A direct connection type double-step threaded joint

A threaded joint and double-step technology, which is applied in the field of double-step threaded joints, can solve problems such as the inability of the casing to enter the well, and achieve the effects of good compression resistance and torque resistance, excellent air-tight performance, and excellent connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The direct-connection double-step threaded joint of the present invention will be further explained and described in conjunction with the accompanying drawings and specific examples below. However, such explanations and descriptions do not constitute undue limitations on the technical solution of the present invention.

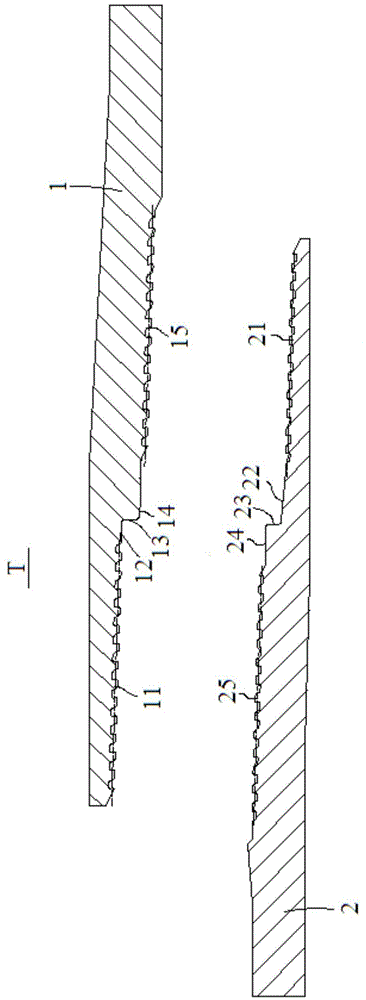

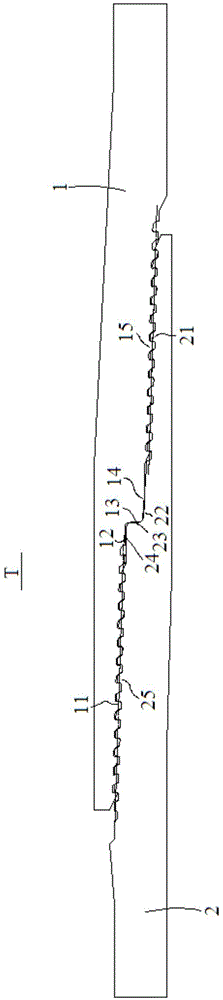

[0036] figure 1 with figure 2 Each shows the structure of the direct connection type double-step threaded joint in an embodiment of the present invention.

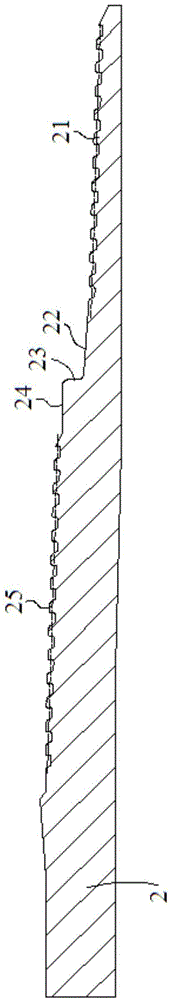

[0037] Such as figure 1 with figure 2As shown, the direct connection type double-step threaded joint T in this embodiment includes a sleeve female joint 1 and a male joint 2 . In the axial direction of the direct-connection double-step threaded joint, the female joint has in turn: a first threaded section 11, a female joint shoulder transition section 12, a female joint torque shoulder 13, a female joint sealing surface 14 and a second threaded section 15, while the male joint 2 has in turn: t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com