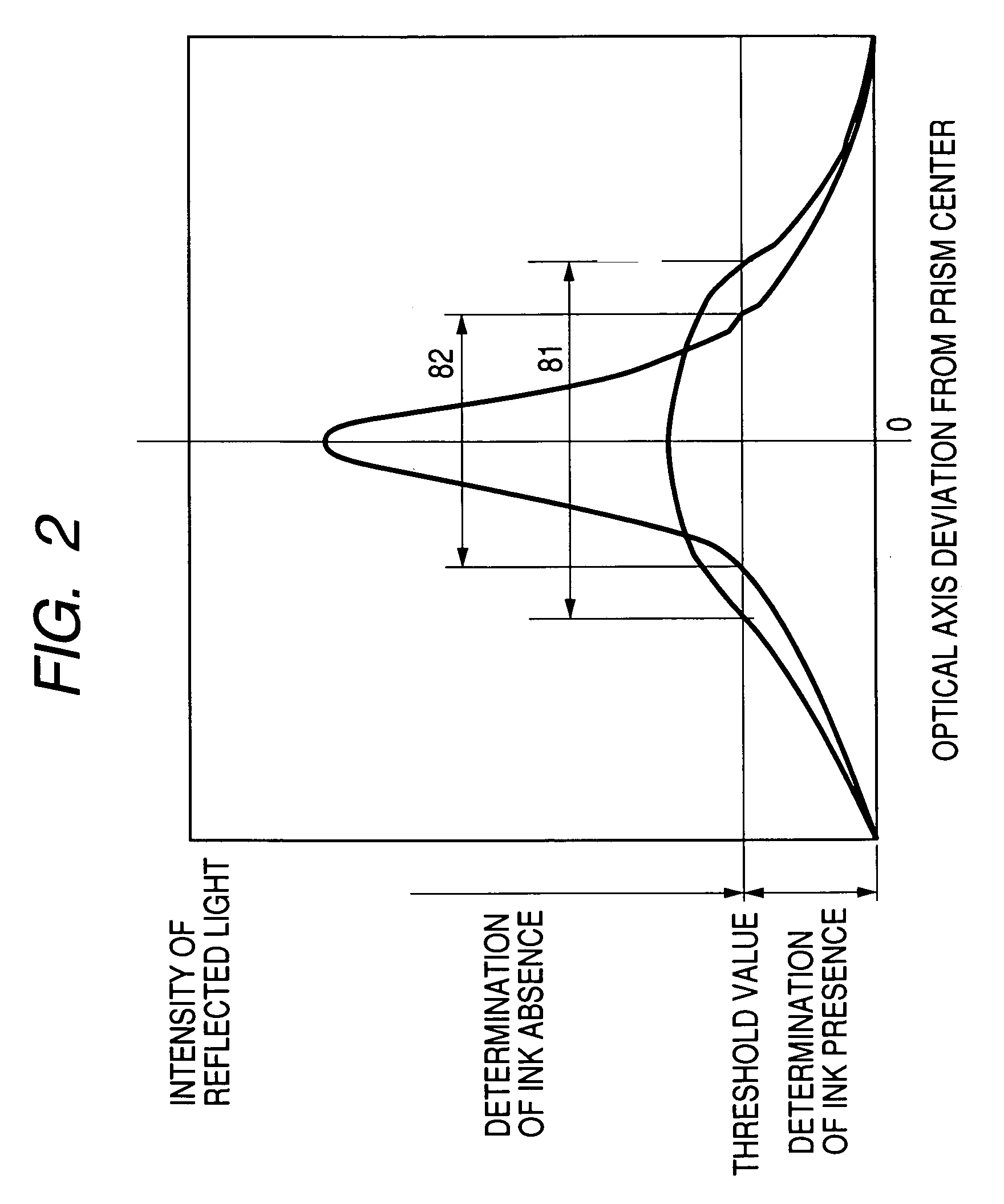

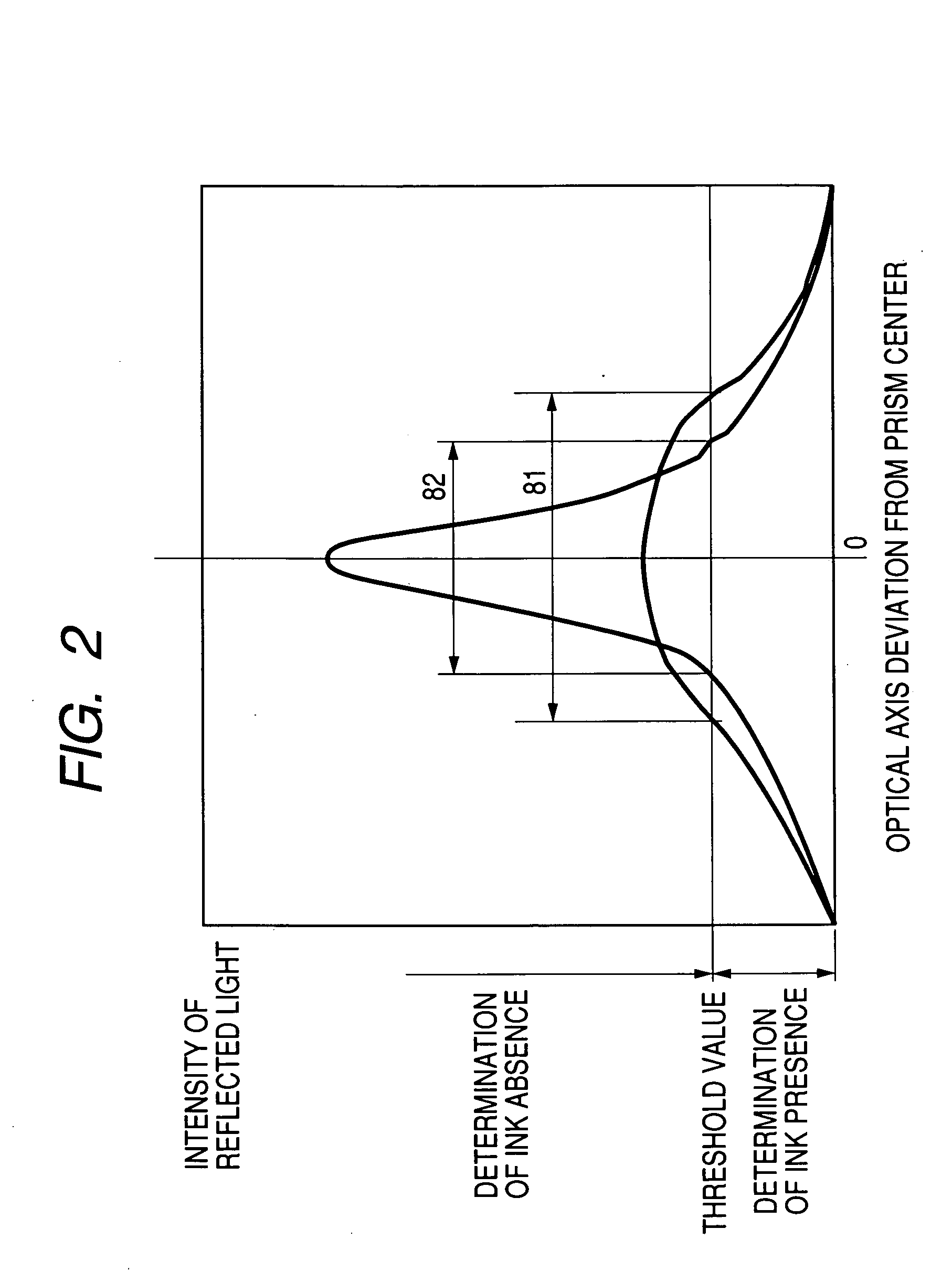

Liquid accommodation container

InactiveUS7147312B2Improve reliabilityLow costMaterial analysis by optical meansMachines/enginesOptical propertyLight beam

A prism of an ink tank has a function for reflecting light, which is incident from the outside, to the outside when no liquid is present in a liquid chamber and not reflecting the light, which is incident from the outside, to the outside when a liquid is present in the liquid chamber, and when the optical characteristics of a material constituting the liquid accommodation container are measured based on a standard according to JIS K7105, the material has optical characteristics equivalent to such optical characteristics that a transmittance of all light beams is 80% or more and a Haze value is equal to or more than 75% and equal to or less than 85%. With the above arrangement, there can be provided an ink tank, which can be operated stably and detect a remaining amount of ink, at a low price.

