Patents

Literature

35results about How to "Large core diameter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

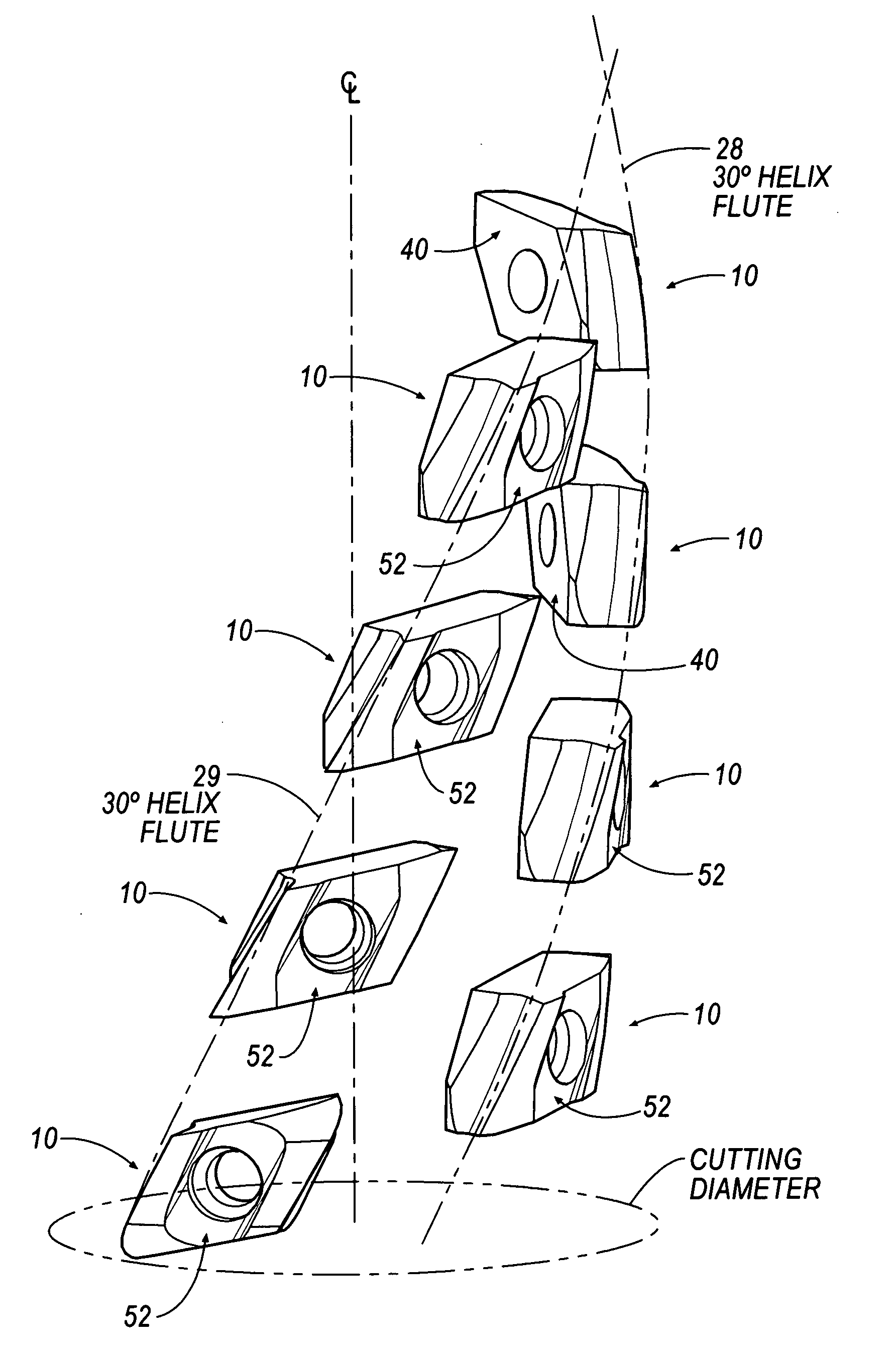

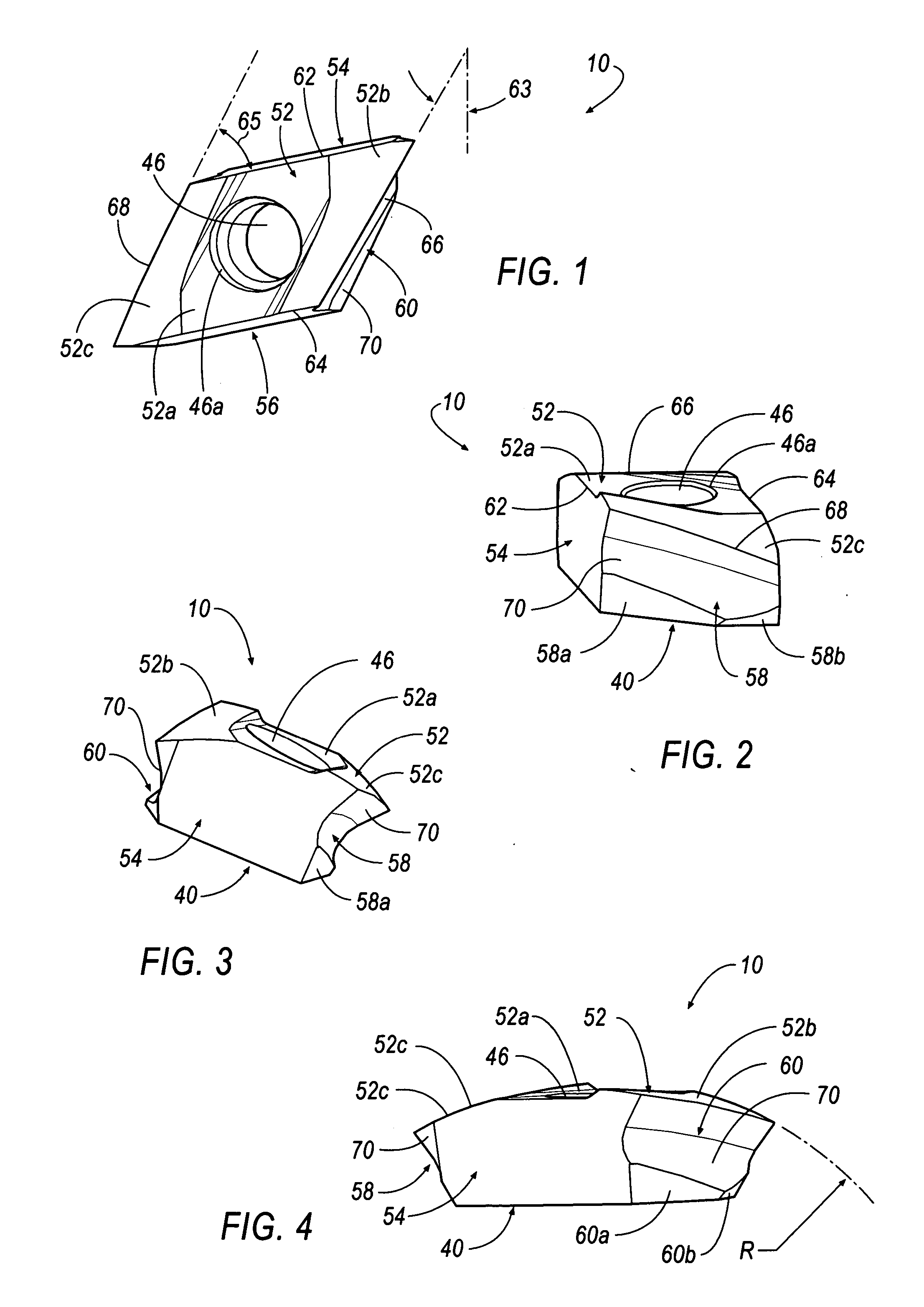

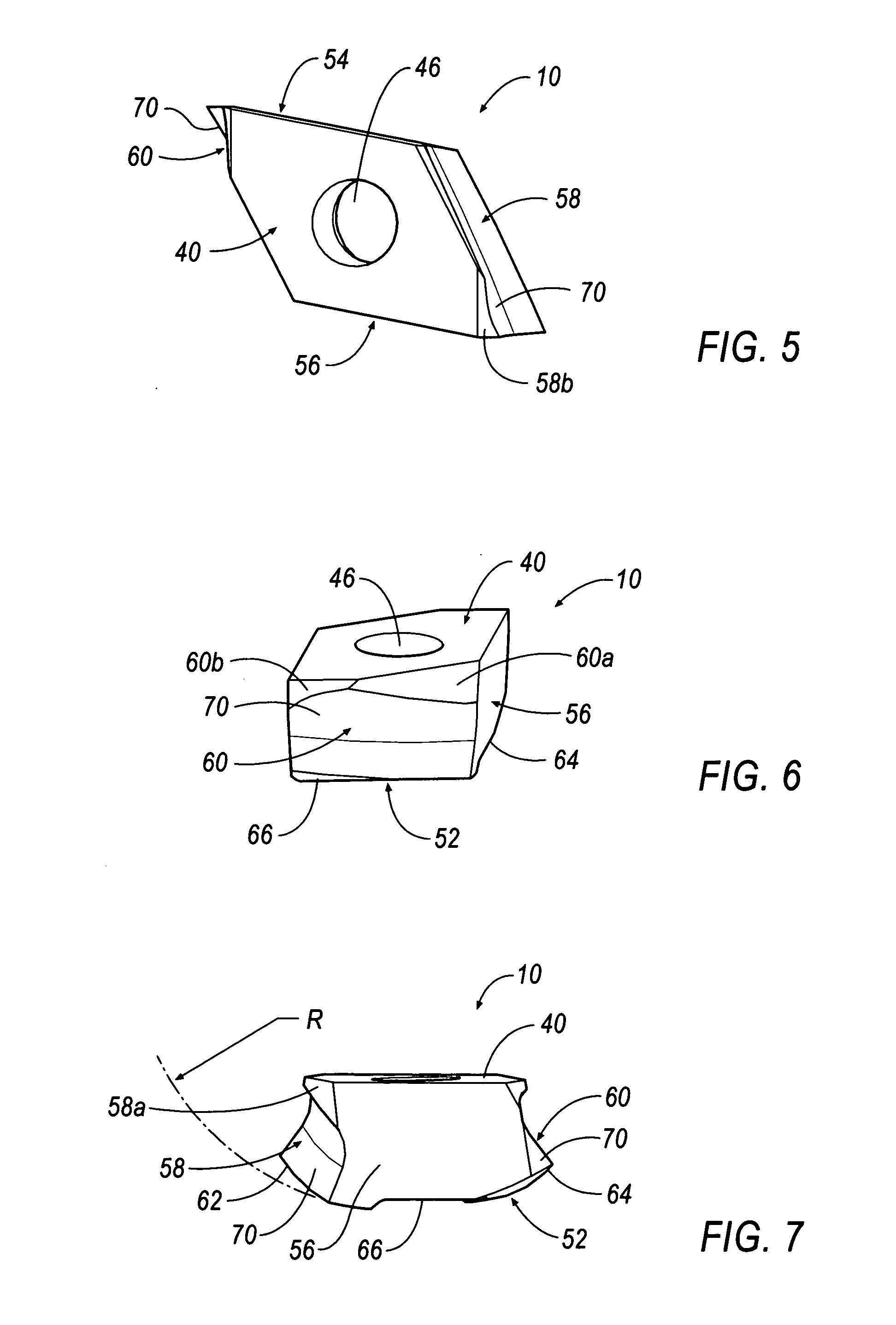

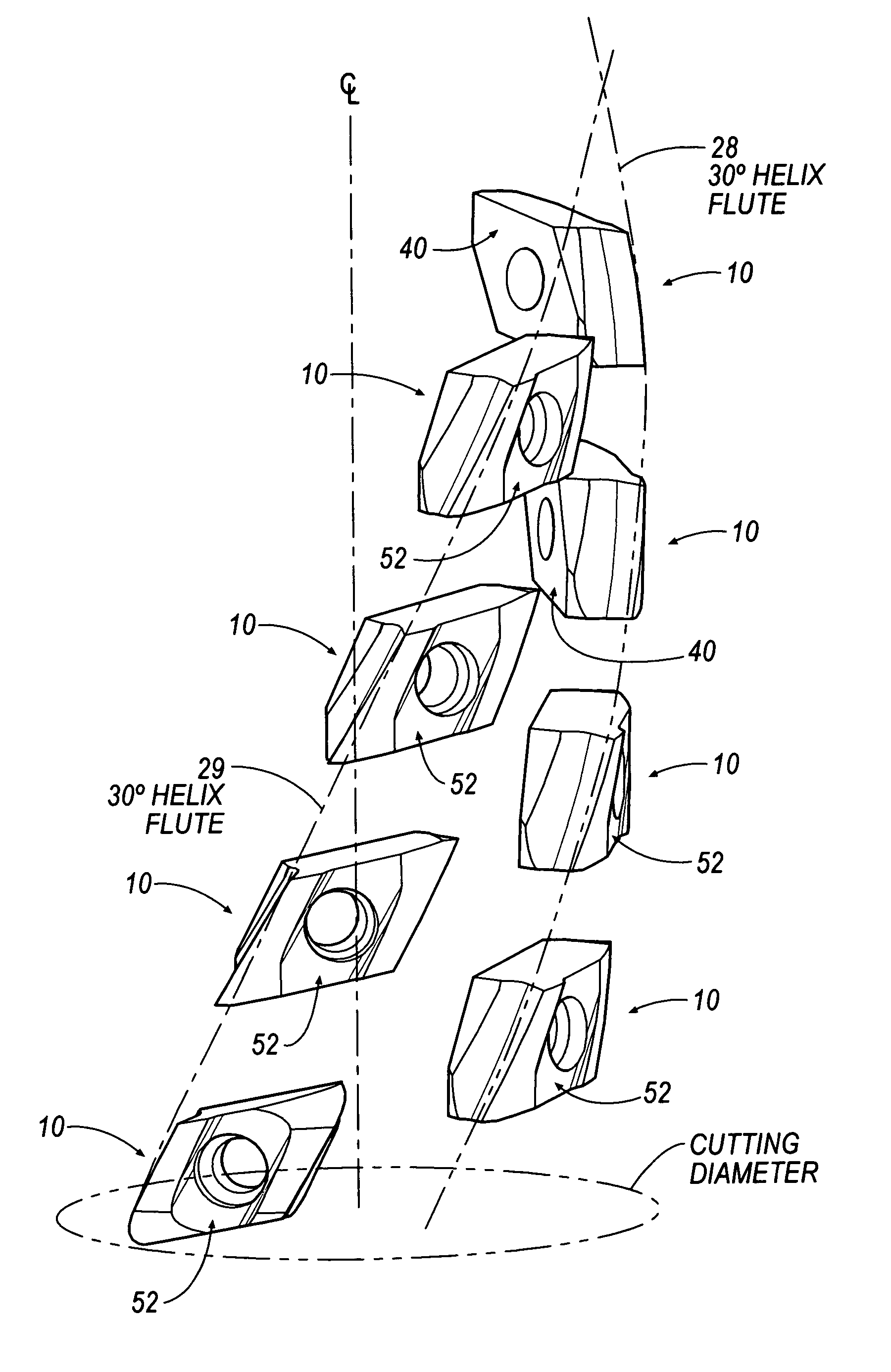

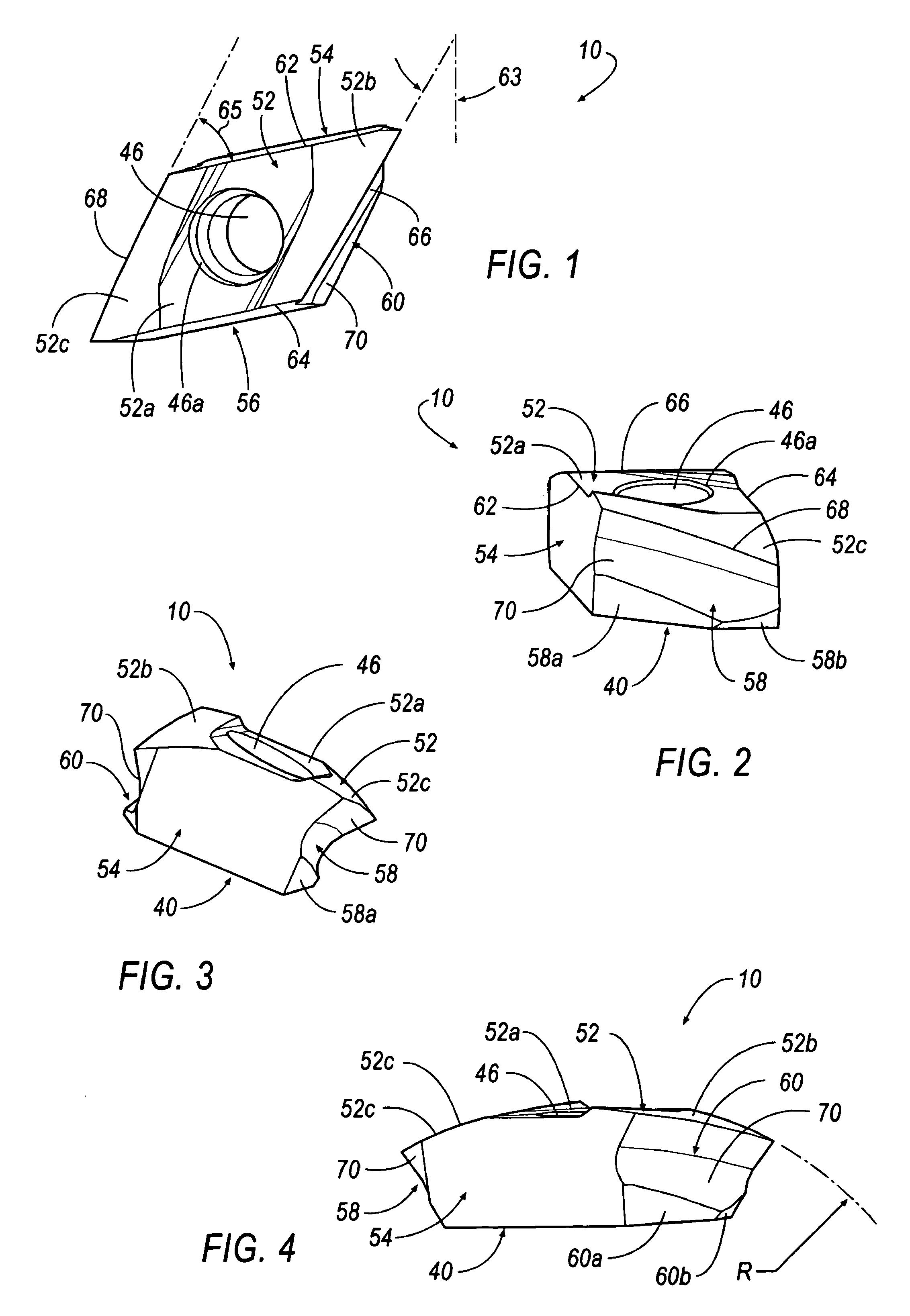

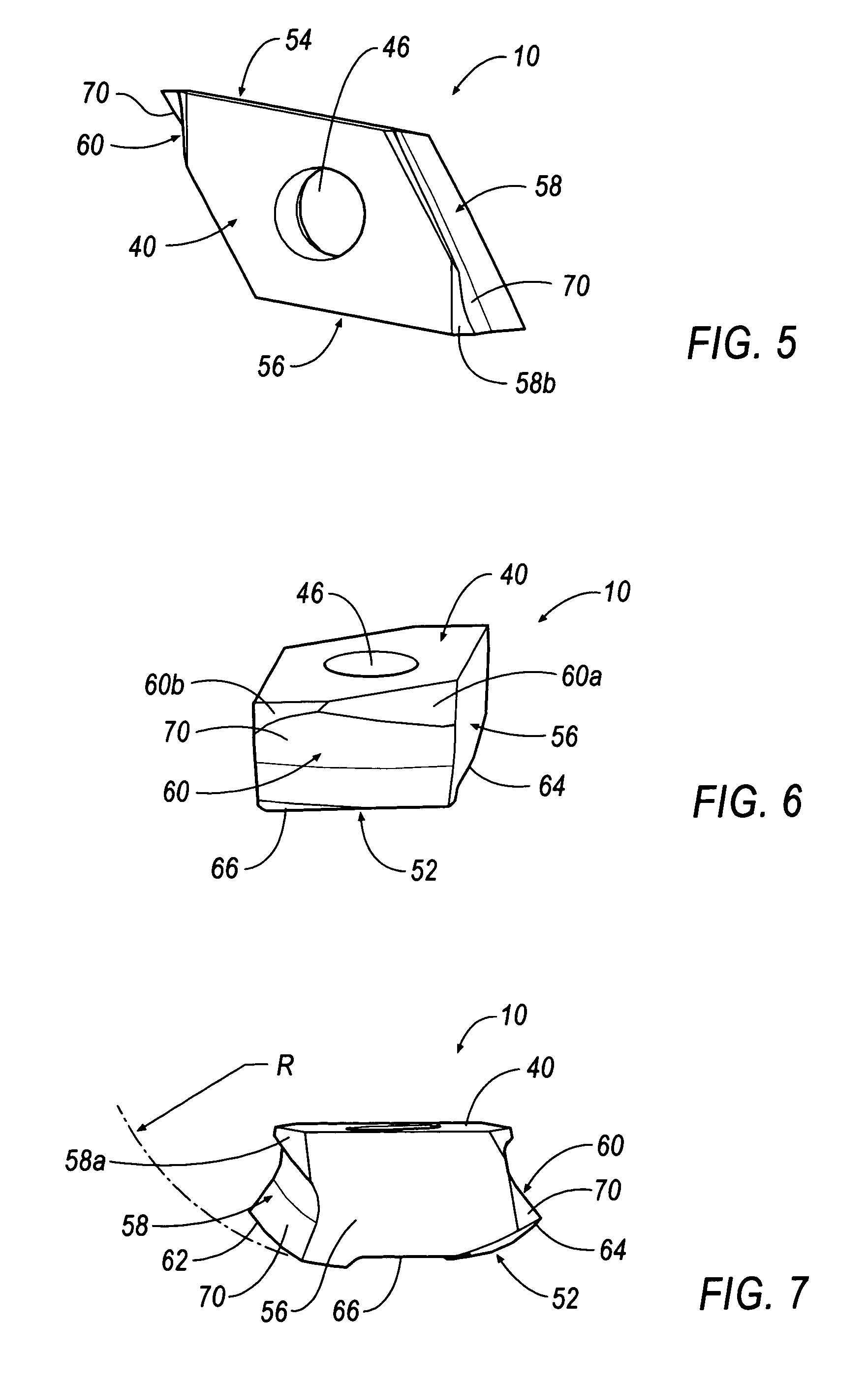

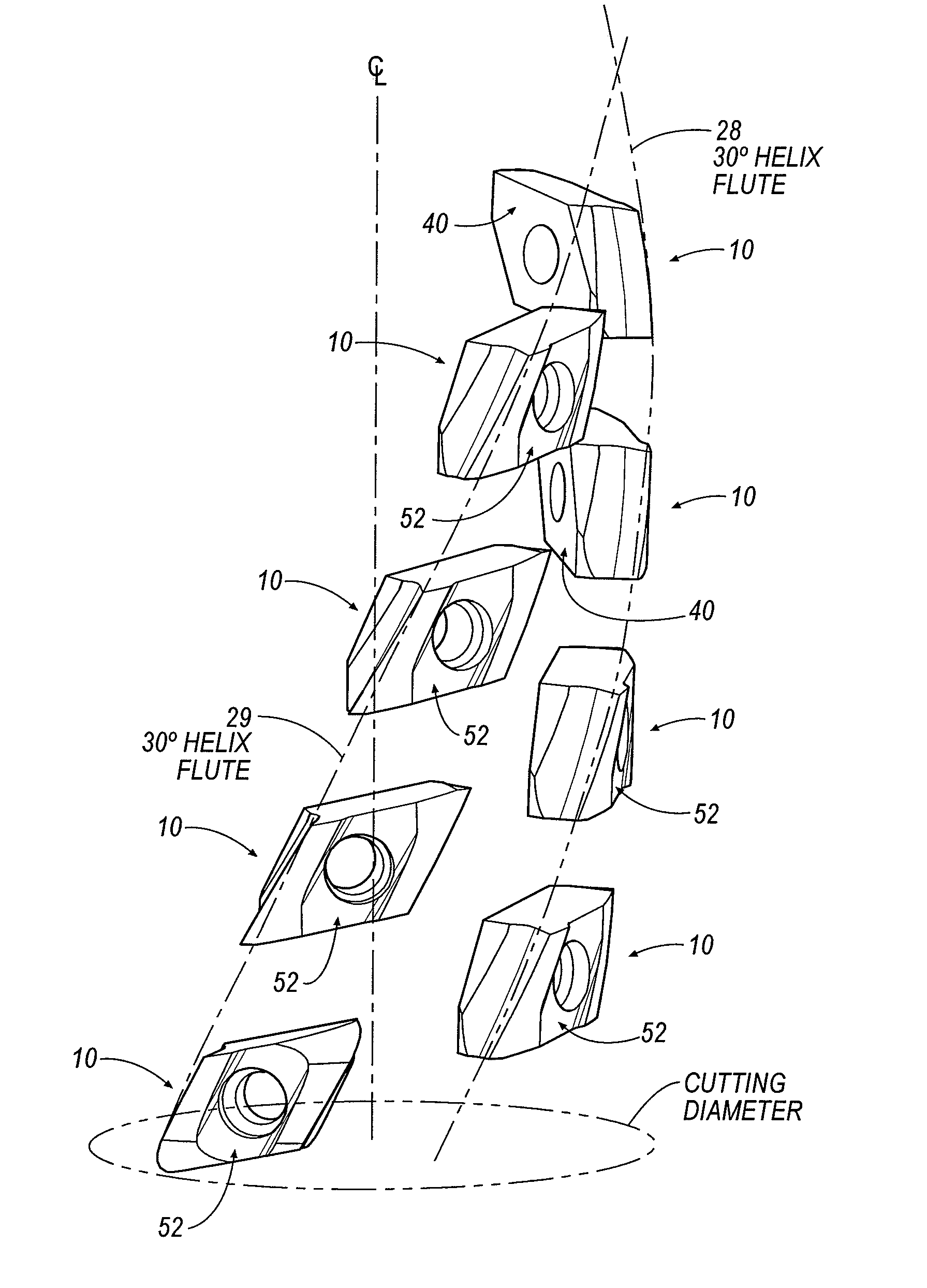

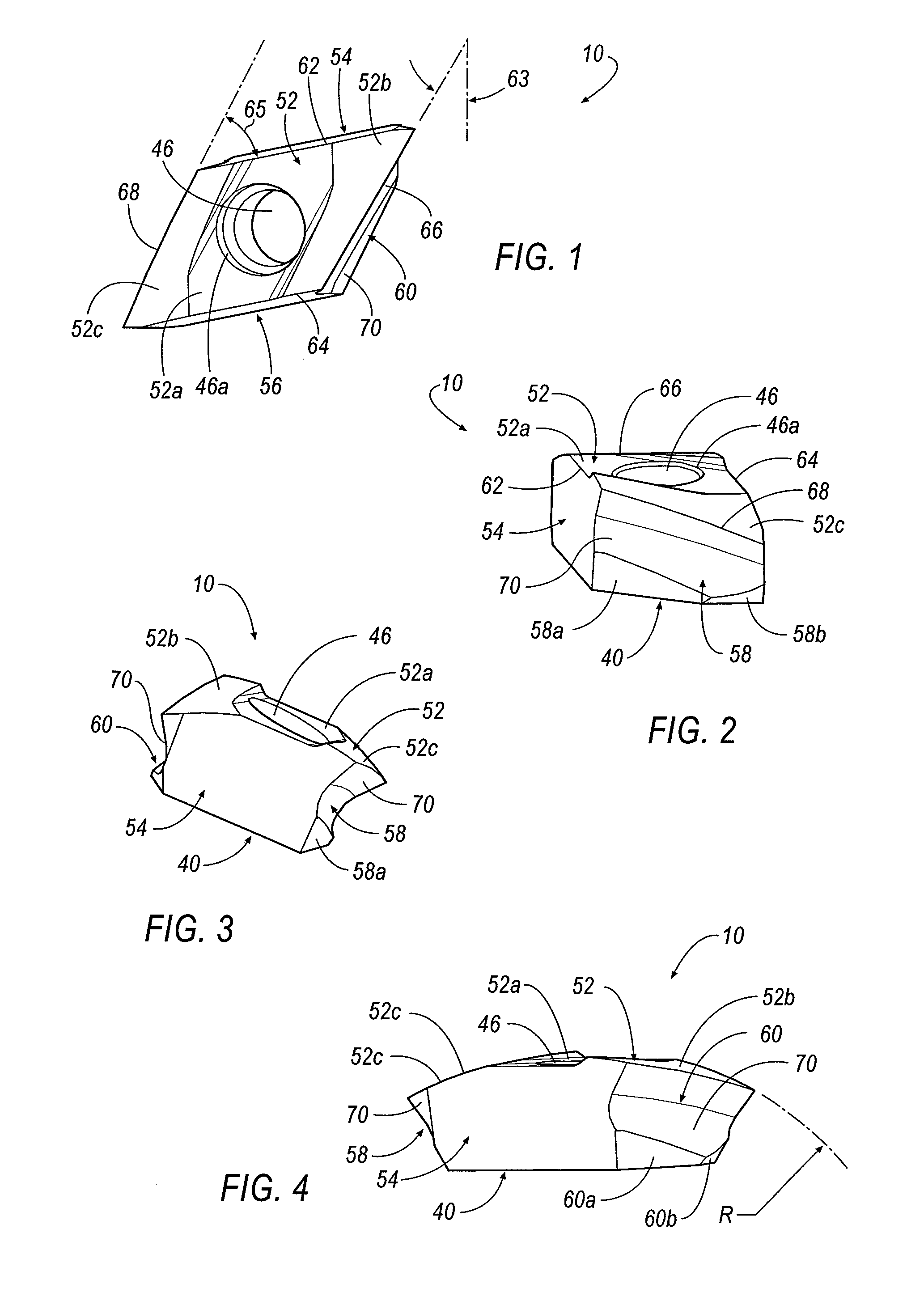

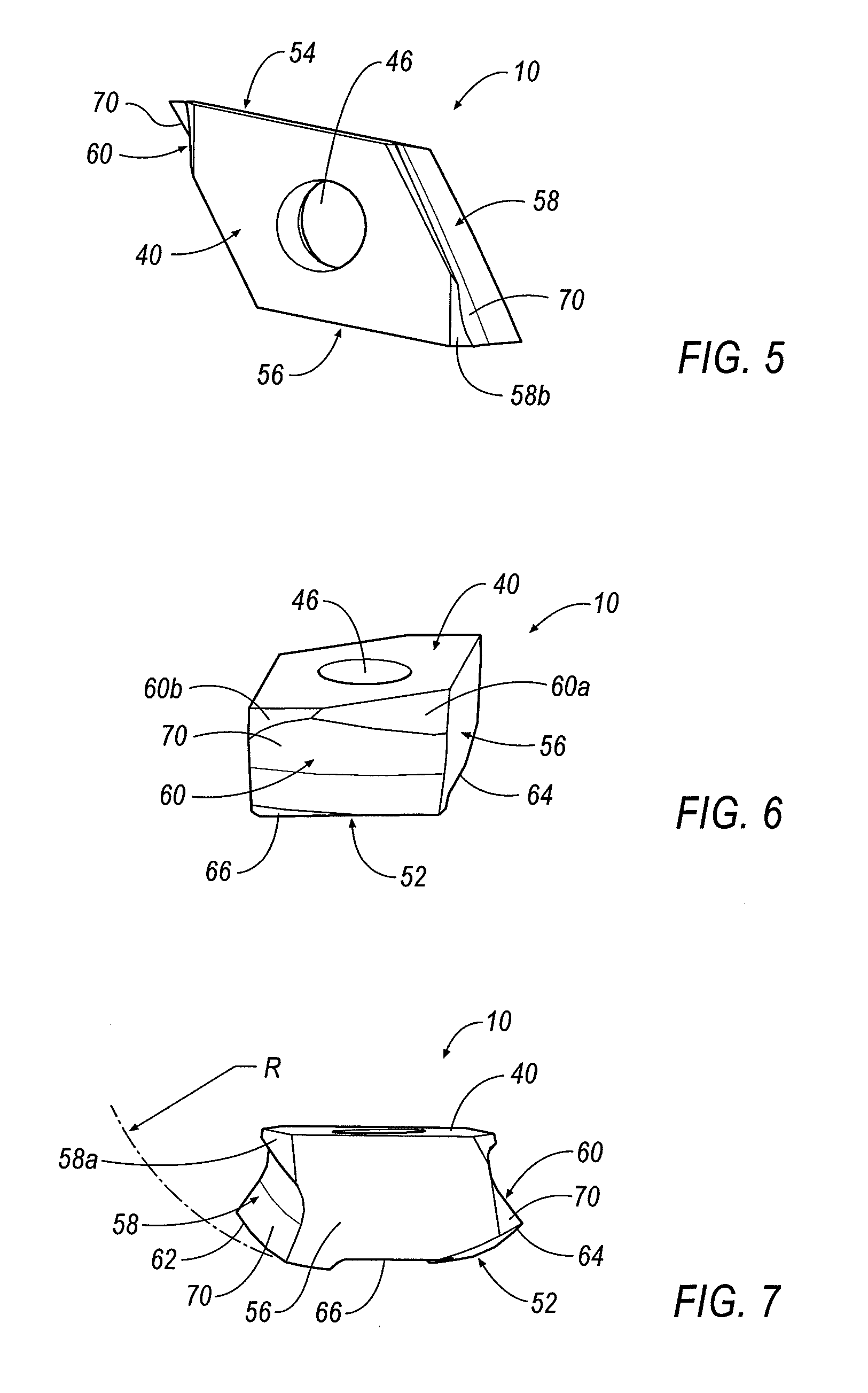

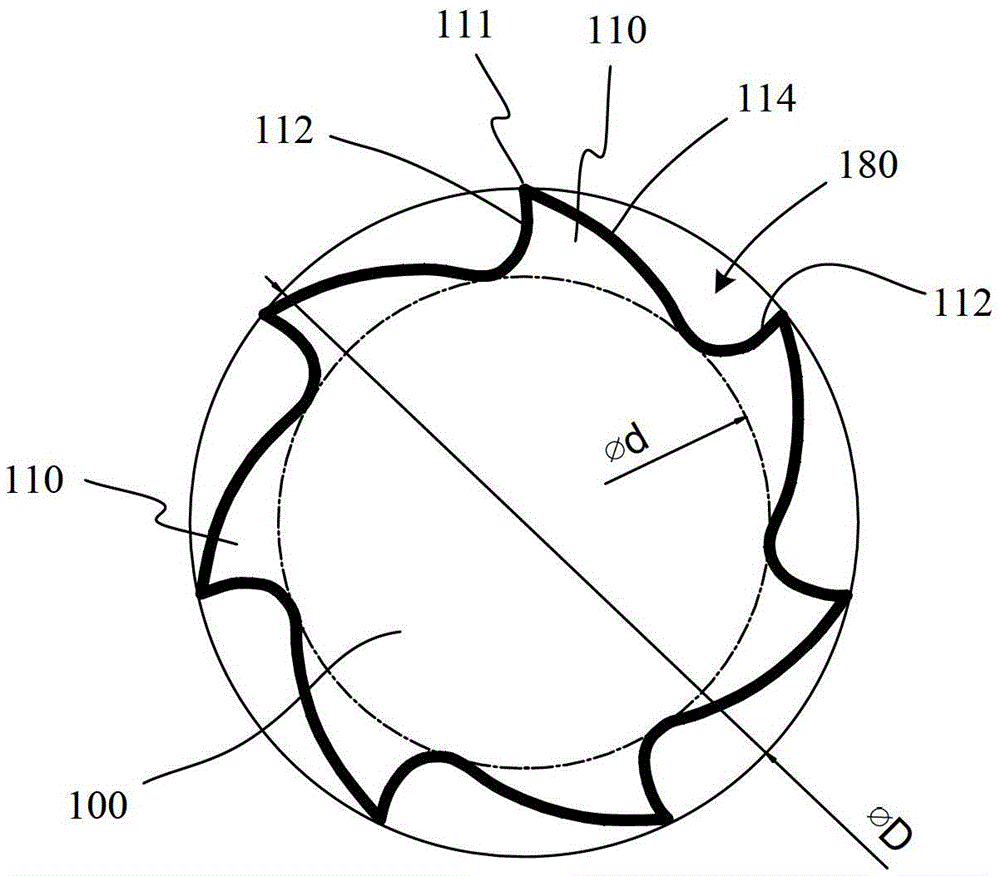

Helical cutting insert with progressive cutting edge

InactiveUS20060280567A1Less powerLess torqueMilling cuttersShaping cuttersEngineeringMechanical engineering

An indexable, helical cutting insert includes at least one axial clearance slash extending from a bottom surface to one of said side walls forming a wiper on an edge of the axial clearance slash. In another embodiment, the cutting insert includes at least one inside cutting edge that extends outwardly a distance from the side wall. In another embodiment, the helical cutting insert includes at least one progressive cutting edge. In another embodiment, the cutting insert includes at least one helical cutting edge that is curved inwardly to enable the cutting insert to perform machining operations on cutters having different diameters.

