Chirped pulse amplification fiber laser system without stretcher

A fiber laser and chirped pulse technology, applied in the laser field, can solve the problems of high energy pulse lasers such as large volume, high price, and high requirements for installation and debugging accuracy, and achieve the limit of reducing the optical damage threshold, large mode field area, excellent Amplifying the effect of laser beam quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

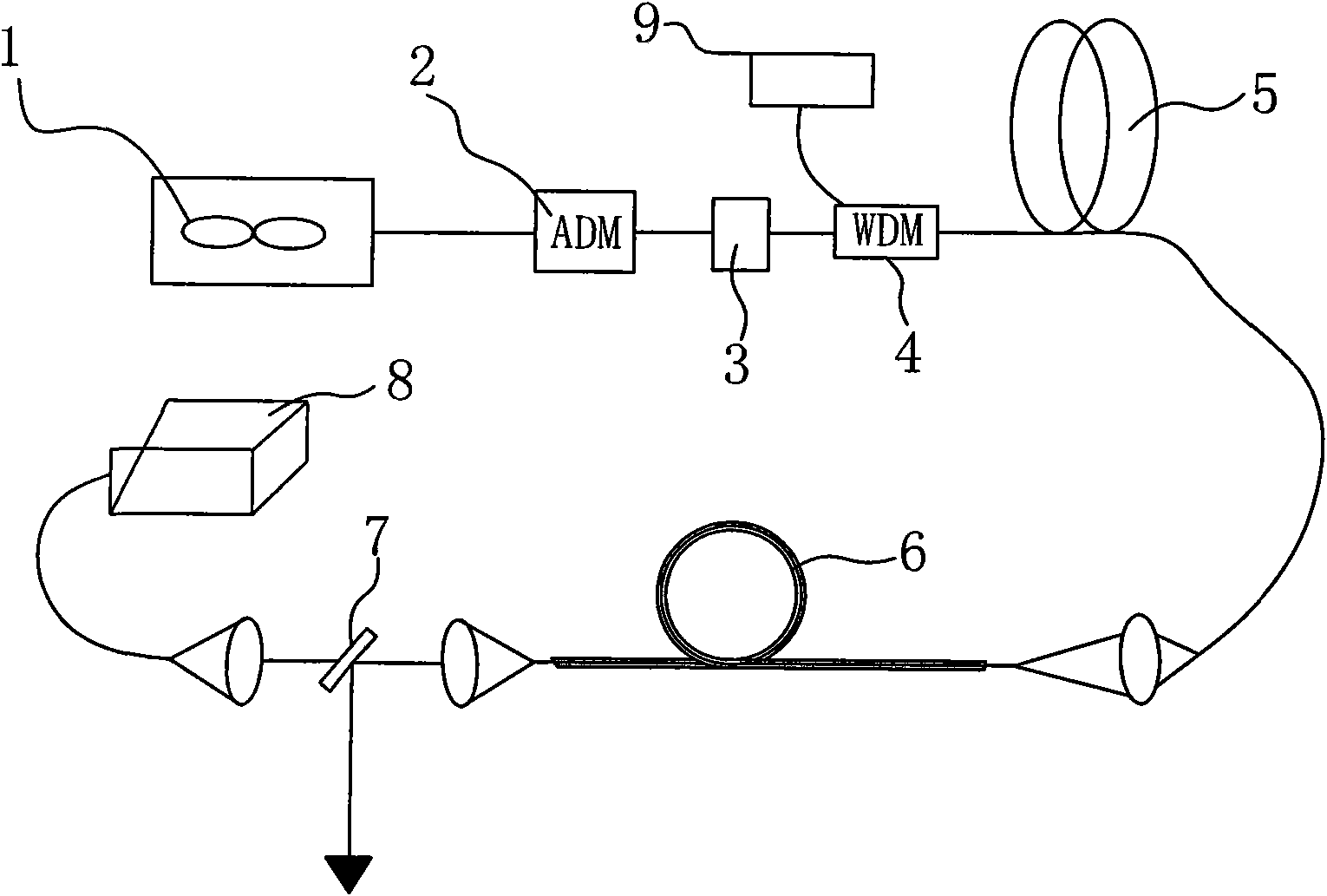

[0026] see figure 1 :

[0027] A chirped pulse amplified fiber laser system without a stretcher, the system includes an "8" cavity mode-locked fiber laser 1, and a pulse selector connected to the output of the "8" cavity mode-locked fiber laser 1 through an optical fiber 2, the single-mode fiber amplifier 3 connected to the output of the pulse selector 2 through the optical fiber, the double-clad ytterbium-doped photonic fiber 6 connected after focusing, and the double-clad ytterbium-doped photonic fiber 6 connected to the other end of the double-clad ytterbium photonic fiber 6 mirror 7; the single-mode fiber amplifier is also connected to a single-mode pump source 9 through an optical fiber, and the system also includes a pump source 8.