Owner:CANON KK

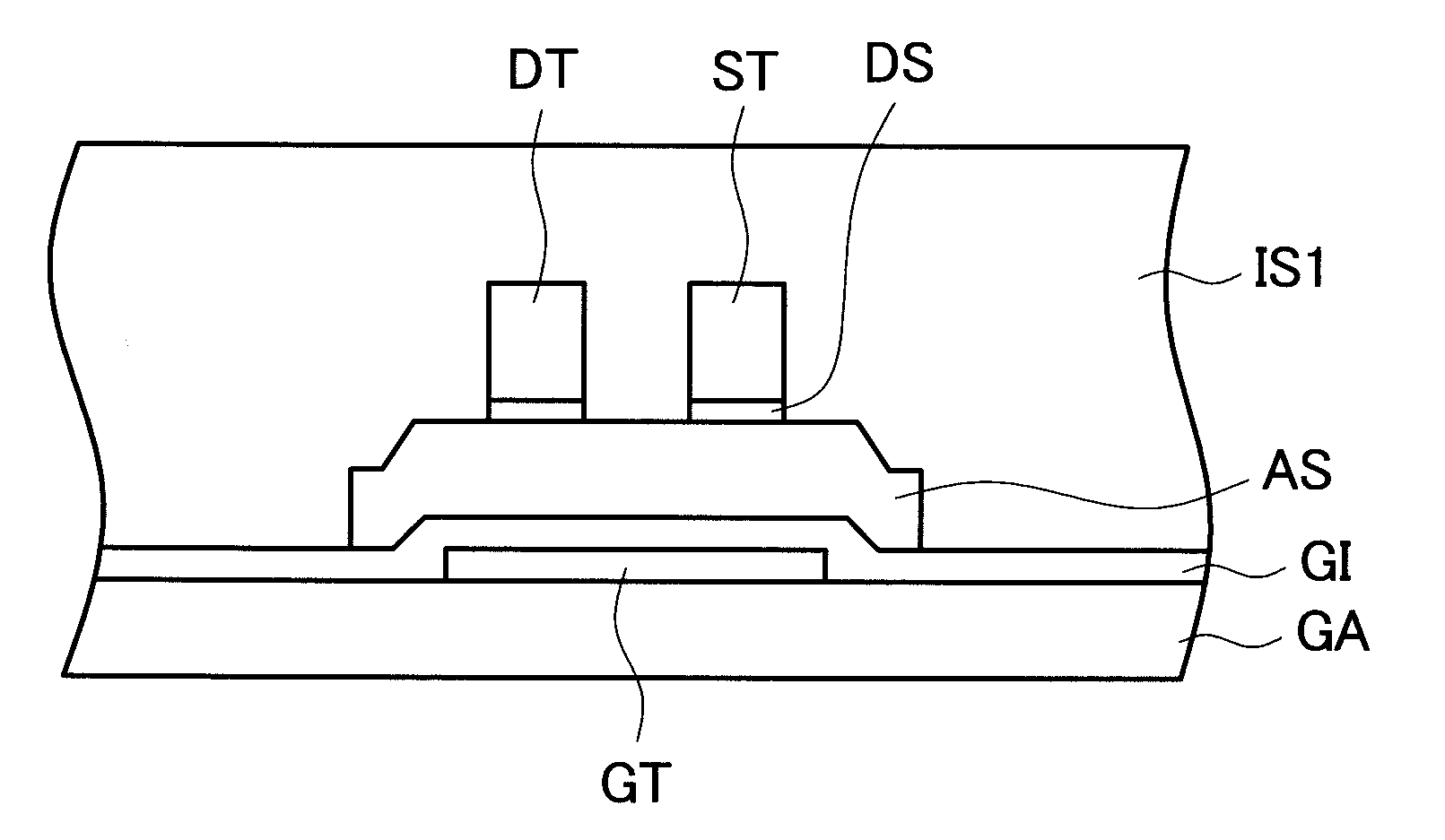

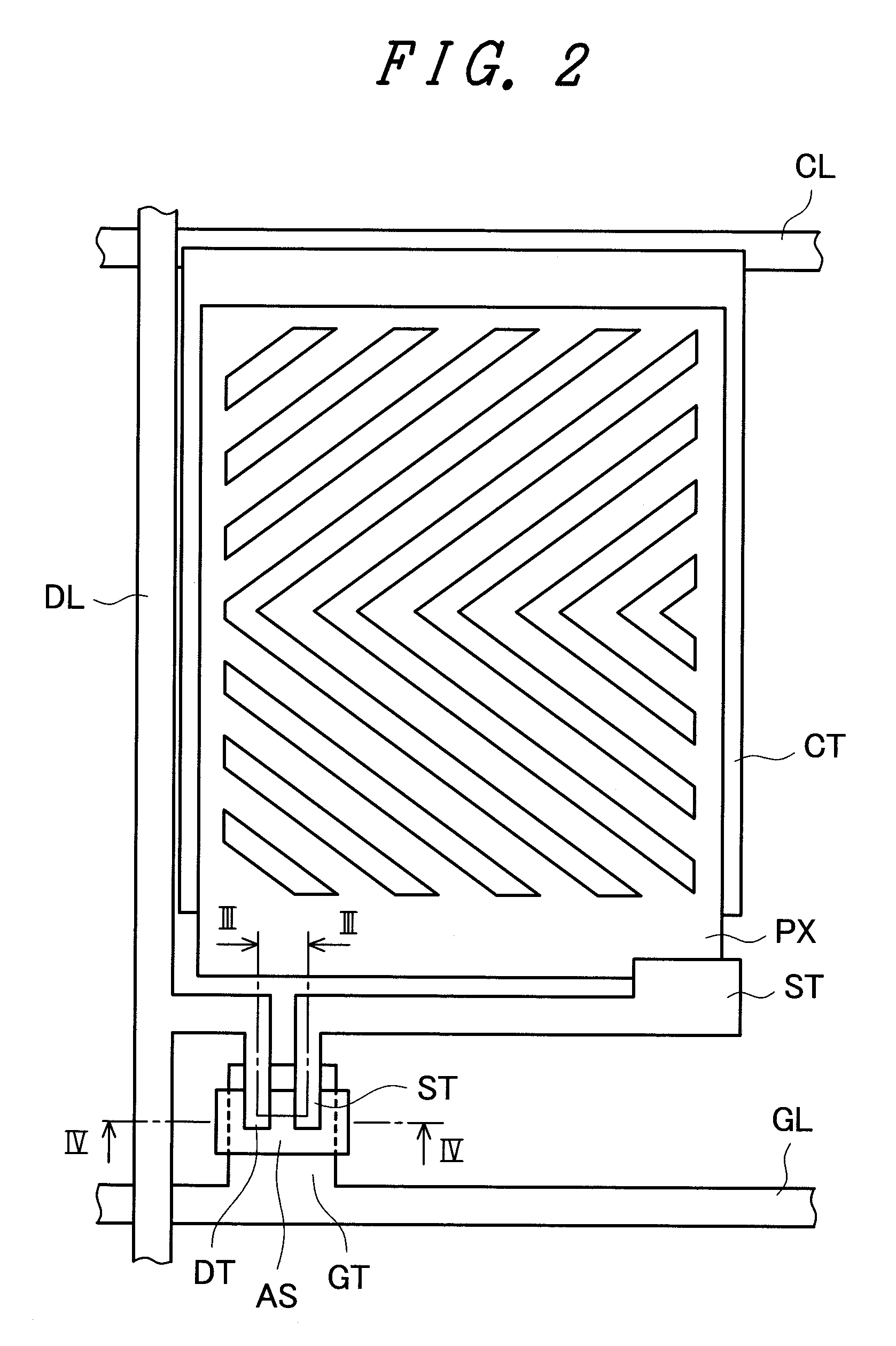

Liquid crystal display device

ActiveUS20110001897A1Current be suppressQuality improvementSolid-state devicesNon-linear opticsElectric fieldLiquid-crystal display

A liquid crystal display device having thin film transistors which can alleviate the required alignment accuracy of a semiconductor film while suppressing the generation of an optical leak current is provided. The liquid crystal display device includes: a transparent substrate; gate electrodes which are stacked above the transparent substrate; source electrodes and drain electrodes which are stacked above the gate electrodes; and semiconductor films each of which is stacked above the gate electrode and controls an electric current between the source electrode and the drain electrode based on an electric field generated by the gate electrode, wherein the semiconductor film is formed into a planar shape, and includes a first region which overlaps with the gate electrode in plane and a second region which does not overlap with the gate electrode in plane, and the source electrode and the drain electrode are not connected to the semiconductor film in the second region, and are connected to the semiconductor film in the first region.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

Liquid accommodation container

InactiveUS20050018007A1Prevent excessive expansionImprove reliabilityMaterial analysis by optical meansMachines/enginesOptical propertyTransmittance

A prism of an ink tank has a function for reflecting light, which is incident from the outside, to the outside when no liquid is present in a liquid chamber and not reflecting the light, which is incident from the outside, to the outside when a liquid is present in the liquid chamber, and when the optical characteristics of a material constituting the liquid accommodation container are measured based on a standard according to JIS K7105, the material has optical characteristics equivalent to such optical characteristics that a transmittance of all light beams is 80% or more and a Haze value is equal to or more than 75% and equal to or less than 85%. With the above arrangement, there can be provided an ink tank, which can be operated stably and detect a remaining amount of ink, at a low price.