Owner:KENNAMETAL INC

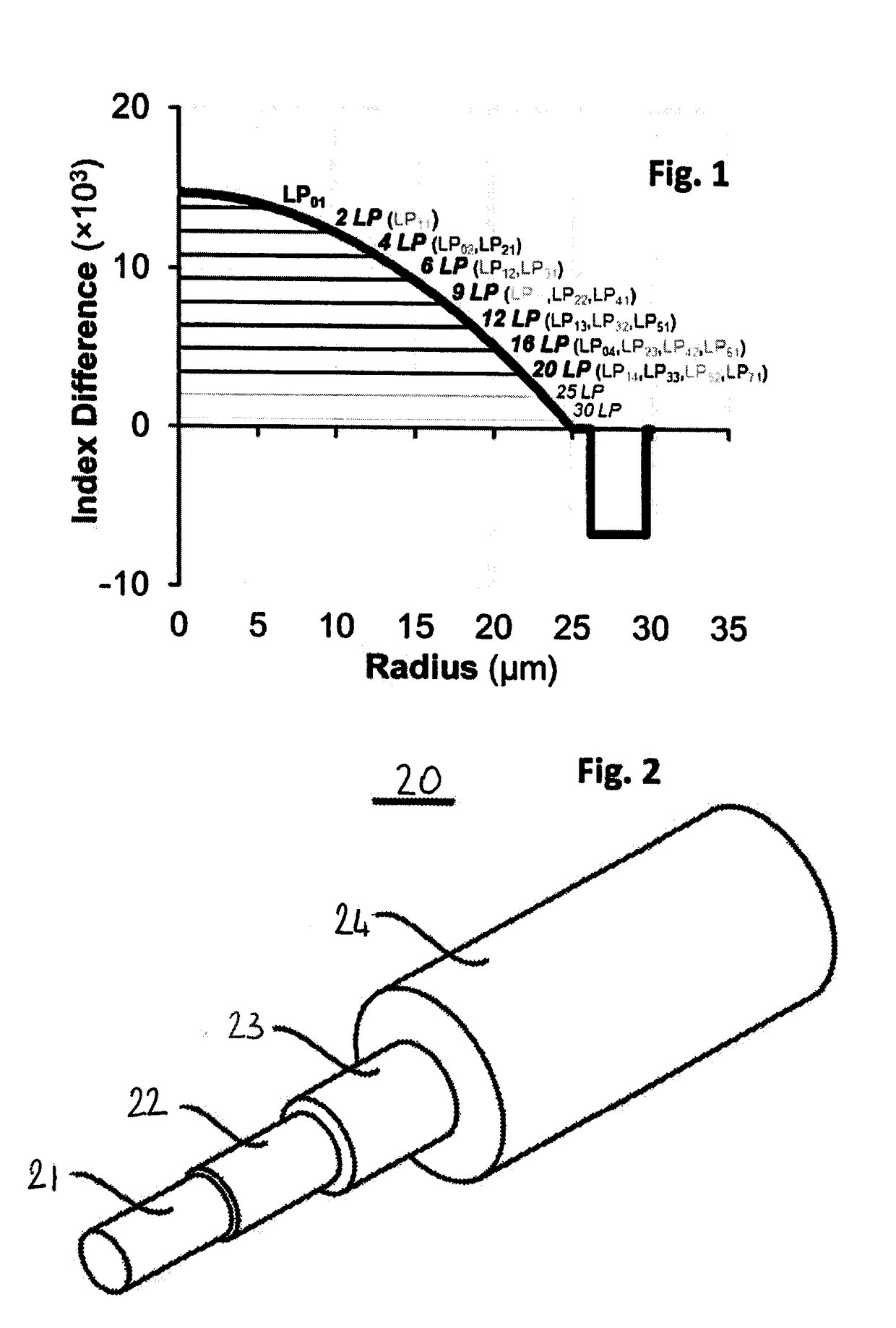

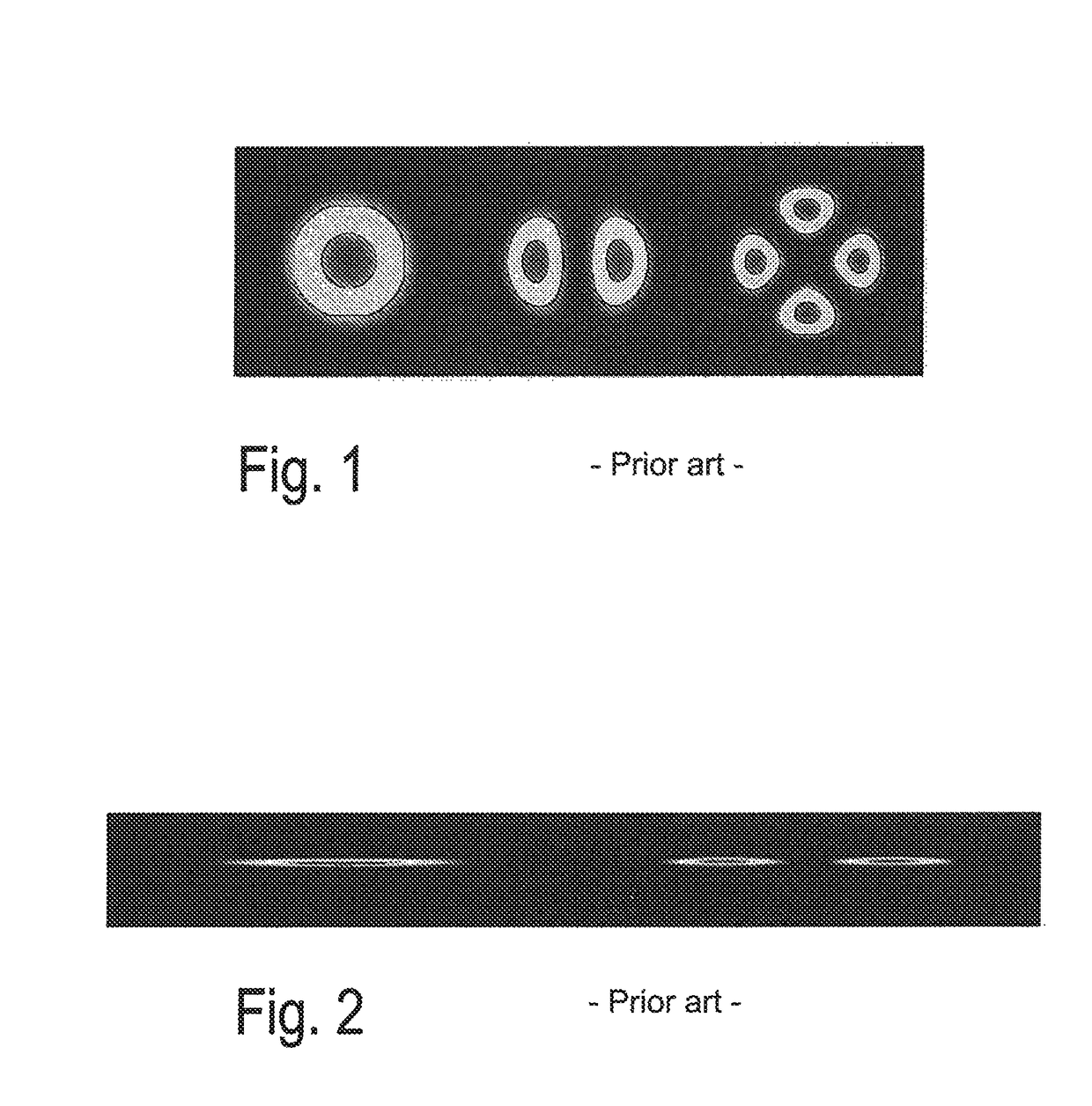

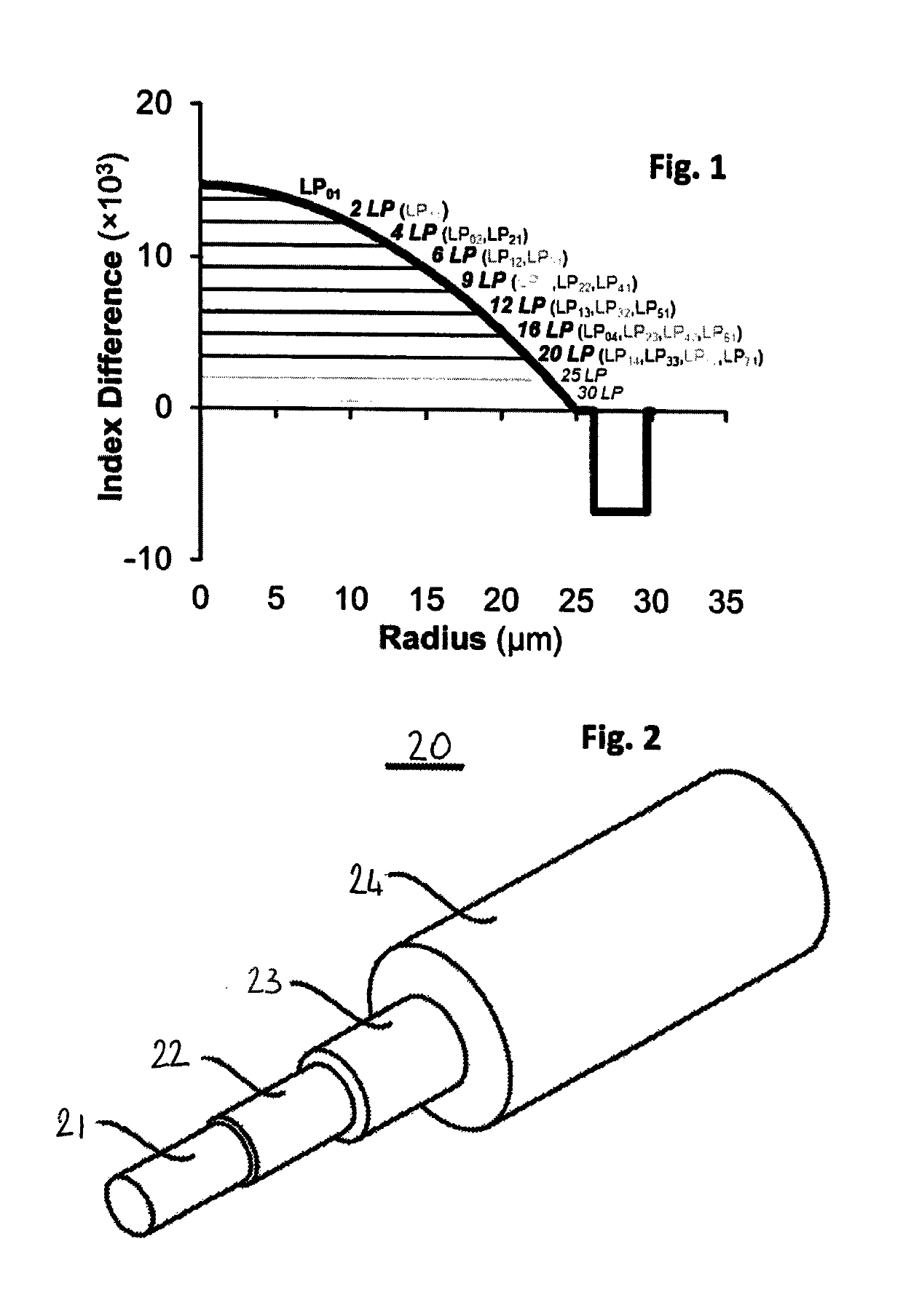

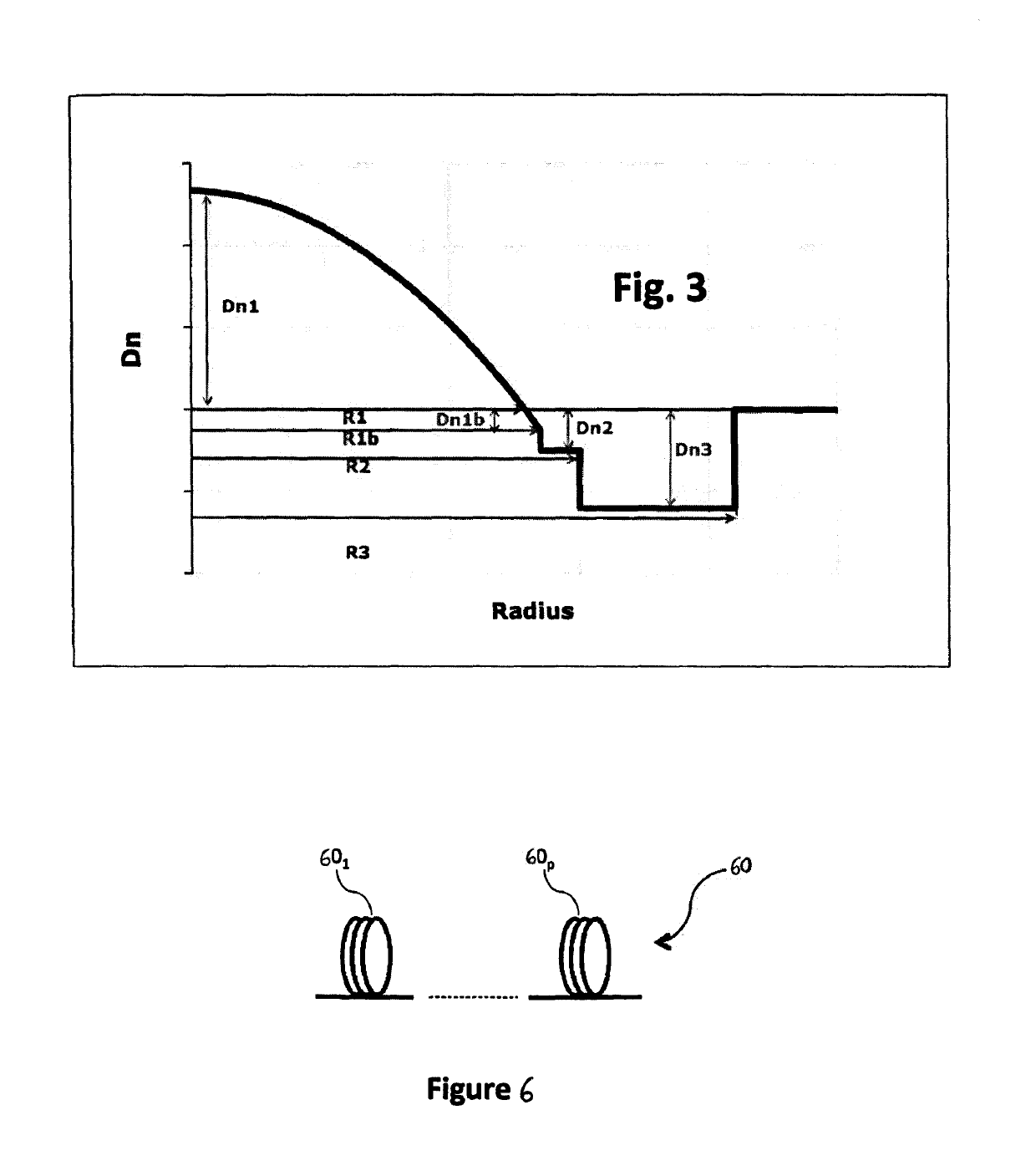

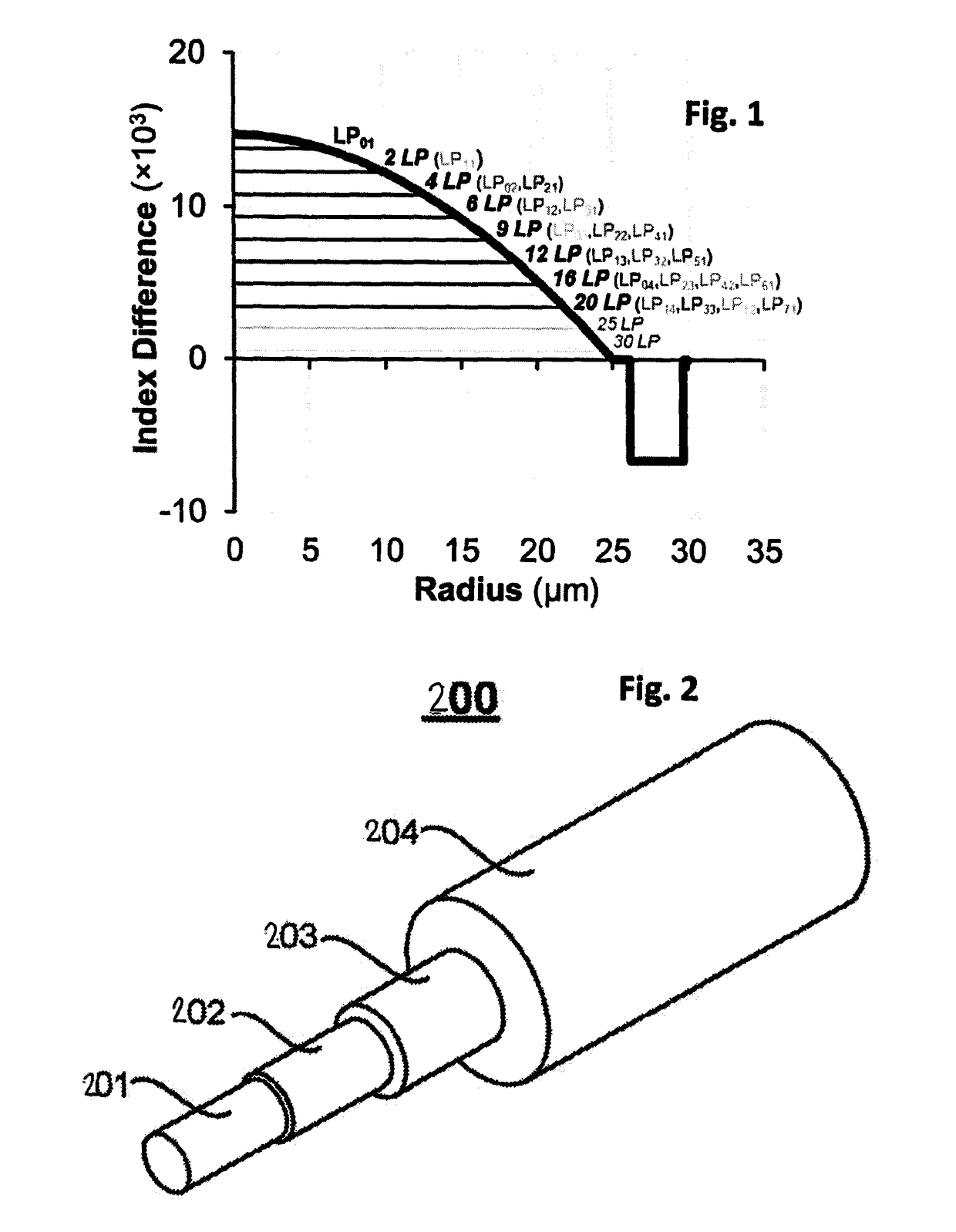

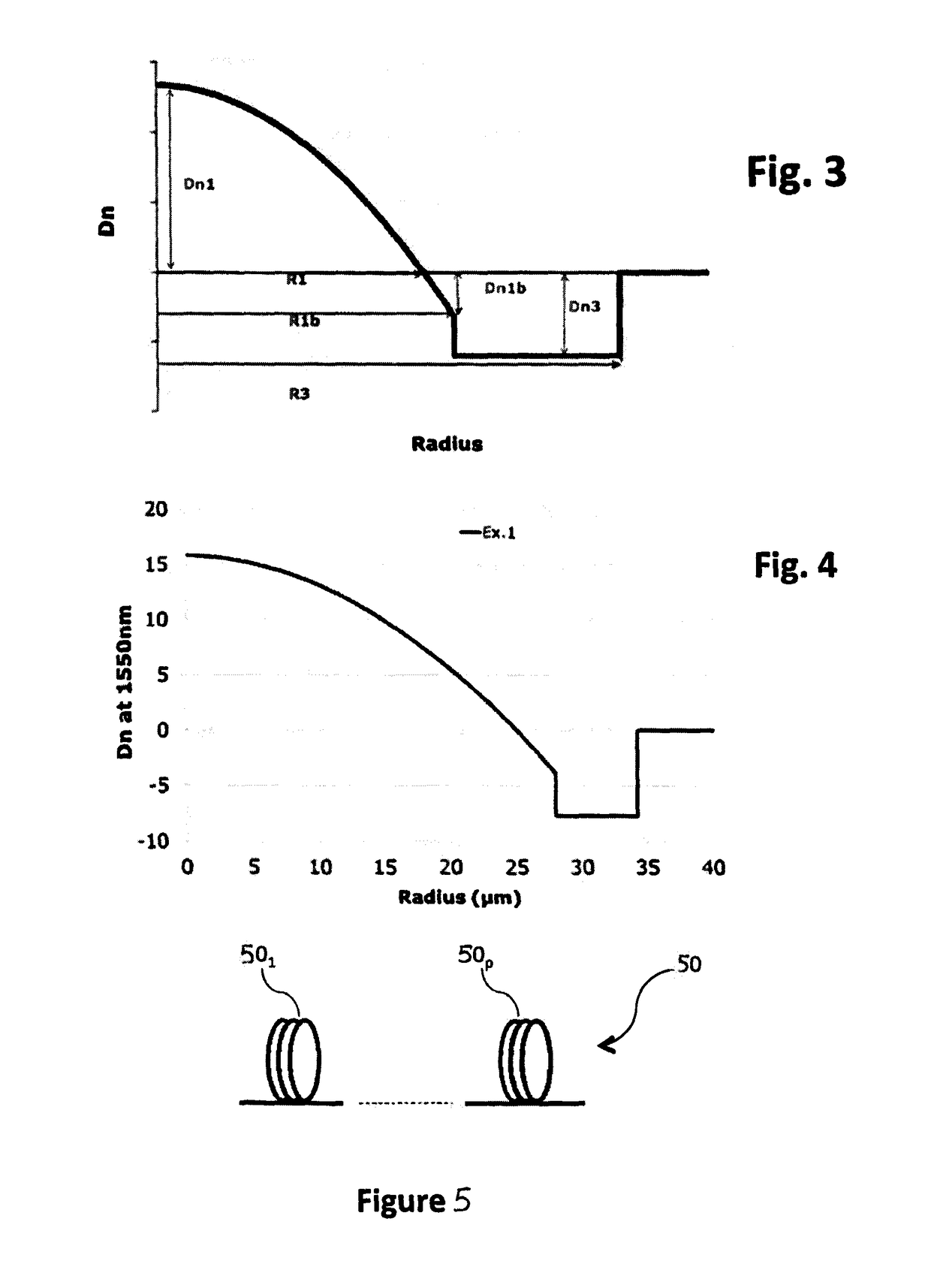

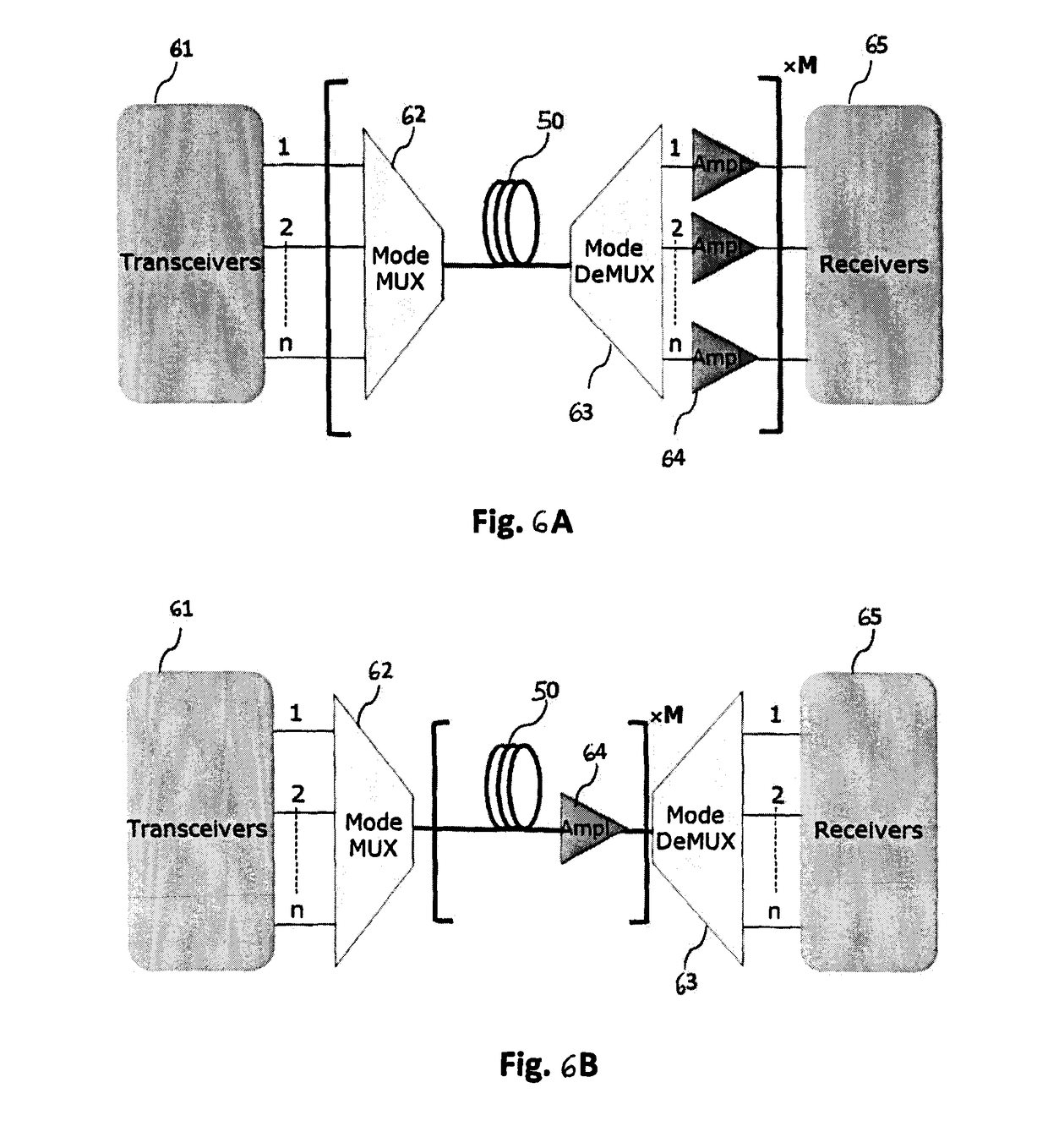

Few mode optical fibers for mode division multiplexing

ActiveUS20190033515A1Improve propertiesIncrease the number ofOptical fibre with graded refractive index core/claddingOptical fibre with multilayer core/claddingFew mode fiberRefractive index

