Formula of anti-skid shoe soles and shoe soles and shoes based on formula

A formula and heel technology, applied in the field of anti-slip sole formula, sole and shoes, can solve the problems of wear resistance, reduced compressive performance, heavy sole, different formula ingredients, etc., to achieve excellent anti-slip performance and maintain wear resistance. Performance, lightweight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

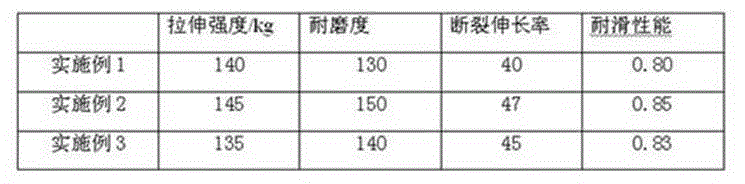

Embodiment 1

[0031] 56 parts of 35L type nitrile rubber, 44 parts of 1052 type nitrile rubber, 18 parts of carbon black, 8 parts of white smoke, 6 parts of DOP, 0.5 parts of accelerator D, 5 parts of zinc carbonate (ZnCO3), 1 part of stearic acid, 1 part of anti-aging agent SP, 0.9 parts of active agent PEG, 2 parts of accelerator OH3, and 2 parts of additive DM.

Embodiment 2

[0033] 50 parts of 35L type nitrile rubber, 50 parts of 1052 type nitrile rubber, 20 parts of carbon black, 6 parts of white smoke, 6 parts of DOP, 0.5 parts of accelerator D, 5 parts of zinc carbonate (ZnCO3), 1 part of stearic acid, 1 part of anti-aging agent SP, 0.9 parts of active agent PEG, 2 parts of accelerator OH3, and 2 parts of additive DM.

Embodiment 3

[0035] 45 parts of 35L type nitrile rubber, 55 parts of 1052 type nitrile rubber, 16 parts of carbon black, 10 parts of white smoke, 6 parts of DOP, 0.5 parts of accelerator D, 5 parts of zinc carbonate (ZnCO3), 1 part of stearic acid, 1 part of anti-aging agent SP, 0.9 parts of active agent PEG, 2 parts of accelerator OH3, and 2 parts of additive DM.

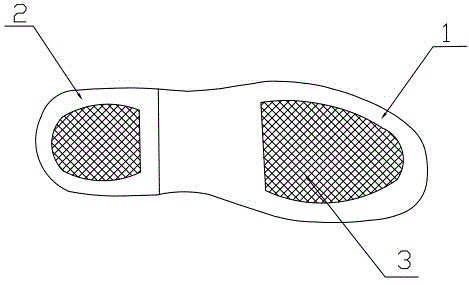

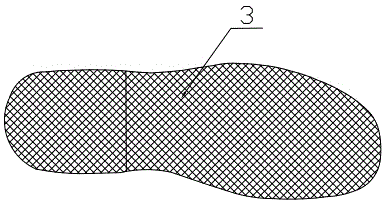

[0036] The shoe sole formulations of the above-mentioned examples 1, 2, and 3 are made into shoe soles, including a forefoot and a heel. The forefoot and the heel are provided with an anti-slip layer, and the anti-slip layer is made of the above-mentioned formulation material. The soles, such as figure 1 As shown, the anti-slip layer is overmolded on the forefoot and heel. Such as figure 2 As shown, the whole sole can also be directly made of anti-slip layer material to play the role of anti-skid.

[0037] The above-mentioned shoe sole is made into a shoe, including a shoe sole and a shoe upper, and the shoe sole is made of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com