Owner:CANON KK

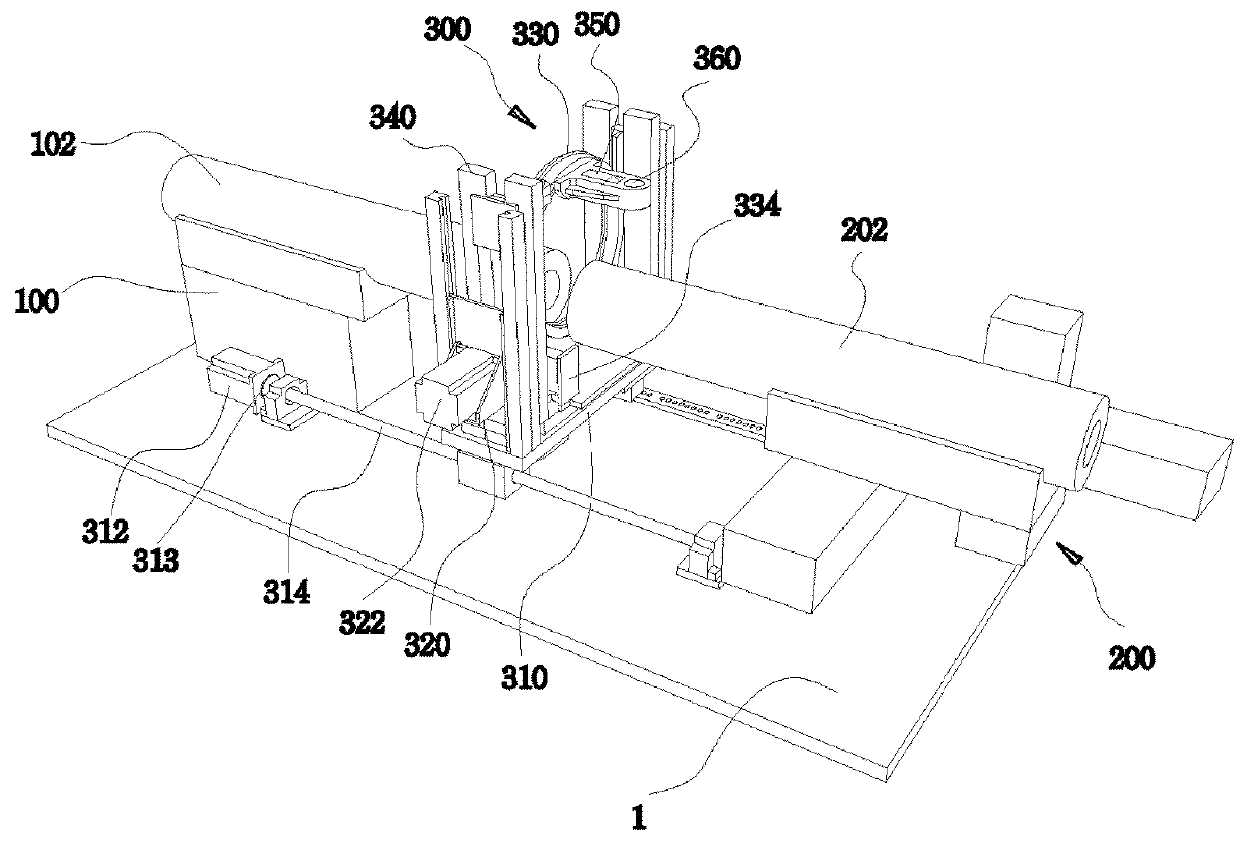

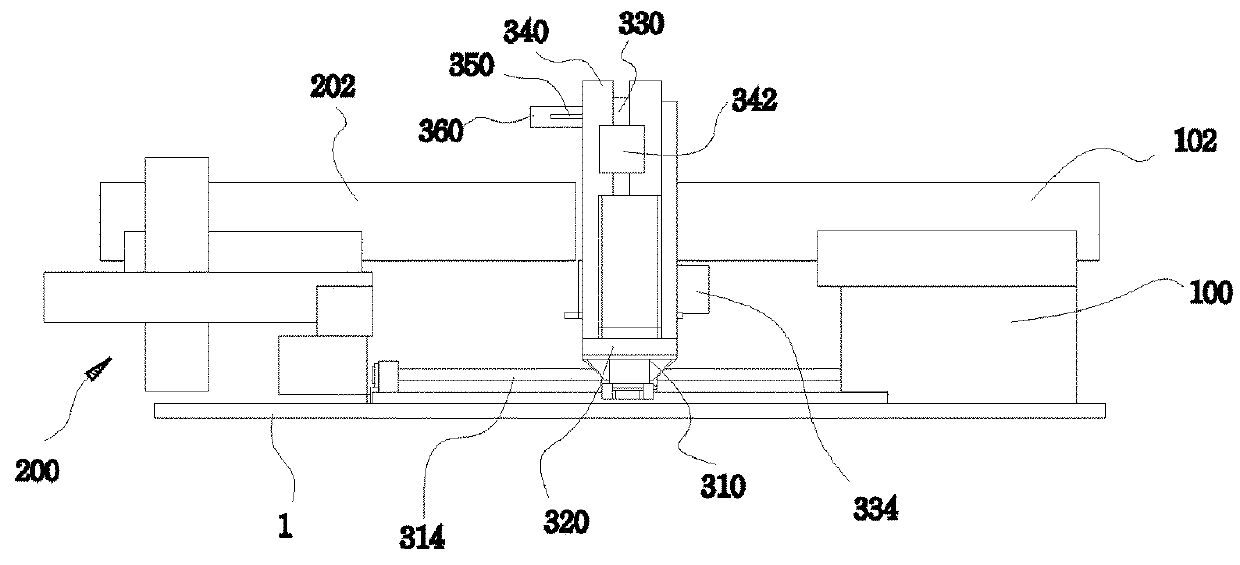