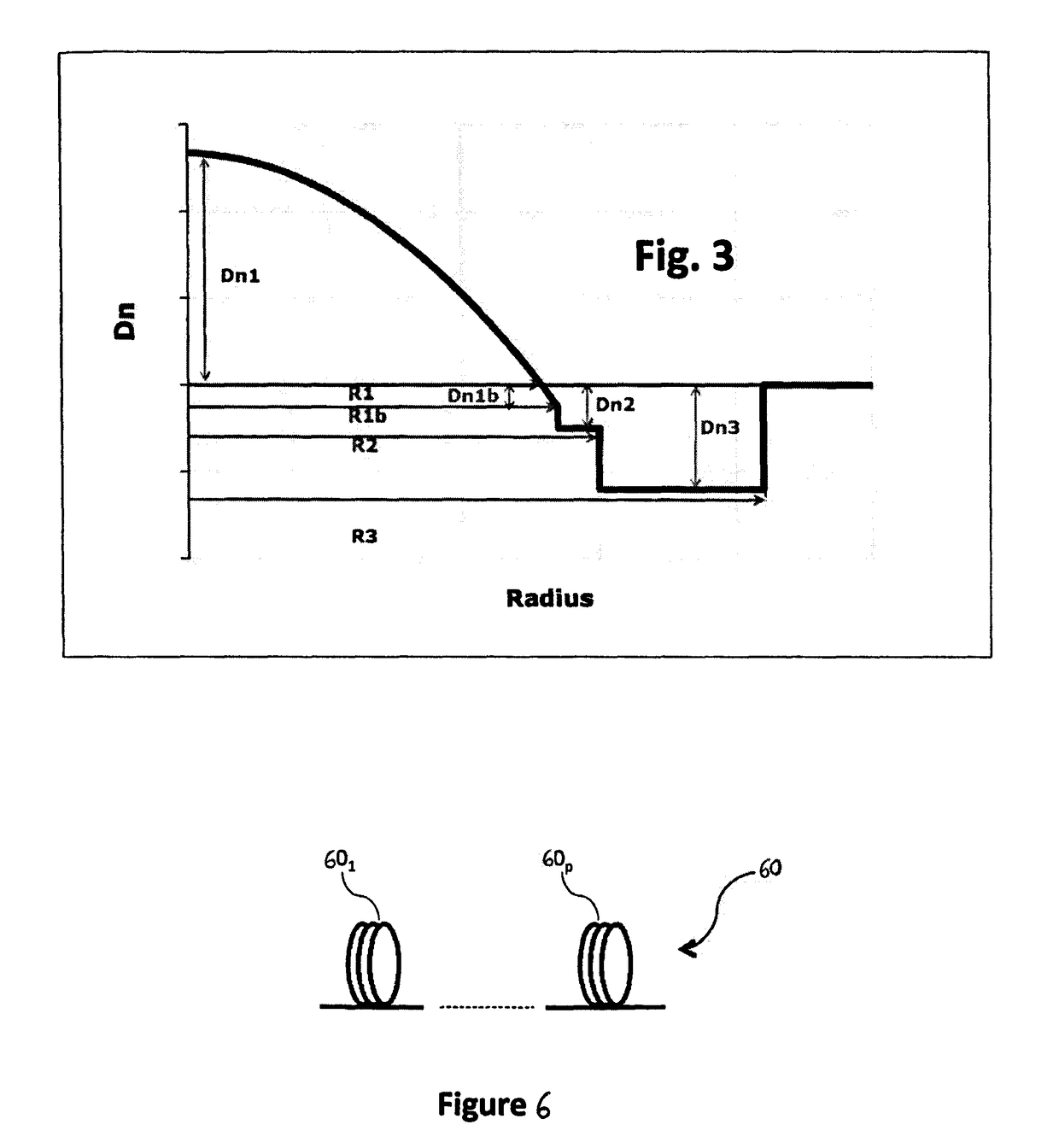

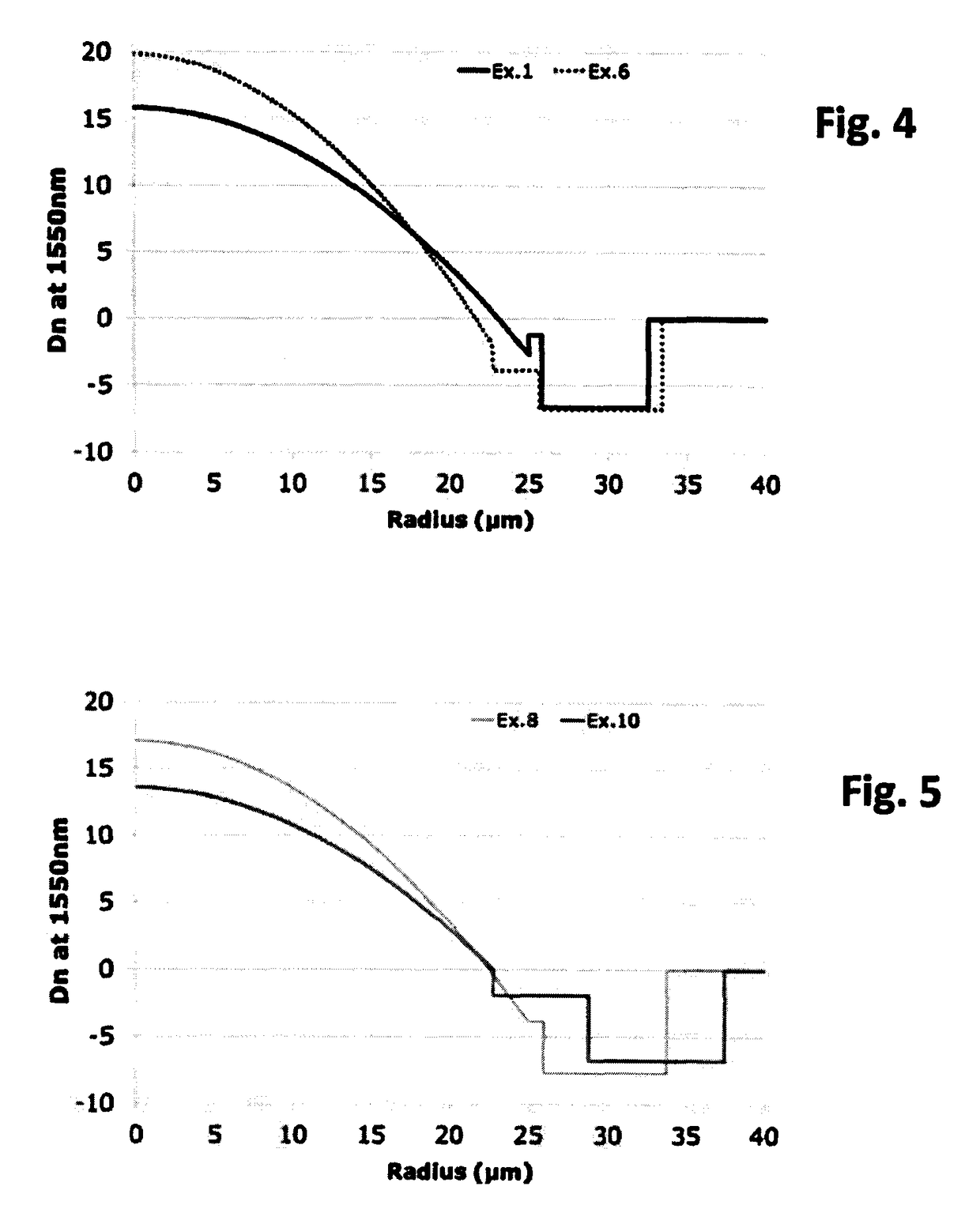

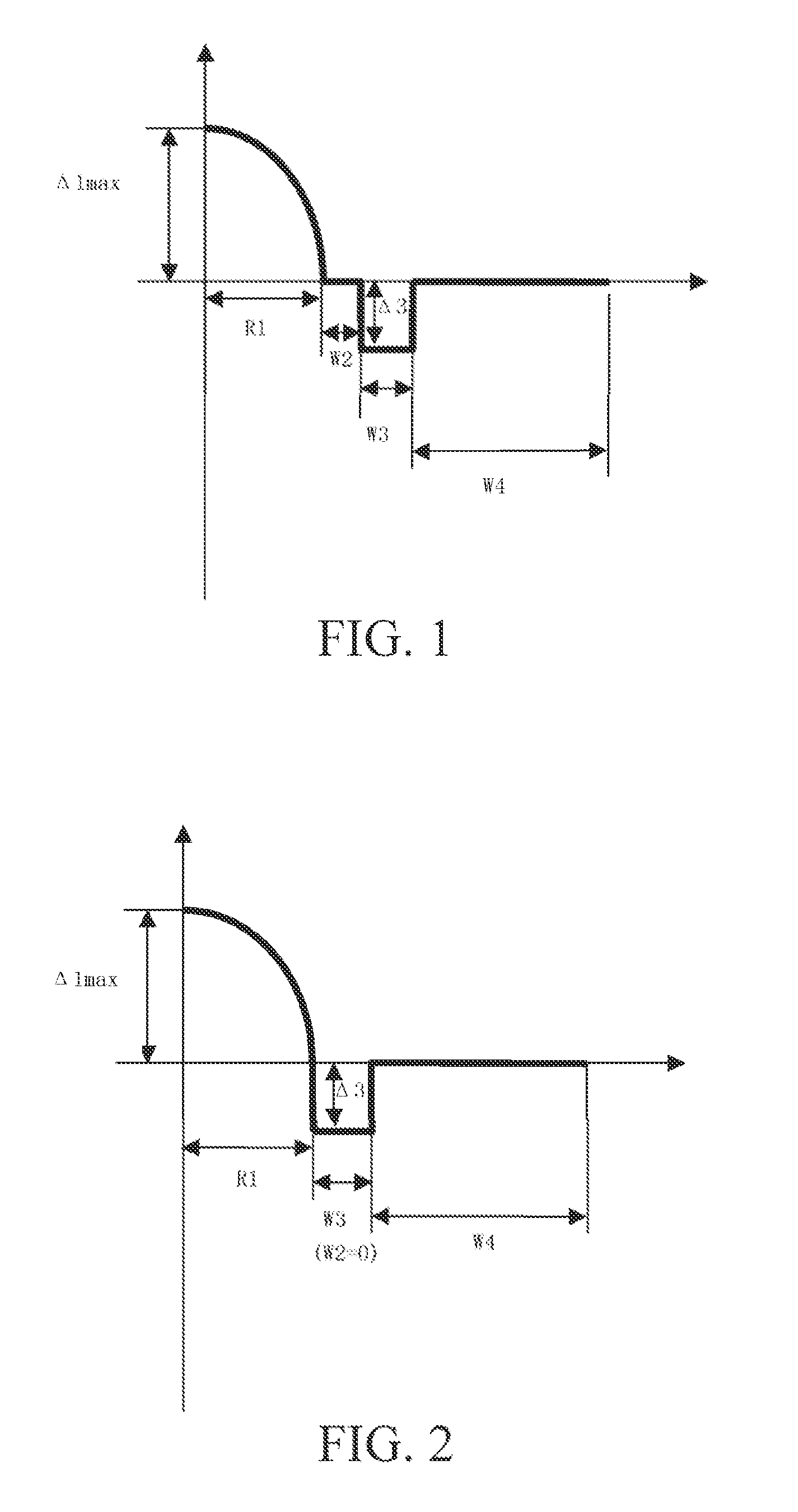

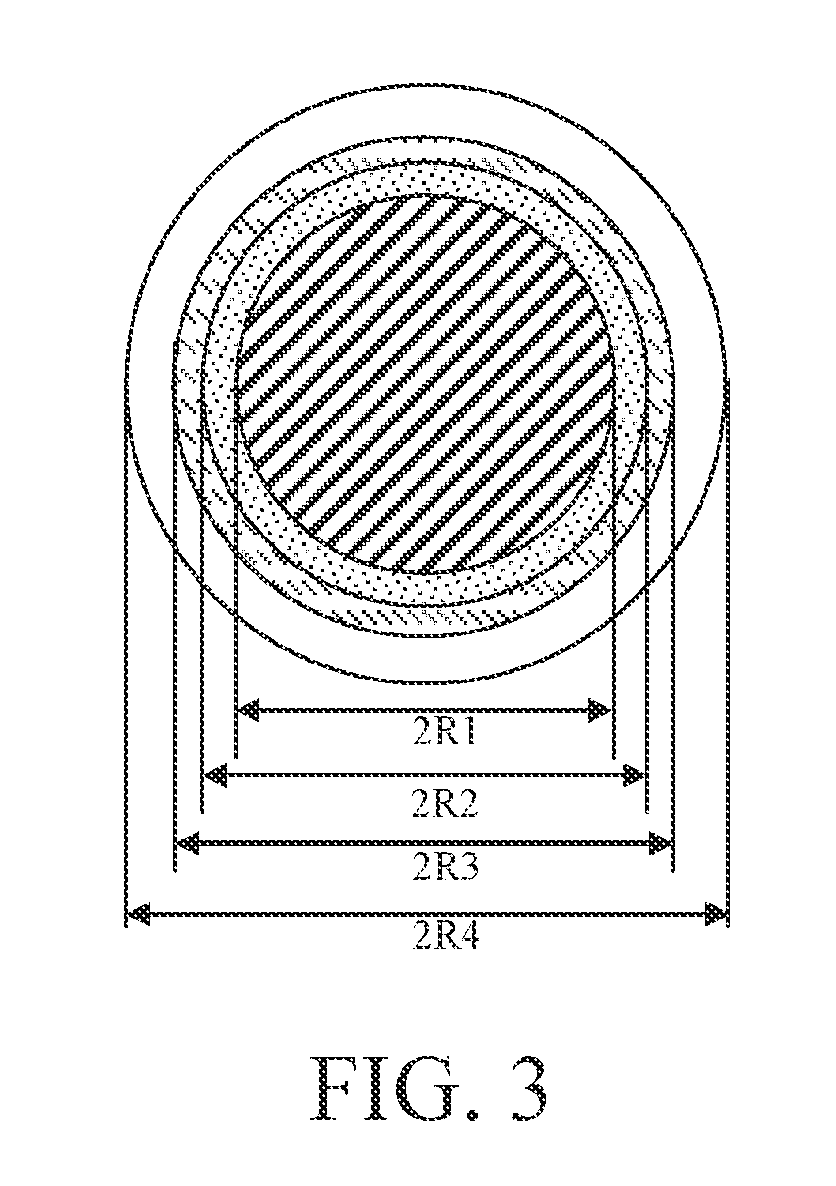

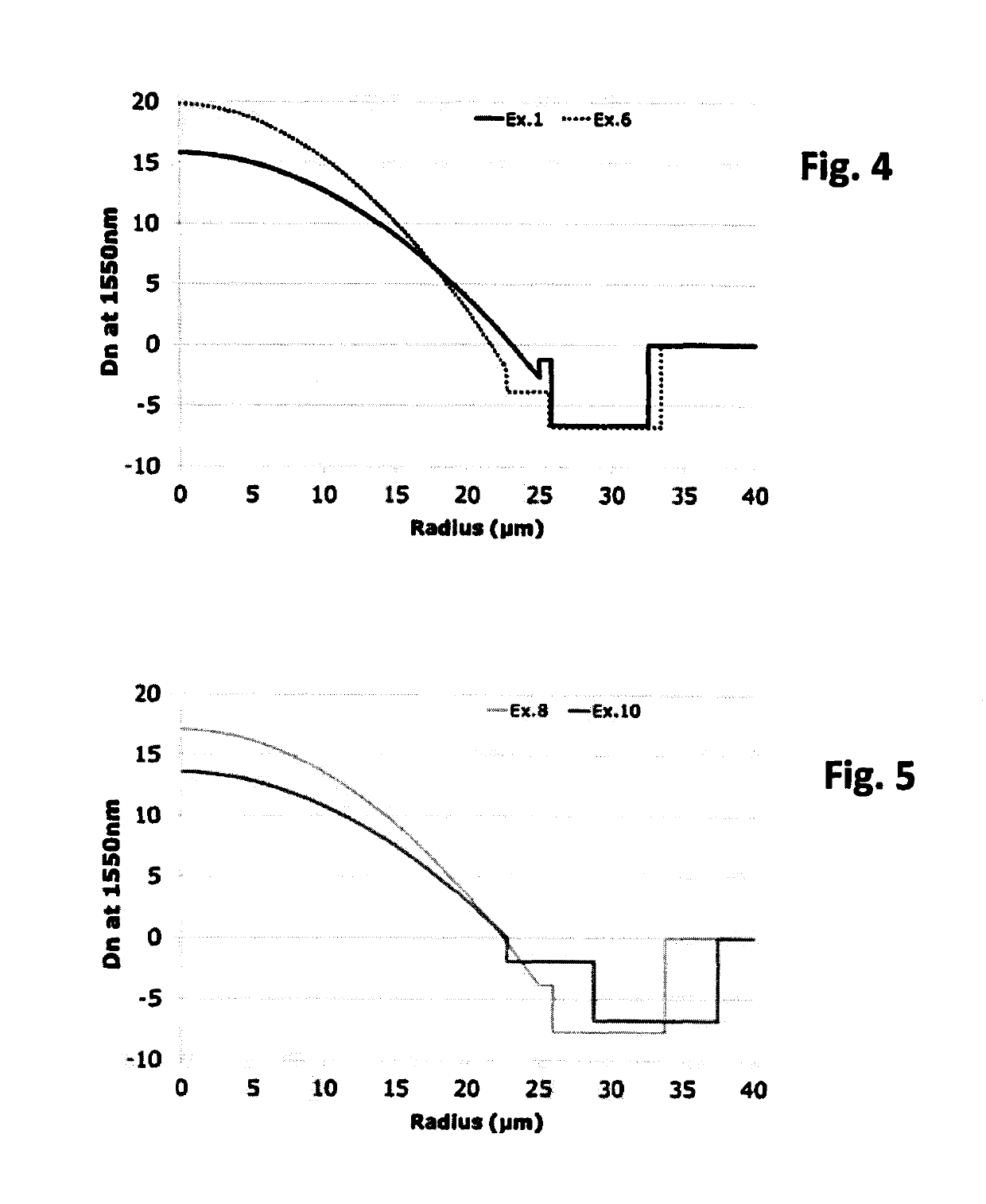

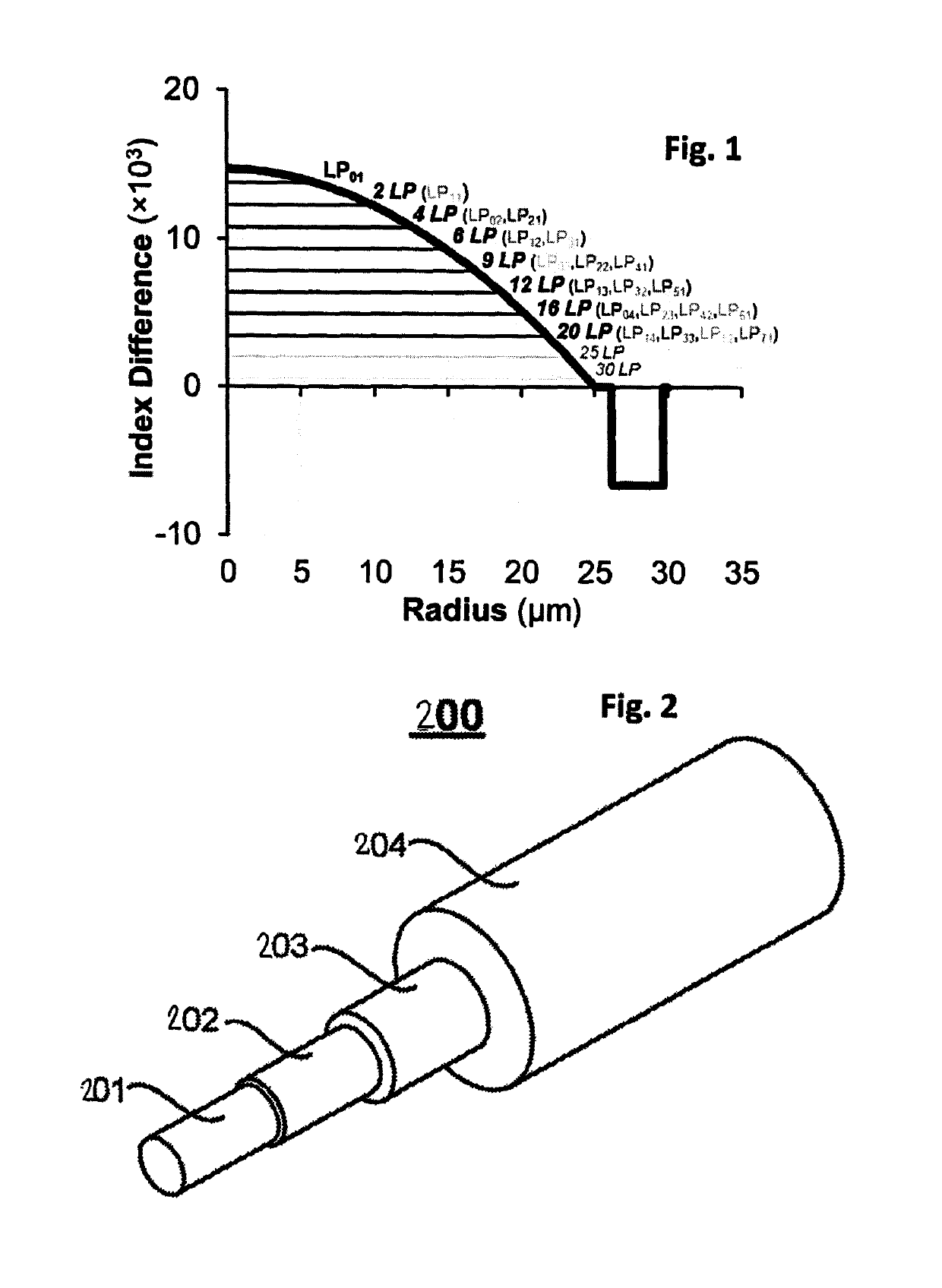

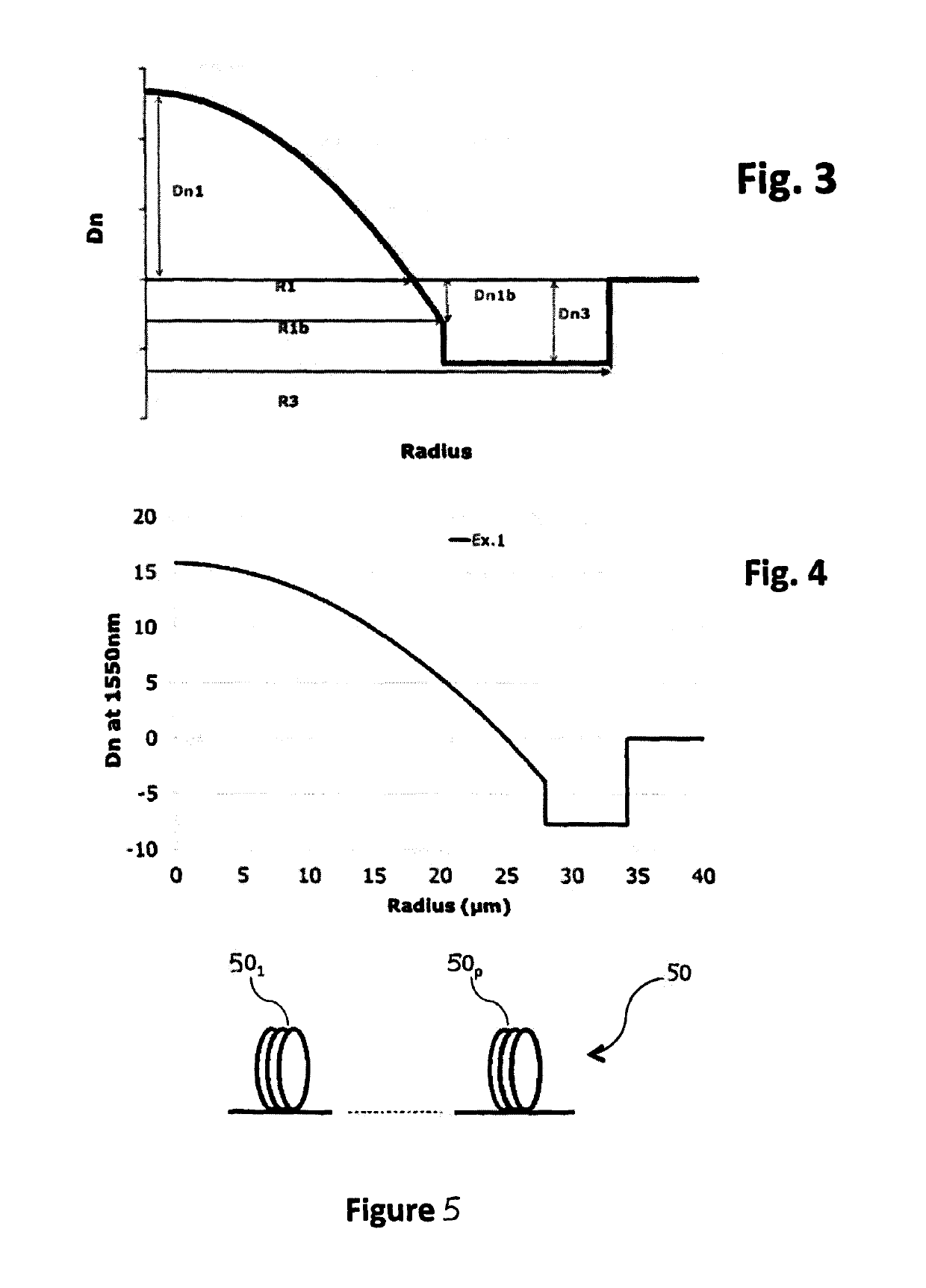

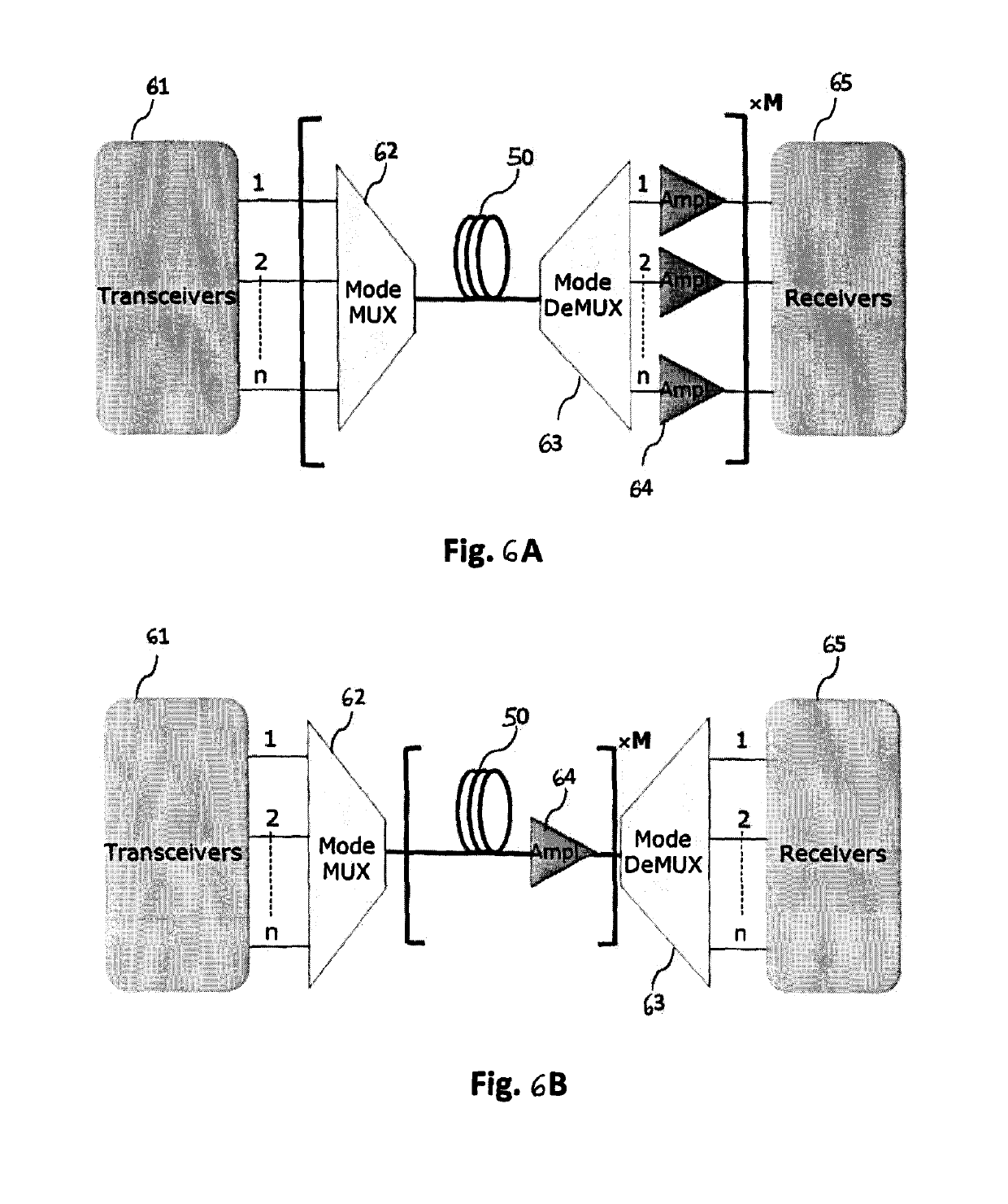

Few mode optical fibers for mode division multiplexing. The Few Mode Fiber supporting 25 or 30 LP guided modes and includes a graded index core with a α-profile, a radius R1 (at 0 refractive index difference) between 21.5 and 27 μm and a maximum refractive index difference Dn1 between 12.5×10−3 and 20×10−3, and an end of the α- profile at a radius R1b, with index difference Dn1b; a trench surrounding the core with radius R3 between 30 and 42 μm and refractive index difference Dn3 between −15.10−3 and −6.10−3, an intermediate depressed trench with a radius R2, with R1b<R2<R3 and a refractive index difference Dn2, with Dn3<Dn2<0, wherein: for |Dn1b−Dn2|>=0.5×10−3, Min(Dn1b, Dn2)≤−1.5×10−3, and for |Dn1b−Dn2|<0.5×10−3, Dn2 is between −5×10−3 and −3.5×10−3.

