Patents

Literature

172results about How to "Guaranteed compression performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

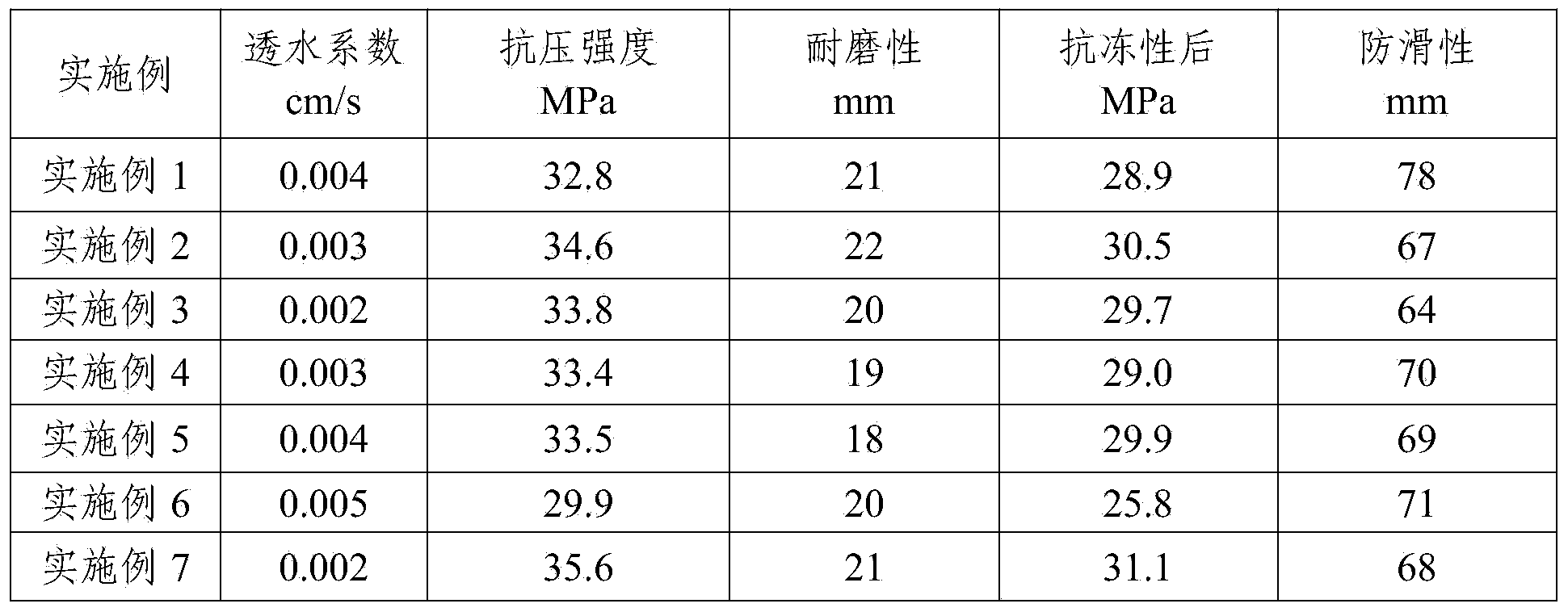

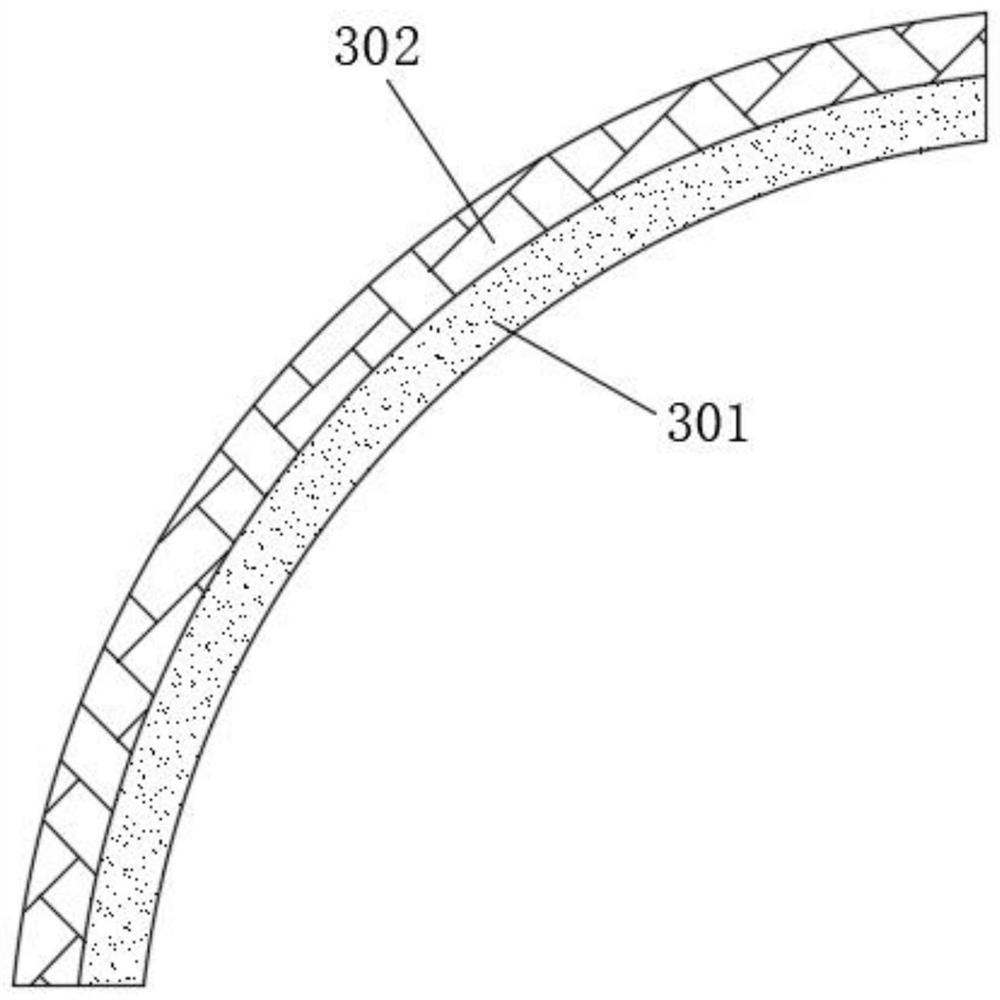

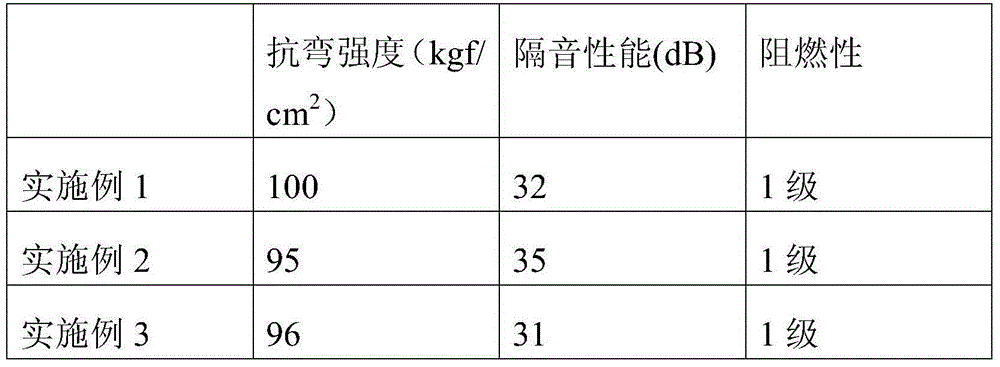

Nano-composite environment-friendly water permeable brick and production method thereof

InactiveCN103290753AGuaranteed compression performanceGood water permeabilitySingle unit pavingsCeramic shaping apparatusEnvironmental resistanceBrick

The invention discloses a nano-composite environment-friendly water permeable brick and a production method thereof. The nano-composite environment-friendly water permeable brick comprises a concrete bottom layer and a mortar surface layer arranged on the concrete bottom layer, wherein the concrete bottom layer and the mortar surface layer are compounded to form an integrated structure; the concrete bottom layer is prepared from the following raw materials in parts by weight: 20-40 parts of cement, 10-20 parts of water, 5-15 parts of fly ash, 50-65 parts of recycled aggregate, 50-65 parts of natural coarse aggregate, 65-85 parts of sand and 0.05-0.2 part of water-reducing agent; and the mortar surface layer is prepared from the following raw materials in parts by weight: 70-100 parts of cement, 5-20 parts of nano-TiO2, 30-60 parts of water, 200-400 parts of sand and 0.1-1.0 part of water-reducing agent. The nano-composite environment-friendly water permeable brick disclosed by the invention is integrally formed and has the advantages of high compressive strength, high flexural strength, good water permeability and good water retention, and a ground surface laid by the nano-composite environment-friendly water permeable bricks can timely dredge and drain rainwater, is conductive to growth of surrounding vegetation and can effectively supplement groundwater, reduce the pressure of a municipal drainage system and reduce the influence of surface gathered water on the traffic; and the nano-composite environment-friendly water permeable brick has a photocatalytic self-cleaning function and can decompose and remove organic stains on the surface of the brick and beautify the urban environment.

Owner:CHINA STATE CONSTR HAILONG TECH CO LTD

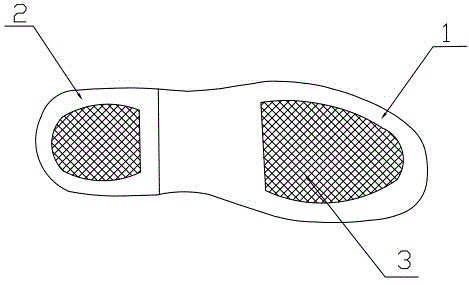

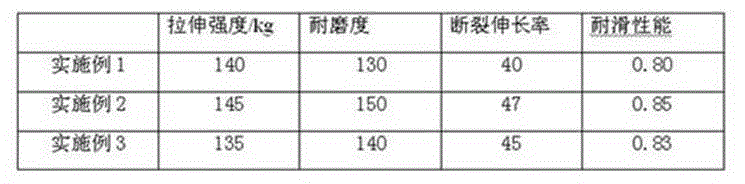

Formula of sole material

InactiveCN102250407AGuaranteed wear resistanceGuaranteed compression performanceSolesElastomerPolyolefin

The invention discloses a formula of a sole material. The sole made of the sole material can be formed in one piece to save cost, and the sole does not contain heavy metal and is light and breathable. The sole material comprises the following substances in percentage by weight: 1, 11.6 to 52.4 percent of ethylene vinyl acetute (EVA); 2, 7 to 13 percent of polyolefin elastomer (POE); 3, 1.4 to 2.6percent of ethylene-propylene-diene monomer; 4, 12.6 to 23.4 percent of standard rubber; 5, 12.6 to 23.4 percent of cis-polybutadiene; 6, 3.5 to 6.5 percent of butylbenzene; 7, 2.8 to 5.2 percent of talc powder; 8, 2.1 to 3.9 percent of white carbon black; 9, 2.1 to 3.9 percent of stearic acid; 10, 0.7 to 1.3 percent of modifier; 11, 1.05 to 1.95 percent of zinc oxide; 12, 1.4 to 2.6 percent of cross-linking agent; and 13, 0.35 to 0.65 percent of sulfur.

Owner:JINJIANG GUOSHENG SHOE MATERIAL LTD

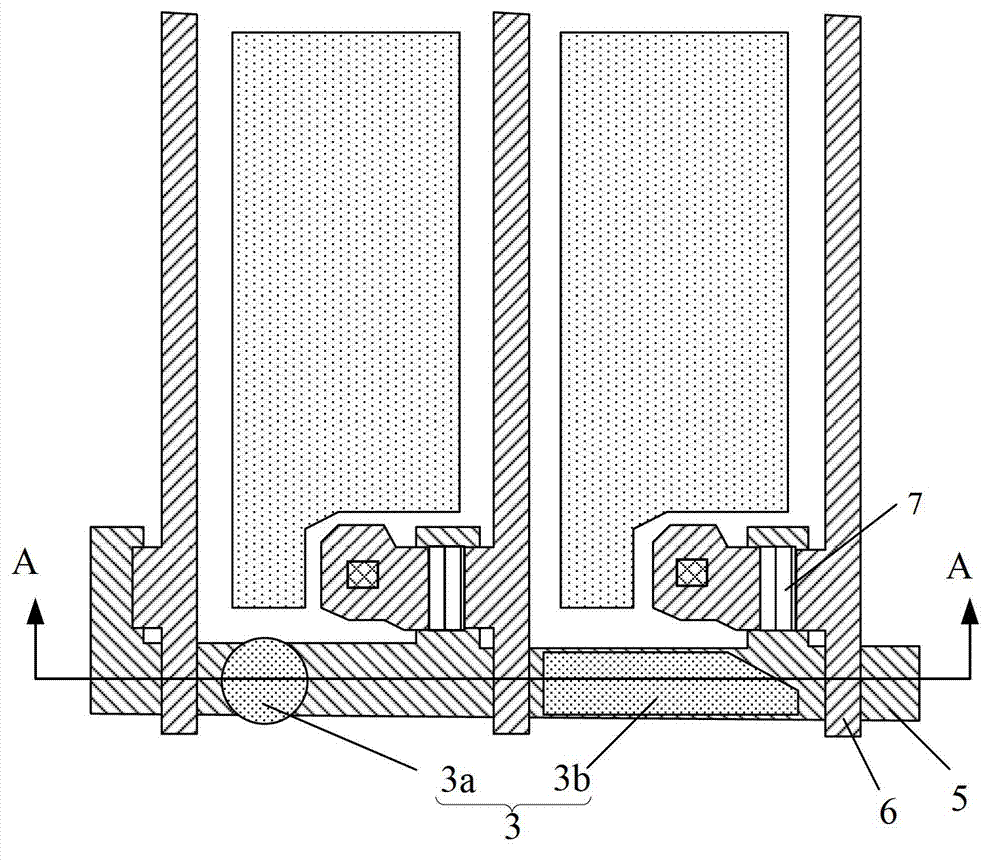

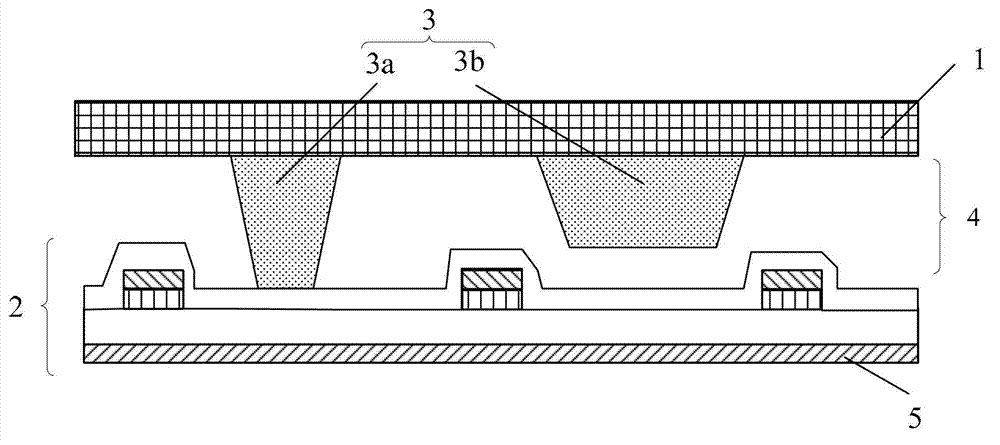

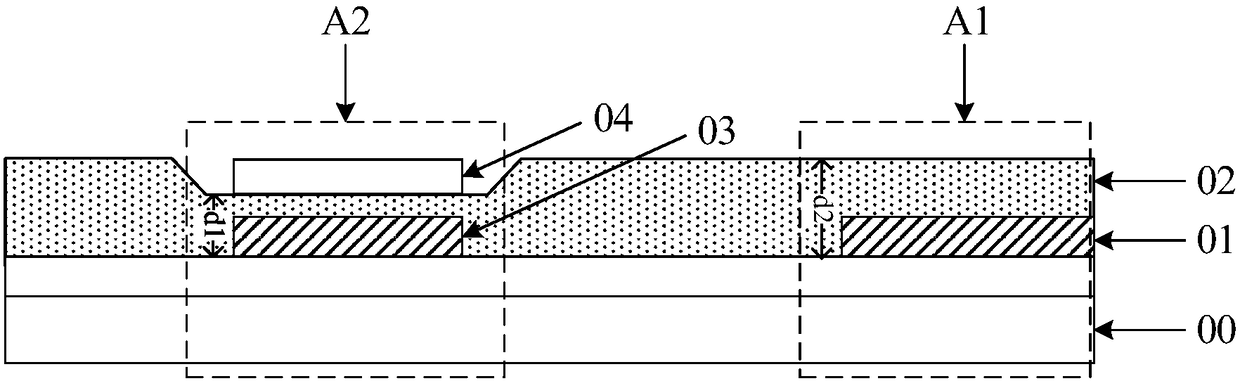

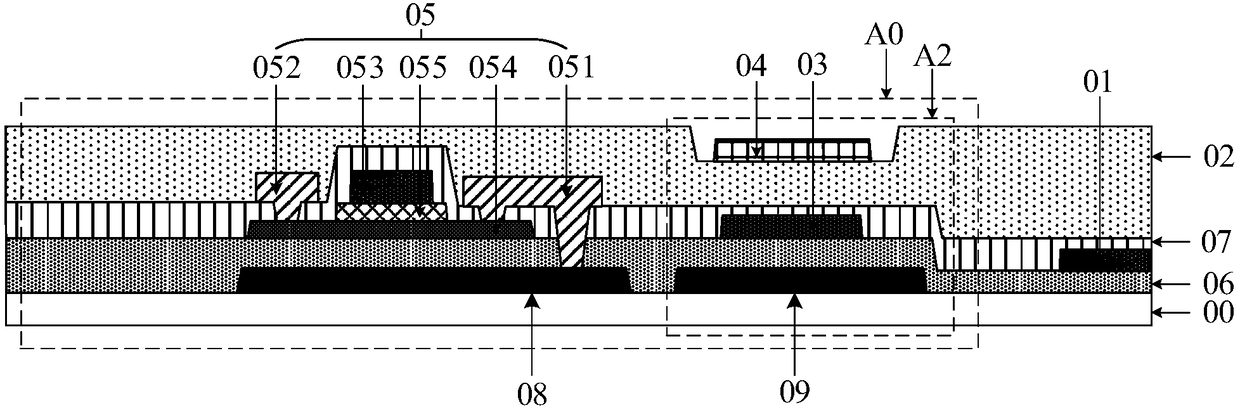

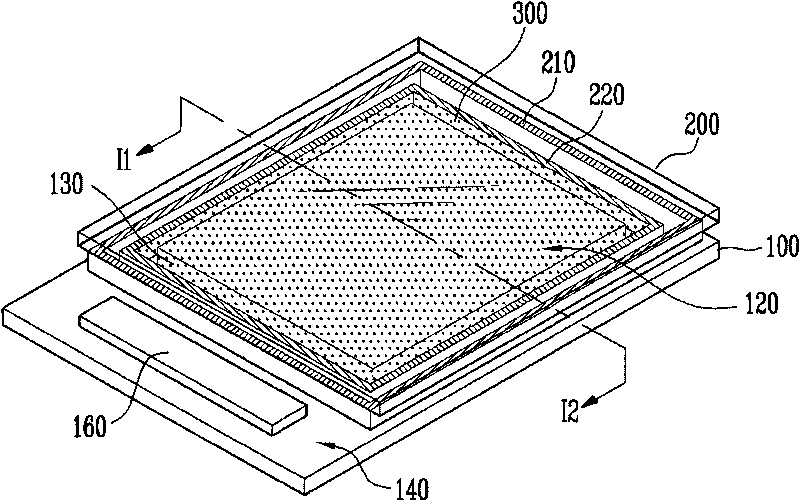

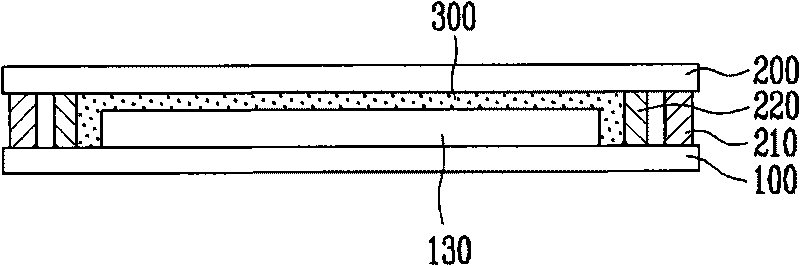

Liquid crystal display panel and manufacturing method thereof

ActiveCN102955297AGuaranteed compression performanceIncrease marginNon-linear opticsLiquid-crystal displayLiquid crystal