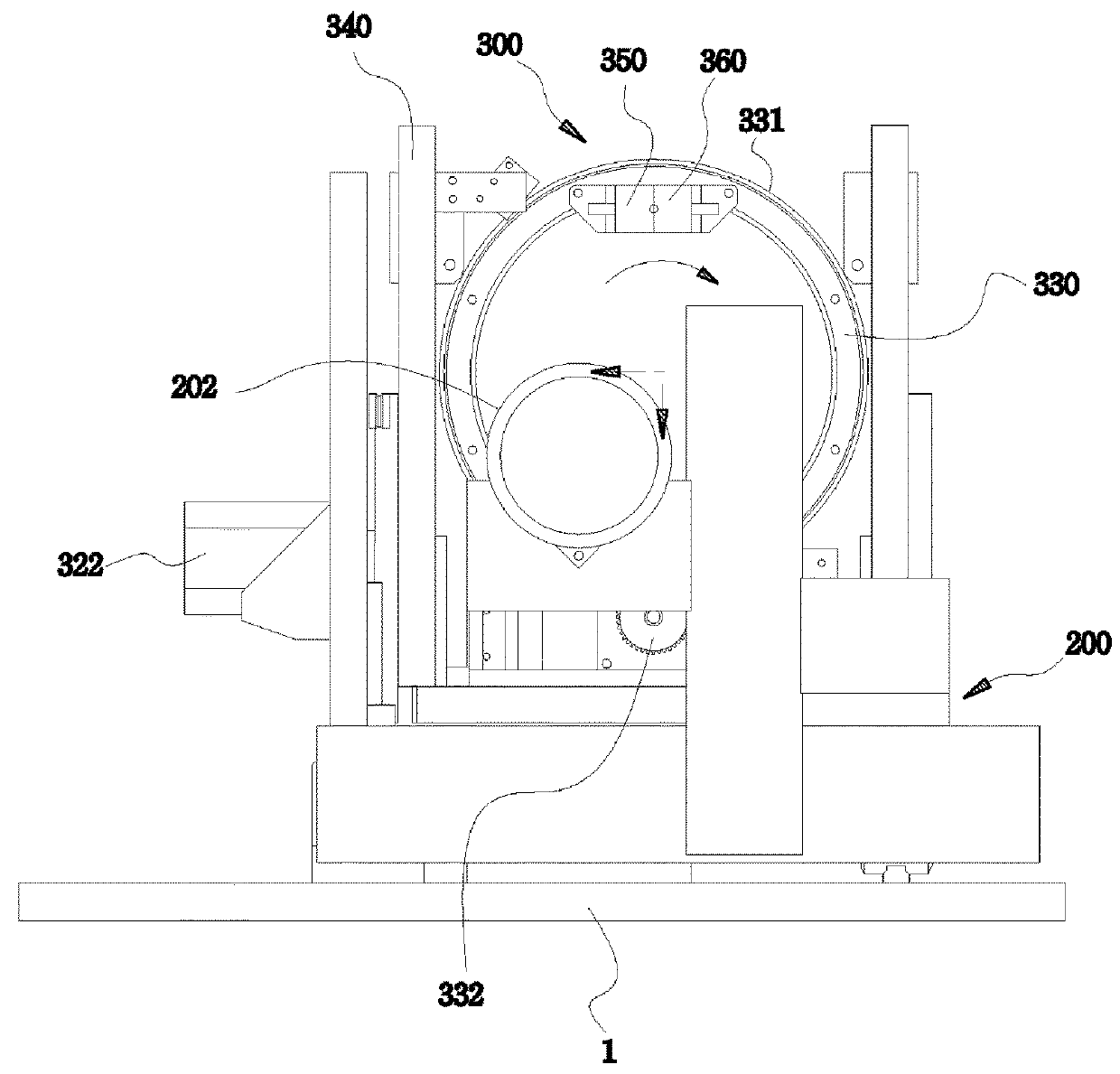

Apparatus and method for detecting piping alignment using image information and laser sensor