Owner:DRAKA COMTEQ BV

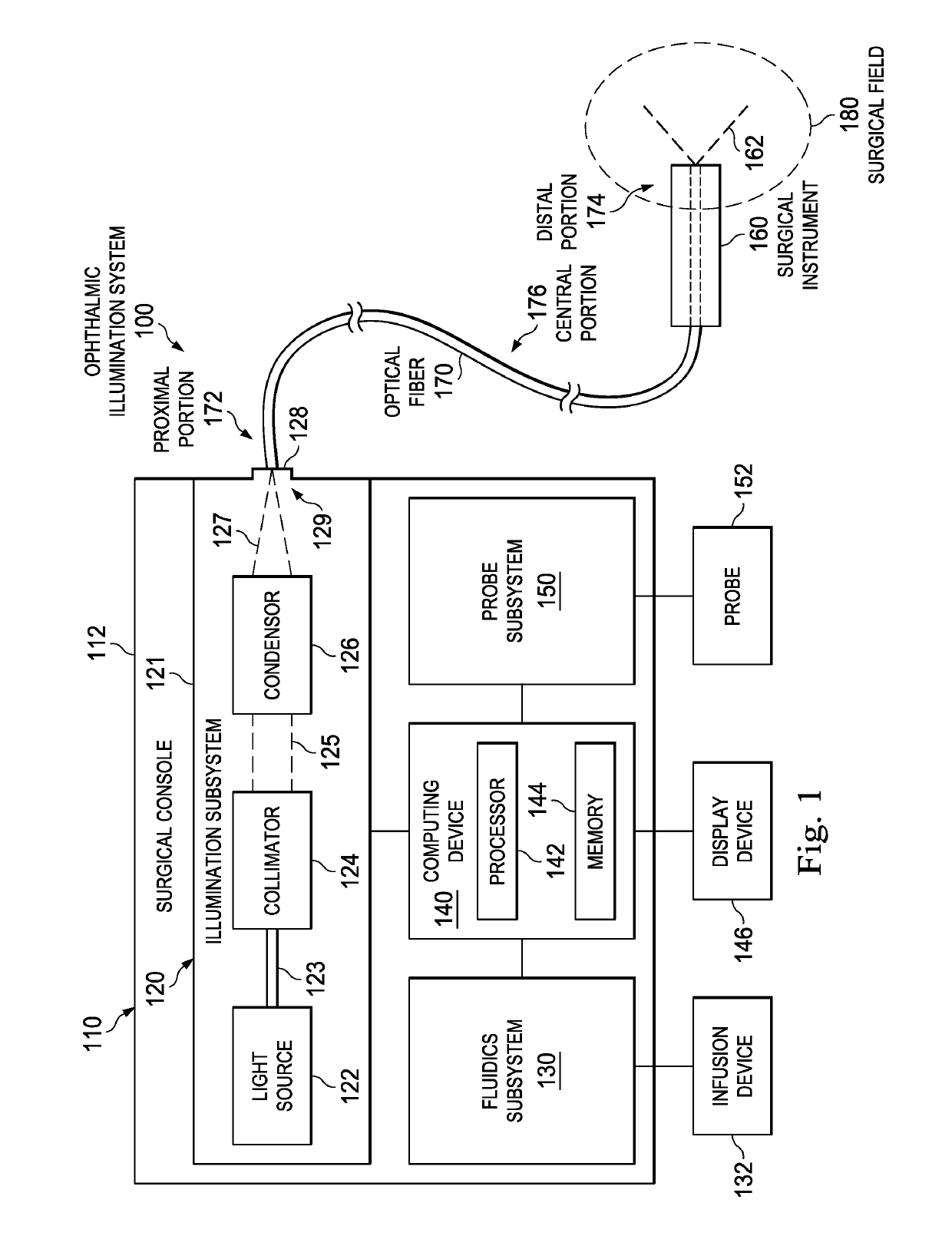

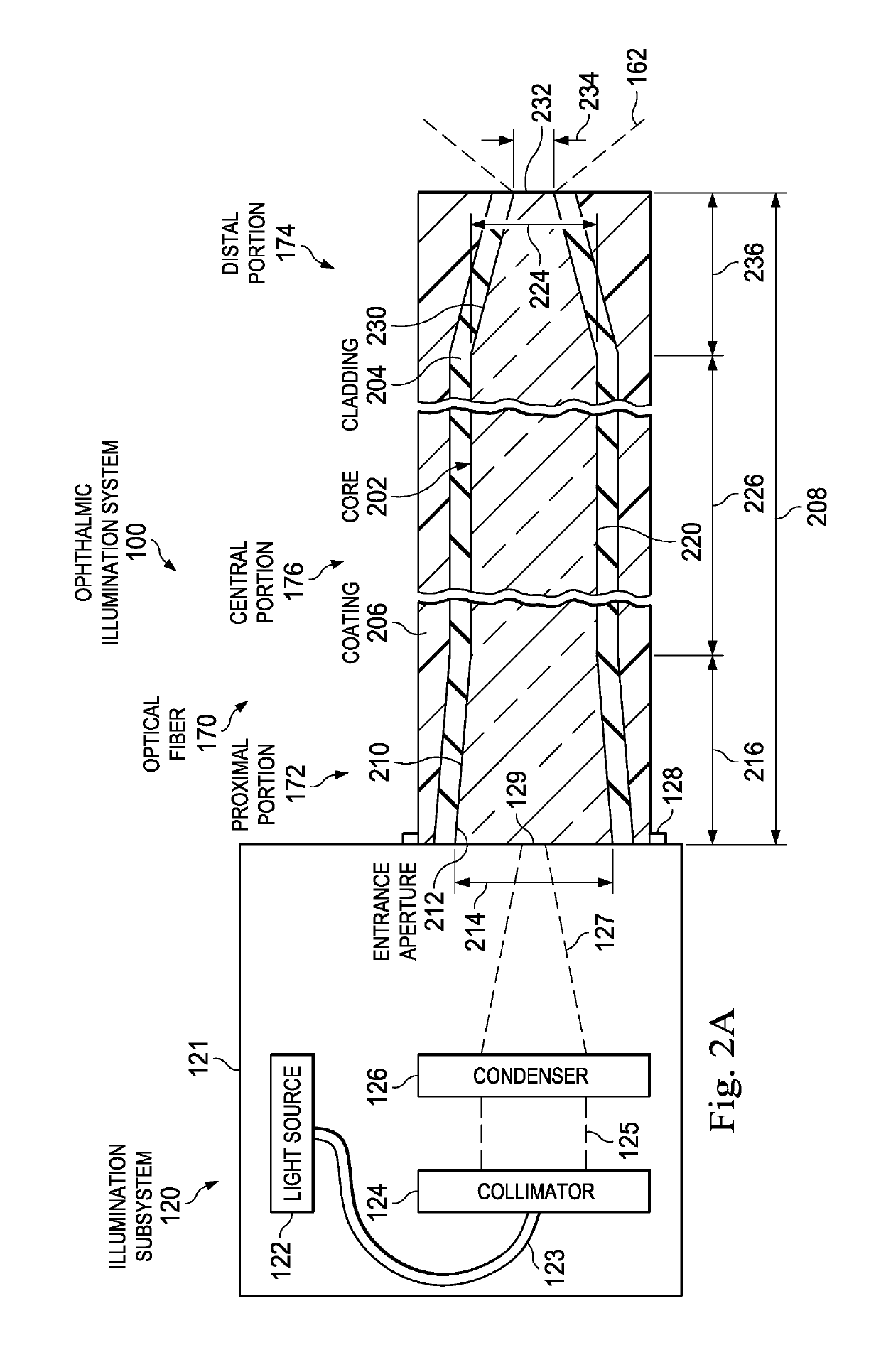

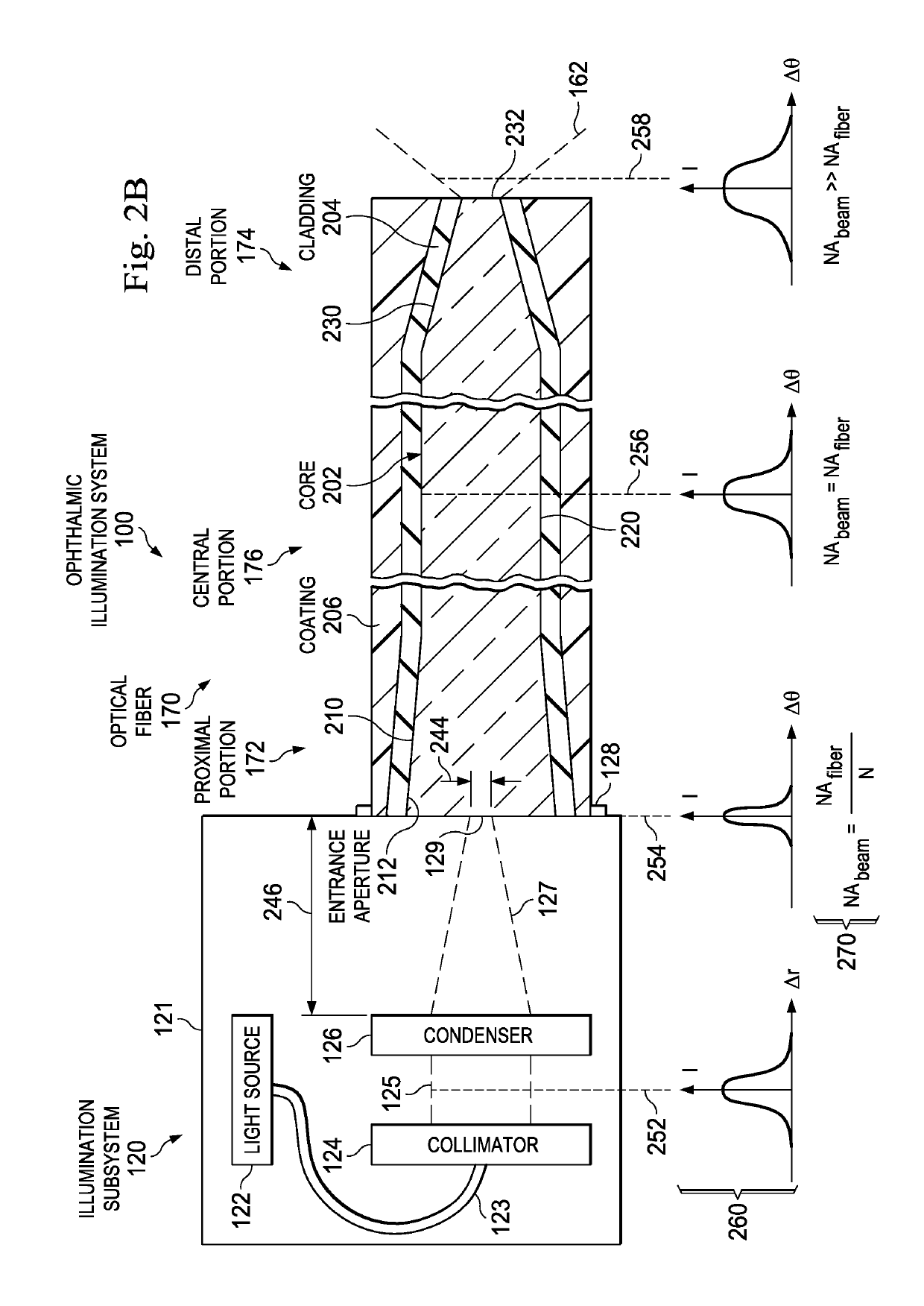

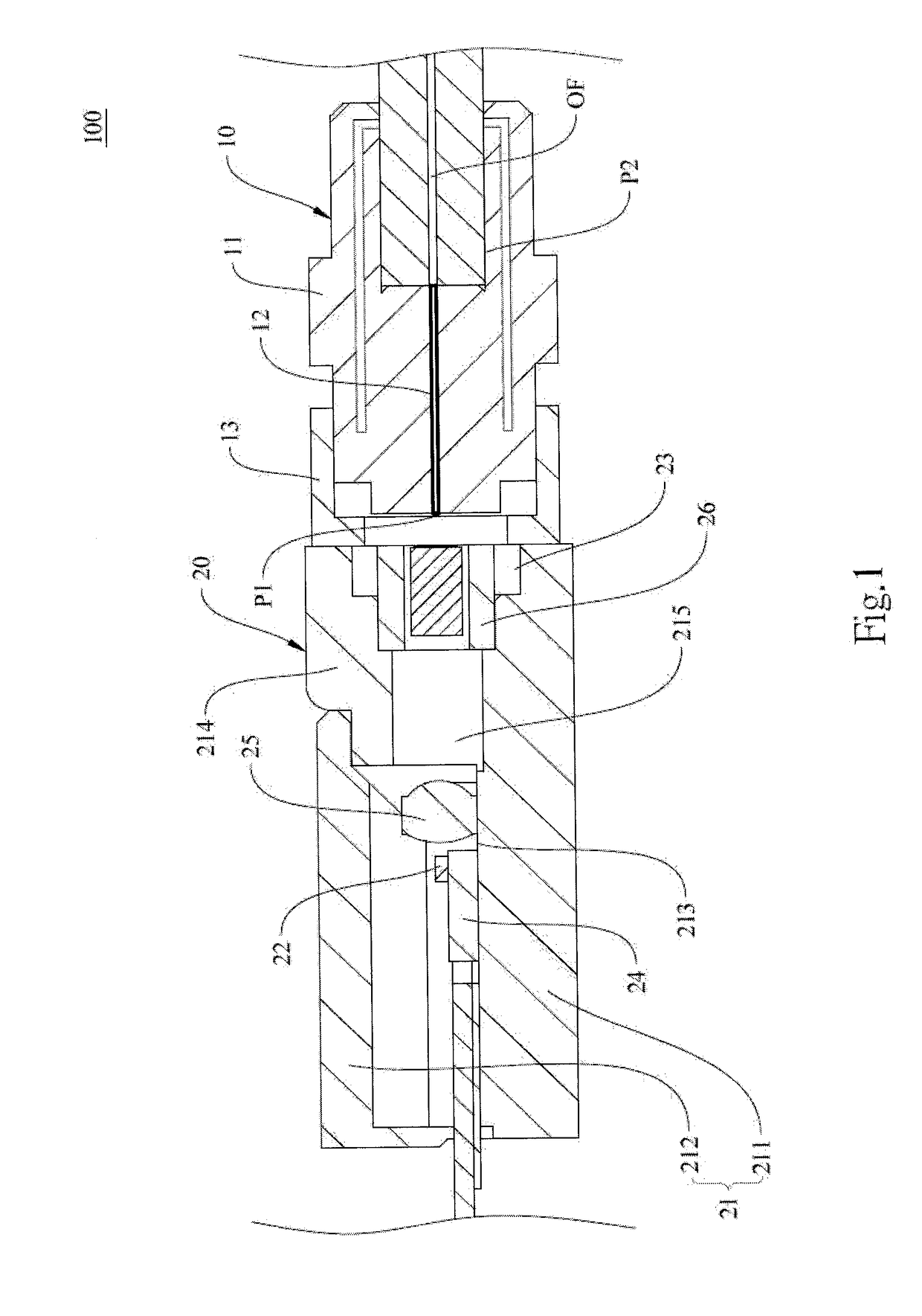

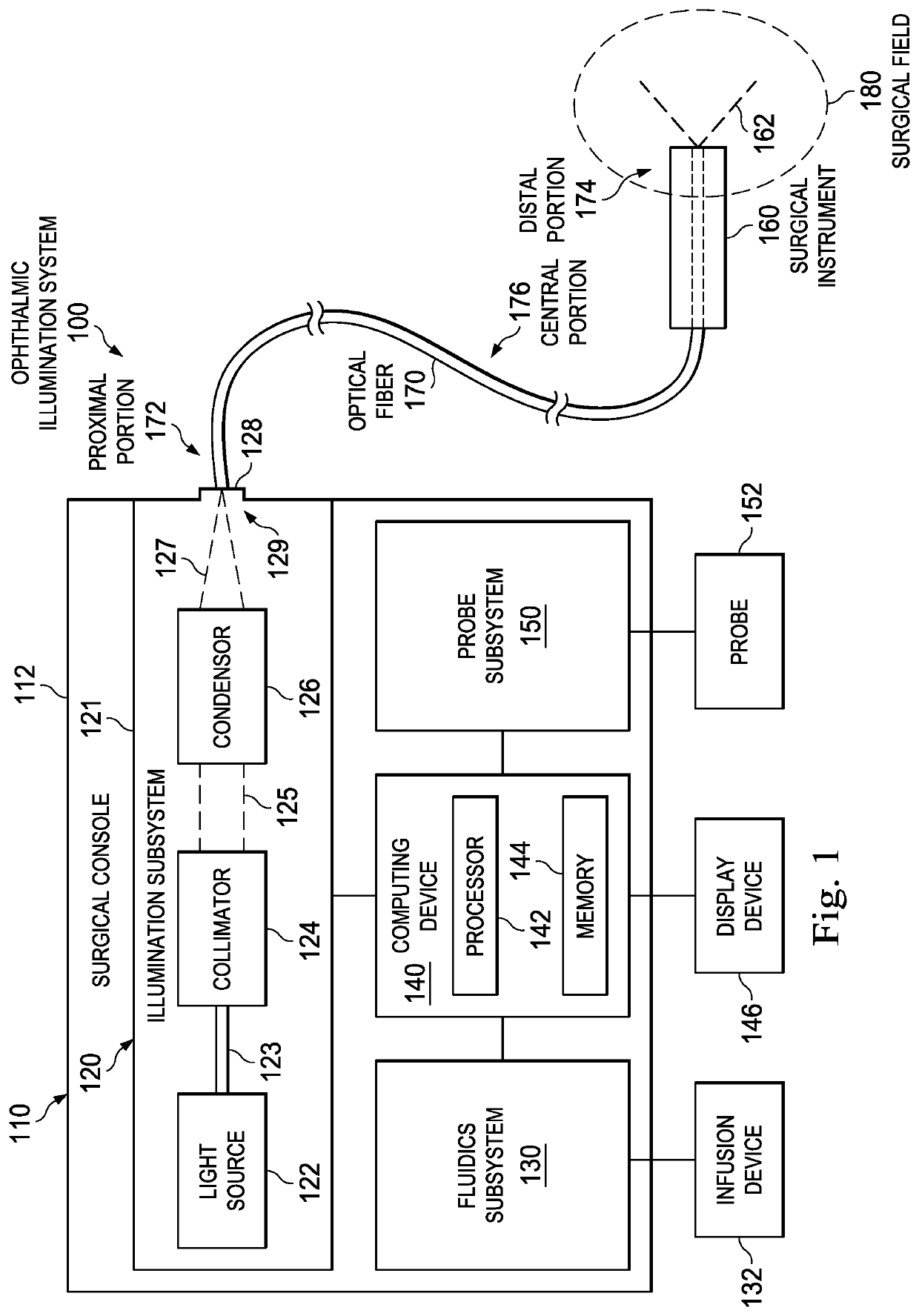

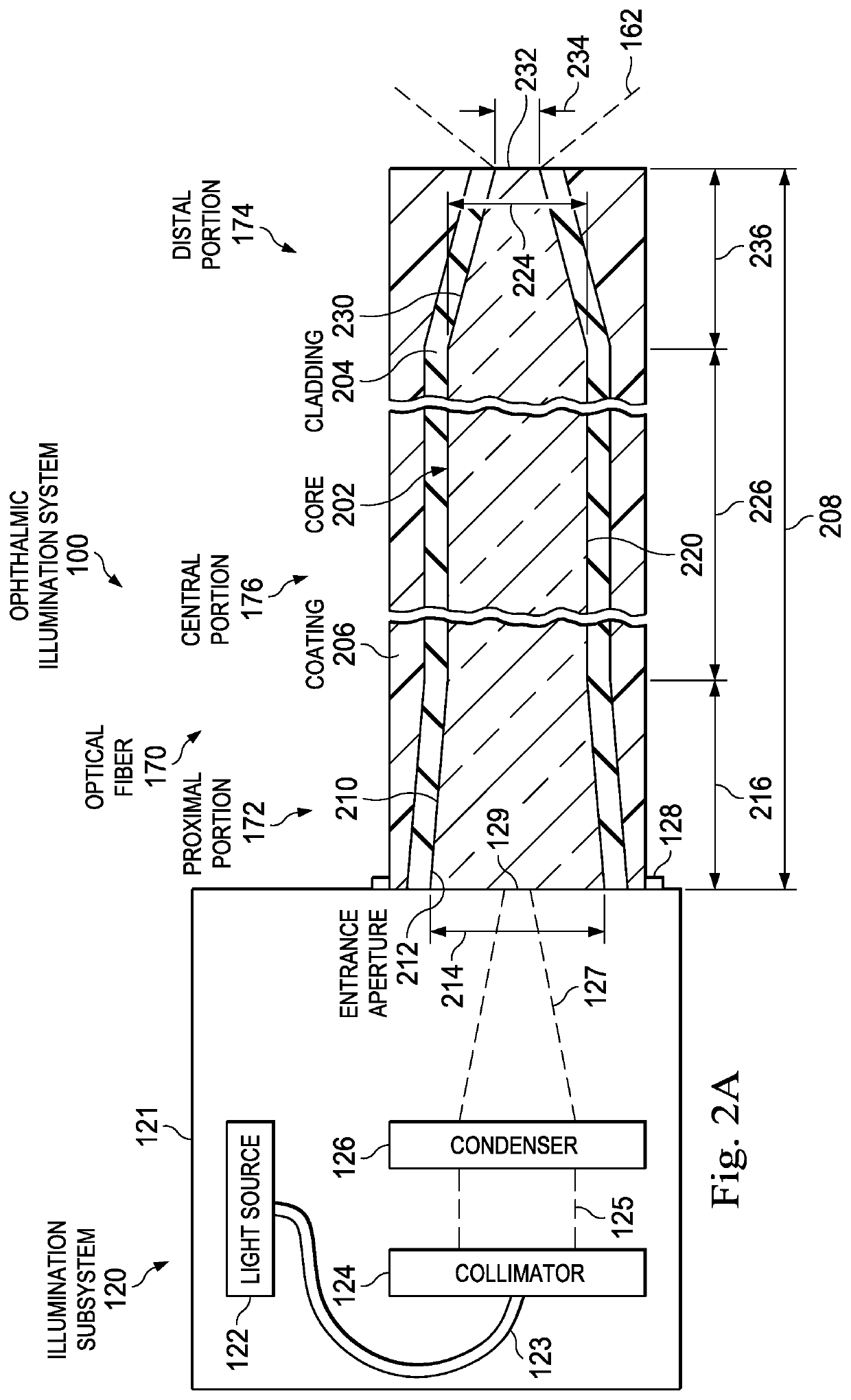

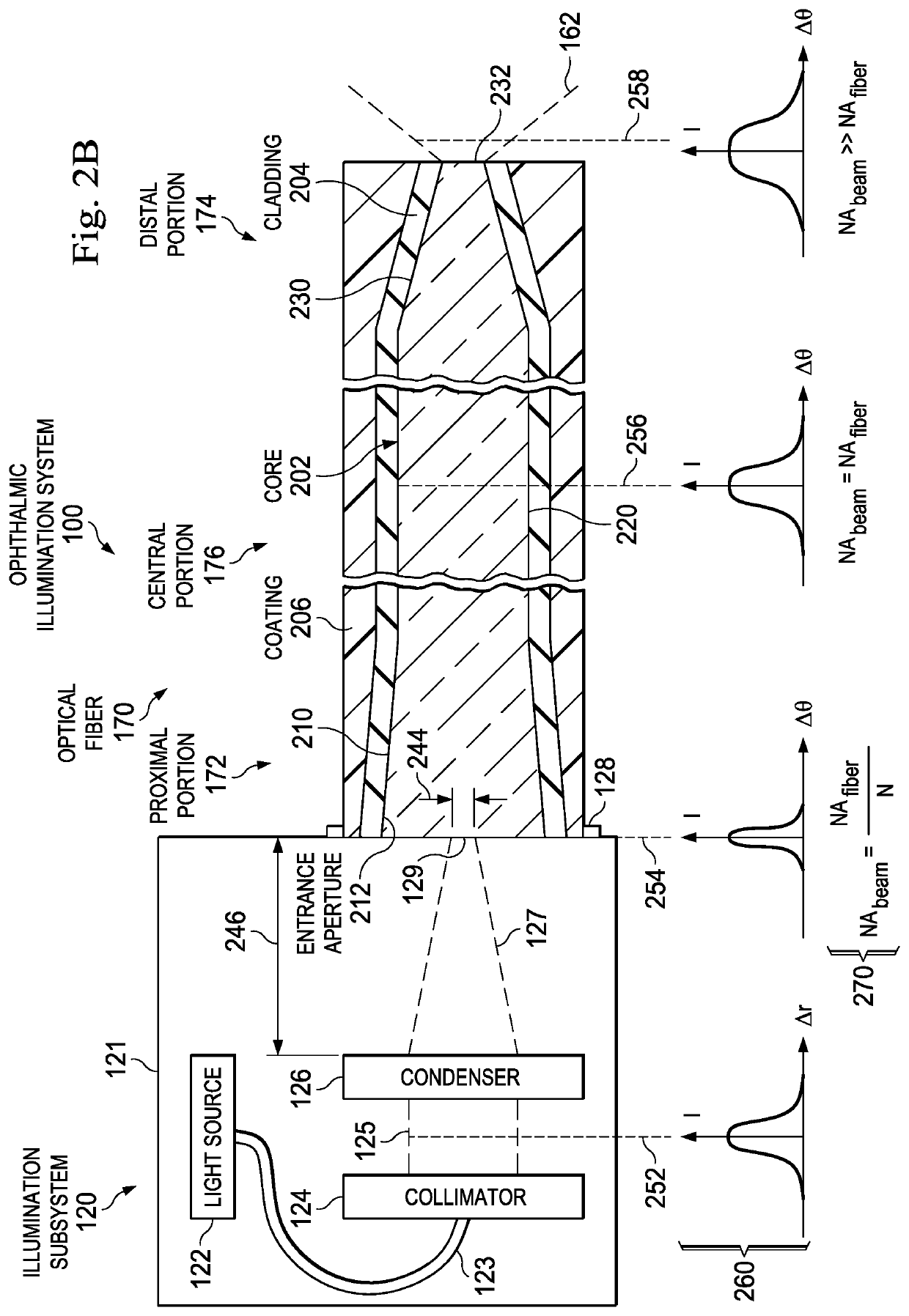

Optical fiber having proximal taper for ophthalmic surgical illumination

ActiveUS10441157B2Reduce sensitivityLarge core diameterMechanical apparatusEye surgeryDistal portionLight beam

An ophthalmic illumination system can include an optical fiber configured to transmit a light beam output by a light source and focused by a condenser. The optical fiber can include proximal, distal, and central portions. The proximal portion can be configured to receive the light beam focused by the condenser. The distal portion can be configured to emit the light beam to illuminate a surgical field. The central portion can extend between the proximal and distal portions. A core diameter of the proximal portion can be larger than core diameters of the central and distal portions. An ophthalmic illumination method can include focusing, using a condenser, a light beam emitted by a light source onto a proximal portion of an optical fiber. The method can also include transmitting, using the optical fiber, the light beam to a surgical field.