The embodiment of the invention provides a liquid crystal display panel and a manufacturing method thereof, relating to the display field. The problem of low-temperature bubbles of the display panel can be effectively solved; and the anti-pressure capability of the display panel can be ensured, so that the quality of a display picture can be ensured. The liquid crystal display panel comprises an upper substrate, a lower substrate, a liquid crystal layer and a spacer, wherein the liquid crystal layer and the spacer are arranged between the upper substrate and the lower substrate; and the liquid crystal display panel is characterized in that the spacer is arranged in an area corresponding to a grid line in the liquid crystal display panel. The liquid crystal display panel provided by the embodiment of the invention is applied to manufacturing of liquid crystal displays.

Owner:BOE TECH GRP CO LTD +1

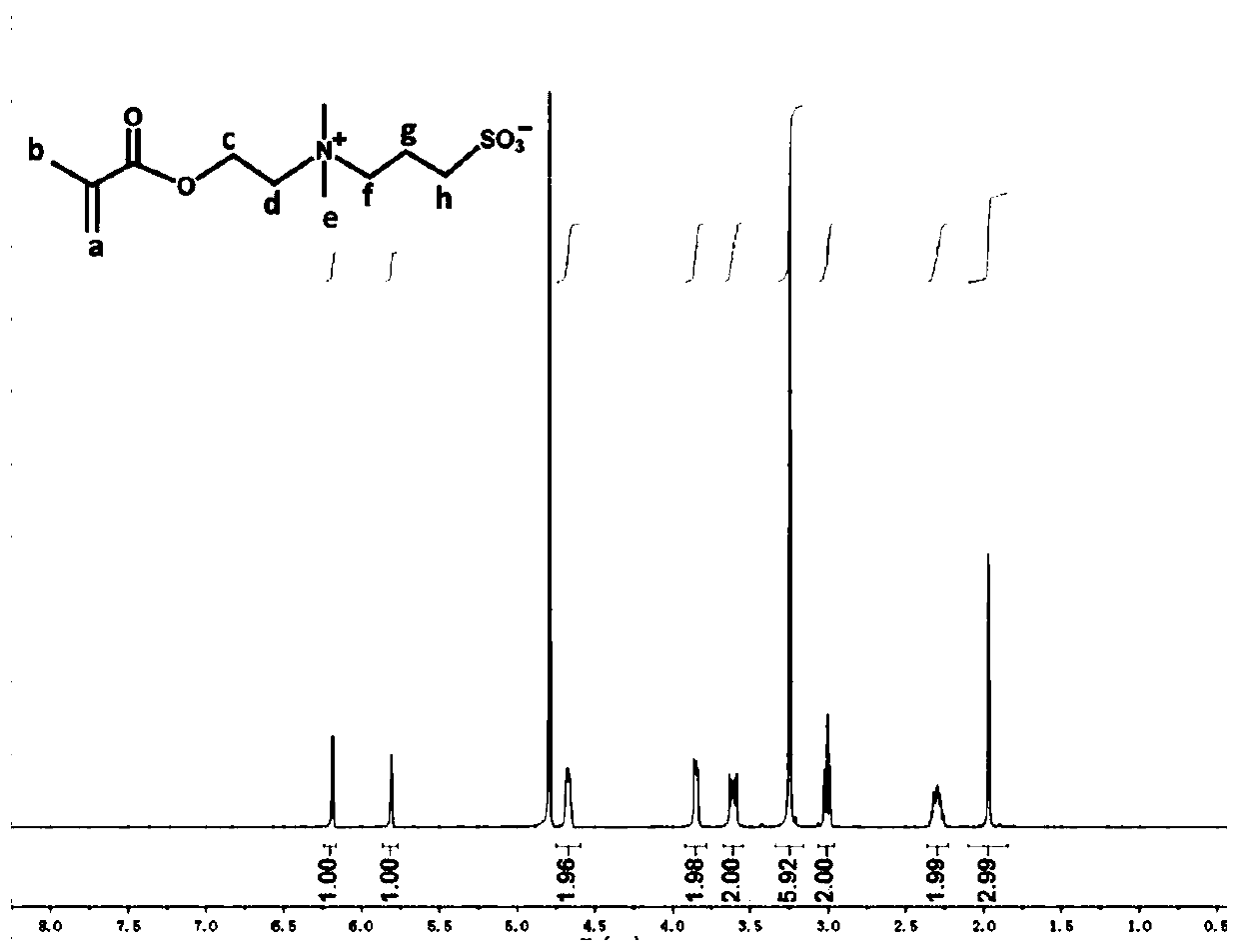

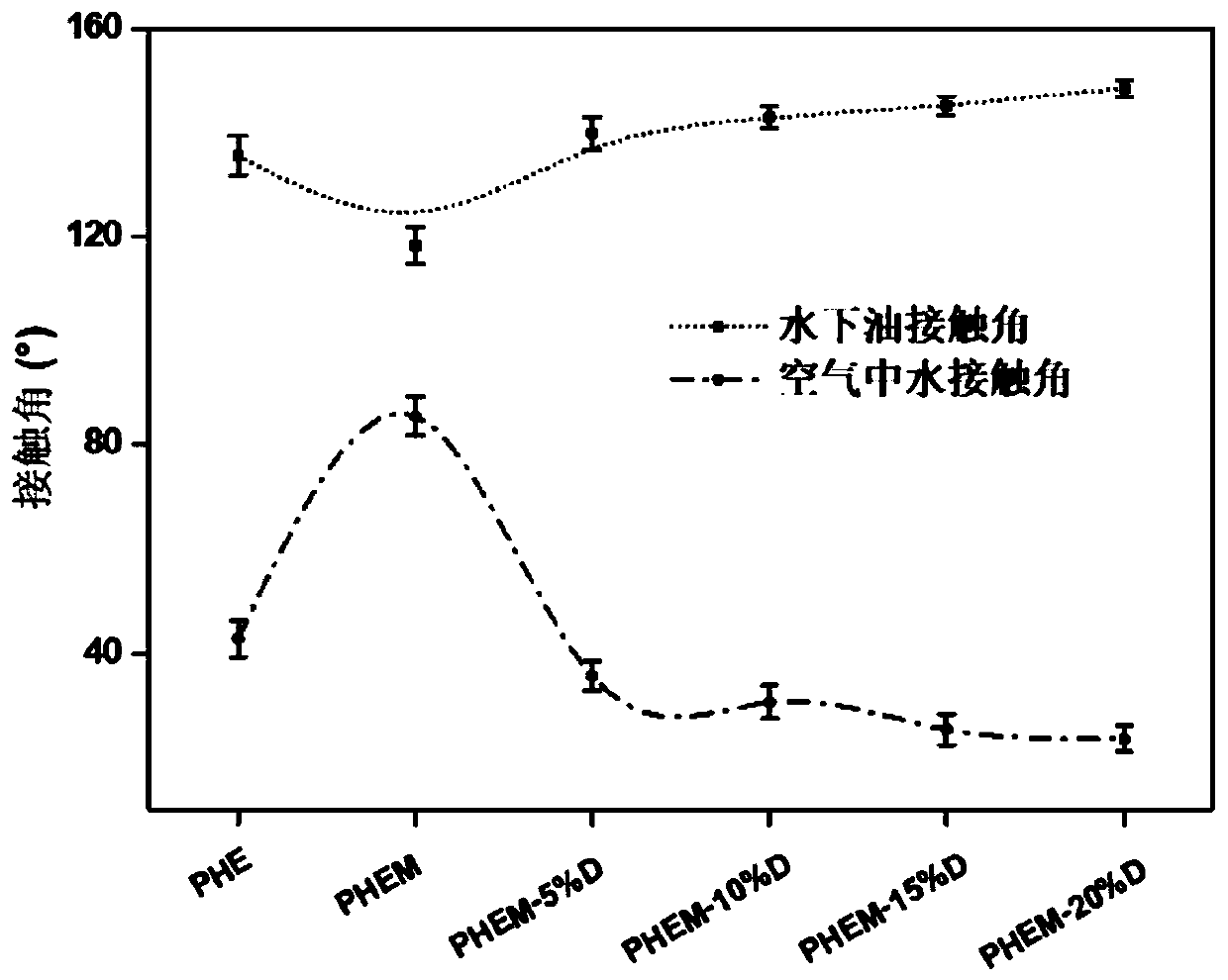

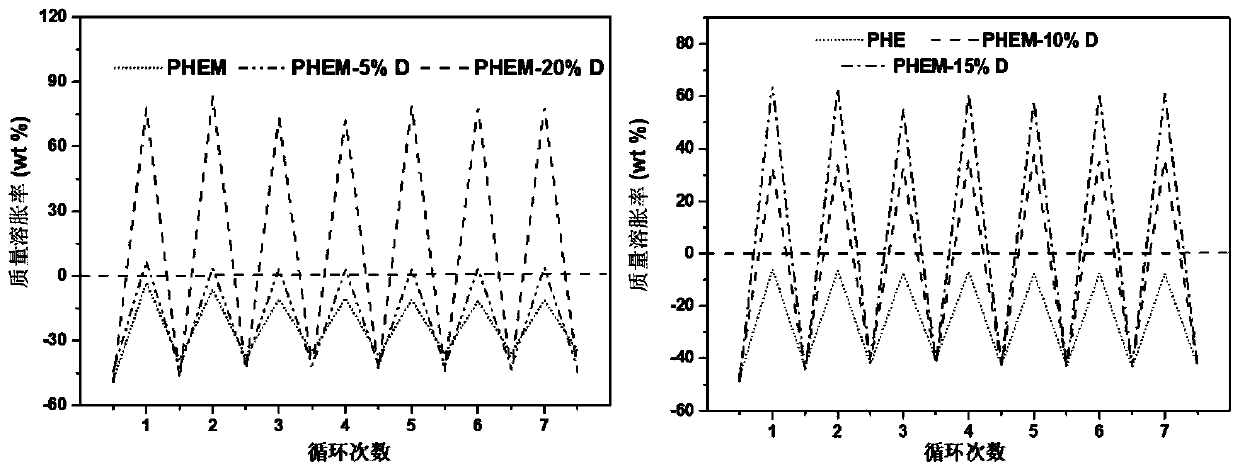

Hydrogel capable of being used for marine antifouling, preparation method and uses thereof

ActiveCN110358006ANo change in compression resistanceExcellent anti-biofouling performanceAntifouling/underwater paintsPaints with biocidesDehydration rehydrationBiofouling

The present invention provides a hydrogel capable of being used for marine antifouling, a preparation method and uses thereof. According to the present invention, the hydrogel does not swell while other gels such as acrylic acid, clay, acrylamide and the like swell heavily; the hydrogel can completely restore to the original state after water loss while other hydrogels such as a PVA gel cannot berecovered; the compression resistance of the gel of the present invention can remain unchanged after dehydration-rehydration circulation, the gel of the present invention has good stability under different shear frequencies at different temperatures, and the hydrogel is transparent while other oil hydrogels are less transparent; and the gel of the present invention has excellent biofouling performance.

Owner:INST OF CHEM CHINESE ACAD OF SCI

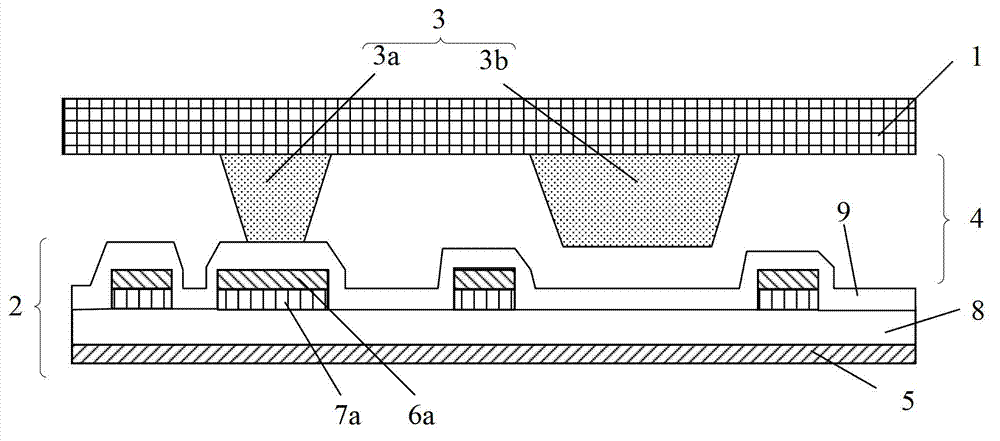

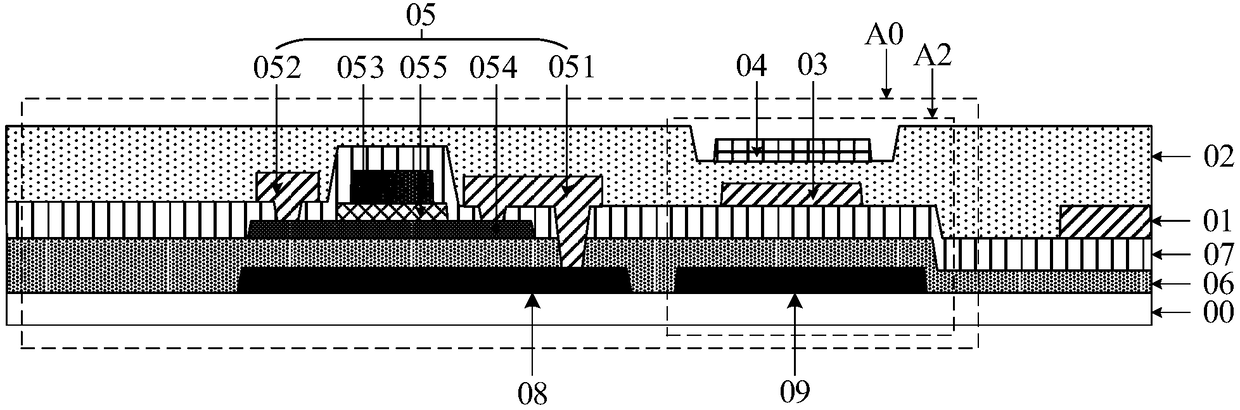

Display substrate, manufacturing method thereof and display device

ActiveCN108550582AGuaranteed display effectGuaranteed compression performanceSolid-state devicesNon-linear opticsCapacitanceDisplay device

The invention provides a display substrate, a manufacturing method thereof and a display device, and relates to the technical field of display. The display substrate comprises a substrate base plate,a metal layer arranged in the periphery region of the substrate base plate, and a passivation layer which is arranged on one side, away from the substrate base plate, of the metal layer and covers thesubstrate base plate. In the capacitance region of the substrate base plate, capacitance electrodes are arranged on two sides of the passivation layer. The thickness of the passivation layer in the capacitance region is smaller than the thickness of the passivation layer in the periphery region. According to the invention, the passivation layer in the display substrate is partially quite thick inthe periphery region; the anti-compression performance is quite good; the passivation region is quite thin in the capacitance region; capacity of the storage capacitance will not be affected; and display effects of the display device are ensured.

Owner:BOE TECH GRP CO LTD

A direct connection type double-step threaded joint

ActiveCN105604499AGuaranteed torque resistanceGuaranteed compression performanceDrilling rodsDrilling casingsConnection typeUltimate tensile strength

The invention provides a direct connection type double-step threaded joint comprising a female joint and a male joint. In the axial direction of the direct connection type double-step threaded joint, the female joint successively comprises a first threaded section, a female joint shoulder transition section, a female joint torque shoulder, a female joint sealing surface and a second threaded section. In the axial direction of the direct connection type double-step threaded joint, the male joint successively comprises a third threaded section, a male joint sealing surface, a male joint torque shoulder, a male joint shoulder transition section and a fourth threaded section. The first threaded section and the second threaded section are internal threaded sections, and the third threaded section and the fourth threaded section are external threaded sections. The first threaded section and the fourth threaded section are in threaded engagement and the second threaded section and the third threaded section are in threaded engagement. The female joint sealing surface and the male joint sealing surface are in interference seal. The direct connection type double-step threaded joint has favorable anti-compressing and anti-torque capability, excellent gas sealing performance and greater connecting strength.