ActiveUS20180180198A1Efficient measurementAccurate valuePipe laying and repairImage analysisEngineeringLaser sensor

The present invention provides an apparatus and a method for detecting a piping alignment using image information and laser sensors capable of precisely and accurately measuring and aligning the alignment of the entire pipes. The apparatus includes: a fixed plate installed on a base stage and having a reference pipe located thereon; a movable plate installed on the base stage along three axes to face the reference pipe and has an aligning pipe located thereon; a circular stage installed between the reference and aligning pipes and is configured to rotate and move along three axes so as to detect levelness and deformations of the reference and aligning pipes; a laser sensor and an imaging device installed on an upper side of the circular stage; and a controller configured to control the laser sensor and the imaging device and determine an alignment of the aligning pipe.

Owner:MOKPO NAT MARITIME UNIV IND ACADEMIC COOPERATION FOUND

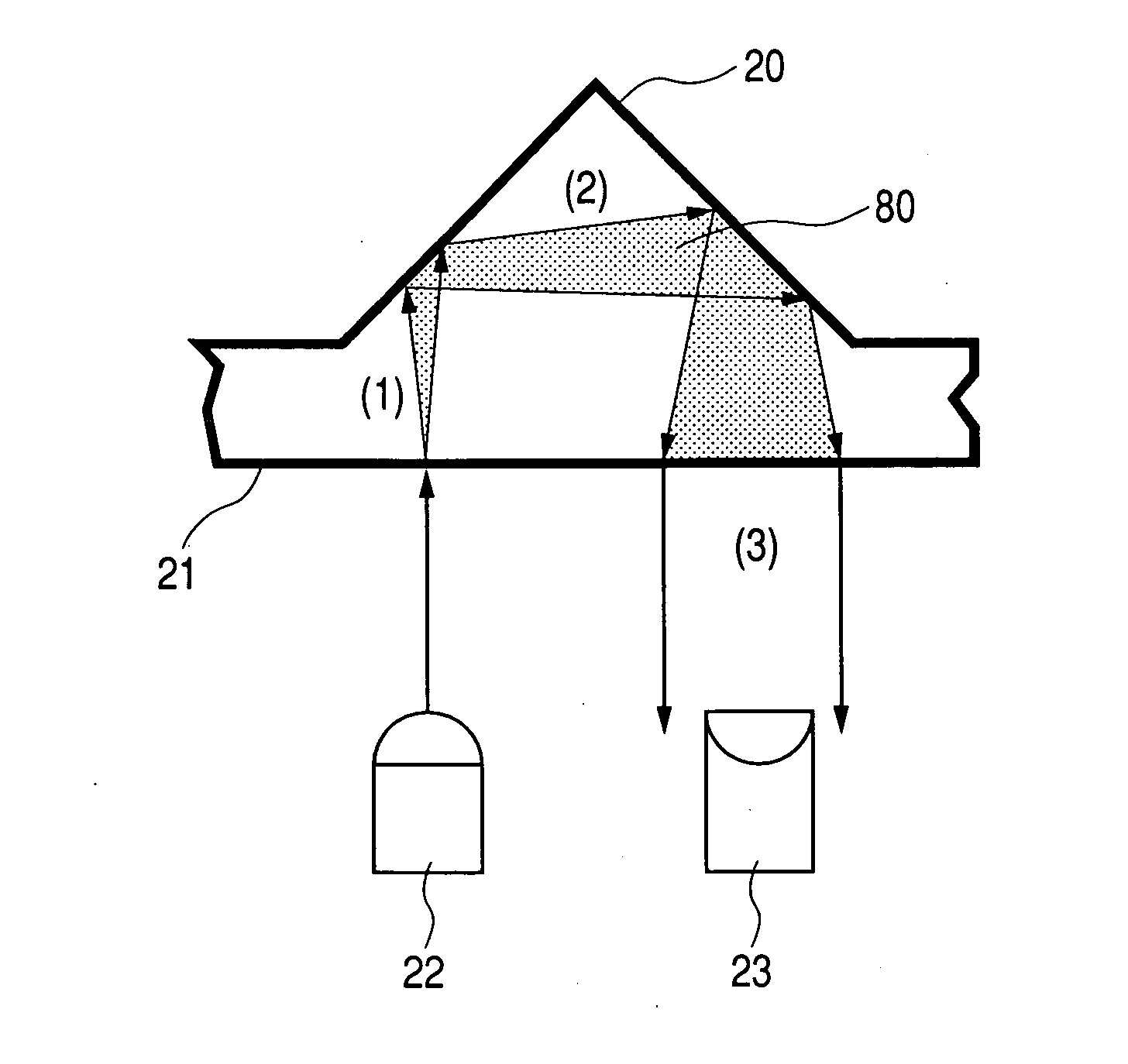

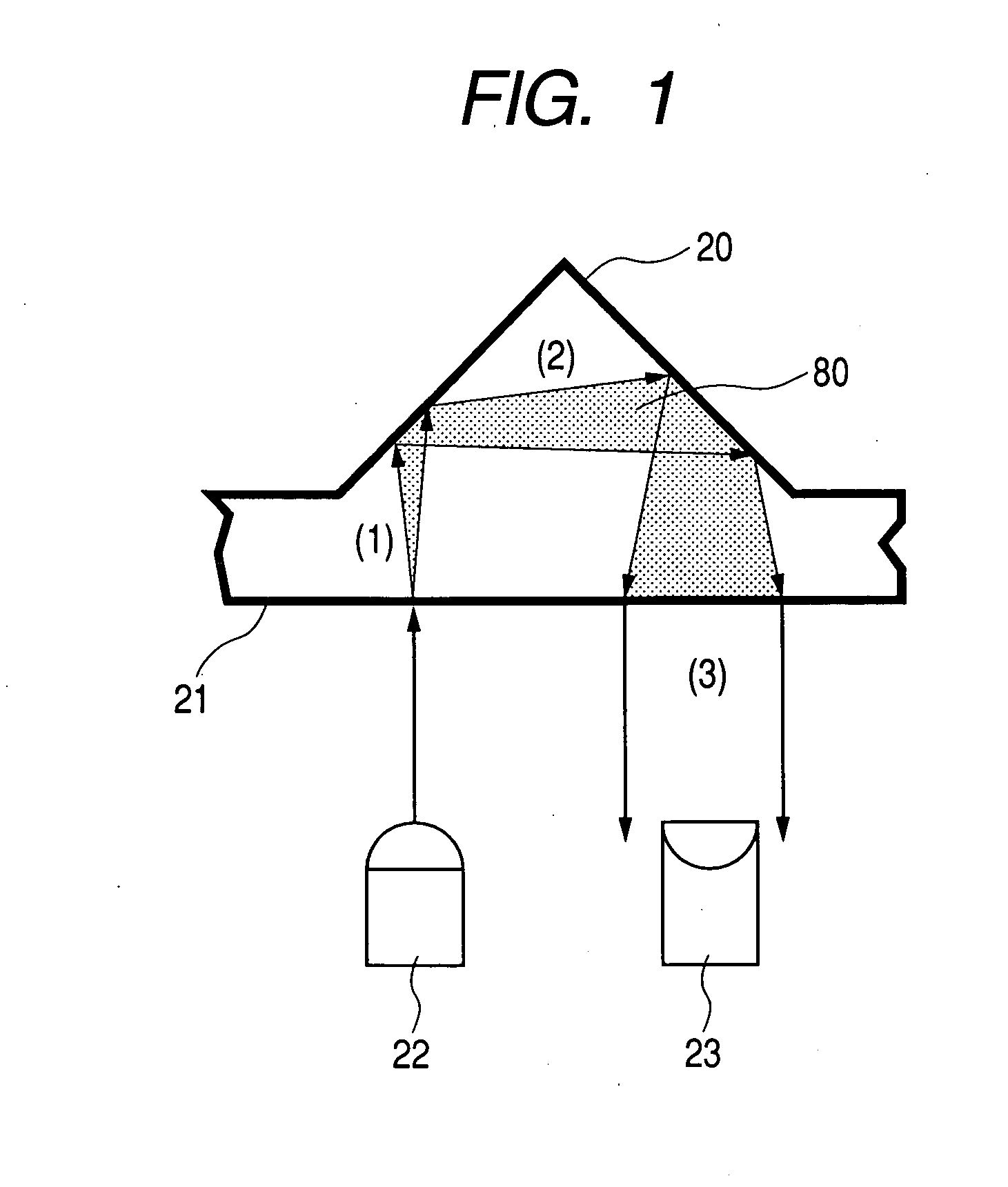

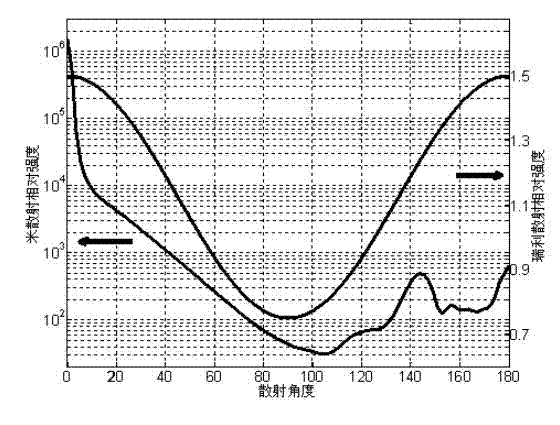

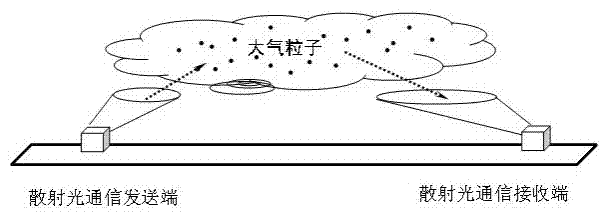

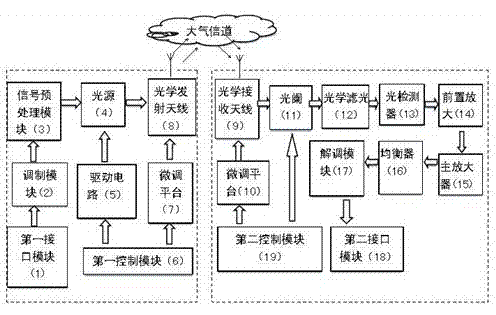

Device and method for wireless light scattering communication on basis of Mie scattering

InactiveCN103209024AReduce alignment accuracy requirementsLight Scattering Communication ImplementationFree-space transmissionRayleigh scatteringTelecommunications link

The invention discloses a device and method for wireless light scattering communication on the basis of Mie scattering. Original light scattering is achieved through rayleigh scattering based on light and gas molecules in the air, and communication distance is short generally. Light scattering communication is achieved through Mie scattering based on light and aerosol particles in the air, common waveband photoelectric devices can be selected as components required by a system, and remote non-line-of-sight light scattering communication can be achieved by using strong forward light scattering characteristics of the Mie scattering. A corresponding device comprises a light sending device and a light receiving device, the light sending end of the system sends light signals, and the light signals are detected and scattered at the receiving end through scattering of the aerosol particles in the air to achieve communication. The device and method for the wireless light scattering communication on the basis of the Mie scattering reduces requirements on accuracy of an optical antenna in a wireless optical communication system, can establish non-line-of-sight communication link between two long-distance points rapidly, and achieves light scattering communication.