Owner:ALCON INC

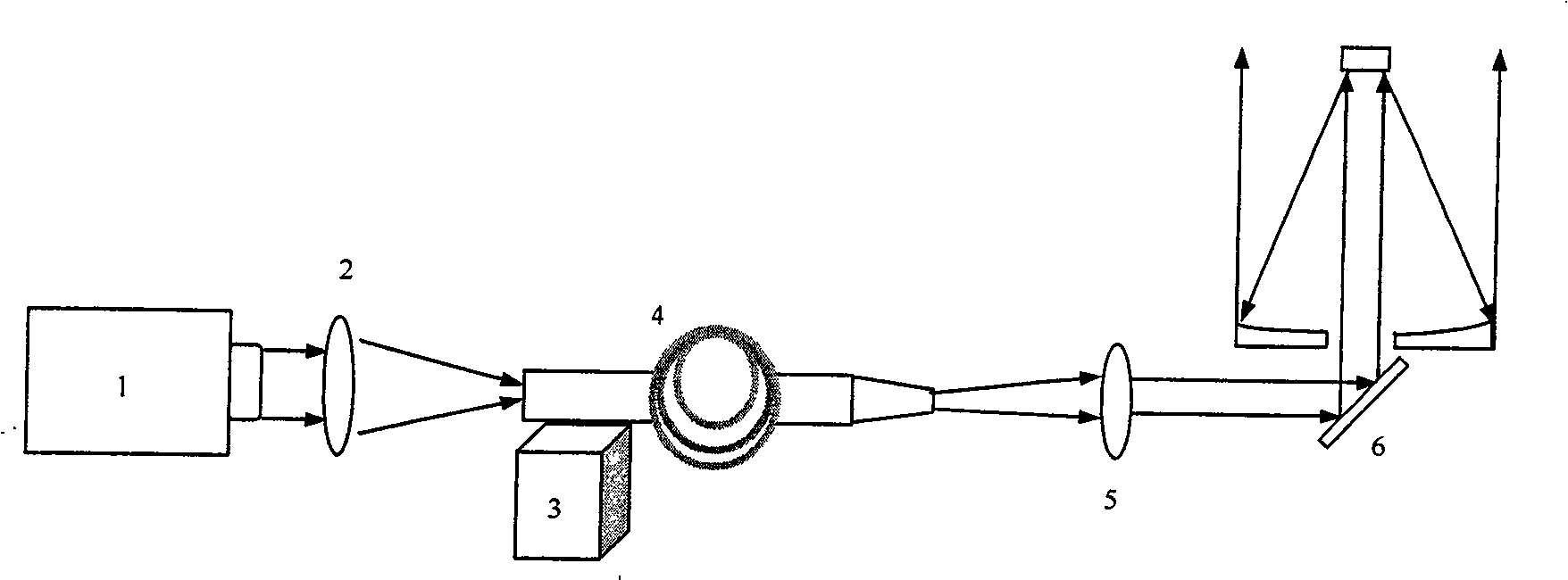

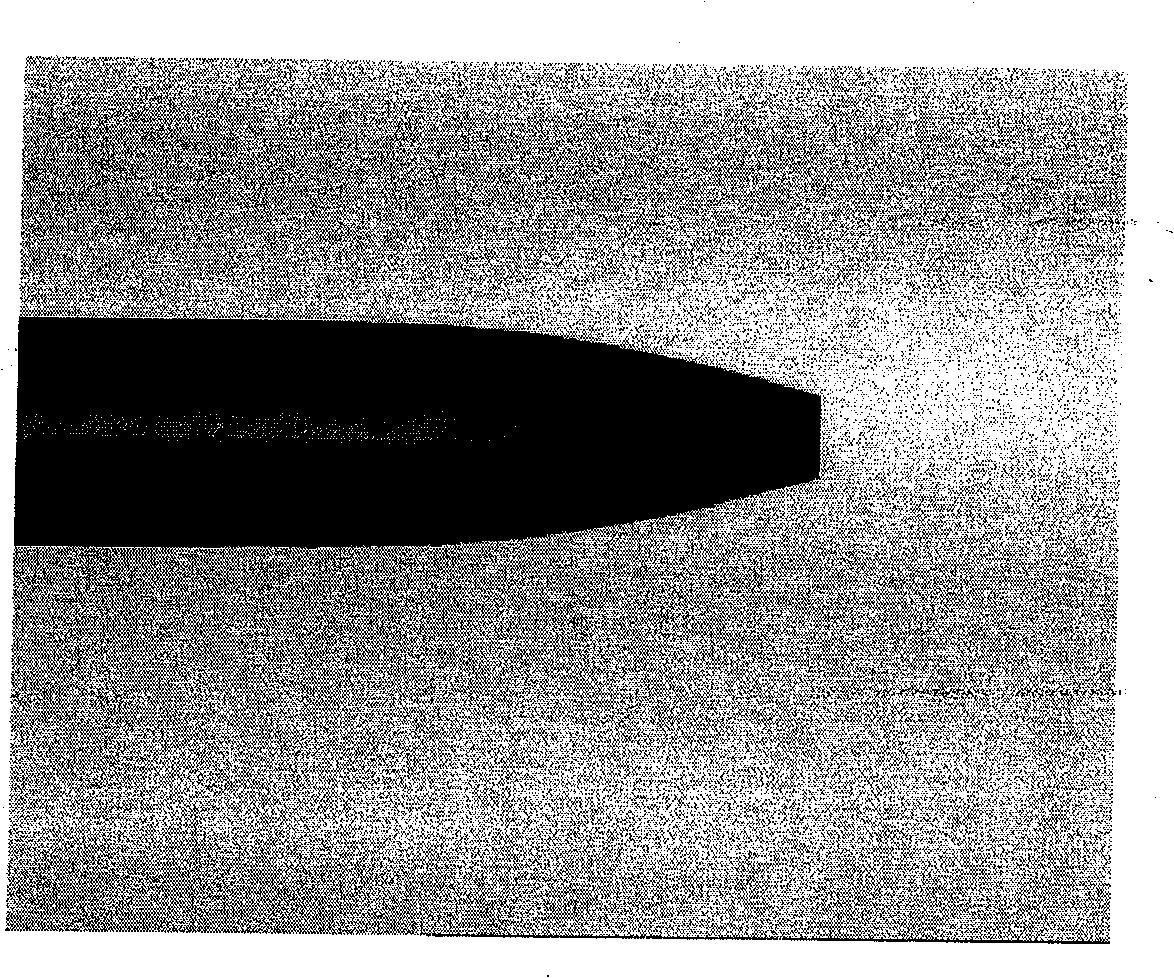

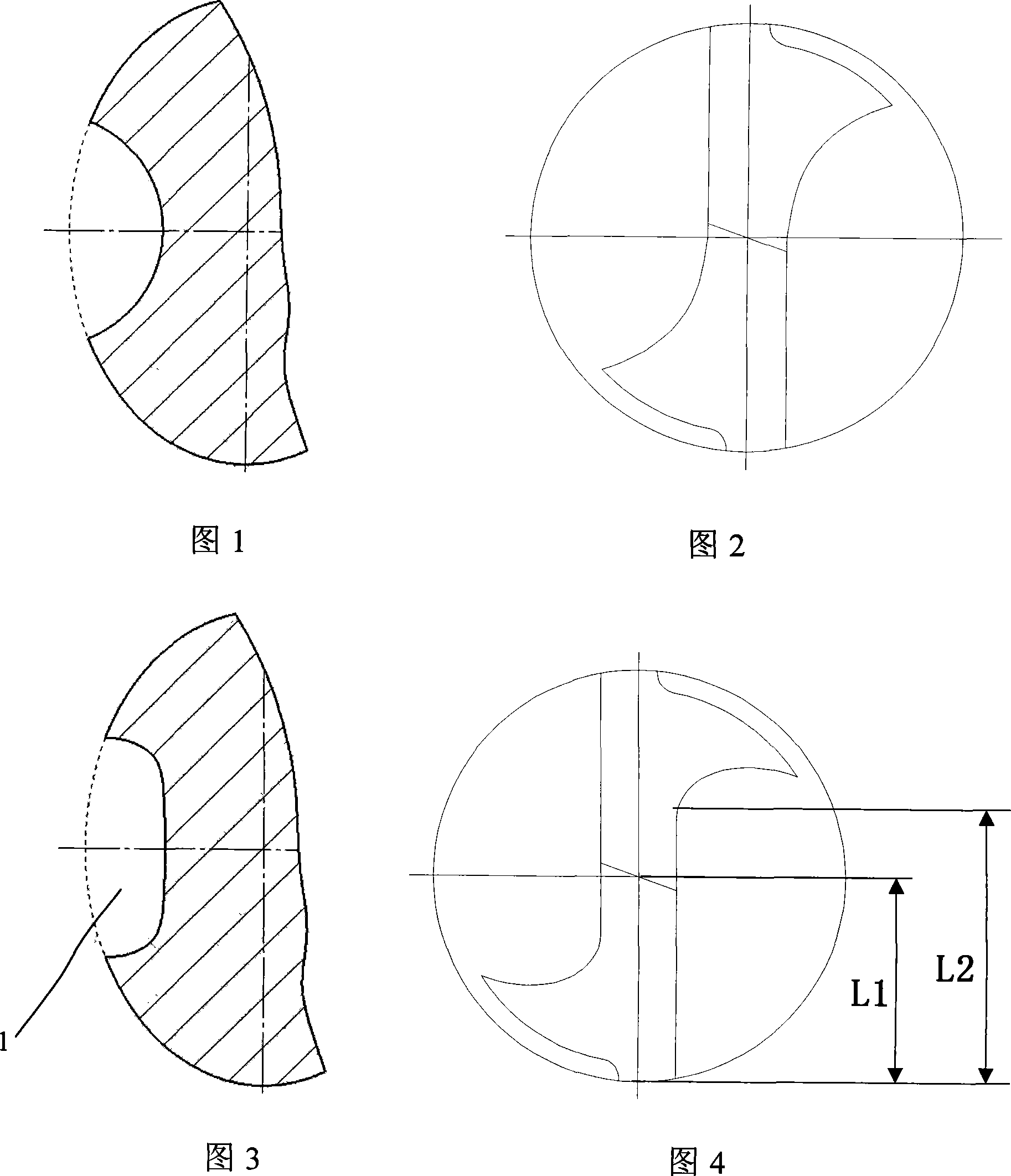

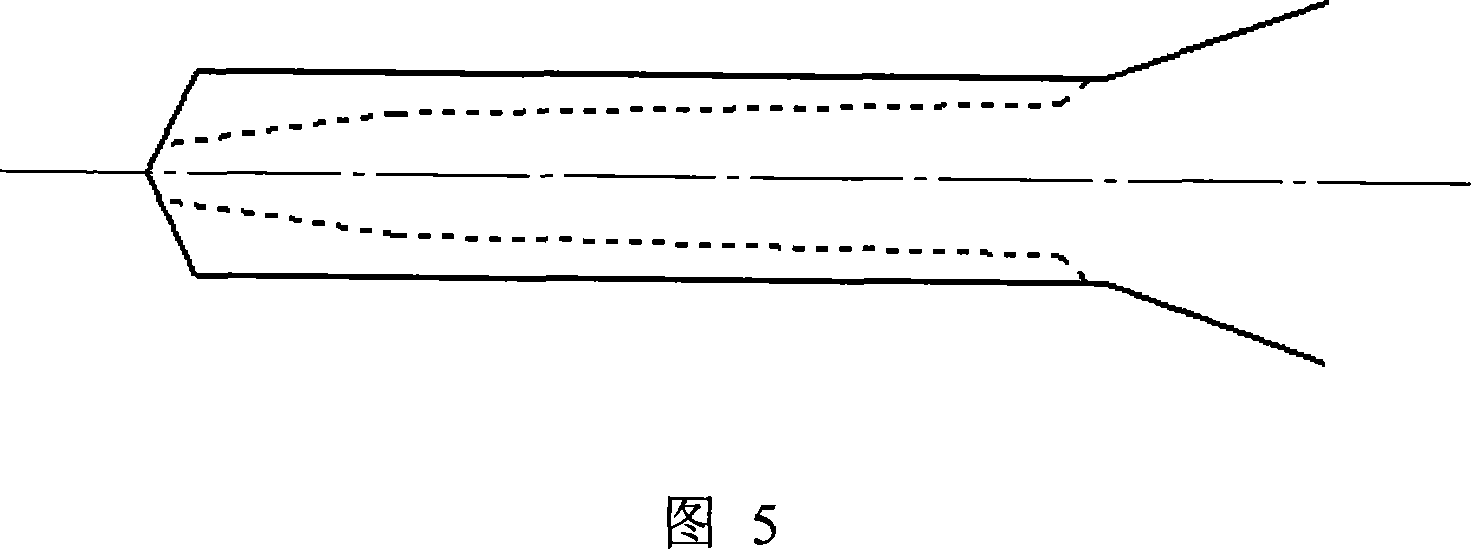

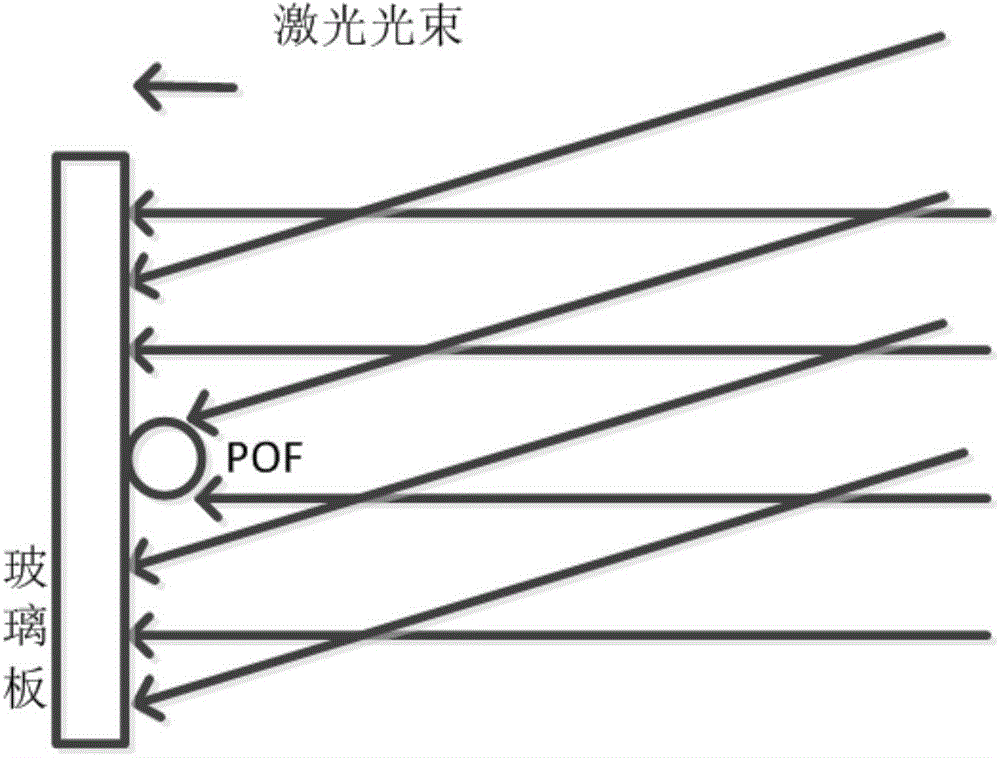

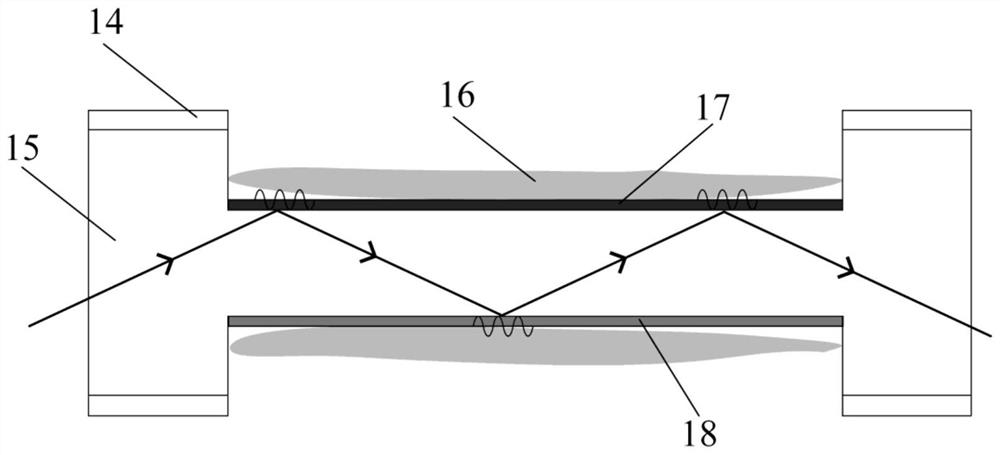

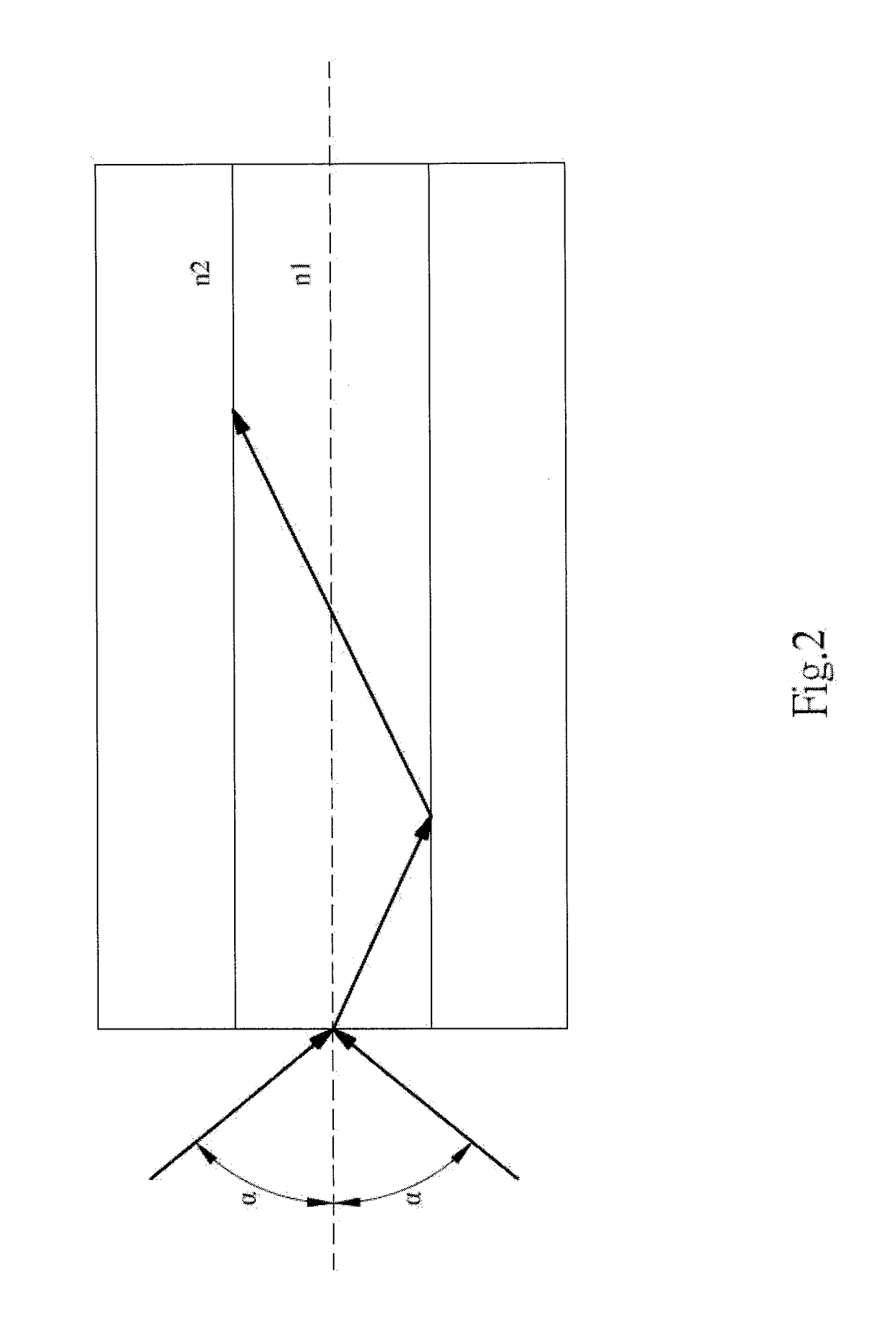

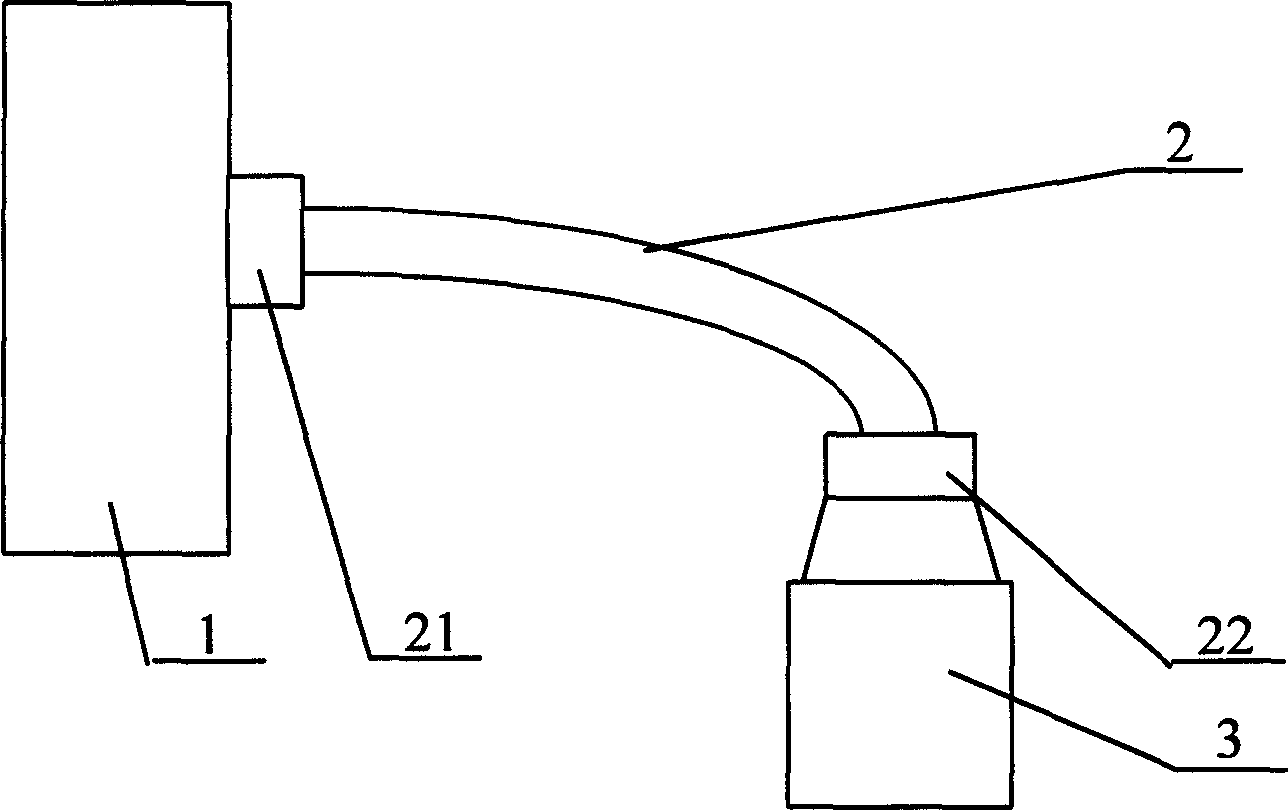

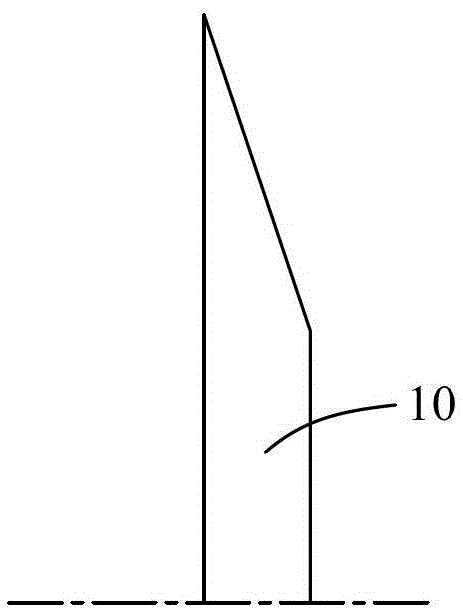

Laser beam optical fiber transmission device in laser sodium guiding technology

InactiveCN101271176AImprove power conversion efficiencyLarge core diameterGlass making apparatusCladded optical fibreFiberLight beam

A laser beam optical fiber transmission device of a laser sodium guide star technology is characterized in that: the device uses a cylindrical multimode optical fiber for producing a conical shape by adopting the melt-pulling method for pulling, then a table is formed by grinding, the device comprises: a cylindrical multimode optical fiber part and a conical table optical fiber part, the conical table optical fiber part is formed at the tail end of the cylindrical multimode optical fiber by direct processing, the other end of the cylindrical multimode optical fiber is an input end of a laser beam, the other end of the conical table optical fiber is an output end of the laser beam, the length of the cylindrical multimode optical fiber is equal to 1 to 1.2 times of the distance from a laser to a transmitting telescope; the radius of a fiber core of the conical table optical fiber which is arranged at the thick end is equal to the radius of the fiber core of the cylindrical multimode optical fiber, and the radius of the fiber core of the conical table optical fiber which is arranged at the thin end meets the single-mode condition for transmitting the laser by the optical fiber. The optical fiber transmission device has the advantages of simple and flexible structure and low cost, the quality of the output light beam is close to the diffraction limit, at the same time, the optical fiber transmission device can effectively overcome the non-linear scattering and other effects during the optical fiber transmission, thus achieving the purpose of transmitting the higher laser power.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

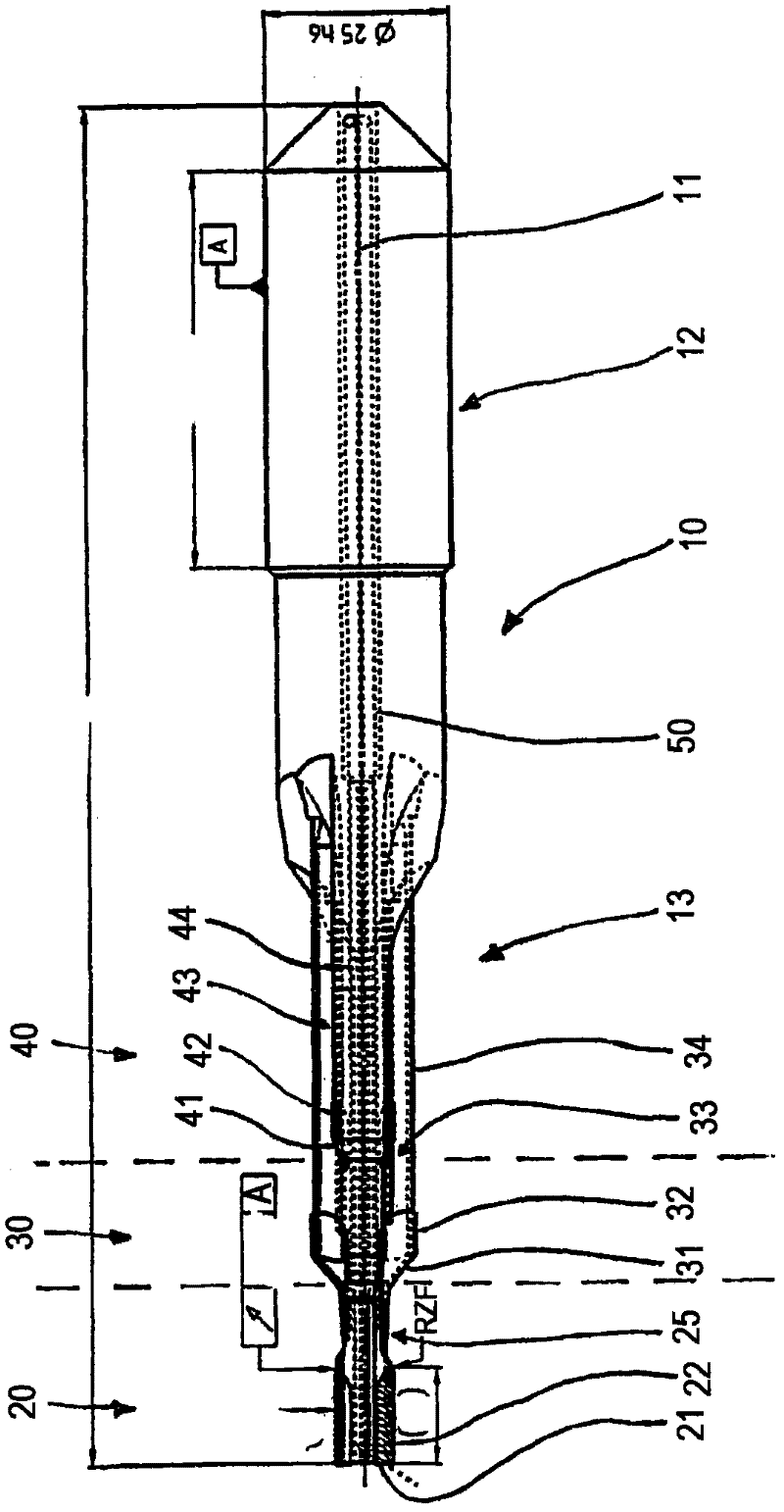

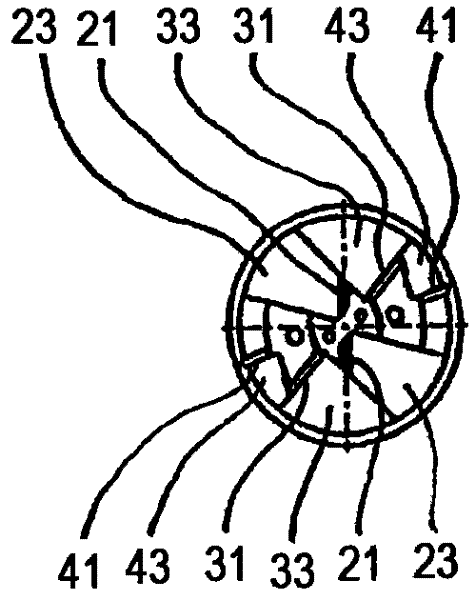

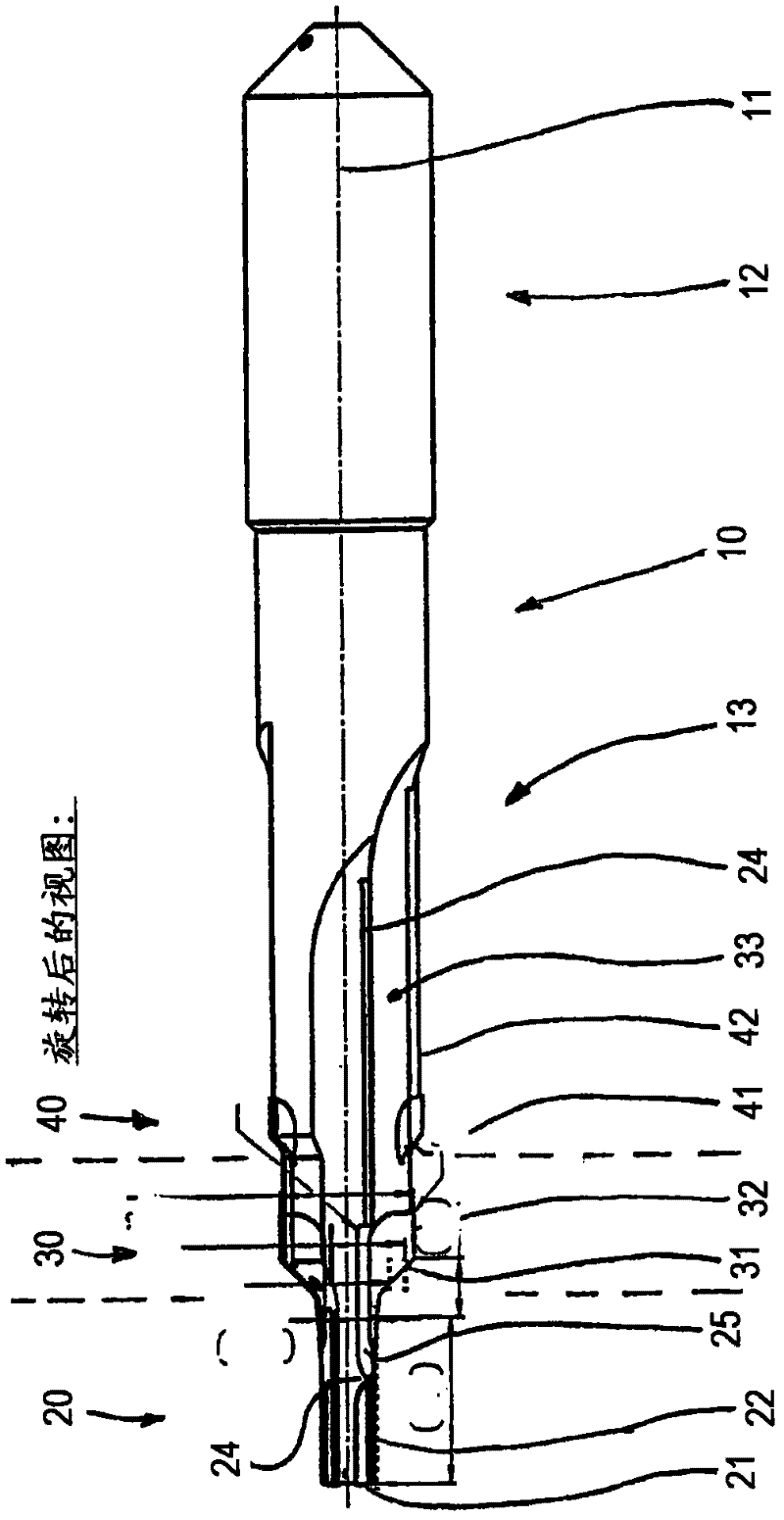

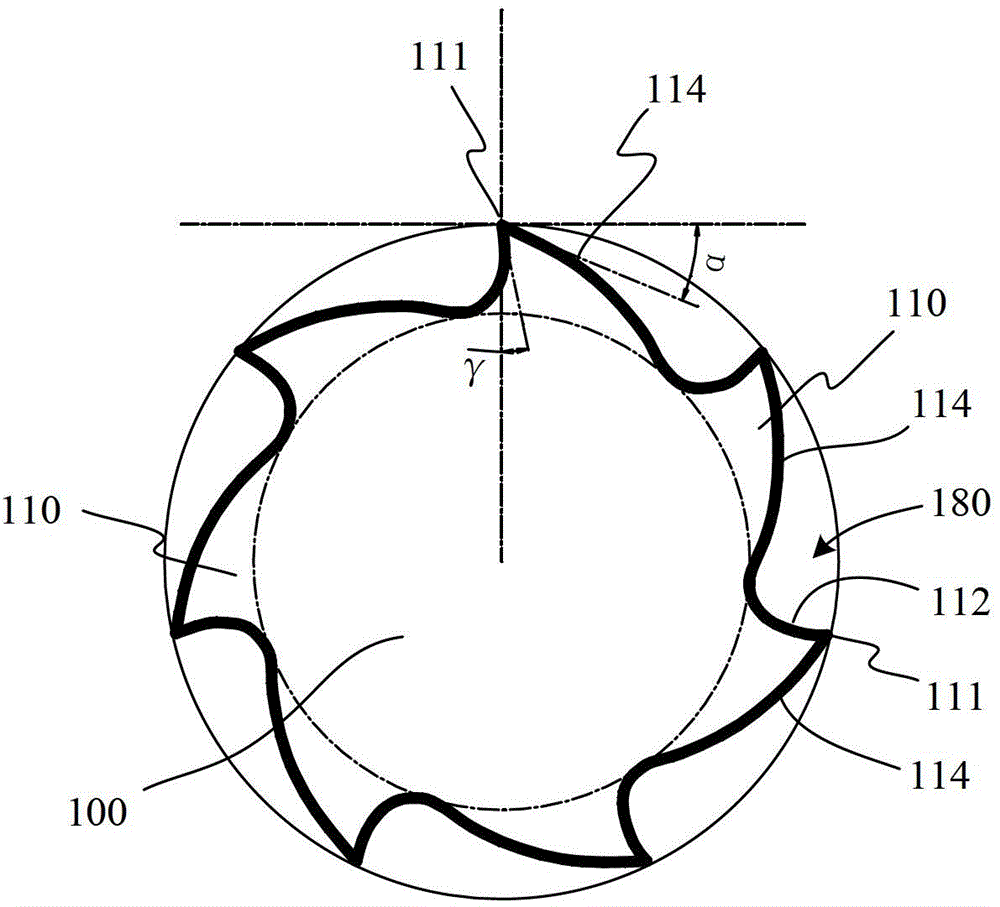

Rotationally driven multi-bevel step tool

InactiveCN102448646AIncrease the lengthIncreased usable chip removal volumeTransportation and packagingWorkpiecesFluteEngineering

The invention relates to a rotationally driven multi-bevel step tool, particularly a step drill for drilling into solid material, comprising a plurality of one-edged or multi-edged cutting steps which are arranged in a staggered manner in the cutting and advancing directions and each have a number of flutes that corresponds to the number of edges. Flutes (23, 33) adjoining each other in the circumferential direction are separated from each other by a web (24). According to the invention, the flues (23, 33) adjoining each other in the circumferential direction of two consecutive cutting steps (20, 30) in the cutting and advancing directions are connected to each other by a metal-cutting window (25) that is open on the circumferential side and interrupts the interposed web (24).

Owner:GUEHRING OHG

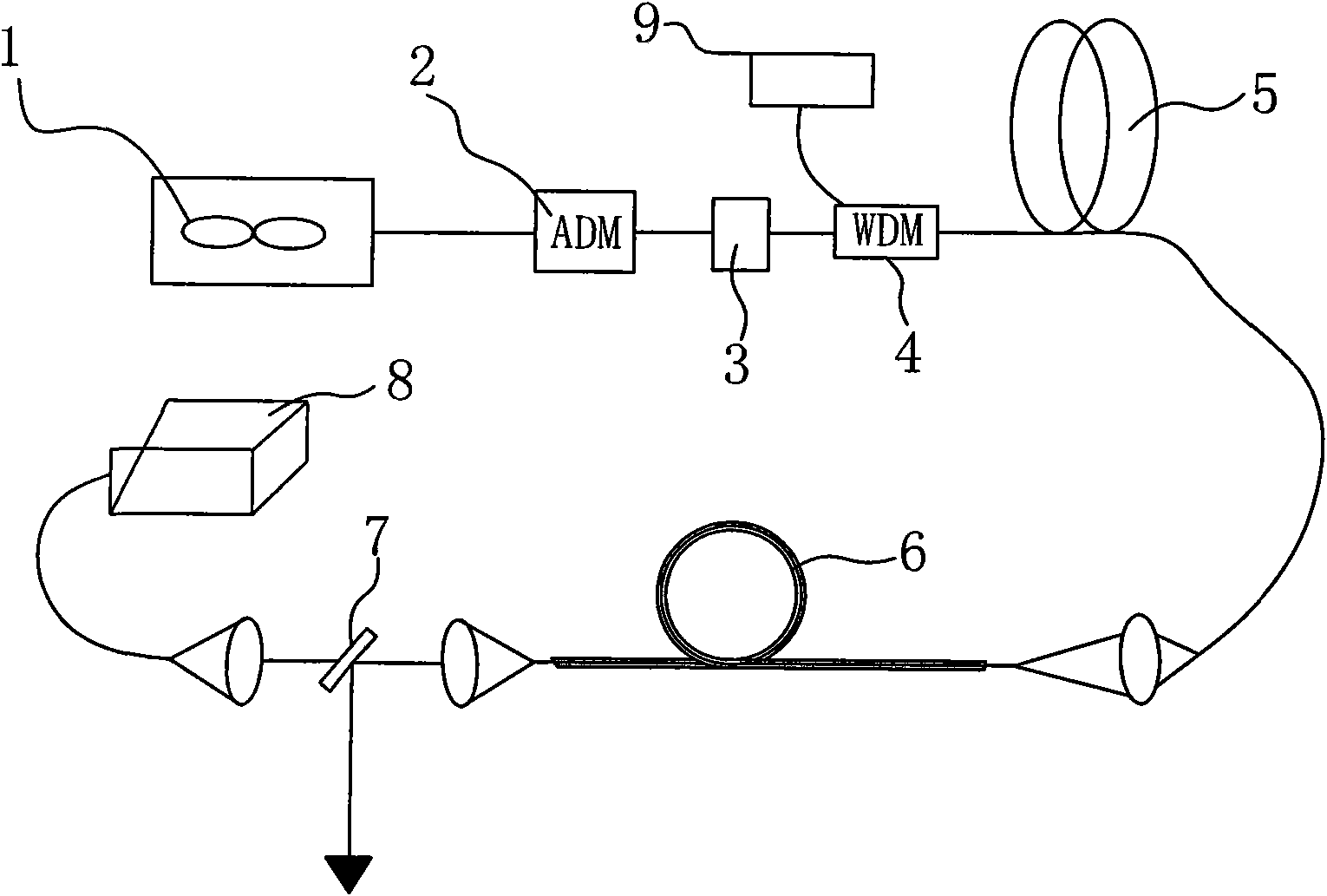

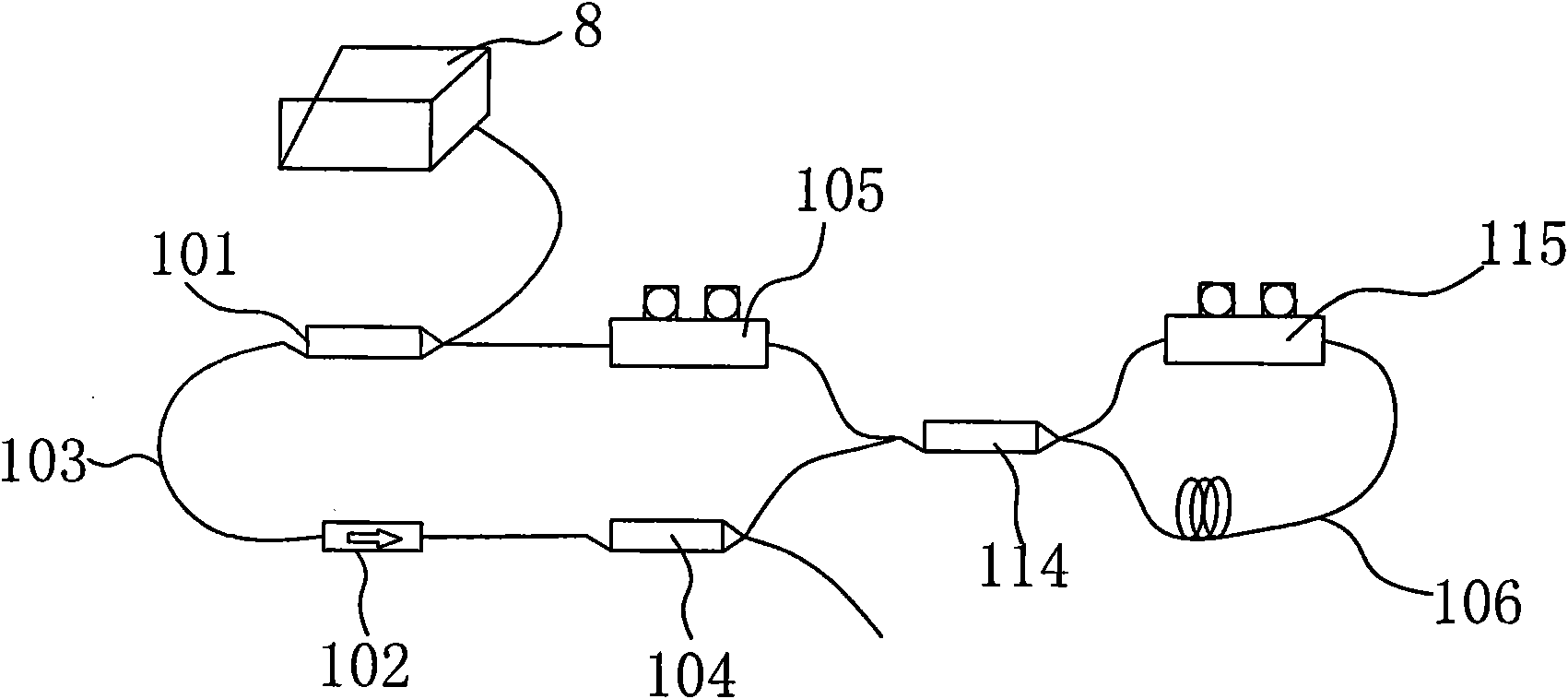

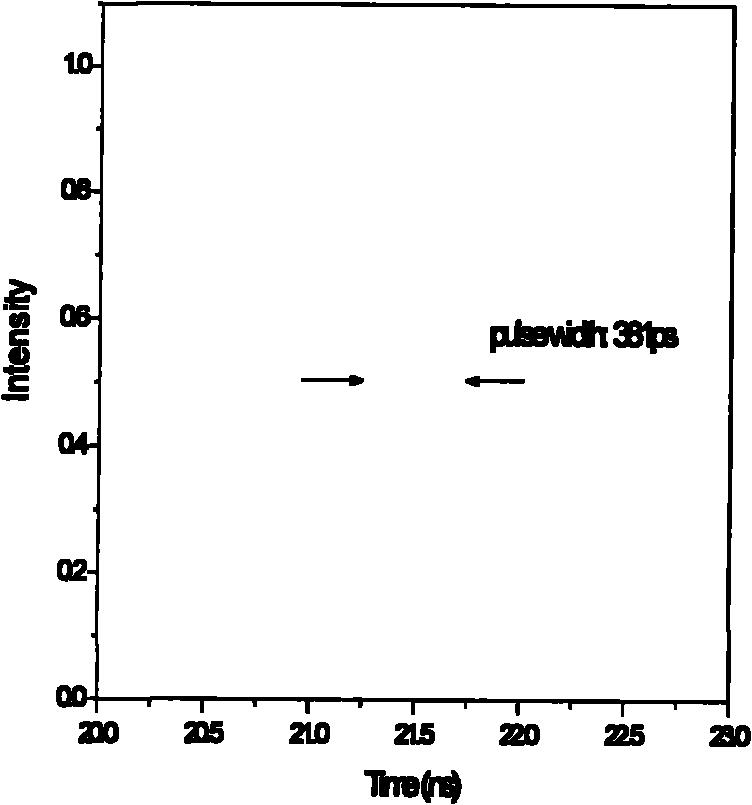

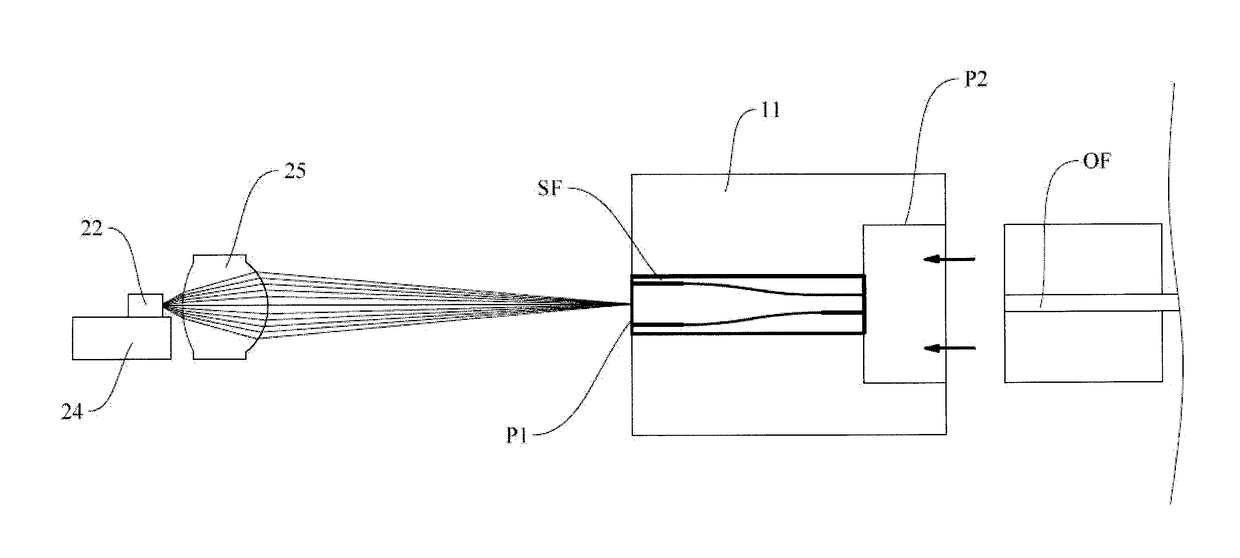

Chirped pulse amplification fiber laser system without stretcher

InactiveCN101771236AReduce peak powerLarge mode field areaActive medium shape and constructionMode locked fiber laserChirped pulse amplification

The invention relates to a fiber laser system without a stretcher. The system comprises a 'figure-eight' cavity mode locking fiber laser, a pulse menu selecting device, a single-mode fiber amplifier, dual-cladding ytterbium-doped photonic fibers, a dichroic mirror, a pumping source, wherein the pulse menu selecting device is connected with the output of the 'figure-eight' cavity mode locking fiber laser through fibers; the single-mode fiber amplifier is connected with the output of the pulse menu selecting device through the fibers; the dual-cladding ytterbium-doped photonic fibers are connected after focusing; the dichroic mirror is connected with the other end of the dual-cladding ytterbium-doped photonic fibers; and the single-mode fiber amplifier is also connected with a single-mode pumping source through the fibers. The fiber laser system solves the technical problems of large volume , high cost, high requirements of accuracy of installation and debugging and the like of large-energy pulsed lasers in the background technology, has the characteristics of large core diameter and single-mode transmission and has the advantage of high quality of amplified laser beams.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Helical cutting insert with multiple cutting edges

ActiveUS7753625B2Less powerSmooth cutting actionMilling cuttersShaping cuttersEngineeringKnife blades