Owner:BAOSHAN IRON & STEEL CO LTD

Ferro-nickel slag water permeable brick for pavements and preparation method of water permeable brick

ActiveCN104163596AEfficient resource utilizationSolve intractable problemsSolid waste managementBrickResource utilization

The invention relates to the technical field of building materials and particularly relates to a ferro-nickel slag water permeable brick for pavements and a preparation method thereof. A great deal of ferro-nickel slag is mixed into the adopted raw materials, so that the resource utilization of the ferro-nickel slag is remarkable, the treatment cost is reduced, a problem that the ferro-nickel slag is difficult to treat is effectively solved, and the environmental pollution is reduced; a modifier gypsum is introduced, so that part of a gel material can be effectively substituted by virtue of active ferro-nickel slag micro powder; by controlling the total mixing amount of the ferro-nickel slag in the water permeable brick to be over 75% and adding an activator, the breaking strength and the compressive strength as well as various indexes of the prepared ferro-nickel slag water permeable brick for pavements are guaranteed, the national comprehensive utilization industrial policy of the waste resources are fulfilled, and a great deal of the ferro-nickel slag can be treated, and thus the production cost and the energy consumption are reduced.

Owner:贵州省建筑材料科学研究设计院有限责任公司 +1

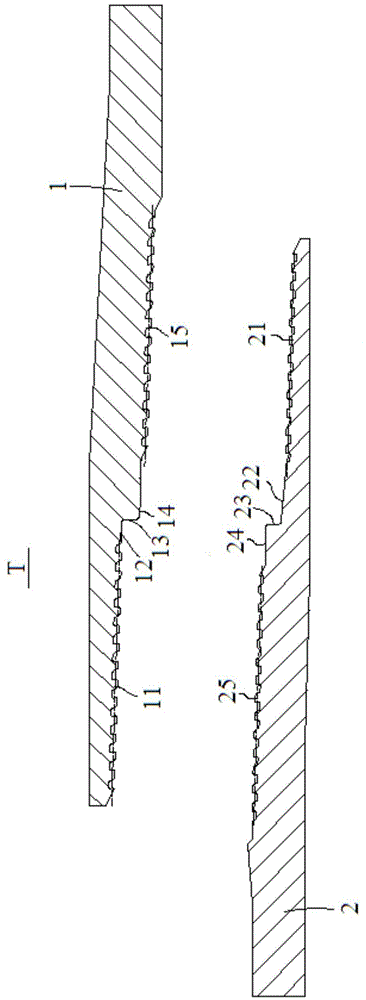

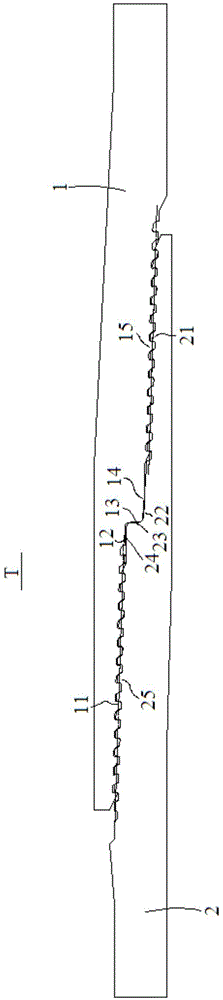

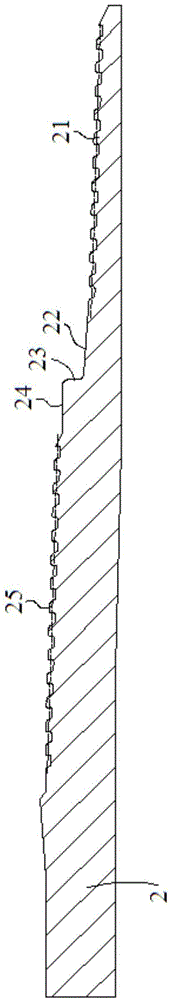

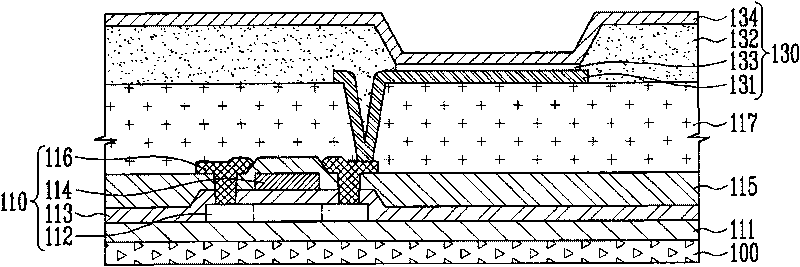

Light emitting display and method of manufacturing the same

ActiveCN101728413AImprove stress resistanceGuaranteed compression performanceSemiconductor/solid-state device detailsSolid-state devicesFilling materialsDisplay device

The present invention is to provide an organic light emitting display and a method of manufacturing the same, the light emitting display including: a first substrate on which a plurality of light emitting devices are formed; a second substrate disposed to face the first substrate; a dam member disposed between the first substrate and the second substrate to surround the plurality of light emitting devices; an inorganic sealing material disposed between the first substrate and the second substrate on an outward side of the dam member and attaching the first substrate and the second substrate; and a filling material provided between the first substrate and the second substrate on an inward side of the dam member and formed of at least one inert liquid selected from the group consisting of perfluorocarbon and fluorinert.

Owner:SAMSUNG DISPLAY CO LTD

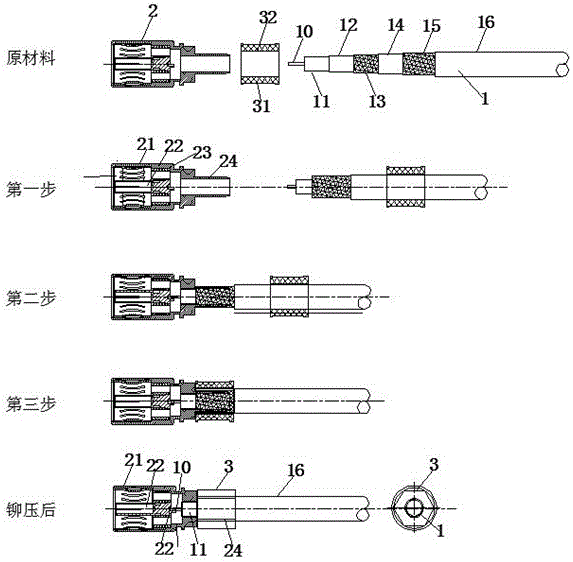

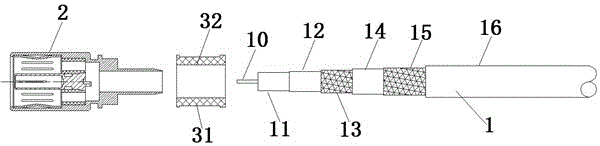

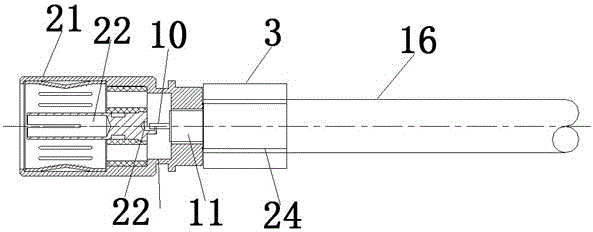

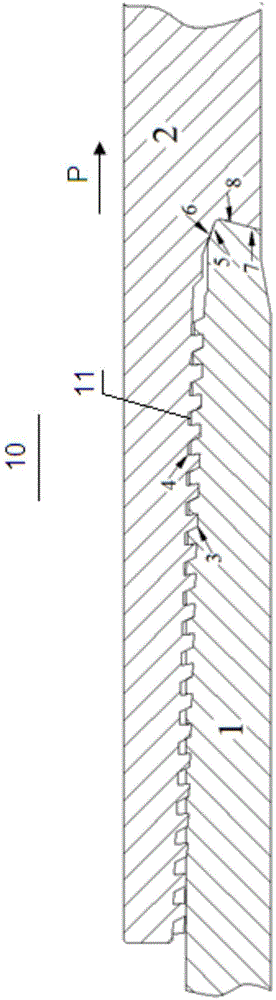

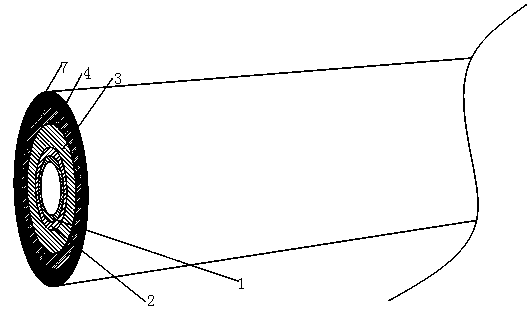

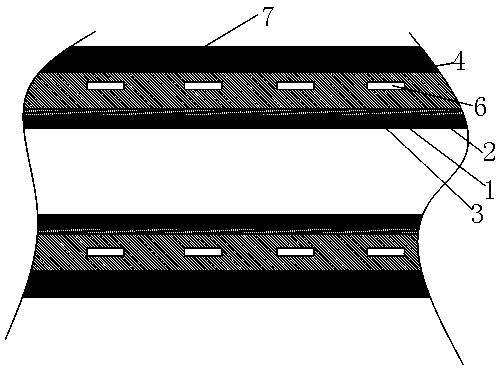

Compression-resistant type coaxial cable for improving shielding effect, and connection method thereof

ActiveCN106711634AMeet the requirements of flexibility and bending resistanceGood screen protectorCoupling device detailsConnections effected by permanent deformationCoaxial cableCorona discharge

The invention discloses a compression-resistant type coaxial cable for improving a shielding effect, and a connection method thereof. The invention relates to the technical field of coaxial cable connection, in particular to the compression-resistant type coaxial cable and the connection method thereof. According to the compression-resistant type coaxial cable, a cable body is compressed and connected with a connector by means of a metal casing pipe provided with an elastic rubber sleeve, the compression-resistant type coaxial cable is suitable to be used in a strong vibration and shock environment, the compression joint strength is high, the tension resistance is good, the radial section of the metal casing pipe is a regular hexagon, no flash is formed after compression joint, the injection molding thickness of a protective injection molding layer is even, the shielding effect for the connector is good, the shielding performance of the coaxial cable is improved, the metal casing pipe further ensures that the coaxial cable is arranged at the dead centre of the connector after installation, can effectively eliminating point discharge, enables the stress to be distributed more evenly, can play a role of voltage equalizing ring so that an electric field at the joint is distributed to the peripheral grounding region, avoids the occurrence of corona discharge, and cannot cause any damage to the cable and the machine.

Owner:HUIZHOU D&S CABLE +1

Airtight seal sleeve joint

InactiveCN104453738AGuaranteed compression performanceReduced risk of stickingDrilling rodsDrilling casingsPetroleum engineering

The invention discloses an airtight seal sleeve joint. The airtight seal sleeve joint comprises a sleeve male end and a sleeve female end, the sleeve male end is provided with an external thread, the sleeve female end is provided with an internal thread, the external thread of the sleeve male end is meshed with the internal thread of the sleeve female end, and the tooth profile of the external thread and the tooth profile of the internal thread are each of a slanting trapezoid shape. In addition, in the feeding direction of the external thread, the part, behind the external thread, of the sleeve male end is provided with a first seal face and a first retreat stop shoulder connected with the first seal face, and the first retreat stop shoulder is located at the tail end of the sleeve male end. The sleeve female end is provided with a second seal face and a second retreat stop shoulder, the second seal face is in interference fit with the first seal face, the second retreat stop shoulder is matched with the first retreat stop shoulder, and the second seal face is also connected with the second retreat stop shoulder. A gap is formed between the internal thread and the external thread. The airtight seal sleeve joint has good stretch resistance, compression resistance and torque resistance capability, better thread gluing resistance and excellent airtight seal performance and can adapt to the work environment of a three-exceeding gas field.

