Plastic optical fiber refractive index sensor on basis of micropore structure and preparation method and application thereof

A technology of refractive index sensor and plastic optical fiber, applied in the field of sensors, can solve the problems of refractive index temperature overlap sensitivity, high price, poor stability, etc., and achieve the effects of refractive index sensitivity, simple production and high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

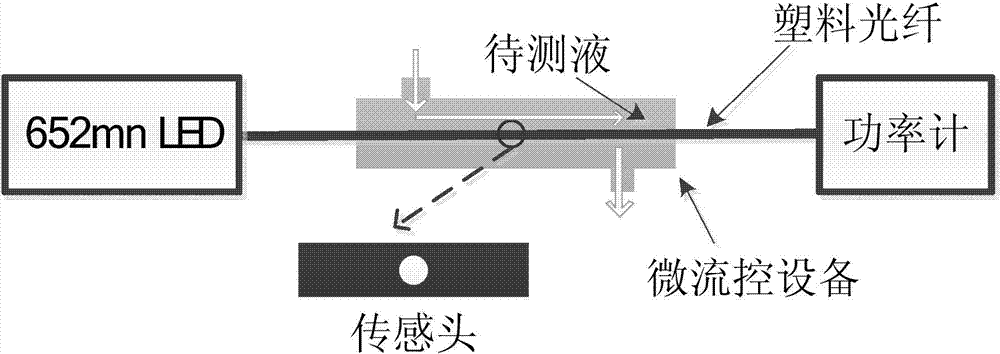

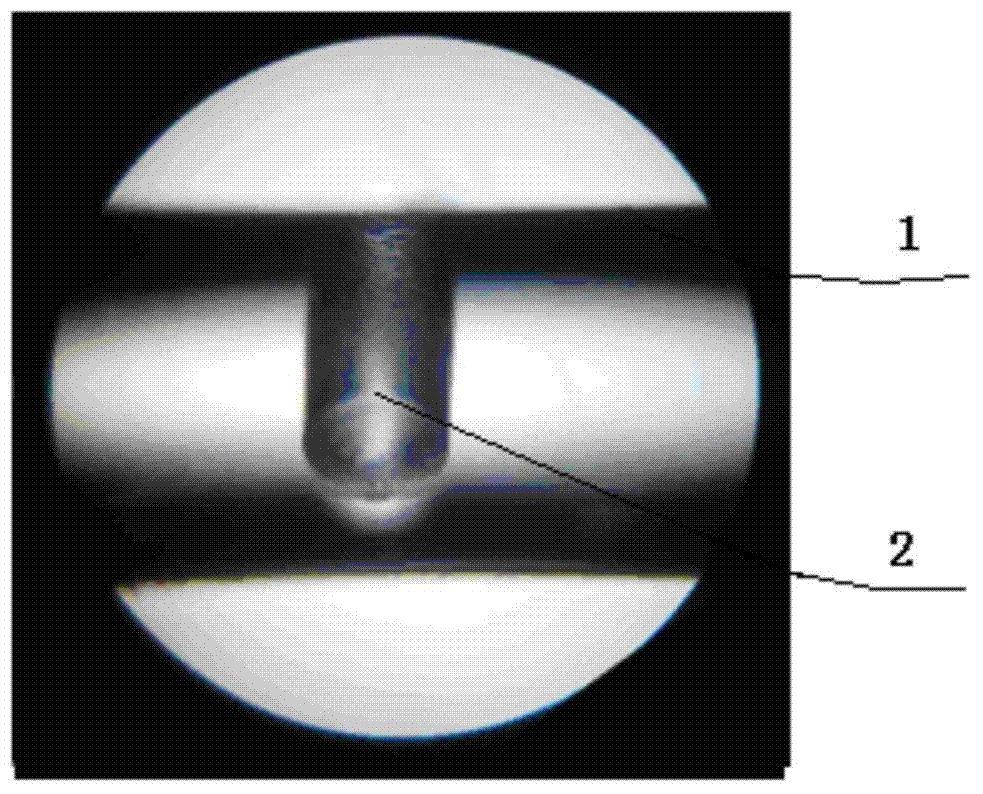

[0035] Such as figure 1 , 2 , 3 shown.

[0036] A plastic optical fiber refractive index sensor based on a microhole structure, including a plastic optical fiber as a substrate and a microhole structure processed on the side of the plastic optical fiber, the axial direction of the microhole is perpendicular to the axial direction of the plastic optical fiber; One end of the optical fiber is provided with a light source providing optical signals, and the other end of the plastic optical fiber is provided with a power meter to detect the power loss of the light source after propagating through the plastic optical fiber. The plastic optical fiber is a plastic optical fiber with a diameter of 0.5 mm. The diameter of the micropores is 0.1-0.4mm.

Embodiment 2

[0038] A plastic optical fiber refractive index sensor based on a micropore structure as described in Example 1, the difference is that the plastic optical fiber is an EL250 plastic optical fiber produced by Mitsubishi Corporation.

[0039] Preferably according to the present invention, the parameters of the plastic optical fiber: the core material is PMMA, the cladding is fluororesin; the geometric size is 480 / 500 μm; the core refractive index is 1.49, the core numerical aperture (NA) is 0.5, and the cladding refraction Rate 1.40; light transmittance / %*m -1 ≥95(570nm), loss / dB*km -1 ≤200(570nm); the wavelength range is 420-680nm, and the applicable temperature is -20℃~70℃.

Embodiment 3

[0041] A plastic optical fiber refractive index sensor based on a microhole structure as described in Example 1, the difference is that the diameter of the microhole is 0.35 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com