Owner:KENNAMETAL INC

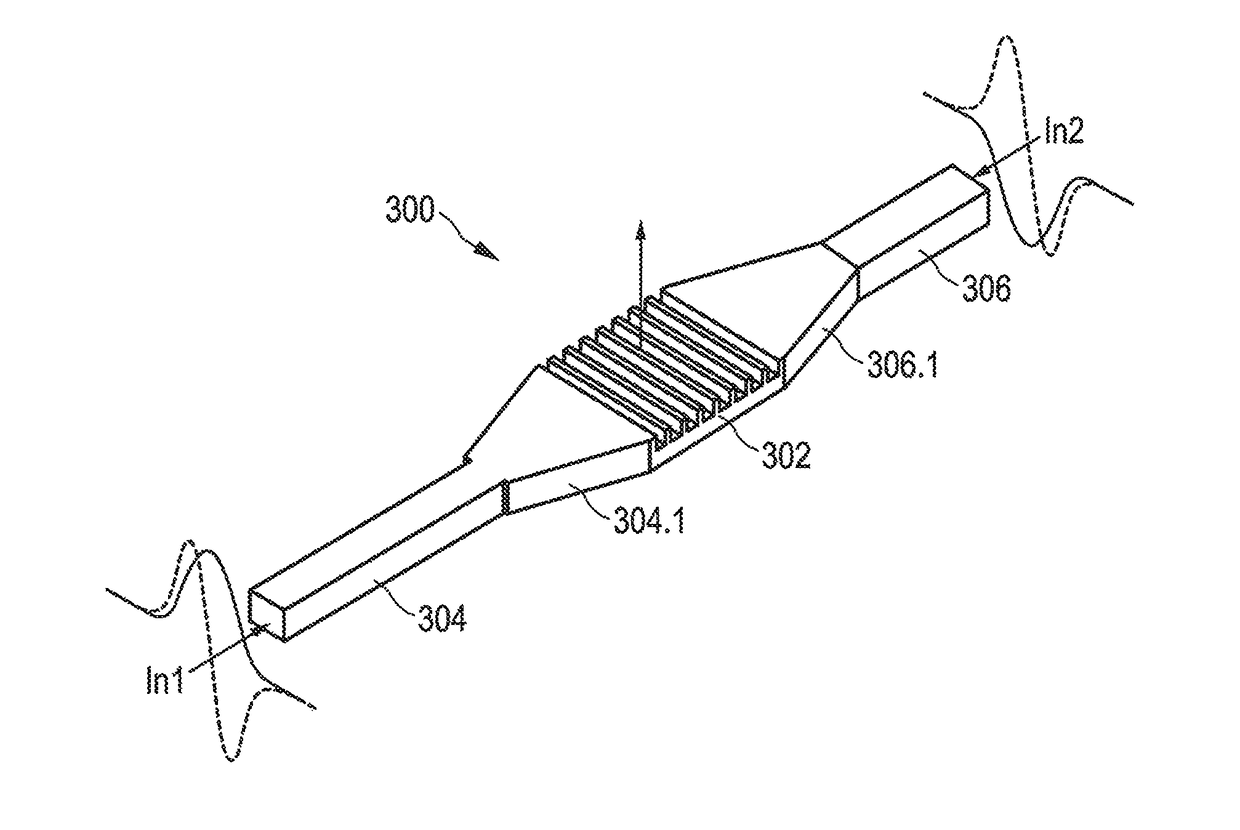

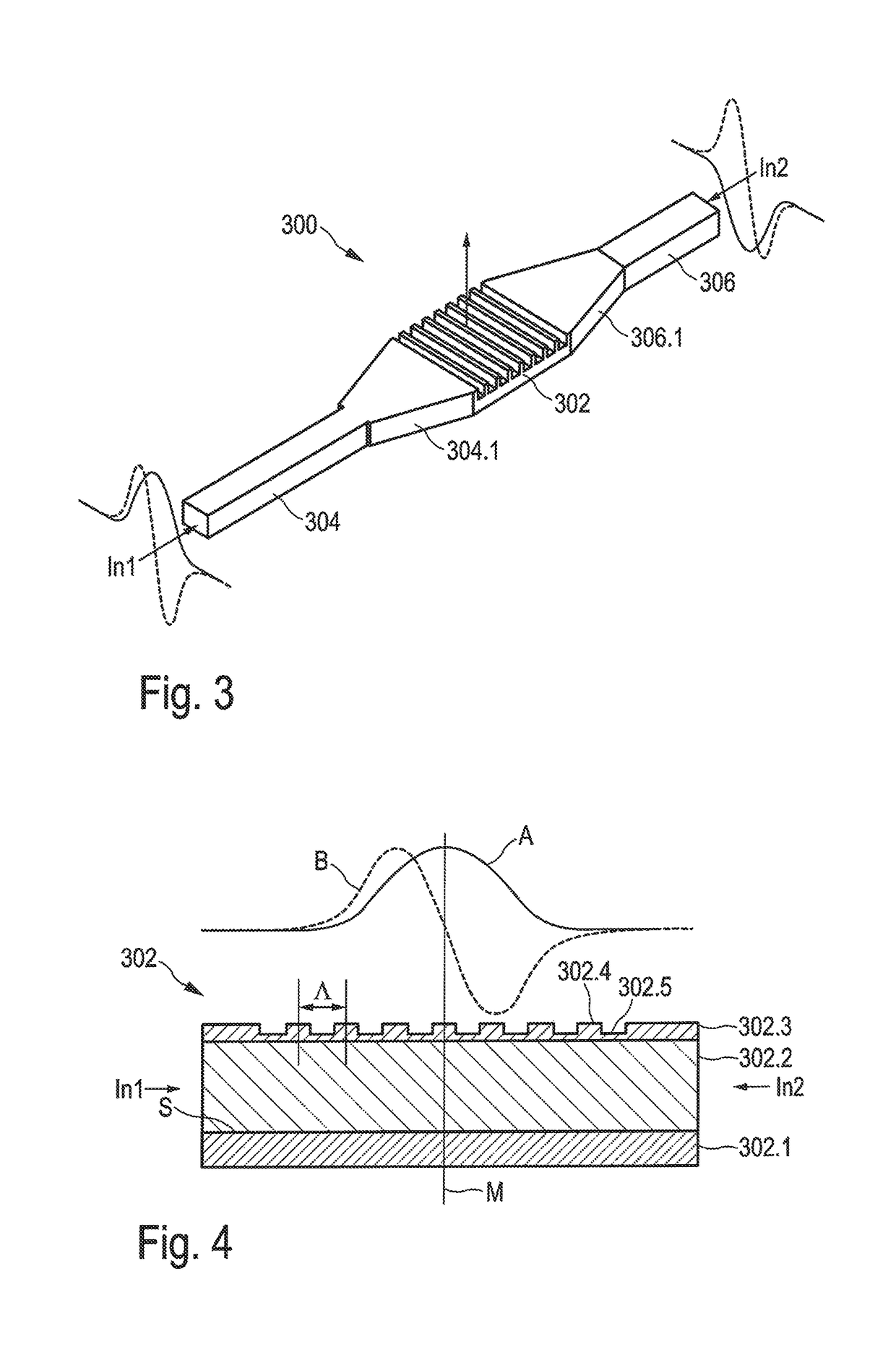

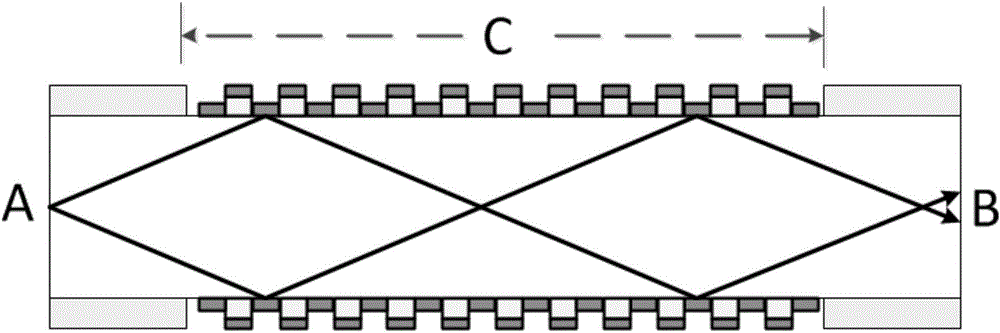

Device for coupling a plurality of different fibre modes

ActiveUS10001601B2Low costImprove efficiencyCoupling light guidesOptical waveguide light guideFiberGrating

An integrated optical coupler device comprising, on a substrate surface: an integrated optical coupling grating extending in lateral directions parallel to the substrate surface and which, by diffraction at its grating structures, either converts electromagnetic waves, guided parallel to the substrate surface, of at least two waveguide modes of integrated optical waveguides into fiber modes propagating perpendicularly to the substrate surface, or converts electromagnetic waves, propagating perpendicularly to the substrate surface, of a fiber mode into electromagnetic waves, propagating parallel to the substrate surface, of at least two waveguide modes, and a first conductor pair, connected to the coupling grating and formed by a first and a second integrated optical waveguide, through which, in mutually opposite first and second directions parallel to the substrate surface, electromagnetic waves of at least two waveguide modes can be conducted to the coupling grating or can be conducted away from the coupling grating.

Owner:IHP GMBH INNOVATIONS FOR HIGH PERFORMANCE MICROELECTRONICS LEIBNIZ INST FUR INNOVATIVE

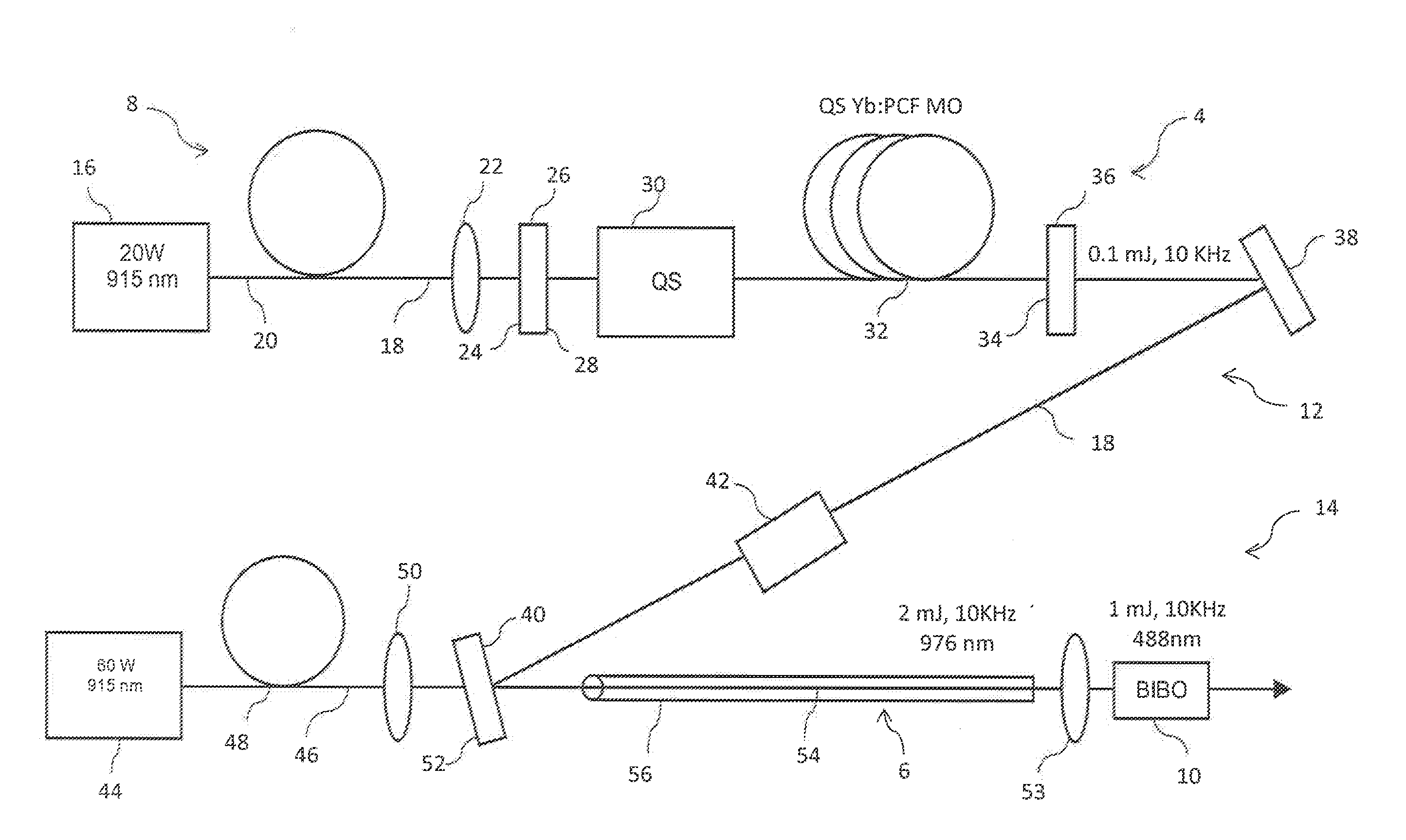

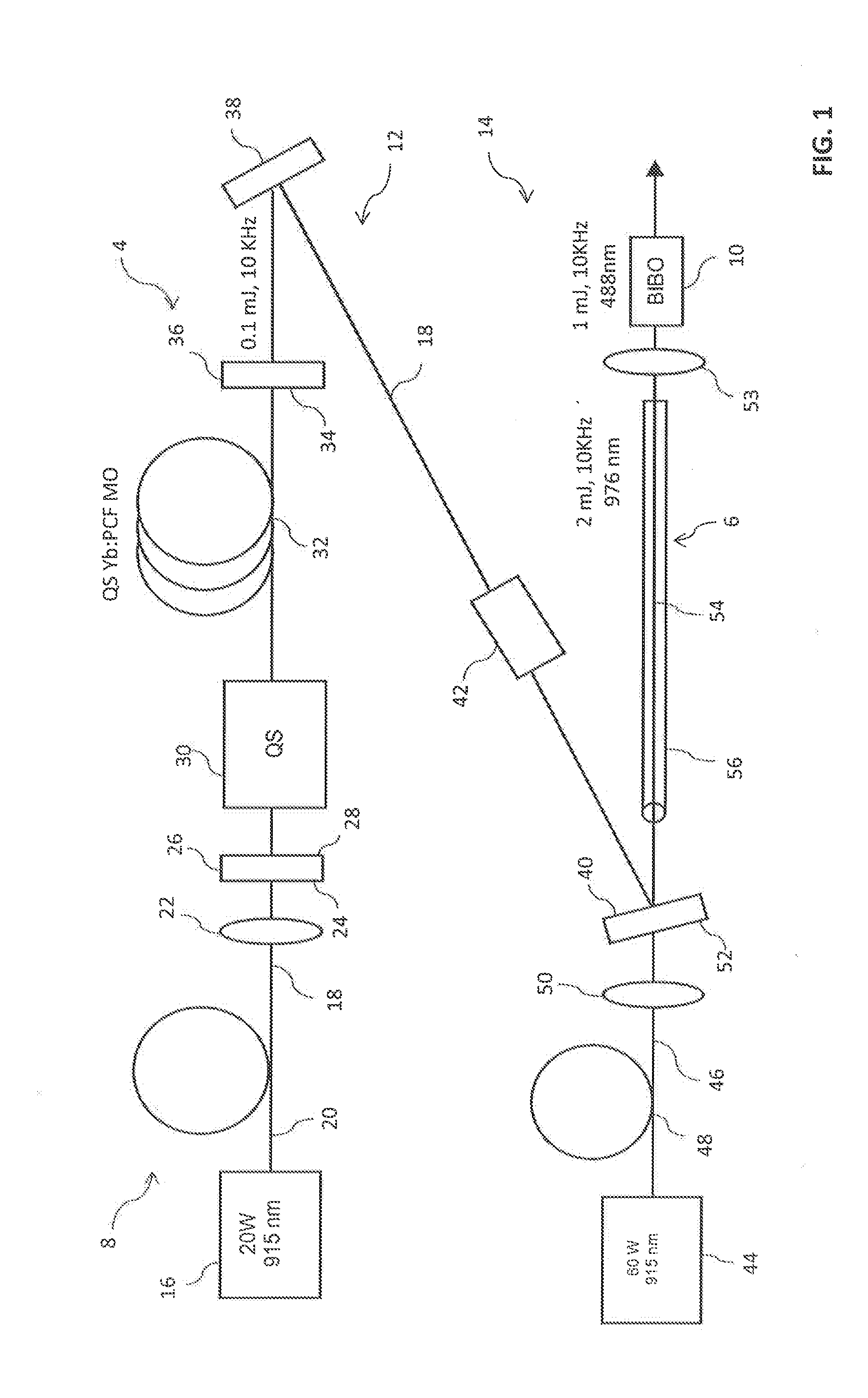

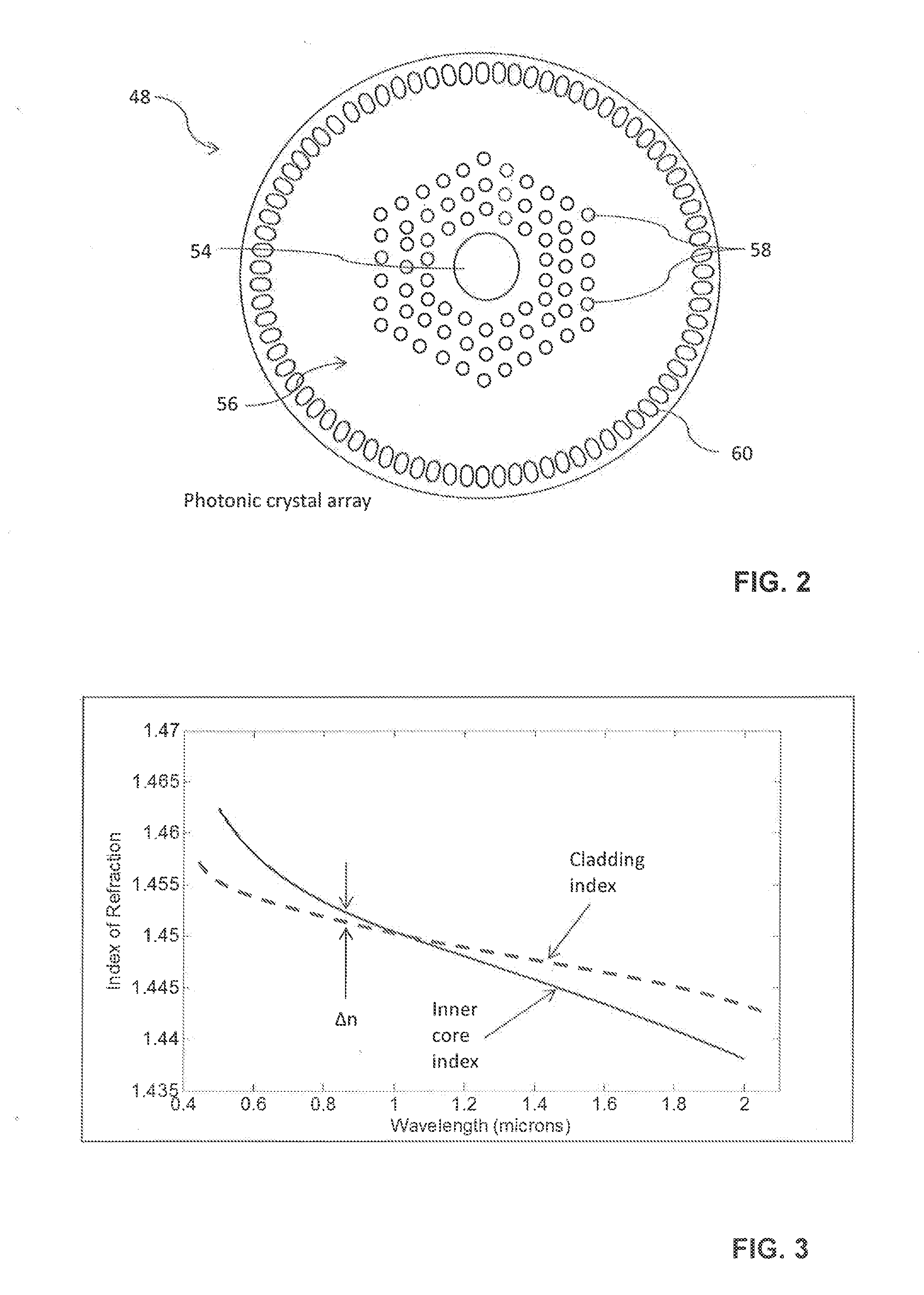

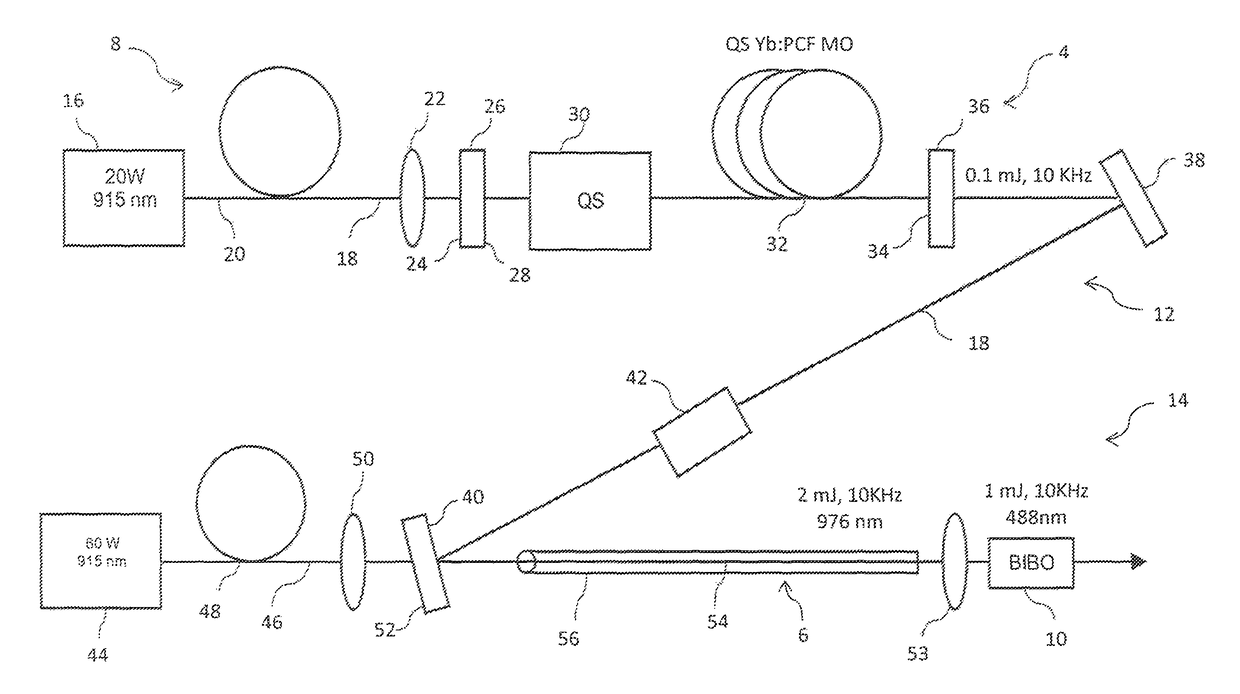

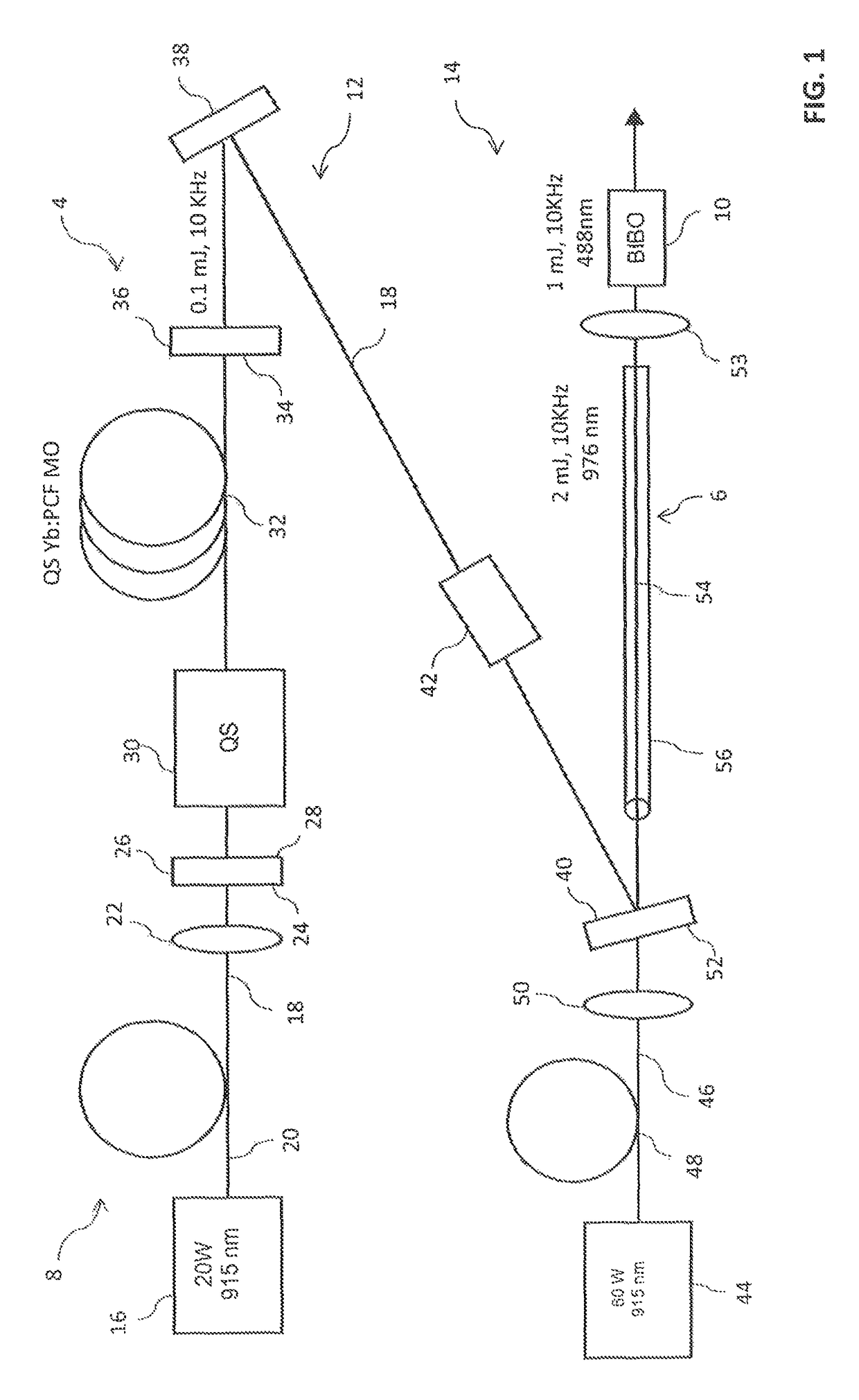

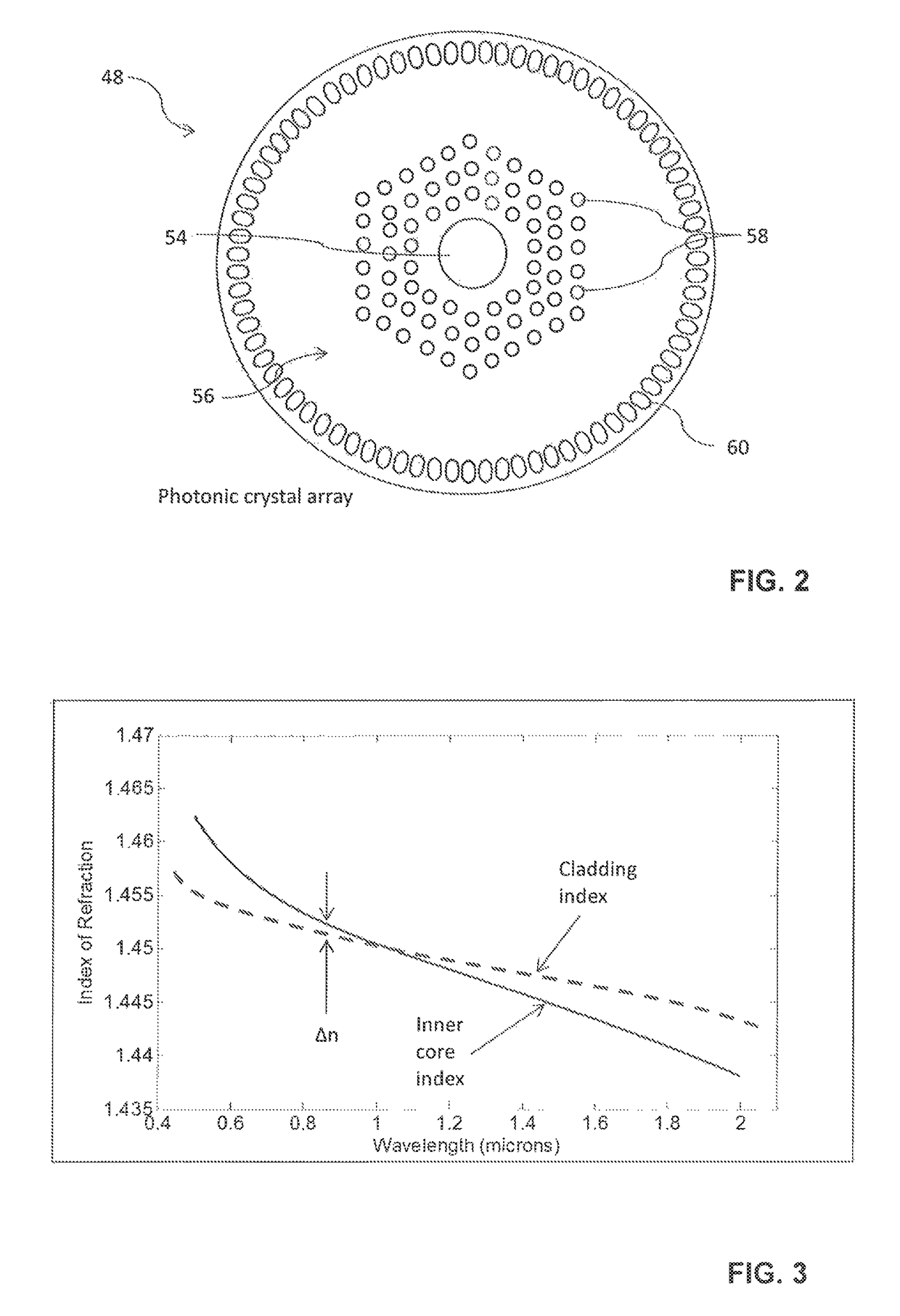

Phosphate photonic crystal fiber and converter for efficient blue generation

ActiveUS20160099539A1Favorable gain propertyImprove featuresActive medium shape and constructionLight demodulationOptoelectronicsPhosphate glass

In the method for generating blue laser light with high optical and electrical efficiency, wherein the improvement comprises the step of using a phosphate glass photonic crystal fiber rod as a gain medium.

