Ultraviolet optical system for fast molding

A technology of optical system and ultraviolet light source, which is applied in the field of ultraviolet optical system, can solve the problems of large transmission energy loss of tapered optical fiber, large environmental impact of reflective optical system, and restrictions on the promotion and application of ultraviolet light, so as to ensure the energy, spot size, and output light The effect of stable energy and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The structure and working principle of the present invention will be described in further detail below in conjunction with the accompanying drawings.

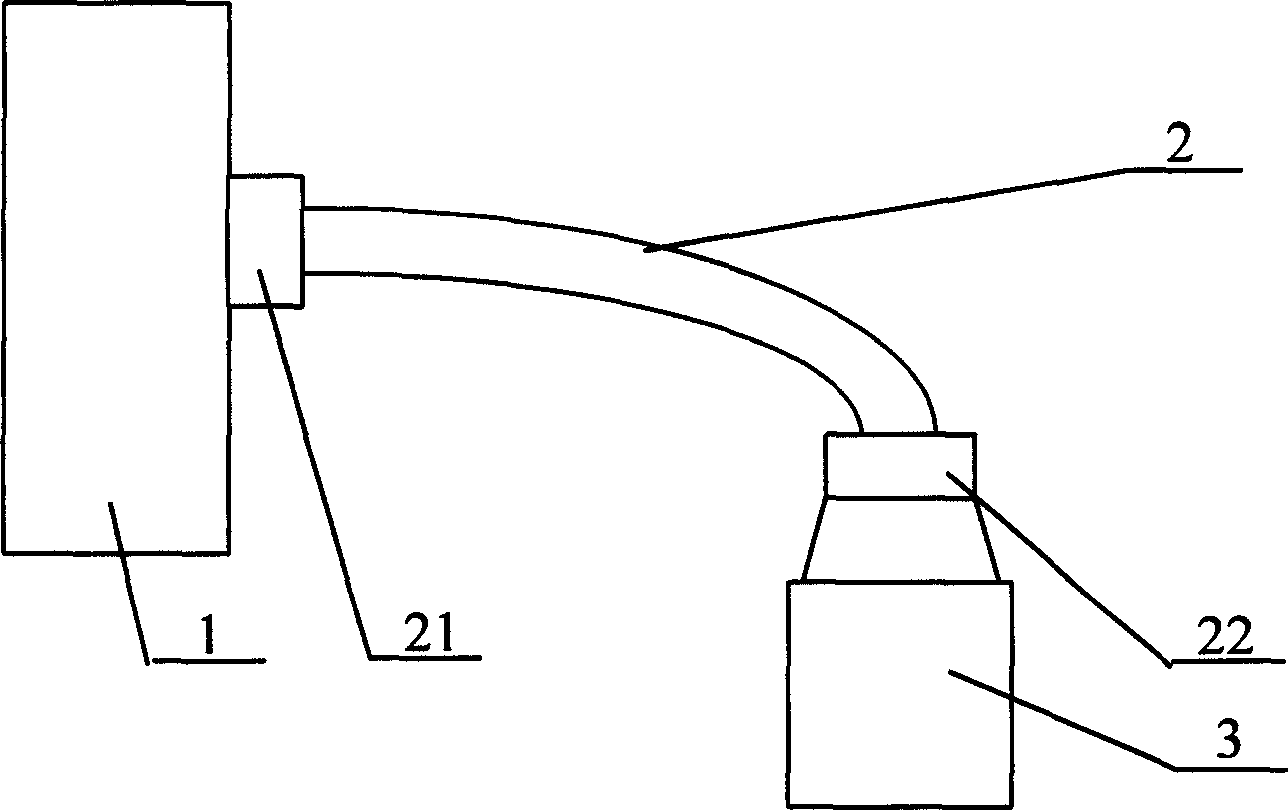

[0012] Such as figure 1 As shown, the present invention is composed of an ultraviolet light source generator, a transmission light guide mechanism and a light concentrating mechanism, wherein: the ultraviolet light source generator adopts an ultraviolet light irradiation device 1 based on a spherical high-pressure mercury lamp, which is used to generate ultraviolet light with a wavelength of 250-500nm Light, the peak wavelength of which is 365nm; according to the curing characteristics of the molding material (photosensitive resin) (the wavelength of ultraviolet light is required to be between 320 and 480nm), the ultraviolet light generated by this ultraviolet light source generator matches its requirements. The ultraviolet light generated by the ultraviolet light source generator is introduced into the optical fiber sys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com