Hole wall directional hot melt coring drilling tool for ice layer

A core drilling tool and hole wall technology, which is applied in thermal energy drilling, ice drilling, and undisturbed core extraction devices, etc., can solve problems such as low drilling efficiency and complex drilling tool structure, and achieve increased drilling efficiency, Simple coring method and light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

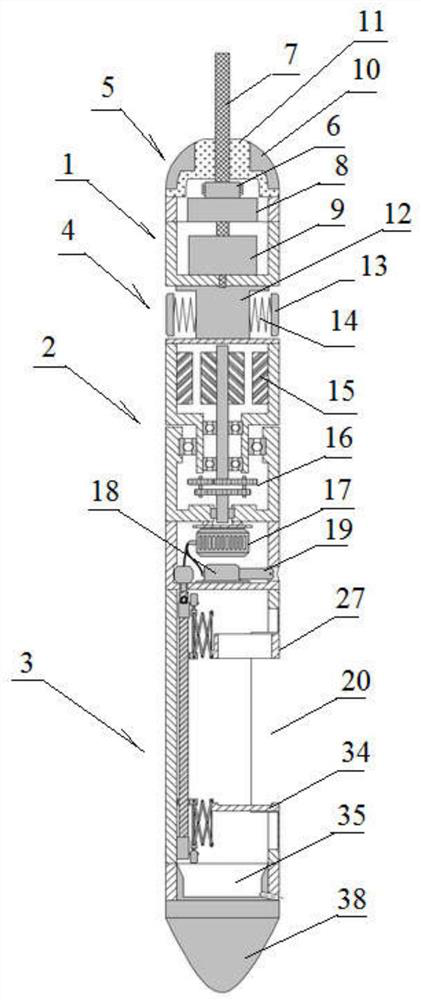

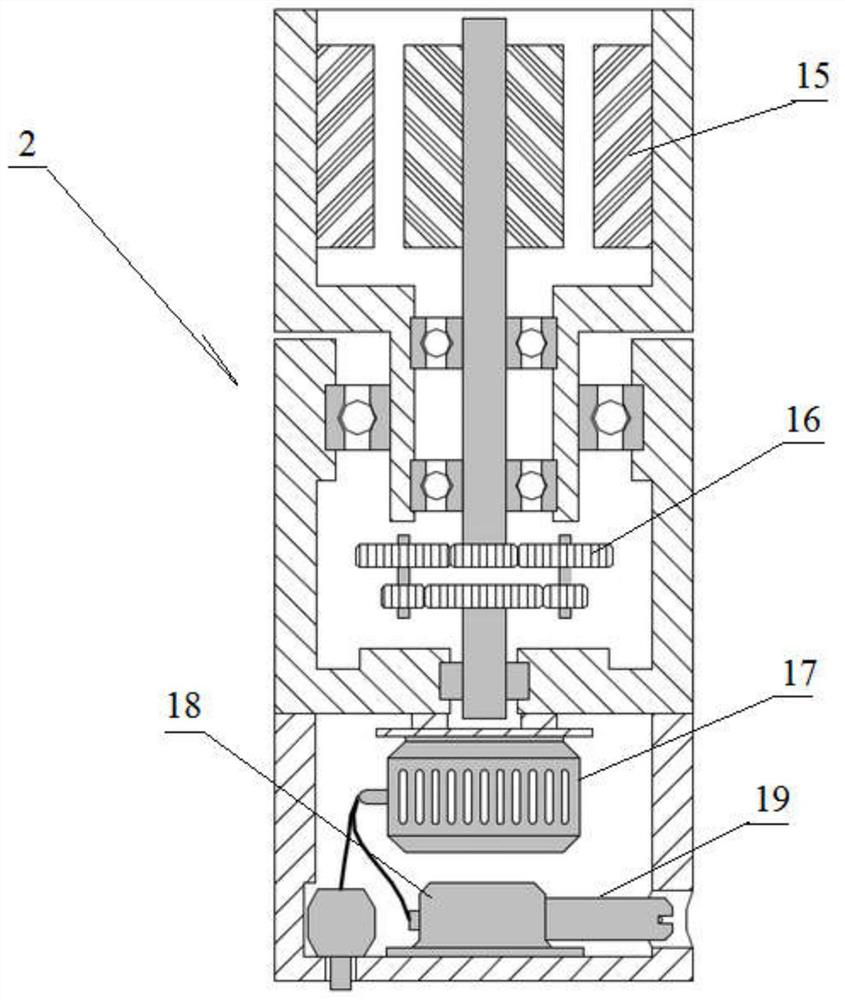

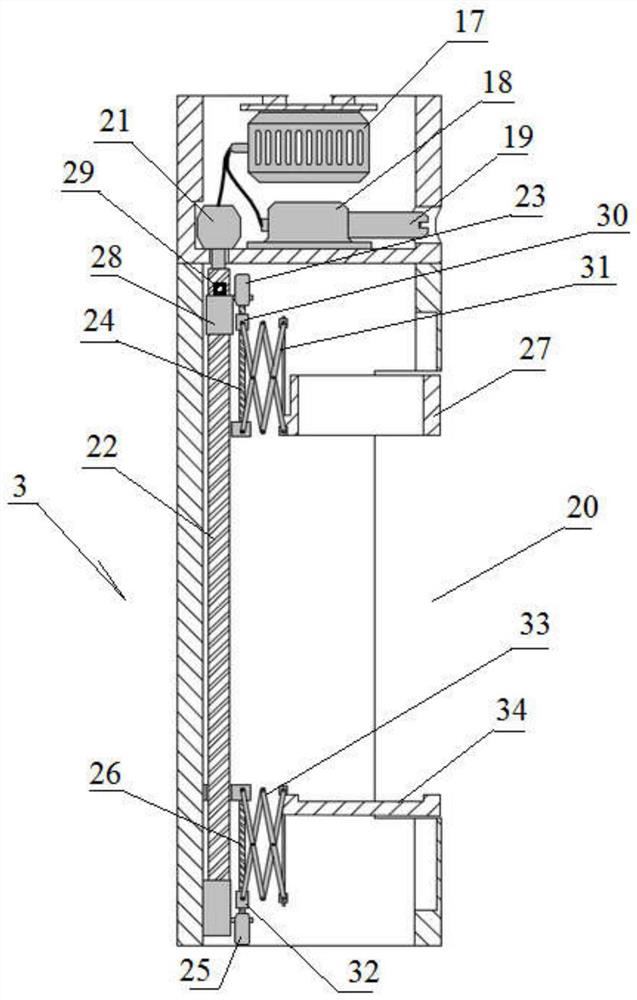

[0037] see Figure 1 to Figure 7 Shown:

[0038] The hole wall directional thermal melting coring tool for ice layer provided by the present invention is a casing structure, including a control cabin 1, a positioning system 2 in the hole and a hole wall coring system 3, wherein the control cabin 1 is arranged on the upper part, and the hole wall The coring system 3 is located at the lower part, and the hole positioning system 2 is connected to the top of the hole wall coring system 3. The hole wall coring system 3 is driven to rotate by the hole positioning system 2, and the lower end of the control chamber 1 is connected with the hole positioning system. A support mechanism 4 is connected between the tops of 2, and the control chamber 1 is respectively connected with the hole positioning system 2 and the hole wall coring system 3. The control chamber 1 can collect the data transmitted by the hole positioning system 2 and the hole wall coring system 3 signal, the control cabi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com