Array substrate of thin film transistor (TFT)-liquid crystal display (LCD) and manufacture method thereof

The technology of an array substrate and manufacturing method, which is applied in the field of liquid crystal displays, can solve the problems of poor process realizability and low pixel transmittance, and achieve the effects of lower alignment accuracy requirements, optimized arrangement mode, and good process realizability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

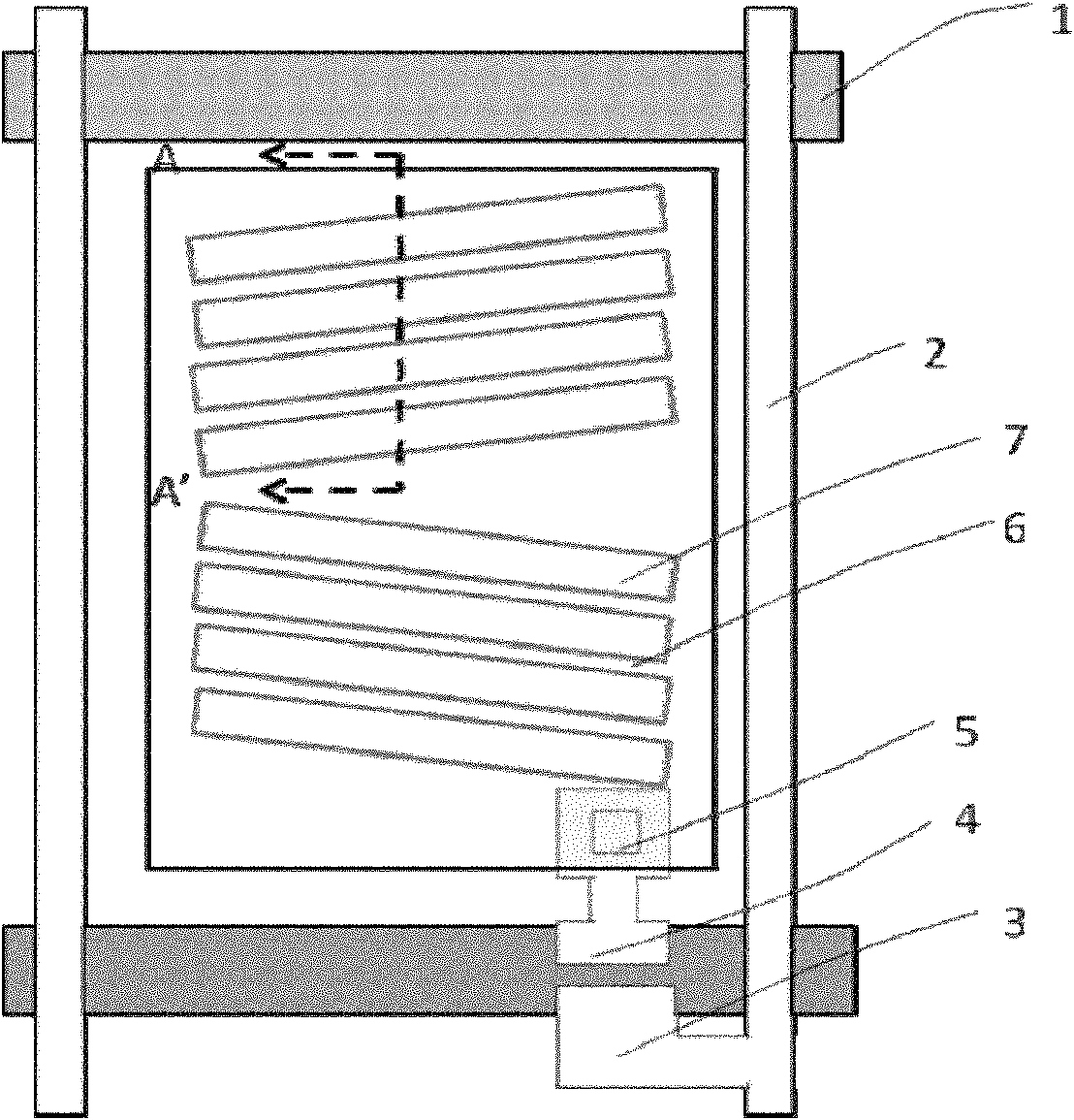

[0043] An embodiment of the present invention provides an array substrate of a TFT-LCD, such as Figure 5 with Image 6 As shown, the array substrate includes: a substrate, a gate line 1 and a data line 2 formed on the substrate; the intersection of the gate line 1 and the data line 2 defines a pixel unit, and each pixel unit includes a thin film transistor, a common electrode, a first pixel an electrode layer and a second pixel electrode layer;