Owner:BAOSHAN IRON & STEEL CO LTD

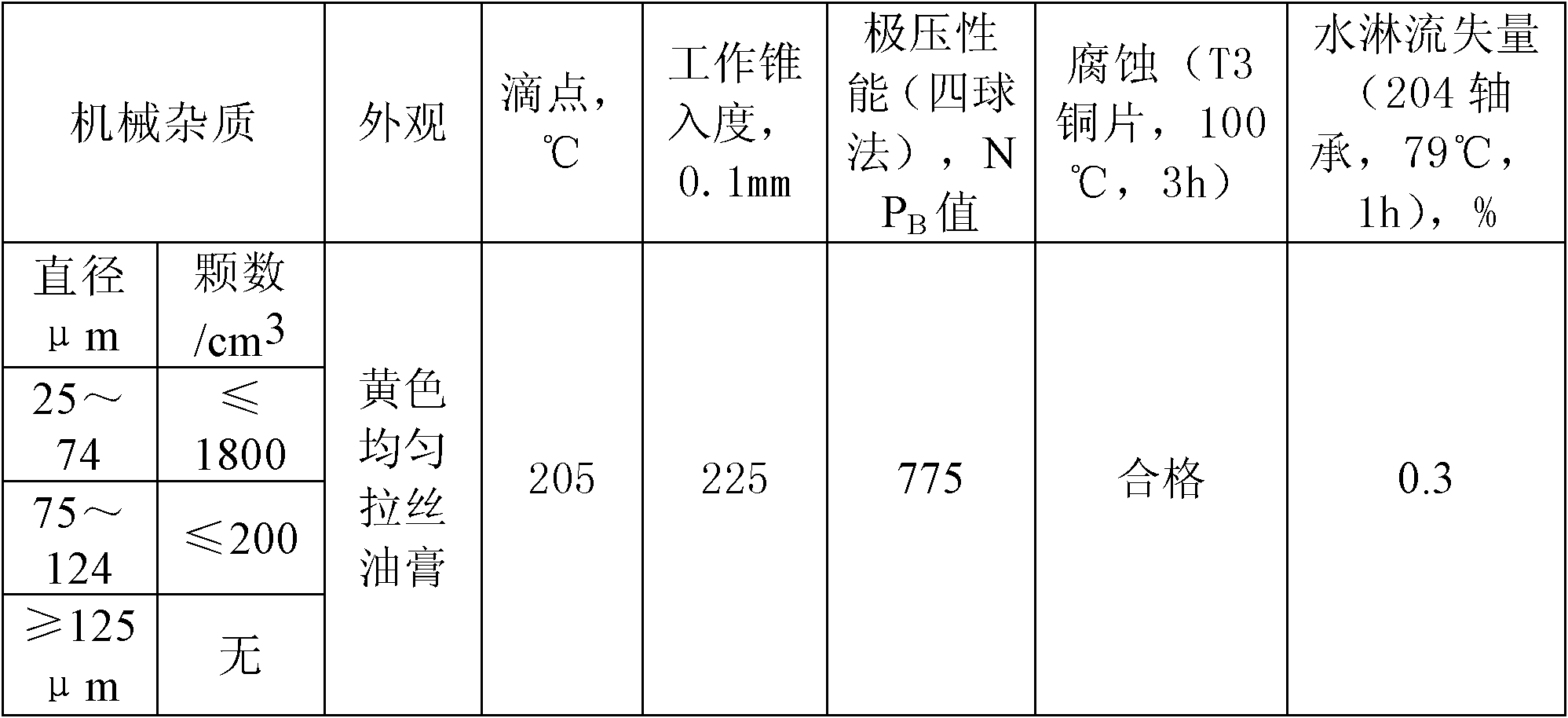

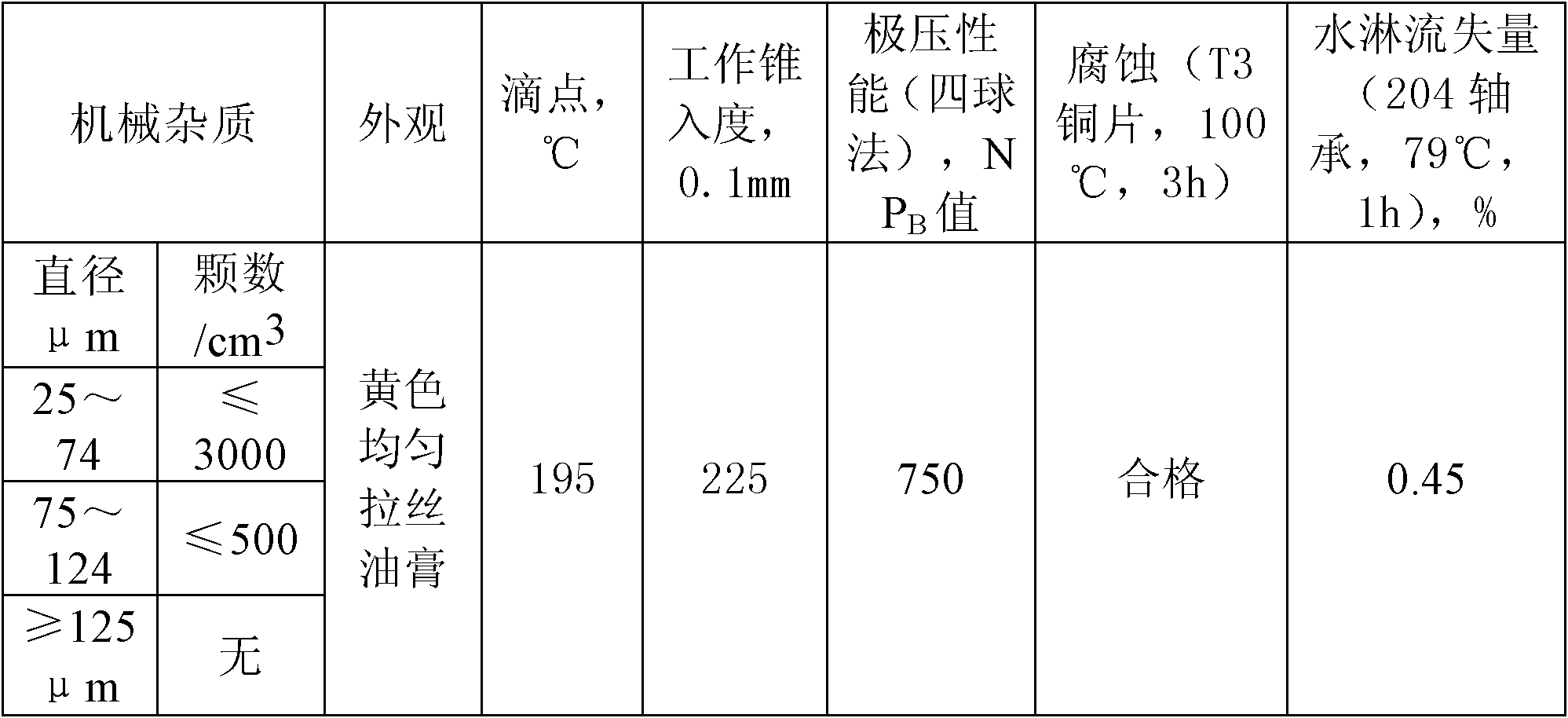

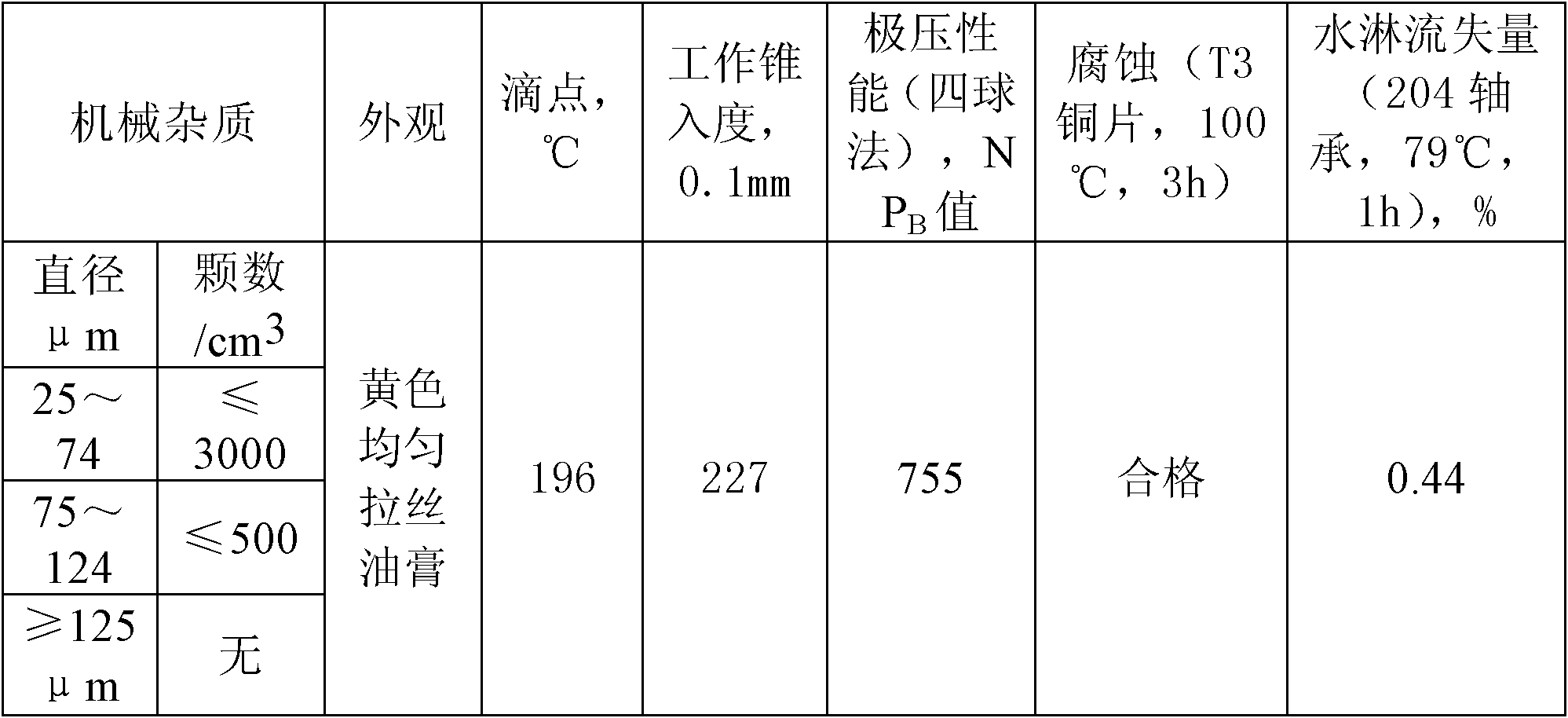

Roll bearing grease lubricant and preparation method thereof

ActiveCN102311844AImprove water resistanceWater splash resistance guaranteeLubricant compositionStearic acidBase oil

The invention discloses a roll bearing grease lubricant and a preparation method thereof. By utilizing a thickening agent, i.e. stearic acid, the roll bearing grease lubricant has a better water-drenching resistance; and the grease lubricant has better adhesivity by matching with adhesive and high-viscosity base oil, so that the grease lubricant is not easy to be washed off by water and has lubrication stability; by combining with addition agents including a water-resisting extreme-pressure anti-wearing agent, an anti-rusting agent and the like, the grease lubricant can guarantee the extreme-pressure lubrication of a bearing in the presence of a lot of water; and therefore, the roll bearing which utilizes the grease lubricant provided by the invention has better water-drenching resistanceand adhesivity, a lubrication stability and a compressive property of the bearing can be guaranteed by the grease lubricant in the presence of a lot of water, the bearing capability of the roll bearing is improved, the service life is prolonged, and the cost is saved.

