FPC and FPC double-sided adhesive tape integrated cutting method

A double-sided adhesive and genre-specific technology, which is applied in the processing of insulating substrates/layers, electrical components, and printed circuit manufacturing, can solve the problems of easy attachment displacement, high precision requirements, and high operating skill requirements, and achieve the reduction of margins. The effect of tearing, reducing the defective rate, and requiring low alignment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

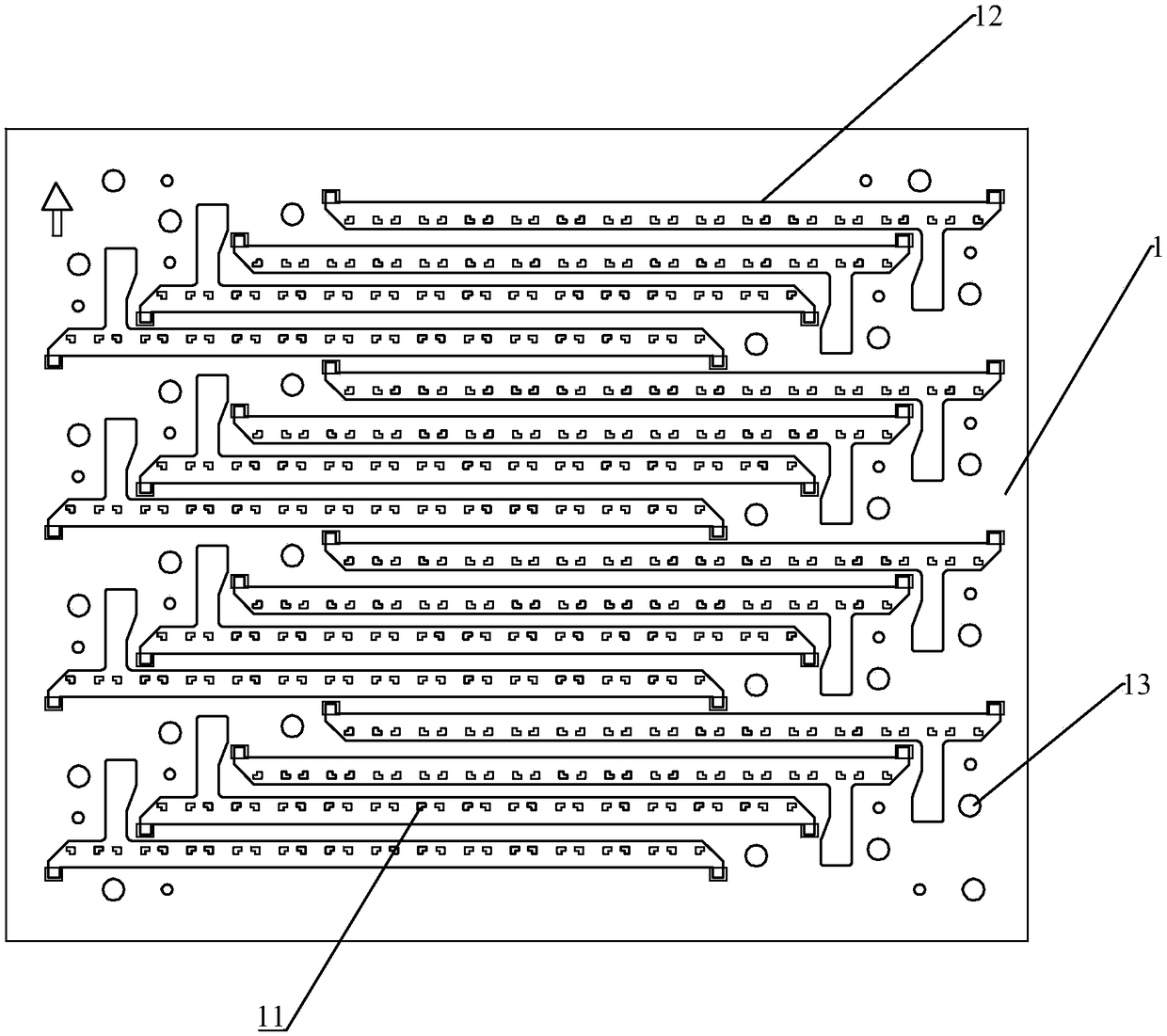

[0022] Such as image 3 As shown, a method for integral cutting of FPC and FPC double-sided adhesive tape comprises the following steps:

[0023] S1. Use the laminating machine to replace the release paper 21 on one side of the FPC double-sided adhesive 2 with an antistatic blue PET film 22. One side of the replaced FPC double-sided adhesive 2 is the release paper 21, and the other side is the Anti-static blue PET film 22;

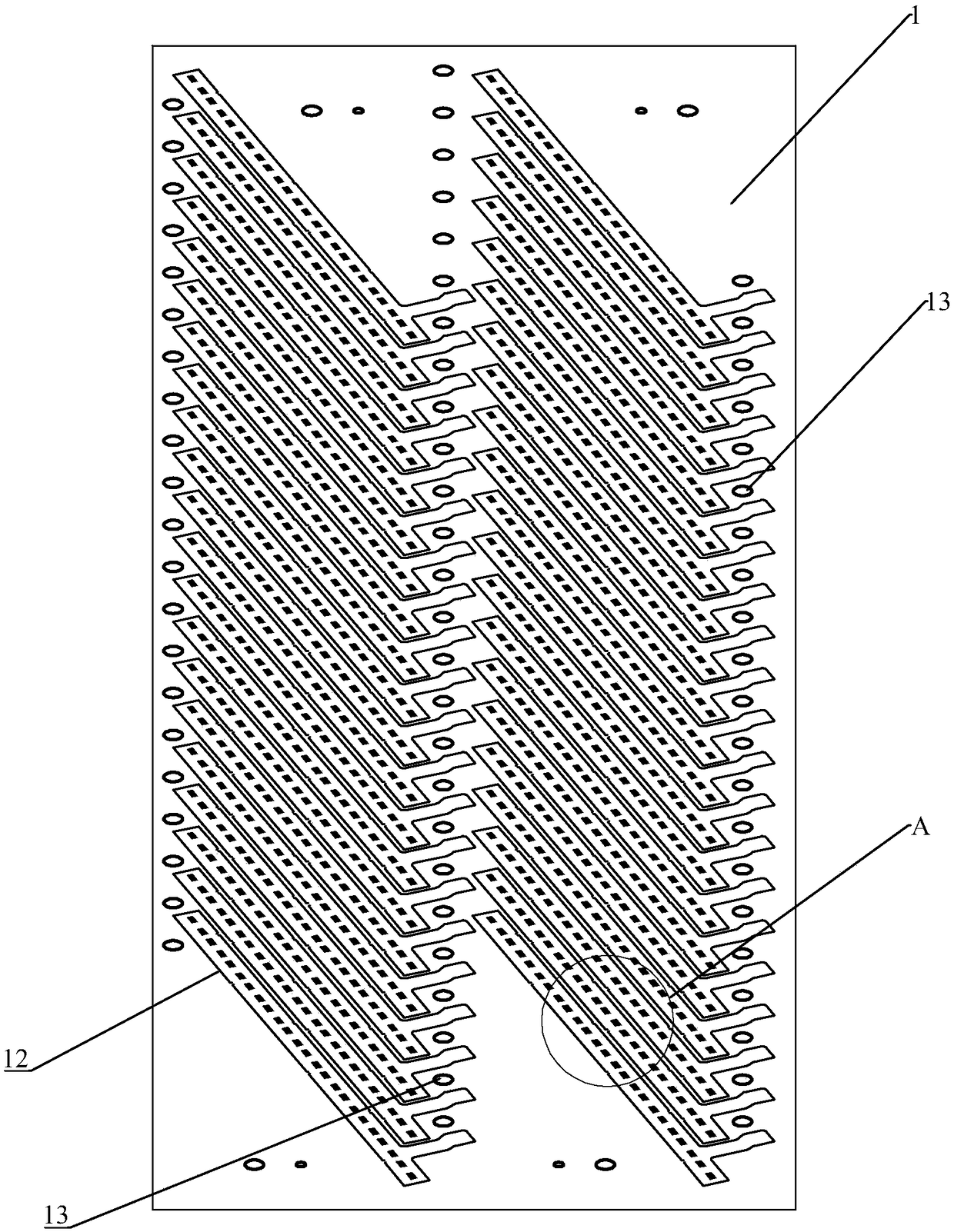

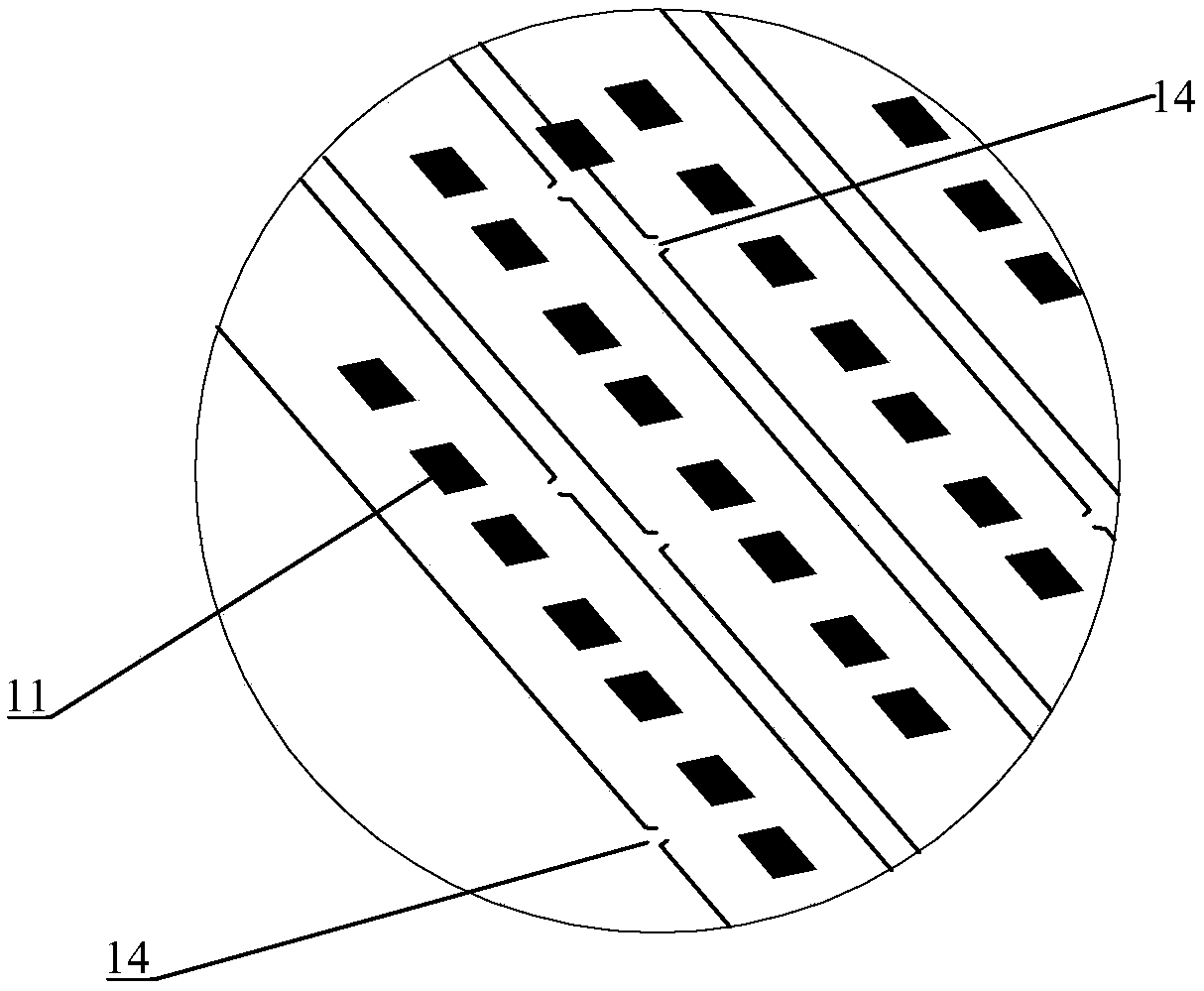

[0024] S2. For the full-page FPC 1, use SMT technology to fix the LED lamp 11 on the full-page FPC 1. The side where the light-emitting surface of the LED light 11 is located is the front of the full-page FPC 1, and the other side is the full-page FPC 1. The back of FPC 1;

[0025] S3. After tearing off the side of the release paper 21 on the FPC double-sided adhesive 2, and attaching this side to the back of the full-page FPC 1, the FPC double-sided adhesive 2 is combined with the full-page FPC 1;

[0026] S4. Place the product obtained in the step S3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com