Owner:PLA UNIV OF SCI & TECH

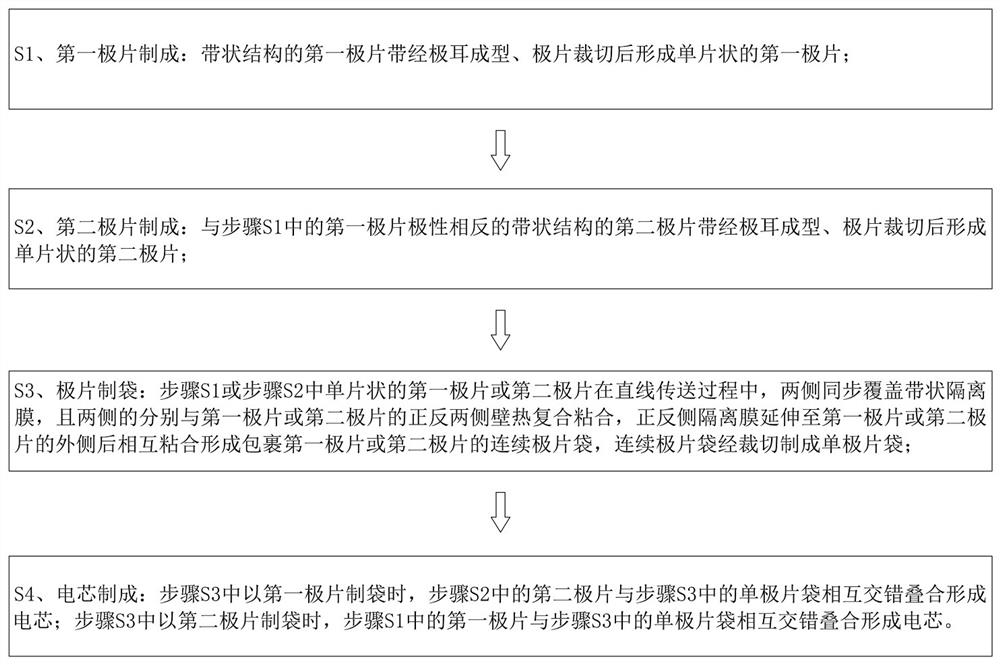

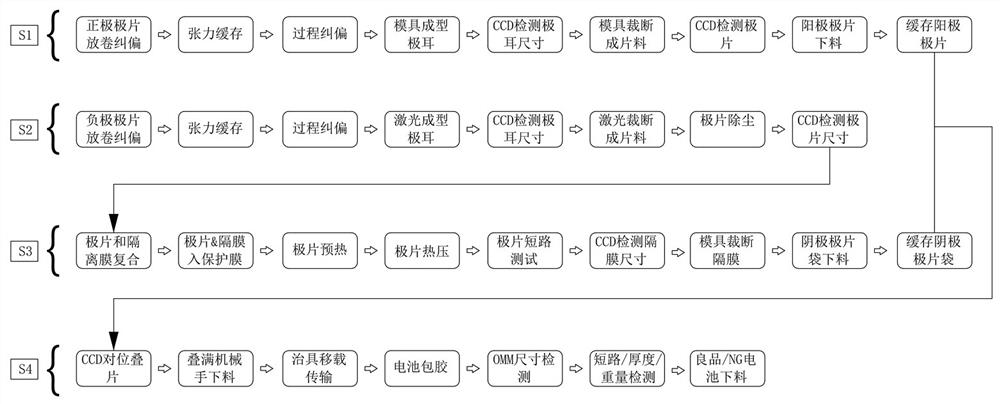

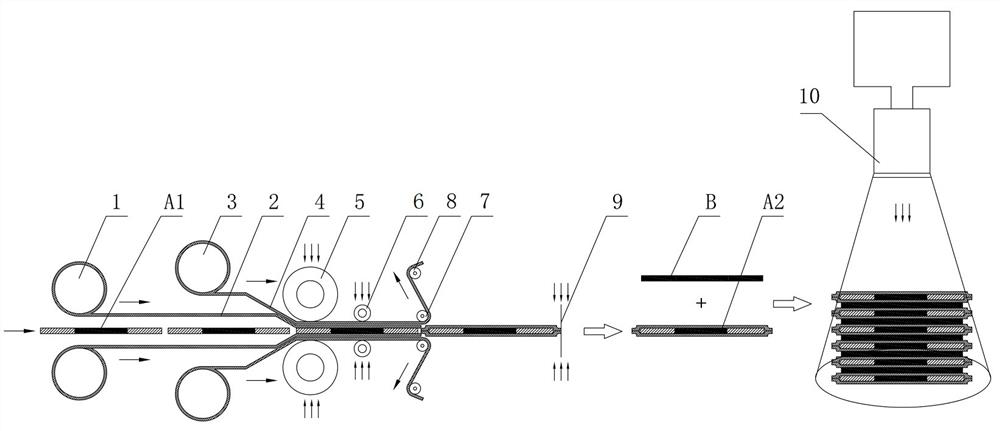

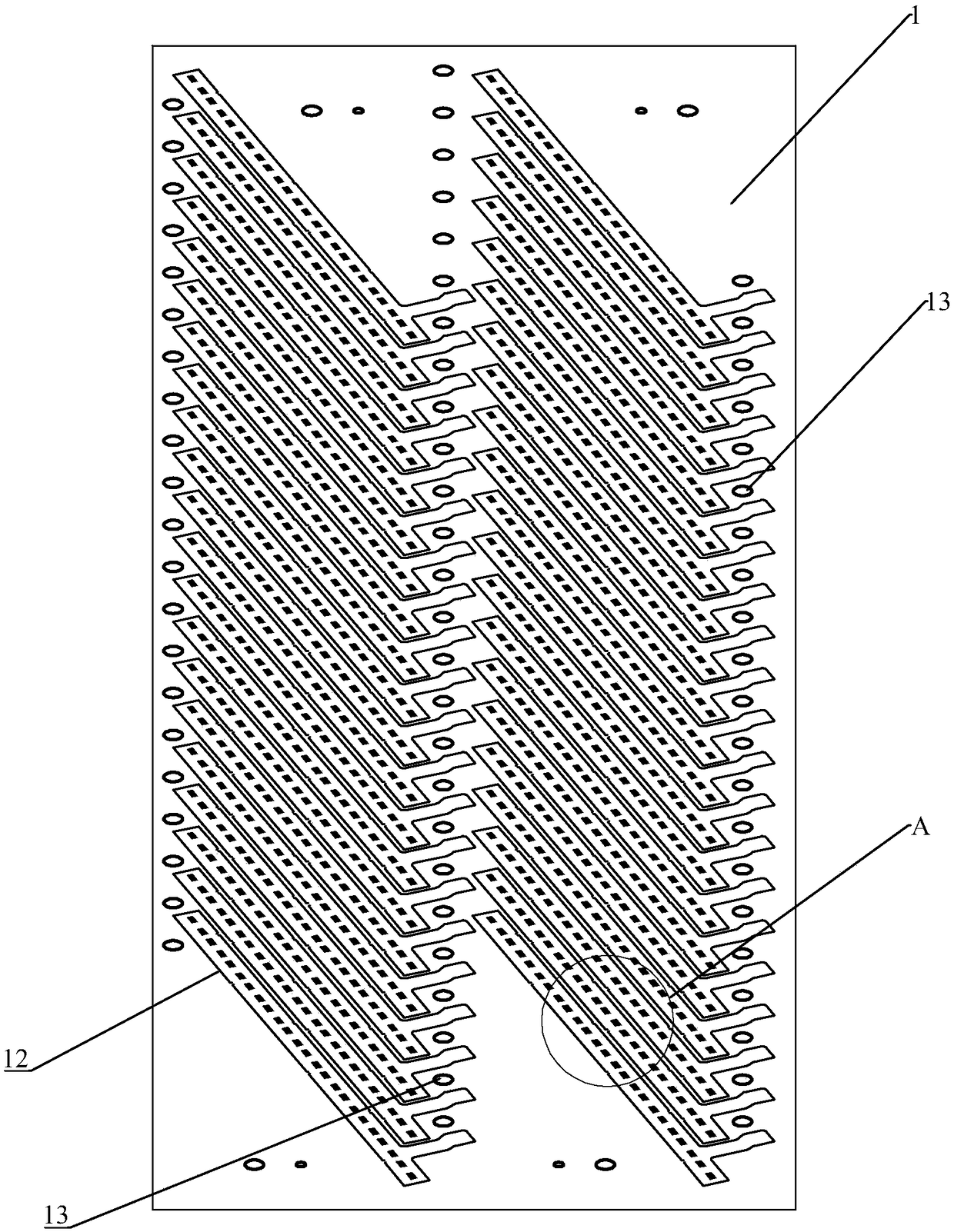

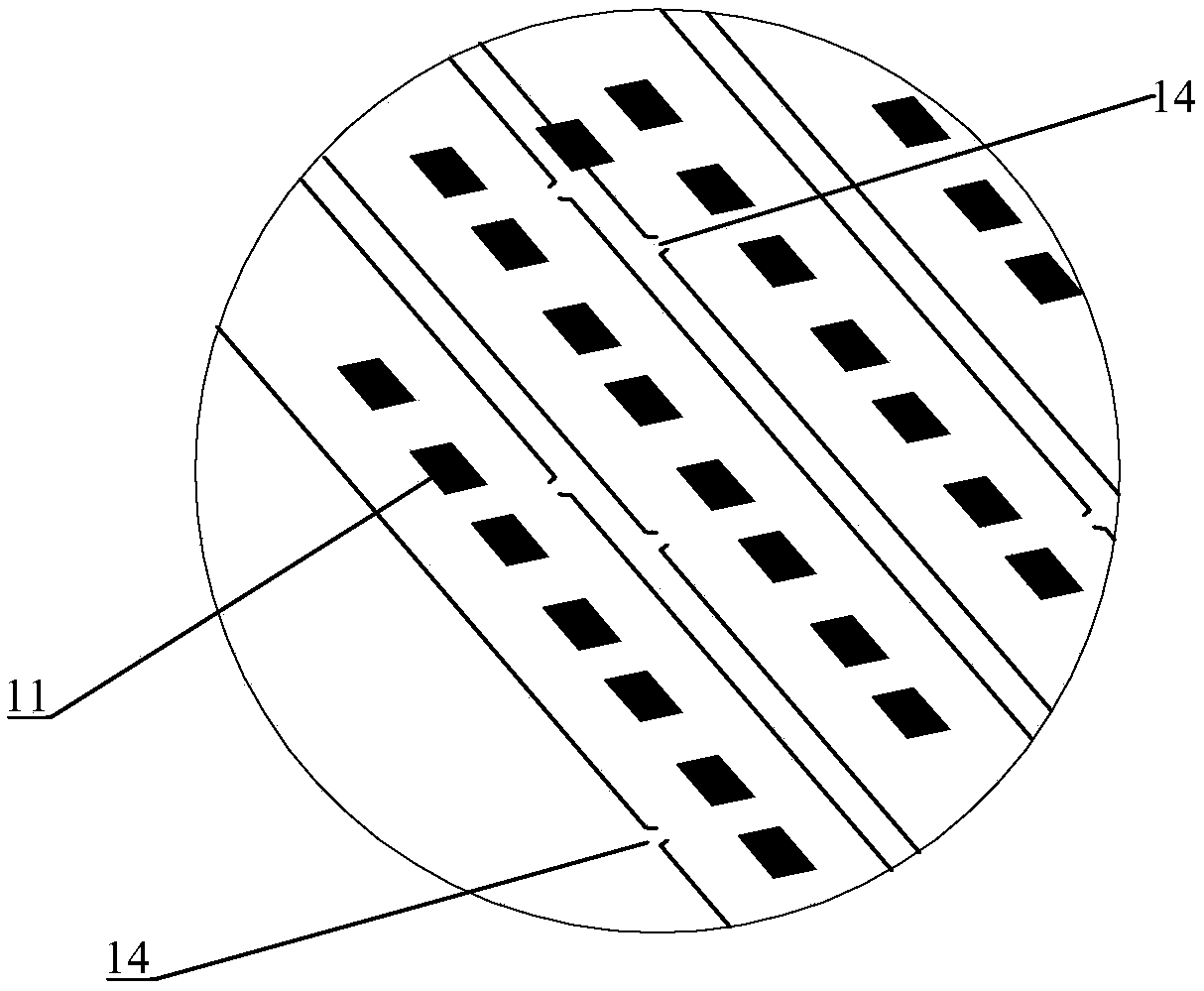

Thermal compounding manufacturing process of battery cell

ActiveCN113782838AGuaranteed Position AccuracyImprove lamination efficiencyFinal product manufactureCell component detailsManufacturing engineeringPole piece

The invention discloses a thermal compounding manufacturing process of a battery cell. The thermal compounding manufacturing process comprises the following process steps that: a pole piece is manufactured, namely, single pole pieces are formed after a pole piece belt with a belt-shaped structure is subjected to pole lug forming and pole piece cutting; pole piece bags are manufactured, namely, a single-sheet-shaped first pole piece or a single-sheet-shaped second pole piece is bonded to the front side wall and the back side wall through diaphragms on the two sides in a thermal compounding mode respectively, diaphragms on the front side and the back side extend to the outer side of the first pole piece or the outer side of the second pole piece and then are bonded to form a continuous pole piece bag, and the continuous pole piece bag is cut into single pole piece bags; and a battery cell is formed, namely, the single pole pieces and the single pole piece bags are mutually staggered and overlapped to form a battery cell. According to the invention, the problem of wrinkling of the diaphragms is solved, the position precision between the positive and negative pole pieces is ensured, the single diaphragm alignment process of the traditional lamination is simplified by adopting diaphragms larger than the pole pieces, the lamination efficiency is effectively improved, combustion caused by short circuit is reduced, and the safety coefficient of the battery is improved.