Owner:AMER TECH CO LTD

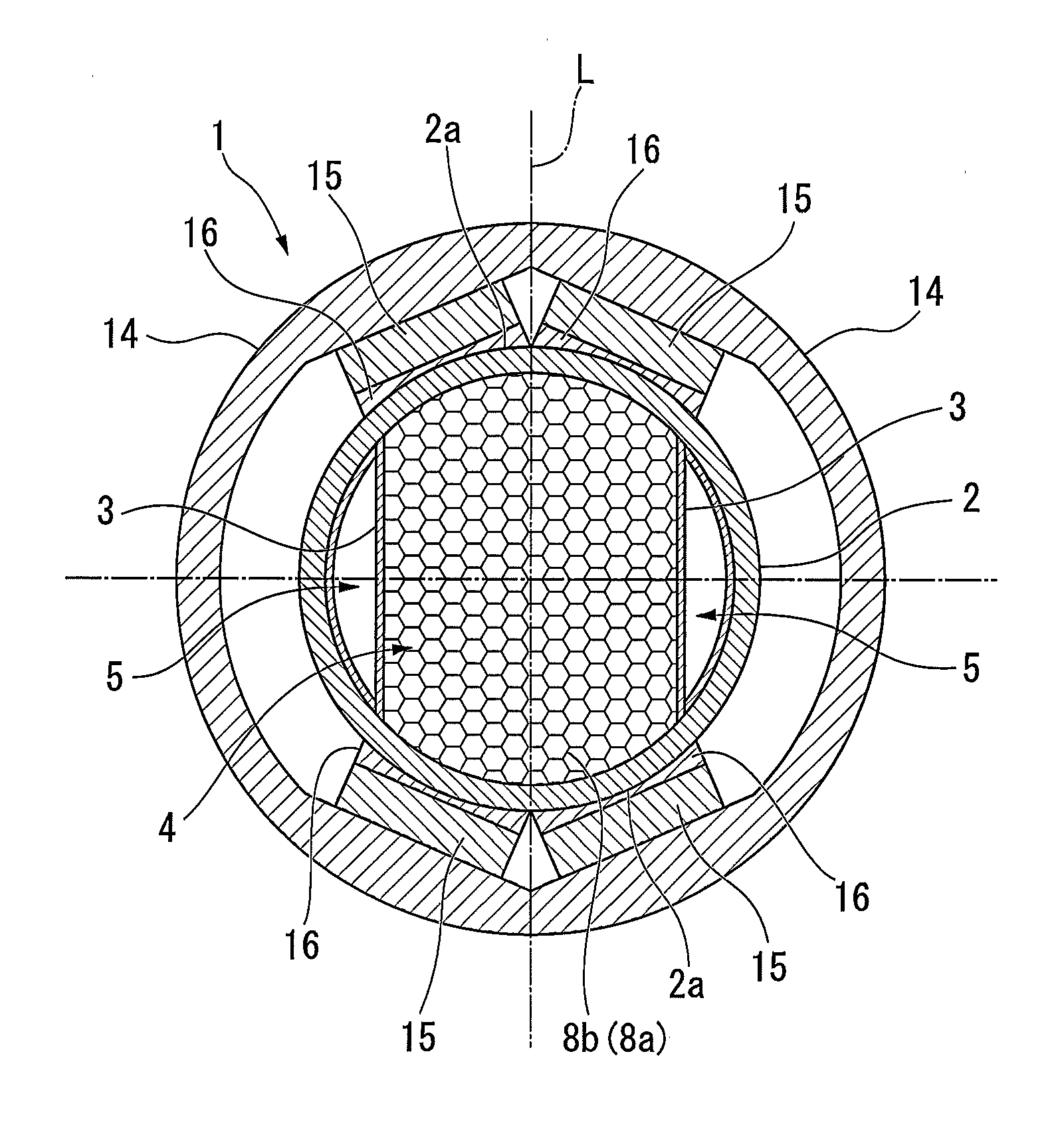

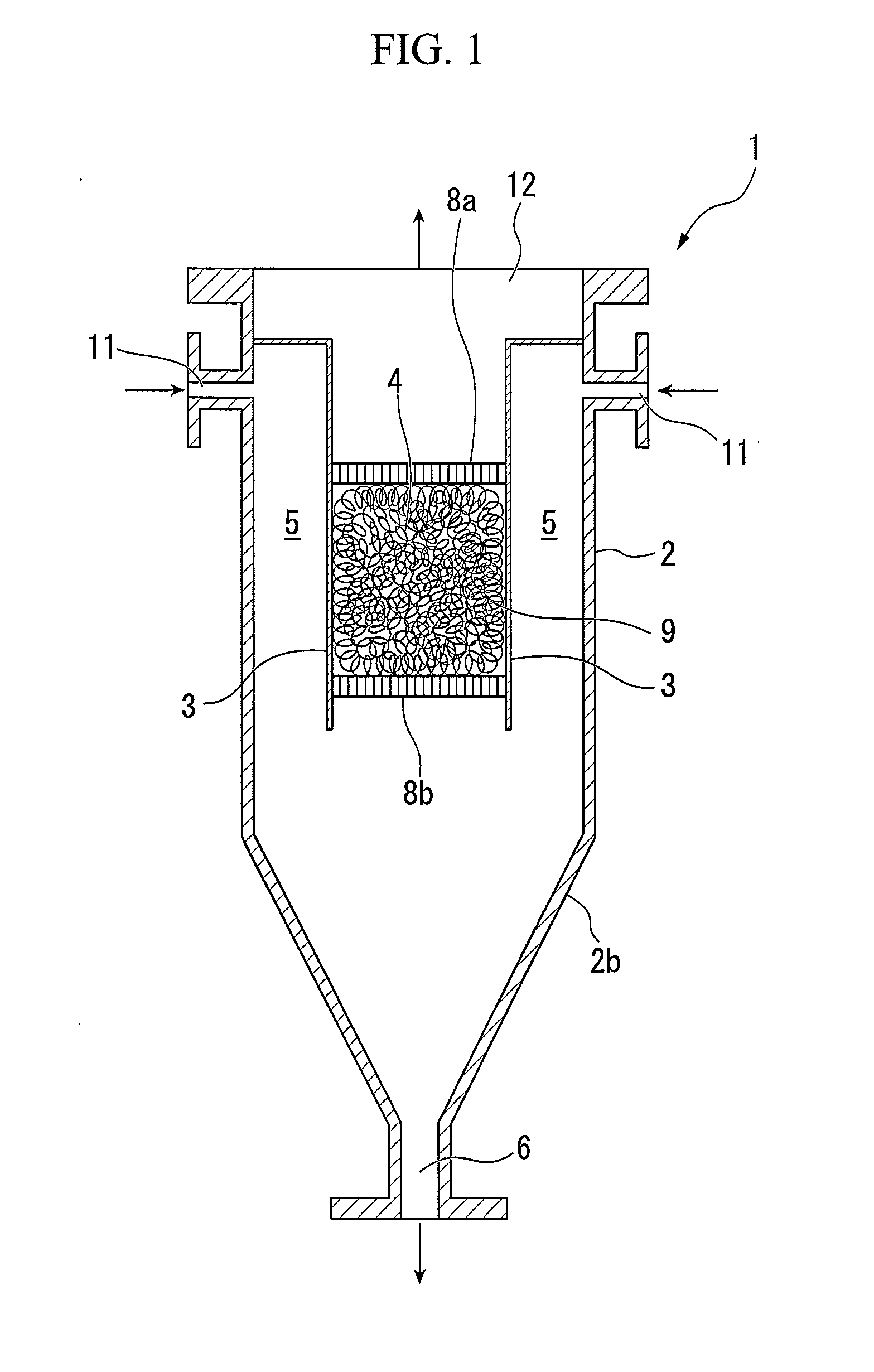

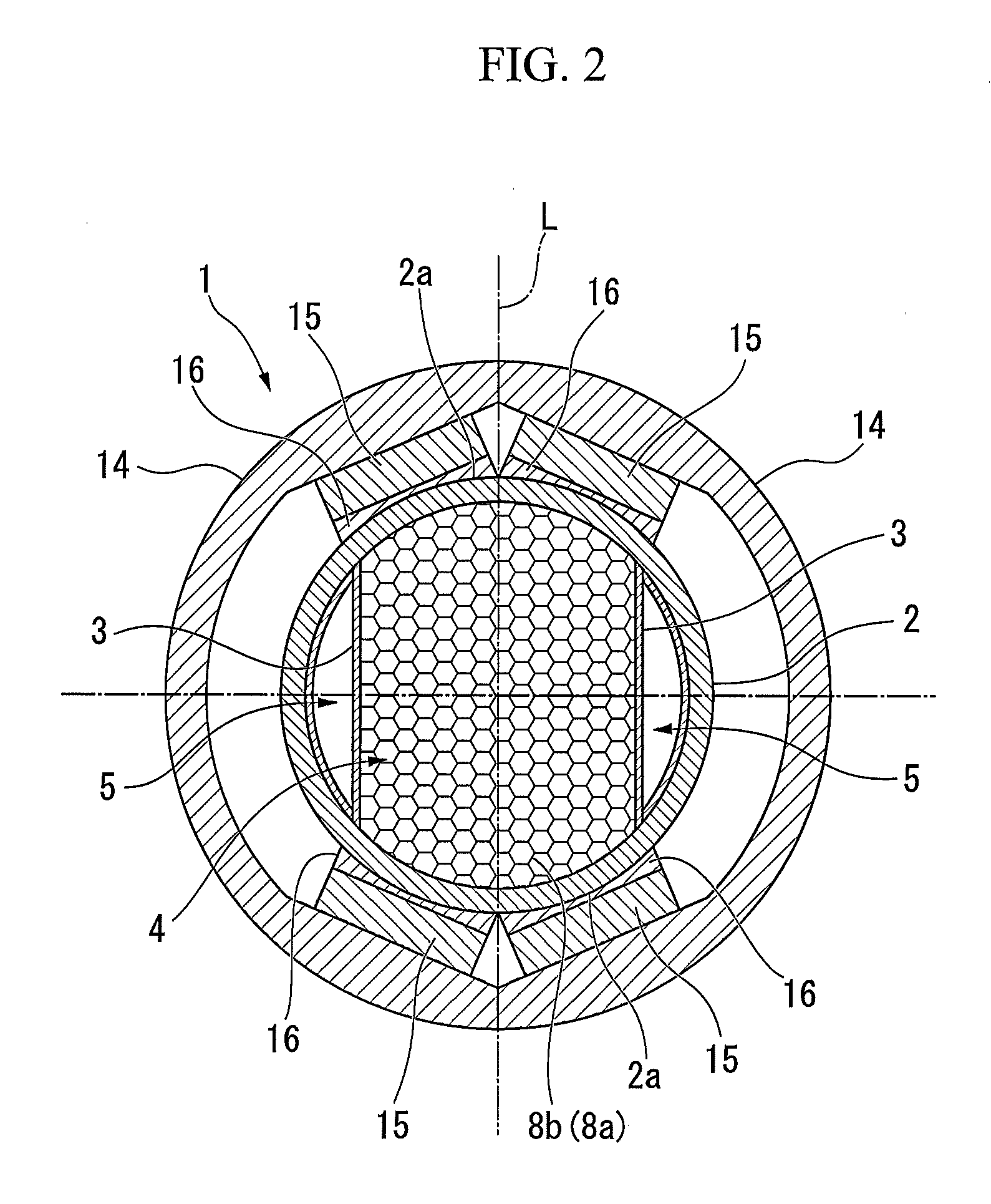

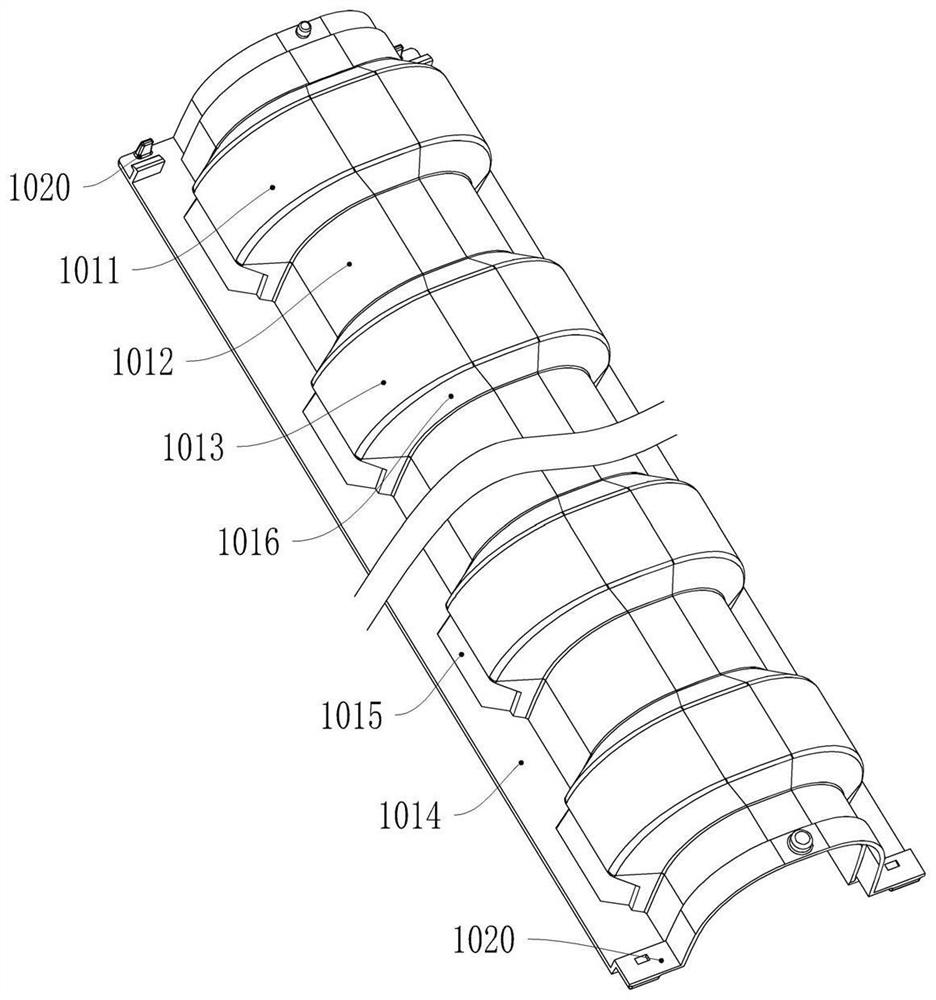

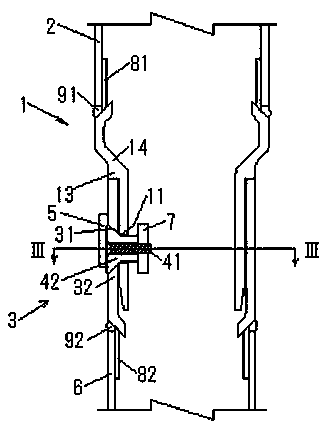

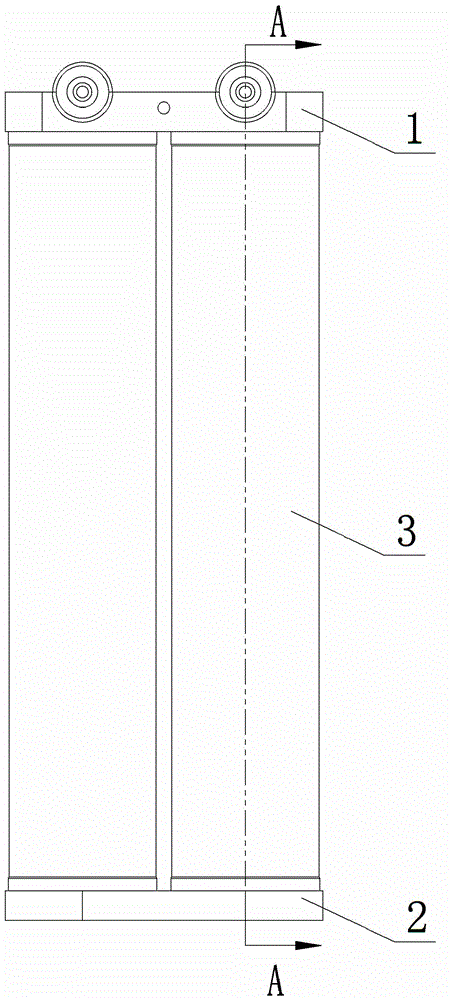

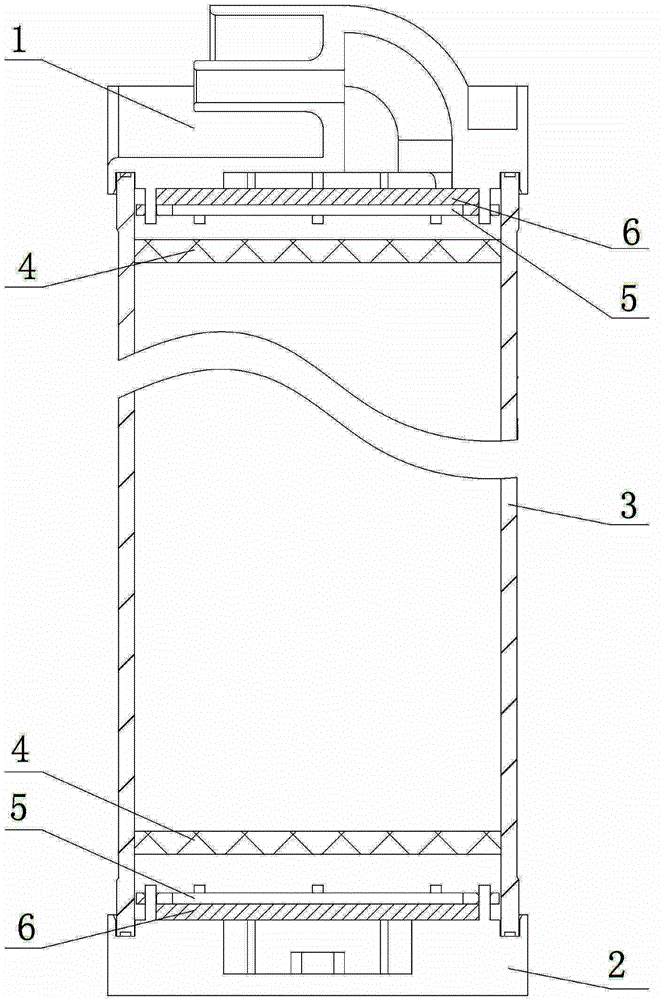

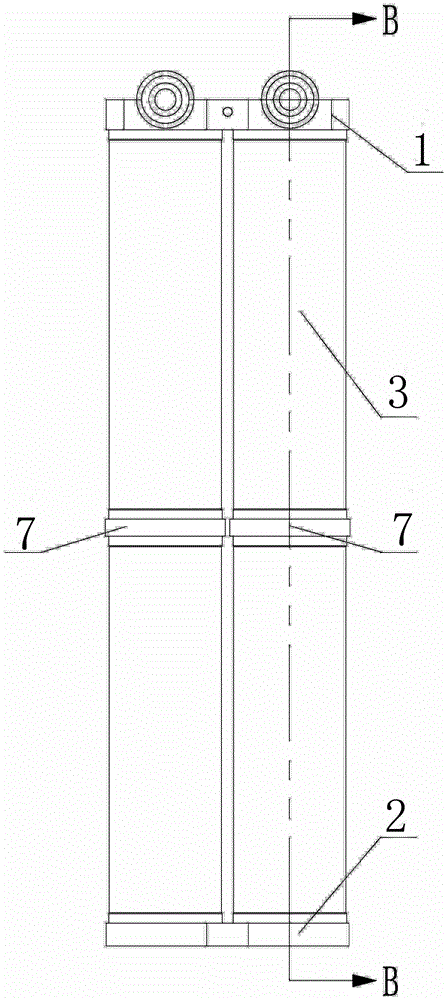

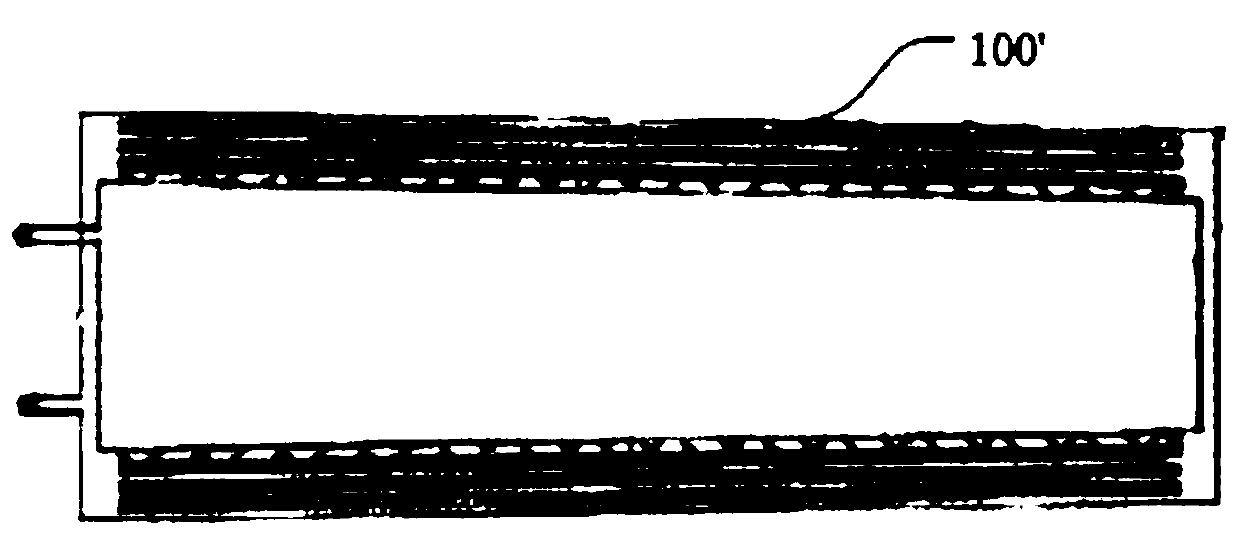

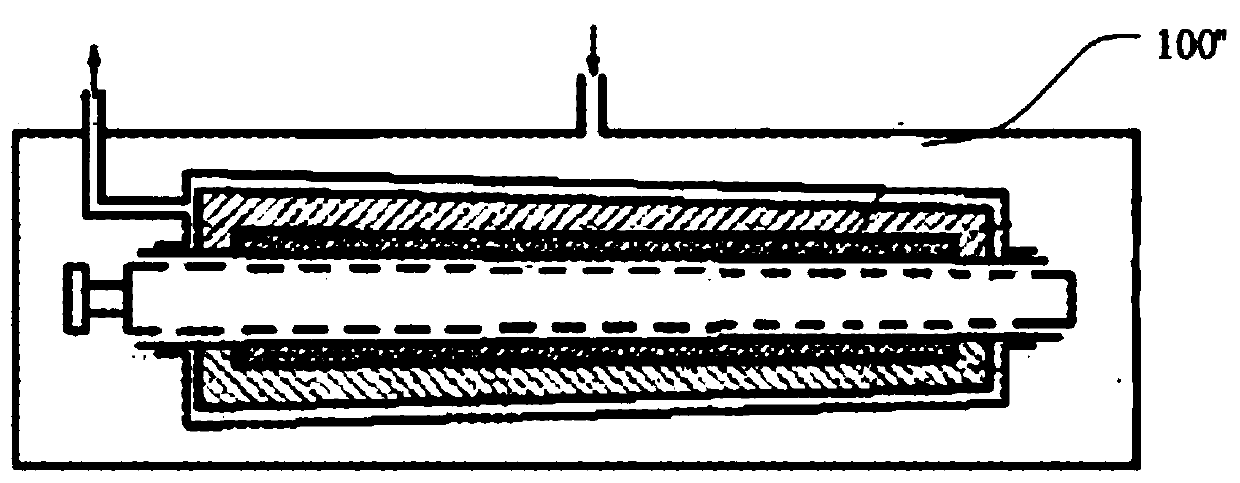

Magnetic-separation filter device

ActiveUS20130327687A1Guaranteed compression performanceUniformly formedSettling tanks feed/dischargeHigh gradient magnetic separatorsFilter mediaAlloy

According to an aspect of the present invention, there is provided a magnetic-separation filter device that removes contaminants of fine ferromagnetic particles from a fluid containing such contaminants, comprising: a substantially cylindrical housing; two partition plates that are disposed in an inside of the housing so as to extend in a vertical direction of the housing, dividing the inside of the housing by being disposed in parallel to each other;a filter medium that includes a fine amorphous-alloy wire bundle filled in a first region defined by the housing and the two partition plates; andplural permanent magnets that are provided on both sides of the first region outside the housing, wherein the contaminants of fine ferromagnetic particles are adsorbed on the filter media by flowing the fluid containing such contaminants through the first region in which the magnetic field has been formed by these plural permanent magnets.

Owner:NIPPON STEEL & SUMIKIN ENG CO LTD

Quartz tailings heat-insulating building block and preparation method thereof

ActiveCN105294017AMeet the technical requirements for sand useImprove qualityRadioactive agentFilling materials

The invention relates to the technical field of quartz tailings applied to building materials and especially relates to a quartz tailings heat-insulating building block and a preparation method thereof. The heat-insulating building block is prepared by combining a hollow block with a filling material; the raw materials of the hollow block and the filling material both comprise quartz tailings powder; the quartz tailings powder is formed by grinding the quartz tailings into fine powder, wherein the fineness is subjected to the screening treatment by adopting a square hole sieve with the size of aperture being 45mu m and the weight of screen residue is 10%; the content of silicon dioxide in the quartz tailings is 70%; the limitation of the raw material ingredients in the hollow block and the filling material is adopted, so that all the raw materials are interacted, especially, the synergic effect between the quartz tailings and the quick lime, the aluminum powder or cement is achieved; the content of the radioactive substance in the raw materials is reduced, so that the radioactivity is reduced and the quality of the heat-insulating building block is increased.