[0028] It works as follows:

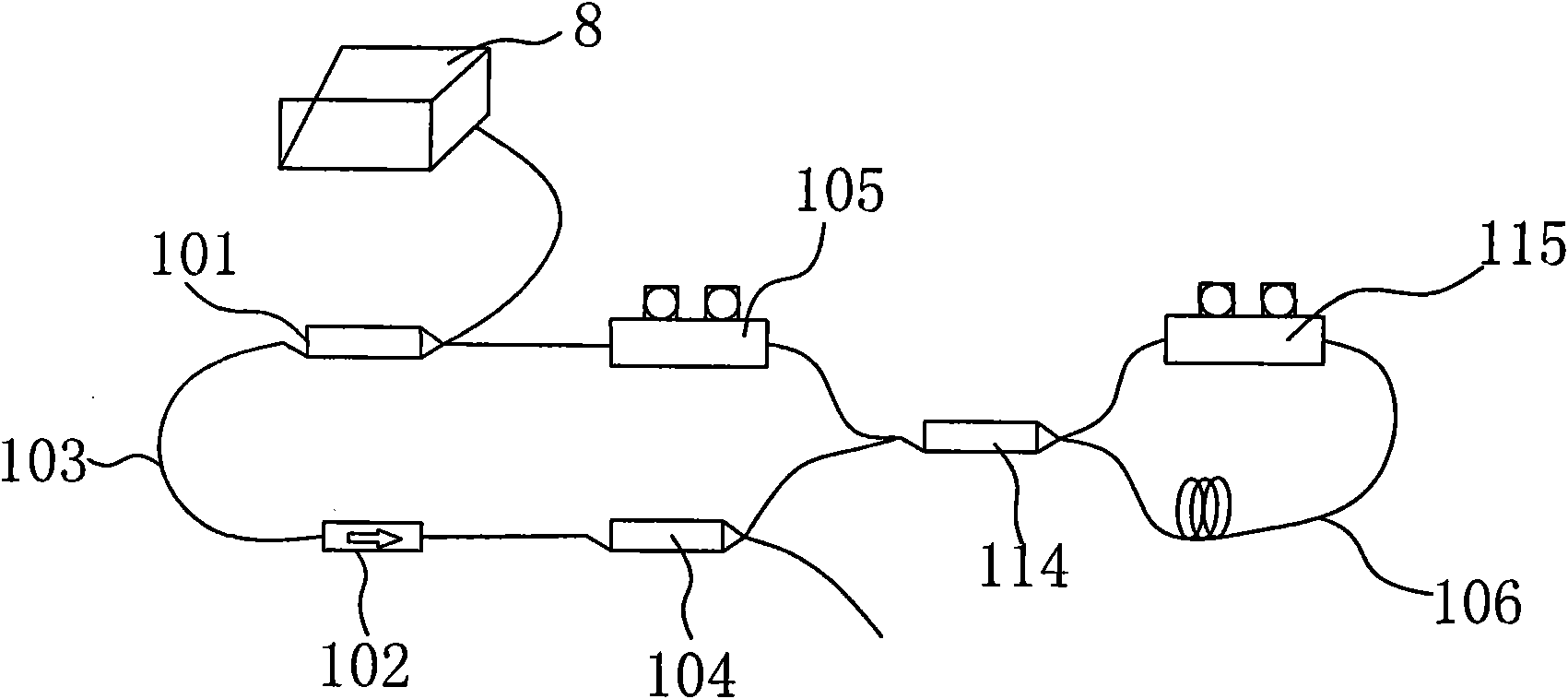

[0029] The stretcher-free fiber laser system generates ultrashort laser pulses through an "8" cavity mode-locked laser. The principle is to use the all-fiber Sagnac interferometer as a nonlinear fiber optic l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com