Owner:BAE SYST INFORMATION & ELECTRONICS SYST INTERGRATION INC

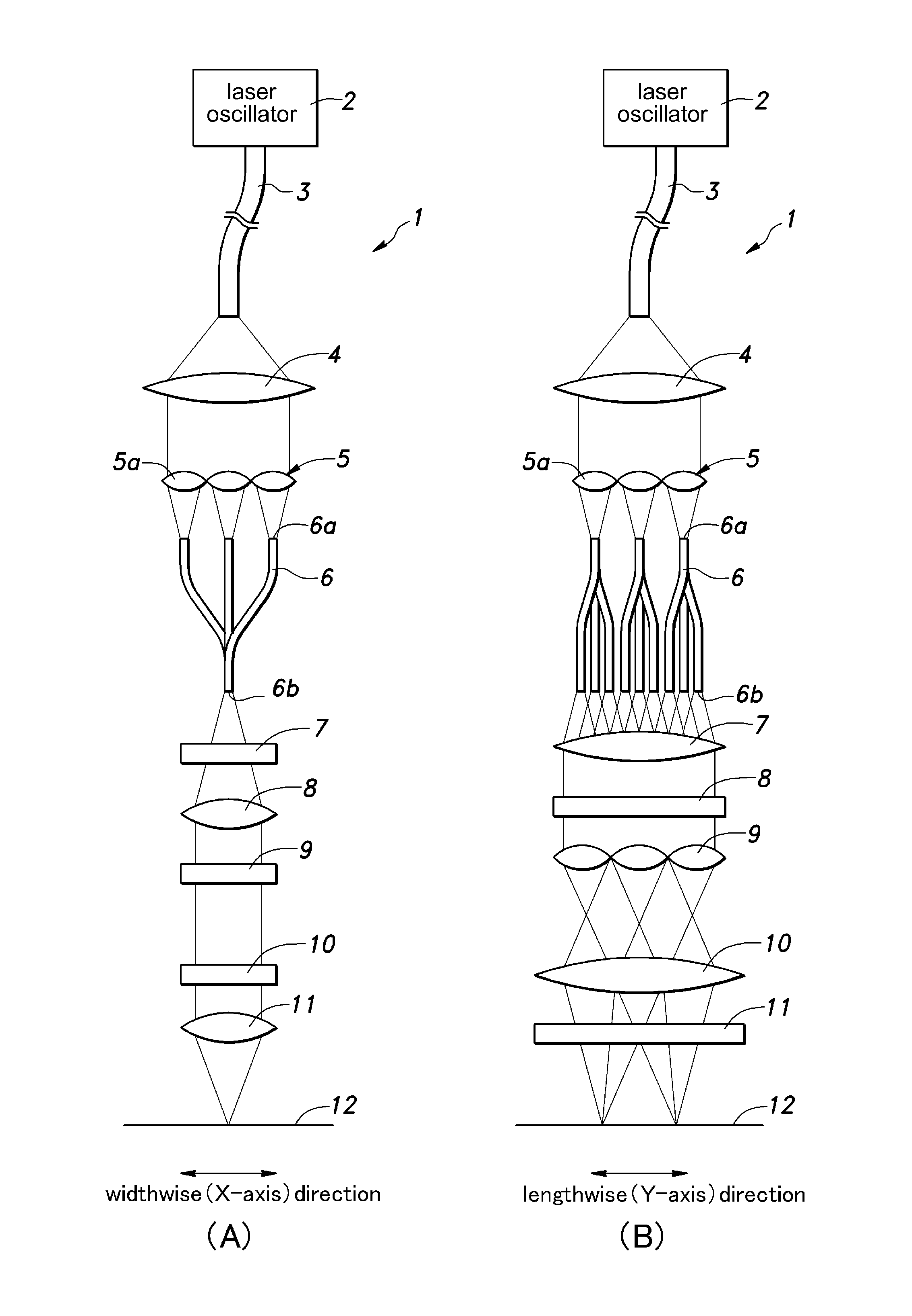

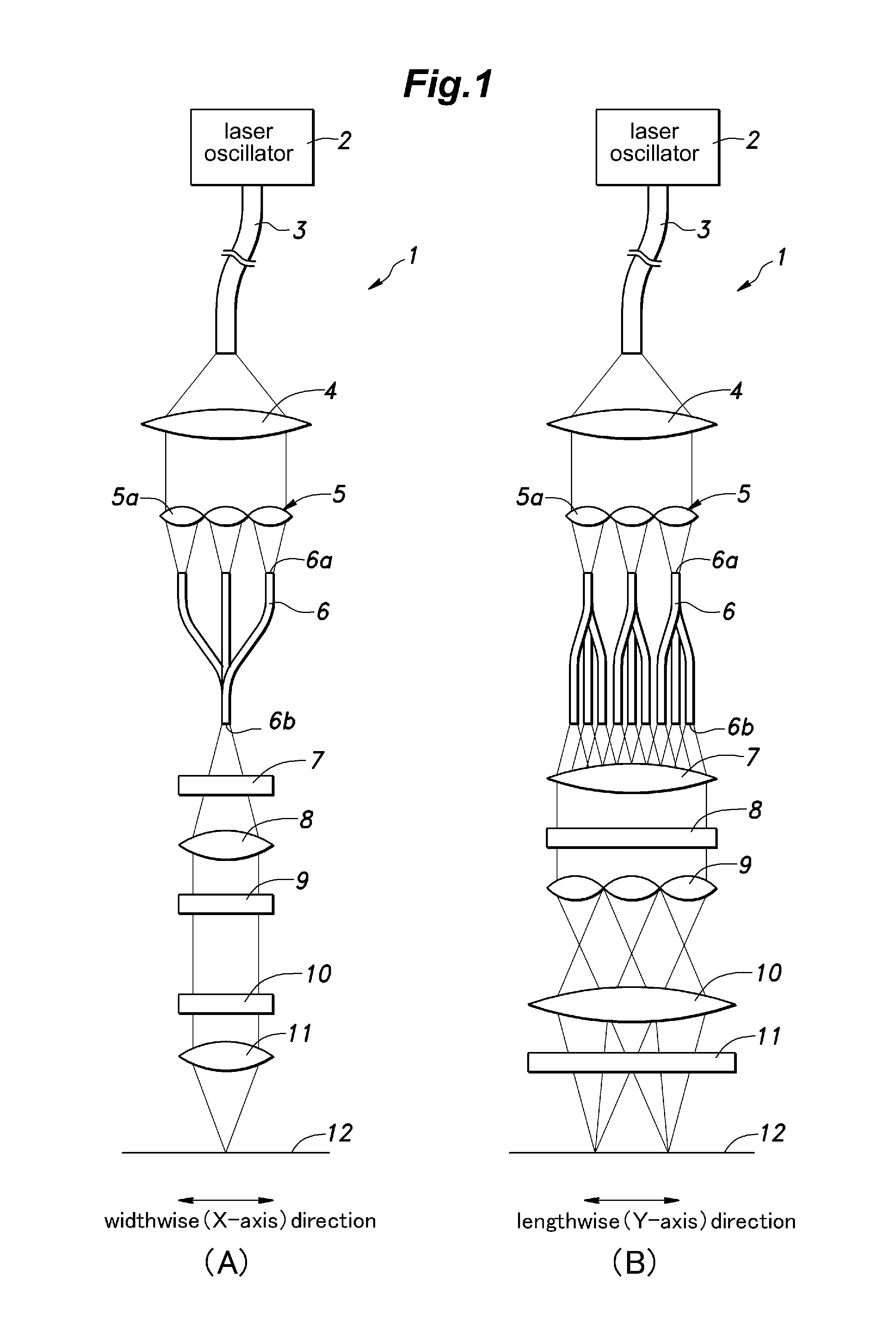

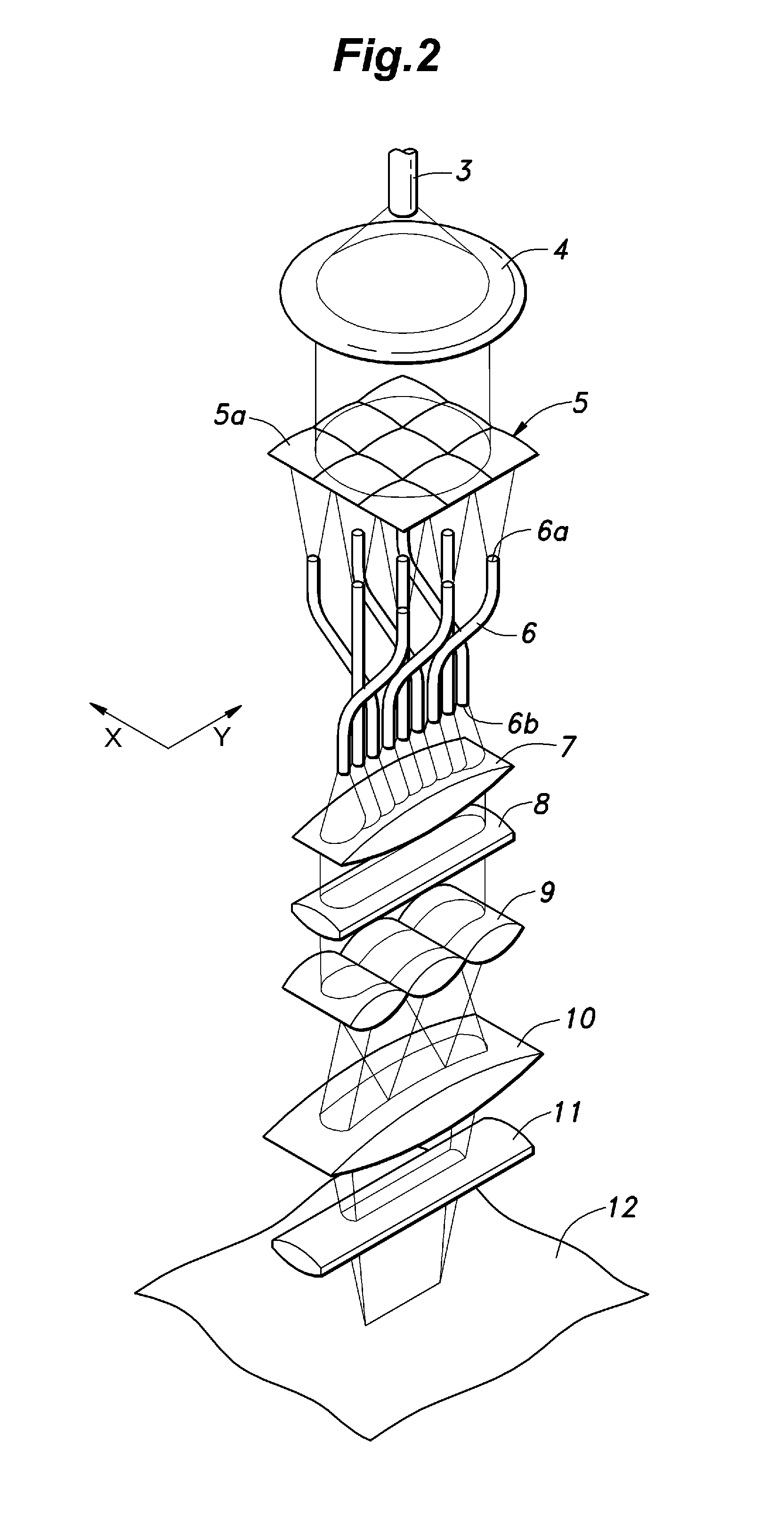

Laser optical system using optical fiber transmission

ActiveUS20130084046A1Increase productionImprove performanceSemiconductor/solid-state device manufacturingFibre light guidesLaser lightLaser optics

A laser optical system using optical fiber transmission, includes a first optical fiber for transmitting laser light emitted from a laser oscillator, a collimator lens for collimating laser light emitted from the first optical fiber, a spherical array lens including a plurality of cells for converging laser light emitted from the collimator lens into a plurality of spots, a plurality of second optical fibers each having a smaller core diameter than the first optical fiber and configured to admit the laser light converged into the corresponding spot by the spherical array lens, the second optical fibers having output ends that have mutually parallel axial lines and are arranged linearly in a single row, and a linearization optical unit for shaping laser light emitted from the second optical fibers into laser light having a linear cross section at an illuminated surface.

Owner:JAPAN STEEL WORKS LTD +1

Minisize drill bit for PCB plate drilling hole

ActiveCN101176930AReasonable groove widthImprove borehole wall qualityTransportation and packagingTrepanning drillsBiochemical engineeringHelix angle

The invention discloses a PCB-drilling micro-bit, comprising an base line at the bottom of the groove and two side lines respectively arranged at both sides of the groove and smoothly connected with the base line, which is characterized in that: a spiral winding groove is arranged on the prismatic face; the cross-section profile vertical to the spiral line of the groove is U-shaped with wide bottom on the whole; wherein, the base line is a straight line segment or a circular arc line segment with large curvature radius; the two side lines are respectively straight line segment or circular arc line segment with small curvature radius. Optimally, Helix angle of the groove is 42 to 45 degrees. The invention has the advantages of having bigger space for removing chips and bigger core radius synchronously through optimizing the groove, not decreasing the width of the groove with the groove becoming shallower, having more reasonable groove amplitude ratio of the rear part in the drill bit, improving the quality of drill wall, the hole accuracy, lowering rod-breaking performance synchronously; by increasing the helix angle to 42 to 45 degrees, the invention improves the dust exhausting ability of the drill bit and the quality of hole wall.

Owner:SHENZHEN JINZHOU PRECISION TECH

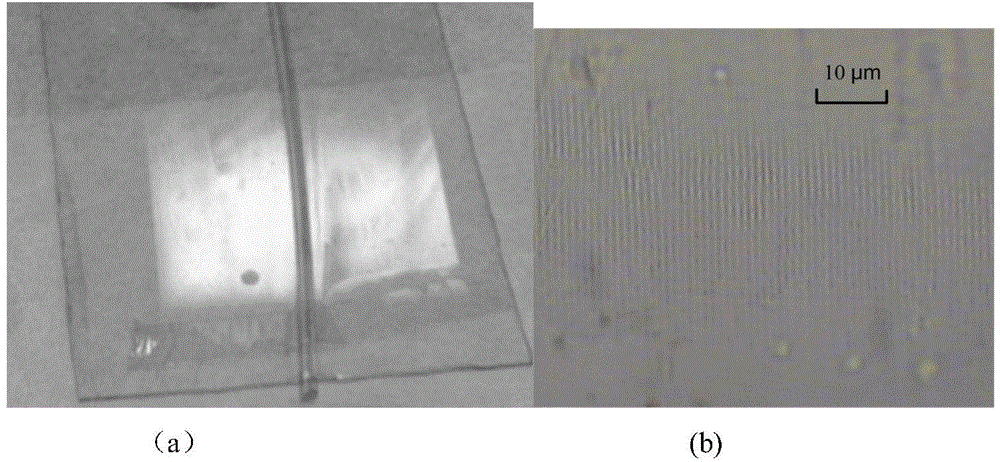

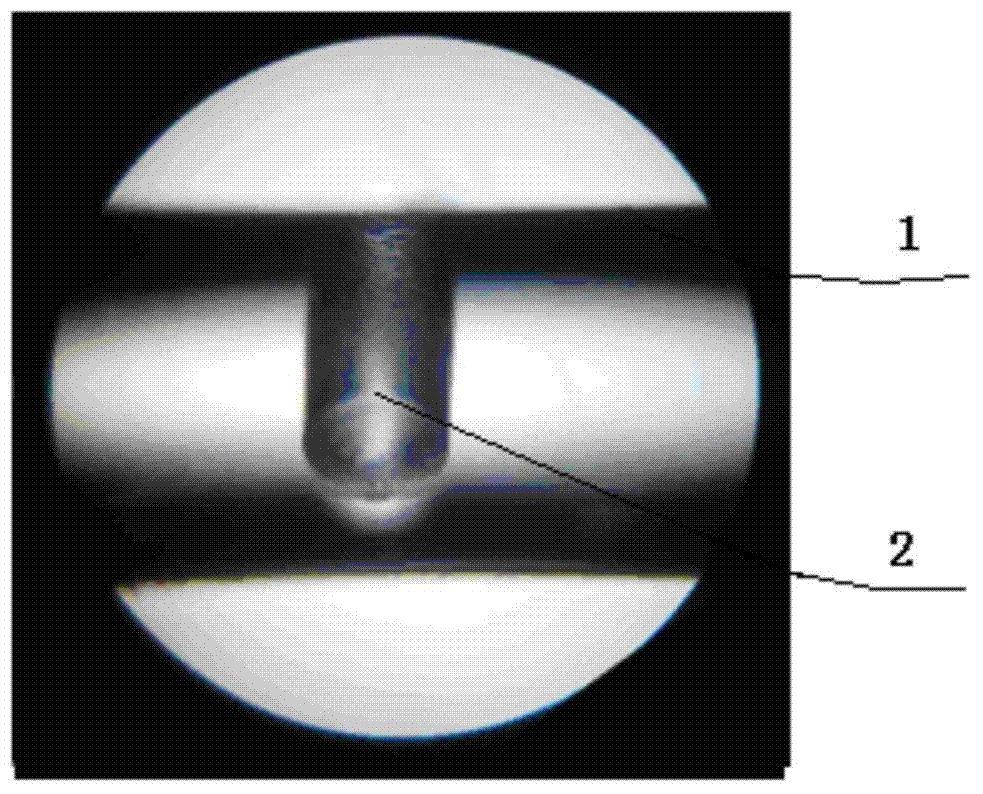

Plastic fiber surface plasma sensor based on bimetallic grating and application thereof

InactiveCN104406939ALarge core diameterImprove toughnessCladded optical fibreScattering properties measurementsResonance wavelengthDual beam

The invention relates to a plastic fiber surface plasma sensor based on a bimetallic grating, which comprises a plastic fiber as a substrate and the bimetallic grating arranged on upper surface and lower surface of fiber; the plastic fiber is the plastic fiber without a cladding and 1mm of core diameter; the bimetallic grating comprises a dielectric layer with a single surface having a concave-convex periodic structure, a metal thin layer is arranged on the upper surface of the concave-convex periodic structure, so that the grating can be formed; the duty ratio of the formed grating is 1; the metal grating is prepared by using a laser dual-beam interference photolithography; and the period and depth of the grating can be adjustable. The bimetallic grating is produced on the plastic fiber surface, the fiber waveguide coupling and grating coupling are combined, so that the bimetallic grating has plastic fiber transmission advantage and metal grating high excitation efficiency advantage, resonance wavelength is tunable, and the stucrture has important application in refractive index sensing.

Owner:SHANDONG UNIV

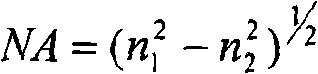

Bending-resistant large core diameter high numerical aperture multimode fiber

ActiveUS9052435B2Increase the number ofEnhanced couplingOptical fibre with graded refractive index core/claddingOptical fibre with multilayer core/claddingHigh numerical apertureRelative refractive index

Owner:EVERPRO TECH COMPANY

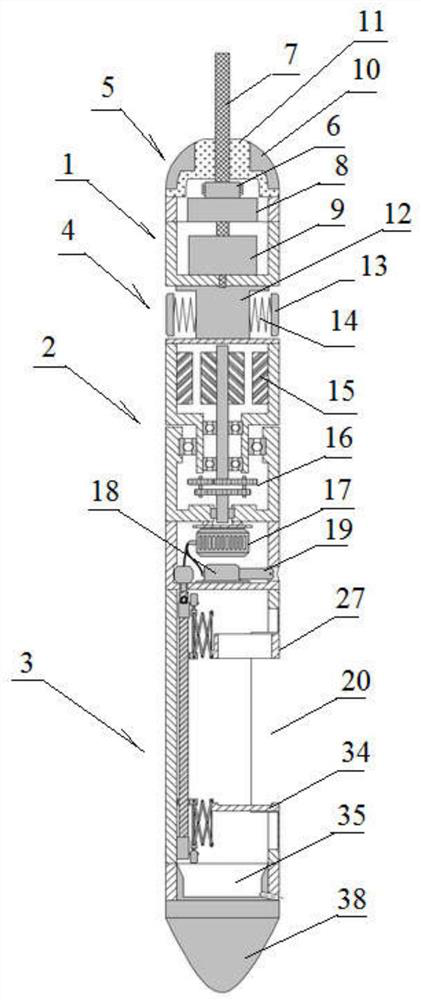

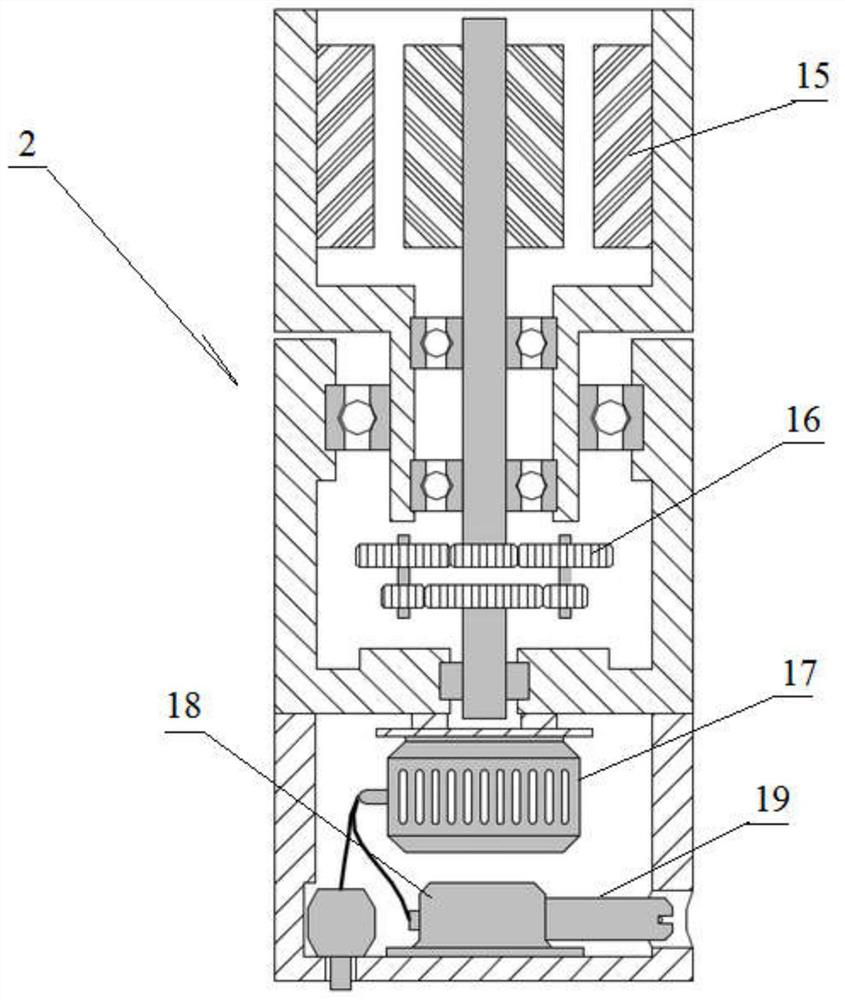

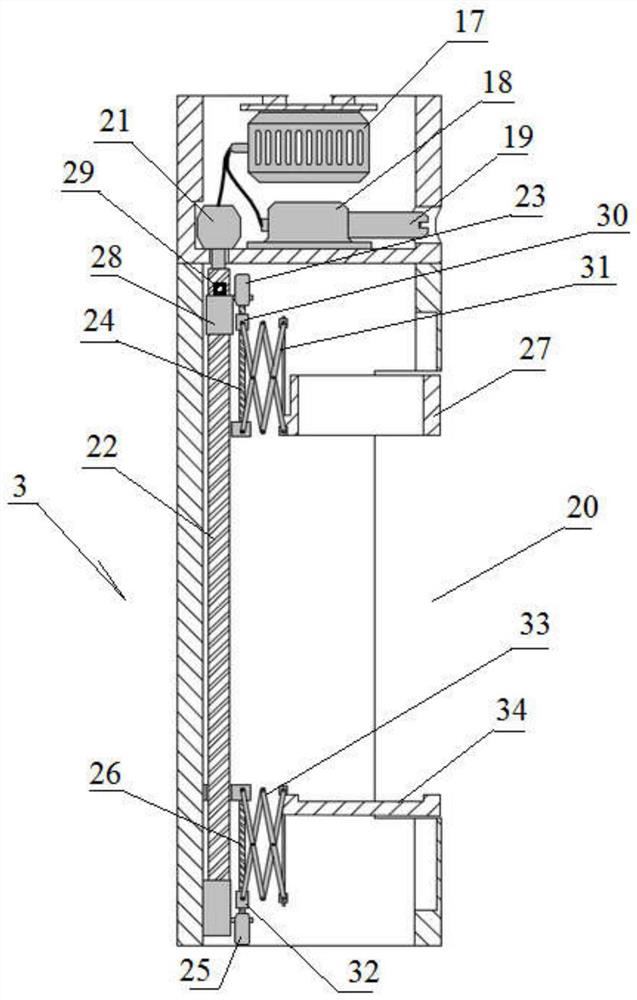

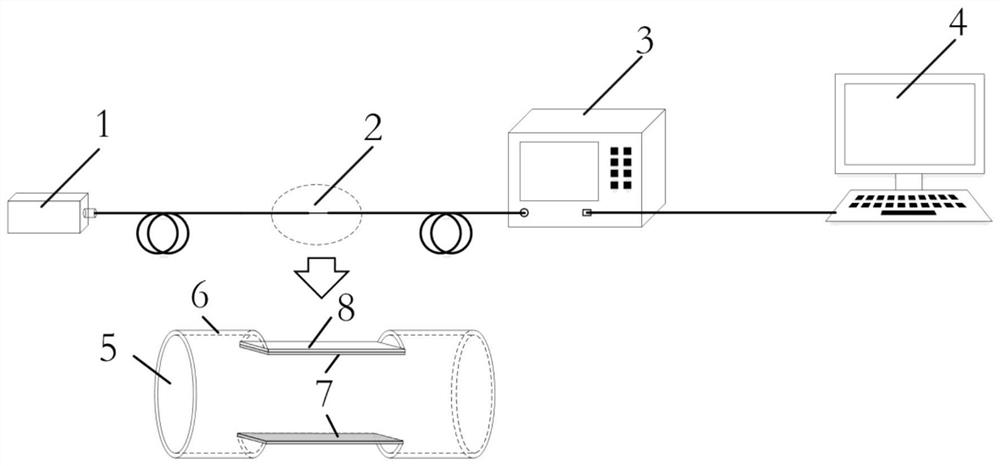

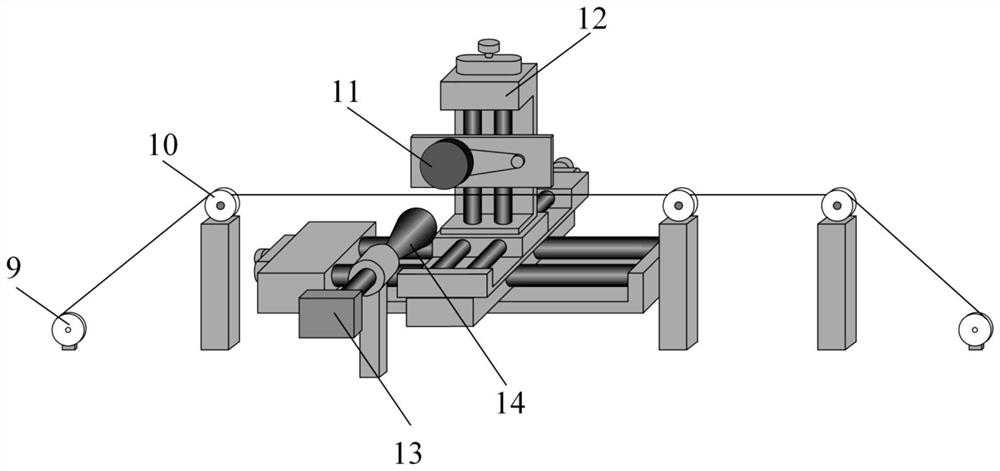

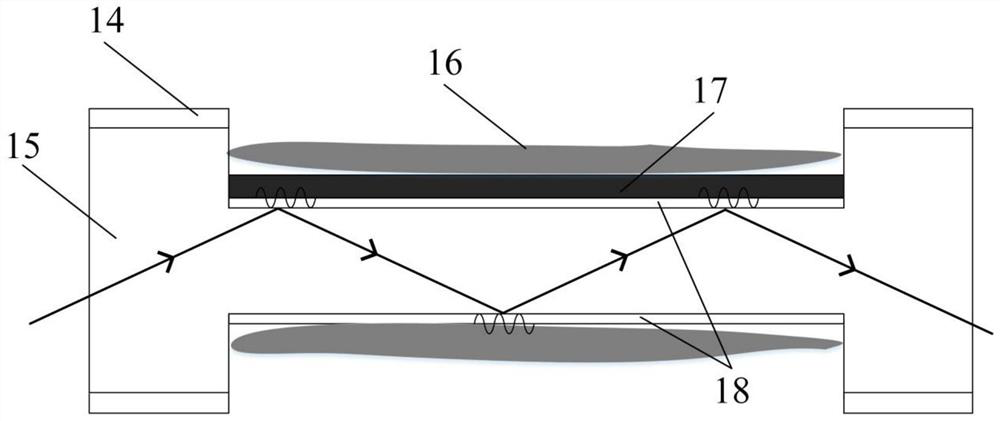

Hole wall directional hot melt coring drilling tool for ice layer

The invention discloses a hole wall directional hot melt coring drilling tool for an ice layer. The drilling tool is of a sleeve structure and comprises a control bin, an in-hole positioning system and a hole wall coring system, wherein the control bin is arranged on the upper portion, the hole wall coring system is arranged on the lower portion, the in-hole positioning system is connected to the top end of the hole wall coring system, the hole wall coring system is driven by the in-hole positioning system to rotate, a supporting mechanism is connected between the lower end of the control bin and the top end of the in-hole positioning system, the control bin is connected with the in-hole positioning system and the hole wall coring system, the control bin can collect signals transmitted by the in-hole positioning system and the hole wall coring system, and the control bin provides power for the in-hole positioning system and the hole wall coring system and controls work of the in-hole positioning system and the hole wall coring system. The hole wall directional hot melt coring drilling tool has the advantages of being simple in structure, light in weight, free of pollution to the environment and large in coring diameter, the drilling efficiency is improved, the interior of the drilling tool has anti-icing performance, and drilling safety is guaranteed. In-hole accurate positioning and coring can be realized.

Owner:JILIN UNIV

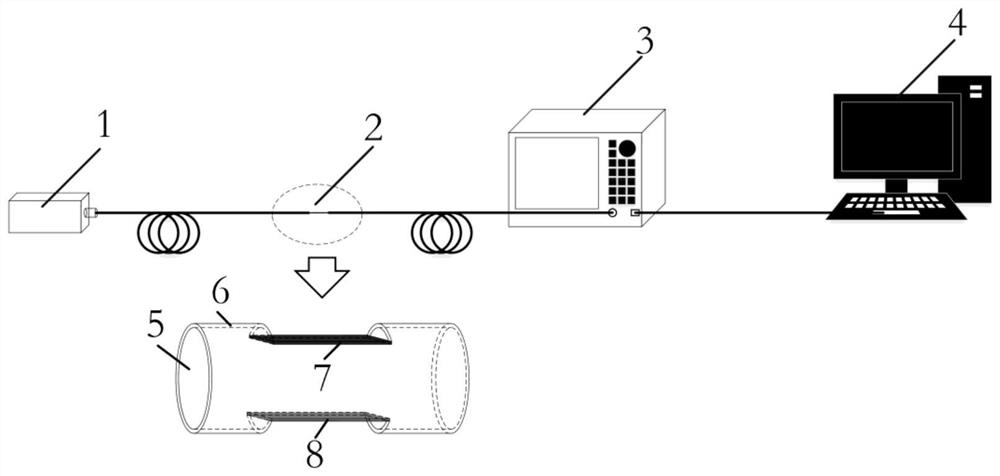

Temperature compensation type polymer optical fiber SPR sensor

InactiveCN112432928ALarge core diameterGood flexibilityPhase-affecting property measurementsThermometers using physical/chemical changesOptical spectrometerNanoparticle

The invention discloses a temperature compensation type plastic optical fiber SPR sensor, and belongs to the technical field of optical fiber sensors. The sensor is composed of a light source, a plastic optical fiber SPR sensing probe with a double-side-throwing double-coating structure, a spectrograph and a computer. According to the plastic optical fiber with the double-side-throwing structure,the plastic optical fiber is clamped on the optical fiber clamp, side-throwing machining is conducted through a side-throwing machine, after one side is machined, the optical fiber is detached, a symmetrical face is machined at the same position, the side-throwing depths of the two sides are the same, and therefore the double-side-throwing structure is obtained. Then the polishing surface is polished, finally, gold nanoparticles are respectively plated on the two polishing surfaces in an ion sputtering manner, and finally, a PDMS film is attached to one of the coated polishing surfaces, thereby forming the temperature compensation unit. The sensor has the advantages of simple structure and preparation process, low cost, high mechanical strength and good integration.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Double-channel plastic optical fiber SPR sensor and preparation method thereof

InactiveCN112432930AReduce hardnessLarge core diameterPhase-affecting property measurementsThermometers using physical/chemical changesSpectrographSurface plasmonic resonance

The invention discloses a plastic optical fiber surface plasma resonance sensor with a double-channel double-side-throwing structure, and belongs to the technical field of optical fiber sensing. The sensor is composed of a light source, a plastic optical fiber surface plasma resonance sensing probe with a double-side-throwing double-coating structure, a spectrograph and a computer. The optical fiber with the double-side-throwing structure is prepared from a plastic optical fiber which is soft in texture, good in flexibility and low in cost. The two polished surfaces of the plastic optical fiber with the double-side polished structure are plated with gold and silver nanoparticles respectively, so that transmission light can generate a surface plasma resonance phenomenon on the two polishedsurfaces respectively, and two resonance absorption peaks are generated at two different wavelength positions of a transmission spectrum of the transmission light respectively; therefore, dual-channelsurface plasmon resonance sensing can be realized. The surface plasma resonance sensor has the advantages of simple structure and preparation process, low cost, high mechanical strength and good integration.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Optical communication module configured for enhancing optical coupling efficiency

InactiveUS20180188458A1Enhanced couplingIncrease light receiving areaFibre transmissionCoupling light guidesCoupling lossDual core

An optical communication module configured for enhancing optical coupling efficiency, which includes an optical butt joint receptacle and a light emitting body provided on one side of the optical butt joint receptacle. The optical butt joint receptacle has a receptacle body and a through hole provided in the receptacle body for a dual-core optical fiber to extend through. The receptacle body has a light-receiving side and an optical fiber insertion groove corresponding respectively to two ends of the through hole. The light emitting body includes a housing, a laser semiconductor provided in the housing, and an aperture provided in one side of the housing for aligning with the through hole so as that the laser beam emitted by the laser semiconductor is optically coupled to the dual-core optical fiber. The dual-core optical fiber has different core diameters and numerical apertures to enhance the coupling efficiency and reduce the coupling loss in between with the external optical fiber.

Owner:LUXNET CORP

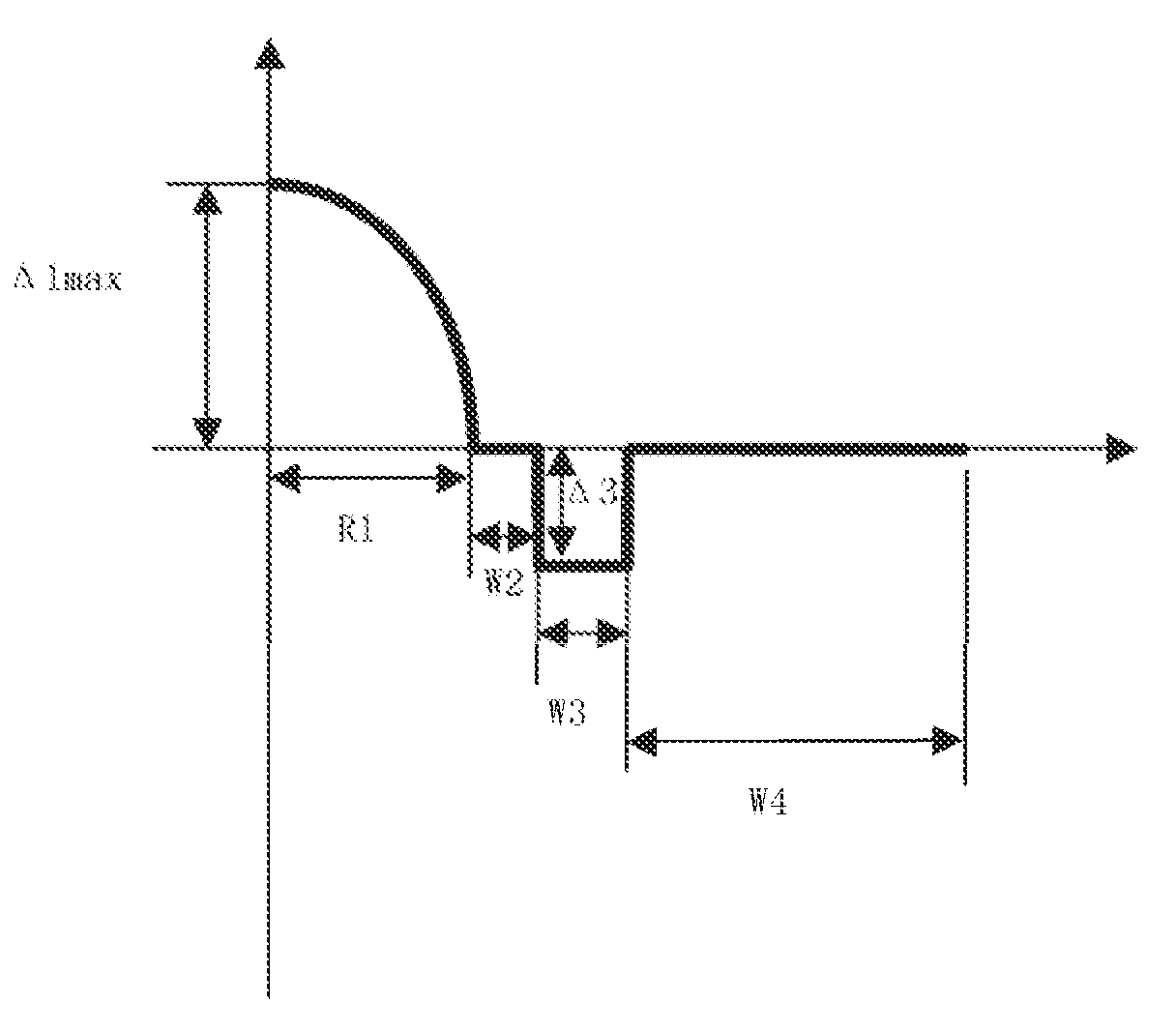

Few mode optical fibers for mode division multiplexing having intermediate trenches

ActiveUS10324253B2Large core diameterIncrease the number ofOptical fibre with graded refractive index core/claddingOptical fibre with multilayer core/claddingFew mode fiberRefractive index

Owner:DRAKA COMTEQ BV

Few mode optical fibers for mode division multiplexing

ActiveUS10295735B2Large core diameterIncrease the number ofOptical fibre with graded refractive index core/claddingOptical fibre with multilayer core/claddingFew mode fiberRefractive index

Few mode optical fibers for mode division multiplexing. The Few Mode Fiber supporting 25 or 30 LP guided modes and includes a graded index core with a α-profile, a radius R1 (at 0 refractive index difference) between 23 and 27 μm and a maximum refractive index difference Dn1 between 14·10−3 and 17·10−3, and an end of the α-profile at a radius R1b, with index difference Dn1b; a trench surrounding the core with radius R3 between 30 and 40 μm and refractive index difference Dn3 between −15·10−3 and −6·10−3. Such a FMF shows a specific design of the interface between the core and the cladding such that R1b>R1, Dn1b between −10·10−3 and −3·10−3, and Dn1b−Dn3≥0.9×10−3.