Owner:贵州省建筑材料科学研究设计院有限责任公司 +2

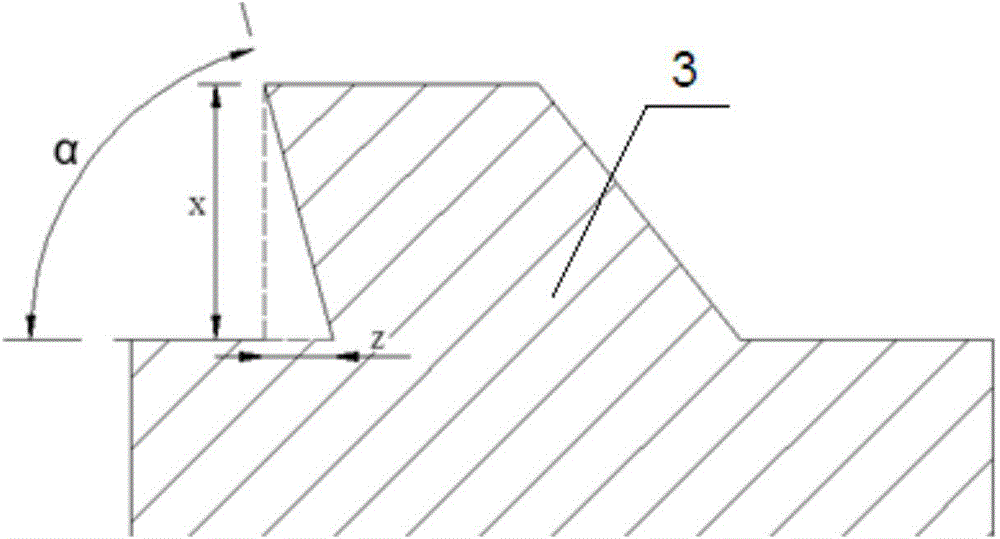

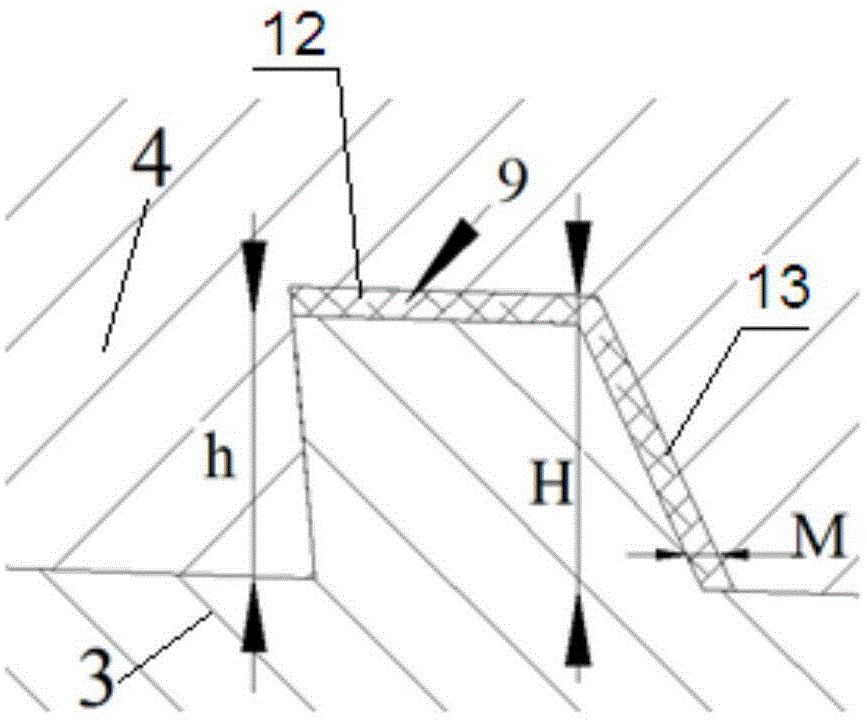

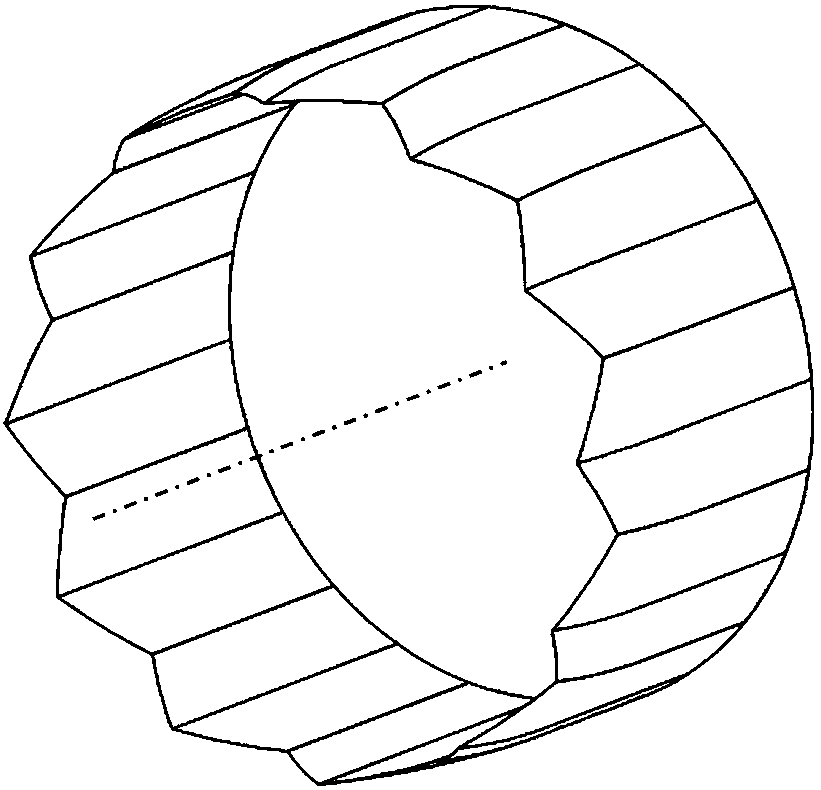

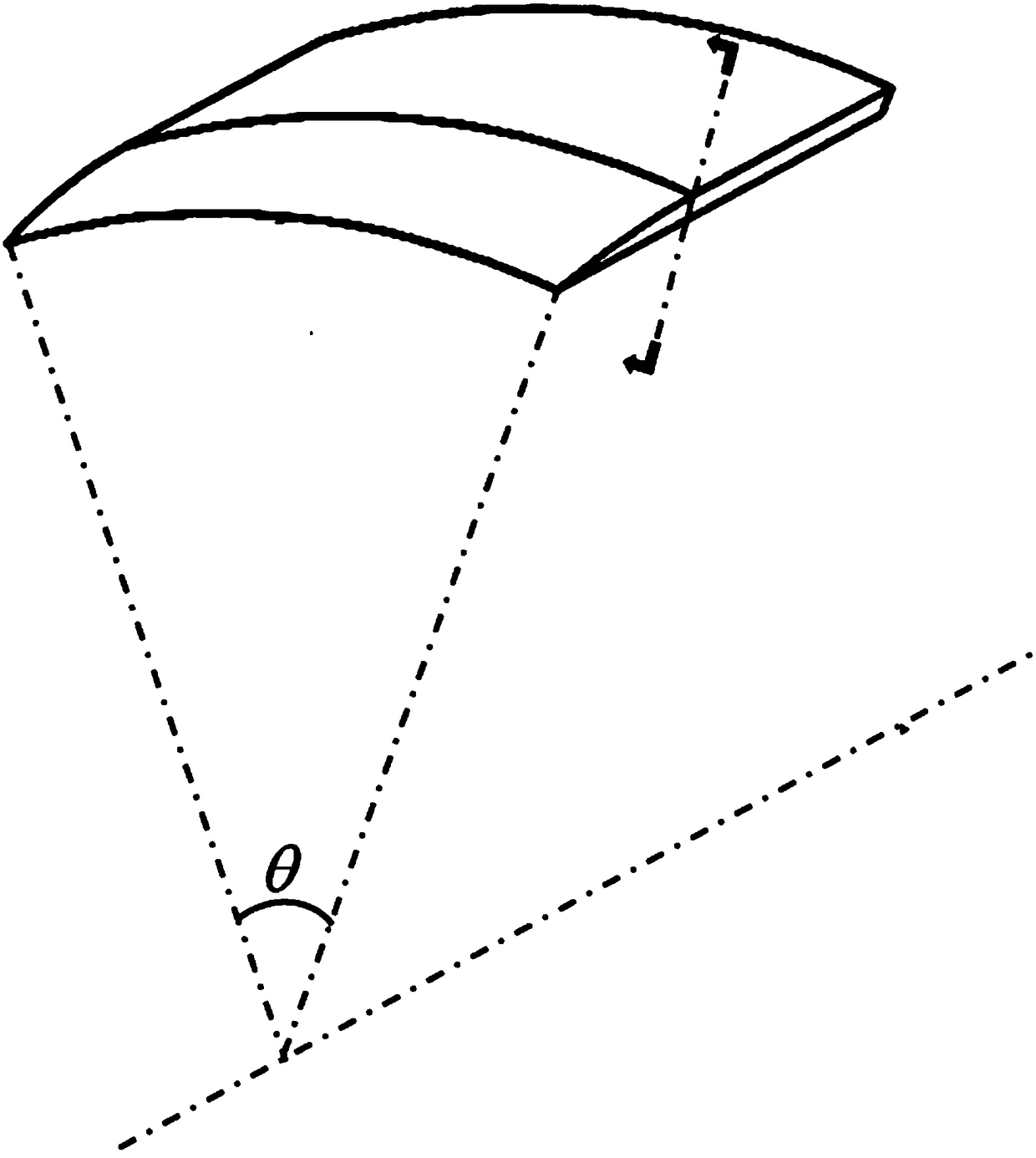

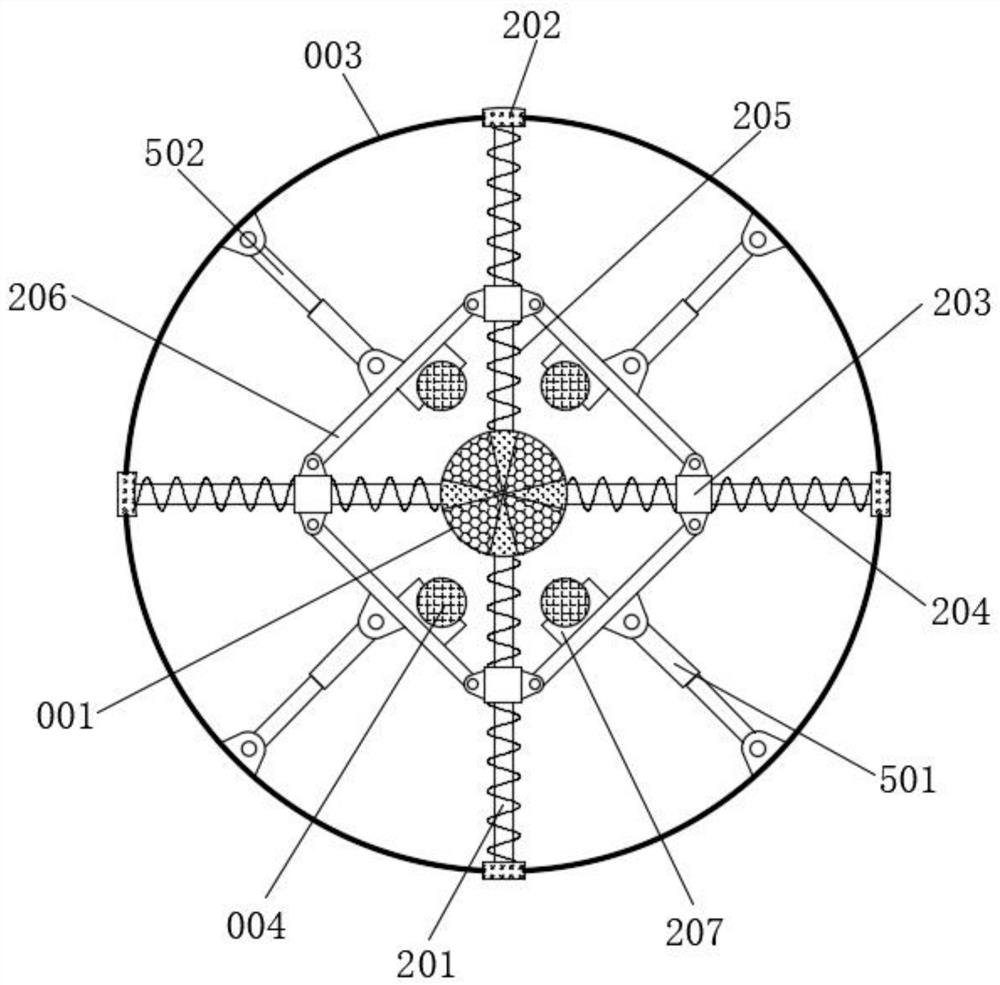

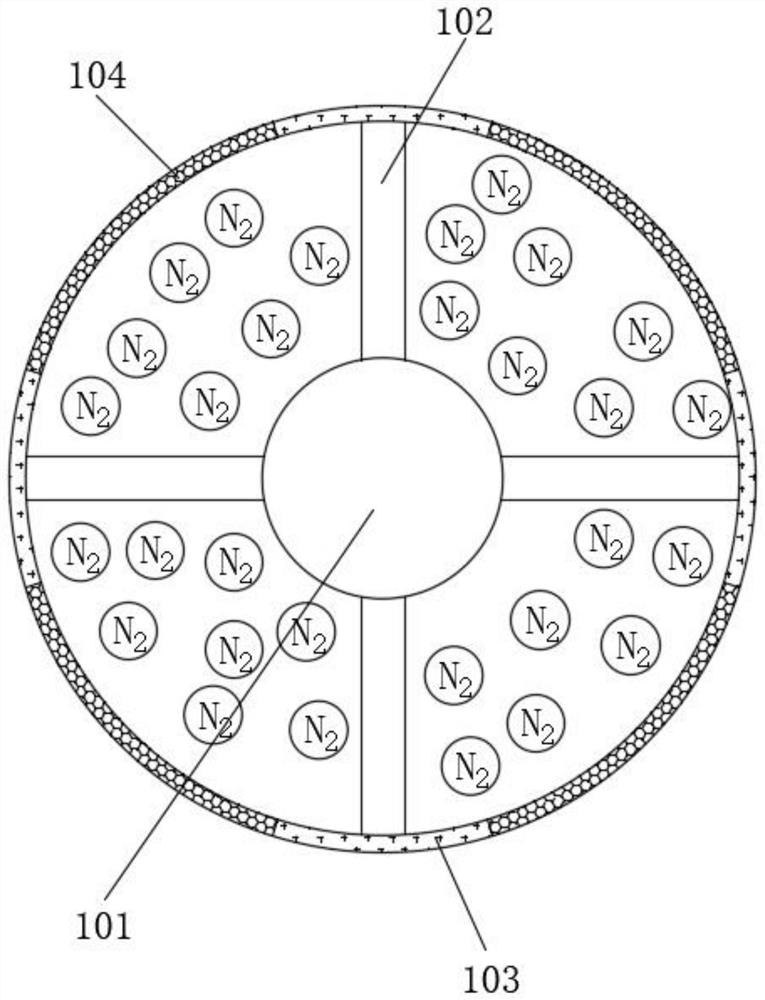

Hypersonic axisymmetric air inlet channel lip and design method thereof

ActiveCN108412618ASimple manufacturing processImprove boot performanceTurbine/propulsion air intakesInlet channelFlight vehicle

The invention relates to a design method of an air inlet channel lip of a hypersonic flight vehicle, and belongs to the technical field of hypersonic air inlet channel application. According to the design method, an air inlet channel is arranged on an engine of the flight vehicle, and the front end of the air inlet channel is a sawtooth-shaped lip; and the sawtooth-shaped lip comprises a pluralityof lip blades, the side walls of the lip blades are connected in an end-to-end mode to form the closed sawtooth-shaped lip, the center of the sawtooth-shaped lip is taken as a revolving axis line, and the lip blades are arranged in an array mode by taking the revolving axis as an array axis. According to the design method of the air inlet channel lip of the hypersonic flight vehicle, a moving mechanism is not introduced, so that the weight and the complexity of the system are prevented from being increased, and the problems of connection, sealing, cooling, control and the like are prevented from occurring; the machining and manufacturing process is simple, the starting performance of the axisymmetric air inlet channel can be improved, meanwhile, the compression performance of the axisymmetric air inlet channel is not influenced, and the capture flow is reduced, so that the working efficiency of the air inlet channel is guaranteed, and the starting performance of the air inlet channelis improved.

Owner:NAT UNIV OF DEFENSE TECH

Preparation method of pressure-resistant aerated brick

The invention discloses a preparation method of a pressure-resistant aerated brick, and belongs to the technical field of building materials. The preparation method comprises the following steps: sequentially weighing fluorite slag powder, cement, gypsum, modified mixed powder, pretreated vitrified micro beads, mixed nano powder, aluminum powder, sepiolite, graphite oxide, talcum powder, calcium stearate, sodium stearate, a dispersing agent and water according to weight parts, calcining the fluorite slag powder to obtain pretreated fluorite slag powder, mixing the pretreated fluorite slag powder with the gypsum, adding water, carrying out stirring and mixing to obtain pretreated mixed slurry, mixing the pretreated mixed slurry with the cement, adding the modified mixed powder, the pretreated vitrified micro beads, the mixed nano powder, the aluminum powder, the sepiolite, the graphite oxide, the talcum powder, the calcium stearate, the sodium stearate and the dispersing agent, carryingout stirring and mixing to obtain mixed slurry, carrying out moulding by casting on the mixed slurry, carrying out pre-curing and demoulding to obtain a blank, and carrying out autoclaved curing on the blank to obtain the pressure-resistant aerated brick. The pressure-resistant aerated brick obtained by the preparation method provided by the invention has excellent pressure resistance.

Owner:嵊州市平隆新型墙体建材股份有限公司

Anti-shearing self-recovery voltage-withstanding cable

ActiveCN112614613ALess squeezeReduce damageClimate change adaptationInsulated cablesStructural engineeringSupport pressure

The invention discloses an anti-shearing self-recovery pressure-resistant cable, belongs to the technical field of power cables, and can realize that a specially-made central support ball, a support pressure-resistant frame, a protection pressed sheet and linkage telescopic rod groups are arranged, when the cable is pressed, the protection pressed sheet is sunken inwards to drive a plurality of linkage telescopic rod groups to generate corresponding changes respectively, so the cable is prevented from being damaged; when the pressure is released, the supporting pressure-resistant frame is rotated to drive the linkage sliding block in the supporting pressure-resistant frame to correspondingly slide, the buffering pressure-resistant function of the supporting pressure-resistant frame is triggered, the pressure received by the cable is greatly buffered, the cable core wire is not directly extruded, the cable core wire is effectively protected, the cable core wire is prevented from being damaged, and after the pressure is released, the cable core wire is prevented from being damaged; resilience of the first buffer spring and the second buffer spring, the resilience of the elastic inner layer and the backflow of air in the elastic air bag can cooperatively drive the supporting pressure-resistant frame and the protection pressed piece to reset and restore, so the cable can maintain excellent pressure-resistant capability, and the practicability is remarkably improved.

Owner:东风线缆集团股份有限公司

Bottom support and refrigeration equipment

InactiveCN104773391AGuaranteed support strengthWith buffer capacityPackaging vehiclesDomestic cooling apparatusForeign objectEngineering

The invention provides a bottom support and refrigeration equipment. The bottom support comprises a bottom support body and a cushion block, wherein the bottom support body is used for bearing the refrigeration equipment, the cushion block is arranged on the bottom support body, is positioned below a compressor in the refrigeration equipment and is used for supplying buffer for the compressor, and the density of the cushion block is less than that of the bottom support body. The bottom support adopts the technical scheme that the bottom support is designed into the bottom support body with larger density and the cushion block with smaller density, the cushion block can generate enough elastic deformation when the compressor collides with a foreign object and falls off downward, so as to absorb the downward falling energy of the compressor and prevent the compressor from continuously falling off downward, and the buffer capability of the bottom support is ensured; additionally, the density of the bottom support body is larger, thereby guaranteeing the support intensity of the bottom support, so that the bottom of the refrigeration equipment can be effectively protected by the bottom support in a transportation process, and the safety of the refrigeration equipment is guaranteed in all directions in the transportation process.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +1

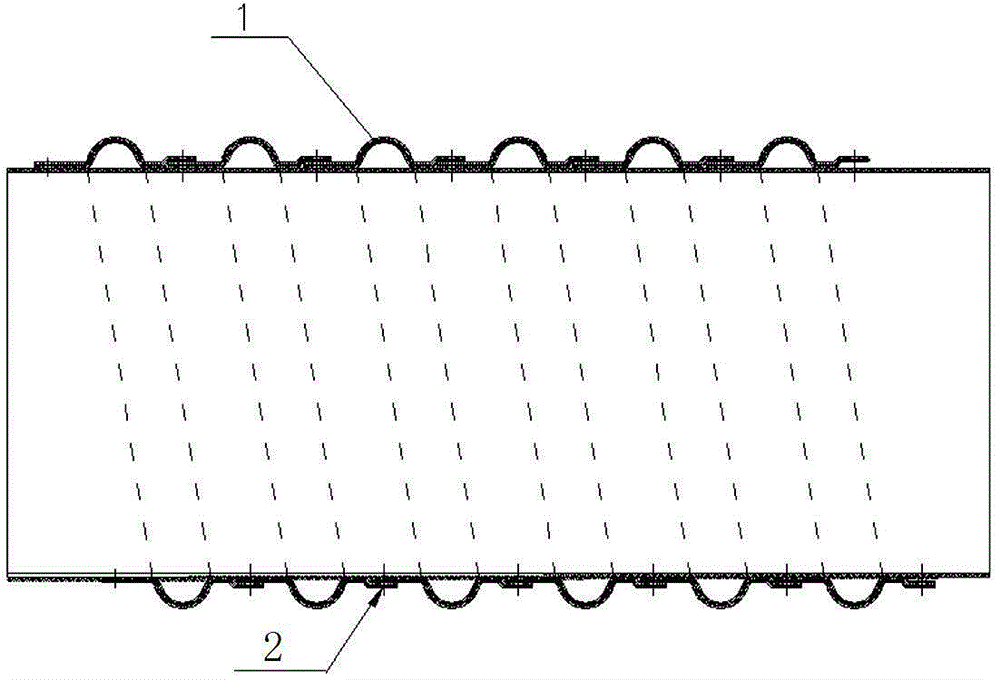

HDPE flatly sealed all-steel-belt corrugated discharging tube and production technology

The invention discloses an HDPE flatly sealed all-steel-belt corrugated discharging tube and a production technology. A tube wall of the HDPE flatly sealed all-steel-belt corrugated discharging tube comprises a polyethylene inner layer, a spiral steel belt middle layer and a polyethylene outer layer which are tightly attached from inside to outside, wherein the spiral steel belt middle layer is formed by sequentially spirally winding concave and convex steel belts from one end to the other end; a plurality of through holes are formed in edges of adjacent spiral units which are in lap joint correspondingly; the through holes are filled with polyethylene and are connected with the polyethylene inner layer and the polyethylene outer layer to form a whole body; troughs are formed in steel belt lap joint positions of the surface of the tube wall of the discharging tube; crests are formed at steel belt projections; the troughs in ends of the discharging tube are filled with polyethylene so that flat end structures are formed at the ends of the discharging tubes. Plastic-steel separation is realized through the design of the connecting steel belts, continuity of the steel belts and integrity of the tube can be realized, and the compressive property of the tube can be guaranteed. In addition, the ends of the discharging tube are flat, so that flat sealing can be convenient to implement when tubes are in butt joint or are mounted in a wellhead, and construction quality is guaranteed.

Owner:东营市天诚建材有限公司

Environmentally-friendly hollow brick used for buildings and preparation method thereof

The invention discloses an environmentally-friendly hollow brick used for buildings. The environmentally-friendly hollow brick is prepared from the following raw materials in parts by weight: 15-25 parts of cement, 25-35 parts of ore tailings, 15-20 parts of purified filler, 3-5 parts of plant powder, 2-4 parts of sulphur powder, 0.5-1.5 parts of nano-zinc oxide, 2-4 parts of glass fiber, 1-2 parts of carbon fiber, 30-40 parts of coal ash, 10-16 parts of emulsion powder and 6-8 parts of industrial mildew preventive. The environmentally-friendly hollow brick used for building decoration has the characteristics of abrasion resistance, high compressive strength, high water absorption, fire prevention and temperature preservation. In addition, the environmentally-friendly hollow brick also has functions of emitting aromatic odor and purifying air, a great quantity of industrial wastes are used as raw materials so as to perform effects on saving energy, reducing emission, preventing environment pollution and being ecological and environmentally friendly. Meanwhile, the preparation method for the hollow brick has the advantages of lower material cost, abundant raw material, simple and clear technology, easiness in operation, easiness in realizing industrial production, higher practical value and good application prospect.