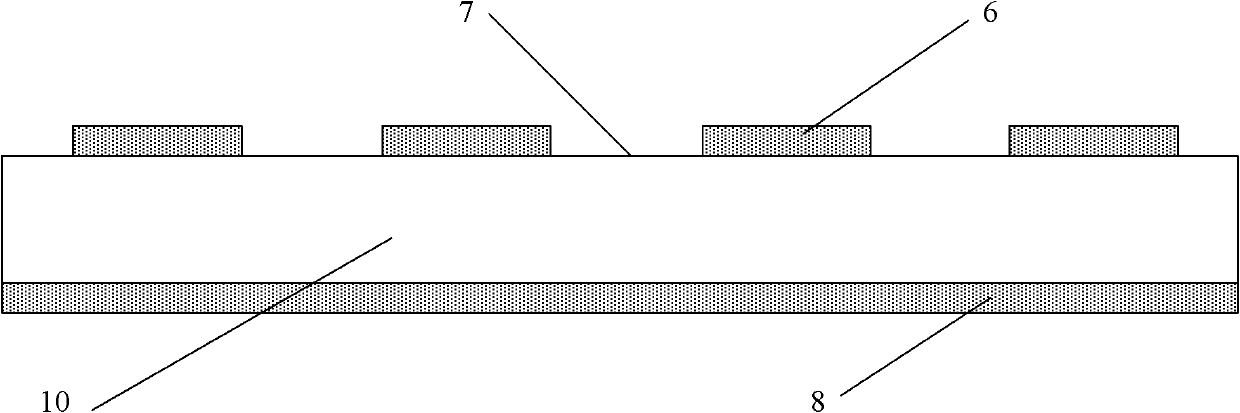

[0044] The first pixel electrode layer is separated from the second pixel electrode layer by an insulating layer 10; the first pixel electrode layer is connected to a common electrode, and includes several first pixel electrode layers separated by openings 9 of the first pixel electrode layer. The pixel electrode 8; the second pixel electrode layer is connected to the drain 4 of the thin film transistor through the drain contact hole 5, including several second pixel electrodes 6 separated by the second pixel electrode layer opening...

Embodiment 2

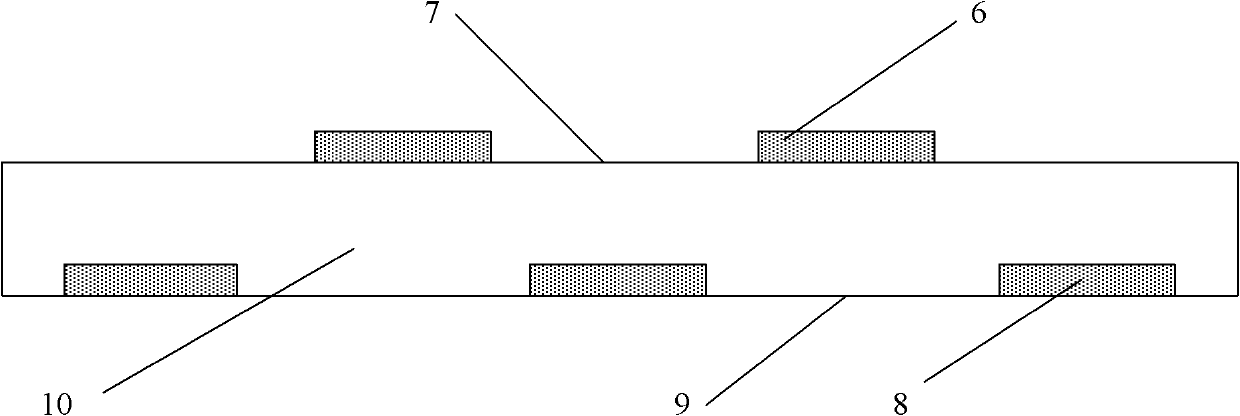

[0052] Such as Figure 7 As shown, there are two overlapping pixel electrodes 61 between the pixel electrodes 62 at two adjacent openings of the second pixel electrode layer. A first pixel electrode 8 is formed on the first pixel electrode layer, which has a width a, and an opening is formed on the first pixel electrode layer, which is the first pixel electrode layer opening 9, which has a width b. The second pixel electrode layer forms a second pixel electrode 6 with a width c, and an opening is formed on the second pixel electrode layer, which is a second pixel electrode layer opening 7 with a width d. Make the two edges of one first pixel electrode 8 of the second pixel electrode layer completely fall within one opening of the first pixel electrode layer. Then the relationship between the width a of the first pixel electrode of the first pixel electrode layer, the opening width b of the first pixel electrode layer, the width c of the second pixel electrode of the second pi...

Embodiment 3

[0056] The embodiment of the present invention also provides a method for manufacturing the array substrate of the TFT-LCD described in the above embodiment, such as Figure 8 As shown, the method includes:

[0057] Step 101, depositing a thin film of the first pixel electrode layer, forming a pattern including the first pixel electrode layer through a patterning process, and the first pixel electrode layer includes several first pixel electrodes separated by openings in the first pixel electrode layer, so The pattern of the first pixel electrode layer is connected to the common electrode;

[0058] Further, the metal layer thin film of the gate line is deposited, and the pattern including the gate line, the gate electrode, and the common electrode is formed through a patterning process, and the pattern of the first pixel electrode layer is connected to the common electrode; the first insulating layer is deposited, and the The source-drain metal layer film is formed by a patte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com