Owner:DRAKA COMTEQ BV

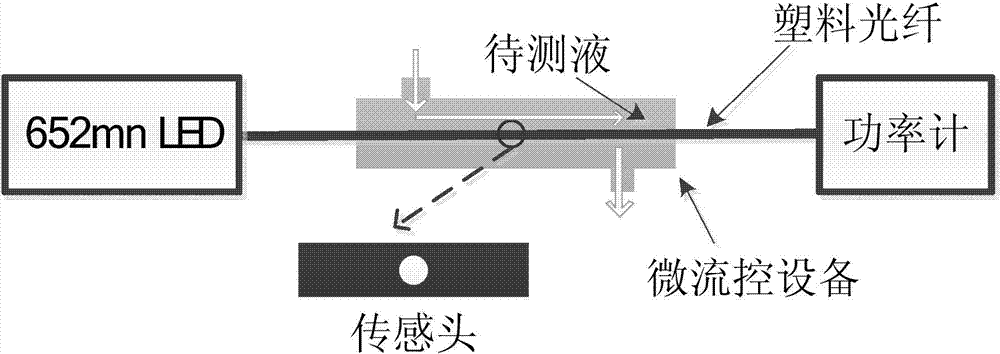

Plastic optical fiber refractive index sensor on basis of micropore structure and preparation method and application thereof

InactiveCN104267000ALarge core diameterImprove toughnessPhase-affecting property measurementsProduction rateLight source

The invention relates to a plastic optical fiber refractive index sensor on the basis of a micropore structure. The plastic optical fiber refractive index sensor comprises a plastic optical fiber used as a substrate and the micropore structure processed on the lateral surface of the plastic optical fiber; the axial direction of a micropore perpendicularly and transversely penetrates through the axial direction of the plastic optical fiber; a light source for providing an optical signal is arranged at one end of the plastic optical fiber; a power meter is arranged at the other end of the plastic optical fiber so as to detect power loss after the light source is spread by the plastic optical fiber. The plastic optical fiber adopted by the plastic optical fiber refractive index sensor is a low-loss optical waveguide and transmission loss in the optical waveguide is ignored under a certain length, and thus, loss of the optical fiber is only related to loss of a sensing head, namely loss of the micropore structure part. According to the invention, a machining method is utilized to make the micropore sensing structure on the lateral surface of the optical fiber; the plastic optical fiber refractive index sensor has the advantages of simple process, high productivity, low cost and the like; and excellent temperature stability enables the structure to have important application in detection of a refractive index.

Owner:SHANDONG UNIV

Helical cutting insert with progressive cutting edge

InactiveUS20070086865A1Less powerSmooth cutting actionMilling cuttersShaping cuttersEngineeringMechanical engineering

An indexable, helical cutting insert includes at least one axial clearance slash extending from a bottom surface to one of said side walls forming a wiper on an edge of the axial clearance slash. In another embodiment, the cutting insert includes at least one inside cutting edge that extends outwardly a distance from the side wall. In another embodiment, the helical cutting insert includes at least one progressive cutting edge. In another embodiment, the cutting insert includes at least one helical cutting edge that is curved inwardly to enable the cutting insert to perform machining operations on cutters having different diameters.

Owner:KENNAMETAL INC

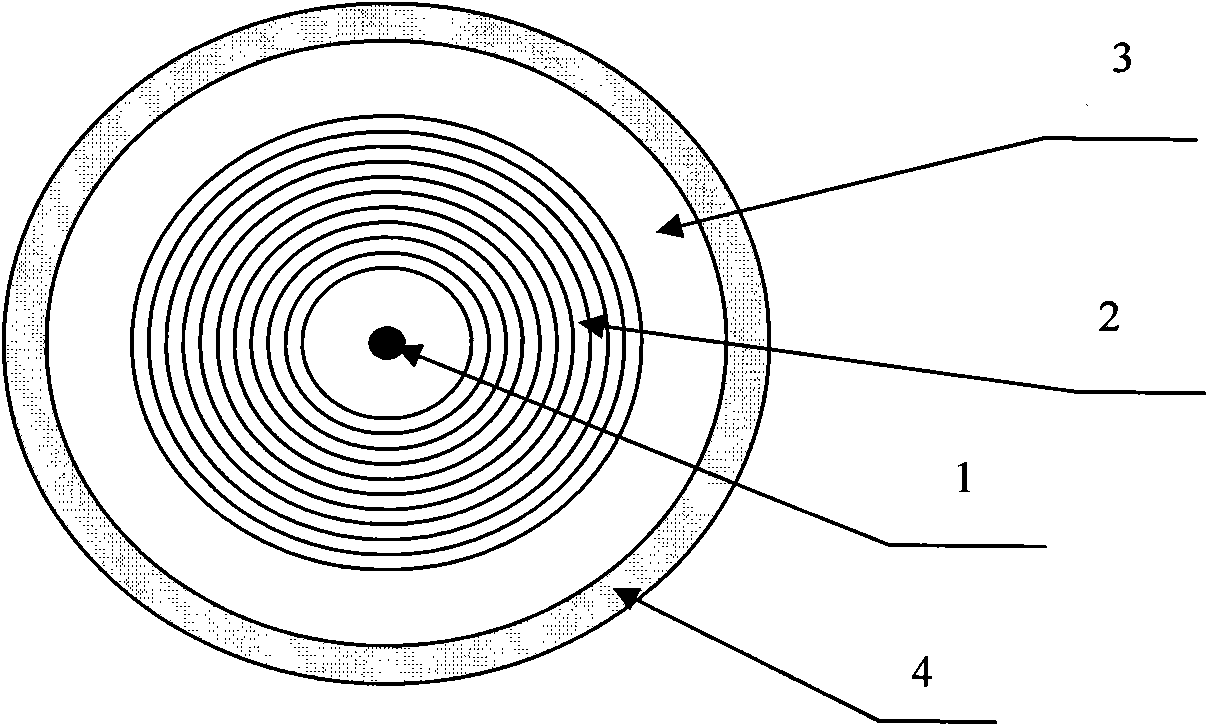

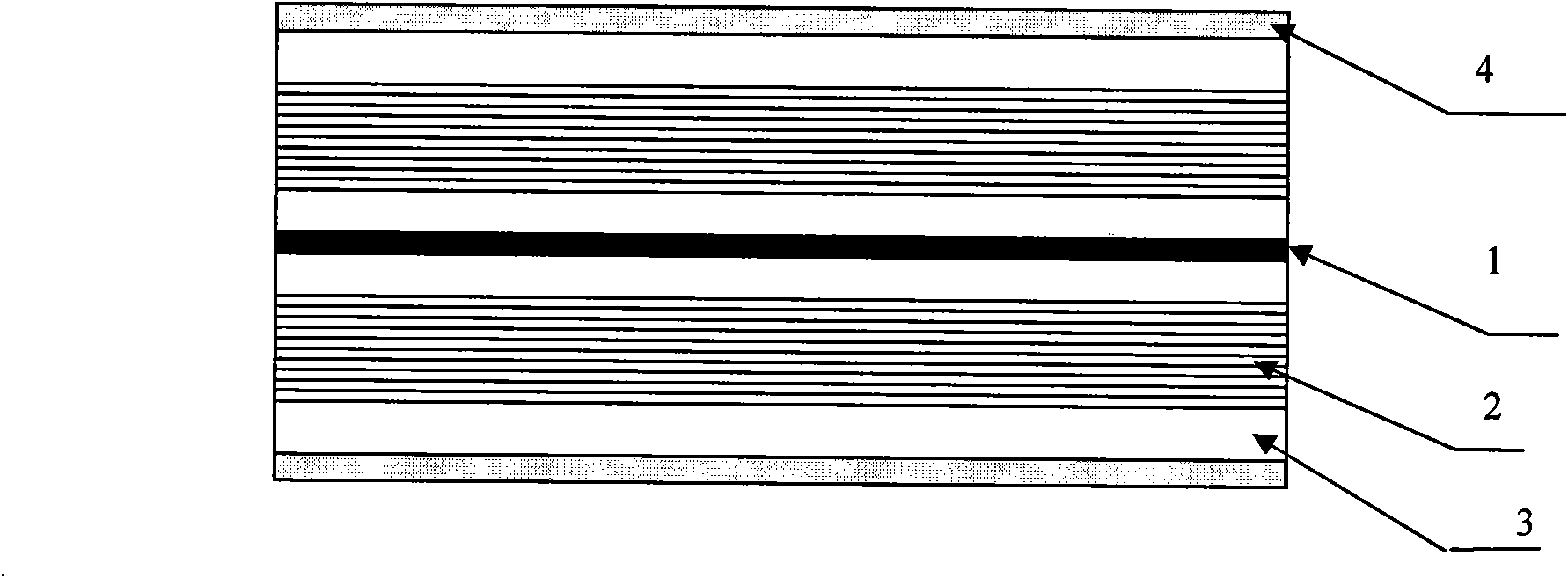

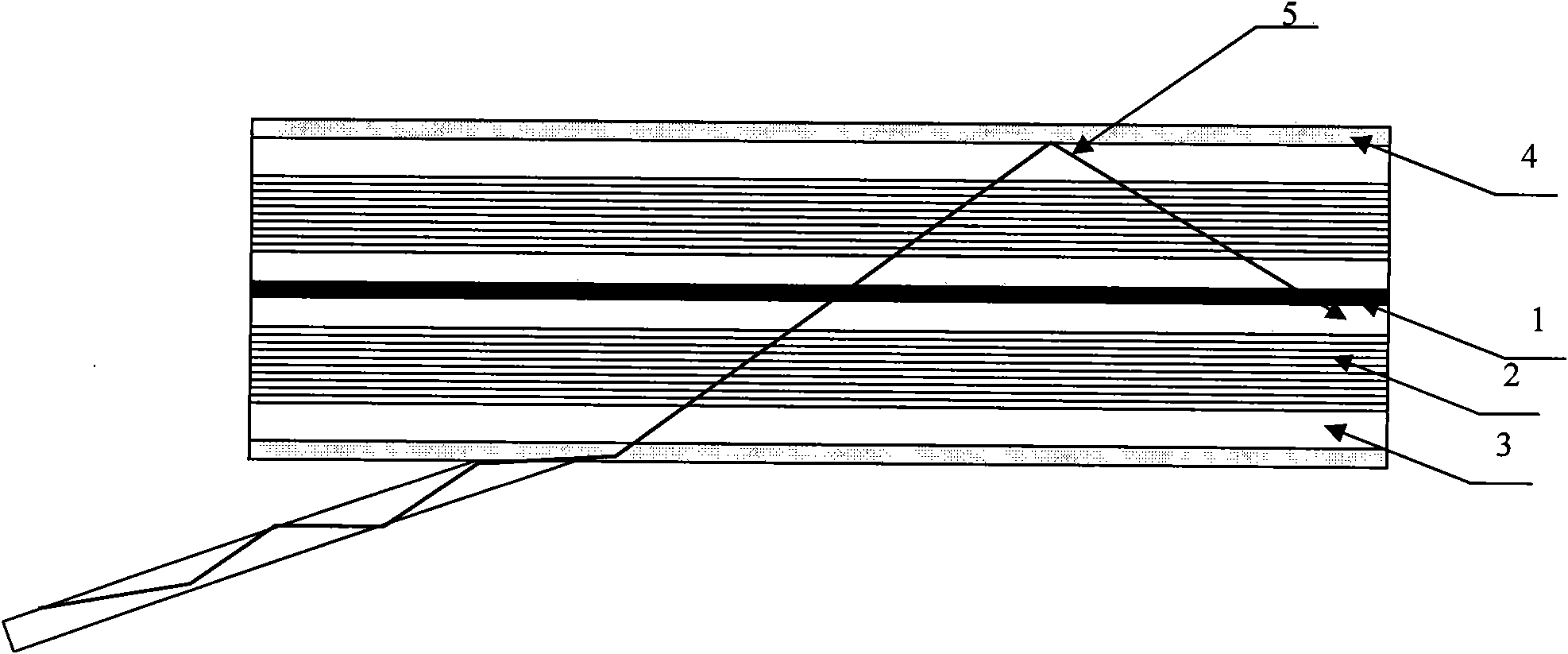

Double-cladding optical fiber with Bragg structure, optical fiber amplifier and optical fiber laser

InactiveCN101969173ALarge core diameterLow NA valueActive medium shape and constructionDouble-clad fiberHigh power lasers

The invention relates to a double-cladding optical fiber with a Bragg structure, comprises a fiber core 1, an inner cladding layer 2, an outer cladding layer 3 and a protection layer 4, wherein a radial coaxial Bragg structure region with high-low refractive index layers, which are periodically distributed in an overlapping way, is arranged on the inner cladding layer 2. The double-cladding optical fiber has large core diameter and low NA value, realizes the high-power laser ground mode output under the condition of not increasing the size of the inner cladding layer by providing pumping light for the optical fiber, and amplifying and propagating signals passing through the optical fiber, facilitates heat management while high-power laser is output and is suitable for manufacturing a high-power and high beam quality optical fiber laser and an optical fiber amplifier.

Owner:SHANXI FEIHONG LASER TECH

Ultraviolet optical system for fast molding

The invention discloses an ultraviolet optical system for rapid prototyping comprising an ultraviolet light source generator which is an ultraviolet irradiation device based on the spherical high-pressure mercury lamp, a transmission light conducting mechanism consisting of optical fiber and connection port A and B, and a light gathering mechanism implemented by an optical combination mechanism, wherein the connection port A connects to the ultraviolet light source generator and the connection port B connects to the optical combination mechanism of light gathering mechanism. It is characterized in that the optical fiber in transmission light conducting mechanism is liquid-core optical fiber. The invention can obtain energy stable emergent light matching to the wavelength of the required ultraviolet for rapid prototyping, can high effectively conduct and gather ultraviolet, and ensure required energy and light spot size for solidifying prototyping materials.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Few mode optical fibers for mode division multiplexing

ActiveUS20190033514A1Small differential mode group delayIncrease the number ofOptical fibre with graded refractive index core/claddingFew mode fiberRefractive index

Few mode optical fibers for mode division multiplexing. The Few Mode Fiber supporting 25 or 30 LP guided modes and includes a graded index core with a α-profile, a radius R1 (at 0 refractive index difference) between 23 and 27 μm and a maximum refractive index difference Dn1 between 14.10−3 and 17.10−3, and an end of the α-profile at a radius R1b, with index difference Dn1b; a trench surrounding the core with radius R3 between 30 and 40 μm and refractive index difference Dn3 between −15.10−3 and −6.10−3. Such a FMF shows a specific design of the interface between the core and the cladding such that R1b>R1, Dn1b between −10.10−3 and −3.10−3, and Dn1b−Dng≥0.9×10−2.

Owner:DRAKA COMTEQ BV

Phosphate photonic crystal fiber and converter for efficient blue generation

ActiveUS9667021B2Favorable gain propertyImprove featuresActive medium materialActive medium shape and constructionPhosphate glassPhotonic-crystal fiber

In the method for generating blue laser light with high optical and electrical efficiency, wherein the improvement comprises the step of using a phosphate glass photonic crystal fiber rod as a gain medium.

Owner:BAE SYST INFORMATION & ELECTRONICS SYST INTERGRATION INC

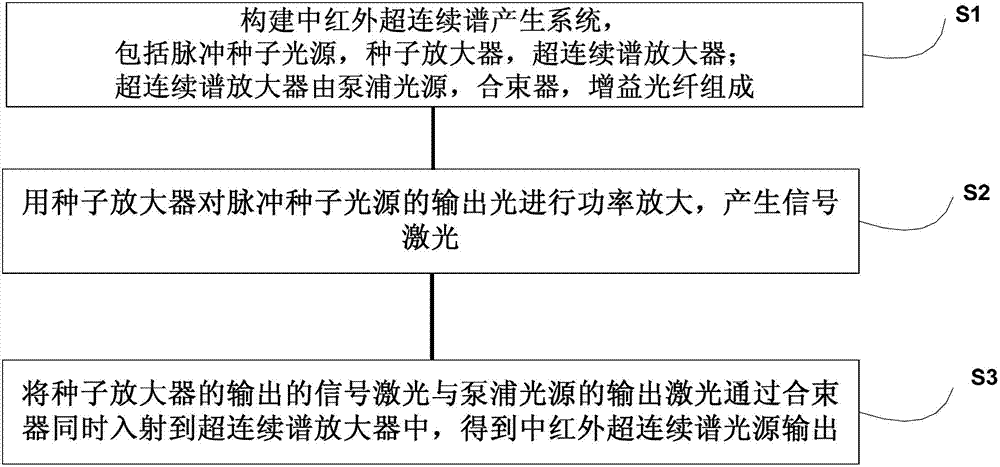

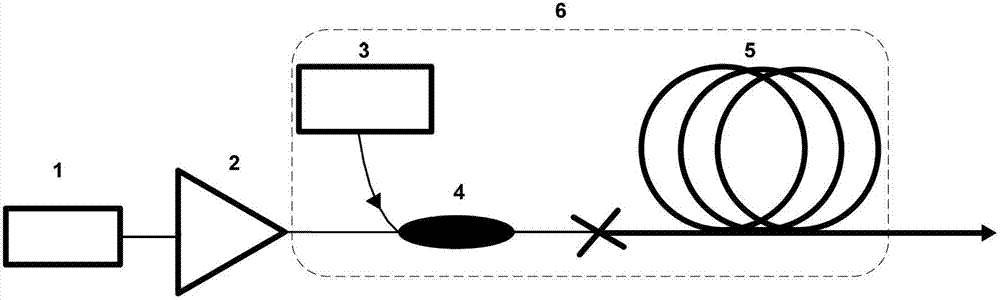

A method for generating mid-infrared supercontinuum directly in amplifiers

ActiveCN103151687BLarge core diameterBreak through the output power limitOptical fibre with multilayer core/claddingActive medium shape and constructionAudio power amplifierSemiconductor

Owner:NAT UNIV OF DEFENSE TECH

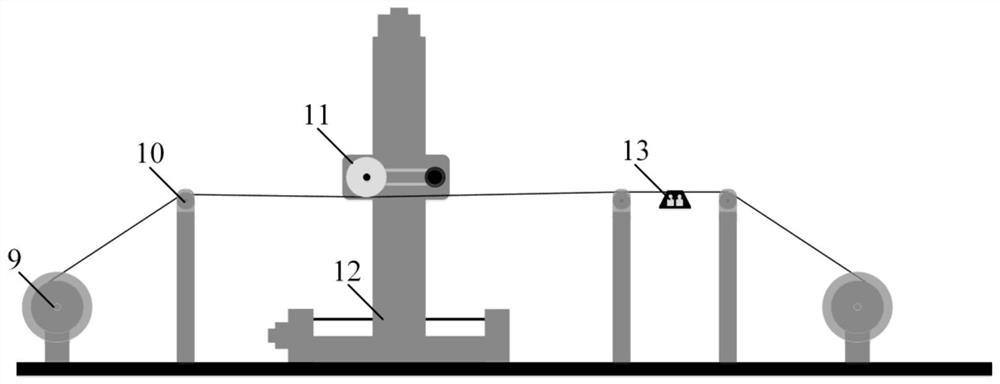

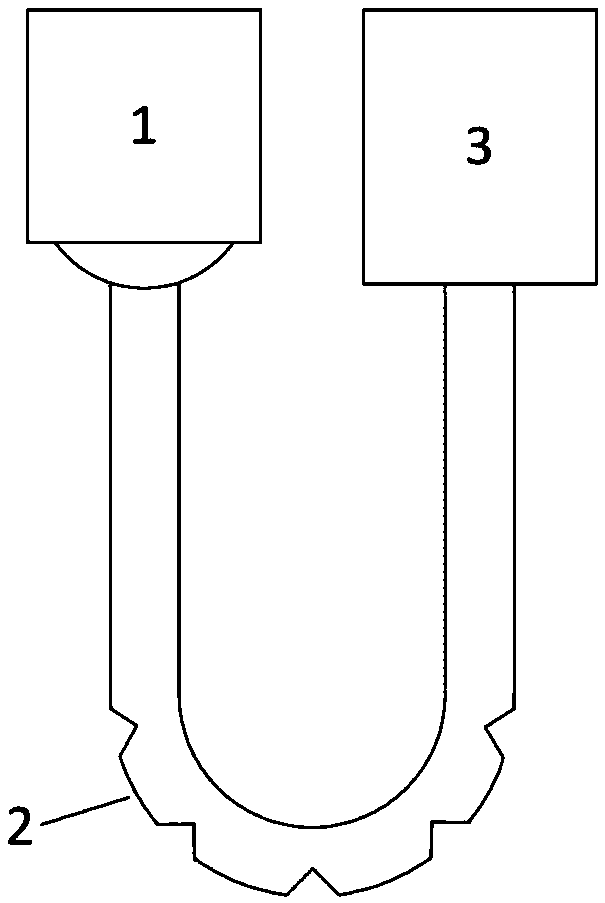

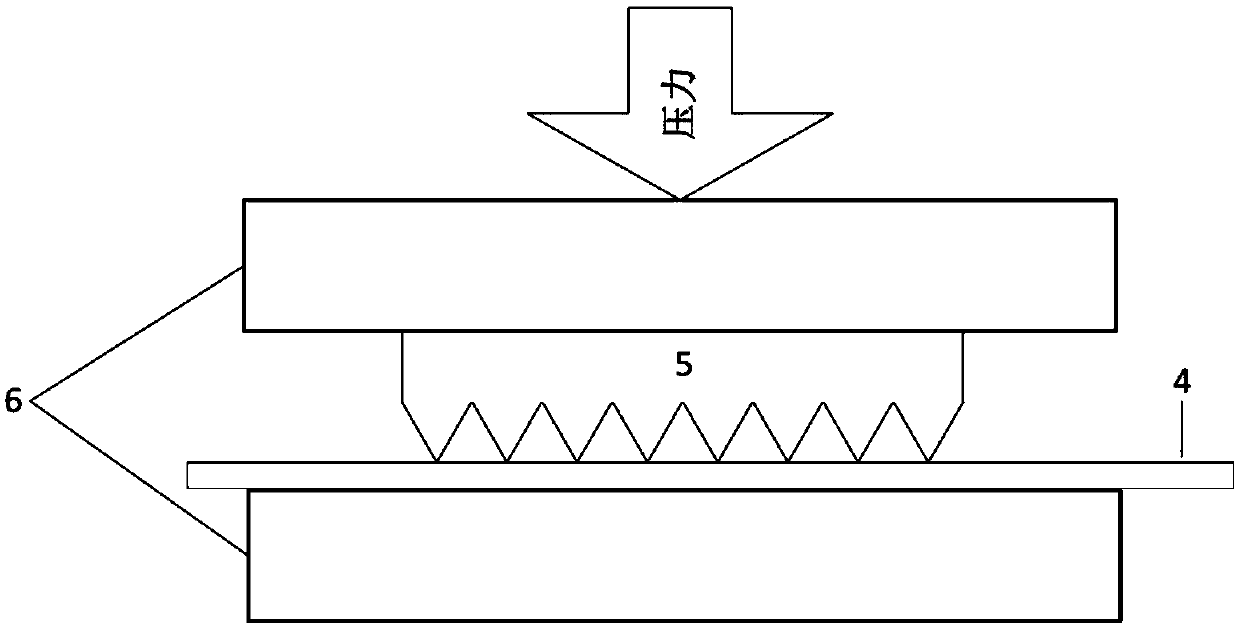

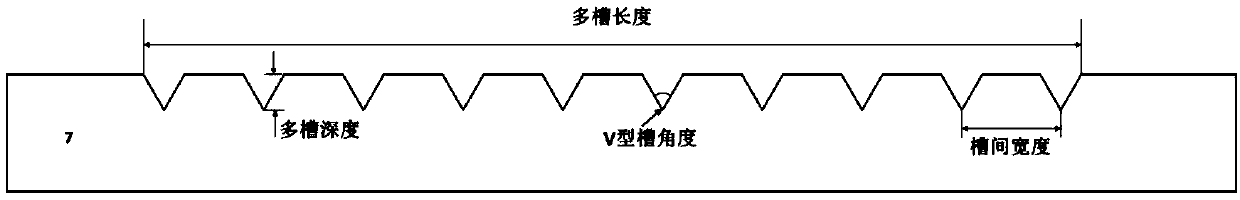

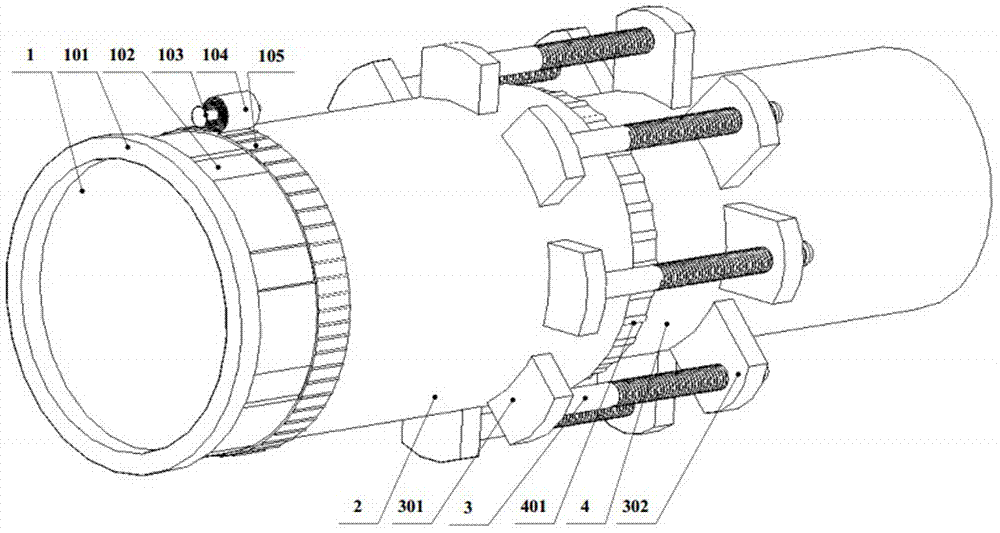

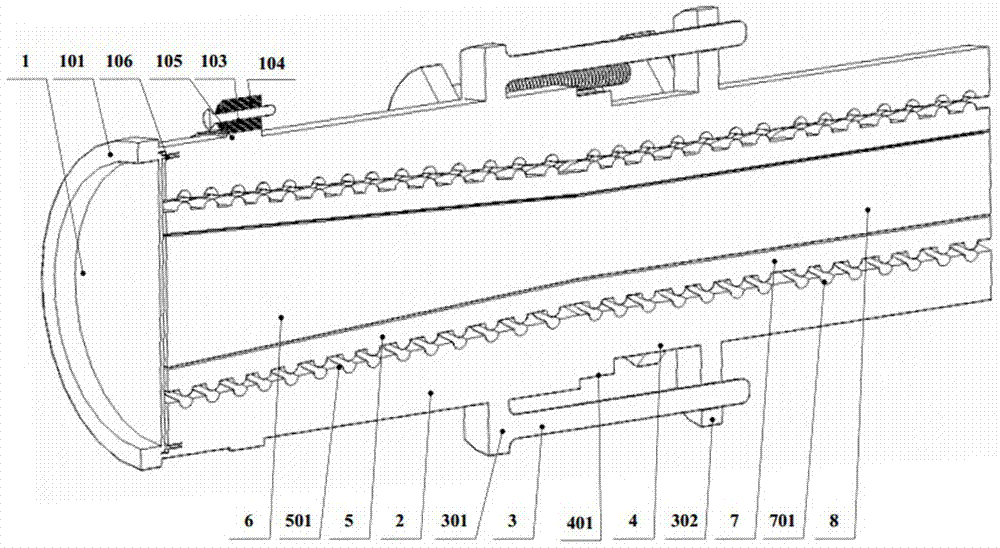

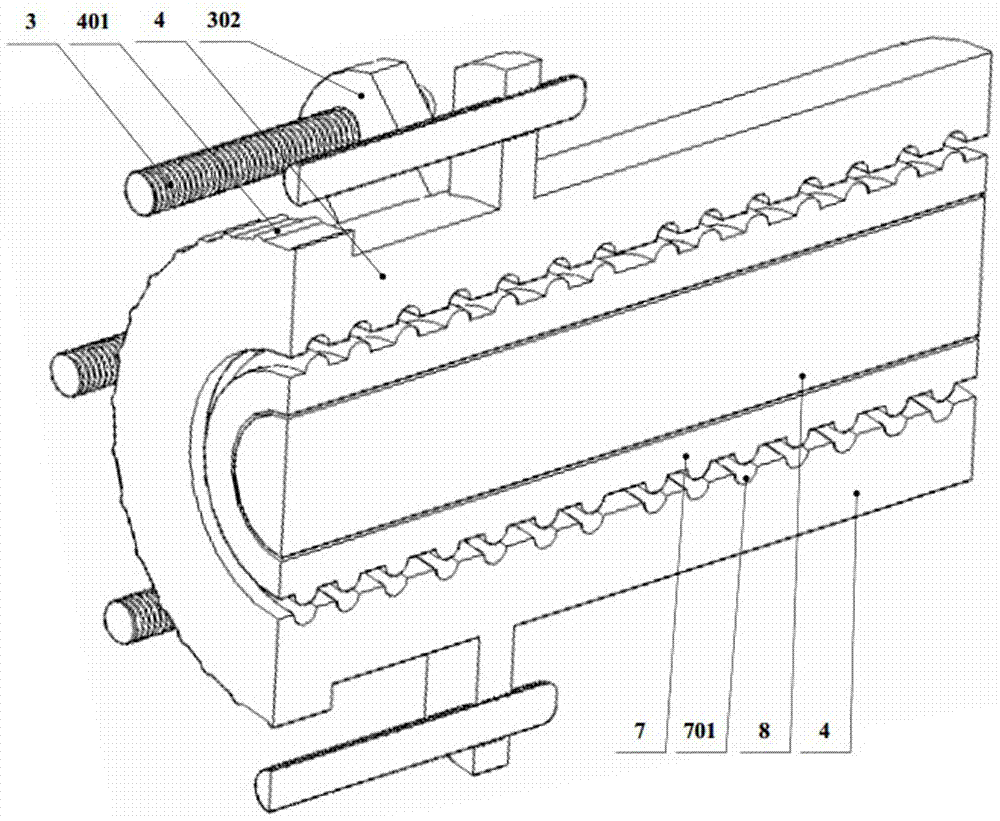

U-shaped plastic optical fiber liquid refractive index sensor with multi-groove structure

InactiveCN106841109BSimple preparation processEasy to controlPhase-affecting property measurementsRefractive indexPlastic optical fiber

The invention relates to a U-shaped plastic optical fiber liquid refractive index sensor with a multi-groove structure, and belongs to the technical field of optical fiber sensors. The U-shaped plastic optical fiber liquid refractive index sensor consists of a light source, a U-shaped plastic optical fiber probe with a multi-groove structure, and a photoelectric detection device. The U-shaped plastic optical fiber probe with the multi-groove structure is characterized in that a plastic optical fiber is vertically arranged at the lower surface of a steel die of which the surface provided with a cross section of a triangular sawtooth structure, and the vertexes of a triangle point to a center line of the plastic optical fiber; the pressure is applied to the steel die by a clamp, and the multi-groove structure with multiple V-shaped grooves is pressed along a fiber core of a centerline cross section of the plastic optical fiber by the triangular sawtooth structure of the die; then, the plastic optical fiber and the opposite other side surface of the multi-groove structure are wound on a cylindrical steel cylinder which is heated to about 75 to 95 DEG C; finally, about 3 to 6N tension is applied to both ends of the optical fiber. The U-shaped plastic optical fiber liquid refractive index sensor has the characteristics that the structure and preparation technology are simple, the cost is low, and the sensitivity is high.

Owner:JILIN UNIV

Light-cone-based forward scatter dust instrument optical system

PendingCN107167406ALarge core diameterMulti-gather scatterParticle suspension analysisForward scatterHigh energy

A light-cone-based forward scatter dust instrument optical system includes a window, an anti-collision sleeve, a connection piece, a rotary rod, an elastic sleeve, an elastic band, an embedding groove, a coating layer I, a cladding layer I, a buffer zone I, a fiber core I, a lower plate, a connecting rod, an upper plate, a coating layer II, a sealing sleeve, a cladding layer II, a buffer zone II and a fiber core II, the window is nested in the embedding groove, the inner side of the anti-collision sleeve is attached to the window, the anti-collision sleeve and the elastic band are connected by the connection piece, the elastic sleeve and the elastic band are connected, the rotary rod is arranged at the center of the elastic sleeve, the lower plate is arranged on the outer surface of the coating layer I, one end of the connecting rod is connected with the lower plate, the other end of the connecting rod passes through the upper plate, and is in nested connection with the upper plate, the cladding layers are arranged in the coating layers, the buffer zones are arranged on the outer surface of the cladding layers, and the fiber cores are arranged in the cladding layers. The beneficial effects are that: (1) the light-cone-based forward scatter dust instrument optical system facilitates collection of much scattering measuring light; (2) the light-cone-based forward scatter dust instrument optical system can ensure the accuracy of monitoring, and has high energy transmission efficiency and small losses; and (3) the light-cone-based forward scatter dust instrument optical system has shock and impact resistance.

Owner:西石(厦门)科技股份有限公司

Optical fiber having proximal taper for ophthalmic surgical illumination

ActiveUS20190374098A1Reduce sensitivityLarge core diameterMechanical apparatusEye surgeryDistal portionLight beam

An ophthalmic illumination system can include an optical fiber configured to transmit a light beam output by a light source and focused by a condenser. The optical fiber can includeproximal, distal, and central portions. The proximal portion can be configured to receive the light beam focused by the condenser. The distal portion can be configured to emit the light beam to illuminate a surgical field. The central portion can extend between the proximal and distal portions. A core diameter of the proximal portion can be larger than core diameters of the central and distal portions. An ophthalmic illumination method can include focusing, using a condenser, a light beam emitted by a light source onto a proximal portion of an optical fiber. The method can also include transmitting, using the optical fiber, the light beam to a surgical field.

Owner:ALCON INC

A precision milling cutter

ActiveCN103433542BIncrease chip removal spaceLarge core diameterLayered productsMilling cuttersMilling cutterEngineering

Owner:SHENZHEN JINZHOU PRECISION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com