Owner:合肥易美特建材有限公司

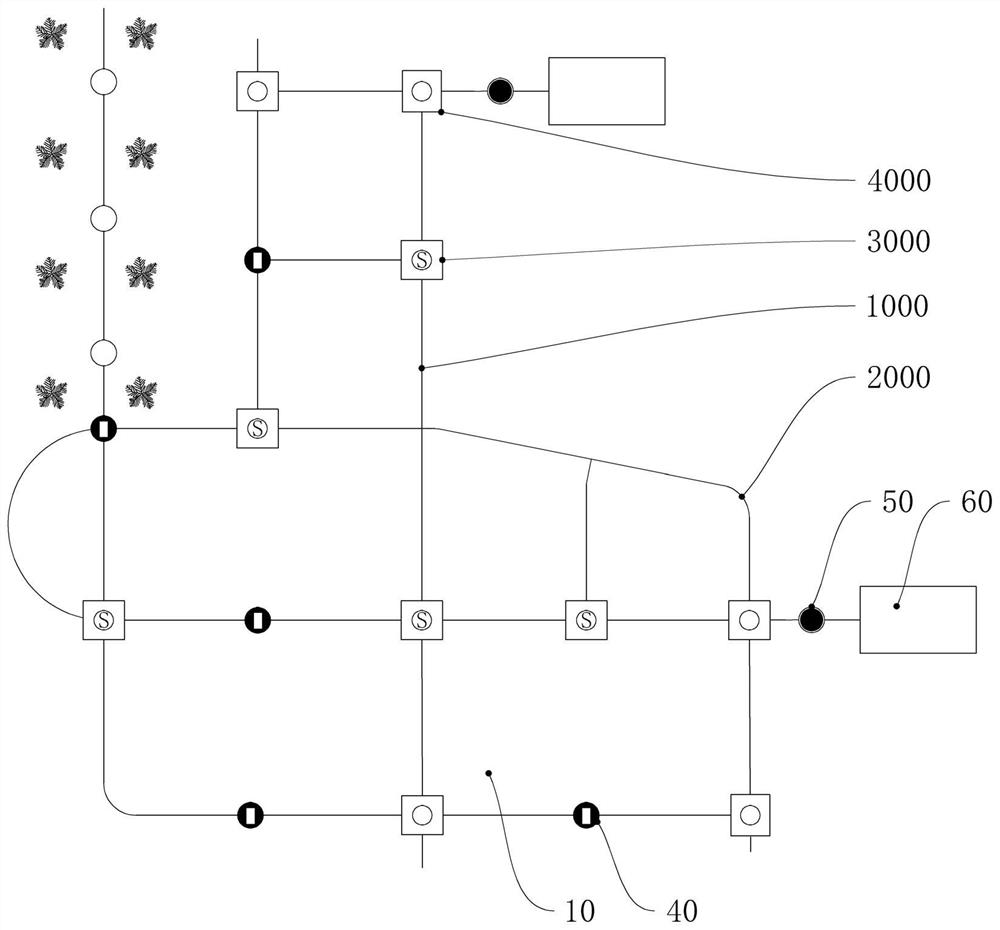

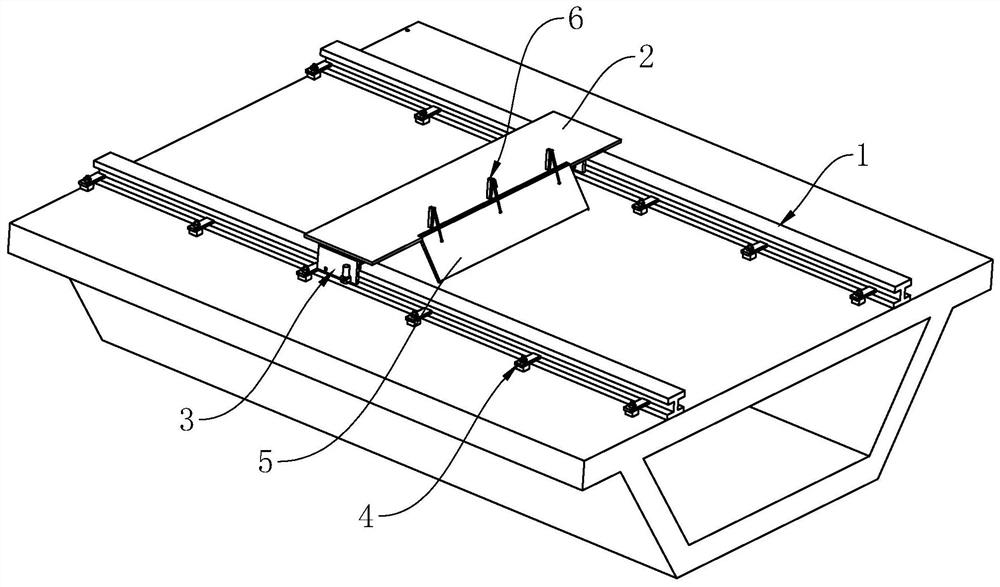

Rainwater management system

ActiveCN113775020AReduce hedgingReduce deliverySewerage structuresGeneral water supply conservationSiphonWater management system

The invention relates to the field of drainage, in particular to a rainwater management system capable of quickly draining rainwater. The rainwater management system comprises a drainage plate, a drainage network and a permeable layer, wherein the permeable layer covers the drainage network, and the drainage network at least comprises a unit area, a plurality of siphon variable-flow devices which are distributed on the periphery of the unit area and are connected through drainage grooves and are used for discharging water out of the unit area, a plurality of variable-flow drainage devices which are distributed on nodes of the drainage network in the unit area and are connected with one or more siphon variable-flow devices through drainage grooves so as to directionally guide water in different positions in the unit area to the siphon variable-flow devices and drainage plates which are distributed among the drainage grooves and are used for receiving water permeated from the permeable layer in the unit area and guiding the water into the drainage grooves. The relation among the drainage plates, the drainage grooves, the variable-flow drainage devices and the siphon variable-flow devices are reasonably arranged, so that the drainage efficiency is improved step by step, and an efficient drainage system is formed.

Owner:KESHUN WATERPROOF TECH CO LTD

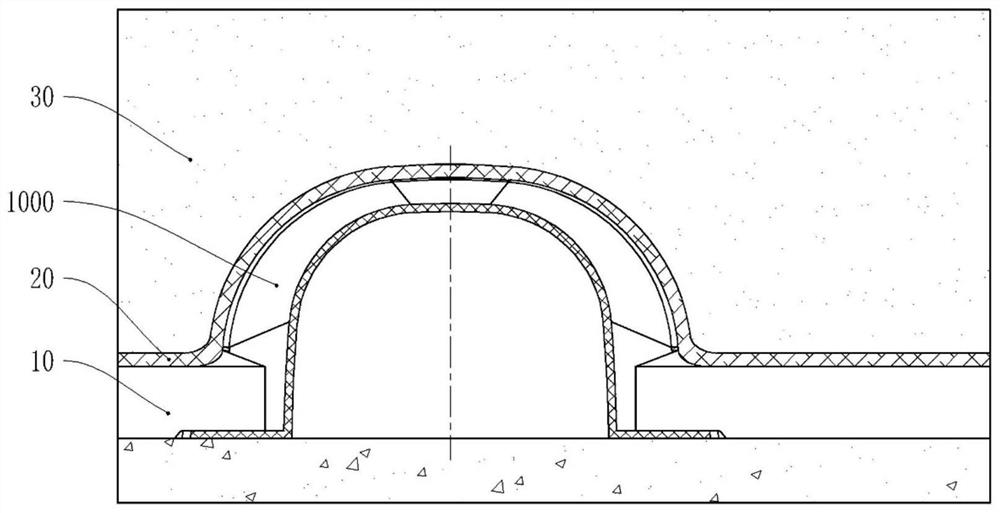

PP high-modulus twining structural wall corrugated pipe and manufacturing method thereof

InactiveCN105034416AIncreased ring stiffnessImprove stabilityRigid pipesTubular articlesHot meltFlange

A PP high-modulus twining structural wall corrugated pipe comprises a body. The body is a pipe molded by twining and fusing specially-shaped strip units. Each specially-shaped strip unit is provided with a square strip-shaped bottom, the bottom is turned outwards in the radial direction of the pipe to form a flange, a gap is reserved between the flanges of every two adjacent specially-shaped strip units and provided with a hot-melting plastic layer, and therefore every two adjacent specially-shaped strip units are fused and molded into a whole. Lining reinforcing ribs are fused between the flanges and the bottoms of the specially-shaped strip units. The positions, connected with the tops of the flanges, of the lining reinforcing ribs are provided with arc-shaped transitional parts. The invention further provides a manufacturing method. The circular rigidity of the corrugated pipe can be effectively improved.

Owner:HUBEI TONGSU PIPELINE CO LTD

Bamboo filament cement board and preparation method thereof

The invention brings forward a preparation method of a bamboo filament cement board. The bamboo filament cement board is prepared by compacting 60-66% of bamboo filament and 40-34% of special cement. The bamboo filament cement board provided by the invention has a wide range of application and can be applied to a wall energy-saving efficient board, a building template, a furniture board, a fireproof door, a construction wallboard and an interior and exterior decorative plate.

Owner:SHANGHAI TENGYIN IND CO LTD

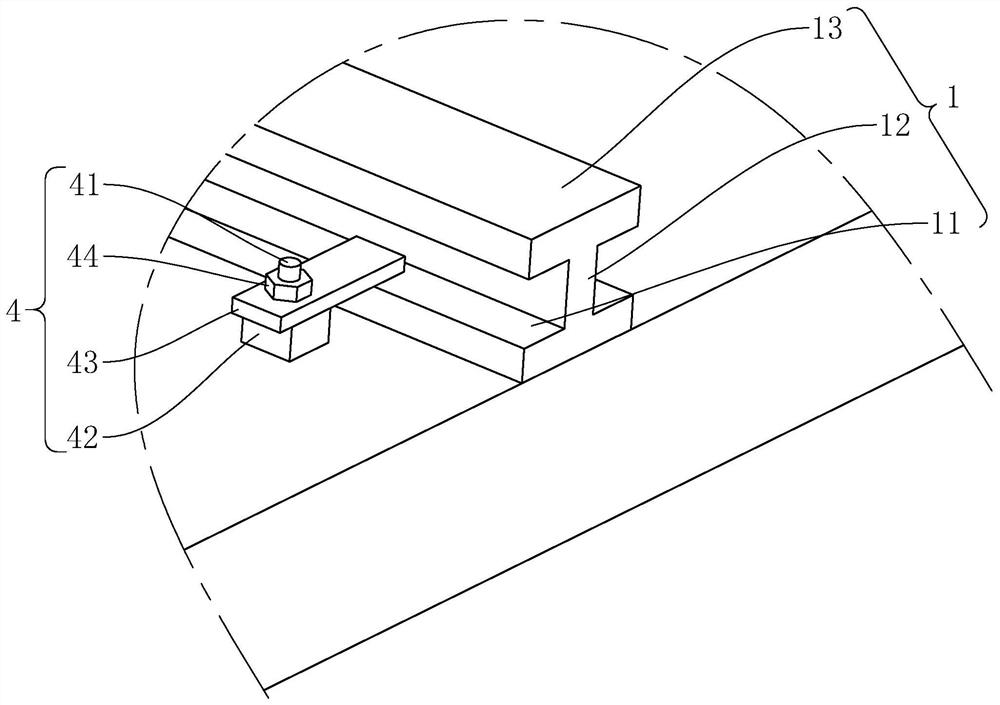

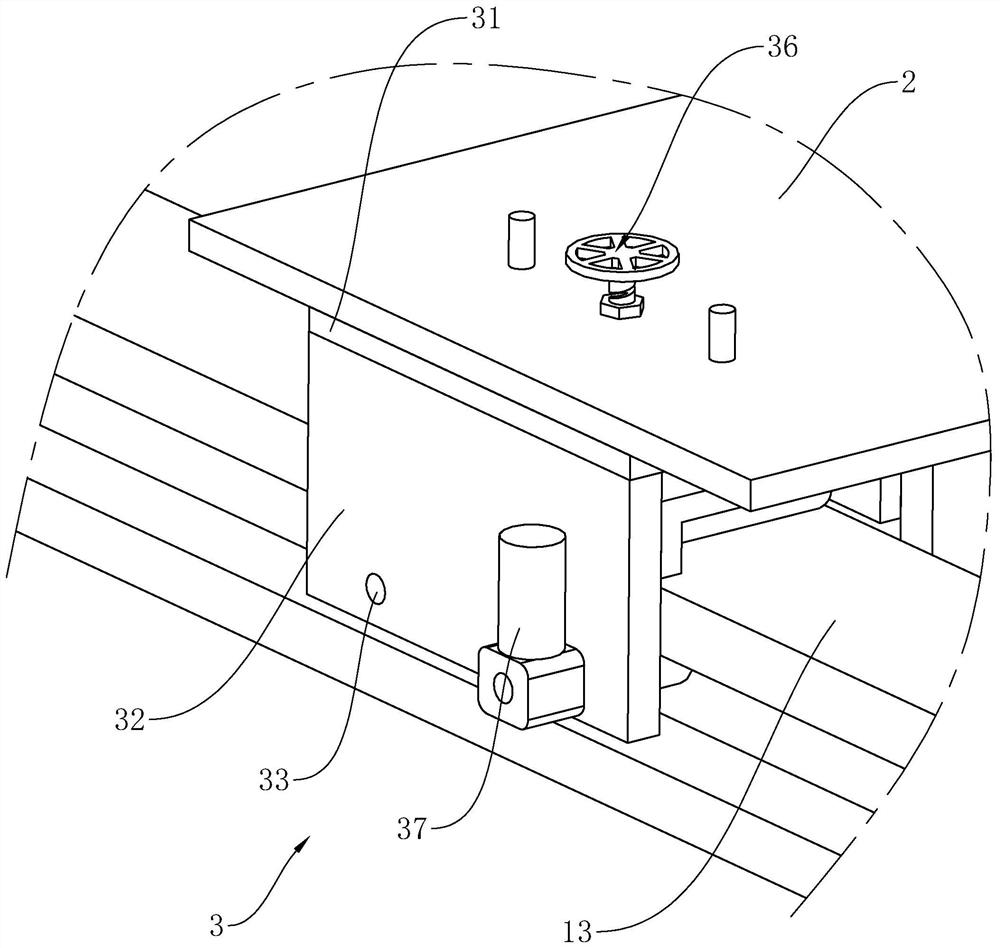

Cast-in-place box girder surface treatment construction device

InactiveCN112127278AAvoid damageGuaranteed carrying capacityBridge structural detailsBridge erection/assemblyClassical mechanicsStructural engineering

The invention relates to a cast-in-place box girder surface treatment construction device. The device comprises a track used for being laid on the surface of a box girder, a workbench arranged above the track and a connecting mechanism arranged between the workbench and the track. The workbench slides on the track through the connecting mechanism. A scraper blade is hinged to one side of the workbench, the end, away from the workbench, of the scraper blade abuts against the surface of the box girder, and an adjusting mechanism for driving the scraper blade to rotate is arranged between the scraper blade and the workbench. The construction method has the effect that the surface of the box girder is not easily damaged when workers construct on the surface of the box girder.

Owner:江苏港通路桥集团有限公司

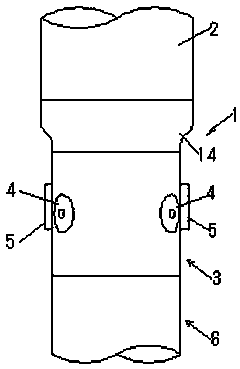

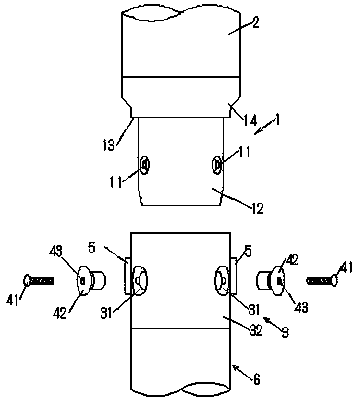

Connecting piece for steel pipe piles

PendingCN108442368AConsistent and consistent connection qualityGood connection stabilityBulkheads/pilesFirst insertionBuilding construction

The invention discloses a connecting piece for steel pipe piles. The connecting piece for the steel pipe piles comprises an upper connecting part coaxially and fixedly connected with an upper sectionof steel pipe pile, and a lower connecting part coaxially and fixedly connected with a lower section of steel pipe pile; at least two first insertion holes are inserted in the peripheral wall of the upper connecting part; at least two second insertion holes are formed in the peripheral wall of the lower connecting part; and when the upper section of steel pipe pile is connected with the lower section of steel pipe pile, at least two first insertion holes and second insertion holes are inserted in the connecting parts to fix the upper section of steel pipe pile with the lower section of steel pipe pile. The connecting piece can quickly finish connection of sections of the steel pipe piles on the construction site, and is stable and uniform in connecting quality.