Owner:SHENZHEN XING GRAIN AUTOMATION CO LTD

FPC and FPC double-sided adhesive tape integrated cutting method

InactiveCN108811329AReduce alignment accuracy requirementsReduce edge tearingInsulating layers/substrates workingEngineeringLED lamp

The invention provides an FPC and FPC double-sided adhesive tape integrated cutting method; the integrated cutting method comprises the following steps that: S1, a release paper on one side of an FPCdouble-sided adhesive tape is replaced with an anti-static blue PET film by a laminating machine, wherein one surface of the replaced FPC double-sided adhesive tape is the release paper, while the other surface is the anti-static blue PET film; S2, and an LED lamp is fixedly connected to the whole board of the FPC by an SMT technology; S3, one side, with the release paper, of the FPC double-sidedadhesive tape is removed, and then the side is attached to the back surface of the whole board of the FPC to enable the FPC double-sided adhesive tape to be combined with the whole board of the FPC; and S4, a product obtained in the step S3 is placed on a lower die table of an outer shape punching die, and the product obtained in the step S3 is cut by a punching cutter of the outer shape punchingdie, so as to obtain a plurality of independent FPCAs. By adoption of the method, the whole board of the FPC and the whole FPC double-sided adhesive tape are attached together firstly, and the cut FPCs do not need to be connected with each other via a connection point, so that the problems of edge tearing, burrs, salient points and the like of the FPCA can be effectively reduced.

Owner:JIANGXI HOLITECH TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com