Laser and silicon optical chip integrated structure and preparation method thereof

A technology of silicon photonic chips and lasers, applied in light guides, optics, instruments, etc., can solve the problems of high alignment accuracy requirements and low coupling efficiency, and achieve the effects of low alignment accuracy, good heat dissipation performance, and high coupling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

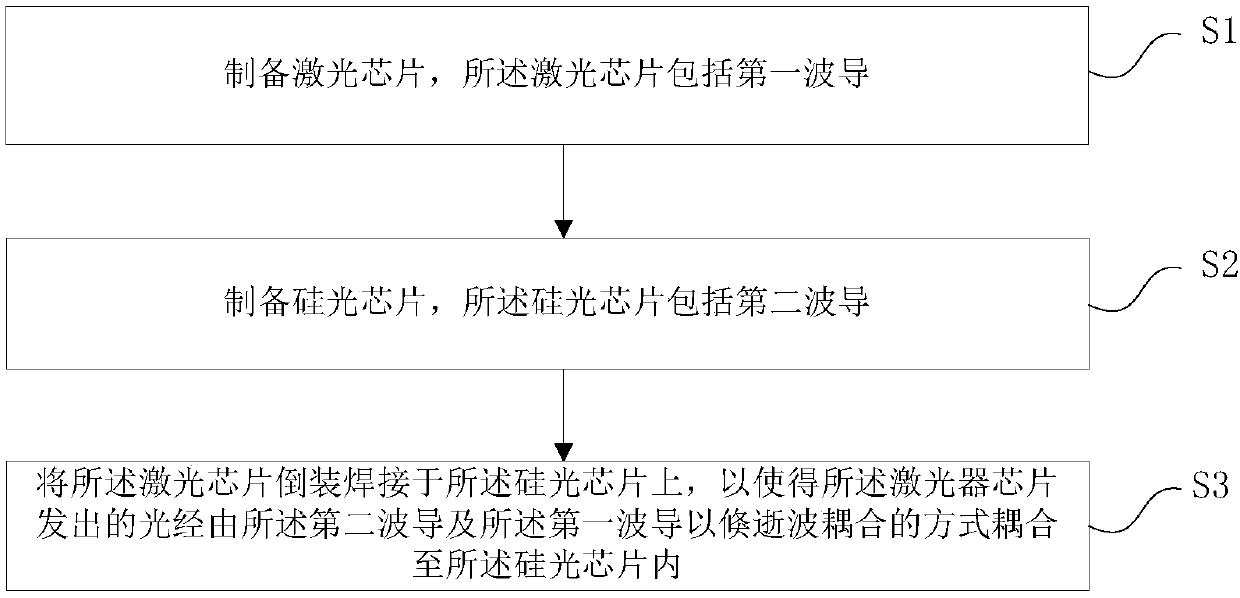

[0095] see figure 1 , the present invention provides a method for preparing an integrated structure of a laser and a silicon photonic chip, the method for preparing an integrated structure of a laser and a silicon photonic chip includes the following steps:

[0096] Prepare a laser chip 1, the laser chip 1 includes a first waveguide 13;

[0097] Prepare a silicon photonics chip 2, the silicon photonics chip 2 includes a second waveguide;

[0098] The laser chip 1 is flip-chip welded on the silicon photonics chip 2, so that the light emitted by the laser chip 1 is coupled to the Inside the silicon photonics chip 2 .

[0099] As an example, the laser chip 1 can be prepared first, and then the silicon photonic chip 2 can be prepared, or the silicon photonic chip 2 can be prepared first, and then the laser chip 1 can be prepared. That is, the order of preparing the laser chip 1 and the silicon photonics chip 2 can be interchanged.

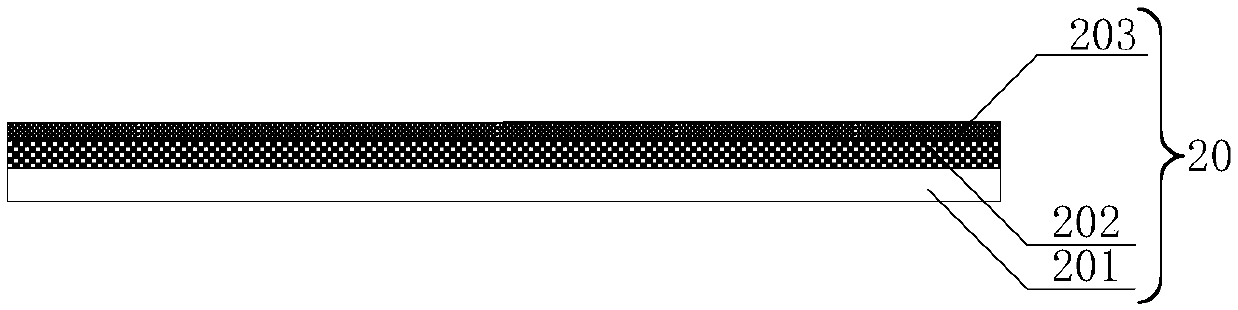

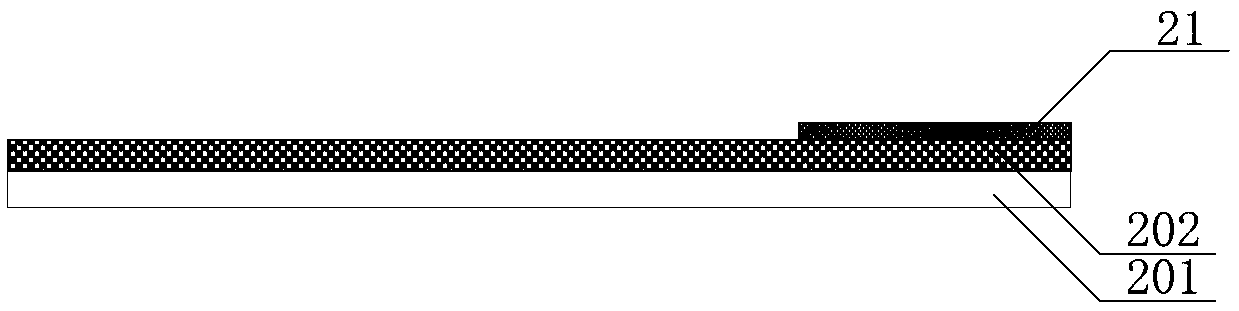

[0100] As an example, see Figure 2 to Figu...

Embodiment 2

[0136] Please combine Figure 2 to Figure 18 read on Figure 19 to Figure 20 , the present invention also provides an integrated structure of a laser and a silicon photonic chip, wherein the integrated structure of a laser and a silicon photonic chip includes:

[0137] A laser chip 1, the laser chip 1 comprising a first waveguide 13;

[0138] A silicon photonics chip 2, the silicon photonics chip 2 includes a second waveguide, the second waveguide and the first waveguide 13 couple the light emitted by the laser chip 1 to the silicon photonics by evanescent wave coupling Chip 2 inside.

[0139]As an example, the first waveguide 13 includes a first inverted tapered waveguide portion 131, a rectangular waveguide portion 132, and a second inverted tapered waveguide portion 133 that are integrally connected in sequence; the second waveguide includes a first silicon nitride waveguide 25 , the second silicon nitride waveguide 23 and the silicon waveguide 21; wherein, the first sil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com