Owner:GUANGXI SHENGHU METAL PROD

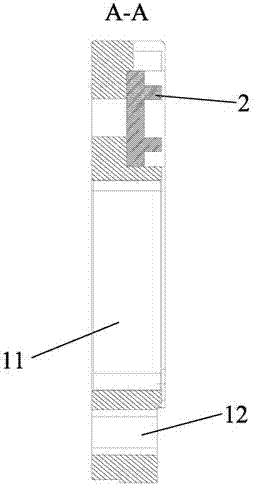

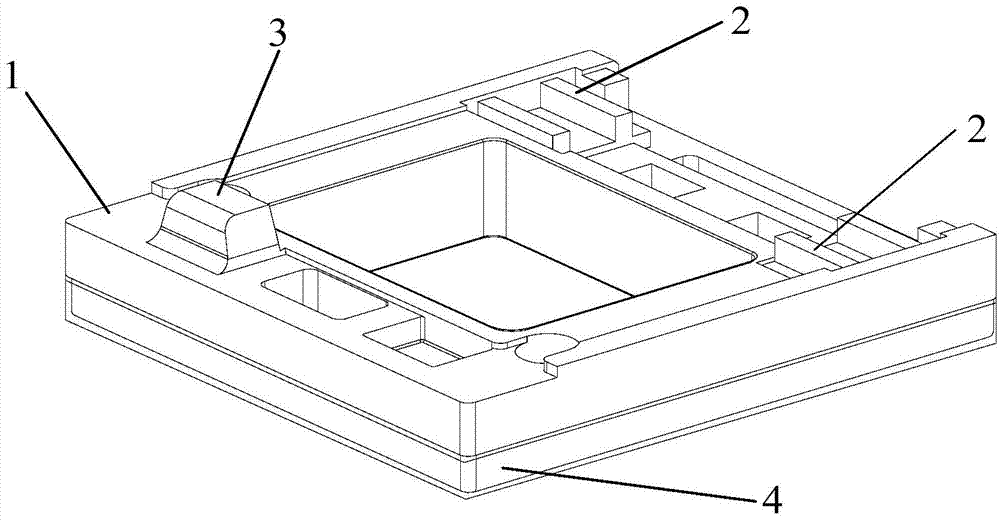

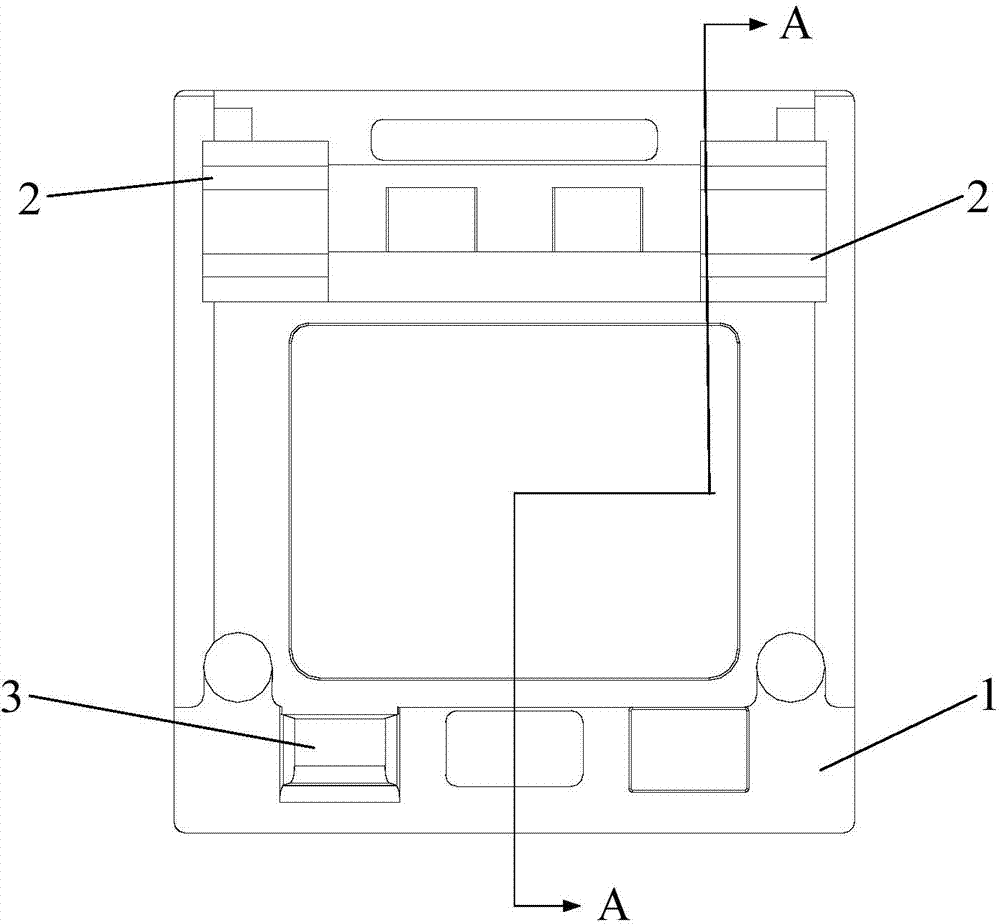

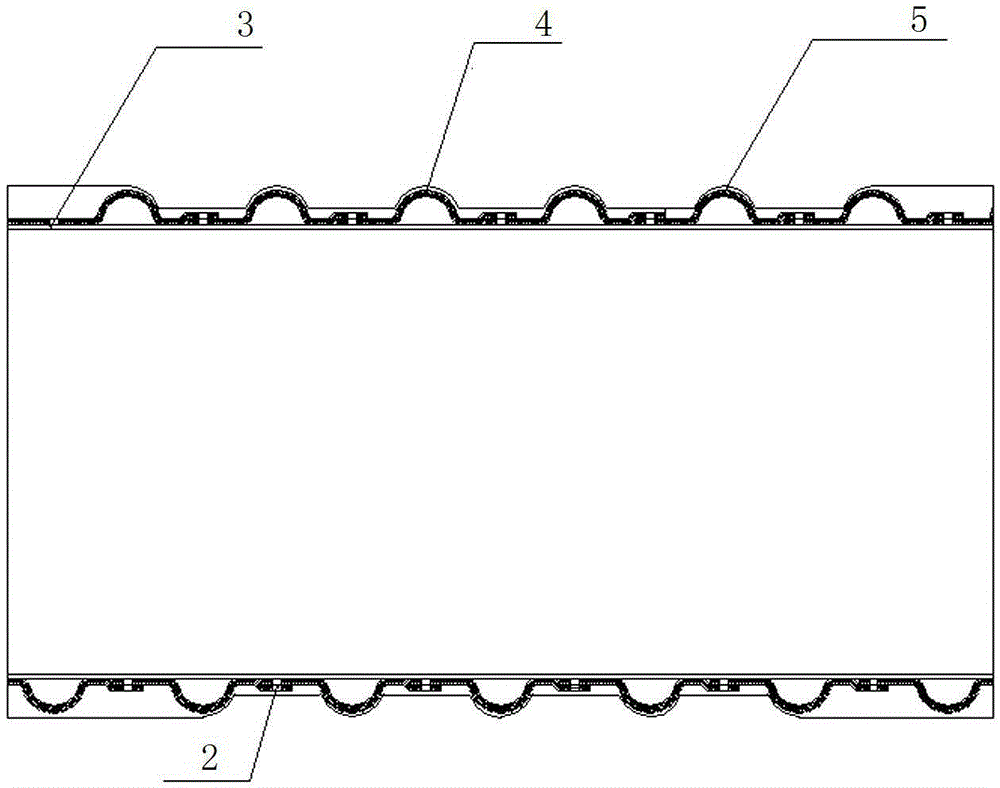

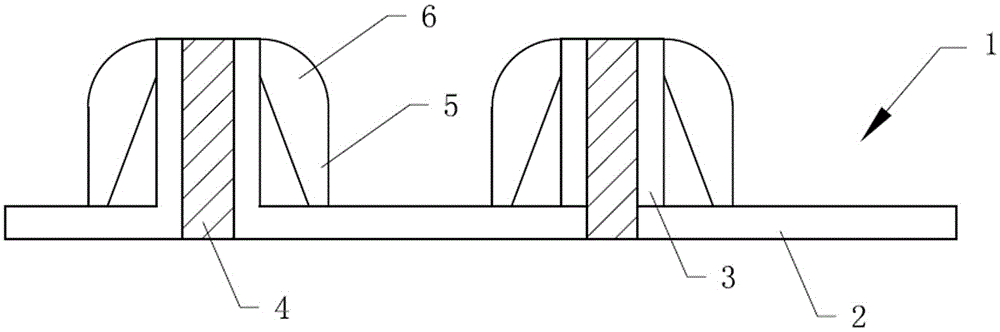

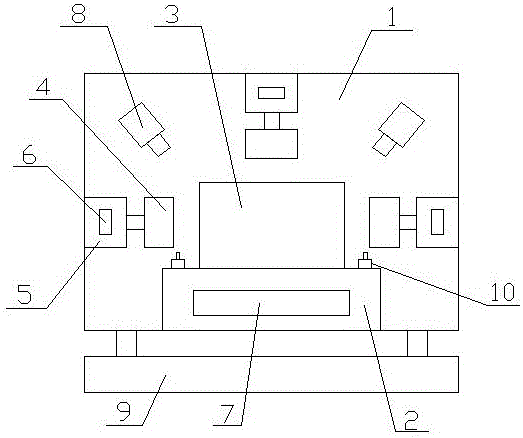

Production process for purification column used for water purifier

ActiveCN104961192ALow densityGood heat resistanceWater/sewage treatment by ion-exchangeNon-contaminated water treatmentFilter materialInjection moulding

The invention discloses a production process for a purification column used for a water purifier. The production process comprises the following steps: S1, stamping: a step of cutting a filter screen with a stamping mold; S2, injection molding: a step of respectively subjecting an upper end cover (1), a lower end cover (2), a purification column body (3), the filter screen (4) and a filter press ring (5) to injection molding; S3, preparation of a microporous filter (6): a step of cutting a sintered and molded filter with a stamping knife mold; S4, welding of the filter press ring (5); S5, welding of the lower end cover (2) and the purification column body (3); S6, filling of resin or filter material; and S7, welding of the upper end cover (1). Hot plate mold welding is employed in the process of welding, and end face welding and side surface welding manners are adopted. The purification column produced in the invention has high size precision, uniform wall thickness of the column and high cylindricity of the column, can be molded in one shot and does not need subsequent processing; and the production process has the advantages of high injection molding efficiency, low production cost and capacity of perfectly guaranteeing subsequent welding.

Owner:SICHUAN ULUPURE ULTRAPURE TECH

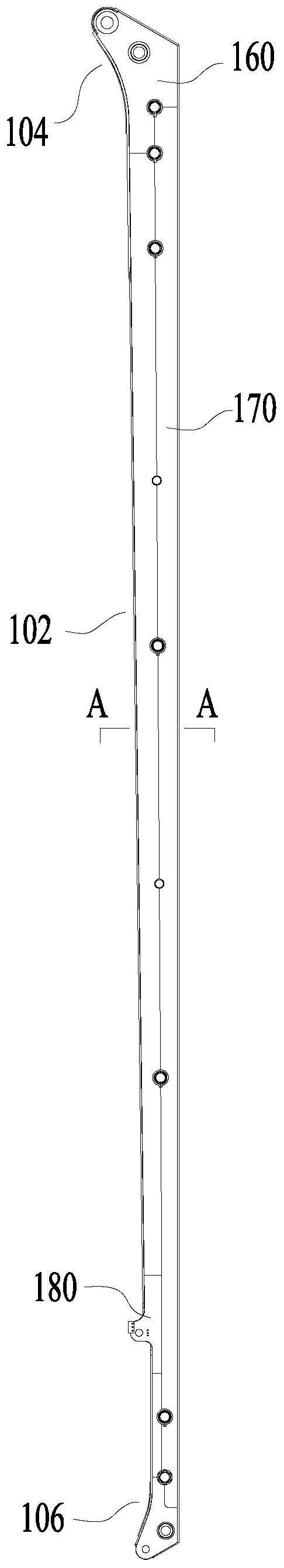

Arm rest and work equipment

PendingCN111335638AGuaranteed compression performanceImprove molding efficiencyFire rescueBuilding material handlingStructural engineeringMechanical engineering

Owner:SANY AUTOMOBILE MFG CO LTD

Formula of anti-skid shoe soles and shoe soles and shoes based on formula

ActiveCN104140577AImprove skid resistanceGuaranteed wear resistanceSolesEngineeringMechanical engineering

Owner:WENZHOU YIHE SHOE MATERIAL CO LTD

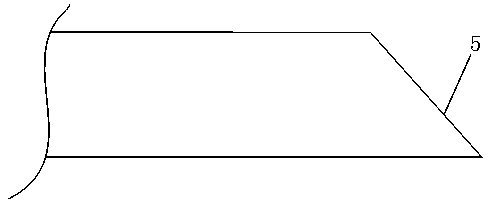

Integrated stainless steel-carbon steel composite tube and preparation process and coating process thereof

InactiveCN103527866ASimple structureIngenious designThermal insulationCorrosion preventionCarbon steelSmelting

The invention discloses an integrated stainless steel-carbon steel composite tube and a preparation process and a coating process of the integrated stainless steel-carbon steel composite tube. The integrated stainless steel-carbon steel composite tube and the preparation process and the coating process of the integrated stainless steel-carbon steel composite tube mainly solve the problems that connection between base layers and composite layers of a lining tube, a bonding tube and a press fit tube is not firm, layering can occur easily, and performance is poor in the prior art. The integrated stainless steel-carbon steel composite tube comprises four layers of structures which are a stainless steel layer, a stainless steel-carbon steel mixed layer, a carbon steel layer and an epoxy resin layer in sequence from inside to outside. The stainless steel-carbon steel mixed layer is of an integrated structure formed by stainless steel and carbon steel in a metallurgical smelting mode, the stainless steel layer and the stainless steel-carbon steel mixed layer are of an integrated structure, and the carbon steel layer and the stainless steel-carbon steel mixed layer are of an integrated structure; the thickness ratio of the stainless steel layer to the carbon steel layer is 1:10. A beveled edge is further formed in the end of the integrated stainless steel-carbon steel composite tube, and the angle of the beveled edge ranges from 30 degrees to 35 degrees. The integrated stainless steel-carbon steel composite tube is simple in structure, low in price and good in performance, thereby being suitable for popularization and application.

Owner:易波

Device for detecting pressure-resistant property of new energy battery

InactiveCN106442149AGuaranteed compression performanceGuaranteed aestheticsMaterial strength using tensile/compressive forcesElectrical batteryPressure regulator

The invention provides a device for detecting the pressure-resistant property of a new energy battery. The device comprises a detection tank, wherein a mounting base is arranged under the detection tank, a to-be-detected object is arranged on the mounting base, compression blocks are arranged on the side of the to-be-detected object and are connected through compression air cylinders on the side, pressure regulators are arranged in the compression air cylinders, and a power supply device is arranged in the mounting base. According to the device, the object on the mounting base is detected by virtue of a position detection device and is compressed by the compression blocks, and the battery is subjected to pressure detection, so that the pressure-resistant property of the battery is guaranteed; the appearance of the battery is detected by virtue of an appearance detection device, so that the aesthetic perception of the battery is guaranteed; and each part of the battery is detected by virtue of an inclination regulation device, so that the yield of equipment is guaranteed, the economic benefit of an enterprise is increased, and the production cost of the enterprise is lowered.

Owner:安徽凯达能源科技有限公司

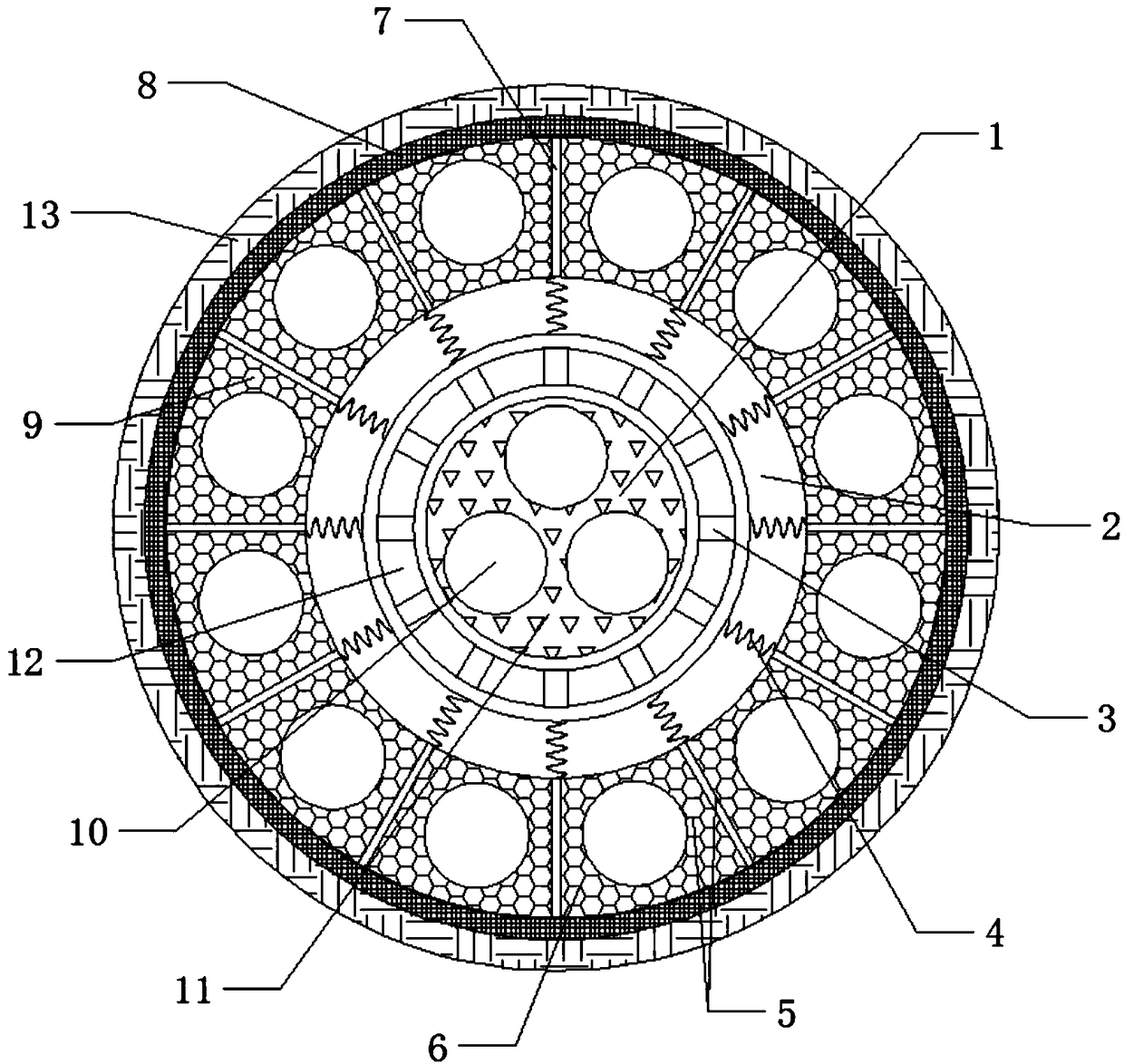

A compression-resistant cable with heat dissipation effect

InactiveCN109065238AStable structureCompact structureInsulated cablesInsulated conductorsEngineeringElectrical and Electronics engineering

The invention discloses a compression-resistant cable with a heat dissipation effect, the invention belongs to a special cable in the technical field of cables, the object of the invention is to provide a cable which combines a compression resistance function and a heat dissipation function, The compression-resistant cable comprises a first cable layer arranged in the middle, wherein a buffer layer is arranged outside the first cable layer, the buffer layer is fixedly connected with the outer wall of the first cable layer through a connecting bar, and the other end of the connecting bar is fixedly connected with the inner wall of the buffer layer; A plurality of springs uniformly distributed along the radial direction of the buffer layer are arranged inside the buffer layer, a second cablelayer is arranged outside the buffer layer, the second cable layer is filled with an air permeable filling base, a heat exchange tube is arranged inside the air permeable filling base, and the heat exchange tube is communicated with the buffer layer; The invention provides a compression-resistant cable with heat dissipation effect, which enables the cable to resist strong external impact force and also satisfies its own heat dissipation effect.

Owner:ZHENGZHOU JIZHI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com